Official Media Partner FEATURES CICA NATIONAL CONFERENCE AND EXHIBITION REVIEW MELROSE CRANES AND RIGGING SYDNEY GATEWAY LIFT BERENDSEN’S INVESTMENT IN HYDRAULIC CYLINDER REPAIR THE DEDICATED RESOURCE FOR THE CRANE INDUSTRY / JANUARY-FEBRUARY 2023 LAUNCH HYBRID CONCEPT 20222022

With over 30 years’ experience, UAA is the largest and most reputable specialist mobile plant and machinery insurer in Australia, New Zealand and globally.

The UAA Group has the knowledge, ability and capacity to insure a wide variety of plant and machinery spanning numerous industries.

Our experienced claims team has access to a network of the very best expert industry repairers, assessors and suppliers.

Our insurance products are tailored to produce a hand crafted solution to meet your business needs

please contact

EXPERTS IN MOBILE PLANT INSURANCE

more information

UAA’s Industrial Special Plant and Procon products,

your Insurance Broker or visit www.uaa.com Industrial Special Plant and ProCon underwritten by QBE Insurance (Australia) Limited. ABN 78 003 191 035, AFSL 239545. Underwriting Agencies of Australia Pty Ltd. ABN 86 003 565 302 AFS Licence 238517. Underwriting Agencies of New Zealand Limited (UAA). 4758199, NZBN: 9429040999678. J6663

For

on

33

38 Tutt Bryant Heavy Lift & Shift TBHL&S manages major demolition project

42 Berendsen Fluid Power invests Berendsen Fluid Power’s investment in cylinder repair.

46 DPW Plant Hire Crane Connection is the ideal choice for DPW’s latest addition.

50 WATM WATM’s new CEO and renewed focus on service and support.

54 Sany Sany’s commitment to the Australian market

58 Tadano’s new all terrain

Tadano launches new 250t capacity all terrain.

62 Two Way Cranes Two Way’s three way Franna lift.

65 GMC First BG Spider crane has landed.

68 McLeod Cranes McLeod continue to invest in Liebherr.

72 XCMG

XCMG cranes working out in WA.

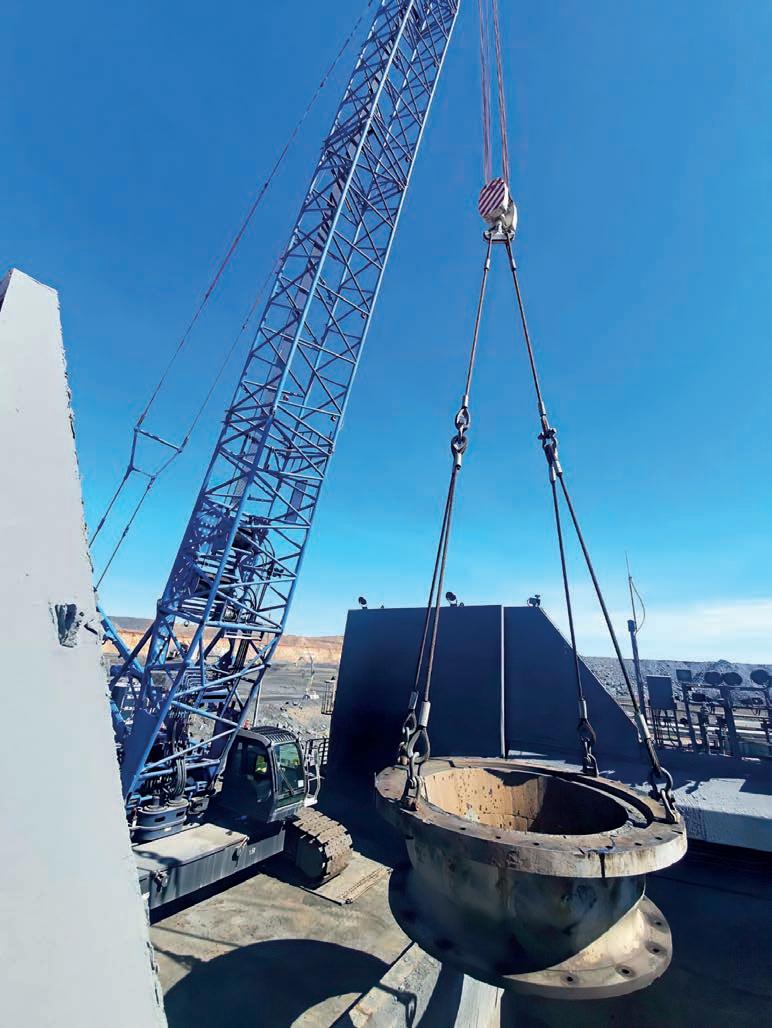

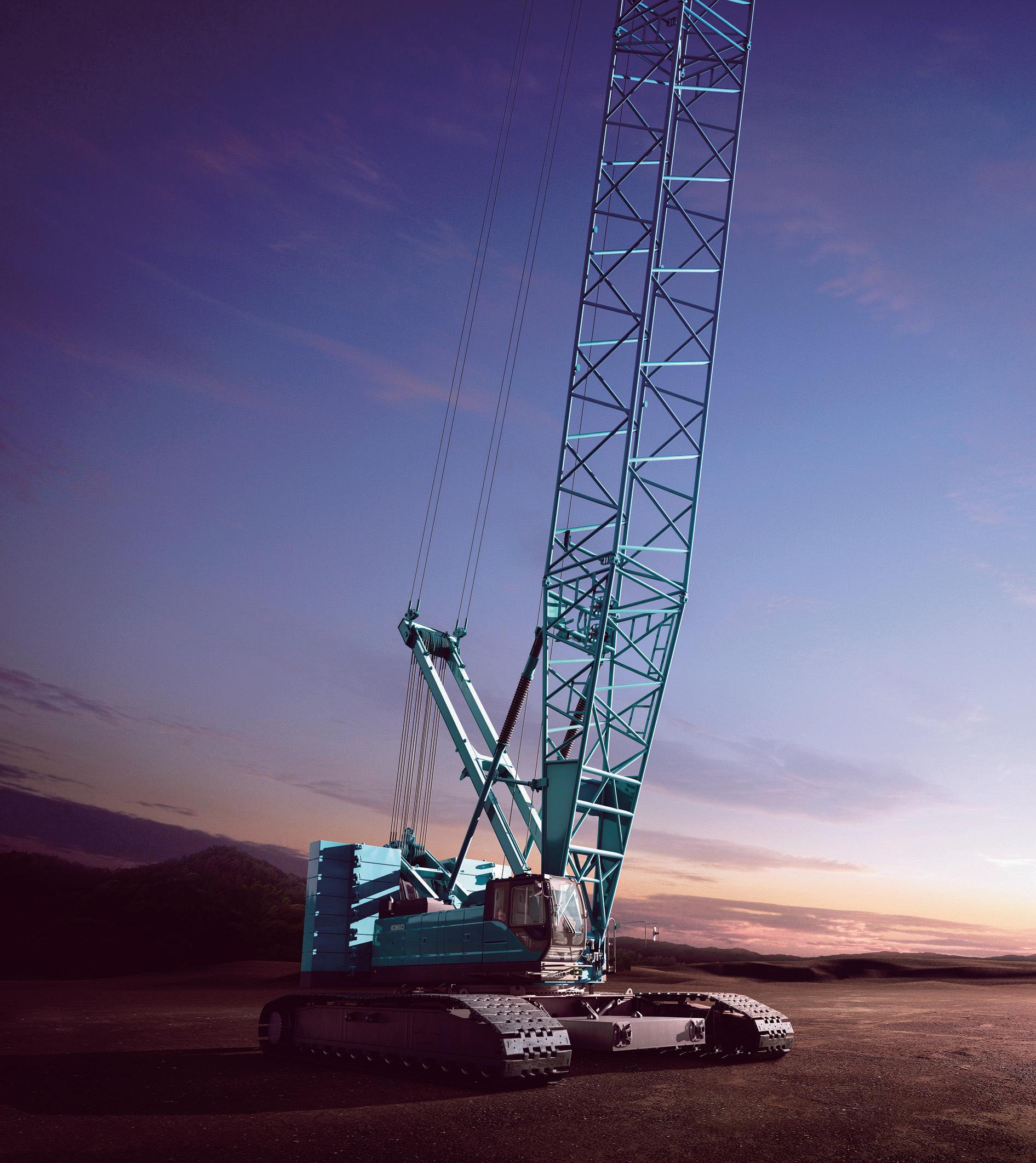

76 Melrose Cranes and Rigging on the Gateway Project Melrose completes heaviest lift yet on Gateway project.

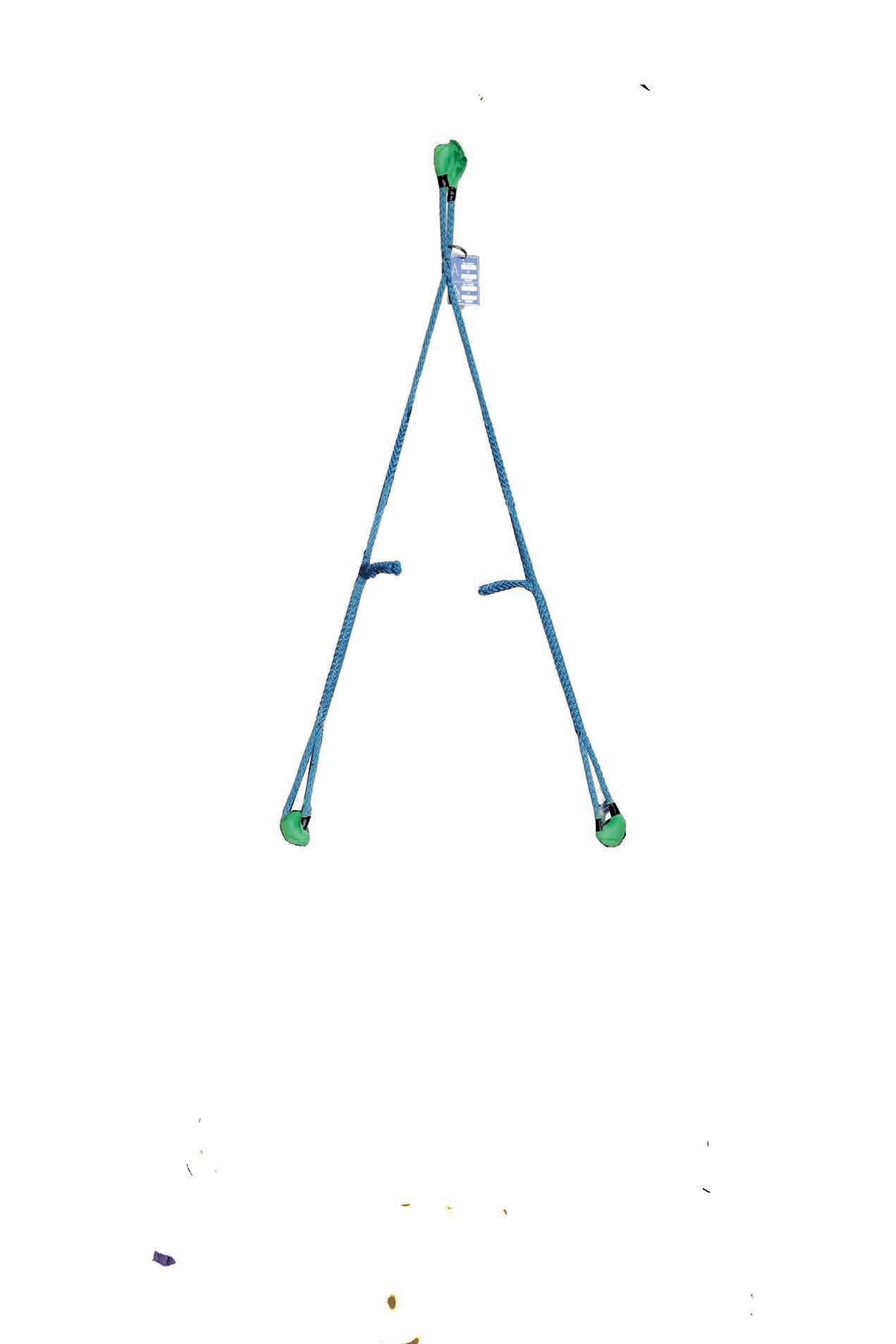

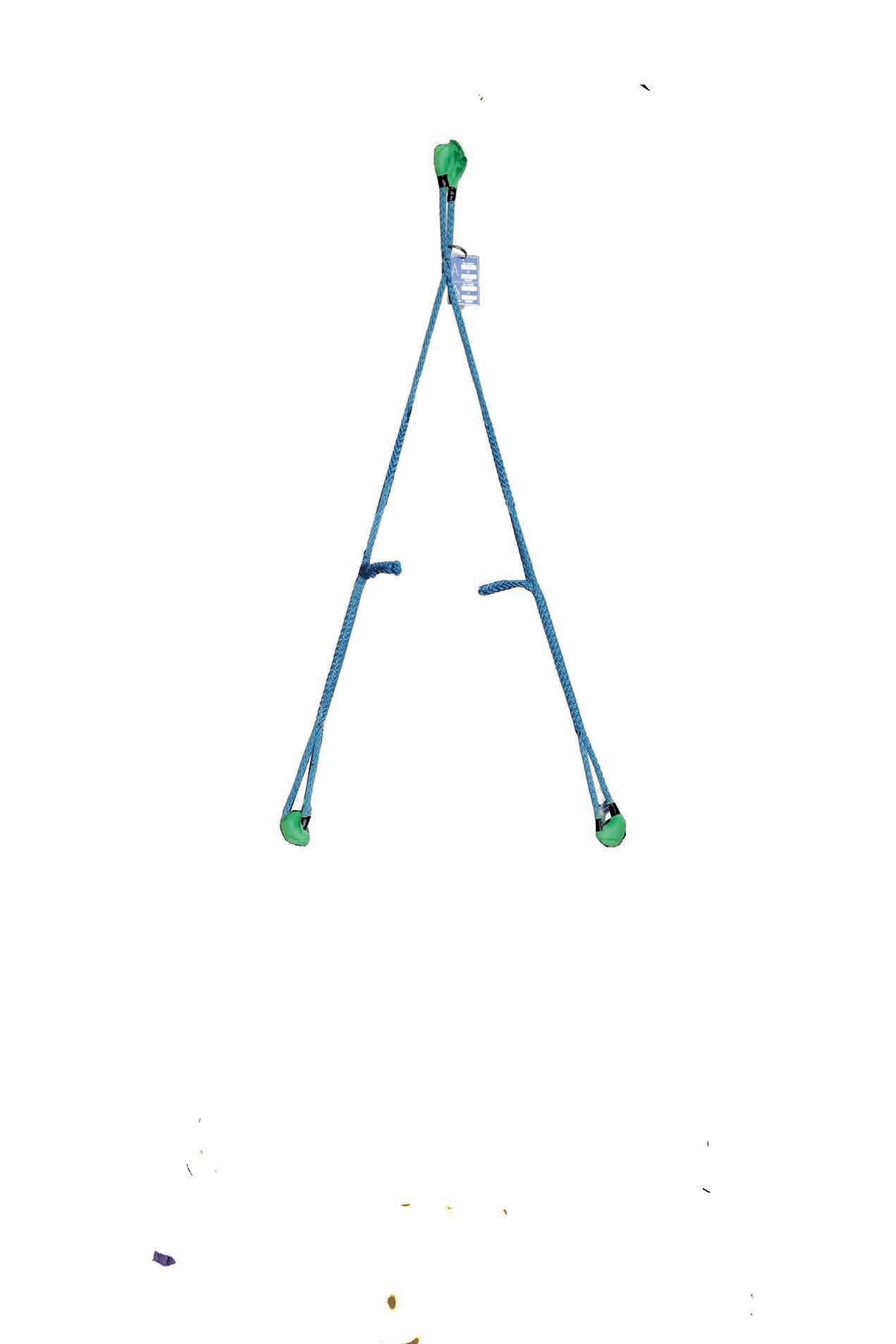

80 Bullivants

Moving with the time with new Adjusta Sling.

84 Borger Cranes and Rigging Services Borger Cranes welcomes third generation into the business.

January-February 2023 CAL / 3 www.cranesandlifting.com.au

12 Upfront with Grove New hybrid launched at bauma. 16 CICA President Report New President with new vision for CICA. 18 CICA Diversity Committee New committee making the industry more attractive. 20 CICA and Holding Redlich Examining the importance of indemnity.

IN THIS ISSUE

22 CICA National Conference and Exhibition Taking a look at the CICA Conference and Exhibition.

CICA wins Safety Award CICA wins award for articulated crane course.

22 76 68

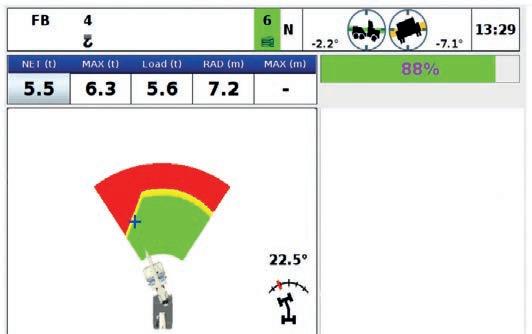

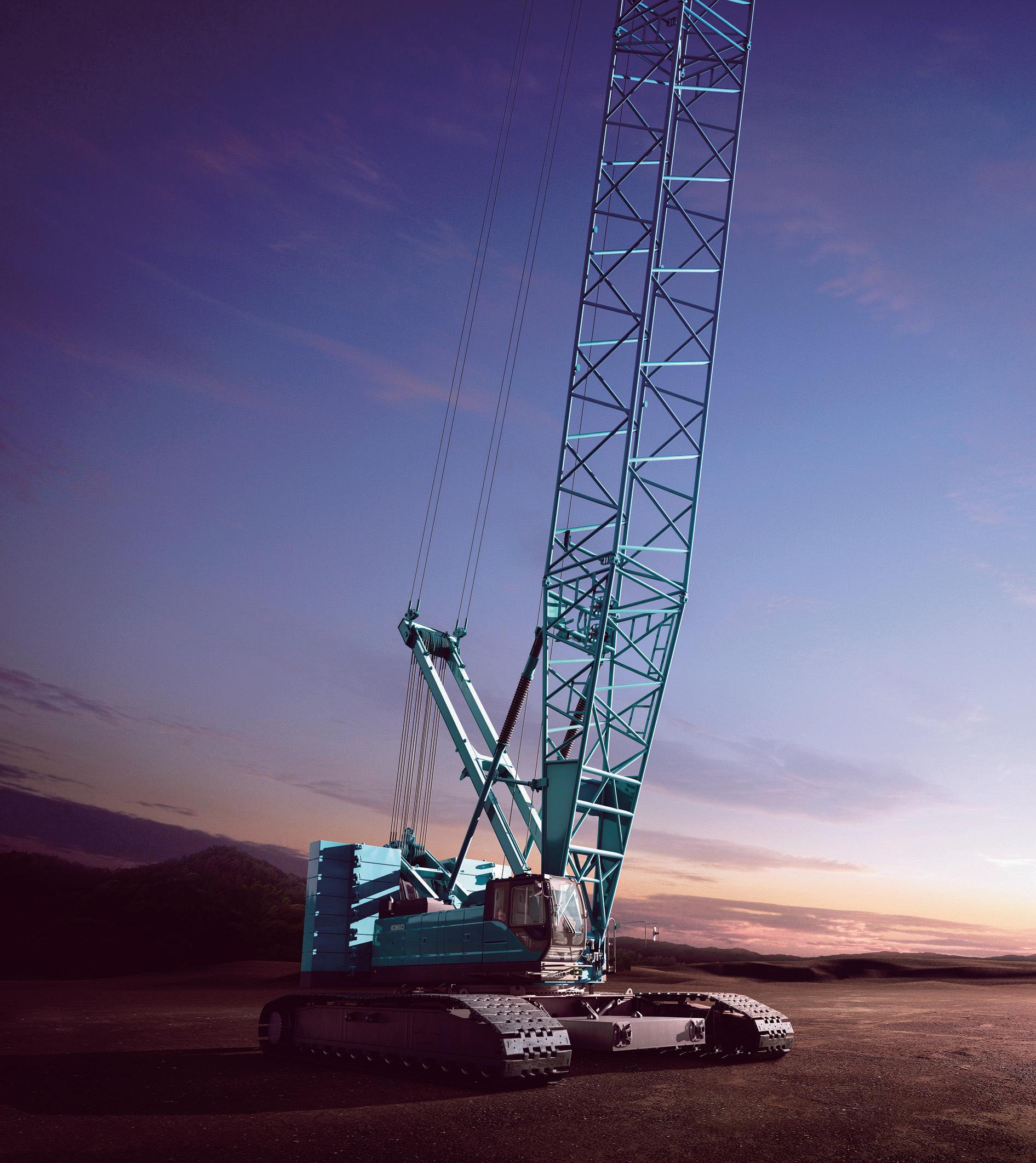

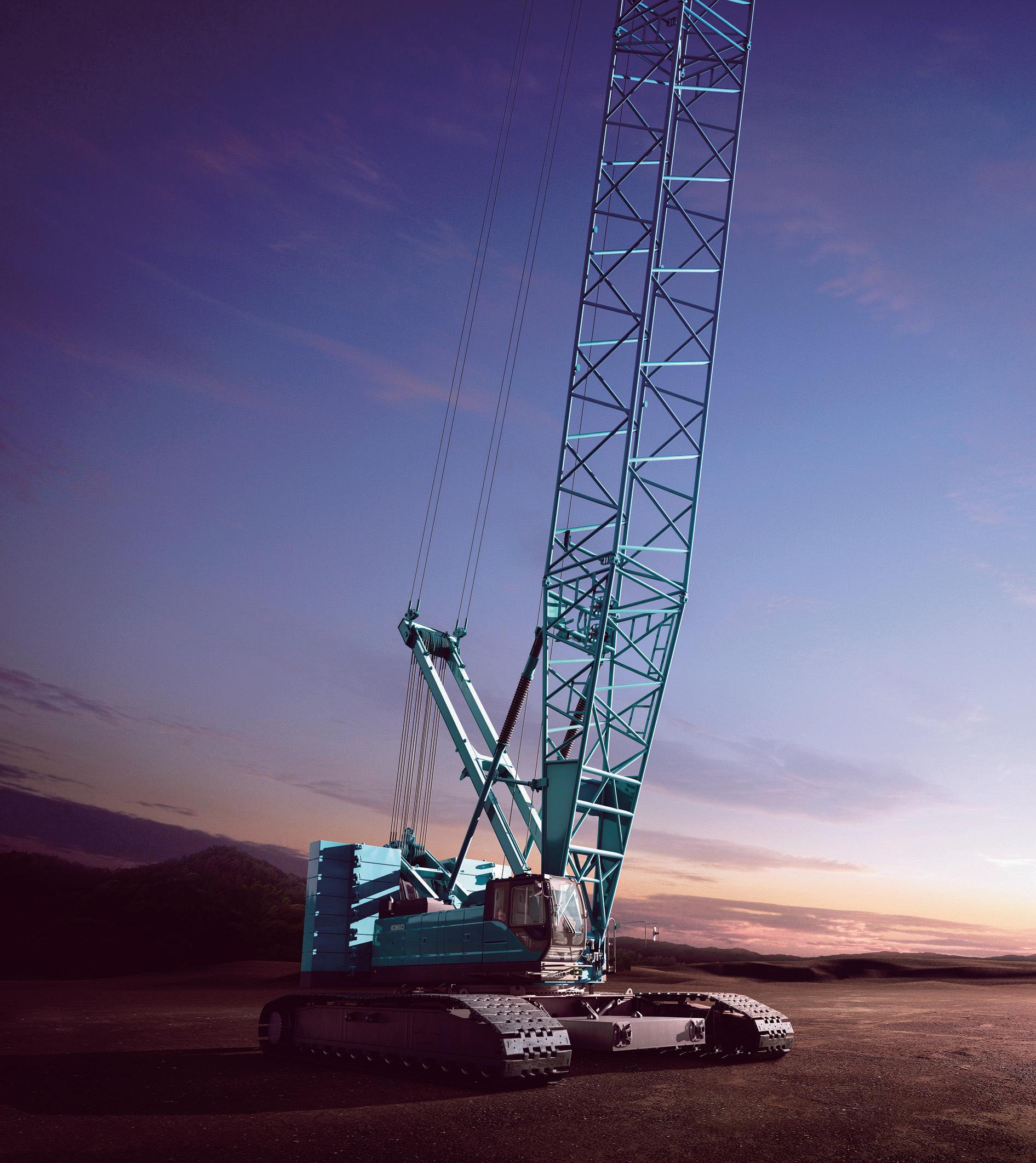

134 Tadano

Tadano launches hybrid initiative.

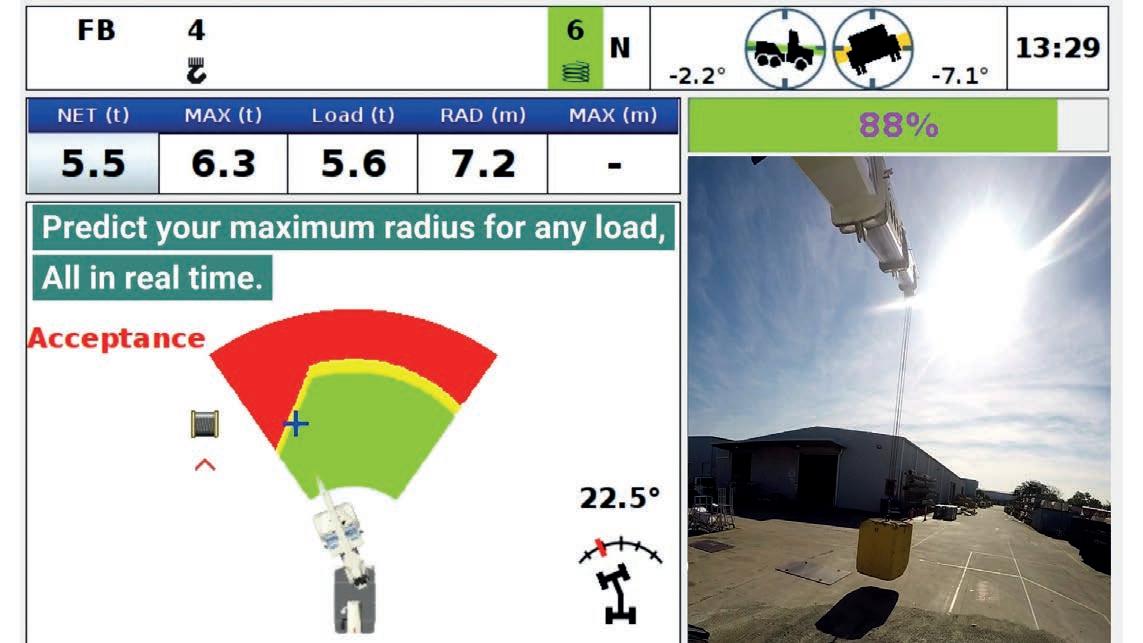

136 UAA and Kinetic Consulting

How Kinetic and UAA streamline insurance claims.

139 Finlease

The Winds of Change are blowing through the industry.

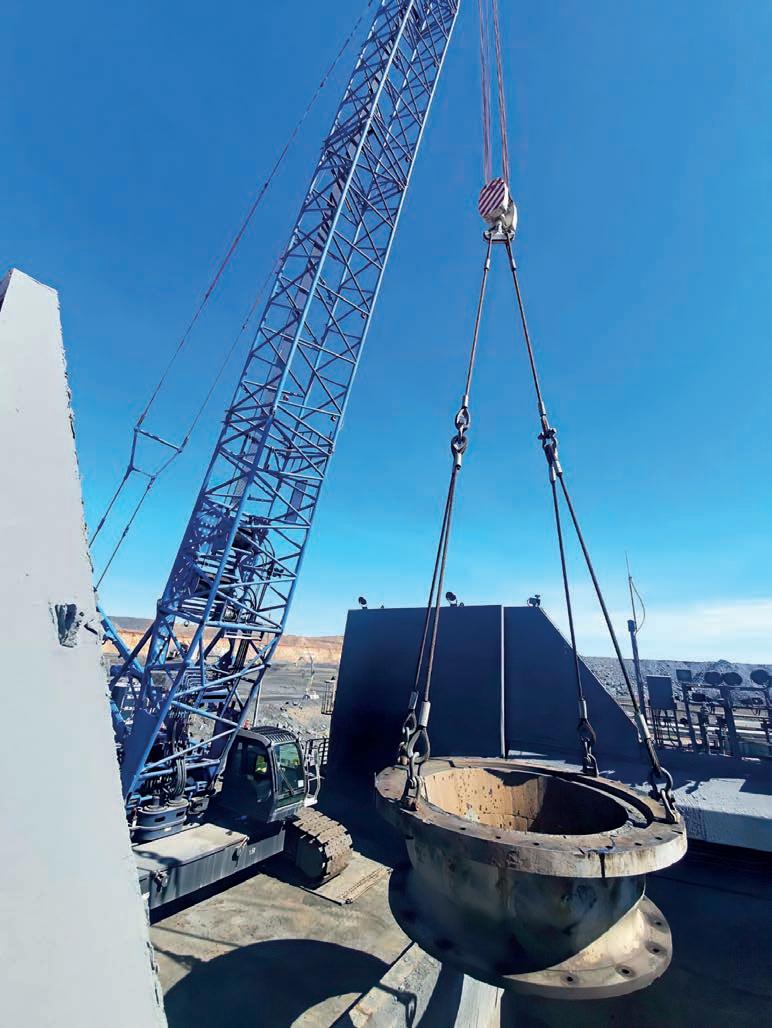

166 Lif t of the Month

Melrose Cranes and Rigging deliver the goods on Sydney Gateway project.

4 / CAL January-February 2023 www.cranesandlifting.com.au IN THIS ISSUE 116 90 Franna Safety Radar officially launched during CICA Conference. 94 LEEA LEEA prepares for a massive 2023. 97 Universal Cranes Universal Cranes reviews 2022. 100 Gleasons Second Zoomlion for Saunders International. 105 Asset Finance Low cost financing Australia wide. 108 TRT Australia and TIDD CICA National Conference and Exhibition big success for TRT and TIDD. 112 Pace Cranes Pace Cranes happy with latest developments. 116 Comansa New product developments from Comamsa. 118 Almac Pacific New products released by Almac Pacific. 112 vWorks Westoz Cranes streamline business with vWorks. 124 Marr Contracting Marr Contracting moves to renewable diesel. 126 Dynamic Rigging Axel Johnson acquires Dynamic Rigging 128 Pilequip New product releases from Pilequip. 131 Cranes and Lif ting 2023 SHOWCASE

118 84

FROM THE EDITORIAL TEAM

WELCOME TO THE JANUARY/ FEBRUARY 2023 SHOWCASE EDITION OF CRANESAND LIFTINGMAGAZINE.

THE TEAM AT CRANES AND LIFTING IS delighted with the response from the crane hire sector, which has taken the trouble to list the premier cranes in their fleets. This year, we received close to 200 entries, including a number of new listings from New Zealand.

In this issue we take a comprehensive look at The Crane Industry Council of Australia’s (CICA) National Conference and Exhibition.

Cranes and Lifting magazine is the sponsor of the CICA Lift of the Year awards and we were delighted to see the number and the high quality of entries this year. We congratulate the winners and plan to feature all lifts in coming issues of the magazine. Start planning your entries for the 2023 Lift of the Year.

I recently read an interesting report from Infrastructure Australia. Entitled the Infrastructure Market Capacity, the report finds improving risk management and proactively sequencing the major infrastructure pipeline will be key to managing the impacts of an overheated construction market, escalating input costs, labour shortages and productivity challenges.

The 2022 edition shows that risks to on-time and on-budget project delivery have increased in the last 12 months, with demand for major public infrastructure projects climbing by $15 billion in a year.

Key findings include:

• Th e five-year pipeline of major public infrastructure projects is valued at $237 billion - an increase of $15 billion in the last 12 months and equal to 6.7 per cent growth.

• Transport accounts for 63 per cent of spend. Investment is concentrated in New South Wales, Victoria and Queensland (84 per cent of spend).

• Th e demand for materials for use in road construction projects is expected to grow to a peak of $7.6 billion in 2023−24.

• I ndustry reports delays of up to 45 weeks in delivery of large diameter concrete pipe.

• L abour scarcity is the single biggest issue faced by construction companies.

• Th e cost of construction materials has risen by an average 24 per cent in the last 12 months.

• A s of October 2022, public infrastructure projects, including small capital projects, face a shortage of 214,000 skilled workers.

• I n 2023, labour demand is projected to increase 42,000 to a peak of 442,000. This is more than double the projected available supply.

Having read the report, it is clear our industry is in for another challenging and busy year. The Cranes and Lifting team wishes everyone the very best for 2023 and we look forward to featuring the brilliant work you do in the coming issues.

Published by:

Simon Gould Editor, Cranes and Lifting

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

CEO

John Murphy

E: john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy

E: christine.clancy@primecreative.com.au

Group Managing Editor Andrew Hobbs

E: andrew.hobbs@primecreative.com.au

Editor Simon Gould

E: simon.gould@primecreative.com.au

Journalist

Joshua Farrell

E: Joshua.farrell@primecreative.com.au

T: 0420 298 087

Business Development Manager

Emily Schlegel

E: emily.schlegel@primecreative.com.au

T: 0466 317 555

Client Success Manager Glenn Delaney

E: glenn.delaney@primecreative.com.au

Art Director Bea Barthelson

Advertisement Designer Lee Mawdsley

Imaging Assistant Paul Breen

Subscriptions Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

6 / CAL January-February 2023 www.cranesandlifting.com.au

Borger

Borger Cranes maintain a modern fleet of cranes and equipment and our fleet boasts two of the largest all terrain cranes on the east cost, the Liebherr 750 tonne and Liebherr 650 tonne all terrain.

With every job, our experienced and industry trained team delivers high quality performance and nothing but excellence. Borger Cranes getting the job done for you.

Wales and Queensland. SYDNEY - HEAD OFFICE 40 Kilto Crescent, Glendenning NSW 2761 P: 02 9832 1044 NEWCASTLE 209 Old Maitland Road Hexham 2322 P: 02 4961 3002

COAST 8 Ainslie Close, Somersby NSW 2250 P: 02 4346 4262 HUNTER VALLEY 10 Rosedale Close McDougalls Hill NSW 2330 P: 02 5504 5525 BRISBANE 119 Brownlee Street, Pinkenba QLD 4008 P: 07 3333 5513 SUNSHINE COAST 65 Enterprise Drive Kunda Parl QLD 4556 P: 07 5445 4900 GOLD COAST 52 City Link Drive Carrara QLD 4211 P: 5588 5158 BORGERCRANES .COM

Cranes is a family owned and operated crane hire and rigging business servicing New South

CENTRAL

MODULIFT TESTS GIANT 2000T SPREADER BEAM AT 30 METRES

Modulift has recently finished testing of another impressive MOD 1100 / 2000t modular spreader beam. Currently the largest supplied standard beam in the Modulift range, with a lifting capacity of 2000 tonnes, the MOD 1100 has been ordered by a Belgian client for Offshore Monopile installations.

The 30 metre long beam comes complete with DNV GL type approval as standard. Fitted with optional extras including upper shackle supports to protect the synthetic top slings when resting and two 45t tugger points on each end. The Pewag PLDW 45t tugger points were supplied by Prolift UK.

The test was carried out in Modulift’s recently upgraded 2200t x 30 metre compression test rig and was third party witnessed by the client and DNV GL. The two drop links were tested in Modulift’s newly built 1500t tensile test rig.

The whole operation was successfully executed over three days with individual tests carried out at 19 metre, 20 metre and 30 metre spans.

For more information, visit www.modulift.com

INDUSTRY NEWS 8 / CAL January-February 2023 www.cranesandlifting.com.au

“The whole operation was successfully executed over three days with individual tests carried out at 19 metre, 20 metre and 30 metre spans.”

ABOVE: The Modulift MOD 1100 / 2000t Spreader Beam

RIGHT: The MOD 1100 / 2000t Spreader Beam in the test rig

The maximum on eight axles

The LTM 1650-8.1

A lifting capacity of 700 tonnes with either a 54 or 80 metre telescopic boom. Global mobility and convenience thanks to Hillstart Aid, ECOmode, ECOdrive, VarioBase and hydraulic VarioBallast. Nothing more is possible on eight axles. www.liebherr.com

Mobile and crawler cranes

Mobile and crawler cranes

MANITOU LAUNCHES ITS HYDROGEN STRATEGY

Group has set off on an ambitious course, in line with the commitments of its low-carbon trajectory.

Following on from the recent electrification of its all-terrain platform and telehandler ranges, the group is also looking to hydrogen as a medium-term alternative for its users.

Manitou Group wants to see its electric and hydrogen ranges used side by side - depending on each user’s applications - aiming to market 43 per cent low-emissions products in 2030.

Manitou Group has new facilities for making its hydrogen development plan a success. By kitting its test centre out with a green hydrogen station, the group now has the means for testing its brand new prototype telehandler.

The first step of this plan involves guaranteeing range and reliability in real-life conditions, while testing the durability of components. The group

based this first prototype on an existing model from its range of construction machines, able to lift loads up to 14m.

This machine will be tested and sent out to construction sites by the end of 2023 with a view to collecting valuable feedback from users to improve on this prototype

Two types of hydrogen technology are currently being evaluated by the market, namely the combustion engine and the fuel cell.

The group’s first prototype is built around a fuel cell, but Manitou will choose the hydrogen solutions that best meet the needs of its customers.

Manitou managing director Michel Denis explains further.

“We are studying all the hydrogenrelated technologies based on what users need,” he says.

“This prototype is only the first step. A second rotating telehandler prototype will be developed in the coming months.

“There are many benefits of green hydrogen with production possible using wind power that has no greenhouse gas emissions at all. This fits in perfectly with our low-carbon trajectory,” he said.

With this first prototype, the group is showcasing its ability to innovate in order to measure the autonomy of this new

energy while offering its customers the hydrogen solution that best meets their needs, but without compromising on performance.

Almost 50 engineers and technicians are dedicated to this approach, which was launched in 2021.

To come up with an innovative solution that can be fully industrialised, the group hopes to rely on the support of the public authorities to develop an emerging ecosystem.

Julien Waechter, vice president of research and development for the Manitou Group, discusses the need to move to hydrogen.

“The green hydrogen sector is gradually becoming more established with the entry onto this market of a number of players,” he says.

“All of the aid mechanisms proposed by the different governments will encourage the transition to hydrogen and will speed up the development of the distribution network and ultimately the reduction in the usage costs of our machines using this energy.”

With these new facilities, Manitou Group hopes to offer its customers new innovative prospects, with a 100 per cent hydrogen-powered telehandler available on the market by 2026.

10 / CAL January-February 2023 www.cranesandlifting.com.au

69m Boom!*

MAXbase Equipped

LEVEL ACCESS THE BENCMARK 150t HAS MORE REACH

The New GMK5150XL is the latest sibling of the GMK5150L-1, with longest boom (69m) and most versatile road weights in class

• Reach further with 69m boom and 30m hydraulic luffing fly

• 50t GVM with outriggers in situ for reduced cost legal travel in all Australian states and territories

• 10.2t counterweight in situ at 12t per axle

• Increased safety and flexibility with MAXbase variable outrigger positioning

• Faster, intuitive set-up with CCS (Crane Control System)

• Grove Connect Telematics

• Capacity: 150t

• Main boom: 68.7m pinned*

• Maximum Jib: 30.2m (40O hyd luff)

• Maximum tip height: 99m

New GMK5150XL

New GMK5150XL

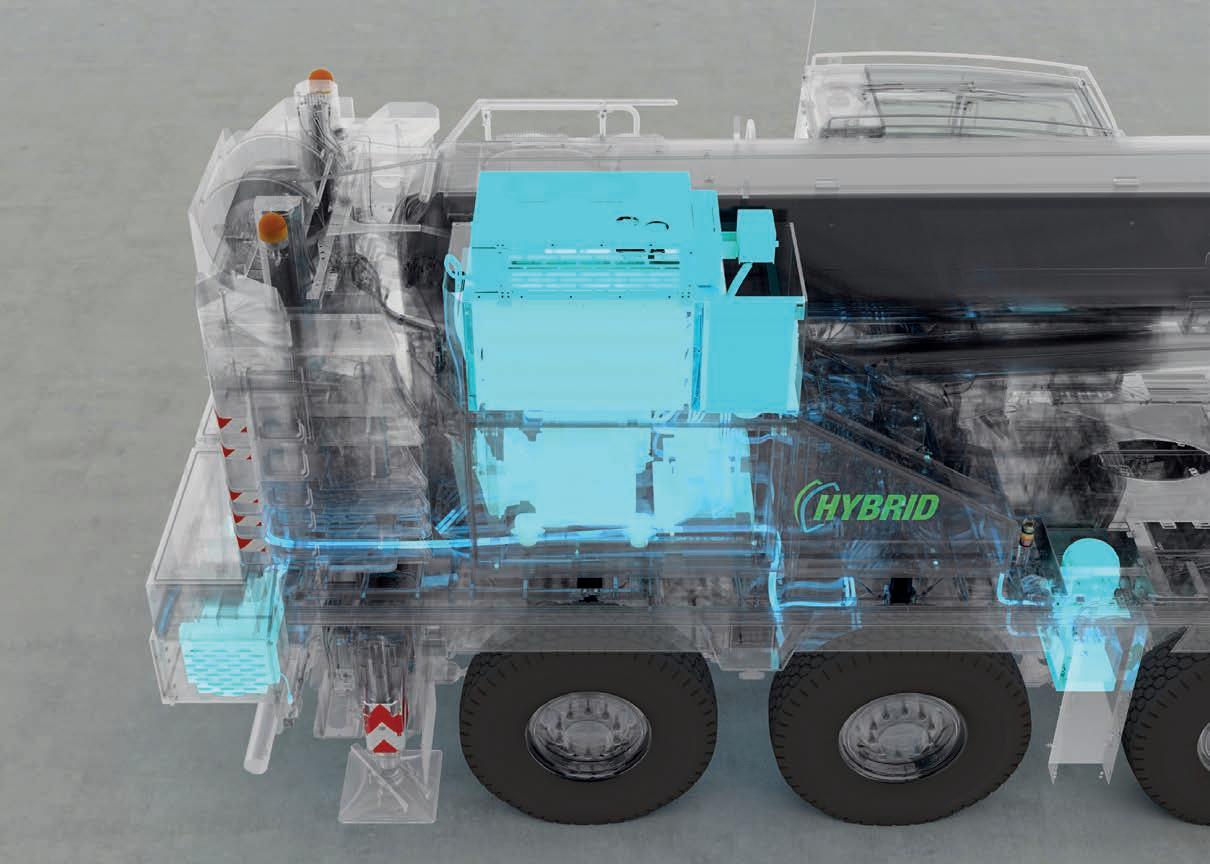

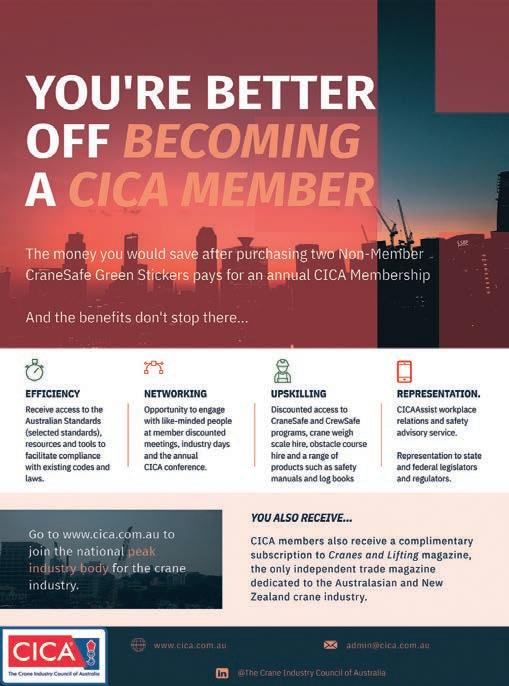

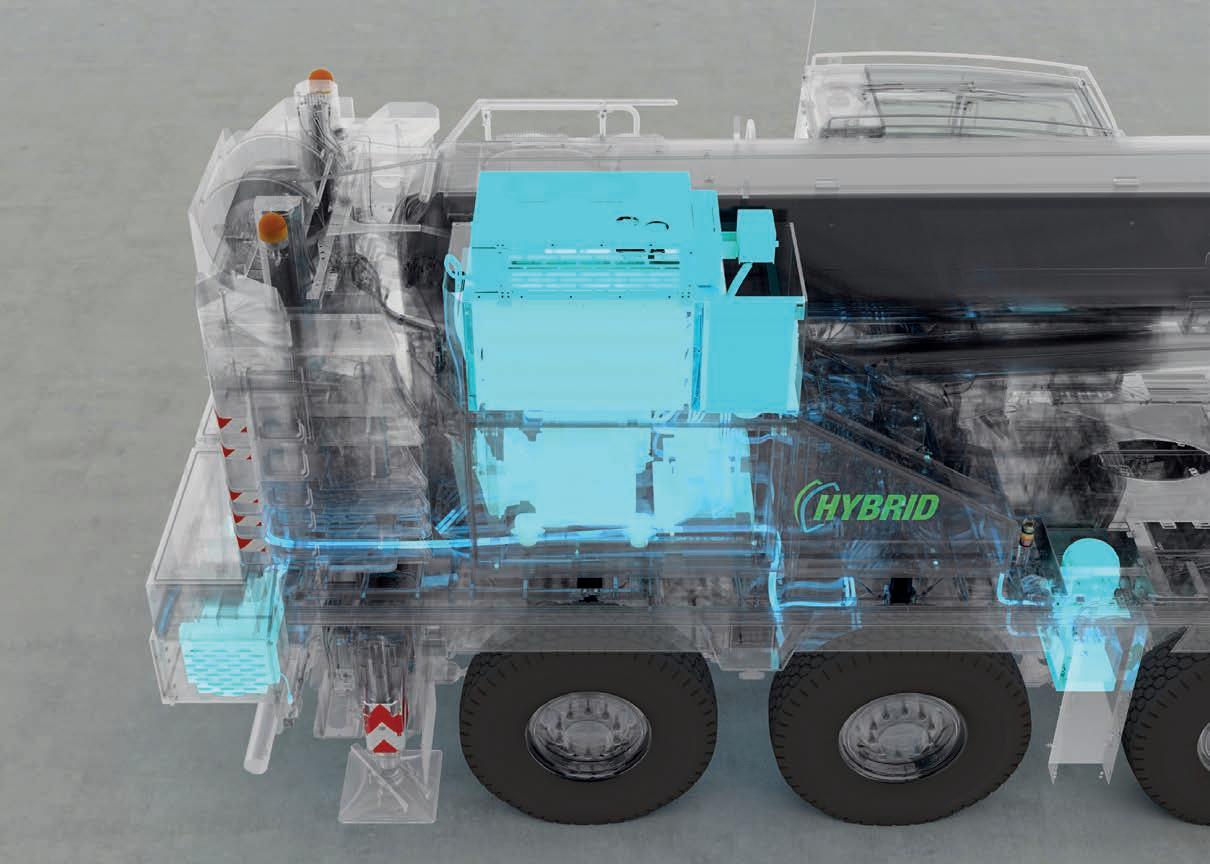

GROVE LAUNCHES HYBRID INITIATIVE

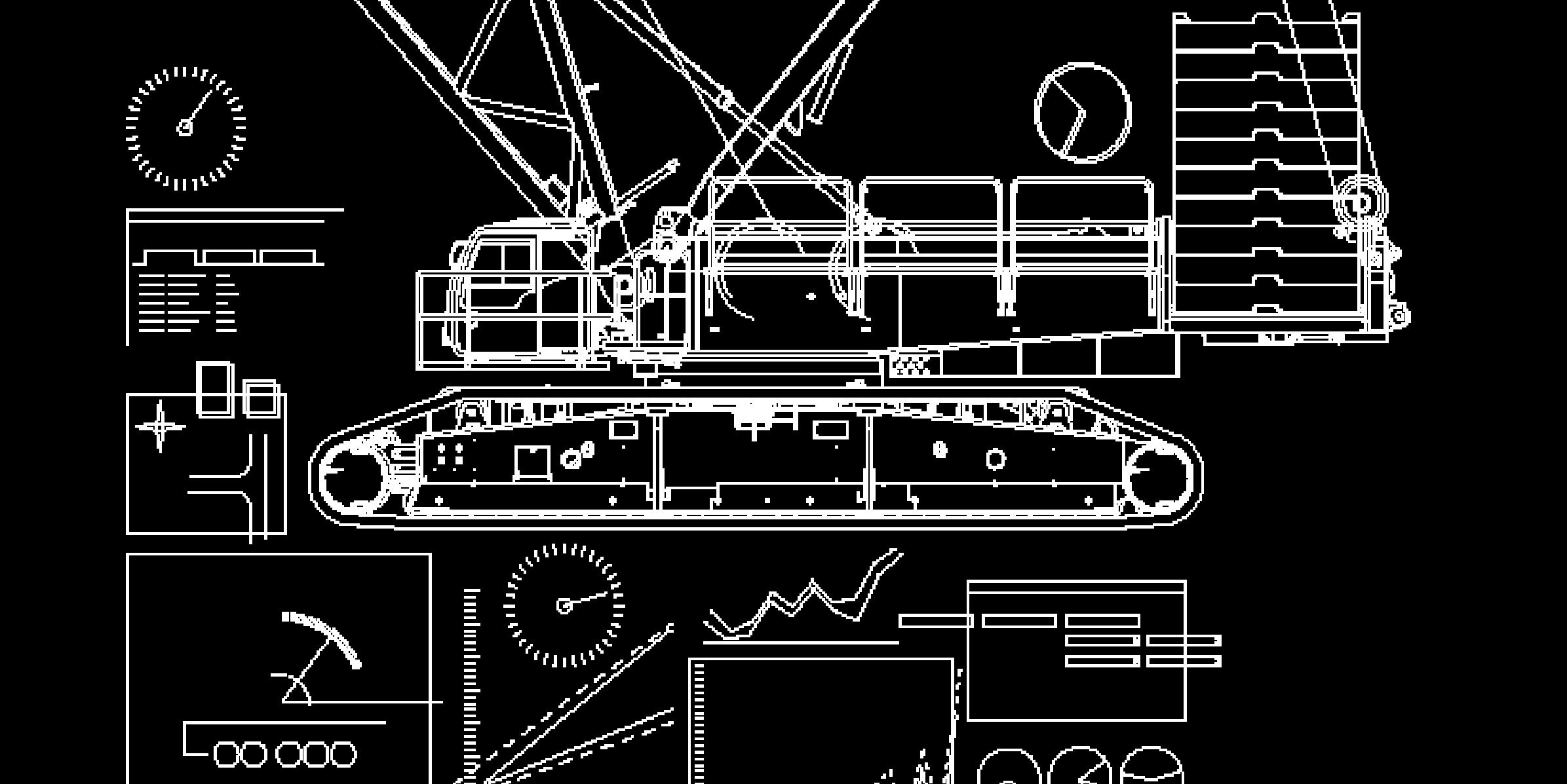

JOHN BENTON, DIRECTOR OF ENGINEERING, is responsible for a team of specialists working in the Future Projects department of mobile cranes developer Grove. He spoke exclusively to Cranes and Lifting about the initiative and Grove’s aims and expectations around hybrid technologies.

Benton has been with Manitowoc for 16 years. He joined as a structural analyst and for the last decade he has been working as a crane architect, providing systems engineering for new products. Most of the projects have been both Grove rough terrain and truck mounted cranes. But over the years he’s been involved in joint projects leading the development of Grove’s “GMK” line-up of all-terrain cranes. Benton made the move to head up the Future Projects department in Germany, 12 months ago.

Benton discusses the background of the hybrid initiative and the aims and objectives of the project.

“A few years ago, the team working in our Future Projects department was working on a number of concepts examining what the future mobile crane could look like. They went through an analysis of examining what was technically possible in terms of power requirements, weight requirements, and overall system architectures,”he says.

“We presented a paper on these concepts several years ago, basically telling the industry, ‘we see that this is coming in the future, and we think it could look like this.’ The COVID pandemic disrupted the development in terms of what we could accomplish. Out of the multiple concepts that were possible, we decided to go for what we thought was the most advanced solution in order to learn as much as

possible as quickly as possible, in order to be a leader in terms of the efficiency of the final product in the ecosystem of these hybrid concepts.”

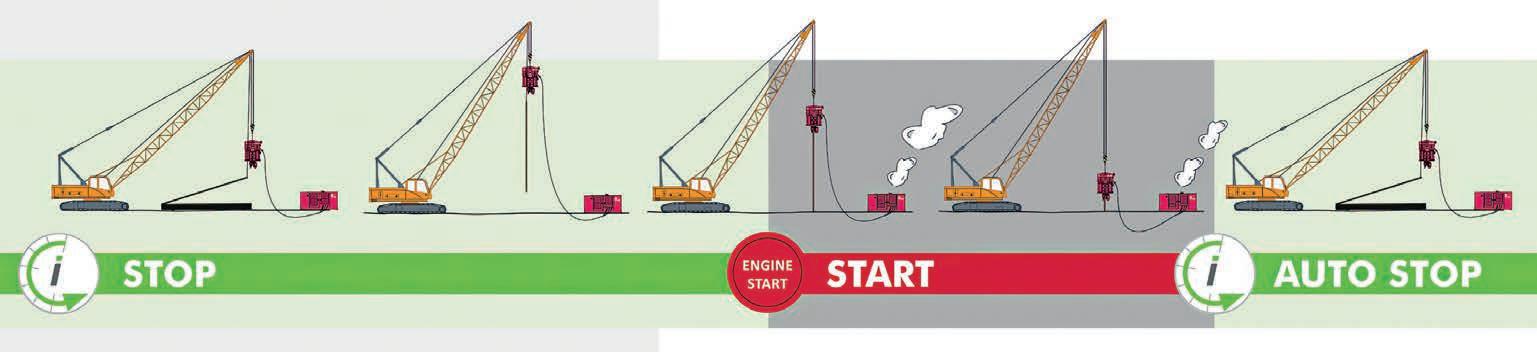

As a result, Grove decided to put in a single motor and a generator that can generate the electricity required, thus providing the possibility of operating the crane without running the diesel engine.

“We felt the technology was there to go farther than that. What you saw at bauma was our engineers showcasing their first concept in order to prove what’s possible to go farther in the electrification of a mobile crane than simply providing a single motor,” said Benton.

“What that opens up for us is the possibility to use technology that we’ve had on tower cranes for many, many years, with direct electric power to the hoist and to the slew drives.

“Both of those rotary motions are something that we think is naturally headed toward direct electrification and the biggest question was about the integration of that and what else it might affect, and how we could optimise the design to stay within the weight limits of a mobile product.”

Benton confirms which Grove model the Future Projects team worked with, and what they have managed to electrify and discusses the performance of the hybrid.

“Given the timing of the project, we had just released the Grove GMK 4100L-2 to the market and so we decided that we would start with that latest generation all terrain crane, already the highest performance four axle product that we have, and build on top of that.

“The architecture for that model is a single engine design, and so we wanted to

UP FRONT / GROVE HYBRID ALL TERRAIN 12 / CAL January-February 2023 www.cranesandlifting.com.au

A major highlight from the Manitowoc stand at the bauma 2022 trade show was the launch of the Grove hybrid initiative on its all-terrain crane.

January-February 2023 CAL / 13 www.cranesandlifting.com.au

bauma saw Grove engineers showcasing their first concept in order to prove what’s possible to go farther in the electrification of a mobile crane than simply providing a single motor.

work from that as a starting point because it is already a very well-optimised design.

“We searched to see what kind of mobile hoist technologies were available. For this machine, we decided that the 19mm hoist, which was already on the crane, had excellent weight performance ratio and so we simply integrated a high performance motor to the hoist.

“That product has a long history of us knowing about its reliability and its performance. So, there’s been optimisation done about how the control works in order to make this hoist responsive, and

we retained the braking system that was already on the hydraulic version of the hoist,” he said.

“In the case of the slew drives, we found that it was possible to integrate motors into those drives as well, and we were able to achieve in both cases the same or better performance to what we had in the hydraulic version. The line pull of the hoist is the same as it was before, and the speed is the same, too.

“With slew drives, we actually have a little wider range of speed available to us. But one of the really exciting things about

the slew drives is that it also gives us really fine control over small movements of that system. We’re exploring this to really understand what that can bring to the user in terms of actual use with moving loads at a long radius and precise movements of the load in those situations.

The hybrid includes a Euromot 5 diesel engine and features a battery system which manages the hoist and slew plus powering the hydraulics for the luff and telescoping operations. The battery is also charged by the diesel engine and regenerates energy from the rotary functions.

UP FRONT / GROVE HYBRID ALL TERRAIN 14 / CAL January-February 2023 www.cranesandlifting.com.au

“Finally, we also integrated a charging system so that you can plug the crane into a 32 amp service and you can charge at that point in a totally ‘emissions free way,”

The hybrid includes a Euromot 5 diesel engine and features a battery system that’s managing the hoist and slew plus powering the hydraulics for the luff and telescoping operations

“For those that are familiar with our single engine concept today in the GMK 4100L-2, we’ve removed the mechanical drive that was in the centre of the bearing and was providing mechanical power to the hydraulic system in the superstructure. As an alternative, we’ve installed a generator in its place in the carrier, and we have two different power sources for the superstructure. One source is the diesel engine which can drive the generator and can directly drive electricity into the superstructure. The other possibility is that the generator can charge the battery and then the battery can drive the superstructure.

“We also integrated a charging system so you can plug the crane into a 32 amp service and you can charge at that point in a totally ‘emissions free way’,” he said.

Benton elaborates on where the Future Projects group is headed with the concept and what the market can expect to see from Grove over the next five years of development.

“I think you will see a real focus on improving the efficiency of our systems. I think we’ll see that industry-wide, but at Manitowoc, we have multiple projects that we’re working on in this space.

“We can’t yet discuss some of those, but we pride ourselves in listening to our customers and responding very quickly to their needs. So bauma was a really exciting time for us going into the show.

“There was some uncertainty about whether we would find the first customers for this solution, but the response has been overwhelmingly positive. And now we’re further discussing with those customers to tailor our solution to exactly what they need. We are really excited to learn that

customers see this the way that we do, which is that they want the flexibility of powering the crane from electric sources, but they also want to achieve better efficiency and better performance while they’re operating.

“It seems Australia, with all the mineral resources and the focus on the environment is a perfect location for our Grove solutions,” he said.

Benton goes on to discuss how quickly Grove will be able to commercialise and manufacture the hybrid.

“We don’t have an exact timeline for that. That said, we’re in the test phase now with our concept and we’re architecting the solutions based on customers’ feedback. What I can say is that it’s a very fast-moving environment in this entire space of electrification, and so you should expect to see things advancing rapidly from Manitowoc in this area,” he said.

January-February 2023 CAL / 15 www.cranesandlifting.com.au

John Benton, Director of Engineering, Future Projects delivering a paper at the CICA Conference and Exhibition.

NEW PRESIDENT LOOKS AHEAD

IT IS INDEED A PRIVILEGE TO HAVE BEEN elected as The Crane Industry Council of Australia’s Board President. CICA has a long and proud history of service to members, and relationships with stakeholders, government and the community, so the prospect of being Board President is an honour and something I am very much looking forward to.

I would like to take this opportunity to introduce myself and share my thoughts with you about what I see are the opportunities and challenges for the crane industry in 2023.

First, I would like to acknowledge the substantial achievements of my predecessor Tom Smith. Tom successfully led CICA through the extremely difficult pandemic years, whcih was a very challenging season for our industry.

Under Tom and Brandon’s leadership and vision, CICA has broadened its reach and has made significant inroads in the areas of road access, training and safety.

On behalf of our Association, I thank Tom for all that was achieved under his leadership and for his ongoing dedicated service to CICA for over a decade.

My involvement with CICA started as member of CAWA in 2010 which then transitioned to CICAWA in 2017 under the One Association project.

I have been a member of the CICA board since 2015 and as a Vice-President of the Board in 2020. In Australia, and abroad, I have been closely involved with the crane industry since 2006.

LOOKING AHEAD

Had I written this report 12 months ago there would, no doubt, have been a different set of challenges. The impact of the recently passed Federal Government’s Secure Jobs, Better Pay Act 2022 is yet to be felt.

Interestingly, employees employed in the on-site general building and construction industry are excluded from the multiemployer EA framework, and this includes employees employed in general building and construction and civil construction (subject to a few express carveouts). We plan to provide more information on changes that will impact you in a future issue of the magazine.

Inflation and higher interest rates pose another set of challenges, there are some predictions that 2023 may see a recession, so we will be watching to see how this impacts future developments.

CICA recently employed Kate Galloway, a training specialist who will work closely with some of the State branches in establishing their State traineeship

programs. We welcome Kate to the CICA team and look forward to seeing a greater uptake of crane traineeships.

The work of CICA includes acting as an enabler to the State branches to help facilitate their growth, so initiatives that can alleviate blockages, increase productivity and improve safety are a priority for 2023.

2022 CICA NATIONAL CONFERENCE

The 2022 CICA National Conference was a tremendous success and provided the right balance of interesting and inspiring speakers and workshops, as well as memorable networking events. Thank you

to Sue Ryman-Kiernan and her team from WISE Connections, to the CICA team and of course the conference presenters, sponsors, exhibitors and attendees. The theme was ‘Leading the Way’, an appropriate theme for a post pandemic event. Everyone I have spoken to found the event extremely valuable, and it once again positions CICA as the authority for the crane industry.

Congratulations to the winners of the awards, presented at the gala dinner. These awards represent national recognition of the outstanding lifting, leadership, commitment, and progress in our industry. The calibre of entries was very high and

16 / CAL January-February 2023 www.cranesandlifting.com.au

Ben Pieyre was recently elected as the new Board President of The Crane Industry Council of Australia. In his first President’s report he looks to the opportunities and challenges f acing the industry.

Ben Pieyre

CICA CEO REPORT

“Congratulations to the winners of the awards, presented at the gala dinner. These awards represent national recognition of the outstanding lifting, leadership, commitment, and progress in our industry.”

we appreciate the time and effort taken by everyone who entered. Look out for the Conference images and recap in this issue.

ANNUAL GENERAL MEETING

The CICA AGM was held just prior to the 2022 CICA National Conference and the CICA Board changed slightly. On behalf of the Board, I sincerely thank Bart Sutherland for his years of service to the CICA Board, and welcome Karli Sutherland to the team. The Board members for 2023 are: Tom Smith (immediate past President), Danny Adair, Danny Black, Andrew Esquilant, Marcus Ferrari, David Solomon, Karli Sutherland and myself. As a team, we’re committed to serving the best interests of our members, and with your support, I am confident that our Association and industry are well-positioned to capture the opportunities of the coming years.

CICA’S AWARD WINNING COURSE

Substantial work was undertaken by Brandon Hitch, Pat Cran, Mick Messer and Danny Adair to establish CICA’s OnRoad Articulated Steering Mobile Crane Training Course

CICA received a grant from the Federal Government through a Heavy Vehicle Safety Initiative through the NHVR to develop this program, and you can read more about the course in this issue.

On 1 December 2022, CICA’s On-Road Articulated Steering Mobile Crane Training Course won the award for Outstanding Solution for Members managing WHS Risk in SafeWork NSW’s Work Health and Safety (WHS) Excellence Showcase, which recognises businesses and individuals for excellence in work health and safety. This was a great achievement, so congratulations to everyone involved.

I urge you to look at this course if you have any articulated steering cranes in your fleet.

I sincerely hope you’ve had a great start to 2023 and I look forward to serving you and working with you all.

Ben Pieyre CICA Board President

CICA BOARD

Ben Pieyre – President

Marcus Ferrari – Vice President

Tom Smith – Director

Danny Adair – Director

Danny Black – Director

Andrew Esquilant – Director

David Solomon – Director

Karli Sutherland– Director

CICA OFFICE

Brandon Hitch Chief Executive Officer 03 8320 0444 0428 228 048 ceo@cica.com.au

Paul Arztenhofer Membership Engagement/ Business Development Specialist 04 9093 9274 paul@cica.com.au

Alice Edwards Technical Project Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran CraneSafe and CrewSafe Technical Advisor 0488 004 274 pat@cranesafe.com.au

Damien Hense CICA Road Policy Advisor 03 8320 0460 0488 007 575 damien@cica.com.au

Julie Turner CICA Executive Assistant / Office Manager/Vic Secretariat 03 8320 0411 julie@cica.com.au

Kate Galloway Traineeship Coordinator 0491 047 118 Kate@cica.com.au

Shane Coupe CraneSafe & CrewSafe Administration Officer 03 8320 0455 shane@cica.com.au

Michelle Verkerk Marketing Communications Officer 0404 938 714 michelle@cica.com.au

Justina Blackman Member Events and Engagement 0403 717 626

justina@cica.com.au

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170 Phone: 03 9501 0078

Fax: 03 9501 0083

Email: admin@cica.com.au

Website: www.cica.com.au

For information, please visit our website or call the CICA office.

January-February 2023 CAL / 17 www.cranesandlifting.com.au

NEW BOARD MEMBER AND NEW DIVERSIFIED FOCUS FOR CICA

Karli Sutherland was recently appointed to The Crane Industry Council of Australia (CICA). Karli and husband Jarrod have been operating Quicklift Crane and Access Hire for 24 years. Karli explains more about the business, her reasons for joining the board and her expectations for the recently formed Diversity Network Committee.

“I’VE WORKED IN OUR BUSINESS ALONGSIDE Jarrod for the past 24 years. I work across the management/administration of our business, OHS & HR in particular with a keen focus on our staff culture

“We have approximately 35 staff - a combination of full-time and casuals

“We have six staff in the office and the remainder are involved in the operational side of the business and are out on site with a combination of operators, doggers and riggers.

“We are a general crane hire company, working across a number of industry sectors including construction, particularly warehouses and factories throughout the Goulburn Valley region in Victoria,” said Karli.

Karli goes on to discuss how she became involved in CICA and her ideas for the Diversity Network Committee.

“During the COVID pandemic I contacted CICA CEO, Brandon Hitch, wanting to initiate some sort of forum that would bring together different people within our industry.

“The idea was to attract people that were not necessarily working on the operational side of businesses, but more on the business side, including the administration of a crane business.

“We are a relatively small industry, but I feel that all too often, crane businesses are trying to reinvent the wheel when there’s no need.

“I felt that a forum involving networking outside of the National Conference would bring people together who could share information and experiences, from different capacities

and from different aspects of industry.

“These were my initial thoughts, and Brandon suggested that we had put together a group of people to initiate the concept. It has since evolved into what’s is now known as the Diversity Network Committee,” said Karli.

The Diversity Network Committee was formed 12 months ago, with Karli as the Chair.

Still in its infancy, the committee is looking at different initiatives based on information gathered from a recent survey of CICA members.

“More recently, I had a conversation with Paul Arztenhofer, Membership and Business Development for CICA and he asked if I might be interested in being nominated for the CICA board.

“My motivations for representing our industry on the board are not so much

around the technical and operational side of the industry, as these issues are well represented by board members.

“I hope I can bring to the board a crane owners’ perspective and in doing so encourage other crane owners to share their experiences on operating and managing a crane business.

“I would like to share with people the experiences and the lessons Jarrod and I have learned in the 24 years we have been involved in the crane industry. In turn I hope to learn from other ‘crane people’ operating and running their own crane businesses,” said Karli.

“I find it very interesting discussing with other people how they operate their businesses, because we can all improve no matter how great we are at our job or how fabulous our business is.

18 / CAL January-February 2023 www.cranesandlifting.com.au

NEW BOARD MEMBERS

Sophie, Karli and Justina at the CICA Conference and Exhibtion

There’s always room for improvement,” she said.

All crane hire businesses face various challenges, but essentially the challenges are similar challenges. And it’s not just in the crane sector, it’s inherent in every business says Karli.

She goes on to discuss the aims and objectives for the Diversity Networking Committee and how she sees the various committee members working together.

“The aims and objectives of the committee continue to evolve, and we are going to be tackling issues which will hopefully help to improve our industry. The committee is not just about networking and sharing of information, we will be examining our businesses and looking at ways to improve efficiencies.

“The crane industry is not a very diverse industry, and it is obviously male dominated. We will examine ways to make the industry more attractive to these underrepresented groups and in particular to women. We all face the challenge of managing an ageing work force and we want to find ways of making the industry more attractive to the younger generations. The average age of crane operators is 44 years –

which is higher than other physical jobs. The age bracket of 45-54 has the highest share of almost 28 per cent,” said Karli.

“In our business, we have guys with upwards of 20 years experience operating cranes and there is no substitute for that experience. But the crane manufacturers are continually evolving the technology in cranes and the computer systems are becoming increasingly advanced.

“We are finding that some of our operators struggle with this new technology and so we are ‘pairing’ our experienced operators with younger operators as doggers/riggers to assist if required. This younger generation has the computer skills, they come out of school having had computers in their hands from a very young age.

“I use computers every day, but I don’t have anywhere near the knowledge these kids have. I think this is something we should be looking at as an industry, we should look at mentors, champions of our industry that have huge amounts of knowledge and pair them with the younger generation to pass on the knowledge they have accrued over the years.

“So, I see the committee working on a number of issues and initiatives to address the fact that jobs in our industry are not attractive to these minority groups. We have a major skills shortage, which is escalating and currently we’re all trying to pull from the same ‘work force pool’ all of the time,” said Karli.

The CICA National Conference and Exhibition was the ideal opportunity for Diversity Networking Committee members to meet in person.

“We are obviously made up of a group of people from all over Australia and the conference saw the largest representation of committee members come face to face which was great. We were fortunate to have Sarah Toase CEO for CANZ join our meeting. “Sarah shared with us how the New Zealand crane sector is working to attract people into their industry. They too are experiencing a skills shortage. Sarah explained to our committee the campaign they are running with great success to encourage minority groups into the NZ Crane Industry. It was great to catch up face to face especially after years of COVID enforced Zoom meetings,” said Karli.

January-February 2023 CAL / 19 www.cranesandlifting.com.au

Diversified Networking Committee L to R: Launa Williams - Williams Cranes, Chantelle Lindores - Lindores Mobile Cranes, Justina Blackman - CICA, Sophie Grimshaw - Mammoet Australia, Ginta Val - Terex , Paige Greenhouse - Terex, Sandra Makinson - Coffs City Cranes, Karli Sutherland - Quicklift Crane & Access Hire, Sarah Toase - CEO - Canz

STOP IN THE NAME OF THAT INDEMNITY

INDEMNITIES ALLOW PARTIES TO identify and allocate risk under a contract. This can either be between themselves or to a third-party. They do this by requiring one party (the indemnifier) to cover the loss or damage suffered by the other party (the beneficiary) under an agreement.

Importantly, indemnities are capable of covering loss or damage that would ordinarily be deemed too remote under common law. For example, if:

1. B ob had a contract with ACME to build a tower which contained a milestone bonus if the work was complete before Christmas.

2. B ob entered into a separate contract with Wendy to hire a crane to construct the tower.

3. Wendy failed to deliver the crane on time, meaning Bob was unable to complete the tower before Christmas and misses out on his milestone bonus. This type of loss could be deemed too remote for Bob to recover against Wendy.1 However, Bob is able to mitigate this risk by including an indemnity clause in the contract requiring Wendy to compensate (indemnify) Bob for the loss of the milestone bonus if she fails to deliver the crane on time.

Wendy may not even realise she could be liable for this type of loss at the time she enters into the contract unless she has read the fine print in careful detail!

Things to consider when drafting indemnity clauses: How an indemnity operates is a matter of construction. Importantly, indemnities will be read against the interests of the person who receives the benefit of the indemnity (contra proferentem). Therefore if you are in the habit of putting broad indemnities in a contract, make sure you carefully consider how the work with the balance of the contract terms.

The below is a non-exhaustive list of some of the other things you should keep in mind when reviewing/drafting an indemnity:

1. W hat are the risks/losses that are being indemnified? Is the indemnity intended to be general or specific (e.g. all loss or liability arising under the contract or only certain losses arising from a specific breach)?

2. A re there any limitation of liability clauses under the contract and how do these operate in relation to the indemnity (e.g. if you intend to limit the type or amount of loss recoverable under the contract, do you intend for this to extend to the indemnity)?

3. D oes the party providing the indemnity have the capacity to deliver it if called upon? There is little benefit in seeking an indemnity from a shell company for all loss and damage that could arise in relation to multi-billion-dollar

construction contract. It is also important to consider if the party providing the indemnity has the authority to do so (e.g. government agencies, entities incorporated under statute or trustees may not have authority to provide the indemnity sought).

4. I s the indemnity intended to protect a party from losses caused by its own breaches or negligence (the general rule is an indemnity will not cover a party’s own negligence unless there is specific drafting to that effect)?

5. W hat is the duration of the indemnity – is it intended to remain after the conclusion of the contract?

20 / CAL January-February 2023 www.cranesandlifting.com.au

The Holding Redlich Construction, Infrastructure and Projects Group works closely with clients to effectively manage contractual and commercial risk and to avoid, minimise and resolve disputes. In this article, Holding Redlich examines issues relating to indemnity clauses.

HOLDING REDLICH

Indemnities allow parties to identify and allocate risk under a contract

6. D oes/should the indemnity contain any rights of subrogation, or can the indemnified party settle the claim(s) without consulting the indemnifier (e.g. in an insurance contract, insurers will often be able to “step into the shoes” of the indemnified party for the purpose of any litigation)?

The above long shopping list of questions shows that there are numerous factors to consider when drafting an effective indemnity clause, including the context of the contract.

It is generally not sufficient to “copy and paste” an indemnity clause from another contract as the

interpretation of an indemnity clause and the way in which it is meant to operate usually requires consideration of the contract as a whole.

Obtaining legal advice is a practical way to ensure that the indemnity clauses in your contract are properly drafted to protect your interests.

In part 2 of this article, we will

look at two different indemnities often provided in crane hire agreements and unpick what they really mean.

1 The above is only provided as an example and there are several circumstances where this could be recoverable, such as if the loss of the milestone bonus was reasonably in contemplation of the parties at the time of entering into the Contract.

January-February 2023 CAL / 21 www.cranesandlifting.com.au

“Obtaining legal advice is a practical way to ensure that the indemnity clauses in your contract are properly drafted to protect your interests.”

CICA ‘LEADING THE WAY’

ATTENDED BY OVER 450 PARTICIPANTS, the conference was an excellent blend of valuable technical and business presentations, networking opportunities and special events. The impressive combination of cranes and exhibitors emphasised the scale and size of the cranes and the exhibitors provided attendees with a chance to familiarise themselves with products, services and innovations on offer to help their businesses.

The banks of the Torrens River provided a perfect backdrop for the Networking Dinner, sponsored by SANY. The sounds of the acoustic guitar and delicious seafood were delightful, trumped only by the wonderful and long missed opportunity to catch up with friends and acquaintances after the pandemic years.

Dr Craig Challen SC OAM had the audience captivated as he delivered the keynote address on his experience as part of a cave rescue operation in Thailand to

evacuate 12 children and an adult from the flooded Tham Luang Cave system. Dr Challen challenged our aversion to risk and shared insights on the importance of knowing the mission, the team and oneself providing valuable and empowering lessons to listeners.

Thanks to the MC for the event, Marianne Van Dorslar, the program ran very smoothly. The panels, presentations, technical and business workshops all provided valuable material and awareness on a vast range of issues that impact crane usage, safety, business efficiency and profitability. Attendees were offered ideas and resources to assist them with navigating the challenges, legislative requirements, fraud detection, succession planning and skills limitations that they face in their businesses.

UAA was the platinum sponsors of the conference and used the opportunity to present its business vision and information

on how it provides insurance products and services that increase productivity and peace of mind.

The sessions were broken up by delectable tea and lunch offerings, which also provided time to connect with other delegates and to wander around the exhibition hall.

The Crane manufacturers panel facilitated by Tom Smith, consisted of: Kieran Hegarty (Terex), John Benton (Manitowoc Cranes), Christoph Kleiner (Liebherr – Werk Ehingen), Frank Schroder (Tadano) and Marco Burgmer (Sennebogen). These manufacturing experts graciously gave of their time to answer questions about manufacturing data, issues and the direction that crane manufacturing is heading.

The technical workshops had updates and discussions on: The development and application of lifting chains; crane technical innovations; safety planning

22 / CAL January-February 2023 www.cranesandlifting.com.au

“Leading the Way” was the theme of the 2022 CICA National Conference, held at Adelaide Convention Centre from the 10th to 12th of November, and it surpassed all expectations.

CICA NATIONAL CONFERENCE AND EXHIBITION

Dr Craig Challen SC OAM had the audience captivated as he delivered the keynote address on his experience as part of a cave rescue operation in Thailand to evacuate 12 children and an adult from the flooded Tham Luang Cave system

and risk mitigation; tyre behaviour; lift planning, and crane efficiency.

Sunnybrae Estate was only a short drive from the Convention Centre, but you’d be forgiven for thinking it was miles away. The heritage-listed estate and magnificent gardens and picturesque backdrops provided the perfect setting for fine food, wine and enchanting entertainment.

A fitting way to end the 2022 CICA National Conference was the Gala dinner on Saturday night, a spectacular evening of dynamic entertainment and delicious food. Time was spent remembering Bob Parker, Rob Way and John Gillespie, CICA’s founding fathers who had sadly passed away in recent years. CICA would not exist today if not for their selfless commitment and invaluable contribution to the crane industry. It was fantastic to have Allan McPherson, CICA Life Member, present. The awards and trophies presented on the night highlighted excellence in the crane industry and gave winners the welldeserved credit for their achievements.

This year CICA received the most ever Lift of the Year entries and judges spent an inordinate amount of time assessing the merits of each submission. CICA would like to thank everyone who entered the Lift

of the Year Awards as the standard of the lifts and submissions were world class.

Congratulations to the following:

• Project of the Year winner - John Holland for the Sydney Football Stadium

• 2020 Lift of the Year more than 20 tonne winner - Universal Cranes for the Kettle Tub Replacement Project

• 2021 Lift of the Year more than 20

tonne winner - Johnson and Young Cranes for the Hyde Street Exit Ramp Span 31 Load Transfer Pass out project

• 2022 Lift of the Year more than 20 tonne winner - John Holland and Tutt Bryant for the Auchenflower Overpass Demolition Project

• Lift of the year less than 20 tonne winner - Fullers Mobile cranes for their work on the White Bay Power Station

• The Innovation Award went to John

January-February 2023 CAL / 23 www.cranesandlifting.com.au

The Crane Manufacturers Panel was as popular as ever and featured John Benton, Manitowoc Cranes, Christoph Kleiner, Liebherr – Werk Ehingen, Marco Burgmer, Sennebogen, wKieran Hegarty, Terex and Frank Schroder, Tadano

UAA was the Platinum Sponsor for the event and Michael ‘Murf’ Murphy and George Grasso reinforced the importance of having the right insurance cover

A NDR OMEDA I NDU ST R IES PT Y LTD Plaited & Woven Division Ph. 02 6760 3773 andromedaindustries.com.au SUPERFLEX

manufacturing • infrastructure

construction

shutdown

leading manufacturer of high quality cable and lifting slings such as our very own cable and Steel Flat woven slings. Featuring aluminium or steel ferrules. Slim tapered under loads. GIVE YOURSELF A LIFT FROM THE BEST IN THE BUSINESS

mining

LNG ops Flat Woven Slings

STEEL SLINGS •

•

•

Australia’s

•

•

Holland and Edwards Heavy Lift for the Precast Concrete Trunnion

• The Bill Shaw Award recipients for the overall best lift was John Holland and Tutt Bryant for the Auchenflower Overpass Demolition Project

THE 2022 PHOTO OF THE YEAR AWARD WENT TO CRANES COMBINED

The other awards presented on the night recognised the efforts of individuals whose outstanding contributions greatly benefit the crane industry in Australia. They also provide a benchmark of excellence and good practice for the entire sector.

CICA EXCELLENCE AWARD

Two Excellence Awards for 2022 were presented.

Simon Buxton and the Tasmanian Department of State Growth stood out for the development, implementation, and proliferation of the Heavy Vehicle Access Management System.

This innovative work continues to provide enormous benefit to the crane industry through the significant reduction in need for road access permits as well as transparency and certainty in road access. Along with a large reduction in resources required for the crane industry, this innovative work has provided enormous

January-February 2023 CAL / 25 www.cranesandlifting.com.au

CICA

FOR TRAINING COURSE

AWARD

It was fantastic to have Allan McPherson, CICA Life Member present at the Conference

Chris Kolodzie, Combined Cranes MD, receives the Photo of the Year award from new CICA President Ben Pieyre

The Fuller Mobile Cranes team celebrate winning the Lift of the Year less than 20 tonne for the White Bay Power Station project

benefit through a significant reduction in need for road access permits as well as transparency and certainty in road access.

Along with a large reduction in resources required for the crane industry, the Heavy Vehicle Access Management System has afforded greater flexibility in crane selection and enabled the crane industry to service the community more efficiently and effectively.

It is also noted that this is the first time this award has been presented to someone from within Government.

The other CICA Excellence Award recipient was Jon Dunn of Dunn’s Twin City Cranes for his contribution to changes with WorkSafe Victoria.

Wodonga-based Dunn’s Twin City Cranes (DTCC) was issued with a Prohibition Notice by Worksafe Victoria. DTCC successfully appealed the notice and consultation with the regulator has allowed CICA to form a steering committee and discussions with WorkSafe Victoria resulted in changes to the requirements of work boxes.

The CICA Legend Award went to Danny Black, recognising Danny’s

www.cranesandlifting.com.au

CICA AWARD FOR TRAINING COURSE

The Johnson & Young Cranes team celebrate the 2021 Lift of the Year more than 20 tonne winner for the Hyde Street Exit Ramp Span 31 Load Transfer Pass out project

Simon Buxton and the Department of State Growth stood out for the development, implementation, and proliferation of the Heavy Vehicle Access Management System

Jon Dunn of Dunn’s Twin City Cranes receives the CICA Excellence Award for his contribution to changes with Work Safe Victoria

The CICA Legend Award went to Danny Black, recognising Danny’s outstanding service to the crane industry.

The CICA Hall of Fame Awards went to Albert Smith and Anthony Grosser for their significant contribution to the crane industry

Jon Dunn of Dunn’s Twin City Cranes receives the CICA Excellence Award for his contribution to changes with Work Safe Victoria

The CICA Legend Award went to Danny Black, recognising Danny’s outstanding service to the crane industry.

The CICA Hall of Fame Awards went to Albert Smith and Anthony Grosser for their significant contribution to the crane industry

LIEBHERR POSITIVE ABOUT CICA NATIONAL CONFERENCE AND EXHIBITION

Liebherr was very happy with the outcomes from the CICA National Conference and Exhibition says Andrew Esquilant, General Manager Mobile Crane and Crawler Cranes.

“WE WERE VERY HAPPY WITH HOW our exhibition booth worked during the conference, we thought it worked really well. The technological display including the simulator from our Liebherr-Werk Nenzing, our crawler and foundation equipment colleagues.

“Our MyLiebherr display generated plenty of interest with customers visiting the booth with expectations of seeing something new and exciting.”

“There also was also a terrific amount of interest around the display of our LTC 1050-3.1, courtesy of Max Cranes,” Esquilant said.

As a thank you for visiting the booth, Liebherr had a free-to-enter lucky draw for a Liebherr fridge.

About 100 visitors entered the draw, and the owner of the winning ticket was

Len Sgherza from Alliance Engineering. Esquilant and the Liebherr team were happy with the exhibition and the quality of the conference delegation.

“Our booth was well visited, with customers from all over Australia popping in and having a chat,” he said.

“We found the delegates that visited our booth were highly engaged and very interested in the topics we had on display including electrification and Liebherr’s digital solutions.”

ABOVE: The Liebherr booth was well visited, with delegates highly engaged and very interested in the topics on display including electrification and Liebherr’s digital solutions.

LEFT: There was a terrific amount of interest around the display of the LTC 1050-3.1, courtesy of Max Cranes.

28 / CAL January-February 2023

LIEBHERR AT CICA NATIONAL CONFERENCE AND EXHIBITION

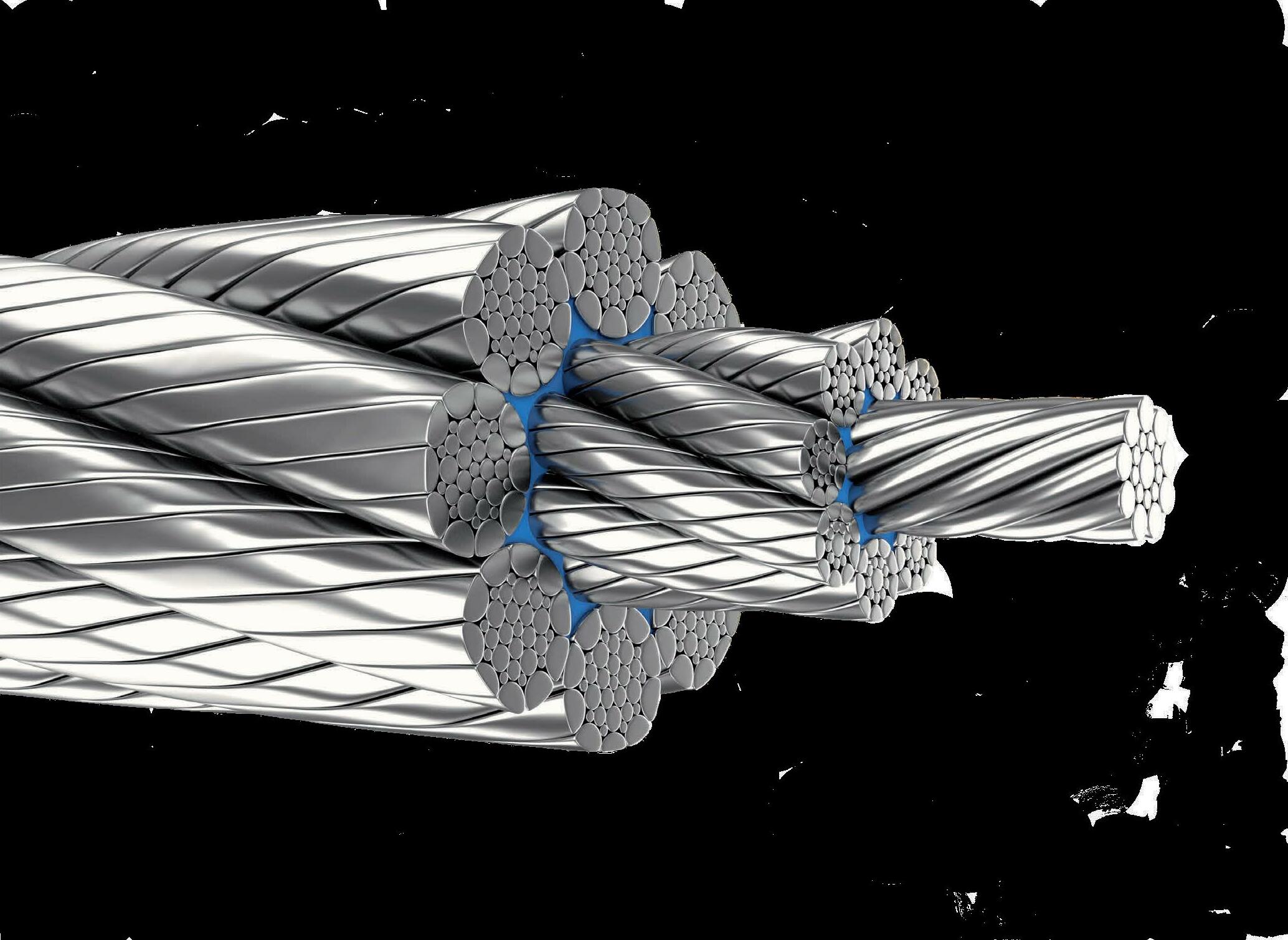

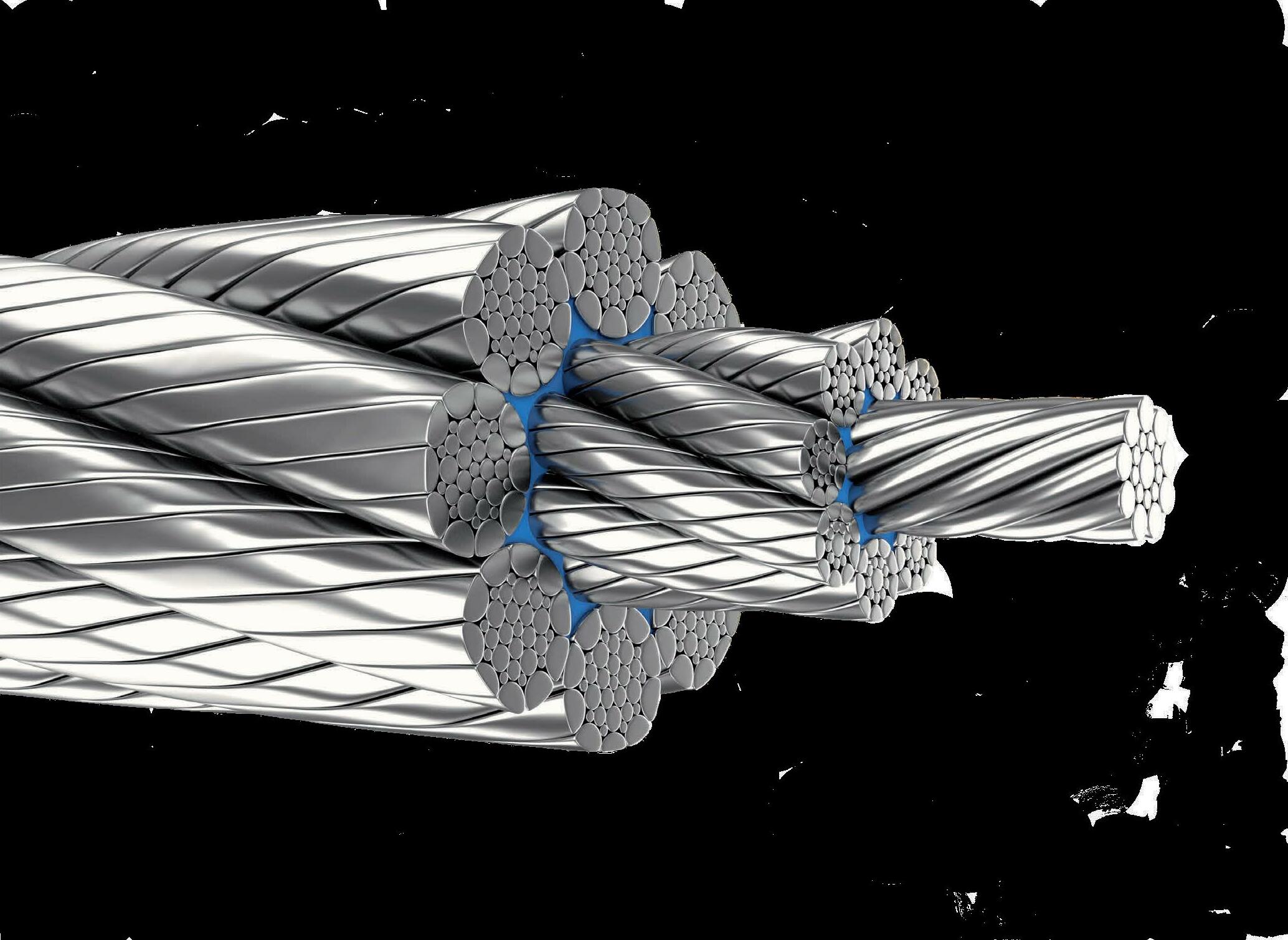

Achieve the highest breaking strength with DSC8 PI MAX Ideal as a hoist rope on overhead cranes or as a luffing rope on many industrial crane applications, Dyform DSC8 PI MAX offers the highest breaking strength, as well as excellent crush resistance on www.bridon-bekaert.com

JOHN HOLLAND WINS MULTIPLE AWARDS

John Holland was awarded multiple awards at the recent CICA Lift of the Year Awards presentation - including 2022 Project of the year.

PROJECT OF THE YEAR WINNER / JOHN HOLLAND SYDNEY FOOTBALL STADIUM

Infrastructure NSW awarded John Holland a contract for the Sydney Football Stadium Redevelopment project. The project required some creative problem solving to provide a modern, world-class venue located within a busy city location. Furthermore, it was delivered during a period that included climactic extremes of NSW drought, floods,

fires and a global pandemic.

The big focus during the project planning was the elimination of risk of working at height. This was achieved through modularisation and assembly on ground of large components of the roof and then landing them on bespoke headstocks that incorporated safe access, large working platforms, integrated lighting and safe retrieval systems.

One of the challenges faced by the project was the enormous amount of

work happening simultaneously on site. In its peak construction phase, there were more than 15 cranes (in addition to other construction equipment and plant) working at once within an area of approximately 250m2. This added extra complexity for the lift design and lift planning, and required sound engineering and risk controls in place. Together with innovative solutions such as a crane working platform with integrated drainage system and bespoke

30 / CAL January-February 2023 www.cranesandlifting.com.au

CICA LIFT OF THE YEAR AWARDS JOHN HOLLAND

Project of the year winner: John Holland Sydney football stadium

lifting devices for the removal of the roof temporary support towers, allowed John Holland to successfully deliver a modern and world-class venue on budget and ahead of schedule.

The Auchenflower Station existing pedestrian overpass, was built during the 1960s, was required to be demolished within a weekend shutdown to be later replaced with a brand-new concourse. The existing overpass was a two-span steel girder with concrete deck structure, placed over four active rail lines and designed to be stick-built. The demolition could not follow the same erection methodology as it would have required a significant disruption to the very busy rail network and also high-risk working activities close to live and essential plant. Detailed logistics and lift planning were required to transport, offload and erect the massive 800 tonne crawler crane with superlift counterweight in the

January-February 2023 CAL / 31 www.cranesandlifting.com.au

2022 Lift of the Year – More Than 20 Tonne Winner/ John Holland and Tutt Bryant, Auchenflower Overpass Demolition Project

The John Holland team celebrate the CICA Awards.

2022 Lift of the year more than 20 tonne winner: John Holland and Tutt Bryant, Auchenflower Overpass Demolition Project.

tight available space, which included a six degrees slope, powerlines and underground services. The John Holland and Tutt Bryant team overcame project challenges with innovative solutions, such as a complex rigging arrangement with hydraulic rams to rotate the structure mid-air, detailed engineering including 3D clash detection analysis, and risk control measures in place.

Innovative thinking with a focus on safety allowed the project team to perform a critical operation with ease, on time and with the full confidence of all stakeholders.

Innovation Award Winner/ John Holland and Edwards Heavy Lift, Precast Concrete Trunnion (Bell to Moreland Level Crossing Removal Project)

Typically, the pier columns that support elevated rail viaducts are constructed insitu with forms and post tensioned. With in-situ pier construction, the installation of both the pier and the crosshead is constrained by the concrete curing time required for stressing.

A precast column cast into the pile cap design was proposed to reduce

the risk of delay to the program from increased curing time, COVID-19related labour impacts and inclement weather. The conventional solutions for lifting precast (lifting inserts with clutches) were deemed not suitable for this application due to the geometry of the piers (curved surface) and the required rotation on site from horizontal to vertical. John Holland and Edwards Heavy Lift came up with the innovative solution and design of post-fixed lifting trunnions. While the concept of a lifting ‘trunnion’ isn’t new – as it’s commonly used in the resources sector to lift large steel vessels- this was the first time that it had been used in the design of a precast concrete lifting system. The design complied with the relevant Australian and international standards and included the selection of specific wire rope and thimbles.

The idea of using voids for postfixing lifting anchors on precast elements is not new either, but it is innovative in this application. Affixing the trunnions via a threaded rod and cast-in conduit system aided in the ease of installation and reuse. It was

cost-efficient and easy to cast and was accommodating to the congested steel reinforcement design.

The trunnion solution allowed safe and smooth tailing and installation, allowing for major cost savings to the project.

Bill Shaw Memorial Trophy Winner for 2022/ John Holland and Tutt Bryant, Auchenflower Overpass Demolition Project

The Bill Shaw Memorial Trophy is for the overall best lift. Among the entries from all categories in 2022, the Auchenflower Overpass Demolition Project stood out with its enormous amount of detailed engineering controls in place, its innovative design of the rigging system, and its tremendous effect on the amount of work to deliver and manage in a short period of time. The project team displayed a commitment to ensuring the work was planned and executed to the highest standards of safety. The John Holland and Tutt Bryant team were thrilled to be named the Bill Shaw Memorial Trophy winner for 2022 for the Auchenflower Overpass Demolition Project.

32 / CAL January-February 2023 www.cranesandlifting.com.au

CICA LIFT OF THE YEAR AWARDS JOHN HOLLAND

Innovation award winner: John Holland and Edwards Heavy Lift, Precast concrete trunnion.

GOOD RESULTS FOR TADANO AT NATIONAL CONFERENCE AND E XHIBITION

“THE TEAM WAS PROUD OF OUR OVERALL presence and the product innovations we were able to highlight and discuss with visitors who came to take a closer look at Tadano,” she said.

“Visitors to the stand were very engaged and it was great to hear positive feedback on our product quality and services from our existing customers. It was also great to have the opportunity to talk to potential customers who were perhaps closed off to conversations with Tadano in the past and are now open and happy to consider doing business with us.”

A drawcard for the Tadano stand was the “Tadano Lift Challenge” which is a strength and endurance test. Participants held a 5kg bag in each hand, straight armed, for as long as they could. Of the 45 plus contestants Alistair Stewart from Riteway Crane Inspections (right) won the event and the Tadano fridge, with an impressive time of 2 minutes and 26 seconds, 24 seconds more than second place.

“Everyone seemed genuinely excited to be in Adelaide and attending the conference. It was great for everyone to be meeting face to face and we were extremely pleased with the engagement and positivity on our stand.

“The presentation of the stands from other exhibitors were impressive

and the ‘Best Stand’ competition must have been hard to judge. We congratulate the winners and admit we were were disappointed not to win, but there is always next year,” said Gen.

“A draw card for the Tadano stand was the “Tadano Lift Challenge” which is a strength & endurance test. It was a good, old-fashioned contest where participants held a 5kg bag in each hand, straight armed, for as long as they could.”

January-February 2023 CAL / 33 www.cranesandlifting.com.au TADANO AT CICA NATIONAL CONFERENCE AND EXHIBITION

According to Genevieve Mustafa, Marketing Manager for Tadano Oceania Region, the Tadano team was very happy with the results from the CICA Exhibition.

Alistair Stewart from Riteway Crane Inspections won the “Tadano Lift Challenge” and the Tadano fridge.

Gen (centre left) and the Tadano team were proud of the product innovations they were able to discuss with visitors who came to take a closer look at Tadano.

ARTICULATED CRANE ACCIDENT PREVENTION

on 11 October 2017. During the coronial review it was determined that articulated steering cranes have unique characteristics that make it difficult to re-gain control in the event of a loss of control at speed.

The Coroner 1 found that these unique characteristics include:

Frame steering results in the driver rapidly rotating in the direction of steering. Trucks, buses and cars have ‘Ackerman steering’, meaning that they are steered by turning the front wheels. The body of these vehicles do not rotate, only the front wheels. Therefore, the driver stays with the body of the vehicle when the wheels and vehicle turn.

wheels on a shopping trolley. When the steering wheel is released after a turn is completed, the caster effect tends to bring the wheels back into a straight line.

Whereas, in mobile articulated steering cranes, when the steering wheel is released, the steering does not tend to naturally straighten up, and as a result, the driver must always remain very attentive and active with their steering.

Stiffly sprung suspension

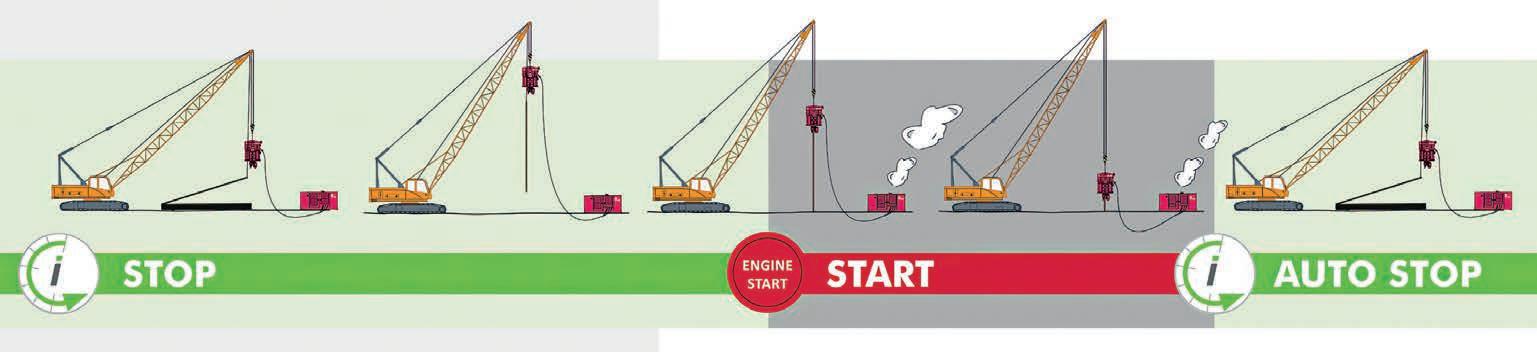

ON 1 DECEMBER 2022, CICA’S ON-ROAD

Articulated Steering Mobile Crane Training Course won the award for Outstanding Solution for Members Managing WHS Risk in SafeWork N.S.W. Work Health and Safety (WHS) Excellence Showcase, which recognises businesses and individuals for excellence in work health and safety.

CICA celebrates the achievement, mindful the course came to be due to a tragedy and a coronial recommendation.

On 16 September 2013, Christine and Samuel Leonardi’s car was struck by an articulated steering crane while on their way to school. The result was devastating. Sadly, Christine and Samuel passed away, the damage to Mrs Leonardi’s vehicle was so extensive that the make and model of her vehicle were unrecognisable.

Coroner John Hutton delivered his findings of the coronial inquest

Whereas mobile articulated cranes have ‘frame steering’. They steer by pivoting (articulating) the crane in the middle, which in effect turns the front wheels in relation to the rear wheels.

A driver of a mobile articulated crane does not steer with the front wheels. The driver is physically rotated with the front half of the cabin in the direction of steering. This leads to a different sensation by the crane driver.

Hydraulic cylinders and lack of feedback leads to ‘twitchy’ steering

The lack of feedback in the steering wheel means that the steering wheel can be turned very quickly with little effort. This can lead to over-steering (i.e. where the driver’s steering over-corrects and turns too far).

Front wheels do not naturally straighten up

The front wheels of trucks, buses and cars have caster angle, which means that they tend to act like the caster

The suspension on some mobile articulated steering cranes is stiff to support the lifting rated capacity, which means road bumps and undulations are felt by the driver, when driving on-road.

The stiff suspension comes about because when the crane is being used as a crane, it needs to lift up a heavy load at the front, and the entire load must be supported by its front suspension.

Mobile articulated cranes are specifically intended to drive around work sites with the load suspended at its front. This stands in strong contrast to other mobile cranes, which rarely travel while suspending a load. Other mobile cranes use outriggers to deal with the large, lifted loads and use dedicated road suspension when travelling along roads.

Coronial recommendations

The Coroner made several recommendations, including to amend the national licensing scheme so that before a driver is authorised to drive a mobile articulated steering crane on a public road, they must undergo a:

1. P ractical assessment on a public road in a mobile articulated crane; and

34 / CAL January-February 2023 www.cranesandlifting.com.au

The Crane Industry Council of Australia recently won an award for its On-Road Articulated Steering Mobile Crane Training Course.

CICA wins WHS Champion Award.

TRAINING COURSE AWARD

Current driver training for heavy vehicles (prime movers and trailers) is the opposite to a safe response with an articulated steering crane.

The recommendation was for a government agency to develop the practical and theoretical assessment; however, after consultation, The Crane Industry Council of Australia (CICA) was approached to deliver it. CICA received a grant from the Federal Government by way of a Heavy Vehicle Safety Initiative through the NHVR to develop this program.

It is important for employers / managers, to understand that their role is to do what is ‘reasonably practicable’ to ensure the health and safety of their crane operators and others on construction sites and on the roads.

“CICA partnered with Area 9 Lyceum, the global leader in Adaptive Learning to use their AI technology, to develop an online training program that can assess the operator’s familiarity with the driving behaviour of articulated cranes.”

CICA’S ON-ROAD ARTICULATED STEERING MOBILE CRANE TRAINING COURSE

CICA developed the On-Road Articulated Steering Mobile Crane Training Course with industry trainers, equipment manufacturers, state WHS regulators, state and national road authorities, and operators with over 30 years of individual experience operating articulated steering cranes.

For the theoretical component, CICA partnered with Area 9 Lyceum, the global leader in Adaptive Learning, to use their AI technology to develop an online training program that can assess the operator’s familiarity with the

driving behaviour of articulated cranes.

This training program uses an Adaptive Learning model, so for experienced operators, the training and assessment will be accelerated; for inexperienced operators, however, the training will be more thorough. This variation in training that credits the industry for existing knowledge while providing additional training for those not yet competent.

The online ‘adaptive learning’ component also provides flexibility, so operators can complete that aspect of the program individually during down time.

This model provides excellent feedback on what the crane operator

January-February 2023 CAL / 35 www.cranesandlifting.com.au

2. Th eoretical assessment addressing the unique handling characteristics of mobile articulated cranes and emergency procedures in the event of a loss of control.

CICA’s Justina Blackman (right) receives the Outstanding Solution for Members Managing WHS Risk award.

does and doesn’t know, which also means the solution is tailored. The course is not ‘one size fits all’, so an experienced operator with a good understanding of how to safely operate a pick and carry crane won’t be required to complete modules for which they demonstrate competence.

The online component is followed by a practical assessment using the CrewSafe app. This app. takes the assessor through a checklist of how to assess an operator’s competence and involves the video recording of task completion.

All training and assessment data is recorded and can be anonymously aggregated to see where gaps in the industry exist. Individual participants have a unique learning profile and can receive customised refresher training through their login profile.

This program aims to make drivers and their employers aware of the knowledge and skills gaps that exist and to substitute or replace them with

that was overlooked in both the heavy vehicle road licence and high-risk work licence.

Currently, this training is voluntary for members of the industry and is not required in the WHS.

The greatest outcome of this project to date has been raising awareness on the issue in such a way, that does not burden or cripple the industry.

Another has been customising the delivery to the user in a way that is easily accessible and encourages participation.

CICA is confident that through CICA’s On-Road Articulated Steering Mobile Crane Training Course, improvement in performance, reduced injuries, lost time, severity and claim costs are all achievable.

CICA is also exploring ways to use the Adaptive Learning framework for other training initiatives.

Crane safety is serious, the fact that most pick and carry crane operators have never been properly trained or assessed, is deadly serious.

This is why CICA is offering 100 free

“This is why CICA is offering 100 free ‘sign-up’s’ to the online component of the course to get its members started (which is a saving of $250). To qualify, the operator must complete all aspects of the training and assessment within 18 months of sign up.”

sound knowledge and understanding of the crane, how it operates in certain circumstances and how to mitigate risks of an adverse event.

OUTSTANDING SOLUTION

Having more operators complete both elements of the on road articulated steering crane program will help make workplaces safer. Developing standardised training assists Small and Medium Businesses that would otherwise not have resources to create this training in-house.

This training and assessment program is now being provided to an industry

‘sign-up’s’ to the online component of the course to get its members started (which is a saving of $250).

To qualify, the operator must complete all aspects of the training and assessment within 18 months of sign up.

To find out more about the CICA Onroad Course, head to the CICA website www.cica.com.au/The-CICA-On-RoadCourse. To receive the code for the free sign up send Paul an email (paul@cica. com.au).

1 11 October 2017, Findings of Inquest into the deaths of Christine Nan Leonardi and Samuel John Leonardi

36 / CAL January-February 2023 www.cranesandlifting.com.au

TRAINING COURSE AWARD

Road incidents involving articulated pick and carry cranes can be devasting.

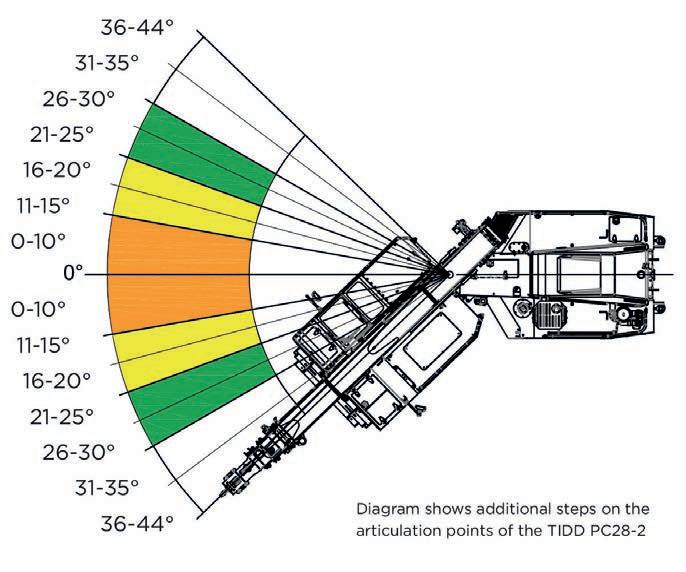

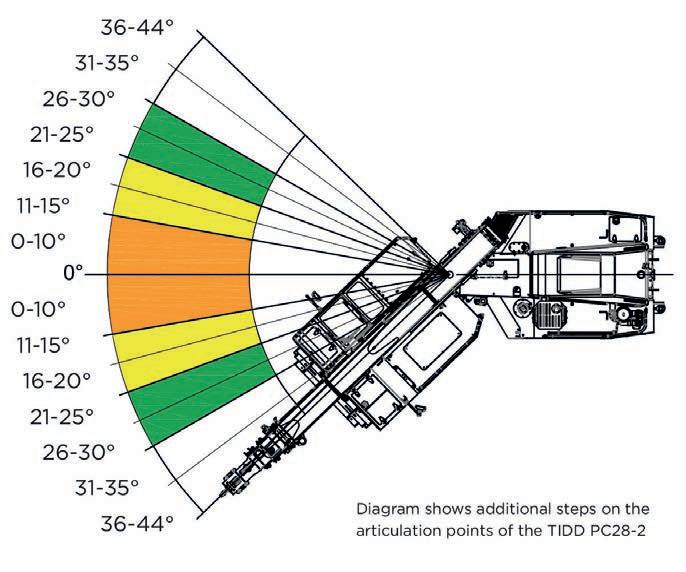

LEADING FROM THE FRONT, TRT CONTINUES TO ENHANCE THE OVERALL OPERATOR EXPERIENCE AND PERFORMANCE WITH THE NEW TIDD PC28-2.

A more powerful front suspension improves lift capacity by up to 17%. New steps in the load chart improve lift control. Faster software processing gives even greater control response and the re-engineered ROPs cab has lower ambient road noise.*

TIDD Crane offers a better experience and a better investment for the life of your crane.

TRT Australia TRT New Zealand QLD, NT, VIC, TAS, NZ PNG, & Asia Pacific 07 3890 8800 cranesales@trtaust.com.au www.trtaustralia.com.au The Baden Davis Crane Connection NSW & ACT 02 9672 1682 anthony@craneconnection.com.au www.craneconnection.com.au Ronco Construction Equipment & Engineering WA 1800CRANES TIDD@ronco.com.au www.ronco.com.au Construction Equipment & Engineering RMB Service Group SA 08 8268 1300 service@rmbservicegroup.com.au www.rmbservicegroup.com.au *Conditions apply. For improvement detail contact us. THE BETTER EXPERIENCE PERFORMANCE, SAFETY, COMFORT AND SUPPORT

TO WATCH! AVAILABLE FROM MARCH 2023 ORDER NOW!

SCAN

TUTT BRYANT HEAVY LIFT & SHIFT MANAGES BRIDGE DISMANTLE

Earlier in the year, the team at Tutt Bryant Heavy Lift & Shift (TBHL&S) managed a complex bridge demolition project in the Hunter Valley region of New South Wales. With extremely limited access and a tight timeframe, the lifts had to be meticulously planned.

OVER THE PAST 24 MONTHS, THE AUSTRALIAN Rail Track Corporation (ARTC) has replaced three bridges in the Hunter Valley region of New South Wales. These include the Hunter River bridge, Muscle Creek bridge and Bridge Street bridge with two new bridges within and next to the rail corridor, in Muswellbrook, NSW. The lifts involved the onsite bridge demolition of the bridge over Muscle Creek and Hunter River. The Bridge Street site involved the demolition of the existing bridge superstructure and central pier.

Kyle Greenwood is the New South Wales Supervisor for Tutt Bryant Heavy Lift & Shift (TBHL&S). He explains more about the complexities of the project.

“The project involved lifting a couple of different bridges out from the one setup. The

only way to execute the project was to use the 600t capacity Demag CC 2800-1 which was set up on a natural jetty between the two rivers, the Hunter River and Muscle Creek.

“We were literally set up on the 18m long jetty that we had engineered and had earthworks completed for the lift so we knew it could sustain the combined crane and lifts being undertaken.

We had to access to the jetty through a caravan park, so setting the crane up was tight with very little tolerance for error.

“We had the whole site aerially scanned as part of the lift planning. They scanned it with a drone and then put it all into a CAD system with which we calculated that we would just be able to manage the lifts. We could only use 66 metres of boom, I would’ve liked to use more, but we literally

IN FOCUS / TUTT BRYANT HEAVY LIFT & SHIFT 38 / CAL January-February 2023 www.cranesandlifting.com.au

could not build more in the area we had,” Greenwood said.

Building the Demag CC 2800-1 was a very complex process in itself, due to the lack of space. To lift the heavy parts of the crawler, like the track frames and counterweight, TBHL&S used a Grove 300t all terrain GMK6300L, Greenwood said.

“There was just enough room for us to get our Grove GMK6300L onto the site and assist with the build. We actually set the Grove up on the Superlift counterweights pad. We had the outriggers fully out on the

lifting side, and then we had the half jacket on the non-lifting side.

“We had to bring the two track frames in on a 7 line steerable Drake platform trailer due to the narrow roads in the caravan park, we then had to unload them, sit them on the ground, and then bring the car body in and install the track frames. If we delivered the car body first, we wouldn’t be able to get the trucks close enough to the 300t Crane to unload as they weight 45t each.

“We couldn’t use the Grove any further because we couldn’t slew it around. So, we brought in a Sennebogen 683 HD 80t capacity tele-crawler for the rest of the build. We walked it up and down the track and walked in the boom sections and Superlift mast and everything else,” Greenwood said.

The Hunter River Bridge was an old riveted steel structure with a calculated weight of 120t to 130t. Using that weight TBHL&S examined assets which would suit the application and all options for the location of the lifts.

Three locations were identified to complete the lift, but the team at TBHL&S had to use a natural jetty in the caravan park as it was the only place to build the boom long enough to get the head height at the required radius.

The next problem was clearing out seven cabins and constructing a crane pad to support the crane and super lift counterweight. After engineering a pad design and surveying the site, TBHL&S’s 600t Terex Demag CC2800-1 was the largest capacity crane that could fit on the jetty, and it had a SWL of 129t at the required radius.