DESIGN Daz

DESIGN Daz

TRUCKIES were reporting an increased police presence at rest stops in North Queensland in the weeks leading up this month’s statewide cattle sector blitz by the NHVR [see story on page 3].

Drivers who spoke to Big Rigs on the condition of anonymity said police have been checking logbooks and conducting RBTs at rest areas in Roma, Charters Towers and Cloncurry.

“The pub test don’t count,” said one truckie familiar with the recent incidents.

“They’ll just bring out the letter of the law which says if you’re in charge of a heavy vehicle you have to have zero alcohol [blood reading].

“But it’s just bullshit, especially at the Cloncurry saleyards now, because it’s so well looked after, a lot of them

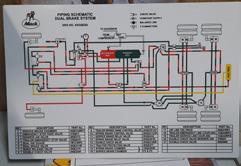

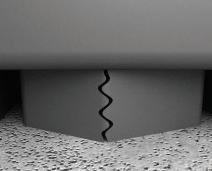

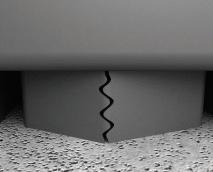

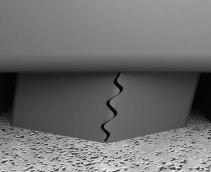

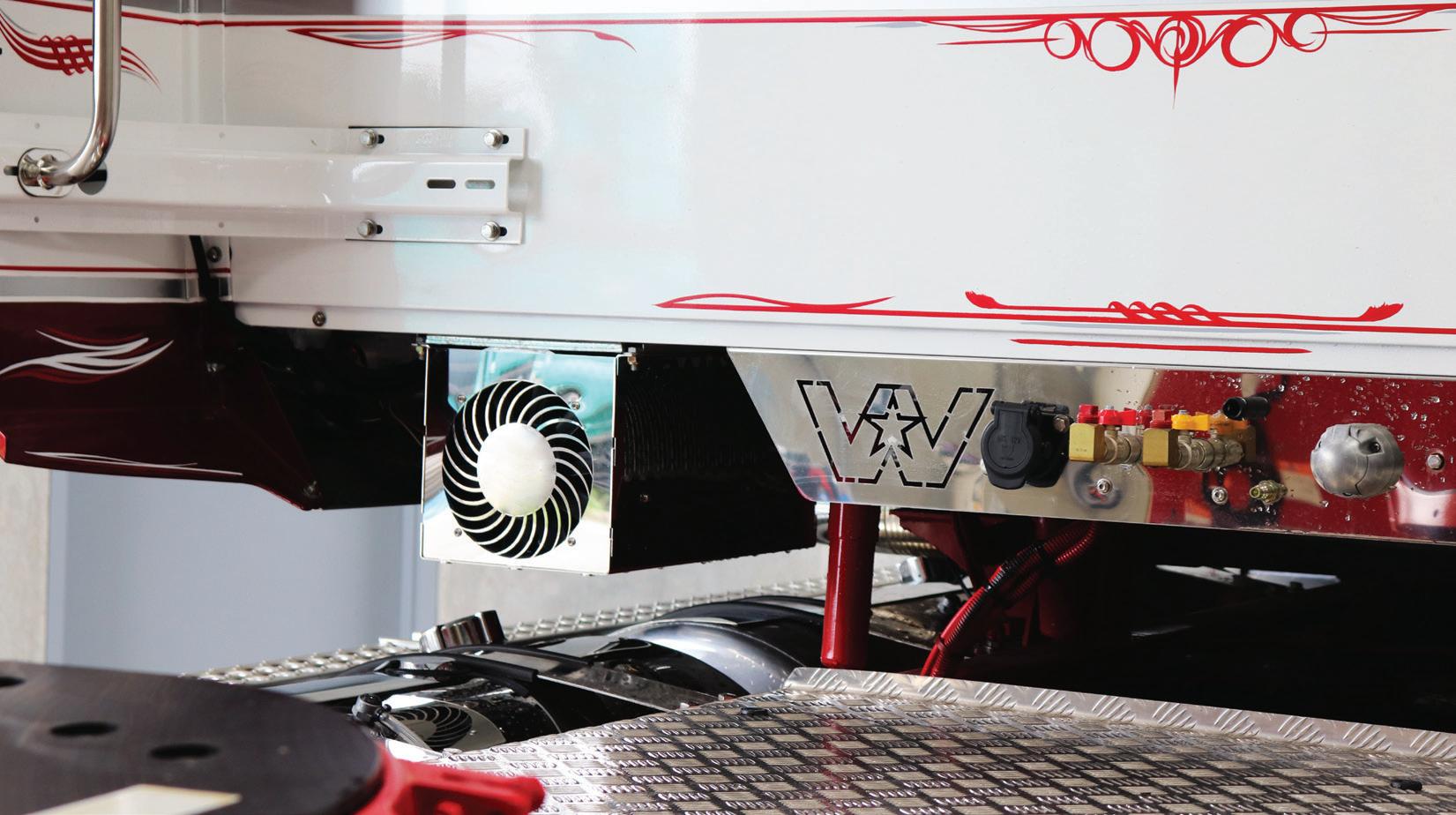

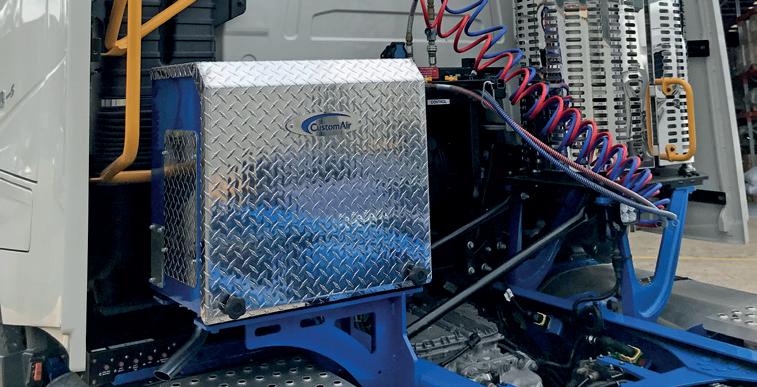

THE National Heavy Vehicle Regulator has shared a warning to truckies after coming across a vehicle with a badly worn pitman at a Programmed Vehicle Inspection site in central Queensland.

The damage was affecting the vehicle’s steering ability, which the NHVR said could have resulted in “serious consequences” on the road.

“Excessive wear like this occurs over a long period of

guys, are using it as a regular stop as they travel through Brisbane to Darwin.

“They pull in there, cook a bit of tea, have a few beers, so straight away they’re over the triple zeros.

“If police go in there and breathalyse them, they’re going to get ‘em.”

Another truckie we spoke to said there was no “rhyme or reason” why the police need to be targeting drivers at their place of rest.

“The normal everyday copper in the towns, they’ll help you rather than try and screw you, but the task force in their candy cars, they’re a different breed of copper.”

Local member Robbie Katter said the Queensland government’s priorities have hit a new low by targeting truck drivers with random breath

tests (RBTs) at rest stops where they’ve pulled up for the night.

“It’s an absolute disgrace that police resources are being used to harass truckies at rest stops, where they’ve pulled over after long, gruelling hours on the road,” said Katter, Katter’s Australian Party (KAP) Leader and Member for Traeger.

“This is nothing short of the state government flexing its muscles on the wrong people while ignoring the real issues plaguing our communities.

He condemned what he called the hypocrisy of the state government’s priorities, pointing out that while North Queensland is battling real problems – like skyrocketing youth crime and crumbling roads – the government instead targeted truck drivers

with petty crackdowns.

“While our roads deteriorate and youth crime spirals out of control, police resources are being misused in a money-grabbing exercise.

“We all understand the importance of road safety but harassing hardworking truckies, who are off the clock is over-policing and intimidation. This isn’t about safety – it’s about squeezing truckies for cash.

“The emotional toll this harassment takes on drivers, who are already grappling with long hours on terrible roads and limited rest areas, is unacceptable.”

The increasing imposition on transport companies, paired with nonsensical regulations, was pushing truckies to the brink.

time, meaning regular checks would have found the issue before it became a serious safety risk,” they said.

“A defect notice was issued to the company and the vehicle was prohibited from use on road until repairs were made.”

A spokesperson for the NHVR told Big Rigs that no Infringement Notice was issued, and the NHVR will “ensure education is delivered to the company”.

“Several North Queensland transport companies have reported to me that it’s becoming increasingly difficult to keep or employ truck drivers, as many are unwilling to endure the constant harassment and overreach from the police,” Katter said.

They added: “The NHVR is reminding drivers and operators that regular preventative maintenance and safety checks reduce the risk of serious incidents occurring on our roads and help keep all road users safe.

“Drivers are encouraged to read the NHVR’s Daily Safety Checklist. By taking a few minutes before each trip to check basic safety items on their vehicle, drivers can iden-

Big Rigs has approached Queensland Police for comment.

tify any issues and ensure the vehicle is safe and ready for the journey.”

The NHVR has urged truckies to report safety issues, to make sure you are not putting yourself or others at risk on the road.

“If you feel pressured to drive a defective vehicle, please contact the Heavy Vehicle Confidential Reporting Line on 1800 931 785,” they added.

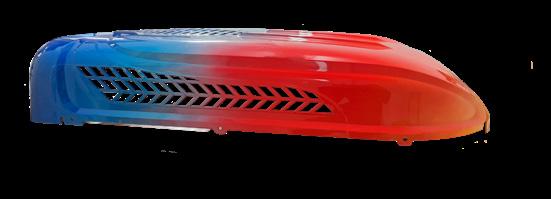

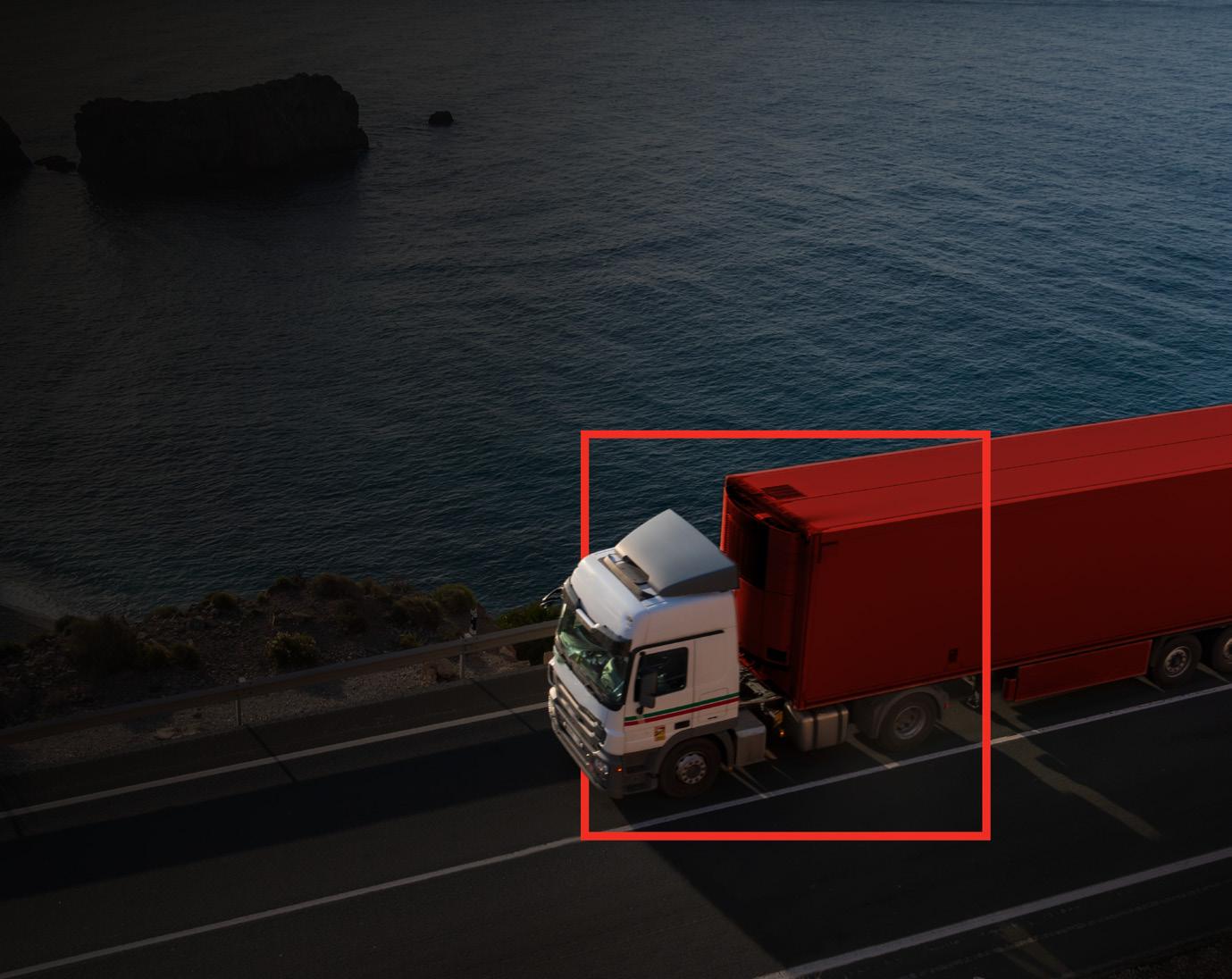

CATTLE sector bosses are urging drivers to remain professional and show NHVR officers respect during a statewide safety blitz this month.

Following an increase in livestock heavy vehicle rollovers in recent weeks, the blitz will focus on compliance with fatigue, mechanical safety, loading, and general compliance with the Heavy Vehicle National Law (HVNL).

During the compliance operation, there will be an increased NHVR presence around scheduled cattle sales, abattoirs and road train routes used to transport cattle.

Frasers Livestock Central Queensland manager and vice president of the Australian Livestock and Rural Transporters Association, Athol Carter, said this isn’t the time for a ‘them and us’ mentality.

“We must work collaboratively with each other to make the industry better,” said Carter, who is also the Central Queensland delegate of the Livestock and Rural Transporters Association of Queensland (LRTAQ).

“It just comes down to having respect for one another during these roadside intercepts – it only takes one to destroy it.

“Livestock drivers are professional and highly skilled people who love their jobs. We

need to remain professional in our conduct and show each other respect.”

Carter said the industry needs to have an overall understanding of the function that the regulator now plays in the livestock sector.

“We are now their customer, and not only do they service us on the road, they are now the one-stop shop as a transport operator.

“They are our one-stop mediator and industry information source for states participating in the HVNL.

“While the drivers might

not be interfacing with onroad intercepts every day of the week, business owners and operators are dealing with the NHVR daily behind the scenes to manage our fleets access, standards and accreditation.”

Carter believes this month’s campaign offers an opportunity to help bridge the “disconnect” of service delivery and functions performed that still exists between the sector and the regulator which only took over on-road compliance and enforcement duties from TMR on April 20 this year.

But he doesn’t believe the vast majority of the livestock sector in Queensland has anything to fear during the campaign.

“There’s always that one per cent, and those operators know who they are.”

LRTAQ president Gerard Johnson, of Gerard Johnson Transport, said he was surprised to hear that the regulator was conducting a monthlong blitz.

He didn’t think the livestock sector warranted the probe, but was waiting to see how it rolled out and what data was collected before commenting further.

He concurred with Carter’s advice for drivers to remain professional at all times, and if they had any concerns to contact the LRTAQ.

“We would be concerned if they were pulled over for any length of time – it always has an impact [on animal welfare],” he added.

“That would be needed to be taken into consideration when intercepting drivers of trucks.”

An NHVR spokesperson said staff will provide information, education and guidance where appropriate, whilst ensuring livestock transportation is safe for the heavy vehicle driver, other roads users and the livestock being transported.

At the height of COVID-19 and the resulting supply chain issues, Ryco’s Z872ST SynTec Oil Filter was put to the test.

Ryco filters earnt their stripes and kept Cummins engines and Australia moving.

Built with innovative synthetic media and robust core design, this filter meets OE requirements. Contact Ryco to discuss your fleet’s requirements at fleetsupport@rycofilters.com.

So, next time you’re servicing your Cummins engine, be Ryco ready.

“The NHVR recognises the livestock industry can be dynamic, with scheduling and driver rosters often determined by bookings at short notice and deadlines for sale days and abattoir schedules,” the spokesperson said.

“The correct preparation, safe transport, loading, unloading and management of livestock are all imperative to ensuring the driver, livestock and other road users are kept safe.”

The NHVR says the operation follows recent data on the transportation of livestock, which indicates an increase in heavy vehicle rollovers.

In one of the most recent rollover incidents, on August 20, the Capricorn Highway at Fairy Bower was blocked for several hours and 20 head of cattle had to be euthanised.

Two weeks earlier, emergency services were left managing cattle after the truck they were being carried in rolled at Condamine.

The driver in his 60s was taken to hospital in a stable condition.

“This operation will help address this increased risk and ensure drivers and operators travelling across Queensland are keeping safety front of mind, and have a clear understanding of the risks associated with non-compliance,” the NHVR told Big Rigs.

Following the transition of heavy vehicle safety services in Queensland to the NHVR earlier this year, the regulator said it is now able to conduct these sorts of operations at both state and national levels across various industries in the transport sector.

The NHVR has also released new regulatory advice aimed at enhancing safety across Australia’s livestock transport sector. To access, visit nhvr.com.au and search ‘regulator advice –livestock’.

BY KAYLA WALSH

BP Archerfield in Queensland recently let customers know that it will begin towing illegally parked vehicles and unhitched trailers from October 1 – and BP has informed Big Rigs that this is part of a broader crackdown on parking violations.

Thomas Gilmour, Dealer & Truckstop Key Account Lead at BP, told Big Rigs the Archerfield site has been chosen as a starting point for two main reasons.

“Queensland legislation supports the towing of illegally parked vehicles and unhitched trailers,” he said.

“Archerfield is one of our most significantly impacted sites in relation to this issue, so it ticks both boxes for us.”

The BP service station at Archerfield has between 70 and 80 truck parking spots on site.

Gilmour said he had visited the servo three times to inspect the parking situation and found on average 32 unhitched trailers taking up valuable spaces.

“We’re now implementing a zero-tolerance policy on unhitched trailers,” he continued.

“If we can free up 32 parking spaces for truck drivers who need them, we are making a big difference in solving the parking problem at Archerfield and then at other sites.”

Gilmour explained towing unhitched trailers is also a practical first step because it’s easier for Archerfield staff to manage.

“With unhitched trailers, there is no requirement to chalk up tyres or get video or photographic evidence, which is what we would have to do if we were to tow a vehicle.

“We’re starting with trailers and we’re planning to extend that to other vehicles, including looking at ways we can target local vehicles.

“The limit for parking for local vehicles is eight hours and we know that sometimes local companies will park one vehicle during the day and then do a switch at night.

“That’s a tough one to manage because if the vehicle is there for less than eight hours, we can’t tow them.”

BP has signed a contract with Queensland towing company Harvey’s Towing, and unhitched trailers abandoned at the Archerfield site will be taken to one of Har-

vey’s Towing’s impound lots. Charges will apply for towed trailers and vehicles, which are capped under Queensland law (Tow Truck Regulation 2024) as follows:

- a standard tow of a motor vehicle from private property capped at $290.05.

- the on-site release of a motor vehicle from private property capped at $174.05.

- a daily charge for storing a motor vehicle towed from private property to the nearest holding yard capped at $29 per day.

BP has erected signage on site to alert drivers of its new towing practices, along with contact details for the towing company.

“There will be signs upon entry to the site, signs upon entry to the store, and in the parking area, informing customers that we have a towing policy for unhitched trailers,” he said.

“By parking at the site, you are entering a contract with BP and agreeing to follow the rules.

“We do not have to inform you if we have towed away your trailer, and that is the same for cars and any vehicle overstays.”

“Archerfield BP offers 24hour parking for interstate truck drivers and acknowledges the importance of reliable parking options so appropriate rest breaks can be taken.”

“At a lot of our sites, we are hoping to get dedicated caravan parking because we know that with the weigh bridges being installed, they are using it a lot more.”

Gilmour said allowances will be made if someone needs to unhitch their trailer for a “genuine” reason.

“For example, if someone has had a bunch of their tyres burst and they need to unhitch the trailer and get it

sorted. If they go in and tell the site, we’re not going to tow them.

“We also have truckies who come in and they have a 36hour rest and they let the site know that they are going to be on the site for 36 hours.

“As another example, we have one truck that has been at a site in NSW for six weeks.

The driver is in hospital and his partner has let us know.

“We covered over the truck for them and facilitated another trucking coming to pick up the load. That’s no problem.”

Gilmour said the main thing they want to prevent is non-

BP customers using the site as a depot or a storage yard for equipment and trailers.

“We work really closely with our partners to make sure we have great facilities inside our stores, from the showers to the food.

“If truck drivers can’t park at the servo, they can’t access any of those things and it makes those facilities pointless.

“If an interstate truck driver is running out of time in their log book, we want them to know that they can pull into Archerfield and have a hot shower and a feed and they’ll be looked after.

“We want to give truck driv-

ers a safe place to rest, but we can’t do it if half the truck parking is taken by unhitched trailers.”

He added that the problem is frustrating and was hoping to come up with a national solution to the problem.

“We want our customers to be able to trust that, if they are doing a run from Townsville all the way down the coast, stopping at eight or nine of our truck stops, they will be able to get a park at all of them.”

Gilmour is concentrating on improving the parking situation at Archerfield before moving on to Eastern Creek in Sydney and Wingfield in Adelaide.

“Eastern Creek is particularly bad from Thursday to Monday,” he said.

“The problem with that site is that it is so busy, and it’s in Sydney so space is at a premium. We have arranged a towing company and signage so that’s the next place we will be looking at.”

BP is working with the staff at Eastern Creek to install security cameras.

Gilmour said BP is aware that availability of truck parking is a major issue for truckies, and resolving the issue is a top priority.

“We get an overwhelming amount of complaints about it – the feedback that we’ve

got is that parking is our biggest issue. We are hoping that targeting the unhitched trailers will have a knock-on effect and deter other people from doing the wrong thing.”

At issue deadline, BP was not yet able to provide the number of trucks towed from its Archerfield site since towing commenced on October 1. However, one truckie who was at the servo on the morning of October 2 told us he noticed a big difference in parking availability.

“The back row has been cleaned out,” he said. “There’s normally rigids and cars parked in the spots when they get their trucks. The guys out the front were saying it’s about bloody time. There are plenty of free spaces now.”

Senator Glenn Sterle, a longtime campaigner on the servo parking issue, also said he was pleased to see action finally being taken.

Big Rigs has contacted other fuel companies, including Viva Energy (Shell), Mobil

Australia and Ampol for comment around the issue of truck parking at their service stations around Australia.

Viva Energy and Ampol declined to comment, while Mobil has not responded to our enquiry.

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164 Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

BY KAYLA WALSH

TRUCKIES fear that BP’s current crackdown on unhitched trailers and long-term parking could have a negative knock-on effect, pushing the problem onto the streets.

Many of our readers took to Big Rigs’ Facebook page to share their concerns that operators and owner-drivers will be reluctant to shell out on yard space.

“All the streets are going to be filled with trucks and trailers on the side of the road,” wrote Mathew Nelson. “Everyone knows they will never spend the money on a yard.”

Meanwhile Debbie Godwin said that while she thinks it’s a “great idea” to punish those taking up parking spots needed by interstate truckies, she’s seen how it could cause issues elsewhere.

“I’m all for it, but they are now vacating to the likes of Arndell Park [in Western Sydney] and dumping trailers or prime movers for days on end,” she said.

“It’s hard for workers to park and trucks to get into their own depots.

“If their boss doesn’t have a yard to park them in, then

find somewhere else.”

Joel Williams agreed that the streets of Sydney are becoming increasingly crowded with parked trucks.

“I used to know a good parking spot in most industrial suburbs, but lately it’s been ridiculous,” he said.

“The streets are lined with trailers and trucks that look like they haven’t moved in months.

“During the day it’s almost impossible to find someplace to park, there seems to be way more cars than ever.

“I don’t understand – this isn’t just one or two suburbs, this is every suburb.

“They want things done by the book but there seems to be no-one on our side demanding change. The industry is growing – that means facilities need to grow also.”

3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110 – 120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Rd, Welshpool WA 6106

Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

ADELAIDE

TAMDELE, 21 Hakkinen Road, Wingfield SA 5013

Ph. 08 8347 1222, email: sales@gitsham.com.au, www.gitsham.com.au

NEWCASTLE/HUNTER VALLEY

Unit 2/13 Hinkler Ave, Rutherford NSW 2320

Ph 02 4932 0600, email: sales@hvss.com.au www.isri.com.au

BY KAYLA WALSH

BP’S announcement that it will initially be focusing on parking violations at its Archerfield, Eastern Creek and Wingfield sites has prompted many truckies to suggest other problem servos.

Interstate driver Wayne Rogerson told Big Rigs that the BP site at Epping in Victoria is “notorious” for trucks and trailers being parked for extended periods of time.

“We drivers have to sign a book to say we are parking for more than the standard length of time,” he explained.

“However, some people choose to use it as their own private depot – they even have mechanics come out to the site and perform services there!”

Rogerson said there has been a Volvo prime mover and an old bus parked at Epping for months without being removed.

“Yesterday, when I was there, the site had three single trailers and six B-double sets unhitched,” he said.

“There are also a couple of

blokes that park their trucks at the site every day and put their car in its place in the morning, so they reserve themselves a spot for their truck in the afternoon.”

Rogerson also pointed to BP Tullamarine and BP Dandenong as sites that need attention.

“Tullamarine BP is also a site that is abused by people parking their trucks every afternoon, getting in their cars that they park there in the morning and going home.

“At Christmastime last year, I was using BP Dandenong and was told not to park my prime mover in the car parking area while I was resting or they would fine me.

“But for five weeks, there were four rigid tippers parked on site, taking up spaces that people like me need to use.”

BP Truganina is another servo that announced they would be cracking down on longterm parking last year.

But according to truckie Shannon Suttle, who runs between NSW Central Coast, Sydney and Truganina, park-

ing is still very much a problem at the site.

“Trying to get a park early morning is near impossible between the Ampol and BP at Truganina.

“The arguments you get into

because the local drivers are holding spots for their mates.

“Sometimes you end up going over your hours just trying to find a spot.”

He said there is signage on site warning about parking

limits and towing, but he has never seen it enforced.

“You can report it to management and BP Complaints and all you get is ‘We’ll look into it,’” he added.

Meanwhile Adam Black said

he wished BP Beresfield would follow suit.

“Parking here is hard to come by,” he added. “BP will take your $2000 in fuel, but heaven forbid if you want a shower or rest!”

OUR recent stories online about BP’s parking crackdown have sparked a massive reaction from readers, with many of them praising the company’s decision to tow unhitched trailers and illegally parked vehicles from Archerfield and other busy sites.

Many truckies also said it was “about time”, and they wish BP had done this years

ago, while others were not convinced that BP are going to stay true to their word. Take a look at some of the comments from our readers below.

Peter Macc

“Good on them. Freeloaders are using these places as their depots or free parking while they’re home having a break

instead of paying to park in a compound.”

Fiona Goodman

“Good stuff. The amount of times the husband hasn’t been able to shower or get a feed thanks to these inconsiderates is too often.

“Trailers are being left at roadhouses instead of yards.”

David Lopes

“Thank goodness! Finally all these 457 drivers will need to pay for parking just like the rest of us!”

David Muller

“Why has it taken so bloody long?”

James Arnoutse

“This has been going on for years, as far back as I can remember.”

Stelios Papoutsidis

“I’ll believe it when I see it. Not the first time they’re ‘going to crack down on freeloaders’. Every few months the same crap comes from BPs but never any real action.”

Courtnay Anderson

“Pfffft, they have been saying they’ll do this for years.”

Brad McDonogh

“It’s all good to threaten to tow trailers, but until it actually happens, nothing will change.”

JJ Easter

“Good in theory, but how are they going to manage that if a customer drops one of their trailers to go and do a delivery with one trailer because it isn’t on a B-double route or not a

B-double friendly site?

“Comes back after unloading to do their second trailer and plans to then return to fuel and go to bed?

“What happens to the trailers left alone while away unloading or loading? What if they need to go and have a mechanical issue resolved? Go to an appointment?

“A changeover driver gets to the site two hours before their changeover turns up. Unhooks from the trailers so they can have an undisturbed sleep while waiting?

“I don’t think this is a onesolution-fits-all.”

Niell Graham

“Let local blokes take their truck home at night and park it outside their own house – that way that’s half the problem solved.”

Jim Gatt

“Also you can add the body trucks. Basically if it’s a day cab without a driver, hook her up!”

Adrian Bates

“Yep, this is a big problem. Depending on each state’s legislation on private property towaways is the big issue.

E.G. Westfield Shopping Centre had the same problem – that’s why they went to a boom gate system.”

Dave Cowan

“The problem isn’t unhitched trailers, it’s local yokels using them as a depot.”

David Wright

“Put a pin lock on the trailers and charge them $1000 to have it unlocked – they will soon get the message.”

BY KAYLA WALSH

A South Australian truckie has been hailed a hero after risking his life to save a 70-year-old woman from her burning car.

Michael Sleep, who drives for Paris Creek Farms in Meadows, was travelling down the Princes Highway between Tantanoola and Millicent when he came upon the scene of a fiery head-on crash between two cars.

Without stopping to worry about his own safety, he pulled over and ran to help grandmother Cleone Bryant, who was trapped inside her vehicle as it began to be engulfed in flames.

Once Bryant was safely out of her car, Sleep immediately went to help the female driver of the other vehicle.

The other driver was not seriously injured, while Bryant is now recovering in hospital with broken ribs and a

cracked sternum.

After the accident, Bryant’s family were initially unaware of Sleep’s identity but managed to find him by putting a call out on social media.

Kerri Bryant, Cleone’s daughter-in-law, told Big Rigs: “We have been amazed by the power of socials to have found Micheal.

“My husband has spoken

to Micheal and thanked him obviously.

“We hope to catch up with him when Cleone’s out of hospital as she would like to thank him personally.

“He really is such a hero.”

Kerri said that Cleone has a long recovery ahead of her, but she is in “good spirits”.

Meanwhile Cleone’s son James also expressed his gratitude to Sleep, calling him an “absolute legend”.

“You saved grandma’s life, you are a hero to us all,” he added.

Sleep declined an interview with Big Rigs, preferring not to take too much credit for his act of bravery.

“I don’t really want much attention,” he said. “I just happened to be in the right place at the right time.

“I’m sure anyone that came across that situation would have done the same.”

“I’m just glad both ladies are going to be OK.”

Sleep’s courage and quick thinking has led to him being nominated for an Employee Recognition Award at his workplace.

“He has been praised by us at work and our team have nominated him for an award.

“We hope Cleone has a safe and speedy recovery.”

Caitlin Johnson from Paris Creek Farms said: “Had he been 30 seconds earlier, he could’ve been caught up in the chaos, or had he been 30 seconds later, the outcome could have been so much worse.

BY KAYLA WALSH

A professor at Griffith University in Queensland is appealing for truck drivers who have been first on the scene of road accidents to get in contact with him.

Dr Darren Wishart is carrying out research as part of the Queensland Trucking Association’s First on Scene Incident Response Training Program, with a view to better understanding what drivers are faced with in these difficult situations, and how they respond.

The study is funded in part by the Motor Accident Insurance Commission in Queensland, and involves a collaboration between the QTA, the Queensland police and St. John’s Ambulance.

Wishart told Big Rigs: “How this initially came about was, the QTA had said that a lot of truck drivers in regional Australia would be the first to come across the scene of a crash.

“In some instances, emergency response could take anything up to an hour.

“A person that’s first on scene in those situations may be exposed to things that not everyone would be able to cope with.”

The QTA, Queensland police and St. John’s Ambulance got together to design a training program to educate heavy vehicle drivers on what they should do if they are first on the scene of an accident.

A total of 129 truckies took part in the face-to-face

course, which was run at seven different locations around Queensland.

“It’s about what to do when you arrive, making the scene safe, what to do in terms of first aid, and what to do after the event in terms of self-care,” Wishart explained.

“There was significant improvement between pre- and post-training in terms of knowledge and confidence around being first on the scene.”

The QTA are currently in the final stages of developing a set of resources to make the training available to more truckies, with “toolbox talks” that companies can share with their staff, as well as an online component.

Wishart is now hoping to

speak to more drivers who have been first on the scene of accidents, to gain further insight and refine the training offered by the QTA.

“We are primarily interested in speaking to any of the 129 drivers who went through the training, to see if they have been first on the scene of an accident since then and if they found the training helpful.

“But of course it was only a pilot program – we hope to reach more people when the QTA rolls out the training in the new format.

“I am also interested in speaking to truck drivers who haven’t undergone the training but have been first on the scene of an accident.

“Any information provided could help improve the train-

ing program.”

Wishart said being the first on the scene of an accident is a stressful experience and he wants to make truck drivers aware that help is out there.

“Many of the truck drivers I spoke to could still recall the incident in a lot of detail, no matter how long ago it happened,” he said.

“It was still in their minds, even a decade later.

“Many truck drivers are not aware of the post trauma care that is available, and we hope to improve coping strategies, mechanisms and resources so it doesn’t get to the point where a driver has to quit the industry.” IF you would like to take part in the study, email Dr Darren Wishart at d.wishart@griffith.edu.au.

EDITOR

JAMES GRAHAM

REST assured; we’ll be watching the crackdown on the servo parking closely.

We know, you’ve heard others try and police this issue before without success.

But this new bloke in charge at BP, Thomas Gilmour, does seem to be making all the right noises – see pages 4-6, if you haven’t already – with towing underway as we went to print.

That’s more than we can say for the other main players who either declined to comment, or ignored our approach.

Maybe they’re sitting back and waiting to see the impact of BP’s new hardline measures before following suit. We can only hope that’s true.

While state governments drag their feet in building more rest areas, it’s imperative that fuel giants play their part in helping drivers manage their fatigue.

Speaking of fatigue management, it was concerning to hear reports of Queensland Police visiting truckies’ rest areas in the central state (see page 2).

I read with interest the article on MC licencing here in Queensland on page six of the most recent issue of Big Rigs [Truck licensing loophole exploited, September 27 ] and would like to make some comments.

The first thing that I actually take offense to is that your source says that the quality of driving schools up here is abysmal.

I have been doing this job for 13 years now, for the same company, and take my job very seriously. We are training people in a weapon of mass destruction, and they need to know how to do it safely.

To bundle all driving schools into a comment like that is very poor, and unless you have seen how they train or

what they do you your source can’t really comment on that.

Secondly, there is actually a guideline for MC licences that the truck should be 75 per cent loaded for testing purposes – this is written into the contract that TMR has with RTOs. The same is not true for MR or HR, however, a number of schools choose to have some weight on the truck. For instance, our trucks run with 4t of concrete blocks on the back, which is around 40 per cent of their capacity.

Thirdly, if you ask any of my students who come and sit for an MC licence, it’s not that easy. Firstly, there is a 50-question test they must complete before driving. They get their learner guides

and practice tests approximately three weeks prior to training, and then on the first day they must complete this under test conditions (not open book) and achieve a result of no more than five incorrect answers. Secondly, the practical driving test, once training is complete, is a 2.5 hour driving test around Brisbane and sometimes out as far as Toowoomba so that they learn how to drive the range correctly.

In this time there are only certain things they are allowed to get wrong before they fail. Just like the tests conducted at Queensland Transport, you will fail for not doing your coupling and uncoupling procedure correctly, you will fail for speed,

running red lights or failing to give way in a 26m long vehicle.

Personally, I probably fail 40 per cent of the students first time, as even after 16 hours of theory and practical they are still not ready or safe enough to drive a B-double.

Fourthly, on the topic of truck schools “getting away with too much”. I’m not sure what your source means by that, but we had an audit in November last year and passed with flying colours due to the systems we have in place and the way we train. We were actually found to be doing over and above what is required. Again, this statement puts all training schools in the same basket, which is not correct.

Fifthly, as far as trucks go, when you come to us you train in full-size, 14-pallet body heavy rigid Izusus. When it comes to MC we train in rigs that are minimum 25m long. So, when you are done you are indeed job-ready. Training in the smaller vehicles that are not much bigger than my 4WD is not something we do. We have recently won an award from the QTA for Excellence in training and skilling for the ‘Road Ready’ program we have been running this year.

That, I believe, speaks volumes as to what we do.

Lastly, a lot of what is spoken about around time frames and weights and size of vehicles is directly relatable back to Queensland government

policies around this stuff. Many driving schools are working to that, and so technically are not in breach of anything. So, for this to change it has to come from the government.

I do agree that time frames around MC licensing in particular are way too short. There certainly needs to be some change around that.

As I hope you can see, I am passionate about this and really don’t like being put in the same basket of Queensland schools getting away with too much.

Sincerely,

Ian Stanley Senior Heavy Vehicle Trainer and

Assessor Strategix

WHEN I started 31 years ago with Les Walkden in Tasmania on a brand new CH Mack, towing a tri-axle semi-tipper carting coal statewide, semis like that were the normal and biggest on the road. Maximum weights were 41.5 tonnes all up with tolerances. Les applied for a permit to run heavier over the drive (which was costly, but price effective if

full weight was carried all the time) and I was one of the first in Tasmania to trial 44 tonne all-up, running heaviest weight on a semi with tri-axle trailer at the time in 1994.

Other than road trains way up north (e.g. Western Australia and the Northern Territory), that was Australia-wide normal.

But geez look now at the

combinations, PBS systems, weights, non-ethnic drivers and young super truckers, that need two trailers at least from the get-go.

Where does it stop?

The industry battles to keep up with itself alone without freight rates chasing along behind trying to keep up, but a lot of the time don’t.

– Heath Rice

DONNY MacGregor is the man behind the wheel of the Bendix Racing Team’s B-double transporter, bringing over $10 million worth of race cars, equipment, truck and trailers to Supercars events across the country.

So, there’s a lot riding on his shoulders.

The pressure is on every time the transporter leaves the team’s Gold Coast headquarters for a race round, but he says risks are mitigated with meticulous preparation and regular safety checks.

MacGregor began his career as a panel beater and painter before a self-professed “love of all things shiny” had him move from fast four-wheeled vehicles to large but equally shiny trucks.

His first truck driving role

was behind the wheel of a 2006 model Kenworth rigid, while his current tenure with Matt Stone Racing (the team behind Bendix Racing) began in 2018.

“The improvements in technology from the trucks of 20 years ago to what we have now are huge,” MacGregor said.

“Back then all the safety systems were rudimentary – now most modern trucks are well equipped with active safety features. Equipment such as advanced emergency braking, adaptive cruise control, forward collision warning and the like, certainly make for a much less stressful drive.”

MacGregor’s current ride is a DAF XF, that’s equipped with Bendix braking hardware straight from the man-

ufacturer’s production facility in Bayswater, Melbourne – though he’s also had the opportunity to test out the new DAF XG+ model recently too.

The truck is still running its original brake pads and according to MacGregor, the performance of the Bendix ProTrans Disc Pads has been strong.

“From my perspective the ProTrans pads are delivering on every level. The combination is grossing around 54 tonnes and they pull up the truck very nicely – there’s consistent pedal feel, the pads bite well and they’re durable,” he said.

“And from a comfort and usability standpoint, they’re also very quiet and produce minimal brake dust, which

helps keep the truck cleaner.”

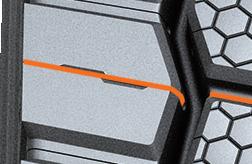

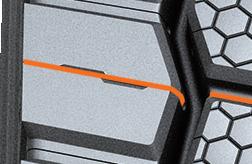

Along with adhering to the truck’s regular OE maintenance schedule, it’s also rolled over the pits every year for its NHVR inspection. Additionally, more checks occur at race headquarters prior to the transporter departing for each round of the series.

“We go over the truck and trailer combination very closely, checking anything and everything, things like lights, tyres, brake hoses and fluids, trailer couplings and

load restraint; we also make sure all first aid equipment and PPE gear is as it should be,” MacGregor said.

While braking technology and using quality friction materials goes a long way in keeping the transporter and its precious cargo safe out on the roads, driver skill is also a major contributor to minimising the chance of an accident or close call.

MacGregor’s main tip in handling the transporter is to drive conservatively and save

the brakes for when you need them.

“Drivers should make the most of the technology that’s available in the latest generation of trucks,” he explained.

“When descending hills, you want to let engine braking and the transmission retarder do the work to maintain a safe and controlled speed. Dab the brakes if necessary, but save them for when you need them rather than cooking them on steep hills.”

BY KAYLA WALSH

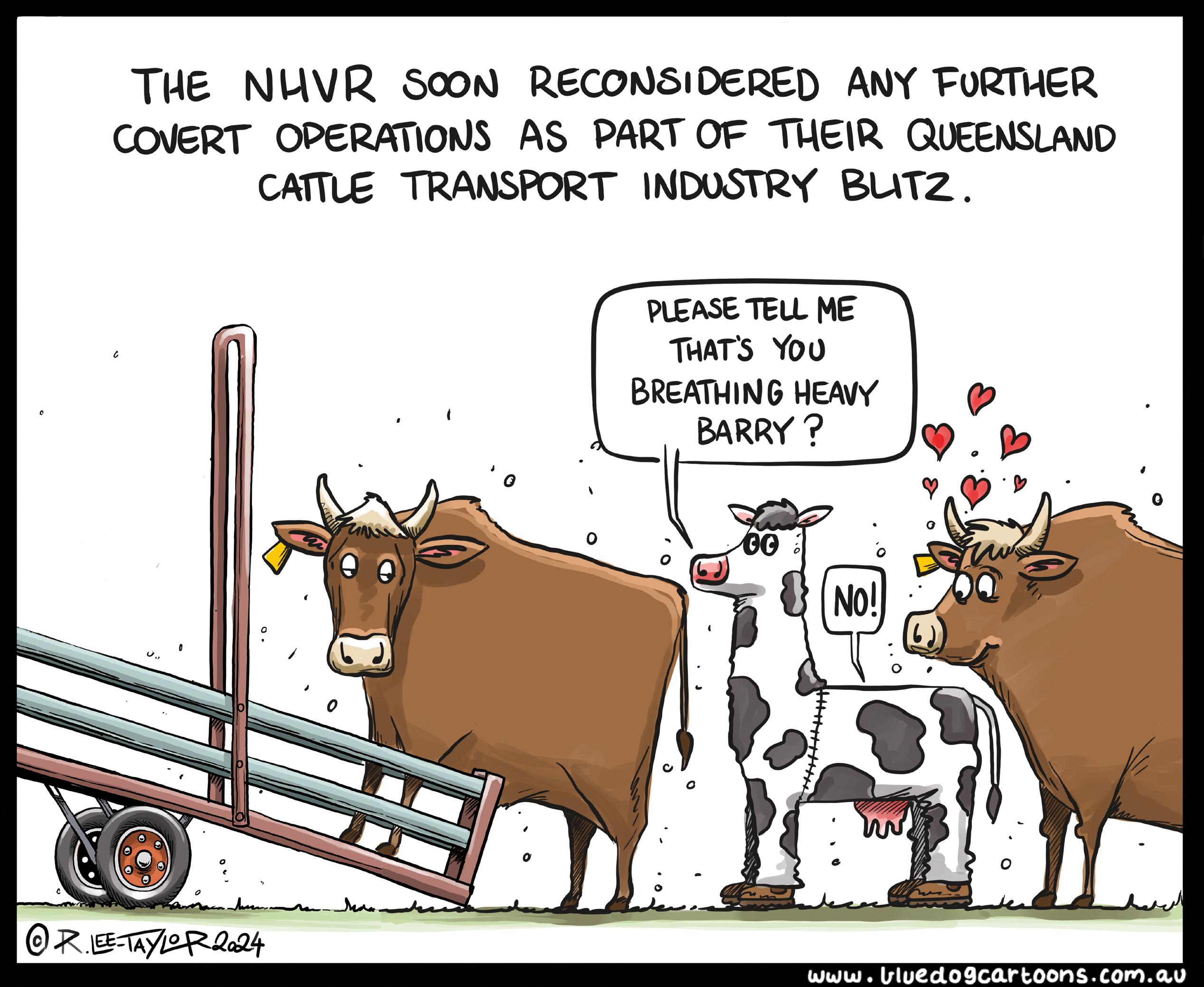

A Queensland truckie with three decades of experience on the road has set up a Facebook group to help new drivers learn the ropes.

John Bellam from Pittsworth is sharing everything from videos on how to unhook trailers to advice on getting a start in the industry. His Facebook group, “Learn the old school way”, is only a few weeks old but has already received a great response with more than 600 members at deadline for this issue.

Bellam, who is currently a driver with MFT Haulage, told Big Rigs: “I decided to set up the group because I would see a fair few young people

asking questions about how to get into trucking.

“My dad was from the old school and he taught me from a young age about the industry.

“I thought I could help the next generation and pass on some of that knowledge.”

Bellam said modern truck driver training programs can leave a lot to be desired, and he recommends starting from the bottom and working your way up.

“I got my first job washing trucks when I was 18, and then I got a job in a timber yard driving a little body truck around town.

“I had plenty of experience before I moved up to driving semis interstate.

“These days because of the driver shortage, if you have a licence and any experience, you’ll probably be put on –but I don’t think that’s the best way to do it.”

He said it’s a shame that modern company policies often prevent drivers taking their kids on the road with them.

“I used to jump in the truck with my dad when he was driving interstate, and he taught me how to load and unload, how to change the tyres and wash the truck,” he added.

Bellam thinks some of the camaraderie of trucking is being lost, with truckies sometimes reluctant to give guidance to newbies.

“There are a lot of truckies out there who don’t want to pass on their knowledge,” he said.

“Or they take pictures of mistakes people have made and make fun of their misfortune on Facebook instead of

helping them.

“My dad always said, never be a know-it-all in this game. No-one’s perfect, and I’m still learning to this day.”

One of the main lessons Bellam wants to share with younger drivers is to take your time.

“I see drivers going at top speed through roadhouses to the fuel bowsers, but I always got taught to slow down and put it in first gear,” he said.

“You might be panicking that you’re going to run out of hours in your logbook, but it’s not worth risking safety trying to rush.

“If you run out of hours, just pull up at a parking bay and wait until your logbook comes good again.”

$177m for WA upgrades

So far $110 million has been spent to upgrade 1050 kilometres of state roads in WA’s Mid West Gascoyne, with a further $67 million in funding on the table to deliver further projects in the region.

Three new projects are due to be completed before the end of the year and another two are scheduled to commence in early 2025.

The works are funded by the Regional Road Safety Program, which works to prevent single vehicle run off road crashes – one of the leading causes of death and serious injury on regional roads – by installing treatments like widened and sealed shoulders, and audible edge lines.

NSW bridge upgrade

Work to get a NSW bridge back in shape is progressing, with the Review of Environmental Factors (REF) Submissions Report now available for public viewing.

The Macksville Bridge is a critical piece of transport infrastructure that has linked the northern and southern areas of the town for 93 years.

Transport for NSW (TfNSW) recently called for public submissions on a review of environmental factors about the plans to carry out repainting, together with extensive repairs and maintenance to the bridge.

“Work includes the safe and environmentally responsible removal of existing paint and repainting, along with repairing and strengthening bridge supports, piers, deck and steelwork,” TfNSW said.

Call to ban carbon tax

NatRoad is urging the NSW and Australian governments to reject any proposals for a carbon tax on trucks.

This comes in response to the recent NSW Freight Policy Reform: Interim Directions report, which recommends the consideration of vehicle charges based on carbon emissions; essentially a carbon tax on trucking.

“This is a recommendation from an independent panel, not current government policy. However, we believe it is vital that all governments immediately rule out this proposal,” said NatRoad CEO Warren Clark.

“A carbon tax on trucks would be devastating to small and medium trucking businesses that are already struggling with rising costs.” NatRoad will also submit a formal response to the report.

$263.2m bridge upgrade

The $263.2 million New Dubbo Bridge is continuing to take shape, with a third of the concrete deck, which will eventually support traffic crossing, now in place.

This major project on the Newell Highway in Dubbo is being jointly funded by the Australian and NSW governments.

“Once completed, the New Dubbo Bridge will transform the way western NSW residents, tourists and freight operators travel through Dubbo,” said NSW Senator Deborah O’Neill.

“The Bridge will reduce travel times in the city centre and improve access across the Macquarie River, particularly during flood events.”

BY JAMES GRAHAM

ROADMASTER’S managing director Geoff Robertson had done his fair share of homework before taking the plunge on a new Volvo FL electric truck for his Sydney-based refrigerated fleet.

He’d been fortunate enough to tour the Volvo HQ in Sweden and visit the big truck shows in Germany a couple of times and seen first-hand the “change of scenery” coming our way.

“Every couple of years you just see that transformation of moving from ICE trucks across to electric and hydrogen trucks,” Robertson said.

“Hydrogen to me seemed to be a lot more complicated while electric seems a lot more straightforward and a good option for metro areas.”

The city-friendly FL option seemed a natural fit for Roadmaster.

The company, which boasts a fleet of over 230 prime movers, trailers and rigids across seven depots, has been with Volvo and VCV for over 30 years now with 95 per cent of the fleet sporting the Wacolbased badge.

“Volvo have always been great from a support point of

view,” Robertson said.

“So obviously, you know, the trucks are great, but we also use their contract maintenance and their finance, and all those sort of things.”

Robertson concedes the investment in the first electric model, however, was still a leap of faith in the sense the big corporates embracing the technology have deeper pockets than the family-run operation.

Although there are initial big savings in maintenance and fuel costs to be had, there is also still no clear idea of total-cost-of-ownership given no one knows what value these trucks will have on the second-hand market yet.

But the early adopter, which prides itself on being at the forefront of many industry technologies over the years, felt the time was right to play its small part in reducing emissions.

“There were some requests from customers about what we were doing to do our bit and that sort of got me thinking,” Robertson said.

“Obviously they’re not cheap [about twice the price of the equivalent diesel-powered alternative], but it’s not all about dollars. I also felt

the fact that we’d spent so long in our partnership with Volvo I felt comfortable that if we did have some challenges, it’s a partnership – they’d support us, and we’d support them.”

Although it’s relatively early days in terms of on-road performance, Robertson says range anxiety “is a real thing” – they’re currently getting between 150-200km – but he is getting positive reports back from the designated driver on how it performs.

The truck also has an all-electric rigid fridge Thermo-King body, essentially like the old off-engine drive trucks that you have around town now.

“But it runs off the ePTO [electric power take off] on the Volvo EV so we think it makes around 50km difference to our total distance that we can do each day.

“So far, it’s worked quite well. There are different ways you can do it, but this is the way we’ve chosen to do this one. Some people are going with an all-electric fridge motor as well, but we’re not doing that.”

The truck is doing between 100-125km a day and takes about four to six hours to

charge each night with email alerts to Roadmaster’s ops team to tell them when it’s fully charged, or unplugged.

It’s put to work each day in the Sydney metro area doing multi-drops for a variety of customers, rather than being linked to one contract.

“That’s probably a big change to what a lot of people do,” Robertson said.

“We’re doing this on our own back, which is a bit unique as well, in the sense that we’re just trying to see how it works, trialling it in our business.”

While it’s still early days, Robertson is encouraged by the interest customers are already showing in the technology, which could lead to specific contracts that will help “share the load”.

“Some people think that we’re a bit mad for doing it, but I think we’ve all got to do our little bit to help where we can as far as the environment goes.

“I’m not a hardcore environmentalist by any stretch, but if we can have equipment that

does the job just as good, then why not.”

Meanwhile, Robertson would like to see the states get behind electric trucks and offer more incentives for early adopters.

Some relief on stamp duty from states would be a good start, believes Robertson.

The stamp duty on the company’s new Volvo is an estimated $9000 more than he’d pay for the equivalent diesel model.

“So, I think some state government support around that would be great just to even up the playing field up a bit.”

In Europe in particular, Robertson said a lot of the governments are supporting the capital expenditure gap between the ICE and EV trucks.

“I know in some countries if an ICE truck is costing $200,000 and an EV is costing $500,000, governments will support that $300,000 difference by up to 80 per cent, which is massive.

“All of a sudden it does become cost-effective.”

FRUSTRATION at the lack of government incentives to decarbonise small truck fleets has led transport industry consultants MOV3MENT to take matters into their own hands.

MOV3MENT is offering a prize of $25,000 to the first small- to medium-sized fleet using its methodology to achieve a 25 per cent carbon emissions reduction before the end of 2025, in what it is billing as the 25x25x25 Challenge.

“We’ve written enough reports that all levels of government should know how to decarbonise road freight. It’s not rocket science, and it certainly won’t be through more studies, more enquiries, and more roadmaps,” said MOV3MENT managing director Mark Gjerek.

“We’ve put a challenging but achievable target out there for fleets, we’ve explained how it can be done, and now we’re

dangling a big carrot to make it worthwhile chasing.”

Gjerek said incentives make a big difference, but they need to be for the right things if they’re going to be effective.

“There are currently no incentives for fleet efficiency improvements, so we’ve put one up.

“We think reducing emissions by 25 per cent is possible if companies follow a robust process and combine several improvements.”

For example, MOV3MENT

helped NatRoad to develop the Get Fleet Fit guide that sets out how a small fleet can collect data, set targets and reduce costs and emissions.

“Fleets want to take practical actions,” Gjerek said.

“They want confidence that their actions will work. Following our process means fleets can plan their transition to a low-carbon future in a way that minimises costs in and suits their circumstances.”

Gjerek said this approach really helps small truck fleets

WE THINK REDUCING EMISSIONS BY 25 PER CENT IS POSSIBLE IF COMPANIES FOLLOW A ROBUST PROCESS AND COMBINE SEVERAL IMPROVEMENTS.”

MARK GJEREK, MOV3MENT MD

under increasing pressure to meet customer emissions reporting and net zero targets who simply don’t have enough information on what they can do.

“We know the headlines are all about electric and hydrogen trucks which are great but expensive. We suggest a range of actions small fleets can take to reduce emissions, without necessarily purchasing the big ticket items.

‘This prize of $25,000 will make a real difference to a small business. We know

because MOV3MENT is a small business too.”

The 25x25x25 Challenge is open to small and medium fleets of 5-50 trucks for any new actions they take. Applicants have to demonstrate they reduced their emissions by 25 per cent while maintaining a similar workload or freight task. They also need to show they followed a stepped process like Get Fleet Fit, with most of the saving coming from fuel efficiency and operational improvements rather than just a one-off action. For more details on the competition and how to sign up for a shot at the $25,000 prize, visit mov3ment.com. au/25x25x25.

DAF PURE EXCELLENCE

DAF is versatile and an all-rounder with the perfect combination of superior comfort and luxury for the driver and maximum vehicle efficiency for the operator. So, you need a prime mover with high uptime and durability? There’s a DAF for that!

Whether your needs are long-distance haulage, city distribution, construction transportation, bulk or tank transport, the versatility of DAF keeps you moving, and that’s good for business.

DAF.COM.AU

Colin Whitcombe reflects on more than 40 years on the road, the sacrifices along the way and what lies ahead in retirement.

AFTER spending more than 40 years on the road, legendary Rocky owner-operator Colin Whitcombe is still getting used to being at home every night.

Just a few weeks into retirement – he officially called time on July 31 – it’s a hard habit to shake when you’ve carted every type of load imaginable from Rockhampton to Melbourne, to Darwin, and all along the east coast, right up to Cairns.

The last 35 years, or so, Colin’s main role was hauling new steel from Brisbane to Gladstone and Rockhampton, and whatever is available on the return back to Brisbane.

No one knows the Bruce Highway better than Colin who had to laugh to himself when he heard a TV report the other night saying the road had been dangerous for the last 10 years.

“I thought straight away, ‘This highway has been dangerous for the last 50 years,” Colin says.

“They do patch-ups on it; they don’t do a proper job. They’re too lousy with the money I supposed, I don’t know.”

“But I’ve been on those new sections of road, Gin Gin, Cairns, wherever you want to mention and the bitumen’s only like an inch thick.

“One shower of rain and it just turns to potholes and some of those can be two foot deep and five and six feet long so you’re going to lose the truck in them.”

If Colin had his way, the Bruce would have been four

lanes from Brisbane to Cairns 20 years ago.

“Not in 20 years from now – it should have already been done.”

Colin, now 68, has to stop and think about how many kilometres he’s clocked up over the last four decades.

He reckons he’d put 3.2 million kilometres on his 22-year-old Kenworth T650, before that, the old Kenworth cabover did the same run for 13-14 years, at an average of 250,000 kilometres a year.

“I don’t know – you work that out [that’s another 3.5 million by our calculations].”

Most of those k’s were incident free. The only accident he did have, a rollover in his 1981 K124 “Foxy Lady” near Caboolture left him with a broken right leg, two cracked rigs and scars he still carries today.

“My right-hand side of my face was also sort of missing and they rebuilt that. I was off for six months.”

When Colin first bought trucks back in the 70s, the rule of thumb was a three-way split when it came to working out costs: a third for the truck, a third for the driver and a third for fuel.

“Nowadays it’s like probably 55 per cent of your earnings going on fuel and the owner gets bugger all out of it, and if you’re paying drivers, it’s even worse.

“With some of the rates, I don’t know how some blokes do it. That’s why a lot of them fall over.”

Colin would love to see the much-debated driver appren-

ticeship model formalised sooner than later.

“Even if it’s only a two- to three-year apprenticeship. They’ve got an older, experienced driver telling them how to chain things down, how to do this, how to do that the right way.

“These fellas know absolutely nothing, and then go buy a truck. They’re an owner-driver. “They’ve got a business, an ABN, but they don’t even know how to put a chain onto a trailer, they put it onto the rope rail. Stuff like that.”

With bigger staff-run fleets encroaching more and more on the role of the owner-driver, Colin fears for the sector’s future.

“Owner-drivers are going to be a thing of the past in 2030 years; they’ll be very, very scarce.”

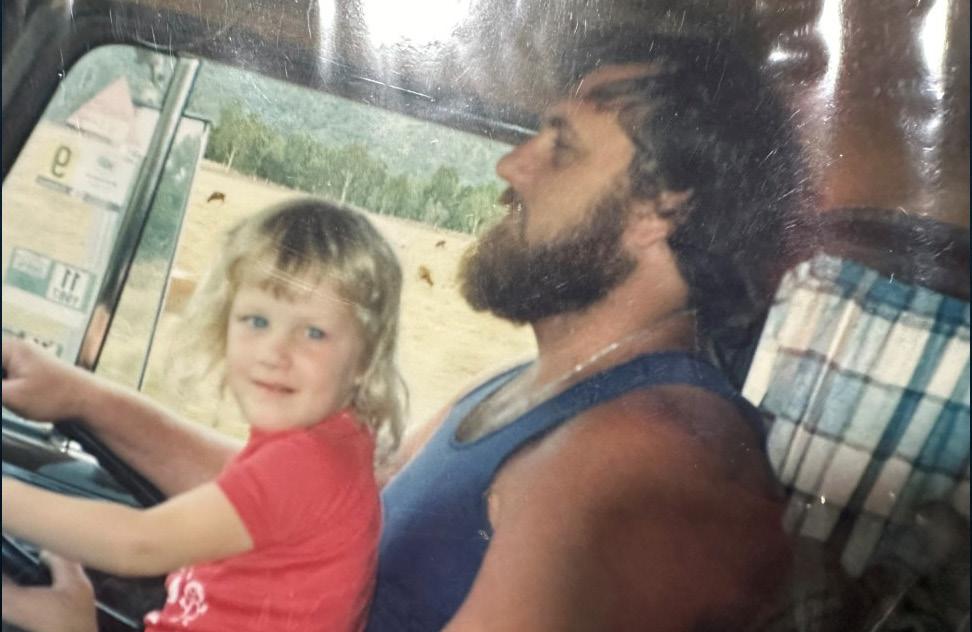

Even so, this third-generation truckie would do it all over again in a heartbeat if he had a chance.

“I loved it. The old man had trucks, he carted timber; he had bullock carts with my grandfather first.

“He had Chevs, Bedfords, and stuff like that. I was brought up in trucks, but I suppose I had no choice.”

Colin can still remember his first truck he drove, his old man’s single-drive Chevy; he can’t have been more than 11 when he was first let loose in a paddock.

There’s been plenty of personal sacrifices along the way, of course, as is all too common for owner-drivers battling to make ends meet.

He was on the road so much he missed out on three of his children’s births – the only one he got to see was eldest son Joshua’s arrival.

Two have since followed him into the industry – sons Joshua, 37, and Brodie, 31 –and wife Karen reckons Colin couldn’t have stayed behind the wheel for so long without their support.

“He couldn’t have done it without our two boys being heavy diesel mechanics, that he’s relied on every time something’s gone wrong,” Karen said.

“They’ve always been there, every weekend for him and supported him, and when he’s got home in the truck, they’re here waiting to fix it.”

His best advice for youngsters following his lead today is to take your time and do it properly.

“And listen to the old fellas.”

He laments the loss of the days when if you broke down, whether you were on the Putty coming out of Sydney, on the flats at Bowen, or out west, you had a couple of trucks pull up in front of you and a couple in behind.

“One of drivers would be boiling the billy and the other four or five would be helping to fix whatever was wrong.

“Nowadays, you haven’t got a place to pull up because

get one in 30 that would stop.”

Colin gave up trying to stop and have a rest or do a check at a “proper truck stop” between Rocky and Brisbane years ago due to the amount of caravans flouting the rules and taking truckies’ parks.

“These days it’s even worse. They just look at you like you’re an idiot. I don’t know how many times I’ve rung the coppers about that sort of thing but they never seem to do anything.

“I’ve even seen some of them break open the power boxes on the lighting systems at some of those weigh pads and poke their vans in to get their air conditioners going and have a cup of tea.”

Colin and wife Karen will be “going for a drive” themselves later this year in the refurbished 1976 Volvo B10 school bus he’s turned into a motorhome with the help of son Joshua.

He promised wife-of-43years Karen he’d have three months completely off the road now C.J. Whitcombe Transport sold its three trailers and beloved T650 “Blue Moon Swamp”, named after the 1997 John Fogerty album and Aussie concert tour by the same name.

But Colin, who plans to keep his licence and medicals up to date, also told InfraBuild he’d cart the odd local load for them from November, if they get stuck.

“I’ll do it, if it comes upthey’ve rung me every week so far.”

In the early years, wife-of-43 years Karen would tag along in the cab, their first-born Rebecca sleeping in the bassinet in the back.

She even got her learners so Colin could have a kip in the bunk while she drove down The Beef Road (now known as the Fitzroy Development Road).

But she’s glad to have the grandfather-of-seven home now after “plenty of lonely nights” farewelling him on the Sunday night and worrying about whether he’d return safely.

“You’re continuously worried about him, until you see him come home.

they don’t make roads wide enough to pull up to even change a tyre.

“Even if you manage to get off the road, everyone is an overnighter, they come around you at a dollar five, 100k an hour – you wouldn’t

“He’s a bit bored being at home now, but he’ll get there.”

“I don’t mind him doing casual work – just casual work, mind you - I know it’s in his blood.”

Story interview

by

Kent Murray

LS001TRP $1,699

Suits T404, T404S, T604, T650, T350, T350A, T401, K104, K104B, K108, T359, T359A & K200

LS002TRP $1,850

Suits T408, T608, T658, T403, T408EX, T409, T609, T659, T408SAR, T409, T610, T409SAR, T360, T360A & T410

From one generation to the next

After starting his business with his late father 15 years ago, this inspiring outback automotive recycler is now passing his skills onto his young son.

BY DANIELLE GULLACI

IF you’ve been watching the last few seasons of Outback Truckers, then Mike Elliott might look familiar. He appeared in season 8 and 9 of the show; and has returned for new episodes in season 10, although he’s had quite the physical transformation.

Big Rigs spoke with Mike, 40, about how he turned his passion for engines into a profitable business, how losing his father made him focus on improving his health, and about the joys of having his son Vinnie by his side as he travels to some of the country’s most remote locations.

Mike runs Outback Cash For Cars, an automotive recycling business that purchases unwanted cars and then on-sells them to commercial wreckers throughout Western Australia.

He’s based in Perth and also has two yards in Kununurra and another in Geraldton.

Mike travels all over the country, to places many wouldn’t venture, picking up trailer-loads full of cars and other vehicles. The blistering heat of the desert and unforgivable corrugated roads are all in a day’s work for this family man – who shares seven kids with his wife of 10 years and business partner Molly Elliott.

Mike admits he hadn’t initially thought of turning his passion for cars into a career. But from his late teens, you’d often find him under a bonnet, tinkering with engines.

While that continued as a hobby, he initially followed in his father’s footsteps and became a plasterer. “We were a family of plasterers and were in that in a big way,” said Mike. “When I started

getting into the cars, people thought I was a bit crazy and was just wasting my money.

“By the time I was 18 I had purchased 75 cars, and by 21, had bought more than 300 cars. I never owned more than four or five at a time. I’d fix them up and then sell them.

“I started buying and selling cars, and then I got bigger and better. I found the more work you can do yourself, the more of the pie you get.”

It was with that in mind that he spoke to his father Richard Elliott about going into business with him.

“Dad and I started this busi-

ness together. We had been working in construction for a long time. Then I showed him how easy it was to flip cars. What we could make in a day as plasterers, we realised we could make in a morning,” explained Mike.

“He was quite hesitant to begin with, because I’d already spent so much on cars. But I showed him what sort of money could be made and we went for it.”

They spent almost four years on the road together, going wherever the work took them, before tragedy struck.

“This was such an adven-

I STARTED BUYING AND SELLING CARS, AND THEN I GOT BIGGER AND BETTER. I FOUND THE MORE WORK YOU CAN DO YOURSELF, THE MORE OF THE PIE YOU GET.”

MIKE ELLIOTT

ture and we got to share some crazy experiences. Dad and I would travel everywhere, even out to the middle of the desert, to buy a heap of cars and then we’d bring them all

back. We were really close,”

Mike recalled.

Sadly, Richard passed away eight years ago, aged just 56, and Mike says that loss affected him in a really big way.

“Dad was a big fella and I

was a big boy too. That’s what got him at the end, it was heart disease. I knew I had to change myself. I didn’t want history repeating itself. I want to be there for my kids.” Mike says he went on to

lose about half of his body weight. “Nowadays I just keep moving. This is very physical work and you need a lot of endurance because it’s just so hot. There’s a lot of groundwork involved in getting those cars too.

“I also exercise everyday now. I’ll run 2-8 kilometres a day, and I do a full workout too. My whole life is very different to what it used to be.”

Vinnie, who just turned 17 on October 3 has been working with his father for close to a year. “He’s such a great kid,” said Mike. “School just wasn’t for him though. It was hard to take him out of school. We spoke about it for around nine months before we finally pulled the pin. I got him to rebuild a gearbox with me, and a year later he’s building performance engines as a hobby. He took to it like a duck to water.

“Vinnie is a really switched on kid. Try to get a maths teacher to teach him and he has no interest, but give him an engine and I’m mind blown at what he can do.

Watching him over this past year has reinforced that taking him out of school was the right decision. It’s been the best thing for him.

“Vinnie is very mechanically minded; he can drive anything. He’s one who I try not to give too much direction to. I like to let him figure it out on his own – and he usually comes up with something better!”

Already, despite his young age, it’s clear Vinnie is destined to follow in his father’s footsteps. “I always knew I’d be in business. I loved the idea of buying and selling and that crossed over with cars, because I loved cars. When I

started doing that, it was so easy, so I’ve continued on that path,” Mike said.

“I’ve never been done for unlicenced dealing because I’ve never done the wrong thing. All of the cars we collect, I’ve purchased, and I keep all of the receipts. I’m super selective of the cars I buy. The logistics of getting the cars though is insane.

“I’ve blown engines, tail shafts and clutches in the middle of nowhere. I had an engine explode on me when heading out to a job one day. The whole harmonic balancer came off and wasted the motor in one hit. That was about 10 years ago, it was a yellow Hino I named Emily – it was just before I met Molly. I had to run a shit truck for about six months before I could afford to buy another truck.”

Mike says he’s grateful he’s been able to turn his hobby into his work. “And I always tell my kids to make sure you’re doing what you love. Don’t just chase the money.

“I tell them just follow your heart, it doesn’t matter where you work, so long as you’re happy inside, that’s what matters.”

Mike currently operates a fleet of four trucks, and a crusher which comes along on almost every journey.

His main truck is a 2015 Freightliner Coronado. “I just upgraded to this one. It has a Detroit DD15. It’s insane to drive – it feels like you’re driving a 700hp engine, which is crazy,” explained Mike.

“Before this I had a 1994 Mack CLR with a Detroit in it as well. I rebuilt that one from front to back and then sold it as a deposit for this one.

I always loved the Macks and Scanias. I never thought I’d love driving a Freightliner but it’s such a good truck.”

Usually, Mike will pull two trailers but does go up to three when required.

“If it’s local to Kununurra, I’ll crush up the cars and can stack nine on a trailer. But if I go further out to the Tanami, I can chop them up, so I can fit up to 70 cars on 3 trailers.

“Location is everything. When you’re going further, you lose time, so I try and bring back as many cars as I can.”

For Mike, his work takes him absolutely everywhere.

“I try to do 14 days on the road and 10 days off, but I haven’t had a rotation like that for ages. We’ve just been too busy. Sometimes we’ll be away for six weeks at a time.

For every five or six cars you do, you might get one car that’s worth the same as five or six cars put together.”

Mike’s oldest truck is a 1987 Nissan Condor, which is only used locally for deliveries in Perth, a late model Hino tilt tray and a 1992 Scania crane truck.

“I’ve had that Scania for 10 years, it’s a real war horse that just won’t die. But I’m ashamed to drive it on the

I GOT HIM TO REBUILD A GEARBOX WITH ME, AND A YEAR LATER HE’S BUILDING PERFORMANCE ENGINES AS A HOBBY. HE TOOK TO IT LIKE A DUCK TO WATER.” MIKE

ELLIOTT

road sometimes,” he laughed. Like Mike, Vinnie was taught to drive the truck very early on. “I used to seat him up on phone books and a pillow when he was little so he could see,” said Mike. “He was already learning to drive trucks around the yard and in the paddocks, from when he was six years old.”

While Vinnie is very keen to get his truck licence, he’ll have to wait a little while longer. In the meantime, Mike says they’ve just “beefed up” an old Landcruiser, which Vinnie will be able to drive alongside him, towing a 3.5 tonne car trailer.

Looking ahead, Mike has some more work planned through Kununurra before the wet season hits, and then he plans on tackling Esperance.

“We try and work Kununurra up until December, which is when it gets intensely hot, with a lot of rain. That’s when we start to go further south,” he said.

“Often, we’ll roll into a town and buy all the scrap cars we can. I’m planning on doing a few trips to Esperance soon. We picked up about 163 cars from Esperance in 2019, so it’s been a few years since we’ve been down that way.

“What I used to enjoy the most was the chase of the cars but now I really enjoy the time I get to spend with my son.”

Season 10 of Outback Truckers is currently being aired on 7Mate on Tuesdays at 8.30pm. Past episodes are available to stream via the 7Plus app. This season, Mike Elliott will appear on episodes 2, 11, 12 and 13

BY KAYLA WALSH

IT’S been a wild ride for truckie Wayne Howsan – from living in his truck without a cent to his name to owning a 100acre ranch in Memphis, Tennessee.

The 60-year-old, who has been married six times, is originally from Mount Molloy in Queensland but moved to the US for love.

“After me and my third wife ended up divorcing, I decided to market myself worldwide, on all the dating sites,” Wayne told Big Rigs.

“A girl in Costilla, New Mexico got a hold of me so I decided to sell everything I had and head to America.”

But the move to the Land of Opportunity didn’t initially work out for Wayne, and he found himself completely broke.

“Here I was with a horse, a saddle and a few clothes, having to start all over again.

“I married the New Mexico girl, but I had no American licence, no work visa and no money.”

With very few options, Wayne got a job driving trucks locally, picking up and dropping off loads of hay.

When his American licence and green card finally came through, he started delivering to some big dairies in Texas.

Not used to the varied American climate and driving conditions, he got himself in some sticky situations while he learned the ropes.

“I remember going up on top of the Rocky Mountains to get a load of square bales,” he said.

“On the way in the morning it was 18 degrees below. I loaded 680 bales by myself, then as I was finishing strapping the load, a blizzard blew in.

“Me being from the Outback of Australia, I didn’t know any better and started to drive back down the mountain.

“I couldn’t understand why there was no traffic – well, I figured it out pretty quickly.”

With two feet of snow on the road and unable to see much of anything in front of him, Wayne had to crawl down the

mountain in second gear.

“It took about four hours to go about 50 miles, but I made it to the bottom,” he laughed.

“A state trooper was there waiting – he had the road blocked off and couldn’t believe I had come down the mountain!”

Although Wayne was working hard, he wasn’t exactly rolling in money, which put a strain on his fourth marriage.

Pretty soon he was out on his ear again, and he ended up moving to Louisiana, where he got a job with a company called Bengal Transport.

“They based me in Shreveport, doing heavy haul and driving a Peterbilt,” he said.

“I was going all over the USA, getting paid to see the country.

“I was thinking about coming back to Australia when I was up in Arkansas doing a load and I stopped at a truck stop up near Fayetteville.

“Bugger me, if I didn’t come across my fifth wife to be.”

Wayne ditched trucking and he and his new bride ran a successful horse training business for eight years, raising her daughters and adopting two of her nieces.

Eventually, though, the call of the highway returned.

“I was getting burnt out, so I decided to get back in the truck,” he said.

“I was driving for a guy from Houston, Texas – but I was only in the thing for three weeks when my wife got herself a boyfriend.”

Again, Wayne had to start over – but this time he had nowhere to live.

Luckily, he landed a new job driving for an Aussie operator in Memphis, Tennessee, who had a 1999 Western Star sitting in his yard.

“We worked out a deal and I bought the truck from him,” he said.

“It was pretty rough, but with a bit of TLC it was able to head out and go work.

“I was now an owner-operator, but I had nowhere to live – so I lived in the truck for two years.”

It was a tough time for Wayne, but he built up enough savings that when he eventually met his sixth wife, they were able to buy property.

Not just any property, either – they now own 100 acres of land, with two barns and a beautiful house.

They’ve also got a 42-ft yacht, a herd of cattle, six horses, a tractor, a pickup truck, a SUV, a Jeep Renegade, and a Ford Bronco, if you’re asking.

“America really is the land of opportunity,” Wayne said.

“I’m very grateful for what I have built, and I’ve worked my ass off to get it.

“It helped that my sixth wife finally jerked me into line and taught me to manage my finances better.

“But I don’t believe that I would have what I have now if I’d stayed in Australia.”

Wayne still works for the same Aussie operator – a bloke called Andy Oberle, who runs Beltana Transport.

Since buying the Western Star, he has rebuilt the engine and put a heavy duty Peterbilt backend on the truck with a pusher axle, making it suitable for heavy haulage work.

“I do oversized loads, heavy haul, big machinery and tanks,” he said.

“Andy’s got a fleet of different types of trailers and any job that comes up, we’re able to bid on it.

“He charges me 25 per cent to use his trailers and I’m happy with that.”

Now 20 years in the US, Wayne has adapted well and said there are a lot of positives to being a truckie over there.

“We’re very spoiled in the US – these guys have no idea,” he said.

“You don’t have to carry any spare tyres on your truck over here because there’s a truck stop every 30 miles or so.

“And there are tyre guys who come out and fix your tyre on

the side of the road and you get going again. It’s that easy.

“If you get a flat tyre in the outback, you’ve got to pull up, jack up your truck and do it all yourself.”

He encourages young Aussies to go to the US and get a taste of trucking life over there.

“If anyone had an opportunity to come over here and get into the trucking industry, they should come and experience it,” he said.

“There are visa programs, for the harvest season for example.

“Then if you meet an American girl and you fall in love, well, you can live happily ever after.”

and sister truckies Craig Goulthorpe and Jodie Black have followed in the footsteps of their inspiring dad in more ways than one.

BY AINSLEIGH BILATO

WHEN siblings Jodie Black and Craig Goulthorpe attended the Shell Rimula Wall of Fame Induction ceremony in 2023, they were excited to see their late father, Garry Goulthorpe, honoured.

They didn’t know that they would each be inducted into the Wall of Fame also, alongside the man who had inspired their own careers in transport.

When Garry got his truck licence at age 16, he would be the first in his family to join the transport industry.

He was able to secure a loan to purchase his first truck, a Commer Knocker, by advising the bank that he owned a farm and needed the truck to help him run his cattle.

The reality was that Garry was a farmhand on a small farm in Victoria that housed just one milking cow. This slight stretch of the truth would mark the start of the five decades Garry spent behind the wheels of his ever-changing fleet.

His last truck, a White 4000, was nicknamed the ‘The Mistress’ as his wife joked Garry spent more time with the truck than he did at home. A self-taught operator himself, Garry would share his exceptional breadth of trucking knowledge and his passenger seat with his children.

Of Garry’s four children, Craig and Jodie would choose to follow in their father’s footsteps in the transport industry.

“I think my first word probably would’ve been truck,” jokes Craig. “From the earliest age I could remember, I was around trucks with Dad.”

Mastering how to change a tyre, tarp a load and get himself out of trouble mechanically, a 13-year-old Craig still remembers the day his father let him drive his road train for the first time.

On a station near Winton, Craig would spend the next two hours navigating a bush track to deliver a load of general freight, a proud Garry by his side. Craig, with this experience under his belt, gained

confidence quickly.