A crushing victory

A Namibian quarry triples production & sheds costs p13

HEAD OFFICE

EDITOR: Guy Woodford

ASSISTANT EDITOR: Liam McLoughlin

CONTRIBUTING EDITORS: Patrick Smith, Dan Gilkes

EQUIPMENT EDITOR: Mike Woof

DESIGNERS: Simon Ward, Andy Taylder, Stephen Poulton

PRODUCTION MANAGER: Nick Bond

OFFICE MANAGER: Kelly Thompson

CIRCULATION & DATABASE MANAGER: Charmaine Douglas

INTERNET, IT & DATA SERVICES DIRECTOR: James Howard

WEB ADMINISTRATORS: Sarah Biswell, Tatyana Mechkarova

MANAGING DIRECTOR: Andrew Barriball

PUBLISHER: Geoff Hadwick

CHAIRMAN: Roger Adshead

ADDRESS

Route One Publishing Ltd, Waterbridge Court, 50 Spital Street, Dartford, Kent DA1 2DT, UK

TEL: +44 (0) 1322 612055

FAX: +44 (0) 1322 788063

EMAIL: [initialsurname]@ropl.com (psmith@ropl.com)

ADVERTISEMENT SALES

SALES DIRECTOR:

Philip Woodgate TEL: +44 (0) 1322 612067

EMAIL: pwoodgate@ropl.com

Dan Emmerson TEL: +44 (0) 1322 612068

EMAIL: demmerson@ropl.com

Graeme McQueen TEL: +44 (0) 1322 612069

EMAIL: gmcqueen@ropl.com

SUBSCRIPTION / READER ENQUIRY SERVICE

Aggregates Business International is available on subscription. Email subs@ropl.com for further details. Subscription records are maintained at Route One Publishing Ltd.

SUBSCRIPTION / READER ENQUIRIES TO: Data, Route One Publishing Ltd, Waterbridge Court, 50 Spital Street, Dartford, Kent DA1 2DT, UK

TEL: +44 (0) 1322 612079 FAX: +44 (0) 1322 788063

EMAIL: data@ropl.com

No part of this publication may be reproduced in any form whatsoever without the express written permission of the publisher. Contributors are encouraged to express their personal and professional opinions in this publication, and accordingly views expressed herein are not necessarily the views of Route One Publishing Ltd. From time to time statements and claims are made by the manufacturers and their representatives in respect of their products and services. Whilst reasonable steps are taken to check their accuracy at the time of going to press, the publisher cannot be held liable for their validity and accuracy.

PUBLISHED BY © Route One Publishing Ltd 2020

AGGREGATES BUSINESS INTERNATIONAL USPS:

is published six times a year. Airfreight and mailing in the USA by agent named

WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA.

PERIODICALS POSTAGE PAID AT BROOKLYN, NY 11256

US POSTMASTER: Send address changes to Aggregates Business International, WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA

Air Business Ltd is acting as our mailing agent

PRINT: ISSN 2051-5766

ONLINE: ISSN 2057-3405

PRINTED BY: Warners (Midlands) PLC

TChina’s key role in the post-COVID-19 recovery

he COVID-19 pandemic has caused massive disruption to the global aggregates and other building materials sectors, not least in this magazine’s core markets of Asia, Africa and the Middle East. To their credit, many national governments across the three regions took swift action to reduce the spread of coronavirus in their respective countries. Now, many nations are starting to emerge from lockdown, most notably China.

The world’s most populous country, home to 1.3 billion people, China is also the world’s biggest producer and consumer of aggregates. To put that in context, a study published last year by Persistence Market Research, a leading global business market intelligence consultancy, stated that 47 billion tons of construction aggregates were sold globally in 2018, at an estimated value of US$300bn. Given such figures, the fact that China is starting to get back up on its giant economic feet will be warmly welcomed by aggregates product producers and manufacturers of aggregates processing equipment.

Retaining a China focus, I read with great interest a new study by GlobalData, a leading global business market intelligence consultancy, looking at how China is continuing to increase its involvement in infrastructure developments in emerging Asian markets.

GlobalData estimates the total value of Asian infrastructure projects (including building materials) in which Chinese contractors are at least partially involved at around US$235bn. In South Asia alone, the project values total $191bn. China’s influence is expanding via its Belt & Road Initiative (BRI) – a more than US$1 trillion 21st century silk road, made up of a ‘belt’ of overland corridors and a maritime ‘road’ of shipping lanes. Under the BRI, China is improving infrastructure in emerging markets across the world, facilitating economic development through the companies that can transport goods more quickly and cheaply between countries along various routes.

Danny Richards, lead economist at GlobalData, notes that although wariness has been increasing among emerging-market

governments over the risks of relying heavily on China for funding and construction contracts, the wealth of opportunities provided under the BRI can be attractive for administrations with limited funding capacity and rising infrastructure needs.

Expanding on Richards’ comments, the BRI also offers highly attractive commercial opportunities to major and ambitious small- to medium-sized aggregates and other building materials producers and quarrying equipment makers.

From a broader perspective, GlobalData analysis shows that if all infrastructure projects in the pipeline across Asia’s emerging markets proceed as planned, spending on projects involving Chinese contractors could reach $64bn in 2020, up from $23bn in 2014.

China is also the most significant foreign player in infrastructure financing and construction in Africa, mainly through BRI. According to Deloitte’s Africa Construction Trends (ACT) 2019 report, China funds 92 projects, one in every five projects, across the continent (20.4% - up from 18.9% in 2018). It is the second-largest funding source after African governments.

The Deloitte report also highlights how China continues to dominate as the most prolific (and single country) builder of projects across Africa, constructing 140 projects (31%). Projects built by China fall primarily within the transport sector.

China has also become an increasingly significant economic player in the Middle East over the past decade, mainly via the energy markets of Gulf states and the BRI. Indeed, as the European Council on Foreign Relations (ECFR) notes, the region is a strategically vital crossroads for trade routes and sea lanes linking Asia to Europe and Africa, giving it a central role in the BRI’s future.

As the global COVID-19 pandemic crisis eases and with China’s strategic big-money investment in BRI and other less grand but still important building projects set to continue apace in the coming years, African, Asian and Middle Eastern aggregates demand in the short- to medium-term will remain strong. GW gwoodford@ropl.com

19 CRUSHING & SCREENING

New and proven premium crushing and screening plant have been very much to the fore in the first half of 2020

24 LOADING

Two new loading machine buys are helping a Scottish quarrying and construction company to maximise its recycling efficiency and reduce the amount of materials it sends to landfill

26 HAULING

Key construction projects give hauling

Mineral product producers keen to widen their income streams can find big commercial opportunities in recycled aggregate and concrete products PORTABLE POWER – PART 1

Portable power solutions for quarrying industry customers are getting greener and embracing new technology WEAR PARTS

Being able to quickly access and install high-performing replacement wear parts on quarrying plant reduces downtime leading to enhanced worksite efficiency.

Specials

07 INTERVIEW

For more than two decades as director of southern Africa’s surface mining industry association, Aspasa, Nico Pienaar has

assocao,spasa,coeaaas directed his energy towards championing high levels of safer, healthier and more environmentally friendly mining practices

10 MARKET REPORT

Building activity loses momentum in the Middle East as the region faces twin challenges emanating from the coronavirus pandemic as well as plunging oil prices

13 QUARRY PROFILE

A recent installation of a Rubble African authorised distributor, Pilot Crushtec International, has helped triple production and reduce the cost of production significantly for a Namibian marble producer

15 ENHANCING QUARRY BLAST OUTCOMES

Having secured distribution rights for the Varistem, ERG Industrial is doing local trials

ase,Gdusasdogocaas to prove the potential productivity increase and downstream savings stemming plugs can provide to African quarries and mines

17

OPTIMISING EXCAVATOR UNDERCARRIAGES

Taking the time to inspect and maintain a crawler excavator’s undercarriage will help

caeecaaosudecaageep increase machine life

DOOSAN INFRACORE SEES BIGGER CHINESE PICTURE

Doosan Infracore is expanding its China market presence by selling large excavators, including its largest 80-ton excavator, the DX800LC, in various regions of the country.

The South Koreanheadquartered global market off-highway machine maker has won a series of new sales contracts for its lucrative large excavators in China, further strengthening its market base in the country.

As part of this, Doosan Infracore has announced that it has recently won orders for a total of 20 large excavators in various regions of China including Qinghai in northwestern China, Inner Mongolia, an autonomous region in northern China, and Shanxi in eastern China.

The industry anticipates that the annual sales volume of excavators in China will surpass the 2019 record of 200,000 units per year amid expectations about the government’s stimulus packages.

Doosan Infracore’s sales representative in China said: “Despite the increasingly intense competition in China, we will pursue sustainable growth by strengthening our line-up of large, highperformance excavators.”

Chinese excavator makers resume production

Chinese equipment manufacturers have pressed the “fast-forward button” to resume production in the wake of the coronavirus pandemic, according to the CCMA (China Construction Machinery Industry Association). Chinese excavator manufacturers sold a total of 49,408 products in March 2020, an increase of 11.6% year-on-year according to CCMA data. Domestic market sales accounted for 46,610 units in March, a year-on-year increase of 11.2%. Meanwhile, export sales were 2,798 units, a year-on-year increase of 17.7%.

Chinese manufacturers sold a total of 68,630 excavation machinery products from January to March (Q1) this year, a year-on-year decrease of 8.2% which was mainly attributable to the effects of the coronavirus pandemic.

The acquisition strengthens Ciments du Maroc’s position in the Moroccan cement sector

Domestic sales have been harder hit than exports. According to CCMA data, 61,277 units were sold in the domestic market in Q1, a year-on-year decrease of 11.6%. Export sales in Q1 increased to 7,353 units, a year-on-year rise of 34.9%.

China’s health authority, the National Health Commission,

claimed that coronavirus-related deaths on the Chinese mainland have fallen sharply in recent weeks.

The CCMA says that stateowned heavy-machinery manufacturer XCMG has returned to 100% production levels for the first time since the pandemic took hold in China in late 2019/early 2020.

Ciments du Maroc completes Atlantic Cement and Cimsud acquisition

Ciments du Maroc has completed the acquisition of Moroccan building materials providers Atlantic Cement and Cimsud from the Anouar Invest Group following an agreement signed in July 2019. The agreement with the Anouar Invest Group means that Ciments du Maroc acquires 100% of the capital of Atlantic Cement and Cimsud. The value of the transaction was not

disclosed. Atlantic Cement is leading the project to build and operate an integrated cement production plant in the Settat province of Morocco. Cimsud operates a milling plant in Laâyoune with a capacity of 500,000 tonnes.

Ciments du Maroc, which is owned by HeidelbergCement, says the acquisition strengthens its position as a major player in the cement

Easing of SA lockdown allows materials to flow

The first steps in relaxing South Africa’s national coronavirus lockdown will allow critical supplies of cement and construction material to reach specified markets.

Local construction materials supplier AfriSam says that the lowering of the national

coronavirus level to Alert Level 4 will allow it to resume some of its production and to supply some customers.

“The company will now be supplying aggregates, ready-mix and cement products to permitted Alert Level 4 customers,” said

sector and marks a further step in the implementation of its strategy to develop its cement, aggregates and ready-to-use concrete businesses in Morocco. Ciments du Maroc operates three cement plants in Aït Baha, Safi, and Marrakech, in addition to two grinding centres in Laâyoune (Indusaha) and Jorf Lasfar, five quarries and 30 concrete-batching plants.

Richard Tomes, sales and marketing executive at AfriSam. The changes were recently signed into law by South Africa’s Minister of Cooperative Governance and Traditional Affairs Dr Nkosazana Dlamini-Zuma, in terms of provisions in the Disaster Management Act.

© Ciments du Maroc

The factory assembly line at SDLG’s Linyi, China HQ

Southern Africa’s surface mining principal

For more than two decades as director of southern Africa’s surface mining industry association, Aspasa, Nico Pienaar has directed his energy towards championing high levels of safer, healthier and more environmentally friendly mining practices. Munesu Shoko sat down with him to discuss his impressive track record and current Aspasa priorities

Armed with a Masters in Labour Law and Industrial Relations, Nico Pienaar spent most of the early years of his career in industrial relations. Notably, he was the first industrial relations advisor to the South African building industry through BIFSA (now Master Builders South Africa), a leading national representative body in the building and construction industry.

He eventually became a trade unionist, and worked for various institutions, including the then Building Industry Society, and eventually the United Building Society before it became a bank, which is today known as ABSA in South Africa.

Some of the biggest lessons he learnt during his industrial relations days were that “it’s always essential to stick to the rules, be fair and consistent”. These are some of the values he has lived by and championed for the past 21 years he has been at the helm of Aspasa, an industry association that initially looked after the interests of sand and aggregates producers in southern Africa, before it broadened its scope recently to become an all-inclusive surface mining association.

A few years after taking over the reins at Aspasa in 1999, Pienaar was also tasked with leading the Southern African Readymix Association (Sarma). He ran the two associations for some 12 years before Sarma was moved out of the Aspasa office to become part of the consolidated concrete industry bodies in 2017. Two years later, Sarma was closed at the end of 2019, “a very sad day” in Pienaar’s life, as he had, for over a decade, put a great deal of effort in building this readymix association. That Pienaar is passionate about what he does is very apparent – and many in the quarrying industry in southern Africa would agree. He has been the force behind Aspasa for two decades now, and has, over the years, revolutionised the association, which has since become a recognised voice of the industry.

For Pienaar, an association has to be of great value to its faithful members. This, he says, is a lesson he learnt during his trade union days. “You have to offer value and be of great help to members, who obviously look up to you as an association. An industry association has to be aware of the issues afflicting its members, something Aspasa has excelled in over the years.”

To meet the ever-changing needs of the industry, Aspasa has in recent years broadened its scope and also extended the range of services it offers to help members comply with the different legislations that apply to the industry.

In 2017, the association expanded its reach from its traditional sand and aggregates focus, to cover several other areas of the surface mining industry, including salt, dimension stone and clay brick. Affiliation now includes mobile crushing contractors, formal quarries, rubble crushing, ash, coal and borrow pit subsectors.

Also included are associate memberships for organisations such as the National Occupational Safety Association and heavy machinery manufacturers. These are all required to be legally compliant with legislation such as the Mine Health and Safety Act (MHSA), environmental legislation and the Water Act.

As the membership scope has been extended, so have been the services offered by the association. Aspasa’s service offering covers legal compliance; local, international and government liaison; health and safety audits and training; environmental audit and training; technical and transport support; as well as training and education.

In terms of legal compliance, the focus has traditionally been on health and safety and environmental practices. In recent months, the association has also added an array of compliance audits, including the Explosives/Blasting Compliance audit, the Quality/Technical Compliance Audit, Mining Charter Audit and a focus on Social Compliance and Community Affairs.

“Aspasa compliance audits assist operations, line managers, top management, boards and shareholders to ensure that operating standards are met in every aspect of the operation. The personal competencies of those operating the business are also addressed by a host of training topics that are covered by the association, while compliance audits point out issues that need attention,” he says.

Flagship audits within Aspasa have always been the health and safety audit, known as the ISHE Audit, and the environmental audit, named About Face.

The ISHE Audit has ushered in new health and safety standards in the industry. Aspasa members have reported no fatalities across their operations for the fifth year running –which is testimony to the level of health and safety excellence at member operations.

Explaining the key drivers behind the success of the ISHE Audit, Pienaar says the objective is two-fold. While it is a compliance audit protocol for legal requirements, own policies, standards, procedures and guidelines, as well as industry-leading practices, it is also an educational process where information is shared during audits on what is going on in the industry, how other operations are implementing required legislation and regulations to ensure high standards in health and safety performance.

ABOVE: Nico Pienaar receiving a special award from South Africa’s Minister of Mineral Resources in recognition of his valuable and ongoing contribution to the Mine Health and Safety Council

A view of Lafarge SA’s Karino Quarry in Nelspruit, South Africa, an Aspasa member operation

The ISHE audit generally covers MHSA regulations and Aspasa has recently received calls to expand it to cover the Occupational Health and Safety Act (OHSA). “We have, therefore, developed an additional audit protocol that will allow Aspasa to audit other functions that are associated with mining operations, such as readymix, bitumen, brick plants and workshops,” says Pienaar.

The environmental stewardship of Aspasa members has improved significantly since the inception of the About Face programme in 1994. This has guided and aided most members to elevate themselves from mediocre environmental performances to being among the best opencast operations in the world.

Pienaar says environmental compliance –from a community and regulator perspective – is also becoming a big issue in the industry. “The good housekeeping type of audits previously done have been changed, with specific focus now on being legally compliant by assisting mine managers to understand their roles and being not so dependent on consultants who often don’t grasp certain important issues themselves,” says Pienaar.

One of the newest service offerings from Aspasa is the Explosives/Blasting compliance audit. With blasting regulations changing, and communities being more aware of their rights, even when not often justified in their complaints, Aspasa has gone into an agreement with a blasting expert to conduct one-day audits to ensure compliance.

“We have decided to offer Blasting Audits to members because the mining industry faces numerous practical legal challenges since the MHSA’s new explosives regulations came into effect on 14 December 2018. There have been various demands made by affected communities and the regulator, the Department of Mineral Resources and Energy (DMRE) officials,” says Pienaar.

Increasing requirement for certified quality aggregates has also driven Aspasa to introduce its own guidelines and auditing systems to ensure testing of aggregates and crushed granular materials is done in accordance with South African National Standards (SANS) 3001 AG and GR series test methods.

In future, quarries belonging to Aspasa will have an option to participate in an annual audit designed to measure compliance of testing facilities, including their apparatus calibration and personnel competence against an abridged ISO 17025 format, to assist in ensuring the correct classification of products.

“Over time, as their systems improve, they can opt to obtain accreditation through South African National Accreditation System (SANAS) for ISO/IEC 17025 – general requirements for the competence of testing and calibration laboratories,” says Pienaar.

Following the publication of the Mining Charter’s Implementation Guidelines and Amendments in December 2018, Aspasa has now extended its service to members with a Mining Charter Audit.

South Africa’s new Mining Charter was developed to boost sustainable growth,

“The good housekeeping type of audits previously done have been changed”

enforce procurement of local goods and to further support broad-based, meaningful Black Economic Empowerment of the South African mining and minerals industry. Pienaar cautions that it’s important for all South African mines to work strictly within the confines of the charter.

Pienaar says the biggest risk facing any operator is to be suspended because of non-compliance. “With the Mining Charter Audit, Aspasa members will be in a position to assess their compliance status and take

compliance inspections – the outcome of which can be punitive, costly and time-consuming.”

The business approach to running Aspasa is one of the reasons why the association has succeeded over the years. “I see Aspasa as a business, my own business,” he says. “I, therefore, have a great interest in all issues that affect the association’s members.”

For example, in the past two years, Aspasa has been tackling some new issues that have traditionally been beyond its jurisdiction. “We have also extended our scope to help members with security issues at mines, including attacks and theft. We have also started a community and social compliance group,” he says.

Pienaar’s efforts haven’t gone unnoticed. In 2018, he was honoured with two separate awards for his contributions to the industry. He was given a special award by South Africa’s Minister of Mineral Resources in recognition of his valuable and ongoing contribution to the Mine Health and Safety Council as director of Aspasa. Pienaar also received a CEO Global Titans Building Nations Award, which recognises unsung heroes of the African

Aspasa has introduced its own guidelines and auditing systems to ensure testing of aggregates and crushed granular materials is done in accordance with South African National Standards

Nico Pienaar visiting one of the member operations in Gauteng, South Africa

Nico Pienaar with the mine manager of Drift Supa Sand, a member of Aspasa

COVID-19 hits Middle East construction activity

Building activity loses momentum in the Middle East as the region faces twin challenges emanating from the coronavirus pandemic as well as plunging oil prices. V L Srinivasan reports

In its regional economic outlook report for April 2020, the International Monetary Fund (IMF) has projected that the Middle East and North Africa (MENA) economies will contract by 3.3% in 2020, the biggest slump in four decades.

The report further said that the twin shocks of COVID-19 and low oil prices were likely to shave off US$323bn, or 12%, of the Arab world’s economy. Of this, $259bn is from the oil-exporting six-member GCC (Gulf Cooperation Council) countries alone.

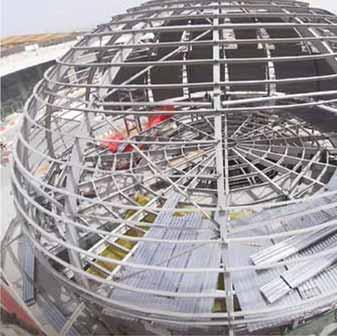

Dubai, which was all set to inaugurate World Expo 2020 on October 21 this year, postponed the event by one year exactly. The UAE government has restricted air travel, announced a stimulus package of $34bn to support the economy, suspended issuance of new labour permits for the time being and has been allowing only essential personnel to visit the sites of projects under construction.

According to a report from Strategy& Middle East, part of the PwC network, the pandemic has hit the construction industry hard. Contractors have been facing budget overruns and delays, due to lockdown measures and strict hygiene and distancing restrictions resulting in low productivity.

Authored by Marwan Bejjani (partner), Alessandro Borgogna (senior executive adviser) and Elias Karam (manager), the

report states that construction materials were taking longer to source due to reduced manufacturing output and other supplychain issues. These are difficult challenges, but contractors in the GCC need to balance short-term measures to survive the crisis with medium-term measures to prepare for the eventual recovery.

“The ultimate impact on the GCC’s construction industry is still unclear, but we estimate that contractors in the region could lose approximately $30bn in revenue (20% of the GCC’s total construction market for 2020) if the current lockdown remains in place for three months,” the authors said.

If the lockdown extends through the end of 2020, the revenue impact would be about $65bn, a drop of around 45%, they added.

Crucial year

General manager of Emirates Building Systems (EBS) Joseph Chidiac said the UAE’s stimulus package aimed to cut the cost of doing business, support small businesses, and deliver significant government infrastructure projects.

companies in the UAE in the wake of COVID19 outbreak,” he said.

The UAE’s total construction contracts across all sectors were forecast to increase from $43.46bn in 2019 to $45.14bn in 2020. This includes the building sector ($25.2bn) followed by energy ($15.58bn) and infrastructure sectors ($4.3bn).

EBS is a wholly-owned subsidiary of Dubai Investments, and one of the leading manufacturers of steel structures in the Middle East with an annual production capacity of over 75,000 tons. “I feel 2020 is going to be a crucial year for construction

“I feel 2020 is going to be a crucial year for construction companies in the UAE in the wake of COVID-19 outbreak”

Joseph Chidiac

Al Maktoum International Airport- Dubai

“With the pandemic, oil price crash and the global economy in tatters, these figures are no longer realistic. The UAE, as well as other countries, are still fighting to keep the virus at bay and projecting a realistic forecast for the year is not possible at this stage,” he explained.

The contractors in the UAE may have to go through the price negotiation process again as project promoters are likely to insist on re-pricing contracts because of the changed circumstances. Even projects awarded as recently as weeks ago are undergoing re-pricing.

“The Abu Dhabi National Oil Company (ADNOC) has terminated engineering, procurement and construction (EPC) contracts it had awarded to the UK-based

Petrofac for its $1.65bn Dalma sour gas field development project. ADNOC has reportedly urged Petrofac for a discount on its contract value, which was turned down,” Chidiac said.

With regard to stock levels, he said that EBS was well stocked to take care of their immediate materials and consumable needs. It always keeps stock for at least six months and is not exposed to foreign suppliers. When required, the company sources from within the UAE or the GCC countries.

“Our policy is to purchase in bulk well in advance of projects’ schedules, and hence, for now, the virus is not having any material impact on us and our production is progressing as normal,” he added.

Downturn in GCC

The scenario is no different in the remaining five countries in the GCC region as the spread of the pandemic forced these governments to announce social lockdowns to contain its spread.

According to leading data and analytics company GlobalData, the region’s construction sector will face a downturn in 2020 over soaring COVID-19 cases and a slump in oil prices. The construction output growth forecast has been revised to -0.8%, down from the previous projection of 1.4% in mid-March (and 4.6% in its Q4 2019 update).

“Dubai’s Department of Finance has also ordered a 50% cut in capital spending and has called for a freeze on new public construction schemes”

Yasmine Ghozzi

*MENA coverage includes all the GCC Countries, north African countries of Egypt, Sudan, Algeria, Tunisia, Morocco and Levant countries such as Jordan, Lebanon, Iraq along with Iran

Source: BNC Intelligence

While Saudi Arabia has been maintaining its renewable-energy programme impetus and Aramco has been issuing tenders for offshore construction works, other parts of the GCC, including Qatar, Oman and Kuwait, are revising their spending and their construction pipelines.

“Dubai’s Department of Finance has also ordered a 50% cut in capital spending and has called for a freeze on new public construction schemes. Outside the GCC, Iraq announced that the COVID-19 pandemic constitutes a force majeure for all projects and contracts, creating uncertainty in Iraq’s construction sector,” GlobalData’s Economist Yasmine Ghozzi said.

Yasmine further pointed out that the outbreak was threatening to devastate Egypt’s $12.5bn-a-year tourism industry, which accounted for 12% of GDP.

In Jordan, the government has put in place a plan to jumpstart the construction sector, one of the most heavily affected by the COVID-19 economic fallout, to reboot the economy and provide jobs for day workers, according to the official Jordan News Agency.

Minister for Public Works and Housing Falah Omoush said the plan was aimed at stimulating the construction sector and addressing the economic ramifications of COVID-19. “Our plan seeks to support

and sustain the small and mediumsized businesses as they struggle amid governmental strict stay-at-home measures to stem the spread of the virus,” the minister said and added that strict safety measures would be followed.

Bahrain and Oman impacted Oman, too, has allocated $13.77bn for projects in its 2020 budget, and they include $7.01bn for industrial projects and services and $3.38bn each for infrastructure and for oil and gas projects.

The government, in tandem with the private sector, has been executing 2,410 construction projects whose combined value is put at around $188bn. They include 1840 ongoing projects valued at around $61bn on urban construction projects, 70 projects worth $39bn in the oil and gas sector, and 150 projects worth $32bn in transport. Additionally, 340 projects in utility and industrial sectors are being implemented, costing around $56bn.

But things changed after the COVID-19 outbreak and low oil prices and Oman’s federal bank – Central Bank of Oman – has announced a package to inject additional liquidity of over $20.8bn into the economy.

As part of the measures to mitigate the impact of COVID-19 crisis, Oman’s finance ministry has instructed all other ministries and civilian units to reduce liquidity for development budgets by 10%. Additionally, state companies will no longer be established for business activity to give way to the private sector.

Things are no different in Bahrain as it has announced that spending by ministries and government agencies will be slashed by 30% to help the country weather the coronavirus outbreak. Bahrain will also reschedule some construction and consulting projects to keep spending within the 2020 budget and make room for other expenditure needs emerging as a result of the disease’s spread, an official statement said.

M R Raghu, Kuwait Financial Centre executive vice president, said that although the GCC construction market continued to remain buoyant, with projects worth $17.5bn announced in February 2020 alone, the supply of materials was bound to face constraints.

Movement of construction materials and labour to construction sites remains a logistical issue due to lockdown and travel restrictions, he said.

Despite these hiccups, some of the GCC governments have allowed for critical construction works to take place provided guidelines issued by governments are followed. “The industry consensus is that, if we could overcome the COVID-19 pandemic in two months, the industry could recover faster,” he said.

“Projects envisioned as part of developmental programmes in Saudi Arabia and Kuwait would receive a renewed push in the post-COVID-19 scenario as the governments expect to accelerate their

“Our plan is aimed at stimulating the construction sector and addressing the issues caused by the economic ramifications of COVID-19”

Falah Omoush

spending in various critical infrastructure projects. These include enhancing capacities of healthcare, education, roads, airports, power and housing projects,” he added.

Corporates join hands

Major companies such as Caterpillar and LafargeHolcim, which have been operating worldwide, including in the Middle East, have joined hands with the regional governments to fight the pandemic.

Caterpillar chairman & CEO Jim Umpleby said that his company remained committed to the safety, health and well-being of its employees around the world. The employees are delivering products and services that enable its customers to provide critical infrastructure essential to support society during the COVID-19 pandemic.

“In view of the pandemic, many governments have classified Caterpillar’s operations as an essential activity for the support of critical infrastructure. Working with our dealers, Caterpillar is delivering products and services that enable our customers to provide critical infrastructure that is essential to support society during the COVID-19 pandemic,” he said.

These products are being used by customers to provide prime and standby power for hospitals, grocery stores and data centres. They are also used to transport food and critical supplies in trucks, ships and locomotives, maintain clean water and sewer systems and mine commodities and extractive fuels essential to satisfy global energy demand.

“While employees who can work from home are doing so, in other facilities that remain open, Caterpillar is implementing safeguards to protect its team members in accordance with regulatory requirements and guidance from health authorities,” he added.

LafargeHolcim’s chief executive officer Jan Jenisch said that his company had also taken necessary measures to protect the health of its employees, customers, suppliers and other stakeholders since the beginning of the outbreak.

“While the construction sector and sites are generally more resilient than other sectors, the company has been experiencing disruptions in operations in various countries,” he said.

In China, the recovery of the construction sector has started, and all the company’s plants outside Hubei Province are operating.

“In most of the other key markets, the construction sector has been disrupted, and we forecast significant volume declines in April and May. While demand in Q1 was solid overall, LafargeHolcim expects a significant negative impact on its business in Q2,” he added. AB

Russian Pavillion at Dubai World Expo 2020

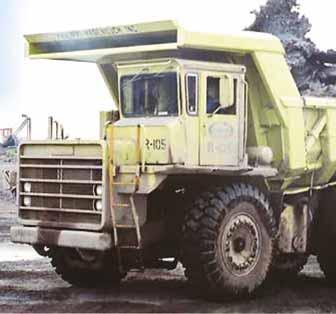

A Namibian quarry took delivery of a Rubble Master RM 90GO! in August 2019, which has helped triple production

RM 90GO! WINS THE DAY FOR NAMIBIAN QUARRY

A recent installation of a Rubble Master RM 90GO! by southern African authorised distributor, Pilot Crushtec International, has helped triple production and reduce the cost of production significantly for a Namibian marble producer. Munesu Shoko reports

To open up new alternative revenue streams, a Namibian marble operation decided to crush rejected marble slabs as a value-add to its business. Materials produced out of the waste comprise 0-1mm for various industrial uses, as well as 1-6mm, 6-15mm and 15-40mm for general aggregate.

“While well entrenched in the market, with a product ranked among the top qualitywise, there were two options to grow the business. They could either produce more marble, which was undesirable as that would compromise the lifespan of the quarry, or they could use waste material that continuously piles up on site. A decision was made to crush waste material into a valuable product,” explains Fernando Abelho, Africa sales manager at Pilot Crushtec. The newly crushed waste material has a number of uses in the

construction and industrial sectors, from tile grout to additives in commercial products –basically anywhere a fine powder is required.

Previously, the operation ran a Metso mobile jaw crusher and screen. However, with the old single-stage crushing set-up, it experienced high inefficiencies, which resulted in re-handling of material, translating into high cost of production per tonne.

“Initially, they were using a jaw crusher and screen to do single-stage crushing, but were achieving very low volumes,” explains Abelho. “The team from Pilot Crushtec spent about six months with the client in order to understand their business. The client did an exhaustive analysis in terms of what other industrial uses there could be for its waste and what specifications were required to compete in that market. Pilot Crushtec was then consulted on how to achieve the required product specifications.”

Pilot Crushtec’s initial idea was to just put in a screening plant to reduce double-handling of material, thus dropping operating costs. Essentially, this meant the material was fed into the jaw crusher, split into three usable products, and a fourth product that was still too large to be of any use had to be reprocessed.

The extra screen, however, would not solve the problem as the client’s production rates were just too low and the cost could not be justified. The only logical solution was to increase production, and the Rubble Master RM 90GO! impact crusher was deemed to be the perfect tool for the job at hand.

“The client needed a reliable crusher that could increase production significantly, provide flexibility in terms of product specifications and produce a high percentage of fines (due to the relatively small demand for aggregate products in the region),” says Abelho.

Capital costs of the equipment were a major concern as the concept was to beneficiate a waste product. While a secondary cone crusher could offer those benefits in the correct application, an impact crusher was considered a much superior solution for this project considering that the feed material is non-abrasive.

“Impact crushers offer much higher reduction ratios than cone crushers, and with variable speeds and crusher gaps, you have significant control over final product curves. From a maintenance point of view, impact crushers are also simpler to maintain and operate than cone crushers,” he says.

“The Rubble Master has been at the forefront of compact crushing and screening for a number of decades and offers premium models that punch above their weight without compromising quality. Combined with Pilot Crushtec’s commitment to parts holding and high calibre of support technicians, the final choice was an easy one for the client,” adds Abelho.

With the Rubble Master RM 90GO! in place, there now exists a thorough two-stage crushing process. The operation’s plant now produces at a much higher volume and with less re-handling. Abelho says during commissioning the plant achieved up to 280tonnes per hour (tph) peak production, which is not sustainable over a long period of time. However, the quarry is currently operating comfortably at between 180-200tph.

“Fixed operating costs have remained relatively the same, but production has increased considerably, while the cost per tonne has been lowered significantly, meaning higher profitability. Higher production and lower costs mean they are more competitive and are able to look for more clients,” says Abelho.

Explaining the mechanics of crushing, Abelho likens the process to driving a car. “One needs to go through all their gears to get to the top speed and it is the same when crushing. You have your first stage that will generally round off the material from 600mm to about 100mm,” he says.

“The second stage will then further reduce the size from 100mm down to

about 25mm. You can, of course, abuse the various stages but this does come at a cost. Your efficiency will suffer, wear and tear will increase and production levels will drop. The client has eliminated these negatives by installing a Rubble Master RM 90GO! and production has almost tripled. They are at a point where they have to find more clients for their industrial products,” adds Abelho.

The philosophy behind the design of the Rubble Master has always been simplicity in operation and maintenance without compromising on quality and performance. Pilot Crushtec often uses it to introduce clients with minimal experience to the crushing and screening industry.

“The Rubble Master is really easy to run. From a maintenance and operation perspective, there is nothing simpler. The control panel literally has four buttons that get the machine going; we call it the one, two, three, Go!. You push three buttons, and you are ready to start crushing. This is great as the learning curve for operators is very short, relative to cone crushers where countless set-up parameters are available via the PLC (Programmable Logic Control). All the intelligence is hidden within the machine,” says Abelho.

“Additionally, the size has intentionally been kept compact as it is often used in urban environments where space is at a premium. We have clients that use the Rubble Master to crush backfill when working on residential complex projects as the machine is incredibly mobile and has great sound insulation.”

The Rubble Master comes in three iterations that serve a wide variety of markets. Typically used in low-abrasion and construction and demolition (C&D) waste applications, the RM range can be used in some harder applications under correct circumstances. The starting point for any prospective client is most certainly the Rubble Master RM 70GO! 2.0 impact crusher.

The compact, track-mounted machine produces cubic-shaped grain in various product sizes and is designed to process a wide range of aggregates material. The diesel/ electric drive makes this unit economic and efficient and, due to its power and versatility, the compact crusher is a vital piece of equipment for companies specialising in recycling. “If you have wider application needs and more demanding power and handling expectations, the RM 90GO! is the answer,” says Abelho.

The RM 90GO! is a low-noise, highperformance crusher suitable for an array of applications. Set-up is simple and the machine is ready for action within a few minutes to rapidly and efficiently process any material, such as C&D waste, concrete, asphalt, glass, coal, natural rock and even reinforced concrete, to produce high-quality construction materials.

Rounding off the range is the Rubble Master RM 100GO! compact crusher. The track-mounted unit produces a high-quality, cubic-shaped grain in various product sizes. Due to its power and versatility, the compact crusher offers a flexible approach to highcapacity crushing. The Rubble Master RM 100GO! is a primary or secondary crusher with a refeeding belt that sends oversize material back into the vibro-feeder and returns it to the crusher.

“Diversification and identification of alternative revenue streams are the keys to success and sustainability in the 21st century. With a variety of applications that open up with the Rubble Master range, it has never been easier to retool or upgrade when the need arises,” concludes Abelho. AB

The newly crushed waste material has a number of uses in the construction and industrial sectors, from tile grout to additives in commercial products

Independent studies also show that the Varistem can increase blast pattern spread by 10% or more, with the same fragmentation for major savings in drilling and explosive costs

Enhancing blast outcomes

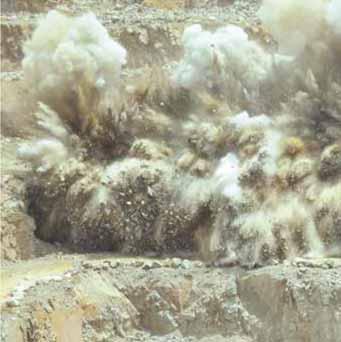

Having secured distribution rights for the Varistem – a patented blast stemming plug for mining, quarrying and civil blasting applications – South Africa-based ERG Industrial is currently doing local trials to prove the potential productivity increase and downstream savings stemming plugs can provide to African quarries and mines. By

Of the various products that have come to market to improve blast performance, flyrock control and productivity, stemming plugs have probably been looked upon with some cynicism. At a time when South African quarries are contending with shrinking business due to a stressed construction sector, ERG Industrial, a young company that in 2019 acquired the distribution rights of the Varistem stemming plug range from United States company, MOCAP, believes stemming plugs are an opportunity to increase efficiency for quarries and mines, thus reducing costs.

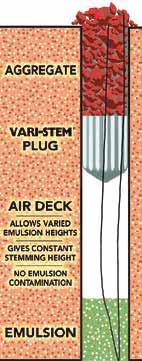

Eugene Preis, MD of ERG Industrial, explains that stemming plugs are placed between the explosive column charge and stemming. Plugs work by creating an additional blocking effect within the drill hole when blast energy is released, directing more energy into the block and less energy upwards out of the drill hole. Upon detonation of the explosives, the plug is forced upward into the stemming material and “locks up”. The explosives gases and energy are prevented from travelling (venting) up through the drill hole.

Typically, the loss of explosive energy through stemming ejection reduces the performance of the blast. The fundamental theory promoting the use of blastimprovement and containment plugs is that they could enhance the effectiveness of stemming material in the blasthole. As a result, this would better contain the explosive energy within the rock mass and yield a more controlled and efficient blast.

Varistem is now available in Africa through ERG Industrial – excluding a few countries like Zimbabwe and Congo, due

to US trade restrictions in those countries. Varistem is a patented blast stemming plug designed for quarrying, mining and civil blasting applications. The plugs are said to contain blast energy for longer, resulting in a range of benefits depending on how it is incorporated into the blast design.

Preis says maximum blast containment means greater fragmentation and microfractures, with more tonnage processed at less cost. “Following ore body fractures created by the explosive shock waves, the Varistem improves expanding gas containment. The greater the gas containment time within the ore mass fractures, the better the fragmentation. Getting your fragmentation right is your fragmenta

“The Varistem also enables consistent stemming heights when using gas emulsions”

Eugene Preis, MD of ERG Industrial

Munesu Shoko

substantially cheaper than having to do secondary blasting or mechanical breakage,” he says.

In some cases, the Varistem has achieved up to a 25% increase in fragmentation, which in turn reduces crushing costs and increases crusher throughput. Independent studies also show that the Varistem can increase blast pattern spread by 10% or more, with the same fragmentation for major savings in drilling and explosive costs. “Benefits abound – the Varistem provides blast confinement, resulting in better ore fragmentation, greater crusher throughput, reduced crushing costs and better blast control (less fly rock, vibration and noise),” says Preis.

There are several ways in which the Varistem can be used to improve blasting performance. One of them is air-decking. Historical studies show air-deck volumes of 10-15% can be realised without any major reduction in fragmentation. These studies used air bags for stemming support, which save explosives but do not improve fragmentation. Air-decking with Varistem achieves up to a 27% fragmentation improvement, while also saving on explosives.

“The Varistem also enables consistent stemming heights when using gas emulsions. Simply reduce the emulsion volume allowing for maximum expansion. Set the Varistem in an air-deck so that stemming heights are consistent in all drill holes. This will eliminate short stemming heights and blow-outs,” explains Preis.

Air-decking with the Varistem allows shorter stemming heights, while also reducing explosive column height to dramatically minimise over-sized cap rock from a common 10% oversized, down to a 2% oversized.

Flyrock and stemming ejection are also controlled.

When it comes to fragmentation, Varistem plugs increase blast-force retention times by two to four times. The blast force contained by the Varistem is conserved and directed into the rock, greatly increasing the level of fragmentation.

“In addition to the other benefits, quarries, contractors and blasters could potentially reduce the volume and expense of crushed stone stemming, allowing them to use less expensive drill cuttings for stemming as well,” says Preis.

There are several secondary cost savings which result from increased fragmentation –easier rock removal, less secondary breakage costs, increased truck capacity, less wear on crushing and grinding equipment – all of which contribute to the cost benefit of using the Varistem, and which will make the Varistem pay for itself many times over.

Varistem also improves blasting performance through increased pattern spread. The blast energy conserved by Varistem permits operations and blasting contractors to do a lot more with a lot less. Multiple studies have demonstrated that Varistem allows blasters to increase their pattern spread by 10-25%, without any reduction in fragmentation. The cost benefit of increased pattern spread is easy to see – 10-25% fewer holes drilled, 10-25% less explosives used – both of which can greatly help reduce the direct expense of drilling and blasting.

Varistem has been used in the United States for the past 16 years, and in Canada and Australia for the past 10 years. It has also been deployed at operations in Thailand, Ghana and multiple European quarries. In one of the flagship studies conducted by Holcim Cement at its St. Genevieve Quarry, data shows that the expanded pattern size of 14 x 19 inch with the implementation of

ABOVE: Plugs work by creating an additional blocking effect within the drill hole when blast energy is released, directing more energy into the block and less energy upwards out of the drill hole

the Varistem plug yielded improved overall fragmentation compared to the existing 14 x 18-inch pattern typically used by the operation.

The added fragmentation performance represented a reduction of 11.6% in the “mean” size of the rock. The increased fragmentation benefit permitted the usual 14 x 18-inch blast design to be increased to the 14 x 19-inch pattern, thus eliminating 6% of the blast holes necessary to produce the same volume of rock with improved fragmentation.

Studies and in-field tests from the very same operation also showed that the Varistem plugs could increase fragmentation significantly. Three test blasts were carried out at the quarry, with the initial test confirming a 27% fragmentation improvement using Varistem.

Elsewhere, Seven Pines Quarry in Ontario, Canada, recorded significant savings and environmental impact reduction from air blast. Using the Varistem, the operation saw double success though reduced noise/ vibration levels and a reduction in explosive costs of approximately 12%.

LEFT: Stemming plugs are placed between the explosive column charge and stemming BELOW: The Varistem is a patented blast stemming plug designed for quarrying, mining and civil blasting applications

Despite the proven successes of this technology, demonstrated by several successful case studies, ERG Industrial’s approach to local African sales is based on proving the capabilities at individual operations before commercially deploying the Varistem stemming plugs.

According to Preis, this approach is driven by the understanding that figures achieved at other locations may not necessarily be achieved elsewhere due to the varying nature of conditions and rock geology, among other factors. Therefore, each operation’s gains will vary depending on conditions on site.

ERG Industrial has already kicked off operational tests at some local quarries in South Africa. Between September and November 2019, the supplier conducted tests at four of Afrimat’s quarries. The main aim of these trials was to reduce flyrock and increase fragmentation.

“At two of the four quarries, we used the 102mm stemming plug to see if we could reduce flyrock and stemming ejection and increase fragmentation. The Varistem plugs were used on benches 10m in height, with stemming heights of 1.4m. Ideally, we would have wanted to increase the stemming height to at least 1.8m for the 102mm trials, but this was not possible at the time. Notwithstanding, we had zero flyrock, but still had some stemming ejection (albeit reduced). In terms of fragmentation, the results were the same as before,” he says.

ERG Industrial did two more tests with Afrimat, this time on 89mm blastholes. “Here, the stemming height was a bit higher, about 1.6m. This is roughly equivalent to having a 1.8m stemming height with 102mm holes. Previously there were problems with flyrock because blasting is very close to public roads. Using the 89mm stemming plug, the trials at the two operations achieved zero flyrock,” concludes Preis. AB

Optimising undercarriage life

Taking the time to inspect and maintain a crawler excavator’s undercarriage will help increase machine life. If the undercarriage is not routinely inspected and maintained, it can easily cost owners valuable time, money and potentially decrease the track’s lifespan. By

Munesu Shoko

The undercarriage of a crawler excavator comprises many moving components that need to be maintained for it to function properly. Regular maintenance, coupled with correct machine operation, significantly reduces undercarriage wear, improves operating efficiency and reduces running costs. Håkan Karlsson, product manager for ground engaging tools, undercarriage and customer solutions at Volvo CE Sales Region EMEA, says a properly maintained undercarriage is important to the overall life of the machine. Wear parts in poor condition will shorten the machine’s service life and increase the risk of breakdowns and unplanned downtime.

Shumani Tshifularo, MD of HPE Africa, the Hyundai and McCloskey distributor in South Africa, says because crawler excavators have a strong, solid-steel construction, maintenance of the undercarriage is often neglected and that can be a costly mistake. “Research shows that repair costs for the undercarriage of a tracked excavator account for as much as half of all repair costs over the life of the machine. A worn undercarriage increases vibration levels of the excavator, which reduces service life of components like pumps, motors, electronics and the engine,” says Tshifularo.

The same view is shared by Garth Labuschagne, sales manager Africa for the Mining Mobile Plant division at Bradken, a Hitachi Construction Machinery company, who reasons that for many operations, the undercarriage is within the top 10 spend items during the life of an excavator. “A poorly maintained undercarriage will require a significant amount of time and money spent on it, which translates into reduced efficiency,” says Labuschagne.

There are several indicators that the undercarriage is not getting enough attention.

According to Labuschagne, typical indicators of a poorly maintained undercarriage include stretch in the track (which indicates pin wear), reduced component life, unusual wear patterns and increased failure rates such as roller surface delamination/compression.

Some of the indicators of a poorly maintained undercarriage, according to Lionel Hearne, national service manager at Wacker Neuson South Africa, include tracks slipping or sliding off, tracks screeching loudly and not moving due to damaged sprockets, tensioners or support rollers.

So, what does a proper maintenance regime of a crawler excavator undercarriage entail? There are several things that should be kept in check, given that the undercarriage comes with several moving components. Tim Nenne, senior undercarriage application specialist at Caterpillar, says one of the key parameters is to keep the tracks properly tensioned.

“A tight track is one of the top reasons for reduced life and failures in an undercarriage. This is especially true for the greased

lubricated tracks on excavators. Tight tracks increase the internal wear rate by pushing the grease from the joint more quickly,” says Nenne.

Karlsson advises that track tension should be checked at least once a week to prevent early wear. Track tension should always be a little slack; if the tension on the track is too tight, the pressure can cause unnecessary wear to the chain and sprockets. “This can happen if the distance from the bottom chain to the frame on the undercarriage has been measured incorrectly. It’s a different measurement depending on the type of material, so anyone carrying out the inspection should always check the operator’s manual,” says Karlsson.

Tshifularo believes that track tension should be inspected daily. “This takes no more than 10 minutes,” he says. “A track

A properly maintained undercarriage is important to the overall life of a tracked excavator

The undercarriage of a crawler excavator comprises many moving components that need to be maintained for it to function properly

tension that is too tight puts extra load on the engine, which wastes fuel and can also cause premature undercarriage wear. A track that is too loose may come off and can also cause additional shock loads and side-to-side wear of components.”

When it comes to correct track tension, Vaughan Ellis, MD of Maximum Equipment, the South African distributor of Hidromek excavators and backhoe loaders, says the rule of thumb is to maintain the width of a hand between the bottom roller and the track, which is about a 12cm gap.

Apart from the track tension, Karlsson believes it’s also crucial to keep in mind that when one replaces any part in the track system, such as a chain, they also have to check the wear on other parts. For example, a worn sprocket may quickly wear down a new chain.

Ellis says leaving the undercarriage dirty for too long is a costly mistake. “Not washing the undercarriage is detrimental to its overall health. If you have been working in clay or muddy conditions, don’t leave the mud stuck to the undercarriage for too long. The mud sits in the pins, bushes and rollers and causes them to wear excessively,” says Ellis.

Nenne shares the same sentiment, saying that material build-up in the undercarriage system and on the roller frame can lead to tight track conditions. Such a build-up also increases wear rates as the links drag over it and it circulates through the link/roller system.

Tshifularo adds that packed debris and dry material should be removed from the undercarriage at the end of every shift, using a shovel, steel bar or water. Dry material increases track tension and prevents rollers from turning freely, which accelerates wear of components.

He also recommends that after every 1,000 hours of operation, a specialist undercarriage company should be commissioned to check the undercarriage. Excessive wear on one component causes accelerated wear on other components in the system.

Tshifularo says it’s also important to look at several other parameters, like total hours of travelling vs digging and total hours travelled in high-speed vs low-speed mode. “Torque setting on all the bolts on the undercarriage

should also be checked – including roller and top idler brackets, track shoes, sprockets and final drives,” says Tshifularo.

Besides maintenance, operator technique is one of the most important factors in the health of an undercarriage. Ellis believes one can tell the difference between a good and bad operator by the undercarriage. “A bad operator thinks the undercarriage is designed to track over anything, including rocks and stockpiles. This is a common scenario in quarries,” says Ellis.

Commenting on the impact of machine operation to overall undercarriage health, Karlsson says operators should always travel and dig with the sprockets at the rear and the idlers at the front. “The idler has springs to protect it from pressure, but operating with it at the back will cause around 30% more wear on the sprocket and chain,” he says.

Tshifularo advises that operators should avoid travelling long distances in high-speed mode. The faster the travel speed, the greater the relative load between components, which increases wear. Over long distances, friction causes heat build-up within the rollers, idlers and drives and this can damage internal seals.

In fact, Nenne says there is a need to limit tramming (walking the machine). Any moving of the machine contributes to the wear on the undercarriage. “Keeping the amount of unproductive movement to a minimum will reduce the amount of wear per hour of machine operation. It is advisable that an excavator should not tram more than 15% of its total operating time,” he says.

TOP LEFT: Sprockets on a Hidromek crawler excavator need to be replaced between 2,000 and 3,000 hours.

ABOVE: Operators should always prepare and make the ground flat under the machine before they start digging. This will avoid uneven pressure to the undercarriage

LEFT: To ensure long undercarriage life, operators should avoid travelling in high-speed mode on rough or hard terrain or inclines

Tshifularo adds that operators should also avoid digging or excavating with the boom over the sprocket. The overhead dig/dump cycle causes stress and wear at the point of sprocket/bushing contact over the sprocket. These forces should be over the idler, where minimal chain-rail wear occurs.

Tshifularo also advises that operators should work up and down a slope rather than along a gradient or slope. Working along a gradient tilts the machine to one side, which increases the load/stress on the lower track and this accelerates overall wear on this track.

“It is also important to balance slew direction under load. Because the dig-slewdump cycle puts pivot stress on the undercarriage on the dump side of the machine, the operator should balance the slew direction by turning the excavator around in the middle of the shift,” says Tshifularo.

Tshifularo adds that operators should try to reduce pivot/counter rotation turns on hard ground. Excavators are useful on restricted work areas because they are able to make pivot turns, but the operator should try to make wider turns to prevent grouser corner wear.

In conclusion, Karlsson says when using a hydraulic breaker, the idlers should always be at the rear. “Hydraulic breakers cause a different kind of pressure, so operators should always keep the sprocket at the front and the idler at the back to avoid unnecessary wear to the sprocket, chain and gear box,” concludes Karlsson. AB

A 2020 crushing & screening premium

New and proven premium crushing and screening plant have been very much to the fore in the first half of 2020. Guy Woodford reports

Pärhä Oy, located in Orimattila, Finland, is famous for high-quality concrete gravel, delivered directly to production facilities. Metso’s diesel-powered/electrical Lokotrack double-stage plant ensures that different types of crushed rock are produced effectively and economically. As a bonus, the new Lokotrack ST4.10 screen operates carbon neutrally, using electricity generated by the tertiary crusher.

“Last year, we crushed more than 600,000 tonnes, of which some 250,000 tonnes were processed into different types of concrete gravel. The majority of the concrete gravel is delivered to five companies operating in the concrete industry in the Päijät-Häme region,” says Jari Pärhä, who is in charge of the crushing operations and production at Pärhä Oy.

“When such volumes are being produced by a single crushing plant, the machinery needs to be reliable. Metso is known as a dependable Finnish company that also provides well-functioning maintenance services.”

The family-owned company, established by Tuomo Pärhä in 1980, shifted from forestry to the gravel business at the beginning of the 2000s. Currently, the company specialises in crushing and transport services. Since the beginning of this year, the company has three partners: Petri Pärhä is managing director, Jari is in charge of the crushing operations, and Tommi Pärhä is taking care of the transport arrangements.

The company acquired its first Lokotrack LT106 jaw crusher in 2013, followed by a Lokotrack ST2.8 mobile screen. When the company decided to focus more on crushing operations, Pärhä Oy asked Metso for a new tertiary crushing plant. It turned out that the existing Lokotrack range did not have the right solution for the company.

“A few weeks later, Mikko Takaniemi from Metso came to demonstrate a raw version of the plant we were looking for. The cone crusher and screen plant included the pre-screen we had requested,” Jari says.

In 2017, a unique diesel-powered/ electrical plant, called Lokotrack LT330GPSE, started operating at Pärhä’s quarry in Nastola. The LT120E jaw crusher replaced the primary crusher, and last autumn, the screen was replaced by ST4.10, a new Metso model, equipped with a 1.5m × 6m three-

When different types of gravel for concrete and gritting are being produced, primary crusher feed enters first the LT330GPSE pre-screen, which removes the fine materials before going to the cone crusher.

“The pre-screen helps us to only feed pure rock material into the crusher, especially in wet conditions. This makes the production more effective and improves the quality of end products. Metso’s pre-screen works just as we planned,” Jari notes.

The double-stage plant and mobile screen produce gravel of 6–12 mm and 12–16 mm at an hourly rate of roughly 200 tonnes. At the same time, the process produces gritting gravel of 3–6 mm and fine rock dust of 0–3 mm. When coarser material is being produced, the capacity increases to 350–400 tonnes.

Pärhä Oy’s vehicles are used to deliver

RIGHT: The three men behind Pärhä Oy: Petri Pärhä, managing director (left); Jari Pärhä, director of Crushing Operations; and Tommi Pärhä, director of Logistics

Pärhä Oy’s primary crushing is done by the diesel-powered/electrical Lokotrack LT120 jaw crusher

operating in the concrete industry, for infrastructure construction and to private customers.

“Quality and documentation are important to us. For example, we check the quality of concrete gravel after every 500 tonnes,” Petri says.

This year, Pärhä will expand its production to asphalt and railway ballast. The company has, therefore, acquired a quarry from Mäntsälä to produce high-quality aggregates.

Sandvik is introducing Peak Screening – said by the Swedish quarrying equipment giant to be an innovative screening solution that helps customers reach their full productivity potential.

A company spokesperson says: “Peak Screening is a complete package offer and performance concept designed to ensure every square metre of a customer’s screening is as productive as it can be for their unique operation.

“Most screening operations, even when they look fine, are capable of more. Often much more. Peak Screening is our term for a complete screening solution, including the right screen, screening media and warranty/ service program for any customer budget or need, all working together towards one goal – maximising the full potential of the customer’s screening operation.”

Sandvik says its screening equipment, screening media and services are designed to work optimally with each other and ensure the screening operation is as productive as it can possibly be. The company says that its customers will also benefit from having ongoing access to experienced Sandvik specialists who can help with the right configuration, optimisation, troubleshooting, and much more.

“Most screening operations, even when they look fine, are capable of more”

Sandvik now has three new ranges of maintenance-friendly, high-performing modular screens that are said to be more versatile, more reliable, faster to get on-site and safer to operate.

All Sandvik screens come with highquality Sandvik screening media as standard, unless otherwise specified. Sandvik says it works closely with customers to determine the right solution for their applications. This includes offering exclusive options such as Sandvik’s WX6500 tensioned rubber screening media with up to a claimed 15x

ABOVE: Sandvik Peak Screening is said to be an innovative screening solution that helps customers reach their full productivity potential

BELOW: As part of its new Peak Screening solution, Sandvik has three new ranges of maintenance-friendly, high-performing modular screens that are said to be more versatile, more reliable, faster to get on-site and safer to operate

The Terex Finlay IC-100RS is one of a four-unit range of IC-compact impact crushers

OBSTRUCTIONS? NO PROBLEM

AMMANN ARX 4-2 LIGHT TANDEM ROLLERS

Ammann ARX Light Tandem Rollers excel in the open, where covering ground quickly is the goal. But other jobsites call for a compactor that can work tight against obstructions, such as curbs, without losing productivity.

Other key features

Ammann ARX series of light tandem rollers deliver in both worlds. They feature industry-leading compaction output to quickly reach targets when working in open spaces. When obstructions are a factor, the rollers can quickly switch from in-line to offset compaction, providing operators with improved vision and precision.

• Latest EU Stage V / U.S. EPA Tier 4f engine from Kubota

• Spacious operator platform with sliding seat

• Electronic drive lever for smooth starts and stops, especially important on asphalt jobs

• Optional ACEforce, the Intelligent Compaction tool for optimal efficiency

• Simple and reliable dashboard with intuitive machine control

• Perfect all-around machine visibility and LED lights for safety on the jobsite

Looking for even more productivity? When the workday is done, maintenance points can be easily accessed from the ground to ensure quick completion of service work.

longer wear life than standard wire mesh, but with the same screening accuracy for better productivity and uptime.

Sandvik’s novel Reliability & Performance (R&P) package is said to protect customer investment. R&P includes two years extended equipment warranty, regular inspections, maintenance recommendations, troubleshooting and performance analyses that can help optimise service intervals and avoid costly breakdowns.

Screening solutions from Sandvik also come with a performance guarantee where Sandvik guarantees that the solution achieves the performance that has been agreed on together with the customer — or Sandvik will work with the solution until it does.

“Peak Screening shows our understanding of customers’ productivity needs, and commitment to solving their challenges in unconventional, industry-first ways. We want to help customers benefit from the competitive advantage Peak Screening can provide, while establishing it as the defining screening performance standard of our industry,” says Mats Dahlberg, vice president Lifecycle Service Stationary Crushing & Screening.

Terex Finlay is expanding its mobile crusher line with the introduction of its IC-Range of compact impactors. The IC-Range of small impact crushers has been designed explicitly for quarrying, construction and demolition debris, reinforced concrete

and asphalt recycling applications.

The new IC-range comprises four models: IC-100, IC-100RS, IC-110 and IC-110RS.

“The addition of these four new models complements our existing range of mobile impact crushers and opens up new opportunities at the smaller machine sector of the market. Each of these models has been rigorously tested and proven in a diverse range of applications. The compact size, ease of transport, quick set-up times and intuitive operation make each of these machines ideal for contract crushers, independent rental houses and small-scale operators,” says Alan Witherow, Terex Finlay lead technical support and product manager.

The IC-100 features an 860mm x 860mm direct-drive horizontal impact chamber with variable rotor speed. The advanced electronic control system monitors, controls and regulates the speed of the VGF (vibrating grizzly feeder) to maintain a consistent feed of material into the impact chamber to maintain optimal crushing capacity. The IC-100 provides operators with a compact and versatile machine that gives high material reduction ratios and produces a consistent product grading.

Based upon the IC-100, the IC-100RS features an onboard recirculating system and detachable sizing screen to provide the versatility of a compact crushing and screening plant on one mobile. If recirculating and sizing materials is not

A LONG WAY TOGETHER

required, the sizing screen can be removed quickly from the machine without the need for secondary lifting equipment. The recirculating conveyor can also be utilised for stockpiling an oversize product.

The IC-110 features a 1034 x 1000mm direct-drive impact chamber with variable rotor speed and hydraulic apron-setting assist in providing convenient and efficient adjustment of the chamber aprons. The chamber is also fitted with a hydraulic overload protection system as standard. For operators in recycling and demolition applications, an underpan feeder is also available as an option.

The IC-110RS impact crusher provides the versatility of a compact crushing and screening plant on one mobile platform for quarrying, construction and demolition debris, reinforced concrete and asphalt recycling applications.

The machine features a direct-drive 1034mm x 1000mm horizontal impact crusher with variable speed control to give operators unprecedented levels of fuel efficiency and productivity. A vital feature of the machine is the onboard 2.74m x 1.5m single-deck screen. For applications not requiring recirculation of oversize material back to the crushing chamber or the stockpiling of an oversize product, the complete screening and recirculating system can be quickly detached from the machine.

In other Terex Finlay news, the company’s

EARTHMAX SR 41

o matter how challenging your needs, EARTHMAX No 41 is your best ally when it comes to operations SR at require extraordinary traction. Thanks to its All th eel radial structure and the special block pattern, St ARTHMAX SR 41 provides excellent resistance EA ainst punctures and an extended service life. In aga dition to long working hours without downtime, add e tyre ensures extraordinary comfort. th ARTHMAX SR 41 is BKT’s response to withstand EA e toughest operating conditions in haulage, th ading and dozing applications. loa

standard subscription for its T-Link plant monitoring and performance optimisation system is now available for seven years.

Introduced in January 2016 the T-Link hardware and software can be used on any Terex Finlay crusher or screener with an electric engine.

It allows operators at any given time to see the exact location and status of their Terex Finlay plant fleet.

Furthermore, T-Link shows what areas to improve upon to optimise profitability.

Now, all Terex Finlay machines that are already in the field and fitted with T-Link hardware and software will automatically roll over to the extended seven-year data subscription.

Alan Witherow says: “T-Link takes the guesswork out of machine monitoring and performance optimisation. Our sevenyear standard data subscription places us at the technological forefront of our industry.”

The Terex Finlay T-Link package provides operators with a userfriendly, unlimited portal to access all the firm’s machines in one place at one time. It also gives them key figures and performance metrics of their connected assets in the form of ‘Actionable Reports’ that they receive automatically weekly.

Superior Industries, a US-based manufacturer and global supplier of bulk material processing and handling systems, has unveiled a new series of modular plant for aggregates crushing, sorting, sizing and washing applications. Known as Fusion Modular Platforms, these pre-engineered, ready-to-build systems still allow customisation to achieve the best performance at each job site.

“Our plant designs are scalable and easily expand with a developing customer site,” says Mark Crooks, product manager at Superior Industries. “Producers can quickly expand capabilities as finances allow, the application needs change and as their market develops.”

Today, Superior has pre-engineered a series of plant packages and is working on designing more for its catalogue. Some examples include jaw, cone and impact crushing platforms, horizontal screening platforms with two-, three- and four-deck models, plus a group of traditional washing and modern low-water washing platforms.