THE ITALIAN ART OF TUNNELLING 2019

Editor

SIG Srl

Via Angelo Scarsellini 14, 20161 Milano

Tel. +39 02 25715805

www.societaitalianagallerie.it

Communication partner

PPAN Srl

COMUNICAZIONE E NETWORKING

PER IL COSTRUITO

Paola Pierotti e Andrea Nonni

Via Nomentana 63, 00161 Roma

Tel. +39 06 87751723

www.ppan.it

Graphic design and layout

PPAN Srl

Alessia Tabbì

Concept and coordination

Andrea Pigorini, Marco Ranieri

Special thanks to Ludovica Roda and Renzo Bindi (SIG)

Special thanks to SIG YMs and in particular to Diego Sebastiani, Agostino Viglione, Roberto Persio, Chiara Agostini, Stefania Fabozzi, Luca Perazzoni, Luigi

D’Angelo, Andrea Lattanzi, Giacomo Armetti and Lapo Baccolini for their collaboration.

The reproduction of the images of this book was authorized by the companies listed in the publication.

Edition April 2019

THE ITALIAN ART OF TUNNELLING 2019

The Italian art of tunnelling

PREFACE

10

PREFACE

11

The Volume The Italian Art of Tunnelling aims to be a presentation “made in Italy” in the field of tunnelling and underground works.

This volume is a reissue of a previous publication, enriched with history, ideas, new projects, challenges faced and won. The Italian Art of Tunnelling 2019 is published on the occasion of the World Tunnel Congress 2019 hosted in Naples, to provide colleagues around the world with the most comprehensive picture of Italian tunnelling excellence.

Tunnelling in Italy dates back to the Roman times when our ancestors had ventured in tunnel construction to cope with the inevitable issues related to the morphology of our territory.

TODAY, FOR US, TUNNELLING MEANS THE ACCOMPLISHMENT OF IMPORTANT PROJECTS PERFORMED BY OUR PLAYERS ALL OVER THE WORLD.

Finally, tunnelling for us means future: new ideas, cutting-edge technologies and projects strongly characterized by an innovative approach, as result of a constant research for new solutions and opportunities.

The introduction of this publication presents an analysis of the railway and road tunnels heritage, enriched with graphs and figures that provide to the reader a clear picture of our history. Such first section also contains a picture of ongoing tunnelling projects in Italy, as well as a short presentation of the future projects, which represents our commitment with the country.

In the second part of the volume, the reader will find a presentation of the entire Italian tunnelling industry: owners and concessionaires, contractors, engineering companies, consultant, industry and other specialists and a description of their main projects. This is what we consider our “made in Italy” in tunnelling. We hope you will enjoy the reading.

12

13

THE HERITAGE OF ITALIAN TUNNELS

01

“All roads lead to Rome”… especially if underground. The roman centric view of the medieval statement, emphasized the road network role as driver of commerce and power, building on the sophisticated and innovative road system the roman empire constructed to connect provinces and colonies within Europe and across mountains and ridges. Modern engineering practice in road design and tunnel design has expanded the network and converted this heritage into modern physical infrastructure assets, developing underground solutions to overcome orographic barriers and urban constrains.

14

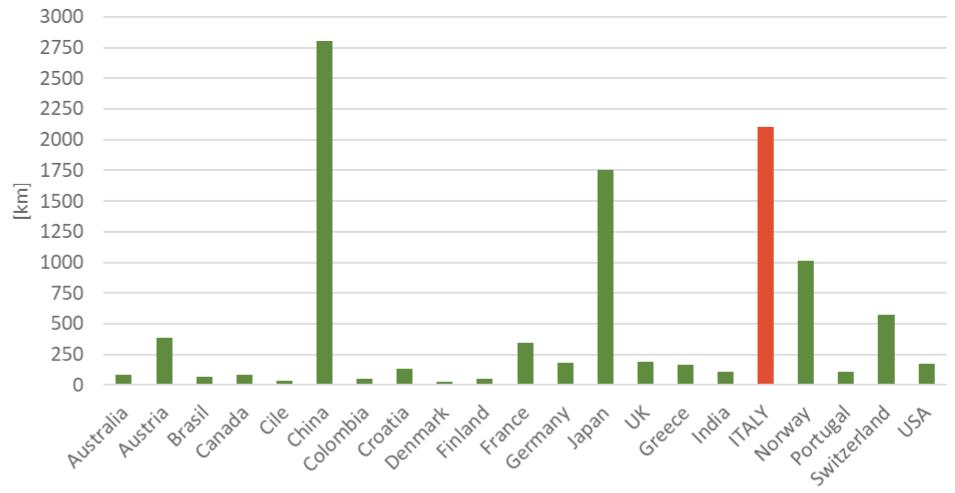

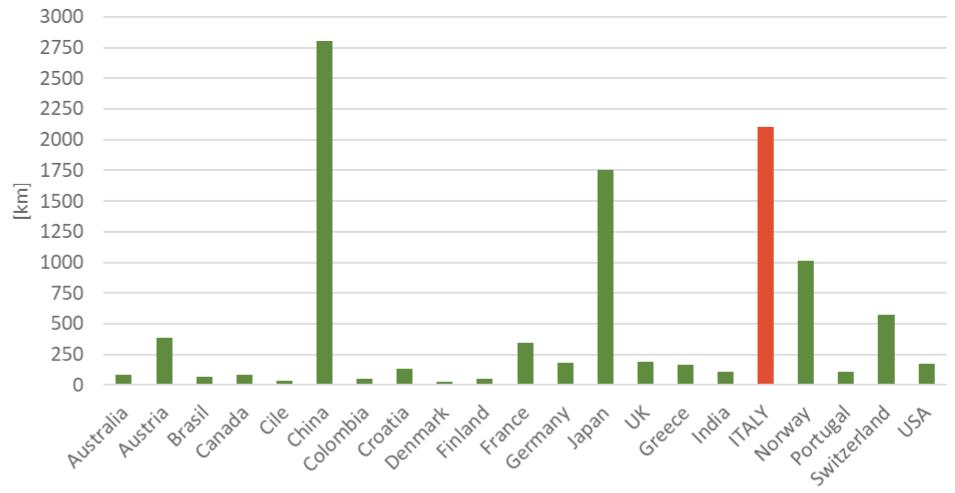

FIGURE 1 Total length of railway and road tunnels up to 2014 (source lotsberg.net)

Italy is the second country in the world for number of tunnels, after China, and leads the European ranking, followed by Norway, Switzerland, Austria and France.

1.1 THE HERITAGE OF ITALIAN RAILWAY TUNNELS

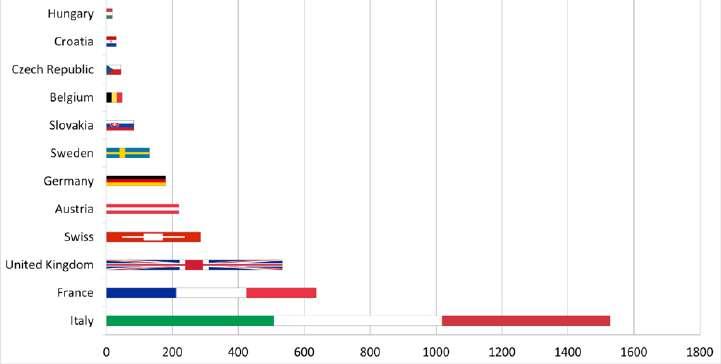

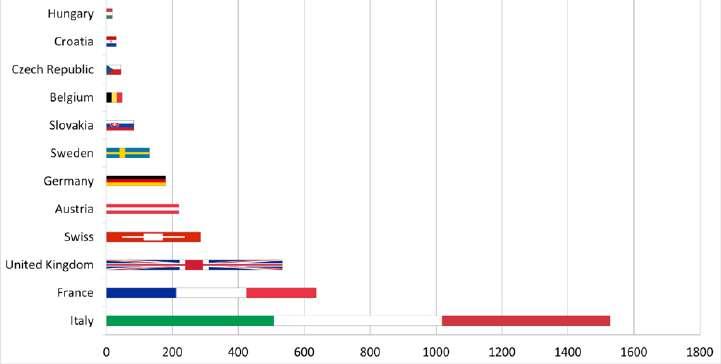

Due to its peculiar orography, Italy is the European country with the highest number of railway tunnels. The operating network, managed by RFI, has an extension of approximately 16,777 km. Among the various construction works, the total length of tunnel is about 1,524 km (figure 2), representing 9% of the entire infrastructure. Tunnels in Italy, constitute by far the most conspicuous patrimony of underground works among all European nations. The tunnels currently in operation in Italy are both the highest in number (1682) and overall the most extended, among European countries.

15

FIGURE 2 Comparison of railway tunnels in several European countries updated to 2019

CURRENT MAJOR TUNNELLING ACTIVITIES

Nowadays, the Italian transport network is quickly expanding thanks to major tunnelling works involving railways, roads and metro projects. The extensive experience and know-how developed by major Italian contractors - involved in several major projects around the world – is crucial for the realisation of the tunnels that will pass through the Alps and Apennine mountain chains.

2.1 CURRENT RAILWAYS TUNNELLING PROJECTS

The major railways tunnelling works are briefly described below.

MILANO – GENOVA HIGH SPEED RAILWAY

The Milano – Genova High Speed Railway line, also known as Terzo Valico dei Giovi, represents one of the 30 European priority projects. It is part of a new HS line that aims to improve the railway connection between the Liguria port system and the main railway lines in Northern Italy and in Europe. The project, as part of the Rhine-Alpine’s TEN-T Corridor, involves the construction of two singletrack tunnels, with a total length of 37km, connected by cross passages every 500 m. The tunnels are located in the

23

02

complex Apennines range, between Piedmont and Liguria, and will be excavated via both conventional methods (for about 65% of the length) and TBM (for about 35% of the length).

MILAN – VERONA HIGH SPEED RAILWAY

The new high speed railway Milan-Verona is part of the Mediterranean’s TEN-T Corridor that connects east Europe with western European Countries. The line runs for 137 km between Milan railway junction and Verona railway junction. The line is divided into two functional sections: Treviglio-Brescia (in operation since December 2016) and Brescia-Verona. The Brescia-Verona section involves the construction of 4 tunnels: Lonato twin tubes single track, San Giorgio, Calcinato II and Colle Bacotto single tube double tracks. The Lonato tunnel, 4,8 km long, will be excavated by 2 EPB shields in fluvioglacial water bering deposit with cobbles of di erent dimension. The tunnel will underpass the A4 motorway, for a 425m long sub-parallel stretch with presence of shallow overburden (10-12m). This critical aspect has requested the adopt of specific ground consolidation techniques.

24

PROJECTS

32

PROJECTS

33

AB TUNNELLING

AB Tunnelling Srl is an Italian company founded in 2010 merging more than 16 years working experience in Tunnelling & Construction field.

AB Tunnelling has been applying main skilles in market targeting analysis, international marketing strategy and R&D of new products and technologies finalizing business Partership with leading Manufacturers with focus on tailormade technical solutions for Precasting & Tunnelling. Segments moulds, TBM precast segments accessories and gaskets, steel & polymeric fibres, special compound of additives for the concrete and robotic welding plant embraces AB Tunnelling portfolio for precasting plants. Products and equipment are mostly ‘engineered & made in Italy’: this guarantees to follow all the steps of the production process starting from the raw material.

Furthermore AB Tunnelling has been working for over 16 years together with DATWYLER Sealing Technologies GmbH taking care of Italian projects and Italian Contractors operating worldwide.

TBM cutting tools, modular service vehicles, gantry cranes and belt conveyors cover the complementary area of AB Tunnelling expertise in Tunnelling sector.

34

abtunnelling.it

PROJECT

NEW CHALLENGES FOR THE FUTURE OF TBM PRECAST SEGMENTS

Today construction companies claim low costs and high quality of the finished product.

Robotic welding plant: A first step is the automation of the production process. “Robotic” solutions for the welding of reinforcement steel cages are one food for thought is to increase the quality of the finished product, but also to reduce the risk of diseases as the inhalation of welding fumes and more generally of accidents at work.

Advantages of robotic welding process:

• Improvement of safety and health (no accidents and welding smoke for men)

• Excellent precision of welding & Respect of dimensional tolerances and concrete cover

• Data recording & Working time 24/24h & Flexibility

Segment formworks and automatic covers: The formworks are ergonomically designed with the aim of improving the satisfaction of the

Location: Precast Plant

Client: Construction Company

operator and the overall performance of the system. The quality of the finished product (i.e. the segment) is closely related to the ease with which the operator can access the formwork during the preparatory stages prior to pouring the concrete.

Compound of additives type AETERNUM: Nanotechnologies applied to additives dramatically cutting down on one side to achieve the mechanical resistance given in the technical specifications and the other by reducing the time needed to have the mechanical resistance at the demoulding of the segments.

The main purpose of the use of Aeternum has been the request of resistance to sulphates and chlorides along a particular path of tunnelling due to aggressive environmental conditions. Standardization of the components: To cut costs we must also think of versatile plants whose components are standardized as much as possible in order to use the same system across multiple projects in various parts of the world. In the near future then we can consider to imagine entirely robotic systems where man supervises the activity of robots (HMI).

35

Two robotic booms welding a steel cage

ANAS

stradeanas.it

Anas is the company of Ferrovie dello Stato Italiane Group in charge of road infrastructures. For nearly a century, it has been building the italian roads, and monitoring their e cient operation and maintenance. The company is a world leader in road design, construction and maintenance, operating the Italian national road network, consisting in 30 thousand km of state roads, highways and highway links.

Anas manages 1,900 road tunnels, a figure representing the half of the total amount of road tunnels in Europe. The company numbers approx. 6 thousand employees at 38 local o ces and is present abroad through its subsidiary A.I.E. (ANAS International Enterprise).

42

PROJECT 01 RENAZZA TUNNEL

The Renazza tunnel project belongs to the A2 Mediterranean highway modernisation, one of the most fundamental connection roads in Italy.

The geological and geotechnical complications identified the Renazza as the most di cult tunneling construction of the entire Northern part of the highway, considering that the rock mass crossed during the construction was characterized by strong squeezing phenomena.

During the excavation phases the invert arch and the definitive lining concrete casting were maintained at short distance from the tunnel front to limit the strain e ects.

Di erent problems a ected the construction such as: ground flowing back due to the water and to the

part of highway.

granular material presence, solved by rock bolts and resins injections; the strong radial convergence that determined the reduction of the steel ribs spacing (up to 60 cm), the increment of their rigidity and the use of invert struts; the tension release of the front excavation due to the tectonic stresses accumulated in the area of the subduction plane. The last phenomena induced a sudden collapse of the excavation front and of 50 m of excavated tunnel.

In the Southern side, some deformation phenomena induced a metric lowering and longitudinal displacement of the

Location: Lagonegro, Italy

Client: ANAS S.p.A.

Construction period: 2009-2014

Contractor: CONSORZIO SIS S.c.p.A.

43

“

The geological and geotechnical complications identified the Renazza as the most di cult tunnel construction of the entire Northern

The collapse in correspondence of the Northern side of the tunnel

BBT SE

bbt-se.com

BBT SE is a European public limited company for the construction of a railway tunnel between Austria and Italy. At the request of the Republics of Austria and Italy and the European Union, BBT SE is planning and building the Brenner Base Tunnel.

The acronym SE stands for Societas Europaea. This is a transnational type of company provided for by European law. BBT SE is 100% publicly owned.

Since Austria and Italy are equal shareholders in BBT SE, this type of company is ideal.

50

THE BRENNER BASE TUNNEL, A CONNECTING PROJECT

The current railway line follows a steep and twisting route with slopes that can reach 26‰. These aspects limit both train speed and maximum load capacity. The new railway line runs from Innsbruck, in Austria, to Fortezza in Italy (55 km). With the Innsbruck railway bypass, endpoint for the Brenner Base Tunnel (BBT), the entire tunnel system is 64 km long and is the longest underground rail link in the world. The construction of the Brenner Base Tunnel intervenes on the most critical part of the stretch, rectifying the slope and basically creating a flat stretch with slopes that are reduced by an entire order of magnitude. The slope in the base tunnel is 7.5 ‰ on the northern side and 4 ‰ on the southern flank of the

Location: Italy (Autonomous Province of Bolzano), Austria (Tyrol)

Client: Ministero delle

Infrastrutture e dei Trasporti (Italy), Bundesministerium für Verkehr, Innovation und Technologie (Austria)

Construction period: 2007 - 2027

Brenner. The maximum overburden is about 1,850 m. The Brenner Base Tunnel project includes two twin single track tunnels, each 8.1 m wide, running 40-70 m apart from one another. For operational and safety reasons, the main tunnels are connected every 333 m with bypasses.

A peculiar feature of the Brenner Base Tunnel is the pilot tunnel

Main tube of the Brenner Base Tunnel

Main tube of the Brenner Base Tunnel

CMC

cmcgruppo.com

Founded in Ravenna in 1901, Cooperativa Muratori e Cementisti - CMC di Ravenna Soc. Coop. is an Italian leading construction company. Thanks to technical and management ability as well as to the extensive experience acquired all over the world in great infrastructure works, CMC ranks among the few Italian general contractors qualified for executing the highest class of contracts.

Particular capability has been achieved during the last decade regarding great TBM’s tunneling projects. Its range of activities comprises the following business segments: transport, water and irrigation works, building projects, ecology and environment, ports and maritime works.

60

ISMAILIA ROAD TUNNEL: THE FIRST TUNNEL BUILT UNDERNEATH THE OLD AND NEW SUEZ CANALS

The Egyptian Government’s Ministry of Defense and the Engineering Authority of the Armed Forces awarded several projects to support growth of the Sinai region in the Eastern part of Egypt. The Ismailia Road Tunnel is one of the investments made as part of the Suez Canal Corridor Development Project. In fact, in addition to the construction of the new Suez Canal, new rail and road tunnels will be built underneath the Suez Canal at three di erent locations: Port Said, Ismailia and Suez. The Ismailia Road Tunnel is located near the town of Ismailia, halfway between Port Said and Suez, and it is the first tunnel built underneath the Old and New Suez Canals. The project consists of two parallel tunnels, about 4.8km long, built using two 13.05m diameter tunnel boring machines (TBMs). The tunnel design assumed 100mm of tolerance on the final position of tunnel lining, accounting for tunnel misalignment and linings deformation, as well as a 50mm gap for the installation of a fireresistant material (either a spayed lining or pre-cast panels). The cross section of each tunnel has an internal diameter of 11.4m, including a two-lane carriageway - each lane being 3.65 m wide - and a

Location: : Ismailia, Egypt

Employer: Engineering Authority of the Egyptian Armed Forces

Construction period: 2016-2019

Contractor: Consortium PetrojetConcord-CMC-Razel

1.0m wide hard shoulder, with tra c barriers on each side of the carriageway. The soil conditions can be can be summarised as predominantly consisting of medium to fine sand, shallow silty clay, very dense sand, deep silty clay and sandstone/limestone. Random, discontinuous silty clay layers are found within the soil profile at several locations. Sandstone and limestone formations of various thickness are also observed at several locations and elevations with the cross section. The main TBM parameters that needed to be controlled in these soil conditions were: contact force, total thrust and advancement speed. These parameters can change depending on the type of soil being the TBM driven through. TBM parameters were continuously checked to take the most appropriate intervention. On this project, the rippers and cutter discs have been replaced at some point, to increase the performance of the TBM excavation and reduce the cutterhead

61

PROJECT 01

ITALFERR

Italferr S.p.A. is the engineering company of the Italian State Railways Group which, since 1984, has been charged with the task of drawing up plans and participating in invitations to tender in addition to directing and supervising the works and project management of all the Group’s large-scale infrastructural investments. The highly qualified body of sta and its specialist knowhow from the very best in engineering tradition not only allow Italferr to play a strategic role in the modernization and development of the national rail network but also provides it with excellent standing in the international market, where it operates fulfilling important contracts.

90

italferr.it

NAPLES-BARI HIGH-SPEED RAILWAY LINE IN SOUTHERN ITALY

The Naples-Bari High-Speed railway line has an overall length of more than 300 km, 120 km of which are currently in design or construction stage, including approximately 68 km of tunnels which feature for the 56% of the infrastructures. The Naples-Bari HS line is part of TransEuropean Scandinavian-Mediterranean Corridor, being Naples a junction dividing two directions: the first provides the connections Naples-Reggio CalabriaMessina-Catania-Palermo, the second runs South-East towards Bari. The new line from Naples to Foggia (180 km) is divided into 11 sections, three of which are in the operation stage, two are under construction, for two sections a public tender has been launched and for four sections the design stage is underway. The Building Information Modelling was implemented for

Location: Naples and Bari, Italy

Client: Italian Railway (R.F.I.)

Construction period: 2018-on going

Contractor/Joint venture:

Napoli - Cancello section: SaliniImpregilo, Astaldi

Cancello - Frasso section: Impresa

Pizzarotti, Ghella, Itinera

Other lots: to be awarded

the design of the infrastructures as an integrated tool for analysis and verification of interferences or criticality in the design phase. The railway line passes through the Southern Appennine Chain by means of 5 tunnels, crossing formations mainly composed by heterogeneous soils and rock-masses, which are characterized by significant degree of complexity resulting from their depositional and tectonic history. The railway line crosses regions with high susceptibility to landslides, both active or quiescent whose state of activity have been investigated both by geological studies and

91

PROJECT 01

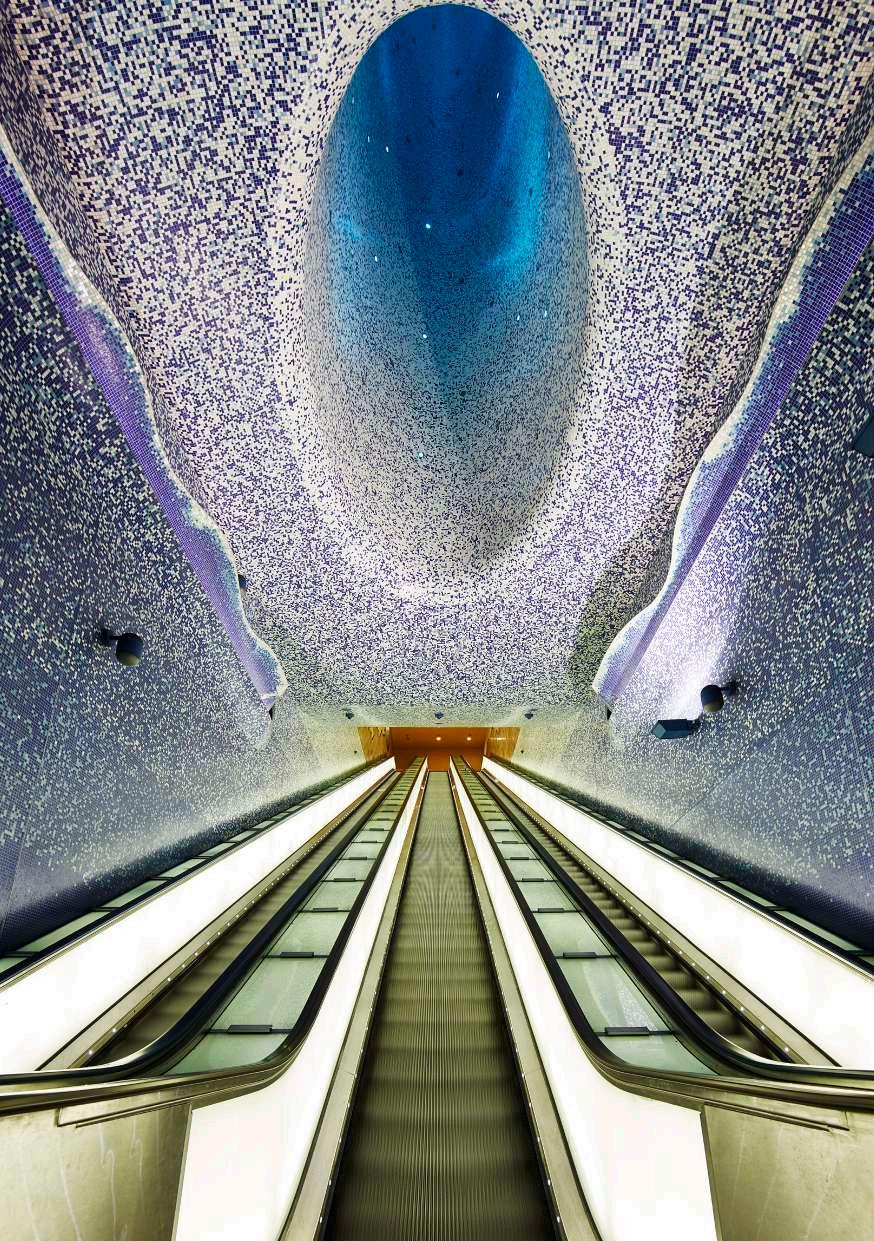

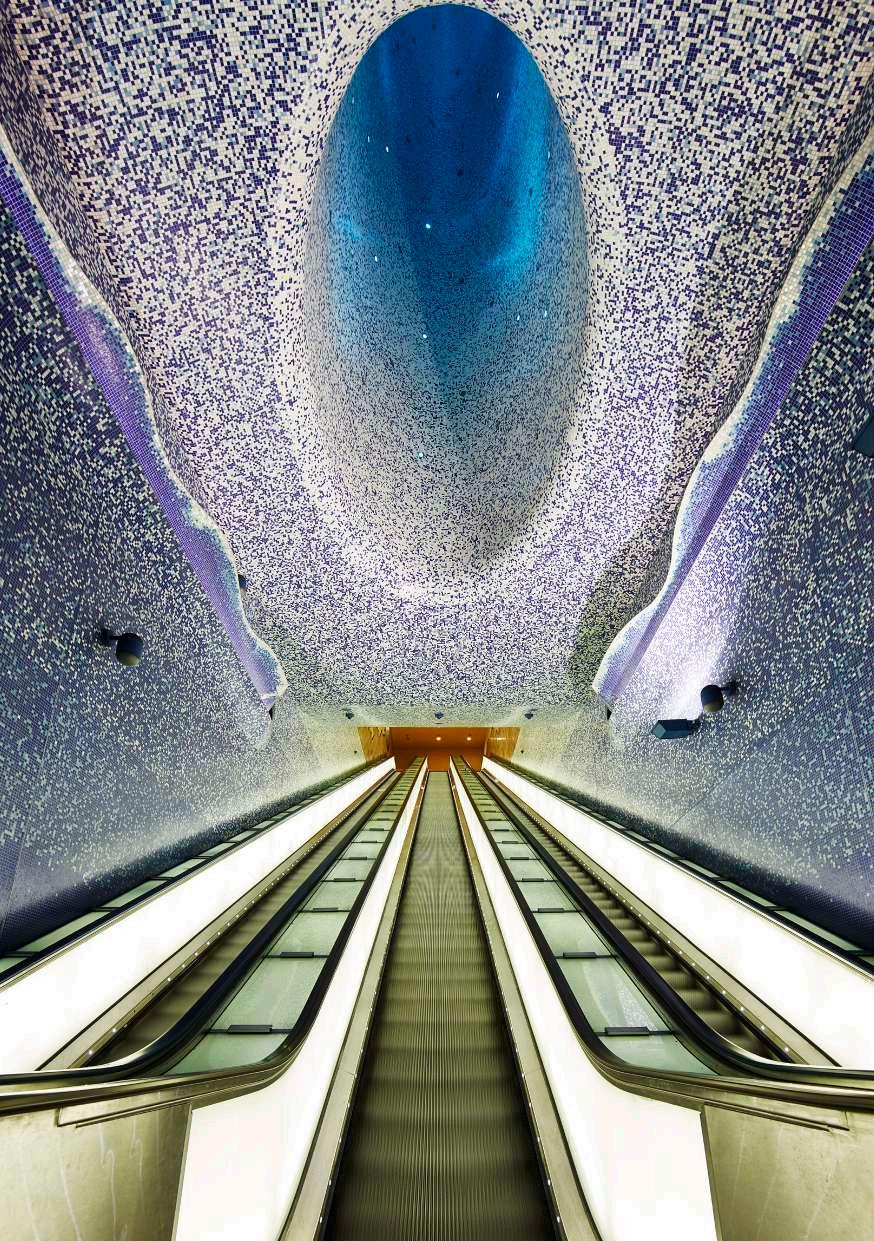

METROPOLITANA NAPOLI SPA

metropolitanadinapoli.it

MN Metropolitana di Napli spa is the concessionarie of the Municipality of Naples for the design, development and costruction of Line 1 of the underground. About 18 km with 17 station of this line is currently in operation.

Completion of Line 1 sets out the creation of a strategic ring wich will close at Piscinola connecting the Port, Raylway statione in Piazza Garibaldi, O ce District (CDN),and Capodichino Airport.

The architectural design of the stations was entrused to famous international architects flanked by contemporary artists with the aim of costructing stations which are functional but also the opportunity for urban requalification and cultural development.

112

PROJECT THE CAPODICHINO STATION

MN S.p.A. is currently engaged in the construction of Line 1 underground between Garibaldi and Capodichino stations. The 4 km long route includes 4 station and a train maintenance depot. The single-track tunnels arrive at the connecting structure, in Capodichino station where two wells have been built to lower the EPBs for the tunnel’s construction.

Capodichino Station has a form of Ω obtained with the combination of a circular and a rectangular shafts. The functional design of the Capodichino station and it electrical substation provides the pedestrian ascents made by means of helical stairs running on the well perimeter.

The platforms are allocated in two natural tunnels located outside the well and connected to it with horizontal pedestrian passages. To perform the tunnels station

excavation a sub-vertical jet-grouting columnar consolidation is planned to be carried out from the ground level. The consolidation measures on the front consist in sub-horizontal columns approximately 16 meters long. The excavation of the platform tunnels is planned to be carried out by two shafts located downstream of the stations, provided for the construction of the tunnels EPBs. The shafts have an internal dimension of 13.50 m and a depth of about 45 m excavated with a diaphgram walls that should not need temporary rods. With Piscinola - Di Vittorio section the line 1 will be completed allowing the passengers to easily reach the Central Train Station, the city’s port and the Capodichino airport.

Location: Naples, Italy

Client: City of Naples

Construction period: 2016-2021

Contractor: MN Spa

View of wells for digging tunnels

communication partner

PPAN Srl

www.ppan.it

Main tube of the Brenner Base Tunnel

Main tube of the Brenner Base Tunnel