- MORE POWERFUL THAN EVER 90cc worth of unparalleled power in an easily manoeuvred and lightweight package. An X-Torq® engine with outstanding torque and acceleration and, to top it off, a razor-sharp X-CUT® chain perfectly in tune with your saw. The end result is best in class cutting capacity, making you better, faster, providing you with unparalleled levels of productivity. In short, a better cutting experience. Explore the Husqvarna 592 XP® today, at husqvarna.com/90cc

Here we are with our third edition in 2022. I wish the AA family well as we get half way through the year. As ever we have some solid articles for you this edition.

First up in my review schedule is an old favourite, Guy Meilleur. His Technical Feature – ‘Documenting Evidence for Credible Conclusions’ covers the work of world-renowned Dr. Julian Dunster. Guy takes us through two tree evaluations and a scientific process of evaluation, specification and documentation to help give our work credibility. Thanks Guy, for the new term –Anastomosis, plus it’s always inspiring to see an old veteran be honoured for posterity. I am sure the Flower Hunter William Bartram would be grateful.

Onto a new writer for AA, we have Leigh De Abreu, a highly experienced climbing arborist and adventure climber. Along with brother Arb Aaron Smith, Leigh featured in my first two parts of the new article series on Ancient Fig Trees. He is the climber responsible for high line set ups to enable access for our 30 and 50m climbs. Recognising his talent for ‘artistree’ and my following up to the call from the AA Publisher Kurt (we advertised for climbing writers in 2021), I asked Leigh for input.

‘Switching Systems’ on Single Rope Technique – SRT is his first Climbing Feature for AA. Same as me, Leigh is an ex Merrist-Woodian. We are glad to have you on board mate.

For the consultants, in support of the Development Application bread and butter projects, we have another solid Technical Feature from Michelle King and Jim McArdle. This piece – ‘Pre-DA Arboricultural Impact Assessments’ covers the essential start up to the development process. Historically, Australian consulting arborists have been called in too late to help protect trees on development sites. As well as protect valued vegetation, the pre-DA impact assessment –supports the streamlining of the development process and reduces stress/cost to the

client. We encourage you to dive into a breakthrough process for trees and Arb.

The Technical Feature from me entitled ‘i-Culture - Land Care via Vegetation Management Part 1 – Background’ was seeded out of a late ‘90s article on ‘Arboriculture the Industry V the Profession’, though I sadly cannot recall the author, this perspective has sat with me for years.

This feature is a bigger picture study on the Vegetation Management professions/ industries and a call to collaboration for New Earth ventures.

With resilience, sustainability and mother earth in mind, I see this as one of the most important articles of my career. This draft is a first, I already have three editors lined up for the second, as I intend to get this piece out to the allied professions involved with VM.

I will draft future parts to this topic, as I see the need for a template to the new earth and see arboriculture as an important catalyst to unite us.

Our Cover Feature – ‘Extend the Longevity of your Climbing Career’ is on the Ronin a mechanised tree ascension device – from ABSAFE, the Australian and New Zealand distributors.

As a past competition level swordsman in Western Martial Arts (Ronin is a name better known in those circles) and a double rope and prussic tree climbing arborist (now retired

– well not as a climber), I well attest to the challenge of the RSI – Repetitive Strain Injury.

I first saw one of these machines being promoted by a past QAA President and used by the legendary Guy Meilleur. I encourage all Arb companies to seriously look at this device, I can see solid provision for rapid aerial rescue ascent.

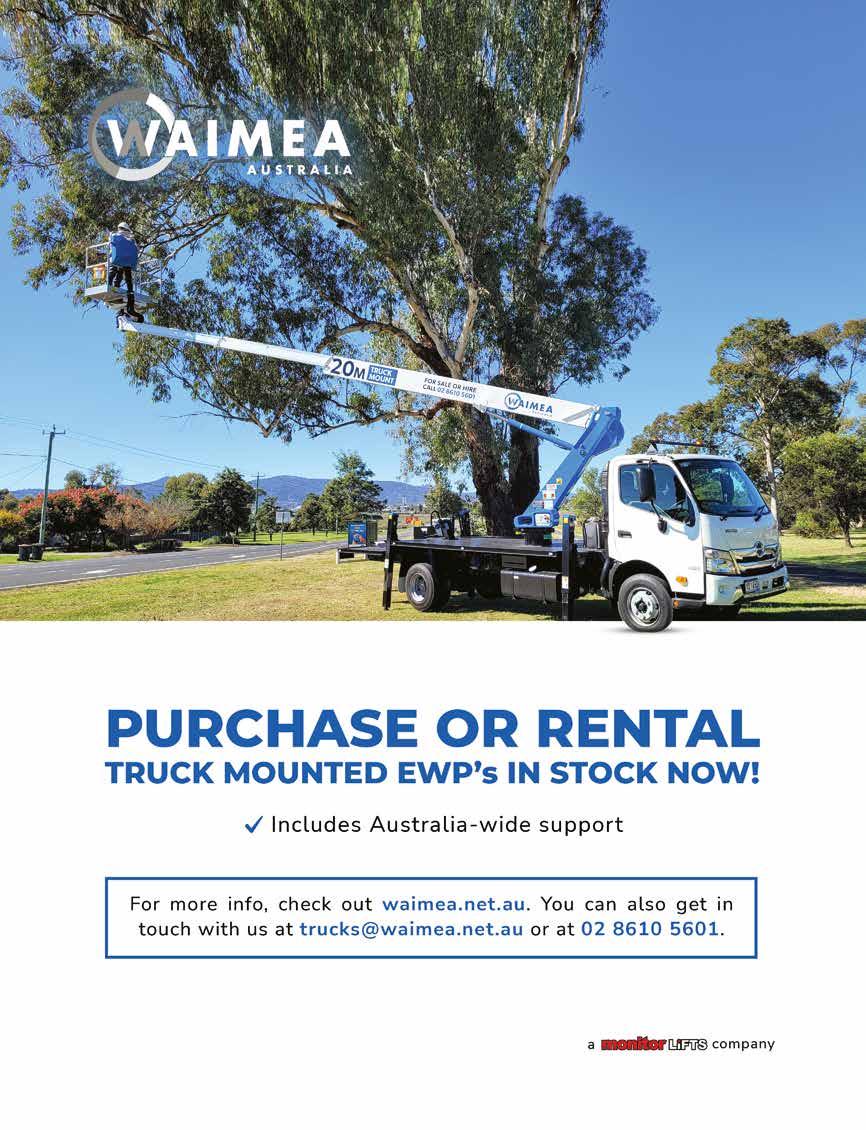

In this edition we also cover the Test Drive of the Monitor 1890 Spider Lift and we delve into the review of Saws and Log Splitters. With regard QAA News there are some great inputs coming in the form of a business resource exploring the true costs of running a business, sponsorship news, member pricing, event recaps (go you climbers), courses/ workshops past and upcoming, (TRAQ and IPZ), a Freestyle climbing comp in Cairns and a major one – the 30 year QAA Gala Dinner Brisbane, mmm – as an old guard past Committee Member/Technical Officer I may just have to attend. Thank you, QAA.

In the brand new Vegetation Management section we look at some of the latest equipment and industry news including the input of TTIA. With the Timber Trade Industrial Association news we have an important article relating to news on Super for Arb employers.

In the next issue we will be announcing the winner of the AA Subscription 2021-2022 prize – a Husqvarna 530iPT5 Pole Saw valued at $1323 and will be launching our new prize for 2022-2023.

Regards, Cassian Rupert Humphreys AA Sub-editor AA

Publisher Kurt M. Quambusch

Sub-Editor

Cassian Humphreys

Production Manager

Arianna Lucini arianna@maynemedia.com.au

Group Sales Manager

KahChi Liew kahchi@maynemedia.com.au 1300 764 688

National Advertising Manager Sue Janjic sue@maynemedia.com.au (02) 8287 0651

Subscriptions

Arlette Kouchakdjian 1300 764 688 (02) 8355 6841 / (02) 9452 4517 arlette@maynemedia.com.au

Design Peter Cartledge art@maynemedia.com.au

ISSN 1327 1784

The Australian Arbor Age is a Bi-Monthly magazine published by Mayne Media Group Pty Ltd. ACN 130 678 812 ABN 27 130 678 812 Postal: PO Box 489 DEE WHY NSW 2099 Australia Ph: 1300 76 4688 Int Ph: + 612 9452 4517 Int Fax: + 612 9452 5319 www.arborage.com.au

Copyright 2022

Mayne Media Group Pty Ltd. Material may not be reproduced or photocopied in any form without the written permission of the publisher. Mayne Media Group Pty Ltd. believes that all material is correct at the time of printing and will not be held liable for any incorrect information supplied within.

Cassian is a Merrist-woodian graduate (NCH-arb - 1991) qualified to Diploma level in Australia (09), his career commenced in Horticulture (85) and transitioned into Arboriculture (89). An experienced tree climber, instructor, arboriculturist, consultant, educator and writer, he has 30 years of experience. He sees his work as making a contribution to the Australian arboricultural profession.

Guy is a Master Arborist and Utility and Municipal Specialist, facilitating the co-existence of trees and people for the past 46 years. His company HistoricTreeCare.com manages the risk in veteran and historic trees by installing lightning and support systems, root invigoration, pruning and community education. Guy writes for tree care publications and works with the ANSI A300 Tree Care Standards committee in the US. He studies the science of arboriculture around the world.

Peter is the CEO of Sydneybased Enviro Frontier (EF). EF utilises over 250 Tree Companies across Australia in managing tree works on behalf of its clients in the Insurance, Government and Facilities Management sectors. All jobs are managed using its proprietary technology platform (TreeManager) making it the leading data provider for the insurance and facility management industry. The company also operates in NZ, UK and Spain.

For almost 45 years Graeme has been based in the Dandenong Ranges East of Melbourne and become world leader in large tree removals.

Working as a production faller for alpine logging operations for three decades, expert witness, Investigator for WHS incidents and Lead Auditor are a sound foundation for him to assist with improving industry safety.

Leigh is an expert climbing arborist with a passion for tree conservation. He is a graduate from Merrist Wood College with a Diploma in countryside and environment and sub-Diploma in Arboriculture. Climbing and leading crews in the south of England, his work/ travels have taken him to Brisbane where he has developed a true passion for adventure tree climbing.

October is National Safe Work Month – a time to commit to building a safe and healthy workplace.

Being healthy and safe means being free from physical and psychological harm. No job should be unsafe and no death or injury is acceptable. A safe and healthy workplace benefits everyone. This is why, during October each year, Safe Work Australia asks businesses, employers and workers across Australia to join National Safe Work Month and commit to building safe and healthy workplaces for all Australians.

Safe Work Australia has released the theme and campaign kit for National Safe Work Month 2022 ahead of the official campaign launch on October 1.

The theme for 2022 is ‘Know safety, work safely’ – encouraging everyone to make health and safety in the workplace a priority.

The campaign will run throughout October and the campaign kit, now available, comes with digital customisable resources.

Start planning your work health and safety activities for October by joining National Safe Work Month. To participate, you can go to the National Safe Work Month Website – www.safeworkaustralia.gov.au/ national-safe-work-month – and download resources from Safe Work Australia campaign kit. You can customise and share the resources with your workplace and follow Safe Work Australia on social

media to keep up to date on new campaign materials and to share National Safe Work Month updates. Use the hashtags #safeworkmonth, #KnowSafety and #WorkSafely when promoting National Safe Work Month on social media.

For more information visit www.safeworkaustralia.gov.au AA

Introducing the Ronin Lift – the revolutionary new tool for Arborists.

Climbing activities, such as ascending tall trees can be harmful to joints and muscles. The Ronin team has addressed this problem by designing an innovative climbing tool that allows tree climbers to access the tops of the trees with significantly reduced repetitive stress.

The Ronin Power Ascender was engineered by a team specialising in the rescue industry who recognised a need for professional Tree Workers, Arborists, Tree Managers and Urban Forestry Workers to have a better tool for their daily climbing and hauling activities.

The Ronin’s lightweight and rugged design makes it easier than ever to get up into the canopy. A max working load of 181kg allows the Ronin Power Ascender to get you and your gear up each tree with ease. A hot-swappable battery means you never run out of power while ascending or winching. Battery power keeps the Ronin quiet, environmentally friendly, and ready for all-day continuous use. No matter your challenge, the Ronin Lift is ready to make sure you complete tasks quicker and safer.

“The Ronin Lift can ascend over 100 metres of rope in a single-line configuration with a maximum load of 180kg.”

The rope wraps around a capstan-style mechanism inside the device that then selffeeds the rope to load. A manual-tensioning knob adjusts rope tension to increase or decrease the device’s grip on the rope. The climber attaches to one of the two attachment points on the device and uses a secondary backup on the rope, such as an ASAP or mechanical rope grab.

By operating the variable-speed thumbwheel trigger, the device ascends the rope with the climber at a maximum rate of approximately 0.50 metres per second. The Ronin Lift has an independent braking system and a speed-reduction gearbox designed to allow climbers to control the descent speed.

The Ronin Lift can ascend over 100 metres of rope in a single-line configuration with a maximum load of 180kg. It can lift up to 544kg when using a 3-to-1 mechanical advantage.

A braking mechanism acts as a primary safety feature, in that it is always activated while ascending and stopping.

The brake can be manually opened for controlled descent. Some models have a power-reverse function that will assist in fully removing the rope from the device.

Best of all it is easy to operate, and the lightweight, durable construction makes it an easy go-to for regular use. The main benefit, though, is to the climber. The Ronin Lift can reduce repetitive stress injuries, which will greatly extend the longevity of a climber’s career.

Absafe Group is the proud Australian and New Zealand Distributor of the Ronin product range, a leading multi-disciplined remedial engineering company specialising in height and difficult access.

Find out how Absafe can help you – call 1300 227 233 or visit absafe.com.au/ronin/

In this article I own that there is a measure of repetition, particularly in relation to plant and soil relations, this is intended as based on current land management operations I believe we need reminding and re-educating. Sustainability refers to the ability for something to maintain or ‘sustain’ itself over time. In earth’s cycle natural systems repeat themselves a little bit better with each ‘generation’, this we call evolution. Because nature time follows such a different timeframe to human time, which is very short, a healthy human relationship to earth has historically been intergenerational for us to understand, let

alone influence nature in a positive way. Though we humans can rapidly destroy, the restoration of the great green and the brilliant blue that is earth takes time. An intergenerational relationship with earth in Australia was certainly true of the First Nation Indigenous people who, generation by generation, practised land custodianship. Modern researchers recognise that Australia was sustainably farmed in a highly evolved systematic and scientific fashion by the Aboriginal Australians, who instinctively and practically carried out land care whilst yielding an abundance of food for all their people. Sustainable land management is

difficult for modern humans to understand, based on our many old addictions, it’s even harder to make change. As a result of the last 100 years of technology we humans are considerably lacking in nature intelligence, lacking the ability to learn from our forebears and are lacking the passion to work the land – whilst being driven by money, separation from community and trusting in a governing system that is broken. Despite this observation, I believe in our capacity to be individually and collectively awakened to the silent lore of nature, our survival as a species is dependent on this. As an arboriculturist, I have great faith in our profession, the tree

Vertical lift arms and a 40-hp (30kW) turbocharged Kohler KDI diesel engine gives the CTX100 exceptional lift and tipping capacities, coupled with the operator-centric features common to all Vermeer loaders. Grasp, lift and move brush and logs with ease and efficiency thanks to Vermeer’s Mini Skid Steer Loader range and the Rotating Log Grapple attachment with 360 degree rotation. Perfect for arborists doing the ground work and all tree care companies. Contact your local RDO Vermeer team today.

VERMEERAUSTRALIA.COM.AU | 1300 VERMEER

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and /or other countries. © 2022 RDO Equipment Pty Ltd (trading as Vermeer Australia). All Rights Reserved.

care movement and our capacity to help inspire such an awakening for the other landbased professions.

The current generations of humanity appear to be led by a movement which clearly has its own agenda (Agenda 2021 and Agenda 2030 is well documented), though such controls are true to the previous generations, many of us are waking up to the fact that this directive is not sustainable. The further we follow global government directive with organisations like the World Economic Forum, the World Health Organisation and the United Nations, supported by the world’s media, humanity is being herded further and further away from a healthy relationship to earth and sustainability. This control-based system has always been focussed on the many supporting the few. We are being sold an idea and a dream, yet the reality to self-sustenance involves getting our hands

and spirit back into the soil, certainly not in this international government directive. This article in part considers the problem behind achieving sustainability and looks at the solution. Yet the solution to those that support the new world order is very unattractive, as this involves personal sacrifice. Because we arborists are hands on with the natural environment, we are in a powerful position to adapt and continue to be in service. Many other industries will not be able to survive as humanity takes responsibility in the face of ‘climate change’, particularly under this imposed order.

Personally, I have far greater faith in earth’s capacity to deal with change than I do our world’s leaders, who put greater trust in academic rather than natural intelligence, who fly the PHD flag like it’s a flagship to real change. Nature by her own volition is free from compartmentalisation, it is being

aligned to the interconnection of nature and natural systems that gives us humans the true edge.

Though systems like the carbon credit system may look good in theory, the fact stands that the way we will champion climate change is by actually re-greening earth, this means plants (and plant associates) in the ground. Researchers agree that we need to achieve at least 60 per cent vegetative cover over earths hot spots to achieve break point over the damage done by us to date, that includes the cities and the other desertified regions to achieve balance.

For the discerning individual, be it landowner, land custodian, manager or agent (contractor or consultant) what do we need to know when it comes to sustainability? With consideration of this and the mainstream narrative It is clear (based on study of the land) that sustainability is much more of an idea or a dream than an experience or a reality. We only need to see the land to gauge a perspective on what is really sustainable, exposed compacted soils, to sparse weedy vegetative cover and sick trees maybe normal to the untrained eye. But prior to 1788 healthy species diverse indigenous ecosystems in soft soils were the ‘Australian’ normal.

Personally, I try to avoid using the term ‘sustainability’ as, thanks to the pseudogreen movement where the notion of ‘things’ green is only promoted to support industry (for example the use of herbicides is common across all the land-based industries), the word ‘sustainable’ has been reduced to a buzzword, something that lacks heart, integrity or credibility. As is reflective of our narrative in AA since 2021, I believe the word ‘resilience’ carries far more weight. Though, having recently heard that the Aussie government is coining this as a term to help implement greater controls, I may well be seeking out another.

From an old school European perspective (the beginnings of modern Australia) when considering our current retarded land management practices, it’s necessary to understand the key difference between industry (that leads many) and the professions (that make up the few) who represent the land. Agriculture – the culture of crops, Horticulture – the culture of gardens and orchards (amenity and commercial), Forestry – commercial timber

“Sustainable land management is difficult for modern humans to understand, based on our many old addictions, it’s even harder to make change.”Fig. 2: Planting vegetative buffer zones (Lomandra species in this case) on edge trees reduces stress load.

The Snorkel EPV16A is a cost effective truck-mounted articulating boom lift designed specifically for the Australian market. This versatile, all-steel boom lift can be fitted to most 5.5-tonne and greater GVM vehicles and features a maximum working height of 15.8m (51.8 ft) and horizontal outreach of 7.1m (23.3 ft). Truck-mounted boom lifts allow the reach and versatility of an articulating boom lift with the convenience of a truck that can travel at highway speeds.

Fig. 3

production and the Nursery industry which interfaces with all three’ – with on a much smaller scale Arboriculture, the culture of trees. Though this is significant business in the cities and in service to the utilities and main roads, next to Horticulture, Agriculture, Forestry and the Nursery Industry, Arboriculture is almost as fringe as Permaculture, Organic, Biodynamic and Syntropic farming. Yet there is a collective genius in the fringe, there always has been. In the three primary land-based industries alone coupled with national parks, the desertified regions (that includes the cities), military, government and private land (which is made up of all the above) we have Australia covered.

With industry, environmental sustainability is never as important as economics. With sustainability in mind, we are served to reflect on the four foundation principles that make up sustainable living – Environmental, Cultural, Social and Economic – Ref: GEN International and GEN Australia (International and National Eco-village movements).

The natural environment when left to itself or nurtured over time is very abundant in resources, this is most strongly recognised in Australia pre-European settlement. Environmental sustainability or resilience farming (in essence all the land-based professions are farming plants to a greater

Fig. 5

and lesser degree) is all about managing resources. The more I consider this essential topic the more I recognise that the First Nations people where actually the best sustainable farmers on the planet. Next to the current economic model sustainability saves money rather than makes money. For an environmental model to be realised, a whole new human movement needs to be established. This I, other fringe professionals and inspired individuals see as the New Earth movement (to my knowledge the New Earth was first documented as a concept by the writer Eckhart Tolle).

It’s the people that make the land-based professions – the project/people managers, the scientists*, the consultants, educators

Fig. 3-4: The use of native Cunjevoi and Rubus species as edge and understory plants likewise assist with reducing impacts on trees. I call this Ecosystem services.

Fig. 5: Based on associate microbiology the use of Lomandra confertifiolia and L. histerix in association with spreading coniferous ground covers is significantly better for trees than turf.

Fig. 4

and tradespeople. The career professionals make professional development a commitment, though their business may be industry driven, it’s their professionalism that comes first. Whereas industry is largely driven by economics and compliance, the profession is driven by education, integrity and experience. It’s the pride of the few driven by being in service that creates the benchmark for professional excellence, which may or may not make money. *In truth science is the observance and record of nature in action, contrary to the ‘new normal’ – science has nothing to do with politics.

Though I am certain the global elite would say otherwise, generally successful living involves personal sacrifice. This is also true of sustainable living. We only need to look at trees and witness the self-thinning rule, whereby in times of scarcity trees sacrifice themselves to benefit their neighbours. This they do by surrendering their resources (sugars) by dumping them into the soil food web – the rhizosphere, yielding their life energy to their forest associates (the soil food web links forest trees as one). Perhaps, it is this natural principle that leads us to love our brothers and sisters who willingly make sacrifices to save others (the fireman, the police, the soldiers, the health professionals etc.), we the people certainly have little love of the hoarders.

Fig. 6: Whereas young Australian trees (in this case - Ficus species) may endure the highly bacterial turf environment in the short term, in the long trees live short lifespans, particularly in fungi deficient Australian conditions. The dieback in this tree’s lower crown would not be present in compatible conditions.

Fig. 7: Roundabouts surrounded by bitumen and the development process are usually highly desertified, plant associates (and the microbiology that accompanies them) make all the difference for trees. In rare cases below ground resources (i.e. old creek systems) sustained during development retain air, humus and water below bituminised surfaces. This demonstrates what can be achieved at planning stage with New Earth ventures in mind.

It’s the wilfully selfish and the unconscious which overspend earth’s resources for the betterment of themselves. The kind of people that put professionalism over industry tend to have greater regard for people-kind. With sustainability in mind this I believe is essential.

For us to embrace conservation of our planet (Conservation Arboriculture is my primary motivation), we have to face the issue of self-sacrifice and accept that personal sacrifice is for the good of the community. With the times that we are in,

as the wealthy elite push for greater control, we the people have no choice but to re-learn community sustainability. The concept of personal sacrifice is far more attractive when we choose it willingly, over being forced to sacrifice by governance. This appears to be the drive in this post Covid world, where a silently complicit humanity weakened by modern living is allowing ‘itself’ to be herded like lemmings over a cliff.

A number of us who see the capacity for the new earth movement understand this and see personal and community adaption as the best form of integration. This perspective and a love of things naturally resilient is driving the eco-village movement. When I started in arboriculture, I had no awareness of the eco-village movement (Findhorn in Scotland was the first I heard of – I visited in 2016). Personally, my drive is to be in service to the trees, to achieve this end in a bid to learn the art of commercial scale humus production over the last decade I sought to be in service to Third World communities, by aligning myself with the Social Justice movement (project development for the Melanesian Islands and Africa). Between Big Pharma and controlled governments (locked down since Covid) this has completely stalled our overseas movement to date, to achieve my objective of soil restoration services in

Fig. 7

support of vegetation I am having to adapt, land care in First World ventures down under may well be the next evolutionary step. Land care to date like the other professions as a new profession/industry has been forced into herbicide usage because of big Ag(ri-culture) and a misunderstanding in the role of weeds in the landscape – (ref: Landsman and OBE winner Peter Andrews author of Back to the Brink and Beyond The Brink).

Historically, top-end arboriculture has done well in service to amenity, with botanic gardens and parklands being the cream sites for many projects. Yet as I see it, we must now adapt to be in service to community. As in a changing world botanical gardens/parklands support a relatively small demographic, the progress I see needs to be in support of community populations via supporting food production.

I see the global ecovillage movement (a future growth enterprise) as being a catalyst for promoting conservation arboriculture, this platform has community at its heart.

“Because we arborists are hands on with the natural environment, we are in a powerful position to adapt and continue to be in service.”

As harvesters and processors of vegetation arborists are in a unique position to support community with a new global initiative, this involves small scale commercial production of humus or forest grade compost. Contrary to the desire of the corporations and business, it is not practical to produce humus and bag it for storage and the global market. This is because the microbiology that we generate by composting via cold processing or even harvesting direct from nature* does not have a shelf life when separated from the microbiome. Organic composts sold by industry are superheated and are inert or void of life, by industry definition these are called organic, yet in truth are not at all. *We can sustainably source probiotic direct from nature in small amounts to inoculate mulch piles.

With integrity of product, for us to provide forest grade humus as an arboricultural service as well as process it ourselves, we have to deliver to a local market. This is a good thing as we, the arborists, working as individuals in association can all prosper with a value add on to our services. Another reason for harvesting and processing locally is that the microbiology that lives in the microbiome varies from site to site, we can never create a ‘product’ that is generic. Study of the definition of the micro-biome clearly validates this – By Whipps et al. “A characteristic microbial community occupying a reasonably well-defined habitat which has distinct physio-chemical properties. The term thus not only refers to the microorganisms involved but also encompasses their theatre of activity”.

There is a growing trend for agencies that know nothing about land care or vegetation management, which put nothing in the soil – to be a business focus, the idea and the dream of sustainability is a greater focus than the activity. The reason for this is about supporting industry and economics, there is more to be made setting up systems and teaching than there is in physically culturing nature. To be true the best teachers and managers are also the doers.

People management ideas and systems aside, the growing of plants has always been simple. Plants support their own energy needs via photosynthesis, all plants need bar sunlight is a soil environment that delivers air, water and (organicbiologically active) carbon. But because of humanity’s excessively large footprint

predisposition to compact soils, we massively impact on a soil’s ability to hold air, water and carbon. For these essential nutrients to be readily available, soils must be friable. The early pioneers of Australia spoke of Australia’s friable soft soils (ref: The Biggest Estate on Earth and Dark Emu), how horses and riders struggled to gain good purchase when travelling. The only ‘compacted’ regions where the aboriginal foot and animal trails (Australia’s animals are by nature soft footed compared to European). Forest clearing, timber extraction, European agriculture, hooved livestock, carts, leading to modern development as we now know it, road building, mechanisation/transport and modern cities, has created the hard soils we experience today.

In Nature soil friability is sustained by geography (not in Australia), climate and the growth/decay of plants/plant root systems, which create vertical and lateral fissures, with plants constantly adding biology via

the above ground (leaves, twigs, branches etc) and below ground (root hairs) shedding processes. Likewise, the earthworms play a vital role in sustaining friable soils by relocating decaying vegetation. All parts that are shed are already seeded with the (microbiological) organisms of their decay before they fall, the associated microbiology (principally the fungi) that interfaces with plants and soils are also key to sustaining soil friability. The soil/root interface is known scientifically as the rhizosphere, in essence the rhizosphere is the stomach of the plant. We humans gain our energy and nutrients from our stomach lining, plants gain nutrients in solution via the rhizosphere.

Plants are at the heart of the nutrient cycle; they act as pumps cycling nutrients from the atmosphere into the soil.

Plants (scientifically described as primary producers) are the vector/transformer

of inorganic (atmospheric) nutrients (or elements) into organic (soil-based) nutrients, animals (secondary producers), humans, the soil microbiology and plant root systems are dependent on oxygenated (friable) soils for organic nutrient exchange.

To help people understand the ramifications of soil compaction, nutrient absorption and the effects on the rhizosphere I compare the stomach of the human to the stomach of the soil. Imagine if after each meal (three meals a day) we humans where punched multiple times (30+) in the gut. How would that facilitate nutrient absorption? Soil compaction on friable soil/plant associations has the same effect. Hence why urban trees only generally live to the first 1/3 of their lifespans.

To help validate this point whilst being true to the topic, I am drawing on edited input from a past article ‘The Heart of Arboriculture, AA Oct/Nov 2021.

“As long as arboricultural education does not include the science and the accompanying cultural practices, then our education is flawed.”

and ourFig. 8: A traffic island I restored myself from desertification to a de-compacted species diverse understory, the full restoration process features in ‘The Heart of Arboriculture’, AA Oct/Nov 2021.

The Heart of Arboriculture (getting down and dirty) with the Soil/root Interface

To truly take the subject of plant growth to heart I invite the reader to reflect on the heart of arboriculture. Back somewhere around the late ‘90s I saw a great AA article on arboriculture the profession V arboriculture the industry, as an arborist that struggles with an industry prerogative, I take great heart in celebrating the profession – as I recognise that somewhere at the heart of that lies true regard for the tree, land care and mother earth, it is this reflection that lead to the inspiration for this 2022 article on Vegetation Management and Land Care.

So, considering trees (as living organisms) where do we start?

Whenever I have a serious question on trees I tend to go to the source (heart) of arboriculture – tree-culture, no better place to look than the father – Dr Alex Shigo.

It was Shigo that got me to see the tree as giant pump – harvesting, synthesising

and sharing sunlight, water and elements, in the light of his science I took a closer look at science and recognised that as living pumps its plants (woody or otherwise) that drive (pump) the nutrient cycles that all life depends on. Carbon – the building block of the physical-body being the most obvious. It is through the bodies of trees that inorganic elements become organic, it’s thanks to the plants (or the primary producers) that we get any nutrients at all.

So back to the tree, a woody plant with the same biological function as all (photosynthesising) plants, though biologically a lot more developed – as a living organism where is its ‘heart’?

We know that trees gain the energy they need from photosynthesis – from sunlight, sunlight energy drives the many parts and processes that make biological function. To quote Shigo, this is harvested from the top end of the pump, the energy is used, stored and shared. We know that trees as highly compartmented organisms grow in height and girth by stacking cells end over end and by laying down cells incrementally.

That, as those cells age (primary wood) their cell walls become thickened with lignin (age altered wood), we know that trees compartmentalise cracks, decay and (often) if allowed to – occlude other bodies such as rocks, buildings and other trees. We understand that trees lay down reaction wood to strengthen trunks, limbs, forks, buttresses and transport roots, to offset tensile and compressive loads.

Referring to ‘heart’ in the context of the

Fig. 9

Fig. 11

source of things I have always wondered where can the vegetation management professions and land care groups contribute the most?

We tend to focus on the top end of the pump, making our pruning cuts as close to trunk collars or lateral limbs (when reducing them) as we can with the aim to ‘manage’ compromise to the tree, to sensitively carry out volume reductions as a means to reduce load on veteranised crown structure. Yet what are we doing in service to the bottom end of the pump? In truth arboriculture is

Fig. 9-10: The rainforest remnant at Mary Cairncross Scenic Reserve is an interesting study relating to the nutrient cycle, the floor of this forest is kept clear of leaf litter by the giant earthworm (1-3m long, 2-3cm thick) a number of species are found throughout Australia’s hinterland ranges. These remarkable creatures clear the whole forest floor of leaf litter and small twigs, dragging the shed organic matter into their tunnels. The important impact this organism has is in the multiple tunnels it creates, earthworms generally deposit their castings above ground, not so the Giant earthworm which deposits its castings below ground. The Trap-door-spider, Fresh-crayfish, and a host of other organisms help keep rainforest soils friable via their tunnels. There are few natural organisms that are counter-arboriculture, thought it can be well argued that modern human beings are not natural.

Fig. 11: We can see the fluffy soil deposited at the site of this excavation, whether created by a worm, spider or freshwater crayfish the fissures in a soil are essential for tree and tree associate (they live in adjoining micron-tunnels, as well as the bodies of the macro-organisms) health.

Fig. 12: Ref. Fig 8, the desertified traffic island restoration project, part of the project involved making three (10cm diameter) vertical fissures (50cm deep) every square metre, the fissures irrigated five times each (until the water drained). Due to soil compaction, a lack of biologically active carbon and fungi in the soil, the soil was completely hydrophobic with rainfall running straight off the soil surface. This project involved the mass planting of 290 tube stock, mulching and the establishment of timber edging and pathways to help mitigate future compaction of the soil. For the full project story Ref: ‘The Heart of Arboriculture’, AA Oct/Nov 2021. Note – for those that wish to access my past The Australian Arbor Age articles you can do so via my LinkedIn profile – www.linkedin.com/in/cassian-rupert-humphreys-888013226/

Fig. 10

Fig. 12

as guilty as all the land professions (bar at times horticulture) in doing little to nothing in service to the trees bottom end.

Certainly, we can see the plant cell generator – the cambium as the source of cell production leading to wood, roots, shoots, flowers and fruit (in the case of cauliflorous plants), is that the heart?

The bio-chemical processes in the leaves (the synthesis of light, carbon and water) is the key source of energy production. Maybe like multiple growing points (dormant and floating buds) trees have multiple hearts?

One thing is clear, for longevity plants need our attention more on the bottom end of the pump, where the root meets the soil. The zone that industry completely forgets, the zone that the profession largely only talks about and the place where true arboriculture happens – the soil/root interface. The place where elements (as essential nutrients) in water are exchanged for carbohydrate – the rhizosphere, for the sake of this article let’s call that the heart of the tree/plant.

It was Shigo that woke me up to the heart of arboriculture in a past 97/98 AA article, an article I have cited multiple times – “Troubles in the Rhizosphere”. This awakening led me on to a study of the work of Paul Stamets and Dr. Elaine Ingham, both microbiologists and like Shigo legends in their field.

The rhizosphere – “(Oxford languages)

The region of soil in the vicinity of plant roots in which chemistry and microbiology is influenced by their growth, respiration, and nutrient exchange.” Described as a jelly-like substance the rhizosphere interfaces the root hairs and soil, less than a micron thick yet encompassing tree root systems and running from tree to tree, in a forest the rhizosphere interconnects all.

The rhizosphere and the soil/plant microbiome are the same, the animal/plant microbiome is the link for all life. This the oldworld cultures called the Web Of Life. This is the world of the mycorrhizae (which enable *10 in nutrient exchange as compared to a root hair which floats alone) where symbiotic fungi and tree root hairs live in complete unison. Ingham describes this interface thus – “The tree low in one element or the other releases a chemical message into the rhizosphere requesting from its associates a mineral top-up, its mates respond with sugar please and the exchange takes place”. Such a dialogue makes fools of us humans with our fertilisers and dollar driven timing, who can replicate such a dance. Best to leave it to nature in the encyclopedia on intelligence.

Fig. 13

Fig. 13: The microbiology associated with the forest is integral to the nutrient cycle that processes timber into humus, fungi are as essential for processing wood (lignin and cellulose) as they are in supporting woody plants to absorb nutrients from the rhizosphere. In live trees the fungi enable solid trunks to lose static ballast by decaying heartwood, cylindrical structure is stronger than a solid, trees as giant highly evolved bio-mechanical organisms are adept at managing force flow. The fungi and the decay process involving brown rot, soft rot and white rot wood decay fungi – process dead wood in live and dead trees standing or otherwise.

Fig. 14: This brown rot* decayed log with its cellulose long gone has become an above ground resource for occupation of feeder roots from a neighbouring live Tallowood gum tree. The log – now more like charcoal than timber – provides a network of oxygenated galleries for the essential associate microbiology and feeder roots. I have seen the same with white rot galleries in standing trees and cut palm logs where the above ground log becomes an extension of the rhizosphere. *Brown rot fungi target cellulose making wood brittle, white rot fungi target lignin making wood soft, whilst soft rot fungi switch between lignin and cellulose – Ref: Professor Claus Mattheck – The Body Language of Trees.

Fig. 15: Ripped logs (cut longitudinally –with the grain) make the best interface between a treated (vertically decompacted fissures filled with humus, charcoal, parent soil or sand) soil restoration area and turf. The raw ripped hardwood logs last a few years becoming compost. These are easy to process, easy to install and easy to replace.

With consideration of the science behind the nutrient cycle and the soil-root interface we easily can also reference this ‘heart’ of the tree as the ‘stomach of the tree’ (with the human perspective in mind). It is here that the many associates (probiotics) operate as a bridge between nutrients in the soil and the plant, in much the same way as probiotics in our gut-lining help us to digest our food.

In arboriculture we know that our activities around trees kill them long before they reach the first third of their lifespans. All the landbased vegetation management industries are excessively dependent on machinery which via compressive load takes a huge toll on the soil environment. We all know that soil compaction is the number one stressor of trees. I believe we are so used to compacted soils that few of us have experience of anything else, so we see hard surface and significant retardation below ground as

You begin each day before dawn with a drive and determination to do more than the day before. When you move at this pace, you know to do more you need equipment that is made for more. That’s why our equipment is built from the ground up to meet your needs, delivering:

More Power and Production

Lower Operating Costs Ease of Maintenance Greater Longevity and Resale Value

If you’re ready to operate equipment that’s made to keep pace with you, then we invite you to contact the authorized dealer in your area of the world. To learn more about our equipment go to www.morbark.com

Morbark

NSW/VIC: Global Machinery Sales 1300 072 926 globalmachinerysales.com.au

QLD: Allclass Construction Equipment 1300 255 252 allclass.com.au

WA: Westco Equipment +61 (8) 9258 9333 westcoequipment.com.au

NZ: Commercial Outdoor Machinery 0800 26 66 88 commercialoutdoormachinery.co.nz

Boxer

NSW/VIC: Global Machinery Sales 1300 072 926 globalmachinerysales.com.au

QLD: Greenstar Equipment 1300767589 greenstarequip.com.au

WA: Westco Equipment +61 (8) 9258 9333 westcoequipment.com.au

NZ: Commercial Outdoor Machinery 0800 26 66 88 commercialoutdoormachinery.co.nz

NSW/VIC: Global Machinery Sales 1300 072 926 globalmachinerysales.com.au

QLD: Greenstar Equipment 1300767589 greenstarequip.com.au

normal (the new normal next to the soft soils known by the First Nations people).

Already mentioned the legendary Australian book Dark Emu discusses accounts of early settlers finding soils so friable they could bury their fingers and even hands to the wrist by pushing/wiggling them into the ground. The historical activities of logging, timber extraction with bullock teams, dairy farming, agriculture, road and park construction, urban development, vehicles and people pressure have left multiple veneers of soil compaction as ‘normal’.

As with many living organisms we know that stressed trees are often subject to premature decline, as a tree risk manager I have long held the belief/experience that even with ‘defective’ trees the best way to reduce tree failures is via soil cultivation practices which boost plant vitality. Healthy trees optimise (strengthen) the weak links in their bodies without the need for human inputs such as failure prevention/fall arrest systems or pruning, as a strategy the latter is best used last. In a past 2014 arborist report, turned three-part 2015 article series I introduced the idea of RNE, Reduction, Nutrition and Exclusion. On reflection the Nutrition could come first as soil restoration involving the vertical treatment, nutrient bed installation capped with a species diverse plant system facilitates tree health, with the combined works acting as a barrier enabling Exclusion. I stand with my five eyes brotherhood (we have no women onboard yet) AUS, NZ, USA, UK and CAN, volume reductions come last, unless we seek to generate the ‘inner’ tree.

The reason for the repetition in this article on ‘what we know’ is a prompt, even in my Merrist Wood (UK) education in the very early ‘90s knowledge on the symbiotic relationship between trees and fungi was part of our education – yet then like now where is the cultural practise?

My question is, what tree cultural practices can we make mainstream (such as pruning – which is often counter-arboriculture when done in excess) to help extend tree longevity? Because what we are doing now is not enough to help amenity/commercial

trees to live into the second third of their lifespans, let alone beyond the first. Maybe as a collective we only wish to see trees live short lives. Perhaps it is easier to recycle them, then let’s get serious and recycle trees into products that benefit other trees, because logs and cooked mulch being dumped into processing depots is throwing away opportunity to practise the i-culture.

As discussed for healthy growth below ground, plants need carbon, air and water. Soil friability is dependent on air-gaps in soils, constant running of mower machinery, cars and people has our parks and city trees surviving in soils like ‘granite’. For sustaining

air gaps, rocky soils (such as shales) fare better with compaction – as the rocks hold the load and the colonies of the beneficial microbiology can continue to function in gaps common to the shales.

With the New Earth model in mind and humanity working in unison, the new earth industries guided by the professions will be far more productive (with sustainability in mind that will not come from big industry, which drives our worlds governments to keep making money to support the few).

There are innovative products and systems galore that will support vegetative growth and economics in all areas of land care.

Turning over money means nothing if we destroy earth’s vegetation/microbiome in the

process. Dr Zach Bush the advocator on the human/earth microbiome maintains that it will take 50 years post the day we stop using glyphosate globally for the earths microbiome to restore a toxic free balance. According to Bush glyphosate toxicity in the food-chains accounts for most if not all the new diseases since WW2, accelerating with the start of chemical agriculture, he regards cancer as the no: 1 symptom of glyphosate poisoning.

To be true to the i-culture in all the land-based professions we need a mass awakening, to truly be in service to the plant kingdom in our modern environments, as a collective we need to be culturing soils.

Whether we undertake this work ourselves, or sub-contract it (this may be

Fig. 16-18: Poinciana – Delonix regia correctively pruned by me after the homeowner, I deliberately left the epi/ endo or elbow limb in the trees canopy (right side) rather than make a large pruning cut on the trees trunk. The trees structural root zone was a major thoroughfare, so I installed a ripped timber perimeter, a log round pathway (and pond for the children), as well as vertically treat the area (including tilling the compacted soil surface) I planted an understory of native tube-stock.

Fig. 19: The traffic island project a 16.5 by 9.5m nutrient bed, 155m ² + treated with approximately 910 fissures (to de-compact and open up pathways for microbiological activity) ranging from 10cm (auger) to tube-stock size, with 290 young plants in the ground, capped with composted forest blend mulch, log rounds (to act as maintenance pathways to prevent future compaction) and ripped timber edging to interface with turf on the western side. Note the timber edging and log rounds help keep moisture in the soil.

more cost effective in the short term) we are to overcome the market resistance to pay arborist rates at soil level. Horticulture, Agriculture and the Land Care professions are paid considerably less than arboriculture for ‘culturing’ soils.

In the 2021 project of mine (Ref: past article ‘The Heart of Arboriculture’, AA Oct/ Nov) with all the materials discussed I priced the restoration of the traffic island at $70.00 per m² for labour and materials (based on arborist plant health care rates), even with adding in the extra variables I am certain that land care (re-vegetation) operates on much less. I know that to gain the value this service deserves we will need to become salespeople of the microbiome, principally the rhizosphere, or soil root interface.

To achieve this, we need to understand it, this means educating ourselves in the science of the microbiome, as long as arboricultural education does not include the science and the accompanying cultural practices, then our education is flawed.

Because mainstream arboriculture is not delivering, we owe it to the tree to practice conservation arboriculture.

In summary to be affective, conservation arboriculture (education and practice) needs to be applied to all the areas of vegetation management/land care, this needs to apply to Horticulture, Agriculture, Orchards, Forestry, the Nursery Industry, Permaculture,

Fig. 20 Fig. 21

Fig. 20-21: I use the same strategy of soil cultivation for vegetable gardens, creating fissures, trenches or simply single digging – of blended humus (90%) charcoal/sand (10%) depending on resource availability. In the case of this salad/vegetable garden I treated under the sleeper pathways to support root generation under the paths. This maximised surface area/water retention, I utilised 1.5m of humus that I harvested straight off an old tree/leaf litter covered horse shed. Personally, I disagree with the no dig garden (the microbiome does just that) when it comes to top soils, plus raised gardens end up being divorced from the microbiome as well as being prone to hydration. From what I have seen of the Wix system is sick plants.

Fig. 22: A past depot sized poster of mine on target pruning and reduction cuts –Horticulturists please read Dr. Alex Shigo or save your secateurs for cutting cellulose and leave the lignified tissues to arborists.

Organic, Biodynamic and Syntropic farming as well as Arboriculture.

Based on arboriculture as it already stands as a profession and industry, it is actually a relatively simple process to switch from producing green mulch which is stockpiled, allowed to super heat and cook, to producing cold processed forest grade compost or humus. To best mimic natures cold process this takes passion, artistry, a controlled environment and commitment to the process – Ref: SFI training Soil Foodweb Institute Australia.

Consider nature, consider plants as shedding organisms made up of leaves, twigs, limbs and trunks. Non-woody plants are made up

of cellulose, woody plants – shrubs and trees are made up of cellulose and lignin (woody cement for thickening/strengthening the cell wall). Yet all plants draw their valuable sugars (energy produced via photosynthesis) back into their bodies before shedding. In the same way the bodies of humans and animals manage their resources with optimal efficiency, the intelligence of nature governs plants. Nowhere in nature is a woody plant processed (chipped) into a green pile. As discussed, when a leaf is shed with its resources withdrawn, the leaf is already seeded with the microbiology necessary to start the composting process. With fall, when that leaf joins the forest floor – along with the carpet of already shed leaves, it twigs and dead wood – the tree’s previous seasons canopy, is decomposed into humus. According to Dr. Elaine Ingham (founder of the Soil Food Web Institute and a host of publications), fungi play the greater role in humus production. Whereas when we humans process green vegetation into mulch piles the sugars in leaf, twig, branch and trunk remain.

Piled chipped green vegetation becomes volatile, bacteria in the chipped vegetation rapidly super heats, with green mulch piles commonly igniting. Even if green mulch does not catch fire if not managed the ‘green’ cellulose/lignin mix cooks. The end result is an excessively woody mulch which is inert, dead, void of the kind of microbiology (largely fungi) that makes humus, humus the chocolate-gold of the forest ecosystem, humus the probiotic of the soil. Human/ animal gut health and soil health are

intrinsically linked via the micro-biome. For a brief yet fundamental background on the importance of soil/gut health and the damaging effect of non-sustainable vegetation management (involving chemical herbicides, fertilisers and fungicides I strongly recommend study of Dr Zach Bush as part of the education process –youtube.com/watch?v=Aw16LPVnNco

The culture of orchards comes under commercial horticulture, it surprises me that there is not a stand-alone descriptive term to describe this, such as ‘Orchardary’. When we consider the Latin i-culture that supports Arbor, Hort and Agr I would expect the culture of orchards to have its own Latin term. When we look to the this – the Latin for Orchard is Pomarium –Pomariumiculture? Yet with sustainability in mind this is another area of essential business that will hugely benefit from conservation arboriculture.

Study of almost all orchards in Australia reveals a major mis-service to the longevity of fruit bearing trees. Most Australian Orchards are topped, forcing the crowns of such trees up rather than out. Topped trees losing their lower crowns fruit higher, making harvesting difficult, not to mention the excessive wounding*, oxygenated wood, decay pockets leading to columns and stressed trees with epicormic crowns that often fail to ‘switch’ to endocormic (Ref: AA Epicormic, Endocormic adapting Veteran Trees and Arborists Minds, April/May 2021). *Flush cutting, wound

dressings and cavitation are common in the Australian orchards that I have seen. Between 2007-12 doing proactive tree assessments on HV from Greater Brisbane to Tin Can Bay I drove through many orchards and witnessed the same.

Drawing on the artistry of formative pruning, training trees to have broader crowns than tall, less trees can be planted with greater fruiting yields sustained. This coupled with soil restoration practices involving de-compaction, the vertical inoculation of soils with probiotics (the chocolate-gold) the installation of cellular confinement systems between harvesting rows and the interplanting of low vegetation to carpet mulched areas, I suspect much greater returns will be made, with trees living two thirds longer. I see greater all-round gains for orchards aligned with Syntropic farming methods. Though having seen a number of syntropic systems I see such systems needing conservation arboriculture to succeed long term. As with Permaculture and Biodynamic farming education grounded in robust cultural practices is missing from syntropic farming. There are many people with only weekend/two-week education courses aligning themselves with a professional status (getting into

education) and yielding nothing in the field. The distinct lack of the ‘fringe’ delivering in the field is a problem that lacks credibility, unlike arboriculture and top end amenity horticulture which is proven.

At this juncture it is important to call out Horticulture – people when it comes to pruning your work is completely off standard, look at the Arb global standards on tree pruning and you will see your pruning work is tree lopping, if you want to train a tree into a shrub - at least start when the woody plant is young two-three years old, cuts that are on older trees, that are inter-nodal, that are in heartwood, fail to honour the tree and your profession. Remember Arboriculture as a profession is part of Horticulture, embrace us as your brothers who know better and learn from us, we embrace you for your top-end land care skills and honour that (but please dump the herbicide).

With this article though I drafted the first draft, I also have invited in another three individuals to co-author the final, as I reach the deadline for this submission, this will have to be a future draft/article, I intend to use this work as a means to break ground with the allied professions, hopefully this will spark a collective unity to get us in

service to the next level. The individuals in Australia I aim to enlist with the second draft (more may be called to input) are –now retired, a leading pioneer in his field of Land Care, Robert Tap. Still active in his, Jason Hilder with a PhD in study of the Eco-village movement and the director of the Soil Food Web Institute Chris Ellery

On the flip side of getting more solid on the background, I intend for follow up parts on this topic. With resilience and the future in mind I perceive the need to professionally and collectively get clear on the template for land care via best practise vegetation management. It's time to roll out the i-culture – via AA we arborists are the first to receive this input, I would love to see Arbor-iculture be the flagship for Land Care.

The New Earth - Eckhart Tolle, The Future Eaters - Tim Flannery, The Biggest Estate on Earth - Bill Gammage, Dark Emu - Bruce Pascoe, Back From The Brink - Peter Andrews. Dr Elaine Ingham – founder of the Soil Food-web Institute (numerous publications). Dr Zach Bush – Optimal health and the microbiome (podcasts/videos).

Cassian Humphreys AAIn this age of misinformation and disinformation, it is a struggle to sort fact from fiction. Opinions abound, but conclusions remain elusive.

Opinions lack certainty, as Dr. Julian Dunster reminds us in Documenting Evidence: Practical Guidance for Arborists. “By contrast, a conclusion is generally considered to be the end point in a series of systematic steps in a scientific process… Evidence used to support a conclusion needs to be clear, irrefutable, and so convincing that it is beyond challenge.”

Documenting such evidence sounds like a tall order! But opinions need staircases of support to become useful conclusions.

This book lays out a system that guides every supporting step, so our inspections and conclusions will have scientific validity. Dunster’s case studies illustrate forensic work after tree failures, but his system applies to other aspects of consulting. This review will use two trees with codominant forks. One is actively failing; the other might.

One case involved a large white oak, Quercus alba, covering the back half of a house. Two other old trees on the site had recently been removed, at the urging of Mrs. Jones, because cavities created concerns

about their condition. Attention turned next to the suspicious looking codominant unions on the white oak. Recently, a small limb fell and dented the family vehicle. All kinds of speculation about the tree followed. Mr. Jones wanted credible conclusions, so he called for a consulting arborist to document and analyse evidence. He confirmed the standard objective: “Maximise health, safety, and longevity.” He sent a picture showing black streaks extending below those unions; perhaps from rain, or something else.

Fig. 2: A gap (pink) in the tree crown is evidence that a big leader(s) has sagged downward. Reduction pruning (red) starts at the top, clearing the limbs below so they can grow more upward, and less downward.

Fig. 3: The stem arising from the compostfilled cavity is fortified by a column of response growth (blue). Mechanoperception triggers thigmomorphogenesis. The 8" bridge (orange) connects the middle of the tree, limiting the strength loss from the cavities.

“Evidence can take many forms… in a tree case, the starting point would be the tree itself.” Here Dunster states the obvious, and restates Alex Shigo’s “Trees must be touched to be understood.” Too often, clients and even consultants can get misled by subconscious bias and internet “research” and forget to touch the tree. I know I have!

A ladder easily reached the main forks, debris was brushed away, and basic hand tools revealed evidence of where the stems were connected, and where they were not. The data were remarkably symmetrical: The outer 8" on both sides was connected. Adjacent to those connections were 16" wide areas where my handsaw plunged deep into the compost between the stems, and extracted 20" long Hedera helix roots. In the centre was a stout 8" wide bridge.

Beyond that fork, some stems that arose from the cavities added ribs of response

Fig. 2

growth on their upper, tension sides. Mrs Jones was quite concerned about a 28" long section where two big limbs had grafted together. She was skeptical that such grafting was a sign of strength, hinting that my report needed references on inosculation, anastomosis, self-grafting, cambial kissing, and swapping of sap and strength.

Two 6" branches that grew toward the sun had failed at their attachments. Further

out were a few signs of smaller branches shedding. Images of the trunk, branches and crown were recorded from all available angles. These and satellite images were deemed adequate, so the drone was not unpacked.

The evidence pointed to reduction pruning of overextended branches and limbs to “take the whip out” and mitigate their risk of failure. Branches at or extending beyond the crown outline were marked for reduction by 3' - 12'. Cuts would be 2" - 4" diameter, back to upright branches or those growing into the open. Limbs that extended over valuable structures, and those adjacent to recent failures, got special attention. Illustrations of cut locations were compared from multiple views, to make them easier to follow. Mr. Jones trusted the company that did the prior removals to follow the specs and illustrations, but a half hour of online review of the PowerPoint report was added to the bill, just to be sure.

Fig. 3

The next tree was much more complicated. It was the second largest Magnolia grandiflora measured in the state of Florida, but it was coming apart. Its two trunks were grafting four years ago, but new cracks up to seventeen inches long have formed. Seeing fibres tearing apart, along with a new view through the core of the trunk, can have a visceral effect, a gut punch. But what facts can we read in empty trunks? “Above all, remember that evidence

establishes facts, not the other way around.” The evidence led to a suite of specifications to lessen the strain on the cracking areas.

The huge old tree has one – very tight! – cable in it. A much higher cable was specified four years ago. That cable was installed just two feet above the first cable, and extended to one codominant trunk above a union. By the looks of the jagged end of the cable, both the cable and the fastener failed. Wounds below the attachment point were from obsolete climbing spikes.

The first step was to ascend the tree and locate the highest location for the second cable. Since this tree is the tallest thing around in a lightning prone region near a body of water, a lightning protection system was installed and bonded to the two cables.

The crown was reduced over land before the second cable was installed. Sprawling ends were reduced back to upright and outward laterals. Space was cleared between limbs, so that new growth could arise upward and inward, instead of being

Fig. 4

Fig. 5

Fig. 4: Illustrations show the approximate locations of a second cable, two rods, two props, and layering.

Fig. 5 (2018) and Fig. 6 (2022): The central crack is opening to reveal the sky; the smaller crack below is fortified by response growth.

Fig. 7: A view of Bartram’s 1774 canoe route. The crown of this old tree has healthy young growth, a reminder that good vitality does not always indicate good structure, and vice versa.

Fig. 6

forced outward. The heaviest Spanish moss Tillandsia sp. that was adding load and suppressing interior growth was removed as well. Most of the lower branches growing away from the water had unfortunately been raised to allow turf maintenance. Two of these limbs have horizontal sections about 12 feet from the trunk, suitable for propping. The trunk over the river was not pruned due to logistical reasons – we had no way to remove the branches from the water.

With half the load reduced, attention went back to the crack. Different standards called for two to eight rods to brace this failing structure(s). Mitigation options were presented: Two brace rods, two props, reduction pruning over the water, carving away bark where the cracks were closing to aid grafting, and securing one limb to the ground, to aid layering (growing roots).

Like live oaks, magnolias show a natural propensity for layering, so this work just helps nature along. One limb sagged over the natural area. It was a couple feet above

grade, but we tied it down so that outer branches, which were abraded where they contacted the ground, could be buried in locally harvested soil teeming with mycorrhizae, to facilitate the growth of new roots from parenchyma stem cells.

Vines make a dense ground cover under a large portion of the branches. Additional wood chip mulch was specified on part of the turf area near the trunk. At the bulkhead, random chunks of concrete were specified to be secured, and the bare area

raked smooth and covered with chopped up magnolia branches. These will be covered with jute webbing to hold them in place while the vines colonise them to provide long-term stability. As soon as possible, the installation of the props and the brace rods and the reduction of the crown over the river will be scheduled.

In 1774, the plant explorer William Bartram, known to his indigenous Seminole hosts as “Flower Hunter” or “Puc-Puggy”, reported camping under a magnolia tree at this approximate location. People say that this could be that same tree. 248 years later, it’s not clear this legend would hold up to scrutiny. But few legends do; anyway, the evidence documented in the annual rings rotted away long ago.

Questing for facts in a legend just gets in the way of a good story. Questing for tangible facts in a report, guided by Documenting Evidence, can lead the way to compelling and credible conclusions – the story the client needs to hear. AA

Bandit ‘s SG75 stump grinder is a class above. With a Kohler 74hp engine and intuitive radio remote control, the SG75 is the perfect machine for your next site. New stock incoming, enquire today!

Leigh De Abreu joins AA from this issue. Leigh is an expert climbing arborist with a passion for tree conservation. A graduate from Merrist Wood College receiving a Diploma in countryside and environment and sub-Diploma in Arboriculture. Climbing and leading crews in the south of England, his work/ travels have taken him to Brisbane where he has developed a true passion for adventure tree climbing. Using all the latest and greatest equipment and techniques over the past nine years to help aid the process, transferring skills back to daily work and passing on his wisdom with like-minded arborists.

In recent years, countless climbing setups have popped up enabling us as arborists, to access and traverse trees in more efficient and safer ways. Having learnt and climbed on moving roped systems from the beginning of my career, starting with the humble English prussik and now to more advanced mechanical devices, the decision to change to a single rope system has undoubtedly made the biggest difference to my time aloft. My aim with this article is to share a few personal insights and uses that have helped change the way I climb for the better.

To first start climbing on a single rope system, a few things must be in place, a few SRS specific devices must be purchased, with an understanding of some industry standard knots and a proficiency with the throwline; together with the basics of

highpoint installation a world of possibilities start to open. Accessing large trees is made a breeze with the addition of a Bigshot or APTA. Truly a game changer for anything over 30 metres. Rapid ascents can be made using a variety of ascending devices paired with proper technique.

Movement up a single rope system, once proficient, requires half the effort if not less than a moving rope system. Thrusting motions are gone, with a more upright position to be adopted (a huge improvement that my back is extremely thankful for). What started as merely a method of access for myself quickly became my primary working system.

Many variations for highpoints are being used currently with the biggest variation being basal or canopy anchor, both have uses in different circumstances. Although personally for a majority of situations the use of a basal anchor is primarily for access, the case being that not only is the anchor at the base of the tree now subject to interference,

but the line goes up one side of the tree and down the other, three points to be cautious of compared to the one of a canopy anchor.

Image 2 and 3: A personal favourite and extremely versatile canopy anchor, using an alpine butterfly paired with a pinto pulley and carabiner. Notice the gate always facing away from the chosen stem to avoid accidental opening of the carabiner. This can be made retrievable by having the tail end of rope reach the ground. Using this same method, the climbing side of the line can be measured out, the tail end then bundled and tied off in a convenient location. This has proved a great situational safety measure for when machines and other hazards could have potential to catch the climbers line. While working a spar as in image 3, the climber can adjust the retrieval length to the size of the logs being cut, descend to the measured-out point, make safe, retrieve the anchor point via the retrieval side of the line and reinstate the anchor point at the new desired location, the process is smooth and reassuring in use. The line being static and choked around the stem greatly increases the speed of decent if injury or other complications occurred; branches that could potentially snag a climber’s line in a moving rope system on decent don’t affect a static line.

Using SRS to navigate the trees canopy is the next hurdle, and one worthy of

“Movement up a single rope system, once proficient, requires half the effort if not less than a moving rope system.”Image 2. Image 3. Image 4.

overcoming. Alterations to climbing style are required for the abilities of SRS to be utilised in full. Once a suitable highpoint is installed, a pathway can be mapped out in the tree using redirects to attain the best positioning for more difficult limb walking. In image 4, the use of two redirects to traverse has enabled a greatly improved rope angle, while limb walking in a large spanning eucalyptus, all the while sustaining a main highpoint which was later returned to access the opposite side of the tree. Redirects can be chained together one after the other with no change to the climbing experience – all friction is dealt with by the climbing device while the rope stays static. In comparison, getting to the same position on a moving roped system would require changing highpoints, or a redirect adding more friction into the system. Bypassing these options and limb walking out would increase risk of a swing and the result would give worse overall positioning.

Image 4 and 5: a redirect using no extra hardware makes this my preferred choice.

Image 5.

To tie, the rope above the climbing device is first looped over the chosen limb and pulled tight, then using the rope above the climbing device multiple half hitches are tied over the loop. This redirect can be made retrievable by clipping the tail of the climber’s line to the rope between the two anchor points and pulling, after weight is taken off the system. I tend to use this over the option of a natural redirect as the forces of a natural redirect will pull the two points together when weighted. This does not happen with a static redirect such as the example in picture 3 and 4. Instead, the two points will move in conjunction with each other sharing the load between the two points.

So, why take the time to learn a new system when the old one works? To put in short, our skillset as climbing arborists is based on consistent results that we achieve using techniques we learn along the way. Learning the technique of SRS expands our possibilities while providing a consistent, fun and reliable climbing experience. AA

A Preliminary Arboricultural Impact Assessment report (or Pre-DA for short) assesses the potential impacts that a proposed development may have on trees prior to designs being drafted.

Pre-DA reports are typically used for drafting pre-development concept plans, for reviewing draft plans, and for other purposes such as correcting the placement of service lines and foundations to ensure the health and viability of trees.

Developments require input from many key personnel such as Arboricultural Consultants, landscape designers, engineers, town planners, heritage consultants, and possibly ecologists for sensitive sites; therefore, changes to structural details and materials, or finding out that trees are structurally sound, healthy or suitable in the new environment proposed, replanting specifications, weed species or are exempt under the 10/50 Vegetation Clearing Scheme can quickly accrue costs, delay progress on key development stages, and be distressing for clients. Time is essential for a development and this process can be streamlined with good quality consultancy, by matching experience with the project size and portfolio, and by having sequential and related programs.

By combining information from planning instruments (e.g. development control plans, NSW Planning Portal, SEED, NSW Rural Fire Service 10/50 Online Tool, etc.) and an arborist’s assessment of the trees’ health and condition, a Pre-DA report can reduce some of the planning costs associated with the re-drafting of plans by:

• Identifying which trees are protected or are desirable for preservation

• Determining what setbacks are required from a tree to minimise impacts from construction and to ensure their viability

• Stating tree defects, hazards and timeframes for intervention (this is a requirement within the Tree Contractors Association Australia’s Tree Management Guidelines)

• Providing recommendations for the management and protection of trees; and by, Caryssa Jones assessing a tree.

• Tabulating the types of checks and certifications which need to be completed prior to ‘frozen plan design’ and future demolition.

Pre-DA assessments also provide strategies to ensure that quality, healthy vegetation is protected. Most clients like to gain yield per square metre rather than keep healthy feature trees, and it’s certainly the consultant who can keep the trees in perpetuity with comments like ‘significant patch’ or ‘high retention value’. Australian Standard® AS 4970-2009 – Protection of Trees on Development Sites allude to design alteration for these types of quality trees, so if a client wants to pursue a higher yield, then they need to be clear on the trees’ current retention status in arboriculture.

To complete a Pre-DA report, a consulting arborist will require a scope of the intended works and a survey plan that pinpoints the location of all trees within or adjacent to a development site that may be impacted. A development site may be a residential plot,

a riparian corridor, or a biodiversity area where tree species belonging to a critically endangered ecological community (CEEC) need to be protected. With increased access to planning tools such as the NSW Planning Portal, the Bureau of Meteorology (BoM), SEED, Nearmap, SIX Maps, pathological laboratories, Euclid, DNA and soil testing labs, additional information can be sourced to check whether there are any development constraints and provisions. The time set aside to use these tools in important with Pre-DA assessments.

The pitfalls of not having a Pre-DA assessment and organised trades are evident when site issues such as soil contamination, land erosion and slip, compaction and deterioration of landscape feature trees arise. These issues can be flagged in the initial stage of a Pre-DA assessment and are more common for sites that have been tenanted or left vacant for many years. The Trees (Disputes Between Neighbours) Act 2006 can also ‘come into play’ when trees on neighbouring sites are

not considered, and going to court can be costly to a client without a consulting arborist on board (see Bowler v Mackney 2022 NSWLEC 1250). With Stephen Williams being the consultant arborist, it was a no brainer that you get bang for buck!