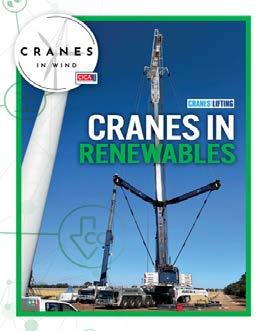

Inside: CRANES IN RENEWABLE ENERGY FEATURES XCMG’S EXTENSIVE ARRAY OF WIND FARM MACHINERY IN PROFILE: BOOM LOGISTICS’ MELIRA LISTER SINOBOOM CEO COMMITS TO THE MARKET DOWN UNDER cial edia artner THE DEDICATED RESOURCE FOR THE CRANE INDUSTRY / APRIL 2024

JOHNSON & YOUNG CRANES

Behind the scenes of

UAAisthelargestandmost reputablespecialistmobile plantandmachineryinsurerin Australia,NewZealandand globally.

Ourinsuranceproducts aretailoredtoproducea handcraftedsolutionto meetyourbusinessneeds

TheUAAGrouphasthe knowledge,abilityandcapacity toinsureawidevarietyofplant andmachineryspanning numerousindustries.

Ourexperiencedclaimsteam hasaccesstoanetworkofthe verybestexpertindustry repairers,assessorsand suppliers.

EXPERTSINMOBILE PLANTINSURANCE FormoreinformationonUAA’sIndustrialSpecialPlantandProcon products,pleasecontactyourInsuranceBrokerorvisitwww.uaa.com IndustrialSpecialPlantandProConunderwrittenbyQBEInsurance(Australia)Limited. ABN78003191035,AFSL239545. UnderwritingAgenciesofAustraliaPtyLtd.ABN86003565302AFSLicence238517. UnderwritingAgenciesofNewZealandLimited(UAA).4758199,NZBN:9429040999678. J6663

Withover30years’experience,

IN THIS ISSUE

Cranes and Lifting Magazine

cranes_and_lifting Cranes and Lifting

6 Johnson & Young Cranes

GM, Brett Horvath, discusses the imperative role the back-of-house team plays at JYC.

10 CICA CEO Report

Brandon Hitch reports on the challenges and opportunities Net Zero 2050 presents.

12 CICA Photograph of the Year winner

Universal Cranes take out photo of the year.

17 CICA Cranes in Wind Forum

A comprehensive look at the highly successful Cranes in Wind Forum.

Cranes in Wind features

20 Boom Logistics

An overview of the company’s extensive wind-farm services.

23 Borger Cranes Hire and Rigging Services

Borger’s renewable capabilities.

26 XCMG

rane anager, tep en room eld, discusses the wind farm machinery o ers

29 Sany

Second Sany 1000 tonne capacity lattice boom all terrain delivered.

32 Empire Cranes and Liebherr

Empire Cranes takes quality used Liebherr telescopic crawler and deploys to a wind farm.

36 Advanced Cranes

Crane Lead, Ben Miller, provides details on a Queensland project.

39 Potain Cranes

58 XCMG

Uplift Crane Hire has acquired a new XGTC100.

60 Tutt Bryant

Bridge Pro put HSC crawlers to good use on bridge build project.

63 Haywards take sixth Grove

63

Five new have been Potains chosen for a major infrastructure project.

42 Cranepower

Cranepower’s new way of powering towers cranes and hoists.

46 Game changing lifting technology Vita Load Navigator lands with rne afety

49 MCT Equipment

s lectric ranes ave o cially landed in the company’s depot.

51 Lawrence Engineering and The Crane Connection

Lawrence Engineering take a second Tidd from the Baden Davis rane onnection

55 Pace Cranes and Maeda’s Telescopic Crawler range

Continued success for Maeda’s Telescopic Crawler range.

Grove delivers 300t capacity all terrain to Haywards on the Apple Isle.

67 Franna and Boom Logistics

200th AT40 delivered to Boom.

70 UAA and Advanced Cranes

67 70

Advanced insurance solutions for Advanced Cranes.

72 LEEA

72

The importance of teamwork in the construction sector.

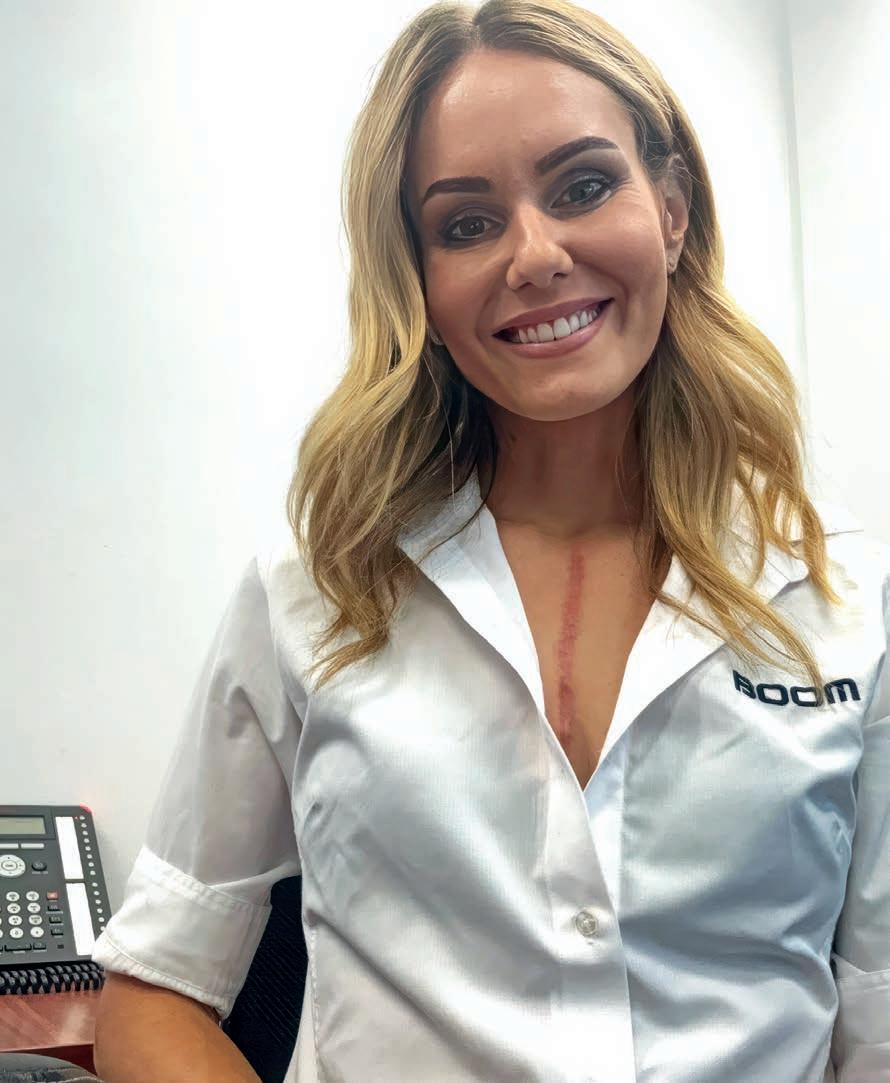

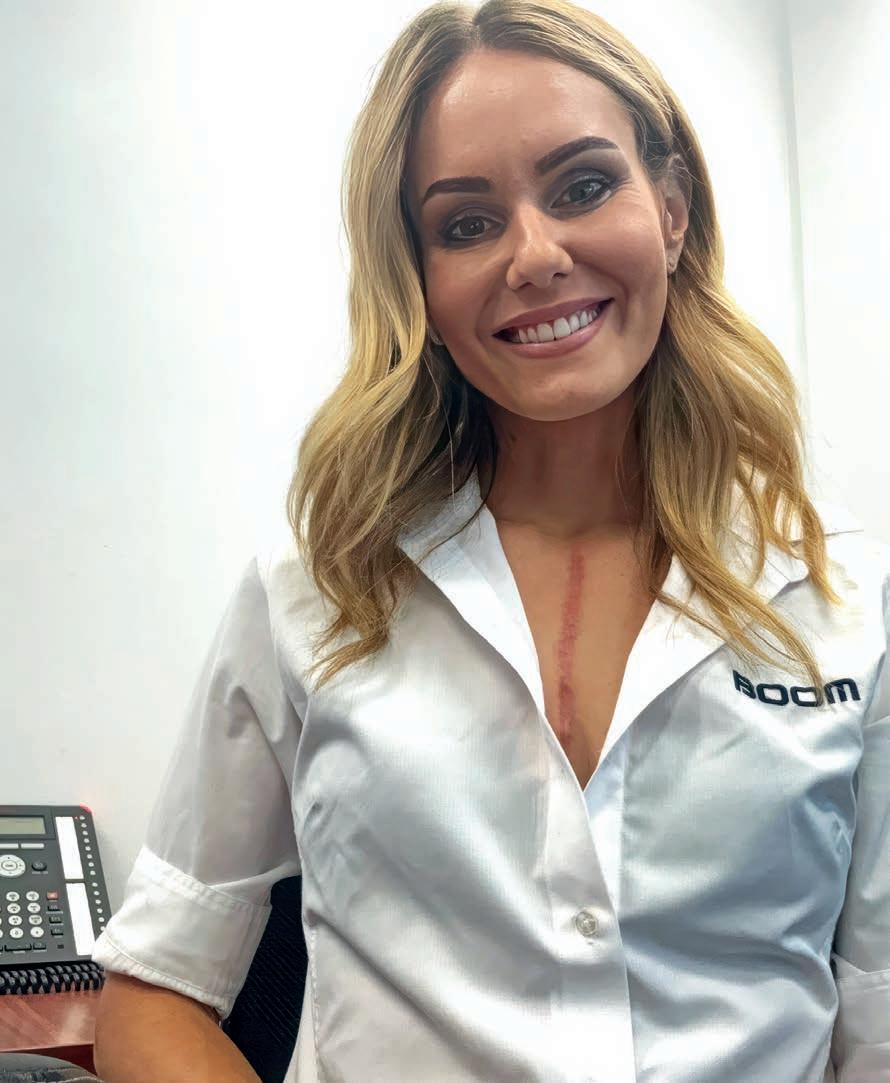

74 Women in Industry

74

Boom Logistics’ Melira Lister discusses her career and open-heart surgery.

EWP features

78 Sinoboom

CEO Susan Xu discusses the company’s commitment to Down Under.

81 Niftylift

Reducing carbon footprints it iftylift

84 AlmaCrawler

JIBBI range wins major rental award.

88 Skyjack

The access equipment company discusses its latest innovations.

90 Lift of the Month

What our industry does best.

SCAN THE QR CODE

TO SUBSCRIBE TO OUR NEWSLETTER

88

April 2024 CAL / 3 www.cranesandlifting.com.au 20

A new way to power cranes. Small power in – Huge power out.

440A output from a 32A input

Power cranes and hoists from a small supply

Utilise regenerative power for the next lift

Zero emission power for cranes

Plug and Play drop in solution

Eliminate diesel generators

Up to 200 tonnes of CO2 emissions reduction per year

info@cranepower.com

cranepower.com

FROM THE EDITORIAL TEAM

Published by:

WELCOME TO THE APRIL ISSUE OF CRANESANDLIFTING

VALENTINE’S DAY SAW THE INAUGURAL CICA Cranes in Wind Forum address the world’s ambi ous plans to achieve Net Zero by 2050.

e idea for the forum was born nine months ago om a conversa on between Boom Logis cs’ Engineering Manager, Nick Morris, and CICA’s CEO, Brandon Hitch, where both agreed on the importance for the indus y to hold a non-commercial event and undertake abrasive, con on ng discussions about the levels of safe and risk being borne by crane hire companies in the cons uc on of wind farms.

e forum a acted 110 a endees represen ng crane hire company owners, general managers, heavy li supervisors, li engineers, safe professionals and wind farm developers. Liebherr Business Development Manager Hans Jörg Nothacker provided a harsh reali check around the prospects of achieving Net Zero by 2050.

To achieve Net Zero by 2050, the world will need to install an ex a two terawa s of wind power per year –meaning larger wind turbines, with larger hub heights. Hub heights have already exploded in size om 20m to 165m, and that upwards end isn’t going to stop. For example, designs om Danish renewables manufacturer Vestas show turbines reaching 199m tall and producing seven megawa s of power.

e other key aspect explored was how terrains and environments di ered across geographical regions of the world, and how those features e ect not only the designs of the wind farms but how cranes engage in cons uc on and maintenance.

Nick Morris and George Grasso, UAA’s Chief Claims O cer, then took the oor to re ect on notable crane incidents on wind farms. Bigger wind farms will need bigger cranes with heavier rigging, meaning all aspects of wind farm cons uc on and maintenance become much higher risk, due to the signi cantly decreased margin for error.

In lieu of the event, a comprehensive review of the CICA Cranes in Wind forum is included in this issue as well as a deep dive into the role cranes play in the renewables sector, on top of a range of stories discussing the key developments in the crane indus y.

As always, the team at Cranes and Li ng magazine has worked hard to bring you this issue of the magazine and we hope you enjoy the read.

Simon Gould Editor, Cranes and Li ng

Simon Gould Editor, Cranes and Li ng

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

CEO

John Murphy

E: john.murphy@primecreative.com.au

Chie erati fficer

Christine Clancy

E: christine.clancy@primecreative.com.au

Managing Editor

Andrew Hobbs

E: andrew.hobbs@primecreative.com.au

Editor

Simon Gould

E: simon.gould@primecreative.com.au

T: 0404 865 109

Assistant Editor

Jack Alfonso

E: jack.alfonso@primecreative.com.au

Business Development Manager

Emily Schlegel

E: emily.schlegel@primecreative.com.au

T: 0466 317 555

Clie t ccess a a er

Glenn Delaney

E: glenn.delaney@primecreative.com.au

Art irector

Bea Barthelson

Imaging Assistant

Paul Breen

bscri tio s

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

April 2024 CAL / 5 www.cranesandlifting.com.au

Image: Borger Cranes

THE FACES BEHIND THE ORANGE BOOMS

General Manager of Johnson and Young Cranes, Brett Horvath, discusses the back-of-house team that help JYC maintain its lofty standards.

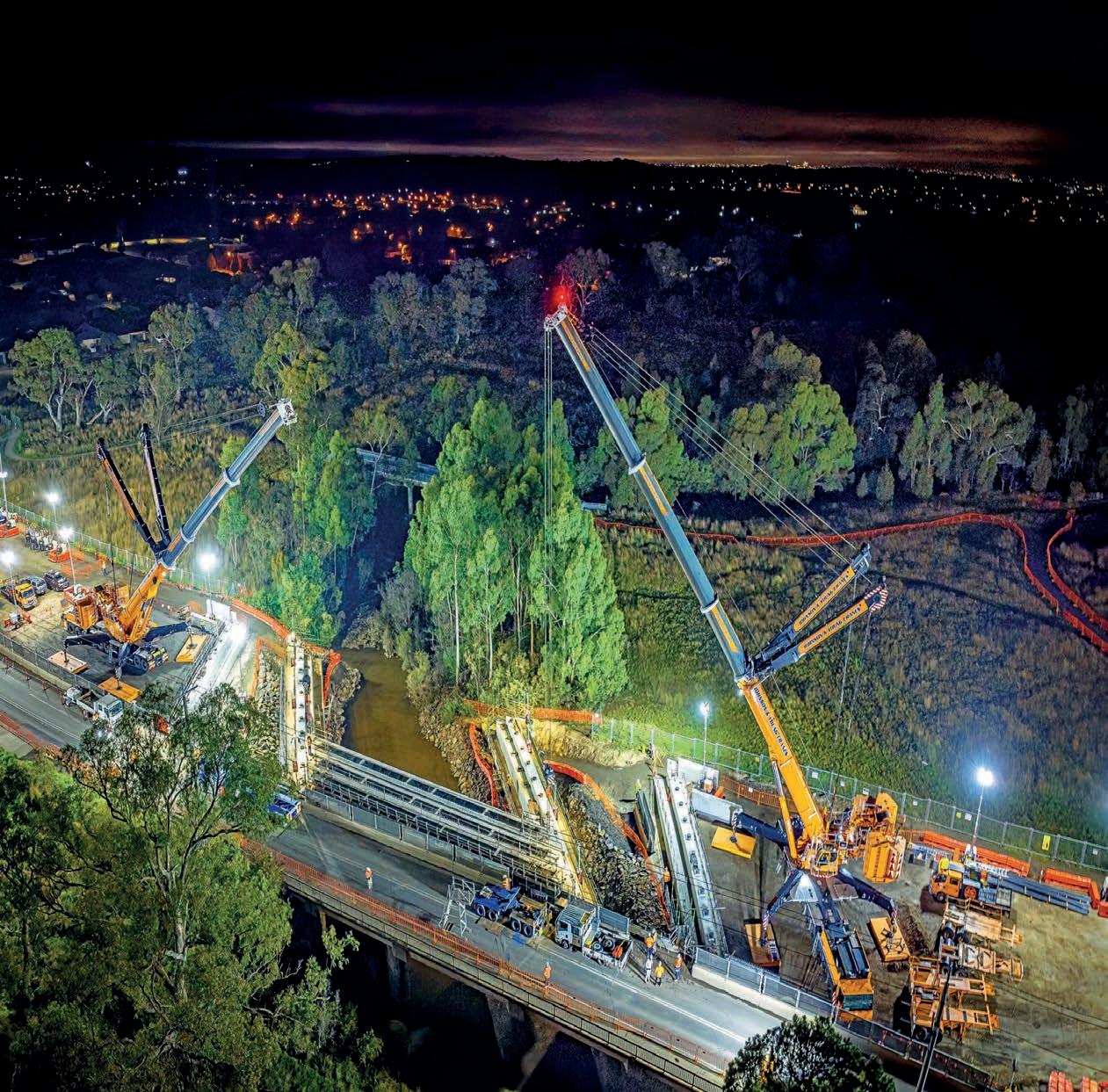

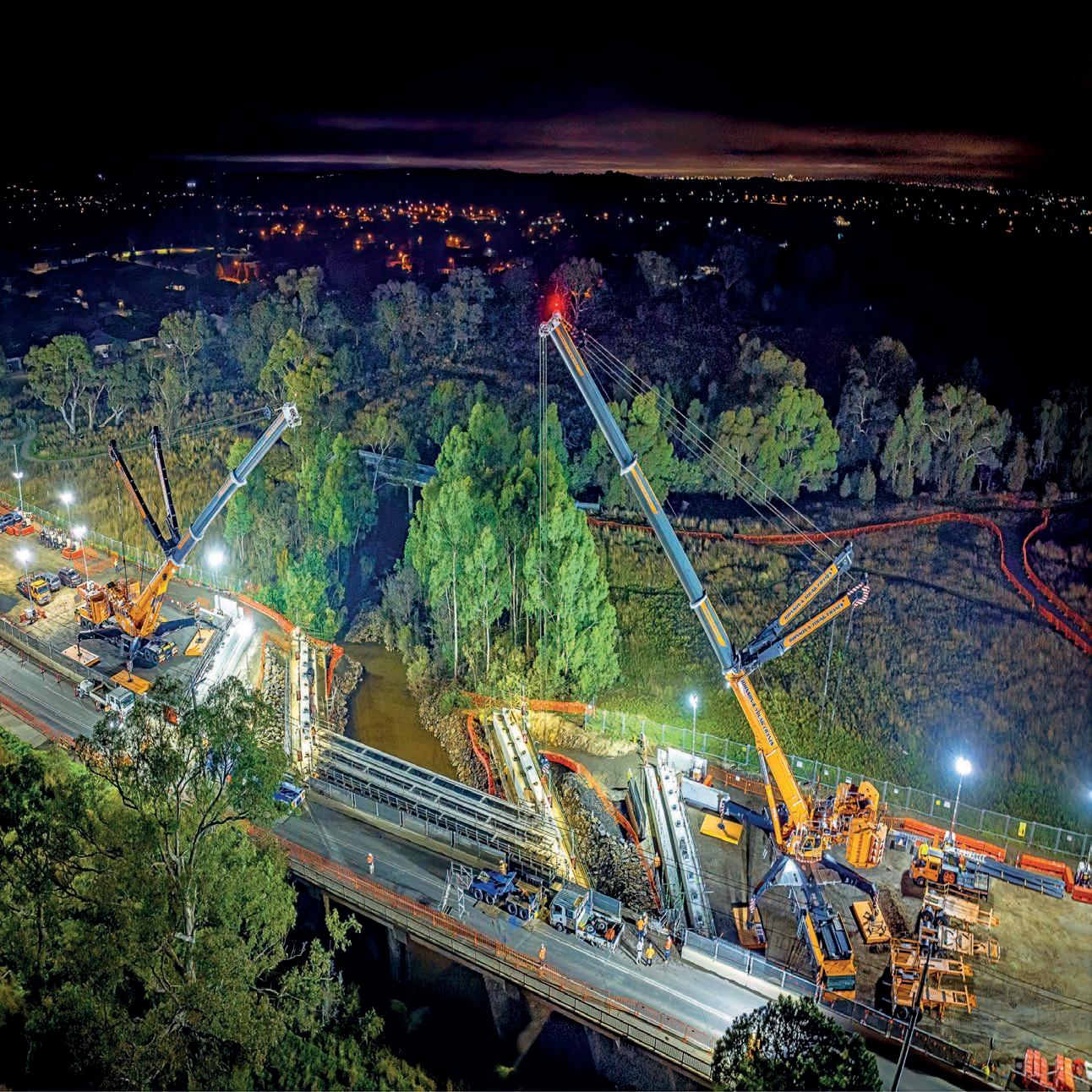

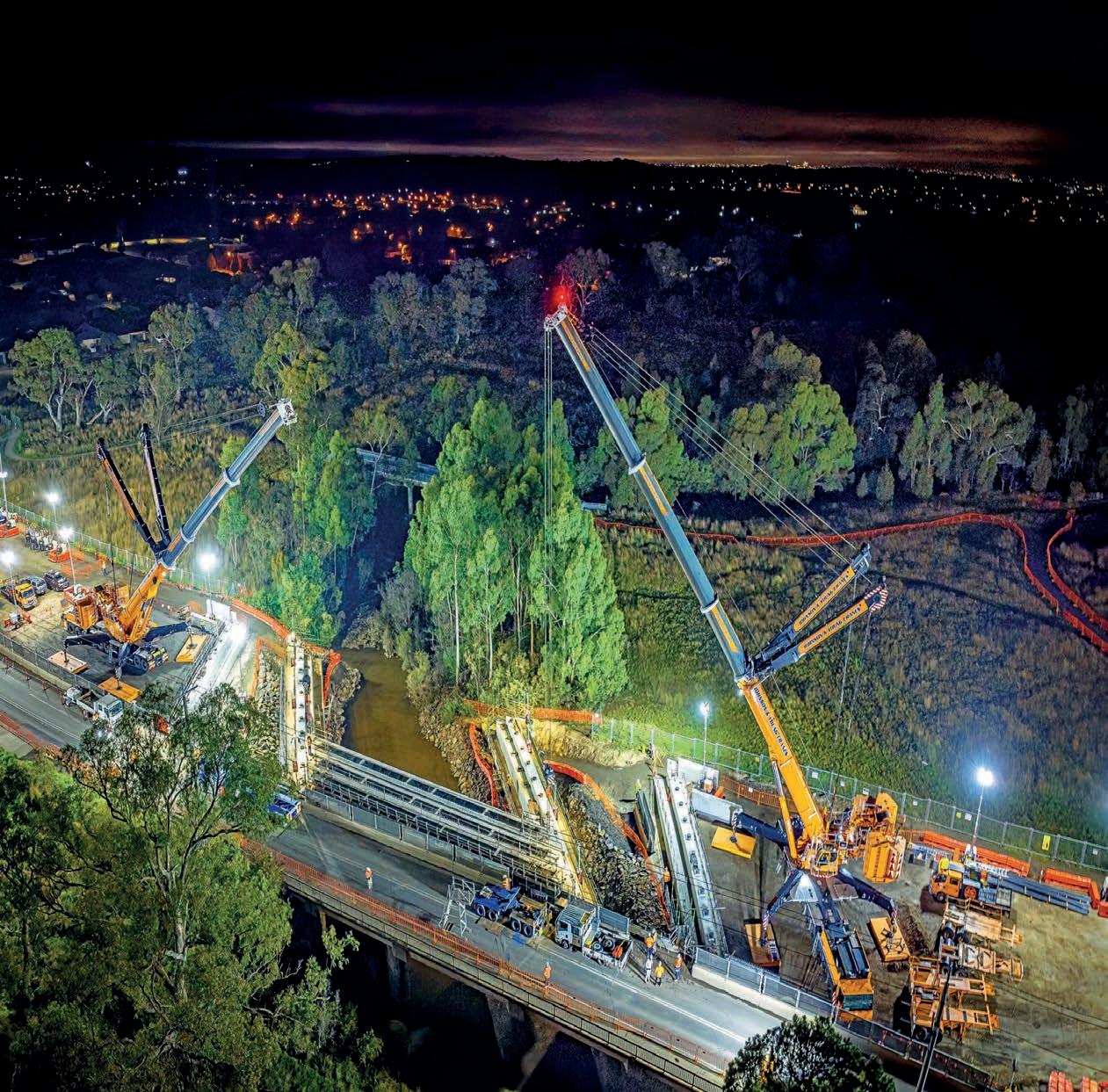

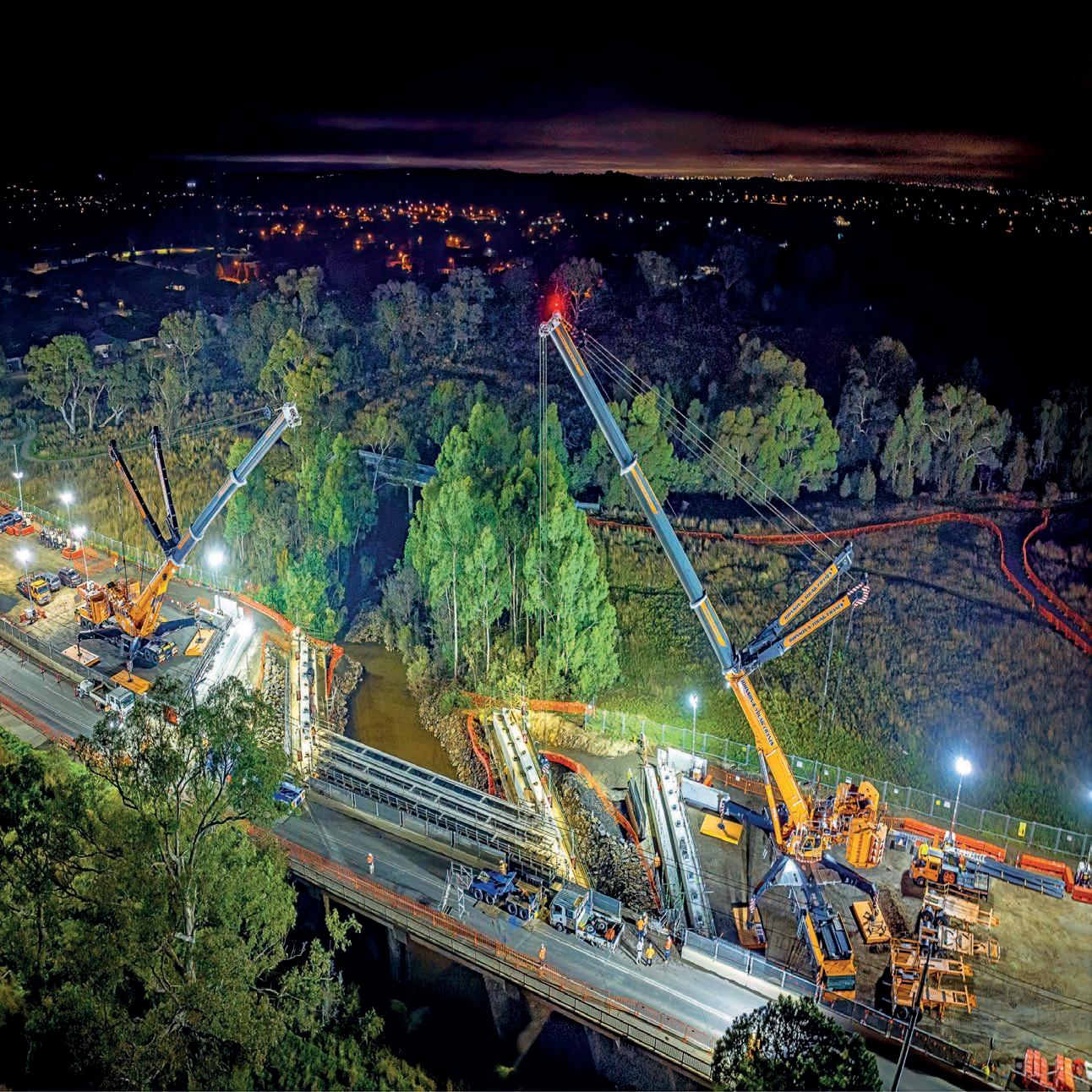

PICTURED ARE JOHNSON AND YOUNG Cranes’ two LTM 1750-9.1 all-terrain mobile cranes working on the Mernda Road Duplica on, dual li ing beams into place to create a new bridge over Plen River in Melbourne’s north.

e photo captures the spectacular sight of cranes in ac on but, as General Manager Bre Horvath emphasises, it’s a team e ort om everyone at JYC that makes such li s possible. Bre highlights the dedica on of the en re team, including owners Brent Young and Reece Johnson, in building a

culture that ensures every aspect of the job is executed awlessly. From the sales, engineering, opera ons, HSEQ, warehouse, and nance teams to the crane crews, uck drivers, and mechanics, everyone plays a crucial role in JYC’s success.

For JYC, the process of delivering a li begins with JYC’s dynamic sales team of Andrew Pi and Jackie Ryan who assess the job’s scope and presents JYC’s solu on to the client. ey are the rst point of contact and play a cri cal role in understanding client needs and expecta ons.

However, presen ng a li ing solu on requires signi cant input om JYC’s Engineering Team, headed by Brek Mans eld and ably supported by Dave, Georgia, Adrian, Oswaldo, Krystal and John. e seven-s ong engineering team me culously plans the li , considering all safe and e ciency aspects catering to the client’s requirements, using their exper se to design innova ve solu ons tailored to each project.

Once the client has accepted JYC’s solu on to the outlined li ing challenge,

UP FRONT / JYC 6 / CAL April 2024 www.cranesandlifting.com.au

The tandem lift on Mernda Road Duplication project.

Image: JYC

the Opera ons Team – led by Jake Tuohey and supported by Emma, Jade and Taylah – ensures crews and resources are allocated e ciently. With the support of Stores and Yard Manager, Jack Helmers, who is charged with making sure the appropriate rigging equipment is serviceable, in test and available for the task at hand, the opera ons and yard teams coordinate the movement of equipment and personnel to and om the site.

is is supported by a close collabora on between Opera ons, HSEQ, and stores who, together, drive the e cient alloca on of crews and resources. e HSEQ Team managed by Amanda Hermoso and bolstered by Chantelle Henley manage the client’s induc on needs, sending requested documents such as crew ckets, site speci c SWMS, and compliance paperwork for both cranes and suppor ng vehicles, ensuring JYC is compliant on all onts. HSEQ plays a crucial role in maintaining both a safe working environment and culture for everyone involved in the projects.

As a 24-hour crane hire company, JYC needs team members ready to take a call and mobilise at any second. is, for Bre , is evinced by JYC’s Crane Crews and Truck Drivers, who make themselves available at a moment’s no ce to mobilise equipment anywhere across Aus alia. According to Bre , their exper se and dedica on ensure that JYC’s equipment is delivered safely, on me, and all li s are executed as planned –regardless of the project loca on.

JYC elds an all-terrain eet of Liebherr cranes, Tadano crawler cranes and Franna pick and carry cranes; and, as Bre says, all of these brands are renowned for their reliabili . However, on the occasion that the crews have an issue with any equipment or when it is me for any servicing and maintenance ac vi es, JYC possesses a team of Mechanics and Field Technicians on standby to provide support, whenever needed, ensuring equipment is well maintained, compliant and safe for use. In tandem with the crane crews and uck drivers, the in-house team of mechanics and eld technicians of Ryan, Chris, John, Steve, Tom and Brodie are available 24 hours, seven days a week if required; as Bre outlines, their proac ve approach

helps prevent down me and ensures that equipment is always in great condi on.

JYC has a team of dedicated li ing supervisors who take over a project once it has been allocated to them, and their con ibu on goes a long way to ensuring that what the sales and opera ons teams have communicated to the client is achieved. Jaie, Ash, Cory and Dan are all onsite well before the crane has le the yard to establish that the site is ready for the mul tude of cranes, ucks, and crew, making sure that mobilisa on to site is smooth and e cient.

Once the team is setup for li ing, the li ing supervisors remain onsite to make any adjustments that may be required, before repea ng the process to ensure that the JYC team leaves site as they arrived: safely, and e ciently.

Both during a project and on project comple on, the nance team, led by CFO Con Tsiolis and supported by Stacey, Carmen, Ti any, Belinda, Hayley, and Ashley, provides the pla orm that assures everyone that they will always be appropriately remunerated, suppliers paid

April 2024 CAL / 7 www.cranesandlifting.com.au

s ngineering eam o n ump ries, drian itoli, re ans eld, Oswaldo Pachon, David Saunders, Georgia Harkin. Image: Prime Creative Media.

The Operations Team: (L-R) Jake Tuohey, Taylah Waldron, Jade Marshall, Emma Rusinek. Image: Prime Creative Media.

on me, and clients are invoiced correctly for the work that we perform for them.

e nance team play a crucial role in maintaining nancial stabili and ensuring the smooth opera on of the organisa on, condensing all the work that has anspired to ensure everyone receives what they need.

JYC’s modern eet that ranges om three-tonne Maedas to its two 800-tonne Liebherrs is a testament to the company’s commitment to excellence in the indus y. However, equally as important for JYC is to invest in its sta , con nuously aining and upskilling to ensure that the team is constantly growing and can tackle even the most complex projects with rela ve ease. Emblema c of the company’s commitment to growing its team in a socially progressive manner, JYC is commi ed to ensuring its team is as gender diverse as possible. With 67 per cent of its back of house sta female, JYC is placing itself at the fore ont of diversifying a adi onally male-dominated crane indus y and crea ng a safe, inclusive space for people to perform their best work in.

As JYC con nues to grow and expand its opera ons, one thing remains constant: the commitment and dedica on of its team. When one sees an orange boom in the

air, it’s down to the back-of-house teams con ibu ng signi cantly to the “amazing” works that are achieved onsite every day as well as the crane and uck crews, according to Bre . e teams of sales, engineering, opera ons, HSEQ, warehouse, and nance to the crane crews, uck drivers, and mechanics, provide the backbone to the company, driving its success and ensuring that every project is completed to the highest standards. As Bre underscores, the o ce-based cons uc on workers are the ue unsung heroes of the spectacular onsite

sights of watching two Liebherr cranes dual li a bridge beam. Emphasising that every li – no ma er how rou ne – requires the same level of detailed planning and execu on om the en re team across all onts, Bre reinforces the collec ve e ort that enables JYC to deliver “excep onal” service to its clients, making it one of the most usted names in the indus y.

Because, if it wasn’t for the e orts of the back of house team, photos such as the one on the ont cover, and projects such as Bridge Inn Road, don’t happen.

8 / CAL April 2024 www.cranesandlifting.com.au UP FRONT / JYC

The Finance Team: (L-R) Hayley Smith, Carmen ollette, i any irepa, Con Tsiolis, Ashley McMahon, Belinda Violi, tacey alter mage rime reative edia

ris elton, ec anic at JYC, and his freshly stickered eld service ute mage rime reative edia

to yan ummerscales, o n ogal, om urns and rodie c aul

GAME CHANGING Has landed LIFTING TECHNOLOGY

The Vita Load Navigator system detects load movement in real-time and adjusts the load with high-powered fans to eliminate spinning, rotations, and other problems that cause site damage or injuries.

The semi-autonomous propulsion-driven device connects below the hook of the crane and is remotely controlled. Measuring over 1,000 data points per second, the system detects load movement in real-time and adjusts the load with high-powered fans to eliminate spinning, rotations, and other problems that cause site damage or injuries.

KEY FEATURES

•Holds load steady mitigating wind and weather delays.

•Reduces the need for taglines mitigating risk to crews.

•Precision control allows the crew to place the pick exactly where needed.

•Memory functionality records lift positions allowing repetitive lifts with the touch of a button.

The Vita Load Navigator comes in various models to meet the needs of all lifting challenges.

For more information contact Maria Maguire

0418 979 199 | maria@ernelifting.com

NET ZERO 2050: THE OPPORTUNITIES AND CHALLENGES

Welcome to the April 2024 issue of

THE PUSH TO NET ZERO BY 2050 presents opportuni and challenge in equal parts to our indus y, globally and close to home. On February 14 CICA held the inaugural Cranes in Wind forum in Melbourne, and I want to take this opportuni to re ect on the event. e goal om the beginning was to provide a space for honest, open dialogue about our indus y’s rela onship with wind farming – the reali , the risks, what can go wrong and how we can turn those missteps into ac onable learnings.

e breadth of knowledge shared was immense.

We looked at the perspec ve of manufacturers, the s uggles of nding a balance in engineering cranes tailored to wind farm cons uc on and maintenance when geographic loca on plays such a heavy part in determining what’s plausible – or possible. Flat plains, craggy mountains, narrow pathways, loose sand and packed rock. ere is no one single blueprint of what it looks like to work in wind.

Demand is growing, and it will keep growing. e ex emes of the turbines, the li s and the engineering needed to meet that call grow with it. Wind farms need cranes, and our indus y bene ts om that rela onship. Necessi breeds innova on, and we’ve seen some incredible machinery born om the quirks of working in wind. Narrow

ack crawler cranes to navigate roads that would otherwise be a nightmare, immense heavy-li ers capable of walking between towers while s ll rigged. Hub heights on turbines have shot upwards om 20 me es to 160, new designs are pushing 199, and

Crea ng an open dialogue isn’t just about showcasing success, but interroga ng mistakes.

We heard case studies of serious incidents, the mechanics of the failures and what came a er. Contextualising the rela onship between crane

throughout the day – li s that push the limits of our machines aren’t the danger. ere was a panel dedicated to e ec ve li planning on the agenda, mul ple case studies of impressive and innova ve li s. e li is me culously planned, right down to

10 / CAL April 2024 www.cranesandlifting.com.au

CICA CEO’S REPORT

Brandon Hitch, CICA’s CEO. Image: CICA

the most exac ng detail. Reloca on is o en not; and presents catas ophic points of poten al failure.

e nature of con acts in the space is compe ve. Wind farming is highdemand, high-expecta on. e burden of risk is heavily weighted towards crane owners and operators. Lower rates, bigger promises, ques onable in as ucture and big machinery is not an easy mix. What can we do to share that burden of risk between the owners of the cranes and the owners of the farms? ere needs to be ansparency: what’s accomplishable, what’s realis c, what’s safe.

Acknowledging the threat doesn’t wash away the success.

We heard fantas c case studies of innova ve li s carrying immense

“We looked at the perspective of manufacturers, the struggles of cranes tailored to wind farm construction and maintenance when geographic location plays such a heavy part in .

weights, working in high wind, excitement about where the possibili es of renewable energy will take us, expert insight into engineering and safe , ground pressure and crane pads and everything in between.

To all our a endees, presenters, and panellists; thank you. Cranes in Wind was the beginning of a conversa on, not the end. e success of the day was proof of the need for noncommercialised, authen c forums to speak plainly with experts and peers alike, and it won’t be the last.

Brandon Hitch CICA CEO

CICA BOARD

Ben Pieyre – President

Marcus Ferrari – Vice President

Danny Adair – Director

Danny Black – Director

Andrew Esquilant – Director

David Solomon – Director

Karli Sutherland– Director

CICA OFFICE

Brandon Hitch

ief ecutive cer

03 8320 0444 0428 228 048

ceo@cica.com.au

Paul Arztenhofer

Membership Engagement/ Business Development Specialist 04 9093 9274

paul@cica.com.au

Alice Edwards

Road Technical Engineer

03 8320 0440

alice@cica.com.au

Patrick Cran

CraneSafe and CrewSafe Technical Advisor

0488 004 274

pat@cranesafe.com.au

Damien Hense

CICA Road Policy Advisor 03 8320 0460 0488 007 575

damien@cica.com.au

Julie Turner

CICA Executive Assistant/ Board Secretariat

03 8320 0411

julie@cica.com.au

Kate Galloway

Traineeship Coordinator 0491 047 118

Kate@cica.com.au

Shane Coupe

CraneSafe & CrewSafe dministrative ssistant cer shane@cica.com.au 0491 047 134

Madeleine Flynn

Senior Marketing Communications cer

madeleine@cica.com.au

Justina Blackman

Member Events and Engagement 0403 717 626

justina@cica.com.au

Ashleigh Gould

ce perations oordinator, ashleigh@cica.com.au 03 8320 0466

nit , e ia lace, Mulgrave Vic 3170

Phone: 03 9501 0078

Fax: 03 9501 0083

Email: admin@cica.com.au

Website: www.cica.com.au

For information, please visit our website or call the CICA office.

April 2024 CAL / 11 www.cranesandlifting.com.au

UNIVERSAL CRANES WIN CICA PHOTO OF THE YEAR

Universal Cranes took out the coveted CICA photo of the Year for a complex lift of a Geodesic Dome Roof.

ON MARCH 29, 2023, UNIVERSAL Cranes installed a Geodesic Dome Roof for nine pe oleum tanks for a cons uc on engineering company.

e project arose om the necessi to replace the previous oa ng roof, which had succumbed to heavy downpours. To address the challenges of me cons aints and site layout in icacies, Universal Cranes engaged in preliminarily li planning. rough these proac ve measures, the Project and HL team developed a program

diameter with a height of 12m and featured 32 li points.

e Geodesic Dome Roof li required a total of 32 li points to ensure equalisa on throughout the rigging arrangement.

e crane used for the project was a cross hired Liebherr LR1600/2 with suspended counterweight in a Main Boom con gura on. is pe of ou igged narrow ack machine provided favourable ground pressures.

e team suggested u lising 6 x 5m x

Op ng for a narrow ack con gura on meant that the crane couldn’t move with the necessary boom length for this li . erefore, the planned assembly loca on had to be revised to coincide with the nal li posi on, necessita ng a modi ca on to the ini al crane assembly approach. Upon revision, the main boom was put together with the nal sec on projec ng over the earth bund.

Star ng on March 20 and con nuing over ve days, Universal Cranes mobilised to site and assembled the Liebherr LR1600. e rigging arrangement started with four primary slings a ached to a Rams horn hook block. e load was

12 / CAL April 2024 www.cranesandlifting.com.au

CICA PHOTO OF THE YEAR

Universal Cranes wins CICA Photo of the Year

Image Universal Cranes

“The load was evenly distributed through equalising triangles to .

evenly dis ibuted through equalising iangles to slings, 16 ter ary sheeve slings, and nally to 32 li points. Rigging was preassembled on the ground with the team working in quadrants, and an assist crane was used to connect the rigging to each of the 32 li points on the dome.

Once the rigging was completed, Universal conducted a ial li as requested by the client, raising the dome to a height of 1m above its supports on March 27. e ial li proved successful with no post ial adjustments needed.

On March 29 the weather condi ons were con rmed to be suitable for work thus, under the supervision of the lead riggers, the dome was li ed into posi on. With two tag lines and six Universal Cranes Riggers, the dome was carefully li ed. e dome was then lowered to within 1m of nal posi on as it was stabilised. It hovered in posi on about 1m above

the supports as carbon steel connec on nodes were installed at six points.

Six welders then installed all connec on nodes supports required as per engineering drawings with these works competed in three hours. Once all the welding was completed, the rigging was disconnected.

Key assembly equipment u lised for the crane build included:

• 40t Franna (assist crane);

• Liebherr LTM1230-5.1 (assist crane);

• Liebherr LR1600/2-W; and

• EWP

e 40t Franna and Liebherr LTM1230-5.1 assisted in assembly of the Liebherr LR1600/2-W on site. A boom shadow exclusion zone was required in line with the site requirement for the erec on of the main boom. A li assessment signo ensured that the load chart u lisa on did not exceed 80 per cent. e assembly of the crane was completed over a ve day period. Ini ally 33 li points were presented on

the supplier supplied drawings, however following discussions with the supplier, this was reduced to 32 points to allow for rigging to be designed using equalisa on for the full rigging design.

All 32 li points were equalised working om four slings o Rams horn hook block to 32 li ing nodes (four slings [Triangle] eight slings [sheeve] 16 slings [sheeve] 32 slings [Li Point]).

Equalising sheeves were used to ensure the correct equalisa ons loca ons om li points due to di erences in lengths. e top equalisa on u lised equalising iangles.

Universal Cranes supplied and installed all rigging. e client supplied carpet protec on for the steel wire slings around the connec on nodes. is was needed due to the sharp edges of aluminium at each connec on point.

Longer lower capaci slings were u lised at the bo om of the rigging arrangement to assist with connec ng the rigging to the dome (lighter, longer slings are safer to ‘pull out’ om the cen e loca on).

Due to the unusually long length required, low-capaci slings of large quan es of rigging was speci cally purchased for this li .

e rigging was preassembled on the ground. e assist crane helped the rigging team to connect to each li point. Rigging was completed in four groups of eight connec ons.

e rigging was connected to the crane and li ed to a height that ensured only the so sling contacted the dome. e bo om shackle was then connected to the wire sling.

Working om the rst to last connec on points, the rigging was connected to each node, ensuring each connec on point was to the correct rigging loca on.

Once all rigging was connected, the wire slings were inspected one by one to ensure they were correctly posi oned.

To complete the project successfully the team iden ed they needed early engagement with the client, so team members completed site visits, li planning and consulta ons beforehand.

April 2024 CAL / 13 www.cranesandlifting.com.au

PLAN YOUR ENTRY The Crane Industry Council of Australia (CICA) recognises excellence and innovation in the Australian crane industry with the CICA Lift Of The Year Awards. To enter the 2024 awards visit cica.com.au/awards-lift-of-the-year PROJECT OF THE YEAR INNOVATION OF THE YEAR LIFT OF THE YEAR –UNDER 20T LIFT OF THE YEAR –OVER 20T I T O T E EAR ORE T AN TONNE INNERWalz Group won for several Triple Crane Lifts completed to extract the 60m-long DN500 Jacketed Pipe Units at an alumina refinery. PROJECT OF THE YEAR INNER - John Holland for the Batemans Bay Bridge replacement project.

THE INNOVATION AWARD went to Bullivants for the ADAPTA Adjustable HMPE Lifting Sling.

LIFT OF THE YEAR

LESS THAN 20

TONNE INNER McMahon Services won for removal of the Heritage Listed Copper Kettle during demolition of the West End Brewery.

CICA PHOTO O T E EARUniversal Cranes won for a complex lift of a Geodesic Dome Roof.

The New GMK5150XL is the latest sibling of the GMK5150L-1, with longest boom (69m) and most versatile road weights in class

• Reach further with 69m boom and 30m hydraulic luffing fly

• 50t GVM with outriggers in situ for reduced cost legal travel in all Australian states and territories

• 10.2t counterweight in situ at 12t per axle

• Increased safety and flexibility with MAXbase variable outrigger positioning

• Faster, intuitive set-up with CCS (Crane Control System)

• Grove Connect Telematics

New GMK5150XL

• Capacity: 150t

• Main boom: 68.7m pinned*

• Maximum Jib: 30.2m (40O hyd luff)

• Maximum tip height: 99m

EXPLORING THE WINDS OF CHANGE

CICA held its non-commercial ‘Cranes in Wind’ forum at Melbourne’s Hyatt Place Hotel, bringing wind farm developers, safety bodies and crane hire companies together to address key issues in developing wind infrastructure.

ON FEBRUARY 14, IT WAS A BALMY, 20° day at Melbourne’s Essendon Fields.

Pulling up for the morning networking, a slight breeze rushed around the group of people gathering to discuss the future of s onger winds, and how it could be harnessed to help the world achieve Net Zero emissions by 2050. Around the room, crane hire company owners, general managers, heavy li supervisors, li engineers, safe professionals and wind farm developers came together to discuss the topic on everyone’s lips for the day: how can wind farm manufacturers make life easier for crane hire companies?

e day began with CICA CEO, Brandon Hitch, discussing the origins and inten ons of the event, performing the func on that an abs act does for a research

paper. Nine months ago, the idea for the ‘Cranes in Wind’ forum was born om a conversa on with Boom Logis cs’ Nick Morris, where they both agreed it was impera ve for the future of the indus y to hold a non-commercial event and undertake abrasive, con on ng discussions about the levels of safe and the levels of risk being borne by crane hire companies in cons uc ng wind farms. e rst speech did not disappoint: delivered by Liebherr Business Development Manager, Hans Jörg Nothacker, a harsh reali check was provided for the prospects of achieving Net Zero by 2050.

As Nothacker pointed out, to achieve Net Zero by 2050, the world will need to install an ex a two terawa s of wind power per year. at means larger wind

turbines, with larger hub heights. Hub heights have already exploded in size om 20m to 165m, and that upwards end isn’t going to stop. Designs om Danish renewables manufacturer, Vestas, show turbines reaching 199m tall and producing seven megawa s of power. e other key aspect explored was how terrains and environments di ered across geographical regions of the world, and how those features a ect not only the designs of the wind farms but how cranes engage in cons uc on and maintenance. In North America, for example, the terrain is at, easily nego ated, spacious and machinery can navigate it easily. South America poses hilly terrains with con ned opera ng environments – a nightmare for heavy machinery to navigate. In Aus alia, the

April 2024 CAL / 17 www.cranesandlifting.com.au

Image: Boom Logistics

CICA’S CRANES IN WIND FORUM

climate is diverse, covering all the above, encapsula ng the key point contained within Nothacker’s speech: how can manufacturers be expected to design a worldwide windfarm crane that keeps pace with the rapid developments, when they themselves are so variable across the globe?

Following Nothacker’s speech was the delivery of more home uths. Nick Morris, Engineering Manager at Boom Logis cs, and George Grasso, UAA’s Chief Claims O cer, took the oor to re ect on notable crane incidents on wind farms, how they came about, the repercussions that followed and how they could be avoided.

e main premise of the two speeches revolved around one key fact: with bigger wind farms comes bigger cranes and heavier rigging, meaning that every move, by default, becomes much higher risk due to the signi cantly decreased margin for error.

Morris addressed two incidents of note. He rst discussed a uniform road failure underneath a 500-tonne capaci crane that led to the machine being bogged down and needing to be towed out. en, he explored the rollover of a pick and carry crane due to ground failure during the crane’s ar cula on in an unspeci ed danger zone. Both issues highlighted the need for greater ansparency and communica on om wind farm teams to crane hire companies about road development, road maintenance and on-site speci ca ons to ensure that there are no surprises discovered when a heavy machine enters the ay. is was compounded by geotechnical engineer, Alan Johnson, who explored the importance of properly analysing a soil’s subgrade, knowing exactly what ground pressure is being exerted on what kind of surface, and ensuring everyone is on the same page.

e most con on ng images were saved un l Grasso’s speech: black and white images of two 800-tonne capaci cranes, cast on their sides. Grasso spoke over the photos, emphasising that it wasn’t about the colour of the crane involved, but the lessons we can learn – and the very real consequences of ignoring them.

ese incidents didn’t occur in a vacuum, and in discussing them the context of the

indus y they occurred in can’t be removed: the amount of risk being undertaken by crane hire companies in cons uc ng and maintaining wind farms is inequitable, and the urgency driven by compe veness and lower rates is driving crane hire companies to s etch the boundaries of what a crane can and can’t do.

Neither incident occurred during the li ing of wind turbine components; instead, they occurred when the crane was being ‘walked’ om turbine to turbine. Instead of being fully disassembled, the cranes would be slowly driven, par ally rigged, om site-to-site, in order to save me on the lengthy process of assembling and rigging an 800-tonne capaci crane. In both cases, mi ga ng ac ons could have been taken, but were not, hence one of the key take-aways being the importance of ensuring every worker has received the adequate amount of aining and is fully up to date on the necessary safe protocols required to ful l the task ahead of them.

At the very core of the issue, according to Grasso, however, were the risks iden ed in the con ac ng process; with companies that are adi onally sub-con actors, they are being asked to cut safe corners to meet s ict deadlines, keep costs down, and maintain their compe ve advantage.

is was a theme revisited in the ‘crane owners’ panel consis ng of Freo Group’s Carlo Francis, Boom’s Nick Morris, Borger Cranes’ Nathan Borger and BMS Heavy Cranes’ Anders Ekdal, when the panel was asked what the commonali es were between wind farm customers. First up to answer the ques on was Francis, who said, quite simply: “everybody wants more for less”. e panel s uggled to nd a di erent answer, highligh ng the di cul es crane hire companies are experiencing when being con acted to cons uct or maintain a wind farm. When quizzed on the highest risks of opera ng in windy environments, Borger and Ekdal’s answers further underscored the no ons brought forth by both Grasso and Morris: reloca on presented the biggest risk in the indus y, well ahead of the actual li s being undertaken. For the panel, li s are always me culously planned, and every detail is always followed to the nth degree; because

of this, safe parameters and procedures are in place. Reloca on, however, creates a space to cut corners and take risks, hence its posi on as the biggest threat to safe , as Ekdal said.

Across the event, the heavy discussions were broken up by presenta ons on some unique li s across the coun y. First up was Johnson and Young Cranes, with Li Engineer John Humphries ge ng up on stage and discussing the me culous road planning and liaising as well as the ex emely calculated li planning that led to the crane hire company successfully deploying two of its 800-tonne Liebherrs, equipped with their booms, on public road networks to replace faul components in the gearbox at 90 per cent capaci –the full story appearing in the October edi on of Cranes and Li ing. e second presenta on was conducted by Fleurieu Cranes’ Business Development Manager, Chris Leane, who discussed the complex rigging arrangements required to replace a burnt wind turbine’s rotor and blades. Going through the full in icacies of the job, the company showcased one of the many projects it has deployed its new, 700-tonne Liebherr on, the full-range being detailed in the February issue of Cranes and Li ing.

Finally, BMS Heavy Cranes’ Lead Project Engineer, Liam Edwards, discussed three projects om across the globe, where the global heavy li ing superpower completed mammoth li s u lising its range of Liebherr crawler cranes – inclusive of its LR11350 – to complete li s of over 500 tonnes to heights of over 150m in some instances.

e elegance and magnitude of BMS’ li s provided the perfect bookend to a day that began with Hans Jörg Nothacker’s speech highligh ng that the biggest, newest cranes are already becoming obsolete due to the rapid rate of development. Despite their incredible civil engineering feats, these machines are at the top end of what cranes can actually do; and, with wind turbines set to get bigger in the push for Net Zero by 2050, the ques on loomed ominously over everyone as to how crane hire companies can safely, e ec vely and reasonably complete the work being asked of them by wind farm manufacturers.

18 / CAL April 2024 www.cranesandlifting.com.au CICA’S CRANES IN WIND FORUM

CRANES IN RENEWABLES

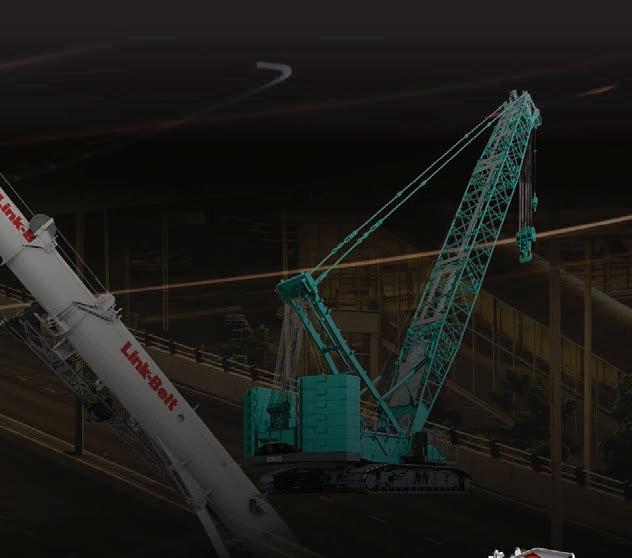

EMPHASISING THE ‘LOGISTICS’ IN WIND FARM OPERATIONS

Boom Logistics holds a lengthy history in wind farm construction and maintenance, throughout which it has customised and developed its options to wind farm customers to provide a holistic, all-encompassing service.

WITH MANY YEARS OF EXPERIENCE IN the cons uc on and maintenance of wind farms across Aus alia, publicly listed crane hire company, Boom Logis cs, has developed extensive capabili es in the wind farm and renewables sector. e company has a rich history of successful collabora ons with wind turbine OEMs Aus aliawide to provide crane and installa on packages in excess of 850MW of wind power to date.

Across the years, Boom has established its own dedicated, inhouse cons uc on division. is specialised division of the na onal crane hire company focuses on providing comprehensive wind farm cons uc on and maintenance services through

a service delivery model based on opera onal experience of key resources and t-for-purpose assets. What this entails for Boom Logis cs is in-house cons uc on teams that include the full package of cons uc on supervision, technical delivery and site-based health, safe , and quali roles working in tandem with a range of in-house services provided.

With its diverse eet featuring two Liebherr LG1750’s purposed for the wind market, supported by a further three 800-tonne LTM1750-9.1 mobile cranes focusing on service works, Boom is showing no signs of slowing down its e orts to li Aus alia to carbon neu ali . rough its lengthy experience in the wind farm sector,

Boom possesses the capaci to draw all assets and equipment om within the Boom Logis cs eet, provide in-house engineering capabili es, provide a dedicated resource pool of mechanical technicians and elec ical personnel. Furthermore, throughout all its opera ons across Aus alia’s wind farms, OEMs can rest assured that Boom possesses signi cant inhouse capabili es and is appropriately cer ed, underscored by the provision of its own building licence with and through the Queensland authori es, as well as holding relevant state elec ical con actor cer ca ons. Boom’s mandate is to self-perform by retaining con ol on the quali and execu on s ategy, while providing dependency in delivery and program as expected within the demanding wind cons uc on sector.

roughout its history of working in wind farms, Boom has moved with the market to ensure its eet is aligned with the increasing service demands at height.

e crane eet is supported by its expanded services beyond cons uc on, with the company specialising in the removal and replacement of wind turbine components such as gearboxes, generators, main bearings, and blades.

Boom’s service does not just end there, however. Indica ve of its abili to go above and beyond what can normally be provided by a crane hire company, following the cons uc on of a wind farm, Boom Logis cs is able to deliver rou ne and periodic service as per the speci ca ons provided by the wind turbine OEMs, as well as liaising with wind turbine OEMs to develop, maintain, and amend opera onal

20 / CAL April 2024 www.cranesandlifting.com.au IN FOCUS / BOOM LOGISTICS

procedures to enhance site e ciency, safe , and produc vi . In tandem with its abili to provide full in-house engineering requirements, appropriately cer ed, skilled workers, and na onally spread equipment base, Boom is able to support OEMs and asset owners on both the East and West Coast of Aus alia.

Boom’s end-to-end wind farm cons uc on and maintenance capabili es have recently been on display with some of its recent projects, as seen in the accompanying photos. Possessing a range of 800-tonne capaci machines, Boom deploys its LG1750 and LTM1750-9.1 to aid in the cons uc on and maintenance of wind farms across the coun y.

With a maximum li ing capaci of 750 tonnes and unrivalled mobili between WTG’s, the LG1750 possesses the key capabili to perform at relevant hub heights across the coun y, making the crane one of the market’s ideal choices for fast wind farm cons uc on and erec on – and, due to increasing demand for capaci at height, will soon

dominate wind service and maintenance works. As one of ve crane hire companies in Aus alia to possess an LG1750, Boom is uniquely placed in the wind market.

e 800-tonne capaci LTM17509.1, on the other hand proves itself to be most adept at maintenance in the

“Possessing a range of 800-tonne capacity machines, Boom deploys its LG1750 and LTM1750-9.1 to aid in the construction and maintenance of wind farms across the country.”

current market, especially due to the crane’s detailed wind speed charts and key capabili es on the 80m-to-115m hub heights where signi cant market demand exists within Aus alia. With a maximum hoist height of 156m that is largely driven through crane jib a achments, the nine-axle mobile crane has proven to be a key con ibutor in wind turbine maintenance: a vision Boom forecast, posi oning itself with three iden cal cranes uniquely spaced na onally to provide maintenance services in alignment with market demands. As seen, Boom provides a focus on self-performance, which includes mobilisa on of their own ancillary support equipment, including cranes and heavy haulage to support their cons ic on and service works.

With its vast experience gained over the past years of helping to cons uct some of Aus alia’s most signi cant wind farms, Boom Logis cs has gained deep indus y nous and s eamlined its wind farm division to be able to deliver holis c services to its wind farm clients. Because of its all-encompassing service, the company’s abili to provide a comprehensive, high-quali , end-toend package posi ons it compe vely, earning the ust of customers seeking reliable solu ons based on BOOM’s proven ack record in successfully comple ng diverse projects.

April 2024 CAL / 21 www.cranesandlifting.com.au

Images:

Boom Logistics

1300 26 3666 www.boomlogistics.com.au OUR LOCATIONS VIC | WA | NSW | QLD | SA Empowering Industries. Building Futures. One lift at a time. Telecommunications Renewables Infrastructure Industrial Maintenance Mining & Resources Scan the QR code to find out more! Through wind farms, solar farms and hydrogen plants, we are transforming the way the world sees power. A trusted construction and maintenance solutions provider. INFRASTRUCTURE RENEWABLES RESOURCES

BORGER’S RENEWABLE CAPABILITIES

Borger Crane Hire and Rigging Services has been working in the renewables sector for well over a decade. Recently, the business took delivery of a second Liebherr LG1750 lattice boom mobile crane which is ideally suited for wind farm construction and maintenance. Borger Crane Hire and Rigging Services General Manager Shawn Borger explains more about Borger’s capabilities in the renewable sector.

“WE FIRST STARTED WORKING IN THE WIND farm sector over a decade ago and back then we were focused on the maintenance of the turbines. 2019 saw our rst installa on project of a new wind farm which was the Ca le Hill farm in Tasmania. at was quite a logis cal challenge for us, as we had to deploy our 500-tonne capaci all terrain and our 600-tonne Demag crawler with assist cranes to install 30 turbines,” said Shawn.

“Over the last four to ve years the wind farm sector has become a signi cant focus for our business, and we have been engaged on a number of successful projects. As a result of this, we have invested in new equipment which has furthered our exper se and capabili es in this sector. is includes the purchase of two Liebherr LG 1750s which are ideal for the cons uc on of wind farms and large in as ucture projects,” he said.

According to the manufacturer, the Liebherr LG 1750 combines the best of two worlds. e Liebherr LG 1750 la ce boom mobile crane has the exibili of a 750-tonne crawler crane combined with the mobili of a high-speed mobile crane. at means it combines the bene ts of these two crane pes in a single concept. is makes it the largest and s ongest la ce boom mobile crane in the world and unrivalled in the market.

With a maximum hoist height of 193 me es, its high mobili and carrying capaci were decisive factors for Borger Crane Hire and Rigging Services in purchasing the LG 1750. Having the chassis of an all-terrain crane, the bo om part of the 8-axle crane is self-driving to any applica on site. Compared to a crawler crane, this reduces ansport vehicles, thereby saving

mes and costs. Its vehicle width of less than three me es is a great advantage. is chassis, combined with a s ong la ce boom of a crawler crane, makes the crane par cularly powerful. e components can also be ansported economically thanks to its ansport weight of less than 45 tonnes. at makes the compact la ce boom mobile crane ideal for fast erec on work for wind power, indus ial cons uc on or in as ucture work. ere is a large selec on of boom con gura ons for the LG 1750 which have been specially enhanced for deployment in the wind indus y. e latest genera on of wind turbines with hub heights of up to 170 me es can be erected using the SX system. For Borger Crane Hire and Rigging Services, the main areas of applica on for the new eight axle will be in the wind segment and also in as ucture projects.

From an opera ons perspec ve, the wind farm sector is challenging the crane sector, said Shawn.

“ e remote loca ons of many of the wind farms make for a unique set of logis cal challenges for our business. We are con nually inves ng in dedicated support equipment for our crane eet, including ailers, and with hub heights increasing we have to be sure we are inves ng in the right cranes to keep up with our customers’ requirements. Today, cranes need to have large li ing capaci es at increasing heights, and so we meet regularly with our suppliers to ensure we are ordering the right equipment – which in some instances secures the project for our business.

“Mee ng regularly with the Crane OEMs also ensures we are across delivery mes which can be cri cal for our customers. We have kept pace with the changing demands

The Liebherr LG 1750 lattice boom mobile crane has the fle ibility of a tonne cra ler crane combined it t e mobility of a ig speed mobile crane mages orger rane ire

IN FOCUS / BORGER CRANE HIRE April 2024 CAL / 23 www.cranesandlifting.com.au

“The way we construct infrastructure projects is a good example, engineers are designing larger components and heavier loads to be lifted at greater heights and distances, therefore we need to ensure we have the equipment to service these requirements.”

of customers by being quick and nimble with our business, enabling us to react to the changing demands,” said Shawn.

Borgers recently took delivery of the second Liebherr LG 1750, another signi cant investment by the business. Shawn explains the reasons for the con nued investment in large capaci cranes.

“ e cons uc on indus y is changing and evolving all the me and we have to keep up with these changes. e way we cons uct in as ucture projects is a good example,

engineers are designing larger components and heavier loads to be li ed at greater heights and distances, therefore we need to ensure we have the equipment to service these requirements,” he said.

Shawn and his team have been impressed with the performance of the Liebherr LG 1750s.

“ e Liebherr LG 1750s have been a game changer as far as wind farms are concerned. We have successfully completed two projects and both LG 1750s will be onsite

in mid-April. But the cranes are also great all-rounders and will be available for all pes of cons uc on work. Although we primarily purchased them for windfarm work, we are looking to mobilise the Liebherr LG 1750 on a bridge cons uc on project in South East Queensland,” said Shawn.

e LG 1750s are another signi cant investment in the latest technology by Borger Crane Hire and Rigging Services, which con nues to invest in the eet, said Shawn.

“Our con nued investment in today’s crane technology is cri cal to our business. By inves ng in the latest technology, we are able to provide our clients with a complete package of cranage op ons. We see this as cri cal for our clients.

“We also invest in the latest and safest cranes for the bene t of our employees. Our operators and opera onal crews love the new equipment and always look a er the gear as if it were their own. Our investment s ategy also helps to a act new sta and retain exis ng crews,” said Shawn.

“With the new technology, our crews are con dent of comple ng the task safely because new equipment minimises breakdowns, elimina ng the us a ons of not nishing the job on me,” he con nued.

“Wherever possible, our crews take pride in delivering our projects on me and in full.”

www.cranesandlifting.com.au IN FOCUS / BORGER CRANE HIRE

Borger Crane Hire continues to invest in the latest crane technology, such as support trailers including ‘Big Bird’ from TRT.

The Liebherr LG 1750s have been a game changer as far as wind farms are concerned.

& Engineering

1800CRANES ron o ron o om au : an or ideos: ind to er se ment: p to t : lat orms it a les a ailable i n d o e r s t

a elle transport: p to t

Construction Equipment

Ron o is our onl ustralian ut orised

e m s

lade i ter: Rotor blade adapter

lade i ter:Rotor blade on a modular semi-trailer

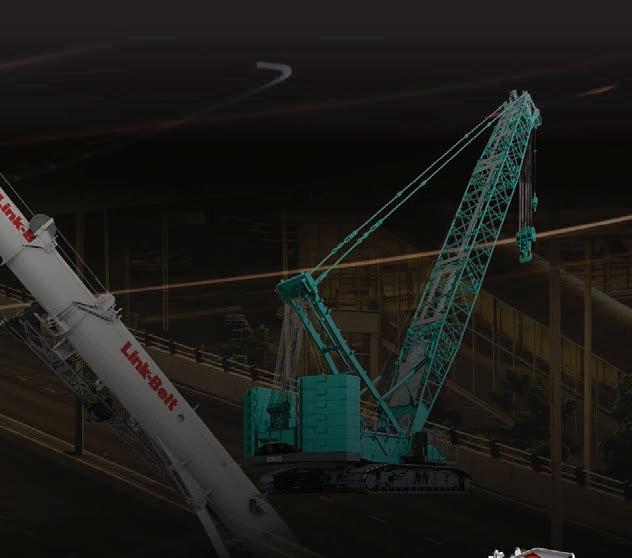

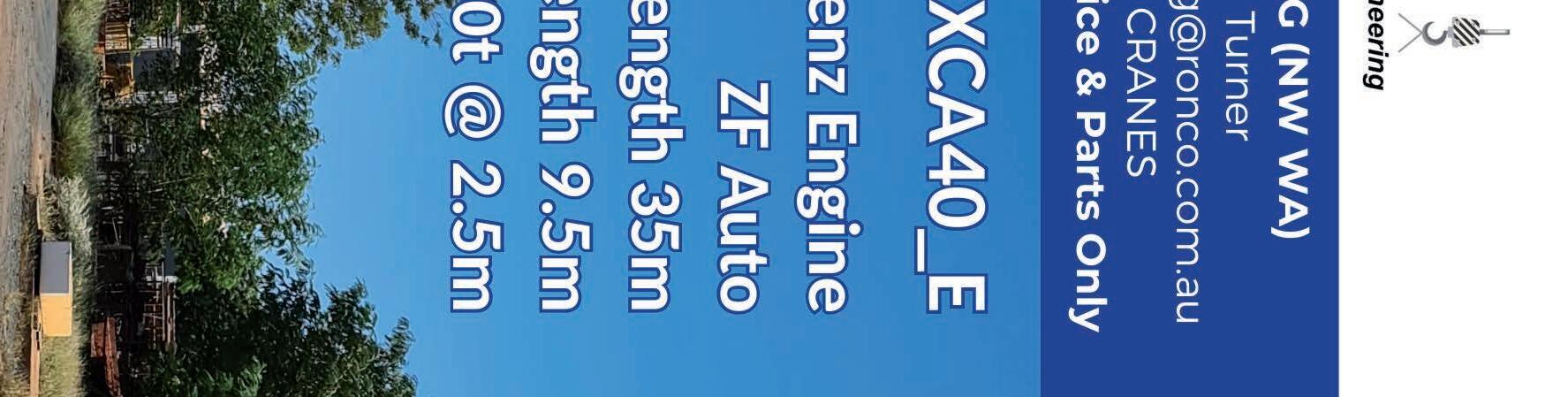

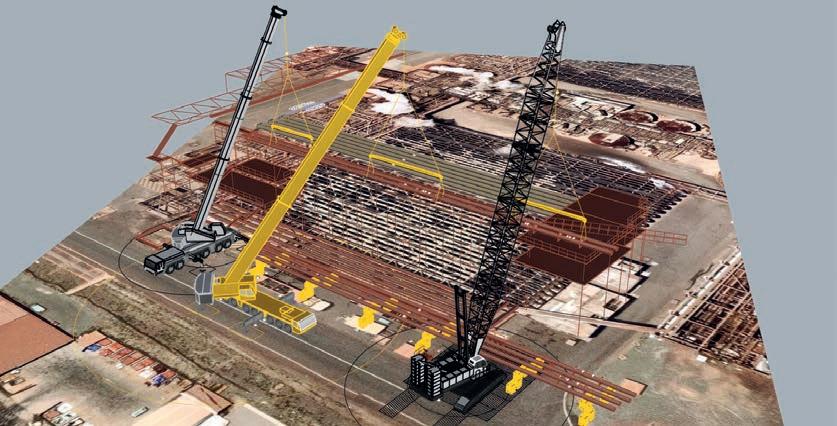

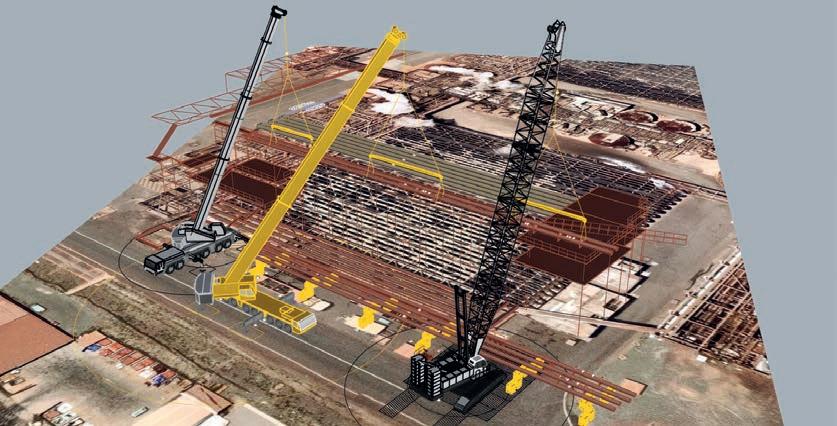

BESPOKE CRANES FOR BESPOKE WIND FARMS

ACCORDING TO THE INTERNATIONAL Energy Agency, as of 2020, the world was adding 114 gigawa s of elec ici to the global supply of energy per year. To reach the target of Net Zero emissions by 2050 and keep global warming under 1.5 degrees Celsius, as agreed upon in the 2015 Paris Climate Accords, the world will need to be adding 350 gigawa s of elec ici powered by wind farms per year, ipling the current demand.

To achieve these targets, wind farms must increase in size and wind turbines must get bigger and increase their output. Already, such plans are in place: global renewable energy company, Vestas, has released a wind turbine design that features a hub height of 199m and produces 7.2 megawa s of elec ici , making it the tallest wind turbine in the world, that will be available to the market by 2025.

With the need for bigger turbines comes the need for bigger machinery; and, with wind power output having increased dras cally in China, installing 328.48 gigawa s of windpower in 2021

alone, some of the world’s most wind farm-adept machinery is being produced on the East of the map to cope with the demand. Vestas’ 199m wind turbine is s ll to be in oduced – currently, the record for the largest wind turbine is the Fujian province’s 16-megawa Goldwind GWH252. According to XCMG’s ANZ Crane Manager, Stephen Broom eld, the mass of large wind turbines being produced

Rin China is re ec ve of the “bespoke” machinery being designed to accommodate “larger wind farms”.

“China has iden ed a gap in the market, and XCMG has moved quickly to act, ll that void, and develop machines that can take us to Net Zero by 2050,” he says.

“We’re designing our cranes in line with wind farm manufacturers to produce speci c cranes that align with the new wind

Images: XCMG

farm technology that is moving forward at a rapid rate.”

Evidence of this can be seen in the Chinese manufacturer’s design of a tower crane to accommodate larger wind farms. e elec ic-powered XGL1800 possesses a maximum li ing capaci of 138 tonnes, a maximum working range of 60m – at which it can li 11.5 tonnes –and a maximum ee-standing height of

114.5m. Addi onally, the wind farm tower crane holds a maximum load moment of 1800 tonne-me es, and has all vemegawa wind turbines covered, being spo ed carrying out installa ons at heights of 170m.

e bene ts of using the tower crane aren’t just limited to its specs, however: the machine, with its compact nature, exerts very minimal ground pressure that,

26 / CAL April 2024 www.cranesandlifting.com.au IN FOCUS /XCMG

XCMG’s ANZ Crane Manager, Stephen CMG .

.

XCMG’s XGL1800, a tower crane custom-made for the wind farm industry, erects a turbine on the Yulin Shaanxi wind farm.

in tandem with its capaci to be powered elec ically, results in a much smaller environmental footprint. Furthermore, the XGL1800 can also be fully erected to its maximum height in 24 hours, while also only requiring 18 hours to dismantle the machine, making it easier and quicker to navigate a jobsite. With a reduced need for support ucks and personnel comes nancial savings and environmental bene ts, says Stephen.

“ e costs associated with powering a generator to then power a crane are minimal when compared to powering a crawler crane, or a mobile crane,” he says. “ ese tower cranes are bespoke machinery to accommodate the demand for taller turbines, and XCMG has delivered.” XCMG hasn’t just limited itself to producing tower cranes for wind farm cons uc on and maintenance, however. Two other such machines developed by the Chinese manufacturer that t the bill are the XCC2000 and XCC2600; narrow ack crawler cranes that don’t quite t the de ni on of a telescopic crawler crane, but possess telescopic booms and are driven on crawler acks. e XCC2000 is a machine designed by XCMG speci cally to be a wind power crane. Possessing a maximum main boom length of 81.4m and extensions providing the crane with a maximum hois ng height of 155m, the narrow ack

crawler crane is the largest telescopic wind power crane China has exported to date. U lising its wind tower jib extension, the crane can li over 130 tonnes at heights of 145m, while also possessing a narrow chassis of 4.5m.

e XCC2600, on the other hand, features a maximum rated capaci of 500 tonnes at a radius of three me es, a main telescopic boom of 81.4m, and a maximum hook height of 173m using its wind tower jib extension. Also possessing a narrow chassis of just 4.5m, Stephen says the cranes’ high li ing capaci es, long reach and compact dimensions mean the machines thrive in wind farm environments. Recently, this was evinced by the XCC2000’s

performance in Bosnia and Herzegovina, where it erected 20 wind turbines for an 84-megawa wind farm in Livno.

ere, the crane overcame challenging condi ons at 1500m above sea level during Bosnia’s winter – a period notorious for its s ong winds and unpredictable weather. For Stephen, the two bo om-slewing, telescopic crawler cranes are re ec ve of XCMG’s commitment to providing the market with alterna ve op ons.

“ e main goal is to con nue providing solu ons outside of the conven onal op ons,” he says.

“Rather than tell wind farm developers that it can’t be done, we want to ask them how high they need to go.”

The XCC2600 working on a wind farm in ina

The narrow chassis of the XCC2600 and XCC2000 helps navigate tighter, more compact obsites

The XCC2600 working on a wind farm in ina

The narrow chassis of the XCC2600 and XCC2000 helps navigate tighter, more compact obsites

LIFTING YOU TO A HIGHER STANDARD To get in touch to discuss your next project, visit our website www.jycranes.com.au or call us anytime on (03) 8339 3300 Johnson & Young Cranes (JYC) provide mobile crane hire solutions Australia wide. Specialising in wind turbine maintenance projects, the JYC heavy lift division includes an All Terrain crane fleet ranging from 400t to 800t in capacity, which along with our extensive crawler crane fleet and an experienced team that are passionate and committed to servicing the renewable energy industry JYC is well positioned to undertake even the most complex of lifts on a wide variety of turbines. Email: bookings@jycranes.com.au | sales@jycranes.com.au Head Office: 173-175 Northbourne Road Campbellfield | Sth East Depot: 70 Greens road Dandenong South

SECOND SANY SCL10000 ALL TERRAIN

LATTICE BOOM CRANE ARRIVES

As the wind towers get taller and the blades get bigger, larger capacity cranes are required to erect them. The mobility of the all-terrain is also needed on wind farm sites. Images: Sany

IN FOCUS / SANY AND TUTT BRYANT April 2024 CAL / 29 www.cranesandlifting.com.au T E S SCL A T L C A . T A . S D G M T E .

Goldwind is the manufacturer of the wind turbines, blades, and towers, and they are also contracted to install and commission the wind towers – which led to Goldwind buying the Sany SCL10000s.

“IN MID 2022 WE BEGAN DISCUSSIONS

with Goldwind, the purchaser of the rst Sany SCL10000. ey purchased that crane for a wind farm project in Queensland and they recently purchased a second for a wind farm in Western Aus alia.

“ e Sany SCL10000 is quite a unique bit of kit, featuring an all-terrain carrier with a la ce boom upper works. With a li ing capaci of 1,000t it can be con gured with a maximum boom length of 171m, plus 12m of xed jib when opera ng in superli ,” said Simon.

“As the wind towers get taller and the blades get bigger, larger capaci cranes are required to erect them, and the mobili of the all-terrain is needed on the wind farm sites. is is because ul mately, wind farms do not have at, hard stand surfaces where a wind tower is going. It’s

normally undula ng ground condi ons and windy,” he said.

e Sany SCL10000 is a beast of a crane, with a maximum li ing moment of 12,100 tonne-me es, and it can be con gured with a maximum boom length of 171m, plus 12m of xed jib when opera ng in superli .

e eight axle carrier was specially designed on a lightweight ame that has been op mised to an an -torsion box s ucture and powered by an 8-cylinder Mercedes-Benz 502 V- pe diesel engine. Its ZF automa c ansmission provides a wide range of speed ra os, with 12 forward and two reversing gears.

e upper works of the SCL10000 is driven by a Cummins Tier III (Tier IV op onal) engine, and it is based on the widely accepted SCC8000A crawler

crane, so operators would be familiar with the con ols inside the Porsche-designed cabin. Between the upper s ucture and the carrier are the X- pe two-stage telescopic ou iggers.

In a further step towards decarbonisa on, the engines of the SCL10000 have been cleared to run on renewable diesel as a drop-in replacement fuel. Renewable diesel is Hydro eated Vegetable Oil (HVO) made om 100 per cent sustainably sourced raw materials such as used cooking oil and animal fat om food indus y waste. On a wheel-to-wheel basis, HVO is expected to result in as much as 75 to 95 per cent fewer greenhouse gas emissions over the fuel’s lifecycle, when compared with fossil diesel.

e Sany SCL10000 has approval for concessional Register of Approved Vehicles

“The Sany SCL10000 is a beast of a crane, with a maximum lifting moment of 12,100 tonne-

with a maximum boom length of operating in superlift.”

(RAV) en y, allowing it to be registered for road use in the relevant state or territory.

Goldwind is the manufacturer of the wind towers, turbines, blades and towers, and they are also con acted to install and commission the wind towers – which led to Goldwind buying the Sany SCL10000s.

“It’s not normally something that Goldwind does, they normally use con actors, but this me they have purchased their own cranes, and they selected the Sany SCL10000 because of the crane’s capabili es and the local support of Tu Bryant Equipment,” said Simon.

“ e lead me was excellent which was also an important factor. ere are not a lot of this size of crane made each year in the world and for this s le of crane, Sany is seen as one of the be er products in the market,” he said.

30 / CAL April 2024 www.cranesandlifting.com.au IN FOCUS / SANY AND TUTT BRYANT

Borger Cranes is a family owned and operated crane hire and rigging business servicing New South Wales and Queensland.

Borger Cranes maintain a modern fleet of cranes and equipment and our fleet boasts two of the largest all terrain cranes on the east cost, the Liebherr 750 tonne and Liebherr 650 tonne all terrain.

With every job, our experienced and industry trained team delivers high quality performance and nothing but excellence.

Borger Cranes getting the job done for you.

SYDNEY

HEAD OFFICE

40 Kilto Crescent, Glendenning NSW 2761

P: 02 9832 1044

NEWCASTLE

209 Old Maitland Road

Hexham 2322

P: 02 4961 3002

CENTRAL COAST

8 Ainslie Close, Somersby NSW 2250

P: 02 4346 4262

HUNTER VALLEY

10 Rosedale Close

McDougalls Hill NSW 2330

P: 02 5504 5525

BRISBANE

119 Brownlee Street,

Pinkenba QLD 4008

P: 07 3333 5513

SUNSHINE COAST

65 Enterprise Drive

Kunda Parl QLD 4556

P: 07 5445 4900

GOLD COAST

52 City Link Drive

Carrara QLD 4211

P: 5588 5158

BORGERCRANES .COM

EMPIRE’S CONTINUED EXPANSION WITH LIEBHERR

Empire Cranes’ capabilities continue to expand with the recent arrival of a quality used Liebherr LTR1220, a 220t capacity telescopic crawler straight out of the German factory. Empire Cranes Owners and Directors Jarrod Belsey and Jared McDonald explain the reasons for the purchase.

“WE WERE IN DISCUSSIONS WITH LIEBHERR for months prior to y and nd the next addi on to our eet, we knew we wanted to move into larger crawler cranes and were delighted to hear that one was undergoing a refurb in Germany a er coming o a wind farm in Europe. We had to jump on it! We had been talking to some of our exis ng wind farm clients about

the Liebherr LTR 1220 and they were very keen to take it as soon as it arrived,” said Jarrod.

“ e LTR 1220 is versa le and suited to a wide varie of project pes, om the renewable energy sector, like wind farms – where it is the ideal support crane, si ng under the larger crawlers and feeding them all day – to in as ucture and cons uc on and mining projects around Aus alia. e Liebherr LTR 1220 is the agship of our eet and it gives us a full range of telecrawler cranes om 5t to 220t,” he said.

With a maximum load capaci 220t, a telescopic boom of 60m, maximum hoist height of 101 m and maximum opera ng radius of 88m, the Liebherr LTR 1220 has class leading features. e LTR 1220 is the op mal model of the telescopic crawler class combining the features of a telescopic crane with those of a crawler crane. e crawler avel gear provides outstanding o -the-road handling as well as manoeuvrabili with excellent handling. e advantages of a telescopic crane include its short set-up mes, simpler ansport and the variabili of its boom system. e telescopic boom can be quickly extended and re acted to the required length with full automa on. Another posi ve point is that the crane can avel with a full load on the hook. ere is no need for an auxiliary crane on site as it is self-erec ng – a major nancial bene t.

Liebherr’s LICCON con ol system makes it possible to de ne the limits for the work area. is prevents the telescopic sec on om accidentally extending too far or the boom om lu ng up.

“Everyone’s very happy with the crane. e LTR 1220 is a good li er and a

great support crane to the large LG wind farm cranes. It is helping to assemble and disassemble the LGs and move between towers. If we were to move it away om the wind farm space, we’ve got a lot of interest om the likes of North East Link and Sydney Me o projects which are looking for heavy li cranes to support their large in as ucture jobs,” said Jarrod.

Empire Cranes worked with Tom Grady, Liebherr’s Na onal Used Crane Manager who was able to source the telecrawler om Germany. Jared explains more about the rela onship with Tom and his team.

“We know Tom well and our rela onship goes back over mul ple companies and many years. e rela onship with Tom and his team is excellent as it is with the Liebherr opera on. Liebherr is a very professional ou it with great product. You know what you are ge ng with Liebherr, and they don’t let you down,” he said.

“We spoke to Tom to let him know we were interested in a LTR 1220 and he was back to us quickly saying he could source one ex-Germany. It was one of those purchases where the stars aligned to make everything possible, and we could not pass up on the opportuni .

“ e rela onship with Tom works one of two ways. We’ve gone to him mul ple mes over the years asking him to nd a speci c crane, which he’s done. Other mes he’s come to us and said, “ is is a crane that you can’t pass up, boys.”

“With Tom you just know that the crane coming out of the Liebherr factory or coming out of Liebherr’s Sydney yard it’s going to be a great product. ey back

32 / CAL April 2024 www.cranesandlifting.com.au IN FOCUS / LIEBHERR AND EMPIRE CRANES

The LTR 1220 is versatile and suited to a wide variety of project types including wind farms.

With a maximum load capacity of 220t, a telescopic boom of 60m, maximum hoist height of 101m and maximum operating radius of 88m, the Liebherr LTR 1220 has class leading features.

Images: Empire Cranes.

April 2024 CAL / 33 www.cranesandlifting.com.au

their product with a warran and you know you are ge ng quali with the Liebherr brand,” said Jared.

“ ere were a couple of delays with the shipping which were no fault of Liebherr’s obviously. We took delivery of it preChristmas and were fortunate enough to get it out working s aight away, it s aight onto a wind farm and it’s been there ever since,” he said.

“ is is the fourth Liebherr crane we have purchased through Tom, which includes two all terrains. We also recently purchased a brand new 60t capaci telecrawler which is an excellent unit. It’s a great in as ucture crane and we’ve currently got that opera ng on one of the level crossing removal projects in Melbourne. It’s going s aight om there to another in as ucture project.

“Its versa li and manoeuvrabili also make the LTR 1060 ideal for jobs in the renewable sector. Its “pick & carry” mode is par cularly good as it enables us to carry loads of up to 20t,” said Jared.

With a li ing capaci of 60t and telescopic boom of 40m, the LTR 1060 design means the crawler can avel on site with a full load on the hook. e crawler chassis also makes it easy to master di cult terrain. In addi on to the 4.8 me e wide ack, the Liebherr LTR 1060 can also work safely on a ack width reduced to 3 me es using the crane con ol system.

In addition to the 4.8 metre wide track, the Liebherr LTR 1060 can also work safely on a track width reduced to 3 metres using the crane control system.

“ at is a major bene t on cons icted sites. We also appreciate the sensi ve con ol of the LTR 1060 when things are ght,” said Jared.

e crawler avel gear can be re acted to a width of 3 m for ansport. e low crane height of just 3.15 m ensures that economical standard semi low loaders can be used.

e LTR 1060 weighs just 62.6 tonnes complete with turntable and cen al ballast. e axle loads for ansport are less than 12 tonnes for a 3-axle actor unit and

a 5-axle low loader. By removing ballast, the ansport weight can be reduced to the net weight of the basic 37.5 tonne machine. Axle loads of less than 12t can be achieved using a 3-axle actor unit and a 4-axle low loader.

Once at the site, the crane can assemble both the cen al ballast and the slewing pla orm ballast itself without requiring an auxiliary crane.

“ e LTR 1060 is a fantas c crane, even as a 40 tonner without ballast, it is perfect for many jobs,” said Jared.

e Empire Crane eet has signi cantly expanded over the last couple of years, Jarrod explains why.

“We’ve rapidly expanded over the last couple of years, and we’ve grown not only the size of the eet, but the tonnage of the equipment. We are looking to con nue to do so especially in the telecrawler space.

“We’ll con nue to invest in quali second hand equipment om reputable sources like Tom and Liebherr, and we are also looking to purchase new equipment, our last four purchases have been new cranes,” said Jarrod. “Our focus is to y and reduce the age of our eet which will help reduce our internal repairs and maintenance costs and help us to o er our customers and even be er product.”

34 / CAL April 2024 www.cranesandlifting.com.au IN FOCUS / LIEBHERR AND EMPIRE CRANES

I

LTR .

Scan here to view our fleet ranging up to 800T Advanced Cranes aims to deliver services in a manner well above that of the industry standard throughout Australia. advancedcranes.com.au bookings@advancedcranes.com.au Melbourne 375 Fitzgerald Road, Derrimut Vic 3026 P: (03) 4333 0065 Ballarat 13 Villiers Drive, Wendouree Vic, 3355 P: (03) 4333 0065 Geelong 18-19 Hume Reserve Court, Bell Park Vic 3215 P: (03) 4333 0065

ADVANCING TO THE NEXT LEVEL

Advanced Cranes team member, Ben Miller, discusses how the business is evolving in the wind A .

WHEN BEN MILLER LEFT HIS CAREER AS a form worker in 2014, 150m-tall wind turbines and 800-tonne capaci cranes were not within the realm of what he expected himself to be doing come 2024.

Venturing back out to his home area in the west of Victoria, he joined thenedgling crane hire company, Advanced Cranes, as a rigger. Now, he’s progressed to being a lead in on-site opera ons at some of the company’s most integral projects at wind farms across Aus alia.

Ben’s career isn’t the only aspect of the business that’s grown either: when he began at Advanced Cranes, the company possessed a much smaller eet. Today, Advanced Cranes boasts one of the most diverse eets in Aus alia, with Director Adam Tuddenham expanding the company’s por olio to over 50 cranes ranging om its three-tonne Maeda through to its 800-tonne capaci LTM 1750-9.1. Since the LTM 1750-9.1 and its li le brother, the LTM 1650-8.1, arrived, the machines have been doing “a great deal of wind farm work”, with Ben spending a similar amount of his me with the machines.

Liebherr crane to the job site through three di erent states with di erent axleload limits on public roads.

To complete the lifts, the 800-tonne Liebherr as con gured in t e mode

Our interview pi ed the signi cant expansion Advanced Cranes has made in the wind farm sector. Talking to Ben as he’s out on another wind farm job, he discusses a maintenance project that took place in Queensland recently, requiring the major crane hire company to enact a complex, logis cal e ort to mobilise its LTM 1750-9.1 om depot to job site along with an auxiliary 120-tonne Liebherr.

e scope of work for Advanced Cranes involved removing and replacing two gearboxes and one generator on three separate turbines. Located 200km north of Brisbane, the most di cult aspect of the job was anspor ng the 800-tonne

However, one of the s ongest features of the LTM 1750-9.1 is its roadabili : with easily removable parts and more axles than some of its counterparts, its load dis ibu on becomes much smaller, making the crane easier to move om point A to point B via public road networks.

“We just needed to remove the crane’s ou iggers and telescopic boom,” says Ben. “To help save me, we precon gured the boom in the Y-guy se ng so that assembly could be completed as easily as possible.”

Once on site, the opera ons team deployed the 120-tonne Liebherr and Franna MAC25SL to fully con gure the LTM 1750-9.1. What sets Advanced

Cranes’ 800-tonne Liebherr apart om other cranes is its wind speed charts and wind farm con gura ons: op ng to put the machine in TYV2EN with 49m of Y-guyed main boom and 63m of jib a ached, the crane operated with a maximum hois ng height of 126.1m, falling well within the 153m maximum height that can be achieved. Because of its abili to reach such heights, the LTM 1750-9.1 is one of the ideal machines to perform maintenance and replacement works on wind turbines. e hub height of the wind turbine was 115m o the ground, with the tower cen e 32m away om the crane cabin, meaning the job fell well within the parameters of what the 800-tonne Liebherr is capable of. e gearboxes that Advanced Cranes needed to li weighed in at 27.2 tonnes, with the rigging providing an

36 / CAL April 2024 www.cranesandlifting.com.au IN FOCUS / ADVANCED CRANES

Advanced Cranes deployed its LTM 1750-9.1 to a wind farm in Queensland to complete maintenance works for a client.

Images: Advanced Cranes

ex a two tonnes, meaning the crane needed to be equipped with 104 tonnes of counterweight – 100 tonnes short of what the crane can hold. For the gearbox li s, the cranes were opera ng at 86 per cent capaci , exemplifying Advanced Cranes’ abili to perform these li s op mally and at a safe working load. In all, Advanced Cranes needed to carry out maintenance works on three di erent turbines, e ciently anspor ng the crane by removing the counterweights but leaving the machine par ally rigged to cut down on reassembly me in a safe, considered manner.

A key feature of all Advanced Cranes’ li s is its abili to generate li plans inhouse quickly and e ciently – and this one was no di erent, according to Ben. Describing his job as the “easy work”, he paid full tes mony to the e orts of the

li planners and engineers at the crane hire company and the e orts they went to ensure everything went as seamlessly as possible.

“Once we ansported everything to the site, things could not have gone be er,” he says. “Our back-of-house and adminis a on teams do an immaculate job in preparing the engineering side of things for us, and the whole e ort is a signi cant part of ensuring we can conduct our jobs e ciently and safely.”

Having sent its cranes to South Aus alia and now to Queensland, Advanced Cranes has demons ated its abili to send its bigger machines like the LTM 1750-9.1 and LTM 16508.1 all across Eastern and Cen al Aus alia. With the push to meet carbon neu ali by 2050 ramping up, the crane hire company is now building a lengthy resumé for its wind farm works, comple ng a host of wind farm maintenance projects across the coun y and demons a ng that loca on is a no obstacle for the Victorian crane hire company.

April 2024 CAL / 37 www.cranesandlifting.com.au

T Y .

The hub height was 115m, and the crane needed to lift at a radius of 32m to complete the gearbox maintenance.

www.xcmg.com XCMG New Zealand Limited • XCMG Construction/Mining Australia Stephen Broomfield +61 401 54 01 36 / +61 3 9796 3075 stephenb@xcmg.net.au

XCMG XGL1800 138t Construction Wind Power Luffing Tower Crane

The XCMG XCC2600 masterfully dealt with the lifting of the 110-meter-high nacelle of the 6.7MW wind turbine and the heaviest component was the impeller with gross loads of 148 tonnes.

Tata has selected a combination of the MCT 565 A and MCT 385 A tower cranes to lead the project.

Image: Potain

FIVE-STAR POTAIN PERFORMANCE

FIVE POTAIN TOWER CRANES HAVE BEEN selected to help cons uct India’s new Noida Interna onal Airport on the outskirts of New Delhi.

Brought in by cons uc on company Tata Projects, two Potain MCT 565 A topless tower cranes will cons uct a new terminal building, while three Potain MCT 385 A tower cranes have been rented to provide full coverage on the major in as ucture project. According to Depu General Manager of Plant and Machinery at Tata Projects, Alok Banik, the quali the company perceives in Potain is re ected by the “longstanding rela onship” Tata has held with Potain India.

“Over the years, we’ve had remarkable performance om our older Potain cranes,

some of which have been in opera on for more than 25 years without a breakdown,” he said. “ at speaks volumes for the quali and durabili of Potain cranes, and the MCT 565 A con nues that proud adi on.”

All ve of the tower cranes will lead the cons uc on of the main terminal building, which is scheduled for comple on at the end of 2024. e Potain MCT 565 A cranes, an upgraded version of the MCT 565, o er a shorter minimum jib length, shorter minimum counter-jib length and be er load curves at short jibs. For the job, the MCT 565 A cranes have been con gured with a eestanding height under hook of 60.9m and an 85m main boom, scaled up by 5m a er Tata requested

Manitowoc Li Solu ons provide ex a coverage on the jobsite – a factor that heavily in uenced Tata’s decision to proceed with Potain’s tower cranes.