GENDER DIVERSITY

INDUSTRY INSIGHT

GENDER DIVERSITY

INDUSTRY INSIGHT

UNLOCKING THE MINE OF TOMORROW

United. Inspired.

The SmartROC T30 R is built for the toughest terrains and remote sites, becoming a powerful, reliable partner for consistent performance. Its Smart RCS technology and Epiroc Hole Navigation System (HNS) allow for precise, automated drilling, saving time and reducing explosive use. Designed to tackle diverse challenges, it offers impressive boom coverage, smart controls, and adaptability, ensuring safe, efficient, and timely project completion with remarkable power in a compact size.

Technology is revolutionising the mining sector, with new solutions improving the synergy of the mining value chain, driving higher safety standards, and creating new environmental opportunities.

The beauty of digitalisation is that while a product might have advanced to the point that is delivering tangible benefits for a mining operation, there is often still scope for continued development.

This is where a mining company plays a key role, providing the local knowledge and data to tailor and smarten systems, with the potential to leverage artificial intelligence (AI) to further augment a solution.

The July edition of Australian Mining celebrates the mining sector’s digital proponents, with innovators offering new ways to unlock competitive advantages on mine sites.

Whether it’s Brennan, which is helping miners enhance decision-making through its data and AI offerings, or Orange, which is changing the way mines communicate for the better, or Dendra, which is harnessing technology to help miners rehabilitate land at scale, there are endless options for miners to digitalise and optimise their operations.

This edition also showcases robotics, blasting technologies, next-generation collision avoidance, and end-to-end mineral processing offerings, to name a few solutions.

The Queensland Mining Expo (QME) also takes centre stage in this edition, with more than 300 exhibitors and countless more attendees set to descend on Mackay from July 23–25 for the 30th edition of the event.

CHIEF EXECUTIVE OFFICER

JOHN MURPHY

CHIEF OPERATING OFFICER CHRISTINE CLANCY

COVER IMAGE: Image Source Trading Ltd/shutterstock.com

MANAGING EDITOR

PAUL HAYES

EDITOR TOM PARKER

Email: tom.parker@primecreative.com.au

ASSISTANT EDITOR

ALEXANDRA EASTWOOD

Email: alexandra.eastwood@primecreative.com.au

Alongside the exhibition floor, QME features a free-to-attend Seminar Series sponsored by Komatsu, a series of masterclass workshops in the 500 Pavilion, live demonstrations and presentations, plus exclusive industry events including the QME Opening Party sponsored by Hastings Deering and the prestigious Queensland Mining Awards Gala Presentation Dinner.

Turn to page 54 and find our QME showguide, where you can find the event floorplan, a list of all the exhibitors, and a series of company profiles to get a taste of what’s in store.

Elsewhere in this edition, we spotlight Australia’s emerging rare earths industry, where the likes of Arafura Rare Earths, VHM, Hastings Technology Metals and Iluka Resources are aiming to join Lynas as Australian rare earths producers.

We also profile Liontown Resources and its much-anticipated Kathleen Valley lithium project, as well as Spartan Resources, which is aiming to brings its Dalgaranga gold project back into production.

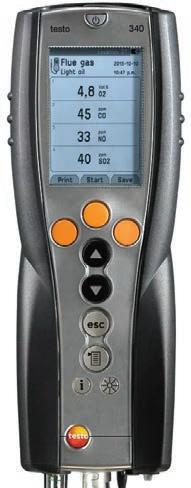

Since its foundation in 1969, ifm has empowered businesses to see the benefits of automation through the development of sensors, controllers and full-scale digital solutions. The family-owned company lives by its commitment to make “technology for everybody”, while protecting what’s important to each customer. This is embodied in solutions such as ifm’s digitalisation platform, moneo, which gives mining companies a simple-to-use means of accessing data analytics from machinery to improve the maintenance, safety and lifecycle of assets.

As part of ifm’s strategy to make technology accessible, the moneo platform is OEM- and vendor-agnostic. This is complemented by a customised service from ifm, whose specialised engineers ensure solutions are tailored to suit a mine’s specific needs.

Tom Parker Editor

JOURNALISTS

OLIVIA THOMSON

Email: olivia.thomson@primecreative.com.au

KELSIE TIBBEN

Email: kelsie.tibben@primecreative.com.au

TIM BOND

Email: tim.bond@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Tel: (02) 9439 7227 Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

ART DIRECTOR MICHELLE WESTON michelle.weston@primecreative.com.au

SUBSCRIPTION

9690 8766 subscriptions@primecreative.com.au

Cover image: ifm

Rare earths enter the spotlight

Australian Mining sat down with some of the biggest players in Australia’s rare earths sector to discuss where the industry is heading.

18 COMPANY PROFILE

Kathleen Valley: Poised for success

With its first production set for mid-2024, the Kathleen Valley lithium project is shining brighter than ever.

22 DIGITAL MINING

Blast modelling in minutes

Amid increasing demand for minerals key to the clean energy transition, mining technology companies like Orica have a critical role to play.

34 DIGITAL MINING

Leveraging the record gold price

Molycop’s processing optimisation services are improving mining operations on a

A tenacious tech-trio Global network and digital services giant Orange Business is helping to revolutionise the mining industry, changing the way mines communicate for the better.

54 WELCOME TO QME 2024

The 2024 edition of the Queensland Mining and Engineering Exhibition marks three decades of Australia’s largest regional mining event.

67 INDUSTRY INSIGHT

A future built on equality Gender diversity has become an essential

to discuss the challenges linked to hydraulic oil cleanliness and the methods mining companies have embraced to overcome these.

By utilising the latest technologies we provide an advanced combination of innovative solutions which optimise our customers mining operations performance, sustainability, availability and safety, around the globe.

• Wear parts and solutions for mineral processing, mobile and fixed plant operations

• Digital and equipment connectivity

• Asset condition and performance monitoring

• Design, engineering and manufacturing solutions

bradken.com We supply:

KEEP UP WITH THE LATEST EXECUTIVE MOVEMENTS ACROSS THE MINING SECTOR, FEATURING TRUE NORTH COPPER, SIBANYE-STILLWATER AND IGO.

True North Copper appointed a new managing director in June, following Marty Costello’s resignation from the position in May.

Bevan Jones began his tenure as managing director on June 10. Jones has nearly 30 years of experience in mine operations and management across a wide range of commodities.

True North said Jones has a proven track record in directing business improvement initiatives and operational transformation.

“These enhancements to our executive team reflect an exciting phase of transition for True North Copper,” True North Copper executive chairman Ian McAleese said.

“We are thrilled to welcome Bevan as managing director and are confident that his extensive operational experience will be a tremendous asset going forward.

“With our focus now fully on restarting mining at our Cloncurry copper project, we are excited to have Bevan on board and believe he has the experience and skill to help us achieve this.”

Jones said he was excited to join True North during what is a pivotal time for the company.

“I am eager to work with the board and team to realise the potential of our prospects, particularly as we set our focus on restarting mining operations at Cloncurry,” Jones said.

Nicholas Curtis resigned as executive chairman of Northern Minerals in May. Curtis will act as a strategic advisor to the company for at least 12 months to provide the company with valuable rare earths and project development expertise.

Adam Handley, a Northern Minerals non-executive director since December 2021, will replace Curtis as executive chairman.

Based in Perth, Handley is a partner of global law firm HFW and was previously president of the Australia China Business Council WA.

He specialises in advising north Asian investors and their Australian counterparts to bridge successful business relationships across a range of sectors including resources, mining and project development.

As Handley joins Northern Minerals, he will primarily focus on fostering strategic stakeholder engagement across state and federal governments and with Iluka Resources, Northern Minerals’ key strategic partner for the Browns Range project in Western Australia.

“I am delighted to have the opportunity to lead the board of Northern Minerals as we advance our vision to deliver Browns Range as a globally significant, Australian-based producer of dysprosium and terbium, two key ingredients in the worlds’ decarbonisation efforts,” Handley said.

May was a big month for moves at the top, with IGO appointing two new leaders to its executive team.

IGO appointed Marie Bourgoin as its chief development officer – lithium, a new role the company created to lead its investment in Tianqi Lithium Energy Australia.

Northern Minerals finance director Shane Hartwig was also promoted to managing director and chief executive officer, where he will carry out functions previously completed by Curtis.

“With the full support of my fellow directors and our new managing director Shane Hartwig, Northern Minerals is well positioned to execute our business strategy, including supplying Iluka Resources’ proposed integrated rare earths refinery at Eneabba, and delivering value for all shareholders,” Handley said.

Sibanye-Stillwater appointed additional members to multiple committees in May.

Harry Kenyon-Slaney and Peter Hancock have joined the audit committee, while Elaine Dorward-King and Philippe Boisseau have been recruited for the remuneration committee.

Boisseau has also joined the investment and risk committees, as well as the social, ethics and sustainability committee.

Like Boisseau, Hancock has joined the investment and risk committees and will also be a member of the safety and health committee.

Bourgoin has over 15 years’ experience working in the resources industry, with previous roles at BHP and Rio Tinto. She will begin her role at IGO in August.

Brett Salt has been appointed as chief growth and commercial officer, where he will be accountable for IGO’s exploration, business development and commercial functions.

Salt has extensive experience working in public and private resources businesses such as iron ore pellet exporter Ferrexpo, Rio Tinto and its subsidiary, Turquoise Hill Resources. He is currently managing director and chief executive officer at Redivium.

Salt’s role at IGO will begin in July.

“I’d like to warmly welcome Marie and Brett to our leadership team and look forward to their contributions as we build on IGO’s outstanding platform for the next stage of growth,” IGO managing director and chief executive officer Ivan Vella said.

“Their initial focus will be on maximising value from our interests in Greenbushes and the Kwinana refinery via the TLEA joint venture. I believe they will bring fresh ideas and energy to these critical assets as we continue to unlock their full potential.” AM

AUSTRALIAN MINING PRESENTS THE LATEST NEWS FROM THE BOARDROOM TO

ALPHA HPA’S FACILITY REPRESENTS THE FIRST COMMERCIAL APPLICATION OF ITS PROPRIETARY LICENSED SOLVENT EXTRACTION AND REFINING TECHNOLOGY.

One of the “world’s largest” historic diamond mines in Western Australia may soon be shining again after its owner was awarded a round of key mining leases in May.

The Ellendale diamond project, nestled in the Kimberley region of WA, hasn’t been touched since 2015 – but new owner Gibb River Diamonds (GIB) has plans to get the mine up and running again.

Since GIB re-assumed 100 per cent ownership of Ellendale from Burgundy Diamonds in 2023, the company has been working towards re-establishing diamond production.

GIB said Ellendale has been one of the world’s largest diamond producers in the past, with previous operators reporting a combined market capitalisation of over $690 million in 2006 on leases now held by GIB.

THE LATEST NEWS EVERY DAY, PROVIDING MINING PROFESSIONALS WITH UP-TO-THE-MINUTE INFORMATION ON SAFETY, NEWS AND TECHNOLOGY FOR THE AUSTRALIAN MINING AND

project execution for the full-scale Stage Two facility having already advanced several key elements of the project’s implementation.

“Construction of the 10-hectare, state-of-the-art, full-scale facility will commence mid-2024, on the existing HPA First project site at Yarwun, near Gladstone, where the company’s Stage One facility is already in small-scale production of its high purity alumina and aluminium materials product range,”

“Stage Two will encompass fullscale production of up to 10,000 tonnes of high-purity aluminium materials per year creating 120 ongoing local jobs on top of 300 jobs

Ellendale’s production included the annual supply of over 50 per cent of the world’s Fancy Yellow diamonds, which were the subject of a special marketing agreement between former operators and Tiffany & Co.

Following the granting of M04/475, M04/476 and M04/477 mining leases, GIB has continued to make progress at the mine.

A heritage clearance survey was scheduled to commence in early June, which is another major step towards recommencing mining.

GIB is also not ruling out any financing options for the project, with debt, equity, earnin partner, joint venture partner, a North Australian Infrastructure Fund partnership, or other government funding schemes on the table.

The theory is simple; to maximize the efficiency of a grinding mill you need the optimal load. But, in practice, the challenge has been to calculate the optimal mill load with precision. Not anymore.

With LoadIQ you can typically increase throughput by 3 – 6%, with some even greater than a 10+% increase in tonnage.

Benefits

■ LoadIQ Smart Sensor technology accurately measures volumetric filling and ore trajectory -- in real-time

■ Combines with data about the ore type and liner profile to determine the optimum mill load

Learn more: flsmidth.com

Carnaby Resources recently hosted a delegation from the Queensland Government at its Greater Duchess copper-gold project at Mount Isa.

The Queensland Minister for Resources and Critical Minerals Scott Stewart was in attendance, as well as Department of Resources Director General Warwick Agnew and Critical Minerals Queensland executive director Paul Holden.

Carnaby said Stewart discussed potential rail haulage options with the company’s managing director Rob Watkins.

“The Carnaby team was delighted to welcome the Resources Minister, Mr Stewart MP as well as Mr Agnew and Mr Holden to the Greater Duchess Project,” Watkins said.

“This visit marks the second by Queensland Government officials in as many weeks.

“Their interest in Carnaby and the wider Mount Isa region is an encouraging endorsement of the potential of the project and its significance as a key development opportunity at a time when battery and critical mineral expansion is required for the energy transition.”

Carnaby is currently progressing the Greater Duchess project to production, with a scoping study set to be released this month.

The Mount Hope, Nil Desperandum, and Lady Fanny major discoveries are standout prospects within the project, where broad high-grade copper mineralisation has been intersected at all three locations.

The tenement package also includes the historical Duchess copper-gold mine which produced approximately 205,000 tonnes at 12.5 per cent copper from 1900–1940.

“Carnaby remains on track to deliver the Greater Duchess scoping study in May 2024 against a backdrop of robust copper and gold prices and continue to advance the project towards development,” Watkins said.

The interest in Greater Duchess comes as Carnaby recently announced a $20 million deal to acquire Hammer Metals’ interest in three sub-blocks at Mount Hope.

The blocks are located at Hammer’s Mount Hope South tenement and adjoin Carnaby’s Mount Hope Central discovery near Mount Isa.

Polymetals Resources has been hard at work since it officially acquired the out-of-action Endeavor silver–zinc–lead mine near Cobar in New South Wales in May.

The company completed a 21-hole due diligence surface drilling program of the upper north lode (UNL) prior to securing the mine, which showed promising mineralisation in all drill holes.

Polymetals has now locked in a geotechnical drilling campaign set to

commence in June and is closing in on a mine plan optimisation study.

“Polymetals has continued its mine plan optimisation work since the release of its initial mine restart study (MRS) in October last year,” Polymetals executive chair Dave Sproule said.

“With the recent strategic investment by Metals Acquisition Limited (MAC), the company is now funded to complete its final optimisation work program, being

geotechnical drilling of the high-grade silver zinc UNL for mine planning optimisation purposes, as well as providing improved resources to reserves conversion.”

Polymetals announced it had formed a non-exclusive strategic alliance with Metals Acquisition Limited on May 27.

The aim of the alliance is to advance the Endeavor mine and MAC’s CSA copper mine, also located in the Cobar Basin.

“We are confident that the planned drilling might generate an uplift in the UNL ore reserves which are planned to be mined over the first two years of production,” Sproule said.

“The high grade and high margin silver and zinc UNL is shallow and has existing mine development allowing immediate access for accelerated mining.

“Results from the drilling will be included along with the additional tonnes identified from within the main orebody in our optimised study.”

25-35% faster delivery

15 in-service life years average Replacement parts costs as low as $0.01/ton

Feed and blend your materials efficiently and effectively with Komatsu’s RF-5 reclaim feeder. Variable speed drives and an adjustable flow gate help ensure smooth operation and minimal maintenance.

For more information, submit your enquiry and our team will be in touch. Exclusive offer: Stock reclaim feeder now available at a special price than customized OE alternatives

SOME OF THE MOST INNOVATIVE PIECES OF TECHNOLOGY TO HIT THE RESOURCES SECTOR WILL BE ON DISPLAY AT THE WA MINING CONFERENCE AND EXHIBITION IN OCTOBER.

The WA Mining Conference and Exhibition (WAME) aims to integrate the innovation and research ecosystem, while addressing the social and environmental standards driving a more sustainable industry.

The significantly expanded exhibition will showcase the technical and digital innovation across the entire mining value chain, while the highly targeted conference will illustrate the economic importance of Western Australia and its contribution to the industry.

WAME will provide mining professionals with the technological insights set to shape the future of the mining industry in WA.

With digitalisation and automation pushing the industry into new frontiers, new technologies will be front and centre, with cyber security managers, technology heads and chief technology

officers in attendance as they look to discover the technological step-change.

WAME show director Siobhan

Rocks said the event is set to feature an impressive number of companies offering advanced technology focused on innovation and decarbonisation.

“The industry has a real appetite for these technologies that are supporting many of the leading mining companies’ goals on decarbonisation and offer costsavings through the latest technological advances,” Rocks said.

As industry and stakeholder engagement is paramount to the success of the mining industry, the conference will also look at the social license to operate and the most effective way to limit the environmental impacts of mining in WA.

Environmental managers, stakeholders, and community engagement managers will hear from industry and government experts.

The conference will also be held in conjunction with the Australian Mining Prospect Awards, which recognise those in the industry who are excelling and going above and beyond.

Last year’s WAME was one of the most successful to date, with almost 5000 visits across the event.

Rocks notes strong attendance among engineers at the last event, representing 20.4 per cent of visitors.

Another 16.1 per cent of visitors identified as senior management.

Major miners were also well represented at the 2023 event, including key personnel from BHP, Rio Tinto, Fortescue, South32 and Newcrest.

“This really is a great event for key industry decision-makers to see what innovative solutions are available on the market,” Rocks said.

“Engineers have also expressed a strong interest in the 2024 event, not only as visitors but also as exhibitors.

“Following popular demand, WAME launched ‘engineering companies offering advanced solutions to the market’ as a new product category for 2024 – and the uptake has been impressive.”

Other new industry categories being launched at this year’s event include Mining 4.0, renewables and circular economy.

WA has long been considered the mining capital of Australia, a veritable cornucopia for the resources industry, where juniors and giants alike come to play.

WAME brings all of this exciting potential together in a single event. AM

The WA Mining Conference and Exhibition will be held at the Perth Convention and Exhibition Centre from October 9–10. Visit waminingexpo.com.au for more information.

ifm are exhibiting at QME JULY 23–25 Mackay Showground, QLD We will be showcasing:

Smart Process instrumentation enabling data-driven decision making for condition-based monitoring.

Collision awareness systems improving personnel safety around heavy mobile equipment.

Vibration Monitoring maximising asset operational uptime and minimising maintenance costs.

Anomaly detection enabling enhanced predictive maintenance of critical assets.

Sensor2Cloud to collect and monitor data from remote assets. Unlock valuable data from your mining operation

IO-Link is an easy and effective way to start collecting data from your assets and improve your business decision-making.

How do you benefit from IO-Link?

Allows devices to send and receive significantly more data

Receive digital measured values and process data from the sensor without any conversion losses

Parameter setting and monitoring via software

Reading and logging of event and diagnostic data

To protect, you need to predict.

The ifm moneo platform goes beyond monitoring and detection, it gives you full visibility over your assets.

Uptime

Throughput

Real-time monitoring

Energy savings

Predictive maintenance

Reduced waste

Reduced costs

Simplify the integration of digitalisation concepts into existing systems.

Scan the QR code to find out more.

AUSTRALIAN MINING SAT DOWN WITH SOME OF THE BIGGEST PLAYERS IN AUSTRALIA’S RARE EARTHS SECTOR TO DISCUSS WHERE THE INDUSTRY IS HEADING.

Rare earths aren’t such a rare phenomenon anymore.

With industry majors and minors alike keenly invested in the future of Australian rare earths, there’s never been a better time to lift the lid on what’s going on in the sector.

Leaders from VHM, Hastings Technology Metals, Arafura Rare Earths and Iluka Resources offered up insights into where the industry’s at and where it’s heading.

But first, what are rare earths? And why is this commodity group becoming such an industry hot topic?

A set of 17 nearly indistinguishable metallic elements with names that can only be described as a mouthful, rare earths have diverse applications in everything from electronic components to magnetic materials.

The most well-known and currently sought-after rare earths are neodymium and praseodymium, affectionately dubbed NdPr.

The products created from the NdPr mix are a crucial part of our renewable energy future. Every electric vehicle (EV) drivetrain requires up to two kilograms of NdPr oxide, whereas a

three-megawatt (MW) direct-drive wind turbine uses 600kg.

It’s an undoubtedly useful cocktail, one the world is going to need more of as the race to net-zero intensifies.

So, who is sourcing rare earths for Australia – and the world’s –critical future?

One prospective producer set to make an impressive debut into the rare earths sector is VHM.

The company’s flagship Goschen project in a premier mineral sands province in north-west Victoria boasts a proved and probable ore reserve of 199 million tonnes (Mt).

The scalability of the project is underpinned by a significant mineral resource inventory of 629Mt comprising measured, indicated, and inferred resources with further resource expansion potential.

Having recently completed the bilateral government public hearing process for the project’s environmental permitting assessment, Goschen is

“Based on just the expected future sales of EVs, the global market is heading into a period of under-supply where producers like VHM will be well positioned to step up and meet demand,” Douglas told Australian Mining.

Of course, any industry has its challenges, and Douglas said the rare earths industry is facing one major trial ahead.

“Right now, the industry is dominated by China,” Douglas said. “It’s hold on the supply chain can change supply and pricing quickly, requiring nations around the world to ask the question: how can we create diversity in supply chains?”

Douglas said the Federal Government is working to shift the ball out of China’s court – a mammoth task for Australia’s nascent rare earths sector.

“The industry is changing,” he said. “One example is we are seeing more detail being provided about pricing mechanisms in offtake agreements.

“There isn’t a handy index for rare earths in China, so the more we participate, the easier it becomes

the benefit of dual commodities, with Goschen set to produce both rare earths and mineral sands products.

“The chance of both our commodities experiencing economic lows at the same time is small,” he said. “It puts the rare earths industry in a great position to operate with stability, especially given rare earths and critical minerals are having their moment in the sun.”

“The timing is perfect for VHM to debut, now we just have to grab the opportunity and deliver.”

Hastings Technology Metals

Hastings Technology Metals’ Yangibana project in the Gascoyne region of Western Australia it touted to contain a rare earth oxide ratio of up to 52 per cent in some areas.

The company is currently progressing the construction of a beneficiation plant at the project, expected to produce up to 37,000 tonnes of rare earth concentrate per year.

The project is well underway with production set to begin in the second

in the supply chain for rare earth materials, the market for rare earths remains challenging in the short-term,” Gilbert told Australian Mining

But Gilbert agreed with Douglas that the long-term outlook is bright, with technologies like EVs and wind turbines likely to drum up rare earths demand.

“We believe the Yangibana project is well-timed to begin production in line with the growing supply gap, which is expected to grow to the size of around 13 Yangibana projects by 2032,” Gilbert said.

In 2024, Gilbert said Hastings will continue putting the building blocks in place to commence construction of the beneficiation plant at Yangibana.

With a 17-year mine life under its belt, Hastings has a long-term vision to unlock the value of Yangibana through downstream processing opportunities.

“Most recently, we announced a multi-stage processing and offtake agreement with Baotou Sky Rock –a privately-owned Chinese magnet manufacturer – which will allow Hastings to realise higher value rare earth oxide pricing for our concentrate

product and deliver attractive project economics,” Gilbert said.

“The increased payability for our rare earth concentrate secured through the offtake with Baotou Sky Rock provides a strong basis from where we can advance project financing discussions.

“We remain focused on ensuring any financing agreement will not only provide for our current and future funding requirements but will be agreed upon in terms that most benefit our shareholders.

“The team will continue to review opportunities to further de-risk the project execution schedule and enhance economic returns.”

Situated 135km north of Alice Springs in the Northern Territory, Arafura’s Nolans project is fully permitted and construction-ready, aiming to become Australia’s first ore-to-oxide rare earths processing facility.

The project has an initial life of more than 38 years, which Arafura managing director Darryl Cuzzubbo said could be extended even further.

“Nolans is one of the few large, hardrock projects in the world that has the potential to help address the significant supply gap forecast to emerge in the global rare earths market over the next few years,” Cuzzubbo told Australian Mining. Cuzzubbo is another rare earths leader all too aware of the challenges facing the industry.

“The key challenge for the rare earths industry – and it has been this way for some years – is establishing a global supply chain beyond China,” he said. “Currently, China processes 90 per cent of the world’s NdPr. That has

led to a very fragile situation around supply security.”

Cuzzubbo said from a risk management perspective, US, Korean and European car and wind turbine manufacturers are eager to support the development of alternative sources of rare earths.

“This is evident in the support Arafura has garnered from car makers Hyundai and Kia and wind turbine manufacturer Siemens Gamesa RE, all of which have signed up as offtake partners for Nolans,” Cuzzubbo said.

“It is also evident in the support the company has received from government agencies Export Finance Australia, Northern Australia Infrastructure Facility and Export Development Canada.”

These agencies have conditionally committed a combined $US525 million ($785 million) in senior debt for Nolans development.

“Reducing Chinese dominance in the rare earths sector won’t be easy on account of the processing capacity and expertise that reside there, but you can see other countries are motivated,” Cuzzubbo said.

“Arafura looks forward to playing an important role by introducing Nolans as another alternative source.”

Forecasts from the likes of Wood Mackenzie have rare earths supply needing to increase at a compound annual growth rate of 6.9 per cent out to 2032 to meet projected demand.

Cuzzubbo believes Arafura is ready to meet that demand into the future.

“The primary objectives for the company this year are to finalise financing for Nolans and begin full-scale construction of the project,” he said.

“From there, we want to ensure that construction and ramp-up to nameplate capacity goes as smoothly as possible and that the company develops into a sustainable, reliable and globally significant supplier of rare earths.

“We want to be able to provide our customers with confidence that the rare earths they are using have been sourced responsibly and in accordance with best-practice mining and processing principles.”

Since the 1990s, Iluka has strategically stockpiled monazite, a rare earths-rich mineral produced from the Narngulu mineral separation plant that forms part of the company’s Eneabba operations in WA.

Now the miner is building a fully integrated rare earths refinery at Eneabba, which has been fully funded under a risk sharing arrangement between Iluka and the Federal Government.

Iluka managing director Tom O’Leary reflected on the future of the rare earths industry at the company’s 2024 annual general meeting.

And like Douglas, Gilbert, and Cuzzubbo, O’Leary is familiar with the challenge posed by China.

“China’s influence over the global rare earths market is pervasive, including through pricing indices such as the Asian Metals Index,” he said.

“For rare earth oxides, China accounts for approximately 90 per cent of all production, and for key heavy rare earths, effectively 100 per cent.”

O’Leary said Iluka has taken a number of concrete steps to catalyse an Australian rare earths industry that is genuinely independent.

“We have entered into a concentrate supply agreement with Northern Minerals that ensures that, upon the development of the strategically significant Browns Range deposit, rich in heavy rare earths, those minerals will be refined in Australia,” he said.

“Discussions with other potential third party concentrate suppliers are ongoing.”

Iluka is progressing key mining developments at Balranald in New South Wales and Wimmera in Victoria, and is commencing a feasibility study into metallisation – the next stage of the rare earths value chain.

O’Leary’s hope is to spread the opportunities provided by Eneabba beyond Iluka to emerging mining companies.

“The principal purpose of these initiatives is to secure the longevity of the Eneabba refinery,” he said.

“But they also serve to spread the opportunities provided by Eneabba beyond Iluka to emerging mining companies, beyond Western Australia to other states, and even beyond Australia producing rare earth oxides for our allies and partners, which is itself a game changing step.”

A strong Australian rare earths industry is steadily coming to fruition every day as operators commence or ramp up production at new mining projects and processing facilities.

While all four of these leaders are keeping a level head when it comes to the future of the industry, there’s no doubting the growing rare earths demand trajectory, with prospective producers like VHM, Hastings, Arafura, and Iluka ready to reap the rewards. AM

We are now better equipped than ever to help you to optimise your comminution and material handling operations for maximum performance, safety and efficiency.

Combining the industry leading screening, feeding and loading expertise of Schenck Process Mining with our mastery of crushing and wear protection, allows us to bring you an unrivalled equipment line-up. We underpin this unique offering with our expert process knowledge, full range of digital tools, high quality OEM spare parts, consumables and life-cycle services.

Scan the QR code to discover why we are the industry’s partner in eco-efficient mineral processing.

Despite the lithium downturn affecting various current and emerging Australian operations, Liontown Resources is only going from strength to strength.

Led by chief executive officer Tony Ottaviano, Liontown has the potential to be a powerhouse of battery minerals production, currently accelerating its flagship Kathleen Valley project to meet growing lithium demand amid the global energy transition.

Located about 60km north of Leinster and 680km north-east of Perth, Kathleen Valley holds a mineral resource estimate of 156 million tonnes (Mt), with over 80 per cent of the mineral resource classified as measured or indicated. Backed by a 23-year mine life and an expected production rate of 500,000 tonnes of spodumene concentrate per annum, Kathleen Valley is well on its way to achieve first production by mid-2024.

Australian Mining looks at some of Kathleen Valley’s most significant achievements over the past 12 months.

Liontown successfully fired its first blast at the Mount Mann open pit in February 2023, signalling the beginning of mining operations at Kathleen Valley.

“Completion of the first blast and commencement of open-pit mining operations at Kathleen Valley is a significant milestone for Liontown, signifying our transition from explorer to mining operator,” Ottaviano said at the time.

“Achieving this milestone ahead of schedule is a testament to the hard work and dedication of the Liontown and Iron Mining Contracting (Liontown’s open-pit mining contractor) teams.”

The first blast area predominantly contained waste rock that was used as bulk fill for construction of the run-ofmine (RoM) pad. A small quantity of the ore blasted was also used to sheet the RoM pad when finalised.

Open-pit mining at the Mount Mann pit concluded in September 2023, paving the way for underground mining to commence in November 2023.

The first blast firing was carried out by Byrnecut and created underground portals at the Mount Mann pit. Liontown said the pit will eventually have six portals to support one-way truck movements and ventilation drives.

The underground mining contract awarded to Byrnecut in August 2023 is the largest for Kathleen Valley, with an approximate value of $1 billion over four years.

“The on-schedule commencement of underground mining at Kathleen Valley is a testament to the dedication and high-quality planning work of our mining team, underground mining contractor Byrnecut, our open-pit mining contractor Iron Mine Contracting, and many others,” Liontown said.

Other companies providing works and equipment to Kathleen Valley include Zenith Energy, Sandvik, Monadelphous, GR Engineering Services, Mid-West LNG, and MidWest Ports Authority.

Liontown launched a $365 million equity raise in October 2023, with proceeds going towards the construction and ramp-up of Kathleen Valley.

That same month, the miner also refinanced an existing $300 million debt facility with Ford Motor

Company, which involved the offtake of up to 150,000 tonnes per annum of spodumene concentrate across an initial five years.

“The launch of the equity raise is a critical achievement in de-risking the development of the Kathleen Valley project,” Ottaviano said.

“This initiative ensures we are funded to first production and beyond.”

The funding included commercial lenders such as Clean Energy Finance

Corporation (CEFC) investing $110 million and Export Finance Australia (EFA) committing $220 million.

“The significant involvement of both EFA and CEFC is another big endorsement for the project and speaks to its global importance,” Ottaviano said.

The equity raise was successful, with 203 million new shares issued to institutional shareholders. Liontown also raised $13.8 million in a share purchase plan.

LIONTOWN PLANS TO INITIALLY DELIVER ABOUT 500,000 TONNES OF SPODUMENE CONCENTRATE PER ANNUM FROM

Federal Resources Minister

Madeleine King welcomed EFA’s commitment to Kathleen Valley, which was provided through an export credit agency facility alongside a group of commercial banks and funds.

“Australian critical minerals projects are vital to ensuring the world has a stable, reliable source of materials to power the energy transition,” King said.

“Global demand for critical minerals needed for electric vehicles and battery technologies is increasing as the world moves to decarbonise, and Australia is key to meeting this demand.”

After Liontown’s $760 million debt funding package fell through in early 2024 amid falling spodumene prices, the company entered into a $550 million debt facility agreement in March to secure the final construction stages needed for Kathleen Valley.

It also ensured the project was funded through first production and the planned ramp-up to 3Mt per annum.

“Having this funding in place provides strong endorsement for our project and a platform of financial certainty from which to move forward,” Ottaviano said.

The $550 million package saw CEFC commit $110 million and EFA $120 million, with the remaining amount coming from other commercial lenders.

Gina Rinehart

Mining magnate Gina Rinehart has been eager to acquire WA lithium assets in recent years. And it was amid this frenzy in 2023 that Rinehart’s Hancock Prospecting snapped up a 7.72 per cent stake in Liontown.

“(Kathleen Valley) is a prospective high quality hard-rock lithium deposit in its development phase, which whilst still having a number of significant risks including resource conversion, construction execution and metallurgical recovery, has the potential to operate at scale,” Hancock said.

“Hancock can contribute to Liontown’s future direction alongside other Liontown shareholders, including in relation to potential investment opportunities for downstream value add in WA.”

October 2023 saw Hancock work its way up to becoming Liontown’s largest shareholder, holding a 19.9 per cent stake.

“Hancock now looks forward to having a prominent influence on Liontown’s future, as its largest shareholder,” Hancock said.

Looking ahead

Construction at Kathleen Valley had hit the 85 per cent completion mark by the end of the first quarter of 2024.

“The March quarter saw tremendous progress across all major work fronts at Kathleen Valley, with construction of the process plant, the critical path to first production, being 90 per cent complete on an earned value basis,” Ottaviano said.

“We are within touching distance of first production and in a very strong position financially with $358.1 million in the bank, together with the undrawn commercial debt facility, providing us sufficient

funding through to first production and beyond.”

To add to the productive start to the year, Liontown crushed first ore at Kathleen Valley in early May.

The milestone was achieved through the company’s crushing circuit at the site, after commissioning of the dry plant commenced in late March.

“The team will now gradually ramp-up the volume of ore through the crusher to build a stockpile of crushed ore,” Liontown said.

“By starting the commissioning process with the crusher, we’re not only testing the equipment but will have clean ore ready for feeding into the wet plant.”

Backed by three foundational offtake agreements with Ford, Tesla and LG Energy Solution, Liontown’s Kathleen Valley project is shaping up to be a leading lithium provider essential to driving a renewable future for Australia and the world. AM

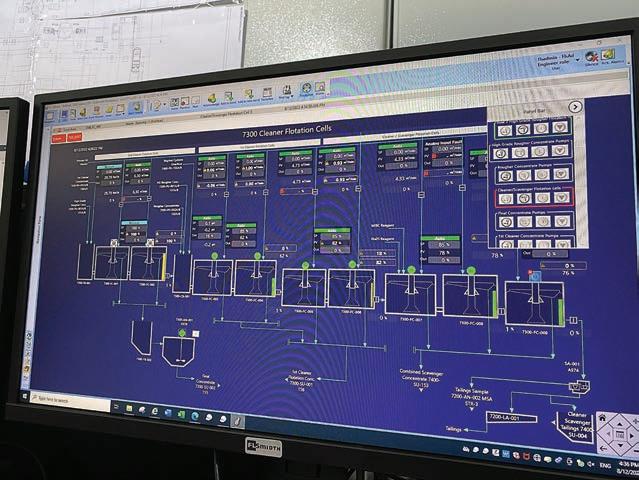

MONEO GENERATES NOTIFICATIONS, WARNINGS AND ALARMS BEFORE ISSUES ESCALATE.

The digital landscape is becoming as well traversed by miners as a road into an open pit. But navigating this new world is tricky without the proper tools to guide the way.

At ifm, the goal is to get miners on the path to success with easily accessible data at the touch of a button.

The company’s moneo platform tracks the minutiae of a mine – every valve released, every gram processed –and collects the data on one platform.

It can be overwhelming and even unnecessary to launch a full-scale data overhaul at once. But ifm’s approach sees the company work with operators to tailor solutions to specific needs.

“moneo serves as the compass, guiding engineers towards operational excellence,” ifm national internet of things business manager Freddie Coertze told Australian Mining

“Our land-and-expand approach ensures that as engineers experience the transformative power of moneo in solving specific challenges, they naturally expand its applications across their operations.”

Digital self-service tools are becoming indispensable assets in the engineer’s toolkit, but what is this data being used for?

“We don’t just want to collect data to be displayed; we transform it into actionable insights operators can use to troubleshoot, analyse and optimise processes seamlessly,” Coertze said.

“The overall mission is to make customers more successful with stateof-the-art technology.”

With ifm’s ‘technology for everyone’ approach, innovative solutions are readily available to all of its customers, whether they want to completely digitise their operation or gather data from one particular area.

“The platform is all self-service with artificial intelligence already built in, so it makes it easy for operators to deploy the knowledge it gathers without needing to be a data scientist,” Coertze said.

“The implementation of that knowledge is made seamless by moneo’s integration with the rest of the equipment on-site.”

“As an agnostic solution, moneo integrates seamlessly with any site’s legacy technology and equipment so there’s no need to develop anything. Our software links up with ifm sensors and collects the data automatically.

“It means there’s no major upfront investment and operators can keep costs low while they decide how they want to expand the technology.”

ifm national product and brand manager Glenn Thornton told Australian Mining that moneo leverages the latest advancements in sensor technology to provide concise real-time digital information about a facility’s operational status.

“These sensors go beyond basic monitoring, offering predictive insights that enable moneo to generate notifications, warnings and alarms before issues escalate,” Thornton said.

“For instance, vibration sensors can detect early signs of bearing faults and excessive machine vibration, allowing for planned maintenance and the prevention of catastrophic breakdowns.

“This translates into significant efficiency gains and productivity improvements for manufacturers.”

Features like level and flow sensors help to ensure optimal lubrication, reducing the risk of downtime and equipment damage.

“By continuously monitoring critical aspects like system pressure and temperature, moneo empowers facilities to maintain optimal operations and achieve increased profitability,” Thornton said.

moneo is designed to reach into and improve every aspect of an operation, from maintenance to stock replenishment – even sustainability goals.

“By tracking elements like how much oil is being used in certain processes and noting anomalies, operators can make macro decisions about reducing waste and lowering carbon footprints,” Coertze said.

“This proactive approach saves time and money, safeguards production schedules and ensures optimal plant performance, all while helping operators reach new levels of sustainability.”

No matter the size of the operation, Coertze said the benefits of using the moneo platform are hard to overlook.

“We’ve had countless operators come to us with feedback saying they’re increasing efficiency across the board,” he said. “And ... with the benefits of remote monitoring, workers are being kept out of sticky situations.

“If there’s a problem, workers know exactly what it is without having to step on-site; they can simply fix it remotely.”

With the future of mining shifting towards autonomy and cloud connectivity, it’s solutions like ifm’s moneo platform that are helping operators take the next step on the journey to fully optimised processes.

“Our goal is to empower organisations with innovative solutions tailored to their unique needs so they can move confidently into the future of mining,” Coertze said. AM

safety

ore recovery Improve visibility of blast outcomes

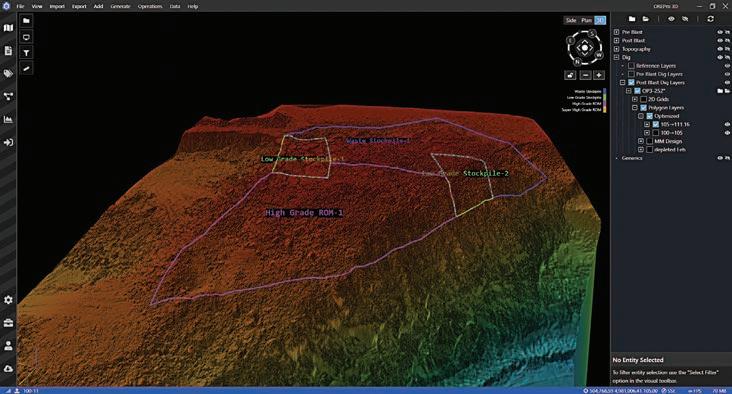

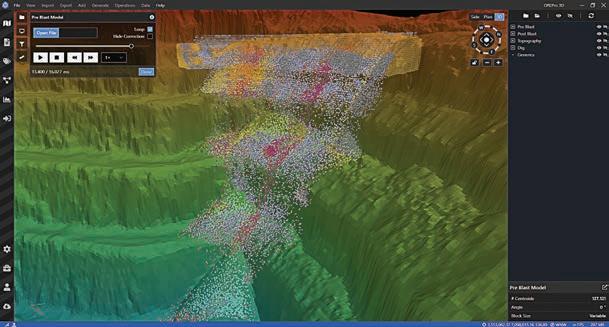

OREPro™ 3D Predict generates blast prediction video that allows you to see the effect of the blast on your grade, and how blasting can maximise recoverable value.

Created using Orica’s blast movement expertise and OREPro™ 3D’s vast blasts database, OREPro™ 3D Predict is a software application that predictively models blast movement without hardware or surveys, enabling iterative blast design for outcomes and improved grade control.

To learn more about OREPro™ 3D Predict and how it can support your operations today, please contact your local Orica representative, or visit orica.com/orepro3dpredict

AMID INCREASING DEMAND FOR MINERALS CENTRAL TO THE CLEAN ENERGY TRANSITION, MINING TECHNOLOGY COMPANIES LIKE ORICA HAVE A CRITICAL ROLE TO PLAY.

Orica has been involved in the Australian mining scene since its earliest days.

Founded in 1874 to supply explosives to the Victorian goldfields, the company has grown to become one of the world’s pre-eminent mining and infrastructure solutions providers.

This year marks 150 years of Orica, and as the company reflects on its proud history, it’s simultaneously compelled to drive the continued evolution of technology and mining smarts.

While deposits are getting deeper and harder to delineate, the demand trajectory for many minerals is surging higher amid an accelerating clean energy transition.

Independent drill and blast solutions are important, but the Australian mining industry is increasingly in need of interconnected, end-to-end solutions that drive improved productivity and safety across a number of operational pillars.

Only then can miners and contractors look to achieve the production targets put to them by boardrooms and greater global demand.

Orica’s 150th anniversary coincides with the 35th anniversary of SHOTPlus, one of the company’s pioneering innovations for blast design and modelling.

“Many of Orica’s significant technological advancements occurred with SHOTPlus,” Orica digital solutions senior manager for technology Matthew Craft told Australian Mining “SHOTPlus has led to and underpinned current products like BlastIQ and OREPro 3D. These fundamental products support our core services but also stand alone as independent products themselves.”

While SHOTPlus has proved to be a revolutionary solution in the design and modelling of blasts, BlastIQ

enables operators to have full control of their blasting process, delivering quality control management of blast design implementation.

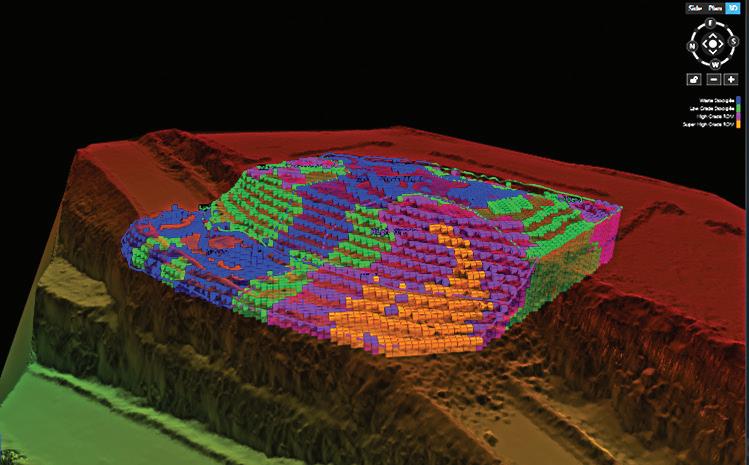

OREPro 3D leverages Orica’s rich background in blast movement and dynamics to provide what is the mining industry’s first solution that optimises grade control in 3D.

According to Orica digital solutions product manager Alfred Tsang, OREPro 3D was developed to meet the mining industry’s demand for a digital solution that ensures safe, precise, costefficient and optimised grade control.

“OREPro 3D enables production geologists to create instructions which help an operation deliver maximum ore value recovery,” Tsang told Australian Mining.

“The technology is not unique to a specific type of deposit. It is used across the industry in multiple commodities, including gold, copper, iron ore, zinc, lithium, nickel and platinum, to name a few.”

The in-situ definition of the ore resource is disrupted when a blast occurs, which means operators cannot

rely on their predetermined assessment of the orebody when recovering the ore and the commodity within that.

OREPro 3D gives operators greater control of the process.

“The OREPro 3D team recognised that there could be a modern blast modelling solution that takes readily available mining data, uses intelligent algorithms to replicate blast movement dynamics, and applies that to the insitu blast volume so operators have an accurate representation of their postblast muck pile,” Tsang said.

“Since OREPro 3D Predict was launched in 2021, there have been some incredible advancements around how we model blast movement and how we optimise the delineation of economical ore in the post-blast space.”

Beyond delivering more accurate post-blast ore recoveries, OREPro 3D helps to achieve better safety and efficiency outcomes.

“With OREPro 3D, we eliminate the need for workers to traverse postblast muck piles,” said Tsang. “It allows operators who would normally conduct in-field measurements to make faster and more accurate assessments from the safety of their office.”

OREPro 3D is automatically calibrated on every blast with the help of topographic surveys, which can be taken by spatial datacapture technologies such as drones, photogrammetry, and light detection and ranging (LiDAR), all of which keep operators out of harm’s way.

Then there’s the efficiency piece.

“Paired with modern computing advancements, the OREPro 3D Predict physics engine is an implementation of Orica’s deep knowledge of blast dynamics,” Tsang said.

“What wasn’t possible a decade ago is now proven.

“In the early 2010s, using the same methodology of blast modelling, where we need to understand material that is broken up into, for example, 10,000 individual rock fragments, this type of processing would take upwards of 24 hours.

“We’re now able to do that same modelling on a blast that’s segmented into hundreds of thousands of fragments in a couple of minutes.

on a production scale, which is important to be able to describe the change in material position from in-situ to post-blast.”

One of OREPro 3D Predict’s key value propositions is its ability to model blast movement ahead of time.

“Once a certain level of calibration is achieved, the OREPro 3D Predict physics engine enables customers to model the potential blast movement and recoverable value before it happens,” Tsang said.

“This is achieved by pairing our OREPro 3D Predict physics engine with a dig line optimiser – an intelligent algorithm that uses modern computer processing power to design and delineate economical ore in the post-blast space.”

St Barbara’s Touquoy mine in Canada reported the benefits of OREPro 3D as a significant reduction in dilution and ore loss.

These numbers are even more impressive when considering that Touquoy is a mill-limited operation.

Reducing waste by 6.5 per cent through the crusher means St Barbara was able to feed additional material from the stockpile, increasing revenue by another $1.1 million.

The ability to conduct accurate pre-blast and post-blast modelling means operators can approach blasts with a multi-dimensional strategy that enables improved ore value recovery and ensures downstream operations can continue at pace.

“Leveraging the speed of the OREPro physics engine and the speed of the dig line optimiser, OREPro 3D can deliver powerful and sophisticated outputs with simple inputs,” Tsang said.

“Because of that drastic improvement in speed, we can afford to have really accurate and granular modelling of that blast movement

Having used OREPro 3D on 33 blasts over 12 months, the mine increased grade by seven per cent and decreased dilution by 6.5 per cent when compared to previous systems. This boosted St Barbara’s revenue by $1 million across the 33 blasts.

“Ultimately, OREPro 3D enables production geologists to meet production pressures and ensures they are no longer the bottleneck in the mine-to-mill process.”

OREPro 3D is made even more intuitive by it’s easy-to-understand workflow, which brings greater functionality and predictability to any mine site. AM OREPRO

Center Sizers are typically used in applications where fines need to be limited, and are often the ideal solution for processing difficult materials such as clays. Due to its design and open passage system, which allows all fines to pass very quickly, sizers can be very compact but still achieve very high capacities.

• Trouble-free operation with sticky and moist materials

• Also applicable for adhesive feed material

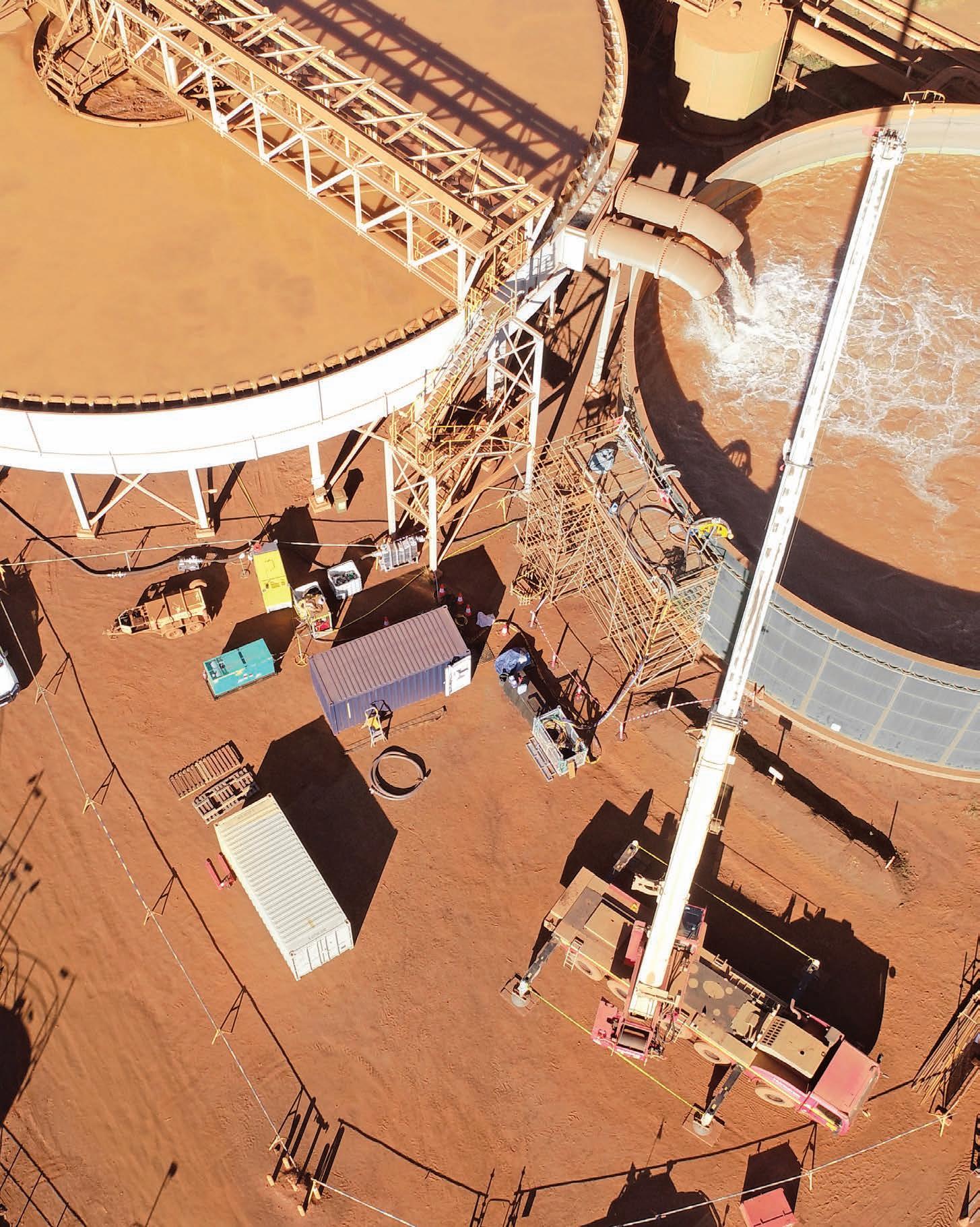

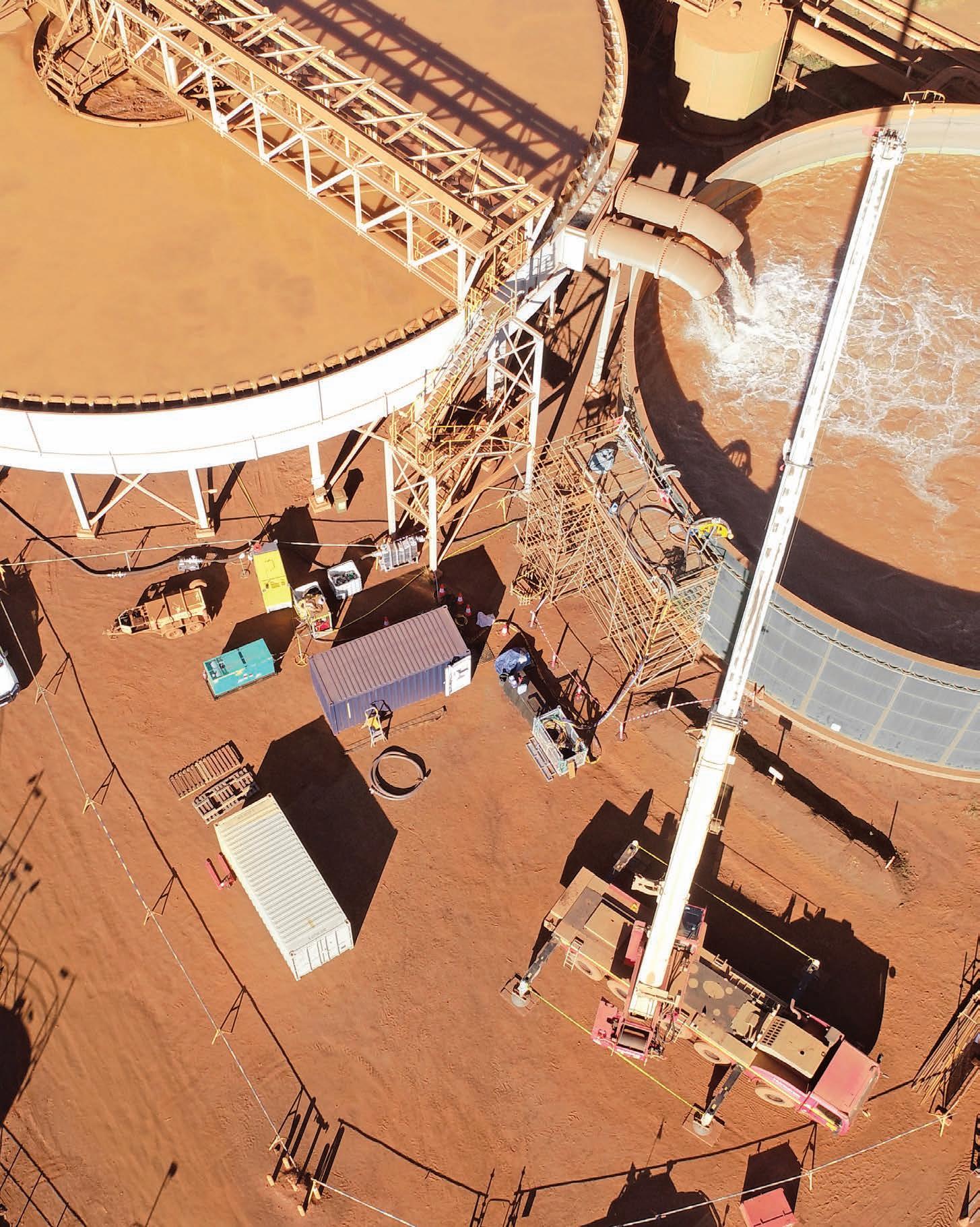

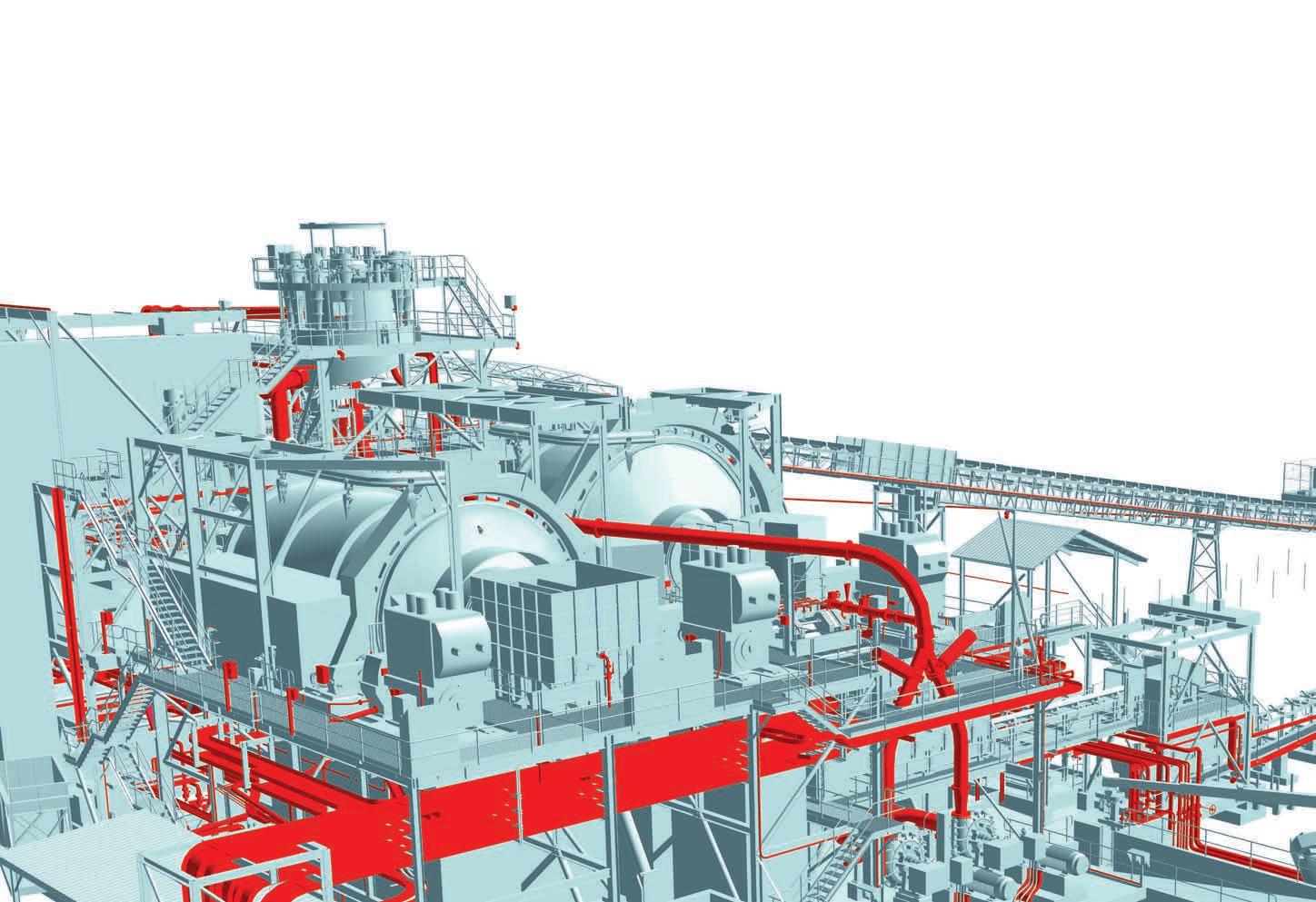

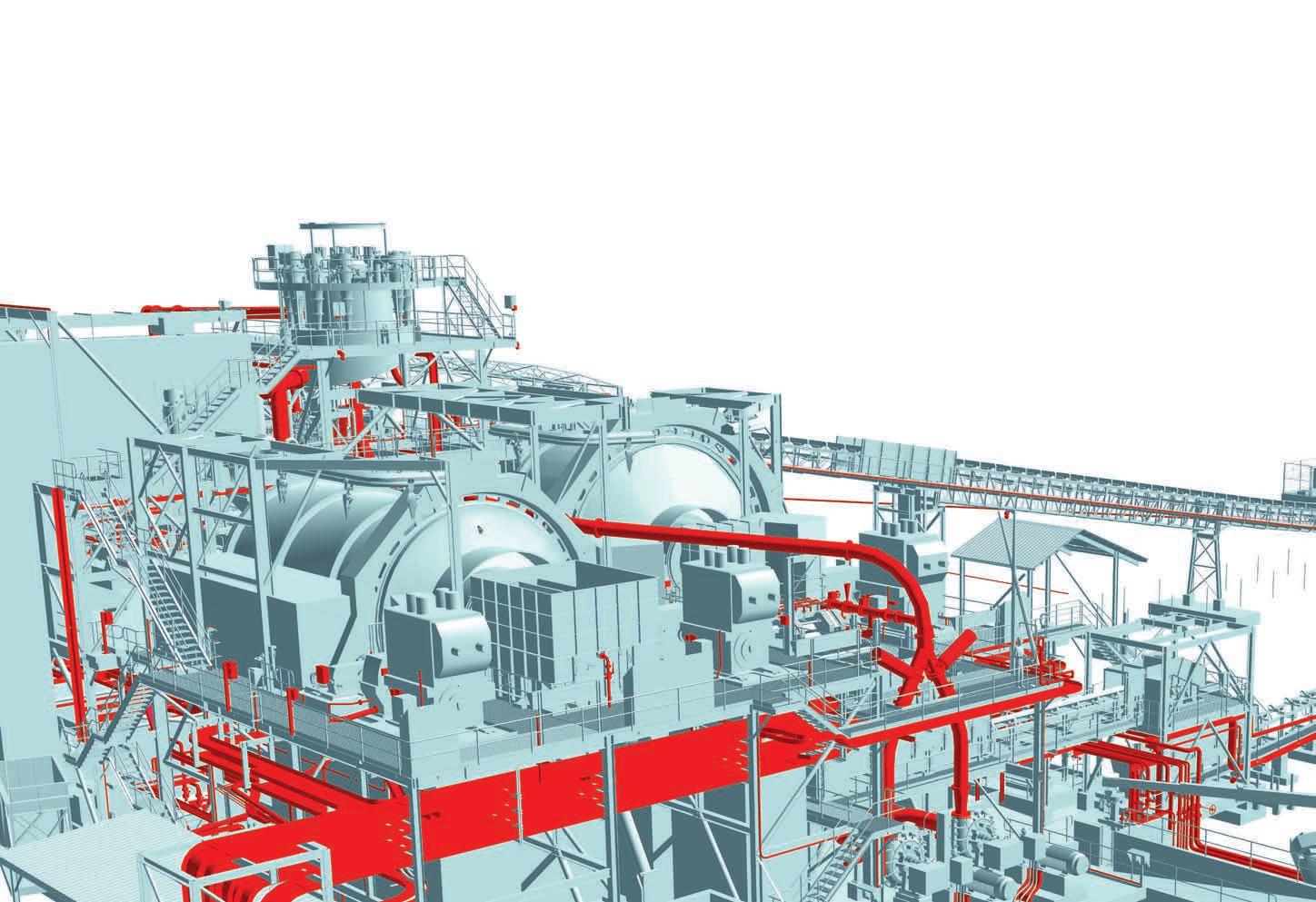

FLSMIDTH HAS BECOME A CRITICAL PARTNER FOR THE AUSTRALIAN MINING INDUSTRY AS THE SECTOR EMBARKS ON A DIGITAL TRANSFORMATION.

FLSmidth (FLS) has been a digital forebearer ever since the earliest computers were invented, with its cement origins necessitating the adoption of pioneering technologies.

In 1969, the same year Neil Armstrong set foot on the moon, FLS developed a digital solution to automate quality assurance in cement production.

The small computer could store up to 16 kilobytes (kB). For context, the computer that transported astronauts to the moon in 1969 had a maximum capacity of 72kB, while a modern-day smartphone has a memory of at least 64 gigabytes.

More than 50 years on, FLS continues to harness its digital ingenuity to boost productivity and efficiency in the mining industry.

While digitalisation isn’t new to the Australian resource sector, it is an everevolving landscape.

“Digital is not new, but it is new when it comes to the relationship between the supplier and the user,” FLS Asia–Pacific regional product line manager – digital Julio Rodriguez told Australian Mining. “In this case, the mining companies and FLS as the technology provider.

“The way in which the user and the supplier interact is new, and therefore we are often asking, ‘How do we structure ourselves internally to best interact with and meet customer needs?’”

For digital offerings to enjoy the greatest uptake, providers need to understand the digital maturity of their clients, while ensuring their digital products are complimentary to a given customer.

As it continues to build out its digital portfolio to match technological advancements in the mining sector, FLS continues to evolve how it supports its customers.

between the OEM (original equipment manufacturer) and the customer, where we are continuously working together to find improvements to a solution.

“This lends to our MissionZero mine, which is focused on efficiency, water management, and licence to operate from a customer perspective. We use digital to achieve this.”

Through the MissionZero mine, FLS has set itself a target of achieving zero-emissions mining through its solutions by 2030. The OEM wants to help miners produce more with fewer resources to create a smaller footprint and reduce operational expenditure.

“One solution that fits into the MissionZero flowsheet is PerformanceIQ, a consultancy and service support program for the adoption of digital technologies,” Rodriguez said.

“We analyse customer data and provide insight into how an operation is performing and whether there are potential pain points that could cause downtime. It is also about ensuring a mine site is operating as efficiently and productively as it can be.

“We jointly adopted PerformanceIQ with Tier 1 miners in North America and South America to great success.”

PerformanceIQ leverages machine learning and artificial intelligence to achieve continuous performance

optimisation. It aims to plug the gap between current performance levels and the ambitious operational targets miners set themselves to meet increasing boardroom expectations.

The PerformanceIQ solution starts with a bottleneck analysis. FLS looks at the various inputs to a mining process, from materials to process control technologies and people, and completes comprehensive audit and technical analysis of operational and maintenance processes.

The OEM then workshops solutions with its customers and identifies opportunities where meaningful improvements can be made. This could see the adoption of FLS’ LoadIQ smart sensor solution, which ensures operators are making the most efficient use of their grinding mill, or the implementation of remote conditionmonitoring services.

Alternatively, PerformanceIQ could determine that an equipment upgrade is needed to avoid breakdowns and downtime in the future.

Opportunities are prioritised based on financial impact and delivery time, and then the lessons are implemented backed by guidance and training from FLS’ PerformanceIQ experts.

The service doesn’t stop there, with FLS continuing to work with its customers to monitor results and make adjustments where necessary.

With a strong international PerformanceIQ customer base, FLS is eager to expand the solution’s presence in Australia.

“In Asia–Pacific, particularly in Indonesia and Australia, we’re starting to see more and more customers enquiring about PerformanceIQ,” Rodriguez said.

“Tier 1 miners have historically completed their technical analysis inhouse, but even they are starting to the see the advantages of partnering with third parties.

“A unique perspective can help operators avoid sophisticated maintenance challenges, particularly when advice is coming from the OEM of their equipment.”

The best operational results are achieved when a miner and OEM lean on each other to get to the root of a problem and develop the best action plan.

“You need the pure OEM perspective because they know every bolt in the system, but you also need the customer because they know exactly how and why they are using a piece of equipment,” Rodriguez said.

“When you’ve got that marriage of the customer bringing their operational knowhow and then the OEM brings their knowhow of the machine, that’s when you see the success stories.” AM

BRENNAN IS ENHANCING RESOURCE OPTIMISATION ON MINE SITES BY USING AZURE AI, A PLATFORM WITHIN MICROSOFT AZURE.

BRENNAN IS HELPING MINING COMPANIES ENHANCE DECISION-MAKING THROUGH ITS DATA AND AI OFFERINGS.

It’s one thing for a mining company to have a wealth of data. But understanding and interpreting that data to achieve key project objectives is a different ballgame entirely.

It’s a situation Brennan understands very well.

With over 27 years of IT experience, Brennan is among Australia’s leading and most trusted systems integrators.

“Key for us is understanding what a company’s objectives are first, then using technology to facilitate those goals,” Brennan Digital director Mal Shafi told Australian Mining.

“In this tight, constrained economy, technological initiatives have to move the business forward while making a return on investment. And that’s what we do.”

One of Brennan’s key portfolios is data, comprising of an extensive range of services and solutions to designed help organisations flourish.

With the emergence of artificial intelligence (AI), data has quickly become an area of increased focus.

One key example is where Brennan is enhancing resource optimisation

on mine sites by using Azure AI, a platform within Microsoft Azure.

“By looking at the large scale of mining, we analyse data from multiple sources to provide a single comprehensive view,” Shafi said.

“From there, mining companies can enhance decision-making around resource allocation, optimising machinery usage, labour and raw materials to avoid downtime and unnecessary spend.

“As one of Australia’s leading Microsoft partners, we use Azure to automate tasks like equipment monitoring and maintenance schedules. This means we can reduce equipment downtime and operational costs through predictive maintenance.

“Using data to predictably, rather than reactively, enhance operations saves time and money in the long term.”

Brennan’s support of AI solutions harnesses and optimises data to identify and analyse potential hazards so companies can ensure they are complying with workplace safety and environmental regulations.

“We can use Azure to improve geological data analysis to enrich exploration by identifying promising drilling areas, increasing the likelihood of discovering new deposits and optimising production planning,” Shafi said.

“An old friend of mine is a geologist and they spend so much time in remote parts of the world collecting huge tranches of data and research to find the next productive mining spots.”

“But if you automate that, you’ll save time and won’t impact the ground as much because identifying higheryielding drill spots are tailored.”

Brennan is deeply embedded in the Microsoft ecosystem, allowing it to deliver unified, scalable and highly efficient platforms tailored to specific customer needs.

“To ensure ease-of-use and immediate value, Brennan has developed Quick Starts, pre-packaged, fixed-price and fixed-outcome solutions that can be rapidly deployed,” Shafi said.

Brennan’s data portfolio has many success stories. One case study involved Brennan building a predictive

maintenance solution to predict the lifespan of a company’s critical assets.

“We have also managed data estates for mining companies by right-sizing and orchestrating the data to ensure its optimised,” Shafi said.

“Previously, people would spend significant chunks of time carrying out database management; by automating that process, those people are able to focus more on business-lead activities. Customer feedback has told us it’s the equivalent of gaining extra headcount.”

Brennan prides itself on improvement and modernisation, ensuring each digital solution it designs, builds and deploys is right for its customers.

“This proactive approach allows us to remain connected with our customers to meet their evolving requirements,” Shafi said. “One of the things they appreciate is our transparency, as well as our ability to look at trending data and go, ‘Hey, this is a common problem in the market. How can we improve it?’

“Brennan wants to be a strategic partner. For every project, our goal is to deliver the outcomes our customers want, providing them with real value.” AM

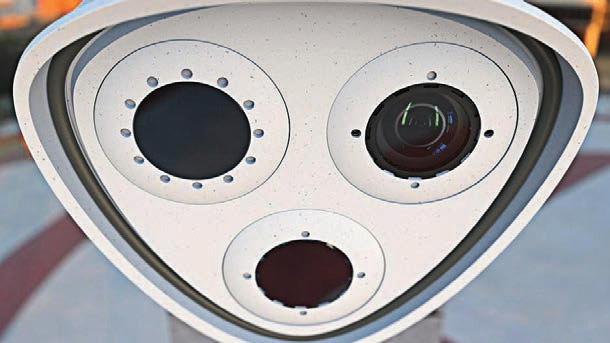

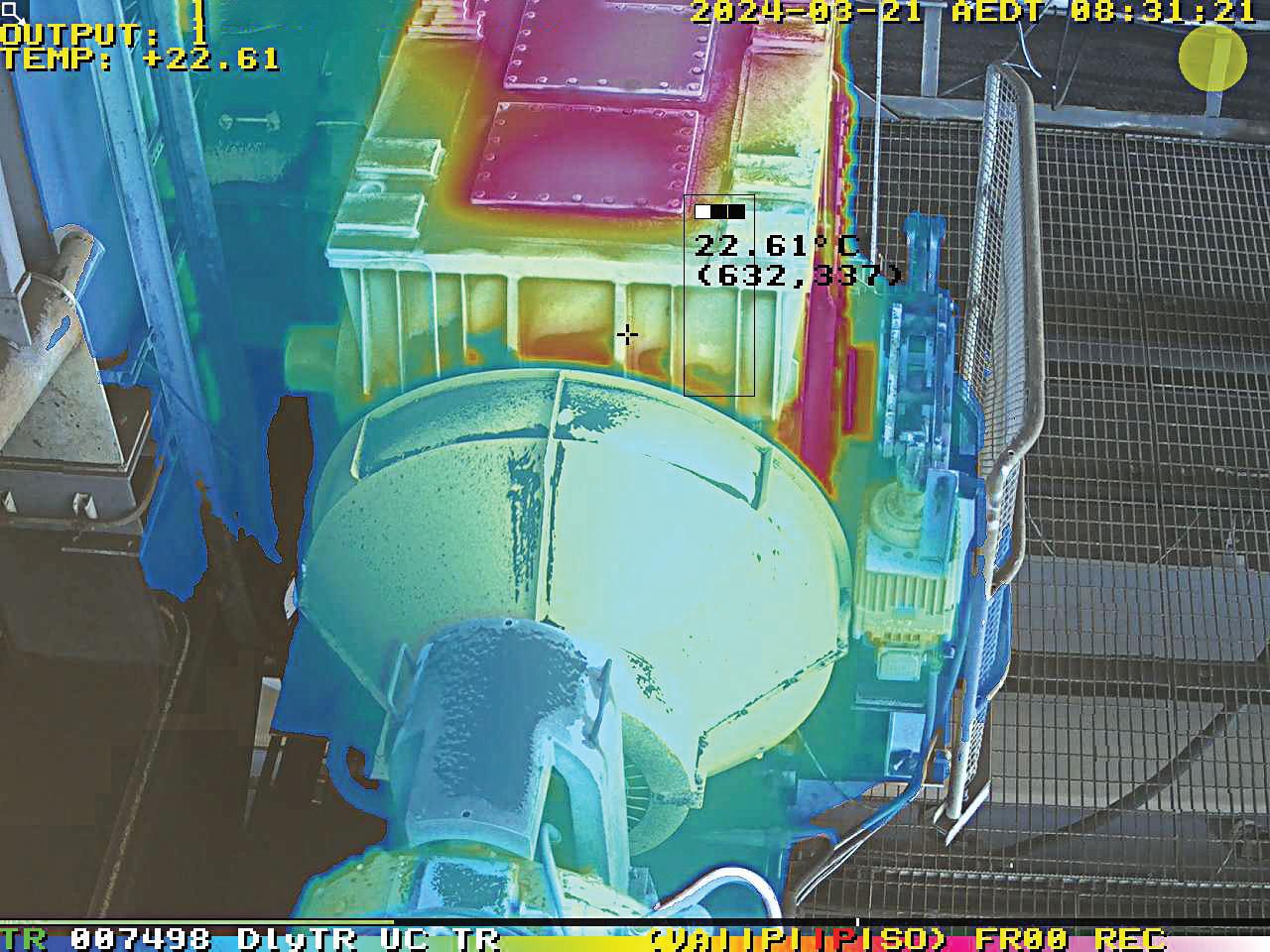

WHEN A LARGE COAL MINE IN VICTORIA NEEDED HELP MONITORING THE TEMPERATURE OF CONVEYOR BELT BRAKES, MADISON TECHNOLOGIES WAS READY WITH A SOLUTION.

An Industry 4.0 enablement partner, Madison Technologies specialises in operational technology solutions architecture, collaborating closely with system integrators and organisations to support deployment.

So when a large Victorian coal mine sought assistance in monitoring the temperature of its conveyor belt brakes, Madison Technologies knew it had the answer.

“Overheating brakes can affect operation of the machinery and lead to breakdown or failure,” Madison Technologies industrial IoT/AIoT program manager Luke Kavanagh told Australian Mining.

“The conveyer belt processes millions of dollars in coal each day and overheating brakes is an early indicator

of potential failure or interruption to service.”

Kavanagh explained the problems faced by the coal miner.

“The purpose of these cameras is to monitor the conveyor brake systems for excessive temperatures as an early warning to prevent fires caused by the ignition of coal dust,” he said.

“Typically the brakes are engaged during the last five per cent of a conveyor slow-down/stop event, however there have been cases of failure causing the brakes to engage while at full speed, thus starting fires due to excessive friction and heat.”

To fix the problem, Madison Technologies turned to Mobotix’s thermal cameras, driven by advanced radiometry artificial intelligence (AI).

While it may seem a simple idea, these cameras do more than just capture images; they also monitor, detect and

prevent fire hazards in real-time.

The coal miner had previously managed the monitoring itself through camera deployment and experienced issues such as false alarms, affecting the accuracy and confidence in the solution.

“Because each camera is covering a large area in order to monitor multiple brakes, false alarms were being generated due to other heat sources in the scene such as vehicles or over exposure due to surface reflection,” Kavanagh said.

“To help with false alarming, we recommended a specific Mobotix AI app that supports monitoring of up to 20 individual areas simultaneously within the camera image.

“By implementing this edge AI, we set up rules to monitor the brakes individually, which improves specificity, performance and reliability.”

An expert in camera solutions, Mobotix is continuously developing

unique solutions for the mining industry. Its new thermal validation app uses machine learning to identify benign heat sources, in turn reducing false alarms.

THE PURPOSE OF THESE CAMERAS IS TO MONITOR THE CONVEYOR BRAKE SYSTEMS FOR EXCESSIVE TEMPERATURES AS AN EARLY WARNING TO PREVENT FIRES CAUSED BY THE IGNITION OF COAL DUST.”

“Our thermal cameras can monitor up to 20 detection zones with custom temperature settings, enabling early fire detection, preventive maintenance, and human exclusion zones within the same field of view,” Mobotix vice president sales APAC Ryan Philp told Australian Mining.

“With modular design, edge processing, in-house app development, key AI partnerships and various communication protocols, we can create tailored solutions for the most complex requirements.”

Mobotix holds five unique certifications for early fire detection using its thermal cameras, including internationally recognised standards. This adherence to safety was one of the main reasons Madison Technologies recommended the Mobotix app to the coal miner.

“Preventive maintenance and early fire prevention through our technology detects anomalies before they are visible to the human eye, potentially saving companies millions in production, but also in lives,” Philp said.

“Additionally, these measures significantly enhance worker safety, a critical priority for companies aiming to protect their employees and maintain their reputation.”

The further benefits of deploying Mobotix thermal cameras are far-reaching.

On top of receiving real-time monitoring and alerts, the coal miner also saw enhanced safety metrics and regulatory compliance, operational

efficiency and predictive maintenance, and increased sustainability and energy management.

The role of technology in the mining industry is constantly evolving, transforming the way the sector protects its workers and its profits. And Madison Technologies is constantly working on developing new and innovative ways technologies can be used to help the sector achieve its goals.

“Robust communication networks ensure seamless connectivity across mine sites, enabling real-time data access and sharing,” Kavanagh said.

“This is crucial for remote-monitoring and immediate hazard response, and boosts safety standards significantly.

“Strong communications networks bridge the physical with the digital,

underpinning every aspect of modern industrial operations, from basic device communication to the complex orchestration of entire operational networks.”

In addition to these networks, Artificial Intelligence of Things (AIoT) and Industrial Internet of Things (IIoT) play a vital role in optimising mining operations.

“Traditional sensors have provided necessary data for monitoring and control, but as demands for accuracy, integration and real-time analysis increase, the industry is pivoting towards more advanced solutions,” Kavanagh said.

“By leveraging predictive analytics, these technologies enable timely maintenance, reducing unexpected downtime and ensuring equipment

WITH MODULAR DESIGN, EDGE PROCESSING, IN-HOUSE APP DEVELOPMENT, KEY AI PARTNERSHIPS AND VARIOUS COMMUNICATION PROTOCOLS, WE CAN CREATE TAILORED SOLUTIONS FOR THE MOST COMPLEX REQUIREMENTS.”

reliability. They also allow for real-time monitoring of environmental conditions and machinery health, providing actionable insights that enhance operational efficiency.”

Camera-based sensors are just one example, but this relatively simple technology has saved the Victorian coal miner thousands of hours of work.

“These sensors not only capture images but also collect rich visual data that can be analysed to inform and enhance decision-making processes,” Kavanagh said.

“The multitude of connected devices in operational environments drives safer, more productive and sustainable mining operations by enhancing data access, connectivity and intelligent decision-making. AM

The ‘80s hardly bring to mind cutting-edge digitalisation.

But in 1983 a digital seed was planted when global software solutions provider IFS debuted its first enterprise resource planning (ERP) solution for a Swedish nuclear power plant.

Nearly 40 years later, IFS has put its years of experience into the latest iteration of its ERP solution, IFS Cloud.

By taking advantage of emerging technology and the changing market landscape, IFS Cloud is designed to maximise the efficiency and agility of mining operations.

It brings together a depth of industry knowledge and embedded innovations like artificial intelligence (AI) and machine learning as well as functionality to support environmental, social and governance (ESG) decision-making.

After seeing great success across Europe and the US, 2MG Solutions is bringing IFS Cloud – and its myriad of benefits – to Australian mines.

Australian-owned and operated, 2MG specialises in project and asset intensive industries such as mining. As an IFS partner, 2MG supports

customers throughout their entire digital transformation journey.

From initial business requirement workshops, solution design, implementation, and ongoing support after the system goes live, 2MG founder and managing director Martin Vestby said the company is fully committed to ensuring its customers maintain an optimal business solution.

“Our close working relationship with IFS ensures 2MG is fully across all the latest functional and technological updates within the IFS Cloud platform. This allows our clients to utilise IFS best practice solutions along with the latest embedded technology,” Vestby told Australian Mining.

IFS Cloud is a complete solution for the mining industry that incorporates and enhances the management of critical

areas such as assets, projects, financials and procurement.

“The solution comes with over 100 inbuilt dashboards known as lobbies, which provide the necessary day-to-day real-time data that mine sites and senior management require,” Vestby said. “With a single source of truth, customers can make well-informed decisions.”

As an alternative to other mining enterprise solutions, IFS Cloud offers a modular, scalable, and functionally rich platform for running a mine site.

“Using the IFS implementation methodology, which combines bestpractice project management principles with focused industry-specific expertise, 2MG ensures that an IFS rollout is tailored to customer requirements, runs smoothly, and delivers on their business objectives,” Vestby said.

This is an ethos 2MG employs when finding the right solution for organisations in the mining sector.

2MG has another ace up its sleeves: 2MG Essentials, an optimised, prepackaged business solution for small to mid-tier miners.

This is a revolutionary introduction to the Australian ERP market where customers benefit from not only the capabilities of a top-tier ERP product but also from the vast industry experience of 2MG solutions, leading to significant time and cost savings.

“The Essentials solution will scale with our clients as they grow and diversify,” Vestby said. “2MG works closely with its customers to ensure they continue to operate with an optimal IFS solution, meeting their ongoing business requirements.”

IFS Cloud enterprise asset management can be implemented as a standalone solution which integrates nicely with customers’ other business systems.

For 2MG, it’s all about finding the best solution for the customer, which Vestby said is the driving force behind all 2MG endeavours.

“We prioritise collaborative partnerships based on trust, cooperation, and result-driven outcomes,” he said. “Whether it is navigating challenging business requirements or integrations with other systems, nothing is too difficult for 2MG.” AM

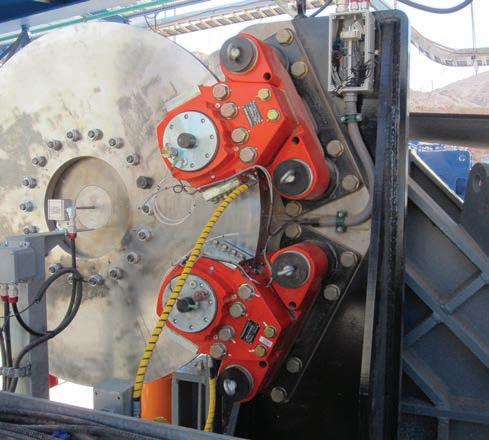

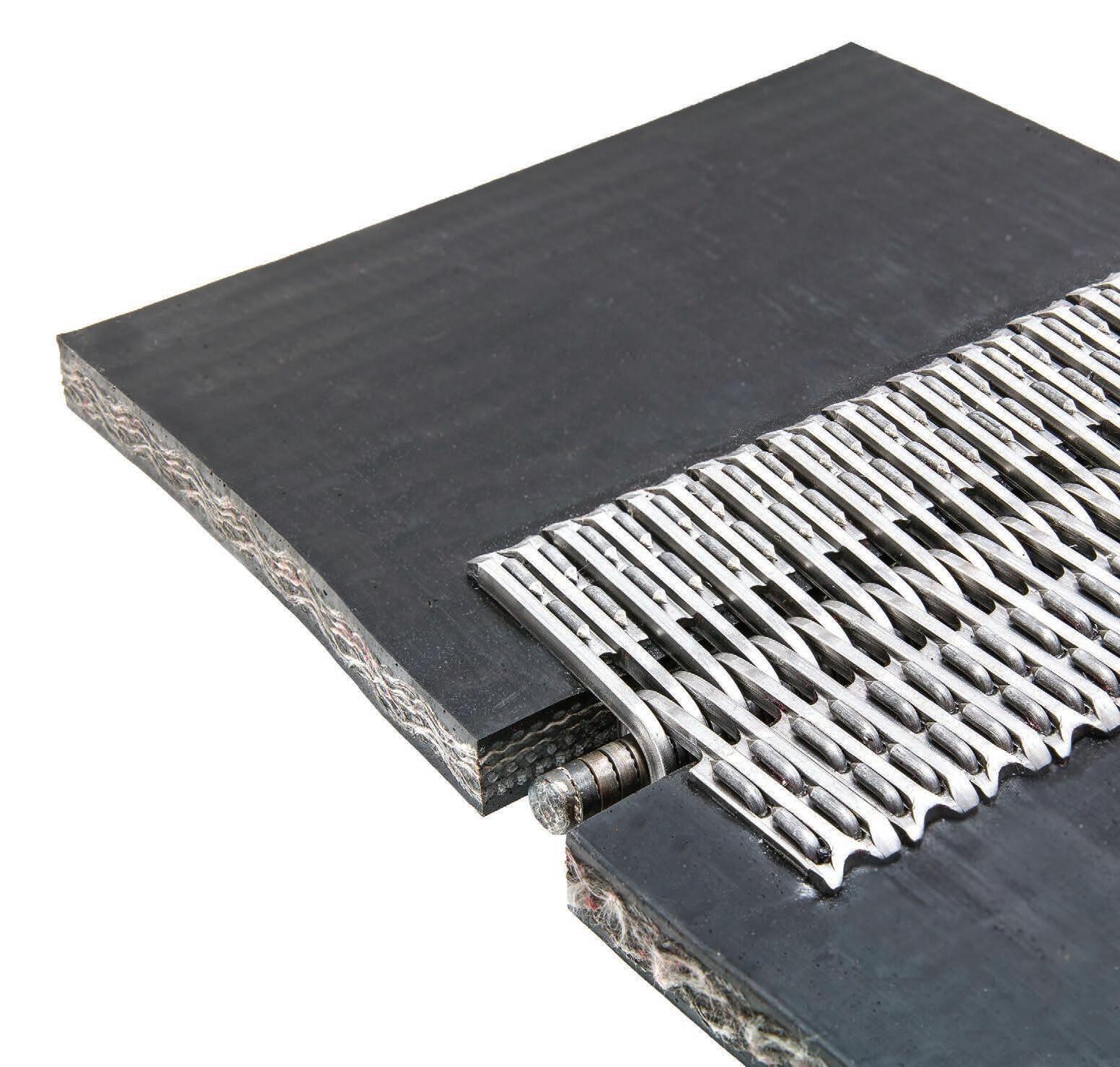

With an increase in tonnages and declining conveyors with several hundred metres of drop, the installation of intelligent soft braking systems to address the starting and stopping requirements under various load conditions is an imperative.

Svendborg Brakes’ unique SOBO® soft braking control provides a range of safety and durability benefits in harsh mining applications. Decelerating and stopping heavy conveyor loads is critical, and controlled braking is essential for a significant reduction of torque peaks, preventing belt and mechanical component damage.

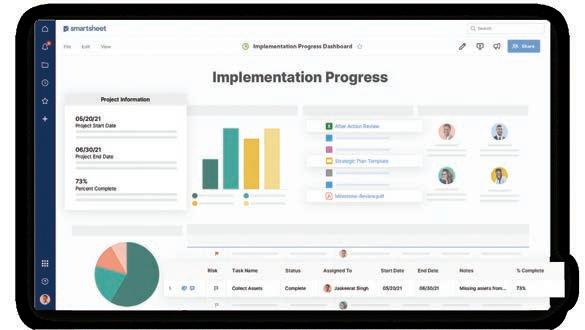

SMARTSHEET FACILITATES REAL-TIME COMMUNICATION, DOCUMENT SHARING AND TASK MANAGEMENT.

FROM HUMBLE BEGINNINGS IN 2005, SMARTSHEET HAS GROWN TO BECOME ONE OF THE WORLD’S

LEADING ENTERPRISE WORK MANAGEMENT PLATFORMS.

When the Smartsheet platform was first created, the vision was simple: empower companies to define which areas needed to be tracked and organised to foster greater efficiency.

“Smartsheet provides what spreadsheets cannot: a single version of the truth presented in a common language anyone can understand, with structure that enables reporting, alerts, automated workflows and better data quality,” Smartsheet account executive for large enterprise James Macartney told Australian Mining

“As the user base has grown, Smartsheet has expanded its vision and continued innovating by targeting larger teams, divisions and, ultimately, whole global enterprises.”

Smartsheet is now present in more than 80 per cent of Fortune 500 companies, with over 13.5 million users across more than 190 countries.

The platform is used to facilitate real-time work management, communication, document sharing and task management, enabling teams to coordinate activities, manage resources, and mitigate risks across a wide range of industries; one being mining.

Mining companies can use Smartsheet to improve access to capital and specialised equipment and services, ensure regulatory compliance, obtain land, and leverage technical expertise, among many additional solutions across the mining lifecycle.

“Australian mining companies can struggle with effective collaboration and consistent reporting due to factors like remote work, siloed operations and inconsistent manual systems and processes,” Macartney said.

“Users can spend a significant amount of time updating projects and gathering incorrect data for strict reporting requirements. Before using Smartsheet, our mining customers were knee-deep in spreadsheets and presentations and were flooded with meetings.

“Smartsheet took away that burden while giving executives the reporting they needed at any location, time or date.”

Smartsheet’s project planning capabilities extend beyond the day-today workflow; it can also help users track and manage tasks associated with environmental compliance, monitoring, and reporting.