8766

Email: editor@bigrigs.com.au

Web: bigrigs.com.au

Accounts: 03 9690 8766

Subscriptions: 03 9690 8766

Classifieds: 0403 626 353

Circulation and distribution queries: 03 9690 8766 info@bigrigs.com.au

EDITOR

James Graham: 0478 546 462

james.graham@primecreative.com.au

REPORTERS

Danielle Gullaci 0478 844 797

danielle.gullaci@primecreative.com.au

Kayla Walsh 0401 551 494

kayla.walsh@primecreative.com.au

DESIGN

Daz Woolley – Art Director

Alejandro Molano - Art Director

GENERAL MANAGER

Peter Hockings: 0410 334 371 peter.hockings@primecreative.com.au

BUSINESS DEVELOPMENT

MANAGER

Treena Heit: 0403 626 353

treena.heit@primecreative.com.au

CLIENT SUCCESS

Katharine Causer: 0423 055 787 katharine.causer@primecreative.com.au

CONTRIBUTORS

Truckin in the Topics/Spy on the Road:

Alf Wilson, 0408 009 301

David Vile, Graham Harsant, Geoff Middleton and Jonathan Wallis.

Big Rigs National Road Transport Newspaper is published by Prime Creative Media. It is the largest circulated fortnightly truck publication in Australia with 22,500* copies per fortnight.

*12 month average, October 2022

TECHNICAL manager Rod Evans had to double-check the date on the infringement notice when it first arrived in the post – he thought it was someone’s idea of a belated April Fools’ joke.

The Toowoomba Regional Council had sent his company, Neil Mansell Concrete, a fine of $64 for parking in a homeowner’s driveway while pouring concrete at the same quiet suburban address on October 3.

An incredulous Evans was left scratching his head – surely there must have been a mistake?

Evans has never had any is-

sues with the council before, there were no complaints from the client who had ordered the delivery, and the truck driver had not even spoken to the council officer who took the supporting pictures.

But no, a review was unsuccessful and the fine still stands, said the council in response to Evan’s request for a second look.

“Please be advised that parking on or across a driveway may obstruct the view of other road users,” the officer wrote in the reply on October 29.

“It is also important to consider the significant risk to persons, including personal

including the information you have provided, and the evidence gathered at the time by our authorised officer, and can confirm the ticket has been issued to your vehicle without error.

“The reasons you have outlined in your review have been considered, and the situation were placed in is noted and understood. However, this does not relinquish your responsibility to park lawfully.”

liability, should an incident or damage occur where it can be shown an unlawful activity had contributed to the cause.

“Council has investigated all aspects of this infringement,

Evans told Big Rigs he’d never seen or heard of anything like it in 30 years in the industry and worries where the council’s stand might end.

“For a $64 fine we first

thought it’s not worth worrying about, but we’re subject to that every day of the week,” Evans said.

“They could start doing this kind of thing to anyone who delivers anything – it’s crazy.”

Evans said there was nothing else the driver could have done differently.

He was under the direction of the customer and had backed up to a tarp from where they were barrelling in the concrete ordered.

“The truck wasn’t stopped. He was discharging the concrete at the time – it’s bewildering in all honesty.”

TRUCKIES have again found themselves dragged into pro-Palestinian protest action in Melbourne’s port precincts.

In a November 22 incident outside the Victoria International Container Terminal in Webb Dock, protesters came armed with tyres, accelerant and matches to light fires to block road access and allegedly brought sharp tools to slash truck air lines.

“In what is a very worrying trend, these criminals have taken to targeting trucks by cutting air lines between the prime mover and trailer sets, leading to deflated tyres and

immovable combinations,” said Neil Chambers, director of peak body, Container Transport Alliance Australia (CTAA).

“Cutting the air pressure also has an impact on braking systems.

“This shows the premeditated nature of these acts with protesters coming armed to commit criminal damage.

“Innocent truck drivers and transport operators, just trying to go about their lawful right to earn a living and keep Victoria’s vital supply chains open, are being targeted.”

CTAA has joined a growing chorus seeking the implemen-

tation of a Protest Permit System in Victoria.

The Victorian Premier Jacinta Allan has previously ruled out introducing a permit system saying that police “already have the tools and resources they need” to deal with rallies.

“However, we believe that the Allen government needs to think again,” Chambers said.

“Container transport operators and drivers in Victoria are feeling increasingly vulnerable to attack, criminal damage and delayed operations costing thousands of dollars in insurance claims and lost productivity.

“A transport worker or a protester are going to get hurt, or worse, if these acts continue.”

Shadow Minister for Ports and Freight, Roma Britnell, said the Allan government needs to stand up to “these thugs” and hold them to account.

“After the Port of Melbourne was shut down during violent protests in January, we are unsure as to whether any charges laid on individuals have stuck,” Britnell said.

“This is a concerning new trend, where protesters who claim to be peaceful instead show the intent to cause deliberate harm to property. This

FOR veteran NSW truckie Dean Holt, the final straw was an abbreviation in his logbook that cost him a $650 fine.

For longer than he cares to recall over 35 years on the road, Holt felt “haunted, hounded and hunted” by authorities at every turn.

“Every time I got pulled up, I never left without paying $250,” said Holt, now 63, and 12 years removed from an industry he still keeps tabs on as he travels Australia in his converted Hino.

“It was more so the cops; transport blokes were a bit more human.”

Holt said he tried to fight his final clash with authorities, sparked by the seemingly trivial oversight of writing ‘Blk Mnt’ instead of ‘Black Mountain’ in his logbook.

“They crucified me in court; I think I lost an extra bloody point, and that’s when I just went, na, that’s it, and sold the truck, trailers, the lot and got out of it.”

Sadly, this scenario has grown increasingly common in recent years, said South Australian Road Transport Association executive officer Steve Shearer.

As submissions closed for the National Transport Commission’s (NTC) review on the draft new Heavy Vehicle National Law (HVNL) and its penalties, Shearer also

shared a story from one of his members about a police intercept that led to a promising young truckie leaving the industry.

The operator said the former driver was travelling through NSW in a B-double when she was pulled over by NSW Police.

“They found no breaches, except a minor admin issue that was utterly absurd.”

The operator said the truckie in question always put the registration number in the correct box on each page and on the comments section immediately after any rest break.

“The registration number therefore appears several times on each page, so there can be no mistake what vehicle she uses.”

On one page, almost two months before the interception date, police allegedly found that she forgot to place the registration number in the box at the top of the page.

“No opportunity was given for her to add it (because it was painfully obvious what truck she had been using), just a fine.

“I made an application to review it on the basis it was trifling, she had complied with the spirit of the law, it was a once off administrative error, not wilful disobedience and there was no safety risk whatsoever.

“That was rejected, and the

matter was to proceed.

“She became despondent after that encounter and eventually left trucking citing police and NHVR behaviour towards truck drivers as a catalyst.

“She was a very good and very compliant driver worth her weight.”

Shearer said this story is a classic example of the “police mindset of find a breach, no matter how technical, no matter how absurd”; no matter what other information is available that actually meets the intent of the requirement of the law.

“Only the most moronic or desperate stats-driven officer would have issued that infringement, when blind Freddie could ascertain the required information, the rego number, from the multiple entries on that page,” Shearer said.

“Yet they gleefully waste limited tax-payers money and limited police resources to trawl for the most insignificant technical breach they can find whilst displaying zero grasp of the intent of the law.”

Shearer said this scenario is so common that it’s damag-

ing the industry and its workforce.

“It’s driving safe, compliant drivers, who as normal humans will make an occasional minor error that is really of no consequence, out of the industry. “Police should get with the program or get out of enforcing the Heavy Vehicle National Law [HVNL].”

Shearer said it was exactly these types of ‘tick-and-flick’ technical infringements the six-year long review of the HVNL was supposed to eradicate, but now fears that opportunity may have been lost [see column on page 44].

In his submission to the NTC’s review last month, Shearer also called for a far more balanced and “fair” penalties regime, including a warning only for first technical, administrative or clerical work diary breaches.

In its submission to the NTC, the National Road Transport Association (NatRoad) also called for transport ministers to reduce fines that don’t improve safety outcomes or admit that six years of reviewing the HVNL have been a failure.

“The proposed changes to penalties would see 21 reductions, but another 50 increases to penalties,” said NatRoad CEO Warren Clark.

“In some cases, it is proposed fines are increased by 100 per cent, taking maximum penalties to almost $30,000.

“The review is a missed opportunity to eliminate minor fines, which are not improving safety, or delivering meaningful reductions to these penalties to make the roads fairer for our drivers.”

Following public consultation on the draft law and regulations, the NTC will present the law reform package to ministers in early 2025. If approved by ministers, the amended law will move through to Queensland Parliament to consider and enact, as the host jurisdiction for the law.

FRUSTRATED by years of talk but no action from governments, a group of industry associations has joined forces in a bid to finally get a truckie apprenticeship scheme off the ground.

Already most state associations have started their own driver development programs, embracing industry calls to do more to create trained, job ready drivers.

But none provide fully funded apprenticeship pathways into a driver’s seat from school, ensuring youngsters aren’t lost to other industries.

With more than 25,000 driver vacancies on Seek.com. au each week and the domestic freight task predicted to increase by 16.4 per cent by 2030, the newly formed

Heavy Vehicle Licencing and Employment Pathways

Working Group believes the issue is now at a crisis point.

“We’re really trying to get this message through to those bureaucrats who just don’t get our industry, who don’t understand what we’re really trying to achieve,” said Peter Anderson, CEO of the Victorian Transport Association (VTA), one of 11 peak bodies to join forces.

“There’s no personal gain in this for anyone in our industry except the individuals who will get a career in their lives.

“Yet we can’t get this through to the bureaucrats –the administrators administrating administration.”

Anderson said providing a career pathway into a truck driver’s seat has been the number one issue for the VTA for the last decade.

The association has had enormous success with its Driver Delivery Program, an eight-day training course that provides individually tailored training, mentoring, and behind-the-wheel practical heavy vehicle driving experi-

But that doesn’t go far enough to help entice school leavers, or anyone else looking to progress through the ranks and learn from the ground up.

“Training people to drive heavy vehicles is not only better for our industry in regards to attracting people, but

it’s safer for the community, and why don’t we have that common goal? Why is that so hard to share?

“The industry wants this. This isn’t a couple of trucking companies going, ‘Oh, hang on a sec, we reckon that if we could do this, we could make a couple more bucks ahead of somebody else’.

“This is the industry saying, ‘We’ll fund this, we’ll do this. Just give us the ability to be able to get people into our industry. And they keep stopping it, they keep blocking it.”

After following the traditional routes to get the message across with no success, Anderson said it’s now time “to go rogue”.

“Now we have to start talking about coming from different directions, getting different stakeholders, trying to force this conversation to be something that will generate interest.

“We need a strong voice of united representatives from different organisations, as many companies along the way as we can to get our voice louder and louder.

“We can’t be quietened down by just ignoring us.”

To illustrate the bureaucratic roadblocks he’s encountered over the years, Anderson cites the story of the time he was put in charge of a state government review of the way truck drivers were trained and licenced in Victoria by a for-

mer roads minister.

He had a VicRoads representative tell him that you can’t train 18-year-olds to drive trucks because their brains aren’t developed enough.

“I said, ‘Where did you get that from?’ He said, ‘Oh, there’s been studies.’”

Anderson said he’d love to stand up in a group of Year 12s and tell them that when they leave school they could be earning $60-80,000 a year in the logistics industry within 2-3 months.

“In three to five years I’d tell them they could be earning $120,000 a year and own their first investment property at 35.

“All of a sudden, we start to see 18-year-olds, smart young people building careers in our industry.”

At present, Anderson said operators are more focused on staff retirement levels, rather than career development.

So, how would that pathway into a heavy-duty truck seat look for a school leaver?

“It could be two years as a forkie, learning of the inside, paperwork, how to allocate, how to run a warehouse, how to manage books, how to be part of a team.

“Learning about what working in an environment with other people is all about, then at 18 they can get their truck licence, and they’ve got their career well and truly underway.

icated to actually improving the road toll and building a better environment upon which our community lives, then this is the sort of thing that needs to change.”

In Queensland, the state government did green-light an apprenticeship scheme in 2022, but the employer, or employee, are still left carrying the cost.

Gary Mahon, the CEO of the Queensland Trucking Association, which is also part of

the new working group, said he now plans to lobby the new LNP government for more support.

“Employers within road freight should get the same treatment that employers of a broad range of other apprentices get and be supported in developing those capabilities with a new cohort of people coming into the industry,” Mahon said.

To rub more salt into the wounds, the federal government also recently announced it had partnered with states and territories to deliver over

$1.5 billion in funding for 500,000 Fee-Free Tafe and vocational education and training (VET) places across Australia to 2026.

But Queensland’s trucking apprenticeship wasn’t included in that list of approved courses.

“So, what we’re asking for is our employers to be treated the same as other employers who are training apprentices and get funding support while those people are in training.”

Mahon said the QTA’s Job Ready program proves the difference a training subsidy can make to employers.

Using an $8000 grant from the NHVR’s Heavy Vehicle Safety Initiative, employers were able to place licence holders into a practical training program incorporating up to 160 hours of supervised onroad driving experience.

The QTA has also had success with its Driving Townsville’s Future Program, a scheme funded by Jobs Queensland through the Grow Your Own (GYO) Funding Program which is designed to tackle regional workforce challenges in

The program aims to create a pathway into the Heavy Vehicle Driving Apprenticeship, Bus Driving and Supply

“Parents in particular will ask the question, over and over, ‘If my kid goes into your industry, what qualification to they get?

“And I can assure you, saying a driver’s licence is no longer good enough.

“We’ve got to get on the job now and open up these channels to get a feeder group coming through.

“It’s time for us to acknowledge that the days of 30-40 years ago are long gone, but you still need a tremendous sk illset to function as a truck driver, and that deserves and warrants an apprenticeship and to be formally recognised as a trade.”

The new working group was formed after a recent roundtable of 37 industry heads at Parliament House called by WA Senator Glenn Sterle to address the industry’s biggest issues.

The former truckie turned politician told Big Rigs that the industry has a crisis on its hands if it doesn’t solve the skills shortage quickly.

“I don’t know who we’re

going to move freight in this nation safely in five, six,10 years; I shudder to think what this is going to look like.

“I’m sick of the talk, and I’m sick of being told by the likes of NTC and Austroads what’s good for the industry.

“We know what the problems are, and we know what the solutions are. This working group that’s industry driven will now take all the solutions to the relevant minister.”

Sterle said it’s clear the industry can go back to the “good old days” of new drivers being trained by other family members.

“But my goodness me, look at the value of having youngsters trained on trucking companies’ forklifts, in their yards, with their trainers, with their workers, with their systems, with their clients’ product in their warehouses.

“This is what we’ve got to do – on the job training but done properly and to an extremely high standard.”

The other parties in the Licencing and Employment Pathways Working Group are: National Road Transport Association, National Road Freighters Association, Australian Trucking Association, Australian Furniture Removers Association, Bus Industry Confederation, Western Roads Federation, Tasmanian Transport Association, Transport Workers Union and Northern Territory Road Transport Association.

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164

Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

ITALIAN truckie Marco Marciano, 33, would love to drive road trains full-time in Australia if he could.

The former hospitality worker fell in love with the trucks on a trip to WA’s northern region a few years back and promptly set about getting his MC licence.

He started out in a heavy rigid, delivering home appliances and white goods around Perth.

He graduated to MC a year later and moved into the mining sector driving triple and quad road trains and delivered mining equipment from an Esperance base all the way up to Newman and Port Hedland.

“I was lucky because the company put their hopes in me and threw me in the deep end,” Marciano said.

“I was working hard - it was my dream job.”

After seven months he had to return to Perth for personal reasons but quickly found work again with Zenith Low Loaders as a float and oversize driver where he developed his skills even further.

When his work visa expired, however, he had to leave Australia for a month and return on a student visa – he’s now studying mechanics – which only allows him to work 24 hours a week.

Zenith got back in touch

when the WA Government launched a state-wide Designated Area Migration Agreement (DAMA) visa system for truck drivers earlier this year.

The DAMA provides access to more overseas workers than the standard skilled migration programs, which currently exclude truck driving.

But after a few months of no word back from authorities, Marciano said Zenith was sadly forced to fill the vacant seat with someone else.

He’s since found driving work again for Cahill Transport doing local general freight driving singles and B-doubles, and is grateful for the opportunity, but would love to return to full-time road train work one day soon.

Ideally, Marciano would like to see truck driving recognised as a trade and put on the Skilled Migration List, providing foreign drivers pass a strict local testing regime.

Meanwhile, he said the state government needs to make it easier for companies to access the WA DAMA system.

“It’s very hard for companies to actually get the level of agreement with immigration to get approved.

“We need people for the industry, it doesn’t matter where they come from, as long as they know how to operate the vehi-

cle. I struggle to stay in Australia, even though I have the skills highly required here.

“I think we [foreign drivers] need to join the table to help the industry.”

WA’s Department of Training and Workforce Development told Big Rigs the new WA DAMA is the fifth DAMA for WA and will complement the existing four visa options and support the whole state.

“Registrations for the WA DAMA are in place and it will be operational in the coming weeks,” said a spokesperson. Truckies can now connect with WA employers by signing up for the Migration WA Portal and creating a profile.

3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110 – 120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Rd, Welshpool WA 6106

Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

ADELAIDE

TAMDELE, 21 Hakkinen Road, Wingfield SA 5013

Ph. 08 8347 1222, email: sales@gitsham.com.au, www.gitsham.com.au

NEWCASTLE/HUNTER VALLEY

Unit 2/13 Hinkler Ave, Rutherford NSW 2320

Ph 02 4932 0600, email: sales@hvss.com.au www.isri.com.au

Common sense prevails

A truck driver fined $1636 and four demerit points for driving too close to the truck and dog that cut him off, has had his penalties dismissed in court.

Garry Hall had dashcam vision and GPS data from the truck, showing his attempts to slow down, but when he approached Revenue NSW to contest the fine, he was unsuccessful.

Though he attempted to get a lawyer specialising in heavy vehicle law, due to the high fees, he decided to represent himself in court – and expressed his relief at the outcome.

“When I got to court, the judge didn’t even look at the dashcam footage. She said she could clearly see from the photos that he pulled out in front of me. They also had the GPS data printed out from work too, which showed the speed.”

A new chapter

For the first time in its 78-year history, Brown and Hurley will be led by its first non-family CEO, with Ryan O’Doherty taking the reins from January 1, 2025.

This follows the retirement of current CEO Paul Hurley, who will remain with the company as a board member commencing July 2025.

Ryan said he’s honoured and excited to join Brown and Hurley as CEO. “I look forward to working closely with the team to continue driving the company’s growth and to build on the solid foundation laid over the past 78 years.”

Brown and Hurley is the Queensland and Northern NSW distributor of Kenworth and DAF trucks.

CMV expands network

Through an expansion of its Hallam Truck Centre Kenworth and DAF dealership operations in Victoria, CMV Group has announced the acquisition of the sales territories of Somerton and Ballarat.

The expansion will see the company take over the existing TRP Ballarat and TRP Somerton parts outlets from January 1 and build a new state of the art Kenworth and DAF Truck dealership at Mickleham, in Melbourne’s north.

The dealership will be known as Melbourne North Truck Centre (MNTC) and will open in 2028. CMV Group managing director, Daniel Crawford, said the new centre will support the ever-growing customer base to the north of Melbourne, along with the inner west, including Ballarat.

Heartfelt fundraiser

Friends of truck driver Luke Vella, who tragically died in a work accident last month, held a special fundraising event for his family.

Luke Roberts and Jake Cusbert arranged a truck meet at Marsden Park in Sydney on November 23, with truckies invited to come along with their rigs.

Luke Vella had planned to marry his high school sweetheart Bec next year. The couple had been together for 15 years and also have four kids under the age of 10. The NSW father died after two trucks collided at the intersection of Agnew-Leinster Road and Agnew-Vivien Road in Leinster on October 21.

BY DANIELLE GULLACI

THE National Heavy Vehicle Regulator (NHVR) recently released the results of a week-long blitz that targeted the Queensland cattle transport industry.

The compliance operation took place in October, with 173 livestock intercepts taking place. A total of 487 heavy vehicle units (trucks and trailers) were inspected.

An NHVR spokesperson told Big Rigs, “The objective of the operation was to ensure the livestock industry understood their safety obligations under the Heavy Vehicle National Law and state-based legislation, with NHVR safety and compliance officers focusing their compliance and enforcement efforts on fatigue, mechanical safety, loading and access on major travel routes, feedlots and saleyards.

“During the operation a number of compliance issues were identified and addressed, with fatigue management and mechanical compliance the most likely to be recorded.”

Of the vehicles that were intercepted in the blitz, the NHVR claims 24.9 per cent were found to be non-compliant.

Throughout the operation, there were also 44 defect notices were issued, with the NHVR revealing 12 per cent of these notices were deemed to be major defects relating to brakes and body/chassis non-compliance.

NHVR safety and compliance officers also issued 15 infringement notices, most of which were for “fatigue-related offending”.

In addition, 56 mass checks were completed.

The NHVR spokesperson said this blitz was “part of our ongoing commitment to boosting road safety outcomes for all motorists”.

“We are pleased to report the operation’s focussed inspections and educational initiatives were both significant in number and well-received by industry, with close to 500 heavy vehicle units inspected and more than 50 education sessions held,” the NHVR continued.

“Such operations provide a boost to the livestock industry’s understanding of its safety obligations, which in turn contributes to overall road safety outcomes.

“Prior to the operation commencing the NHVR held consultative meetings with Transport and Main Roads, operators, industry

groups and stakeholders such as the Livestock and Rural Transporters Association of Queensland.”

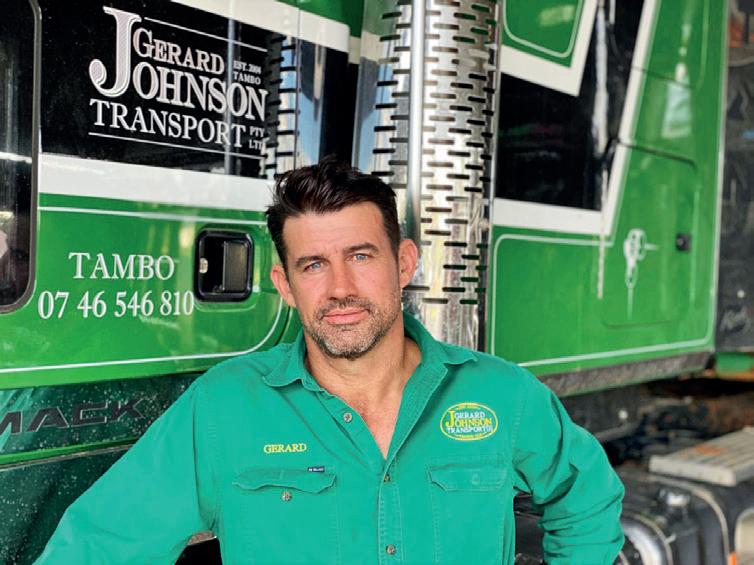

Speaking to Big Rigs, president of both the Australian Livestock and Rural Transporters Association (ALRTA) and Livestock and Rural Transporters Association of Queensland (LRTAQ), Gerard Johnson, said he was happy with the overall results of the blitz.

Along with his roles heading up the state and national livestock associations, Johnson also runs his own livestock transport business too, Gerard Johnson Transport, based in Tambo.

“There were 44 defect notices issued, but most of those would have been for very minor things. I think the livestock sector has come up pretty well compared to some of the other transport sectors,” he said.

“With infringement notices, most were fatigue related, and the majority of driver education was done roadside.

“I think livestock operators are doing a pretty good job. We’re underrepresented in accidents as a whole and just need to continue doing what we’re doing. Of course there are some areas we’ll keep working on, but we’re pretty happy with the results as a whole.”

He added that from the feedback he’s had, interactions between drivers and the NHVR’s safety compliance officers also went really well.

Online, Big Rigs readers also shared their thoughts, with many revealing they’d like to see more detailed information around compliance issues and defect/ infringement notices in future, when results like this are shared.

“NHVR should state what every defect was for – A tail light out? A clearance light out? A simple brake imbalance,” asked one commenter.

“I bet it was 24 per cent trivial crap that has no bearing on road safety.”

Another said, “59 mass checks were done? But de tails as per usual weren’t pub lished.”

While numerous other readers commented on the issues around the state of our road network.

One reader wrote, “As usu al our vehicles need to be checked in these so called blitzes… No shortage of money to build huge gantries and millions on high tech cameras for everything from number plate recognition to peer through your windows

– but oh sorry we don’t have enough money or resources to fix these disgusting piles of busted up rubble we call roads.”

Another said, “If you’re so worried about safety for the motorists, how about fixing the Bruce Highway where there’s the majority of accidents in Queensland. You expect the vehicles to be compliant – What about the roads? How about rest areas with public conveniences like lighting?”

And this driver shared a similar sentiment, “The whole fact that we are driving on roads built to 1950s-60s standards is a joke. Population has more than doubled in 2024: traffic on roads has tripled. And we’re still on goat tracks. It seems more important to government to hand out millions to overseas countries than to spend on infrastructure. All capital cities should be linked with four-lane dual highways.”

THE takeover of all heavy vehicle regulatory services in Queensland has contributed to a $5 million dip in the National Heavy Vehicle Regulator’s (NHVR) total surplus for the last financial year.

In its recently released annual report, the NHVR recorded a surplus of $5,017,000 in 2023-24, down from $10,200,000 in the 2022-23 period.

“The NHVR’s total surplus decreased in the 2024 financial year due to increased staffing and other associated costs relating to the transition of heavy vehicle regulatory services in Queensland, which has already provided significant productivity and safety benefits for the heavy vehicle industry,” said an NHVR spokesperson.

“Any surplus is used to help fund future assets and projects in line with the NHVR’s Corporate Plan, which also outlines the NHVR’s budget. This includes delivering focused national operations to address identified risks to enhance safety for the heavy vehicle industry as well as all road users.

“The NHVR has always valued safety over infringements, and our main priority is informing and educating drivers on how to comply with their safety obligations and to change driver behaviour.”

Another item of interest to truckies might be the income derived from work diaries, down from $4,746,000 in 2023 to $4,138,000 in 2024.

According to the annual report, it costs the regulator $2,741,300 to distribute the diaries to various outlets.

Outgoing boss Sal Petroccitto used much of his final CEO report – his last day in the role is January 24 – to reflect on the NHVR’s achievements in its 10 years of operations.

The NHVR’s total income for the year was $244,861,000, up from $235,041,000 yearon-year.

Regulatory income – the regulatory component of heavy vehicle registration charges from the Heavy Vehicle National Law signatories – is the biggest component at $184,308,000, up from $182,133,000 in 2023.

Grants and fee income were much on par, year-on-year, but ‘other income’ spiked from $30,014,000 in 2023 to $36,339,000 in large part to a full year of service in annual heavy vehicle inspections on behalf of Transport for NSW and the equivalent inspections in Queensland from April 20, 2024.

Sundry revenue, which includes penalty revenue and court fee reimbursements, decreased from $7,734,000 in 2023 to $6,812,000 in 2024.

“Since our inception in 2013, the safety of our customers and the community has been at the centre of all that we do,” Petroccitto writes.

“A 10-year journey to a single national heavy vehicle regulator In April 2024, we completed our National Services Transition program, bringing in Queensland as our final jurisdiction which now sees the NHVR ensuring compliance with the Heavy Vehicle National Law across 6 Australian jurisdictions, namely, the Australian Capital Territory, New South Wales, Queensland, South Australia, Tasmania, and Victoria.

“The transition of Queensland was a significant achievement for the NHVR. We can now take a consistent approach to compliance and enforcement from the roadside to interventions, border-

less operations and delivering timely, national responses to critical compliance issues right across the country.”

Petroccitto said he is now confident that, through the NHVR’s “forward looking national approach to heavy vehicle compliance”, we will see a safer and more productive heavy vehicle industry across Australia.

He did, however, acknowledge that in 2023–24, 192 people died in crashes involving heavy vehicles, including 99 deaths in crashes involving articulated trucks and a further 81 deaths in crashes involving heavy rigid trucks.

“These tragic and alarming figures tell us that we need to be doing more to ensure greater safety outcomes for all road users,” he said.

“While we continue to work constructively with the heavy vehicle industry, we know that more education needs to occur with light vehicle drivers who remain the at-fault party in most fatal crashes involving trucks in Australia (77.4 per cent).

“In response to this, we are continuing to undertake public road safety campaigns. These are aimed at educating and informing all road users how to share the roads safely with trucks. We have a particular focus on high-risk cohorts such as learner and

provisional platers.”

Another highlight for Petroccitto in the last financial year was the release of the National Network Map (NNM), consolidating road network information across Australia into the NHVR online Portal.

“This key initiative improves heavy vehicle access and decision-making by combining state-based heavy vehicle road networks and displaying them in one online location, the first time that this has been achieved,” Petroccitto said.

“It is the single and authoritative location for the heavy vehicle industry to map journeys across state and territory borders for their entire fleet.”

The Advanced Fatigue Management digital application was upgraded to the portal in 2024.

Every Cascadia comes with a complete suite of connected technology and fully integrated safety features to help you get on with your work.

Equipped with a driver airbag, Side Guard Assist, forward-facing camera that automatically sends footage for incident reports, and Active Brake Assist capable of detecting moving pedestrians, the Cascadia sets a new standard for safety.

EDITOR

JAMES GRAHAM

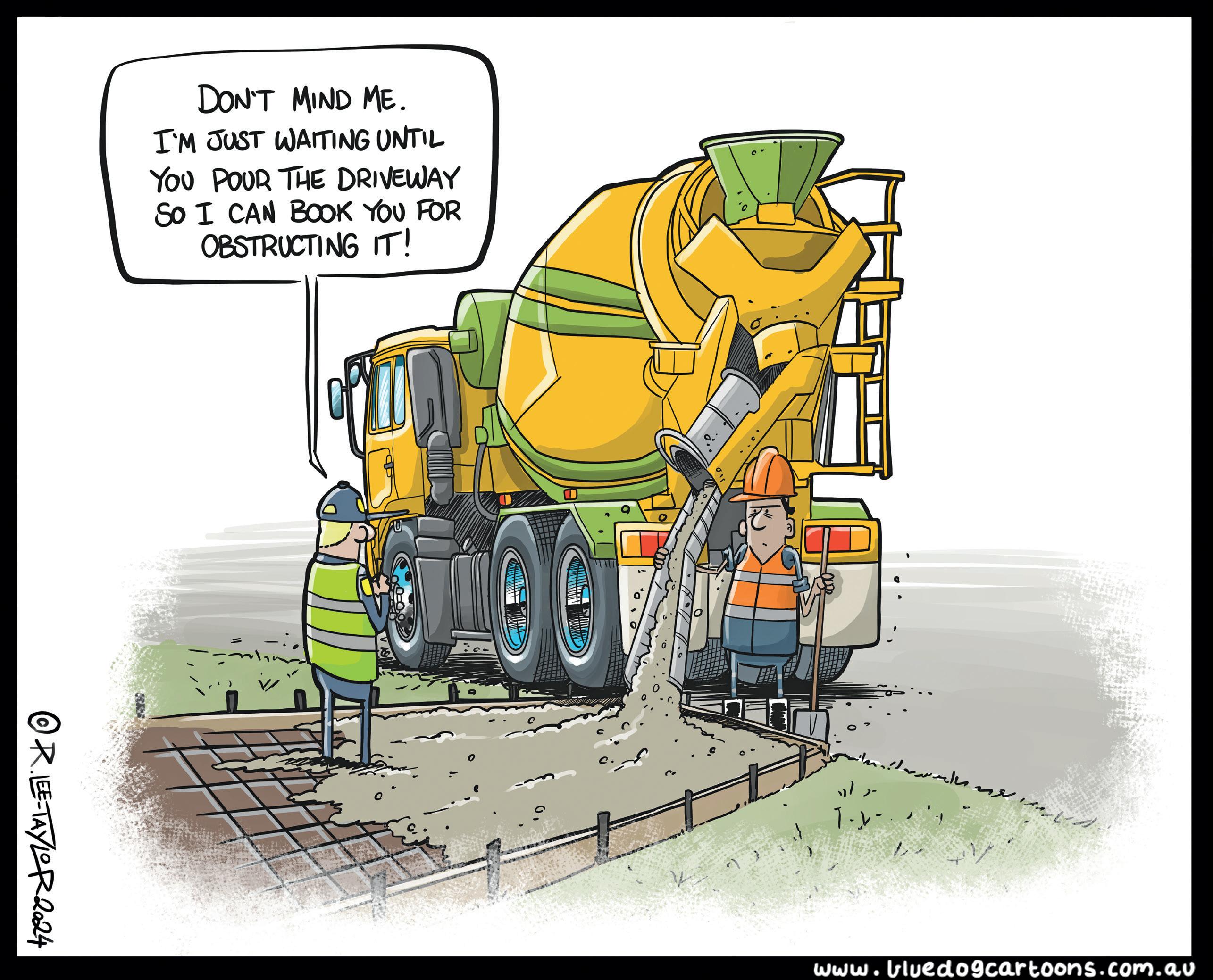

in Toowoomba recently in which a company was fined for parking a concrete truck in a suburban driveway (see page 2). Our cartoonist Ryan-Lee Taylor has brilliantly captured just how farcical following the letter of the law can be at times in his latest drawing on the right. It’s a shame this kind of message isn’t getting through to police.

While the NHVR must be commended for its education over enforcement policy, all that good work seems to unravel with the police. We can only hope that the long-awaited revamp of the national law will take on board what industry is saying (see page 3) and reduce, or eradicate, penalties for trivial things.

There’s more than enough pressure on drivers as it is.

REGARDING the new technology, and seeing these things have been out for a while now, if they are so good why is there a 27 per cent rise in accidents in 12 months?

They can’t be that good then. Or is it just the fact that the drivers are s##t these days and don’t give a f##k? Can it be too much regulating by the NHVR? I believe it is. How is all this technology being invested into the industry, but the people are getting more stupid.

Can someone show me the percentage of accidents from 2000 to 2010? I bet it’s bugger all. There were still hundreds of kilometres of single lane highway, 50 per cent of the trucks had 110km on the pedal, that was just standard.

Everyone would mostly communicate with each other, it was a game of cat ‘n mouse with the highway cars and the biggest thing, everyone drove, cause you had to, otherwise you were

going be a one of the small percentage of drivers that did come undone.

So, stop the bullshit safety argument, it’s not about safety at all, not with the NHVR and all the tech companies selling this s##t to these managers telling them about all the good stuff it does … please. It’s all about money, that’s it. So, my argument is, stop manufacturing and selling automatic trucks.

That’s the first way to weed out the ones who have no de-

sire to actually want to drive and actually do something about the ones who contin ually stuff up, and we know who I’m talking about.

Just let people drive and get off everyone’s back about going over a 100 off a hill, etc. Just let the true passion of truck driving come back and let it be fun again.

We’re all adults and we don’t need to be told that we are tired.

Matty

BY DANIELLE GULLACI

THE Travelling Jackaroo is now behind the wheel, working as a contractor for Queensland towing company Clayton’s Towing.

The Travelling Jackaroo –whose actual name is Sam Hughes – recently completed his 27,000km charity trip around Australia and returned home to Maleny on the Sunshine Coast in August, after three and a half years on the road in his trusty old 1957 Chamberlain tractor.

The 21-year-old was able to raise a whopping $260,000+ for three charities, sharing his adventures with his Facebook followers, which have now surpassed 274,000.

While most of that time was spent behind the wheel of a tractor, Sam is no stranger to tilt tray and recovery work, having spent some time

working for Berry Springs Mechanical, while in Darwin earlier in the year – as he saved up for the final stretch of his trip.

Hughes started with Clayton’s in early November and says he’s really enjoying the new role.

He’s behind the wheel of an Isuzu dual cab, which is a far cry from the vintage tractor he was used to. “It’s bloody fantastic to drive. Any vehicle post 2000 feels new to me,” he laughed. “It’s got every little thing in it like air conditioning and air suspension.

“The work has been fantastic. I enjoy doing it because I get to help people – and I get a few coins in the kitty as well.

THE WORK HAS BEEN FANTASTIC. I ENJOY DOING IT BECAUSE I GET TO HELP PEOPLE – AND I GET A FEW COINS IN THE KITTY AS WELL.” SAM HUGHES

really great on the training side – I did a week’s training before heading out, so it was nice having that.

were to begin working on it very soon, Hughes says he doesn’t want to rush it.

“It’s very similar to the work I did in Darwin. When I spoke to Mike [Clayton’s Towing CEO], he said if I was looking for work, they had an opening here in Maleny. They get a lot of work up here with breakdowns and repairs, and they needed someone to help out, so they offered me a job as a contractor.”

“Kev is the trainer there and he’s really knowledgeable. Everyone at Clayton’s has been really supportive and helpful. And there’s someone we can call to talk to 24/7 too.”

Hughes says the training offered at Clayton’s Towing was second to none. “They’re

The work sees Hughes travel through the mountains and down to the coast, all within the local area.

“I can do as many or as few

jobs as possible but I prefer to do as many as I can to keep busy. The Clayton’s team as a whole is great, especially dispatch who work hard and do their job to a very high standard to keep the wheels rolling!”

With the tractor trip completed earlier in the year, Hughes’ next project is a mobile museum he plans to put together, which he’ll then take across the country. It will be centred on the people who helped to shape Australia.

Though his initial plans

“I’ve worked out what I want to do and I want to make sure I do it well – so I’ll probably work with Clayton’s for a year or two so I can save up a bit of money for it. If I put in the hard work and put a few miles under my belt, I should be able to make it all happen.

“But Clayton’s is something I could be looking to do long term. It’s a family business and they’re really supportive and really look out for you.”

BY KAYLA WALSH

THE Balranald Roadhouse on the Sturt Highway in New South Wales has had a major revamp, now offering a free gym for truckies.

The small gym features some free weights, an exercise bike, and a selection of other weight training machines –handy for truckies who often struggle to get enough exer cise while on the road.

The roadhouse, which is open 24/7, also has an up graded 70s-inspired diner with a free pool table, arcade games and a massage chair.

Plus there’s a comfortable lounge area with a TV and leather couches.

Singh said there is B-double access and plenty of truck

When Big Rigs shared the news of the gym online, several truckies said it was a great idea.

Manager Dajinder Singh told Big Rigs that the new faago, and he’s had great feed back so far.

“Truck drivers have been using the gym, they are very

“We also have 24/7 barista coffee, toilets and showers, and a mini mart offering groceries, engine oil, and

If you can’t stay long, the roadhouse has fresh takeaway meals like spaghetti bolognese, sausages and veggies,

“That’s what they need, all we hear about is rest time!” commented Linden Watson.

“If they have to have a long break, nothing better than an hour limbering up!”

While others suggested focusing on diet rather than exercise due to time constraints during breaks, Damien Martin argued: “A 10 to 15 minute walk on a treadmill every day won’t hurt.”

‘This is as good as it gets’ Trucking wasn’t always on the cards for this third-generation truckie, but he’s glad he made the switch, as he takes to the road in a brand new K220.

BY DANIELLE GULLACI

LUKE Read, 40, admits he always had a thing for trucks, sparked by his grandfather Alick Earl, who ran a transport business.

“Pop had his own trucks, carting sand in the tippers. So as a kid, on the school holidays, the highlight for me was getting up at 3am and getting in the truck with Pop,” Luke fondly recalled.

“As he was an owner driver, they were his trucks, so he was paying for them and doing all the maintenance, so I think that instilled a good mindset for me about the importance of really looking after the gear.”

Despite his early introduction to trucks, life led Luke on a different path – working in medical imaging for 10 years.

But when Covid hit, it forced him to re-evaluate what it was he really wanted to do.

“I was working at a hospital in a job I enjoyed – and then Covid took all the joy out of it. I decided to pack my family up out of Wollongong and we moved to Young,” said Luke.

And he and his wife, along with their four children –aged eight, six, three and almost two – have called Young home ever since.

MC in December 2023. He says he’s lucky to have had such exceptional mentors, teaching him how to do the job – and do it right!

His first driving role was with Madden’s Transport, where he was mentored by trucking veteran Jeff Gunning, who Luke describes as “an old school truck driver who just loves being out on the road”.

It was general freight work, with Luke starting out with his HR licence. “Tony put me in the truck with Jeff and for the next three months, he was there with me, in the passenger seat,” Luke explained.

NEVER IN MY WILDEST DREAMS DID I THINK THIS WOULD HAPPEN SO SOON. I’VE NEVER BEEN HAPPIER IN A JOB – THIS IS AS GOOD AS IT GETS.” LUKE READ

“Jeff taught me everything tails about driving a truck and

everything else that goes with it, even how to use the pallet jack. He’s still driving trucks and is such a good operator. Jeff was the best person to have as a mentor. Even today when I’m working, I still hear Jeff’s voice in my head.

“I used to collect apples with Jeff in the mountains and he taught me about driving on inclines and on the goat tracks they call roads. I got to spend all that time with Jeff, who shared his years of experience, and he was really good at communicating all of that.”

In early 2023, Tony Madden decided to close his doors, after almost 50 years in business, so he could retire. “I was given an opportunity at Paul Lawton Freight through Jeff Gunning, who had already started there. He put in a good word for me and I worked there until I started in my current role with Rocky Lamattina & Sons,” revealed Luke.

“Even though Jeff and I don’t work together anymore, I still speak with him nearly every day. I’ve been able to work through so many different scenarios in this job because of what Jeff taught me. I owe him for a lot of the confidence I now have in the truck.”

It will be one year this month since Luke started working with Rocky Lamattina & Sons.

“I finished with Paul Lawton Freight on December 23 last year and the next morning was up at 6am to do my first B-double run in a Lamattina truck, delivering my first load of carrots on Christmas night.”

Rocky Lamattina & Sons operates a fleet of 16 trucks – all Kenworths, including K200s, T909s, and five new K220s all delivered since July.

Family owned and operated, Rocky Lamattina & Sons is the country’s largest carrot producer – growing the product all year-round and processing up to 1000 tonnes of carrots each week.

It was started by Rocky in 1991 and is now run by his sons Angelo, Phil and John.

In the colder months of the year, the company’s carrots are grown from their 6000acre home base property in Wemen, on the banks of the Murray River in northern Victoria. In the summer months, carrots are grown at a cooler climate 6000-acre property at Kaniva, Victoria, right near

the South Australian border. Along with a third property at St George in southern Queensland, on the banks of the Balonne River.

Rocky Lamattina & Sons operates quite the unique fleet of trailers – from innovative PBS-approved 30-pallet singles up to B-triples and B-quads. These B-quads can operate at 107 tonnes gross with a payload of 74 tonnes.

Interestingly, Luke and the Lamattinas go way back, with both families heavily involved in racing Top Fuel Dragsters – with Phil Lamattina, and Luke’s brother, also named Phil, tasked with racing them around the country.

Luke’s father Jim Read also has his own truck – an ex-Lamattina 2004 Kenworth K104 – which is used as a car transporter, travelling the dragster circuit.

“Both the Lamattina and Read families have Top Fuel Dragsters, 11,500hp fire breathing machines that reach speeds of over 500km/h in just 3.7 seconds so we’re

talking drag racing royalty with my dad Jim being an international drag racing hall of fame member and along with his dad, both Phil Lamattina and my brother Phil have won Australian Championships,” explained Luke.

“I’ve known the Lamattina family for years through the drag racing. One day my dad was speaking with the Lamattina guys about the work I was doing and then they called and offered me a job. I put in my two weeks resignation without hesitation that day and then started with them.

“I always looked at the Lamattina trucks and thought to myself, man they’re beautiful – and I put that as being my benchmark for being able to say I’ve reached my goal. Now I’m driving the trucks I admire most. The trucks are immaculate at Lamattina, their maintenance schedule is pretty first class.

“Never in my wildest dreams did I think this would happen so soon. I’ve never been happier in a job – this is as good as it gets,” he added. Luke started out in a 2015 model single steer K200, pulling B-doubles filled with carrots from the company’s farms to produce markets and supermarkets; as well as occasional runs with a B-triple from the Wemen farm to a processing facility in Adelaide.

His role sees him travel predominantly to Sydney, Mel-

and

Continued page 16

Jayden Pooley was unable to finish high school due to various health issues, but his love of trucking has been a welcome distraction

BY KAYLA WALSH

AN 18-year-old with autism, ADHD and epilepsy has told how he had to drop out of school because of his health struggles – but his passion for trucking has helped him maintain a positive outlook on life.

Jayden Pooley from Caboolture in Queensland was diagnosed with autism and ADHD at the age of four. A few years ago, doctors also discovered that he had epilepsy when he began suffering from seizures – and at one point they got so bad that he ended up in intensive care.

He struggled to keep up in school and had to drop out in the middle of Year 10, when he was 16.

“It was very hard for me last week, because that’s when I would have been graduating,” he told Big Rigs.

“I didn’t really have friends in school, but knowing my classmates all graduated without me was tough.”

Academia wasn’t the right path for Jayden, but he has a keen interest in the transport industry.

His dad Mick has been a truckie for the past 15 years, and the young truck fan loves hopping in the passenger seat of his Freightliner Coronado.

“I started going out in the

truck with dad because when I was having seizures, I wasn’t allowed to be home alone,” he said.

“I used to go every day, but now my seizures are under control, I just go with him on weekends.

“Dad carts fresh produce and I help him unload at the markets, and every few weeks I’ll also go on a run to Townsville with him.”

Jayden likes the opportunity to explore Queensland and spend time with his dad, while also being captivated by the impressive size and pow-

er of trucks. He’s also a big fan of truck shows and has attended several in the past year, including Casino, the Lowood Truck Show, Lights on the Hill and the Brisbane Convoy for Kids.

The shows are an opportunity to check out cool rigs, but also to socialise with truckies.

“I have made lots of friends in the transport industry now, there are some really good people,” said Jayden.

“I have more in common with them than I did with my classmates in school.”

He has picked up truck

I HAVE MADE LOTS OF FRIENDS IN THE TRANSPORT INDUSTRY - I HAVE MORE IN COMMON WITH THEM THAN I DID WITH MY CLASSMATES.”

photography as a hobby and set up his own Facebook page (Snap that Shot Photography) to showcase his work.

“Every now and then I will take photos at shows or from the side of the highway,” he said.

“It’s a passion of mine.”

Because the teenager has not suffered a seizure for the past 18 months, he has been able to get his car licence –and one day he would love to upgrade to a truck licence.

He also dreams of becoming a diesel mechanic.

“I would love to be a mechanic, so I could be around trucks and learn to fix them.

“I want to do an apprenticeship and I’m in the process of

trying to figure it out.

“It’s a bit confusing, but I have a support worker to help me.”

Jayden is grateful that his interest in trucks has given him an outlet to help him through his health battles.

“Things have been hard sometimes, but my passion for trucks has given me something to focus on.

“It helps to take my mind off things!”

Innovative single trailer has same payload as a B-double

From page 12

SINCE last month, Luke’s been in a new twin steer K220 with a single trailer – and it’s not just an ordinary set-up either. As Luke explained, “The trailer set-up for the company’s twin steer trucks was designed by Angelo. These 30-pallet singles can carry the same payload as the B-double, but with one less trailer.”

The 30-pallet units run at a length of 22.5 metres, replacing the 32-pallet B-doubles being purchased previously.

The design was Angelo

from point A to point B.

The trailers were manufactured by Southern Cross Trailers and just like the B-doubles in the fleet, can achieve a payload of around 36 tonne.

As Angelo explained, “It’s getting hard to get drivers so having a vehicle like this means the operator doesn’t have to worry about connecting and disconnecting the trailers, which isn’t as hard on the back.

“The beauty about this particular vehicle is that even though we’re carrying the

these ones are 62 tonne GVM – because you’ve got less axles, one less fridge motor and the trailer isn’t as long.”

Interestingly, the Lamattina brothers had kept Luke’s new truck completely under wraps. “It was all kept secret, I had no idea. I knew this truck was the latest one that came in. After it turned up, Lamattina put all their bells and whistles on it, but it hadn’t been allocated to a driver yet,” Luke revealed.

“When I got there, I saw it had ‘Road Train’ signs on it. Phil and Angelo put their

wouldn’t be driving my truck anymore, I quickly worked out what the good news was.

“I’ve driven a lot of mod ern trucks, but this is the first brand new one I’ve ever had. You don’t always get the brand new truck when you first start somewhere, so this was a pretty nice reward.”

The new K220 features Kenworth’s Big Cab and is equipped with all the crea ture comforts including a television, fridge, freezer and more. “It’s like a small bed room in there, which is great because I spend more time in the truck than I do at home,” said Luke.

“It could be a booming 30 degrees outside, but in the truck with the air con on and curtains closed, you wouldn’t even know it’s not nighttime.”

The truck also features an automatic transmission and though Luke admits he was a little apprehensive at first, after coming out of a manual, he quickly came around. “I was used to the Road Ranger and when you’re driving long hours, it gives you something else to do. I got used to the auto pretty quickly though –it’s one less thing the driver

has to worry about.”

Going from two trailers to one has also had its advantages too. “The first night I had to unload was really nice. When you have to split up your trailers two or three times in a few hours, having the single trailer really makes a difference. It makes the job easier and more efficient – and there are lots of advan-

tages on the maintenance side of things too.”

Angelo added that it’s great to see his drivers happy in their role – and their trucks. “We do a lot of work to try and please our drivers. I’m really happy to see that in this case, Luke is happy with the new truck – that means we got the result we’re looking for!”

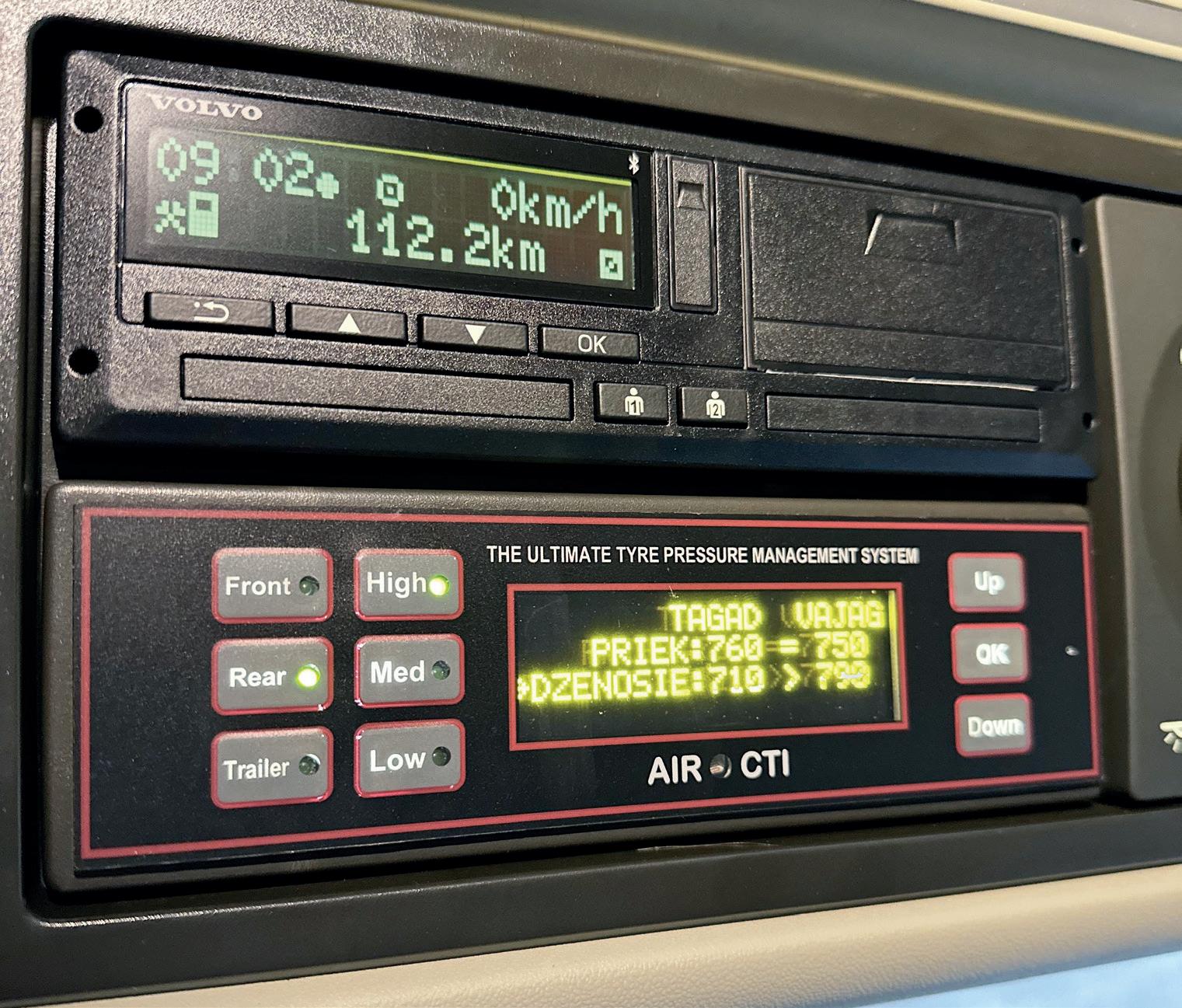

Our test driver is thrown the keys to Volvo’s latest cabover to hit the Australian market for a fully-loaded run from Brisbane to Sydney.

BY GEOFF MIDDLETON

IT’S hard to make a heavy-duty cabover truck aerodynamic. Simply by design, they have the drag co-efficient of a dunny door.

It’s a lot easier to make a bonneted truck slippery through the air than it is to make a cabover streamlined.

However, the big European truck manufacturers have done their best over the years to get the most efficient aero shapes out of their trucks to eek out the last few percentage points of fuel savings through aerodynamics.

The latest of these is the Volvo Aero which will be able to be ordered as this story goes to press.

We were fortunate to be offered a drive of one of the first Volvo Aero cabs in the country for a run from Brisbane to Sydney.

Aerodynamic improvements have been achieved by extending the front of the existing FH cab by 240mm, allowing for a smoother more rounded frontal area to reduce drag and energy consumption whilst remaining within the 26-metre B-double limit.

The Aero will be available in Australia with a choice of 13-litre and 17-litre Euro 6 diesel engines well as Volvo’s heavy-duty electric driveline.

Our test truck was powered by the I-Save turbo-compound 13-litre engine which is rated at 500hp and puts out an impressive 2800Nm of torque.

Volvo tells us that this engine is ‘the ultimate fuel saver’ and in testing it proved to be up to 14 per cent more economical than the regular 13-litre engine.

The new Aero cab also adds to the fuel savings and in European testing, we’re told that the Aero cab got 5 per cent better economy than a regular cab.

So, what we’re looking at here, on paper at least, is a fuel saving of nearly 20 per cent.

THE TORQUE IN THIS TURBO-COMPOUND VOLVO WAS IMPRESSIVE FROM THE START WITH THE TRUCK SKIPPING UP THE GEARS TO THE TOP OF THE BOX IN NO TIME.”

The proven 540hp engine also remains an option for Aero as does the new D17 powerplant in ratings from 600hp and 3000Nm up to 700hp and 3400Nm. Aero cab options span sleeper, Globetrotter XL and Globetrotter XXL cabs.

To add to the aerodynamics and subsequent fuels savings, the Aero cab has no external mirrors. In their place is Volvo’s recently released Camera Monitor System (CMS) which comes as standard equipment on the FH Aero. CMS has digital cameras instead of mirrors. Two screens mounted on the A pillars in the cab provide a great view down the sides of the truck. They feature a zoom-out function, automatic panning that tracks the rear of the vehicle while negotiating intersections, fixed reverse panning and an infra-red mode for low-light conditions.

Externally, all you can see are two stalks high on the cab which house the cameras. The camera lenses are heated and will automatically activate depending on the outside temperature to give a clear view in all weather conditions.

Our test truck was also fitted with Volvo’s Dynamic Steering which is an electrically assisted steering package that helps in low-speed manoeuvring as well as being more accurate on the highway at higher speed.

The Dynamic Steering also enables the Aero to have the new Pilot Assist feature which is Level 2 autonomous steering that ‘reads’ the line markings on the road and actually

steers the truck for you.

It is actuated from the cruise control buttons on the steering wheel and not only gives the active steering but also radar cruise control, so it really does make the driver a steering wheel attendant!

I used this a bit on the highway and found it actually gives the driver a break when there isn’t too much traffic about.

Of course, being a Volvo, the FH Aero is fitted with all the other latest safety features. These include air bags, downhill cruise, hill hold, Collision Warning with Emergency Brake, Driver Alert Support, corner camera, lane departure warning, ESP, and more. Inside, the FH is familiar territory. The expansive dash has everything close to the driver and the view is great –

especially so in the area of pe ripheral vision as there are no mirrors to impede the view.

Our test vehicle was in a ‘fleet spec’ which included dash-mounted transmission buttons as opposed to the usual small T-bar shifter close to the driver’s seat.

This meant that the fridge was closer to the driver which isn’t a bad thing, but it also meant that if you wanted to manual-shift, you have to reach for the buttons rather than drop your hand down beside your thigh.

Getting comfortable in the big Volvo is easy with the steering wheel being multi adjustable, as is the driver’s seat.

The seat itself is a beauty with arm rests on either side

and a heater for those chilly morning starts. Fire up the 13-litre six and you’re greeted with a lovely burble and next to no vibration. Hit the button on the auto shifter and flick of the electric park brake, give a little tug test and we were off in the early morning on our way to Sydney from Volvo’s HQ in Wacol.

Wacol, incidentally, is where these trucks will be built starting next year.

Our truck was towing a B-double set of tautliner trailers weighing in at just a smidge under 60 tonnes which is a pretty honest load for a 13-litre.

However, the torque in this turbo-compound Volvo was impressive from the start with the truck skipping up the gears to the top of the

box in no time. This partic ular version of Volvo’s I-Shift transmission is an overdrive box meaning that 12th gear is overdrive and 11th gear is direct 1:1.

The diff ratio is 3.09 and it all translates to a very low-revving engine. In fact, at 100km/h in top gear, the engine is spinning at just 1250rpm and on the hills it will lug down below 1000rpm before kicking down to a lower gear.

And it’s quiet. With no mirrors and no external visor – it has a very effective pulldown internal visor – there is next to no wind noise, and the insulation from the engine bay is fantastic.

There is no problem having a conversation with your passenger or listening to some music on the newly-upgraded stereo. In fact, as we were cruising down the coast we could hear the cicadas in the trees, it was that quiet.

The ease of driving is worth noting too. It seems that heavy-duty trucks are getting easier and easier to drive, and once I got used to the controls and the steering wheel buttons, I found I was basically driving with my thumbs.

Setting the cruise and the downhill speed on the steering wheel and using the engine brake stalk for slowing – it was a breeze.

Then, if you factor in the Pilot Assist which steers the truck, there really isn’t much

to do. I admit to being initially sceptical about these semi-autonomous options on big trucks but I admit that if they’re used frugally, they can be a big asset.

The Pilot Assist doesn’t let the driver fully take their hands off the wheel, you have to apply some pressure or input or the system will flash up a message on the screen. If you fail to acknowledge the message or put your hands back on the wheel, the system will assume that something has happened to the driver, and it will bring the truck to a stop and turn on the hazard lights. So, it is actually a safety feature.

It is difficult to say what benefits to economy the Aero cab actually has without doing a back-to-back comparison test with a regular FH cab, for that we’ll have to go with the European testing and accept their five per cent figure.

But we did keep a record of the fuel figures we achieved on our run from Brisbane to Sydney.

On the run, which totalled 944 kilometres, we achieved a best fuel figure of 2.2 km/ litre (45.5 litres/100km) and an overall fuel figure for the run of 2.17 km/litre or 46.6 litres/100km which is very good considering we were at 60 tonnes.

It’s also worth noting that this truck was new. When I picked it up from Wacol, it had less than 2000 kilome-

tres on the clock, so as the engine loosens up, the economy is sure to improve.

After my drive, what was really noticeable was how I felt after 12 hours in the saddle (minus the mandatory rest breaks, of course).

The smoothness and quietness of the truck really make it easier to do long runs, and after this run, I came out feeling great.

In the final wash-up, the combination of the Aero cab and the I-Save turbo-compound engine works on a number of levels.

Firstly economy. There is no doubt that this is an economical truck for doing me-

Specifications:

Engine: D13K Euro 6 Step E

Max Power: 500hp (368kW)

dium-weight line-haul work. Secondly, it’s a comfort able truck. Driver comfort is all-important these days and if the driver is comfortable, he or she is more likely to en joy their job and stay in the truck.

Finally, safety. Volvo has always had safety at the forefront of its truck designs and this truck, with all its features and now with Pilot Assist and Front Short Range Assist for detecting vulnera ble road users such as cyclists and pedestrians, has to be one of the safest trucks on the market today. And that is surely what we’re all after.

Max Torque: 2800Nm at 900 to 1250rpm

Transmission: I-Shift 12-speed overdrive auto

Front Axle: 7.1 tonne

Rear Axle: RTS2370B single reduction tandem

Axle Ratio: 3.09:1

Wheelbase: 3100

Fuel: 970 litres

AdBlue: 150 litres

Max GCM: 70 tonnes

Safety: Volvo Safety Platform incl adaptive/downhill cruise, air bags, ABS/EBS disc brakes, auto hold, collision warning with emergency brakes, driver alert support, camera monitoring system, corner camera, rear camera, lane keeping, ESP

BY GEOFF CROCKETT

THE competition was tighter than ever as the trucking community came out in force at the 36th HHA & Larsen’s Castlemaine Rotary Truck Show in Victoria.

Braving the 32-degree heat on Saturday November 23 and a good smattering of rain on Sunday 24, thousands of spectators turned out to be part of one of the last truck shows of 2025.

More than 250 trucks registered at the two-day event which saw Campbells Creek Recreation Reserve come alive with trucks, truckies and their families out to celebrate the transport life.

It also featured a truck convoy on Sunday morning through the main street of Castlemaine that saw the streets lined early as locals sheltered under shop awnings to enjoy the parade of chrome that took nearly half an hour to roll through.

Heavy Haulage Australia boss Jon Kelly, who has co-sponsored the event for three years with Larsen’s Truck Sales, told the crowd this year’s judging was ex tremely difficult.

scoring process. Lots of trucks to get through, over 250 reg

istered trucks, 300 trucks on the ground,” he said.

When it came to the Truck of the Show, things became particularly challenging.

“Just to give you some background, top score in terms of truck show presentation is you can have a score of 30 out of 30. We had two trucks with a score of 30 out of 30,” Jon said.

“Normal truck shows, I suppose you see around the country, push the trophies around to share them around to different people. And I think the results should lie, where the results lie, and that was the decision we left with this weekend.

“As the result of that we’ve actually done a first, second and third place for the Truck of the Show here, for the first time ever at Castlemaine.”

The Truck of the Show went to 2023’s champion truck, a stunning 2022 Kenworth Legend SAR, owned by the Cornwill Transport. Second place went to Colli Timber and Hardware’s 1981 White Road Boss from Western Australia, while third place went to Maloney Bulk Transport’s

phies were handed out on the day across a range of categories, with Daniel Booby’s Peterbilt 379, owned by Spinefex, the most celebrated truck of the day, taking out the People’s Choice category, along with Best Paint (artwork), Best Interior and Custom categories.

Rotary Castlemaine president Terry Walsh said about 150 volunteers from Rotary and the local community helped to make the event a success, involved in everything from traffic management to cooking food, registering trucks, setting up and packing down the site.

“The Rotary Club here in Castlemaine consists of around 40 members, and we have a few honorary members who turn up to anything that’s got a Rotary badge on it, so we probably number about 50-ish,” Terry said.

“But there are a lot more people who’ve contributed across the weekend. So, all the community groups that we support through the year with funds have supplied their labour across this weekend, and we thank them enormously.”

Funds raised from the event are used to support a range of

People’s

BY KAYLA WALSH

THE 20th anniversary of the Illawarra Convoy was a huge success, with an incredible $2,502,020 raised for sick children and their families.

Over 700 trucks took part in the event, making their way from Illawarra Coal’s West Cliff Colliery at Appin through the streets of the Illawarra, winding up at Shellharbour Airport for a jam-packed day of family fun.

A whopping $1.6 million was raised for the Illawarra Community Foundation through the auctions for the convoy’s Lead Truck and Lead Bike, before a single engine even revved.

For the first time, the team from Tiny Tins and Wollongong Crane Trucks were given the honour of leading the convoy after donating $300,020 to the cause.

Tiny Tins, a family business who deliver skip bins throughout the Illawarra, has organised a series of fundraising events over the past year, including two major boxing events called Battle of the Businesses and a Halloween disco for kids.

Tiny Tins co-owner Karlie Zec told Big Rigs that the team were over the moon to have been able to donate such a large amount.

“We’re absolutely amazed,” she said. “It’s been a really tough year for fundraising, and we’ve worked really hard over the last 12 months to get to that figure.

“We were actually sitting at around $200,000 on the morning of the lead truck bidding, and we raised $100,000 in a couple of hours thanks to the help of the local community.”

Karlie described the atmosphere on the day as “beautiful and overwhelmingly emotional.”

She continued: “We’ve been doing the convoy for the past few years and I think it was the biggest crowd that we’ve seen yet.

“We were a bit worried it was going to rain but it was really sunny. It was just great to see so many people from the local community, the trucking community and the motorbike community coming together.”

Karlie said Tiny Tins wanted to support the Illawarra Community Foundation, which helps families battling

life- threatening and life-lim iting illnesses, for a number of reasons.

selves and lucky to have happy, healthy children but not every one is in the same position as us and needs a little bit of extra support,” she said.

“We’ve always loved to give back to the community now that we are in a position to do that, financially.”

Tiny Tins also has a personal connection to the cause as the six-year-old son of a family friend has a condition called

to his central line overnight that gives him everything he needs to survive. He’s had a real tough life but he’s the happiest, most energetic little boy you’ll ever meet.”

Ase was the star of the show on Sunday, leading the convoy out of the West Cliff Colliery in a miniature truck.

“He was leading until we actually got on the road, of course!” Karlie added.

“He had the best day ever.”

Hot on Ase’s heels, the lead full-size truck was an Isuzu Npr 200 driven by Orlane Mortimer from Wollongong Crane Trucks.

“Orlane and I are best friends and we’ve been a team for the convoy from the start,” Karlie said.

“We started fundraising

together four years ago. The first year we only raised $8000, the second year was $35,000 and then last year was $261,000 so we just keep

“The Illawarra Convoy will always be part of our work

ra community that sees this event grow each year.”

SHELL Rimula has partnered with Big Rigs in a big way – so there are even more reasons to send in your best truck shots.

Each month, the Big Rigs team will choose a #PicOfTheMonth, with the lucky winner receiving a $500 Shell Coles Express Gift Card.

Keep an eye out for our regular posts on the Big Rigs National Road Transport Newspaper Facebook page, calling

for your best truck photos and add yours in the comments, or email them to kayla.walsh@ primecreative.com.au.

Don’t forget to include a brief note about the truck and where the photo was taken. We’ll feature some of the best photos in each edition of Big Rigs Newspaper, with one win ner announced each month.

Keep those amazing truck pics coming!

When the going gets tough, truckies keep everyone going

BY KAYLA WALSH

THIS year’s Dane Ballinger Memorial Truck Show in Bathurst was a smash hit, with over 170 rigs registered and many more turning up to join in the fun.

Event organiser Haylie Osborne said the crowd was the biggest one she’s seen since the show started in 2016.

“It was a great day,” she told Big Rigs. “We changed the layout of the event this year, moving the stage and the trade stalls to a central area, so it was quite different.

“We were a bit nervous about changing something that’s been running for so long but it went really well, everyone seemed really happy.

“And the weather was glorious, which was a bonus.”

Haylie said truckies came from far and wide to take part in the show, with some even travelling from as far as Tasmania.

Over 50 awards were handed out on the day, with the same rig as last year taking out Truck of the Show – Adrian Fenech’s immaculate 2013 K200.

“For him to win two years in a row, it’s just a testament to the truck,” Haylie said.

“The judge said that for a truck that works like it does, for Adrian to have it in that condition – you couldn’t pick anything else.”

After successfully adding a heritage section to the show last year, the organisers decided to bring it back again, with the trophy for Best Restored going to a 1970 C-Line International owned by Peter and Val Fitzpatrick.

Proceeds from the event will go to the 2bs and B-Rock Toy Appeal.

“Through multiple charities, they put together toys and hampers for local children who would otherwise not go without for Christmas,” Haylie said.

“We were happy to support such a great cause.”

Best Tanker

Fenech Haulage

Best Stock Crate

JAJ Trucking

Best Curtain Sider

JDN Transport

Best Tray Top

Chris Watkins Furniture

Best Tipper (2021 – 2024)

Hangan Transport

Best Tipper (Up to 2020)

Diamond Excavations

Best Intrastate

Dawsons Removals

Best Interstate

Chris Watkins Furniture

Best Tilt Tray (2021- 2024)

GRS Towing

Best Tilt Tray (Up to 2020)

GRS Towing

Best Heavy Tow Truck

GRS Towing

Best Prime Mover (2021-2024)

Dawsons Removals

Best Prime Mover (2016-2020)

Ball Haulage

Best Prime Mover (up to 2015)

Fenech Haulage

Best Tanker – Painted

Brookes Transport

Best Pantech (2021 – 2024)

Lawrence Transport

Best Pantech (Up to 2020)

Chris Watkins Furniture

Best Tautliner (2021-2024)

Winston Express

Best Tautliner (Up to 2020)

Lawrence Transport

Best Flat Top

Tytan Transport

Best Logging

Combination

C & T Dwyer Transport Best Tipper

Hangan Transport

Best Tipper / Dog Combination

Topsoil Organics

Best Interstate (2021 - 2024)

Tyton Transport

Best Interstate (Up to 2020)

Lawrence Transport

Best Intrastate (2021 – 2024)

Brookes Transport

Best Intrastate (Up to 2020)

JDN Transport

Best B-Double (2021-2024)

Schaeffers Transport

Best B-Double (Up to 2020)

Chris Watkins Furniture

Best Prime Mover & Low Loader

Winston Express

Best Old Working (1995 - 2011)

Tri Clark Brothers

Best Old Nonworking (1995 - 2011)

Robert Starcic Best Specialised (2021 – 2024)

Schaeffers Transport Best Specialised (Up to 2020) Davtrans

Tarp

Transport

IMAGINE if you could get your vehicles repaired quicker, and back on the road faster.

That’s where NTI’s in-house Repair Management Team comes in.

As Australia’s largest heavy vehicle insurance specialist, their 24-person Repair Management Team is made up of experts with industry backgrounds, including mechanics, panel beaters, spray painters and more. The team operates nationally, meaning someone can be on the ground assessing vehicles across the country – while liaising with their claims teams and repairer network to ensure time off the road is kept to a minimum.

“Our team motto is we insure Australia-wide, and we assess Australia-wide,” said Dion Cooper, NTI’s manager – repair management and assessing.

“Our team specialises in heavy vehicles, so customers aren’t dealing with assessors that don’t understand the industry. We’re from the industry, and we know heavy vehicles inside out.”

Thanks in part to the work of NTI’s Repair Management Team, NTI on average gets heavy vehicles back on the road many days faster than other insurance providers.

WE ALWAYS TRY TO MAKE EVERY CLAIM GO AS SMOOTHLY AS POSSIBLE AND AIM TO GET OUR CLIENTS BACK ON THE ROAD IN THE SHORTEST AMOUNT OF TIME.”

DION

COOPER

The team in action

When a claim comes through to NTI, it gets directed to the most suitable team member, who gets in touch with the customer and arranges an in-person visit.

Dion explained: “It’s a big part of our service offering that we are there in person and assess exactly what needs to be repaired. “Also, if customers need any refurbishment work done at the same time, or any new accessories fitted – for example, a bull bar put on – this can be arranged. That’s the type of relationship we have with our customers and our repairers.”

The sum of many parts