To the AA family – readers, sponsors, contributors, our heart goes out to the flood affected and to those heroes who helped and are helping Australian refugees.

I recently connected with a survivor who lost her home. Her stories of community survival were far from mainstream news coverage. We commend those nongovernment heroes of the storm who rescued so many with their own limited resources. I pray the people of the Northern Rivers Region receive the help they deserve.

To this edition with the feature series by Peter Dubiez – Failure and Resilience with Ben Lawson of Shane’s Trees. Ben, you blew me away with your incredible story of progression in your business. The fact you openly reference the double-edged sword of inner and outer work is a strong measure of you as a leader. This journey is tough and many of us arborists with limited education, support and mentorship have to work it out the hard way. Reading your story prompted some fire in me as I struggle with similar commitments, as I personally kick off a new business.

it’s so great to get input from around the world. In this edition he brings us a feature article with ‘Trees of Ukraine’ and introduces us to Ukrainian arborist Igor Singer. Some of the observations discussed here remind me of observations I made in Berlin in the very early ‘90s (just after the Wall came down), where I worked as a tree surgeon – old Catalpa bignonioides trees are there

too. I hope the war there comes to a swift conclusion and look forward to seeing more of Igor’s work in association with you, Guy.

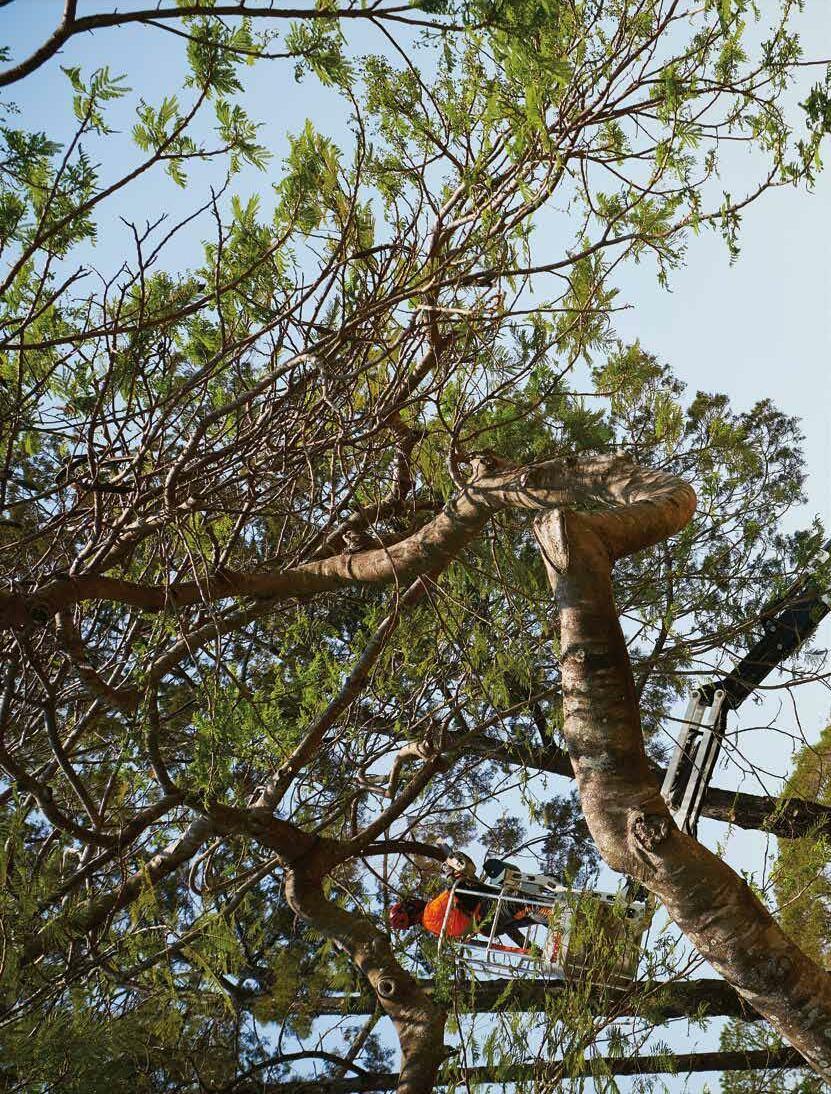

With ‘The Balancing Act of Branch Lifts’ we get some input from Joe Harris and Vermeer, on trees and crane work, a part of the Australian Arborists Seminar Series.

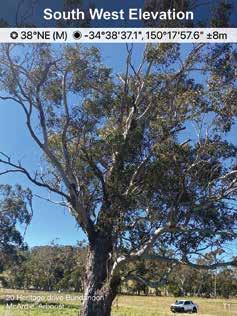

Jim McArdle and Hephzibah Crossing in association with the Tree Contractors Association Australia run an article on the ever-expanding world of trees and risk with ‘Proactive Tree Risk Management in The Arboricultural Industry’.

QAA are celebrating their 30th anniversary with a full-on schedule for 2022. In their news section we have a recap of their first two workshops of the year and an update on the upcoming events, including the Freestyle Climbing Competition in Cairns.

In closing I make reference to my feature article, The Body Language of an Ancient Sentinel - Part 2 – The Queen of The Forest – a project carried out in association with the High Climbers Brotherhood. Now that I have a number of other ancient figs in my sights I am starting to get really excited about the next chapter of this series. When appraising trees like this, we have no idea what we are going to find or experience, stepping into the unknown of a giant tree for The Australian Arbor Age – bring it on.

Publisher

Kurt M. Quambusch

Sub-Editor

Cassian Humphreys

Production Manager

Arianna Lucini arianna@maynemedia.com.au

Group Sales Manager KahChi Liew kahchi@maynemedia.com.au 1300 764 688

National Advertising Manager Sineade Sullivan sineade@maynemedia.com.au

Arlette Kouchakdjian 1300 764 688 (02) 8355 6841 / (02) 9452 4517 arlette@maynemedia.com.au

Design Peter Cartledge art@maynemedia.com.au

ISSN 1327 1784

The Australian Arbor Age and Forestry is a Bi-Monthly magazine published by Mayne Media Group Pty Ltd.

ACN 130 678 812 ABN 27 130 678 812 Postal: PO Box 489 DEE WHY NSW 2099 Australia Ph: 1300 76 4688 Int Ph: + 612 9452 4517 Int Fax: + 612 9452 5319 www.arborage.com.au

Copyright 2022

Mayne Media Group Pty Ltd. Material may not be reproduced or photocopied in any form without the written permission of the publisher. Mayne Media Group Pty Ltd. believes that all material is correct at the time of printing and will not be held liable for any incorrect information supplied within.

Cassian is a Merrist-woodian graduate (NCH-arb - 1991) qualified to Diploma level in Australia (09), his career commenced in Horticulture (85) and transitioned into Arboriculture (89). An experienced tree climber, instructor, arboriculturist, consultant, educator and writer, he has 30 years of experience. He sees his work as making a contribution to the Australian arboricultural profession.

Guy is a Master Arborist and Utility and Municipal Specialist, facilitating the co-existence of trees and people for the past 46 years. His company HistoricTreeCare.com manages the risk in veteran and historic trees by installing lightning and support systems, root invigoration, pruning and community education. Guy writes for tree care publications and works with the ANSI A300 Tree Care Standards committee in the US. He studies the science of arboriculture around the world.

PETER DUBIEZ

Peter is the CEO of Sydneybased Enviro Frontier (EF). EF utilises over 250 Tree Companies across Australia in managing tree works on behalf of its clients in the Insurance, Government and Facilities Management sectors. All jobs are managed using its proprietary technology platform (TreeManager) making it the leading data provider for the insurance and facility management industry. The company also operates in NZ, UK and Spain.

For almost 45 years Graeme has been based in the Dandenong Ranges East of Melbourne and become world leader in large tree removals.

Working as a production faller for alpine logging operations for three decades, expert witness, Investigator for WHS incidents and Lead Auditor are a sound foundation for him to assist with improving industry safety.

is a Science graduate who holds a Bachelor of Science in Agriculture (Hons) – Sydney University. Hephzibah is currently a technical writer for McArdle Arboricultural Consultancy. She is interested in both agriculture and app development and is currently dedicating her time to a project that combines these two passions.

practical measures to ensure they keep their workers safe and businesses open.”

Treasurer Matt Kean said we know some businesses in NSW have faced challenges and it is vital we get them the support they need to stay afloat and keep their workers in jobs.

The package includes financial support for small business to buy rapid antigen tests (RATs) to help keep their workers safe and a new Small Business Support Program to assist businesses to help keep their workers employed.

Premier Dominic Perrottet said that the NSW Government is determined to support those businesses that have been most affected during this wave of the pandemic.

“As part of the package, we are introducing the Small Business Support Program to help support businesses that experienced the worst effects of the Omicron wave,” Mr Perrottet said.

“We are also providing support to business to help reimburse the cost of rapid antigen tests for their workers, extending the Commercial Landlord Hardship Grant and delivering additional funding for the performing arts sector.

“This targeted package provides support for businesses who experienced cashflow issues and the immediate economic impacts of the Omicron outbreak.

“NSW is tracking better than expected and confidence is returning. And as we did with earlier recoveries, we will come through this recent challenge stronger than ever.

“We’ve got the backs of businesses, as we have throughout this entire pandemic.”

Deputy Premier and Minister for Regional NSW Paul Toole said the support package would provide a statewide response to the Omicron wave of the pandemic, targeting those businesses that need it the most.

“Our regions have felt the impacts of Omicron, and it’s critical we give them a helping hand to recover and get local economies humming again,” Mr Toole said.

“This package shows that the NSW Government continues to have the back of residents and businesses in the bush with

“The Small Business Support Program helps those businesses with annual turnover of between $75,000 and $50 million with a decline in turnover of at least 40 per cent by providing a payment covering up to 20 per cent of their weekly payroll.

“By ensuring businesses keep their doors open and their employees paid, we are confident our economy will bounce back strongly as it did last year.”

Small Business Minister Eleni Petinos said the program was important to ensure small businesses have the resources and cash flow they need to survive this outbreak and bounce back.

“We know that the over 800,000 small businesses in NSW are the lifeblood of local communities and that many of these businesses experienced challenges due to the Omicron wave of the pandemic,” Ms Petinos said.

“This package will help relieve some of the costs of small business including keeping workers safe, assist with cash flow and support small businesses to continue trading.”

The Small Business Support Program provides eligible businesses a lump sum payment of 20 per cent of weekly payroll with a minimum payment of $500 per week and a maximum payment of $5,000 per week.

In addition, the existing Small Business Fees, Charges and RAT Rebate will be increased by 50 per cent from the current $2,000 limit to $3,000 and employing businesses will be able to use the rebate to obtain RATs. This will support worker availability by helping reduce costs to small businesses and enabling healthy staff who have been exposed to COVID-19, but test negative, to return to work.

For information please visit nsw.gov.au AA

Businesses and workers across NSW are all set to benefit from a major financial support package of more than $1 billion to help those that have been hardest hit by the Omicron wave.

The new Husqvarna 90cc chainsaw is developed to meet the toughest of demands, in the most user-friendly way possible, for demanding tree professionals. Designed to meet heavy-duty challenges with power output, user-centric design and excellent manoeuvrability. It is built to endure and to be truly reliable. In short, it is made to provide you with the very best workday.

More powerful – best in class cutting capacity

The cutting capacity is the result of a combination of the extremely powerful X-Torq® engine and the razor-sharp X-CUT® chain, and the end result is unparalleled levels of productivity. It’ll make you better and faster and provide an improved cutting experience.

More efficient – best in class power-to-weight

When compared to competitor models in the same displacement class, the new 592 XP® offers an unbeatable combination of low weight and high power output levels, making you more efficient. The saws optimised balance is a result of optimised centre of gravity and, with the X-Tough™ Light bar, will provide for easier manoeuvring and a more efficient workday.

•

More reliable – vital reliability and easy starts

Husqvarna 592 XP® features new starting technology that makes the chainsaw more reliable and provides easier starts. Thanks to AutoTune™ 3.0, the engine settings are always optimised for maximum performance in all conditions, keeping you going no matter the challenges. The starting procedure is simplified and only one starting procedure is required no matter the conditions, or the temperature of the engine, which further improves the reliability. Additionally, it’s

equipped with a heavy-duty air filter with rubber sealing and a robust crankcase that handles bars of up to 36".

The new 592 XP® saw will deliver impressive cutting capacity by being equipped with the combination of the X-TOUGH® Light or X-TOUGH® bar, and a razor-sharp X-CUT® chain with hard to match stay-sharp properties. The X-TOUGH® Light bar is a robust bar with reduced weight that greatly improves manoeuvrability. The X-TOUGH® bar made

•

•

•

“Husqvarna 592 XP ® features new starting technology that makes the chainsaw more reliable and provides easier starts.”

HUSQVARNA 592 XP®

90cc worth of unparalleled power in an easily manoeuvred and lightweight package. An X-Torq® engine with outstanding torque and acceleration and, to top it off, a razor-sharp X-CUT® chain perfectly in tune with your saw. The end result is best in class cutting capacity, making you better, faster, providing you with unparalleled levels of productivity. In short, a better cutting experience. Explore the new Husqvarna 592 XP® today, at husqvarna.com/90cc

A study in collaboration with the High Climbers’ Brotherhood.

As I embark on this study of a truly massive Moreton Bay Fig, Fig. 2 in our series on ancient Fig trees, I invite arborists from all over Australia to join the next step in this journey.

For me this study is as much on the history of the landscape we found this tree in, as it is an individual ancient and her adaption from a forest tree into a giant field pasture specimen, wider than she is tall. A study that took me to National Parks and a letter to the editor of the Local Mary Valley community magazine seeking history and pieces of the jigsaw that make up the trees story.

The Body Language of an Ancient Sentinel

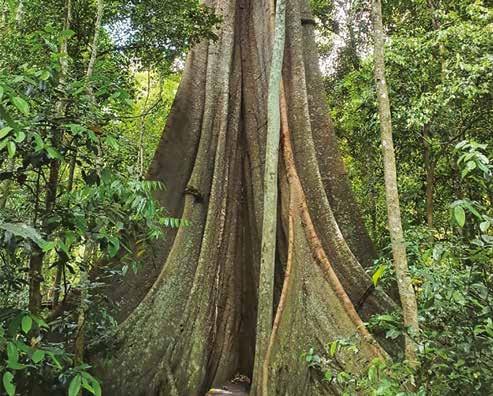

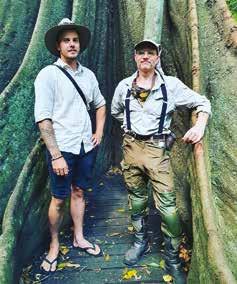

Following our first edition in this series for The Australian Arbor Age - December/January 2021/22 and the study of an ancient White Fig - Ficus virens, with the most dynamic body language I have ever seen, in this edition we appraise a truly gargantuan Moreton Bay Fig – Ficus macrophylla. I first observed this tree whilst working the Energex VTA (Visual Tree Assessment) Program in around 2009. This massive specimen was appraised by the Brotherhood over two consecutive weekends in early December 2021. Fellow arborists Leigh, Aaron and I climbed the tree and got the internal photographs the first weekend. Ryan and I came out with his drone for some outer canopy footage the next.

Located on the top of a forested hill flanked by the Mary River to the east and Little Yabba Creek to the south (more of a river than creek at present), with MalenyKenilworth road crossing Little Yabba Creek (that feeds into the Mary) and flanking the hill to the west, this tree stands dominant on a large Island of forest vegetation (see Fig. 2 and 3). The tree is at the centre of a small patch of forest, part of Conondale National Park between Conondale and Kenilworth (Sunshine Coast Hinterland). To access this monster of a tree you have to park up in a Little Yabba Creek Park (with car parking), where we are standing in Fig. 2 and walk into the forest via a footbridge that runs alongside Maleny-Kenilworth road which bridges Little Yabba Creek. The Fig tree is located in rain forest opposite Sunday Creek Road via Fig Tree Walk. For camping Yabba Creek Park is a great spot.

We measured her 50m height against our longest lifeline and got a good ground-

Fig. 2: The band of brothers and the Queen on her hill – Conondale National Park.

Fig. 3: Mary River to the East – the drone shots truly enable the greatest appreciation of this huge Moreton Bay Fig tree.

Fig. 4: Accessed by Fig Tree Walk, opposite Sunday Creek road (parking at Little Yabba Creek park opposite Yabba creek park) Fig tree 2 is the largest remnant tree in this patch of forest.

Fig. 5: The Fig tree flanked by the Mary River to the east and Maleny-Kenilworth road to the west stands at 50m with a crown spread measuring 57m north to south. The drone shots truly enable the greatest appreciation of this huge Moreton Bay Fig tree.

Fig. 6: Maleny-Kenilworth road to the west.

based measurement via a timber deck that circles the tree via foot paths to the circle deck approaching from the north and south. The easily visible and measurable structural root area was recorded at 14.5m by 16.5m, including the trunk and buttress, that area comes in at 240m2 of woody mass at ground level.

Based on the measurements given us for SRZ’s (Structural Root Zones) and TPZ’s (Tree Protection Zones) by the Australian Standard for Protection of Trees on Development Sites – AS4970-2009, this tree with a 5.5m diameter would require a TPZ radius of 15m and an SRZ radius of 6.8m. As discussed in the White fig article (Part 1), such measurements are entirely misguided for rainforest giants such as fig trees. Most fig trees regardless of Genus have structural root zones that are largely quite visible with major buttresses extending into minor buttresses and visible surface transport roots. Based on visual assessment and actual on-site measurements, the SRZ on this tree ranges from 8m to 9.5m in radius from the trunk. Though I tracked one major above ground 320cm thick

transport root (close to the buttress) 25m into the forest until it sunk below ground (this root heads east toward the Mary river), another I measured with a 255cm diameter – 15m into the forest and a third at 230cm diameter – 10m into the forest, all three of these transport roots where at least 40cm in diameter where they sunk below ground. I think it reasonable to expect most major buttresses to have similar sized transport roots radiating out into the hill – below ground. Obviously, this is well beyond the SRZ given by the standard. Should this tree be subject to development (thank God it’s in a National Park) one could reasonably argue for a 30m SRZ, as for the TPZ – let’s call it the whole hill!

This tree in many ways is very different to our first subject ancient tree – The White Fig (Ref: AA Dec/Jan 2021/22 edition) which was a gold mine of a VTA study. A study of body language that led me to believe we were dealing with a 400 - to 600-year-old tree with wood ropes, pillars, welds, struts, life belts, grafts, tubular triangles and the never seen before star growth formations (I hypothesised these where to strengthen the trunk to branch attachments of the massive 22m limb). However, this specimen – Fig tree 2 the much larger Moreton Bay Fig, has body language far more the norm to a much younger specimen. The kind of body language (wood ropes, pillars a few small lifebelts and early grafts) typical to the many (150-250 year old) field pasture dairy farm fig trees (largely F. macrophylla) scattered throughout the hinterland from the Sunshine Coast to the Gold Coast Hinterland regions. To be true I suspect that this tree is the oldest as well as largest Moreton Bay Fig I have studied. Even working as a tree surgeon in S.E. Qld (91-2007) my experience of studying ancient fig trees is limited, our survivors are all too young, probably too young to be described as ancient based on European standards.

Stepping back in time I had the privilege of being employed by National Parks to do an aerial inspection (to determine failure likelihood) on another similar sized Green Leaved Moreton Bay Fig (Ficus watkinsiana) on Mount Glorious in the mid1990s. That specimen (sadly later felled by National Parks) like fig tree 2 started life as a strangler fig on a host tree in a high crowned rainforest setting.

Had I been the experienced investigator I am now in 1996 when I climbed the Mt Glorious fig, I would have got some measurements, but I do recall that (like this Moreton bay fig) there were little visible signs of the original host tree. The only major sign was audible, in wind you could hear the decaying host groaning under load and movement of the fig tree. Tragically this was mistakenly why that old giant was felled, it was misperceived that the groaning sound of

the fig on the host was structural impairment on behalf of the fig tree. With pressure on the National Parks Ranger (fuelled by fearful private homeowners who had foolishly freshly built under the leeside of the leaning Glorious giant) my reasoning was not heard. In truth that fig as I saw it had no faults at all. But the experience of having climbed and appraised that tree gave me some solid reference points in how stable strangler figs are.

“This iconic tree is the largest/oldest Moreton Bay Fig I have seen in Australia.”Fig. 7: The southern side of the Conondale National Park Fig tree accessed by Fig Tree Walk.

No job is out of reach with the RUTHMANN Bluelift SA31 tracked spider lift - designed for close proximity and rough terrain. Ideal for arborists in Australia, this model is suitable for many maintenance tasks thanks to its narrow width and lightweight design. With a maximum working height of 17.8m and maximum horizontal outreach up to 9.3m, this tracked spider lift can easily reach high elevations. A self-stabilizing system locks the spider lift into place for safe work at height.

My assessment of Fig tree 2 conveys an interesting study of what I perceive spans the last 150 years. I consider it reasonable to consider that the hill this tree stands on was clear felled of trees in or around the 1860s (typical to the region), that it is reasonable to consider the forest was cleared twice (I suspect again in the 1950s). That is bar fig tree 2 and perhaps the neighbouring Brachychiton and Giant Stinging tree (approximately 1m DBH), which were left, the timber of such trees was considered valueless. I likewise consider it likely that this fig was already an established 30m+ tree (but with a much narrower forest crown), it probably already had established the classic braiding network of roots/trunk tissues over the host by then, faint signs of the historic braiding are still visible (now buried under increments of wood), having studied and reported on reaction wood braiding before I see such structure as being the strongest. The now much broader tree is wider than tall with a classic field pasture or paddock crown, I perceive this tree to be 400 years old.

Our challenge with estimating the ages of our largest and oldest fig trees is that we have little to nothing of a recorded or historic benchmark, though the area was made a National Park in 1977 and prior to then was managed as State forest (speaking to the State foresters who locally farm Araucaria species is also to be on my agenda). All we have is scraps of information based on a

limited human historical record.

Our profession generally started less than 60 years ago, having only really come of age since Shigo’s publications. That, based on the underpinning colonial and governmental programs we were subject to – trees have been only really valued felled. This in part explains why we have so few ancient trees to learn from.

Based on the trees health evidenced by her exceptional body language, the vast nutrient bed her root system is covered by and her dominance over the forest, it is clear that even with forest clearing the tree has the best possible resources available. A forest mulched hill, deep in humus, with multiple natural fissures as a result of a re-generating forest system yields optimal nutrition via the multitude of microbiological associates (collectively known as the soil food web). This is far from a turf soil/root environment – the curse of many parks and field pasture trees which lack needed microbiological association for nutrient exchange.

It is however possible that the forested hill was never cleared. A hiking appraisal of the hill was suggested by the head National Park Ranger (whom I met with and questioned), she remarked to look for tell-tale stumps as indicators of timber getter history.

In truth I have found no stumps to indicate past clearing, the bulk of the trees surrounding the Queen are young, bar the neighbouring trees already discussed,

the average larger diameter trees are only 250cm, though the bulk of the surrounding trees are 9cm saplings. Perhaps the tell-tale stumps have been lost to decay. I can well imagine that there was a forest of equally large trees surrounding this one. But then how can we really know? I like the idea of the hill having not been cleared as this would well support the figs exceptional vitality (health), helping the tree to achieve such a large bodily mass. This supports her youthful maiden-like status, but still does not really help in aging her.

Having had experience of working in New Guinea and Vanuatu I have seen fig trees with girths upwards of 10m in diameter, this raises the question of fig trees living up to 1000 years old. I have seen footage on Indonesian bridges constructed out of spliced together roots and crowns of fig trees said to be 2000 years old.

We also have to question the variation of age between species of figs, though our ancients are so few that a comparison

between the ages of species is all but erroneous, because we need data on the individuals that we have left first.

At this point I pay homage to the support of The Australian Arbor Age for me to gather such data to share it with our profession.

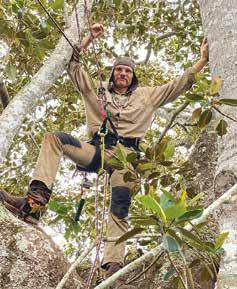

Having climbed/appraised the upper crown of the tree with Leigh and Aaron I was inspired to find no evidence of historic live limb failure, with such a large crown and being such a target to wind load it is a testament to the tree that the only limbs shed were dead branches, I measured samples of dead shed broken limbs (fragmented due to the fall and decay) on the ground at 14cm in diameter. Based on aerial inspection, these were shed at trunk collars.

On appraisal, I counted a total of 10 buttresses emanating from the trunk and bisecting into 20 large buttresses until ground level where the buttresses bisected again into a total of 34.

Going by the body language of the trees trunk the fig leans more predominantly to

the west, with the tension side in mind the most active (reactive) trunks to root flexation I witnessed is on the south eastern and north eastern sides. Though in truth the tree is very well buttressed on all sides. Interesting to see two reactive ropes helping hold a tree up, usually we see one, considering the braiding nature of Fig trees I am reminded of their advanced capacity. The greatest current reactive growth (observed as lighter brown stretch marks) can be seen as spines of active reaction wood (running up to 10m up the trunk) corresponding down into the lower buttresses and the largest, longest visible transport roots (collectively acting as guy lines) previously mentioned as being 25m long (south eastern corner) and 15m long (north eastern corner) until they go below ground. The western side of the tree (the leeside) likewise has two active buttresses (making current reactive growth on the compression side) which likewise link into lower buttresses/transport roots, the longest is visibly 10m until going below ground.

“The now much broader tree is wider than tall with a classic field pasture or paddock crown, I perceive this tree to be 400 years old.”Fig. 11 and 12: Northern and southern sides of the 5.5m diameter Moreton bay fig tree. Fig. 12

Though all the fig trees buttresses are clearly pumped (strong by the lore that is VTA) these four points are the most reactive based on current load and optimisation. Because this tree has such good vitality it can be well recognised (or argued) that these four points play a key role in the trees stability. Due to the surrounding vegetation it is awkward to be clear on the relative configuration of the trees crown in relation to the trees lean. It maybe that the lean is historic, that based on the trees well balanced crown spread –the lean is now negligible in proportion to the trees crown. To be true the surrounding vegetation limits my ability to easily form or capture my observations (photographically), I have done my best.

In Fig. 13 we can clearly see one of the active buttress ropes (red arrow) the larger rope leads into the 15m transport root (15m until it goes below ground). The blue arrow indicates the active buttress which links into the 25m transport root (at 25m it goes below ground) its active ‘spine’ of reaction wood

Bandit Mobile Service trucks are launching soon. All part of our promise to deliver outstanding customer support and backup across Australia. We’re here to support your success. More to come!

can not be seen on this angle. Based on visual assessment alone, both these active buttresses/adjoining transport roots act as 35m and 25m guy lines, in reality these guy lines are likely to be 50m long, though proving that is not possible without further investigation and disruption to the tree.

See the action shots on the left.

Fig. 14: Leigh Antonio de Abreu powering past me as I labour up a single rope, Leigh is our high line installer. Fig. 15: Aaron Smith checks out what looks like a young Ficus obliqua in a 40m branch fork. Climbing these ancient fig trees for me has burst a bubble, prior to our last article I had never seen figs growing on figs, with three different species already found up our first two adventure climbs I have had to take stock. Fig. 16: Leigh giving perspective to the forest below. Fig. 17: Having switched to my favoured old school double line I was free to explore the fig trees upper crown.

Conclusion – comparative study to Fig tree 1

The Conondale National Park Moreton Bay Fig tree, located on a forested hill between Maleny-Kenilworth road and the Mary river, stands at 50m with a spread of 57m and a trunk diameter of 5.5m. This iconic tree is the largest/oldest Moreton Bay Fig I have seen in Australia. Having measured a number of buttresses leading into transport roots I perceive it likely that the trees root system covers the whole hill. The trees growing environment and body language is optimal, as evidenced by foliage size, colour, density, the trees well optimised

You begin each day before dawn with a drive and determination to do more than the day before. When you move at this pace, you know to do more you need equipment that is made for more. That’s why our equipment is built from the ground up to meet your needs, delivering:

More Power and Production

Lower Operating Costs Ease of Maintenance Greater Longevity and Resale Value

If you’re ready to operate equipment that’s made to keep pace with you, then we invite you to contact the authorized dealer in your area of the world. To learn more about our equipment go to www.morbark.com

Morbark

NSW/VIC: Global Machinery Sales 1300 072 926 globalmachinerysales.com.au

QLD: Allclass Construction Equipment 1300 255 252 allclass.com.au

WA: Westco Equipment +61 (8) 9258 9333 westcoequipment.com.au

NZ: Commercial Outdoor Machinery 0800 26 66 88 commercialoutdoormachinery.co.nz

Boxer

NSW/VIC: Global Machinery Sales 1300 072 926 globalmachinerysales.com.au

QLD: Greenstar Equipment 1300767589 greenstarequip.com.au

WA: Westco Equipment +61 (8) 9258 9333 westcoequipment.com.au

NZ: Commercial Outdoor Machinery 0800 26 66 88 commercialoutdoormachinery.co.nz

NSW/VIC: Global Machinery Sales 1300 072 926 globalmachinerysales.com.au

QLD: Greenstar Equipment 1300767589 greenstarequip.com.au

crown structure and reactivity (reaction wood development), all examples of high levels of vitality. I see this specimen as being benchmark to the Genus and species. Conondale National Park was founded in 1977. I sense that the hill was cleared of vegetation twice, in the 1860/70’s (Red cedar timber getters) and again in the 1950s for a national bulk order to China of timber to be used as railway sleepers, according to an old source, this further (considerably in his words) denuded the land of trees up and down the east coast. The 90 year old retired timber merchant (Mt Mee) informed me that they felled anything (even wattle) regardless of quality for that shipment.

As with the White fig (Fig 1 of our ancient fig series) from the Dec/Jan 2021/22 edition of The Australian Arbor Age I see a parallels to Fig tree 2 the Moreton Bay fig, in that both trees where originally within a forest, but were then subject to forest clearing, that both trees started life as strangler figs on already established host trees. With consideration of early Australian settlement this would have been true for many surviving fig trees up and down the east coast (in fact this will be true of our third fig tree study – Numinbah Valley Gold Coast Hinterland - Part 3). The difference here is that Fig 1 (the White Fig) was veteranised by storm damage (I recorded a number of 50cm diameter live limb branch-break-outs), whereas Fig 2 has an unbroken ‘virginal’ crown.

Based on the presence of the numerous young trees, saplings mostly with a 9cm diameter, (the larger up to 250cm diameter) under both fig trees (Fig 1 and 2) it is likely (without question for Fig tree 1) that there has been a period of forest clearance where both trees where subject to field pasture growing environments. Certainly, in the body of the White fig (Fig tree 1) there has been a period of stressed times and subsequent optimisation as mulch levels and

conditions that benefit the soil food web have improved. Note – with reflection on Fig tree 1 I suspect that the cause of the historical cavity (since optimised) was fire damage. Stress optimisation is less apparent with the Moreton Bay fig (Fig tree 2) which may have always sustained optimal health levels due to its environment, the lack of historical storm damage or limb failure supports this observation. Another comparison with these trees is that they both had access to creeks to help sustain them through lean years of resource availability, I suspect this is a key observation. I also perceive that both fig trees share the same age of 400 years old. In a future article I will hopefully have some historical footage to share. My contact with the Mary Valley Voice (Mary Valley community magazine) has yet to fruit, my letter to the editor requesting historical pictures of the hill or the tree gets published to the region later in March.

With closure on this study, I wish to thank a fellow traveller I know as Fiona, I met her during the Moreton Bay fig appraisals. She donated the cover photograph (Fig. 1) and Fig. 20. – both of which honour the fig trees form perfectly.

I also wish to acknowledge another traveller, a British consulting arborist, writer and the inspirator of this ancient fig tree series David Lloyd-Jones. David is part of a small scale ‘5 eye’ collaboration on Conservation Arboriculture, between Australia, Canada, Britain, America and New Zealand, composed of David, I, Guy Meilleur, Ryan Redvers and other leading arb thinkers/writers. David contacted me in late 2021 and posed that as writers we owe it to the tree to raise the bar on our writing. That it’s time we pay homage to the unspoken spiritual side to trees, in fact he advised I go and find an ancient tree to receive a timely gift. In truth the logic side to myself was somewhat challenged by this, yet deep down I heard his call. It was with Fig tree 2 late last year that I received that contact.

With regard to receiving the call, between 2003 and 2006 I was in dialogue with Dr Alex Shigo (the father of arboriculture), it was he who inspired me to write commencing in 1999. It was his feedback on a past article of mine on CODIT (AA 2003) that kept me writing. His motto of Touch Trees has always sat with me, it was in one of our dialogues (by fax – pre internet) that I understood this from him, that touching trees is a two way

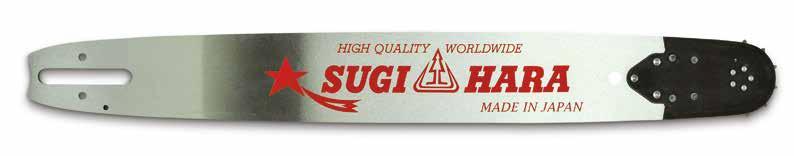

Quality and excellence represents Prokuts Sugihara range of bars suited for commercial forestry and aborist professionals. With over 50 years of manufacturing chainsaw bars in Japan, the home of outstanding knowledge in forging and working steel; Hideo Sugihara has really raised the bar within the industry with this quality range.

FEATURES:

• Professional premium quality, solid, replaceable sprocket nose guide bar.

• Super tough steel, heat treated up to 4 times on different parts of the guide bar, provides superior bar-body strength and tough rails with excellent resistance to wear and chipping.

• Manufactured from a single piece of steel, featuring superior durability and stiffness characteristics.

• High durability sprocket nose.

• Polished lacquered finish.

experience. That in the course of a lifetime of touching trees that he himself had been deeply touched. I also realised that late in his career he had been pained by judgement from those in the profession (the curse of the pioneer) that did not understand that (passion). I also understand that those consumed by scientific or mainstream perspectives alone are unlikely to know what it is to be touched by nature, which in my experience is being touched by god. With the Shigo call and David’s prompt in mind I am pledged to pay homage to this other ‘thing’ that we humans struggle to discuss let alone integrate. From here on my writing will where appropriately reflect on this, for those that cannot read such reflection I hope that the rest of the narrative is sufficient enough to keep your attention engaged. I pledge to save such reflection for the conclusion so you can easily gloss over that should you choose.

A solid example of the experience of the divine aspect of nature or god is something we cannot deny in the early stage of human love relationships, that falling in love phase which fuels the emotional sides to our nature. This sense of god we also classically experience in relationship to our children, especially when young, we can clearly see the divinity in our babies and toddlers. We also know the utter value of true friends, who stand by us through the rigours of life. Another area where I have had direct experience of this is with bodily near misses. On a number of occasions in my youth I have been in error alone up big trees as a climber, usually through being overly tired (when I first worked in Greater Brisbane in 91-96, there were no other spurless climbers to work with). I have had experiences where I could have or maybe should have died, yet around trees miracles happen. I can say the same of my experience of the 2008 Gap storm (a 2009 AA article), where I saw countless examples of people and property protected by trees, where I met countless people in gratitude to the broken and unbroken trees in their gardens. Another example of spirituality that our Editor Kurt Quambusch can also relate to is on the back of adventure motorcycles. Riding off road in extreme conditions I generally have to surrender to spirit to survive the ride. Also having a background in security, I can say the same of ‘combat’ extremes where violence is the challenge

and spirit which overcomes – the miracle.

In the course of my career, I have been open to the idea of experiencing god in nature (perhaps a lifetime of touching trees was the preparation I needed), though until I found this Moreton Bay fig late last year (maybe it was I that was found) the experience of divinity in giant woody plants was only an idea. Now that I have been touched by the divine aspect of mother nature I recognise a balance point, in myself and around me. Embracing the idea and experience of god has been a commitment these last two years. Prior to meeting this remarkable tree I already had embarked on

what I perceive as a healthy relationship with the divine masculine aspect of god. Yet the gift this tree bought me, the experience of the divine feminine aspect has for me bought home God (masculine and feminine elements combined) on a whole other level.

Beliefs and passions aside, I doubt any of us could not be moved by the presence of this fig tree. I hope you enjoyed this article, I look forward to our next sojourn with an ancient fig. I feel the call to Numinbah Valley and Part 3, I know of the perfect candidate, thank God for trees.

Fig. 1

These images of trees were recorded during a 2017 tour of that beautiful country, facilitated by a leading Ukrainian arborist. I had encountered Igor Singer on LinkedIn, and he seemed like a brother from another planet. So, while I was in Europe, I took a detour to see him and his trees. As of this writing, the war in Ukraine is 12 days on. We added the words during the bombardment of his neighbourhood outside Kiev, and promised to meet with the trees together, after the war. Maybe the post-cyclone system of triage can inform the care of trees after bombing. Maybe not. Igor’s working on that right now. Hopefully, his efforts to restore remaining trees can play some part in the renewal of his country.

Igor’s main goals are to conduct environmental education and perform tasks to solve environmental problems in Kiev. He’s always keen to cooperate with arborists from other countries. Today’s improved translation technology makes that easier all the time. In 2017, the software was not so good. My Ukrainian was non-

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 2:

Fig. 3:

Fig. 4: Allees of Populus sp. line the main walkway at Babyn Yar.

Fig. 5: With sign language, Igor describes (I think) ram’s horns, where scar tissue rolls inward as it closes cavities.

existent, and Igor’s English was poor. When translation software failed, which was far too often, we were reduced to sign language and German. His was OK, but mine was learned in fourth grade, and by hearing my mother muttering curses. We probably looked and sounded like raving maniacs – which is maybe not too far off. There’s a lot I missed from him; I hope we can try again.

Tens of thousands of innocent human beings were shot and buried when Nazis

From its unique doubly secure interlocking anchor bollard, to the highly efficient oversized ball bearings, this is a block with a difference.

– Compact, lightweight

– Double security at the anchor bollard

– Ideal for both everyday rigging and winch operations

– Hollow axle facilitates multiple configurations

– Hauling loop simplifies hauling, transfer and storage

– Fairleads flairs help maintain efficiency even in suboptimal set up

invaded Ukraine in 1943. Tree stumps are common themes for memorials; avatars of lives lost, and grim reminders of man’s inhumanity to man – when men are crazed by nationalist dreams of empire. One alleged premise of the 2022 invasion was “denazification”, but the mass murder of innocent civilians with modern killing technology looks worse than ‘Renazification’. The tools of Putin’s evil madness are far more destructive than Hitler’s.

It was common to see poplars brutally topped in Russia – it even happens in England! – but these are just side-trimmed using an aerial lift. Most of the trunk flares were visible at ground level, indicating some savvy about proper tree planting. The landscape was designed and managed as well as the parks elsewhere in Europe.

Ukrainians avoid NDD – Nature Deficit Disorder – by using their green spaces, and show their respect for nature (and for themselves) by keeping them fairly clean.

Hollow trees fascinated us both, so we

visited many of them. We came to some understanding about burls; their causes, features, management challenges. Igor’s pet peeve is concrete filling cavities. On one tree, Igor went to great pains to remove the concrete, but when he returned and found the tree re-filled with concrete, he found a way to laugh it off. Ukrainians are notorious for their sense of humour. Finding comedy within tragedy, laughter is the best medicine for seeing one through difficult times. Another peeve was the bright green paint that I saw commonly applied to tree wounds on street trees in Kiev. Painting pruning wounds is not popular, and we all have heard why. But applying sealant inside cavities is quite different. In Russia I saw several cavities coated with some brown stuff for decades that actually seemed fungistatic, if not fungicidal. But many of those trees were Quercus robur, which is highly resistant to decay to begin with. Igor said (I think) that he was working on some secret sauce to do the same thing,

Fig. 6

Fig. 8: Ukrainian people, like Ukrainian trees, know how to fight their way out of a tight squeeze!

Fig. 9: Catalpa bignonioides shades a busy sidewalk in Kyiv.

Fig. 10: Not all mistletoe is created the same.

Fig. 7

but when I pressed him for details, he said (I think) something about a patent. The rest was lost in translation.

Like jackrabbits in Australia, red oak trees in Europe take over, and wreak havoc. They grow so fast, and get so big, and have fairly strong wood. I’ve seen beautiful specimen red oaks in places like France. But genetics is a problem, when many are grown from the same problematic parents. And invasiveness is a huge problem with red oaks in Ukraine.

Unlike red oaks, catalpa trees are wellbehaved North American natives, and don’t get too big for their own good. Their wood is very tough, and they excel at compartmentalising wounds. The practice of painting tree trunks white is fairly common in Ukraine, and many other countries. When

Fig. 8

the paint is “whitewash”, calcium carbonate, this practice is also known as mineral feeding via trunk drenching. Anyway, it does not seem to bother the trees, or the people around them. The tight spacing of the street trees indicates an eagerness to soften and civilise the harsh appearance of the rectangles known as Soviet architecture.

Phoradendron sp. is fairly common in the eastern US and western Europe, while the smaller-leafed Viscum album plagues the western US, and eastern Europe.

I saw 300+ historic but infested Tilia trees in Slovenia that almost got the axe. Now they may get black paint applied to the base after cutting it off. The same will be tried in Ukraine, after the war. Paint is effective on Phoradendron, so hopes are somewhat high. Will the world keep bullying its neighbours, like red oak trees? Will it keep extracting resources and leaving them to die, like small-leafed mistletoe? Or will we act more like Catalpa, exchanging benefits and modeling resilience? It's up to us. AA

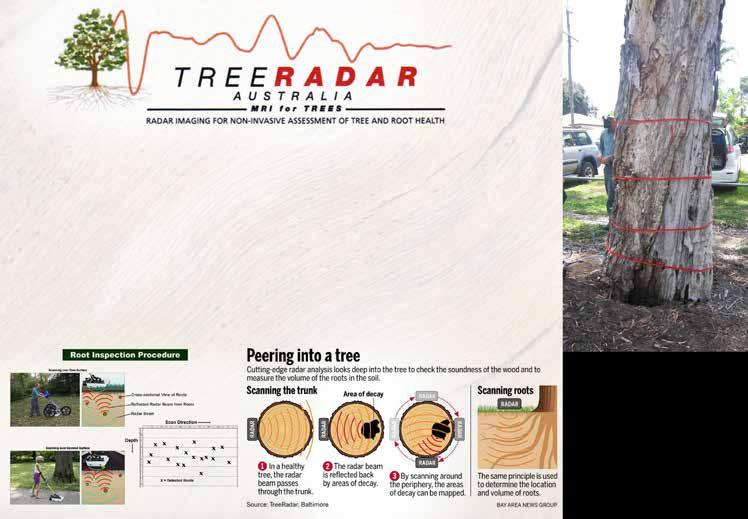

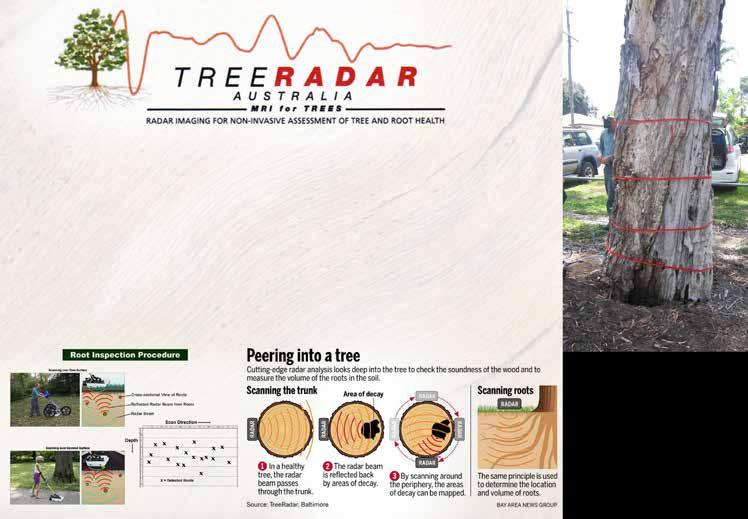

Tree Decay is a severe problem which can put all the structure around a tree at risk. With Tree Radar Units™ decay detection, Tree Radar can scan for decay in any tree regardless of its height. The Tree Radar unit can give an accurate read out of the severity of decay in a tree without having to penetrate the Tree’s surface.

Tree Radar Australia uses a ground penetrating Radar Unit to provide the only, completely non-invasive method of tree decay detection and tree root detection available in Australia. YOU CAN’T JUDGE A TREE BY ITS COVER TREE RADAR HAS BEEN IN AUSTRALIA SINCE 2005

“Ukrainians are notorious for their sense of humour. Finding comedy within tragedy, laughter is the best medicine for seeing one through difficult times.”

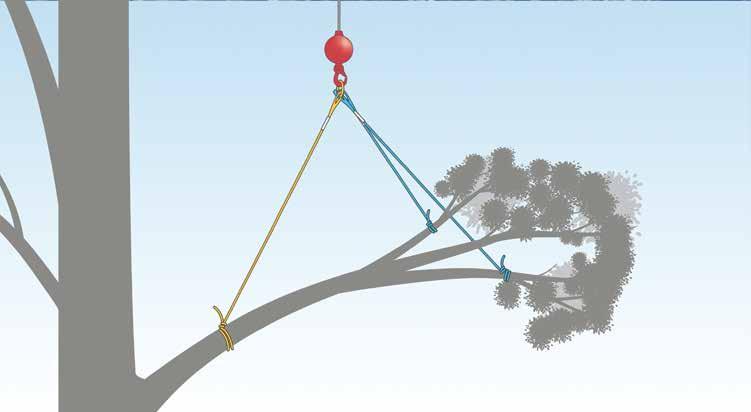

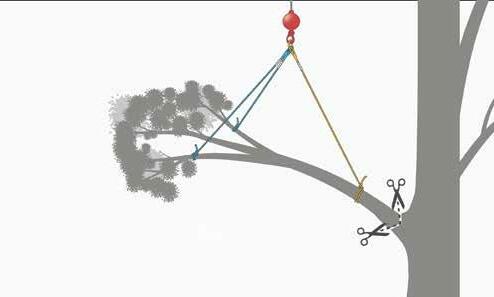

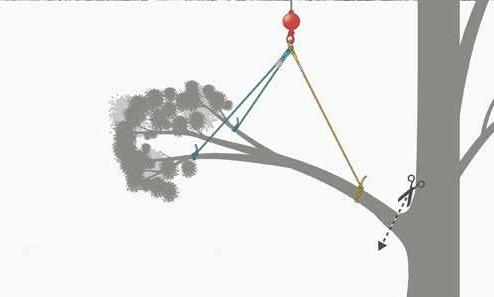

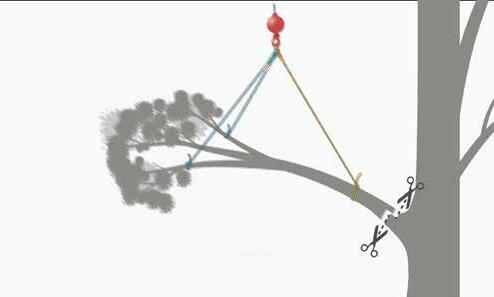

Joe Harris from Into Trees participated in Vermeer Australia’s Arborist Seminar Series last year, talking through the balance branch lift technique, and best practice for arborists to use this method safely and efficiently. Here is some of what he had to say.

The right sling for the job

There are two different types of slings that can be used when lifting a branch: chain or textile loop slings.

“Chains can come in different sizes and lengths, and it’s common to have two to four different sized chains attached to the crane hook to balance the branch,” Joe says.

“The main issue with chains is that they

can create a lot of slack, which can be hard to manage and manipulate lengths. Wrapping or shortening the chain can work, but this can still cause issues with managing the length.

“Textile loop slings are super light and easy to manipulate compared to chains. They are also safer for climbers – if they are to swing from a branch they are not as heavy or dangerous.”

Joe says the right choice depends on your preference and what is available at the time of the job, but textile loop swings are his preferred option.

How to sling a branch for a balance lift Joe says there are a couple of key elements

to a successful balance lift using a textile loop sling.

“First, you need to ensure your sling is set at the centre of gravity of the tree. Then, depending on the size of the branch, use different lengths and slings and space them out across the branch to ensure balance. Your longer sling should also be positioned at the blunt end of the branch so there is slack when the branch is cut and lifted.”

Joe also says when positioning your shorter slings, ensure they are angled at around 90° between the longer slings to assist with the removal. Your pre-load weight of the crane also comes into play here, which will determine positioning of the slings (Fig. 1).

When using a crane to dismantle and remove branches from a tree, there are a few different methods and techniques to consider.

Fig. 2

Different cuts for different branches “Now you have your branch slings set, and your crane weight pre-loaded, it’s time to cut the branch. There are a few different cut techniques when using the balance lift, and the right one depends on the type of branch, and the area you’re working in.”

Straight cut through. Use when branch is perfectly balanced. Can be made top-down or bottom up.

Fig. 3

This is the simplest cut. Can be made topdown or bottom-up (Fig. 2).

Bottom cut inboard of top cut. This creates a step or lip to stop the butt ‘kicking up’ at the climber. There can be different variations of this depending on pre-load weight (Fig. 3).

Stops the butt kicking up or dropping down. Start with undercut, then finish with a top cut last (Fig. 4).

Step cut. Bottom cut outboard of top cut. Creates a step for the butt to sit on. Use with less preload, ≥ 75% of weight.

Fig. 4

V cut. Stops the butt kicking up or dropping down. Make top cut last with 85% preload.

To find out more about Vermeer Australia, including more information on the Vermeer Australia Arborist Seminar Series, head to vermeeraustralia.com.au AA

In arboriculture, widely recognised acceptable risk levels do not exist and so an industry-based approach should form the foundation standard of what is considered to be acceptable tree-related risk. – G.Moore (2020).

Users of tree risk methods should understand the relative strength and weaknesses of any method that they use. It could be relatively simple to challenge the results of a tree risk assessment in a court of law based on the limitations inherent in the underlying methodology, particularly if the user was not aware of them and had failed to take them into account in interpreting the outcomes.

Trees are often managed reactively; this article highlights the importance of proactive tree risk management.

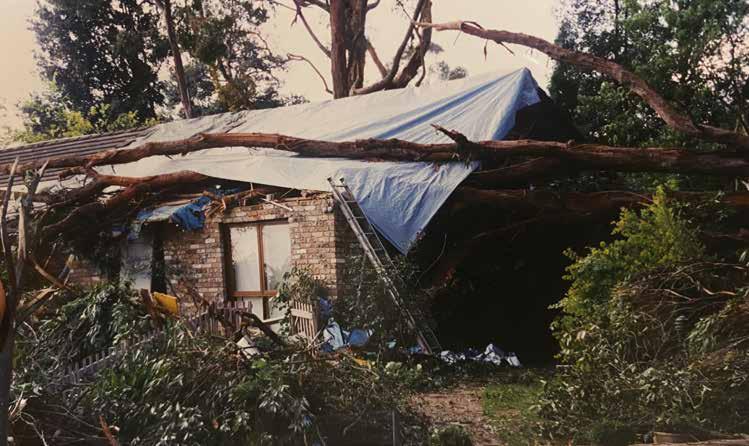

“… proactive management approaches, report a long-term reduction in costs, as the demands to clean up after storms, to conduct risk management and pruning, to manage community complaints and to manage damage caused by failures are reduced.” – Cunningham (2011).1991 - Storm damage at 27 Carters Rd Dural, NSW.

From a bush fire perspective, the strategic removal of declining trees can aid in the reduction of the forests fuel load (McCaw 2013).

This strategic removal of trees in bushland can be seen in the United States. Mechanical fuel load reduction (MFLR) treatment involves mechanical thinning of trees to decrease the probability and severity of bushfires (Ximenes et al., 2016). It is noted that large fallen trees can be hazardous through increasing flame (Ximenes et al., 2016).

Trees in an urban setting have been observed to increase in failure probability with increase in decay during windstorms (Cihan et al., 20140). In an investigation on the dynamic loading of wind, trees with a large proportion of weight in branches, increase the sway potential and likelihood of tree failure due to wind (Kenneth et al., 2006). A vTRATM visual Tree Risk will competently assist the facility manager to reduce risk of tree failure incidents on site. An assessment removal of mass from trees through pruning can aid in tree retention with management (James et al., 2006).

In an independent inquiry, large trees with clearly identifiable defects have been recommended for proactive management by councils (Cunningham 2011). Proactive tree risk management can improve tree structure and longevity (Cunningham 2011).

Trees are a resource which should be preserved and managed accordingly. Proactive tree risk management, which

Above: Tree with multiple pathogens and Phellinus sp (Bracket fungi).

Right: The VTA allows for level three assessment. The VTRA calls this a level three assessment. John Dee from Bees Knees Trees Service, Sydney climbing an E. pilularis tree and resistograph testing at Lindfield.

may include monitoring, pruning, further investigations and calculations of risk probability, can ensure the tree, and its associated value, can be maintained.

Proactive tree risk management is ensuring appropriate methodologies / tools are used which allow better observations leading to more specific interventions or specifications in long-term reducing costs.

VTRATM visual Tree Risk Assessment is proactive as it also is the only assessment that assesses the residual risk. It is utilised by many regional and local councils at a national level and utilised in the DET schools and many other facilities.

Risk management is defined as: The systematic application of management policies, procedures and practices to the tasks of, communicating, establishing the context, identifying, analysing, estimating, evaluating, treating, monitoring and reviewing risk.

Risk: Risk is simply the chance of a specific undesired event occurring within a specified period. Risk = Likelihood x Consequences (Standards Australia 2004) or as it relates to Visual Tree Risk

Assessment; Failure Potential x Risk Target Rating = Risk Assessment.

Time factor: The assessment period is critical as it allows an evaluation of likelihood to be undertaken. All tree risk assessments must be defined by a timeframe. (Norris 2007).

Essential factors to be considered to improve tree safety on sites are:

Utilisation of a site

If a tree fails, what is the impact to persons or property?

1. Occasional Use:Biodiversity areas, fenced areas, out of bounds area, restricted and inducted areas

2. Intermittent Use: Parking lot, oval, golf course

3. Frequent Use: Busy street adjacent, typical schoolyard, childcare centre, gateways

4. Constant Use: Occupied rooms, buildings, residences, sit-down lunch areas

5. Continual use: Access paths, assembly areas, Gathering areas.

In terms of further condensing these areas, 5 and 4 are considered High use areas, 3 and 2 are Medium use, and 1 is Low use.

Minimal usage areas that will be occupied by students, staff or peers for educational and/ or recreational purposes (e.g. campsites, bush trails, ecology areas will require an inspection by a competent person (this may be (an arborist) using the Annual Tree Inspection and Checklist¹ to identify hazards prior to entry.

Relates to defects, toxicities and poor management practices relating to trees, including pruning from unqualified operators or untrained personnel.

Elevated hazards: These trees have defects which make them likely or somewhat likely to fail or expose a person or property to damage. When such a tree is identified in a High use area, the extent of the risk is categorised into very likely or somewhat likely to fail.

Lesser hazards: Where trees are unlikely or highly unlikely to fail or cause harm (except in higher use areas), mitigation rather than removal is undertaken.

In the visual Tree Risk Assessment (vTRA)© which utilises the tree risk matrix, tree risk can be assessed as ALARP – (As low as reasonably possible), Medium, High 1, High2 or High 3. The vTRA© that are identified within the scope of the recent facilities including School review – in the arborist report will be documented. Mitigation

of these risks may include pruning, tree removal, fencing off and isolating high-risk trees, and specifying the type of approach (including hierarchy of control).

The Vtra© utilises the three levels where level 1 and 3 are relating to risk assessment and level 2 is the VTA-Visual Tree Assessment which is undertaken for health and structure. Level one can be undertaken by an AQF 2 or 3 and determines if a level 3 inspection is required. Level 3 – three is undertaken by an AQF level 5 arborist who is competent in the use of vTRA.

It is the facilities manager’s responsibility to manage the safety of the remaining and future tree specimens within their site. Understanding the basics of the proactive vTRA and addressing the risks associated with trees will ensure the benefits of the facility and prolongs the life of a tree.

Records and photographs of near-misses and damaged trees should be included into the yearly inspection register. This will assist new staff in managing tree risks.

Observation and awareness of tree issues and behaviors are necessary to provide optimum safety. Arborists in many cases have to balance protecting trees with protecting persons and property. Simple observations of these past failures can reveal a great deal about a particular location. The strongest conclusion should be formed based on an assessment of the area (locality) and attention to local weather patterns and storm events, including lightning strike.

1. Monitor the trees’ condition, especially during weather events

2. Do not occupy areas near or under trees during storms or windy weather. A wind index of greater than 40km/hour to evacuate areas around trees is a suitable guide

3. Observe trees in the early morning, as evidence of branch drop is more probable when the plant cells are turgid

4. Review the health of the trees using the TCAA checklist

5. Discuss the notes with people who have access to your site (toolbox talk or staff meeting)

6. Evaluate the whole tree as part of the contextual environment it is in

Graduates will have basic theoretical and practical knowledge and skills directed work.

Graduates will have theoretical and practical knowledge and skills for work.

Graduates will have theoretical and practical knowledge and skills for specialized and/or skilled work.

Graduates will have specialized knowledge and skills for skilled and/or paraprofessional work.

Graduates will have limited factual, technical and limited theoretical knowledge of specific areas of work.

Graduates will have factual, technical and some theoretical knowledge of specific areas of work.

Graduates will have broad factual, technical and some theoretical knowledge of specific areas or a broad field of work.

Graduates will have broad factual, technical and some theoretical knowledge of specific areas or a broad field of work.

Graduates will have a range of cognitive, technical and communication skills to select and apply a basic range of methods, tools and information to complete routine activities and communicate / transmit solutions problems.

Graduates will have a range of cognitive, technical and communication skills to select and apply a specialized range of methods, tools and information to complete routine activities and provide and transmit solutions to problems.

Graduates will apply knowledge and skills to demonstrate autonomy and judgement and have deferred limited responsibility within known parameters.

7. Monitor moisture of soil and watering. Using the hand-feel method to determine if soil moisture is optimum or saturated for soil heave in trees

8. Site notes on abiotic and biotic conditions are useful

9. Compare with other known specimens of a similar maturity and species. Utilise the arborist methodologies for vTRATM.

It would be beneficial to engage an AQF Level 5 arborist at most times; however, AQF level 3 arborists can determine whether a tree has defects or has an imminent failure or threat (as per level 1 assessment). AQF Level 2 arborists would be able to exclude trees and identify these basic hazards, including hanging branches and defective fractured trees (as per level 1 assessment).

AQF Levels and their application is contained in the Table above relevant for tree inspections. (Courtesy Bill Sullivan 2021)

Duty of Care would allow for a person who has experience within the locality and if they are certain of a tree defect or change to allow for AQF Level 5 arborist to investigate and assess the risk. A Level 2 assessment would be suited to these assessments, as a Level 1 inspection would not be fit for

Graduates will apply knowledge and skills to demonstrate autonomy and judgement and take limited responsibility within known parameters.

Graduates will have a range of cognitive, technical and communication skills to select and apply a specialized range of methods, tools and information to complete routine and non routine activities and provide and transmit solutions to both predictable and unpredictable problems.

Graduates will apply knowledge and skills to demonstrate autonomy and judgement and take limited responsibility within known parameters.

Graduates will have a range of cognitive, technical and communication skills to select and apply a specialized range of methods, tools and information to complete routine and nonroutine activities and provide and transmit solutions to both predictable and unpredictable problems. Transmit knowledge and skills to others.

Graduates will apply knowledge and skills to demonstrate autonomy and judgement and defined responsibility in known or changing contexts and within broad but established parameters.

Level

purpose within a school environment unless it was a biodiversity area that has been fenced off.

A Proactive Pre-climb inspection may utilise the vTRA level 1 by a competent person trained as AQF level 3 with practical knowledge and skills for access. Pre-climb assessments which can be are utilized to ensure that a satisfactory method of approach to access a tree which may trigger the hierarchy of control depending on the level of hazard which may be presented in a tree.

Level 3 assessments are completed only by an AQF level 5 arborist and are useful for determining a tree’s risk of failure and include aerial inspections, photographic journal, sounding (both with a mallet and the ground), resistograph testingTM, root mapping, Picus testingTM, load testing, and other invasive testing; which may be reviewed on its own merits, periodic assessment for monitoring. The facilities manager or principal will decide about engagement scope. Reiterating the point;

1991-

a vTRA level 3 must be completed by the AQF level 5 Arborist.

The TCAA are able to advise on the levels of inspection which would be covered under the scope of works and where necessary as an independent representative of the industry – Email admin@TCAA.com.au.

The minimum qualification required for an arboricultural consultant should be AQF Level 5, and arborists from the Tree Contractors Association Australia (TCAA) arborists have relevant industry experience.

If a facilities manager has reason to seek further advice or an assessment of trees and intends to engage an AQF Level 5 Arborist, it is important that a prehistory of the trees – including previous tree risk assessment

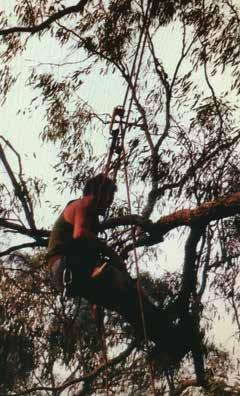

Installing a nesting box tree and assessing tree for a pre-climb using the EWP. Hierarchy of control allows for EWP as a suitable way of access and when it cannot be used then a pre-climb assessment must be done prior to donning the climbing harness.

reports, tree inventory data or other induction registers – are supplied to the arborist who will make tree management decisions. This can be cost effective to the facility.

A complete tree inventory can be costly, but it provides the most accurate data –especially on a facility that has lots of trees.

A partial survey focused on high occupancy areas (e.g. assembly areas and buildings) will suit limited budgets without limiting the goals.

Where necessary, the tree inventory should also include trees on neighboring properties – especially where they are large or known toxicogenic species or have had poor management practices applied. Walkways, access driveways, central administration buildings (offices) are also key areas to survey around.

By compiling and analysing the tree inventory data for trees on your facility, this should assist in identifying works that will merge into your program with a focus on sequencing works according to budgetary constraints. Although, emergency issues may arise and override this planned program.

By reviewing the given report, the facility manager or principal can identify high risk or problematic tree species and seek to sequence and structure a works program.

¹ Annual Tree Inspection Checklist is developed by the TCAA in conjunction with the DEC.

Australia Inc.

Ciftci, C., Arwade, S. R., Kane, B., & Brena, S. F. (2014). Analysis of the probability of failure for open-grown trees during windstorms. Probabilistic Engineering Mechanics, 37, 41-50.

Cunningham, B. (2011, September).

Independent inquiry into management of trees on public land: Final report extract. In 12th National Street Tree Symposium 2011 (p. 71).

James, K. R., Haritos, N., & Ades, P. K. (2006). Mechanical stability of trees under dynamic loads. American journal of Botany, 93(10), 1522-1530.

McCaw, W. L. (2013). Managing forest fuels using prescribed fire–a perspective from southern Australia. Forest Ecology and Management, 294, 217-224.

Pike, D. A., Webb, J. K., & Shine, R. (2011). Chainsawing for conservation: Ecologically informed tree removal for habitat management. Ecological Management & Restoration, 12(2), 110–118.doi:10.1111/j.1442-8903.2011.00582.x

Ximenes, F., Stephens, M., Brown, M., Law, B., Mylek, M., Schirmer, J., ... & McGuffog, T. (2017). Mechanical fuel load reduction in Australia: a potential tool for bushfire mitigation. Australian Forestry, 80(2), 88-98. Australian Standards (AS4360:2004) and adopted for this research.

TCAA has Tree Management Guidelines for members which are available on the TCAA website and which have been eight years in the production. For further information contact Tree Contractors Association Australia, P.O Box 207, Galston, NSW 2159, by calling 1300 660 379 or email www.admin@tcaa.com.au AA

“Proactive tree risk management is ensuring appropriate methodologies / tools are used which allow better observations leading to more specific interventions or specifications in long-term reducing costs.”E. resinifera Red Mahogany, Dural. Jim McArdle, TCAA President.

2714 Spider Lift in action by EWP specialist Monitor Lifts. December 2019, Sydney, NSW Australia

2714 Spider Lift in action by EWP specialist Monitor Lifts. December 2019, Sydney, NSW Australia

When did you take charge of Shane’s Trees?

Dad loved a Foster’s and often drunk them up a tree while sharpening a Stihl 090. His idea of safety was only cans of beers could be sent up to him in the tree as bottles could smash and cut someone. It wasn’t unusual for dad to drink a six pack of “Blue heelers” (Foster’s cans) before lunch. How he survived I will never know.

Back in 2011 my dad had retired and sold all his gear. I thought if Dad could run a business drunk, surely I could do it sober. I had a friend of a friend that wanted a job done so I bought a Stihl 200t on my credit card and did the job stacking it in an old ute. I’d bring the waste home, cut it up and fill the neighbourhood green bins for weeks.

Our business was built on residential tree work but commercial is now a large portion of our business.

As our systems and people improve, we are now targeting council and commercial work. We are focusing on this work for consistency and to ensure we are competing with other genuine business that have quality people and safety systems in place.

What did you change to grow from a few staff to now 40 plus?

Myself. Every time the business has grown it is after I have put a considerable amount of work into improving who I am as a person. I’m a strong believer that your business will never outgrow your skillset as a leader. I have developed a passion for personal development and reading, this has really helped me to expand my mind and see opportunities for improvement.

About five years ago I looked for and built connections with quality mentors and coaches. These people have really challenged my own limiting beliefs and poor

habits that no longer served me – although if you ask my Mrs some habits persist.

Ten years. Five years of hard work followed by five years of smart work. But the hardest part was going from one crew to two crews. It’s a crazy time in business, as the owner you are doing it all, because the business is not at a scale to afford a management structure.

In the last three years we have added a crew every year. That’s been some crazy growth and has required a keen eye on cashflow. It’s interesting how the requirements of the business and systems change for every crew that is added.

Wow. Big question. There have been days when it’s thunder and lightning and there is a 130t crane setup that’s going to cost $7000 plus wages and no work gets done. Those days are testing. I’ve had a couple of fleeting

moments thinking ‘why am I doing this?’. There was the time all my gear got stolen three months after I started. That near killed me. The time my good mate and team leader cut through his arm at the bicep and I had to climb the tree and finish the job.

When I went through a separation in 2017, I remember crying in my hands thinking there is no way I can get through this. I just could not see a way to keep the business. Until I had a good night’s sleep.

But give up… No way, there is always a way.

You specialise in marketing – social especially – what made you focus on that area?

There was a time on a 40-degree day I put up a post about buying the boys a beer for every share and it went viral. I was buying the boys beer for months. This really made me realise how much time people spend online.

On reflection I realised how much time I was spending on social and thought everyone else must be doing the same thing. I’ve had some incredible mentors and watched the social trends in other industries so I thought I would give it a good crack. We have become very consistent on socials. Posting one or two videos a week. Stories and posts every day.

Do you need to be disciplined to make it work?

I don’t see myself as a disciplined person. There was seven to eight years when I was balls to the wall and worked my absolute guts out through fear of failure.

I try and focus on the most important task as often as possible. I’ll leave discipline to the Olympians.

You have made a statement to train 100 world class arborists by 2030 – what made you decide on that and how is it going?

When I think about what brings me the most joy in business and lights me up, it’s training people and watching rough kids bloom into quality arborists that contribute to society.

I’m so proud of some of the young men that have become world class arborists through Shane’s Trees. More than 15 so far.

Big shoutout to a young man that came to us, rough as they get – Josh Whitinui, so much respect for the effort he has put into developing himself as a person and a climber.

“I was “just’ a climber a few years ago, now I’m helping take a technology and tree business global. That’s an opportunity few will ever have and fewer will seize.”Ben and his dad Tommy. Ben Lawson from Shane’s Trees.

Last year you decided to live in the UK – how did you set up your business to allow this to occur?

Lots of trying, failing and learning. It has always been my goal to have a lifestyle business that I did not need to be in daily. It took me 18 months of preparation and a few 4–6-week holidays out of the business to find where the weak points were that I needed to fill. It’s not just the systems we have but the people. I constantly look at how I can coach, mentor and grow our people. People give back in loyalty when they realise how much they have learnt.

Beyond the people, I have developed a lot of tools that give me solid numbers to show how the business is performing. I review these number religiously and ask questions when they seem off.

What involvement do you have from oversees? What reporting do you get?

I have a weekly meeting with our GM, marketing and accounts. I review everyone’s goals weekly.

Smash out a few emails. I get daily reports from each team, our profitability daily and per job as well as weekly marketing reports. Approximately five hours a week is what is required from me. Although I love it so normally do more.

You have partnered with Enviro Frontier to be their UK Director – like starting over – what challenges – what is exciting? It’s going to be a hit to my lifestyle… haha. But really, it’s back in the grind, doing the simple things repeatedly. Getting in front of clients, understanding the market and hustling like I just bought my first chainsaw again.

It’s a monumental challenge to start a business in a new country and there is a lot of fear I have had to overcome to leave Shane’s

Trees in the capable hands of our team.

I have always admired Enviro Frontier as a business model and it excites me to help take it global. I pinch myself. I was “just” a climber a few years ago, now I’m helping take a technology and tree business global. That’s an opportunity few will ever have and fewer will seize.

The challenges and unknown aspects of this next chapter really send shivers down my spine. I’m sure there will be a few moments that will be comparable to my spurs slipping

out for the first time. But with the people around me I’m confident there will be a lifeline to catch me so I can keep climbing.

Just like learning to climb. You must push yourself and overcome a variety of fears. The best way to do this is with mentors that have done it before. I remember the confidence it gave me when an old climber was on the ground talking me through my fears and the next move in the tree. It’s the same in business, I will surround myself with mentors. At Enviro we have some great mentors in the technology space that have taken multiple business to 8-9 figure turnover. I’ll ask them quality questions, implement and execute.

If I keep reading, learning and asking questions, it’s only up from here.

The more you give the more you get. Pass on your knowledge, love and experience wherever you can. It will come back in spades. AA

Vertical lift arms and a 40-hp (30kW) turbocharged Kohler KDI diesel engine gives the CTX100 exceptional lift and tipping capacities, coupled with the operator-centric features common to all Vermeer loaders. Grasp, lift and move brush and logs with ease and efficiency thanks to Vermeer’s Mini Skid Steer Loader range and the Rotating Log Grapple attachment with 360 degree rotation. Perfect for arborists doing the ground work and all tree care companies. Contact your local RDO Vermeer team today.

VERMEERAUSTRALIA.COM.AU | 1300 VERMEER

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and /or other countries. © 2022 RDO Equipment Pty Ltd (trading as Vermeer Australia). All Rights Reserved.

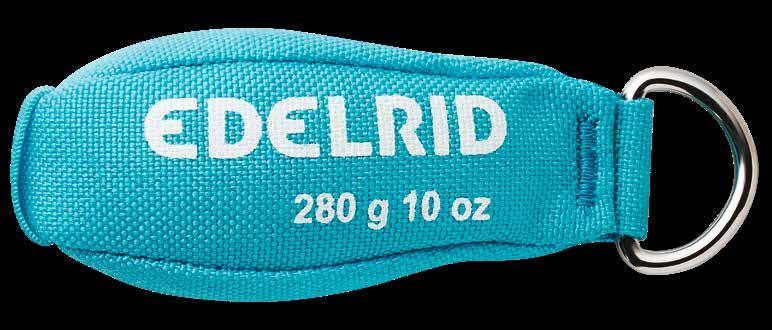

APOLLO 280g and 340g.

EDELRID

The HOUSTON is a foldable bag for transporting throwlines and accessories and can be divided into two sections. This makes it possible to separately store two throw lines and two throw bags per line whilst keeping them tangle free.

Once opened up, the HOUSTON has a stable form thanks to the integrated magnets. When the HOUSTON is collapsed, the throw lines are neither folded nor twisted, preventing knots.

APOLLO 280g and 340g

APOLLO is a super tough throw bag for rigging from ground level. EDELRID’s choice to fill with extra small steel balls as compared to lead pellets of others on the market is an ecological benefit in the rare instance the bags do become damaged and spill into the environment.

The outer material made of Cordura is specially sewn and extremely durable.

The balls are also secured in an inner balloon in case the outer sheath becomes damaged further preventing the release of balls into the environment.

EDELRID CASK 28L and 55L

EDELRID CASK is a robust rope carrier bag with hard-wearing construction for high durability. With its rigid freestanding design for easy storage of ropes, the CASK 28 has the capacity for approximately 60m climbing rope or 100m static rope.

The CASK 28 can be placed inside the CASK 55 for easy transport and organisation. It comes with front mesh pockets for extra storage including the HOUSTON in the CASK 55 – keeping all of your climbing kit organised and together in a single bag for

EDELRID CASK 28L and 55L.

For further information and to find your local stockist, contact Expedition Equipment on (02) 9417 5755 or get in touch via email – sales@expeditionequipment.com.au

Prokut was made of the simple need of creating a range of quality bar, chain and outdoor power equipment accessories for the Australian market.

Prokut’s parent company GA Power Equipment Spares has been the industry leader in aftermarket spare parts in the outdoor power equipment industry for more than 40 years. As a proudly Australian owned and operated company, they understand the needs of Australians as well as what our tough, yet beautiful country can throw our way.

Within the huge product offering from Prokut, a real standout is the Sugihara bar range, ideal for commercial forestry professionals and arborists. The range offers a lineup of 27 solid and 8 lightweight reversible bars to fit everyone’s favourite chainsaw brands and last the long haul. Trust us, this range does not disappoint.

Now, a little about the background of the bars. Hideo Sugihara started manufacturing chainsaw bars in Japan more than 50 years ago and since then the production of the bars have been in the same factory. Japan’s

reputation for excellence in forging and working steel is displayed through these bars.

The thought that has gone into this range speaks for itself with the bars being manufactured from a single piece of steel, which features superior durability and stiffness characteristics. The excellence in steel work is proven with just how tough the steel is, being heat treated up to four times on different parts of the guide bar. This provides superior bar body strength and tough rails with excellent resistance to wear and chipping. These bars are also finished with polished lacquer which sets the range apart from others in the industry, providing less friction allowing you to slice through any timber like butter.

Paired with the highest quality control standards the Prokut Sugihara bars allow you to really go the extra mile.

Want to learn more about this great range or see what else Prokut has to offer? Prokut has a huge dealer network of close to 450 nationwide, so you’re not far off from owning some of this exquisite Prokut gear.