COPPER SPOTLIGHT

INDUSTRY INSIGHT

VOLUME 116/07 | AUGUST 2024

NEXT-GENERATION TECHNOLOGY CAPTURES INDUSTRY ATTENTION

COPPER SPOTLIGHT

INDUSTRY INSIGHT

VOLUME 116/07 | AUGUST 2024

NEXT-GENERATION TECHNOLOGY CAPTURES INDUSTRY ATTENTION

United. Inspired.

Introducing the new long feed SmartROC C50, designed to maximize productivity and reduce costs. This advanced COPROD rig extends drilling time and minimizes rod changes, leading to less wear on consumables and lower fuel expenses. Renowned for its speed and efficiency, the SmartROC C50 is now capable of greater hole depths, of up to 37 meters. Ideal for mining and quarrying, it combines power and precision for superior performance.

Dubbed the world’s largest mining show, MINExpo takes over Las Vegas from September 24–26, bringing together all the big mining industry names.

Caterpillar, Komatsu, Liebherr, Hitachi, Sandvik and Epiroc will feature prominently at the event, as will the Australian Pavilion, located at booth 2921 in the North Hall.

Presented by Austmine, the Australian Pavilion will host 34 Aussie companies doing great things in the mining industry. Each will have their own booth inside the pavilion.

This includes software pioneers, safety innovators, training providers, AI specialists and everything in between.

As Austmine chief executive officer Christine Gibbs Stewart attests, MINExpo is significant in more ways than one.

“While MINExpo is in the United States, it’s not strictly a US show because it attracts people from all over the world,” Gibbs Stewart told Australian Mining.

“While you have a lot of US miners walking through, you also have miners from Latin America, Europe, Asia, Africa, and Australia.

“Companies want to promote what they do, talk to potential customers, make new connections, and find out about the US market and how it works.”

You can turn to page 50 to see what’s in store for MINExpo 2024.

This edition of Australian Mining also gives us the opportunity to celebrate Mineral Resources’ (MinRes) achievement at its Onslow Iron project, a groundbreaking

CHIEF EXECUTIVE OFFICER

JOHN MURPHY

CHIEF OPERATING OFFICER

CHRISTINE CLANCY

MANAGING EDITOR PAUL HAYES

EDITOR

TOM PARKER

Email: tom.parker@primecreative.com.au

ASSISTANT EDITOR

ALEXANDRA EASTWOOD

Email: alexandra.eastwood@primecreative.com.au

iron ore operation that’s unlocked stranded deposits in the west Pilbara region of WA.

MinRes recently celebrated its first Onslow iron ore shipment, with 113,000 wet metric tonnes setting sail for China.

Elphinstone graces the cover of this edition, with the associated story showcasing the company’s range of mining products, including the E15 range of machinery which has seen Elphinstone partner with Jetcrete Oz and the Ernest Henry copper-gold mine northern Queensland.

Elsewhere, we showcase offerings from the likes of Tier 1 original equipment manufacturers Caterpillar, Hitachi and Komatsu, while innovations from Hexagon, Vocus, Orica and Bradken also take the spotlight.

On the events front, Australian Mining profiles all the winners from the recent Women in Industry Awards. We also look back at the 2024 PNG Industrial and Mining Resources Exhibition and Conference.

Rounding out this edition is a look at the unheralded critical minerals. Turn to page 90 to find out more.

With 45 years in mining, Elphinstone is an authorised Caterpillar OEM and a leading manufacturer of quality products for the global underground and surface mining industries.

Elphinstone’s product range includes specialised underground support vehicles, mine extraction devices, and surface mining solutions including extended distance off-highway haulage trucks and water tanks to suit Caterpillar articulated trucks.

Elphinstone introduced its new low-profile E15 series in January, which has been a welcome addition to the existing range of E10 (formerly WR810) underground support vehicles.

Models in the E15 range include the 7m³ agitator, the E15 delivery (with wireless remote crane), E15 flat deck, E15 water tank for dust suppression, and E15 fuel and lube service truck, with various other configurations presently in development.

Tom Parker Editor

JOURNALISTS

OLIVIA THOMSON

Email: olivia.thomson@primecreative.com.au

KELSIE TIBBEN

Email: kelsie.tibben@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Tel: (02) 9439 7227 Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

ART DIRECTOR

MICHELLE WESTON

michelle.weston@primecreative.com.au

Cover image: Elphinstone

Onslow Iron: A new era

With its infrastructure set for completion in the second half of 2024, the Onslow Iron project is set to redefine mining in Western Australia. 12 COVER STORY

Mixing with the best

As a growing niche manufacturer, Elphinstone has been able to respond quickly to demand, whether it’s an individual customer or global markets.

SURFACE MINING

The Zenith of ground engaging tools

Bradken has expanded its GET range to include Zenith plate lip GET to further support Australia’s mining sector.

SURFACE MINING

Maximising payload productivity worldwide

Schlam’s Hercules open-cut dump body is now a household name in the mining industry.

IN Golden bull charges on copper

While gold has always been Newmont’s bread and butter, the major miner may have its eye on a copper future.

42 M

The AI mining revolution Miners are unlocking the potential of AI in their operations thanks to a swathe of new digital infrastructure being built in the Pilbara.

50 W

Australian Mining sat down with Austmine chief executive officer Christine Gibbs Stewart to preview

90 CRITICAL MINERALS

The unheralded critical minerals Australian Mining spotlights three Australian-based companies with bright critical minerals futures.

Bradken’s Zenith® Plate Lip ground engaging tools are engineered to minimise dig energy required for penetration and extend wear life.

•Bradken Zenith® Points and Adapters are available in three options to suit multiple applications.

•Easy conversion to Zenith® GET from existing plate lip fitments or complete new lip.

Our unique design reduces change-out time with a truly hammer-free pin, and dedicated point removal tool to enable safer removal.

Discover the benefits of our latest surface mining innovation

D ELIVE RING AN

KEEP UP WITH THE LATEST EXECUTIVE MOVEMENTS ACROSS THE MINING SECTOR, FEATURING EVOLUTION MINING, ST BARBARA, NEW HOPE AND NORTHERN STAR.

Former Fortescue chief executive officer Fiona Hick has joined Evolution Mining as a non-executive director and member of the company’s risk and sustainability committee, which took effect July 1.

Hick holds 29 years’ experience in the minerals and energy industries. Aside from her tenure at Fortescue, Hick previously held senior roles at Rio Tinto and Woodside Energy, with Hick working at the latter for 22 years.

At Woodside, Hick held leadership positions in areas such as health, safety and environment, strategy and planning, and engineering. She was also the executive vice president of the company’s Australian operations.

Hick has also been a member of the University of Western Australia’s strategic resources committee since 2019.

“Having recently accompanied the Evolution board on a visit to the Cowal and Northparkes operations, it has reinforced my view of the quality of the people and assets within the company,” Hick said. “I’m thrilled to be joining the board and supporting Evolution’s exciting future.”

Evolution executive chairman Jake Klein welcomed Hick to the board.

“I’m delighted to welcome Fiona to Evolution’s board,” Klein said. “She is a highly regarded executive and her depth of experience, and skills will complement those of our existing directors and further enhance the board.”

Barlow had been a non-executive director for New Hope since 2015, where he served as the chair of the nomination and remuneration committee and a member of both the sustainability committee and audit and risk committee.

director and AMB Holdings’ executive chairman. He was also a member of the Australian Takeovers Panel for nine years.

July also saw Stef Loader step down from her role as non-executive director at St Barbara.

Since her appointment in November 2018, Loader has served on the audit and risk committee and the safety and sustainability committee.

“On behalf of the board I would like to acknowledge Stef’s significant contribution to St Barbara over the last six years, including as chair of the safety and sustainability committee and more recently as chair of the remuneration and nomination committee,” St Barbara nonexecutive chair Kerry Gleeson said.

“The board has greatly benefitted from Stef’s skills and experience and I am particularly thankful for her support in facilitating a smooth on-boarding and transition to Mark (Hine), Joanne (Palmer) and Warren (Hallam) who were appointed as new directors in September 2023. We extend our sincere thanks to Stef and wish her all the very best for the future.”

New Hope Group non-executive director Todd James Barlow resigned from the board, which took effect from June 30.

“On behalf of the board and management team, I would like to thank Todd for his outstanding contributions and service to the company throughout his tenure,” New Hope chair Robert Millner said.

Brent Charles Albert Smith replaced Barlow from July 1.

He is employed by Washington H. Soul Pattinson & Company and holds a Bachelor of Business from the University of Technology Sydney and a Graduate Diploma of Applied Finance and Investment from the Financial Services Institute of Australasia.

Smith will stand for election at New Hope’s annual general meeting in November.

“We welcome Brent and look forward to him joining the board,” Millner said.

“Brent’s depth of knowledge and experience will complement the skills and expertise of the current members of the board.”

Northern Star Resources recently welcome a new independent nonexecutive director to its board.

Michael Ashforth has almost thirty years’ experience in law, investment banking and corporate advisory.

Ashforth was previously a Freehills partner, Gresham Partners’ managing director, a Macquarie Capital executive

Most recently, Ashforth was a regional adviser with Goldman Sachs. He is also currently a director of the Wunan Foundation, a not-for-profit organisation based in Kununurra that empowers and supports Aboriginal people in the east Kimberley region of Western Australia.

“As Australia’s largest ASX-listed gold producer, Northern Star has an enviable portfolio of gold-producing assets and I look forward to helping it continue to provide superior returns to its shareholders,” Ashforth said.

Global power technology leader Cummins also welcomed a new executive managing director to its Asia-Pacific arm.

With over 14 years of experience Cummins, executive managing director Africa and Middle East, Annie Chu, took on the top job from July 1.

Chu will be based in Singapore and will oversee Cummins’ operations in Australia, New Zealand, Papua New Guinea, Southeast Asia, Japan, Korea and the Pacific Islands.

Cummins Asia-Pacific welcomed Chu to the role.

“Her strategic thinking, customer-centric mindset, and teamwork have been evident throughout her career,” Cummins said.

“Chu’s leadership in Africa and the Middle East has been marked by significant achievements, including record financial performance and transformative initiatives to enhance both customer support and employee engagement.” AM

MINRES DELIVERED FIRST ORE ON SHIP ONE MONTH AHEAD OF SCHEDULE IN MAY.

Iron ore has had a fluctuating year.

The commodity saw strengthened prices early in 2024 thanks to a boosted hunger for the steelmaking ingredient and China bolstering its economy.

Prices hovered around $US125 per tonne (t) in January and February, an improvement from a previous $US98/t slump in mid-2023.

A swift fall to a seven-month low in March and April reflected increasing concerns about a rapid build-up of Chinese iron ore inventories amid sluggish growth in steel output.

But there is still hope for Australian iron ore in 2024.

As additional greenfield supply comes online, Australian export volumes are forecast to increase by 1.6 per cent annually through to 2029.

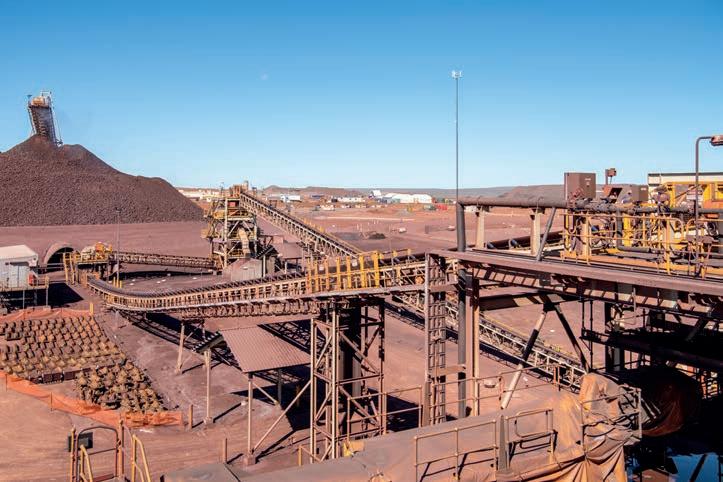

A development set to unlock billions of iron ore tonnes is Mineral Resources’ (MinRes) Onslow Iron site, one of the largest iron ore projects currently being developed in Australia.

Located 150km east of Onslow in the west Pilbara region of Western Australia, Onslow Iron is forecast to have an annual capacity of 35 million tonnes across more than 30 years.

The project is being developed by MinRes and its Red Hill Iron joint venture (RHIJV) partners China Baowu Steel Group, AMCI and POSCO. MinRes purchased its stake in the RHIJV in 2021, which has since grown to 60.3 per cent.

The RHIJV sees MinRes deliver all mining services and infrastructure for Onslow Iron.

“The original joint venture for Onslow Iron project was studied for 15 years and, at the time, the market had largely written the project off, believing the capital costs and development challenges were too great to overcome,” MinRes managing director Chris Ellison told Australian Mining.

“However, MinRes is built on the love of a challenge and Onslow Iron had three major challenges, each requiring innovative thinking and technology to overcome.”

In late April, MinRes welcomed its first convoy of road trains equipped with autonomous haulage solutions (AHS) technology developed with autonomy specialists Hexagon.

The Kenworth C509 quad road trains were transported from Perth in a

WITH INFRASTRUCTURE SCHEDULED FOR COMPLETION IN THE SECOND HALF OF 2024, THE ONSLOW IRON PROJECT IS SET TO REDEFINE MINING IN WESTERN AUSTRALIA.

two-and-a-half-day journey spanning more than 1280km.

According to MinRes, the singleengine road trains are the “biggest in the world” and can haul 330 tonnes of iron ore each. The full fleet of 150 trucks will be fitted with AHS technology at a rate of around 10 per month.

The road trains are to be operated by MinRes’ CSI Mining Services and will carry Onslow Iron product along a dedicated and fenced 150km haul road running from the Ken’s Bore mine site to the MinRes transhipping terminal at the Port of Ashburton.

“Safety is at the forefront of the project’s design,” MinRes said. “Grade separation will ensure there is no interaction between the road trains on the haul road and vehicles using public roads.

“A range of jobs will be created to support autonomous haulage operations, including automation specialists, dispatch and logistic offices, mechanics and auto electricians.”

In June, it was announced Morgan Stanley Infrastructure Partners would purchase a 49 per cent stake in the haul road for $1.3 billion.

Under this agreement, MinRes will retain majority ownership and exclusive rights to use, operate and maintain the haul road. Any tolling payments for iron ore volumes above 40 million tonnes per annum will also be fully owned by MinRes.

Once Onslow Iron product reaches the Port of Ashburton, it will be shipped via an initial fleet of five transhippers.

Onslow Iron’s first two transhippers – MinRes Airlie and MinRes Coolibah – were transported from China to the WA coast on a specialised heavy-lift vessel called Xin Guang Hua in May.

On arrival at the Port of Dampier, the heavy-lift vessel was partially submerged so the pair of transhippers could be unloaded in a complex maritime operation.

From there, the transhippers were towed to anchorage and linked to a pair of tugs named MinRes Thor and MinRes Odin.

Each transhipper has a shallow seven-metre draft to reduce its environmental footprint and associated costs.

“The cost and environmental impact of building a deepwater port

was overcome with our shallow draft transhippers,” Ellison said. “Expensive heavy haul rail was replaced with our autonomous road trains.

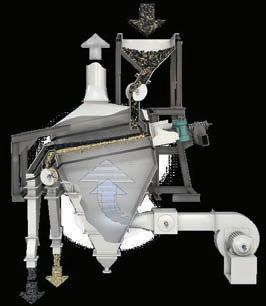

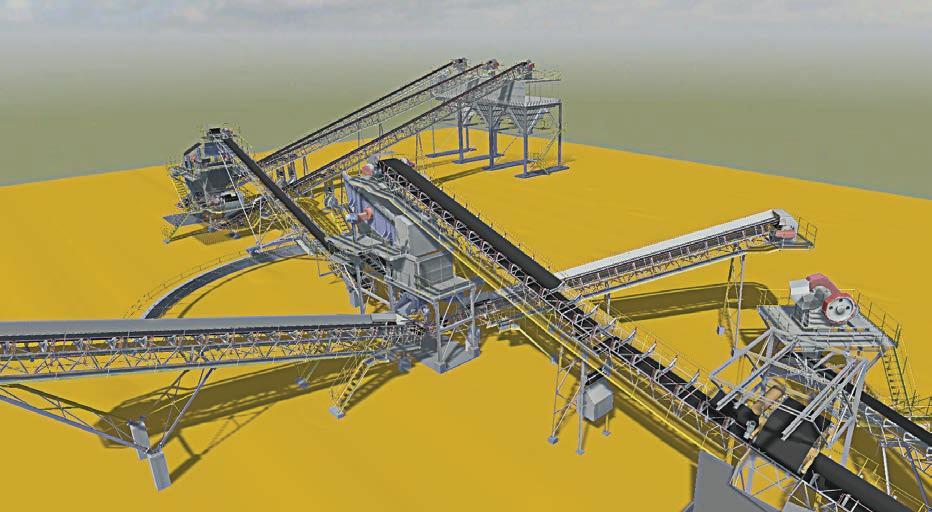

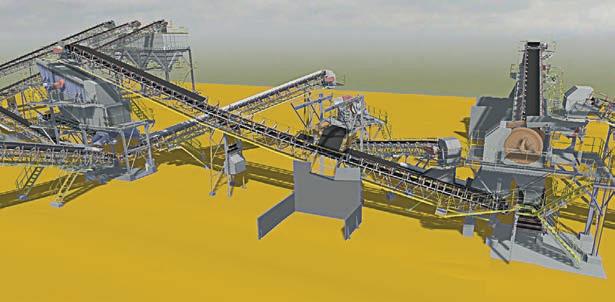

“And the high capital cost of mine infrastructure construction was overcome with the installation of our modular NextGen crushers.”

Measuring 123m long and 36m wide, the MinRes transhippers can hold 20,000t of ore to be distributed throughout the hold via a selfloading system.

The transhipper barge is then propelled out to sea by a powerful tug that also serves as accommodation for the crew. When the barge and tug are locked together, they operate as one vessel.

“This innovative approach has enabled the project to be developed in record time, just 21 months after the final investment decision and only one year after major construction commenced at the mine and port – an amazing feat,” Ellison said.

The third transhipper is expected to arrive at the Port of Ashburton in mid2024, the fourth by the end of 2024 and the fifth in early 2025.

Onslow Iron will eventually expand

“While cost and timeframes were important, we also wanted to minimise the impact of the operation on local communities, leading to Onslow Iron being the first mine-to-ship, dustfree iron ore project in Australia,” Ellison said.

of the RHIJV partners and the world’s largest steelmaker.

“This historic moment for MinRes cements our position as Australia’s leading commodity infrastructure business,” Ellison said.

“We have unlocked a whole new iron ore region for Australia, while Onslow

history with MinRes and a true demonstration of the industry-leading innovation and can-do attitude that forms the foundation of our business,” Ellison said.

“It’s an extraordinary display of the unique capability of MinRes’ infrastructure and mining services, technology and methodologies, Onslow

Tto unprecedented levels if demand is to be met in time for impending netzero targets.

But the resources sector is in the midst of a reckoning as to how those resources will be extracted.

Now in its seventh year, the AusIMM Thought Leadership Series (TLS) offers a unique platform to bring together mining executives, financiers, governments and resource professionals.

The aim is to explore global issues surrounding the mining industry, exchange ideas and foster the kind of thought-leadership that drives innovation and transformation.

The 2024 TLS theme ‘responsible mining in a digital era’ aims to build on last year’s conversations that reviewed the shifting paradigm of sustainable mining.

In the second session of the series titled ‘Investing in a sustainable future’, a panel with more than 100 years combined industry experience explored the challenges and opportunities in solving energy transition and environmental, social and governance (ESG) issues across the mining value chain.

A key focus of the evening was the ramp-up in production needed to achieve a sustainable future, with special focus on the challenge of attracting investment to new and emerging projects.

Whincup emphasised the complexity of the sustained growth needed from the Australian mining industry.

“We’ve got to double-to-quadruple the amount of critical minerals extracted and processed today within the next 15 years,” Whincup told the audience.

“Tier 1 assets are getting harder to find and we’re spending less on greenfield exploration – a market that is dominated by juniors who are often underfunded and under-resourced.

“Building momentum and capacity around asset discovery is getting harder.”

Once an asset is found and funded, Whincup said it takes 17 years on average to reach operation. Then there are geopolitical considerations associated with mineral processing chains.

But it’s not all doom and gloom for the sector. Far from it.

“The opportunity is there,” Whincup said. “We should be able to overcome the challenges.

The final step in the public review stage wrapped up in June when the Victorian Government-appointed Inquiry and Advisory Committee (IAC) issued its recommendations report on the project’s environment effects statement (EES) to the Minister for Planning.

The Minister will make an assessment of the environmental effects of the project after considering the IAC’s report, as well as the EES public submissions, and any other relevant matters.

A positive ministerial assessment for the Goschen EES will trigger the Earth Resources Regulator assessment of VHM’s mining licence application and be the green light for VHM to apply for its relevant permits.

Douglas told Australian Mining events like the TLS are critical in bringing the resources sector together to tackle challenges like regulations collaboratively.

“Challenges shared by the panellists resonated with the audience because they are experiences in common,” Douglas said. “This was the resounding takeaway for me and highlights that

operate in recent years, the reduction of our capital costs ensures that this project is competitive and at the bottom of the cost curve,” Douglas said.

According to Douglas, the diversity in the panel perspectives offered a broad insight into the complexity of the project investment landscape for critical mineral assets and exploration in Australia.

“Rhetoric around Australia’s inherent need to grow its domestic downstream capabilities in industries linked to renewable technologies and global netzero aspirations has been amplified by media attention,” he said.

“This TLS event was timed perfectly to discuss the role of critical mineral mine and processing developers, project funding strategies and government support on the road to net-zero.”

Southern Cross Gold (SXG) is another junior making a name for itself in Victoria. General manager Lisa Gibbons was in the audience and found SXG’s experience reflected in the panel’s discussion.

“As someone involved in a junior company that has a significant gold and antimony critical mineral exploration

and development project, I feel the panel precisely understood and expressed the current difficulties and future opportunities in developing critical mineral projects in Australia,” Gibbons told Australian Mining

“They highlighted that most critical mineral exploration is carried out by junior companies and despite the world’s scramble to secure critical minerals, junior mining companies struggle to raise equity to continue exploration, and to raise finance to bring projects into production. This is due to the loss of global institutional investment over the last 10 years.

“There are of course many facets as to why this is, such as small markets and opaque commodity prices for some critical metals, global challenges with permitting, lack of trust from stakeholders about our industry, and that the new critical mineral incentives from the government don’t fill the gap in securing equity that the junior companies are searching for.

“We believe we are fortunate that conventional gold production will predominately finance our future operation and that our critical mineral, antimony, which is about 20 per cent

standard and conventional flotation process to produce antimony-gold concentrates. But global supply chains to smelt the concentrate have been fragmented.”

In June, Southern Cross Gold announced it was set to merge with Canada’s Mawson Gold to consolidate ownership of the Sunday Creek asset in a deal that will list the company on both the ASX and Toronto Stock Exchange.

as well as local stakeholders and Traditional Owners.”

The company’s Sunday Creek project is one of Australia’s most significant gold-antimony exploration projects. The asset is well on the way to being Victoria’s next gold producer.

“The Sunday Creek project is a significant gold and antimony discovery, and we are already beginning to assess our pathways for permitting in Victoria,” Gibbons said. “Southern Cross Gold is a company that has been built to reflect the high ESG values that Victorians will require in order to permit any future mining project.

“As we look to the future, we are having positive discussions as to what permitting will look like with all stakeholders including local council, State and Federal Governments

Gibbons addressed the TLS panel with a question on how industry and regulators can work together to ensure the Australian mining sector continues to thrive.

“One consistent theme we have encountered is there is a lack of understanding by less senior regulators as to the importance of critical minerals in our everyday life and how junior companies work and raise funds, and that our people, assets, money and time are limited and fungible across many jurisdictions,” she said.

“My question to the panel was around how we as an industry can educate the regulators that we need home-grown critical minerals projects and that government support through accelerated permitting validates and de-risks our projects for investors, which in turn attracts new capital.”

The panel was in agreement that there is a need for consistent communication at all levels, to educate, engage and bring the regulators along on the journey.

“We as individual companies and as an industry need comprehensive and proactive strategies on how we manage our environmental impacts, foster positive social relationships, and ensure robust governance, and how we communicate all of this to gain the trust of our regulators and larger stakeholder group,” Gibbons said.

Through its latest seminar, AusIMM proved yet again the value in bringing together industry representatives to discuss issues and opportunities at hand.

As the mining sector continues to reckon with the demands of the environment, governments, the public, and the industry itself, forums like the Thought Leadership Series will continue to offer a platform for collaboration and discovery. AM

AN INDIVIDUAL CUSTOMER OR GLOBAL MARKETS.

When Elphinstone introduced the new low-profile E15 series to the market in January, it was a welcome addition to the existing range of E10 (formerly WR810) underground support vehicles.

Models in the E15 range include the 7m3 agitator, the E15 delivery (with wireless remote crane), E15 flat deck, E15 water tank for dust suppression, and E15 fuel and lube service truck, with various other configurations presently in development.

Headlining the series, the new E15 agitator 7m3 specialises in the transport of shotcrete or concrete for backfilling voids, featuring outstanding ride and handling at full capacity, improving cycle times and increasing productivity.

These features quickly captured the attention of Australia’s leading ground support specialist, Jetcrete Oz Pty Ltd and Evolution Mining’s Ernest Henry copper-gold mine in Queensland.

Mixing with Jetcrete

The relationship between Elphinstone and Jetcrete Oz originated in 2018, resulting in the purchase of a fleet of Elphinstone WR820 10m3 agitators

still in operation across Australia today.

Jetcrete has extensive experience in all areas of ground support, providing a complete service for each stage, including manufacture, supply, delivery and application.

The repeat orders were a testament to the success of the WR820 machines; however, on review, Jetcrete identified a need for a smaller machine with greater manoeuvrability to access and deliver the right amount of shotcrete to the headings.

Additionally, Jetcrete wanted more seating, greater comfort and safety, machine diagnostics and monitoring features.

“Operator comfort in the E15 was a key consideration for Jetcrete throughout the machine review process,” Elphinstone regional sales and support manager Kyle Allen said.

Jetcrete’s considerable experience in underground and surface applications has provided “work hardening” and valued feedback, which allowed Elphinstone to improve the E15 7m3 agitator even further.

After an extensive design and review process, Jetcrete took delivery of a new E15 7m3 Agitator in March of this year.

“Since arriving at Bluestone’s

Renison mine in Tasmania, the machine has been working around the clock, which is encouraging from a new product introduction viewpoint,” Allen said.

In mid-February, Elphinstone delivered two new E15 7m3 agitators to the Ernest Henry mine.

The two E15 7m3 agitators featured colour-coordinated agitator bowls requested by the mine to promote breast cancer (pink) and prostate cancer (blue) awareness.

“On delivery, the pink and bluebowled agitators were positioned at the entrance of the underground portal for a group photo,” Allen said.

The mine’s owner, Evolution Mining, has since ordered a third agitator with a green bowl to raise mental health awareness.

These and several other initiatives underpin Evolution Mining’s social responsibility approach, investing in meaningful community projects and developing engaged and lasting relationships with stakeholders and wider communities.

“Feedback so far has been excellent; in fact, the ride and comfort are so good that none of the operators want to

operate the old agitator trucks,” Allen said. “Evolution has now decided to standardise their support fleet with E15 machines and, as they say, there is no better testimony than a repeat order”.

Ernest Henry also has two E15 flat deck delivery trucks on order completing their fleet of five machines.

The E10 and E15 platforms have been designed and built to work in some of the harshest underground environments. Maximising the comfort and safety of the miners who operate in these conditions is vitally important.

More broadly, the E15 series – which has been continuously improved since its introduction alongside the E10 in 2017 – has a lower profile than the existing E10 (2.4m in height versus 3m), a key consideration for mining operations overseas.

At a height of 2.4m, the frontmounted operator cabin on the E15 features three-person air suspended seating, climatecontrolled air conditioning, an ergonomic central driving position with a clear 180° view, and a dial controller for the retarder, speed and implement controls.

There are also some thoughtful

smaller details, such as a cooled compartment for lunchbox storage, cupholders and smartphone charging ports.

An A-frame front axle suspension, combined with the oscillating hitch and air-suspended seats, delivers a high level of machine comfort to the operator and passengers.

The oscillating hitch means all wheels are constantly on the ground offering superior traction in rough or wet conditions.

Although the E15 machines are typically longer than the E10s, the common rear frame and axle position mean that the machine has a better turning circle improving manoeuvrability.

An optional safety feature of the E15 is the front and rear hydraulic jacks. The front jacks operate with a “park” function to enable the operator to safely exit the cabin with the engine operating. The rear jacks are used to level or lift the machine for discharge. All jacks can lift the machine off the ground for changing tyres.

The machine features intelligent electronic speed control that combines the functions of the heavy-duty electromagnetic driveline retarder, engine speed and the correct

transmission gear to control speed while descending into the mine, reducing wear and tear on the service brake components.

Operator presence, onboard brake testing and advanced machine diagnostics ensure that the operator is in control of the machine and has the right information to diagnose any issue on the 12 inch touch screen dashboard.

All service points such as tanks, filters, lubrication points and compartment drains are conveniently located at ground level for servicing.

Downtime during service and maintenance is reduced markedly on the E15 due to clever engineering and placement of service points with service personnel in mind.

Quick-change air filters and 500hour oil service intervals reduce downtime and keep machines in operation longer for greater productivity. A centralised on-board service centre includes fast fill, evacuation, and fluid sample points for analysis.

“Product support, parts and components are readily available through Elphinstone and our authorised Caterpillar dealers,” Allen said.

With E15 delivery and flat decks in production, the Elphinstone team is confident the E15 range will continue to grow in popularity among customers

OPERATOR COMFORT AND MACHINE DIAGNOSTICS WERE KEY CONSIDERATIONS FOR JETCRETE.

both in Australia and overseas.

“We’re looking forward to exhibiting on stand 13751 at MINExpo in Las Vegas this September,” Elphinstone global sales and marketing manager Tim Mitchell said.

“We’ll be displaying an E15 Delivery

(with wireless remote crane and flat deck) and a MED210 mine extraction device used for extracting bogged or buried machinery underground. Both are new machines in our continuously expanding range of underground hard rock mining support vehicles.” AM

TO FURTHER STRENGTHEN ITS EX-7 EXCAVATOR SERIES, HITACHI CONSTRUCTION MACHINERY AUSTRALIA IS ABOUT TO RELEASE TWO NEW TECHNOLOGY SOLUTIONS.

For over 50 years, Hitachi Construction Machinery has been a pioneer in manufacturing equipment, machinery and parts for a range of industries.

To expand its global footprint, the company founded Hitachi Construction Machinery Australia in 1999.

“We’re a supplier of surface mining and construction equipment to Australian operations within the mining, civil and forestry sectors,” Hitachi Construction Machinery Australia general manager – mining sales Sean Ryan told Australian Mining

One of Hitachi Australia’s flagship offerings is the Hitachi EX-7 series of excavators, which first hit the global market in April 2019.

While the series has seen over 120 units sold, Hitachi is all about improving and innovating its range to meet customer feedback.

It was customer consultation that planted the seed for the long-life boom and arm and operator assist systems, both of which Hitachi has developed over the last five years.

“The boom and arm system extended the component’s maintenance life

by 1.5 times, improving the durability and serviceability of our ultra-large hydraulic excavators,” Ryan said.

“To bolster durability, we have implemented cast steel technologies in high stress connection points, specifically the connection points of the boom to the arm and the cylinders to the boom. This has improved the strength and quality of those structures.”

Hitachi also placed manhole covers inside the boom to improve serviceability.

“The manhole covers have allowed easy access to the internals of the boom so non-destructive testing inspections can be carried out throughout the life of the component,” Ryan said.

“We haven’t increased the weight of the boom and arm, so we don’t reduce the capabilities or bucket sizing of the equipment.

“We also looked to improve the welding processes by using new design techniques and technologies. This included alleviating high stress areas.”

Further supporting digging and loader operations is Hitachi’s new operator assist system, which aims to reduce burdens such as operator fatigue.

With the help of sensors, a digging assist function helps to automatically improve control of the hydraulic excavator, while the loading assist function helps to avoid collisions by automatically controlling the front attachment when material is loaded onto a dump truck.

“The operator assist system makes it safer at the dig face, increasing productivity by maximising the use of the machine’s capabilities,” Ryan said.

“Rather than having a fully autonomous piece of digging equipment, which is very difficult because of the variabilities of mining conditions at the dig face, we can make

part of that process automated, so operators realise the greatest efficiencies of the excavator’s capabilities.”

Ryan said decarbonisation was a key driver behind the creation of its boom and arm and operator assist solutions.

“The operator assist system is about looking at how you can get the most efficiency out of the fuel burn for your operation,” he said. “While the boom and arm seeks to extend the service life of components, therefore extending the overall life cycle.

“With every ultra-class mining piece of equipment that gets scrapped at the end of its life, an estimated 400 tonnes of CO2 (carbon dioxide) is generated. If we can extend serviceability and overall life, it reduces the need for new replacement components and it improves our decarbonisation position.”

The operator assist system has undergone successful trials that commenced in early 2024. The system was fit to a Hitachi EX3600-7 backhoe excavator operating in the Pilbara region of Western Australia.

As a result of the effective trial, Hitachi is aiming to achieve practical application of the operator assist system in stages from 2025.

“The operator assist system is retrofittable, meaning it can be set up with any EX-7 mining series excavator,” Ryan said.

The boom and arm solution has also seen a successful trial in the Pilbara,

being fitted with the product as standard at the start of 2026.

To aid the rollout of the boom and arm and operator assist system over the next few years, Hitachi Australia has 19 mining branches located in regions such as the Pilbara, Townsville,

Mackay and Brisbane in Queensland, and Muswellbrook in New South Wales.

“With over 1300 employees, more than 900 are electric and mechanical tradesmen who are there to service our customers and their Hitachi products in the field,” Ryan said.

“We also have a division that manages any parts required for equipment across Australia and two remanufacturing centres in Brisbane and Perth where components get repurposed at the

end of their lives and are sent back to customers, reducing the amount of raw material and carbon emissions that come with new products.”

Alongside its extensive excavator range, Hitachi Construction Machinery Australia manufactures rigid dump trucks and wheel loaders for a variety of mining applications, among other solutions.

“We provide the whole service for overburden or mineral product removal from a mine site,” Ryan said. AM

Areport from the Rocky Mountain Institute, there are around 28,000 large haul trucks operating globally.

Almost all of these haul trucks are diesel-powered, with each consuming around 900,000 litres of diesel and emitting 68 million tonnes of carbon dioxide (CO2) per annum, making these vehicles a significant contributor to global carbon emissions.

To combat this sustainability hurdle, Hexagon’s mining division has stepped in to help.

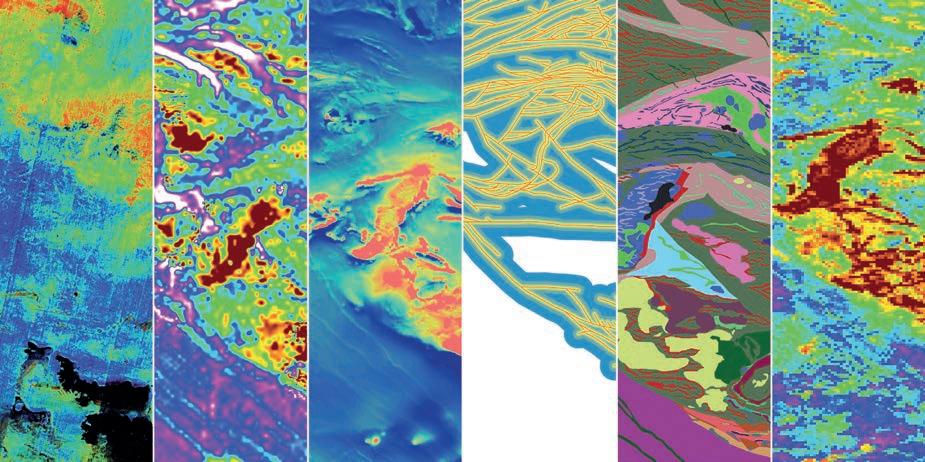

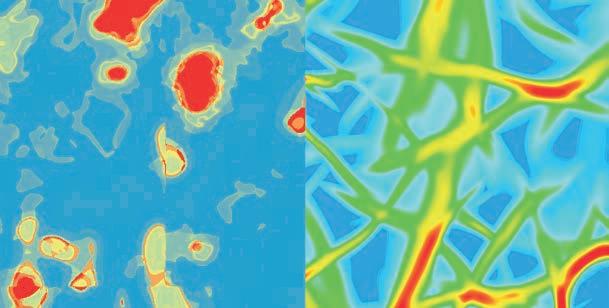

Describing itself as “an enabler of a sustainable future, providing solutions that address the main environmental and social challenges that companies and nations face today”, Hexagon has a diverse range of products and solutions that can help mining companies reduce their haulage emissions.

ESG and fuel optimisation

Hexagon has advanced its MinePlan Schedule Optimiser, a digital solution that determines the most productive cut mining sequence to achieve the highest project profitability, and then

project schedules.

One of the flagship benefits of the solution is the way it improves equipment efficiency by including the ability to constrain time spent hauling material for a more practical schedule, as well as minimising or maximising haul hours.

The MinePlan Schedule Optimiser can now measure an electric haul truck’s energy usage and downhill energy generation.

“Load and haul represent the majority of greenhouse gases within a mine and a large source of costs,” Jesse Forgues, head of product – resource optimisation, Hexagon’s mining division, said.

“By modelling alternative energy sources and integrating them within our current solutions, such as the MinePlan Schedule Optimiser, we can ensure the mine plan is being assessed to minimise energy usage costs, which positively impact mineral extraction costs and ultimately trickle down to the end consumer.”

For the last decade, Hexagon’s MinePlan Haulage solution has been providing inputs into MinePlan Schedule Optimiser.

planning process and reflects the extraction sequence using the fleet available,” Forgues said.

“Fuel consumption is modelled based on the route and vehicle type.

Fuel consumption is then calculated for each route, allowing the user to quantify trade-off scenarios based on fuel usage.”

This process can now be followed for an electric haul truck.

“We can model the kilowatt hours required to move the required amount of tonnes against the optimal routes, considering both the energy usage uphill and the energy generation downhill,” Forgues said.

“This approach results in a mine plan that reflects the specific model or models of truck being assessed.”

This integration will help mining companies increase their efficiency and profitability while reducing emissions.

“The integration between MinePlan Haulage and MinePlan Schedule Optimiser boils down to enabling better decision-making that is considerate of all aspects of the mine plan, ensuring that the economics

Forgues said.

“It also allows for seamlessly understanding trade-offs of different fleets and mixed fleets so that optimal outcomes can be determined with minimal user intervention.”

Hexagon is committed to supporting its customers and suppliers in their CO2 reduction plans, further evolving the company’s journey towards a greener future.

“Hexagon’s sustainability strategy is to empower and create a positive ESG impact either through our solutions and partnerships, or through our value chain and people,” Hexagon chief strategy officer Ben Maslen said in the company’s 2023 sustainability report.

“Strengthening our performance on the sustainability side will feed directly into a stronger performance on the business side and vice versa, and our success in business is tightly linked to our contribution to sustainability.”

“Our goals and expectations are deliberately set high, and whether you are a valued shareholder, customer or employee, we look forward to sharing our journey and progress with you.” AM

PROPRIETARY RUBBER AND COMPOSITE FORMULATIONS

OPTIMIZATION OF WEAR PARTS & PROCESS EFFICIENCY

TAILOR MADE PARTS

ASSET MANAGEMENT

INSTALLATION AND WEAR MONITORING PROGRAM

DESIGN SUPPORT

BRADKEN HAS EXPANDED ITS GET RANGE TO INCLUDE ZENITH PLATE LIP GET TO FURTHER SUPPORT AUSTRALIA’S MINING SECTOR.

Given the often-harsh conditions of the Australian resources industry, it is critical that mining companies select the right ground engaging tools (GET) for their operation.

Premium GET solutions extend machinery wear life and lessen the risk of equipment failure, minimising costly downtime. The right GET tooling also delivers reduced dig energy and improved penetration.

That is why Bradken has continually advanced its own GET solutions, ensuring customers always have the right option at hand. This includes the Zenith series, the latest addition to Bradken’s GET range suited to 100–250-tonne hydraulic excavators.

Bradken GET principal product manager Glenn Baxter explained the evolution of the company’s products.

“Bradken’s GET range has evolved from being regionally based with a suite of first-generation products, to now being more globally focused with a second and third generation of innovative products, all backed

by a global original equipment manufacturer (OEM) in Hitachi Construction Machinery,” Baxter told Australian Mining

“The Zenith technology is Bradken’s next generation of plate lip GET products, so it’s one of the latest solutions in the Bradken GET range.”

As Bradken developed an improved GET solution for higher tonnage hydraulic excavators, the company had several research and development (R&D) objectives.

“In the development of the Zenith range, we had a focus on creating an efficient tooth system from a machine performance and maintenance perspective,” Baxter said.

“We wanted to minimise the size of the tooth (without compromising strength) so the machine uses less power during each cycle, and simplify the locking system so it’s intuitive to use and easy to maintain when required.”

The Zenith locking system requires only 180° of rotation to be actuated, with the locking pin pre-installed in the point, which is another simplifying aspect of the range.

THE ZENITH SERIES OF GET IS SUITED TO 100–250-TONNE HYDRAULIC EXCAVATORS.

ZENITH PLATE LIPS CURRENTLY COME IN STANDARD, LONG AND HEAVY-DUTY OPTIONS TO SUIT ALL APPLICATION REQUIREMENTS.

Other key benefits of the unique design is the reduction in change-out time and improved safety with the truly hammer-free pin and dedicated point removal tool enabling a safer removal process. Together these improve the ease of use and enable greater diversity in the workforce.

The Zenith points currently come in standard, long and heavy-duty options to suit all application requirements. And they can be used to extract any commodity, including copper, gold, coal or iron ore.

Baxter said operators have resonated with the intuitiveness of the range with simple installation and removal, along with the flat contact surfaces between the point and the nose enabling easy rebuilds if required.

“Maintenance teams will often have a list of tasks to complete on a shift, and when they come to changing their Zenith GET, because of its simplicity, personnel can easily make their tooth changes without having to constantly refer to the instruction manual,” he said.

“GET can be replaced in a consistent short timeframe, meaning maintenance personnel can plan and spend more time on other tasks that might be of a higher priority.”

A product comparison demonstrated the efficiency of the Zenith range, with teeth able to be replaced in one minute each, whereas a generation-one tooth took on average 11 minutes to replace.

“When changes are made to six teeth, operators can save a lot of time on maintenance and spend more time in production,” Baxter said.

“Our R&D teams conducted numerous simulations during the design

phases and when compared to our generation-one system, the Zenith teeth penetrated material using up to five per cent less power, which is a significant advantage over the long run.”

The Zenith range also has on average an 11 per cent longer wear life than Bradken’s first generation system, based on recent infield performances.

Bradken understands that not only can it supply customers cost-effective and reliable solutions such as its Zenith GET range, but it can also bring together solutions from other product lines to provide a holistic offering.

“We’ll continue to expand the Zenith range as part of this new generation of plate lip products,” Baxter said.

“More broadly, Bradken is combining the recent structural development work undertaken on our mining excavator buckets – including the addition of a cast upper structure – with our GET solutions on the front of the bucket.

“Our design team specifies the right sizes for the operating conditions, and by using machine parameters we can take a more holistic approach, rather than just provide the GET solution alone.”

Baxter said Bradken’s digital portfolio is also advancing.

“The advancement of our tailored condition-monitoring solutions, where we can track the performance and wear of the GET in real-time, demonstrates that there is some pretty exciting R&D occurring at Bradken,” he said.

“And through all our innovations, Bradken is fortunate enough to be backed by a Tier 1 OEM in Hitachi Construction Machinery, who support our product development and the speed with which we can innovate.” AM

Offering clients a range of proven benefits from increased payload capacity to extended asset longevity, Hercules is a true testament to Schlam’s business.

With a commitment to customer service and a foundation built on strong values, Schlam partners closely with its clients to tackle unique challenges and optimise payload productivity.

Guided by a commitment to customer service and backed by a strong set of values, Schlam has a reputation for assisting its clients in overcoming any challenge. Innovation continues to play a big part in Schlam’s success, demonstrated by the triumph of its Hercules open-cut dump bodies, which continue to deliver significant payload savings for miners across the globe.

According to Schlam Payload AsiaPacific managing director Hendrik Mueller, the success of Hercules has ensued from a culture of continuous product improvement, based on the specific needs of clients.

“Our clients are our partners, and we collaborate to tackle the payload challenges they encounter,” Mueller said. “Their challenges drive us to push our limits, resulting in continuous improvements in our payload products.”

The Hercules open-cut dump body, characterised by its innovative curved shape, has become one of the most sought-after payload solutions among leading miners.

Hercules bodies offer both reduced body weight and a longer service life, achieved by targeting weight reduction in all non-wearing areas and optimising lighter materials for structural components – all without sacrificing structural integrity.

“Traditionally, miners have faced a choice: a lightweight body that offers a greater payload but has a shorter lifespan, or a heavier body that lasts longer but reduces the payload capacity,” Mueller said. “Hercules was developed to offer both.”

To maximise asset investment, most mining operators plan for a long asset service life. Hercules dump bodies are designed to experience less structural fatigue, prolonging the life of the asset and ensuring compatibility with any site production strategy.

Schlam also assists operators in further extending the service life of their Hercules body by designing the ideal wear package for installation during manufacturing, and providing an optional product lifecycle support program.

The lighter Hercules body means it can accommodate a wear package without sacrificing payload performance. A Hercules body fitted with a bespoke wear package usually weighs less than a comparative OEM (original equipment manufacturer) dump body.

Schlam’s optional product lifecycle support program includes site visits and inspections where wear rates are measured, enabling corrective measures to be prescribed.

“Hercules bodies typically have a longer service life, which can be further extended with the right wear mitigation strategy. For instance, one Hercules dump body was recently decommissioned after a long 12 years of operation,” Mueller said.

Schlam works closely with its clients to address site-specific variables, including wear, material flow, and asset lifecycle management, to design and engineer every Hercules body individually.

“Each mine site is unique,” Mueller said. “One site might struggle with abrasion, while another could be dealing with material hang-up.

“We invest significant effort in designing each Hercules for maximum performance at each specific site.”

Trusted by Tier 1 mining companies, contractors, and OEM truck suppliers, the demand for Hercules dump bodies has only continued to increase across the global mining industry.

The first Hercules was manufactured in Australia in 2003. Today, Hercules dump bodies are actively engaged in mining operations across six continents.

From the deserts of Australia to the plains of Kazakhstan, Hercules dump bodies consistently deliver the payload advantages they were individually designed for.

Strengthening its global presence, Schlam has formed partnerships with quality-driven manufacturers in China and Mexico, allowing the company to quickly respond to the demands of clients in key international markets.

In 2023, Schlam opened a dedicated Americas office in Tucson, Arizona, to better serve its clients within the region.

In the same year, Schlam supplied a leading miner in Kazakhstan with seven Hercules bodies.

“In a relatively short time, we’ve developed into a truly global company,” Mueller said. “We’ve achieved a lot, and celebrated many milestones along the way, including the recent 2000th Hercules body.”

As a category-leading manufacturing business, Schlam is focused on technology and innovation.

By investing in automation, robotics, and other advanced technologies, the company ensures consistent product

quality, enhances manufacturing efficiencies, and creates more rewarding career opportunities.

Schlam also continues to research and address new challenges and opportunities presented in the mining industry, including autonomous haulage and decarbonisation.

“We continue to work with our clients throughout the evolution of autonomous fleets, especially in the iron ore mining centre of Western Australia,” Mueller said.

“We’ve even made modifications to Hercules designs to accommodate autonomous technologies, and seen Hercules bodies adopted by major autonomous mining fleet operators.”

With a commitment to taking global sustainability seriously, Schlam is also assisting mining operators to address the growing challenge of reducing carbon emissions.

While Hercules contributes to significant savings in fuel consumption

(per tonne produced), allowing miners to reduce carbon and other emissions, Schlam continues to work towards developing lower-carbon product options.

“Decarbonisation has become a priority within the resources sector, and we are proud to be developing product options to help our clients achieve their net-zero goals,” Mueller said.

“We are also excited to see Hercules included in new fleets using alternative fuel sources, including hydrogen.”

Schlam’s journey from a regional player to a global innovator is testament to the company’s dedication to excellence and client satisfaction.

With a widespread global reach, and with long-term supply contracts in place with some of the world’s major miners, Hercules remains committed to its overarching goal of being the partner of choice for the world’s leading hardrock miners. AM

Tbeen upgraded with multiple new product developments.

manager David Rea said they’re built on an advanced platform with common electronic architecture, cab and controls.

“These next-generation mining trucks feature a flexible technology platform and optional configurations to help each mining operation meet their goals,” Rea told Australian Mining

All models are direct mechanical drive and boast the latest electronically controlled transmission with advanced electronic control strategy.

The transmission offers smooth gear shifts for a smoother ride and delivers productivity and efficiency improvements.

“The walkthrough cab offers 34 per cent more space than the D series,” Cat 793 product applications specialist Rob Shea told Australian Mining

This results in more room for the operator and trainer, increased storage, and added space for third-party or dealer-installed options.

The new trucks also feature cuttingedge connectivity that offers increased data transfer speed, power of electronic control modules and advanced underlying architecture.

New enhanced automatic resistive braking control takes speed control to a

three to six per cent higher speeds on average during resistive braking.

“Field data shows operation speed during resistive braking can increase up to 25 per cent, elevating the average skill level of all operators to that of an experienced operator, while protecting the asset,” Shea said.

Next-generation trucks now offer hill start assist with anti-rollback – two separate features that work together.

Anti-rollback stops the machine with automatic brake application when the truck rolls in the opposite direction of the selected gear.

If drive is selected, the truck won’t roll backward, and if reverse is selected, it won’t roll forward.

Hill start assist uses grade and payload to determine the necessary rimpull to keep the truck stationary on a hill, simplifying truck movement in the selected direction.

The next-generation trucks also include Cat’s AutoHoist, which helps simplify body dumping to provide lower cycle time.

Integrated with the transmission control, AutoHoist consolidates four continuous operator hand and foot inputs into two simple hand inputs.

On previous models, the operator shifted the truck into park, applied the park brake, moved the hoist lever in the raised position and held the accelerator to dump, increasing the opportunity for inconsistency and inefficiencies.

With AutoHoist, the operator moves the truck into park, holds up the lever and pushes the up button on the gear shifter, and the truck takes over.

“It can reduce typical dump cycle times in some instances by up to 12 seconds and potentially reduces fuel burn during the cycle,” Shea said.

Significant safety advancements, a new dynamic stability control system and an anti-lock brake system (ABS) provide operators with better truck control to improve cycle time and safety in poor underfoot conditions.

The four-wheel, oil-cooled brakes in Cat mining trucks have always allowed for four-wheel braking at any speed to enhance truck controllability and safety. Now, when a locking wheel is detected, ABS regulates the brake pressure to maintain traction and truck control, so the truck keeps tracking forward.

The new dynamic stability control modulates the brakes while braking and turning.

It monitors operator steering intention through the brake and throttle inputs – plus the inertial measurement unit informs the system of the truck’s travel direction – and modulates the brakes to keep the machine tracking with the operator’s steering inputs.

This brings the truck back under control and keeps it travelling straight if a locked wheel or slide is detected AM

It’s been a busy 12 months for Newmont.

With its $26.2 billion acquisition of Newcrest wrapping up late last year, the miner has gone from major to universal, firmly taking its place as a global gold powerhouse.

Now, Newmont is evolving its strategy. A flurry of activity in recent months has seen the miner put a host of gold mines up for sale, including

the Telfer operation it inherited in the Newcrest takeover.

When it comes to gold, it seems Newmont is only hungry for Tier 1 assets. The company brought in 1.7 million attributable gold ounces (oz) in the 2024 March quarter alone, 1.4 million of which was driven by the company’s Tier 1 portfolio.

As Newmont optimises its gold portfolio, the major hopes to have 10 Tier 1 gold mines under its belt,

more than half of the world’s largest gold mines.

But the sell-offs may offer more than a leaner, more stable profile defined by world-class assets. Newmont chief executive officer Tom Palmer recently revealed the company is looking to maximise its copper potential.

With the future importance of copper being increasingly understood, a host of majors are eager to boost their exposure to the base metal.

In a recent fireside chat at the Melbourne Mining Club in June, Palmer said Newmont’s “bullish” attitude towards gold will help it gain a foothold in a copper future.

When asked where he wants Newmont’s copper to be in the next decade, Palmer said it’s a “more complicated equation” to work through.

“Our project pipeline is all copper,” he said. “How do we develop our project, in what order, at what pace and which communities are we working in?

“If we’ve got the support of the permitting, we’ve got projects here that are going to deliver appropriate returns with that view on copper and copper pricing, and gold and gold pricing.

“So it’s looking at all those variables and making decisions about where we (should) invest our next dollar after

the existing projects … it’s more about understanding how you develop that project pipeline successfully.”

As host to the third-largest copper reserves in the world, Australia is a big part of Newmont’s future.

The major’s existing Australian projects are industry behemoths already putting the company ahead of the curve.

Perhaps Newmont’s best-known copper-gold operation is Cadia.

Nestled underground near Orange in New South Wales, Cadia produced over 98,000 tonnes of copper last year alone.

One of Australia’s largest coppergold mines, Cadia is touted to contain over 3.6 million tonnes of copper.

It’s a crown jewel in an already impressive portfolio, one that doesn’t even consider Newmont’s copper hotspots across the globe.

Palmer said half of Newmont’s costs come from labour – a cost that needs to be balanced if the major is to continue building its pipeline of copper projects.

“The potential for Australia to miss that opportunity because we can’t get ourselves organised and have policies to support the development of copper resources here would be a shame,” Palmer said. “That capital will go elsewhere if we don’t get ourselves organised in Australia.”

Palmer emphasised the right policy settings need to be in place to attract investment from miners looking for opportunities to develop Australia’s copper deposits.

“You’re going to see the demand for copper either drive opportunities where you can buy or where you can build,” he said. “I think there’s a real opportunity for Australia to participate in the energy transition and copper, but we need to get a wriggle on.”

It’s no secret the energy transition is going to demand a massive effort from the Australian resources sector, and Palmer said new mines and collaboration are going to form a golden ratio for success.

“We’re going to need to build more copper mines,” he said. “What will differentiate mining companies in the future will be the capability to build mines and the capability to form longlasting strategic relationships.”

The extent of Newmont’s future partnerships will continue to unfold, but for now, it’s clear copper is a commodity to watch as hunger for the base metal grows worldwide. AM

Through its specialised engineered mining solutions, MASPRO prides itself on being “exceptional in the market”, with the ability to solve pressing equipment headaches quickly and effectively.

MASPRO will often be presented with intricate time-critical issues, some of which require novel solutions. The company’s engineering team will then go to work to reverse engineer an ailing component to not only understand the problem but conceive the solution.

In addition to leading the charge with its ability to crack complex engineering codes, MASPRO is also a technology frontrunner, with four automation work centres at its engineering headquarters in Condobolin, NSW.

Complementing these centres, MASPRO has implemented optical 3D metrology equipment, which can complete the measurement of millions of data points in seconds, and advanced computer numerical control (CNC) machining tools to enhance precision and safety.

These technologies remove the need for many hands-on tasks and assist MASPRO in expediting its engineering and manufacturing processes without losing out on build quality.

This means jobs can be turned around quicker, and mining customers can implement their re-engineered parts sooner, which, in MASPRO’s case, is within a matter of weeks.

MASPRO production scheduler

Arnold Small explained the company’s typical process.

“When a customer has a problem with a part, that goes to MASPRO’s engineering department, which will analyse the component to see what a re-engineered part might look like and how it can be improved,” Small told Australian Mining

“This is where Tony (Waterman, MASPRO head of engineering) and his team come in to re-engineer the part. We then start our NPD (new product development) process, which is where myself, Tony and his team get together.

“We will discuss the problem, look at its engineering to see how it could be improved and the number of parts that go into it. We will then determine whether the solution is a potential candidate for our automated work centres.”

Automation removes the need for MASPRO employees to complete more monotonous, time-intensive tasks, and the fact that robots can operate around the clock means the company can significantly enhance and accelerate its production scope.

Robots never act in isolation, with MASPRO’s team of highly skilled technicians providing high-level monitoring and management during the production process.

Some of the automated technology MASPRO has implemented includes the Agile Flex 35D automated CNC machine loader, which loads pre-cut steel blanks in sync with machining software ready for batch production. This removes the need for manual handling and eliminates the risk of repetitive stress injuries.

The ATOS ScanBox takes 12 million points of measurement per scan, creating three-micron repeatable part item reports, removing set-up times and repetitive tasks associated with

A T-SCAN Hawk hand-held scanner enables fast digitisation to facilitate informed research and development (R&D), while MASPRO also boasts a suite of automated welding and

MASPRO understands that some of its products, such as inner zooms and cradles, are complicated to manufacture, requiring precision welding that can be difficult for even the most skilled welders.

The Corner Cell welder and X-Wing welding positioner are designed to remove human error from the process while delivering precise finishes, leading to improved product manufacturing.

While automation isn’t a new concept, MASPRO is maximising its own operability and synergy of automation to create an agile interconnected engineering capability that delivers premium mining solutions.

“Automation is there, but to combine automation like we have is new,” Small said. “We are one of the first companies in the mining sector to cross-pollinate automation across different engineering workstreams to create an end-toend operation.

“This enables us to keep our automation systems operating around the clock to satisfy customers with premium products and on-time delivery.”

And at MASPRO, robots don’t replace humans, with skilled engineers more important than ever in an era of automation and artificial intelligence.

“Automation offers faster, safer, more precise production, and can give us economies of scale; however, skilled employees will always be a critical part of this exciting and innovative new era for the mining industry,” MASPRO managing director Greg Kennard said.

“Innovation via robotic equipment, programming and automation will help the industry free up time for their skilled engineers and internal experts, removing dull manual tasks and clearing the decks for creative thinking and design. This is what the industry desperately needs more of right now.

“The culture of innovation that Australia is known for is sure to remain strong when we collectively give our best people more time to think, create and experiment.” AM

Designed to be a highly productive unit, achieved through its market leading blade down force, a 426 horsepower engine and weighing in at nearly 47 tonnes, Komatsu’s new GD955 really is built from the blade up.

No two mining operations are the same, so it stands to reason no two mines will require the same equipment set-up. It takes an experienced hand to determine the unique requirements of any given site.

Enter McLanahan, an equipment manufacturing specialist with over a century of experience meeting the Australian mining industry’s mineral processing needs.

The company has seen great success with its range of apron feeders, which director of global sales – mining Lee Hillyer described as the “ultimate” in flow control.

“Integrating a McLanahan apron feeder ensures peak efficiency,” Hillyer told Australian Mining. “Our crawler undercarriage design has been a proven success in hundreds of apron feeders still in use today.”

McLanahan apron feeders work by channelling material at a controlled speed, handling anywhere between 10–6000 tonnes per hour.

The feeders come in six chain sizes, 16 standard flight widths and an infinite range of lengths – all designed to meet the changing needs of a site.

An alternative feeder is McLanahan’s wobbler feeder, which is perfect for applications with particularly wet, sticky materials or where excessive fines could cause trouble down the track.

“All undersized material falls through the rotating elliptical bars rather than into the sizer where it can potentially cause wear on the teeth,” Hillyer said. “It’s an alternative that has gone out of fashion in recent years but is making a swift comeback thanks to its efficacy.”

A key feature of a McLanahan wobbler feeder is its scrubbing action, which cleans sticky fines from larger lumps.

As material is moved from the feed end to the discharge end, large lumps of material are forced up and down within the load, scrubbing against each other.

Hillyer said the company has had positive feedback from customers looking for such a solution.

“Users of the wobbler feeder have told us it works incredibly well,” he said. “We have also had strong feedback on our sizers, which are the next step along the mineral processing chain.”

McLanahan’s primary sizers are one example of the company’s quality equipment making an impact on a number of underground and surface operations across the country.

Primary sizers are selected based on the specific material and lump size to be crushed, whether it be coal, bauxite, clay, or other friable materials.

By selecting the correct tooth profile, material is easily grabbed and pulled into the crushing zone for maximum efficiency.

Hillyer said McLanahan is one of the world’s most experienced manufacturers in the design and production of sizers.

“We have sizers installed and operating around the world,” he said. “In addition to our great success in the coal industry, McLanahan sizers have proven extremely capable in helping other mineral sectors achieve necessary size reductions as well.”

When it comes to McLanahan equipment, Hillyer said the dynamic reality of daily operations are at the centre of its design considerations.

“We’ve designed our equipment to be super maintenance friendly and easy and safe to maintain,” he said. “Our aim is to provide a great product at a costeffective price.”

This consideration has led to McLanahan’s base models including features typically considered as extras.

“We have incorporated rapid-changeout shafts that can be easily swapped out within a single shift,” Hillyer said. “The sizers also come with individually replaceable teeth and an adjustable breaker bar to adjust sizing as needed.”

MCLANAHAN’S WOBBLER FEEDER IS PERFECT FOR APPLICATIONS INVOLVING WET, STICKY MATERIALS.

communication and listening to customer needs. requirements,” he said. “As a result, the range we offer is well defined

Cutting-Edge Technology: Maximise efficiency with features like Load Sensing hydraulics for unmatched control.

450 kW Volvo Engine: Dominate any material with effortless digging force.

Safety & Operator Comfort: Experience a panoramic view and intuitive controls in a safe, ergonomic cab.

Volvo’s unique ECO Mode and an advanced electro-hydraulic system, achieving outstanding fuel efficiency.

CYBERSECURITY IS CRITICAL FOR AN INCREASINGLY DIGITALISED AUSTRALIAN MINING INDUSTRY.

In recent years, the digital transformation has revolutionised the way mining companies operate.

Delivering a multitude of benefits, including reduced costs and improved operational performance, introducing digital solutions is a no-brainer.

However, an aspect of digitisation that isn’t widely discussed in the Australian mining industry is cybersecurity. This is something Brennan is working to change.

Drawing on extensive experience in the mining sector and boasting over 27 years of IT expertise, Brennan has evolved into one of Australia’s leading and independently owned systems integrator.

With cybersecurity woven across their business and within their solutions, Brennan understands that improved technology availability has created more opportunities for threat actors to interfere with mining operations.

“With mining companies increasingly using technology to manage their operations, they’re effectively becoming technology companies,” Peter Soulsby, Brennan’s head of security, told Australian Mining

“The challenge with that is more technology means more opportunities for disruption.

“Disruptions can take many forms. They can be the unintentional kind, created by users, employees or contractors. Or they can be intentional, created by threat actors such as hackers.

“The modernisation of mining has inadvertently created more risks, which is why cybersecurity is just as important in mining as it is in any other industry.”

Utilising cybersecurity technology can help users understand risks, such as what could go wrong and how those events could occur and unfold. In turn, this can inform the strategies needed to protect businesses against unwanted outcomes.

“Cybersecurity incidents can erode trust, potentially affecting revenue and opportunities to generate new business,” Soulsby said. “On the flipside, cybersecurity is an investment that will protect your operations, revenue and profit, as well as establish your brand as trusted and safe.”

Brennan proactively identifies and

assesses the risks identified as important to its mining customers, using these as a starting point to find the best solutions for their needs.

“We map business priorities and risks with IT and cybersecurity priorities and risks. It’s crucial that we understand what’s important to a business, and don’t just deliver a solution for the sake of it,” Soulsby said.

“When you understand what those risks are and what they mean, we can implement controls to mitigate those risks.”

As an ISO 27001 certified partner, Brennan’s outsourced IT services are underpinned by a comprehensive cybersecurity framework that follows the Essential Eight mitigation strategies.

These include patch applications, patch operating systems, multifactor authentication, restricting administrative privileges, application control, restricting Microsoft Office macros, user application hardening, and

regular backups.

“We’ve developed cybersecurity reference architecture to ensure bestpractice cybersecurity practices are in place within Brennan and across our client base,” Soulsby said.

“We use this architecture to help our clients efficiently deliver cybersecurity, helping them both understand the importance of cyber protection and protecting their company from pressing cyber threats.”

Like many sectors, the mining industry is facing cyber challenges related to identity, with corporate email addresses and passwords susceptible to being compromised.

In large part, this is due to different authentication systems requiring various forms of identity, often resulting in the creation of several identity systems that then makes identity management more difficult.

“What Brennan does is successfully implement solutions that enable better identity management. It means that

commonly recurring actions, such as onboarding a new starter, keeping track of a contract’s lifecycle, or offboarding an employee at the end of their employment, is made simpler and more secure,” Soulsby said.

“We view security solutions through three lenses: what the security market is telling us and what emerging technologies are out there; securing managed services; and client feedback and demand for new capabilities.”

Through its team of certified experts, Brennan removes the complexity around cybersecurity technology by evolving the links between cybersecurity and IT, as well as operational technology (OT).

“By managing identities across IT and OT and breaking the boundaries that previously existed between the two, we’re proving cybersecurity can be done across the entire mine value chain,” Soulsby said. AM

From CNC machines to robotic arms, MASPRO is using automation to transform our production process, enabling us to consistently deliver superior parts and components for mobile mining machinery with unparalleled efficiency. Our advanced facilities leverage cutting-edge technology to optimise production processes, ensure the highest standards of quality and meet the demands of modern industry.

MST’S HELIX SOFTWARE IS STREAMLINING DATA MANAGEMENT AT MINES ACROSS THE WORLD.

MST has been a household name in the underground mining industry for over 30 years since the development of its first personal emergency device (PED).

A key safety system for underground mines around the world, the PED’s ability to transmit critical data from the surface to workers or PED receivers underground paved the way for generations of groundbreaking advancements in MST’s safety offering.

One of those developments came in 2010 when MST launched 2D visualisation and tracking software, ICA.

These are offerings that have not only helped shape the underground mining experience but have also empowered safety and productivity improvements across Australian operations.

Now part of the Komatsu family, MST’s software tracking engine has made strides in the decade since, and with that the company birthed its next-generation software platform: HELIX.

The platform works by integrating on-site sensors with a digital ecosystem tailored to the needs and existing technologies of a given site.

MST product management and marketing general manager Alex Gawad said HELIX is designed based on a modern software stack with a focus on system scalability and cybersecurity.