Elevate every project with Komatsu’s Smart Construction technology.

Designed to optimise workflows, reduce costs, and boost productivity, our excavators give you the power to build smarter.

Scan the QR code below to explore our range.

*Terms and conditions apply.

2023 CATERPILLAR 320 ZBN Machine #ZM009088

$272,800 + GST

2024 CATERPILLAR 966GC SGW

2024 CATERPILLAR 307.5 GW7

$140,800 + GST

2019 CATERPILLAR 950GC M5K

Machine #ZM009084

$328,000 + GST

2021 CATERPILLAR 313D2GC MTM Machine #ZM009087

2023 CATERPILLAR 950GC M5K Machine #ZM009100 Machine #ZM009101

$520,000 + GST

2024 CATERPILLAR 303CR MY3 Machine #ZM009090

$76,800 + GST

$190,000 + GST

2018 CATERPILLAR 930K P3K Machine #ZM009104

$218,000 + GST

$126,800 + GST

2023 CATERPILLAR

320GC DKJ Machine #ZM009074

$218,000 + GST

In this issue, Unicontrol releases its 2D machine control system, Vermeer expands its reach with a Queensland vacuum truck acquisition, Teletrac Navman launches new asset trackers and a Hydi hydrogen-producing unit is leading to fuel savings, plus much more 06

United Heavy Industries has released its UME800 mini self-loading dumper 10

Volvo's 14–35-tonne excavator range offers the versatility needed for projects across the board 14

Shell Lubricants is driving innovation in the construction sector as your trusted lubricant partner 18 ZELVi Equipment's hire customers keep coming back for CASE Construction Equipment 22

Caterpillar is inviting the world’s most skilled operators to compete in its Global Operator Challenge 28 Jetland’s range of loading ramps are helping make transport easier for ProPag Civil & Earthworks 30 Striker is providing a custom-designed pugmill for long-term client WA Limestone

PCA Ground Engineering is using a Cat remotecontrol operation system for enhanced safety 42

JCB's Teleskid 3TS-8 offers the extended reach of a telehandler with the mobility of a skid steer loader 44 Hunter Region’s Daracon has added a new Komatsu

Editorial &

Editor Cat Fitzpatrick

catherine.fitzpatrick@primecreative.com.au

Journalist

Jackson Haddad

Contributors

Cathryn Greville, Damian Long

Managing Editor Eugene Duffy

Art Director Daz Woolley

CCF QLD's Damian Long discusses how the Queensland government can support industry

In this issue's Women in Industry profile, we speak with Kathleen Kelly and her efforts to improve safety in Tasmania's construction industry

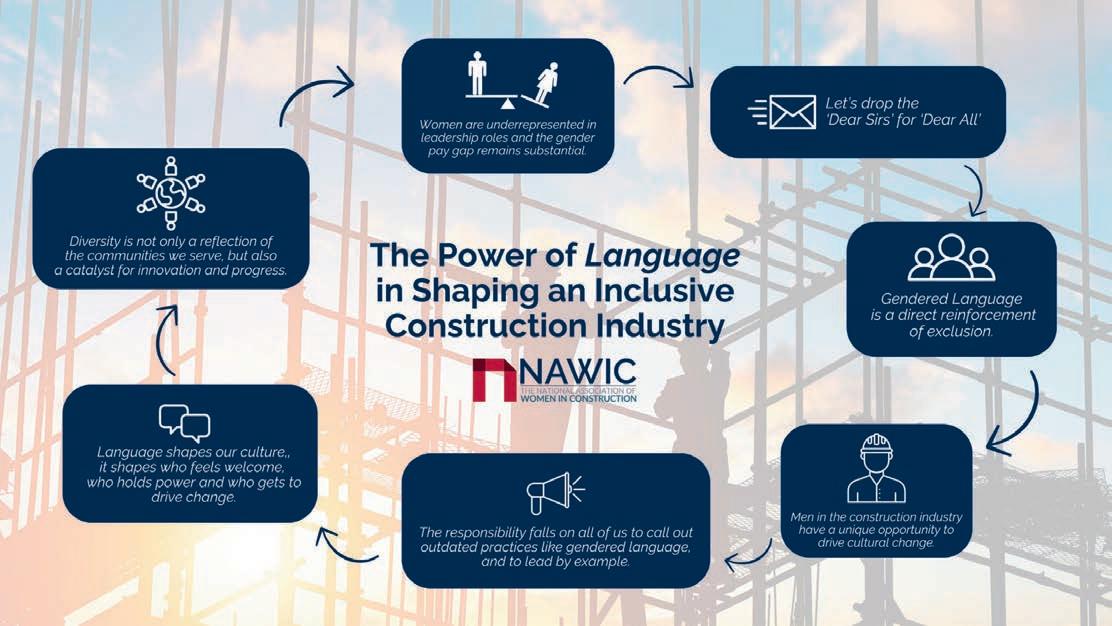

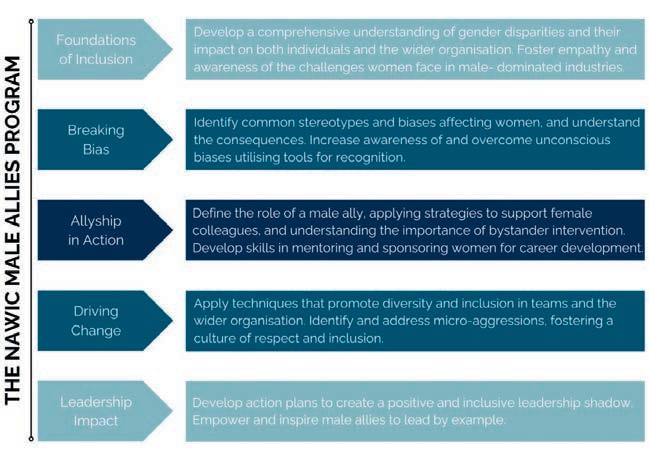

NAWIC's Cathryn Greville highlights the power of language in shaping an inclusive construction industry

Aimed at smaller contractors, Unicontrol is offering up a simple cost-effective machine control option

Unicontrol says it has a tailored solution for small to mediumsized construction companies looking to incorporate machine control into their operations – the Unicontrol2D system.

It says the solution is designed to make precision excavation easy to use and open to everyone, as well as providing a future-proof first step on the journey to 3D machine control.

Unicontrol says 2D machine control is the ideal choice for companies facing tight budget constraints or those without a continuous project pipeline. Users can start reaping the benefits immediately as it can be easily retrofitted to existing equipment.

With small and medium-sized construction businesses finding it particularly hard as costs rise and margins are squeezed, 2D machine

control technology can provide the helping hand they need to achieve their goals. Unicontrol2D means they can work faster, more precisely and more efficiently, increasing margins, minimising rework and preventing over-digging, Unicontrol says.

Following Unicontrol’s recent acquisition by Spectra Precision, a manufacturer of laser positioning systems, the new 2D system integrates with Spectra Precision’s high-quality lasers and laser receivers, providing instant feedback and accuracy to +/- 2 mm. Real-time guidance, remote diagnostics and updates, and a built-in cut/fill display ensures the correct depth and slope is achieved every time.

Vermeer Corporation has acquired an ownership interest in Vac Truck Industries

Global manufacturer of industrial and agricultural machines Vermeer Corporation has announced it has taken an ownership interest of Gold Coast-based Vac Truck Industries (VTI), an Australian manufacturer of specialised vacuum trucks.

Vermeer Corporation and VTI will partner together with current in-country manufacturing, branding, sales and support of vacuum trucks, jetter systems, suction trucks and customised solutions.

Founded in 2017, VTI serves a variety of sectors including civil construction, oil

The 2D control system assists operators for increased digging accuracy, and can be retrofitted to existing machinery. Image: Unicontrol

Unicontrol’s solution comes with straightforward upgrade paths to 3D machine control, simply by adding GNSS antennas, as business needs evolve.

“Unicontrol’s new 2D machine control solution is not just a tool for today – it’s an investment in your company’s future,” Unicontrol CEO Niels Bjerregaard says.

“Unicontrol2D allows companies of all sizes to embrace the technology of the future without the initial financial strain.”

and gas, electrical, infrastructure, mining and drilling.

Since its inception, it has grown to approximately 45 employees focused on sales, design, fabrication and assembly, along with aftermarket support for the broader vacuum excavation industry.

“This is an exciting opportunity to work with a team focused on the unique solutions needed in the Australian and New Zealand markets with products that meet the most trusted and recognised accreditation in the region,” Vermeer Corporation industrial solutions president Doug Hundt says.

“Vac Truck Industries is known for their market-leading products, high levels of quality, excellent customer support and outstanding team, and we are excited to partner with them.”

,

ASSET TRACKING

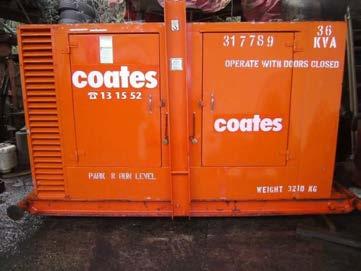

Teletrac Navman launches new asset trackers

Teletrac Navman has unveiled significant updates to its asset tracker portfolio, with the launch of one-time install devices that include new indoor tracking capability for real-time location visibility.

The market-leading asset trackers, designed for indoor and outdoor equipment, offer a 10-year battery life that minimises disruption, lowers maintenance costs and addresses the challenges of managing assets across various locations.

The improved, high accuracy indoor tracking also makes them a perfect fit for a wide variety of applications, including warehouse asset management, construction equipment, and other high-value asset monitoring, it says.

Further, Teletrac Navman’s AI powered TN360 and TN360 ACM platforms will provide a single pane of glass view for real-time asset location. The platforms have been designed for fleet, asset and construction equipment management, providing visibility into location, maintenance and utilisation across powered and non-powered assets. This gives

Teletrac Navman’s new trackers can be used to monitor a variety of assets in real time. Image: gui yong nian/stock. adobe.com

businesses the ability to make informed decisions regarding asset mobility, enhanced management efficiency, security and sustainability.

“Our customers’ assets are becoming more utilised and operations more dispersed and challenging to manage,” Teletrac Navman product management director Doug Haebig says.

“The last thing you want is indemand assets disappearing from your tracking platform because of shorter battery life or signal strength capabilities, and the associated costs of refitting them with new trackers.

“Businesses need greater robustness and functionality, as well as improved connectivity to alleviate some of their operational challenges. Our new market-leading devices will give asset managers the visibility they need to streamline and protect operations through a one-time install.”

An excavator competition in New Zealand put operators’ skills to the test, including pouring a cup of tea

Eight operators from New Zealand’s Southland region competed in a Civil Contractors New Zealand regional excavator operator competition recently.

Hundreds of spectators were in attendance to see the operators tackle extreme excavator challenges that required precision skills.

Challenges included using an excavator’s bucket to slam dunk a basketball through a hoop, construct a pergola within a confined space, and delicately pour a cup of tea.

It also involved more routine tests of operator ability and knowledge, including a hazard-spotting assessment and health and safety quiz.

Invercargill’s Brad Fallow was announced the winner, which was his third time taking out the title from four attempts at the Southland competition.

Fallow has now secured his spot in the national finals at the Central District Field Days in Feilding in March.

It will be his second appearance at the national finals, where he will represent Southland against 11 other winners from regional competitions.

“Last year I got a taste of the finals so I’m looking forward to getting back there,” he says.

“Hopefully I won’t be a nervous wreck like I was my first time around.”

A major project in WA has seen significant fuel efficiency benefits from the addition of a hydrogen-producing unit to a wheel loader

Western Australia’s METRONET

Byford Rail Extension Project has trialled the use of a hydrogenproducing unit on one of its wheel loaders, which adds hydrogen to the diesel in the engine to reduce emissions and fuel use.

Developed by South Australian hydrogen technology company Hydi, the compact, self-contained unit was installed on a Cat 962 loader by contractor Laing O’Rourke to produce hydrogen on demand for its engine.

The Cat 962 loader is being used in works to extend the Armadale line from Armadale to Byford, south Perth, which includes the building of a new station in Byford, the rebuilding of Armadale Station, the removal of several level crossings and the addition of parking areas and bus interchanges at the two stations.

Hydi general manager sales and marketing Craig Gilbert says the Hydi hydrogen unit creates hydrogen on demand, using distilled water, which is then fed into the engine to improve the efficiency of fuel combustion and reduce the emission of diesel particulate matter.

“It’s truly innovative because there is no storage of hydrogen required,” he says.

“Using just minimal power from the machine’s alternator, we feed the hydrogen into the air intake and that creates a more complete combustion. This reduces the amount of unburnt fuel, and in some cases we’ve managed to reduce diesel particulate matter emissions by 95 per cent.

“This also means that you have more torque, so improved productivity and less fuel use. Plus,

with the filters being cleaner, the service intervals are extended.”

Hydi says that for a 15-litre engine, one litre of distilled water will last for 30 hours of operation.

Before the Hydi unit was installed on the Cat loader, the machine used 8.18 litres of diesel per hour. After installation, fuel consumption improved to 6.56 litres per hour – a 19 per cent increase in fuel efficiency. Over 130 hours, the unit saved approximately 210.6 litres of diesel and used only 3.5 litres of distilled water.

Hydi units will continue to be used on other pieces of equipment on the project moving forward, with the project team aiming for a minimum of 10 per cent improvement in fuel efficiency across various equipment.

CATERPILLAR

140M3

2015,AccugradeReady, AirConditioner,Air SuspensionSeat, Beacon,Lighting, Mirrors,MoldboardSize -14',OnlineOwner's Manual,ProductLink, Pushblock,Radio-AM FMRadio,RipperMulti-Shank,ROPSEnclosed,Scarifier. N9D00466. TA1232534. $381,700

CATERPILLAR

972M

2021,AirConditioner, AutoLube,Beacon, Bucket,Fire Extinguisher,Lighting, Mirrors,OnlineOwner's Manual,ProductLink, Protection12Months 1500HrsEPP,RadioAMFMRadio,Ride Control,ROPSEnclosed,Weight MonitoringSystem. M8W20255. TA1213828. $456,500

CATERPILLAR

AP600FLRC

CATERPILLAR

730-04LRC

2020,AirConditioner,Air SuspensionSeat,Am FmRadio,AutoLube, CustomerValue Agreement(Cva)24 MonthsHDAdvantage, EROPS,Lighting,Online Owner'sManual, ProductLink,Protection 12Months1500hrsEpp. RearView Camera,Tailgate. 3F300510. TA1173354. $577,500

CATERPILLAR

930K

2019,AirConditioner, AutoLube,Beacon, Bucket,Hydraulic Coupler-Quick,Fire Extinguisher,ForksPallet,Lighting,Mirrors, OnlineOwner'sManual, Protection12Months 1500HrsEPP,Ride Control,ROPSEnclosed,Weight MonitoringSystem. P3K00732. TA1232292. $324,500

2018,3DGradeControl -Capable Beacon Generator

OnlineOwner'sManual ProductLink

Screed,ExtensionsHydraulic SonicGradeSensors WashdownTank. JA600105. TA1205008. $183,700

962M

2017,AirConditioner Counterweight Lighting Mirrors

OnlineOwner'sManual ProductLink Radio-AMFMRadio RideControl ROPS

SteeringType-Wheel. EJB00947. TA1223308. $313,500

CATERPILLAR AP300FLRC

2021,CustomerValue Agreement(CVA)24 MONTHSHD ADVANTAGE HEATEDENDGATE OnlineOwner'sManual PRODUCTLINK ProtectionREMAINING FACTORYWARRANT 36/3000PREMIER. YES00126. TA1186026. $247,500

CATERPILLAR

326-07

2019,3DTopCon System AirConditioner AuxiliaryHydraulics BoomCheckValve IncludesTiltMudAnd1 GPBucket OnlineOwner'sManual Protection12Months 1500hrsEPP StickCheckValve. MFJ00134. TA1185595. $275,000

For a huge range of new and used Cat® parts visit CatUsed.com today.

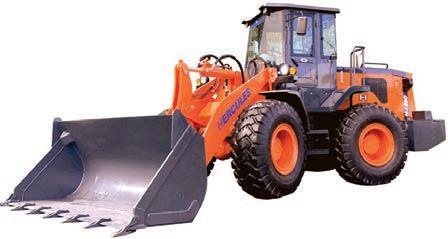

Australian OEM United Heavy Industries (UHI) has significantly expanded its presence since being founded in 2018, with multiple branches across the country.

Not only does it serve the Australian market with locations in Sydney, Brisbane, Perth, Melbourne, Adelaide, Townsville and Darwin, it also operates in North America through four branches in Canada and its newest site in the USA.

Specialising in construction and agricultural machinery, UHI offers a plethora of different equipment, including dozers, loaders, graders,

skid steers, elevated work platforms and even tractors.

One of the most recent additions to UHI’s product portfolio is its UME800 mini self-loading dumper, having only arrived in the past few months.

There are many different mini dumpers across the earthmoving market, however it is much less common to see these machines equipped with self-loading capabilities, UHI business development manager Ken Low says.

“Most conventional dumpers

require a supporting machine, such as an excavator or loader to fill the bucket,” he says.

“Without an additional machine you’d most likely have to manually shovel to load the bucket.

“With this mini dumper, it’s got an extra bucket on the front that enables it to load itself.”

Controlling the dumper is easy –the operator simply stands on the rear platform and drives the machine to the desired material that needs to be loaded. Using the joystick, it can then be controlled to load itself up and unload where required –reducing manual labour.

Since a secondary machine is not required to load the mini dumper, this reduces operating costs and fewer people are needed to load the material. This means staff can be put to better use, thus improving efficiency within a business.

“A lot of other dumpers don’t have that self-loading capacity,” Low says.

“They normally just have the dumping bucket itself, without the extra bucket at the front.”

Weighing in at 920kg and with a width of only 780mm, the compact

The self-loading capabilities of United Heavy Industries’ mini dumper remove the need for a supporting machine, helping to improve efficiency and reduce costs It is easily controlled by different joysticks

The mini dumper’s size allows it to access tight spaces

nature of the mini dumper allows operators to access tight spaces that would be more difficult with larger dumpers.

This manoeuvrability means the UME800 is suited to a wider variety of applications, including all types of construction sites, residential projects and even farms.

Another key differentiator of the UHI mini dumper is the use of tracks instead of wheels, which are more commonly seen on larger dump trucks.

Low says the machine was designed like this to improve accessibility for the operator, by reducing the chances of getting stuck in mud and other uneven terrain.

“Wheeled dumpers can sometimes get bogged in soft ground or unstable soil,” he says.

“It’s always an advantage for a machine to have tracks because they can move everywhere.”

Small but mighty

Able to handle loads up to 800kg and with the capability to dump at a height of 1.7m, the UME800 is equipped to tackle your earthmoving requirements.

Customers can rest easy knowing that the machine is powered by

a 14hp (10.4kW) Kubota engine –a brand that Low says has a high reputation within the industry.

This mini dumper comes with a price tag of $12,990 including GST, which perfectly encapsulates UHI’s simple brand ethos – ‘small machines, big savings’ – reflecting its dedication to providing top-quality products at an affordable price.

“The UHI mini dumper is much more affordable in the market compared to competing European makes,” he says.

“You get similar capabilities, with the benefit of being almost half the price – this makes it a very popular machine.”

Greater confidence can be instilled

in the customer through UHI’s full parts and labour warranty for the first year, as well as a key parts warranty for the second year of use.

“In the unfortunate event something goes wrong with the machine in its first year and it’s an issue covered by warranty, we’ll cover the labour for fixing it,” Low says.

“It doesn’t matter where the machine is, we’ll send somebody out, or we’ll organise somebody locally to go and fix the machine.”

Not only is UHI committed to providing top-quality products at affordable prices, but it also offers a comprehensive aftersales support system to ensure customers have only the very best experience with their machine.

“We’ve sold lots of machines across the country at UHI, backed up by our quality and the aftersales service we provide,” Low says.

“The UME800 mini self-loading dumper is available nationwide through all our branches.

“We recommend that customers call their individual branch and see if it is available in stock to ensure they don’t miss out.”

For more information on UHI’s UME800 mini self-loading dumper, visit www.unitedheavyindustries. com.au or call 1800 000 844.

Australia has a large range of pressure and level measurement technologies.

VEGA Australia will showcase its range of measurement solutions at Converge 2025, demonstrating the role of instrumentation in modern construction

As Converge 2025 gathers momentum, VEGA Australia is bringing its instrumentation expertise to the stage, highlighting the critical but often understated role of measurement technology in construction and municipal works. With decades of experience and innovation in pressure and level measurement technologies, VEGA’s participation underscores the event’s emphasis on innovation and collaboration.

A hub for industry innovation

Converge is the only Australianowned major event showcasing the latest tools and technology across municipal works, civil and commercial construction. Bringing together leading decision-makers, it will highlight developments and solutions that are helping shape the nation’s future.

The event serves as a one-stop shop for subcontractors, project engineers, council fleet managers and large-scale construction contractors seeking solutions to challenges within the built environment.

in motion

VEGA’s solutions are built to meet the unique challenges of construction,

from monitoring cement silo levels in dusty environments to ensuring precision in concrete batching plants.

This accuracy not only improves efficiency but also helps companies minimise waste and enhance safety – priorities for an industry navigating increasingly complex demands.

At the VEGA exhibition stand, attendees can expect to see the company’s flagship technologies in action, including radar level sensors and high-resolution pressure transmitters.

These tools, designed to deliver real-time, reliable data, streamline operations in municipal and commercial construction projects.

Whether it’s automating water and wastewater infrastructure monitoring or optimising bulk material handling, VEGA’s innovations reduce the time and resources spent on manual processes.

“Instrumentation may be a small part of large-scale construction projects, but it has a big impact,” VEGA business development manager for NSW Tony Scarborough says.

“By getting involved early in the project lifecycle, we can help engineers avoid costly errors and ensure our technologies are

integrated seamlessly into the broader operation.”

This focus on early engagement is a core part of VEGA’s strategy. According to VEGA business development manager SA and NT Nick King, collaborating with engineers and contractors from the outset allows VEGA to tailor its solutions to specific project needs.

“Our goal is to provide certainty and repeatability in critical processes,” King says.

“With our expertise, we can help clients achieve greater efficiency and reliability from day one.”

Municipal works and infrastructure projects are key areas for VEGA, with its systems already standardised by many local councils across Australia.

From sewer and potable water networks to tunnelling and road construction, VEGA’s instrumentation is designed to perform in harsh environments, delivering consistent results that support long-term sustainability and efficiency goals.

“Converge 2025 offers us a platform to amplify the importance of instrumentation,” Scarborough says.

“Our technologies are indispensable when it comes to accuracy and efficiency. We look forward to connecting with industry leaders who share our vision for innovation and collaboration.”

With VEGA on board, Converge 2025 is set to shine a light on the often-overlooked yet indispensable tools that drive progress in major projects.

To learn more about VEGA’s solutions and how you can get involved in Converge 2025, visit convergeexpo.com.au

The ECR145E is the smallest model in the short-swing range, weighing in at 14 tonnes

Choosing the right excavator is key for achieving success and Volvo’s 14–35-tonne excavator range offers the versatility needed for projects across the board

Selecting the right excavator size and capabilities optimises job site performance. Bringing innovative features and flexibility to the fore, Volvo’s midrange lineup includes the ECR145E, ECR235E and ECR355E models.

These excavators blend advanced technology with practical design features. Their short swing radius works well in tight spaces, and improved fuel efficiency systems add value. The machines deliver versatility and power from urban construction sites to quarry operations.

Here we take a look at how these excavators match different operational needs to achieve project efficiency and cost management.

Volvo 14–35-tonne range

Available in Australia through CJD Equipment, Volvo’s mid-range excavator lineup is remarkably versatile in construction projects of all sizes. The lineup has three main models designed to meet specific operational requirements.

Volvo’s E-Series short-swing excavator range includes the ECR145E (14-tonne), ECR235E (23tonne), and ECR355E (35-tonne) models. These machines feature a narrow body design with a centrally positioned boom that enables precise operation in tight spaces.

E-Series excavators deliver 25 per cent better fuel economy than their predecessors. The electrohydraulic control system stands out by providing smooth and precise movement of the excavator’s boom and bucket.

These machines have a smart cooling system for optimal performance, engine speed regulation and pump optimisation, plus auto-engine idle and shutdown features that reduce fuel consumption.

Volvo says its short-swing excavator range has powerful capabilities that make them exceptional in their class, with machine testing of their

performance showing a balance of precision and power that leads to outstanding performance.

The short swing radius design lets operators work in tight spaces without losing functionality, with the ECR range exceling in urban settings where space limits challenge traditional excavators. The ECR145E, ECR235E and ECR355E maintain full power and lift capacity while offering better manoeuvrability.

As well as urban environments, these models can also handle demanding quarry operations with ease due to their high level of stability. The integrated working mode system with G4 mode optimises fuel efficiency and productivity. Operators can tackle tasks from precise trenching to heavyduty excavation with consistent performance, it adds.

Volvo says its technology sets new benchmarks for excavator intelligence and efficiency. It created

The D8 engine technology in the ECR355 excavator delivers up to 10 per cent lower fuel consumption

sophisticated systems that boost operator productivity while the operator retains control.

The Volvo Active Control system streamlines processes by automating boom and bucket movements. Password protection lets operators store settings for up to 20 different attachments. Operators can also adjust hydraulic flow and pressure from inside the cab.

Electric pedal systems give exact control for attachments. Built-in valve technology works smoothly with ECO mode to improve fuel efficiency.

Understanding an excavator’s financial aspects helps machinery buyers make smart investment decisions.

Volvo says that its latest D8 engine technology delivers up to 10 per cent lower fuel consumption than previous generations. Several breakthroughs made this possible:

1. Volvo’s Eco Mode with electronic pump control technology

2. a n auto-idling feature with customisable activation times (3–20 seconds)

3. a n electronic pump control for reduced flow losses.

Fuel represents the largest operational cost, exceeding labour,

maintenance and insurance expenses. By implementing our advanced fuel management systems, operators can reduce idle time to around 25 per cent from the industry average of 50 per cent.

Volvo excavators are engineered with maintenance efficiency in mind. Features include grouped filtration

and greasing points near ground level, wide-opening compartment doors for easy access, and a builtin service interval display for monitoring critical components.

The purchase price is just one component of ownership costs. Volvo’s complete approach to total cost of ownership includes an up to 25 per cent improved fuel economy than previous models; reduced maintenance costs through proactive monitoring; and extended component warranty options (threeyear/6,000-hours). *T&Cs apply.

Volvo puts operator wellbeing at the forefront with its 14–35-tonne excavator range design, with the Volvo Care Cab ensuring low noise levels, minimal vibration and unmatched visibility through large glass panels with slim cab pillars.

The cab also includes an industryleading air circulation system with 14 well-placed vents, a multi-adjustable seat with up to 12 different position settings, ergonomic armrests and joystick console mounted on the same suspension to absorb shocks

better, and customisable control patterns and joystick responsiveness that operators can personalise from the monitor.

Several vital features showcase Volvo’s commitment to operator safety.

The cab structure meets ROPS (roll over protective structure) certification standards and protects

operators in challenging conditions. Better visibility is achieved through Volvo Smart View, which provides an immediate 360-degree overhead view of the machine, as well as side and rear-view cameras displayed on the colour monitor. A low machine hood design improves rear visibility.

The machine’s safe movement features include 3-point right-hand

side access that ensures safe entry and exit, bolted anti-slip plates to provide superior grip and highvisibility handrails and guardrails.

Volvo’s excavator lineup features the ECR145E, ECR235E, and ECR355E models in the 14–35 tonne range. These machines excel in construction projects of all types and use 25 per cent less fuel than previously.

Dig Assist and CareTrack telematics provide immediate monitoring and automated controls that make daily operations easier. The electro-hydraulic system delivers precise movement control.

Smart View and multi-adjustable seating in the ergonomic cab design keep operators safe and comfortable throughout their shifts.

The short swing radius design makes these machines ideal for urban construction sites. Operators can work at full power and lift capacity, even in tight spaces. The ActiveCare proactive maintenance system reduces downtime and helps operators work efficiently.

For more information on Volvo’s 14–35 tonne range, visit CJD Equipment at cjd.com.au. Plus, up to the end of June 2025, when you buy an excavator in this range you will have a chance to win an eco-friendly electric excavator.

As the smallest pup in the Toyota Huski skid steer loader range, the 4SDK4 is compact in size, yet strong enough to handle the toughest jobs. With a 320kg operating load its nimble size makes limited access applications possible, and it's ideal for many industries due to it being lightweight and towable.

discount of $1,500.00

Right now you’ll score a great Toyota deal across new 2023 plated Huski 4SDK4 skid steer loaders, currently in stock. Plus you’ll also enjoy a discount of $1,500 on 2023 plated 4SDK4 skid steer loaders ordered before 31st March 2025*. To take advantage of this offer contact your local Toyota Material Handling branch today.

Shell Lubricants are driving innovation in the construction sector as your trusted lubricant partner

In the ever-evolving world of construction, the importance of reliable and innovative lubrication cannot be overstated.

With Shell’s extensive experience as a leading lubricant solutions partner and having just retained its status as the number one global supplier of finished lubricants for an 18th consecutive year2, businesses can trust Shell Gadus grease to optimise their earthmoving equipment’s performance day in and day out.

Viva Energy Australia, the Shell lubricant macro distributor in Australia, is helping construction and industrial businesses look beyond greases that just meet manufacturer specifications

towards high-quality grease products like Shell Gadus that help reduce equipment downtime.

As noted by a survey conducted by Shell Lubricant Solutions, it was found that 56 per cent of construction companies often experience equipment breakdown due to ineffective lubrication1.

In addition, 76 per cent of people believe a lubricant supplier that can share expertise would be valuable to their company 1.

Shell has a history of leading technological innovation, which includes the invention of lithium grease technology 80 years ago.

Since then, Shell has amassed over 300 lubricant and grease patents globally3 and designed and support service is available to ensure customers match the

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

correct grease to their application, including pins and bushes for excavators and the option to book on-site engineers for greasing, fitting and condition monitoring.”

The Shell Gadus grease production centres ensure consistent product quality worldwide, adhering to a harmonised quality control system.

This enables exceptional product performance and is complemented by world-class technical support.

Shell Lubricant Solutions boasts research and development centres in Germany, USA, China, India and Japan.

With over 500 scientists, these centres work collaboratively to address the diverse needs of global markets.

To simplify the selection process, Shell Gadus greases feature an easyto-understand naming convention.

“When choosing a grease, it is essential to consider four key properties – thickener type, base oil viscosity, operating conditions and NLGI consistency [National Lubricating Grease Institute],” Farrugia says.

“These properties are clearly indicated in the naming convention for each Shell Gadus product.”

Shell Gadus greases are supplied with a range of properties to support low to high-load applications and rotating speeds.

The NLGI grade provides a measurement of a grease’s consistency, ranging

SOURCES: 1 Shell Lubricant Solutions Construction global performance one-pager. Statistics used in this

company Edelman Intelligence, between March and April 2018, based on 350 interviews with

UK) who purchase, influence the purchase of or use lubricants an greases as part of their job.

from 000 for fluid to 6 for block greases.

Shell Gadus adds value to equipment and machinery by offering enhanced wear protection, extended grease life, reduced maintenance spend and optimised system efficiency and performance, especially for operators navigating the energy transition.

It is important for businesses to understand the critical role that greases play in construction machinery, to help minimise equipment downtown.”

For further information about the Shell Gadus product range, reach out to Viva Energy Technical Helpdesk on 1300 134 205.

2 https://www.shell.com/business-customers/lubricants-for-business/news-and-media-releases/2024/shell-leads-global-lubricants-market-for-eighteenth-consecutive-year.html 22nd edition of Kline & Company’s report, Global Lubricants: Market Analysis and Assessment 2023.

3 https://file.blackwoods.com.au/a/Shell-Grease-Selection.pdf Shell tops global lubricants market for 18th consecutive year Shell Global Shell Lubricants are named the number one leading lubricants supplier, globally, for the eighteenth consecutive year by

Machinery hire leader ZELVi Equipment has found that its customers keep coming back for CASE Construction Equipment

ZELVi Equipment is often top of the list for businesses in Perth and regional WA that need quality equipment on short notice.

Headquartered at a new purposebuilt office and warehouse complex at its premises in the southern Perth suburb of Forrestdale, the familyowned and operated company specialises in delivering machinery to worksites quickly.

From excavators to water trucks, ZELVi ensures tools are available when needed most, with a broad range of machinery needed to meet the demands of projects across the state.

Its equipment has been used on several major projects across the state, including the Byford Rail Extension, Tonkin Gap, Yanchep Rail Extension and other MetroNet works.

ZELVi Equipment general manager

Damien Dadd says the main priority is to help clients achieve success by providing top-quality machinery and equipment hire.

“If you have a short-term or longterm project but don’t have the equipment or machinery you need, then ZELVi can help,” he says.

“Our modern fleet of hire equipment is always available and ready to help with any project.

“Our machines are regularly serviced and safety checked before each commissioning, ensuring the highest performance and total reliability, and if customers are unsure on how to use them, we can show them the ropes.”

ZELVi’s customers are generally those in the civil industry – anywhere from road building, drainage, plumbing to construction work, electricians and more.

He emphasises that the quality of ZELVi’s fleet is paramount to the business.

“We understand that time is money and there is nothing worse than subpar equipment, which is why our hire range is comprised of leading brands,” Dadd says.

One of which is CASE Construction Equipment.

“The brand is well-known, the machines are fresh-looking, they’re reliable and perform well, and have a very helpful dealership in the form of McIntosh & Son,” Dadd says.

“We started this business back in 2018 as we saw a need in the market with the ever-growing construction industry in WA.

“We based our business on service and started with small machinery. It wasn’t long before we introduced CASE equipment into

The short radius CASE excavators are easy to transport and ideal for tight work spaces

our fleet, starting with the 14-tonne excavators.”

As expected with these machines, he adds clients want quality specifications such as dig depth, fuel efficiency and power. On top of Dadd’s list would be reliability.

“CASE machines just keep on going, ensuring that the jobs get done on time and users don’t waste time with maintenance and stuff like that,” he says.

“The CASE machines are always available on our yard. They’re always

being hired out: as soon as they come back, they get cleaned. Because they’re so low maintenance, they get sent straight back out on hire.

“They tick a lot of boxes with our customers, particularly for projects like plumbing and trenching.”

Helping build up ZELVi’s CASE fleet – including a whole line of 14t, 20t and 25t excavators, as well as 12t and 15t wheel loaders – is Andrew Cox, a construction sales representative at McIntosh & Son, Perth.

“We started working with Damien

about three years ago, and started with a CX145C excavator and that’s been really good for him,” Cox says.

“Damien ended up buying a fair few CX145s and CX235 short radius excavators.

“The versatility of attachments that we’ve got also allows him to cover a wide range of customers.”

Reiterating this, Dadd says the quick tilt hitch is a stand-out feature of the CASE excavators.

“It makes everything so much easier when switching attachments, because I know a lot of my clients do use a variety of different attachments on the machines, from grapple buckets to trenching ones,” he says.

The zero tail swing was another winner.

“This feature is definitely really handy when customers need to get into tight spaces and don’t have a lot of room to move, especially with civil work,” he says.

“For example, when working on roads with cones around and traffic passing by, you can’t have the machine swinging out all over the worksite.”

Driving the CASE machines has also been a joy for him, with various features enhancing operator comfort. These include a spacious cabin with powerful heating and air conditioning systems, cup holders,

high tech touch screens and GPS systems.

Cox says that McIntosh & Son has provided ZELVi with several more excavators as well as different compact track loaders and wheel loaders.

“We’ve grown with him and it’s been a really enjoyable experience,” he says.

A key aspect of the relationship has been the level of service.

“It’s important to minimise downtime,” Cox says. “While the CASE machines are extremely reliable, if anything needs to be addressed, Damien just needs to call me and we can talk to our service and parts department.

“We have three parts warehouses throughout Australia, and we’ve got four on-the-road field service mechanics that we can get out and about, backed by plenty of other

sorts of service networks that we can use, whether it be regionally or around town.”

All CASE compact track loaders, mini excavators (under 6t), skid steer loaders and backhoe loaders are covered by a three-year/3,000hour plan, while all excavators (over 6t) and wheel loaders (over 10t) are covered by a three-year/5,000hour plan.

The PROCover Plus Protection Plan program provides coverage in the unlikely event of a failure caused by a defect in materials or workmanship and can even be extended beyond the three-year period if required.

Dadd couldn’t be happier with the backup from Cox and McIntosh & Son.

“They’ve been great; I’ve been able to get in touch with the whole hierarchy of the business right from general management through to the sales guys and they’ve been really accessible, from meeting them and getting invited to their big days and other trade events,” he says.

“We have really been welcomed and been appreciated as a client.”

For more information, visit: mcintoshandson.com.au

Secure your place at the 2025 Heavy Equipment & Machinery Show to make sure you don’t miss out on this landmark event

The 2025 Heavy Equipment & Machinery Show (HEMS) is returning to the Brisbane Showgrounds from May 15–17, 2025, promising an allin-one platform for businesses to showcase their innovations and connect with key players in the civil construction industry.

HEMS is one of the fastest-growing construction expos in Australia, and as Queensland’s largest civil-specific event, securing your space at the expo isn’t just an opportunity – it’s a strategic move to elevate your brand in a booming market.

Since its inception in 2019, HEMS has seen exponential growth. Starting with 900 attendees, the event’s strategic partnership with the Brisbane Truck Show in 2021 brought in 3,500 visitors.

By 2023, the show attracted over 5,500 attendees to the Brisbane Showgrounds, cementing its status as a must-attend event on the industry calendar.

With 2025 expected to surpass these numbers, the time to secure your exhibition site is now.

Exhibitor Hastings Deering can attest to the event’s benefits, having had a successful site at HEMS for several years.

“Hastings Deering has been a long-term supporter of the Civil Contractors Federation Queensland Ltd and it’s been great to see a number of our customers and new prospects at HEMS,” Hastings Deering customer support manager Ben Gierke says.

“It’s definitely grown in size and people, and it’s also good to see some families here and new generations of machinery lovers.”

The 2025 expo will once again have fully reciprocal ticketing with the Brisbane Truck Show, free shuttle buses between the two events, and with the ever-popular CCF Queensland State Conference running on the opening day of the show at the same great venue – the Royal International Convention Centre at Brisbane’s Showgrounds.

Gierke is already looking forward to HEMS, saying the previous events have seen a great industry turnout.

“We can’t wait to see you here at HEMS in 2025,” he says.

“We’re not just here with salesmen, we’re here with product specialists and technology specialists, so we’ve got the whole suite of what we can offer our customers.”

If this not enough evidence for why you should secure your place at HEMS now, here are a few more reasons from the HEMS organisers on why sites are already in high demand.

HEMS draws a diverse audience of construction professionals, industry leaders and decision-makers eager to discover the latest equipment, technology and services.

Exhibiting at HEMS puts your brand directly in front of a targeted B2B audience, ensuring maximum visibility and return on investment.

HEMS allows businesses to showcase their innovations to a diverse audience of construction professionals, industry leaders, and decision-makers

The event aligns with the renowned Brisbane Truck Show, creating a synergistic environment that attracts a shared pool of visitors.

The Brisbane Showgrounds, with its central location and great facilities, provides an accessible and dynamic backdrop for exhibitors to shine.

HEMS offers a range of exhibition and sponsorship packages to suit businesses of all sizes.

Whether you’re a global industry leader or an emerging innovator, there’s an option tailored to your goals. From indoor booths with high foot traffic to outdoor spaces perfect for showcasing heavy machinery, you’ll find the ideal set-up.

Participating in HEMS isn’t just about showcasing products – it’s about aligning your brand with excellence.

Join the ranks of industry leaders who have leveraged this platform to enhance their reputations and drive meaningful business connections.

Exhibition sites for HEMS 2025 are in high demand, with many prime positions already secured by returning exhibitors.

Act now to ensure you don’t miss out on being part of this landmark event. Bookings are now open via www.heavyequipmentshow.com. au. Contact the HEMS team to discuss your needs and secure your site.

“Together, we’ll make the 2025 Heavy Equipment & Machinery Show your most successful event yet,” event manager Jasmine Collins says.

“Let’s build the future of heavy equipment and machinery — one connection at a time.”

For more information about HEMS 2025, please contact event manager Jasmine Collins on 0408 689 577 or jcollins@ccfqld.com

Caterpillar is inviting the world’s most skilled operators to create their own legacy through its third Global Operator Challenge

Heavy equipment operators from more than 40 countries have been invited to compete in Caterpillar’s third Global Operator Challenge, with the worldwide title up for grabs.

Thousands of machine operators will put their agility, resilience and versatility to the test on a wide range of construction equipment and technology, in what Caterpillar says is its largest challenge to date.

“For nearly 100 years, our customers have been pushing the limits with our machines,” Caterpillar Construction Industries group president Tony Fassino says.

“This challenge helps showcase and celebrate the exceptional skills of the expert men and women in this important profession as they forge their legacies of being the best operators in the world.”

Competitions will feature at least three different challenges on at least three separate pieces of equipment.

Scoring is based on the operator’s skills, safety, efficiency and competence in using integrated technology such as payload, grade control and operator ease-of-use features to enhance the machine’s performance.

Cat dealers in Australia and New Zealand will be hosting local challenge events during the first round, being held from February to June 2025.

First place winners from each local Australian and New Zealand dealer events will then advance to the regional semifinal competitions at the end of October in Japan.

Here, they will meet other Asia Pacific finalists, with the

top three finalists going on to represent the region.

Globally, nine finalists will emerge from the regional semifinals and participate in the final competition in March 2026 at Caterpillar’s outdoor Festival Grounds exhibit during CONEXPO-CON/AGG in Las Vegas.

The winner receives either a $10,000 cash prize or an equal value trip for two where Caterpillar has a location worldwide.

More than 140 Cat® dealer competitions were held during the 2022–2023 challenge, which attracted more than 10,000 operators from 32 countries. Patrick Doheny from Australia was crowned the champion at the previous Global Operator Challenge competition held at the CONEXPO

industry event in Las Vegas.

He was awarded a trip for two to a location where Caterpillar has one of its worldwide production facilities.

“I am beyond thrilled to have earned the title of the best Caterpillar machine operator on the planet,” Doheny says.

“Kudos to Caterpillar for hosting such an incredible event to highlight

the importance of our profession.

“It is truly a dream come true to see your life’s passion be rewarded in such an amazing way.”

The 2025–2026 challenge aims to include more events, countries and operators than previous programs, Caterpillar says.

For more information and official rules about the Global Operator

Australian Cat dealers will be hosting the first round of local challenges from February to June

Challenge, including how to participate, visit www.cat.com/ operatorchallenge.

NSW/ACT: WesTrac 1300 881 064

WA: WesTrac 1300 881 064

VIC/TAS: William Adams 1300 923 267 QLD/NT: Hastings Deering 131 228

Cavpower 08 8343 1600 NZ: TERRA 0800 93 39 39

Operators will compete in different challenges on at least three separate pieces of equipment

loading ramps are

Jetland’s range of loading ramps are helping make transport easier for ProPag Civil & Earthworks

Melbourne’s ProPag Civil & Earthworks is still a relatively new business, but director Jesse Pagonis and his close-knit team have achieved a lot in a short time.

“We started about three years ago, just doing small earthworks jobs with a 5.5-tonne excavator and a tandem tipper,” he says.

“We were doing pretty much just whatever work we could to keep the business going.

“Since then, I’ve put together a great team of three other young guys, and we all get along and work together really well. My partner has since joined the business too. She handles all the admin, advertising, and finds all our work for us. It’s a good system.”

Not only has the team grown but also its fleet, with ProPag’s machinery now encompassing two additional excavators, a John Deere compact track loader and two more tipper trucks.

“We want to keep growing as long as we’re able to maintain the level of quality we deliver on our projects,” Pagonis says.

Delivering quality work has been the key non-negotiable in all ProPag’s work since its inception, whether it’s been earthworks, driveways or tree removals.

Having quickly established a reputation for well-executed projects, the ProPag team has seen demand increase to the point where it has been able to lean more heavily into its preferred earthmoving niche –predominately focusing on site cuts and retaining walls.

Pagonis says the business has become so busy with retaining walls that it’s considering creating an entire team dedicated to them, and then running a separate crew to do site cuts and excavation beforehand.

“We all have a passion for machines, using them to build things, but then we all like being able to get out of the cab and work with our hands too,” he says.

“Our growth has been far quicker than I’d expected, it’s just taken off, which has allowed me to add to the fleet, and put together a really good team.”

In putting together ProPag’s fleet, Pagonis has kept efficiency front of mind.

An unsung hero of the fleet are tough and reliable loading ramps, purchased from Jetland.

Jetland’s loading ramps were first procured by Pagonis when he was looking to streamline the loading and unloading of his machinery from trailers, and these handy accessories have certainly helped achieve this.

Reaching out to Jetland due to its local Mordialloc-based warehouse, Pagonis says this decision quickly proved to be a good choice for all the right reasons.

“Firstly, they were open on Sundays, so that was a bonus given we’re generally working six days a week,” he says.

“I called [owner] Jimmy [Fang] up, and he said to come down and check out the range.

“He’s a very nice bloke, very accommodating, and was keen to chat and learn about my business. I ended up purchasing a set of ramps

then and there, and I’ve bought another two sets since.”

Despite seeing daily use, Pagonis adds that the Jetland ramps have not missed a beat.

“All of our sets are in the six-tonne rated range, in a couple of different lengths for different situations,” he says.

“We’ve pushed them to their limits, but we’ve still had absolutely no issues whatsoever. They’re very high-quality products.”

Another reason Jetland has stood out to Pagonis is the fact that Fang and his team are committed to refining and improving their products.

“No matter how good your product is, there’s always something to improve on,” Pagonis says.

“That’s something that’s great about Jimmy – he’s always thinking about improvements to the designs, and his products are always getting better.”

This is evidenced though most recent set of Jetland loading ramps bought by ProPag, which are approximately 20kg lighter than its last pair, according to Pagonis.

“I was a bit worried at first, thinking that they wouldn’t be able to hold up like the last set, but like the older ones, they’ve been absolutely perfect, and they’re much easier to handle,” he says.

Custom-designed ramps have also been a topic of interest at ProPag, with

Fang and his team more than willing to make this happen.

“We’re hoping to get something made to allow us to drive from a tag trailer into the back of a truck without removing the trailer,” Pagonis says.

“No one makes aluminium ramps for that purpose, and Jimmy’s open to working with us on that, and doing a bit of R&D together.

“He was the only one who was willing to talk to me about this line of work. Everybody else either wasn’t interested, or just wanted to make them out of steel – but they’d just be far too heavy.”

Based on his experience so far, Pagonis is confident that anything Jetland manufactures is going to withstand anything he and his team can throw at it.

“We just want to be able to use our ramps without worrying about them,” he says.

“And with Jetland, there’s just no concern as to whether they’ll be okay. We’ve never had an issue wi1th them, so it’s one less thing to think about. We highly recommend Jetland loading ramps.”

ProPag is looking forward to purchasing custom-designed ramps from Jetland

CATERPILLARD5K2XL 2019,4,500hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrservice,workshopreport..S1201. TA1225199. $249,900plusGST

CATERPILLARD8RSERIES2 2003,11,500hrs, SUtilt,CAT4Cylinderripper,servicedwith workshopreport.S1197. TA1225194. $369,900plusGST

CATERPILLAR259D3 2021,1,850hrs,4in1 bucket,250hrservice,verygoodtracks..S1200. TA1225198. $94,900plusGST

KOMATSUD61EX 2018,5,800hrs,6wayblade, MSripper,TopConwired.S1067. TA1163362. $309,900plusGST

CATERPILLARD5K2XL 2018,2018 CATERPILLARD5K2XL233.233. TA1166133. $258,390inc.GST

CATERPILLAR12M3 2015,2015 CATERPILLAR 12M3239.239. TA1166139. $362,890inc.GST

CATERPILLAR12M3 2016,Graderwith4,950hours. 14ftblade,joysticksteering,Autoshift,Lightpackage, soldwithMSripperandpushblock.This12M3Grader willbesoldclean,detailedandservicedwithour comprehensiveworkshopreport.S1013. TA1139678.

CATERPILLARD6K2XL 2017,4,900hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrserviceandworkshopreport..S1199. TA1225197. $269,900plusGST

KOMATSUD39EX-24 2021,1,200hrs,6wayblade, 95HP,MSripper,suitnewbuyer.ThisD39EX-24willbe soldclean,detailedandservicedwithour comprehensiveworkshopreport..S1108. TA1173489. $274,890IncludingGST

JOHNDEERE450K 1400hrs,6wayblade, sweeps,screensandMSrippertobefitted. S1063. TA1163359. $229,900plusGST

CATERPILLARD6TLGP 2017,6,590hrs,ARO wired,6wayblade,tankguarding,Conventional undercarriage,rearscreen.Soldwith250hr serviceandworkshopreport.S1165. TA1198871. $419,000plusGST

CATERPILLARD6TXL 7,150hrs,VPAT,ARO wired,nextgenMSripper,goodU/C.Soldwith 250hrserviceandworkshopreport.S1198. TA1225196. $439,900plusGST

MSCHYDRASCREW100 hydraulicorelectricdive.W71.

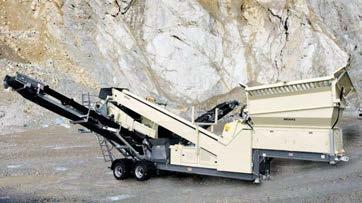

MCCLOSKEYJ50V2

2020,1270x735jawopening,Catengine,magnet,sidebelt 54tonne.KM97. TA999690.

$575,000+GSTEXDepot

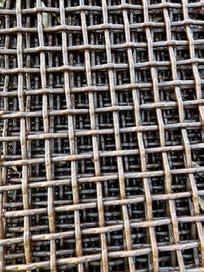

MCCLOSKEYS130

14'x5'twodeck,100mmremotetippinggrid,Cat130hpInstocknow.SM248. TA908181. POA

MCCLOSKEYJ50V2

2019,1270x735jawopening,Catengine,wellmaintained andregularlyserviced.KM91. TA1232332.

$620,000+GSTExKingIsland

MCCLOSKEYS130

2019,14'x5'doubledeck,Catengine,15'hopper.SM225. TA1198773.

$290,000+GSTExMSCdepot

MCCLOSKEYS190

2020,20'x5'twodeck,100mmgrid,readyforwork condition.SM237. TA1203702.

$345,000+GSTExMSCdepot

MCCLOSKEYI3CR diesel/hydraulicpowered,adjustableimpactapron 27,500kg.KM138. TA859307. POA

MCCLOSKEYJ40

1016x610mmjawopening,Catengine,magnet,sidebelt 37tonne.S167. TA1227406. POA

A successful relationship spanning over 35 years has led Striker to provide a custom-designed pugmill for WA Limestone

Western Australian crushing and screening leader Striker has been providing innovative solutions for the quarrying, mining and construction industries since 1998.

The family business has significantly grown over the years, and so too has its range of mobile equipment. Striker now offers cone, jaw and impact crushers, scalpers, screeners and conveyors for not just the Australian market, but around the world.

Building relationships that last has always been a key aspect of Striker’s success, and there’s no better example of this than with fellow local and family-owned business WA Limestone.

Family ties

WA Limestone has been operating for over 50 years, with quarries

strategically located all over the Perth Metropolitan area, making it one of the largest suppliers of road construction materials in the state.

Founded by two brothers, Michael and Renzo Della Bona, and their brother-in-law Peter Zamboni, the company’s relationship with Striker’s founder Craig Pedley can be traced back to 1988.

Although Striker wasn’t established until 10 years later, Pedley had already worked alongside the WA Limestone team to design a mobile jaw crusher for them.

When he eventually founded Striker, it was inevitable that WA Limestone would continue working with him into the future.

Thanks to this thriving relationship, WA Limestone now has over 50 pieces of Striker equipment

Striker custom-built and manufactured the Eco Mix pugmill to WA Limestone’s requirements. Image: Striker

and continues to choose it for its crushing and screening needs.

This is set to continue with the next generation of both family businesses, as Steven (son of Michael) and David Della Bona (son of Renzo) have assumed the roles of directors at WA Limestone, while Jordan Pedley (Craig’s daughter) is set to lead Striker into an exciting future.

Having this relationship and understanding of each other’s business is a big reason why WA Limestone has once again chosen Striker to design and manufacture its next piece of equipment.

“Craig is very knowledgeable and experienced within the industry,” Steven says.

“His understanding of our business and the aggregates that we crush makes him a pretty easy choice to come back to. He has a great ability

to understand the requirements of what’s needed by us as a customer, and he delivers that.”

The most recent collaboration between Striker and WA Limestone came in the form of a research and development project that was 10 years in the making.

It all started when Steven approached Striker about a customdesigned pugmill for WA Limestone, coming fully prepared with his own design in mind and drawings to showcase it.

“I gave Craig the drawings and asked if he could build it for me,” Steven says.

“He came up with some designs and tailor-made it to our requirements.”

Dubbed the ‘Eco Mix’, the Striker fully custom-designed and manufactured pugmill with a 12ft (3.7m) mixing chamber,

recently arrived at WA Limestone’s operations.

The specially designed plant was created to make what WA Limestone calls its ‘2 per cent bitumen and limestone emulsion mix’.

Although WA Limestone is extremely experienced with this product, having made it for more than 20 years, Steven says the Eco Mix was needed to replace an older and outdated plant.

“We’ve probably had the old plant for 30 years now and it’s getting harder to maintain,” he says.

“The Eco Mix was designed to be easy to work on, safe to clean and easy to maintain.”

With cleaning and maintenance of the machine being such an important factor for WA Limestone, Striker integrated special features on the pugmill, such as on-board pressure cleaners and pressure washers.

Compared to WA Limestone’s older

pugmill, Steven says these features make cleaning the Eco Mix much easier and safer.

Steven is looking forward to seeing the Eco Mix in action, having had a fantastic experience with all of Striker’s pieces of equipment that are part of the WA Limestone fleet.

He adds that his idea and concept wouldn’t be able to come to fruition without the help of Craig and Striker.

“It comes down to the relationship I have with Craig, I told him my idea and asked if he could it, and he did,” Steven says.

“That’s the relationship we have, Craig knows what we need.”

WA Limestone north metro quarry manager Joe Concei has already been impressed with the customdesigned machine.

“The old plant was producing about 200-tonnes an hour, whereas we will be able to get 350 tonnes an hour comfortably with the Eco Mix, possibly even 400,” Concei says.

“The old system also required an operator to control the flow rates of the feed, water and bitumen, whereas the Eco Mix is fully automatic, so you can dial the feeder to 350 tonnes an hour and you don’t need an operator to control it.”

A three-man team would usually be required to operate the old plant, including two wheel loader operators

– one to feed the material into the hopper and one to take it away and stockpile – as well as the pugmill operator.

Now with the Eco Mix, the pugmill operator is removed, which Concei says generates significant cost savings for WA Limestone, while also improving efficiency.

WA Limestone and Striker’s relationship is strengthened by the fact that they are both family businesses and ‘on the same wavelength’, according to Steven.

Sharing the same values and understanding of the industry and the people in it is invaluable to both business’ relationship.

Steven knows that Craig, Jordan and Striker will continue to provide innovative solutions for WA Limestone into the future.

“You can’t beat the feeling of having someone to ring up any time of the night or the day when there’s an issue and know that they’ll answer the phone and resolve it,” Steven says.

“With Striker, you also know that you’re dealing with the people that have designed and built the plant. They carry all the spare parts, so you know they’ve got everything that you’ll need.”

For more information on Striker’s crushing and screening solutions, visit strikercrushing.com

On-board pressure cleaners and pressure washers have been integrated on the machine. Image: WA Limestone

YANMARC50R-3A 2007,Dumper,rubbertracked,2 speedhydrostaticdrive,ROPSframe,rotatingseat, dropsides,4-5toncarryingcapacity,strong dumper.S477.

$38,000+GST

TOROSTPF-30 2024,Forkliftbrandnew,3tonlifting capacity,powershifttransmission,dieselpowered, containermast,sideshift,lights,beacon,3mlift, runningaroundouryardshowing5hoursonly.S462. TA1221932.

$22,500+GST

CATERPILLAR303CR ExcavatorwithMagnet,fitted withsteeltrackswithrubberpads,canopy,2speed tracks,backfillblade,comeswith500dia.verystrong magnetalso450wideGPbucket.Worked3400hours, runswell.S473.

CATERPILLAR910LOADERMOUNTED AGT-SSFM81 ForestryMulchernew,2024mountedon Caterpillar910loader,4in1bucket.Mulcherisquick hitchmounted,hasownrearmountedpowerpack withDeutz4cylinderengine,60hp100litresper minute.Runswell.S464. $60,000+GST

YANMARC50R-3C 2013,rubbertrackedcrawler dumper,4cylinderturbodiesel,hydrostaticdrive, ROPSframe,forwardandreversedrivepositions, workedonly1800hours.S471.

$35,000+GST

DOOSAN12-56 2012,AirCompressor,IngersolRand 12-56,200 cfm capacity,4cylinderturbodiesel, operatingpressure2000psi,4airoutlets,allmounted onsilencedtrailer,onlyworked1730hours.S463. TA1223429. $19,000+GST

CATERPILLAR303.5CCRWITHHYDRAULICSAW 2010year,ROPScanopy,2speedrubbertracks, backfillblade,comeswithhydraulictimbersawhead and600mmmudbucket.Sawwillcut100mmtimber easily,versatileunitworked2980hours.S474.

CASE480-E fittedwith4in1bucketwithnew edge,ROPScabin,poweredbyCummins4cylinder engine,powershiftforwardandreverse,6,000 hours.Goodloader.S429. $18,000+GST

DYNAPACCC102 2005,RollerDynapacCC102,2005 year,tandemsmoothdrumvibratingroller,Deutz engine,hydrostaticdrive,ROPSframe,worked2,200 hours,runswell.S479. TA1254481. $14,500+GST

KOMATSUD21A-8 2006,Bulldozer,fittedwithROPS andFOPSframe,hasangleandtiltblade,2speed powershifttransmission,comeswithTrimble automaticbladelasercontrol,weighs4ton,strong dozeronlyworked3,300hours.S476. TA1238570. $35,000+GST

$10,800+GST

AGTKTT23 2024,Minibobcat,new,fittedwith rubbertracks,hasauxiliarypiping,weighs900kg, lifts375kg,23hpelectricstartmotor,brandnew. S475. TA1237057.

REXSOILSTABILISERGRINDERHDS-PULVI fitted withcabwithcertifiedROPSframe,Detroitengine, hydrostaticdrive,drumhasbulletteethandcuts1.2m wide,has1200litrewaterorlimetankwithhydraulic pumptosprays.Runswell.S438.

CATERPILLAR321DLCR 2013,Fittedwithhammer piping,2wayflow,heavycabguarding,quickhitch, 1200widebucket,verygoodzeroswing excavator, onlyworked5100hours.S447.

VERMEERBC1800XL 2011,Woodchipperpowered byCummins170hpengine,hassmartfeedsystem, hydraulicwinch,rotarychute,materialcapacityupto 480mmdiameter.Worked4,590hours,runswell,job completed.S478. TA1252593. $35,000+GST

YANMARC10R minidumper,dieselpowered, hydrostaticforwardandreverse,1ton capacity,isonly950wide for tightsites, workedonly550hours,runswell.S481. TA1255779.

$9,000+GST

KOMATSUD21A-6 Bulldozerfittedwith canopy, 6wayblade,hydraulictiltandangle,4cylinder diesel,3speedpowershifttransmission,weight 4-5ton,2600hours.Goodstrongdozer.S480. TA1255316.

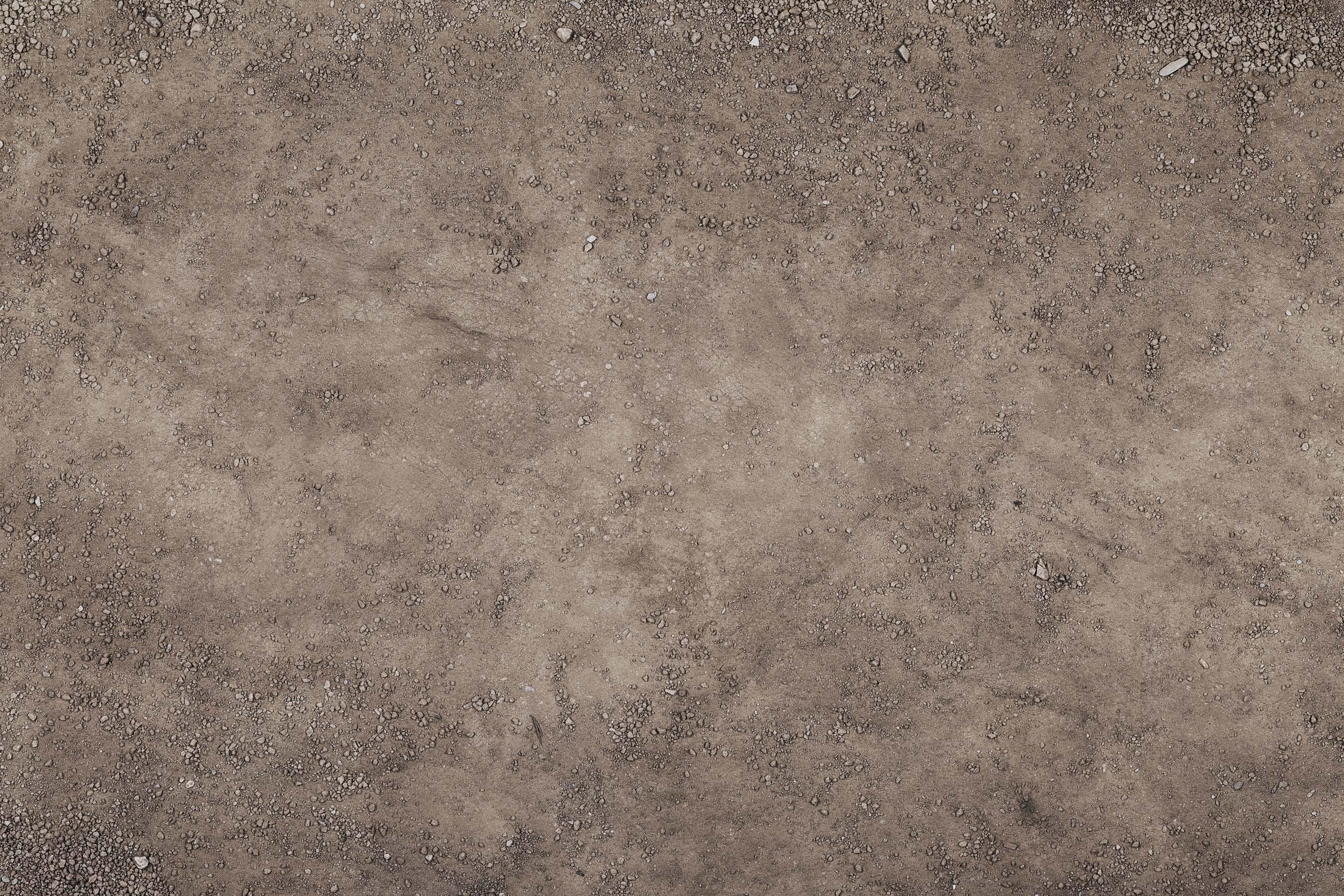

SKELETONBUCKETROCK rockscreeningbucket withrippermiddletooth.Suit40to50tondigger.Pins

KOMATSUPC800-6FINALDRIVES 1990,Komatsu finaldrives,tosuitKomatsuPC800-6excavator,one hashydraulicmotor,onewithout,workingwhen removedfromexcavator.A466.

ATLASCOPCOXAS350GD aircompressor,700 cfm capacity,125psiworkingpressure,6cylinderdiesel powered,allmountedonsteerable4wheeltrailer. Runswell.S407.

$18,000+GST

NPKS24XL Pulveriserprocessorshear,hasmanual rotatinghead,pickuphas100bossespinnedto80, 370betweenearswith520pincentres,weighs2ton, suit25-30tonexcavator,goodcondition.A468. TA1231469.

$14,000+GST

CATERPILLAR910 Loaderordozerhydraulic angleblade,25-30wide,hasquickhitchpick up,suitCat910sizemachine.Goodorder.. A477. TA1248986. $5,000+GST

$33,000+GST

CATERPILLAR950-960SIZE BulldozerbladesuitCat 950-960sizemachine,3800wide,hastwinvariable angleplussideshift,reversablecuttingedge,good strongblade..A472. $10,000+GST

C.W.E.ROCKTUNGSTONCOREDRILLS Rock drillingbits,largecorebarreltungstentippedbits, C.W.E.brand,1x1100diameterrockbit,1x1050 diameterrockbitand1x900diameterdiggingbit.3 bitsallingoodorder,have200mmsquaredrive,price for $11,000+GST

CATERPILLAR312D 2024,Longreachboom,unused, suit12tonexcavators,will fit Caterpillar312-D,comes withGPbucketandbucketram,reaches13.8m,new boom.A474. TA1237064. $21,000+GST

CATERPILLAR9104 IN 1BUCKET FrontEnd Loader, articulated,3speedpowershifttransmission,Cat3204 engine,opencab,goodtyres,newhydraulichoses, hasextravalve for rippers,weighs7.5ton.Strongwell maintainedloader.S453. TA1206819. $31,000+GST

RAMMAX1404F Compactor,TrenchRoller,820mm wide,hascableremotecontrol,poweredby2cylinder diesel,weighs1.4ton,runswell.S470. TA1231476.

JEC2T concreteprocessorcrusher,hasmanualrotating head,reobarcutter,opensto800wide,headplatehas80 pins,centresare500,distancebetweenears320to340. Unitweighs2ton.A341. TA1035074. $18,000+GST

4TEFCP3061 2021,platecompactorvibrating,brandnew 900wide,headhas80pins,460centresand335between ears.Weightis1060kg,newcompactorplatereadytogo. A426.

TAG40-50TON bucketstosuit40to50ton excavators,suitHitachiEX450,strongwellbuilt buckets.A306. TA960182. $7,500+GST

HITACHIZX450-H SuperDemolitionBoom,fits HitachiZX-450-HExcavator,reaches25.5m,comes completewithrams,hoses,pinsetc,wouldsuit mostexcavatorsinthe45-60tonclass,hashad littleuse.A461. TA1209975. $41,000+GST

CATERPILLAR950-966SIZE Dozerblade,suit Caterpillar950966sizemachine,hasquickhitch pickup,bladeis3450wide,hasanglebothways andsideshift.Verygoodorder.A459. TA1209973. $10,500+GST

CAPTOKSBO5 2024,Rockbreakerunused,suit1.5 tonexcavator,modelSB05,oilflow10-20LPMat 100-120BAR,headhas45bossespinnedto25,95 pincentres,120betweenears.Brandnew.A471. TA1237059.

$2,500+GST

PALSONIC7B7B 1999,piledriver,99yearofmanuafacture,

LABOUNTYMDS-112R steelshear,jawopeningis545mm, hasheadtosuitCaterpillar345excavator,120pins,585pin centreswith490betweenears.Comeswithowncarryframe, weightis3ton.Strongshear.A429.

USEDMAGNETIC pulverisermagneticusedsuit22-28 tondigger,80mmpinsat500mmcentresand330mm to370mmbetweenears.Magnetneedsgensettorun. A194.

$21,000+GST

WIZARD2000320D 2000,SteelShear,hasmanual rotatinghead,bigblades,headhas100mmbosses, 360betweenearswith500mmpincentres,weighs2.2 ton,willsuit25-30tonexcavator.Strongshear..A475. TA1238569. $19,000+GST

NPKSTEELSHEAR SteelShear,hasmanualrotating head,hastips for concretedemolition,headhas80 pin,570centres,315to370ears,weighs2.2ton. Goodshear.A457. $19,000+GST

JEC1800 pulveriser,suitableforconcreteorrock,head has90bossespinnedto80mm,distancebetweenears 330to410,reobarcutter.Crusherwillcrushmaterial downto40mmminus,weighs1.8ton.A340.

Bulldozerblade,suitCat 950-966sizemachine,hashydraulicangle,bladeis 3700wideand1240high,reversablecuttingedge, $10,000+GST

NIPPONSHARYONP-70 1990,PileDriver Hammer,hydraulic,doubleactingimpact,ram weight7ton,willdrive300-800diameterpiles. Unitweighs14.3ton,goodorder.A465. TA1221938. $35,000+GST

OKADAPULVERISER opens900wide,hasreo barcutter,headhas80pinat440centreswith 370betweenears.Strongrobustpulverisersuit 20-25tonexcavator.A456. TA1209970.

BOBCAT2060320D 2024,Unusedbobcat scrubbucketwithhydraulictopclamp,2060 wide,bigcapacitybobcatbucket.A479. TA1248988. $4,000+GST

$23,000+GST

SUMITOMOLECH-20F7-S6.5TON 2008,Magnet excavator,large,20082mdiameter,weighs6.5ton, headhas130and120pins,530betweenears,710pin centres,suit50-65tonclassexcavator.Bigmagnet. A485. TA1255778.

TROMMELLTROMMEX TrommelBucket, Trommexbrand,hydraulicrotating,bucketis 1500long,1250highwith55mmgrids,headhas 80pins,450centreswith330ears.Willsuit20-25 tonexcavator,goodorder.A483. TA1255173. $7,000+GST

PCA Ground Engineering has invested in Hastings Deering’s Cat® Command Line-Of-Sight technology

PCA Ground Engineering is using a Cat® remote-control operation system, offered by Hastings Deering, to increase safety for its excavator operators

Keeping operators safe on the job site is of the highest importance for construction and earthmoving businesses, so eliminating potential risks goes a long way in ensuring this.

As technology continues to advance across the globe more and more innovations such as

remote-control operation can help to support job-site safety.

It’s only a matter of time before these types of technologies become the new norm across the industry.

One business that has already introduced this type of technology and seen significant benefits is PCA Ground Engineering.

Based on the Gold Coast, PCA Ground Engineering is a specialist in piling, grouting, earth retention, civil construction and engineering. While every project is executed with precise attention to detail, PCA truly shines in managing complex and demanding undertakings.

These complex projects often test the limits of engineering and machinery; showcasing the company’s depth of expertise and experience.

To tackle these challenges headon, PCA remains committed to investing in the latest equipment, including advanced machinery and specialised attachments tailored for specific tasks.

It consistently strives to protect the health and safety of employees and contractors, which is why PCA has

The Cat Command Console enables remote operation of PCA’s Cat

PCA specialises in managing complex projects on the Gold Coast

recently invested in the Cat LineOf-Sight (LOS) Command system, enabling its Cat 325 excavator to be remotely operated.

By removing the operator from the cab, this cutting-edge technology ensures a safer working environment in hazardous conditions.

Having procured machinery from all around the world, PCA general manager Robert Bollman says PCA looks for global best practice, leading the business to Cat dealer Hastings Deering.

With an initial brief provided by the PCA team, Hastings Deering sales representative Steve Rykiert says PCA had two key priorities in mind –it wanted to able to run a drill and the machine needed to be operated via remote control.

“This was one of the first Cat LineOf-Sight Command remote control excavators in Australia,” he says.

“The idea behind the remote was that it needed to be able to do everything that the operator in the cab can do.”

With PCA’s excavator able to be operated from up to 400m away, the Cat Command Console is a remote that enables PCA users to work safely and comfortably outside the machine, with all the same

functions that would be available inside the cabin.

While using the remote, PCA operators always remain onsite and in direct visual contact with the machine. Operators’ remote inputs are sent directly to the machine electronics via a dedicated radio transmitter/receiver, offering realtime control.

Aside from the safety gains for PCA operators, general manager Robert Bollman says the technology has also provided productivity benefits.

“Environmentally, we find that the operators do fewer track movements, because they can actually see,” he says.

“Often an operator will go back and forth to get the right visual – with the command system, you don’t need to do that.”

Bollman adds that PCA operators have been able to put various

attachments on the machine, while working with millimetre precision –all from a safe distance.

Up to 10 hours of continuous operating time is offered with the Cat Command Console, with a charging time of four hours or less. It also doesn’t require any on-site communications infrastructure.

Testing the technology and controlling PCA’s excavator himself, Hastings Deering technology onboarding specialist Zach Sales says the user has full functionality of the machine.

“I found it to be really smooth and responsive,” he says.

“There’s also a non-line-of-sight option, where the machine can be almost anywhere with a mesh network.

“You could operate the machine from Brisbane, or be operating out of the mine site in Moranbah.”

Reflecting on the successful partnership, Rykiert says a lot of hard work went in to making this possible.

“Our Hastings Deering technology team were in contact through video call with the Cat technology team in America who designed the program,” he says.

“We met with Rob [Bollman], his workshop and his supervisors, and the brief was the machine needed to do the work – I think that’s what we’ve accomplished here.”

For more information on the Cat® Command Line-Of-Sight technology, visit www. hastingsdeering.com.au

PCA’s Robert Bollman (middle) with Hastings Deering’s Zach Sales (left) and Steve Rykiert (right)

JCB’S Teleskid 3TS-8 offers the extended reach of a telehandler with the mobility and toughness of a skid steer loader

JCB has a long history of pursuing innovation. The telehandler concept it pioneered in 1977 is a testament to that – not to mention the iconic backhoe loader Joseph Cyril Bamford invented in 1953. The JCB Teleskid 3TS-8 is the

latest example of how innovative thinking can shake up the norm.

Combining the flexibility of the telehandler’s single telescopic boom with the mobility and toughness of a skid steer loader, the Teleskid offers a compelling package of versatility, safety and productivity.

The company has always strived to be “innovators, not imitators”, JCB CEA’s national government business manager for backhoe loaders and compacts Glenn McLeod says.

He adds that the Teleskid provides a unique offering for the Australian local market, due to the massive popularity of the machine in the United States since its debut in 2017.

“It’s just going gangbusters over there,” he says.

“We can’t produce enough of them to satisfy the American market. We’re trying to play catch-up.

“The demand shows there was definitely a gap in the market for such a versatile machine.”

Before the machine was released in Australia, local interest had already built up with a pile of preorders – based purely on what information had been available to prospective buyers online.

“We had a very significant number of Teleskid 3TS-8 models

ordered by the Australian Defence Force for use across a range of applications,” McLeod says.

The machines are being used for earthmoving, construction and everything in between.

“They were even transported by air and deployed to target locations by parachute,” he says.

As with the company’s existing range of skid steer loaders, JCB’s single-side boom allows room for an extended offset cabin, as well as side-door access. McLeod says this design gives JCB an edge with safety.

“Your typical skid steer requires ingress and egress through the front of the unit,” he says.

“With our side-door access, there’s no clambering over a loaded bucket or a bulky attachment to get in.”

Another key safety and productivity feature is the 270 degrees of visibility from within the Teleskid’s cabin. McLeod says the large front windshield is also easily removed for quick exit in case of an emergency.

The main attraction though –and the Teleskid’s biggest point of difference – is the telescopic boom, McLeod adds.

He says the versatility this provides can have an enormous positive impact on productivity.

“Because you’ve got a 1.7 metre

reach at full height, it allows you to dump debris into the centre of the truck body, for example,” he says.

“A conventional skid steer struggles to attain that sort of height, and it certainly can’t dump into the middle of the truck body because it has no forward-reach.”