In the ever-evolving landscape of tools and equipment, the pursuit of efficiency and innovation is an unending quest.

WBT’s Tite-Reach Extension Clamp, a true game-changer in the realm of tool innovation, has once again raised the bar with its latest offering —the V2 Extension Clamp TRI-PACK, a testament to versatility redefined.

This TRI-PACK isn’t just a mere upgrade; it represents a comprehensive refresh, introducing two additional sizes, MINI and MAX, alongside the standard mid-length 10.5” model. This expansion isn’t about redundancy; it’s about providing users with an arsenal of options to tackle an array of tasks, transforming the Extension Clamp from a mere tool into a versatile problem-solving solution for every tight spot imaginable.

Imagine this scenario: you’re working on your vehicle, frustrated by a bolt nestled in a spot just out of your hand’s reach. Or perhaps you’re grappling with the irksome wait for a scorching muffler or radiator to cool before reinstalling a bolt. The Tite-Reach Extension Clamp emerges as the antidote to these common challenges, saving you not only time but also considerable effort. With the TRI-PACK, bid farewell to the hassles of dismantling other components to access confined spaces—the Extension Clamp seamlessly becomes your go-to solution.

What sets the V2 Extension Clamp apart is a series of meticulous design improvements over its predecessor, the V1 model. The V2 clamp jaws exhibit a remarkable 1 5/8” width, a substantial 30% increase from the previous iteration. Moreover, the jaws stand approximately 35% taller, significantly enhancing the user’s ability to secure a tight hold on the fastening task at hand. The thoughtful addition of light knurling on both jaws further amplifies its grip, ensuring a steadfast hold even in the most challenging conditions.

A standout feature of the Extension Clamp is its vice-like design, offering a secure grip without necessitating constant tension. Unlike traditional pliers that demand a continuous squeeze to maintain their grip, the Tite-Reach Extension Clamp’s tension nut enables you to secure the part without the fear of dropping it until you decide to release the tension. This feature proves invaluable in precarious situations where dropping the clamped item could lead to irreparable damage or loss.

The TRI-PACK’s inclusion of three sizes—the standard 10.5”, the compact 7.5” MINI, and the extended 14.5” MAX—opens up a world of possibilities for users.

Whether you’re engaged in intricate auto body repairs, tackling household DIY projects, or involved in meticulous airline maintenance, having this range of sizes at your disposal ensures that no tight spot is too challenging to navigate.

Feedback from various industries has attested to the Extension Clamp’s efficacy across a broad spectrum of applications. From automotive enthusiasts to professional mechanics, users have found the Tite-Reach Extension Clamp to be an indispensable addition to their toolkit. Its adaptability and reliability make it a must-have for anyone seeking a versatile and efficient solution for those hard-to-reach spaces.

In conclusion, WBT’s Tite-Reach Extension Clamp TRI-PACK represents a substantial leap forward in tool innovation. By addressing common frustrations with a

thoughtful redesign and the introduction of additional sizes, this TRI-PACK stands as a testament to WBT’s commitment to providing practical solutions for professionals and DIY enthusiasts alike. Say goodbye to limitations and embrace the freedom to tackle any task with the confidence that comes from having the right tool for the job—the Tite-Reach Extension Clamp.

A standout feature of the Extension Clamp is its vice-like design, offering a secure grip without necessitating constant tension.

Dismantlers – like other blue collar trades – have always had a grungy aura. Stereotyped as a role associated with scrap yard and a Mad Max-like persona.

We paid a visit to ACM Parts and one of its dismantling centres to learn more about the people who get into dismantling. The company is one of Australia’s leading recycled parts distributors, and a percentage of its operations is keenly dedicated to taking vehicles apart and saving usable components where possible.

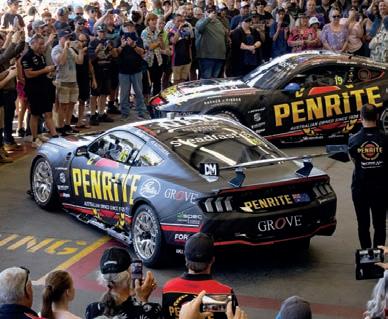

To me, there’s nothing quite as Aussie as a day at the Supercars. Waking up early, grabbing the fold-out chairs, stocking the esky, finding a good spot on the hill – it’s quite the cathartic experience.

It helps that no matter where you are, from Tassie to Darwin, the Supercars will be roaring through your neck of the woods.

I’ve been lucky enough to get access to the pits, both as a kid and as a professional. The odour of fuel and oil overcomes the senses while your eyes are treated to some of the best vehicular hardware money can buy.

The organised chaos of technicians scurrying about with tyres and tools, all the while sponsor banners hang high and drivers ensure they take sips from CocaCola and not Pepsi, or vice versa.

Last year we saw the introduction of the Gen3 Ford Mustangs and Chevrolet

Camaros as the sport looks to mitigate the enormous costs of repairs to previous cars.

There’s certainly a lot to love about muscle cars sputtering around the tracks, even if they’re not as speedy as their predecessors.

A year later and teams are settled in to the new format and ready for another cracker season.

The Bathurst SuperFest kicked off the season, and Australian Car Mechanic is here to cover off on some of the storylines to keep an eye on the rest of the way.

Inside, you’ll find all kinds of super reads to get you fuelled up for the coming season.

If Supercars isn’t your speed, you can read up on all the latest parts and pieces shaping the mechanics’ industry.

Harry Murtough – Editor

CEO

John Murphy

COO

Christine Clancy

Sales Director

Bradley Buchanan

Editor

Harry Murtough harry.murtough@primecreative.com.au

Client Success

Arianna Lucini

arianna.lucini@primecreative.com.au

National Advertising Manager

Rachael Kahui

rachael.kahui@primecreative.com.au

M. 0481 181 334

Design

Blake Storey/Daz Woolley

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au

Website

www.mechanics-mag.com.au

Background image

Supplied by Supercars

Copyright Australian Car Mechanic magazine is owned by Prime Creative Media and published by John Murphy. All material in Australian Car Mechanic magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronicor mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Australian Car Mechanic magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office

Suite 3.06, 1-9 Chandos Street

St Leonards NSW 2065, Australia

P: +61 2 9439 7227

There are many roads that draw people toward becoming dismantlers. One thing’s certain - it’s the shared passion for cars and their parts that built the

dismantling team at ACM Parts.

ACM Parts has been a leading company in the reclaimed parts industry for more than a decade. Its site in Broadmeadows – to Melbourne’s north – is home to a team of dedicated dismantlers.

This team carefully takes damaged vehicles apart before ACM Parts reintroduces components to the market.

They come from all kinds of backgrounds but find themselves sharing a passion for tinkering with cars, taking them apart, and reclaiming the parts that can be reused.

Built for success

Tom Swift is one such dismantler who firmly believes he’s landed his “dream job”. The 22-year-old lives just down the road from the Broadmeadows site in Fawkner but only recently got involved in the dismantling industry.

He started his professional life as a

qualified tiler but had been fascinated by cars since he was young. “Throughout my apprenticeship, I developed a passion for cars,” he said.

“That’s all I’d be doing after workworking on cars. I decided I wanted to do something for the rest of my life that I truly enjoy.”

Once he joined the team at ACM Parts, Tom took his love for cars to another level.

The process of taking apart vehicles and cataloguing their components is a tad more meticulous than playing with the pride and joy in the backyard. Nonetheless, Tom said his time tinkering away on his own car held him in good stead coming into dismantling full-time at Broadmeadows.

“Through that, I was able to develop a deep understanding of how most vehicles are put together,” he said.

“With this job, I’ve learned the terminology as well as the various parts

of the dismantling trade in terms of QC (quality check), cataloguing, and identifying components on a vehicle.

“Without that hands-on experience I had previously, I wouldn’t have been able to keep up with all the new terminology that’s coming through.

“I kept on it – head down – for the last four or five years basically. “I’ve been able to come into this and work competently by myself and keep up with quotas.”

Once a vehicle comes to Tom’s space, he’s given a list of parts he needs to take out and catalogue.

Barely a scrap goes to waste at ACM Parts, so nearly everything from a damaged car is re-used elsewhere, whether through the Reclaimed parts line or other product lines offered by the company.

Tom is one of 12 dismantlers on-site, all of which have their own workstation and vehicle(s) to take apart.

Despite having separate stations, Tom

said he had a blast with the team every day he’s been working with ACM Parts.

“I tell everyone this is my dream job –coming from construction to this has been a massive improvement for me,” he said.

“It’s steady work in a nice work environment with friendly workmates. You’re not competing or battling with them; they’re always here to help and lend a hand.”

As well as a top-notch team, Tom said the high-quality tools and equipment ACM Parts has at its disposal is enough to make any car-lover’s eyes water.

“Honestly, the best part is buying the tools,” he added.

“Anything new and good – I just love it.

“When I got the opportunity to sink a bit into a decent toolbox and setup, I jumped at it.

“It’s been so good using decent tools and seeing how well they perform over sub-par tools.”

Dismantling wasn’t a career choice Tom considered when he was in his teens, but through his opportunity with ACM Parts,

he’s landed a job that combines his love for cars with his love for mateship.

He encouraged anyone who wanted something similar to seriously look at dismantling as a possible career choice.

“I’m not going to lie, taking everything apart and not having to put it back together is a satisfying and great feeling,” Tom added.

“If you can take it apart – you can do this job and everyone’s here to help and train people if they want it as a career.”

ACM Parts Reclaimed is a vital part of the company’s DNA. Executive General Manager Adam O’Sullivan said the arm of the company was a primary reason behind its inception.

“Over time, while it’s a smaller portion of the business nowadays, it’s still a key part of what we do,” he said.

“We believe ACM Parts has the range that no one else has. We have a range of either new, aftermarket or reclaimed part to meet a customer’s choice.

Tom has been working with ACM Parts for about two months, but has loved every moment since coming aboard.

“No one else in Australia has that range.”

Adam added that ACM Parts Reclaimed gives customers a cost-friendly repair choice, as well as find parts for vehicles across the car parc, including older or rarer models.

“It also enables us to extend the life of vehicles for customers who have older cars to keep that mode of transport going,” he said.

Lee Mottershead is the Production Manager for ACM Parts at the Broadmeadows site.

He leads the 20 staff work on-site, including the 12 dismantlers. Other team

members include forklift drivers, quality control officers and inventory specialists.

All play a vital role in ensuring the site is a well-oiled machine when it comes to processing cars and parts.

Like Tom, it was Lee’s love for cars that lead him down the road to joining ACM Parts and its Reclaimed teams.

He said dismantling’s not often a job car enthusiasts consider, but no one who works with him has any regrets.

“They come from everywhere – I’ve got ex-mechanics, or people just looking for a change,” Lee said.

“This is an easier role compared to a

Most – if not all – components taken from vehicles by ACM Parts will be repurposed or sold in one aspect or another.

mechanic because you’re just taking parts off.

“We do also get plenty of people who love cars outside of work, and love taking them apart as a hobby.

“It’s a perfect role for them to get paid for something they love to do.”

• Damaged vehicles are purchased from auctions and are brought to the dismantling site.

• Inventory quality checks the vehicles to ensure they have the correct parts in the desired condition.

• Dismantlers take vehicles apart, cataloguing components and conducting quality checks as they go.

• Once dismantled, the parts are checked once again to ensure the quality is good.

• Parts are packed accordingly in stillages, before being transferred to another warehouse where they are sold and dispatched.

The Capricorn Rising Stars Award is the confidence boost every apprentice needs. Nominations are now open for 2024

Mark Smith, an auto-electrician with The Battery Terminal in Belconnen, Canberra, was the first-ever winner of the Capricorn Rising Stars Award, in 2018.

At the time, his prizes included an allexpenses-paid trip to the Gold Coast to watch the Supercars race and a customer service training package from The Workshop Whisperer for The Battery Terminal — his parents’ business. But the real prize was something far less tangible.

“I got a lot more respect from a lot of peers and from the businesses that we deal with,” Mark said. “But the main thing for me was just the confidence from knowing that everyone had respect for me at such a young age. It allowed me to learn off a lot of other people who wouldn’t normally talk to an apprentice from another business. Business owners of other mechanical shops were actually talking to me about electrical problems, rather than always going straight to dad.

“So, that’s one of the biggest things Rising Stars gave me—just the confidence. Now I’m sort of second in charge, and in charge when Dad’s not there, and it’s definitely given me the confidence to do that.”

It’s a boost Mark said every business owner can give their apprentice by nominating them for this year’s Capricorn Rising Stars Award. Nominations are now open for 2024.

The prestigious achievement award recognises talented apprentices who show initiative, thirst for knowledge and commitment. The competition is open to all Capricorn Members.

Capricorn Group CEO David Fraser is proud of the competition.

“Encouraging and acknowledging future leaders is an important part of growing and supporting the automotive industry.

“We know that finding and keeping apprentices is one of the big challenges for the industry. By celebrating apprentices like

Mark, we hope to encourage more to join, and stay, in the industry,” David says.

Over $27,000 shared cash and prizes is up for grabs for the top five apprentices, overall winner and nominating workshops. Capricorn thanks long-term program sponsors Castrol, Repco and The Workshop Whisperer for taking part in this most valuable automotive aftermarket industry recognition program.

Mark was nominated for the Capricorn Rising Stars by his parents, Capricorn Members Steve and Julie Smith, of The Battery Terminal.

If you’d like to nominate your apprentice and give them the kind of confidence boost Mark talks about, visit cap.coop/stars.

Disclaimer:

2024 Capricorn Rising Stars Terms and Conditions apply, visit cap.coop/tc

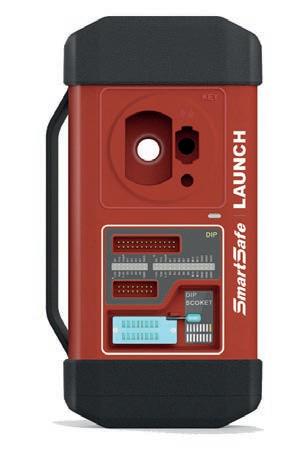

Launch will be front and centre at stand number O28 at the Australian Auto Aftermarket Expo 2024 (AAAE) with its litany of high-quality diagnostic tools.

The expo bi-annually serves as Australia’s biggest aftermarket event where suppliers, technicians and business owners can see the best in auto technology.

This includes Launch, who’ll be presenting the following products designed to upgrade mechanics’ diagnoses capabilities.

The expo is being held at the Melbourne Convention and Exhibition Centre between April 11-13. It will be held in conjunction with the Collision Repair Expo, which is at the same venue. For information or free tickets to the expos, visit autoaftermarketexpo.com.au or collisionrepair.com.au.

You can find more information on Launch’s products at launchtech.com.au or call 1300 369 788.

Featuring a 13-inch display, this advanced tool covers over 100 car brands. With 39 service and reset functions like brake reset, coolant bleeding, air level calibration, battery, and clutch matching, the Euro Tab III stands out. It supports various communication protocols such as CAN, CAN FD, DoIP, J2534, D-PDU, and RP1210. The user-friendly interface simplifies a mechanic’s tasks, complemented by built-in training and repair modules. Offering three years of free software updates, the Euro Tab III ensures mechanics stay current. Boasting 256GB storage, wireless connectivity to the VCI, and running on Android 9, it efficiently handles high-speed tasks with ease.

Australian mechanics facing a constant stream of jobs demand diagnostic tools that keep pace with their hectic schedules. The AUSCAN 4, Launch’s latest scan tool designed for Aussie mechanics, proves to be the ideal solution. It sports a powerful Quad-Core 2GHz processor, 4GB of memory, and 64GB of storage. This advanced tool offers OEM level access to over 110 vehicle manufacturers globally, with a focus on Australia, Asia, the USA, and Europe. Specifically tailored for Audi and VW specialists, it provides over 30,000 supported functions. The AUSCAN 4 ensures efficient and intelligent diagnosis, automatically identifying VINs when connected either via cable or wirelessly. It also features built-in training videos and repair information for easy accessibility. Mechanics can benefit from remote diagnostic functions, facilitating communication with other workshops. The AUSCAN 4 stands out by providing three years of free updates.

An all-in-one key programming and advanced vehicle diagnostic bundle—a reliable solution for your repair business. It supports key functions like matching/copying, anti-theft IC reading & writing, and ECU reading & writing. Additionally, it enables hassle-free anti-theft modules replacement, enhancing both security and diagnostic capabilities.

This robust chip reading device is designed for reading/ writing keys to vehicles. This module seamlessly integrates with X-431 series diagnostic scanners, empowering users with Anti-theft type identification, Remote control matching, Key chip reading & matching, anti-theft password reading, and antitheft component replacement capabilities.

This tool from Launch easily detects high-level faults in electrical components like sensors, actuators, and circuits. When integrated with X-431 scan tools, it provides precise diagnostic information, expanding their functionality for shops and technicians.

A valuable tool aiding technicians in inspecting hardto-reach areas within vehicles. Featuring 6 adjustable levels of light strength, technicians can effortlessly customise brightness based on the environmental conditions. Compatible with Launch X-431 scanners or any Android device, this module seamlessly streams live video, enabling technicians to view, record, and save images and videos.

This Kit includes testing cables for various vehicle brands. Activate and download battery pack diagnostic software, along with new energy vehicle diagnostic software, using the included activation card. This kit equips technicians with essential tools for efficient testing and analysis of electric vehicle battery packs.

The Battery Test Module is ideal for technicians, ensuring safety with anti-heat features and protection against electrical sparks during system diagnosis, preventing potential backfires.

A powerful tool that enhances X-431 diagnostic tools, offering new features and revenue opportunities for mechanics.

Advanced vehicle diagnostic and calibration technology provider, Repairify, has appointed Tristan Sender to spearhead its growth in the Australian automotive repair sector.

The new general manager comes to the tech provider with experience in driving growth in start-up businesses including as CEO of GoGet Carshare and will lead Repairify’s launch into the Australian and New Zealand markets.

At GoGet Carshare, he led the expansion of Australia’s first subscription-based carsharing organisation where membership grew from 4,000 to over 100,000 and the fleet expanded from 150 to 3,000 vehicles.

Sender also has over 16 years’ experience working in the automotive industry both in Australia at GoGet Carshare and the UK with Enterprise Rent-A-Car.

Repairify Board Chair, David Fraser said he was delighted to appoint the accomplished business development and technology leader as Repairify’s inaugural General Manager.

“His exceptional leadership skills, understanding of automotive technology and entrepreneurial acumen make him an ideal choice to lead Repairify,” Fraser said. “We have great confidence in his ability to set up Repairify for success in Australia and New Zealand.”

Sender has also, most recently, held the role of CEO and Co-Founder at Floraly, where he grew a flower gifting start-up into a nationally recognised brand. He led the successful launch into new markets across Australia, resulting in the establishment of a comprehensive nationwide flower gifting service.

A key factor contributing to the success of these ventures has been Tristan’s ability to build exceptional teams, foster a culture of ownership and deliver an exceptional customer experience.

These skills, along with his enthusiasm for embracing cutting-edge technologies, will be instrumental in driving the growth of Repairify and helping mechanical workshops and collision repairers tackle the challenges of the ever-evolving automotive industry.

Global automotive services company Repairify specialise in giving workshops remote access to the latest diagnostic technology, intelligence and service to meet the demands of modern, dataintensive vehicles.

In July 2023, Repairify Australia Holdings Pty Ltd and Capricorn Society Limited entered into a joint venture agreement to deliver advanced automotive remote diagnostic services to repairers in Australia and New Zealand.

Capricorn Society Limited is a memberbased organisation proudly operating by cooperative principles to support the automotive industry to build stronger businesses.

For more information visit repairify.com.au

DBA OFFERS UNCOMPROMISING QUALITY AND MAXIMUM PERFORMANCE - FROM THE ROAD TO THE TRACK.

Australia’s leading brake rotor manufacturer

Backed by over 45 years of local experience

Preferred rotor brand by Australian workshops

What are the key issues facing the collision repair industry in 2024 and what are the best ways forward?

That is the focus of an idea-packed day in June, hosted by the National Collision Repairer magazine, that will bring together thought leaders and industry veterans at Symposium24.

A key theme to be explored across the stimulating day will be the challenges facing the industry, including technology, recruitment and policy and processes that affect the industry’s operation.

But the one-day event, titled The Collision Preparer; Fixing your future will also be firmly future focussed and help turn the changes to come into opportunities.

A combination of expert panels and interactive Q&A’s will focus on the future of the repair industry in Australia and what are the best solutions to help it to thrive.

Symposium24 will take an in-depth look at future technology, specifically the advent of increasing EVs in workshops, the need to adapt to the uptake of ADAS systems along with the opportunities posed by artificial intelligence.

It will also explore the crucial issue of getting the right people for your business to thrive, including future recruiting and succession planning.

Part of the investigation into recruitment

challenge will also discuss how the industry can reframe its image to be more attractive to a new generation of talent.

Experts will also look at the key policies and processes which will shape the industry’s future over the next few years.

For anyone who wants to learn more and prepare for the future of the repair industry, the special one-day event will be an important opportunity to learn, discuss and take away your own solutions.

The highly interactive event will also encourage attendees to get involved, with plenty of Q&A opportunities on issues across the sector.

Collision repair sector experts will be onhand to provide their analyses on the state of the industry.

The event will be held at the Novotel at Sydney Olympic Park on Wednesday June 19.

Supporting Symposium24 are some of the biggest names within the Australian automotive industry, with limited opportunities for others to join.

Australia’s largest automotive cooperative; Capricorn, its largest repair group AMA Group and leading global coatings giant PPG will all support and be featured as sponsors.

“Capricorn are proud to be a sponsor of the National Collision Repairer Symposium again in 2024,” Capricorn Group CEO David Fraser said.

“Events like these are so important as they allow people to get together, learn about the latest information and meet others working in the collision industry.

“NCR always put on a really interesting and engaging event and we’re excited to be involved.”

There are still opportunities to become a Gold Sponsor of Symposium24.

You’ll be able to sponsor a session and even a chance for one of your senior experts to join a session as a panellist. Sponsorship also includes visual benefits collateral in the form of a half- page in the Symposium24 handbook, pop-up displays and pre/post event coverage in National Collision Repairer and Australian Car Mechanic magazines.

Learn more about joining Symposium24 at ncrsymposium.com.au/become- a-sponsor

Scan here to become a sponsor.

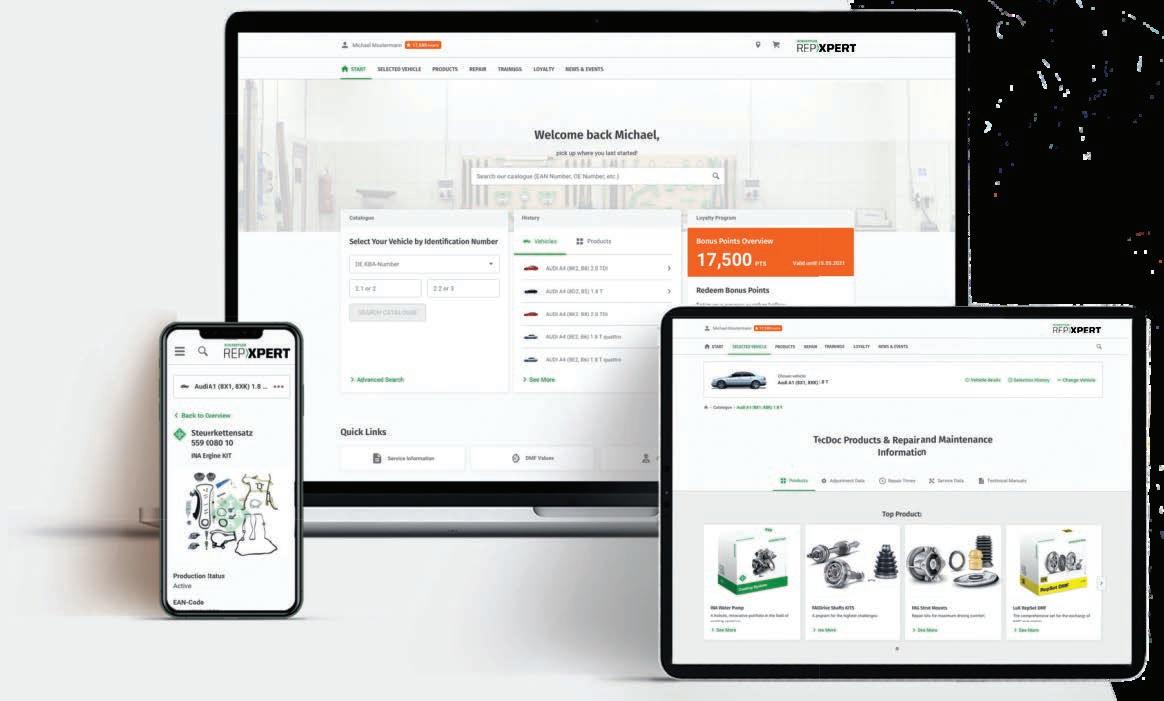

REPXPERT – Schaeffler's next level garage portal

• App available for Apple, Android or desktop

• Fast access to in-depth technical content

• New look and easy to use layout

• Personalized dashboard, clear navigation and intuitive search for an optimized experience

• Free to download

• Bonus shop

Come to stand J J18 and meet the team at the Australian Automotive Aftermarket Expo April 11th-13th! See and learn about Schaeffler's latest e-mobility technology and try REPXPERT for yourself!

www.repxpert.com.au

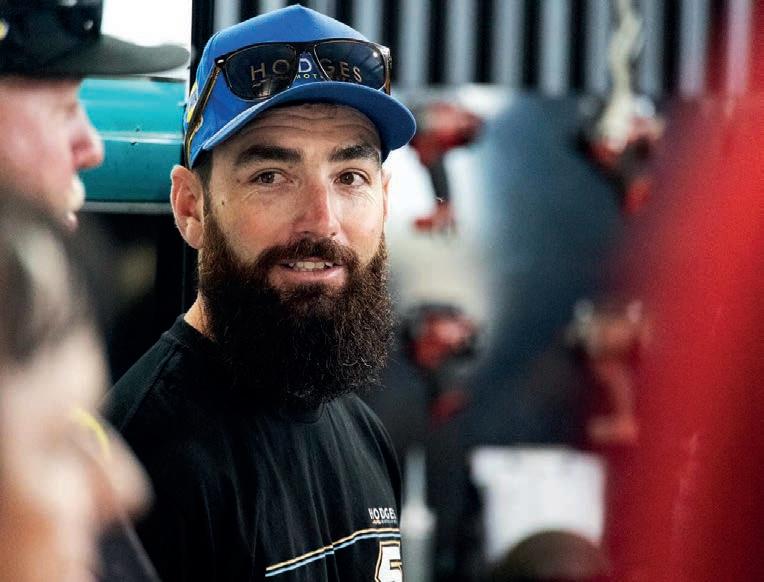

NAPA Auto Parts proud to support James McFadden and Hodges Motorsport

Luck may not have been on the side of the NAPA Auto Partssupported Hodges Motorsport entry spearheaded by local ace James McFadden, but the potential was proven during the 2023/24 Speedway season.

In its second year of partnership, NAPA Auto Parts and James McFadden proved it was a frontrunner during a competitive season of speedway competition.

A collision at Max’s Race at Premier Raceway, Warrnambool kickstarted the season after finishing fifth in the opening heat before the new Toyota engine was installed post-Christmas for the annual Speedweek beginning at Borderline Speedway in Mount Gambier where third was the result.

McFadden was quickest overall in the second night action at Avalon as the narrative of the summer continued where strong pace was curtailed by further contact as the Hodges Motorsport crew repaired the entry ahead of another trip to Premier Speedway in Warrnambool.

Wheel’s up

A superb drive from 11th led to third for McFadden as the President’s Cup at Avalon was scheduled next, though adverse weather led to it being delayed

until later in the campaign, though Hodges Motorsport elected to skip this to prepare for the Australian Sprintcar Championships.

But before this, it was time for the prestigious Grand Annual Classic at Warrnambool and McFadden was once again near the front scoring second, but in the main event the leader lost control in front of the NAPA Auto Parts entry leaving nowhere to go.

One more event is the Australian Sprintcar Championship to be run again at Premier Speedway in Warrnambool where McFadden is certain to be a contender.

It’ll cap off a superb season for NAPA Auto Parts and Hodges Motorsport as it continues to build the profile of this discipline through McFadden’s various media appearances no matter if it was in print, podcast or video.

The Flying Horse Hotel in Warrnambool has been a keen supporter through the Speedway season by activating the J-Mac Bar, a beer dedicated to the local driver on tap and McFadden’s Knoxville Nationals winning entry on display.

McFadden continues to demonstrate why he is regarded as one of the best Australian drivers and will this year return to the United States to contest the World of Outlaws Series.

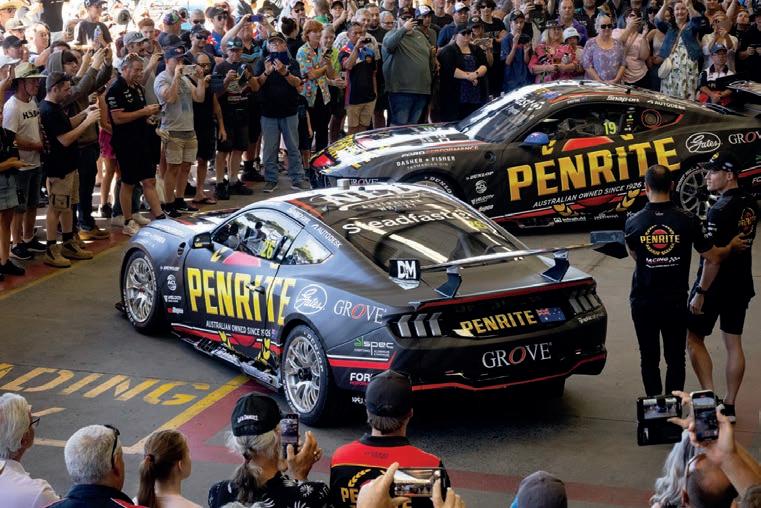

innovation reign supreme, Penrite Oil stands as a testament to the enduring value of expertise, dedication, and a relentless pursuit of perfection. As Supercars racing continues to evolve in the Gen3 era, the partnership between Penrite Oil and Penrite Racing remains a shining example of how an Australian, family-owned lubricants company can play a pivotal role in driving the success and excitement of top-tier motorsports. Penrite’s journey alongside Supercars is not just a sponsorship – it’s a thrilling collaboration that fuels the spirit of competition and pushes the boundaries of what’s possible on the racetrack.

Bendix has joined forces with Matt Stone Racing (MSR), as the new naming rights partner on Nick Percat’s 2024 Supercar, for the full 2024 racing season.

It’s the first time Bendix has participated in Australia’s top tier motorsports category as a naming rights partner of a team, with the livery revealed on Percat’s Gen3 Camaro at MSR’s launch day on February 9.

“It’s great to have such a fantastic brand like Bendix partnered with Matt Stone Racing and involved in Supercars this year,” Team Owner, Matt Stone, said.

“There is a lot of continuity with Bendix and many of our other partners that are involved in the automotive space. It really bolsters the strength of the MSR family of partners as we head into a big season.

“The Bendix Racing Supercar that Nick looks great in the renderings, and I can’t wait for fans to see it in a few weeks’ time.”

FMP Group Australia – Bendix CEO, George Kyriakopoulos, said the company was excited about its new association with MSR, and the opportunities the partnership would bring.

“Bendix is looking forward to supporting a professional and competitive outfit such as MSR in 2024, while at the same time reaching important demographics for our company: motorsport and driving enthusiasts,” George said.

“Among Bendix extensive range of friction and braking components to suit passenger vehicles, four-wheel-drives and commercial vehicles and buses, are product lines including Ultimate+™ Disc Brake Rotors and Brake Pads, and Street Road Track™ Brake Pads.

“These are dedicated to owners who regularly enjoy pushing the limits of their vehicles at the racetrack in high-speed driving environments, or for drivers who enjoy extra braking confidence on the road as part of the daily commute, or for a weekend blast on a favourite ribbon of tarmac.

Akey element in the appeal of Supercars is that they are based on production models, albeit heavily modified for racing purposes.

It started with the Jaguars of the first Australian Touring Car Championships of the early 1960s, through the Fords, Holdens and Chevrolets of the late 60’s and early 70s. Ford Mustang dominated in 1965 to 1969 and then Holden had their first win. From that point on the Ford vs Holden battle was on.

There were some notable exceptions. In 1971 and 1972 Bob Janes won in his Chevrolet Camaro ZL-1; in 1983 Allan Moffat triumphed in his Mazda RX-7. In 1985 and 1987, fans saw Jim Richards win in a BMW 635 CSi and then in a BMW M3. In between Robbie Francevic won in a Volvo 240T in 1986. Jim Richards and

Mark Skaife brought Nissan home first in 1990,1991 and 1992. But from 1993 to 2022 it has been either Ford or Holden.

Ford with the EB, EF, EL and FG Falcon models, Holden with VP, VR, VS, VT, VX, VZ, VE, VF, ZB Commodores. All legendary vehicles.

So many Australians not only have fond memories of these cars, but they’ve also got one in their garage. Ford registered over 1.5 million Ford Falcon sales over the 1982 to 2017 period. Over 40,000 of these vehicles are still registered.

The iconic Holden Commodore was Australia’s top selling car for 15 years in a row, selling a whopping 3.1 million vehicles. A recent KPMG report indicates that Holden Commodore is still the most

common model registered.

Older cars need care and attention and the right parts. When it comes to the vital suspension, transmission, and engine mount parts mechanics turn to Transgold. Their vehicle coverage is exceptional. From the Holden HT Monaro of the early 70s to the last true VF Commodore, Transgold regularly supplies rubber parts to enthusiasts and their mechanics. It is the same story with Ford. From the early Mark 1 GT Cortina to the Ford Mustang GT, they’ve got it covered. In all they stock hundreds of parts for Holden and Ford models.

They even ensure that you’re going to get the correct part through their professional Part Finder service where you can use the vehicle VIN or registration number to order the correct part.

Aussie car fanatics, start your engines.

The Supercars Championship season has returned, with drivers well and truly acclimatised to the Gen3 Camaros and Mustangs.

The season got off to a suitably historic start at Mount Panorama, with the Bathurst 500 kicking things into gear.

Last year’s winner Brodie Kostecki and Coca-Cola by Erebus took both the driver and teams championships respectively. However, a new season brings with it plenty of changes throughout the many teams and drivers who’ll compete for Supercars immortality in 2024.

Another team undergoing change this season is Blanchard Team Racing (BRT). The squad is doubling in size – two cars will hit the tracks for the team this season.

“The journey from one car to two is a testament to BRT’s growth and potential,” team Co-Principal Tim Blanchard said at the season launch.

“We are incredibly excited about this twopronged attack in 2024 with our dynamic duo of drivers in James and Aaron, and cannot wait to see what we can achieve together.

“We are hungry for success and ready to make our mark on the championship.”

James Courtney and Aaron Love will be driving for BRT this season.

“The entire team has put in a lot of work during the off-season, and our results will speak for themselves,” Courtney said.

“I look forward to working with Aaron this year. He is truly one of the rising stars of the sport, and I am eager to help push him and our team forward.”

Drivers James Courtney and Aaron Love will lead Blanchard Racing Team and its two-car campaign in 2024.

Melbourne’s Team 18 has a reunion on its hand as David Reynolds joins the team for 2024. He’ll be back with Mark ‘Frosty’ Winterbottom – the pairing raced under the same colours in 2015 when Winterbottom claimed the Supercars championship and Reynolds third overall.

“I’m really looking forward to this new chapter, I’d been with my previous team (Penrite Racing Team) for three years,” Reynolds said at the announcement.

“I’m in a Camaro now, so it’s going to be a bit different for me, but I’m really looking forward to getting to know everyone, understanding how they work, see what knowledge I can bring and see how far we can get up the grid and win races.”

Reynolds finished ninth in the driver standings last year, while Frosty finished 15th.

To kick things off for the season, the spiritual home of Aussie motorsport – Bathurst came

alive with the roaring of sportscars for the Bathurst 12 Hour.

The field was rife with Porsche 911s and Mercedes AMGs, with a few more exotic cars including a McLaren Artura, Lamborghini Huracan and Ginetta G55 all making appearances during the endurance classic.

Driving these spectacular beasts were a mix of racing royalty including Valentino Rossi and Craig Lowndes, as well as current Supercars studs such as Chaz Mostert and Broc Feeney.

By the end of the race, it was Queensland’s Matt Campbell who’d take top podium for Manthey EMA (Porsche 911 GT3R). It was his second Bathurst 12 Hour victory.

“Feels awesome, obviously second win, tough day, the weather, everything like that,” Campbell said.

“We were always running at the front and it wasn’t easy with the mixed conditions, thanks to Larry (Laurens) and Ayhancan, they did a fantastic job.

“We kept it off the walls and it was phenomenal. Second win, it’s unreal.”

This will be the second season Supercars teams will use their Gen3 Chevrolet Camaros or Ford Mustangs to compete.

1. B. Kostecki, 2888 pts

2. S. van Gisbergen, 2631 pts

3. B. Feeney, 2441 pts

4. W. Brown, 2,294 pts

5. C. Mostert, 2287 pts

6. C. Waters, 2099 pts

7. A. Heimgartner, 2016 pts

8. A. de Pasquale, 1818 pts

9. D. Reynolds, 1806 pts

10. W. Davison, 1786 pts

It’s a cool relationship with your mechanics,” says decorated Supercars driver Will Davison.

“It means a big deal when they’ve got a can-do attitude, and you know they’ve got your back. You put so much trust and faith in them.”

Will’s the type of driver and personality you just know a team will get behind. Eloquent, amusing and extremely professional, it’s backed by a driving ability that’s seen him reach legendary status after two decades in Supercars. There’s been the 22 victories, 79 podiums and 28 poles. He was runner-up in the

2009 Driver’s Championship, and who can forget those two Bathurst 1000 victories – 2009 and 2016?

Australian Car Mechanic spoke with Will ahead of the 2024 season opener at Bathurst, quizzing him on what happens during his off-season, how important car development is with his Dick Johnson Racing team, and what it’s like to pilot that instantly recognisable Shell V-Powerliveried Gen3 Ford Mustang GT.

Dick Johnson has acknowledged last season was a toughie, but the team’s co-

owner and Will Davison are confident going into 2024, recognising how much work’s been done during the off season. It’s fascinating to hear how motorsport truly never sleeps. “The two chassis we finished the season with, they’re effectively stripped down to a bare chassis,” Will explains. “It’s a very controlled category now (Supercars), but we’re always looking how we can effectively tidy up our build quality; whether that be losing any weight wherever you can, tidying up welds and bracketry and looking to refine build quality. It’s only when you get back to zero can you do that.”

There’s been a mighty amount of offseason development, aiming to get the Shell V-Power Racing Team back at the pointy end. “Aero testing has been done over in America, then we’ve had two or three days of engine testing very early in the new year,” Will says. “Our guys have had a hugely busy off season, with the cars built from the ground up with engine and aerodynamic changes this year.”

Rest assured, Will’s not lording it up on a Monte Carlo yacht downing endless champagnes once the flag falls on a race season. Instead, he’s the consummate professional fully in-tune with what’s

needed before the Supercars circus fires up again. “After the last round there’s a fair bit of tidying up loose ends with the team,” he explains. “We debrief the season, discussing performances, any team restructuring, and attending sponsor events. It takes a few weeks, but then from mid-December I try to make a purposeful sign-off, otherwise it’s allconsuming.”

Fast, not furious

He’s not wrong. Race season runs from February to November, and between events he’s always on call, talking about racing, thinking about it and being in the thick of things at the Queensland factory. With age has come wisdom – at 41, Will’s now an elder statesman of the field – and he applies himself accordingly. “Having had as many years in the sport as I’ve had, you must be mindful to force yourself away from it to recharge the batteries mentally.”

Today’s drivers are proper athletes, and Will’s no different. He’s a regular at Australian triathlons, including the world’s largest at Noosa. Last year he was part of the entertaining Legends Triathlon

ahead of the event proper, taking the start line with the likes of Susie O’Neill, Mat Rogers and Glenn McGrath. “I used to enjoy having a few weeks of no training in the off season, but I actually find it’s therapeutic to get stuck into something on my break,” he says. “I make sure there’s some enjoyable training in there, and I don’t mind then if I’m doing something on Christmas Day or New Year’s Eve.”

Fitness is one thing, but so is staying injury free. How does Will balance the risk versus reward equation? “There’s risk management from a team perspective, and I’ve some things in my contract I can’t participate in,” he says. “You must take a lot of responsibility on your own shoulders. Ultimately, it’s you who pays the price if you end up doing something silly.”

To that end, Will has spent less time cycle training on the road. He’ll use a stationary smart trainer at home with the Zwift cycling app, then hit a criterium (bike) track if he has a triathlon coming up. “I’ve had a few close calls (on the road), been knocked off and suffered road rage incidents,” he says.

“It’s become more common, drivers swerving at you. I do enough dangerous

stuff, I don’t need it on a road bike too!”

Drivers must also keep their eye in between race seasons, so Will says his home simulator gets a decent workout. “It’s a lot about hand-eye reflexes,” he says. “You get the same thing playing ball sports or going mountain biking. You must stay sharp and coordinated and keep those skillsets up. The driving is pretty natural for me to be honest, it’s not

something I get rusty at after a few weeks off over Christmas.”

Will’s raw driving talent has always been at the fore.

He began in karts where he won multiple state and national titles, excelled in Formula Ford and Formula 3, and by 2004 was a test driver for the Minardi F1 team. His full-time Supercars career began with Dick Johnson Racing in 2006, and over the years has driven everything from the BA Falcon to the VE Commodore, MercedesAMG E63 and Ford Mustang GT for the Holden Racing Team, Ford Performance Racing, Erebus, Tekno, 23Red Racing and now, once again, for Dick Johnson.

Having driven such a rich variety of

Supercars across almost 20 seasons, how did the Gen3 Ford Mustang feel on first try last year? “It was a huge change from a driver’s point of view,” Will says. “The cars were simplified and dulled down quite a lot; nothing blew your socks off from a driver’s perspective. There were a lot of things in the design that were controlled rather than custom, so straight away there were a heck of a lot of things you wanted to change because it wasn’t as nice as you were used to.”

With more controlled items in the category – suspension, front geometry, roll bar systems and the like – the opportunity to innovate was lessened. “Things we had a lot of engineering leeway with in the years prior, where we could redesign things how we wanted, we now

couldn’t,” Will explains. “We had to think outside the square, whether that’s how we set the car up or me adjusting my driving style a bit. It still had the core DNA of a Supercar, but engine power delivery and how it handled with less aerodynamics were different. It didn’t do thing we were used to.”

No doubt frustrating for all involved, but improvements are in place for 2024. “The longer we run these cars, the more we’re going to truly unlock their full potential,” says Will. “Last year, early on, the car didn’t do things as good as our old car that we’d designed in-house and had one hundred percent freedom over. But you find new ways to come up with solutions.”

This is where the driver working with the team’s management, engineers and mechanics is vital. Will says after testing the new 2024 Mustang, some fundamental changes to engine mapping and aerodynamics means he’s immediately felt some gains. “In the off season you spend a lot of time doing trial and error,” Will explains. “When you get to the first test session you don’t want to be doing that; you need that spec locked down so you can fine-tune setups and suspensions and any new ideas you may have.”

Engineers are focused on performance, but it’s the mechanics who assemble everything and then prepare the car perfectly. “The mechanics get given a whole heap of numbers they’ve got to input into the car,” Will says. “There’s a lot of jigging from a scrutineering point of view; the way the car sits, the wheelbase, tracking, where the wings sit. They make sure the car’s measured right with toes, cambers and ride heights, and that can change between every single session.”

This is all well and good in the factory, but at the track and against the clock, Will knows the pressure’s immense. “The mechanics are working under the pump, making very quick changes in three or four minutes. Springs in, shocks in, shocks out, ride heights, geometry changes. And they treat the car like it’s their child; they always think they can do things a bit nicer. Look at the adjustments in the cockpit. The angle of my pedals, the way the seatbelts sit, the gear stick material. You’re tweaking and tweaking in a confined space with shed loads of stuff in there!”

Teamwork is everything, isn’t it? Let’s hope it’s a cracking Supercars season with Will and his Mustang mixing it at the front.

Automatic transmissions play a crucial role in the modern vehicle, enabling smooth gear shifts and optimal engine performance. Despite manufacturers’ claims of ‘fill for life’ transmissions, this article aims to shed light on the necessity of regular servicing, especially for individuals engaging in city driving and towing caravans. Additionally, we will explore the impact of high outside and working temperatures on automatic transmissions, unravelling the complexities of maintaining these intricate systems.

WORDS:

JEFF RICHARDS, NATIONAL PRESIDENT, IAME.

WORDS:

JEFF RICHARDS, NATIONAL PRESIDENT, IAME.

Numerous car manufacturers promote their automatic transmissions as “fill for life,” implying that these systems require no maintenance throughout the vehicle’s lifespan. However, this assertion often neglects the real-world stresses that transmissions encounter, particularly in challenging conditions like city driving and towing.

City driving, characterized by frequent stops, starts, and short trips, subjects the transmission to increased stress and heat generation. Over time, this elevated temperature can lead to the breakdown of transmission fluid, resulting

in decreased lubrication effectiveness and potential damage to internal components. Regular servicing is essential to flush out deteriorated fluid and replace it with fresh, high-quality lubricant, ensuring the transmission’s longevity and optimal performance.

Towing caravans places an additional burden on the transmission, as it grapples with the extra weight and strain imposed by the towing process. The increased load translates to higher transmission temperatures, accelerating fluid degradation. In this scenario, regular servicing becomes paramount to prevent overheating, ensure proper lubrication, and maintain the transmission’s overall health and durability.

Understanding the specific challenges posed by towing activities allows vehicle owners to appreciate the importance of proactive transmission maintenance in preserving the functionality of these intricate systems.

Automatic transmissions are highly susceptible to the adverse effects of high temperatures, originating from both the external environment and the heat generated during operation. Prolonged

exposure to elevated temperatures can lead to fluid breakdown, increased friction, and accelerated wear on transmission components. Regular servicing plays a crucial role in mitigating these issues by replacing degraded fluid and ensuring the transmission operates within optimal temperature ranges.

Exploring the intricate relationship between temperature and transmission health provides valuable insights for vehicle owners, guiding them in adopting preventative measures to safeguard their vehicles’ crucial components.

While some manufacturers propose extended service intervals, a more proactive approach is advisable, especially for those engaged in city driving and towing heavy loads. Regular servicing, including fluid changes and filter replacements, not only extends the life of the transmission but also enhances overall vehicle performance. Adopting best practices in transmission

maintenance contributes to a safer and more enjoyable driving experience, ensuring the vehicle remains reliable and efficient. Understanding the nuances of service intervals and best practices empowers vehicle owners to take charge of their transmission’s health, reinforcing the importance of routine maintenance for longterm reliability.

In conclusion, the purported “fill for life” claims by some manufacturers may not fully encapsulate the nuanced demands placed on automatic transmissions, especially for individuals involved in city driving and towing caravans. The impact of high temperatures on transmission health further emphasizes the need for regular servicing to maintain optimal performance.

By adhering to proactive service intervals and embracing best practices, vehicle owners can ensure their automatic transmissions remain reliable and efficient, contributing to a safer and more enjoyable driving experience. The intricacies of transmission maintenance underscore the importance of staying informed and proactive in preserving the longevity and

functionality of these critical components in modern vehicles.

Often vehicle manufactures will list in the vehicles owner’s manual, between what they consider when the vehicle is driven under normal conditions and or extreme/abnormal conditions. This can be considered with city driving and or in towing conditions.

In majority of cases this information can be obtained in two ways by reading and checking the vehicles owner’s manual or contacting your local automatic transmission specialist and asking for advice, as each circumstance can require slightly difference advice to be given.

So, this will or can influence if and when your automatic transmission requires servicing and or attention. By understanding this advice you can schedule a more precise servicing needs that your vehicle requires making it more reliable, safer and better in servicing your needs.

Installing underbody protection can help mitigate a loss of airflow from a bulbar. Image: IAME.

There are also other avenues that can be explored in helping when towing caravans to try and keep the possible issue of the transmission experiencing high temperatures and that is by fitting an external automatic transmission cooler, but making sure that an external cooler application is available for the prescribed vehicle that you have on hand.

In conjunction with this, driving the vehicle in a combination of “D” mode and manual mode so that once the vehicle is up to speed and cruising to the surrounding road conditions, so that the engine and transmission are not under extreme load or the engine rev range is not excessive or the engine/transmission is not hunting up or down, but the engine is purring nicely.

To achieve this state, it may mean that the automatic transmission is not running in its highest gear ratio.

For an example in a Y62 Nissan Patrol V8 with a 7-speed automatic transmission; the cruising gear that it can be mostly comfortable in, is in manual “5th” selection at a cruising speed of around 100km/h, with a possible rev range of around 2,000RPM.

This is only an example as the driving conditions can change and or the vehicle or the vehicle being towed, weight wise can vary. It sometimes can come down to, if there is a headwind or a tailwind being experienced at the time.

Extra

towing caravans and transmission wear continued:

Another area or item is when a Bullbar is fitted to the front of a 4WD, and the vehicle is going to be used especially for towing. When a Bullbar is fitted and because of its design it protrudes more forward of the front of the vehicle than the original bumper bar. Therefore, the gap between the rear bottom side of the Bullbar and the front of the radiator is quite extensive.

So, as the vehicle is driven, the normal amount of air hitting the front of the vehicle comes through the vehicle grill and if applicable, also through the air slots in the front of the Bullbar, but then because of the extensive gap mentioned, the majority of air can take the least line of resistance after passing through the grill and is dumped down onto the road surface and then flows under the vehicle.

Then there is less air that continues through the radiator core reducing the performance of the normal cooling process compared to when it had a standard Bumper Bar fitted. To return to a similar correct amount of air flow that should be, install an underbody protection to the front of the vehicle, please see picture, from the rear of the Bullbar to the front Chassis rail.

Apart from protecting the engine sump area, the major effect it has is to act as a small dam which can then allow a similar amount of correct air being directed through

the radiator keeping it to a similar cooling performance as if the vehicle still had the original Bumper bar fitted.

The referred picture is there as a strict reference as to the message that is trying to be conveyed and has no reference as to what manufacture is required to used.

PLEASE SEE PICTURE AS A REFERENCE ONLY.

Most vehicles in Australia are classed as world cars as they are sold on the world stage. Australia can subject these vehicles to some conditions that are unique to this country so seeking advice from your local or closest transmission specialist about the automatic transmission in your vehicle would help in maintaining and keeping your vehicle in a reliable safe state.

As the vehicle and the transmission moves up in mileage a certain amount of wear particles, because of their micron size can be encapsulated within the transmission oil, so that as the oil is moving around within the transmission so are the wear particles which can over time add further wear and tear to the various components of the transmission.

This can shorten the overall life of the transmission. By changing most of the transmission oil on a regular basis, you are removing a range of these wear and tear particles.

In some front wheel drive or all-wheel drive vehicles the Automatic Transmission filter is incorporated inside the transmission, so, in this situation it would be impossible to change the filter when performing automatic transmission service, therefore changing the oil regularly becomes more beneficial to the longer life of the transmission.

Most vehicle manufacturers now specify and list a certain type of automatic transmission oil that suits their vehicles, so it is critical that the correct oil that is specified for your vehicle is used.

In most cases, it is strongly recommended using the original specified type genuine vehicle manufacture oil that they have listed for your vehicle.

At the time of this article being written, the author experienced the situation with

the automatic transmission in his own vehicle, a, Holden Acadia 2019 with 49,000km where the transmission oil had changed to a very dark red to a black colour depending on the light source used. The start of the oil colour change was noted around the 40,000km mark. Most of the mileage was a combination of stop- start city driving with some trips to and from Brisbane, Sydney, and Melbourne. This mileage driven aligned with the general rule within the industry that the transmission service intervals are

References:

performed between 40,000 to 60,000 km of mileage travelled. So, a transmission service was performed, changing as much oil as possible, and using oil purchased from the local genuine listed dealer. The transmission oil is now a clean bright red colour.

The maintaining a maintenance schedule over the life of your vehicle is the key to a safe and ongoing happy motoring.

Always stay safe and drive safely and keep abreast of what is happening around you.

1. Smith, J., “Understanding Automatic Transmission Fluids,” Society of Automotive Engineers, 2010.

2. Johnson, A., “The Impact of Towing on Vehicle Transmission Systems,” Journal of Automotive Engineering, 2015.

3. Automotive Manufacturer’s Service Manuals and Recommendations.

4. Brown, M., “Effects of High Temperatures on Transmission Performance,” International Journal of Mechanical Engineering, 2018.

High-octane Power Perks program to help grow customers’ businesses while sparking daily joy through exceptional perks.

The newly rebranded Niterra Australia – formerly NGK Spark Plugs Australia –is revving up the benefits for mechanic workshop owners across Australia with the launch of its Power Perks loyalty program.

The leading supplier of automotive and technical ceramics has launched the Power Perks loyalty program, with this Australian developed program designed to be the leading automotive Loyalty Program for Australian Automotive workshops, as well as a showcase for other regions with its simplicity and ease of use.

The new program will see customers instantly rewarded for every NGK, NTK or KYB product they purchase. Points earned for purchases can be redeemed for a digital gift card and a wide range of exceptional rewards, from tools and cool merchandise to travel vouchers and experiential packages.

The Power Perks Program also provides a channel to offer exclusive competitions where winners can take home valuable

prizes from Niterra, there will be prizes like gardening/outdoor tools, electronic and white goods, as well as various vouchers.

Always-on benefits, including discounts for a range of experiences and brands, will also be included as part of the program.

Get rewarded!

“The program will provide our valued customers with a reliable workshop mate that helps them grow their business, while also positively impacting their daily life with some great perks,” Niterra Australia Executive General Manager of Sales and Marketing Paris Mouratidis said.

“Power Perks is about ensuring all our customers feel part of the Niterra Australia family, no matter who they are, where they are located or even how much they purchase – there’s no hierarchy in this program. It rewards everyone who participates,” She said.

Mouratidis said plans are already underway for Power Perks to be extended with exciting new features and functionalities, including gamification elements and competitions with regular

prize draws. Leader board competition will enable friendly competition between mechanics workshops around Australia.

The points breakdown is simple, for every product you purchase you receive a certain amount of points, see below the breakdown of each product and points allocated:

• 1 point for every NGK Spark Plug purchased

• 2 points for every NGK Glow Plug purchased

• 5 points for every NGK Ignition Coil purchased

• 5 points for every KYB Suspension product purchased

• 5 points for every NTK Sensor purchased

Additionally, the program offers the following benefits for members when signing up:

• Earn 50 points on joining

• Earn 50 points on your birthday

• Earn 30 points for completing profile information

• Points can be redeemed for a digital Mastercard, with every 1,000 points earning $20.

RECOGNISING TOP APPRENTICES who are passionate about the aftermarket industry

Over $27,000 in cash and prizes to be won!*

Entries close 30 April 2024

Nominate your apprentice at cap.coop/stars

cap.coop/tc

When it comes to re-using parts, mechanics and their customers can naturally be hesitant.

That’s why ACM Parts implements thorough and diligent quality checking to ensure each component it brings back into the market is of the highest possible quality.

ACM Parts Reclaimed deals with dismantling damaged vehicles every day to harvest components that are fit for re-using in the market.

Vehicles are purchased at auctions across the country, with ACM Parts’ team paying particular attention to quality as well as in-demand parts.

Once a purchased vehicle arrives on-site, it’s carefully checked again to ensure the desired parts are of the best quality they can be for dismantling.

ACM Parts Executive General Manager Adam O’Sullivan said components are checked throughout the process.

“From a Reclaimed perspective, we only sell what we classify as A Class parts,” he added.

“We ensure our inventory person at each site conducts a visual inspection before they can be put into the dismantling process.”

Once a part has been removed from the vehicle and is tagged ready for cataloguing, it’s checked again.

From there, it’s taken to one of ACM Parts’ warehouses, ready for distribution to customers.

O’Sullivan said peace of mind was hugely important to the ethos of ACM Parts.

“We fully appreciate with an engine or transmission, there’s usually hours of labour involved in changing that component,” he said.

“It’s important to us that we give customers confidence that if they’re going to buy a Reclaimed component from ACM Parts, they know they can install that with confidence.

“If there is an issue, we’ll stand behind

that part being replaced and possibly labour hours being covered by warranty.”

Not only does ACM Parts ensure it’s reusing quality components, it’s also playing a role in reducing waste.

Whether it’s through Reclaimed or another arm of ACM Parts, dismantlers take as much as they can from a vehicle from nuts and bolts, even to oils and lubricants.

“A part we can reclaim through the process is a part that doesn’t have to be manufactured in the first instance,” O’Sullivan added.

“Fundamentally, there’s no greenhouse gas emissions involved in the reproduction of those parts. You have the benefit of having the raw materials and not having to start again.”

Autorecyclers in Canada found that reusing an engine can save about 21 tonnes of carbon.

O’Sullivan said those offsets are on top of the environmental and financial costs of bringing new parts from overseas.

“Australia’s a long way from the rest of the world, and the transit cost of moving parts here can be significant to the environment,” he said.

“Not to mention the economic impact; we’re able to put those parts on sale for generally about 50 per cent cheaper than a new part.”

For more information, visit acmautoparts.com.au

Ryco’s specially developed air filters extend vehicle life and reduce dust ingestion by >90 per cent compared to OE parts. Image: Ryco

Australia’s leading filter company Ryco Filters has announced the release of a world class air filter designed specifically for the harsh Australian environment, developed utilising new Air Filter technology originally designed for the GEN3 Supercar program.

Ryco engineers have continued to research and design new ways to ensure fine dust environments are no challenge for their filters. The all-new Ryco NanoCel™ High Efficiency Air Filter was developed and tested in Australia to do just that. Ryco utilised Australia’s only dedicated filtration laboratory with stringent testing procedures to design something that could not only uphold OE standards, but exceed them, taking into consideration what could work for the Australian climate and conditions.

The new patented honeycomb cell structure made up of nano-fibre media was

the inspiration behind name for the newest edition to their range, and incorporates a total of 4sqm of filtration area. For comparison, that’s 4x the filtration area of the OE equivalent. Allowing for a greater amount media to fit into small spaces maintains the engine’s life and flow by acting as a stronger catchment for dust and particulates not visible to the naked eye.

General Manager of Engineering and Innovation, Alastair Hampton, said this of Ryco’s newest air filter; “Research shows there is a direct correlation between dust ingestion and engine life.

After working with Supercars, we knew if there was something we could do in motorsport to extend engine life, we could translate that technology to passenger vehicles. Preventing dust ingestion from

happening early on by designing filtration performance made specifically to combat Australian silica and ambient dust levels would mean fine dust environments are no match for the A5001R.”

The new addition to Ryco’s wide range of products also boasts easy installation, a unique seal design based off the Supercars seal, flame retardant material, and a reduction of dust ingestion by >90 per cent compared to OE. It is just the first release in Ryco’s newest range with more applications coming soon.

The new A5001R Ryco NanoCel™

High Efficiency Air Filter is available from all good Ryco stockists. For full product specification sheets, contact your local Ryco representative.

So, when you’re in the harshest and most rigorous of Australian conditions, Be Ryco Ready.

So many times, in any kind of workshop; automotive, wood working, engineering a job can be held up for days waiting for a small replacement part that snapped. It would be a much better use of time to simply repair the part. That’s where the JB Weld range has you covered when it comes to bonding with three products that enable you to bond anything from glass and tiles to fibreglass and wood.

PlasticWeld

When it comes to bonding hard plastics, ABS, fibreglass, PVC, glass, vinyl or composite materials PlasticWeld will do the job quickly and hold fast.

PlasticWeld is a high strength epoxy adhesive that is quick setting and will bond rigid plastics such as PVC, ABS as well as glass, tiles and metals. It features a high bond strength, cures within five minutes and is clear after curing. It sets in 5 minutes at room temperature and is fully cured in one hour.

Using a 1:1 mixing ratio, PlasticWeld combines to a tensile strength of 3900 PSI.

PlasticBonder Tan or Black

Plastic Bonder Tan and PlasticBonder Black are similar products one sets in a tan colour the other black and these can be used for filling dents, repairing bumper bars, automotive trim, composite panels, fibreglass and a host of plastic parts. This is a quick setting, two-part urethane adhesive.

PlasticBonder Tan and PlasticBonder Black are strong but flexible adhesives that provides long lasting bonds and can be used as gap fillers in many plastics. This flexible bonder cures in just 30 minutes.

These two products are both quicksetting, two-part, urethane adhesives that provide strong and lasting repairs and work on thermoset, carbon fibre composites, thermoplastics, coated metals, as well as concrete.

Using PlasticBonder Tan or Black with a mixing ratio of 1:1 will set in 15 minutes and can be sanded after 30 minutes and offer a tensile strength of 3770 PSI.

These products are not for use on polypropylene or polyethylene.

JB Weld products are available in Australia through HPP Lunds. For more information visit www.hpplunds.com.au or call Ben Leonard on 07 3722 1111.

For auto businesses engaged in longer term projects, Projecta’s INTELLI-START (IS) IS1400 and IS2000 jump starters with patented Rapid Recharge Technology (RRT), are a perfect additional to the equipment list.

RRT adds efficiency and convenience for users and owners. Once the vehicle has been started, the INTELL-START Jump Starter can fully replenish the energy that was discharged during the starting process in just 40 seconds. Simply keep the clamps connected to the running vehicle’s battery and the jump starter is ready for next time.

This technology means INTELLI-START Jump Starters can be used time and time again before needing to be recharged, making it ideal for workshops, holding yards and roadside assistance work. When recharging is finally needed, this can be done using the supplied 5V USB charger. Another benefit is their ability to jump start vehicles that use a variety of battery types including Lithium, Wet, AGM, Gel and Calcium.

The IS1400 is suitable for 12V electrical systems and offers 500A clamp power and 1400 peak amps, more than enough to start petrol-powered vehicles up to 7.0L displacement and diesel engines as large as 5.0L.

The IS2000 uses an all-in-one protection system which prevents overheating, short circuits and surges.

The larger – but still compact – IS2000 model provides even further versatility, with its auto sensing clamp connections making it convenient for use on both 12V and 24V electrical systems. The IS2000 will jump start 12V petrol vehicles with engines up to 8.0L and up to 6.0L for diesels. It can also jump start 24V vehicles – both petrol and diesel – with engines up to 7.0L. This level of performance makes it suitable for passenger vehicles, small trucks, agricultural equipment and mid-sized earthmoving machines. Additionally, the IS2000’s integrated, ergonomic handle allows for easy portability, making it an ideal alternative to cumbersome lead-acid jump starters that are normally moved around on a trolley.

Common to both units are premium spark-free clamps, ‘no solder’, high current

connections for added longevity and performance, intuitive LCD display with real time updates, in-built LED work light, EVA storage case, USB charging port and the ability to be used as a powerbank. The IS2000 also features a ‘set and forget’ docking station for hassle-free benchtop charging.

The INTELL-START range is equipped with premium LiFePO4 batteries, the safest lithium technology available. Projecta’s jump starters also provide more starts with up to 2000 battery cycles – around four times more than competitor Lithium Cobalt based jump starters. This range delivers a substantially longer operating life and provides a smooth and reliable start, time after time. Added durability comes from the range’s rubber moulded impact and drop resistant housing and IP-rated dust and water ingress protection.

MELBOURNE 10 APRIL 2024

Peter Kiourkas has the patience of a saint. Here’s me, a motoring writer, just arrived back in the pits after a dozen full-chat test laps around Winton Motor Raceway. It’s in the updated 2024 Hyundai i30 Sedan N, and I have - once again - failed to properly activate the lap timer, plus I need help going through the car’s many custom menus to select a stiffer adaptive damping setting.

The ace technician at Hyundai calmy and knowledgably takes care of it all, then asks how the brakes are performing and if I need fuel. Next thing I know he’s turned the wheels to full lock, inspecting the inside of the front tyres. “Look how much tread there’s left, you’re not trying hard enough,” he says with a grin.

The 53-year-old is great company at the track, and an absolute font of knowledge about seemingly every aspect of a vehicle. That could be about an old Norton motorcycle motor, the absolute correct tyres and pressures for a 40C track day, right through to the multiple ECUcomplexities of Hyundai’s latest battery electric car. A master of all trades, if you will.

Peter served his mechanic’s apprenticeship at a garage in Belfield in Sydney’s southwest. “We did everything from lawnmowers to trucks, motorbikes, boats and a whole range of vehicle marques,” he says. “Anything to do with a motor, really. It was a driveway service, so I had to fuel cars, check the oil, check the water. It was great to work on a variety of cars, rather than one type of brand.”

As a kid, Peter had always tinkered with push bikes and small motorcycles, disassembling them to discover how

everything worked. “My cousins had little motorbikes, and I’d help take apart the likes of 4-stroke Briggs & Stratton motors to see how to improve them, and what makes them run. It was a great learning process, with a lot of trial and error.”

After serving his apprenticeship, he stayed with the workshop for four further years, becoming expert in BorgWarner transmissions and servicing fleets of hire cars. He then bought a VIP Car Care franchise so he could run his own business, with one of his clients in the early 2000s being Volkswagen Australia. “I was their mobile detailer, and then I started doing Daewoos and Inchcape (Subaru distributors) cars as well,” he said.

Peter’s professionalism and talent were recognised with a VW contract in 2002, looking after its head office’s cars, and assisting with VW’s racing Beetles and Mk4 Golf R32s. “I was mechanic on the team, and also did everything from fitting stickers to loading the transporter,” he says.

It was here he was first introduced to what’s involved when a new car is launched in Australia.

Lights, camera, action

The media get shipped in from all over the country to test the latest products, and the cars must be at their absolute best to ensure they make a positive impression. Last thing you want is an influential journalist reporting on a new car that arrives dirty, with the wrong tyre pressures, not run in properly or with an annoying squeak or rattle.

Ever wonder how those promo shots of cars look so good? It’s partly thanks to people like Peter who ensure a car is looking/performing its best.

After a decade with Volkswagen helping manage its press fleet of vehicles he moved to Hyundai. This was in 2012, just as the Korean brand was really hitting its stride to become one of the biggest players in the Australian car market. “The Hyundais are strongly-built,” Peter says of his current employer. “I don’t need to change as much on them as I used to with Volkswagens. And with Daewoo, you could see how they were

built to a price. When I looked after them and saw how they were put together and the quality, I see why they didn’t last!”

When a new Hyundai model arrives in the country, Peter’s role is key. “A lot aren’t on the market yet, and all-new models may have some teething issues,” he explains. “They’ve come from Korea and may be the first of the right-hand-drive ones. If there are little issues here and there, we report

back to the factory for things to get sorted before going on sale. We give them a heads up to have a look on the production line, improve a certain feature or how it’s put together.”

These seemingly small changes can be the difference between a satisfied and dissatisfied car buyer. “A facelifted car is normally already pretty sorted, but if it’s a brand new platform, we check suspension tuning and steering feel, as the Korean

tune will be different to what we want in Australia.”

Before the media get their hands on cars, Peter and his colleagues must work fast. “There’s not much time between getting a car and the launch date,” he says. “The engine and brakes have to be run in, we must check everything’s working, all software and maps are up to date, and

experience the car ourselves to make sure it performs for what’s it’s been designed. The media are the voice to sample our cars, and explain to your mums and dads what a car can do.”

The job’s not always easy. Transporting cars interstate can open a can of dramas. Bumpers may be damaged loading or unloading, suffer stone chips or worse. “I’ve known a truck driver hit a kangaroo and jackknife, or fall asleep at the wheel and run off the road.” There are no winners there, not least the new cars being transported.

Hyundai’s well-received performance ‘N’ brand vehicles are now well established in Australia, and Peter’s been guardian angel for these cars as journalists track test them to extremes. On our test day at Winton, I take a look over what he’s brought along. There’s a trolley jack, some car stands, a compressor with hose and fittings, a battery jump starter pack, puncture repair kit, windscreen patch kit and spare globes. Being prepared comes with experience. He throws in “a pretty decent tool kit” and easy access things like window cleaners, sprays and lubricants. “You’ve got to be prepared for everything,” he states.

Typically, tyres and rims are things most