In a world where environmental standards are constantly changing, asphalt producers can survive – and even thrive – with the help of a plant retrofit.

A retrofit upgrades an old plant, so it meets new environmental standards – at a fraction of the cost of a new purchase. All projects are managed by the Ammann Retrofit Centre, which relies on proven processes and experienced technicians to troubleshoot any issues and ensure superior results.

What can you get with a retrofit from Ammann

•Increased RAP utilisation

•An electrically heated bitumen tank system that is so cost effective it pays for itself in a few years

•Noise levels that are reduced up to 20 dB without an impact on daily production

•An ability to use low-temperature mixes that reduce fuel usage and emissions

Contact us to arrange a free analysis to learn the best opportunities for cost-effective, environmental improvements at your plant.

HEAD OFFICE

EDITOR: Guy Woodford

ASSISTANT EDITOR: Liam McLoughlin

CONTRIBUTING

EDITORS: Munesu Shoko, V.l. Srinivasan, Shem Oirere, Partha Basistha, Eugene Gerden, Shadrack Kavilu

EQUIPMENT EDITOR: Mike Woof

DESIGNERS: Simon Ward, Andy Taylder

PRODUCTION MANAGER: Nick Bond

OFFICE MANAGER: Kelly Thompson

CIRCULATION & DATABASE MANAGER: Charmaine Douglas

INTERNET, IT & DATA SERVICES DIRECTOR: James Howard

WEB MANAGER: Sarah Biswell

SOCIAL MEDIA MANAGER: Tatyana Mechkarova

MANAGING DIRECTOR: Andrew Barriball

PUBLISHER: Geoff Hadwick

CHAIRMAN: Roger Adshead

ADDRESS

Route One Publishing Ltd,

Second Floor, West Hill House, West Hill, Dartford, Kent, DA1 2EU, UK

TEL: +44 (0) 1322 612055

FAX: +44 (0) 1322 788063

EMAIL: [initialsurname]@ropl.com (gwoodford@ropl.com)

ADVERTISEMENT SALES

SALES DIRECTOR:

Philip Woodgate TEL: +44 (0) 1322 612067

EMAIL: pwoodgate@ropl.com

Dan Emmerson TEL: +44 (0) 1322 612068

EMAIL: demmerson@ropl.com

Graeme McQueen TEL: +44 (0) 1322 612069

EMAIL: gmcqueen@ropl.com

SUBSCRIPTION / READER ENQUIRY SERVICE

Aggregates Business is available on subscription at the rate of: £85 / US$145 / €111 per annum. Single copies £20 / US$35 / €26 Email subs@ropl.com for further details.

Subscription records are maintained at Route One Publishing Ltd.

SUBSCRIPTION / READER ENQUIRIES TO: Data, Route One Publishing Ltd, Waterbridge Court, 50 Spital Street, Dartford, Kent DA1 2DT, UK

TEL: +44 (0) 1322 612061 FAX: +44 (0) 1322 788063

EMAIL: data@ropl.com

No part of this publication may be reproduced in any form whatsoever without the express written permission of the publisher. Contributors are encouraged to express their personal and professional opinions in this publication, and accordingly views expressed herein are not necessarily the views of Route One Publishing Ltd. From time to time statements and claims are made by the manufacturers and their representatives in respect of their products and services. Whilst reasonable steps are taken to check their accuracy at the time of going to press, the publisher cannot be held liable for their validity and accuracy.

PUBLISHED BY © Route One Publishing Ltd 2023

AGGREGATES BUSINESS USPS: is published six times a year. Airfreight and mailing in the USA by agent named World Container Inc, 150-15, 183rd Street, Jamaica, NY 11413, USA.

PERIODICALS POSTAGE PAID AT BROOKLYN, NY 11256

US POSTMASTER: Send address changes to Aggregates Business, World Container Inc, 150-15, 183rd Street, Jamaica, NY 11413, USA. Air Business Ltd is acting as our mailing agent

PRINT: ISSN 2051-5766 ONLINE: ISSN 2057-3405

PRINTED BY: Warners (Midlands) PLC

Having taken the reins as the new director of ASPASA (the Aggregate and Sand Producers Association of Southern Africa) in January this year, Letisha van den Berg has reiterated her commitment to giving a voice to small-scale miners. Driving the industry’s quest for zero harm, skills development and ensuring environmental compliance are some of her immediate key focus areas, she tells ABI correspondent Munesu Shoko in this issue’s big interview feature.

Reading through what is a must-read piece, I was struck by van den Berg’s view that environmental compliance will grow in importance to surpass industry safety objectives.

The new ASPASA director explains to Shoko why the issue of royalties will be a key issue for her and her management team. Over the years, payment of royalties has been a hotly contested issue among southern African quarry owners and operators regarding where the value of a mined product needs to be determined to calculate exact payments.

The industry’s dispute with the South African Revenue Services (SARS) exists over the first point of sale at which the value of royalties needs to be calculated. The ‘taxman’ argues that royalties should be calculated from the stockpile, while the industry insists it should be from the muckpile. It will be fascinating to see the new ASPASA leadership’s impact on this longstanding debate.

From southern Africa to southeast Asia. Based on public declarations, it was great to hear that CEMEX Philippines recently achieved a new record CO2 emissions reduction in the cement industry, re-emphasising its Mexican parent group’s commitment to decarbonising its operations through its Future in Action programme.

CEMEX Philippines (CHP) achieved a 50% reduction in CO2 emissions generated by its two cement subsidiaries, Solid Cement Corporation and APO Cement Corporation, from 1990-2022. From 2020 to 2022 alone, CHP reduced 18% of its net CO2 emissions, representing 36% of

the total CO2 reduction since 1990, demonstrating the company’s accelerated efforts to further reduce its cement operations emissions.

“This milestone CO2 reduction was possible because of our team’s high commitment to achieve net zero. We are on track to meet our ambition of less than 430kg of net CO2 per ton of cement by 2030 and deliver net-zero CO2 concrete by 2050,” remarked Luis Franco, CEMEX Philippines president and CEO.

CHP’s vice president for operations, Santiago Ortiz, says the subsidiary has implemented various projects to help it reach its 2030 and 2050 targets.

He says the company is “challenged but confident” that it can reach an up to 67% reduction by 2030 as it continues to increase its use of alternative fuels and decarbonated raw materials while reducing its business’s clinker factor. Ortiz says CHP will focus more on using clean energy in its cement operations and pay more attention to water usage in cement production.

CHP has been making significant progress in reducing its carbon footprint with investments made in waste heat recovery facilities in Solid and APO cement plants. This has increased the use of clean energy in its operations.

Eco-minded CHP is also said to be leading the industry in the production of low-carbon cement products, such as APO and Rizal Portland and APO and Rizal High Strength. These are categorised as as Vertua products with a CO2 footprint reduction of at least 25% for its Vertua Plus line and more than 40% for its Vertua Ultra category, making it the most sustainable cement in the Philippines.

CEMEX’s Future in Action programme recognises that the opportunity for reducing emissions is not limited to the production process but to the entire life cycle of its products and transforming the industry’s value chain. Future in Action focuses on achieving sustainable excellence through climate action, circularity, and natural resource management to become a net-zero CO2 company. GW

09 INTERVIEW

ASPASA director Letisha van den Berg is a new voice for SA quarry operators

13 MARKET REPORT - 1

Aggregates demand remains strong in South Korea, driven mainly by new housing needs

16 LIUGONG

LiuGong to continue along rapid global growth path

19 MARKET REPORT - 2

Despite numerous challenges within the French aggregates, quarrying and construction equipment markets, good sales opportunities remain

47 QUARRY PROFILE

Danoher Group is championing operational efficiencies at its Bloemspruit Quarry

The first fully electric construction machines from Volvo Construction Equipment (Volvo CE) for Southeast Asian customers have arrived in Singapore and were formally launched for the region’s market at a gala event on 7 June 2023 on the island of Sentosa. More than 100 guests gathered to celebrate the landmark moment and see the exciting new technology up close.

At the launch event were senior leaders from the country’s most important building and construction companies, Volvo CE dealers from Southeast Asia, and Volvo CE leadership from Asia.

Tomas Kuta, president of Volvo CE’s Asia region, kicked off the launch by sharing insight into the sustainability goals of Volvo CE.

“Our company wants to reach net-zero emissions by 2040, and as part of that and our commitment to Science Based Targets, we want to reduce emissions from our product line by 30% by 2030, as well as reducing emissions from our operations by 50% in the same timeframe. For the Singapore construction equipment market – Change Starts Here. Singapore is a natural market for electric construction machines with a strong focus on sustainability,

efficiency, and safety in its construction industry. We are launching our first electric machines in Southeast Asia, and we believe it will act as a launchpad for further sales in Singapore and the wider regional market.”

Volvo CE aims to have 35% of the machines it sells powered by electromobility by 2030. It already has the widest range of electrically powered construction machinery available today. To begin in Singapore, the company has launched three models: the ECR25 Electric compact excavator, the L25 Electric compact wheeled loader, and the EC55 Electric excavator.

More than 70 start-ups worldwide have applied for a pioneering scheme to make low-carbon concrete. The Global Cement and Concrete Association (GCCA) says that its member companies are on a mission to fully decarbonise concrete, the world’s most used material after water. The Innovandi Open Challenge brings together start-ups and the industry’s leading manufacturers to work together on innovative ways to cut emissions and accelerate progress.

In April, applications were invited from start-ups interested in working with leading companies on new materials and ingredients for low-carbon concrete – a vital element in the

Jenny Egermark, chargé d’ affaires a.i., at The Embassy of Sweden in Singapore, was among the VIPs at the event and paid tribute to Volvo CE’s ongoing drive for change: “I am delighted to see Volvo’s innovative Swedish construction machines launching in Singapore. They are excellent additions to Singapore’s robust construction industry. Both Sweden and Singapore have ambitious goals toward sustainability and reducing carbon emissions. The launch of Volvo’s first electric construction machines brings us one step closer to achieving these common goals.”

GCCA’s Concrete Future 2050 Net Zero Roadmap. Applications were received from every region of the world.

A shortlist will now be drawn from applications by the GCCA and its member companies of the most promising and deployable technologies. Those ultimately accepted for this year’s Innovandi Open Challenge will gain unique access to industry plants, labs, key networks and the expertise and infrastructure of the GCCA’s 40 members worldwide. They will also receive guidance from the GCCA and its members to help them develop new technology and business strategies.

It is the second year the Innovandi Open Challenge has been running. The first

programme, launched in 2021 and primarily focused on carbon capture and utilisation, has already seen two projects go to the pilot stage.

Claude Loréa, GCCA cement director and nnovation lead, expressed her delight at the number of applications: “To

receive more than 70 quality applications from start-ups for this year’s Innovandi Open Challenge is hugely encouraging and shows what level of interest and work is being done to help drive climate action, with applications received from every region of the world.”

Chinese construction machinery manufacturer

XCMG reports healthy 2023 trading after a strong 2022 – including a vibrant export business. The firm had a total revenue of US$13.57bn last year and a net profit attributable to shareholders of $622.78mn.

In Q1 2023, XCMG posted revenue of $3.46bn and net profit attributable to shareholders of $216.9mn, with the company projecting growth.

“As a globally leading provider of construction machinery and sustainable development solutions, XCMG can consolidate its strategic advantages through the economic slowdown affecting the industry, prioritising technological innovation and internationalisation in its strategic roadmap to grow with resiliency,” said Yang Dongsheng, the company’s chairman.

In 2022, XCMG invested $831.45mn into R&D overall,

a 6.13% increase year-on-year, and it accounted for 6.13% of the total revenue of the year, which was a significant increase compared to 4.64% in 2021.

XCMG had 5,767 R&D personnel as of the end of 2022, a 14.97% increase year-on-year, making up 21% of the total number of employees. Most of the new talent who joined XCMG in 2022 are experienced

researchers committed to tackling the most challenging bottlenecks. The firm benefited from sales development in overseas markets with significant export growth. It responded to a peak in China’s construction machinery industry during 2021, focusing on developing its exports instead.

In 2022, XCMG achieved US$4.03bn of international

HD Hyundai Infracore is targeting the Middle East and Africa (MEA) market with its new brand, DEVELON, formerly Doosan Construction Equipment. The company recorded revenue of $330mn last year in the MEA region, a sharp increase of 116% compared to $150mn in 2020.

The number of machines sold has also exceeded 2400 units, marking a 60% increase in sales compared to 2020, mainly due to the company’s focus on securing large-scale customers with new advanced technology-equipped machine launches and customised services.

The construction equipment market volume in MEA increased from 16,720 units in 2020 to 32,786 units in 2022, which shows that the market is experiencing a steep growth with a 96% increase over the past three years.

According to a global market research agency, Research and Markets, the MEA construction equipment market is

growing annually by 4% and is expected to grow to $6.4bn in 2028 from its current volume of $4.26bn.

HD Hyundai Infracore has been paying great attention to strengthening its presence in the Middle East through its office in Dubai and is contesting for first place in Saudi Arabia whilst pulling ahead of other global competitors after winning business on large-scale construction projects in UAE. This year, it aims to sell 1200 units in UAE, an increase from 1000 units sold last year.

With Saudi Arabia planning the world’s largest project, Neom City, which is expected to exceed $500 billion in volume, HD Hyundai Infracore anticipates that this will result in more constructionequipment demand shortly.

HD Hyundai Infracore has recently established a new African office in Accra, Ghana, to expand its network and secure more customers in Western and Central Africa, where the market is growing.

revenue, a 50.5% growth yearon-year, and an export income of $3.13bn saw a 70.5% growth year-on-year. It also saw a higher gross profit margin in international markets of 22.33%, compared to 19.32% in the domestic market.

XCMG now exports to 191 countries and regions worldwide, and its export market share has increased by 2.42%.

XCMG’s international subsidiaries also showed strong performance in 2022. XCMG Brazil’s revenue grew by 86.35%, while XCMG Schwing grew by 30.33%. XCMG’s India company improved local production capacity in its first year of operation.

Strategic global R&D bases to support innovative technology development and international strategies have been established by XCMG. The manufacturer is projecting a 10% revenue growth in 2023 based on industry, domestic, and international trends.

Having taken the reins as the new director of ASPASA in January this year, Letisha van den Berg has reiterated her commitment to giving a voice to small-scale miners. Driving the industry’s quest for zero harm, ensuring environmental compliance, and skills development are some of her immediate key focus areas. Munesu Shoko reports

Quarries and small-scale mines play a crucial role in developing any economy.

As well as providing essential construction materials, these operations stimulate local communities through investment and providing jobs. Yet, in South Africa, they are currently faced with a number of challenges that threaten their existence. The lack of meaningful infrastructure investment in the past ten years has presented a major economic hurdle for the industry. In addition to tough economic challenges, small-scale miners have to grapple with their legislative obligations. Compliance by its very nature costs money, and a lot of it, which is why van den Berg has set her sights on providing small-scale miners with cost-effective solutions to comply.

Her passion for the small-scale mining industry is not only rooted in her 25-year experience in the quarrying industry but also in the fact that she kick-started her decorated career at a small AfriSam (then Alpha Cement) aggregates and ready-mix concrete operation back in 1998.

“I started out as an admin clerk at an operation in KwaZulu-Natal. In this role, I was more of a ‘jack of all trades’, which exposed me to the various functions on-site, all the way from technical and plant maintenance

to cost management, and everything in between,” she says. “Managing costs for such a small operation was particularly critical, and we successfully found ways to comply within our limited means. That’s where my passion for small-scale miners stems from because I have first-hand experience of how things work in their world.”

However, from the onset, van den Berg had a great passion for health and safety. In 2003, she moved to AfriSam’s Verulam Quarry, where she was granted her wish to focus on health and safety, and the rest is history. Two years later, she was appointed AfriSam’s regional safety practitioner for KwaZulu-Natal, before she assumed the role of group health and safety manager for the company’s Construction Materials Division in 2010.

After 17 years at AfriSam, she moved to Afrimat in 2017, where she was appointed group health and safety executive, a role she held until her recent appointment as the director of ASPASA in January this year.

Leveraging her wealth of health and safety management experience, van den Berg is determined to further accelerate the industry’s quest for zero harm. While ASPASA members have achieved a remarkable sevenyear fatality-free feat, she believes that a lot more can be done to eliminate accidents and injuries on sites.

“We cannot deny the fact that our industry works in a potentially dangerous environment. However, having been in the industry for so long, I understand the reasons behind some of the injuries we still record at our member operations. One of my immediate objectives is to find ways to curb these injuries, which is key to our quest to achieve zero harm,” she says.

On the health and safety front, van den Berg’s tenure at ASPASA coincides with the recent gazetting of the Collision Avoidance Systems (CAS) regulations by the Department of Mineral Resources and Energy (DMRE).

During the Zero Harm Forum of the Minerals Council South Africa (MINCOSA) in October 2022, the chief inspector of mines (CIOM) expressed his concerns about trackless mobile machinery (TMM)- related fatalities and the slow implementation of collision-avoidance systems. He consequently requested that the technology readiness date of December 2023 be brought forward to January 2023. At the Mine Health Safety Council summit last year, organised labour also advocated for early technology implementation.

In late 2022, MINCOSA met with the TMM technical team and offered reasons why this was not practical. However, the 17 TMM-related fatalities at both surface and underground operations did not help the industry’s case, says van den Berg. On December 6, 2022, the Minister of Mineral Resources and Energy subsequently signed an order for sub-regulations 8.10.1.2 (b) and 8.10.2.1 (b) in Chapter 8 of the Mine Health and Safety Act, 1996, to come into force.

However, advises van den Berg, operations can ask for exemption from all or part of the requirements of the Act. The Act gives provision that mines may request an exemption from the Minister. If satisfied that

Under van den Berg’s leadership, ASPASA will further cast the spotlight on environmental compliance, which in her view will grow in importance to even surpass safety in the near future

the employer has consulted appropriately with the affected employees or their representatives, the Minister may exempt the employer from any or all of the provisions of the Act or from a notice or instruction under this Act.

“If any mine owner decides to go the exemption route, firstly it is important to explain how they are going to manage the ‘significant risk’ on site – that is principal,” she says. “Then they also need to provide the basis or references upon which past and future CPS ecosystems are based on. These include traffic management processes, TMM fleet size, competencies of operators and an explanation of their environment (production throughput, blasting frequency, tonnes moved and employee complement).

“The motivation for exemption can also include issues such as skills shortage and the

prohibitive costs of installing CAS systems at small surface-mining operations. The motivation, however, should be based on how the operation is going to reduce significant risk, citing tasks that have been completed to date and those in the process of being implemented,” she adds.

Based on feedback from multiple industry stakeholders and those in the legal field, ASPASA has determined several options for its members. “Firstly, members can engage with the DMRE regarding the way forward in their respective regions. We have already spoken to the DMRE in various regions, and some have indicated that there is a threemonth window for implementation, as with any other code of practice that is gazetted,” she says. “Others have indicated that they are waiting for the head office to give guidance. We are of the view that the department must

first determine how this legislation will be enforced,” she says.

Another option is to engage with OEMs on the technology, its availability and warranties. Mines can also apply for an exemption from the requirements of the Act. “Operations should use this time to reassess their risk-based approach and confirm that no CAS installation is required as reasonably practicable measures have been implemented and no significant risk to persons exists in terms of diesel/diesel collisions. It is also critical to keep documented proof of the process to present to the DMRE if required,” says van den Berg.

Under van den Berg’s leadership, ASPASA will further cast the spotlight on environmental compliance, which in her view will grow in importance to even surpass safety in the near future. “We cannot deny

the growing focus on Environmental, Social and Governance (ESG) in the mining sector. It is, however, still a concept that fits into the global environmental plan, but not everything has been legislated yet, but one can see that it’s coming,” she says.

The lack of environmental compliance, she says, can have dire consequences for operations. “Remember it is one of the key aspects that can lead to the revoking of a mining licence. In my view, it is as important as safety management, but not everybody understands that. To provide context, there are mining CEOs who are in jail and some who have paid up to R5-million fines related to the environment.”

One of van den Berg’s first initiatives in December 2022, well before she even officially started her tenure, was to run a survey to gauge ASPASA members’ sentiment on the growing importance of environmental compliance.

“They all rated their safety and environmental audits highly, but have also asked the association to close some compliance gaps. We will compile all the gaps and see how we can support our members,” she says.

Owing to South Africa’s poor economic performance and a struggling construction industry, the quarrying sector has been under severe pressure over the past few years. “We cannot downplay the economic situation and its impact on our members,” she says. “As an association, we have looked at various ways to help small surface mines to comply in a cost-effective manner.”

To help ease the burden of economic challenges, van den Berg has implemented a levy structure change, which at the time of writing, was awaiting approval by the association’s management committee (MANCOM).

“As we continue to identify a few roofs that we can take off to unlock further cost benefits for our members, we believe this new levy structure will be a welcome relief for an industry that is reeling from the current economic burden,” she says.

Another key focus area for van den Berg and her team is the issue of royalties. Over the years, payment of royalties has been a hotly contested issue among quarry owners and operators as to where the value of a mined product needs to be determined in order to calculate exact payments.

The industry’s dispute with the South African Revenue Services (SARS) exists over

Owing to South Africa’s poor economic performance and a struggling construction industry, the quarrying sector has been under severe pressure during the past few years

the first point of sale at which the value of royalties needs to be calculated. The ‘taxman’ argues that royalties should be calculated from the stockpile, while the industry insists that it should be from the muckpile.

“We are busy exploring ways to join forces with other industry bodies on the royalties battle for small-scale miners. If successful, that will offer another economic benefit for members,” she adds.

Skills development is another area of critical importance for van den Berg. She acknowledges that the current skills shortage, exacerbated by the brain drain, is a major challenge, not only for the quarrying industry, but for the mining sector at large. This is particularly hostile to business growth.

To help the industry close the skills gap, ASPASA has taken a decision to work closely with the Institute of Quarrying Southern Africa (IQSA).

“We have hit the ground running, with a couple of initiatives already achieved since the start of the year. We look forward to further providing immense value for our members”

“One of the first decisions we made was to re-establish our collaboration with IQSA. We are handing over the whole training leg of our service wheel to IQSA. We are therefore looking for a young, dynamic professional to run the training department. We are also looking at starting a mentorship programme. I believe we have some brilliant people within ASPASA who can drive this forward,” she says.

To further enable action on the ground, ASPASA is creating a new level within its setup. Traditionally, there has been the MANCOM and the director. “We are bringing in a new level called Steercom, which is basically a regional chairperson per region,” she says.

In addition, the association has reviewed its service wheel, based on the survey van den Berg conducted in December. This, she says, will help realign the association’s service offering with industry needs. AB

Industry stakeholders say there are indications of gradual recovery in South Korea’s aggregates sector, with demand expected to increase this year for the first time since the pandemic. Liam McLoughlin reports

South Korea’s aggregates sector is gradually recovering to pre-COVID levels of production, but ongoing challenges remain including a slowing domestic construction market and increasing materials prices. Willis Rooney, economist at GlobalData, says the South Korean construction industry shows a continued weakness, with low external demand and a slowing of consumption growth likely to weigh on new investment in the short term. This directly impacts on demand for quarry and aggregates products in the country.

The construction industry in South Korea registered marginal growth of 0.2% in real terms in 2022, according to GlobalData research. This followed four successive years of decline.

“The industry’s growth was constrained by the impact of multi-year high rates of inflation, the aggressive unwinding of monetary support by the Bank of Korea and the slowing global economic growth on new construction demand,” says Rooney. “These factors are expected to continue to weigh on the

construction activity in South Korea this year, though full-year growth will pick up to a marginal expansion of 0.8%.”

Cho Byoungyoung, head of marketing & retail support, KSS at Volvo Group Korea, says there are indications of gradual recovery in the country’s aggregates sector.

Last year the actual supply and demand for aggregates decreased by 4.8% compared to 2021, with a total of 232,190,000 m3 of aggregate supplied, according to data contained in the Ministry of Land, Infrastructure and Transport’s ‘Aggregate Supply and Demand Plan’.

However, Cho states: “Despite this decrease, the statistical data suggests that the South Korea quarrying and aggregates sector is on a path towards recovery, as aggregate demand in

2023 is expected to be 238,987,000 m3 based on the domestic construction investment forecast and the amount of aggregate input per billion won in construction investment.

“Although ongoing pandemic-related challenges may cause some fluctuations in production levels, the South Korean quarrying and aggregates sector is showing gradual signs of recovery. By observing this data, we can therefore conclude that the South Korean quarrying and aggregates sector appears to be on a path towards recovery, although there may still be some challenges and fluctuations in production levels due to ongoing pandemic-related obstacles.”

Market figures shared with Aggregates Business International by the World Cement Association show that cement production in South Korea rose slightly in 2022 to 46.8m tonnes from 46.7m tonnes in 2021, out of a total national capacity of 60.8m tonnes.

“The market situation is stable with only small changes in market share,” the WCA said in a statement.

“Statistical data suggests that the South Korea quarrying and aggregates sector is on a path towards recovery”

Cho Byoungyoung, head of marketing & retail support, KSS at Volvo Group Korea

The Global Aggregates Information Network (GAIN) says that aggregates demand in South Korea is driven mainly by new housing needs.

It adds that COVID restrictions have been lifted, and there is a determination in the administration of President Yoon Suk-yeol of the People Power Party that was elected in March 2022 to drive the economy forward.

“Access to aggregates resources is an ongoing challenge and marine aggregates are seen as a significant opportunity,” GAIN states.

In a report published in February this year by the Korean Society of Economic and Environmental Geology, authors Sei Sun Hong and Jin Young Lee wrote that, of the total aggregates produced in the country in 2021, 47 million m3 was sand and about 88 million m3 was accounted for by gravel.

The report states that the main sources of aggregates in the country have recently come from screening crushed aggregate and forest aggregate.

It estimates that of the 135 million m3 of aggregates produced in South Korea in 2020, about 49.6% came from screening crushed aggregate, 36.8% from forest aggregate, 2.6% from land aggregate, 6.8% from sea aggregate, 2.6% from washing, and 0.2% from river aggregate.

In 2021, aggregates were produced in 148 local government areas. The 10 leading producing local governments were, in descending order of volume, Hwaseong, Ongjin, Paju, Pocheon, Gwangju, Youngin, Cheongju, Gimhae, Anseong, and west EEZ. The combined production of the ten leading local governments accounted for 30% of the national total, and 47 local governments

produced more than 1 million m3 of aggregates.

In terms of quarrying equipment that is popular in the country Chris Sleight, managing director of Off-Highway Research says that there is strong demand for wheeled excavators in South Korea. He adds that they replace some of the demand which is more usually met by crawler excavators in many other countries.

Cho says that South Korean quarry operators are particularly interested in purchasing excavators and wheeled loaders that meet the requirements set out in ‘Article 19’ of the ‘Enforcement Decree of the Aggregate Extraction Act.’

“The trend seems to be moving towards the purchasing of larger equipment with higher performance capabilities to meet the goal of reducing labour costs that have risen significantly due to the COVID-19 pandemic and improving productivity,” he says.

In addition, quarry operators are looking to lower the number of worksite accidents by reducing the number of workers onsite by using larger and more robust equipment. Cho says this is due to the introduction of the ‘52-hour workweek system’ across all workplaces in July 2021 and the ‘Severe Accident Punishment Act’ which took effect in 2022.

“By enlarging equipment, quarrying operators can reduce the number of workers required, which, in turn, can help reduce the likelihood of worksite accidents,” he says.

“These factors have shifted the specific type of quarrying equipment that South Korean quarry operators are interested in purchasing, particularly larger excavators and wheeled loaders with specifications that meet these legal requirements.”

The South Korean aggregates sector is being impacted by state policies on sustainability, and the government’s aim for a net-zero society. Environmental, social and governance (ESG) management is being highlighted to realise carbon neutrality, resulting in the need to minimise resource waste and promote resource circulation-type construction because, compared to other industries the construction industry has higher carbon emissions.

“This means it is now necessary to utilise recycled aggregates actively to improve and strengthen ESG management in the construction industry while changes in government policies are also required to secure sustainable aggregate resources,” says Cho.

The South Korean construction industry declined by 0.5% in 2022, according to estimates by ResearchAndMarkets. This followed contractions of 2.6% in 2021 and 1.3% in 2020.

The research company said the industry's downturn in 2022 was primarily caused by a combination of rising construction costs, rising inflation, higher energy prices, and increased supply chain disruptions influenced by China's zero-COVID policy. According to the Korean Statistical Information System (KOSIS), the construction industry's value-add declined marginally by 0.2% in the first three-quarters of 2022, decreasing from KRW61.2 trillion (US$48.8bn) during January-September 2021 to KRW61 trillion (US$48.6bn) during JanuarySeptember 2022.

In addition, these disruptions had a significant impact on infrastructure and energy development projects, and consequently on aggregates and quarrying demand. The infrastructure construction sector contracted by 4.9% and the energy and utilities construction sector by 4.2%, respectively.

Despite these persistent headwinds, ResearchAndMarkets says the construction industry is expected to record growth of 0.8% in 2023, aided by industrial project development.

In July 2022, the government committed to provide financial and regulatory support to pave the way for the semiconductor industry to invest KRW340 trillion (US$271.1bn) over the next five years.

The construction industry is expected to record an annual average growth of 4.1% between 2024 and 2026, supported by the development of transportation, energy, residential, and commercial projects. In 2021, the Korean government announced it plans to invest KRW114.7 trillion (US$91.4bn) in order to expand the railway network from its current 4,274km to 5,137km by 2030.

Furthermore, Hyundai Merchant Marine announced a five-year investment plan worth more than KRW15 trillion (US$12bn) in July 2022 to expand its South Korean logistical base.

In terms of the major current opportunities for quarrying-equipment providers in South Korea such as Volvo CE, Cho says the trend following the five-day work week and the Severe Accident Punishment Act has resulted in an increased preference for high-quality, large-sized equipment. He says this has been gradually increasing in the stone industry to reduce labour costs. “This presents an opportunity for Volvo CE to promote its large excavators and wheeled loaders, which are ideal for use in quarrying and mining operations,” he adds.

Cho says that articulated haulers are popular in quarrying and mining sites due to their excellent and reliable work performance, high productivity, low fuel efficiency, and strong durability. This creates an opportunity for Volvo CE to market its articulated haulers to complement its large excavators and wheeled loaders, potentially leading to increased sales in the South Korean market.

Over the next 18 months, Cho says the South Korean quarrying- and aggregatesequipment sectors are expected to experience major developments centred mainly around the need for equipment that prioritises productivity and safety. This is in response to the large demand for the aggregate supply required for the government-sponsored Social Overhead Capital (SOC) infrastructure construction projects from 2023.

“We predict that this is likely to result in accelerated equipment development and innovation in equipment design, technology and maintenance - presenting a potential shift towards equipment that is more sustainable and environmentally friendly,” says Cho.

Also impacting the materials sector are the steps being taken by the South Korean government to address safety concerns in the construction industry by revising the Aggregate Collection Act’s Enforcement Decree in 2023. This is in response to an accident at a construction site in Gwangju

City. The revised decree aims to strengthen the quality-control standards for aggregates and prevent similar accidents from happening in the future.

Cho states that, while this may result in stricter quality-control standards, it may also potentially lead to a reduction in aggregates supply and demand which, in turn, may impact the demand for construction equipment.

“While this may impact the quarrying/ aggregates sector, the full extent of its impact remains to be seen and will depend on various factors including the specifics of the revised standards and how they are implemented and enforced,” he adds.

The South Korean Ministry of Land, Infrastructure and Transport is taking a number of measures to address the decreasing trend of natural aggregate sources and improve the promotion of recycling construction waste in the country. One of these is the passing of the Act on Promotion of Recycling of Construction Wastes (Act No. 17939), which was enforced on June 17, 2021.

In response to these efforts, Cho says the quarry industry is actively promoting the development of technologies to improve the quality of recycled aggregates.

“While the current usage rate stands at only 14.6% as of 2022, new technology that lowers the variability of recycled aggregate quality and meets the strengthened quality control standards is being developed rapidly,” he says.

“As a result, the usage rate of recycled aggregate is expected to accelerate at a rapid pace in the near future. We believe this is an important step towards sustainable development in the construction industry, and it will likely have a significant impact on the quarrying industry in South Korea.”

As part of its sustainability and electrification efforts in South Korea, Volvo CE has announced an investment into

battery-pack production at its excavator plant in Changwon.

With the SEK80m (US$7.8m) investment from Volvo Group, a new production facility and equipment will be built at the Changwon plant – which at around 1.1m m2, is the largest excavator production site in Volvo CE, producing around 55% of its total excavator volumes.

The new facility at the Changwon plant will produce a wide range of common electric-storage solutions (battery packs) for Volvo Group and become a core competence centre for electric excavators. This will enable Volvo Group to offer more sustainable solutions to its APAC markets in a more flexible, cost-effective and agile way and include supply chain, manufacturing and logistics.

Andy Knight, head of operations excavator and managing director of Volvo Group Korea, says: “As the largest plant in Volvo CE and the core site for excavator development and production, Changwon is at the forefront of our shift to a sustainable future.

“This investment is an important milestone in our electrification roadmap and supports our recent investments in production facilities for electric excavators. Changwon is ideally located close to batterymodule supply partners and other key suppliers in South Korea to meet the needs of customers in the future. We are also home to a highly skilled and motivated workforce who are fully committed to meeting our future environmental targets.”

The new production facility will be built inside the current component workshop at Changwon – without disruption to the existing operation. Once complete, the facility will be approximately 2,500m2, including assembly and logistics areas. The building work will begin in April 2023, with batterypack production expected to commence in June 2024. AB

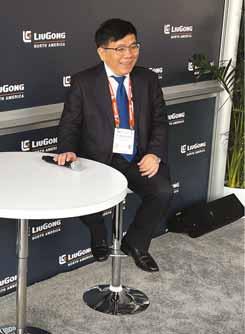

Chinese off-highway major LiuGong had a strong presence at CONEXPO-CON/AGG 2023, with trade media at the manufacturer's well-attended press conference hearing about a strong growth strategy reaping dividends in North America and beyond. Guy Woodford reports

Zeng Guang'an, LiuGong chairman & CEO, and Andrew Ryan, president of LiuGong North America, were not short of things to highlight after welcoming those gathered for the LiuGong press conference at CONEXPO/ CON-AGG 2023 (14-18 March). But the pair need not have opened their mouths for their audience to realise there was much ground to cover. Anyone visiting LiuGong's Festival Grounds stand at the Las Vegas Convention Center will have seen the company's impressive 19-machine line-up, including eight new products and two new batteryelectric vehicles.

One of LiuGong's battery-electric vehicles, the mid-sized 856H-E MAX wheeled loader, was among the machine highlights. The 856H-E MAX can enhance job sites where traditional combustion engines aren't allowed or fixed-site operations where investments in charging infrastructure make sense.

The 856H-E MAX has already proven its reliability in the field, with more than 2,000 electric wheeled loaders operating in the world's toughest conditions as of October 2022, and exponential growth is expected.

LiuGong debuted two new quarrying application-suited, large-sized excavators at the exhibition. The 36-ton class 936F excavator is a step above medium-sized

excavators, while the 95-ton class 995F excavator will become the largest in the LiuGong excavator portfolio.

LiuGong, whose North American subsidiary is headquartered in Katy, Texas, also featured its HV Series wheeled loaders at CONEXPO-CON/AGG 2023 (838HV, 856HV, 890HV). The HV Series of products have progressed to Stage V emissions standards and include updated transmission and hydraulic systems.

"While we have 19 pieces of LiuGong equipment on our stand, it is only a fraction of our global product line. We manufacture over 300 products and actively market about half that product line in Mexico and around 30% in the US and Canada. We expand that product line yearly as we invest more in research and development to update those products with emissions-compliant engines, enabling us to sell them into our [North America] markets," said Andrew Ryan during LiuGong North America's exhibition press conference.

The last two years for LiuGong have seen records in profit, revenue and growth. While other manufacturers scaled back production, LiuGong has increased its production and inventory, making it, the company claims, the world's largest single producer of wheeled loaders.

LiuGong ranks as the world's 15th-largest construction equipment manufacturer. In 2020, the Liuzhou-headquartered company achieved US$4.046bn in sales revenue, selling more than 75,589 units with 37.1% year-over-year growth.

Renowned globally for its wheeled loader design and production, since 1958 LiuGong has produced more than 420,000 of the machines. As well as wheeled loaders, Liugong manufactures excavators, forklifts, Dressta dozers, pipe layers, motor graders, rollers, pavers, cold planers, skid steer loaders, backhoe loaders, aerial working platforms, truck cranes, lorry-mounted cranes, off-highway trucks, rotary drilling rigs, hydraulic diaphragm wall grabs, hydraulic diaphragm wall drilling rigs, trench cutters and hydraulic cutting and mixing rigs.

"Regarding our forklift product business, it will represent nearly 50% of our US and Canada revenue in 2023," said Ryan. "That business has grown rapidly with the help of some very good dealer partners.

"The 856H-E MAX wheeled loader is the world's first commercially available, batteryelectric mid-sized wheeled loader. We've made the first sale of it in North America and will be handing over the keys [during the exhibition] to the Los Angeles County Sanitation Districts.

"These are readily available machines rather than science projects. We can have these machines on a customer site and operational within 90 days."

LiuGong employs approximately 10,000 people, with more than 1,000 engineers working in five world-class research and development facilities. In 2019, LiuGong invested more than $65mn into its R&D programme.

In the coming years, LiuGong expects to add to its current line-up of strategically placed regional offices in the United States, South Africa, Brazil, United Arab Emirates, India, the Netherlands, Poland, Singapore, Russia, China, Mexico, Indonesia and the UK.

As well as its US parts distribution centre, LiuGong has overseas parts distribution centres in Mexico, Brazil, Indonesia, India, the Middle East, South Africa, Moscow and Chita in Russia, Singapore, Poland and the UK. A rapidly growing network of more than 300 dealers across six continents more than 100 countries supports LiuGong's global product lines.

Ryan said one of LiuGong North America's big CONEXPO-CON/AGG 2023 goals was to engage with its dealers and new dealer candidates. "We've significantly expanded our North American construction dealer network. In the last 12 months, we've nearly doubled our footprint, securing some great partners in the US and Canada. I mentioned our great forklift business, and we've added 15 forklift dealers in the US, and another 15 are being appointed to fill out our distribution footprint.

"We want to continue to help our North American customers become acquainted with the LiuGong brand and its meaning. There

has long been an association with Chinese products being inexpensive. There might also be a perception of low quality. I am proud to say that we have very competitive prices and we have nothing to apologise for on quality.

These are top-notch, excellently engineered machines with world-class components that deliver great on-site performance.

"Our plans for North America are to continue to grow. In broad terms, our North American business grew by around 90% between 2020 and 2021 and by around 75% between 2021 and 2022. We also expect to grow by more than 50% this year."

As Ryan's press conference comments indicated, LiuGong places intense emphasis on quality, demonstrated by a commitment to Six Sigma methodology and compliance with ISO 9000 standards. As a result, after a rigorous review, LiuGong was awarded China's National Quality Award in 2008 and again in 2014.

Responding to a press conference question about LiuGong's partnerships with leading global machine telematics providers, Ryan said: "In the North American market, we have two different solutions on telematics: our homemade iLink for customers in Mexico and Central America offers all the basic telemetry functions like operating hours, fault codes, and monitoring fuel burn. In the US, we partner with Topcon. We made a breakthrough with them in integrating all Cummins engine data into the Topcon database. This lets us share complete information about their machines with customers to help guide their fleet planning and maintenance."

Acquired by LiuGong in 2012, Dressta has more than 80 years of heritage as a global manufacturer of heavy construction equipment and seeks to redefine crawler

dozer productivity and durability with a customer-focused approach to design and manufacturing.

The company's global headquarters are based in Stalowa Wola, Poland, with seven global offices and parts distribution centres, a growing network of more than 70 dealers in 60 countries, and regional offices in the USA, Brazil, United Arab Emirates, South Africa, Russia and Singapore.

As one of only five dozer manufacturers in North America, Dressta places significant focus on this category of the heavyequipment space. Great emphasis is placed on maximising operator comfort, optimising owner costs and providing unrivalled technical support while reducing inspection time. Dressta offers crawler dozers that range from 190 to 575 horsepower (hp). The company can configure its products to provide excellent performance in various applications.

In 2023, Dressta is launching two new crawler dozers to the North American market, the TD-15M and TD-25M. Built for mid-sized and heavy-sized classes, the duo offers operator-cab enhancements and a mix of versatility and power that follow Dressta's tried-and-true, rugged and reliable mantra.

Ryan commented on Dressta's telematics and machine control offer: "We will integrate Leica's machine control and guidance plate control technology into our Dressta products, ready for installation when they leave the factory. We are also brand agnostic on retrofitter aftermarket machine control solutions. We can work with Topcon, Leica, Trimble and others."

Guang'an highlighted the efficiency gains telematics solutions could deliver for the company's quarrying customers.

"We run these solutions in a quarry with a fleet of 30 to 35 machines. We connect all the machines, and the quarry's operating efficiency improves by 30% in the first year. In the second year, it improves by 40%. Just think how much this will reduce our quarry customers' operating costs. This new technology can also improve quarry site safety by identifying and acting on operators with bad habits."

Commenting on LiuGong's plans to develop its battery-electric product lines in North America and beyond, Ryan said: "We are proud to be out in front on this [with the 856H-E MAX], but we have a whole range of wheeled loaders that need to undergo electrification. Our view is that there will be more than one technology. We focus on battery electric if the available technology can power that equipment size. After that, we look at more hybrid solutions. Under the chairman's leadership, every LiuGong product line must create electrified options. We have pilot lithium-ion battery skid steer loaders and a 20-ton lithium-ion battery excavator on test with a European customer. We will be ready to scale up production on those machines before long. I expect any of our excavators from 1.8-20 tons to have an electric option in time."

Guang'an added: "When you use a battery-electric machine, it is zero emission, and the noise level is 30% lower [than a diesel-hydraulic machine]. This bothers people in a city, for example, far less.

"Also, if the battery-electric machine works two or three shifts daily, you get a far bigger cost saving. In China, the average saving from these machines is 60 to 70% as electricity is very cheap. You don't have trouble with the engine and [don't] need so much weekly or monthly machine maintenance. You also get, on average, more than 10% more productivity."

Ryan said that LiuGong North America had not, unlike many original equipment manufacturers (OEMs), suffered from significant supply chain disruption in the

last couple of years. "We are joint venture partners with Cummins in China, and our very close relationship helps us supply customers. Similarly, we have a joint venture manufacturing arrangement with ZF on transmissions. We have partnered with them in research and development on axles and driveline components. Our ability to leverage our strategic partnerships and China-based supply chain throughout those [market] constraints put us in a good position to respond when dealers came calling in 2021 and 2022 and so far in 2023. The reality is that customers have good experiences with our products, and dealers are making good money selling them. We are seeing customers from 12-18 months ago returning for repeat purchases and buying in more quantity." AB

There are numerous challenges to be faced within the French aggregates and quarrying and construction equipment markets, but good sales opportunities remain. Guy Woodford reports

The latest market overview from UNICEM, the trade association bringing together the French mineral-extraction industries and manufacturers of construction materials, highlights how the sluggishness in the French building-materials sector in 2023 follows on from a difficult trading landscape in 2021 and 2022. In just three years, the French building-materials sector, like many other sectors, has had to deal with great challenges linked to the COVID-19 pandemic and the Russia-Ukraine war. If the sector had shown itself to be resilient in its 2021 return to pre-COVID-19-crisis activity levels, 2022 saw it face the full aftermath of the pandemic, with high inflation and rising production costs linked to supply chain disruption affecting materials availability. This contributed to aggregates and readymixed concrete (RMC) production falling 4% in 2022.

According to early 2023 production estimates, UNICEM says building-materials production is set to be down again in 2022. Ready-mixed concrete production in March 2023 was down 8.2% compared to March 2022. Taking a 12-month rolling basis, the RMC trend was visible (-5.5% ) in March 2023.

On the aggregates side, activity again declined at the start of the year (-0.7%) between February 2023 and March 2023

(CVS-CJO data). Production in the year to 31 March 2023 was down 11.8% compared to the previous corresponding period.

Part of this is down to a particularly good aggregates-production start to 2022.

During the first quarter of 2023, aggregatesproduction decreased (-3.5%) compared to the previous months. Moreover, it was down in the same period of 2022 (-11.8%). At the end of March 2023, rolling year-on-year aggregates production volume was down 7.5%.

After observing a decline of 3.6% on a year in the fourth quarter and 3.1% in 2022, the French building-materials indicator contracted 9.8% in Q1 2023 (CJO data). This includes the impact of reduced concreteproduct production in early 2023.

According to the monthly French construction industry survey conducted by INSEE, the deterioration of the business climate, which began in January 2023, continued throughout the first quarter and April. While its level is still well above its long-term average, many signals confirm that the high point has passed and that the erosion of industry confidence will continue.

While legacy orders are still keeping material-producerbusinesses fairly busy, sector entrepreneurs are fearful about the future health of the marketplace. Tensions are evident around declining new building-

material orders, while supply chain and staff recruitment difficulties remain.

Moreover, the latest indicators of the French new housing market testify to a decline in housing demand. New-home sales on a 12-month rolling basis were down 32.4% at the end of March 2023, according to Markemétron (at 88,300 units, the worst number in 15 years).

Among promoters, with barely more than 102,000 reservations for apartments and houses in 2022, the dropout reached -14.6% over the year, the trend worsening in the second semester. Social housing demand does not look better, with 15% fewer 2022 block sales (9,107 units). These trends correlate with a downturn in issued housing permits that started a few months ago. Permits issued increased by 3.2% year-on-year in 2022 (to reach the ‘comfortable’ level of 483,400 units) but plunged 25.4% year-on-year in Q4 2022 and 30.9% year-on-year in Q1 2023 (to 441,400 units).

As for housing starts, they show a decrease of 5.2% in 2022 (at 371,000 units), still visible in the first quarter of 2023 (12.8% over a year). The non-residential segment is doing better with ‘authorised surfaces’, which, after an increase of +10.7% in 2022, remained positive Q1 2023 (+0.3% over one year). The economic climate to encourage new construction has taken a significant hit. The upgrading of the

usury rate drives this. Meanwhile, the rate of French ‘loans to habitat’ (mortgages) continues to grow rapidly, reaching 3.15% on average in April, a multiplication of 2.4 in just over a year.

At the same time, real estate inflation in new construction continued (+2.8% in one year and + 15.6% since 2020 for a house) under the effect of rising material prices and the introduction of RE2020, which, according to the FFB Housing division, increased construction costs by an average of 7.4%. With insolvency increasing, households face rapidly rising mortgage-refusal rates (+46.5% November 2022-January 2023 compared to the same months of the previous year).

Thanks to a new increase in activity in March 2023 compared to February 2022 (+1.5% in data CVS-CJO at constant prices), the volume of public works carried out rose compared to last year (+4.5%). However, over a rolling 12-month period, activity still showed a contraction of 5.1% as of 31 March 2023, according to the results of the investigation conducted by the FNTP (La Federation Nationale des Travaux Publics). Orders did, however, experience a strong rebound at the start of the year (+22.4% in Q1 2023), but this is exclusively attributable to the contract award for the third line of the Toulouse metro and does not reflect wider, stronger investment by public and private players.

Bergerat Monnoyeur (BM) is Caterpillar’s France dealer. Farida Selmani, BM’s marketing manager, says that as the aggregates and quarry business is a demanding sector where efficiency and productivity can make the difference between profit and loss, the company offers French customers a wide range of Cat products and services to support their goals.

“With fleets usually working long hours, a strong fleet management and maintenance programme are key to remaining productive and maximising uptime. We see a significant take-up for Customer Value Agreements (CVA). Those include preventive maintenance, remote diagnostics and fleet connectivity with VisionLink, the web-based

GlobalData’s March 2023-published report, France Construction Market Size, Trend Analysis by Sector (Commercial, Industrial, Infrastructure, Energy and Utilities, Institutional and Residential) and Forecast, 2023-2027, states that following marginal growth in 2022, the French construction industry in France is expected to shrink by 0.6% in real terms this year, owing primarily to subdued investor and consumer confidence, high consumer and construction-cost inflation, rising interest rates and supply chain disruptions which are

all expected to continue to weigh on the industry’s performance.

According to the National Institute of Statistics and Economic Studies (INSEE), the average construction-materials cost index registered a year-on-year (Y-o-Y) increase of 17.1% in the first nine months of 2022. A sharp decline in consumer confidence will also affect the industry’s output in 2023. According to the INSEE, the average consumer-confidence index fell by 13.3% last year, following a growth of 3.5% in 2021.

The industry is, however,

expected to rebound at an average annual growth rate of 2.6% from 2024 to 2027, supported by investments in transport and renewable-energy infrastructure projects. The government aims to reduce greenhouse gas emissions by 35%, compared to 2015, by 2030. To support this target, it is focusing on increasing renewableenergy capacity across the country.

In November 2022, the French Senate approved new legislation which requires all car parks – with at least 80 spaces – to be covered by solar panels by 2028. Previously

in February 2022, the French state railway utility SNCF also announced a plan to install approximately 190,000m² of solar panels in 156 stations across the country by 2025 and 1.1 million m² of solar panels in railway station areas by 2030. Moreover, in January 2023, the European Investment Bank (EIB) announced that it had provided €9.9bn in long-term financing to the private sector and regional authorities in France in 2022. Of the total, €5.9bn was allocated for renewable energy, green transport, and energy efficiency.

fleet management tool. CVAs allow customers to plan their future costs and limit uncertainty.”

Asked what type of quarrying equipment quarries in France are particularly looking for, Selmani says: “More than ever, quarry owners are looking for fuel-efficient equipment that delivers the lowest cost per tonne, as fuel costs remain a challenge. To reduce those costs and maximise efficiency, customers often opt for the Cat XE range, such as the 966 XE, 972 XE, 982 XE, 988K XE wheeled loaders and the D6 XE dozer as they provide increased fuel efficiency and premium performance.

BM Rent, allow customers to fill production gaps and expand their business without growing their balance sheet.

She says about large French construction projects influencing national aggregates and equipment demand: “Canal Seine Nord remains a huge opportunity over the next two years. Another large project is Tunnel Euralpin Lyon-Turin (TELT), creating the Tunnel de Base de Mont Cenis, which will run 57.5km from France to Italy. Early predictions call for the opening of many quarries to

forecasts. In addition, the demand for our core quarrying products – the large Zaxis-7 excavator range – remains strong due to their industry-leading reliability and durability, says Dimitrov. He continues: “The feedback from our customers is also positive, and we remain committed to serving their needs with our technical support, parts, fleet management systems and maintenance contracts. In addition, Hitachi Construction Machinery’s (HCM) Premium Used and Premium Rental products are gaining popularity in the French market.”

“Large excavators and rigid trucks remain among the most popular equipment combinations to transport aggregates to stockpiles or distribution centres. The range of Cat next-gen quarry excavators is expanding with the introduction of the Cat next-gen 350 that joins the 374 and 395 models. The 350 consumes up to 13% less fuel than the Cat 349 and is equipped with technology features such as Assist that help increase efficiency and Payload on-board weighing, which gives real-time weight estimates to achieve precise load targets.”

Selmani notes that another solution for customers is rebuilding equipment that allows a machine to have a second or, sometimes, a third life. “Through Cat Certified Rebuild, we rebuild Cat equipment in our workshops and return machines, components and systems that have reached the end of their life to a like-new condition. On average, we re-use 65% of the parts in a Certified Rebuild.”

Selmani also stresses that short- or longterm rentals through BM’s sister company,

“We believe that the building-materials market is continuing to grow in line with industry reports and forecasts”

Trayan Dimitrov, general manager of Hitachi Construction Machinery (Europe) France

support the project, one is expected to be the largest in France, and extraction is estimated to last for the next ten years.”

Like Caterpillar, Hitachi Construction Machinery (Europe) does good business in the French quarrying and large construction equipment market. Trayan Dimitrov, general manager of Hitachi Construction Machinery (Europe) France, and Patrick Top, director of sales and marketing, Hitachi Construction Machinery (Europe), see good market opportunities.

“At Hitachi Construction Machinery (Europe) (HCME), we believe that the building-materials market is continuing to grow in line with industry reports and

Dimitrov sees potential for HCME to further expand its quarrying sales and productsupport services in all regions of France, home to around 3,400 quarries. He sees further growth potential for HCME in other parts of the French construction industry.

“This is one of the reasons behind HCME’s recent decision to acquire its authorised dealer Cobemat (now rebranded as Hitachi Construction Machinery France – HCMF). HCME’s ambition is to expand its sales and rental network in France, in line with its strategy to expand the value chain, and there will soon be a new dedicated HCM rental company established in the Île-de-France region,” Dimitrov explains.

Top says HCME’s “market-leading” 50-90 tonne excavators – the ZX490LCH-7, ZX530LCH-7, ZX690LCH-7 and ZX890LCH-7 – remain the number one choice among its French quarrying customers. “These customers have a wide range of options at their disposal. These include the availability of heavy-duty and bulk excavation arm and boom types and strengthened arms, booms and undercarriages for harsh conditions,” he notes.

Top adds: “In particular, the ZX490LCR-7, ZX690LCR-7 and ZX890LCR-7 models are reinforced to work in the harshest conditions. And there is a wide range of high-quality attachments, such as buckets and breakers,

Hitachi Construction Machinery (Europe) continues to see strong quarry customer demand for its large Zaxis-7 excavator range, including the pictured ZX490LCH-7

and ground-engaging tools for HCM owners to choose from for their specific quarrying needs.”

Asked by Aggregates Business what role digitalisation, automation and machine telematics play in quarrying/buildingmaterials-processing-customers' application needs, Top responds: “The French market is one of the leading markets in this respect. For example, the first HCME Customised Solutions Zaxis-7 excavator with factoryfitted Leica Geosystems 3D machine control solution was delivered to the French contractor, Kerleroux. This is one of the optional extras available directly from HCME’s Amsterdam factory, empowering our customers to work more independently, productively and precisely.

“Further signs of growth are seen in the digital side of the industry. HCME is not only a manufacturer of equipment and machines but also a solution provider. Digital solutions have cut through in almost all areas, both on- and off-site, from telematics and datapowered machines to remote and fleet management solutions.”

Regarding the importance of sustainability issues to HCME’s French quarrying/ building-materials-processing customers,

Heidelberg Materials’ Bussac-Forêt cement plant

Top says: “As an indicator of the importance of sustainability within the industry itself, the annual UEPG [European Aggregates Association] sustainability awards receive an increasing number of entries every year. Traditionally, quarrying may have been perceived as a polluting and noisy industry, but it is fighting against that view by playing a bigger role in local communities across Europe. An example of this can be found in France, where one site was used for theatrical productions when the quarry was not in use.

“Developments in technology are key to helping the aggregates sector to face the challenges of sustainability and lowering the cost per tonne. Equipment manufacturers are taking an innovative approach with electrification and alternative powertrains, but adopting such innovations will take time”

Top notes that quarries find it difficult to go fully electric due to the infrastructure required. “There are more elements to be considered in a quarry than a mine, for example, and the associated costs. Quarrying is also a relatively conservative industry, and it is challenging to convert operators massively to a sustainable agenda.

“Nonetheless, they are interested in new

technology, particularly regarding potential fuel savings and reduced costs. While technology in mining is often considered too capital-intensive for quarrying, there is potential for both sectors to inspire each other, for example, concerning renewable energy and biodiversity.”

Dimitrov highlights major infrastructure projects using HCME machines: “The best example is the French government’s multibillion-euro investment between 2018 and 2037- the Grand Paris Express - the largest transport project in Europe and France’s biggest current infrastructure project.

“HCME’s acquisition of Cobemat and ongoing cooperation with its other dealers in France – will enable the company to take advantage of the new opportunities presented by key accounts. Existing customers will benefit from the availability of deals direct from the manufacturer and a nationwide service structure.

“Additionally, HCMF’s territory covers the Île de France province, the largest and most challenging region driven by OEMs. External trends influencing this acquisition include upcoming large projects, the high rentalpenetration ratio, and the needs of these key accounts.” AB

Heidelberg Materials is investing €65mn to accelerate the decarbonisation of its Bussac-Forêt cement plant in western France.

The plant will be expanded to include a facility to produce calcined clay, which can replace parts of the CO₂-intensive clinker in the cement. This will allow the launch of a new range of lowcarbon calcined clay cements containing less clinker.

"Our most recent investment in innovative technologies in France demonstrates Heidelberg Materials' strong commitment to decarbonise our products.

The launch of the transformative project in Bussac-Forêt will be supported by a favourable administrative and regulatory environment", said Dr Dominik von Achten, chairman of the managing board: "The project will reduce the site's CO₂ emissions by up to 20% and thus have a significant positive impact on Heidelberg Materials' carbon footprint in France."

Dr Nicola Kimm, chief sustainability officer and managing board member, added: "In Bussac-Forêt, we are investing in a technology with great potential. It will allow us to significantly expand the range

of low-carbon products. Using calcined clay as a clinker substitute is an important measure to reduce the carbon footprint of cement and concrete. In principle, a CO₂ reduction of up to 40% is possible when substituting cement clinker with calcined clay."

The company is currently piloting calcined clay technology in Ghana, where the world's largest flash calciner is being built with a capacity of more than 400,000 tonnes per year.

This latest investment is in addition to the €46mn already committed by Heidelberg

Materials to decarbonise the Bussac-Forêt cement plant by increasing the alternative-fuel rate from 30% to 80%. The Ecological Transition Agency financially supports the project as part of the France Recovery programme and benefits from support from the Nouvelle-Aquitaine region. It is fully in line with Heidelberg Materials' climate strategy, which has set targets to reduce specific net-CO₂ emissions per tonne of cement by 47% by 2030 compared to 1990. The Group aims to achieve net-zero carbon emissions by 2050 at the latest.

SBM Mineral Processing’s new AI-featuring REMAX 600 impact crusher during its official launch in Ramsau,

The incorporation of technologies such as artificial intelligence can revolutionise the crushing & screening equipment sector. Liam McLoughlin reports

More than 170 visitors to the Ramsau quarry in Lower Austria recently got an insight into the potential future of the crushing and screening equipment industry. The quarryoperated by Hans Zöchling GmbH - was the venue for the official launch of SBM Mineral Processing’s revolutionary new REMAX 600 track-mounted impact crusher, which features AI capability.

The machine was a major attraction at the 2022 edition of bauma, and the Ramsau event featured performance demos in natural stone and typical recycling materials that demonstrated the all-round qualities of the new 600 t/h crusher.

SBM cooperation partners from the University of Leoben (Montanuniversität of Leoben) gave insights into the ongoing development work around AI-based "autonomous crushing", which should soon be possible with the REMAX 600 and other SBM plants.

Helmut Haider, SBM sales director processing, says that more than three years of intensive development work by SBM and external experts have gone into the new machine.

"We have once again delivered on time," says Haider in view of the closely timed model premieres in recent years, with which the processing specialist has expanded its range of track-mounted JAWMAX jaw crushers and REMAX impact crushers into a highly up-to-date, well-rounded portfolio with six models each ranging from 23 to

160 tonnes transport weight. With the exception of the large jaw crusher JAWMAX 800, all models offer compact dimensions for economical one-piece transport, despite the diesel-electric hybrid drive with plug-in option and largely class-leading crushing and screening equipment.

SBM has been collaborating for several years with, among others, the Innovation Centre for Raw Materials (IZR) at the University of Leoben. The cooperation with the university has featured computeraided or experimental validation of new or further developed processing solutions and components from SBM’s own R&D department at its headquarters in Oberweis, Austria.

The aim is to develop "intelligent", selflearning mobile crushers that enable the decisive step from crushing, which is already largely monitored and optimised in terms of the interaction of all process steps, to autonomous, fully-automated production. The first milestone and ideal technology carrier for further development is the now market-ready "conventional" REMAX 600 with its extensive technical equipment, the further optimised electric drive and the latest generation of the CRUSH CONTROL machinecontrol system, which already processes a large part of the machine data generated today.

The teams are currently working on the development of the advanced sensor technology that will enable the machine to automatically detect the type and composition of the feed material and the particle-size distribution of the end

products. Together with the load conditions of the crusher and conveyors, which are also determined in real time, the CRUSH CONTROL system transmits all the values determined in the field via a cloud solution to the SBM headquarters. A ‘digital twin’ created there compares the actual machine performance with thousands of stored reference data from 1:1 quality tests, laboratory tests and computer simulations (rock properties, grading curves, particle shapes, etc.). The resulting optimisation potential is fed back into the machine's control system and, thanks to innovative machine-technology solutions, enables all process stages, right down to the air classifier and magnetic discharge, to be adjusted immediately and continuously on-site without interrupting operation.

According to SBM, autonomous crushing is designed to provide significant support and relief for operators and operating personnel: for example, the system can be configured precisely to requirements on a data-based basis, even before a change of location or material, through the correct selection of screening media. An interactive menu-control system allows even inexperienced operators to set up production precisely, depending on whether maximum output, minimum fuel consumption (‘eco-mode’) or optimised production of certain valuable aggregates is required. A new type of integrated tool monitoring in the impact crusher also helps to reduce quality losses due to wear during production and provides important support for predictive maintenance.

With the newly-developed REMAX 600,

SBM Mineral Processing relied on the highly mobile plant concept, which offers natural stone producers and recycling companies alike the full flexibility and high productivity of a large impact crusher.

SBM says the REMAX 600 defines a completely new performance segment in mobile primary and secondary crushing with the 600tph of its further developed 1400 impact crusher 13/14/4 with an intake of 1,380mm x 1,000mm (W x H) for feed sizes up to 900mm. Up to five high-quality fractions can be produced in one pass, thanks to efficient pre-screening, triple air classifying and high-efficiency magnetic separation, as well as the optional single/dual/triple-deck secondary screen.

Depending on the equipment, the REMAX 600 only weighs between 60 and 80 tonnes on the low bed – even when fully equipped, the machine measures a slender 22.0m x 3.49m x 3.80m (LxWxH).