VOLUME 116/08 | SEPTEMBER 2024

HIGH-PURITY ALUMINA

DIGITAL MINING

MINING EXCELLENCE BENEATH THE SURFACE

VOLUME 116/08 | SEPTEMBER 2024

DIGITAL MINING

MINING EXCELLENCE BENEATH THE SURFACE

United. Inspired.

The zero-emission Scooptram ST18 SG is built for demanding underground applications, offering 20% longer drivetime and up to 5 hours on one battery charge. Automation-ready with Epiroc’s advanced systems, it reduces CO2 emissions by 648kg during an 8-hour shift. Prioritising safety, it features the highest energy density in the industry. Its electrical drivetrain enhances productivity with unmatched acceleration and traction, improving the local working environment by reducing heat, water vapour, and noise.

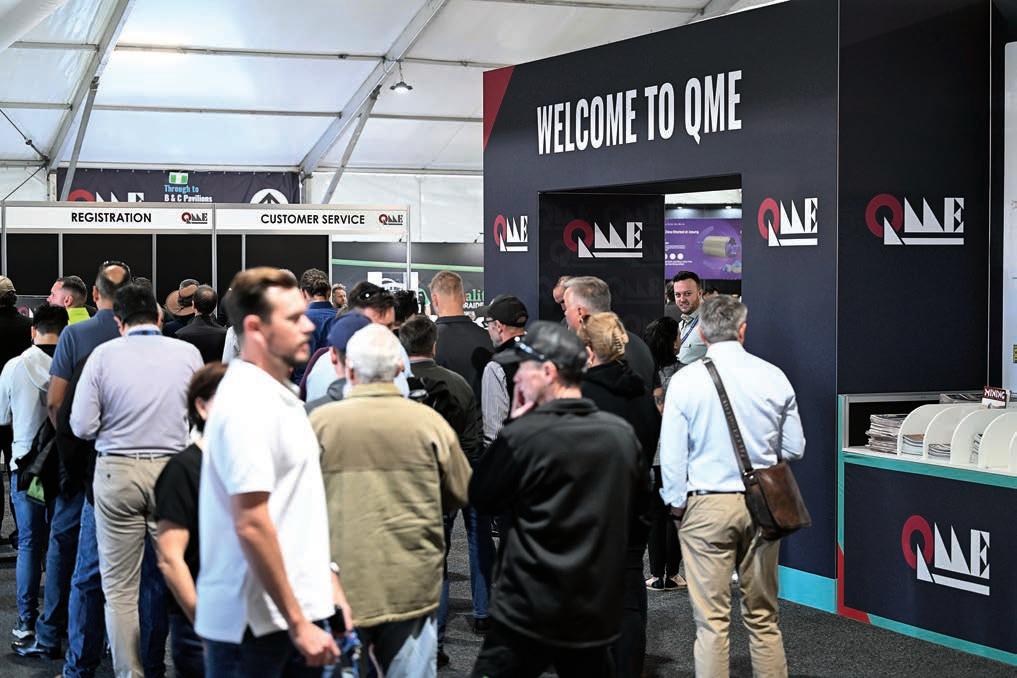

Queensland Mining & Engineering Expo (QME) celebrated its 30th year with a record-breaking event in July. With more than 300 exhibitors showcasing their technologies and innovations, QME welcomed in excess of 5000 delegates to the Mackay Showgrounds. Having been on the ground at the event, it really felt like the entire Queensland mining industry had made its way to Mackay for the expo, with many miners seemingly popping in immediately after a shift to peruse the exhibition floor.

QME 2024 proved the importance of face-toface events, not only because of the networking and relationship-building opportunities on offer but also because of the potential for product discovery.

And an event of QME’s stature is just as important for the Queensland mining industry as it is for the local community, turning the city of Mackay into a hive of activity for three days.

The September edition of Australian Mining provides the opportunity to reflect on QME 2024, with a post-show review highlighting some of the event highlights and featuring exclusive exhibitor interviews.

Elsewhere in this edition, we focus our attention on the underground mining industry, with several key mining equipment, technology and services (METS) companies discussing how they are enabling safer and more efficient operations under the surface. This includes Epiroc and its 18-tonne ST18 SG batteryelectric underground loader, which is the most powerful loader yet in the original equipment manufacturer’s battery-electric range.

CHIEF EXECUTIVE OFFICER JOHN MURPHY

CHIEF OPERATING OFFICER CHRISTINE CLANCY

GOUP MANAGING EDITOR PAUL HAYES

EDITOR TOM PARKER

tom.parker@primecreative.com.au

ASSISTANT EDITOR ALEXANDRA EASTWOOD alexandra.eastwood@primecreative.com.au

JOURNALISTS

OLIVIA THOMSON olivia.thomson@primecreative.com.au

Komatsu highlights a digital success story, with its collaboration, with Centennial Coal enabling an important step change in the miner’s maintenance practices.

Hexagon is also featured, with its collision avoidance system boosting safety outcomes underground. The Hexagon Underground Collision Avoidance System (UG CAS) can provide 360° operator awareness for surrounding vehicles and equipment.

This edition also offers the opportunity to celebrate the success of Alpha HPA, which is set to establish the world’s largest singlesite high-purity alumina products refinery in Gladstone, Queensland. We sat down with Alpha HPA managing director Rimas Kairaitis to found out more about the company’s novel solvent extraction purification technology.

Looking further south, Victoria has long been a historical gold mining jurisdiction, and while there seemingly isn’t the same gold fever in the state as there was during the gold rush in the 1860s, a slew of exploration companies are looking to commence mining operations once again. This includes Southern Cross Gold and its Sunday Creek gold-antimony project.

We were able to catch up with Southern Cross Gold managing director Michael Hudson to see how the company is progressing, and his insights were fascinating.

Throughout the years, Komatsu’s continued investment in core capabilities and strategic acquisitions has connected smart, diverse people and cutting-edge technologies with a shared belief that partnerships are the best way to solve challenges and meet society’s needs.

As the world grows and evolves, the people who power modern society and develop infrastructure count on partners they can trust to empower them and create value.

For a century, Komatsu has been by your side with ‘dantotsu’ quality, reliability, insight and support. Through manufacturing and technology innovations, Komatsu partners with its customers to create the solutions needed to achieve a sustainable future where people, businesses and the planet can thrive together.

Tom Parker Editor

KELSIE TIBBEN kelsie.tibben@primecreative.com.au

DYLAN BROWN dylan.brown@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227 janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Tel: (02) 9439 7227 Mob: 0498 091 027 jonathan.duckett@primecreative.com.au

ART DIRECTOR

MICHELLE WESTON

michelle.weston@primecreative.com.au

Cover image: Komatsu

QME continues to go from strength to strength, with the 2024 edition breaking exhibitor and attendance records.

18 UNDERGROUND MINING

An electrification bellwether Australian Mining sat down with Epiroc to discuss the company’s 18-tonne ST18 SG battery-electric underground loader.

22 UNDERGROUND MINING

A Matrix of safety and efficiency Matrix Design Australia is expanding its reach across the country through three new distribution partners.

32 UNDERGROUND MINING

E15: A special delivery

Choosing the right support vehicle for an underground mine can significantly increase the productivity of the fleet and reduce operational costs.

42 EQUIPMENT

A historic milestone for Hastings Deering Hastings Deering recently delivered the 6000th Cat D11 dozer to the Lake Vermont coal mine in Queensland. Australian Mining looks at how the Cat dealer made it happen.

46 RECONCILIATION

Balancing opportunity with responsibility

A mining company’s Reconciliation Action Plan provides a solid framework to better support Indigenous communities.

54 EQUIPMENT

A powerful Advantage

When HSE wanted to upgrade its 2500hp Cummins QSK60 engines, Cummins’ Advantage solution was the obvious choice.

62 INDUSTRY INSIGHT

Australia’s critical commodities

Australian Mining takes a look at the outlook for three commodities that will be critical to the energy transition.

68 EVENTS

In the event of excellence

Early-bird registration is now open for the WA Mining Conference and Exhibition, with this year’s show set to be better than ever.

KEEP UP WITH THE LATEST EXECUTIVE MOVEMENTS ACROSS THE MINING SECTOR, FEATURING DE GREY MINING, FORTESCUE, RIO TINTO, AND MORE.

De Grey Mining welcomed Geoff Fenton as the new general manager – operations of the Hemi gold project in Western Australia.

Fenton has over 25 years of experience in mine and technical operations and will commence his role at Hemi on September 2.

In the role, Fenton will be responsible for the operational readiness of Hemi, as well as the transition from development to operations. He will be responsible for the selection of mining contractors, major supply contracts and building out the operations team.

De Grey managing director Glenn Jardine said the company is pleased to welcome Fenton to the role.

“Bringing Geoff into the business as we prepare for construction will provide an early focus on operational readiness for a successful commissioning and ramp-up phase of Hemi through to steady state operations,” Jardine said.

Fenton’s recent roles have been as senior project manager at Hancock Prospecting/Roy Hill and general manager operations and planning at the Karara iron ore operation.

In his role at Hemi, Fenton will work alongside project director Peter Holmes to guide senior management in achieving mining and processing objections and ensuring legislative and regulatory compliance.

A big reshuffle marked the month of July at Fortescue, with a new chief operating officer (COO) and chief financial officer (CFO) appointed in a bid to establish a more “lean, impactful, and agile” company.

Current chief corporate officer Shelley Robertson was appointed COO after joining the company in October 2023.

Fortescue said Robertson is an experienced executive with a career spanning 30 years in oil and gas, mining and renewable energy.

Acting CFO Apple Paget officially moved into the role of group CFO after serving 11 months acting in the role.

Apple joined Fortescue in January 2023 as group manager finance and tax and has 25 years’ experience as a finance executive.

Assistant secretary Navdeep (Mona) Gill has also been moved up to company secretary.

“The company must continually evolve to ensure it remains lean, is best positioned to deliver on its strategy and generate the maximum value for shareholders,” Fortescue said in a statement.

“The streamlined One Fortescue team will be reflective of Fortescue’s board, compromising of nearly 50 per cent women.

“Diversity will continue to be a key measure of our performance, with new targets implemented to drive diversity across the business.”

In August, Noel Pearson, a prominent Indigenous leader, social advocate and lawyer, joined the Fortescue board as a nonexecutive director.

Pearson is the founder of the Cape York Partnership, an organisation focused on advancing economic and social outcomes in northern Queensland. He also established Good to Great Schools Australia, which aims to improve educational results for all Australian students, and the Cape York Land Council, a key body representing Indigenous people in the region.

“I am honoured to be a member of the Fortescue board and I look forward

to making a contribution to this diverse, progressive, and successful business,” Pearson said.

“Fortescue is a proud Australian company that is led by its values from mine site to the boardroom – something I have great respect for.”

Rio Tinto recently welcomed Katie Jackson as the new chief executive officer (CEO) of its copper business.

Jackson holds international experience in the energy sector, having worked in operational and commercial roles for companies such as Shell, Anadarko, Equinor and BG Group.

Jackson is currently National Grid Ventures’ president, where she is responsible for the development and operation of large-scale energy infrastructure assets. Jackson will begin her tenure at Rio Tinto on September 1.

“I am inspired by Rio Tinto’s ambition to deliver the materials the world needs,” Jackson said.

“It is an exciting time to lead the copper business when we have such a central role to play in delivering a low carbon future and I believe my current role delivering major infrastructure projects will help me bring a new perspective.

“I look forward to collaborating with our teams across the globe, in partnership with communities and governments, and lead the business to an even stronger future.”

Jackson replaces Bold Baatar, who is set to become Rio’s chief commercial officer in September.

“Katie brings diverse experience from across the energy sector,” Rio Tinto chief executive officer Jakob Stausholm said. “Her leadership will be invaluable as we shape our copper business for a successful future.”

Global Lithium Resources recently announced the appointment of Ron Mitchell as executive chair.

Mitchell joined Global Lithium in March 2022 as executive director and was then appointed as managing director two months later.

Since May 2022, Mitchell led the signing of an offtake agreement with Canmax, bringing in Mineral Resources as an investor, strategic mergers and acquisitions, and the delivery of a 69.6-million-tonne resource base across the Manna and Marble Bar lithium projects in Western Australia.

“It is an honour to be appointed executive chairman of Global Lithium at this pivotal time in the company’s development,” Mitchell said.

“I look forward to continuing to lead Global Lithium towards the important

milestones in front of us, including transition from explorer to developer.”

The board also appointed current non-executive director and founding director Dianmin Chen as executive director, effective immediately.

As executive director, Chen will work closely with Global Lithium’s project development and executive teams to complete the Manna definitive feasibility study in 2024, as well as work towards a final investment decision in 2025.

“I am also delighted that Dr Dianmin Chen has been appointed executive director,” Mitchell said.

“As the original founder of Global Lithium and with his extensive background in the mining industry, Dr Chen’s expanded role will be a great asset to the development of Global Lithium and the Manna lithium project.”

Mitchell’s appointment coincides with the resignation of non-executive chair Geoff Jones.

Austin Engineering has appointed Sybrandt (Sy) Van Dyk as its new managing director and CEO, taking effect from July 1 2025.

Van Dyk is an experienced financial and resources industry executive who has been president of Perenti’s drilling services division since October 2023.

Before DDH1 was acquired by Perenti in October 2023, Van Dyk had

Sand Quarries Australia Pty Limited, a wholly owned subsidiary of MAAS Group Holdings Limited, has been convicted and ordered to pay a fine of $210,000 in Dubbo Local Court for two water pollution offences. The prosecution was brought by the Environment Protection Authority (EPA).

The offences occurred at the Rawsonville Quarry, also known as Dubbo Sands (the Quarry).

In January 2023, an unknown quantity of polluted water was discharged from the Quarry into the Macquarie River. The water from the Quarry contained high levels of sediment and caused significant erosion to the riverbank. The offences contravened s 120 of the Protection of the Environment Operations Act 1997.

This is Sand Quarries Australia Pty Limited’s first conviction, and it remains committed to reducing adverse environmental impacts and supporting the Dubbo community.

On 24 June 2024, Dubbo Local Court convicted Sand Quarries Australia Pty Limited of the offences and ordered Sand Quarries Australia Pty Limited to:

1. Pay a fine of $210,000

2. Prepare plans of action to restore the environment and prevent the recurrence of the offences.

3. Pay the EPA’s legal and investigation costs; and

4. Publish this notice.

been DDH1’s managing director and CEO since October 2018.

Prior to his tenures at Perenti and DDH1, Van Dyk worked at Macmahon Holdings as CFO from March 2014 to June 2015. He was then promoted to the managing director and CEO positions, both of which he served until October 2016.

Bruce Cleaver holds extensive commercial and mining experience. He was previously CEO of De Beers Group, a global diamond company, from 2016 to early 2023. He then became co-chair of the company, a role Cleaver served until the end of 2023.

Sand Quarries Australia Pty Limited convicted of water

Van Dyk also spent almost 13 years at WesTrac, working in various roles such as chief operating officer WA, CFO and acting CEO.

Before becoming De Beers’ CEO, Cleaver had been at the company since 2005. During those 11 years, he was general counsel and held various executive roles spanning business development and strategy.

Sand Quarries Australia Pty Limited, a wholly owned subsidiary Limited, has been convicted and ordered to pay a fine of $210,000 for two water pollution offences. The prosecution was brought Protection Authority (EPA).

“I am delighted to be given the opportunity to lead Austin from FY26 (the 2025–26 financial year),” Van Dyk said. “David has built Austin to be a fully integrated, global business, and I will be steadfast in my focus on continuing that work.

On July 1, Cleaver became chair and a non-executive director of Gemfields Group, a UK-based gemstone company listed on the Johannesburg Stock Exchange (JSE) and the Alternative Investment Market.

“I will bring my expertise in operational performance and customer focus to ensure Austin remains the global market leader in customised heavy haulage mining equipment.”

At AngloGold Ashanti, Cleaver will serve as a member of the audit and risk committee and the social, ethics and sustainability committee.

The offences occurred at the Rawsonville Quarry, also known Quarry).

Also joining the company was Nicky Newton-King, the former CEO of JSE. Newton-King is a corporate finance and securities regulation lawyer who holds broad expertise in legal, business, regulatory, capital markets and sustainability matters.

In January 2023, an unknown quantity of polluted water was into the Macquarie River. The water from the Quarry contained and caused significant erosion to the riverbank. The offences Protection of the Environment Operations Act 1997 .

Van Dyk replaces David Singleton, who will retire as managing director and CEO on June 30 2025. To ensure a smooth transition, Van Dyk will commence a handover period with Singleton on May 1 2025.

AngloGold Ashanti has appointed two new independent nonexecutive directors, taking effect from July 22.

While at JSE, Newton-King was key in modernising the stock exchange through the implementation of the JSE’s socially responsible investment index, the first index of its type globally. AM

This is Sand Quarries Australia Pty Limited’s first conviction, reducing adverse environmental impacts and supporting the

Fully electric system Remote controlled Flexible cutting profile

This simplified, automated method brings more control to the process and requires up to 50% less equipment than batch methods.

• 100% clean up ⎯ no secondary material removal required

• Up to 50% less equipment needed versus batch process

To get in contact with the Hard Rock team, scan the QR code.

STAGE 2 OF THE HPA PROJECT WILL COMPRISE FULL-SCALE PRODUCTION OF UP TO 10,000 TONNES OF HIGH-PURITY ALUMINA MATERIALS PER YEAR.

AUSTRALIAN MINING SAT DOWN WITH ALPHA HPA MANAGING DIRECTOR RIMAS KAIRAITIS TO DISCUSS THE COMPANY’S NOVEL SOLVENT EXTRACTION PURIFICATION TECHNOLOGY FOR ALUMINIUM.

Aluminium, like many metals, doesn’t spring from the ground fully formed – this essential commodity must first be made from bauxitecontaining alumina.

But the process of converting aluminium to high-purity alumina (HPA) can be energy-intensive, and with the global goal of reaching netzero by 2050 rapidly approaching, miners are constantly looking for more ways to limit their environmental impact while meeting the increased demand for HPA.

According to Global Market Insights, the HPA market size exceeded $US2.8 billion ($4.27 billion) in 2023 and is projected to grow to $US8.8 billion ($13.4 billion) by 2032.

The demand is driven by factors such as the increased use of light-emitting diode (LED) lighting, as well as HPA’s key role in lithium-ion batteries for the

electric vehicles needed for the global energy transition.

The importance of HPA was further highlighted when the Federal Government added it to its critical minerals list in March 2022.

HPA is at the heart of Alpha HPA, an ASX-listed company that operates a downstream chemical materials processing facility.

Alpha HPA managing director Rimas Kairaitis told Australian Mining that the company evolved out of an upstream mining business.

“Going back a few years ago, we were looking at extracting nickel, cobalt and aluminium from a resource in central New South Wales,” Kairaitis said.

“It was when we were assessing technologies to extract and purify aluminium into a high-value product that we connected with the technology provider we now work with.”

Traditionally, the mining industry takes aluminium metal, dissolves it,

then oxidizes it in a pure environment to produce HPA oxides and chemicals.

Because aluminium metal is energyintensive, this process produces high amounts of carbon and chemical emissions and creates a significant amount of waste, which can cause harm to the environment. It is also one of the most expensive metals to produce.

However, Alpha HPA’s purification process is changing the game. Dubbed Smart SX technology, this process uses established solvent extraction (SX) to transform aluminium.

SX is commonly used on metals such as copper, zinc, uranium and nickel, with about a quarter of the world’s copper going through an SX circuit.

Alpha HPA’s Smart SX technology has commercialised what the company is calling the “world’s first” adoption of SX purification on aluminium.

The technique isolates aluminium into a purified chemical process stream, which can be turned into a variety

of aluminium forms. By combining aluminium in its ionic form (AI+3) with oxygen, HPA is produced.

By combining AI+3 with water via Smart SX technology, HPA hydroxides can be created. Combining AI+3 with sulphates produces ultra-pure aluminium sulphates, demonstrating the technology’s flexibility and versatility.

“The technology was recognised as being quite novel as it was able to extract aluminium from any aluminium-bearing solution and deliver a high-purity process stream that allowed us to make HPA and other HPA products,” Kairaitis said.

“It was this that made us realise this world-first technology required our sole focus. Rather than operating an extractive mining process, we’re better off leveraging consistent, semi-refined input that could be provided from alumina refineries in the Gladstone region of Queensland.”

Smart SX sees up to 70 per cent lower total carbon emissions in comparison to historical HPA processes by not using aluminium metal as feedstock.

Instead, it uses alumina hydrate from Rio Tinto’s Yarwun alumina refinery near Gladstone, operating at atmospheric pressures and lower temperatures.

“The alumina hydrate is consistent and relatively pure already,” Kairaitis said. “We prepare that material to implement into a solution to present to the extraction technology.

“This is a more efficient use of the technology as it simplifies the business in that we no longer manage extraction of minerals. We are purely in the mineral processing sector.”

As part of its decarbonisation efforts, Alpha HPA recycles 100 per cent of its key chemicals as by-products. Alpha HPA’s proprietary technology requires reagents to purify raw materials, which blasting systems company Orica manufactures at its plant in Yarwun, Queensland.

Alpha HPA sends the by-products to Orica and they are returned as reagents via a waste-free process.

“The technology works through high volume reagent flows that come in and out of the process,” Kairaitis said. “Under a set of

“By being in close proximity to Orica, it allows us to have an almost zerowaste facility … we have by-products coming in and by-products going out, with the net cost to our business being lower and more environmentally and commercially sustainable.”

Further cementing Alpha HPA’s presence in Gladstone is its soon-tobe established HPA products refinery, which is benefiting from the company’s established relationships with Orica and Rio Tinto.

“We’re leveraging Orica infrastructure that’s 50 metres away and Rio Tinto’s aluminium processing infrastructure that’s 2.5 kilometres

“It’s incredibly lenient having your key inputs within close proximity to the business.”

Alpha HPA describes its HPA First project as its Smart SX Technology “in action and at scale”.

Set to be one of the largest single HPA refineries in the world at 10-hectares, the HPA First project comprises two stages.

Stage One is currently in production and represents the first commercial application of Alpha HPA’s Smart SX technology to produce 99.99 per cent pure aluminium products.

“Stage One has been a key enabler for

“It’s allowed us to operate our Smart SX technology at a small commercial scale to produce aluminium products across our full range for our customers and deliver them at a volume that is meaningful and de-risks the process with respect to the project’s technical and commercial components.”

In May 2024, Alpha HPA made a final investment decision (FID) on Stage Two of HPA First, which followed the successful construction, commissioning, and operation of Stage One.

The Stage Two FID is supported by a $400 million loan from the Federal Government, an amount comprising

THE GLADSTONE FACILITY REPRESENTS THE FIRST COMMERCIAL APPLICATION OF ALPHA HPA’S PROPRIETARY LICENSED SOLVENT EXTRACTION AND REFINING TECHNOLOGY.

raising by Bell Potter Securities and Macquarie Capital, as well a share purchase plan.

The Stage Two FID allows Alpha HPA to begin project execution and construction, which is expected to commence in August 2024.

Once operational, Stage Two will create 120 full-time job opportunities for the local community and generate more than 300 jobs during construction. The site will run on 100 per cent renewable energy, further decarbonising the process.

“All the engineering is well advanced, and that will see us in production by late 2026,” Kairaitis said.

“Stage Two is full-scale commercial implementation of the Smart SX technology … The operational knowledge that builds (in Stage Two) is an important de-risking step because we’re taking skilled people and training them in a new process.

“Through this training, they gain a discrete skillset and become the only people in the world that can run our technology.”

for their ultra-high purity requirements and product specification demands,”

Kairaitis said.

“We will continue to add new names to the business as we work through technical qualification. Unlike a traditional mining business, we don’t have one or two customers. We’re a specialty materials business that might have 30 or 40 customers. It’s quite a different model.”

Further aiding Alpha HPA’s global expansion is its memorandum of understanding (MoU) with Orica, which will see the companies investigate the feasibility of establishing a new HPA manufacturing facility in North America similar to the one in Gladstone.

“We see a lot of interesting demand coming out of North America,” Kairaitis said.

“Geopolitically, they have a lot of focus on reshoring supply chains. As a result, the forecast demand in North America for the semiconductor sector is looking promising. Having a facility in North America in five to 10 years

the Smart SX technology because we’re going to run up against not having enough material to meet demand, so we’ll need facilities,” Kairaitis said.

Alpha HPA’s product range goes beyond HPA. It also includes products made from alumina hydrates, aluminium nitrates and aluminium sulphates.

we’re in a wonderful position to have been funded and are now progressing to make our materials and selling them,” he said.

“For the remainder of 2024, we want to advance Stage Two of the HPA First project to the construction phase, hold our schedule and budget and keep adding customers to the business.” AM

As Australia’s largest regional mining event, the Queensland Mining and Engineering Exhibition (QME) welcomed over 5000 visitors to Mackay Showgrounds over three days in late July, hosting over 300 exhibitors and 29 seminar sessions.

The Seminar Series, sponsored by Komatsu, opened with a keynote address from Federal Resources Minister Madeleine King, who highlighted the importance of holding events like QME to remind people of the value regional centres like Mackay provide to the economy.

“People in Mackay and in central Queensland understand how important the resources industry is to Queensland’s economy,” she said. “And Queenslanders understand how important the resources industry is to the prosperity of the state and nation.”

King said the whole country feels the benefits of a strong resources industry but implored the mining sector to not rest on its laurels.

“The economy is changing,” she said. “The nature of global trade is changing … Australia needs to respond to these

EVERYTHING FROM DIGGERS AND DOZERS WERE ON THE GROUND AT QME 2024.

changes so we can create jobs and wealth for future generations.”

The 500 Pavilion hosted the Decarbonisation Accelerated program on the Wednesday, with BHP vice president climate Graham Winkelman giving the opening keynote address.

“In the 2022–23 financial year, BHP’s operational greenhouse gas emissions were already 32 per cent below the baseline,” he said. “This performance has been achieved primarily by introducing renewable electricity via power purchase agreements.

“The path ahead of us remains consistent with our operational greenhouse gas emissions targets, and we continue to make good progress towards it.”

On hand at QME 2024, Australian Mining caught up with a range of the country’s brightest mining equipment, technology and services (METS) companies to discuss why events like QME are so important.

Komatsu had its GD955–7 grader on display at QME – a machine specifically built for mining operations, able to grade

33 per cent more area per hour than the previous model.

The GD955–7 is well matched to larger haul trucks, making it a strong addition to mining fleets. The machine also comes standard with Komatsu’s 360° camera system, KomVision, housing a five-camera system to provide a view around the vehicle.

Komatsu also sponsored the QME Seminar Series, with Komatsu Australia sustainability product manager Kevin Mascarenhas discussing the company’s sustainability strategy.

Mascarenhas’ presentation highlighted how Komatsu integrates eco-friendly technologies in its machinery, optimises their use and reduces environmental impact through efficient manufacturing and operations.

When asked about the importance of events like QME, Mascarenhas said it provides an important opportunity to connect with the workers that own and operate Komatsu machinery.

“Komatsu is a global business, but the people that work on and operate Komatsu machines, they attend shows like this,” he told Australian Mining “Operators have the opportunity to understand what Komatsu’s

global strategy looks like and how it translates into their sites bringing in new technologies like autonomy or electrification like batteryelectric machinery.”

Mascarenhas said there is so much innovation on offer at events like QME, with plenty to be gained from walking the grounds and engaging with other exhibitors.

“Australia is one of the most advanced mining industries in the world,” he said. “We’ve pioneered automation and many other mining solutions and events like QME enable people to see what everyone’s working on and where the industry is heading.”

Having been part of the event for the past decade, Hastings Deering sees QME as an important opportunity to connect with the community.

“We rarely get the chance where we’re not at the coal face to meet our customers in a different environment and have that opportunity to catch up and build on our partnerships,” Hastings Deering executive manager for site performance Matt Small told Australian Mining.

Small said Hastings Deering is nudging 1000 employees in Mackay alone, highlighting the company’s strong presence in the regional city.

“People expect us here and we expect to be here,” he said. “We’re part of the community, we’re tapping 1000 employees and have 68 apprentices here in Mackay, and their families expect us here as much as our customers.”

Hastings Deering had the Cat 988 XE wheel loader on display at QME 2024, which Small said was a “good size for an event like this”.

“The 988 XE wheel loader has an electric drivetrain, which provides many different efficiencies including greater fuel economy,” he said.

An electric drivetrain has the potential to reduce the total cost of ownership of the 988 XE, with reduced wear and tear a key benefit, while the loader has proven its ability to meet or exceed production targets.

Small said customers largely do their own legwork and research, with events like QME important to “see the iron in the flesh”.

FLS has built a strong presence in north Queensland, with many of its plant and technologies fitted at coal and hard rock mines across the region.

FLS Asia Pacific head of eastern region sales Karl Spaleck said events like QME provide an important opportunity for companies to highlight their commitment to the region.

“We’ve got great innovations and equipment, and we’re also finding ways to better service our customers,” Spaleck told Australian Mining

“We see QME as an opportunity to show people who we are and demonstrate our presence in the region – we’ve got service centres in Mackay and Rockhampton to support our north Queensland customer base.”

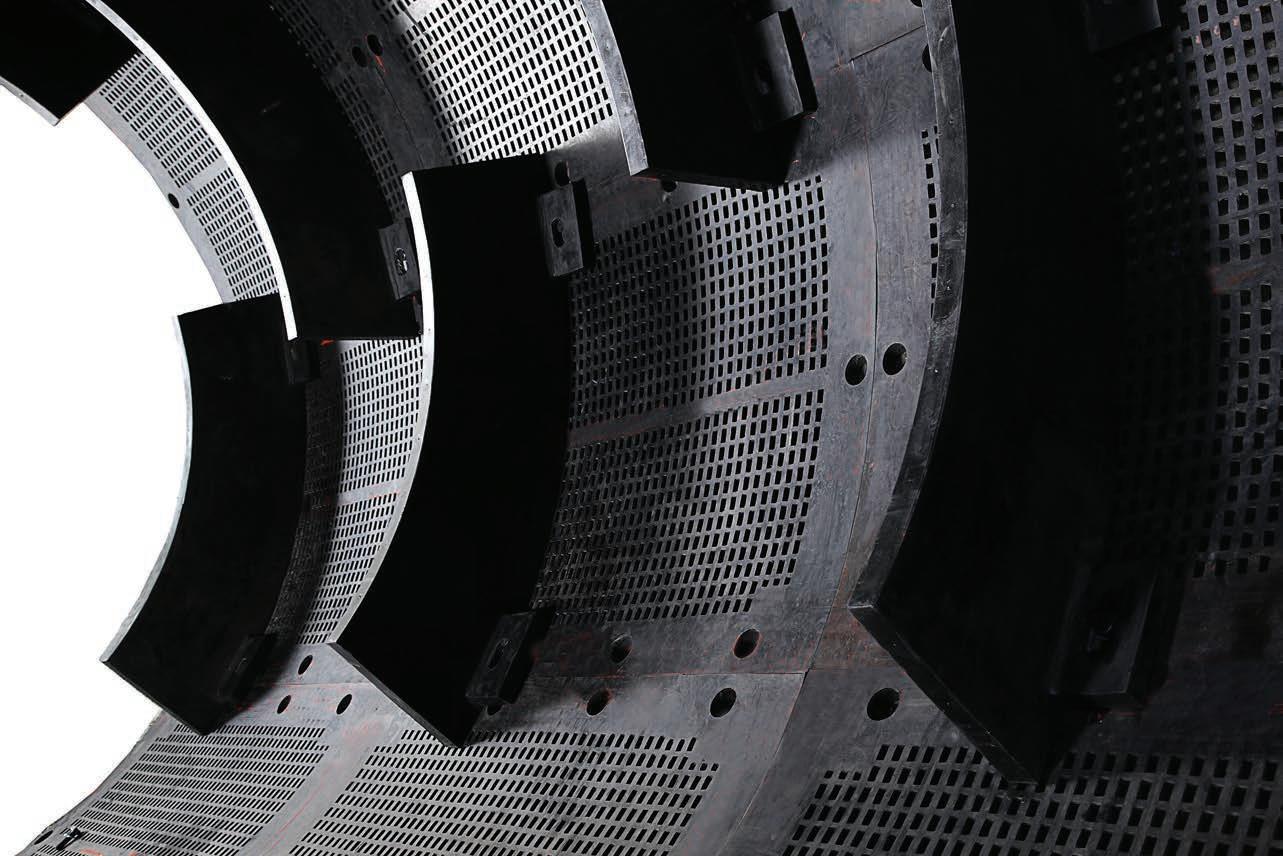

Spaleck said FLS’ REFLUX technologies – which offer enhanced separation efficiencies in mineral processing – are fitted at mines in north Queensland, while the company’s grinding mills and crushers are also located throughout the region.

“When attendees hear that you can reduce tailings, electricity and water, for example, these are things that sometimes don’t get highlighted in the day-to-day running of an operation,” he said.

“But if you look at a yearly consumption rate, you can see how much you can save, and you can turn that into million-dollar savings, so it’s a significant number. People can get awareness of that through conversations had at QME.”

Dredge Robotics had it all at its QME booth as the company showcased its cutting-edge robotic dredging technologies.

Attendees had the opportunity to explore Dredge Robotics’ advanced systems that integrate automation and precision to streamline dredging processes, reduce operational risks, and improve environmental outcomes.

Dredge Robotics chief executive officer Antony Old said attendees were pleasantly surprised at how the company’s products can effectively and safely dredge ponds without damaging the protective liner.

“We had people come up to us and say they didn’t know this technology existed,” Old told Australian Mining

“In other dredging processes, you typically have a person on a barge, in an excavator or in the pond digging with equipment. You’re exposing your staff to whatever’s in the pond, but with the robotic dredging system, those risks are totally eliminated.

“Our robots are versatile, allowing them to operate in various environments from small assets to large tailing dams, all while maintain efficiency.”

Dredge’s fleet of robots can cut the need for a scheduled shutdown as the robot can clean tanks with all

types of sediment, from light mud to compacted clay. This includes sediments that have low or high pH levels, cyanide, corrosive liquids and heavy metals.

“Our online robotic solutions use an advanced suite of sensors and GPS to clean with pinpoint accuracy while your wastewater assets remain in service,” Old said.

“People didn’t realise we can desludge your wastewater ponds, raceways, digesters, oxidation ditches or sedimentation tanks.”

AusProof was a prominent participant at QME, recognising the critical importance of reconnecting with customers and industry peers.

The event provided a valuable platform for AusProof to engage directly with clients, reinforcing relationships that have been pivotal to the company’s success.

AusProof Queensland sales representative Craig Feil said the face-to-face interactions are vital for understanding customer needs, discussing innovative solutions, and receiving direct feedback.

“To be able to help someone in person and take feedback from customers is where we find the most value at QME,” Feil told Australian Mining.

“You may speak to a customer once or twice a year and not know what they look like other than their email or phone number.”

With a passion for innovation and exploring the unknown, AusProof’s research and development (R&D) team is always looking for the next

MacKellar

MacKellar used QME as an opportunity to foster relationships with mutual exchanges.

QME provided the perfect backdrop to celebrate the company’s ongoing work and collaboration on Queensland projects such as the Jellinbah, Carmichael, Callide and Middle Mount coal mines.

MacKellar general manager, business development Dave White said QME allowed the company to engage with

“It’s good to get an understanding of the suppliers in the region as suppliers are so important to us,” White said. “We are also here to fly the flag for MacKellar as a place of choice to work.”

White highlighted the major players involved in the event such as Anglo American and Coronado, making QME a prime networking opportunity.

He also noted MacKellar’s strong regional reputation and ambitious growth plans, including geographic and commodity diversification into critical

mining, civil works, and infrastructure construction, Mackellar showcased its extensive capabilities, supported by a robust fleet and a workforce of nearly 1500 employees.

Revizto

Revizto used QME as an opportunity to network extensively across the mining sector.

Highlighting the company’s evolution from dry hire services to comprehensive

Revizto Asia Pacific sales executive Nick Seibel said the company saw plenty of value in engaging with a diverse array of professionals from different regions and specialties, including international attendees.

“It’s been great to network with a large number of people who have come from different areas, different sectors of mining and different places,” he said.

The primary focus was on introducing Revizto’s digital engineering solutions which facilitate collaboration, design coordination and on-site delivery using 2D drawings, drone scans, and 3D models.

“We’ve been looking at introducing Revizto to the mining sector ... it’s been great to introduce new technology that is immensely useful for industry,” Seibel said.

QME provided a balanced mix of meeting new contacts and reconnecting with existing clients, fostering meaningful conversations and potential collaborations.

With record-breaking attendance numbers and the introduction of new and innovative technology, there’s little doubt that QME 2024 was one for the history books. AM

–

–

AUSTRALIAN MINING WITH EPIROC TO DISCUSS THE COMPANY’S 18-TONNE ST18 SG BATTERY-ELECTRIC UNDERGROUND LOADER.

The mining industry is changing, with traditional practices increasingly challenged as heightened sustainability obligations are placed on miners.

Through measures such as the Australian Government’s Safeguard Mechanism, companies that aren’t vigilant about managing their carbon footprints are being penalised, with potential impacts to profitability.

And the need to decarbonise is only set to increase going forward, with more and more miners adopting electric technologies to best position themselves ahead of a green future.

A key electrification partner is Epiroc, a global original equipment manufacturer (OEM) and digital pioneer driving new frontiers in mining innovation.

Epiroc recently introduced its 18-tonne ST18 SG battery-electric underground loader, the most powerful loader yet in Epiroc’s battery-

gas emissions.

“The ST18 SG is the evolution of our ST18 S diesel product,” Epiroc’s Australasia regional application expert, material handling, Cameron Kings told Australian Mining.

“We’ve brought the machine into a BEV (battery-electric vehicle) spec but kept many of the proven characteristics of the ST18 S, with the front-end the same and the operating system largely

to less vibration,” Kings said. “The machine also emits zero DPM (diesel particulate matter) of course, which is becoming increasingly important in an underground environment.”

Such is the quiet nature of the machine, Kings explained how workers can freely have conversations within an underground mine while the ST18 SG trams back and forth.

The ST18 SG also has its

dirt, an operator of a diesel machine needs to be mindful of, ‘What’s my engine doing? If I bog down too much, I’m going to lose pile penetration and lose my hydraulic capability’.

“Whereas the battery-electric ST18 SG has two isolated systems, with a single traction motor for the propulsion circuit, so the machine can drive completely independent of the hydraulics, which are powered by their

“So when you’re digging, from a throttle perspective operators only have to concentrate on pile penetration. Then as you use the controls to manipulate the boom and bucket, they’re on a separate circuit.

“You’ve got the auxiliary motor ramping up and down, controlling the hydraulics so you’re getting optimal hydraulics while you’re digging, but then you’re also getting optimal traction by controlling the machine with the throttle pedal.”

Kings said the ST18 SG’s ability to deliver 450kWh of usable battery capacity is a “significant jump” from other machines on the market, resulting in fewer charging stops and longer uptime.

There is also capacity to further prolong battery life with opportune charging.

“The good thing about these batteries is you don’t have to charge them from empty to full,” Kings said.

“When we talk about a charge cycle, we’re talking about energy in and energy out. We can charge from 20 per cent to 50 per cent, unplug the machine and use it, then bring it back.

“With opportune charging, we look at the application. If you’re extracting material from one heading, once the heading is depleted, you’ve got 45 minutes to plug it back on the charger.

“Depending on available charging infrastructure, the battery can take around 90 minutes to charge from 10 per cent to 90 per cent with current technologies. After 45 minutes, it gives you a good 30 to 40 per cent of charge back in the battery, which is ample to then go and do the next heading.”

Kings highlighted a raft of safety benefits too, with the ST18 SG boasting a thermal management system.

“Regardless of how you wish to charge your battery, our battery is always being

life by keeping temperatures in the correct range so as not to overheat the battery.”

Epiroc has also installed other safety measures on the ST18 SG, including a high voltage interlock loop (HVIL).

“The idea of the HVIL is, if you go to the machine and it’s live, and you open a cover or a lid on a box that may have voltage in it, the HVIL cuts the machine out and shuts the battery down,” he said.

“Every cover on the battery has a HVIL switch on it, so any time there’s

And as more and more deployments are proven successful, the pool of electric adoption is growing wider.

But, as Kings explained, it’s not a “flick of the switch”.

“I was involved with installing the first Epiroc battery machine into Australia, and, like any foundational technology, there were some hurdles,” Kings said. “While there are those in the industry enthusiastic about going to a full battery fleet, they need to understand that there is a lot of

Ex-certified and suitable for use in underground operational sites, including Group 1 hazardous environments, AusProof’s stainless steel products can also be used in metalliferous sites if a higher level of durability is desired.

Restrained plugs and receptacles range from 660V - 3,300V, with 11kV couplers available for your high voltage needs. Reduce downtime while increasing safety and maintenance efficiency through replaceable flamepaths, with other features and accessories available to further aid in these areas.

Do you have a question about what solution will suit your site? The AusProof team is available to answer your questions and help you find the ideal cable coupler to meet your needs.

AUSTIN ENGINEERING HAS BECOME A PROMINENT NAME IN THE INTERNATIONAL MINING INDUSTRY FOR ITS INSPIRED ENGINEERING SOLUTIONS AND SERVICES.

Austin Engineering is driving innovation in the underground mining industry with its advanced truck bodies and tyre handlers.

The company’s latest offerings aim to enhance safety, efficiency, and cost-effectiveness, reinforcing its position as an esteemed provider of mining equipment.

Austin Engineering chief executive officer David Singleton said the company is dedicated to delivering high-tech, custom-designed products that cater to the specific needs of mining operations worldwide.

“Each of our truck trays are custom designed to suit particular sites, payload requirements, and other applications, ensuring customers get the very best out of their equipment,” Singleton said.

The JEC underground truck tray is one of the standout products in Austin’s range.

Designed with a curved structure, the JEC tray ensures safe ore transport while minimising material hang-up. Its adaptability allows the tray to be mounted on any underground truck chassis using hoist and pivot pins.

The tray incorporates several key features, including solid impact plates and curved leading edges for impact resistance, shallow angular transitions to reduce carryback build up and reinforced areas for structural protection.

Development of Austin’s underground truck bodies dates back to 2010 when a major mining client approached the original equipment manufacturer with issues related to significant carryback.

The presence of wet material was impacting their overall payload

capabilities, and the client needed a solution.

Austin’s engineering teams collaborated closely with the miner, addressing challenges such as high material impact, abrasion from minimal blasting practices, and confined space risks.

The resulting tray design offered solutions to these issues, including improved carryback reduction, increased wear resistance, and enhanced operational efficiency.

“The JEC underground truck body design was a result of having worked collaboratively with our client to provide a solution for a particular problem,” Singleton said.

“This has enabled our client to achieve continuous improvement and deliver the lowest ‘cost per tonne’ solution for their operations.”

In addition to its truck bodies, Austin Engineering has developed a range of tyre handlers for both surface and underground applications. These tyre handlers have contributed to the development and evolution of today’s dual-arm tyre handler industry standard, which dates back to the 1990s.

The company’s dual and threearm tyre handlers, with between 2500–10,000kg capacities, are fully hydraulically controlled. This feature can deliver variable force and enables precise control when moving the tyre handler.

Austin’s dual-arm tyre handler is a cost-effective option designed for versatility across the entire tyre and rim spectrum and are fully adaptable to loaders, telehandlers and tool carriers.

The dual-arm tyre handler offers features such as body and pad rotation, side shift capabilities, and a quick

hitch for added convenience. Optional accessories like crane jibs and fork frames further enhance the tyre handler’s functionality.

The JEC T3 three-arm tyre handler is in a league of its own when dealing with confined spaces. It has a 30° slew capability for precise alignment, fully adjustable clamp arms, and safety lock valves.

Austin designed the JEC T3 tyre handler in response to a serious accident in 2010 involving a tyre change on an underground loader in the Goldfields region of Western Australia. This highlighted the risks associated with traditional tyre handling methods.

Having effectively addressed these risks, with safety features including added protection from flying debris in case of a tyre explosion and the ability to compress the tyre sidewall without causing damage, the JEC T3 tyre handler is currently being successfully used in mines across Australia and internationally.

Austin provides customer support for the lifecycle of its products, including inspection, maintenance and

spare parts. The company also provides customer support for its Mainetrack asset management and wear monitoring system fitted to its trays and buckets.

Operating across four continents, Austin designs its products to meet the specific needs of different mine sites and commodities. Having this global experience results in efficient operations and a strong investment return for Austin customers.

Looking to the future, Austin is focusing on product design and innovation, particularly as the mining industry’s needs evolve.

The company is committed to creating sustainable solutions, which include reducing steel usage, increasing payload capacity and minimising carbon emissions.

“We firmly believe that this process will ultimately result in better products that will reduce impacts on the environment and support the transition to a more sustainable future,” Singleton said.

“While these represent challenges to the whole industry, they also offer opportunities to evolve the way we do business.” AM

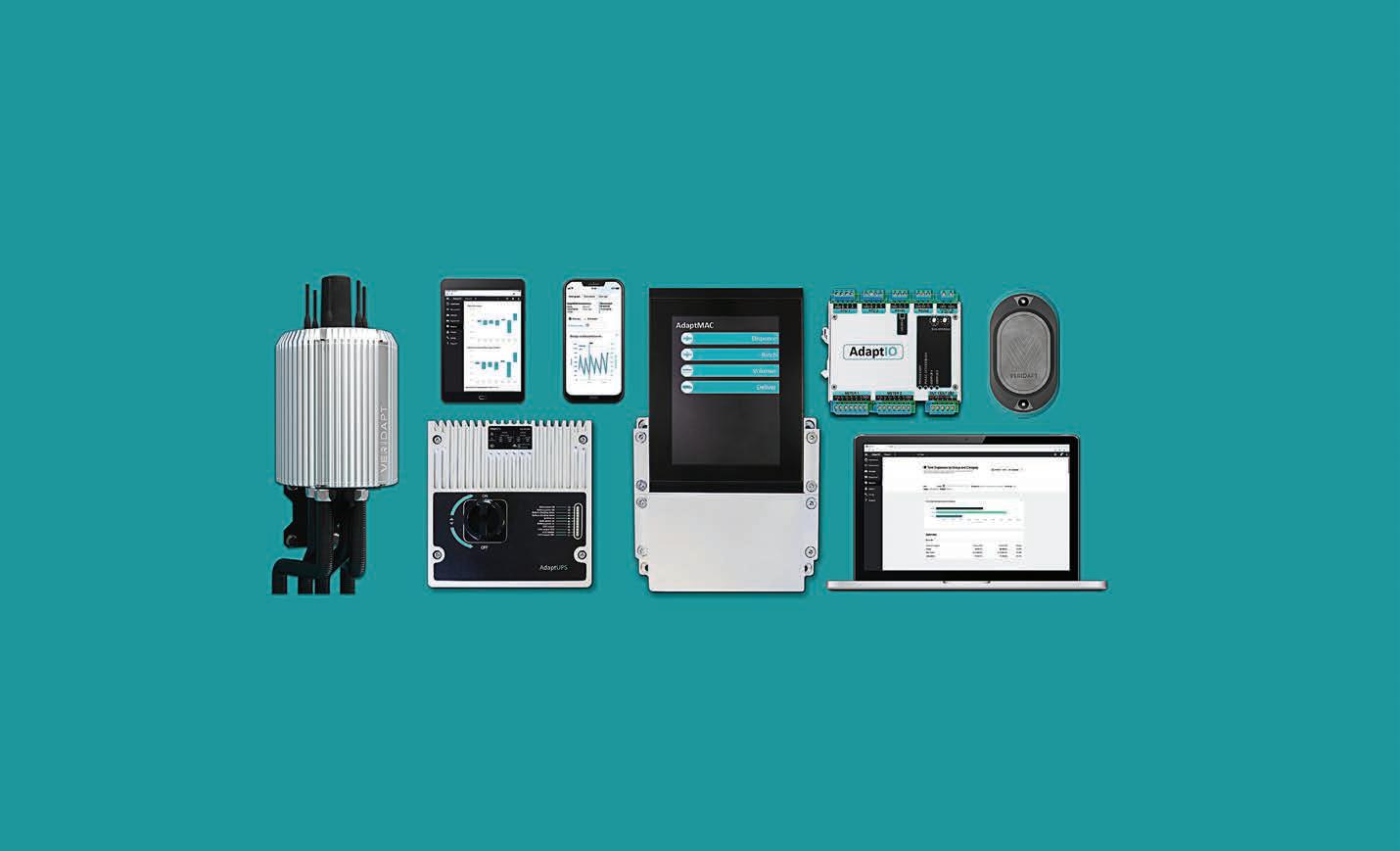

MATRIX DESIGN AUSTRALIA IS EXPANDING ITS REACH ACROSS THE COUNTRY THROUGH THREE NEW DISTRIBUTION PARTNERS.

Safety has always been at the heart of Matrix Design Group, an international company that provides operations-friendly applications that meet the mining industry’s ever-changing regulations.

As part of its global expansion, Matrix founded its Australian branch in March 2022 to support the Australian and New Zealand markets with its leading safety technologies: the IntelliZone proximity detection system (PDS) and OmniPro Vision AI visual artificial intelligence collision avoidance system.

Matrix’s new Australian distributors are further aiding this reach.

In 2016, Matrix formed a strategic partnership with Monitech Mine Monitoring Systems, which saw Monitech become the sole South African distributor of IntelliZone.

“We saw what Matrix did in South Africa with a distributor, and it worked really well,” Matrix Design Australia and New Zealand general manager Pieter De Klerk told Australian Mining.

“The success of our relationship with Monitech in South Africa really helped establish the business model we

like-minded engineering companies with strong values and first-class technical capabilities, who are highly customer focused.”

After considering several options, Matrix chose Specialised Engineering Technologies (SET) as its New South Wales distributor, Cap Coast Engineering Services (CCES) as its Queensland distributor, and Nolara Automation Solutions as its distributor in Victoria and South Australia.

When a distributor sells and delivers Matrix’s solutions to a mine site, they use their local experience and understanding of working with large original equipment manufacturers to help customers understand specific Matrix applications.

“Matrix Australia started two years ago but the company has been in the Australian market since 2018, so the distributors knew about Matrix’s products by working on the mines and seeing trials take place,” De Klerk said.

“Once we officially partnered with our distributors, we jumped straight into the technology, which they picked up very quickly.”

Through this training, SET, CCES and Nolara learned best practices for installation, various software

many adjustments for fine-tuning to the customer’s needs. When the team needs additional support, Matrix Design Australia is at their disposal.

“If you take the three distributors and the Matrix employees in Australia, we probably have 400–500 years of combined experience in underground mining,” De Klerk said.

SET

SET general manager Jacob Brown said SET and Matrix have had a close working relationship for over 12 months.

“Since becoming involved with Matrix, I’ve been extremely impressed with the company’s international business structure,” Brown told Australian Mining. “Matrix has key

“They are very supportive. Whenever we need help, they’re always there to pick up the phone and respond to emails within a quick timeframe, which makes our job as distributors easier.”

SET distributes both IntelliZone and OmniPro. IntelliZone is designed for use on various types of underground mobile equipment, allowing users to create customisable caution, shutdown and operator zones.

It has been fully IECEx-certified for underground coal in Australia since 2018.

Brown first heard about IntelliZone while working as an electrical engineering manager across multiple underground coal mines in NSW.

“PDS has been discussed over the years, but there was always a sense of uncertainty about reliability and how these systems would be practically implemented,” he said.

“I attended my first IntelliZone presentation at a mine in Narrabri in early 2023 and the feature that stood out to me was the patented SharpZone technology and its ability to shape the zones.

“The SharpZone technology is a game changer and what sets the Matrix

product above competitors who utilise basic bubble zone technology.”

IntelliZone detects workers in lowvisibility or obscured line-of-sight locations and zones, automatically extending or contracting based on mobile equipment direction and speed.

“The SharpZone technology provided SET with the confidence that the product could be successfully implemented in a reliable and practical way as it allows people to stand in safe positions while still completing their job,” Brown said.

IntelliZone is durable, easy to maintain and complies with EMESRT (Earth Moving Equipment Safety Round Table) levels 7 and 9.

“IntelliZone has an easy interface to work with, learn, configure, change and commission,” Brown said. “Everything about it is well designed and set out.

“The solution’s componentry is sent to Australia from the US, but all the IntelliZone enclosures and kits get manufactured and assembled locally in Australia.

“Matrix has a local Queensland warehouse stocked of kits and spare parts that are easy to access. This means

we aren’t relying on shipments coming from overseas.”

SET is currently implementing IntelliZone at seven NSW mines, all of which have different machines, operational challenges and mining techniques.

“With IntelliZone, you can customise it to suit each mining application,” Brown said.

“We will set up a particular set of zones and configuration files for one mine, which will work perfectly for them. Then we go and adjust it for the next mine because they might have a different operating technique which requires slightly different safe standing zones.

“That’s the biggest advantage with this solution.”

Established in 2021, CCES offers engineering solutions across a range of disciplines, including proximity detection and collision avoidance.

CCES first encountered IntelliZone in 2017.

“I first met Wes Chitwood, Matrix vice president of international operations and the US Matrix team when they came to a mine I was working at in a technology role,” CCES owner and director Loz Hemmings said.

“The IntelliZone system was demonstrated in an office environment and although it ticked all the boxes for me and my project, the appetite at the time wasn’t there for the company in terms of a PDS solution.

“Following my departure from the company, the creation of CCES and having known De Klerk for many years, we started having conversations about how the two businesses could complement each other.”

It was the ease of use, repeatability and software-based structures in IntelliZone and OmniPro that made CCES want to represent Matrix in Queensland.

“A core selling point for me is that we want to give a customer consistency and reliability with the solutions we provide, and the Matrix systems fit this mould,” Hemmings said.

Through CCES, interest for Matrix’s solutions is increasing, with enquiries coming from several mine sites and active demonstrations taking place.

“I am excited to see what the future brings with Matrix’s greater presence in Australia and the way the system can evolve as it embeds itself into the Australian mining industry,” Hemmings said.

Backed by more than 15 years in the mining industry, Brendan Nolan founded Nolara Automation Solutions in 2021.

The company is dedicated to bringing automation to big and small businesses. A way in which Nolara does this is by distributing OmniPro across Victoria and South Australia.

“The Matrix values and goals align with those of Nolara,” Nolan said. “Matrix’s products are focused on improving safety in the workplace, which is the most vital application for automation.”

OmniPro uses visual AI technology to immediately detect personnel or objects moving in the projected travel path of mobile equipment, even in lowlight and all-weather conditions.

Like IntelliZone, OmniPro creates zones within the view of the camera that can alert the operator if someone is close to the machine. These zones can be customised to meet specific needs.

Again, like IntelliZone, OmniPro generates caution zones in yellow and alert zones in red. OmniPro also minimises nuisance alerts that often desensitise workers to alarms and operates without the need for personal wearable devices or tags. The technology can identify individuals in any posture.

“OmniPro brings cutting-edge AI technology into practical application for increasing safety of people around machinery,” Nolan said.

“At Nolara we are focused on building solutions through automation, and OmniPro is a central building block for applications that keep people safe from harm.”

With distributors locked in on Australia’s east coast, Matrix is looking to further expand in Western Australia and the Northern Territory in the near future.

“We’re also doing a lot of work in New Zealand and there is a lot of interest in Papua New Guinea, so the plan is to continue expanding in those areas,” De Klerk said.

Backed by experience, intelligence and now three Australian distributors, Matrix provides award-winning safety solutions that speak for themselves.

CAPS

COMPRESSORS

BACKED BY OVER FOUR DECADES OF EXPERIENCE, CAPS AUSTRALIA IS DELIVERING THE NEXT GENERATION OF AIR COMPRESSORS.

The Australian mining sector has long had a focus on keeping its operations efficient. To achieve this goal, emphasis must be placed on the machinery being suited to the climatic conditions in which it operates.

Air compressors are a key part of supporting mining applications such as exploration drilling, maintenance, blasting and underground ventilation systems.

With more than four decades of experience, 10 Australian branches and 24–7 maintenance and emergency breakdown services, CAPS endeavours to lead the industry through its compressed air and power solutions and services.

As part of its efforts to provide those services, CAPS has been supplying Ingersoll Rand equipment since its conception. This long-founded partnership has recently led to CAPS joining the Ingersoll Rand family, giving CAPS the ability to increase its portfolio of products and continue to deliver its range of solutions.

“The air compressors from Ingersoll Rand have been proven to be durable and reliable, especially within the mining industry,” CAPS compressed air product manager Paolo Lazzari told Australian Mining.

Ingersoll Rand’s stable of compressors includes the M Series M160, a single-stage rotary screw air compressor that delivers a capacity of 918 cubic feet per minute at a maximum working pressure of 8.5 barg and 160-kilowatt nominal motor rating.

Key features of the M160 compressor include its motor, which operates at peak efficiency under full-load conditions to help ensure maximum energy savings, and its airend, which requires minimal maintenance.

Another feature that makes the compressor stand out in the market is its cooling air configuration, which sees the cooling air flow from side-to-side, rather than coming in from the side and being discharged from the top.

“You don’t want the hot cooling air to recirculate back into the compressor, causing it to overheat and operate inefficiently,” Lazzari said. “The Ingersoll Rand cooling system keeps it at optimal performance temperature.”

Using its technical expertise in adapting standard compressors, CAPS tailors M160s to meet the needs of specific mining operations.

“We take a standard machine and modify it to suit the required application by configuring a 400volt motor to 1000 volts, the latter of which is standard voltage in the mining industry,” Lazzari said.

CAPS offers an underground miner’s pack that features a M160 compressor, a miner’s pack skid and frame, outdoor modifications, a high-dust filter, an incoming power isolator, marine windows, a VR2400S wet air receiver, and an automatic detection firesuppression system.

“We add marine windows to the controller to ensure the brains of the compressor do not fail under harsh conditions, as well as an incoming isolating switch to the power,” Lazzari said.

“Furthermore, we take the compressor and package it completely, with the air receivers, isolation valves and safety valves all certified for mining applications.

“Overall, we take a standard globalleading product and ensure it is fit for purpose for the harsh conditions of Australian mining applications.”

With so many services on offer, CAPS continues to be a customerfocused company dedicated to providing the best possible aftermarket support.

“CAPS already stocks approximately 98 per cent of the consumable parts for M160 compressors,” Lazzari said.

“We hold spare parts at our head office and at all our branches across Australia. Our service agreements further our support of customers,

with our qualified service technicians going out to site to perform the correct service intervals.”

The CAPS underground miner’s pack has become a tried-and-true solution to multiple mine sites in Western Australia, with one using the solution for more than 80,000 operating hours.

“They were so impressed with the longevity of their machine and the way it’s been operating, that they’ve made the pack a standard feature on the mine site,” Lazzari said.

“Whether they need compressed air on the surface or underground mining packs, we are the first port of call.” AM

The Integrated Extraction Simulator (IES) is an innovative simulator that enables rapid evaluation of processing scenarios across the mineral extraction value chain to enhance plant productivity, optimise economic value, and minimise the environmental impacts of mining activity and mineral recovery.

By seamlessly integrating physics-based equipment models with machine learning, IES enables optimisation of all or part of an operation. Accessible via a web-based platform, it delivers operational insights that guide short, medium and long-term optimisation goals.

To learn more about IES and how it can support your operations today, please contact your local Orica representative, or visit orica.com/IES

To increase the profitability of underground mining operations, it’s essential to maximise mineral extraction while controlling costs. Significant among these costs is underground ventilation, which is critical to ensuring safe and efficient underground operations.

As Smart-VOD operations manager Stuart Twiss explained, there are ways to minimise ventilation costs.

“Historically, the capital expenditure (capex) of ventilation system components were a major part of total ventilation costs, leading to standardised inventory with limited fan size options,” Twiss said. “This often resulted in oversized fans running inefficiently, especially during shorter development stages of a drive.

“Ventilation requirements evolve as declines and drives are developed. Optimising ventilation starts with a good ventilation network designed by experts. The network should effectively and efficiently ventilate working areas without impacting operations.”

A ventilation on-demand (VOD) system overlays a well-designed ventilation network and helps to optimise the system.

“VOD provides a practical approachto energy savings by tailoring ventilation needs based on real-time demand by recognising that most mine drives are vacant for large portions of the working week,” Twiss said.

“In a drive with a dual-stage fan, both stages may be required during bogging, shotcreting and blast clearance processes, whereas a singlestage fan provides sufficient air for other activities.

“Whole-of-mine VOD systems involve substantial capex. However, incremental approaches targeting ‘lowhanging fruit’ can yield significant savings with minimal investment.”

Key components of ventilation ondemand systems:

• A method of controlling air delivery, such as a variable speed drive (VSD), variable output fan, dual-stage fan, dual-speed fan or dampers

• A demand control signal, which is crucial for achieving energy savings, more so than the control method itself

• A monitoring and reporting system, which allows for continuous performance tracking to ensure the system operates efficiently

There are three main methods used to implement ventilation ondemand in the Australian mining industry.

The first is manual control, which commonly sees an operator on the surface manually controlling underground fans using a supervisory control and data acquisition (SCADA) system.

The second method is schedule-based control, where the shift work schedule is entered into scheduling software that controls underground fans using a SCADA system.

The third method of implementing VOD is automatic control, in which fans are controlled based on vehicles in a ventilation zone, which can include other factors such as air quality.

Twiss said ventilation energy costs make up a large portion of a mine’s total expenses and can significantly impact key financial metrics such as the all-in sustaining cost (AISC).

SYSTEM INVOLVES AN INCREMENTAL APPROACH TO ENERGY SAVINGS.

“A mid-sized gold mine deploying ventilation on-demand in the 10 most active areas on-site can reduce AISC by 10 per cent, significantly enhancing profitability,” he said.

A recent addition to the VOD arena is Smart-VOD’s VOD-as-a-service.

“In this case VOD can be delivered incrementally and without capex,” Twiss said. “VOD-as-a-service can be implemented in a single working area, or across several working areas in a mine.

“The system can additionally control primary ventilation fans for further savings, speed-up exhaust of blast gases and allow accelerated return to mining operations after a blast.

“Offering a detailed dashboard, Smart-VOD displays system status in real-time, along with savings and vehicle location information.”

By targeting ‘low-hanging fruit’ in ventilation on-demand implementation, miners can yield substantial energy savings without significant upfront costs.

“Smart-VOD offers an adaptable and scalable ventilation solution that enables mines to achieve immediate and impactful cost reductions, ultimately improving sustainability and profitability,” Twiss said. AM

Optimising Sustainable Mining Operations: Your Partner for Shutdowns, Logistics and Maintenance

Scan the QR code to find out more!

Empowering Industries. Building Futures. One lift at a time.

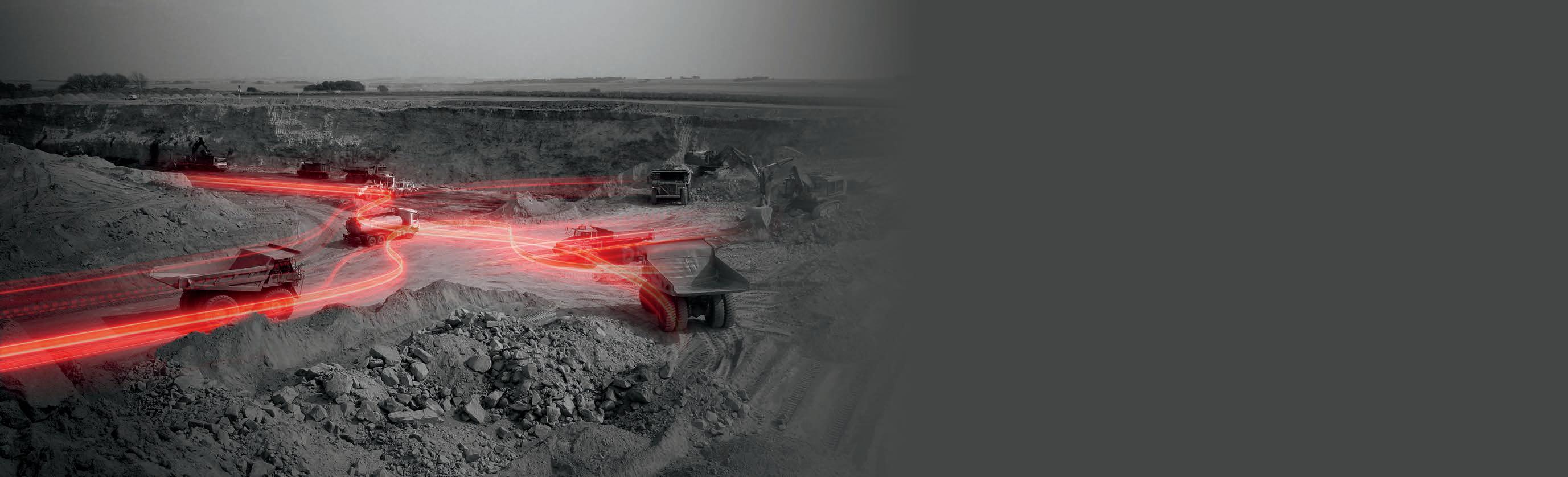

HEXAGON IS INTRODUCING ITS UNDERGROUND COLLISION AVOIDANCE SYSTEM AS PART OF ITS EFFORTS TO INCREASE SAFETY IN THE INDUSTRY.

As mining goes deeper and deeper underground, the need for smarter and more robust safety measures continues to increase.

Hexagon, a leading digital reality solutions provider, understands this situation well. The company’s approach to mine safety – ‘everyone gets home safely’ – has seen it develop some of the premier solutions in the mining sector.

But Hexagon isn’t content to rest on its laurels. The company is continuously developing new technology to make mining even safer, and its customers will soon be treated to a new kind of technology in underground safety in the Hexagon Underground Collision Avoidance System (UG CAS), providing 360° operator awareness for surrounding vehicles and equipment.

“Safety is a core pillar at Hexagon, and we are always working on innovating and improving in the mining safety solutions space,” Hexagon head of product – underground Mateus Quintela told Australian Mining

“Right now, there is a huge opportunity to increase safety in the underground mining market. UG CAS was developed to enhance safety and efficiency in mining operations, even in the most challenging environments.”

While UG CAS deployments are still in progress, Hexagon is looking forward to sharing success stories about the system soon.

“Hexagon is well established as an expert in mining safety, with over 60,000 Hexagon CAS installed in surface mines worldwide,” he said. “Now we’re bringing our extensive safety expertise underground.”

Hexagon’s UG CAS works by providing vehicle operators with 360° awareness via non-intrusive cabin display units when travelling at any speed and in all conditions.

Operators see other vehicles’ locations and where they are heading. The system incorporates path prediction and leverages auditory and vibration alarms that alert drivers to collision risks.

This innovative technology is easy to install and quick to configure.

UG CAS isn’t the only new Hexagon solution turning heads in the industry. The company acquired HARD-LINE in July 2023 in a bid to strengthen its mine safety, automation and underground offerings.

The acquisition added more than 28 years of global experience to Hexagon’s already substantial pedigree in the industry.

55-ton payload

Move more material in less time

6x6 traction Unstoppable in tough terrain

Haul Assist

Optimise your hauls with real-time data

VOLVO A40G • 24m³ • 39,000kg • 347kW

Spacious cab

Robust design

Fast cycle times

Comfortable and ergonomic design

Built for the toughest quarry conditions

VOLVO A45G

• 25.1m³

• 41,000kg

• 347kW

Get more done in less time

VOLVO A60H

• 33.6m³

• 55,000kg

• 492kW

Centennial Coal faced a challenge at its Springvale mine in New South Wales: parts were wearing out faster than expected.

Springvale uses longwall mining methods to extract coal, but an expansion into new territory had brought with it harder lithology, meaning harder wear on critical parts and equipment.

“We really went through hell on the first block,” Springvale mechanical engineering superintendent – production Hayden Ticehurst told Australian Mining. “Our usual maintenance program didn’t cut it, and we needed data quickly.”

That’s when the coal miner contacted mining equipment solutions specialist Komatsu.

Starting with the implementation of a simple tool for gathering data on part usage, the team at Komatsu quickly realised the mine would need a more holistic solution to keep Springvale on track.

Enter the company’s asset management program (AMP) which, according to Komatsu’s reliability engineer Rob Hancock, allows Springvale to look at the intricacies of its operations like never before.

“We gather machine metrics, such as tonnes produced, from a customer’s machine and combine it with data gathered from tailored maintenance and production inspections on site,” Hancock told Australian Mining tracking each piece of equipment and its parts, we can generate a HART (health and remaining time) report that predicts wear.

“We then use that data to predict any unforeseen problems the mine may face and schedule maintenance and part replacement accordingly, reducing unplanned breakdowns.”

Komatsu’s AMP takes every aspect of the mining chain into consideration, helping Springvale improve equipment availability, reduce unplanned downtime, and mobilise actively, rather than reactively, to the wear of parts.

Komatsu field service coordinator Craig Roberts was on-site to implement the AMP. He said a key pillar of the AMP’s success comes from building up a site-specific resource.

“The AMP builds a history based on conditions,” Roberts told Australian Mining. “It’s not a history of what wear Komatsu might get out of a certain part nation-wide; it’s about giving the

customer tailored information they can use to plan maintenance, overhaul costs, and plan for the future.

“It has been a massive step-change to take Springvale’s asset management from an excel spreadsheet to a fully realised mobile rounds platform that’s set for the service engineer.

“The whole process has since been streamlined with data able to be input into tablets underground and uploaded as soon as they reconnect with Wi-Fi, allowing greatly improved timeliness in getting reports to the customer.”

As Komatsu ramps up the AMP’s scope, it has the potential to integrate data from a range of metrics like vibration, oil, and digitised work procedures.

An embedded service engineer is now also on-site three days a week to help Springvale make the most of its new world of data.

“That ongoing support is there to assist Springvale with every aspect of its asset management,” Roberts said.

“Clear communication lines in place help Springvale and Komatsu work together to optimise the mine’s parts and maintenance planning into the future.”

Before the implementation of the AMP, Ticehurst said Springvale wasn’t making full use of its service engineers.

“If you send your service engineers underground for tasks like changing oil and parts, you’re missing out on the opportunity to break the mould of predictive maintenance,” he said.

“By treating our original equipment manufacturer (OEM) engineers like the experts – and not just labour hire –we are leaning on their knowledge and we are able to get results we’ve never seen before.

“By approaching the AMP collaboratively with Komatsu, we have gone from a spreadsheet to a fully-fledged data collection and consultation process.”

Looking to the future, the relationship between Springvale and Komatsu is set to go from strength to strength as it continues to optimise the miner’s operations.

“It takes work to build up a data history and put a plan in place to use it and the team effectively,” Ticehurst said. “But the results are so worth it.” AM

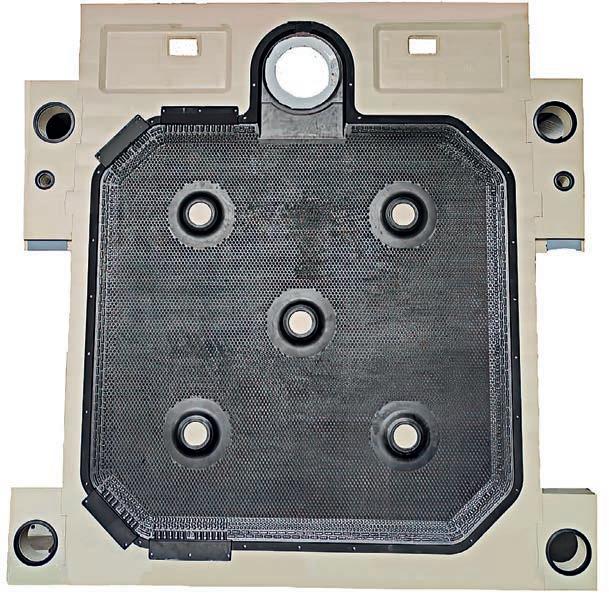

CHOOSING THE RIGHT SUPPORT VEHICLE FOR AN UNDERGROUND MINE CAN SIGNIFICANTLY INCREASE THE PRODUCTIVITY OF THE FLEET AND REDUCE OPERATIONAL COSTS.

Elphinstone’s new range of E15 underground support vehicles is designed to thrive in the harshest underground hard rock mining environments.

The E15 is a highly configurable, 15-tonne nominal base platform, comprising an agitator (7m3), delivery truck, fuel and lube truck, and water tank for dust suppression.

The E15 Delivery is the second model in the series to be released, adding another application to the existing Elphinstone E10 (formerly WR810) and rapidly expanding the E15 support fleet with new configurations in development.

“We are expanding the range of applications to meet the underground support equipment requirements of our customers,” Elphinstone global sales and marketing manager Tim Mitchell said.

With a payload of 16,500kg, the E15 Delivery ensures parts, components, equipment, and maintenance personnel are transported safely and securely throughout the mine.

The 4.5m x 2.5m deck features a steel tread plate floor bordered by multiple tie-down points and provision for ratchet load binders. Dual-sided threepoint access with high-visibility green handrails is enhanced with a cleverly designed removable guard rail system and onboard storage.

Other features include five storage compartments and a hand wash dispenser.

The Hiab X-HiDuo 092 crane features a rated lifting capacity of 8.8m and a 7.7m outreach, providing a reliable solution for day-to-day heavy lifting.

“Operated by manual lever control or wireless joystick remote, the operator can manoeuvre loads from a distance with built-in intelligence and automatic speed control for safe and effective load handling,” Mitchell said.

Safety features include emergency crane stops located on the manual control station, a wireless joystick remote and a programmed exclusion zone to prevent lifting over the operator cabin.

The stabiliser legs manually pivot and extend, featuring levelling sensors and easy pack-up for safe transit.

An A-frame front axle suspension combined with the oscillating hitch and air-suspended seats delivers a high level of machine comfort to the operator and passengers.

An optional feature of the E15 is the front and rear hydraulic jacks. The front jacks operate with a park function to enable the operator to safely exit the cabin with the engine operating.

The rear jacks are used to level or lift the machine. All jacks can lift the machine off the ground for changing tyres.

The intelligent electronic speed control utilises a high-capacity electromagnetic driveline retarder, engine speed and the correct transmission gear to control speed while descending into the mine, hence reducing wear and tear on the service breaks, parts and components.

All service points are conveniently located at ground level for servicing.

Downtime during maintenance is reduced markedly on the E15 due to clever engineering and design features, incorporated with service personnel in mind.

Quick change air filters and 500hour oil service intervals reduce downtime and keep machines in operation longer. A centralised onboard service centre includes fast fill, evacuation, and fluid sample points for analysis.

“Product support, parts and components are readily available through Elphinstone and our authorised Caterpillar dealers,” Mitchell said.

The C7.1 ACERT Tier 4 final engine arrangement is optional, offering 151 kilowatts (kW) of power and adhering to European Union Stage V exhaust emission standards

WITH A PAYLOAD OF 16,500KG, PARTS, COMPONENTS, EQUIPMENT, AND MAINTENANCE PERSONNEL ARE TRANSPORTED SAFELY THROUGHOUT THE MINE.

The C7.1 ACERT Tier 3 engine arrangement rated at 168kW is the standard option for less stringent emission regulations. Matched to the engine is a Cat five-speed (three-speed reverse) transmission fitted with a lockup torque converter.