Address:

Address:

LONG-RUNNING Wol-

longong trucking operator

Barnett’s Couriers has closed, blaming a crippling cyber-attack earlier this year for its demise.

Big Rigs couldn’t reach the company for further comment, but a recorded message on an emergency mobile number con rmed the news.

“As you know, Barnett’s Couriers has been the victim of a cyber incident and consequently our business cannot operate productively,” said the message.

“Although we have been working tirelessly with leading IT consultants to restore our systems, regrettably we have been unable to overcome these challenges and have made the di cult decision to cease oper-

ating Barnett’s Couriers.

“We want to thank you, our customers, for the loyalty you have shown to our business over 40 years.”

e message goes on to relay email addresses for further inquiries – quotes@barnetts. com.au, or accounts@barnetts. com.au.

Both, however, triggered automatic responses similar to the voicemail, with the accounts email adding the below:

“We have a small team who will be nalising all outstanding accounts in the coming weeks. Your patience is appreciated whilst our team also work through the backlog of queries that we have received.”

In a radio interview last week, TWU’s NSW secretary Richard Olsen said he was

deeply concerned to learn that Barnett’s had abruptly closed and was urging the company to provide clarity on the situation and ensure workers are fairly compensated.

Olsen understands that the majority of its truckies were owner-drivers, totally reliant on work through the company.

*12 month average, publisher’s claim October 2022

“What we’re very concerned about is that these people are probably paid on a monthly basis, at best, so there’ll be thousands of dollars outstanding to these owner-drivers.”

Barnett’s truck driver Dave Bailey told the Illawarra Mercury that he was still paying o loans for his prime mover that

he bought last December and now faces an uncertain future at 62.

“I’m not the only one, who’s going to employ us?” he said.

According to the same report, employees were given a payment equivalent to three weeks’ notice, while most of the drivers who worked as contractors, were given a one-o loyalty payment of $1000 during the stand-down period.

Up until the supposed cyber-attack, the company seemed to be in good health, with trucks heading out and returning with full loads. e company had assured drivers that their personal information – including bank account details – had not been compromised during the attack.

A 57-year-old truck driver –who worked for ve di erent transport companies while receiving injury compensation – was caught out after a social media post about his new role as an interstate driver. e driver was sentenced in the Echuca Magistrates’ Court on Wednesday April 24 after pleading guilty to one charge of

dishonestly obtaining nancial advantage by deception.

He has been ordered to repay $73,062, ned a further $10,000 after continuing to claim injury compensation payments while working for multiple transport companies, and also ordered to pay costs of $2000.

e court heard the truck

driver was working as an interstate truck driver when he was seriously injured in a crash in 2014 and began receiving weekly workers compensation payments.

e fraud was uncovered in December 2018 following the social media post.

An investigation found the driver had earned about

$55,000 as a truck driver for ve di erent transport companies between February 2017 and August 2018 while continuing to tell his GP, insurer and an independent medical examiner that he had not returned to work. Return to Work Victoria executive director Jason Lardelli said there was no excuse for this level of dishonesty.

“Our workers compensation scheme is there to help those who genuinely need it to support their recovery and return to work,” Lardelli said.

“ e Victorian public expects us to safeguard these funds and those who actively seek to defraud the system by using it for personal gain will be held to account.”

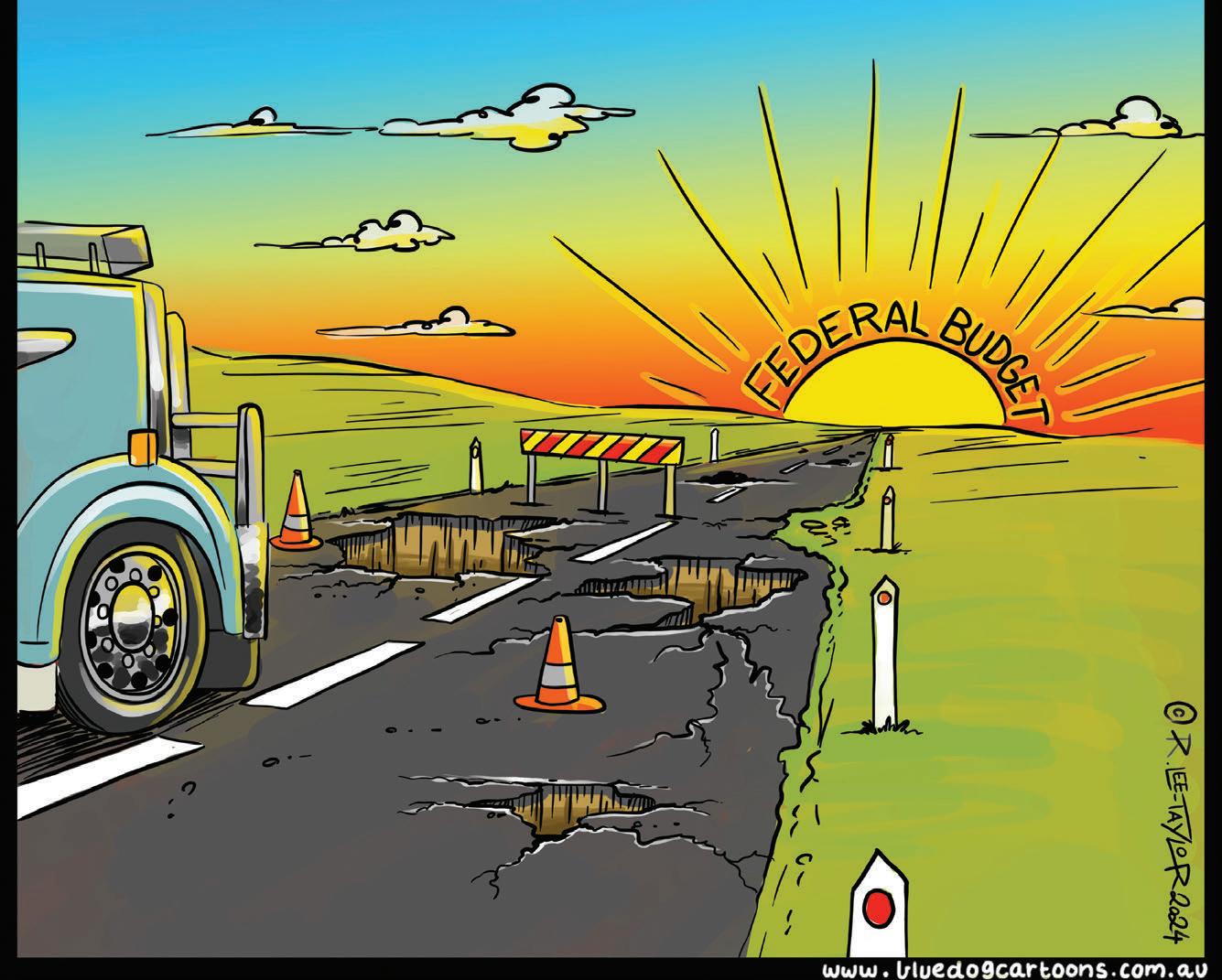

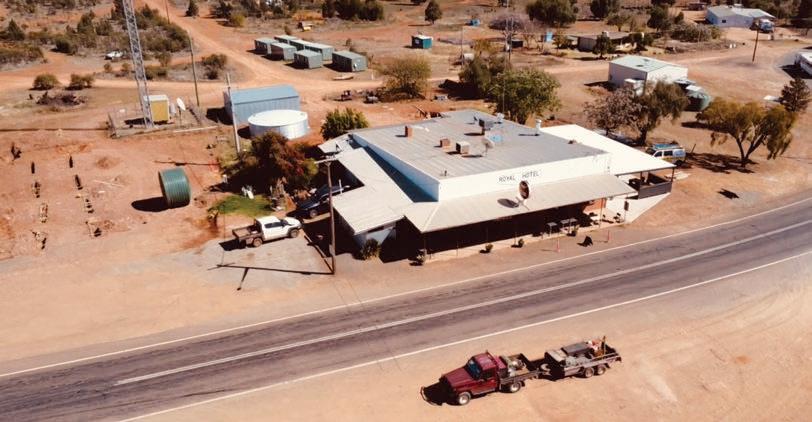

QUEENSLAND trucking is celebrating one of its biggest wins with news that the federal government is committing $720 million in this year’s budget to help build the Inland Freight Route (IFR).

e future of the 1185km highway between Mungindi and Charters Towers, otherwise known as the Second Bruce, had been in limbo as infrastructure minister Catherine King reviewed a wide range of projects, 50 of which were subsequently axed.

e Albanese government is also sticking with the original 80:20 investment split with the state government, rather than the 50:50 model King put in place following the probe last year to stem $33 billion in cost blowouts and delays on infrastructure projects approved by the previous government.

“We’re thrilled to see that [the IFR has been approved] – it’s the culmination of four years of pretty solid work,” said proud Queensland Trucking Association CEO Gary Mahon

“It’s a great moment for Queensland, and for the association. We’ve really been putting it on the line and making it our

biggest priority for some time.

“It’s progressive for the regions but it’s also positioning the industry so much better for the future.”

Mahon said federal investment funds are available now in the project investment schedule and will roll out over the next six years, along with the state’s commitment of $200 million.

To trigger the rst tranche, all the state needs to do is submit its project plan, said Mahon.

“ e advice I’m getting is that those works will be underway in the next several months.

“ e state has already committed $103 million to that

program of works. e design work, all the project parameters have all been completed over the last few years, so they’re ready to go.”

Mahon understands the biggest chunk of the initial budget-spend will be xing the roughness on the Belyando, in the southern half of the road between Clermont and Charters Towers.

After that, Mahon understands some turnouts, gradients and bridge work will be the next priorities.

“So that basically moves us to be able to start concentrating on access on the Warrego, and a more appropriate treatment for Bremmer River.

“ e Cunningham’s Gap project is coming along quite well, so what we’re seeing forming now is a genuine alternative for big multi-combinations.

“We still have the challenge of bringing that sort of e ciency into Brisbane, because at the moment it’s held up in Gatton.

“But as that Inland Freight Route is further progressed, it’s giving us a genuine alternative for big multi-combinations to head up into the highly productive northern provinces of

northern Queensland, in particular.”

Mahon said it also gives industry added ood immunity during the major weather events that have shut down large sections of the Bruce in recent years.

“ e thing we’re most pleased about is starting to really form a genuine road freight network in this state.

“I also took note that at this stage, there’s no particular announcements about Inland Rail.

“So, I think that further reinforces how important that road connection’s going to need to be from Toowoomba into Brisbane and being able to access the port, the advanced manufacturing and a whole variety of other important facilities along that corridor from Rocklea through to Plainland.

Mahon said that region, along with Toowoomba, is becoming an increasingly vital logistics hub

“You put all those elements together being progressive with this investment [in the IFR] is particularly pleasing news.

“Not only that, it’s such a great boost for Queensland

regions as well. is is critical to an industry which will require the use of diesel-powered trucks for some years while waiting for the progression of zero emission heavy vehicle advancements and infrastructure investment in the state.

Mahon also welcomed the news of an extra $467 million in spending on the Bruce Highway, which included $154m for improvements along the north corridor.

But he understands that the large percentage of the funds will go towards the upgrade of the Pine Rivers Interchange.

“It’s a welcome investment to improve congestion in Brisbane as you roll o the motorway onto the Bruce, but what we want to see more of is investment in the Bruce in the regional areas; overtaking lanes, bypasses of towns, pavement widening, bridge improvements, and rest areas.”

When you choose Ryco, you’re not just buying a filter; you’re buying industry leading quality, round-the-clock technical support, innovative solutions, and unparalleled expertise.

This means that when a truck is serviced utilising Ryco Filters, fleet managers can be confident their New Vehicle Warranty is protected, whilst reducing downtime and maintenance costs.

Contact Ryco to discuss your fleet’s requirements. So, when you need to get the job done, be Ryco Ready.

THE National Road Transport Association (NatRoad) has pointed to a range of funding promises in the federal budget it says are good news for the transport industry Support for low carbon fuels, road safety funding, and power bill and tax relief for small businesses were given the tick by NatRoad, with its CEO Warren Clark stating that the budget delivered a range of positive initiatives for operators.

“A 12-month extension to the $20,000 instant asset write-o will help small businesses claim an immediate tax bene t on new assets through to June 2025,” Clark said.

“ is is something we’ve pushed hard for in a number of budgets.

“Eligible road transport businesses will also appreciate the modest $325 rebate on their power bills.”

Clark welcomed increased funding for the Roads to Recovery and Black Spot Programs too.

“NatRoad hopes that the $10.8 million in 2024-25 for a one-year National Road Safety Education campaign

has a heavy emphasis on truck awareness,” he said.

“ e $21.2 million over six years to improve the reporting of national road safety data via the National Road Safety Data Hub is important and long overdue.

“Whilst we welcome additional road funding where the routes are relevant for freight, ultimately we still need to see all governments, including the states and territories, implement road service level standards so we know our tax dollars are going to the roads which need it, with an increased focus on road maintenance.”

While NatRoad believes the budget delivered “mostly good news”, it did fall short on a

number of areas the associa-

tion had been pushing for.

Among these was the establishment of a $3.5 billion Clean Transport Fund, which NatRoad has been advocating for, for some time. It had hoped that such a move would help the industry tackle decarbonisation and the transition to alternative approaches to heavy vehicles, like electric, hydrogen and low emission trucks.

NatRoad’s pre-Budget submission had also called for a National Service Level Standards Framework, to drive more infrastructure spending, and act as a mechanism to cap future increases to road user and registration charges. It had also hoped for practi-

cal action to reduce red tape, through investment in better heavy vehicle road access with an accelerated roll-out of a national automated access system.

In a newsletter distributed to its members last week, ahead of the Budget announcements, NatRoad said, “Too many operators like you are caught in the red-tape trap of applying to local road managers for permission to access roads and bridges.

“Opening up as-of-right access, and having access maps accessible online, would remove frustrations for operators, boost road freight e ciency and take costs out of the supply chain for consumers.”

A SERIES of road safety programs will receive a huge funding boost, as announced in the 2024-25 Federal Budget.

Programs to benefit from additional funding are the Roads to Recovery Program, Black Spot Program, and the new Safer Local Roads and Infrastructure Program which merges the Heavy Vehicle Safety and Productivity program with the Bridges Renewal Program.

Set to receive the biggest piece of the pie is the Roads to Recovery Program, which supports the construction and maintenance of the nation’s local road infrastructure assets.

Funding for the Roads to Recovery Program, which is available to all local government areas in Australia, will progressively rise from $500 million to $1 billion per year.

Roads to Recovery operates on a five-year funding period.

In the current funding period, from 2019-20 to 2023-24, $2.6 billion was made available nationally. Since the start of this funding period, recipients have delivered repairs and upgrades to almost 12,000 road sites.

From July 1, 2024, a new five-year funding period will commence. The available funding for the Roads to Recovery Program will increase until $1 billion is available per year under this ongoing program.

For the Safer Local Roads and Infrastructure Program, the Federal Government has committed at least $200 million each year.

“To ease the administrative burden on applicants, we have merged the Heavy Vehicle Safety and Productivity Program and the Bridges Renewal Program into a new Safer Local Roads and Infrastructure Program,” said a government media statement.

In a bid to improve driver education around safety, $10.8 million will go towards a oneyear National Road Safety Education and awareness campaign, and $21.2 million over six years to improve the reporting of national road safety data via the National Road Safety Data Hub.

“This Data Hub will ensure vital and more harmonised road-safety data can be used effectively by everyone, including decision makers in all states and territories,” a statement said. In addition, $100 million will be invested into a new Active Transport Fund open to states and territories, funding new and upgraded bicycle and walking paths.

While funding for the Black Spot Program will increase from $110 million to $150 million per year. This initiative focuses on safety improvements to road locations where there has been a high incidence of crashes.

A $10.2 million spend on camera enforcement for truck bans in Melbourne’s inner-west is doomed to fail, predicts the Victorian Transport Association (VTA).

e investment was announced in the recent state budget and touted as a victory for the community and lobby groups, such as the Maribyrnong Truck Action Group (MTAG).

But VTA CEO Peter Anderson believes the argument that the monitoring equipment will solve all the issues in the area is fundamentally awed.

“ ere’s still going to be trucks on the street, this is what they don’t understand ey think that this is going to eradicate all trucks o the streets at all times, and it is by no means going to do that.”

e Victorian Government said it will begin enforcing 24hour truck bans through video analytics technology upon the completion of the West Gate Tunnel Project next year.

Preparations for the 24/7 ban have been underway over the past year with data cameras in operation throughout the inner west, monitoring

the movements of trucks and forming the basis for future enforcement.

But Anderson asks: “What trucks do you want to get o the streets? e garbage trucks? e fuel trucks? e food trucks?

“ e trucks that are moving the concrete to x up the roads and water system? What trucks don’t want on your streets? It’s alright, the people in the inner-west will be living a lovely life. eir property values have gone from $200,000 to $2 million in 10 years. Fantastic.”

Anderson said the noise and pollution issues for residents could have been managed a di erent way.

ose options included the VTA and MTAG-conceived Cleaner Freight Initiative in 2018, which proposed incentives for operators using lower emission trucks, but was scrapped two years later by the Victorian Government before it could get o the ground.

Anderson said other cheaper options include using a RFID system in which you can register a truck going through a certain sensor, and also allo-

cate roads to do certain things.

“ en you could manage them and control them accordingly. ey’re jumping up and down and saying look at all these recalcitrants, but where do you want them to go?

“ ere isn’t a tunnel under the Maribynong yet so where do you want them to go to do the job that they have to do?

“You don’t buy a truck and drive it around for fun. ese people have a job to do and the trucks are made to move between two separate points, Point A and Point B, and they try and do it the most e cient way they can.

“We have to get the trucks through as productively and e ciently as we can and if we’re not going to build alternative routes for them, we have to use the routes that are available to us now, and they’re complaining about that, saying we don’t want them.

“Well, stop buying things.”

Overall, Anderson said the state government had done the best it could with “what they’ve got”.

Highlights include $6.6 billion for road maintenance over

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164

Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

3/120 Gardens Drive, Willawong QLD 4110

10 years, and $237 million for works to support regional rail.

e VTA is also pleased that funding commitments have been maintained in what it described as a “di cult” budget for key road infrastructure projects under construction, including North East Link and the West Gate Tunnel projects.

“ ere’s been a lot of money spent on infrastructure and the transport industry can’t complain about that.

“Could it have been better spent? ere’s always di erent opinions and perspectives and that’ll always be like that, no matter what you spend it on.”

Anderson said it’s not always about spending more money, it’s about better managing the money the industry does have.

“Have we managed road maintenance the right way?

And I’ve got question marks on that, not on whether there’s enough money.”

Other VTA highlights include:

• $964 million this year maintaining the state’s road network this coming year.

• $100 million to repair ood-devastated roads, in-

cluding pavements, infrastructure, and xing landslips.

• $17 million to improve metropolitan Melbourne roads and intersections.

• $62 million for upgrades to make regional roads safer and improve freight routes.

• Regional Roads Upgrade Program.

• Western Highway/Dimboola Bridge – structure upgrade.

• Princes Highway East/ Ma ra-Sale Road/Myrtlebank-Fulham Road/Myrtlebank Road intersection upgrade, Myrtlebank.

• London Bridge safety improvements, Talbot.

• Western Highway/Dadswell Bridge – structure upgrade.

• Princes Highway East bridge strengthening of seven bridge structures for High Productivity Freight Vehicles access, Drouin, Warragul, Hernes Oak and Morwell.

• Rutherglen Alternative truck route Roads Package.

• Princess Highway East Duplication Stage 3.

• Hall Road (Skye) Upgrade.

• Bridge Strengthening Program (statewide) for freight e ciency.

Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY , Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH R , WA 6106

Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

ADELAIDE

TAMDELE, 21 Hakkinen Road, Wingfield SA 5013

Ph. 08 8347 1222, email: sales@gitsham.com.au, www.gitsham.com.au

NEWCASTLE/HUNTER VALLEY

Unit 2/13 Hinkler Ave, Rutherford NSW 2320

Ph 02 4932 0600, email: sales@hvss.com.au www.isri.com.au

AS part of its 2024-25 state budget, the WA Government has announced a $7.2 million boost to its Heavy Vehicle Driving Operations training program, which will provide an additional 500 program places a year until the end of 2027.

e funding is part of a $195 million spend on training, which aims to build the state’s skilled workforce and help more Western Australians get into jobs.

is latest funding for the Heavy Vehicle Driving Operations program is targeted in WA’s South West. It follows a $3.5 million expansion of the program into the Kimberley and Pilbara, which was announced in last year’s state budget.

During her budget speech to Parliament, WA treasurer and transport minister Rita Sa oti explained that the program had already seen 650 people trained and employed as truckies, with almost 40 per cent of them being women.

She said it was, “An incredible achievement considering women make up around ve per cent of the industry na-

tionally. And this Budget, we are expanding the Heavy Vehicle Driver Training Program to the regions, as part of our overall investment of $1.1 billion for training in regional WA.”

e WA Government has committed a total of $195 million on education and training in its latest budget, with a focus on making training more a ordable and helping more local workers into the “jobs of the future”.

Other elements of the funding package include an $8 million top-up for the Fee Free

TAFE program; $5.6 million for the Skilled Migrant Job Connect Program over three years; and $85 million for initiatives to grow WA’s construction industry workforce.

Since being rolled out at the start of 2023, the Fee Free TAFE program has seen over 62,000 enrolments, with the initiative being targeted towards local industries in need of workers.

e record investment in TAFE infrastructure upgrades has also been increased to $250 million under the Re-

building Our TAFEs program.

“Investing in our training system is fundamental to giving everyone the opportunity to set themselves up for their future,” added Sa oti.

“Having access to free training and job pathways is lifechanging, and we’re proud to continue investing in our highly successful Fee Free TAFE initiative, which has allowed more Western Australians than ever before to train and take advantage of the vast job opportunities available across our economy.”

USING the latest in road safety cameras and technology, the WA state government is expecting to bring in an additional $40 million in revenue from fines over the next four years.

That’s according to details released as part of the WA State Budget last week.

The WA Government is bringing in a raft of road safety technologies. Among this is an extra $6.1 million being spent on new Smart Freeway camera sites on the Mitchell Freeway.

According to budget papers, “Advancements in road safety

technology have created opportunities to address unsafe driving behaviours, including driver distraction and a failure to correctly wear seatbelts.

“Trials on Western Australia’s roads and experience from other Australian jurisdictions demonstrate that investment in safety camera technology will influence positive driver behaviour.

“The latest road safety camera technology, paired with powerful data analytics, will enable targeted and effective enforcement focused on improved road safety outcomes.”

HEAVY-DUTY truck sales’ records continue to be set in 2024 with the 1550 sales recorded for the month of April smashing the previous April record of 1295 sales in 2023.

Volvo leads the charge and is building a strong lead in the heavies category of the latest Truck Industry Council (TIC) T-Mark database report o the back of its 353 deliveries in April.

ose sales put Volvo 155 sales ahead of its closest competitor, Kenworth, for the year so far – 1141 to 986, in a segment that has delivered an impressive total of 5338 trucks to market this year.

Across all of the truck sales categories, including

heavy-duty, medium-duty, light-duty and commercial vans, 4043 sales were recorded for April, an 11.9 per cent increase on the 3,613 sales recorded for April 2023.

For the year to date, 14,387 vehicles have been delivered across all of the sales categories, up from 14,071 sales for the same period in 2023, reecting overall growth of 2.25 per cent.

In the medium-duty segment Isuzu continued to dominate in the April results, with its 347 sales bringing it to 1272 sales for the year and accounting for 53 per cent of the sales in the segment so far in 2024.

e nearest competitor, Hino, sold 189 medium

trucks in April, hitting 683 sales for the year and 28.5 per cent of the category.

A total of 2400 medium-duty trucks were sold in Australia up to April 30, 8.75 per cent up from the 2207 sales in the category reported for January 1 to April 30, 2023.

On the light-duty front it was another win for Isuzu, and a drop in sales overall for the category.

Of the 1148 little trucks sold for April, Isuzu sold 523, followed by Hino with 199 sales, Fuso on 162 sales and Iveco with 97.

For the year-to-date in the little truck market, Isuzu’s 1943 sales saw it account for 45.4 per cent of the light truck

deliveries made so far this year. e overall category yearto-date sales result of 4277, fell well short of the 5199 sales achieved in the rst four months of 2023 – a drop of 17.73 per cent.

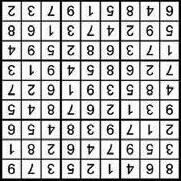

Category summaries: Heavy-dutry

A total of 5338 heavy-duty trucks have been sold in Australia so far this year, up 8.71 per cent on the 4910 sales records for the same four months in 2023.

For April, the top 10 brands in terms of sales results are: Volvo (353), Kenworth (285), Isuzu (220), Scania (145), Mercedes-Benz (88), Mack (84), UD Trucks (78),

Fuso (71), Hino (67), and DAF (57).

Medium-duty

A total of 659 medium-duty trucks were sold in April 2024, an improvement of 50 trucks from April 2023 when 609 trucks were sold. In the past month the top 10 brands in terms of sales in this category were: Isuzu (347), Hino (189), Fuso (73), Iveco (12), UD Trucks (11), Hyundai (9), Volvo (9), Man (4), Mer-

cedes-Benz (2) and DAF (2).

Light-duty

April 2024 saw 1148 light-duty trucks delivered to the market, a decrease of 129 trucks when compared to the results for April 2023. e top 10 brands, by sales volume for April 2024 in this category are: Isuzu (523), Hino (199), Fuso (162), Iveco (97), Fiat (75), Mercedes-Benz (47), Hyundai (23), Foton Mobility (8), Ford (7) and Renault (5).

THE National Road Transport Association (NatRoad) has launched a new set of resources to help operators play their part to help achieve the nation’s net zero emission targets.

Unveiled earlier this month at the TruckShowX 2024 event in Victoria, the Get Fleet Fit initiative for small- to medi-

um-sized operators outlines five practical steps to enhance fuel efficiency, reduce operational costs, and decrease carbon emissions.

“The trucking industry is a significant and irreplaceable arm of the nation’s freight hauling sector. Australia cannot run without trucking, and we will

fail to achieve emissions reduction from road freight unless the transition is cost effective,” said NatRoad CEO Warren Clark.

“Transport customers are increasingly looking to reduce their supply chain emissions, which will increase the need for trucking operators to be able

to understand their own emissions and the different strategies for emissions reduction.”

“It is these members and operators who are best placed to make the decisions and changes required to ensure they remain viable, while making a real contribution to emissions reduction. That’s the purpose

of these resources, to help guide and advise them.”

The Get Fleet Fit initiative offers truck operators the tools they need to succeed in a changing economic landscape, said NatRoad.

This is the first phase of the project, with further detailed guides being provided for each

step over the coming months. “Our aim is to not only assist our members to transition to lower emissions, but to also encourage a collective approach among all stakeholders in the industry,” Clark said.

To download a copy of the Get Fleet Fit guide, please visit natroad.com.au.

EDITOR JAMES GRAHAM

EDITOR JAMES GRAHAM

HUGE congratulations to CEO Gary Mahon and all the team at the Queensland Trucking Association for the biggest federal budget win of all for industry, the confirmation that the feds will stump up with more than $700m to help build the $1bn Inland Freight Route.

The QTA’s tireless lobbying behind the scenes for the last few years has helped secure a massive productivity win for trucking that will play out for many years to come.

It’s just a shame there wasn’t more to celebrate on other industry fronts.

Yes, there is increased funding for local roads and black spots, but talk to any operator out there and they’ll tell you that money won’t go far enough.

The extra $467 million for the Bruce Highway is welcome, but it doesn’t reach far enough into the regions, or offer any more for rest areas. And where are the incentives for operators to play their part in helping Australia reach net zero emissions?

I AM writing with my full support of Nicholas Hales’ letter to you that was published in your last issue.

I have forwarded an email to you that I sent to an industry representative in August last year [see edited extract on right] voicing my concerns with safety issues running eastwest interstate.

I am 54 and have more than 28 years of transport experience. I have run ‘ e Paddock’ for a long time, mainly solo driving, and back in the early 1990s when everyone, and regulations, were still a bit loose, when it was mainly single trailer work east-west and evolved into the B-double and road train era. We were probably the last of ‘old school’ era, the last of that generation that was

taught the ‘old school’ ways. e trucks were quick, some real quick. e unwritten industry rule of thumb was Perth - Melbourne solo - 36 hours; Perth - Sydney - 44/46 hours solo driving.

If you couldn’t consistently do these times, you probably wouldn’t have had a job on wages driving interstate unless you were an owner/driver.

e camaraderie on the road was second-to-none. Many of my closest friends today are from being on the road in that era. ere seem to be less accidents; we never had to worry about who was coming at us, or if they were over the centre line.

It was common courtesy to move to the left fog line for an oncoming truck and it was al-

ways returned, even if we were sitting on a ‘dollar-thirty’.

As unregulated as those times were, and a lot of things not by the book, there was an etiquette that you followed on the road that bred mutual respect.

Drivers got taught how to restrain loads properly by the old boys that had done it for years. We are all particular about knots, neatness, tucking buckles up, and who had the best tarp job. It was almost like a competition, there’s no way any decent operator would be seen down the road with loose ballooning curtains, or tarps looking like parachutes!

You just don’t wake up one day with this knowledge. It’s gained only by hands-on experience and taught by those that have the experience.

Email from August, 2023: I want to make one thing extremely clear and it’s the opinion of ALL decent, respectful, responsible heavy vehicle drivers and operators here in the west: this IS NOT a race issue – it’s a SAFETY ONLY issue.

Every time the issue around a certain cohort of overseas drivers is raised and the lack of experience they have, especially driving multi-combinations, someone pulls the race card.

But it’s going to end in tears unless someone in prominence in transport has the guts to speak out and to somehow find a resolution.

This is purely about if you’re experienced enough to safely and competently operate multicombination heavy vehicles on our city roads and highways Australia-wide with other day-to-day road users so we can ALL return home safely to our families and loved ones.

We are having two or more rollovers a week here in the west and there have been weeks of more than two.

These rollovers, side swipes, headons and running off the road just don’t happen on rural WA roads, these are a common occurrence on Tonkin and Roe Highways in Perth city.

Grain haulage within WA is the biggest issue currently with grain trucks accounting for the majority of rollovers.

One of our major grain haulage contractors have lost 11 combinations this year alone.

There is also an attitude issue that’s nearly at boiling point out on the

highways where experienced drivers are getting abused over the UHF & returning it.

In just about every transport yard I’ve been in over here that has overseas MC drivers doing pick-ups or deliveries they can’t reverse a B-double or back a trailer and dolly.

If you are an MC driver this is a skill that is part of your job and part of the reason we hold an MC license to start with.

The Northam and Wubin road-train assembly areas are an absolute comedy show on Tuesday and Friday night and it doesn’t take long before tempers are frayed, and the facilities end up gridlocked.

Along with the lack of experience there is a massive lack of commonsense or common courtesy with trailers getting backed into, trailers dropped on the ground, A-frames constantly being bent, and tearing around like they are in a race car, high beams and spotlights up.

It is well known the industry is short of drivers and the big companies are desperate to put bums in seats, but surely not at the expense of others lives and safety?

How can this issue be publicly raised in a diplomatic way and resolved in a timely manner?

I consider this to be one of THE biggest issues currently facing the transport industry today.

Cameron Deans Corrigin, WA

THE co-owner of a driving school based in Canberra has claimed some truck driving schools in the ACT are just out for a “money grab” and don’t care about the quality of training or assessment they provide.

Kate Beck, who operates Beck’s Transport Training with her husband Anthony, said the truck driver training industry in the ACT is far too unregulated and inconsistent with other states.

“ ere are so many driver trainers that are just ticking and icking,” she said.

“ ey don’t care about safety or the quality of drivers they are putting out on our roads.

“ ere is also no minimum number of hours that you need to complete for a licence upgrade in the ACT.

“ ere is no consistency between the states and it’s very frustrating.”

Beck said her driving school has never been audited in the ACT in the four years since they started their business.

“We operate in NSW and the ACT, and we’ve only ever been audited in NSW,” she said.

“We have actually asked to be audited in the ACT and it still hasn’t happened!

Beck said she’s heard many “horror stories” of what goes on at other truck driving schools.

“We have heard stories of local providers who will sign o on competencies, but when you question the student, they haven’t been taught those things.

“And these are important competencies, like load restraints and coupling and uncoupling trailers.”

Beck and her husband are

frustrated because they are trying to do the right thing but claim others just “don’t care”.

“We’re battling against these organisations that will o er a shorter cut or a cheaper rate,” she said. “We can’t drop our rates because we’ve got to put a roof over our heads.

“We’re not willing to damage our reputation just because people want a quick, easy x.”

She shared a story of one stu-

dent who came in expecting to be given his licence even though his skills weren’t up to scratch. He had an international licence and needed to change over to an Australian licence.

“He failed the assessment in a couple of areas, so we couldn’t pass him. He then wrote a letter of complaint to us and left us a bad review online, saying, ‘Why couldn’t you just turn a blind eye?’

“He said he had already told his employer he passed, because he was too embarrassed to say that he failed.”

Beck said she and her husband couldn’t live with themselves if they knew they were allowing unsafe truck drivers to head out on the roads.

“My husband is an ex-driver, so we have experience of both sides of this,” she said.

“I was the wife waiting for my husband to come home, petried something would happen.

“Whenever there is an accident, the rst thing that goes through our heads is ‘Was that one of our students?’

“We have a responsibility and a duty of care, and unfortunately you can’t instill that in every driver trainer.”

Beck would like to see the auditing process for RTOs brought under the jurisdiction of the NHVR. “ e states don’t want to relinquish control, but the NHVR is meant to be the national regulator – it makes no sense that they have no power in that area,” she said.

She also wants to see nationwide consistency when it comes to licensing rules.

“At the moment, people are changing their address on paper and coming to Canberra to get a truck license easier, and

that has got to stop. “ ere needs to be one Code of Practice for all trainers and assessors nationally, and minimum training hours for every state.

“Finally, there needs to be more auditing of trainers and assessors to make sure they are actually doing what they say they are doing.”

ere are currently 40 heavy vehicle assessors accredited in the ACT. According to an ACT Government spokesperson, “You must be accredited to teach and assess heavy vehicle learner drivers in the ACT.” Access Canberra is responsible for accrediting driving instructors and the regulation of heavy vehicle assessors. “ is includes assessing complaints and safety concerns.”

e spokesperson added that Access Canberra has a team of ve auditors responsible for auditing heavy assessors, motorcycle assessors, and accredited driving instructors. “All complaints received are assessed in consideration of the Access Canberra Regulation, Complaint and Investigation.

“Concerns regarding road safety in the ACT can be lodged using the Access Canberra website feedback and complaints form.”

“YOU hear all these issues about the drivers on our roads but at the end of the day they’re giving licences away willy-nilly,” said truck driver, turned driver-trainer and assessor John Skinner.

Following in the footsteps of his father – who was a truck driver his whole working life –50-year-old Skinner spent over 30 years doing everything from local to interstate road trains, before health issues forced him to give it up.

“I became a show kid at about 16, so I left home and got into trucks. I started out driving trucks on a car licence, then got my truck licence at 21 and MC at 28. Due to my health issues, I had to give up driving interstate so I got my licences and certificates and became a driver trainer and assessor four years ago,” explained Skinner.

He says that his move into driver training was a real eye-opener – and not in a good way.

“I just thought, this isn’t right. Don’t get me wrong, there are a lot of good trainers out there. Then there’s those who got their truck licence recently or years ago then become trainers or assessors, with no industry experience, but it says you must have five years industry

experience to be a trainer or an assessor,” said Skinner.

“You’ve got all these people blaming the drivers but at the end of the day, they’re coming through our system.”

Skinner spent around three years working for another truck driving school, before going out on his own and opening Gold Coast Truck Driving School in January 2023.

Since moving into training and assessing, he says, “I’ve heard of other assessors signing everyone off for their licence

and never failing anyone.”

One of the biggest issues with driver training, adds Skinner, is that many trainers are “only teaching truck drivers how to drive in a straight line”.

“You’ve got these truck drivers who get their licence and then we say look at these idiots, they can’t even back the trailers. But they were never taught!

“When I was doing MC training and passing students, I had most of them learning how to back around corners. Some struggled with that but

met the standard of reversing in a straight line, so at the end of the day, I’d have to pass them because they passed all the protocols.

“I’ve been pulled up in the past and asked why I wasn’t just doing everything as per the standards – but that I was doing a good job because I was teaching them how to reverse. So they said just keep doing what you’re doing.”

Since opening his own training school, Skinner claims he’s had multiple phone calls from people asking: “Is this the

school where everyone passes?”

His response: “I say no mate, I don’t do that! But I know there are training providers where that’s happening.”

Skinner believes in some cases it’s more about the paperwork than actual skills. “I know of one particular trainer who’s just a good businessman. He has no industry experience, he’s now training trainers who have no industry experience and the person doing the testing has no industry experience.

“You need to have experience to be a trainer or an assessor,

but I know a good percentage don’t have that experience. It’s not enforced, it’s not checked. It’s an absolute joke that this is even happening.

“Even some of the Queensland transport government workers have no industry experience at all and they’re doing the testing and deciding who passes.”

According to Skinner, “There are too many people sitting at desks – and they’re good at the paperwork – but they don’t really know or understand the industry.”

He says safety standards just aren’t where they should be.

“When I was young, I could go out with my old man, and that was some of the best training you could ever get. Now we’ve got this shortage of drivers because we’re not getting the next generation coming through like we used to. But we’ve still got all this freight that has to be moved. And that to me, is the biggest glaring issue.

“You could have your car licence, then get your HR licence with me tomorrow and then 12 months later go for your MC. So you could effectively go from car licence to MC in one year and one day, and then go and transport a loaded B-double from Melbourne to Sydney.”

STRAPS

•Keep your load safe.

•Available in Coaming Hook, Rave Hook and Tie Rail Hook configurations.

•Silver Strap only. $14

MUDGUARD PACK SPECIAL.

•1x Mud Guard in your choice of colour.

•4x Adjustable Guard Bracket.

•2x Mudguard Poles w/reflectors

KRUEGER 11M WINCH STRAP.

•50mm x 11m Strap.

•Rated to 2.5T

•Comes with quality Hook & Keeper.

• Comes

The first of 150 Kenworth C509s featuring autonomous technology have arrived in the Pilbara, ready to be put to work in coming months, hauling up to 330 tonnes of iron ore.

They were transported via drop deck trailers, making the 1280km journey from Perth to Onslow, over two and a half days.

The trucks will be used to support Mineral Resources’ (MinRes) Onslow Iron project.

They will travel on a 150km dedicated and fenced haul road running from Ken’s Bore mine site to the MinRes Transhipping Terminal at the Port of Ashburton.

Over $24k raised

When long-time truckie Warren ‘Woz’ Acott was diagnosed with MND, he decided he wanted to try and make a difference, launching his Mow Down MND campaign.

He set off on a gruelling 11day, 772-kilometre trip from Victoria to Canberra on his ride-on mower in a bid to try and make MND a notifiable disease.

He was able to raise $17,098 for MND Australia and $7577 for MND Victoria.

A petition was also launched to make MND a notifiable disease, which collected a total of 13,845 signatures.

Fearless truckie

A fearless truckie was singled out by police for helping them arrest five alleged car thieves in Cairns earlier this month.

The truckie reportedly assisted to stop a stolen Range Rover and also aided officers to detain the offenders who scattered after crashing into his trailer on Lyons St. Detective Inspector Kevin Goan said they were part of a larger group who went on a house break-in and car stealing spree through Mount Sheridan, Edmonton and Brinsmead.

Officers from the Cairns Property Crime Unit with assistance from the Tactical Crime Squad, Dog Squad and Rescue 510 helicopter charged a total of nine teenagers between the ages of 14 and 17 with 104 charges in relation to allegedly stolen vehicles in Cairns in the week leading up to this arrest.

Blindsided

Truckie, politician and transport industry advocate

Clynton Hawks says he was completely blindsided by his party’s decision to drop him, just six months out from the Queensland election.

The 25-year-old was told he would be disendorsed by the Katter Australia Party (KAP).

“It was rough,” he said. “I definitely wouldn’t have guessed it after five years of advocacy not only in the transport space, where we had a big win with AdBlue, but also with the cost of living.

“And it wasn’t even in a faceto-face meeting, which was pretty disrespectful and rude.

“This was my job, as well as driving a truck at the same time and juggling a young family – and it’s not like I wasn’t doing anything, I was out there campaigning every day.”

BY DANIELLE GULLACI

BY DANIELLE GULLACI

ORDERED three years ago, this special limited edition Peterbilt 389X has nally arrived on Australian shores just in time for its owner’s 60th birthday celebrations.

When Craig Membrey of Membrey’s Transport and Crane Hire ordered the ‘Green Dream’ – a limited edition Peterbilt 389X – he didn’t expect it would take as long as it did to arrive down under.

But as it hit home soil –arriving at Adelaide port on May 3 – it was a very welcome sight.

Peterbilt’s popular model 389 was rst introduced in 2006 and will cease production by the end of the year to make way for the new model 589.

e brand released 1389 units of the limited edition 389X model and Craig was lucky enough to snap one up.

“It’s a birthday present to myself,” said Craig, who cel-

ebrates his 60th on June 7. “ ere are six 389s coming into Australia but mine is the only limited edition one.”

Based in Melbourne, Membrey’s Transport and Crane Hire was started by Craig’s father Jack Membrey in 1962 – with Craig taking the reins in 1989, putting in the hard yards to grow the business into what it is today, with over 250 pieces of gear.

He well and truly lives by his motto of ‘make it happen’. “How lucky am I to have the only Peterbilt 389X in the country!” he said.

Craig was actually handed the keys to his new beast in May 2023. He and his kids Leah (19) and Jack (16) headed over to the Peterbilt factory in Denton, Texas, for the occasion. ey were lucky enough to have timed the trip to coincide with the new truck coming o the production line.

At the time, Craig expected it would take no longer than three months to get his

newest toy home – but due to shipping delays, it was a whole 12 months before he laid sight on it again. ough it isn’t Craig’s only Peterbilt – there are two oth-

IT’S A BIRTHDAY PRESENT TO MYSELF... THERE ARE SIX 389S COMING INTO AUSTRALIA BUT MINE IS THE ONLY LIMITED EDITION ONE.” CRAIG MEMBREY

ers in his eet – this is the rst one he’s purchased brand new.

e Green Machine is truck number 1029, in honour of his son Jack’s birthday on October 29. ough he’s still at school, he looks set to eventually follow in his father’s and grandfather’s footsteps.

“I was lucky to get the serial number 1029 for Jack’s birthday, obviously in America they ip the month and date around. I have two limited edition Kenworths in the eet – a Legend 900 and Legend SAR which are both number 29. I couldn’t get number 29 with the Peterbilt but was lucky enough to

get build number 1029,” explained Craig.

Before Craig gets to take the truck for a spin on Australian roads, it’ll be converted from left-hand to right-hand drive, along with being highly customised – or “Membreyised” as Craig calls it – with all the “bling and shine”.

Craig has enlisted Truckworks in Adelaide to do the conversion and once complete, the truck will make its way home to Melbourne.

“I’ve been to the Peterbilt factory four times now and kept dreaming. Now I’ve put it all together. But there’s things you’ve got to do so it’ll probably be a few months until I get it on the road.

“For a long, long time, a new Peterbilt has been on my bucket list. Peterbilts are the Lamborghinis of trucks.”

While much of Craig’s eet is put through its paces in some of the most demanding jobs, that won’t be the case for the Green Machine. It will be more of a show truck, though Craig says he’ll still be doing the odd job with it too.

FOR Queensland based transport business, R & K Bulk Haulage, several trucks serve as moving billboards for causes close to the owners’ hearts.

Based in the small town of Jondaryan, Queensland, R & K Bulk Haulage is a family owned and operated business, started by Russell and Karen Strasburg in 2005. Its 44-strong truck fleet stands out in the crowd, with many of the truck and trailer combinations sporting vibrant colours and/or impressive airbrushing.

But it’s the latest addition to the fleet, a purple Kenworth T909 and matching A-double set of trailers that’s been turning heads.

Dedicated to epilepsy awareness, the new truck’s theme is in honour of Russell

and Karen’s daughter Skye Strasburg – with purple being the international colour for epilepsy.

March 26 each year is Purple Day, a global initiative dedicated to raising epilepsy awareness, dispelling myths and furthering support for those living with epilepsy.

Now 29 years of age, Skye was diagnosed with epilepsy

when she was seven years old. R & K Bulk Haulage is very passionate about making some of their trucks moving billboards to promote awareness for various causes. The purple epilepsy truck joins a pink breast cancer awareness truck, and a light blue prostate cancer awareness truck, a disease which Russell has himself been battling.

Skye says she absolutely loves the new truck. “I think it is beautiful and am so thankful that my sister Brandee put forward the idea to have a truck done up for epilepsy. She continued, “I am extremely thankful to my mum and dad for doing it. This helps bring awareness to the four states the truck will be travelling in. They asked me what I

wanted written on the side of the bonnet. ‘Tiny is loving it all’ comes from my nickname and the company motto of ‘loving it all’. The fact that you must enjoy every day because you never know if it will be your last, as epilepsy unfortunately takes people’s lives.”

Russell added, “This truck is special to me, as not only has epilepsy affected us as a family but it has also affected my daughter’s life daily, along with her two daughters and partner. To spread awareness across the country is something special and can have a huge positive impact on people suffering with epilepsy.”

The purple epilepsy truck, which is driven by company driver Brad Hoadley, travels across various routes through Queensland, South Australia, Victoria and New South Wales.

It may now be a publicly listed company, but the ‘family’ ethos forged in those early years of operation runs deep for a loyal band of drivers.BY GRAHAM HARSANT

THE history of Lindsay Brothers, and its successor, Lindsay Australia Limited, has been well documented over the years. Established by Tom and Peter Lindsay at Co s Harbour, NSW in 1953 with a couple of second-hand tray trucks, the brothers initially transported local fruit and veggies to the railway for shipping to the Sydney markets. e business grew to encompass fuel deliveries and many other areas of the transportation business.

Shortly after Peter Lindsay’s sudden passing in 1998, the company was listed on the Australian Stock Exchange and continued growing into the hundreds of red and white liveried Kenworths that we have all seen traversing our highways.

To the drivers of old however, the friendships, the camaraderie, the respect, the loyalty and the ‘family’ ethos came from those years between 1953 and 2002 when Lindsay’s was a family-run business.

And so, when Tracey Lindsay, daughter of Peter, decided to organise a reunion at Sawtell, NSW – just down the road from Tom and Peter Lindsay’s rst depot at Co s Harbour - some 160 former employees of Lindsay Brothers gathered from around the country to share memories of

those long-ago years - to reminisce and catch up with old mates and their families.

ere have been Lindsay Brothers reunions in the past on a smaller scale including one last year which Tracey attended.

“ at was also in Sawtell and I just happened to be home, so was able to attend what was a great night and realised how much fun it was,” said Tracey.

“A couple of my boys – the older ones that I grew up with when I was 5 to 10 years old, weren’t travelling too well so I realised that in another couple of years they might not all be around.

“ at was the incentive to try and gather as many of the ‘family’ together as we possibly could.

“When I decided to do it, I rang Gimmy (Warren Gim) and Frankie orn to see if they would help, at the same time warning them that I’d constantly be on the phone or in their faces for the next eight months. Of course, they didn’t hesitate.”

In sending out invitations, Tracey and the crew asked if anyone happened to have photographs of old workmates who had passed on. is resulted in a poignant four minute ‘Vale’ video featuring dozens of the Lindsay Brothers family no longer with us. e silence in the room was ‘deafening’ as the video played, fol-

lowed by sustained and heartfelt applause.

To the delighted surprise of the guests – some money was put behind the bar by Graham Sebbens of Brown & Hurley to get everyone in the mood.

From there, and throughout the evening, the function room at the Sawtell RSL was a cacophony of sound as old friends caught up and reminisced – pausing only to watch another two video presentations played through the evening.

A ra e was drawn with painted drums on o er, as well as Kenworth du el bags emblazoned with the Lindsay Brothers Reunion 2024 logo.

A drawing by Brad Truck Art of an early Lindsay Bros Ford, purchased by old time subbie,Terry ‘Red Bull’ urwood was presented to Tracey in recognition of her e orts.

ere was also an amazing quilt made by Tracey and emblazoned with old Lindsay Bros photos which was ttingly won by the oldest attendee, and only one from the 1950’s, Col Jones.

Walking around the room throughout the evening, the most commonly used words were ‘family’ and ‘respect’.

“Peter and Tom could be hard-arses,” said more than one attendee. “But after you got kicked up the bum it was always a case of, that’s done and dusted, let’s move on.”

“Great, fantastic, top, thumbs up, great e ort, wonderful evening, great team, special and sensational”, were just some of the plaudits offered at the end.

“I’ve been going for three days and there is still one to go,” said Gimmy, referring to the Last Man Standing to take place at the Sawtell Hotel the following day. ere’s been a lot of good stories dredged up from the past and it’s been fantastic catching up with old mates, some of whom I thought were dead”

Terry urwood met Frankie orn in Bundaberg on a Friday over a drink in the 80s and they have been mates ever since. “ ere was a lot of drinking going on back then,” said Terry.

Terry usually ran across the Hay Plains, but on this occasion was in New England and it was snowing buckets.

“I’d never seen snow before and I rang Frankie, who I knew was in the area and said, ‘what’s the deal with this snow, mate. I can’t see a bloody thing’,” he recalled.

“Frankie’s only advice was to put my seatbelt on and hang on for dear life! So, I did, and I’m still here, which I thought I mightn’t be at the time. Loved those Hay Plains ever since!”

“I think our boys are pretty unique,” said Tracey, who was backed up by Colleen Foster who said, “Over the years there was never anybody like Lindsay Brothers.”

Tracey’s brother Rod encapsulated the family’s feelings when he said, “Dad and Tom started the company. You guys built the company. ank you very much.”

Loyalty to an employer is something earned by the employer, not the sta . It cannot be bought by money, it is certainly not made by threats or cajoling.

It is gained by respect, honesty and being treated as a person, not a number. It is gained by recognising that your success has only been achieved by those who work with and for you.

It was obvious throughout the evening that Peter and Tom Lindsay worked tirelessly to earn that loyalty from their ‘family’, as evidenced by the turnout this night.

Congratulations to Tracy, Gimmy, Frankie and everybody else involved with the event. It was humbling to be there and to witness the love in the room.

David and Kevin Murada have sworn by Kenworth trucks since 1979 and are delighted to be honoured as Kenworth Legends.

BY KAYLA WALSH

BY KAYLA WALSH

EVERY so often, you come across some real characters in trucking – and David and Kevin Murada are prime examples.

e 66-year-old twin brothers, who have run Wollongong-based operation Metal Transport Industries for the past 45 years, were named this year’s Kenworth Legends at the ATA’s national conference in Canberra.

ey started out carting scrap metal for BHP, which is now BlueScope, but as time went on, they moved into heavy haulage – carting up to 90-tonne loads.

Although David and Kevin are well-known and respected in the transport industry, they don’t take themselves too seriously.

“ e heavy haulage side gives you challenges, and I still love the challenge,” Kevin said.

“When you’re out west and you can’t drive at night with an oversize load you get to go to a lot of hotels.”

His brother added, laughing: “Kev could write a book on the pubs.”

e Muradas said you have to have your wits about you when the loads get heavy and wide and high.

“ ere’s a bit of pressure on you when you’re up and down the highway, especially with narrow bridges,” Kevin explained.

“ ere are so many damned if you do, damned if you don’t decisions that you have to make.”

David chimed in: “We dodge a lot of power lines. We wouldn’t have pulled any down, of course...”

David and Kevin originally set up their business with their brother Peter, who sadly died in the early 1990s.

“We were triplets, and Pete was with us in the business for about ve years,” David said.

“ en he moved to Sydney, and he was into a few things, trying to make some money.

“He passed away in ‘92, which was pretty sad.

“We were always hoping he would come back to work with us, but that wasn’t to be.”

e heavy haulage side of Metal Transport Industries came about organically, as word got out that they knew how to move big machines.

“At one stage with the scrap, we were hiring our dad’s machines to do our jobs,” said David.

“He had excavators with shears on them to cut scrap, and a loader machine that you put a magnet on, to lift the scrap.

“Because we moved machinery, we had people ringing us up to come and move their machinery, so the heavy haulage side slowly grew.”

BlueScope was one of the company’s very rst customers, and they still work at their Port Kembla steelworks –though not directly for them.

“We still do one job inside BlueScope and we move 3500 to 4000 tonne a day, 365 days a year, 12-hour shift, carting slag, which is a by-product of making iron and steel,” David said.

“We don’t work for Blue-

Scope anymore, we work for Australian Steel Mill Services, who look after the slag material.

“ at’s a hard job. We cart 70-tonne, 80-tonne loads, going around and around in circles with o -road, minespec Kenworth trucks.”

David and Kevin have sworn by Kenworth trucks since 1979 and are delighted to be honoured as Kenworth Legends.

“We’re both very passionate about the Kenworth product,” David said.

“It has proved itself over and over again.

“It’s built here in Australia, and you get to pick what you want on the trucks – you can have one fuel tank, two fuel tanks – you can have six fuel tanks if you like.”

Although the brothers had 40 trucks in their eet at one stage, they are now back down to 21.

“ e more trucks you get, the more problems come with it all,” David said.

“We had 40 trucks but after we got out of a big contract, we sold 20 of them.

“Like most companies, our eet goes up and down, but

we’re pretty comfortable.”

e eet is set to increase slightly again as David and Kevin gear up to collect two new Kenworths – a C510 and a K200. Kevin was also getting his new 909 tted out as we were going to print with this story.

e K200 will hit the road, while the 510 will head to the BlueScope steelworks, joining the ve 509s they already have there.

“ e 510 has a Cummins engine, 600 horsepower, with 1400 tyres,” David said.

“In the 509s we would break springs and new bolts because we were pushing the six rod with what we were carting.

“In the 510 there’s a di erent suspension, you can put 50-tonne on the drive and it can handle the weight.”

Kevin still gets out and about in a truck most days, and said he is de nitely not an “o ce person”.

“I think I did a little bit in the o ce in the ‘90s and then we employed another bloke and I’ve mostly stayed out since then,” he said.

“Dave will answer the phone and I’ll quote jobs and we’ve got a good system going.

“I don’t mind jumping in and helping the mechanics or whatever. I just do what needs doing.”

David joked: “You can probably guess how well Kev’s little o ce stint went.”

e twins have seen a lot of changes in their four decades in transport, but they think most of them are for the better.

“In NSW, the RTA makes us put the trucks over the pit every 12 months,” David said.

“We struggled to get used to that idea at rst, but now we think it’s for the better.

“It evens the playing eld and makes sure everyone’s truck is roadworthy.”

ough they are as passionate about trucking now as they were when they started out, they have concerns about the current driver shortage and the future of the industry.

“It is a sad indictment that we can’t get the young guys to come through,” David said.

“If you drove around in the 80s, trucks were going pretty damn quick.

“Now we’re driving 100km/h and we think that’s fast, but insurance companies

are still making it so expensive to employ someone under 25.

“I think they could let that rule go and make it easier to hire young people.”

ey may be coming up on retirement age, but the twins don’t think they’ll be hanging up the keys to their Kenworths any time soon.

“Our wives bring it up quite a bit,” David laughed.

“But no. In saying that, we do take our holidays.”

“If I had to pass on one message to anyone in the trucking game, it’s that you should always take your holidays!”

Despite seeing each other almost every day at work, David and Kevin’s holidays are almost always spent together too.

“We work together, and we play together,” Kevin said.

“We’ve got a good connection between us.”

After leaving his brother hanging for a moment, David agreed: “...Ah no, we do.

“We live in the same suburb, and we have the same mates. We’re always together.”

He added: “We’ve been around for a long time, we’ve survived, and our Kenworth trucks are here to stay.”

AFTER 63 years in business, this Cairns-based truck body builder and trailer repairer will shut up shop.

Founded in 1961 by Malcolm Beattie, 88, and operated alongside his sons Darryl and Gary Beattie for decades, B-T Industries became a much loved and respected family business in Far North Queensland.

Over the years, the business developed a solid reputation based on their high levels of workmanship and exceptional customer service.

“We’re pretty well known up here. We’ve been around for a long time now and are a bit of an icon up here,” said Darryl.

Both he and his brother Gary worked by their father’s side for over 40 years.

Gary did his apprenticeship at B-T Industries in the early 1970s, while Darryl did his apprenticeship with a major ship building company, before joining the family business in 1980.

When Gary retired a few years ago, Darryl, now 64 and his father, who is now 88, kept the business going – with Darryl in the workshop and Malcolm in the o ce.

e family had hoped to sell the business so it could carry on its work, but it was unfortunately to no avail.

“We did try to sell the business because we did have a very good business and a good reputation, but I think up here we just don’t have the volume so couldn’t nd a buyer,” explained Darryl.

“ ere were a few younger people interested but they couldn’t get the nance. So it’s a real shame that all this knowledge and everything we’ve built up over the past 60+ years is just going to go.”

When Malcolm rst started his business in 1961, he was actually involved in steelworks for homes, producing things like handrails and the like. at progressed into repairs for earthmoving equipment, before moving onto truck bodies.

“ ere was nobody really

thing was a lot smaller than what they are now – they were all single axle. As the industry grew, we were able to grow with it. Even though we didn’t start out as engineers, we were able to grow and develop an understanding as designs changed and progressed.”

It was in the 1970s and 1980s, when the gold and tin mining boom hit Far North Queensland, that B-T Industries hit its peak. “At that point we were building about 100 bodies a year. at was a pretty big deal for us up here in Cairns – the population was only about 120,000 at that stage,” recalled Darryl.

“ e most sta we ever grew to was eight, but we were lucky

tandem trucks, then dog trailers came into the market so we designed and built dog trailers too. All of a sudden it went from a single axle dog trailer to tandem and then three axle dog trailers, then they went to four axles.”

Before long the business had outgrown its workshop, so the family had a choice to make – expand their business or cut back on the new trailer builds.

ey chose the latter option.

“Everything was getting too big for us and the workshop wasn’t big enough to handle the bigger trailers so we decided to scale down instead of going bigger,” said Darryl.

“We would’ve had to do a big expansion because our work

2017 and we moved into repairs and maintenance.

“In 2017, we also decided it was going to solely be a family business so we scaled back and it was only Gary, myself and my father up until Gary retired. at was hard work and long hours because we were trying to keep all our customers happy.”

at move kept the business going strong, thanks in part to the strong relationships built with major trailer builders such as Shephard Transport Equipment, Hercules Engineering and Hamelex White, who entrusted the Beattie family with warranty work for operators within the area.

B-T Industries had customers coming in from Townsville down south through to Moss-

ing tarps, among other things,” Darryl added.

“At that point we were so at out with work – and we’ve been going at out ever since. We’re only a small company but we have a good reputation. I can honestly say the biggest thing we’ve tried to do is get operators back on the road as soon as we could – because when their equipment is in here getting xed, it isn’t making them any money.”

And Darryl says they put in the hard yards to get the job done – whether it meant opening the doors early or staying back late, as many customers can attest.

Howard and Andrew Plumb were among B-T Industries’ loyal customers, having turned to the business for its truck body needs for decades. ey also purchased the very last body manufactured by B-T Industries seven years ago.

ey said they were saddened to hear B-T Industries closing its doors. “We have been a customer for only 30 years but during that time, Malcolm, Daryl and Gary Beattie have been the benchmark of what excellence is.

“ e Beattie family have well and truly earned some time o , after dedicating their careers to the people of Cairns and others who have come because of word-of-mouth recommendations.

“Malcom and the boys had

myself needing one and, in my mind, it was a B-T body or none. No other builder comes close to what B-T Industries can build and I’ve owned and seen plenty of others in my 30 years with trucks.

“Seven years ago, after months of nagging, they nally caved, and I am proud to say my family owns the last body they built. Our son bought the truck that that body is on from us. He knows the condition of buying the truck o us, is that when he is ready to sell that truck, the body stays in our family, until we too are ready to retire!” ough B-T Industries will o cially close at the end of July, Darryl says he’s not ready to give it up completely just yet.

“I’m sort of retiring but still keeping a nger in the pie,” he said. “We’ve come to a stage where it’s become too much. I’ve enjoyed the industry and it’s the same with my father but we’ve been in it a long time, so we’ve decided to bow out gracefully. We would have liked to sell the business, but it wasn’t to be.

“I’ll keep doing blue plate modi cations certi cates and will be involved in advising companies up here on how to do any modi cations that may need to be done on any truck or trailer. I don’t mind doing a bit of part time work – Dad is retiring but for me, it’s a change

Our writer hitches a lift in an eye-catching rig for the final 100km stretch of this year’s Crawlin’ the Hume from Melbourne to Albury.

BY DAVID VILE“WELL, I don’t think those fellas that sell AdBlue will be getting much business out of this lot today,” said Malcolm Leech with a big grin as he red up the Cat Diesel in his Peterbilt 379.

‘ is lot’ was the diverse contingent of around 300 historic heavy vehicles that were taking part in the 2024 Crawlin’ the Hume in early April, which made its way from Melbourne to Albury running the old Hume Highway.

In an event that drew participants from as far a eld as Queensland, Malcolm had kindly o ered me a lift on the roughly 100km stretch northbound from the lunch stop at the Winton Raceway near Benalla to the end of the run at the Albury Racecourse.

Hailing from Newstead, near Castlemaine in Victoria, Malcolm and his family operate Fouremile Trucking, with the company trucks running all manner of general freight across the country.

e eet comprises of three Peterbilts, two Western Stars, two Ford Louisvilles and a couple of Kenworths, and Malcolm’s 379 has been a faithful servant for over 20 years.

“She’s a 1988 model, ex-Freestones, I believe it was bought out as a glider kit. It’s been a colossal truck - she has had a couple of whacks and a bit of cosmetic surgery, but she still holds together.

“ e motor seized about 12 years ago and we put a new head on it and have swapped the 13-speed out for an 18 double over box. She only tares around 9 tonne full of fuel. I wouldn’t have a clue what mileage it’s done over the years, but she still works each week, it’s got good legs and its good on fuel.”

With the Cat rumbling Malcolm eased the big Peterbilt out through the gates of the Winton Raceway past the ruins of the Winton Roadhouse and onto the old part of the Hume, bound for Glenrowan.

e old Hume is a long way removed from the double-lane freeway of today and as we headed along Malcolm reminisced about his rst forays into trucking many years ago.

“ e rst truck I bought with my brother was an F8000 Ford which we did with Cubico work to Sydney, and then I got a 1968 Diamond T with a 6/53 GM in it – I could hardly hear myself think in it!

“I bought it from a wrecker’s for about $3000. It had been working as a log truck, so I shovelled the dirt out of it and got it working.”.

Along the way he has also had stints driving for ompsons and Parsons Transport and then taking the plunge again as an owner-driver working for Col-

in Rees (CRT) - with the blue CRT colour carried over to the Fouremile eet.

Heading up and over the current Hume Freeway the convoy wound its way into Glenrowan and with the town famous for all things bushranging, it was no surprise to see the six-metre-tall statue of Ned Kelly with shotgun drawn overseeing the passing procession through the town. e new Hume in a lot of places runs parallel to the older version and saw a number of towns including Kilmore, Broadford, Seymour, Euroa and Wangaratta all progressively bypassed.

Today the modern Hume could be regarded as somewhat of a boring drive with Malcolm having experienced what many would consider the best era of the Hume in the 1970s and 1980s, which saw faster trucks and a greater spirit of adventure amongst those making their way up what was fondly known as ‘Sesame Street’.

“It was really good on the old road, but you had to be on the ball and be across what you were doing. e towns used to break it up a bit too, coming through places like Benalla and Wangaratta you had to slow down and then get going again. We used to travel in groups of 10-15. You would be yacking on the CB radio and before you knew it you were at Holbrook” he said.

With the convoy heading into Wangaratta the lineup of trucks making their way through numerous sets of tra c lights allowed many people to enjoy the slow-moving procession, and also provided Malcolm with only his second visit to the regional city since the bypass was completed in 1993.

Fast forward 31 years today and it is hard to imagine the once constant ow of trucks changing down and making their way through the town centre at all times hours of the day and night. With plenty of chatter over the radio and the

Peterbilt building up speed we picked up the ‘new’ Hume highway out of Wangaratta headed towards Springhurst and Chiltern.

Along the way we pass Malcolm’s daughter Haley headed southbound behind the wheel of one of the company trucks, and with Malcolm’s son Joel and brother also driving for the Fouremile operation, it’s a real family a air.

Back at home Malcolm is restoring his father Gary’s 1969 AT-4 Dodge which is a labour of love.

“She used to go real well on the old road. It’s got a 6/53 in it, which he did interstate with. Once you got her wound up she was good for about 78 mile an hour (125km/h) so she was pretty quick.”

With the Jake brake slowing the Peterbilt, Malcolm wheels o the Hume once again and into Chiltern, a town that has embraced its Highway 31 heritage with one of the largest turnouts of people to wave and greet the trucks headed through

town with the crowd spilling out of the Telegraph Hotel and Conness Street.

With a few blasts on the horn to the people waving and aiming their cameras at the trucks passing, Malcom shook his head in wonder at the number of people.

“For the whole event it’s been awesome with the turnout of people - it has been massive right along the way.”

Slowing through Barnawartha, the last of the small towns that used to be on the old Hume, once again the new Hume is crossed over as we approach the Murray River and the end of the trek at the Albury Racecourse.

“ at’s one thing I remember about Albury on the old road, there were a lot of sharp left and right turns,” said Malcolm as we turned onto the Lincoln Causeway, known to many as the ‘Mad Mile’ linking Wodonga to Albury.

Indeed, there was, with many trucks coming to grief at the infamous ‘Rollover Corner’ at

the Viscount Motel. e 17km internal relief route through Albury, after having been rst put on the drawing board in the 1970s was nally completed in 2007, in the process removing around 18 sets of tra c lights for trucks heading through to negotiate.

Once again navigating the corners and tra c lights, one nal right turn puts us onto Fallon Street which signals the end of the trip and a dinner and social gathering with no doubt many stories to be told well into the night.

For Malcom, the trip has been a great day out and he is looking forward to the next one in 2026.

“I reckon there will be some thirsty people here tonight,” he smiled before continuing.

“You don’t get the full grasp of how big this event is until you see them all sitting on the pad there ready to depart Melbourne this morning and here again now. is was my rst Crawlin the Hume, and I will be de nitely doing it again.”

Enrol in the Hydrogen Fuel Cell Electric Vehicle Training program

Hydrogen energy has the potential to cut Australia’s greenhouse gas emissions to onethird of current levels by 2050. Developed in collaboration with industry experts, these future focused Microskills pave the way for a greener, more sustainable future. Equip workers with the fundamental knowledge and skills to safely operate and integrate Fuel Cell Electric Vehicles. Upskill online, on-demand in less than 2 hours.

Microskills for a macro impact

Our Microskills focus on three key areas that lay the foundation for a sustainable future:

1. Hydrogen Energy Fundamentals

2. Introduction to Hydrogen Fuel Cell Electric Vehicles

3. Refuelling of a Hydrogen Fuel Cell Electric Vehicle

In collaboration with:

What started as a tidy-up wound up as a complete $55,000 rebuild of this 1987 Ford LTL workhorse that was once part of the Lindsay Brothers’ fleet.

BY KAYLA WALSH

BY KAYLA WALSH

FARMER and diesel mechan-

ic Mitch Underwood is by no means a man of expensive taste – but when it comes to restoring old trucks, he’s not too worried about going over budget.