“An MB Crusher BF90.3 bucket on a Hitachi Zaxis 220LC excavator is proving a big hit with a prominent Indian quartz mines and quarries business.” p48

COVER STORY:

05 COMMENT

Navigating the statistical maze with an open mind

06 NEWS

Afrimat posts record interim results; Sandvik Q3 earnings boost

11 MARKET REPORT

The Indian aggregates sector is in good health thanks to Prime Minister Narendra Modi’s huge transport infrastructure works programme

48 EQUIPMENT UPDATE

Global OEMs’ new equipment launches and applications

50 EVENTS

All the key events in the quarrying & aggregates world Features

19 AGGREGATES PRODUCTION

How a premium crushing and screening plant is helping OSF Group meet huge demand for ballast for the Basque Y highspeed rail project

22 LOADING

Innovation is a key feature in the modern global quarry loading machine market. Aggregates Business assess three major recent model launches

A leading articulated hauler maker discusses big machine development plans

27 WASHING – PART 2

Aggregates washing plant solutions are getting increasingly sophisticated and efficient

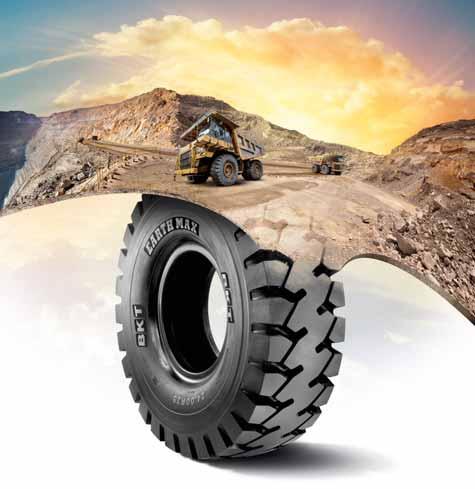

Many Indian cement producers are looking to acquire higher capacity rigid dump trucks to help meet rising demand for their products

31 ENGINES – PART 2

New models and how best to future-proof the off-highway engines industry

37 BLASTING & ALTERNATIVES

The use of technology such as visualisation and drones is enhancing the efficiency and safety of blasting operations at quarry sites

39 RECYCLING – PART 2

OEMs aware of rising demand for recycled aggregates globally have been busy highlighting new and proven recycling-suited plant

08 INTERVIEW

As Metso’s recently appointed senior vice president for Africa, Qasim Abrahams is leading the quarrying equipment giant’s ambitious double-digit regional growth targets for the next three years

14 RDTS FOR INDIAN CEMENT INDUSTRY

India’s major cement producers are increasingly eyeing larger rigid dump trucks as they look to increase their production due to high market demand

16 TAIWAN AGGREGATES SECTOR

Taiwan’s aggregates industry has gone from strength to strength over the last decade

35 SMILEY MONROE –THE FIRST 40 YEARS AND WHAT’S NEXT?

The Northern Ireland-headquartered conveyor-belt solution specialist remains highly ambitious after an impressive first four decades

43 EMBATTLED KENYAN QUARRY MINERS

Court cases stand in the way of Kenya’s quarry miners’ attempts to work new mining fields as they strategically position themselves to supply region’s booming aggregates market

45 QUARRY PROFILE

After tripling production volume and significantly reducing water usage, CDE’s cyclone technology is proving a big hit with a South African sand & aggregates producer

HEAD OFFICE

EDITOR: Guy Woodford

ASSISTANT EDITOR: Liam McLoughlin

CONTRIBUTING

EDITORS: Patrick Smith, Dan Gilkes

EQUIPMENT EDITOR: Mike Woof

DESIGNERS: Simon Ward, Andy Taylder, Stephen Poulton

PRODUCTION MANAGER: Nick Bond

OFFICE MANAGER: Kelly Thompson

CIRCULATION & DATABASE MANAGER: Charmaine Douglas

INTERNET, IT & DATA SERVICES DIRECTOR: James Howard

WEB ADMINISTRATORS: Sarah Biswell, Tatyana Mechkarova

MANAGING DIRECTOR: Andrew Barriball

PUBLISHER: Geoff Hadwick

CHAIRMAN: Roger Adshead

ADDRESS

Route One Publishing Ltd, Waterbridge Court, 50 Spital Street, Dartford, Kent DA1 2DT, UK

TEL: +44 (0) 1322 612055 FAX: +44 (0) 1322 788063

EMAIL: [initialsurname]@ropl.com (psmith@ropl.com)

ADVERTISEMENT SALES

SALES DIRECTOR:

Philip Woodgate TEL: +44 (0) 1322 612067

EMAIL: pwoodgate@ropl.com

Dan Emmerson TEL: +44 (0) 1322 612068

EMAIL: demmerson@ropl.com

Graeme McQueen TEL: +44 (0) 1322 612069

EMAIL: gmcqueen@ropl.com

SUBSCRIPTION / READER ENQUIRY SERVICE

Aggregates Business International is available on subscription. Email subs@ropl.com for further details. Subscription records are maintained at Route One Publishing Ltd.

SUBSCRIPTION / READER ENQUIRIES TO: Data, Route One Publishing Ltd, Waterbridge Court, 50 Spital Street, Dartford, Kent DA1 2DT, UK

TEL: +44 (0) 1322 612079

FAX: +44 (0) 1322 788063

EMAIL: data@ropl.com

No part of this publication may be reproduced in any form whatsoever without the express written permission of the publisher. Contributors are encouraged to express their personal and professional opinions in this publication, and accordingly views expressed herein are not necessarily the views of Route One Publishing Ltd. From time to time statements and claims are made by the manufacturers and their representatives in respect of their products and services. Whilst reasonable steps are taken to check their accuracy at the time of going to press, the publisher cannot be held liable for their validity and accuracy.

PUBLISHED BY © Route One Publishing Ltd 2019

AGGREGATES BUSINESS INTERNATIONAL USPS: is published six times a year. Airfreight and mailing in the USA by Agent named Air Business, C/O WorldNet Shipping USA Inc., 156-15 146th Avenue, Jamaica, NY, NY11434. PERIODICALS POSTAGE PAID AT / US POSTMASTER

ADDRESS CHANGES TO: Aggregates Business Europe, Air Business Ltd, C/O WorldNet Shipping USA Inc., 156-15 146th Avenue, Jamaica, New York, NY11434

PRINT: ISSN 2051-5766

ONLINE: ISSN 2057-3405

PRINTED BY: Warners (Midlands) PLC

he great American writer Mark Twain, famous for his late 19th century novels, The Adventures of Tom Sawyer and The Adventures of Huckleberry Finn, once said that “facts are stubborn things, but statistics are pliable”. Fortunately, while I don’t have Twain’s enchanting grasp of the written word, I don’t quite share his pessimism when it comes to statistical analysis.

In my Comment page in the last issue of Aggregates Business International – Asia, Africa & Middle East, I talked about Persistence Market Research’s (PMR) encouraging new study of aggregates demand across Africa, which, PMR forecasts, will see a compound annual growth rate (CAGR) of 5.4% over the 2019-2029 period.

This time another report, Global Construction Outlook to 2023 – Q3 2019 Update, by data and analytics company GlobalData, has hit my desk stating that global construction output growth in 2019 has been revised down to 2.7%. If realised, it will be the slowest pace of growth in a decade, while simultaneously suppressing mineral products demand.

GlobalData says that a chief cause of its revised forecast is that the deterioration in construction output growth across emerging markets has been worse than previously expected, particularly in the U.S. and the Middle East.

The firm’s analysis tips global construction output growth to increase to 3.2% in 2020 and then stabilise at 3.4% over the remainder of the forecast period, which runs to 2023. According to GlobalData, these numbers are partly based on a projected improvement in the global economy in 2020, which in turn relies on improvements in financial market sentiment and stabilisation in some of the larger, currently troubled emerging markets.

In the new report, Danny Richards, lead economist at GlobalData, comments: “Some major advanced economies have struggled to generate growth momentum, including the

US, the UK and Australia. In China, where the authorities are stepping up investment in infrastructure to prevent a continued slowdown, growth will remain positive, contributing to a slight acceleration in growth in total output in the emerging markets.”

Richards adds that geopolitical risks are intensifying, which could potentially undermine investor confidence and disrupt capital flows in the early part of the forecast period. He said that risks to the overall forecast stem primarily from a possible escalation in the trade war between the US and China, as well as inflamed tensions between the US and Iran following the recent drone strikes on Saudi Arabia’s largest oil processing centre, which were blamed on Iran.

“The emerging markets of South-East Asia will invest heavily in new infrastructure projects, supported by private investment, and this region will be the fastest growing, expanding by 6.4% between 2019 and 2023,” Richards concludes.

This uplifting appraisal of likely SouthEast Asian construction output over the next four years will hearten ABI readers. Just don’t expect Mark Twain to be joining in any chorus of approval.

Putting statistical interpretation to one side, this edition has a strong African feel. Shadrack Kavilu looks at the ongoing Kenyan legal battles between Katani quarry miners eager to up their aggregates production to meet insatiable demand for building materials for new infrastructure projects, and residential property owners, angered by quarrying activities such as blasting near their homes.

Meanwhile, this issue’s Quarry Profile sees Munesu Shoko learn how Ground Breakers, a South African sand and aggregates producer, is tripling production and significantly reducing water usage at its Lindley Quarry, Johannesburg site, after investing in a CDE Combo – said to be the world’s first all-in-one wet processing plant.GW gwoodford@ropl.com

LafargeHolcim has taken note of a French appeal court decision to drop the charge of complicity in crimes against humanity brought against Lafarge SA over its operations in Syria, the French-Swiss cement maker said in a statement.

“LafargeHolcim deeply regrets the unacceptable errors committed in Syria”, the company said in a statement reported by Reuters news agency, adding it “continues to cooperate fully with the French judicial authorities”.

The French company is still facing charges of the financing of terrorists, endangerment of people’s lives and violation of sanctions, Lafarge Holcim added, confirming an earlier report by Reuters.

Dangote Group (Dangote), the Nigerian industrial conglomerate, has signed deals to build a cement factory and make phosphate into fertiliser in Togo. Dangote signed a deal to build a cement factory in the small west African country at a cost of around $60 million. Construction of the factory is set to start in Q1 2020, and it will begin producing by the end of next year, a Togo government statement, reported by Reuters news agency, said. The cement would serve the Togolese market as well as export to neighbouring countries.

Togo’s vast phosphate resources are mostly exported in their raw form, and Dangote’s project would process some of that phosphate to make fertiliser in-country, aiming to export it to the region. The cost of the project is around US$2 billion, the government statement added, without specifying how much of that would come from Dangote. The cement and fertiliser deal is Dangote’s first push into Togo, setting up billionaire Aliko Dangote’s group for competition against Germany’s HeidelbergCement.

Afrimat, a major South African open-pit mining company supplying construction materials, industrial minerals and bulk commodities, is celebrating a record set of interim results for the six months to 31 August 2019, with revenue up 19.9% to R1.7 billion (US$112.98mn).

Operating profit was up an eye-catching 56.9% to R318mn (US$21.13mn), while Afrimat’s headline earnings per share rose by 94.3% to 181.9 cents.

The firm’s Bulk Commodities segment, consisting of the Demaneng iron-ore mine in Northern Cape, South Africa, continued to deliver a healthy contribution to the group results, amounting to 28.9% of overall revenue. Bulk Commodities segment revenue increased by 77.5% from R280.4mn to R497.7 (US$33.07mn) and operating profit increased by 176.2% from R50mn to R138.2mn (US$9.18mn) as a result of an impressive increase in volumes and favourable pricing during the period. The Construction Materials and Industrial Minerals business

segments, the former including sales in Mozambique, also recorded revenue rises over the analysed sixmonth period.

New business development remains a key component of Afrimat’s growth strategy, according to a group board statement released with the six-month trading figures.

The statement continued: “The group is well positioned to capitalise on its strategic initiatives. It

foresees continued growth from an excellent asset base and expects further expansion of its range of unique products. The continuation of selective acquisitions is expected to deliver good results.

“Operational efficiency initiatives aimed at expanding volumes, reducing costs and developing the required skill levels across all employees, remain a key focus in all operations.”

Pilot Crushtec International – the southern Africa distributor for Metso aggregates and mobile products – walked away with the Best Sales Growth Award at Metso’s second global aggregates Distributor Days, held on October 7-8 in Tampere, Finland.

Responsible for Metso’s aggregates product range, including static, tracked and wheeled crushers, scalpers and screens in southern Africa, Pilot Crushtec was nominated in four categories: Best Innovation; Best Lokotrack Sales; Best Sales; and Distributor

of the Year. This year’s award comes on the back of yet another achievement at the previous Distributor Days in September 2017. The Jet Park-based crushing and screening specialist received the accolade for Best New Services Distributor, barely 16 months after taking over as the Metso distributor in southern Africa.

Pekka Vauramo, CEO and president of Metso, commended Pilot Crushtec’s capabilities, saying the dealer’s appointment has ushered in new levels of growth for Metso in southern Africa. “We have enjoyed a very successful cooperation with Pilot Crushtec. Testimony to their capabilities is that they have become our third-largest distributor globally in three years,” says Vauramo.

Demand for construction machinery in the Asia-Pacific region is projected to increase by 4.9% per year to reach US$123bn in 2023, according to new research.

Freedonia Group, which authored the study, says that the rapid growth in Asia-Pacific will be driven by a number of factors such as rising labour costs and mechanisation rates throughout the region.

Other factors behind the predicted growth include the

widespread availability of affordable models (many of which are locally produced), increasing use of more sophisticated and better performing machinery in mature markets, above-average growth in both regional construction and mining activity, and expanding investment in regional infrastructure (such as via China’s Belt & Road Initiative).

Freedonia Group says that trends in China – the world’s largest national producer and purchaser of

A new key report states that the African cement industry’s value will grow at a compound annual growth rate (CAGR) of 5.9% a year to 2029 due to the growing number of infrastructure projects across the continent.

The African Cement Market Report 2019 by ResearchandMarkets.com, a leading industry market research consultancy, states that the rise in consumption of cement is expected to result in cement consumption of around 4.5 billion tonnes per annum by the end of 2019.

Global cement consumption has been growing at a CAGR of over 5.2% for the past ten years, driven mostly by consumption from emerging markets such as China, India and Brazil.

construction machinery – will particularly underlie regional market gains.

For example, after a relatively poor sales performance in recent years, replacement product demand in China is expected to rebound. Continued swift economic growth, inflows of foreign investment, and impressive fixed investment spending gains (among other factors) in the country will also bolster sales.

National cement markets analysed in the report include Egypt, South Africa, Nigeria, Ethiopia, Morocco, Kenya, Ghana, Algeria, Angola, Tunisia, Tanzania, Cameroon, Ivory Coast, Togo, Mozambique, Zambia, Senegal, Uganda, and Zimbabwe.

Twelve major cement companies are also profiled in the new report: AfriSam, ARM Cement, Ashaka Cement, Bamburi Cement Limited (Lafarge), Cement Company of Northern Nigeria (CCNN), Dangote Cement, East African Portland Cement Co., Heidelberg Cement, LafargeHolcim, Tanga Cement Company, Tanzania Portland Cement Company Limited (Twiga), and PPC.

Hyundai Construction Equipment is establishing a new research and testing centre to focus on quality.

Hyundai Construction Equipment (HCE) is focusing on performance and quality with its new project to establish a Reliability Assessment Centre. This research and development facility will be constructed in Yongin, Gyeonggi-do (South-Korea), in a bid to strengthen Hyundai’s quality competitiveness. The firm has held a groundbreaking ceremony for the construction of the reliability assessment centre and a performance evaluation laboratory for finished equipment on a 40,000m² site at the Mabuk-ri Research Institute in Yongin, Gyeonggi-do. The project is costing US$64.4 million (KRW 77 billion) and the project is intended to boost the operation of the evaluation laboratory, which was previously operated in Ulsan. The new reliability assessment centre will allow integrated research from parts to finished products and will be completed in August 2020.

The World Cement Association has urged the industry to more swiftly adopt new technologies and put greater focus on innovation to make progress on reducing CO2 emissions.

Speaking at the association’s third annual conference in Shanghai, China, WCA president and CNBM chairman Song Zhiping emphasised the importance of an industry-wide response to climate change.

intensity in production, fuel use and ultimate product use to realise sustainable development.”

Song underlined the role of WCA as the voice of the worldwide cement industry and praised WCA’s unique founding principle of equal representation.

“WCA supports a sustainable cement industry and encourages technical development and other steps to achieve full decarbonisation” said Song.

“The development direction of the cement industry must be to spare no effort to reduce carbon

“All WCA corporate members have the same rights, whether large or small, whether from emerging economies or developed countries,” he said. “We aim to provide a platform where even the smallest producers have a voice and to offer practical services to help members improve their business through knowledge exchange and sharing of best practices.”

As part of its development in Africa, Metso has declared Africa – previously managed from the Middle East – an independent market area. Qasim Abrahams has been appointed senior vice president for Africa and will drive the region’s ambitious double-digit growth targets for the next three years. Munesu Shoko reports

Africa is one of Metso’s 13 market areas. Africa and the Middle East currently contribute about 10% of Metso’s global business. Barely four months into his new role as CEO and president of Metso, Pekka Vauramo made a strategic decision in February this year to declare Africa an independent market area within the Metso organisation.

It was previously managed from the Middle East office as part of Metso’s Middle East and Africa market area. Vauramo says the continent is a very important market with massive growth potential, hence the strategic decision to have it run locally by a dedicated team of people who understand the local operational conditions.

“One of the key decisions we made in the first few months of my tenure was to declare Africa an independent market area within the Metso organisation. I felt so strongly about it when I joined the company. I discussed it with the management team and everyone was more or less aligned to the idea. We had a well-run market area when Africa was still combined with the Middle East, but the management team was based in Dubai and we felt that the distance was not favourable for quick turnaround on key decisions,” explains Vauramo.

In February this year, Metso appointed Qasim Abrahams the senior vice president for Africa to head up the business on the continent. He was previously the company’s vice president for sales and service in southern Africa. His new role entails the end-to-end management of the business, including sales and operations across both the mining and aggregates segments.

Commenting on the decision to appoint Abrahams, Vauramo says the people factor is very important in every company. “We make

equipment and cutting-edge technologies but people are behind everything that happens in the company. It’s important to have the right person with the right profile and personality to head up such an important market area. We have seen that Abrahams has those qualities to lead the team here and has what it takes

“To understand local challenges, we need to be part of the local environment,”

to drive the Metso business to the next level. We have already seen better interaction between the business units operating on the continent in the few months he has been in this position,” says Vauramo.

South African-born Abrahams was definitely the perfect candidate to lead the business in Africa; having extensively worked on the continent, he understands the intricacies of doing business in Africa. Doing business in Africa is different to anywhere else in the world, and can prove to be backbreaking for the uninitiated.

So, what does Metso’s strategy in Africa entail? Abrahams explains that it’s all about making decisions closer to home. For the company to deliver value to its African customers, there is a need to understand the local African challenges. “To understand local challenges, we need to be part of the local environment,” says Abrahams.

Metso’s narrative in Africa is driven by the company’s quest for further growth on the continent. Abrahams and his team have ambitious growth targets for the years 2019-

2022. “We have set a three-year growth target, aiming for double-digit growth year-on-year between 2019 and 2022 – both on orders and net sales, while maintaining consistent profitability,” he says.

“We are going through a phase of execution, making sure that we deliver on all our objectives. Last year was about getting the concepts right. We have laid down the strategy and for the next two years it’s all about execution, while the third year will be about stabilisation,” he says.

To achieve these ambitious growth targets, the team has clearly defined objectives. “The first objective that the senior leadership of Africa and myself have is creating a shared vision and strategy that we can communicate across the market area. Things have changed quite dramatically within the industry across the region in recent years, and our strategy and vision need to be aligned accordingly,” says Abrahams.

Another key focus area in the short term is to drive a customer-centric approach to the business. That includes migrating from a general sales approach to a key account manager approach. Abrahams considers the company’s key accounts as a ‘marriage’ between the customer and Metso.

The next focus area will be operational efficiency, followed by developing Metso’s presence on the continent. The company wants to develop an optimum footprint across the continent to better service its customers and products.

“In the long term, we want Africa to be the leader within the Metso group when it comes to customer-centricity and innovation. It is a major focus for us because we want to grow together with our customers,” says Abrahams. “We are already on the right track. To give an idea, during a recent review of Metso’s Lifecycle Contracts, we came out tops across

the Metso group in terms of positive customer feedback.”

“We have spent a lot of time reorganising ourselves to further improve and become more professional. The goal – in the long term – is to grow the numbers, the people and our customers’ business,” he adds.

Over the past 18 months, Metso has been redeveloping its business in Africa. Abrahams has been part of a team that started the process under the previous vice president. He says results of these efforts are demonstrated by a marked increase in customer satisfaction between 2017 and 2018. A key part of the efforts has been the expansion of Metso’s indirect or strategic partner channels across the continent.

“We have spent time on developing our dealer and agent footprint in the past 12 months in countries like Zambia, DRC, Zimbabwe, Ghana, Mauritania, Ivory Coast, Senegal, Burkina Faso and Morocco, among others,” says Abrahams. “The strategic

partner network allows us to be closer to the customer.”

The dealer development programme has primarily focused on the aggregates side of the business, with a few agents appointed to support the mining business. Metso’s aggregates business in Africa has grown in recent years to constitute about 40% of the total business on the continent. Appointing capable dealers such as Pilot Crushtec International has been one of the major drivers. Metso has enjoyed a successful relationship with Pilot Crushtec, which has become the third-largest distributor in the world in three years.

To further drive growth across other regions on the continent, Abrahams says during the past six months Metso has added three new dealers to its network in West Africa. They are already existing dealers of other brands in the region – with an established customer base – but mainly supplying yellow metal equipment.

“As we further seek to develop our aggregates business on the continent, in October this year we will be launching some new products which will primarily service the needs of this market. In 2018, we also introduced a mid-tier, Chinese-made crusher range called Sharoui, which comes at a considerably lower price than our premium offering and speaks directly to the needs of our aggregates customers, especially in West and North Africa,” says Abrahams.

Commenting on current market conditions, Abrahams says the sentiment remains positive in Africa despite a slow start in 2019. “We had few enquiries in the first quarter of this year on the capital side of both the aggregates and mining businesses. This is projected to change during the second half of the year. We expect an increase in enquiries and orders in the third and fourth quarter of this year. We are positive that we will see a marked increase in capital sales for our aggregates and mining businesses,” concludes Abrahams. AB

Metso CEO and president Pekka Vauramo officially marks the opening of the extended Metso India facility in Alwar, Rajasthan

Partha Pratim Basistha reports on a period of change in the Indian aggregates and construction equipment industries

India’s construction equipment and aggregates sectors are passing through an interesting phase. Despite demand fundamentals remaining firm, under the recent directives of India’s main Central Reserve Bank state-managed banks and non-banking financial institutions are releasing less finance to construction companies, quarry owners, and equipment rental agencies. This has slowed down equipment acquisitions. This year’s extended monsoons have been a further demand dampener for earthmoving equipment and rigid dump truck sales. The hardening financial assistance stance is due to large volumes of non-performing assets accumulated over recent years.

Due to tightening financial support for new equipment purchases and the general running of operations, plant and machinery owners are increasingly seeking new equipment models that are cost-effective to own and operate. They are, however, willing to invest in advanced levels of service support from original equipment manufacturers (OEMs) and dealers that can result in higher levels of existing equipment utilisation and help keep operating costs in check. As a result, Indian and foreign equipment manufacturers are tailoring their product and service offerings accordingly.

Ashoktaru Chattopadhayay, Sandvik’s global business development managerCrushing & Screening Plants Solutions, said the company is increasingly entering into operational contract support for its plant owners. “Backed by this support, they are able to park or timely arrange for funds for carrying out their operation maintenance schedule. It allows for timely procurements of parts, the taking care of wear and tear and for higher availability of plants. Our support also helps customers to keep their capital and operational expenditure under control.”

Sandvik India is providing an operational support contract to J.M. Mahtre, one of India’s biggest road contractors, which is helping to build Navi Mumbai International Airport, in Mumbai, Western India. The airport is due to become operational in 2023. On the infrastructure megaproject, J.M. Mahtre is deploying 12 Sandvik plant with capacities ranging between 200 and 400 tonnes per hour. The fleet includes a mix of CJ 211 cone crushers, CJ 409 jaw crushers, and CH 430, CH 440 and CH 550 cone crushers.

Metso India is also working towards reducing the costs of customer plant operations by offering higher additional-value services support. “Backed by a mix of our annual maintenance and operational services

contracts, which is based on our philosophy of life cycle offerings, plant owners in India with Metso solutions can focus on the core business of marketing their aggregates,” said Pekka Vauramo, Metso president & CEO, during an interview with ABI during his recent visit to inaugurate Metso’s extended plant in Alwar, Rajasthan, Northern India.

Newer business strategies to reduce ownership costs via product reengineering and a wider product portfolio, coupled with newer services, are becoming the norm among Indian crushing and screening manufacturers.

Propel Industries, a major Indian manufacturer of mobile and stationary crushing and screening plant and solutions for manufactured sand production, has recently set up a state-of-the art facility for manufacturing tracked plant in Coimbatore, South India.

V. Senthil Kumar, the company’s managing director, said: “The character of Indian rocks is quite different and varies from region to region. We have been carrying out design improvisations to suit local plant owner requirements, while also fully ensuring the right cubicle shape of the crushed aggregates to deliver better strength. Led by our strong engineering integration, beginning with the designing of the plants to manufacturing, we

are able to provide international solutions at Indian prices.” Propel has recently been exporting its plant to Middle East markets.

The digitisation of products and services via the internet of things (IoT) is an emerging trend, helping curtail costs of plant operation in India. Equipment owners are increasingly looking to maximise output from existing solutions, delaying fresh acquisitions due to tighter access to banking and non-banking institution finance.

Hitachi ZAXIS GI series excavators in India now come with Global e-Service – a platform developed by Hitachi, Japan. It includes a premium offering called ConSite, which is offered as standard with all GI machines.

ConSite uses comparative data of similar class machines operating in the region to provide insightful advice and recommendations to improve operations. There is also an alarm service which uses machine events and acts as an intelligent filter to communicate machine breakdown and raise alarms with unit owners and their dealers.

Volvo India’s CareTrack excavator telematics system gives equipment owners access to a wide range of machine monitoring information, enabling higher model utilisation.

KOMTRAX (Level-3) for Komatsu excavators monitors machine health, watches performance and provides economical operation guidance to operators. Besides basic data like machine location and operating hours, it provides vital information on fuel consumption, mode selection, energy saving and guidance, while also tracking maintenance schedules and offering timely alerts.

Telematics has been beneficial for larger-sized quarry owners and ready-mixed concrete plant operators with sizeable equipment fleets.

Saurabh Agarwal, director, LSC Group, said: “Telematics has been extremely advantageous for us with operating margins

To reduce aggregates usage, the CRRI is stressing the need to use hot and cold recycling during road rehabilitation projects.

India

under greater pressure. We have our centralised office at Rudrapur in Uttarkhand, North India, with plants operating across nine locations. Volvo’s IT-enabled Matris solution in our excavators enables us to centrally access real-time data on fuel consumption, idling hours and switch-off time. It allows us to keep operating costs in check and optimise excavator usage on-site. Telematics solutions offered by Hitachi and Liugong have also been beneficial.”

LSC was the first crushing plant owner to acquire LiuGong’s H-Series intelligent wheeled loaders for its Uttarakhand facility.

Ashok Leyland, an Indian heavy commercial vehicle and tipper truck manufacturing major with a strong presence on quarrying and cement plant sites across the country, has digital initiatives to increase the availability of its trucks, thus increasing customers’ profitability.

Mullagiri Surendranath, Ashok Leyland vice president, said: “Under our ‘I-Alert’ digital telematics solutions, our individual customers and, most importantly, fleet owners, will be acquainted on a real-time basis with the various operating conditions of their trucks. This includes fuel consumption and trip cycle times. This greatly assists with quicker redeployment of the tipper if found idling. Quicker redeployment is a vital requirement in the newer, bigger capacity cement plants. With various codes being generated in case of functional anomalies, I-Alert will also facilitate preventive and predictive maintenance and help encourage safer utilisation of the trucks, as driver shortcomings, like fast driving on sharp bends, harsh braking, and fatigue, can be gauged and acted upon.”

In January 2019, Volvo Trucks India set up a Centralised Uptime Centre in Bangalore, South India. The centre offers an extensive end-to-end, real-time product services programme based on analysis through telematics, utilising the remote diagnostics of Volvo trucks to enable their timely maintenance and repair.

V. Venkateswarlu, vice president, Aftermarket, Volvo Trucks India, said: “The centre gathers real-time information on where and how the trucks are working. The information is then analysed, and measures are suggested to rectify the problem.

“The ambitious target of constructing 15,000 kilometres of National Highways by 2020 has led to a colossal consumption of aggregates”

Sanjeev Kumar

“To curtail usage of aggregates, it is essential to use hot and cold recycling for road rehabilitation projects”

Dr. Satish Chandra

Monitoring is done on the driving pattern of the operators to see whether advanced features of our trucks, such as advanced I-Shift transmissions, are being utilised to optimise performance. Braking frequencies are also monitored, as frequent braking can bring pressure on the axles.

“Since our trucks are engineered to deliver faster cycle times, the centre monitors their unloading time and number of trips made. In case of reduced cycle times, possible reasons like unwarranted operator behaviour and probable breakdown are taken into consideration. Following this, a dedicated cross-functional team at the centre analyses the causes and works out the required solution. Based on the record of the vehicle’s utilisation rate, the centre will communicate back to the vehicle on preventive and predictive maintenance needs, along with an advice on parts replacements.”

There are 12 Volvo Trucks Uptime Centres in India. The centres extend knowledge support to their customers and dealers. The Centralised Command Centre in Bangalore gathers information from various centres and recommends proactive and reactive services.

The Command Centre is presently monitoring 5,800 Volvo Trucks India models. Trucks sold by Volvo India since 2014 have been assimilated with the centre’s digitised monitoring system.

Volvo Penta will use its tried and tested selective catalytic reduction (SCR) technology for Indian OEMs when the stringent BS CEV IV emission norms come into effect in India in October 2020. The major engine maker has products ready for the BS CEV IV in off-highway applications.

“Since mid-2019, we have been working with several customers and OEMs on BS CEV IV-compliant engines. We undertake extensive field-testing on engine performance, installation and application, including in the most abusive field conditions for thousands of hours so that we can develop robust engines.

“With the stringent emission regulations, all the engine suppliers will have to move to electronic engines with an after-treatment

system. In fact, Volvo Penta had introduced electronically controlled engines in 2006 in India, independent of the emission regulations. Along with a cleaner environment, the machine owner and operator benefit from a lower cost of ownership, greater reliability and stable operations over the lifetime of the engine,” said Miron Thoms, vice president & head - Volvo Penta India.

Kirloskar Oil Engines Ltd. (KOEL) is a major Indian on- and off-highway engine manufacturer that supplies its solutions to leading Indian and foreign OEMs in India.

Sanjeev Nimkar, KOEL chief operating officer, said: “Kirloskar Oil Engines has initiated field trials for its BS IV engines for use in backhoe loaders, compactors, wheeled loaders, motor graders, self-loading concrete mixers and cranes. These are all complied with stringent BS IV emissions in Phase I, and for excavators which will have to comply in Phase II. Our new BS1V engines will provide the same ease of operation, fuel efficiency, robustness, durability and reliability that Kirloskar engines are known for.”

While there are stronger, concerted initiatives on behalf of equipment manufacturers and owners towards reducing owning and operating costs of equipment, stakeholders, government agencies, project owners and developers are increasingly looking to deliver more ecologically-minded and sustainable road construction projects.

Sanjeev Kumar, chief engineer at India’s Union Ministry of Road Transport and Highways (MoRTH), said: “The ambitious target of constructing 15,000 kilometres of National Highways by 2020 has led to a colossal consumption of aggregates, estimated to be about 150 million tonnes. This is despite India’s National Highways constituting only two per cent of the total road network. Though construction of roads is indispensable for any

growing economy, there is a dire need to curtail exploitation of natural resources and reduce greenhouse gas emissions during road construction projects. To make this happen it will be essential to recycle and reuse bituminous materials, backed by milling technologies.”

MoRTH has issued guidelines on the utilisation of recycled materials, in which it stresses the use of fly ash. The Indian Road Congress has also framed guidelines on the usage of waste plastic, with 350 kilometres of roads being identified for this purpose. Through this utilisation of geosynthetic materials, dependence on virgin aggregates can be largely reduced.

Sharing India’s Central Road Research Institute’s (CRRI) blueprint for sustainable road construction, Dr. Satish Chandra, director, CRRI, said: “As availability of aggregates is reducing fast, Indian Road Congress IRC 37 2018 guidelines stipulates usage of polymer stabiliser mixed with base course materials. To curtail usage of aggregates, it is essential to use hot and cold recycling for road rehabilitation projects. CRRI has recently undertaken some critical research on cement grouted bituminous mix (CGBM). The advantages of CGBM are wide, as its life cycle is longer than bituminous concrete.”

Dr. Chandra continued: “We have recently looked at the use of steel slag on the Ranchi-Jamshedpur (Eastern India) highway rehabilitation. We have also conducted studies of the utilisation of ferrochrome as a provider of greater [highway] strength.”

According to Dr. Chandra, MoRTH will soon be announcing more waste plastic and slag for highway rehabilitation trials. He added: “CRRI can be a suitable partner to this venture as Tata Steel has approached us for utilisation of waste slag.” AB

There is growing demand for rigid dump trucks within the Indian cement industry, as cement producers across the country continue their major capacity expansions. Partha Pratim Basistha reports

The Indian cement sector’s ambitious plans involve both expanding existing site production and setting up newer facilities through major capital expenditure. The moves are being fuelled by projected rising demand for cement from India’s roads and airport infrastructure sector.

According to the estimates of Indian cement producers, present national production capacity is between 300-330 million tonnes. Based on companies’ ongoing projects, an additional 400 million tonnes of cement production capacity is set to be added over the next 18 months. Longer term, another 600 million tonnes of capacity is due to be added in the next three-five years.

Major cement companies which are set to implement large-scale output increase proposals include UltraTech Cement. The company is increasing its production capabilities in Karnataka and Chhattisgarh, in South and Central India respectively, and in Rajasthan, North India. A significant production volume increase is also in the pipeline for ACC- Lafarge in Maharashtra,

Western India, while enlarged cement production capacity works by Ambuja Cements, JK cements and Shree Cements in Rajasthan are also underway. Furthermore, North India-based cement-producing major Wonder Cements is undertaking a significant cement capacity increase at its Rajasthan unit. Finally, South India-based Ramco will soon be undertaking key capacity expansions at its sites in Kerala and Tamil Nadu.

The great Indian cement industry production expansion includes further development of companies’ limestone mining sites, with new grinding facilities created and higher capacity crushing units installed, supported by newer conveying systems. Higher production throughput made possible by capacity expansions has created an urgent need for higher capacity rigid dump trucks (RDTs). This is already visible as cement business bosses aim to haul higher volumes of raw materials thanks to faster cycle times due to reduced production downtime. Maximum production uptime is key to lowering the production cost per tonne, enabling them to remain commercially viable in the highly

competitive Indian cement industry.

Vijay Kumar Mali, senior vice president UltraTech Cement, said: “The heavier loads to cater for the expanded production facilities have made it necessary to deploy higher capacities of rigid dump trucks. However, more than that, it is the rising safety requirements based on newer regulations that have made it imperative to use higher capacity 40, 50, 60 and 100-tonne models. The recent directives of the Directorate General of Mining Safety in India (DGMS) state that limestone mines belonging to cement plants that feature higher levels of undulation and steep gradients will have to mandatorily use higher capacity off-highway RDTs instead of conventional-size RDTs.”

DGMS’s new directives came in after several fatal accidents at cement industry sites involving on-highway-sized haul trucks with faulty brakes.

Mali continued: “The heavier RDTs feature multiple braking arrangements. Furthermore, the trucks are ROPS-[roll-over protective structure] and FOPS-[falling-object protective structure] compliant. This makes them safer

to use on steep gradients.” A further safety feature of larger RDTs is their bigger-diameter tyres. Cement producers have also gained from higher capacity RDTs’ longer lifecycle compared to smaller rigid haulers.

“In many cases, the 60-tonne 567kw engine Cat 773E RDTs we are using at our Ravivyas facility has clocked close to 85% availability running between 20,000 to 75,000 hours,” highlighted Mali. “Usage of the higher capacity trucks has prevented overcrowding of the sites, which can be a feature of running a fleet of smaller capacity RDTs. Besides, it has made operations safer for us.”

According to senior plant managers from Rajshree and Ambuja Cements, higher capacity Caterpillar RDTs have delivered higher levels of fuel efficiency and greater tractive ability, allowing them to comfortably cope with steep and sometimes slippery haul-road surfaces.

Rajshree Cements is using nine 100-tonne 567kW Cat 777Es at its facility, while 13 50-tonne 480kW Cat 772Gs have been used by Ambuja Cements to haul limestone boulders to the grizzly feeding unit. Meanwhile, 12 40-tonne Cat 770, 283kW are also being utilised by UltraTech Cement.

However, despite Caterpillar RDTs’ popularity with some cement industry heavyweights, a spokesman for the manufacturer’s India dealer, Gainwell, said that the short turning radius at limestone mining sites was deterring plant owners from acquiring 60-tonne-plus capacity RDTs in a “major way”.

Indian truck manufacturing major Ashok Leyland has a considerable presence in the cement and quarry industry. It has recently

delivered 14 new Captain 2523 6x4 rigid dump trucks to the limestone crushing facility of JK Lakshmi Cement. The trucks transport the limestone boulders six kilometres from the firm’s Garoli captive mines in Udaipur, Rajasthan, to the mineral processing facility at the plant’s Udaipur Cement Works.

D.S Charan, senior plant manager at Udaipur Cement Works, said: “The Captain series trucks have delivered lower operating costs and faster cycle time enabling the plants to run very efficiently.”

Arindam Das, head – Construction & Mining Vertical, Ashok Leyland, said: “The Captain series trucks come with BS 4-compliant engines, meeting the new Indian emission norms. Lower cost of operation is delivered in a major way by iEGR [intelligent exhaust gas recirculation] technology working on the engines, compared to SCR [selective catalytic reduction] technology. With iEGR

technology in place, there is no requirement for AdBlue.” Ashok Leyland also manufactures its own H-Series common rail engines.

For 35-tonne-class RDTs, Ashok Leyland offers the CT3118 with 18m³ body, powered by a 134kW engine, the U3123 with 22m³ body and an air-conditioned cabin, and the 171kW-engine-powered Captain 3123 with 22m³ body and a “world-class” cabin. These products are said to be ideally suited to the needs of customers looking for premium or value for money trucks. Ashok Leyland also recently introduced the N 3532 RDT. The new rigid hauler has a 239kW engine and a 19m³ body.

“The new higher capacity [domestic rigid dump truck] solutions come with lower initial purchase and operating costs than those offered by international RDT manufacturers operating in India’s bulk heavy-haul segment,” said Das. AB

Authorities in Taiwan have acted to improve the quality of the island’s aggregates and combat the lack of controls on some construction projects. Liam McLoughlin reports

The Taiwan Construction Research Institute has authored a certification system for the country’s mixing plants and quarries. Xu Minhuang, leader of the engineering services group at the institute, says a system for the management of aggregates is required because the lack of controls on their quality has led to “jerry-built” construction projects being found repeatedly around the island.

“There are more than 100 aggregatesproducing sites in Taiwan,” says Xu. “The annual consumption of aggregates is 70 million tonnes, so it’s a small-scale industry.

“We certify aggregates as they are a very precious commodity,” says Xu. “In the past they were called black gold. We have had the certification system for quite a long time, and it is how we increase the quality of the industry as a whole.”

The certification system was introduced following the major earthquake in 1999 that

destroyed over 50,000 houses on the island.

“We needed a system for the certification of the raw materials that were required for rebuilding,” Xu says. The system adopted the ISO 9001 standard.

Experts review each application using 98 different criteria before awarding certification.

In an ongoing review process, small factories are tested twice a year, mid-sized factories three times a year, and large plants four times a year. Certificates are reviewed every three years.

“Because of Taiwan’s hot climate we pay particular attention that pipelines are of the right standard,” said Xu.

So far more than 60 enterprises have been awarded certification, equating to around a third of the aggregate plants in Taiwan.

He adds that the size of Taiwanese aggregates enterprises is getting larger. Previously most businesses were private operations, but now they are increasingly

run by the government. The quarrying and mining sectors on the island are regulated by the Mining Bureau at the Taiwan Ministry of Economic Affairs. The bureau says that over 20 types of minerals are mined or quarried in Taiwan.

A spokesperson at the bureau’s Earth and Stone Management Group said: “Taiwan is limited by geological terrain, environmental protection and related laws and regulations.”

Taiwan has a limited number of quarries. Its aggregates resources – specifically sand and gravel - mainly come from the dredging of rivers, with secondary sources being surplus earth from construction works and imported aggregates.

The island relies heavily on imports to meet the demand for materials, and the Mining Bureau spokesperson said that it currently imports at least 8-10 million tonnes per year of sandstone aggregates from mainland China, although this figure is declining year-on-year.

In total, Taiwan imports around 20 million tonnes of manufactured aggregates from China each year.

In 2017, approved investment from mainland China into the Taiwan mining and quarrying sector totalled US$22.7m, according to research from Statista, compared with US$9.21m in 2016. Mainland Chinese investment in Taiwan was its highest in recent years in 2013 when it reached US$31.75m.

The production value of minerals in Taiwan generates less than NT$40bn (US$1.01bn) in annual revenue, accounting for 0.4% of the country’s gross domestic product (GDP). When imported mineral products are included, minerals contribution to the output value of construction and other industries combined can reach up to NT$200bn (US$5.06bn) which accounts for around 2% of GDP.

Looking at future trends for aggregates supply and demand in Taiwan, the Mining

Bureau says that a reduction of river-dredging aggregates will be an issue and that, while the supply gap can be supplemented from mainland China, the supply of aggregates from the mainland could be at risk from any changes in the political situation between the two countries.

A small amount of aggregates is imported from the Philippines, and the bureau says that other Southeast Asian countries are unable to supply sufficient amounts due to issues with exports and freight charges to Taiwan.

Despite this the bureau says it should be possible for the profit levels in the Taiwan quarrying and aggregates sector to maintain the sustainable development of the industry.

As has taken place in mainland China, there has been a growing emphasis on environmental protection in recent years with companies being required to pay more attention to land reclamation and pollution control.

Xu Minghuang of the Taiwan Construction Research Institute

“Because of Taiwan’s hot climate we pay particular attention that pipelines are of the right standard”

As part of the ongoing environmental efforts the Mining Bureau has recently commissioned scientists at the National Taipei University of Technology to develop a geopolymer cement and concrete that can reduce carbon dioxide emissions during cement production. The bureau says that this type of cement prepared with mining waste could have the potential to make improvements in this area by not requiring a high-temperature production process. The Mining Bureau states: “Since the green cement and concrete do not need a hightemperature process, they can be manufactured at ambient temperature, and can fully achieve the purpose of energy-saving and carbon dioxide reduction.

“The results of this project have found that marble-based geopolymer green concrete has excellent properties such as high compressive strength, fire resistance, acid/alkali resistance, and can significantly reduce carbon dioxide emissions.”

The bureau adds that the green concrete will be promoted and applied to engineering applications in the future, following appropriate testing.

Non-metallic minerals in Taiwan can be classified into three different types: industrial raw materials (including marble, limestone, sulphur, quartz, clay and dolomite), construction materials, and precious or semiprecious stones. A small amount of limestone and clay has historically been produced in western Taiwan, but the main minerals production areas are in the eastern areas of Keelung, Hualien and Taitung.

Limestone deposits are scattered in western Taiwan’s foothill belts and eastern Taiwan’s coastal area. Coral limestone deposits in the west have been used to produce cement, while fossil limestone deposits in the east are mainly used as building materials.

Due to environmental considerations, limestone quarrying in the west ceased in 2010 and the cement industry has now shifted its operations to eastern Taiwan where plentiful marble reserves remain. In recent years more than 20 million tonnes of marble have been mined annually, worth around NT$1bn (US$3.28m). Marble is mined by the open-pit bench mining method. Previously, the blasted marble pieces were transported out of the site by truck. However, to boost transportation efficiency in largescale mining, the blasted marble pieces

Dolomite is obtained on the eastern side of Taiwan and is chiefly used as a building material and industrial raw material. It has traditionally been mined by the open-pit bench mining method, but the tunnel mining method has now become prevalent.

The best-known precious stone produced on the island is Taiwan jade, which is predominantly obtained from Hualian county. Its dense texture and lustre after being polished has seen Taiwan jade become an in-demand item both domestically and for

Jasper and Aragonite.

The Mining Bureau estimates that there are approximately 300 billion tonnes of marble reserves in the Keelung, Hualien and Taitung areas.

The Mining Bureau also estimates that annual production of industrial raw materials totals is around NT$3bn (US$9.84m). It adds that the cement industry on the island depends heavily on limestone and marble. Various types of sand, gravel and stone are used in the construction industry. AB

Situated near Haro, a town in northern Spain’s stunning La Rioja province, Ofitas de Santutis (Santutis) quarry has been owned by Iñigo Ajuria’s family business, Ofitas de San Felices Group (OSF Group), since the 1960s. After a long period of closure due to reduced market demand, OSF reopened the ophite rock-rich site in 2016 as the company looked for extra mineral resources to produce ballast for the ambitious Basque Y highspeed rail project linking three major Basque Country cities – Vitoria-Gasteiz, Bilbao and Donostia-San Sebastián.

Originally due to be completed by 2023 but now behind schedule, the 194km(157km double track and 37km single track) route will transport passengers and cargo, the latter between the ports of Bilbao and Pasaia. Basque Y is set to reduce journey times between Vitoria-Gasteiz, Bilbao and Donostia-San Sebastián to less than one hour, compared to anything between one hour 40 minutes and two-and-a-half hours currently. The new line will also connect the Basque Country with the rest of Spain.

The impressive all-Metso plant set-up at Santutis quarry includes an LT125 Lokotrack jaw crusher, two HP4 cone crushers, two CVB 2060 screens, conveyors, feeders and a cutting-edge plant control system.

“At Santutis we are producing around 800,000 tonnes of material a year – 30% of which is ballast,” says Ajuria, during a September 2019 visit from Aggregates Business. “The Metso plant was very simple to install and is simple to run. The long experience we have of working with Metso

and the trust and personal relationships we have built up made the commissioning of the plant easy. For this site, we were extremely clear on what we needed.”

Ajuria says his HP4 cone crushers have proved ideal for ballast production. “They have proven over time to be the best kind of cone crusher for this kind of product. This is based on their capacity, the quality of the final product and the longevity of wear parts. HP cone crushers are also highly reliable machines. Given the hardstone in our quarry,

Guy Woodford sees first-hand how a premium crushing and screening plant is helping OSF Group meet huge demand for ballast for the Basque Y high-speed rail project. Meanwhile, a sector giant is expanding a major cone crusher range, while another ambitious plant manufacturer has staged a major demo-days event in Scandinavia

which has a Los Angeles abrasion value of 10, reliability is not always evident with every cone crusher. We also find that the Metso CVB screens are highly reliable and efficient. We’ve had our CVB 2060s for some time.”

Santutis’s Metso plant control system includes cameras on the jaw and cone crusher feed openings, for early detection of any oversized material blockages or other production issues. The quarry’s conveyors are not fixed to ground foundations to allow for production flexibility, easier engineering maintenance and cleaning. This is said to be a first conveyors set-up of its kind for Metso. Santutis operates 8am-5pm Monday to Friday for 10 months each year, closing in January and February due to the Basque Country’s severely cold winter weather.

As well as being renowned for its high-quality ballast, Santutis also offers customers high-quality 4-12mm, 12-20mm and 20-25mm aggregates products, plus a 0-4mm sand product for concrete production.

Santutis’s aggregates product customers, including general construction and highway contractors, are situated anywhere in a 150km-radius of the quarry. They either collect their purchased products from the quarry, or OSF delivers them by either one of the company’s own or a hired-in truck.

Santutis has 15 million tonnes of mineral reserves, allowing Ajuria and his OSF leadership team to plan for many more years of fruitful aggregates and ballast production at the site.

“In the future, we are looking at bringing

in another Lokotrack jaw crusher to meet demand on the Basque Y high-speed rail project. This will allow us to double our ballast output,” explains Ajuria, whose OSF business also operates the spectacular Ofitas de San Felices quarry, next to his own vineyard, near Haro, and a third quarry in Granada, southern Spain.

Swedish quarrying equipment giant Sandvik is expanding its 800i series of connected cone crushers to include three new crushers for aggregates and mining applications.

The three new models are the CH830i, CH840i and CS840i, and the manufacturer says that each crusher comes with its new Automation and Connectivity System (ACS) as standard.

Sandvik adds that the new 800i series of premium cone crushers features mechanical upgrades, connectivity, advanced automation and rebuild possibilities to predict performance, maximise uptime and offer sustainability at the lowest possible cost.

Connected to the My Sandvik customer portal, the 800i crushers are designed to enable managers and operators to make decisions based on facts and see areas for improvement directly, increasing uptime and availability. My Sandvik can be accessed using a smartphone, tablet or computer.

The 800i connected crusher series features the new generation ACS as standard. The system continuously monitors and optimises crusher performance and controls the complete lubrication system, increasing uptime and reliability.

The 800i series has been toughened and improved to offer greater reliability, higher availability and a low risk of critical failure.

Bolted rather than welded top and bottom shell liners are designed to make changing 90% faster.

“New, digital technologies will transform the way mines and quarries work,” said Mats Dahlberg, VP Lifecycle Service, Stationary Crushing and Screening, Sandvik. “My Sandvik is the first major step in gaining insights into productivity and predictive

forward. It’s great to offer our customers a service that will truly make a difference to their profitability.”

Keestrack’s dealer for Norway and Sweden, Fredheim Maskin, staged its 10th demo-days event at its Spydeberg, near Oslo, HQ on 17-19 October 2019.

A shuttle service to a nearby granite quarry was organised to showcase Keestrack’s solutions for modern aggregates production. Event attendees saw a fully electric-powered, 200tonnes per hour production plant line producing six end products. Machines on show comprised an electric feeding hopper on skids and a heavy-range Keestrack H6e cone crusher with infeed belt, single deck pre-screen and three-deck after screen with recirculation belt, which was supplying material to a K3e screen. To facilitate stockpiling, there were two S1e stackers with automatic swivelling function and one S5e track mobile stacker.

All plant line units, which also included a B7e primary jaw crusher and K7e scalper, were electrically powered by the H6e’s drop-off engine/generator unit. Keestrack says the key advantage of such a drop-off engine unit is it lowers the service costs due to less dust emissions in the filters, less vibrations, easier and safer maintenance due to working on ground level and lower machine noise levels.

had a combined fuel consumption of less than 90 litres per hour (l/h). The power needed by each plant is calculated at the following ratio: B7e 25 litres/hour (l/h), K7e 8 l/h, H6e 45 l/h, S1e both 1l/h, K3e 5l/h, S5e 5 l/h.

The granite-processing production line showed the huge saving potentials of the Keestrack ‘e’-version hybrid electric plug-in concept. Keestrack says gains would have been even higher if the complete production line was connected to the mains by plug-in. Compared to conventional diesel-hydraulic systems, Keestrack says plant production energy costs can be reduced by up to 80%, with plant noise levels during emission-free plug-in operation down by around 30%.

Keestrack says its modern ‘e’-version plant remain as flexible and highly mobile as conventional technology without having to add a lot of additional transport weight, compared to diesel-hydraulic plant.

The 700kVA genset supplying plug-in power to all the quarry-showcased

Even the larger hybrid plant can be transported in one piece, without dismantling. This, says Keestrack, also contributes to short set-up times. The full integration of all electrical system functions is controlled by intelligent Keestrack plant control. This includes numerous automated routines (sequential start/ stop) and comprehensive monitoring, with bi-directional transmission of machine and production data, via the satellite-based Keestrack-er system. AB

Ammann focuses on technologies that incorporate high percentages of RAP – and considerably reduce operating and materials costs in the process. These technologies aren’t baby steps – they’re significant advances that can greatly impact your business. And they’re PROVEN technologies that are in use at hundreds of plants around the world.

Ask us how a new Ammann asphalt-mixing plant or retrofit can help your business turn waste into profit.

Innovation is a key feature in the modern global quarry loading machine market. Mike Woof, Munesu Shoko and Guy Woodford assess three major recent model launches

It’s an exciting time when it comes to wheeled loaders and crawler excavators for quarrying customers, with many top global manufacturers having brought or preparing to bring new models onto the market this autumn.

Komatsu is introducing its highperforming WA475-10 wheeled loader, which replaces the previous generation WA475. Power comes from a 219kW diesel engine which meets the stringent Stage V emissions requirements for Europe, as well as the Tier 4 Final legislation.

First seen in prototype form at the bauma exhibition in Munich, Germany, in spring 2019, the machine’s key feature is its innovative, Komatsu-developed driveline. This K-HMT system utilises a combination of both hydrostatic and mechanical drive to deliver power smoothly and effectively. The combined powershift and hydrostatic transmission is integrated electronically with the engine to ensure effective moderation between the parallel drive systems. At low travel speeds the hydrostatic system allows precise control, while at high speeds the mechanical drive provides high torque. The system ensures that the engine runs in its optimum range and product manager Shayan Dadgar said: “We have a variable rate of output. The rpm is lower, but we drive in the effi ciency zone.”

due to its sophisticated driveline. Of note is that Komatsu has the confi dence in its sophisticated new technology to offer the WA475-10 with a five-year/10,000-hour warranty covering the driveline.

The engine itself benefits from performance gains in addition to its low emissions, providing a 15% increase in torque at lower rpm. The fuel filter system life is now 1,000 hours compared with 500 hours on the previous model while coolant does not need replacing until 6,000 hours, compared with 5,000 hours for the outgoing version. The diesel particulate filter (DPF) meanwhile achieves 98% passive regeneration and Dadgar claimed, “We have the best after-treatment system on the market.”

fleet management, allowing monitoring of operating parameters and providing alerts for service issues. Additionally, the system can track operator performance and highlight issues that may require amendments to working practices or additional training.

The cab is larger than on previous models giving plenty of space for the operator, while large glass windows give a clear view all round. Dadgar said, “It’s the biggest cab we’ve ever had on a wheeled loader.”

He said that because of the effi ciency of the integrated mechanical and hydrostatic transmission matched to the engine, fuel savings of up to €32,000 can be achieved over a five year/10,000 working hour operating life (based on average fuel prices across Europe). At low speed the hydrostatic system allows precise movements and Dadgar added: “It’s also much smoother to operate.”

High efficiency is delivered through the power range due to the new transmission and Komatsu claims that the machine offers fuel savings of up to 30% over the outgoing model, predominantly

Novel control features include a function that raises the boom quickly without the operator needing to increase engine rpm. Another is the button that allows the operator to shake out any material retained in the bucket. And there is also a fast arm-lower function to return the bucket to carry height. The bucket confi guration has been refined to optimise filling when entering the muckpile.

Liebherr Africa has launched the new Liebherr R 9150 B excavator with a specific design focus on increased productivity, efficiency and reliability – three key parameters that can provide African quarrying and mining sectors with some insulation against the cold whims of the market.

With an operating weight range of 128-148 tonnes, depending on the type of wear packages and attachment the customer requires, the new Liebherr R9150 B is a perfect loading tool for 50-tonne up to 135-tonne dump trucks.

Abie Kriel, technical manager Mining at Liebherr Africa, says the launch of the new B model is in line with the company’s strategy for the 100-150-tonne class excavators, which has been identifi ed as one of the major growth drivers for Liebherr’s Mining Division. As part of that strategy, Liebherr Africa also introduced the 100-tonne T 236 rigid hauler late last year, which can be perfectly paired with the new R 9150 B.

As with other machines in the range, the loader is equipped with Komatsu’s remote monitoring package, KomTrax. This latest version allows more effective remote

Tom Munch, director Mining at Liebherr Africa, says the contract mining market is a major driver of the 100-tonne class. “We are working in a contract mining market. If you look at the type of equipment this group of customers requires currently, it’s mainly 100-tonne class excavators and 100-tonne dump trucks. This is due to the mobility they require, given that their contracts are limited to 3-5 years at most,” says Munch.

The R 9150 B’s productivity hinges on the machine’s fast cycle times, precise machine motions, high digging forces, power-oriented energy management and an exclusive EVO bucket solution.

With fast cycle times in mind, like all other Liebherr mining excavators, the R 9150 B uses a closed-loop swing circuit. The main hydraulic circuit comprises a combination of three main valves fed by three working pumps, providing flexibility of attachment control and force distribution, while allowing full oil fl ow integration for fast movement and fast cycle times.

“All Liebherr Mining excavators are equipped with a closed-loop swing circuit. Kinematic energy is recovered when the swing motion is used during deceleration, to drive the main and auxiliary pumps, reducing fuel consumption and allowing faster boom lift motion,” explains Kriel.

The R 9150 B integrates the Litronic Plus electronic control system, allowing for easy control even when simultaneous movements are required. The patented Liebherr electronic bucket cylinder damping system provides controlled end-cushioning for smooth attachment motions, thus increasing machine productivity. The integration of the electronic control system also enables maximum machine versatility and the use of various long-reach attachments and specific tools.

“The R 9150 B’s attachment is equipped with pressure-less, boom-down function to enable fast cylinder retraction without the need for pump energy. Intelligent energy management diverts the pump flow during boom lowering, allowing other cylinder motions to operate unimpeded,” explains Kriel.

Furthermore, the new R 9150 B comes with the exclusive EVO Bucket Solution with patented Liebherr design to maximise the loading capacity and ensure optimal penetration efficiency. Thanks to the contoured sidewalls and the augmented depth, the EVO Bucket backhoe bucket has a capacity of 8,8-9,6m³ for the R 9150 B. The bucket takes about four passes to load a 50-tonne off-highway truck.

Hyundai Construction Equipment Europe (HCEE) is launching its new HL900 A-series model range with three Stage V compliant wheeled loaders: the HL940A, HL955A and the HL960A.

All new series machines are fi tted with new Cummins B6.7 engines with an all-inone exhaust after-treatment system. The engine is said to be easy to maintain, thanks to its connected diagnostics to Hi-Mate, the long service intervals and the DPF soot reset function for cleaning. As the exhaust after-treatment system does not need a manual DPF regeneration and is exhaust gas recirculation (EGR)-free, the platform is said to offer increased engine reliability.

HL900 A-series wheeled loaders’ IWM (Intelligent Work Mode) menu allows for three engine operation modes: Power, Power Smart and Economy, offering full engine power or reduced fuel consumption depending on the application. The Power Smart Mode is said to result in reduced energy losses and average 3% - 5% fuel savings. In addition, the engine performance is optimised to deliver higher torque at lower rpm. This provides another

means for improved fuel efficiency, while optimising engine power and improving engine response time.

Hyundai HL900 A-series wheeled loaders are equipped as standard with a rear-view camera developed in-house. Hyundai also offers an optional reverse-drive radar system, like a car’s, allowing the operator to quickly and reliably detect obstacles within 10 metres during day or night.

For increased safety on the job site, Hyundai’s AAVM (advanced around view monitoring) four-camera system is available as an option. The system informs you when people or dangerous objects are detected, giving the operator high-precision control over the machine and the surroundings. The camera system comprises two major features: AVM (around view monitoring) and IMOD (intelligent moving object detection). Four cameras film at each side of the machine which means the AAVM system offers a 360° overview of the machine’s surroundings. The IMOD indicates all movements around the machine. Movement is shown on the monitor by putting a rectangle around the moving object or by indicating the side at which there is movement by arrows.

The HL955A and HL960A come with an increased rear-axle capacity for better durability. Both machines can be ordered with an optional heavy-duty front axle for waste handler and specific industrial fields. The all-in-one main control valve – a combination of the ride control valve and the electronic proportional pressure reducing (EPPR) valve – leads to improved uptime as there are fewer hydraulic hoses –and subsequently a smaller risk of damage by leaks.

At Hyundai’s annual Construction Equipment dealer conference staged at the company’s European headquarters in Tessenderlo, Belgium, on 14 November, a brand-new look for A-series machines was revealed by the HCEE management team.

The new A-Series models, which include excavators as well as wheeled loaders, will now adopt a ‘fresh’ new colour combination - and the traditional yellow arm and boom, will be replaced by a modern grey-green tone, which is identical to the current colour of the undercarriage. AB

Extensive improvements have been made to Terex Trucks’ Motherwell HQ since the company was acquired by Volvo Construction Equipment in 2014

There is a hive of activity at one leading articulated hauler maker, while other prominent hauling machine and linked-technology solution manufacturers have been talking about eyecatching, forthcoming and current, cost-saving products. Guy Woodford reports

An expert team at Terex Trucks is hard at work across three key projects. During a recent visit by Aggregates Business magazine to the Volvo Construction Equipment company’s Motherwell, Scotland HQ, Paul Douglas, Terex Trucks managing director, explained how new Scania Stage V emissions-compliant engines for European customers would be introduced on the firm’s 28-tonne TA300 and 38-tonne TA400 articulated haulers in mid-2020, with a new state-of-the-art transmission on the TA400 also set to be introduced in the future. Longer term, work is also well underway on Terex Trucks’ next-generation articulated haulers.

“We’ve already installed a new highperformance transmission on the TA300, which offers 5% better fuel efficiency than its predecessor as well as improved performance, productivity and operator comfort. As far as the new transmission for our larger articulated hauler platform goes, our development work and tests show that we are on track to deliver similar efficiency savings as the TA300. We’ve been developing the concept layouts and key component specifics of the next-generation models. They

will continue to be robust machines with a strong emphasis on operator safety and comfort as well as total cost of ownership. Our customers like our machines because they are simple to operate and easy to maintain, so our future products will stick to this philosophy.”

Douglas says that Terex Trucks is lucky to be part of Volvo CE, where engineers are focusing on key areas for future development such as electromobility, connectivity and autonomous machines. But although he says the company will capitalise on the Volvo Group’s advances in these areas, there are no plans for this to happen in the immediate future. “Our next-generation ADTs will be connected machines, but they will have a diesel engine. We won’t be leading the way when it comes to testing future technology. It’s not what our customers are telling us they currently want, and their requirements always come first.”

Another big focus for Terex Trucks is expanding its dealer footprint. “We currently have 88 dealer partners across the world, and we’ve been working to expand this in key territories such as France, Germany and the US,” Douglas explains. “We are working

with strong partners who understand the local customers and can provide them with high-quality support and solutions, with the backing from us here at the factory.”

Five years on from Volvo CE’s acquisition of Terex Trucks, Douglas believes the integration of the brand into the Swedish construction and quarrying equipment giant’s portfolio was a turning point. Since then, there has been significant investment in the product, people, processes, equipment and the site itself.

During the trip to Motherwell, Aggregates Business had a first-hand look at the extensive improvements made to the site’s factory, as well as the strong emphasis Terex Trucks places on quality control and testing all the articulated haulers that come off the production line.

“Our facility here is nearly 70 years’ old. When Volvo acquired the site, there were investments they wanted to make around safety, quality, environment and efficiency.

“Under Volvo CE’s ownership, there has been a capital expenditure flat-rate spend on this site of about £2 million a year – so we’ve spent £10 million so far. On top of that, there’s been exceptional spend on one-off

Terex Trucks is working on a new state-of-the-art transmission for its popular TA400 articulated hauler