Official Media Partner FEATURES Borger Crane Hire Gold CoastTRT Made PossibleSpecial Feature on Telehandlers THE DEDICATED RESOURCE FOR THE CRANE INDUSTRY / JUNE 2023 FULL CHARGE IN 2 HOURS! INTRODUCING THE TADANO ELECTRIC ROUGH TERRAIN

With over 30 years’ experience, UAA is the largest and most reputable specialist mobile plant and machinery insurer in Australia, New Zealand and globally.

The UAA Group has the knowledge, ability and capacity to insure a wide variety of plant and machinery spanning numerous industries.

Our experienced claims team has access to a network of the very best expert industry repairers, assessors and suppliers.

Our insurance products are tailored to produce a hand crafted solution to meet your business needs

please

EXPERTS IN MOBILE PLANT INSURANCE

more information

UAA’s Industrial Special Plant and Procon products,

Insurance Broker or visit www.uaa.com Industrial Special Plant and ProCon underwritten by QBE Insurance (Australia) Limited. ABN 78 003 191 035, AFSL 239545. Underwriting Agencies of Australia Pty Ltd. ABN 86 003 565 302 AFS Licence 238517. Underwriting Agencies of New Zealand Limited (UAA). 4758199, NZBN: 9429040999678. J6663

For

on

contact your

IN THIS

6 Industry News

Liebherr launches new narrow track crawler crane.

12 Tadano Up Front

Tadano launches EVOLT, the first all-electric rough terrain.

16 CICA WA Chair Report

Training is high on the agenda for CICA WA.

18 CICA Regional Meeting

Massive fundraising effort from CICA NSW and dedication honoured.

22 CICA Member Profile

Changing of the guard in Gladstone.

26 Liebherr Unplugged Select Liebherr showcases its batterypowered electric cranes.

TELEHANDLERS FEATURE

30 MCT

The Magni rotating telehandler is a game changer

36 JCB

JCB unveils net-zero products, paving the way for the rest of the world.

40 Beaver Technology Services

BTS discusses its new crane related safety products.

44 Tutt Bryant

CCS’ Elliot Bird discusses all things Tutt Bryant and his new Sany crane.

46 TRT

TRT Made Possible looks at TRT’s continued evolution.

50 Mammoet

Introducing the Dutch company’s 6,000t ring crane.

52 Borger Crane Hire

Borger Crane Hire continues Queensland expansion.

56 Gayndah Cranes

Dan Leggett of Gayndah Cranes discusses operating in a rural town.

57 Cer tex

Certex Lifting is now one of the countr y’s largest lifting equipment and service companies.

58 Franna

A delve into the broad servicing and logistics capabilities of Franna.

62 XCMG

XCMG launches a new European 120t capacity all-terrain crane.

64 Under writing Agencies Australia UAA appoints new CEO and reinforces commitment to customer service.

68 Pace Cranes

Andrews Crane Hire takes delivery of new Maeda and Tracked Carrier.

71 New Grove Rough Terrains

Grove’s Italian plant expands manufacturing range.

74 Liebherr Unplugged

New all electric piling rigs out and working.

76 LTE Construction and Zoomlion

Gleason Cranes deliver new Zoomlion crawlers.

78 Lif t of the Month

What our industry does best.

June 2023 CAL / 3 www.cranesandlifting.com.au 34

34 Manitou Manitou’s new range of telehandlers and ultra-light machines.

SCAN THE QR CODE TO SUBSCRIBE TO OUR NEWSLETTER 62

ISSUE Cranes and Lifting Magazine cranes_and_lifting Cranes and Lifting

Published by:

WELCOME TO THE JUNE ISSUE OF CRANES AND LIFTING .

NEW GUIDE TO BENEFIT CRANE INDUSTRY

The Andrews Labor Government is making it easier for Victoria’s mobile crane operators to access key information and processes, thanks to a new Australian first guide for the industry.

Minister for Ports and Freight Melissa Horne recently released the new Crane Industry Guide which is online for the crane operation sector to use.

The guide has been designed for current and future mobile crane operators as a single, valuable reference point for industry and includes information on crane importation, registration, legislation, regulation and road network access.

It’s been developed in collaboration with the Crane Industry Council of Australia, VicRoads, the National Heavy Vehicle Regulator and Freight Victoria.

The guide complements information and processes accessed through the National Heavy Vehicle Regulator to enable the importation and registration of a crane and associated certificates required.

It also builds on the Labor Government’s reforms to make it easier for heavy vehicle operators to move around the state. In August last year,

eight pre-approved maps, which give mobile crane operators information about where they can travel on the road network, were also published to improve safety and efficiency for the industry.

This issue of Cranes and Lifting includes articles relating to products manufactured to meet the increasingly onerous emissions targets within the construction sector. We talk to Borger Crane Hire about its continued expansion in Queensland and TRT explains the importance of its people within the business. We report on the CICA NSW Regional meeting in Canberra which included a massive fund raising auction and we continue to highlight the ‘Changing of the Guard’ within our industry.

As always, the Cranes and Lifting team has worked hard to bring you this interesting content and as always, we hope you enjoy the read.

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

CEO John Murphy

E: john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy

E: christine.clancy@primecreative.com.au

Managing Editor Andrew Hobbs

E: andrew.hobbs@primecreative.com.au

Editor Simon Gould

E: simon.gould@primecreative.com.au

T: 0404 865 109

Journalist

Jack Alfonso

E: jack.alfonso@primecreative.com.au

Business Development Manager

Emily Schlegel

E: emily.schlegel@primecreative.com.au

T: 0466 317 555

Client Success Manager

Glenn Delaney

E: glenn.delaney@primecreative.com.au

Art Director Bea Barthelson

Imaging Assistant Paul Breen

Subscriptions

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

4 / CAL June 2023 www.cranesandlifting.com.au

FROM THE EDITORIAL TEAM

Simon Gould Editor, Cranes and Lifting

brisbane | sydney | melbourne adelaide | perth tuttbryant.com.au1300 658 888 Peter Lawgall0411 256 388Peter.Lawgall@tuttbryant.com.au Philip Chadwick0457 510 097Philip.Chadwick@tuttbryant.com.au Follow us on: “EU STAGE V EMISSIONS COMPLIANT” INTRODUCING... CR-130RV 13T CITYRANGE CRANE ENGINE: HINO J05E-VA EU STAGE V GET YOUR ORDERS IN NOW! L : 7,465mm W : 1,995mm H : 2,870mm 13,000kg 13t x 1.7m (5.3m Boom) 5.3 ≈ 24.0m (6 sections)

Liebherr has unveiled the successor to its successful 600-tonne LR 1600/2W narrow track crawler crane With more power and greater lifting height, the LR 1700-1.0W offers the best prerequisites for efficient assembly of modern wind turbines in wind farms. To meet the challenging demands for driving and steering, Liebherr has equipped the crane’s new narrow track travel gear with components from its next larger crane class. The new 700-tonner is now the benchmark for narrow track cranes worldwide.

Narrow track crawler cranes are optimised for use on wind farms: they can travel from one turbine to the next along the existing routes and be deployed very quickly. Liebherr developed the first narrow track lattice boom crawler crane 20 years ago, the LR 1400/2-W. However, in the intervening years wind turbine

towers have become taller and wind power components heavier. For this reason, Liebherr launched the significantly more powerful LR 1600/2W back in 2010, of which around 50 units are currently in operation worldwide. However, assembly of the latest generation of wind turbines now requires cranes with an even higher lifting capacity.

Just as the LR 1700-1.0 replaced the LR 1600/2 in Liebherr’s line-up almost two years ago, the narrow track version of the 600-tonner is now also being replaced by the new 700-tonne LR 1700-1.0W.

Liebherr has designed a narrow crawler travel gear and a new centre section with star support for the existing slewing platform. The boom systems from the standard crane can be adopted to a large extent. At 5.9 metres, the crawler travel gear is only 10 cm wider than its predecessor. When

driving, the supports are folded forwards and backwards.

The biggest differences to the predecessor model, the LR 1600/2W, are the new crane’s significantly higher lifting capacities and greater lifting heights. The basis for this is a more powerful basic machine as well as the 3.5-metre-wide H-lattice type sections in the lower area of the main boom, which increase the lateral stability of the entire system.

Comparing the longest windturbine boom with the derrick system on the predecessor model (156-metre main boom plus 12-metre lattice type fixed jib) with the new crane with the same boom length results in a 64 per cent increase in lifting capacity (from 73 to 120 tonnes). In addition, the new LR 1700-1.0W can be built up higher: with derrick system plus 15 metres, without derrick system plus 6 metres. The new crane thus meets the more challenging requirements of working on modern wind turbines with hub heights reaching 170 metres. Liebherr also offers the LR 17001.0W with a luffing jib. This option was not available for its predecessor.

The V-frame and VarioTray have more than proven their worth on the LR 1700-1.0, LR 1800-1.0 and LR 11000 crawler cranes. Therefore, the narrow-gauge variant of the LR 17001.0 also receives these innovative systems.

The V-Frame ballasting system is a hydraulically adjustable folding frame that allows the ballast radius of the 700-tonne crawler crane to be adjusted continuously between 13 and 21 metres. A rigid ballasting system is thus no longer required for large radii. These innovations offer great advantages, especially for wind turbine assembly.

The new narrow track crane also gets the LR 1700-1.0’s modern lattice type fixed jib, which can lift up to 170 tonnes and is designed for both single and parallel operation. Limited rope length is no longer an issue because two winches can work simultaneously over the jib.

INDUSTRY NEWS 6 / CAL June 2023 www.cranesandlifting.com.au

LIEBHERR’S MOST POWERFUL NARROW TRACK CRAWLER CRANE ON THE MARKET

69m Boom!*

MAXbase Equipped

LEVEL ACCESS THE BENCMARK 150t HAS MORE REACH

The New GMK5150XL is the latest sibling of the GMK5150L-1, with longest boom (69m) and most versatile road weights in class

• Reach further with 69m boom and 30m hydraulic luffing fly

• 50t GVM with outriggers in situ for reduced cost legal travel in all Australian states and territories

• 10.2t counterweight in situ at 12t per axle

• Increased safety and flexibility with MAXbase variable outrigger positioning

• Faster, intuitive set-up with CCS (Crane Control System)

• Grove Connect Telematics

• Capacity: 150t

• Main boom: 68.7m pinned*

• Maximum Jib: 30.2m (40O hyd luff)

• Maximum tip height: 99m

New GMK5150XL

New GMK5150XL

MODULIFT LAUNCHES MULTILIFT

Introducing the Multi-Point: Modulift unleashes flagship all-in-one beam to the lifting industry.

“Featuring an optional 360-degree swivel hook and extended support stands, the Multi-Point is a perfect option for tandem lifts with two cranes when there is only one lower lifting point required and rotation of the load is critical.”

Modulift recently announced the release of the Multi-Point; a strong, versatile lifting system designed to save rigging time and maximise use across multiple lifting applications.

Expertly designed and engineered for use as a semispreader or a lifting beam and also ideal for tandem lift operations.

Multi-Point gives the operator the power to lift across multiple points at varied spans.

The Multi-Point Beam is the most versatile and adaptable in the Modulift range.

The Multi-Point gives unrivalled Modulift strength and reliability with additional features to suit different lifting scenarios.

With lifting points on the top and bottom, the Multi-Point Beam can be reused for multiple lifts.

The Multi-Point can be supplied with or without swivel hook, allowing for tandem lifts where there is only one lower lifting point required. It can be used as a semispreader to give a steadier lift, and as a lifting beam.

Designed using the latest 3D Linear Analysis, and manufactured to BSEN 13155, the Multi-Point gives peace of mind with safety and practicality at the forefront of its design.

Engineered for any lift, anywhere in the world, multiple connection points on the top and bottom provide ultimate flexibility for the beam to adapt to any situation – whether lifting a boat, reel, tank, turbine or anything else in between.

Featuring an adaptable and versatile modular design, the Multi-

Point is ultra-portable, robust and can be reused for hundreds of lifts. With easily detachable components, the beam lifts at spans from 3 to 12m, with a lifting capacity from 12t right up to a jawdropping 600t.

Simply unbolt the sections to lengthen or shorten the Multi-Point and change the rigging set-up.

Featuring an optional 360-degree swivel hook and extended support stands, the Multi-Point is a perfect option for tandem lifts with two cranes when there is only one lower lifting point required and rotation of the load is critical.

A truly innovative piece of kit, the Multi-Point Beam can also be used as a semi-spreader to give a more balanced lift, or as a lifting beam when headroom is restricted.

INDUSTRY NEWS 8 / CAL June 2023 www.cranesandlifting.com.au

MultiPoint Beam with Hook

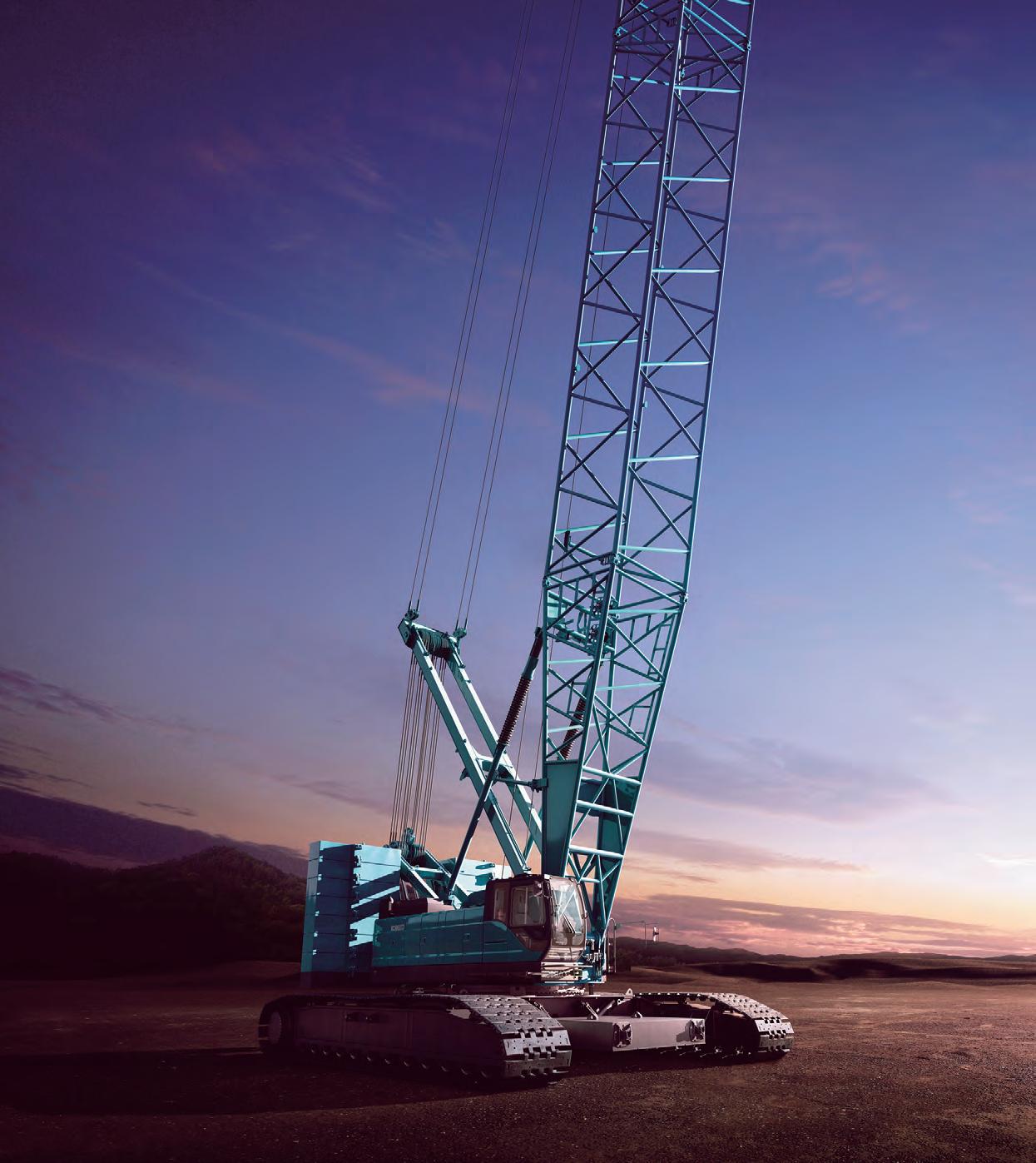

Our market proven CKS range is reliable, efficient, economical and built to exceed expectations.

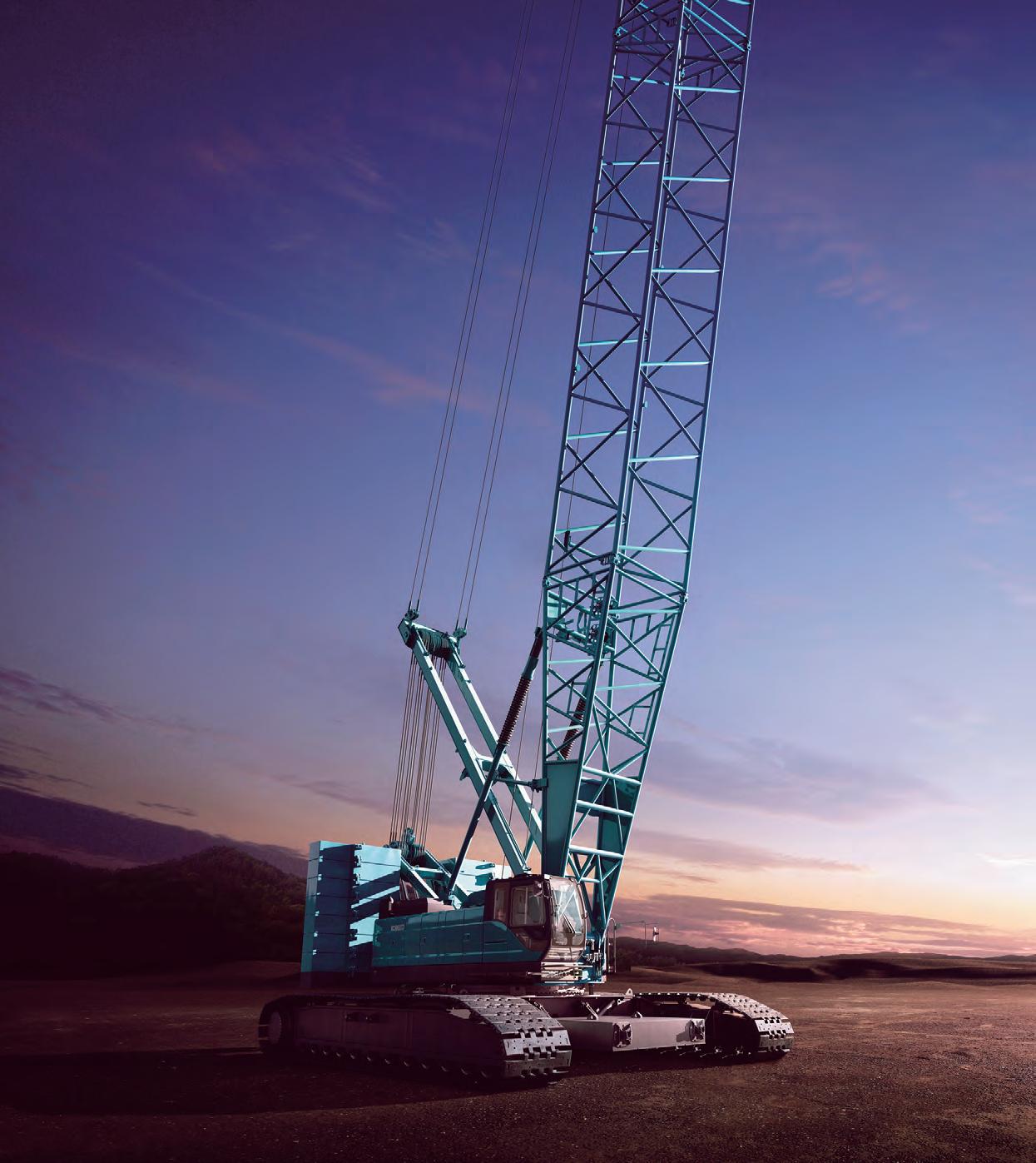

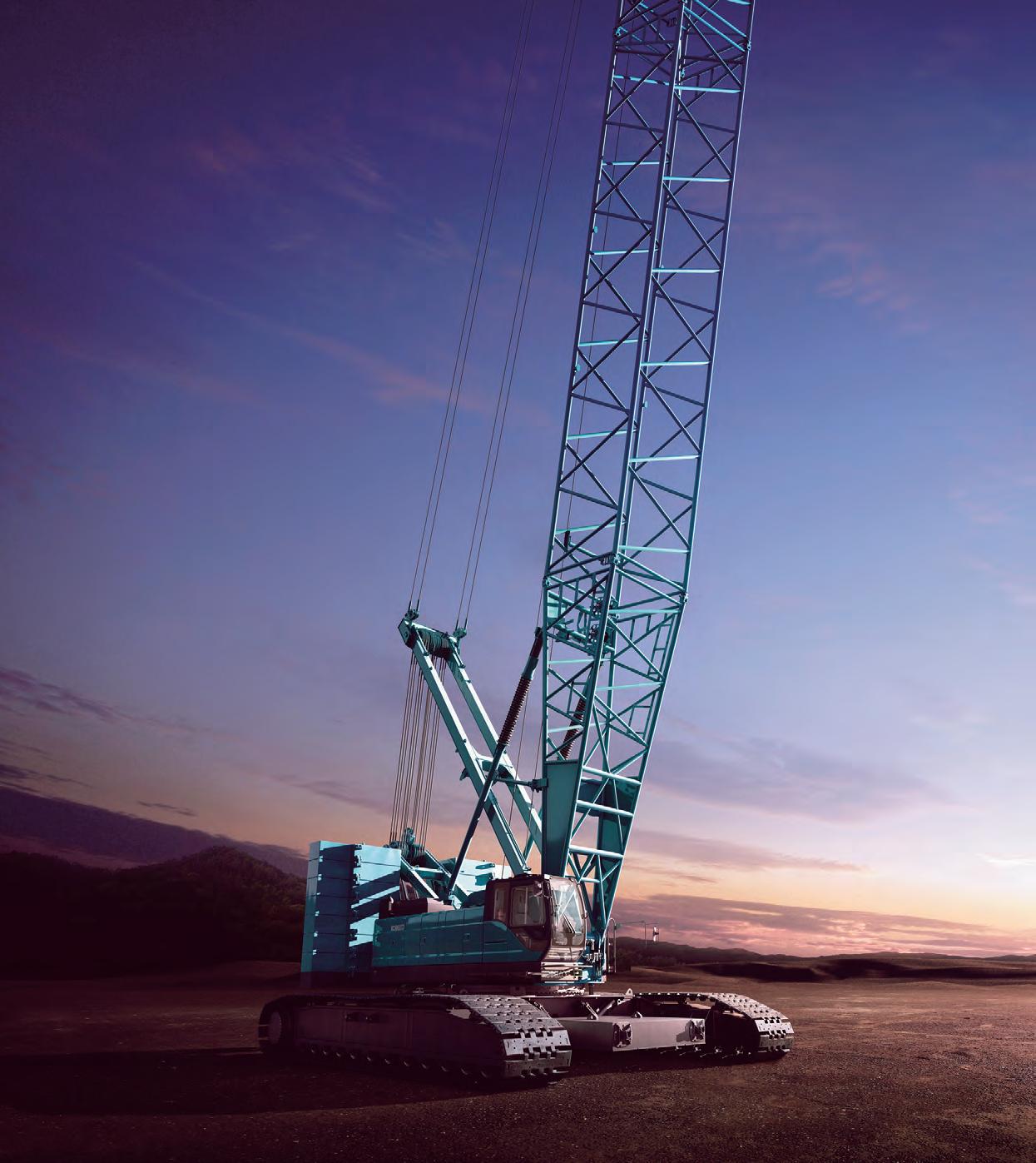

ORDER NOW!

With limited production slots, talk to us today to secure your next CKS Lattice Boom Crawler.

Plus we’ve got you covered with full backup sales, service, parts and support Australia wide with TRT.

TRT are your Asia-Pacific agents for Kobelco. Talk to us today about your next project!

07 3890 8800 www.trtaustralia.com.au

ROBORIGGER APPOINTED DISTRIBUTOR FOR LUDWIG HOOKS

Roborigger has been appointed as Ludwig Hook’s exclusive distributor in Australia. while increasing safety at the same time. Ludwig hook can be used on all types of cranes including mobile cranes, tower cranes and harbour cranes.

The first Ludwig hook system sold in Australia was recently delivered to NEWest Alliance, a joint venture between Downer EDI Works & CPB Contractors, and it will be used to lift steel masts for railway electrification.

Unhooking loads by hand is a time-consuming and often dangerous job. Ludwig Hook makes work safer and more efficient by enabling loads to be released remotely, from a safe distance, at the push of a button. The Ludwig Hook and slings can remain on the crane hook, making ladders, elevated work or lifting platforms unnecessary. The Ludwig hook speeds up the lifting operation

Ludwig hooks are made by Ludwig System Gmbh & Co. KG in Germany and exported worldwide. Ludwig System is Roborigger’s agent in Germany, Austria, Switzerland, Belgium, and The Netherlands.

“Ludwig Hook makes work safer and more efficient by enabling loads to be released remotely, from a safe distance, at the push of a button.”

INDUSTRY NEWS 10 / CAL June 2023 www.cranesandlifting.com.au

Roborigger appointed distributor for Ludwig Hooks.

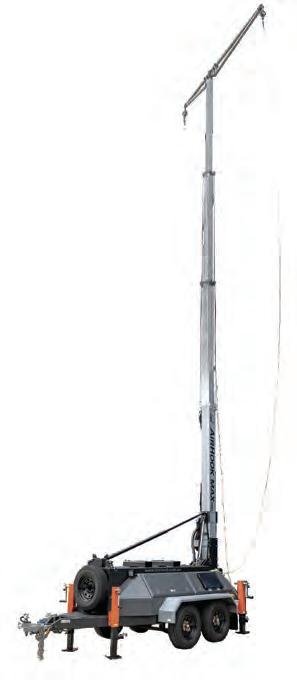

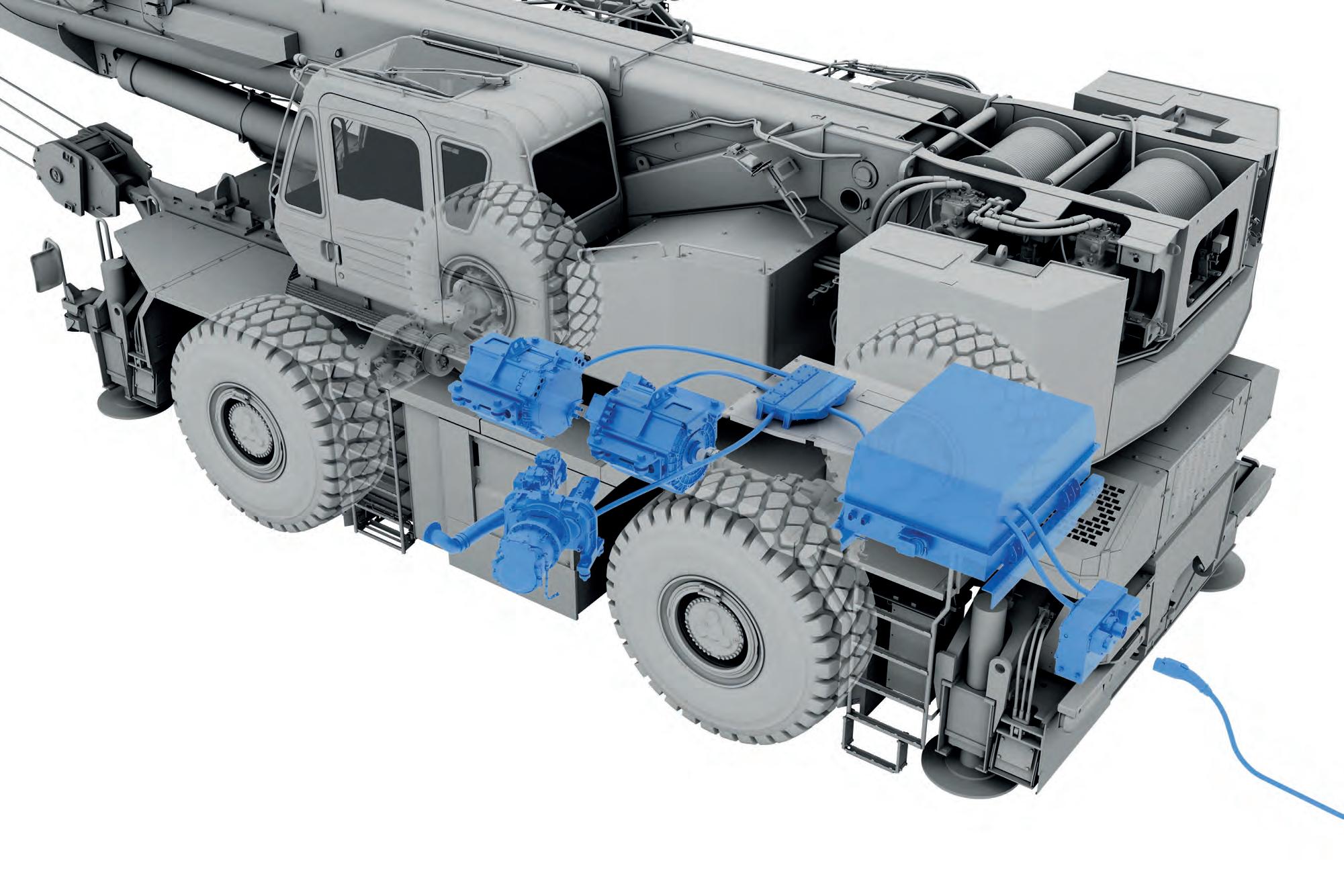

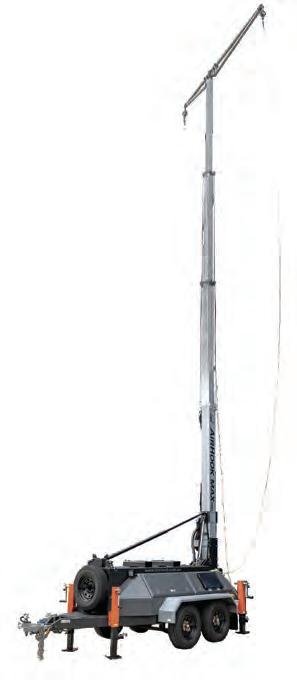

TADANO LAUNCHES EVOLT ELECTRIC ROUGH TERRAIN

In April 2021, Tadano announced that it was working on a fully electric rough terrain crane. Two years later, the EVOLT GR-1000XLL EVOLT was showcased at t his year’s ConExpo to industry members for the first time as a fully functional prototype.

THE CRANE CAN TRAVEL TO WORK SITES and take care of all lifting operations there exclusively with energy supplied by its batteries, making fully zeroemission operation possible. A single battery charge is enough for up to nine hours of crane operation, or five hours of crane operation with a travel distance of up to 20km.

Meanwhile, the charging time is a mere two hours with fast charging on a US-COMBO CCS1 connection and only about seven hours with normal charging on a three-phase 240 VAC. In addition, unlimited operation with the crane plugged into a power outlet is available as well.

The powerful electric motor delivers a maximum output of 194 kW, ensuring that the GR-1000XLL EVOLT has the equivalent lifting capacity and operating speed as its diesel-driven sibling, the GR-1000XLL-4.

But where the GR-1000XLL EVOLT truly stands apart from its diesel counterpart is environmental

friendliness, with Tadano calculating savings of around 8,328 litres of diesel and a resulting reduction of close to 22t of CO2 emissions a year for an average crane usage scenario.

The GR-1000XLL EVOLT will be launched in 2024 - first in the USA and in Canada with releases in other countries, such as Australia, to follow.

“This crane will make an invaluable contribution to achieving our goal of reducing the CO2 emissions from our products by 35 per cent by 2030,” says Toshiaki Ujiie, President and CEO of Tadano Ltd.

It is worth mentioning that the crane’s lifting performance is exactly the same as that of its diesel-driven counterpart, the GR-1000XLL-4.

The powerful electric motor delivers a maximum output of 194 kW, ensuring that the GR-1000XLL EVOLT has the exact same lifting capacity and operating speed.

It offers a top speed of 11.2 mph (18 km/h), and its dimensions are

exactly the same as those of the GR1000XLL-4.

Please note, there might be slight changes in specifications compared to the prototype, as the design and production plan is finalised.

AN ELECTRIC DRIVE THAT COMES WITH MANY MORE ADVANTAGES

The electric motor not only provides the rough terrain crane with environmentally friendly operation, but also with significantly lower noise levels during work, all while eliminating exhaust emissions. These two factors come with considerable advantages for customers in a multitude of scenarios, including projects in urban areas with noise regulations, nighttime lifting work, and indoor assignments.

During ConExpo Tadano also introduced its diesel-driven APU

UP FRONT / TADANO EVOLT 12 / CAL June 2023 www.cranesandlifting.com.au

auxiliary power unit for the first time ever on a GR-800XL-4 rough terrain crane. The unit is already currently approved for use as an optional accessory for new orders of Tadano RT models GR-1000XLL and GT1000XL-4 in the USA and Canada.

The nine-hp two-cylinder engine on the unit has an extremely low fuel consumption rate of only 0.75 litres of diesel fuel per hour.

June 2023 CAL / 13 www.cranesandlifting.com.au

The powerful electric motor delivers a maximum output of 194 kW, ensuring that the GR-1000XLL EVOLT has the equivalent lifting capacity and operating speed as its diesel-driven sibling, the GR-1000XLL-4.

“This crane will make an invaluable contribution to achieving our goal of reducing the CO2 emissions from our products by 35 per cent by 2030.”

“This crane will make an invaluable contribution to achieving our goalof reducing the CO2 emissions from our products by 35 per cent by 2030,”

Moreover, by producing an output of 972 W, the APU is able to supply electric power for numerous important crane functions while the onboard engine is off.

This includes the floodlights and aviation obstruction beacon, the wipers for the windshield and roof, the HVAC system, the USB outlet, and, of course, all important display functions inside the cockpit.

Tadano calculates that the APU can reduce fuel consumption and CO2 emissions by around a fourth when compared to the energy used by the idle running of the onboard diesel engine on the crane.

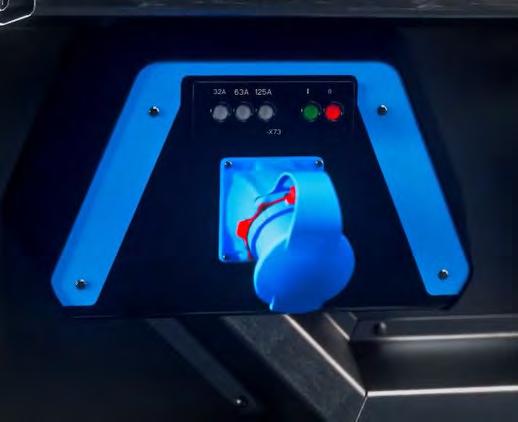

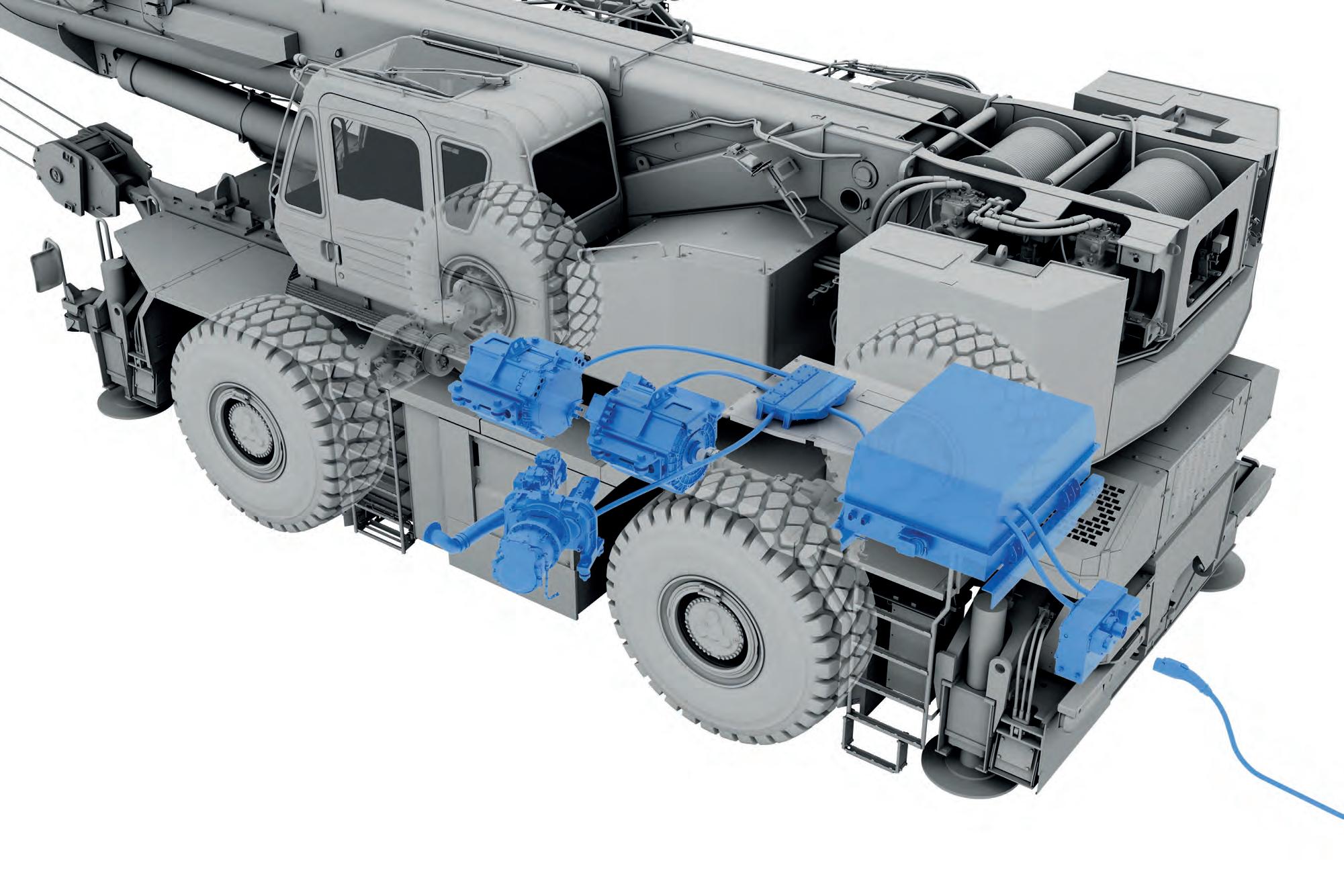

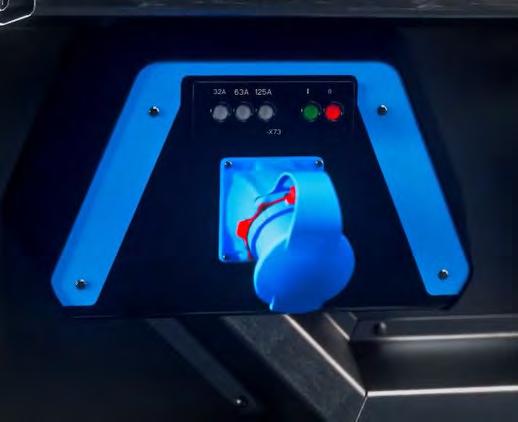

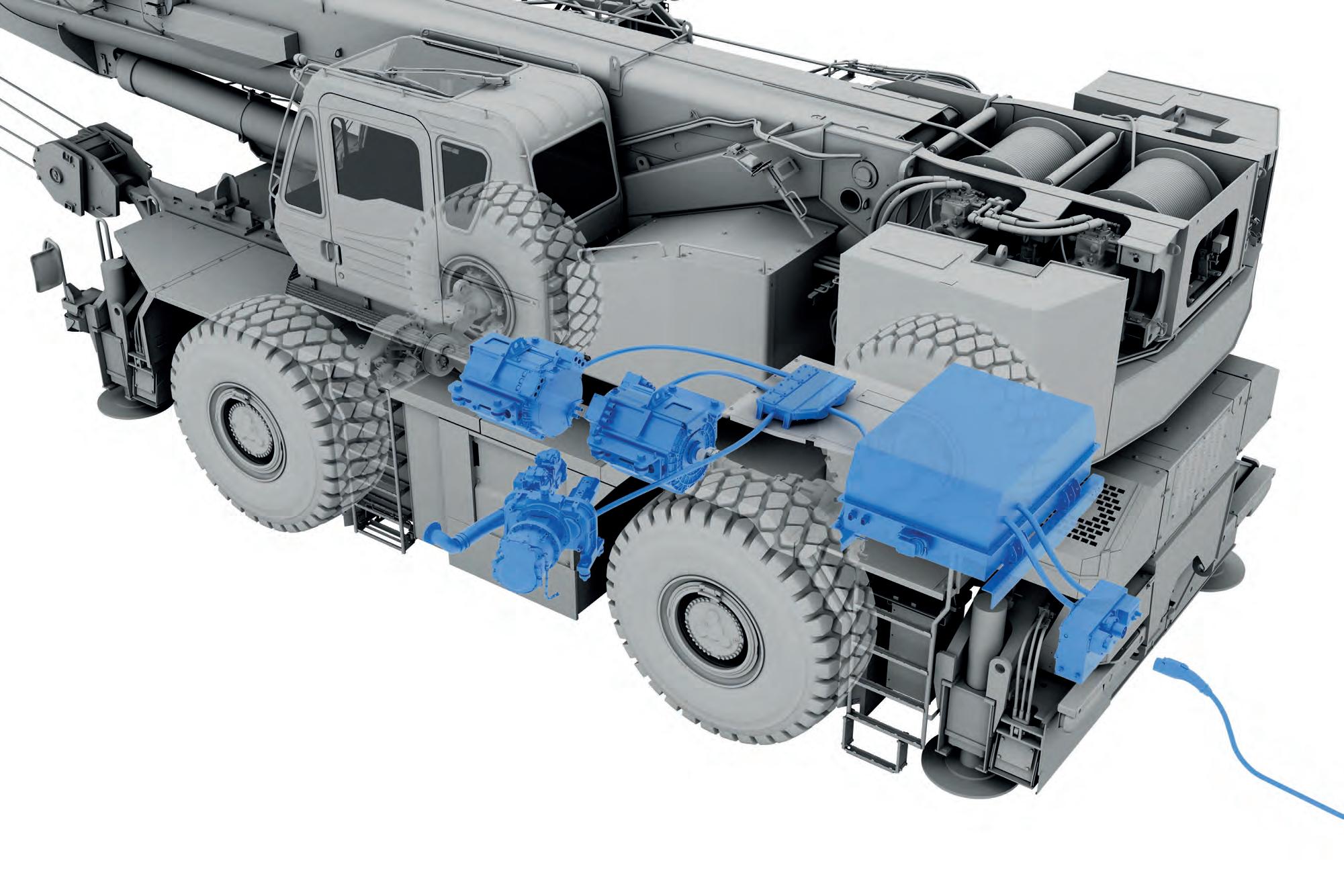

ELECTRO-HYDRAULIC “E-PACK” MAKES ZERO-EMISSION CRANE OPERATION POSSIBLE

Tadano introduced its e-PACK in Europe all the way back in 2019. It is an electro-hydraulic system featuring an integrated 32-kW electric motor that works with zero emissions and nearly zero noise – and without any loss in lifting capacity to boot.

All that is needed is for the crane to set down the e-PACK where it will be used so that it can be connected to an external 400 V / 63 A or 400 V / 32 A power supply.

The e-PACK is currently available

for all new Tadano AC cranes with lifting capacities of up to 80 tonnes, as well as a retrofit for existing cranes.

To register your interest in the GR-1000XLL EVOLT, scan the QR code printed below here.

Signing up will keep you up to date on product availability, specifications, and pricing for the Oceania region.

SCANNING THE SMART

You will be informed with updates on product availability, specifications, and pricing for the Oceania region.

UP FRONT / TADANO EVOLT 14 / CAL June 2023 www.cranesandlifting.com.au

“The e-PACK is currently available for all new Tadano AC cranes with lifting capacities of up to 80 tonnes, as well as a retrofit for existing cranes.”

CODE allows you to register your interest on the GR-1000XLL EVOLT.

says Toshiaki Ujiie, President and CEO of Tadano Ltd.

P.A. Construction Equipment Pty Ltd (Pace Cranes) was established in 1987 to provide the construction industry with an independent Australian owned and operated crane sales, crane service and crane spare parts organisation.

For over 30 years Pace Cranes have offered premium quality equipment to the Australasian market with a dedicated and unrivalled service, supported by specialist technical advise across the full range of equipment sold.

Mini Crawler Cranes Crawler Cranes

Electric Cranes

Mobile Cranes Telescopic Crawler Cranes

Duty Cycle Cranes

Glass Lifting Devices

Tracked Carriers

Crawler Cranes

Knuckle Boom Cranes

Electric Pick & Carry Cranes

Glass Manipulators

Mini Crawler Cranes Crawler Cranes

Electric Cranes

Mobile Cranes Telescopic Crawler Cranes

Duty Cycle Cranes

Glass Lifting Devices

Tracked Carriers

Crawler Cranes

Knuckle Boom Cranes

Electric Pick & Carry Cranes

Glass Manipulators

pacecranes.com.au +61 2 9533 5411 sales@pacecranes.com.au

Bi-level Multi Loaders

SKILLS DEVELOPMENT GETS A BOOST IN WESTERN AUSTRALIA

State Chair update: CICA Western Australia

IT’S A PRIVILEGE TO SHARE AN UPDATE from CICA Western Australia. We’ve had a great start to 2023. Last year the W.A. State Training Board approved and gazetted the Certificate III + skillset for mobile crane operations. Crane operators are front-and-centre of the many major construction, mining and renewable projects in our State, so proper skill development for mobile crane operators is essential. This investment into future

operators will create a safer industry.

On Wednesday 3 May, CICA WA held a Traineeship information evening for employers. This evening was well attended, and those who came along heard about the economic and business benefits of well-trained operators, how to use the Traineeship to retain good staff, and to upskill the existing team using RPL (Recognition of Prior Learning) credits.

The next CICA Traineeship intake is in July, which will add to the twelve already progressing well through their training. The intake numbers are predicted to increase as the Traineeship becomes more widely known. It’s not too late to sign up, if you have a potential trainee in mind or would like more information head to the CICA website, www.cica.com.au

Another CICA initiative to make

16 / CAL June 2023 www.cranesandlifting.com.au

CICA WESTERN AUSTRALIA UPDATE

Anthony Grosser State Chair WA.

the workplace and industry are both components of the On-road Articulated Steering Crane program. This standardised training and assessment tool assists small and medium businesses that would otherwise not have the resources to create this training in-house.

Thank you to Franna for hosting our WA members who took the opportunity to complete their Articulated Steering Crane On-road training and assessment, earlier this year.

Sheltered and pristine, the Pullman resort at Bunker Bay was the perfect location for the W.A. Members Retreat / Regional Meeting in March, which was well attended and very enjoyable. Dunsborough, Margaret River and the South-West are wonderful places to visit if you are considering doing some extra touring before or after the 2023 National CICA Conference in Perth later this year.

This year, serving on the CICA WA branch executive are Rod White, Ben Pieyre, Allan McPherson, Darryl Reeves, Ray Martinez, Robin Ghosh, Craig Meldrum and Lester Fernandaz. We welcome any ideas or feedback that you may have, so come along to the branch events which can be found on the CICA website.

CICA WA recently said ‘goodbye’ to Dave Adams who had provided secretarial support to our branch for 7 years. We’d like to take this opportunity to thank Dave for his hard work and wish him all the very best in his future endeavours.

Anthony

Grosser

CICA WA State Chair

CICA BOARD

Ben Pieyre – President

Marcus Ferrari – Vice President

Tom Smith – Director

Danny Adair – Director

Danny Black – Director

Andrew Esquilant – Director

David Solomon – Director

Karli Sutherland– Director

CICA OFFICE

Brandon Hitch Chief Executive Officer 03 8320 0444 0428 228 048 ceo@cica.com.au

Paul Arztenhofer Membership Engagement/ Business Development Specialist 04 9093 9274 paul@cica.com.au

Alice Edwards Road Technical Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran CraneSafe and CrewSafe Technical Advisor 0488 004 274 pat@cranesafe.com.au

Damien Hense CICA Road Policy Advisor 03 8320 0460 0488 007 575 damien@cica.com.au

Julie Turner CICA Executive Assistant / Office Manager 03 8320 0411 julie@cica.com.au

Kate Galloway Traineeship Coordinator 0491 047 118

Kate@cica.com.au

Ashleigh Gould

Cranesafe and Crewsafe Administration Officer

Phone: 03 8320 0466

Email: ashleigh@cica.com.au

Michelle Verkerk Marketing Communications Officer 0404 938 714 michelle@cica.com.au

Justina Blackman Member Events and Engagement 0403 717 626

justina@cica.com.au

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170

Phone: 03 9501 0078

Fax: 03 9501 0083

Email: admin@cica.com.au

Website: www.cica.com.au

For information, please visit our website or call the CICA office.

June 2023 CAL / 17 www.cranesandlifting.com.au

“The next CICA Traineeship intake is in July and this will add to the twelve already progressing well through their training.”

CICA CANBERRA REGIONAL MEETING: EDUCATIONAL, REWARDING AND INSPIRATIONAL

The CICA Canberra Regional meeting attracted an audience of over 50, including a number of crane owners from various regions throughout the ACT and NSW as well representatives from crane manufacturers and suppliers to the industry.

EDUCATIONAL

NSW Vice Chair Stephan Becherand hosted the event and introduced various topics and industry updates delivered by leading industry experts. These included updates and presentations from Steve Miller and Rochelle Mathews from NHVR, Brett Graham from TfNSW, a finance and market update from Chris Burke, a National CICA update from Brandon Hitch, and presentations about Road Vehicle Standards Legislation from

the Federal Department of Infrastructure, Transport, Regional Development, Communications and Art, and separate presentations from Graham Evans and Finlease and a Roads Update from CICA’s Damien Hense. These presentations will be covered in more detail in future editions of Cranes & Lifting.

For many, a highlight of the day was the Crane Original Equipment Manufacturers (OEM) Question and Answer session, with panellists including

John Stewart from Manitowoc, Neil Webb from TRT representing TIDD and Kobelco, Michael Cawston from Pace Cranes representing Sennebogen and Maeda, Matt Molross from XCMG, Andrew Esquilant from Liebherr and Jay Gower from Tadano. The audience was left in no doubt that our industry will continue to navigate difficult times relating to the parts supply and availability of new equipment. However, the Crane OEMs reassured attendees that the transition

18 / CAL June 2023 www.cranesandlifting.com.au

CICA CANBERRA REGIONAL MEETING

NSW Vice Chair Stephan Becherand, Sarah and Jon Brookes and Paul Heeks, Pace Cranes.

to alternate fuels was underway and will be managed in an orderly manner with various options being researched and developed.

REWARDING

The meeting then moved to dinner and the fundraising auction, which is always a highlight, but before this commenced CICA had two surprises. John Farrier from FS Cranes and Anthony Davis from The Baden Davis Crane Connection were recognised for their dedication to the industry. Both have given hundreds of hours over decades to various CICA committees and lobbying government departments for the betterment of the crane industry.

INSPIRATIONAL

CICA ACT & NSW had decided the proceeds of the auction would be donated to the battle to eliminate children’s cancer. With the help of Paul and Anthony Heeks the audience was introduced to an inspirational young lady, Sarah Brookes, and this is her story.

“Like most other children I was a happy and healthy. I played about every sport possible and enjoyed every part of it but more than anything else I loved soccer and had made a high-level representative development team,” she told attendees.

“During late 2015 and into early 2016, aged eight, I started to develop a sore right shin. As anyone would, due to the amount of sport I was playing, we put it down to bruising, growth, or a twisted ankle.

“Unfortunately, the pain became worse, with no bruising or obvious swelling. Because of the pain I began coming home from dancing crying, and was unable to run around and kick a ball on the pitch. Noticing this unusual behaviour mum and dad decided to take me to the physio,” said Sarah.

Upon initial consultation, it was suspected that Sarah may have developed a stress fracture. However, a week later subsequent scans revealed that Sarah had a rare cancerous tumour in her shin bone called osteosarcoma.

The next two years were filled with emergency rooms, isolation,

chemotherapy, surgeries, scans, blood tests, infections, feeding tubes, transfusions, bed sores, orthopaedic appointments, plastic surgeon appointments, physiotherapy…the list went on.

“Throughout these two years I was never home for more than two weeks at a time before returning to the Sydney Children’s Hospital in Randwick. I would reach temperatures of 38 degrees-plus and I was forced to return to avoid spread of infection.

“It also became very apparent, in unfortunate circumstances, how lucky I was to have the support of my family and friends. Mum and Dad never left my side with Mum taking the day shift and Dad staying nights whilst both, together with other family members, tried to keep life as normal as possible for my younger sister at the time,” said Sarah.

Sarah underwent many rounds of strong chemotherapy between August and November of 2016. Two weeks before major surgery to remove the tumour routine scans were done in preparation.

“Unfortunately, after the months of chemotherapy, we were told the tumour

had not reduced in size but instead had continued to grow. On November 7, 2016, I underwent a 10-hour operation to remove the tumour from my shin. The tumour was radiated and my shin placed back into the tibia. My fibula (a non-weight bearing bone) was removed and grafted onto the tibia with a 20 cm plate and multiple screws.

“Following this I spent many days in the intensive care unit. We could not rate the medical team or hospital staff highly enough but like many of these procedures it was not without complications. For example, after the surgery and whilst in ICU, alcoholic wipes were accidentally left between my body and the bed, dissolving the skin. So whilst my leg was in traction I was treated as a burns victim as well,” said Sarah.

Sarah also had adverse reactions to blood transfusions, which were resolved incredibly with antihistamines. Chemotherapy commenced again at the start of December and continued for another six months. On May 3, 2017, on her 10th birthday, she rang the bell.

“I was cancer free and in remission. Whilst I was cancer free, I was unable to

June 2023 CAL / 19 www.cranesandlifting.com.au

“CICA ACT & NSW had decided the proceeds of the auction would be donated to the battle to eliminate children’s cancer.”

CICA recognised Anthony Davis for his contribution to the crane industry.

my body was without an immune system. I endured many sessions of physiotherapy to learn to walk again and I underwent further surgeries to remove central lines which had been placed during my treatment. As a result of my weak bone structure the plate and screws that had been placed in my ankle snapped, which required replacing.

“In 2018, during my final year of primary school, I decided I wanted to do something to give back and ultimately make the brutal reality of childhood cancer one that would never have to be endured by any other child or family. I was inspired by a young girl who had made handmade bracelets to raise money for childhood cancer research,” said Sarah.

“With the help of my mum and the sacrifice dad made in letting me turn his man cave into a candle factory, I was able to develop Sarah’s Charity Candles from which I have donated one hundred per cent of all proceeds to Children’s Cancer Research.

“Since then, I have been fortunate enough to participate in various charity events, fundraisers, and school fairs, together with my own candle sales, raising over $51,000, all of which I have been so proud to donate to kids cancer research and awareness.

“Please never underestimate the need and appreciation of your support. I remain one of the lucky kids who survived; however, many others sadly do not. We live for the day zero childhood cancer becomes a reality.”

Jon Brookes introduced his daughter with these words.

“In 2015 I sincerely considered myself to be the luckiest man in the world, having a beautiful wife, two beautiful daughters and a successful business, the result of of over 25 years hard work. As a family we wanted for, nor needed anything.

“However, an Xray, followed by a scan and phone call turned our world upside down with our daughter Sarah, aged 8, being admitted to Sydney Children’s Hospital Randwick with osteosarcoma, an aggressive bone cancer.

“Like so many, I grew up in an environment where I was told if you work harder, trained harder and studied

harder, you will have every opportunity to succeed in our Lucky Country. In this instance, I learnt very quickly it didn’t matter what I had worked for, what we had and who we knew, we simply couldn’t buy our daughter’s health,” said Jon.

“In a heartbeat, I would have swapped places rather than have my daughter exposed to this insidious disease and the treatments including extensive chemotherapy and major surgeries. But as we all know, it unfortunately doesn’t work

“With the assistance of an amazing team of doctors, oncologists, orthopaedic surgeons, nurses and various affiliated organisations, Sarah thankfully faced and beat adversity and today, we remain one of the lucky families.

“So many families don’t share the same

prognosis and story and have sadly lost their child to this insidious disease. We remain forever grateful to organisations such as CICA, which are generous with overwhelming contributions. These will continue to make a difference in realising our shared wish that one day, we will all live in a world free of childhood cancer. We would also like to thank Anthony, Paul and Faye of Pace Cranes for the invitation to be involved in CICA’s special occasion and tell our story,” said Jon.

With the audience listening to every word, it was apparent that when Sarah finished her story, there wasn’t dry eye in the room. This translated to vigorous and generous bidding on the many and varied items and CICA was delighted to announce the auction had raised over $42,000!

CICA New South Wales has once again demonstrated such incredible generosity. Thank you to everyone who donated to such a worthwhile cause, who spoke at the event and who attended.

20 / CAL June 2023 www.cranesandlifting.com.au

CICA CANBERRA REGIONAL MEETING

“We remain forever grateful to organisations such as CICA, which are generous with overwhelming contributions. These will continue to make a difference in realising our shared wish that one day, we will all live in a world free of childhood cancer.”

CICA recognised John Farrier for his contribution to the crane industry

Unplugged series Zero-emission. 100% performance LAS-LANSales@liebherr.com www.liebherr.com Signature look

A CHANGING OF THE GLADSTONE GUARD

“The company was formed in 1979 by my parents Neil and Beth, and it generated its first invoice in January of 1980. Dad was working locally for EDI Hire and he could see the region of Gladstone was entering into a construction period, and he saw an opportunity to buy his own crane.

“His boss at the time was Ivan Rusik, Rusik supported Dad’s decision to branch out on his own. Ivan happily utilized Dad as a subcontractor while he grew his own customer base, Ivan also assisted Mum in learning how to run the books. Once the business was established, his passion for operating cranes and enjoyment of working with his customers provided a good income for our family and built a stable platform for me to build on. For Dad he was just doing what he loved it never felt like a job,” said Wayne.

The first crane Neil bought was an 8t capacity BHB tractor crane. Wayne continues the story.

“Dad was doing all a whole range of work with that crane, from day one it was mostly general hire and this included housing, domestic construction and light commercial work. He also worked on wharf expansions around Gladstone harbor and secured some project work on the building of Boyne Smelters Limited, which remains one of our key clients today.

In the mid-’90s, Wayne’s sister Tanya and brother-in-law joined the company, with Robert being trained by Neil and Tanya learning from Beth, it’s then that they bought their second crane.

“It was dad, my brother-in-law in the

field, and my sister assisting with the accounts when I joined the company in 2000 having finished my diesel fitting apprenticeship. It was around that time that we bought our third pick and carry crane, which was 20t Linmac and we still own and operate two of them to this day, these were the cranes that built Matherson Crane Hire,” said Wayne.

In the early 2000’s Jason Williams was the first employee outside of family to join Matherson Crane Hire, and he’s still with the business today.

“Jason is my Operations Manager and right-hand man. He was an eager young boilermaker that showed a lot of interest in cranes and practical skill when dad showed up onsite. He appeared to be eager and interested, so Dad offered him a job,” said Wayne.

Wayne goes on to explain how the

growth of the business reflects the growth of Gladstone and the surrounds.

“The growth of the business was due to a combination of local market demands and also, in 2005 the introduction of the Rigger Law, meaning you had to have a rigger under the hook for all lifts. Prior to this, we’d run around in the crane, jump out, sling our own loads up and jump back in the crane. The new law forced us to get more labor to support the cranes. Then, around 2010 we began looking at slewing cranes and we purchased a Kobelco RK-160 and a Demag AC-55 city class. We then acquired

22 / CAL June 2023 www.cranesandlifting.com.au

After more than 43 years servicing the Gladstone area community and industry sectors, Matherson Crane Hire has sold to become part of the Smithbridge Group of Companies and Universal Cranes. Wayne Matherson, Managing Director of Matherson Crane Hire provides the background to his company and the reasons for selling.

CICA MEMBER PROFILE: MATHERSON CRANE HIRE

Neil Matherson started the business with an 8t capacity BHB tractor crane.

a Liebherr LTM 1055-3.2 and a Demag AC100-4L in 2012. The 100t purchase fulfilled a dream of owning a 4 axle All terrain crane of which came to me during my apprenticeship, after working alongside Vic Maben’s 4axle 80t Demag at Capella in the mid 90’s,” said Wayne.

The growth in Glastone has been cyclic and there was a boom in the mid 2000’s, but Wayne and his team were not distracted by the boom.

“We were focused on establishing and consolidating relationships with our current clients and new key industrial clients and that is when we acquired the Demag AC100-4L and established our secured first official industrial contract with Boyne Smelters Limited. The 100 tonner was the big jump, and we knew with that extra capacity we could service then BSL Contract and also allow us to expand what we had to offer all our clients, I never lost sight of the small people that helped us become what we are today,” said Wayne.

The next big step was two years ago when the business invested in a Liebherr LTM1250-5.1

“We’ve had the 250t for two years now, and that was a crane I’ve never envisioned in my wildest dreams of owning. Then opportunities presented and we took a calculated risk on building a market for this

capacity of crane and it has paid off,” said Wayne.

Wayne goes on to discuss the work culture of the business emphasizing there is no business without people.

“The culture of our business was key to our success and has always been very much about trying to treat everyone as equal, employees and clients alike. Maintaining a high value on family, valuing our people and establishing a culture of taking pride in the work we complete in the field for our customers, the presentation and quality of equipment we operate.

“Maintaining our equipment to the highest standards has proved to a winner for the business as I have people line up to buy my secondhand cranes because they know they’re so well-looked after due to our maintenance programs. This also gave clients piece of mind that our equipment was always reliable.

“Kurt Williams is our Maintenance Manager, and he does a brilliant job, but because we essentially assign a crane to a team member and give them ownership and then give them whatever they need to keep the crane well maintained, clean, polished and shiny, this generates a lot of pride in the presentation of our fleet,” said Wyane.

Wayne has spent the last two to three years establishing the business in a good debt

asset ratio position, and maintain a high quality, young aged fleet that’s attractive to potential buyers and with a workload to pay for it. He explains how the growth of the business and being on call 7 days a week, over a concerted period of time, impacted on the individuals involved.

“In the early days of the business we were working six and seven days a week, and on we were maintaining and servicing our fleet on top of this. The first step to alleviate the work load, was to recruit employees who wanted overtime which provided us the opportunity to have weekends off and take the occasional family holiday.

“The second step was to build a management structure which enabled me to step away from the business to a degree. The significant and defining moment for all of this was the retirement of my dad in 2009. He was 65 and only had 12 months retirement with mum before she passed away.

“At that point, I realized I wanted to build the business so I could be in a position to make decisions regarding my retirement and not wait until I was 65. I was aiming for 50, but I’m 44 so that is kind of nice.

“More recently it got the point, where I realised it was time to release the stress. I’m still passionate about the industry and love what I do and proud of what we have

June 2023 CAL / 23 www.cranesandlifting.com.au

Wayne Matherson, his father Neil and Operations Manager Jason Williams with the Liebherr LTM1250-5.1 they never dreamed of owning.

“Without question it is going to be a good fit for everyone. Universal Cranes is large and successful company and the owner Albert Smith, operates very morally and has a great track record with his people.

“I have enjoyed dealing with Albert and I have been working closely with Adam and Sarah Bauer who are the branch managers here in Gladstone. Adam has come from a family business background of Ballina Cranes, which his family owned so he knows what a family-owned general hire business is all about.

“I know he’ll carry on a respectful relationship with my staff and with my clients. I’m excited for the greater opportunities for my guys in a company of this scale, for sure. Within the negotiations

of the sale, Albert has been very reasonable in ensuring 100% of my teams’ entitlements transfer, including entitlements we didn’t have to by workplace law.

“Negotiations are always tough, but I can walk away knowing that I’ve done the best by everyone in this situation. We’ve ensured everyone has an offer of a job with the company, right down to the 2nd year apprentice diesel fitter that we have, which was my key concern in this job market. The adults will find a job anywhere, but the young fellow left school to start his time with me, and I needed to make sure his employment was secure and was continuing his trade, and he is, which is really nice,” said Wayne.

Being passionate about the industry has seen Wayne take an active role within The Crane Industry Council of Australia (CICA).

“I initially became involved in CICA because I could see that as the leading industry body it would help me remain informed as things change, and CICA has been brilliant in both affecting change and relaying the details of the changes to its members.

“Over time I developed an interest in being more involved and became a committee member for Queensland, and also sat on the code of practice review committee. I stepped into the Vice-Chair role for Queensland. I was in that role for about two years under Steve Gonano and latter stepped up to the role of Chair.

“Unfortunately, I wasn’t in the role for long, I was only there for about six months before gracefully stepping down to focus on the business and my personal life.

But during that short tenure I had a bit of a milestone moment as we managed the biggest ever Regional Meeting that CICA Qld had held at Mackay. We had an excellent attendance and put on a good display for the TMR members and local government members. In a bid to educate and work toward better road access,” he said.

Wayne then takes a look at what the future might hold for him.

“Initially I plan to take a bit of time out, but as the saying goes, ‘you can’t keep a good man down. I’m still passionate about the industry and I’m looking to develop some practical upskilling for the industry.

“I’m developing a training program to teach better operational practices and improve skills which I see currently as a major shortfall in our industry. The current licensing system is presented well by most RTO’s, but it takes years to learn the skills to be a competent operator. I see the primary issue stemming from projects and companies just needing “bums on seats” and are too busy to teach extra skills. Along with the knowledge that Dad has passed to me and knowledge that I’ve learnt through being in the field for over 20 years.

“The upskilling will be in the pick and carry crane sector, which I am extremely passionate about. I’m tired of seeing pick and carry cranes laying on their side due to lack of operator training. Unfortunately, due to the nature of pick and carry, operators can be well within the capacity of the cranes, but there are always variables that the operator needs to be aware of and know how to adapt accordingly to stay safe.

The cranes are a super versatile and efficient tool in all sectors and manufacturers of pick and carry cranes are doing great work to improve safety systems but the cranes will never be intuitive and be able to see and predict all the variables a pick and carry crane face, this is where the human comes in.

I want to teach and improve the knowledge and skills around dealing with those variables. I’ve already started creating notes and modules for the program. It is absolutely my intention to give back to the industry which has been so generous to my family over many years and I hope to improve the skill sets of the operators now and in the future,” said Wayne.

24 / CAL June 2023 www.cranesandlifting.com.au

CICA MEMBER PROFILE: MATHERSON CRANE HIRE

The growth of the business was due to a combination of local market demands and also, in 2005, the introduction of the Rigger Law which meant a rigger needed to be under the hook for all lifts.

Neil and Beth Matherson.

ENGINES/ GEARBOXES DIFFERENTIALS/ TRANSFER CASES BARE/GLAZED CABS UPPER AND LOWER SERVICE EXCHANGE HYDRAULIC CYLINDERS BOOM SECTIONS/ FLYJIBS BEN BADEN SERVICES PTY LTD | PH (02) 9679 8333 | 43 HOLBECHE ROAD ARNDELL PARK 2148 MECHANICAL STRUCTURAL PAINTING MACHINING AND LINE BORING ENGINE AND TRANSMISSION OVERHAULS CASAR WIRE ROPE DISTRIBUTOR BEN BADEN SERVICES NO DOWNTIME! MOBILE CRANE REPAIRS COMPONENTS EXCHANGE PROGRAM DRY HIRE AVAILABLE WHILE YOUR CRANE IS BEING REPAIRED!

SELECTING LIEBHERR UNPLUGGED

SELECT PLANT AUSTRALIA RECENTLY TOOK

delivery of two 250t capacity all-electric Liebherr LR 1250.1 unplugged crawler cranes, the first to arrive in Australia.

With over 30 years of global experience, Select Plant Australia delivers various innovative, sustainable and high-quality construction solutions. With its industrial transportation services and depots in New South Wales, Victoria and Western Australia, Select delivers plant and site setups to every corner of the country.

Select offers a comprehensive range of services, from plant hire to logistics, which includes transport management and safety compliance, as well as Site Solutions, which supplies and installs on-site accommodation facilities. Select primarily caters to the construction, civil engineering, rail, infrastructure and utilities industries. By keeping up with the latest technological developments, Select provides its customers with the most advanced and cuttingedge solutions, as evidenced by its recent purchase of Liebherr’s electric crawler cranes.

SELECT’S CRANE FLEET

Select manages a fleet of crawlers, mobile, tower cranes and access equipment. Its mobile and crawler cranes range from 60t capacity rough terrains up to 350t capacity crawler cranes with Superlift capabilities. The range of tower cranes varies from small, flat-top type hammerheads to larger capacity luffing cranes.

Select’s crane fleet is predominantly utilised in the building and infrastructure sectors and more recently, in the resources sector, in the Pilbara and Goldfields of Western Australia.

The majority of Select’s crawler crane fleet consists of Liebherr cranes with capacities ranging from 60t to 350t and has been bolstered by the addition of the two

new 250t electric crawler cranes.

SUSTAINABILITY IS THE TARGET

Select Business Unit Leader Nathan Mitschuinig explains why Select purchased the Liebherr unplugged crawlers.

“We brought the Liebherr crawler unplugged range on board to lead the market towards a sustainable future. Working hand in hand with our parent company Laing O’Rourke, we are committed to achieving net zero operational carbon emissions (Scope 1 & 2) by 2030 and net zero Scope 3 emissions by 2050,” said Nathan.

“We have invested in building a modern, innovative and environmentally sustainable fleet that includes electric, solar and hybridpowered solutions. We already have two site compounds operating off solar power, and

surrounding community,” said Nathan.

“As with most electric vehicles, the initial cost (for now) is more than that of their petrol or diesel equivalents. However, the complete reduction of diesel fuel requirements and lower services played a large part in Select’s decision-making process.

“Financially, we have a clear return on investment expectations from capital expenditure – this shifts the decisionmaking towards justification against market rates for traditional assets. We considered both the reduction in mechanical maintenance as well as the performance unknowns of the battery-powered asset in the Australian environment when measuring its return on investment,” said Nathan.

The company turned to its colleagues

our fleet is growing weekly with low and zero-emissions plant.

“The Liebherr LR 1250.1 unplugged will play a role in helping us achieve our net zero targets,” he said.

ELECTRIC VERSUS DIESEL

One of the main reasons Select purchased the LR 1250.1 unplugged was to provide an environmentally friendly alternative to clients, allowing them to contribute to lowering emissions on site.

“The Liebherr electric crawler made economic sense for the team at Select as lower fuel expenses and maintenance costs are a major plus for our clients. The electric crane is noticeably quieter than the diesel version, which is an excellent advantage for metro projects as most construction sites want to lower their noise pollution for the

at Select Plant Hire in the United Kingdom to provide a level of reassurance and expectations of performance and productivity of the Liebherr LR 1250.1 unplugged. The crane offers immediate benefits such as producing zero emissions and very low noise levels, while its battery and electric power make Select’s clients less susceptible to fuel price fluctuation. In the long term, it is expected to save on running and maintenance costs compared to the diesel equivalent and a reduction in carbon emissions.

ZERO EMISSION EQUIPMENT IN AUSTRALIA

Whilst Australia currently has no requirement to have zero emission machinery on site, Select is passionate about innovative and sustainable solutions. Select recognises the importance of

IN FOCUS / SELECT PLANT AUSTRALIA 26 / CAL June 2023 www.cranesandlifting.com.au

Select Plant Australia has brought the first electric Liebherr crawler crane into Australia, utilising experience from its sister companies in the United Kingdom to ensure it could adequately support the addition.

“We brought the Liebherr crawler unplugged range on board to lead the market towards a sustainable future.”

Select has a vast array of cranes in its fleet but is very excited by the prospect of bringing the first Liebherr electric crawler crane to Australia

June 2023 CAL / 27 www.cranesandlifting.com.au

reducing its environmental footprint and wants to contribute to a more sustainable future, while setting a benchmark for the construction plant hire industry in our region.

“Public sector ambition for emissions abatement coupled with high investment in infrastructure across all states sees the need for more sustainable equipment fast approaching. The current scarcity of zero and low emissions products in the domestic construction market and a high barrier to entry for these assets made the Liebherr unplugged a smart investment for Select,” said Nathan.

Select Plant Australia prides itself on market differentiation through its modern and sustainable fleet and solutions offering. The LR 1250.1 unplugged is a flagship product in the fleet and signals serious ambitions to be the provider of choice to the Australian construction market.

“Select will encourage users to charge the crane with Greenpower offset mains electricity or renewable power on remote or off-grid sites. We currently use mains power which Greenpower offsets in our yards but plan to install solar in all of the depots to ensure the crane is as green as possible,” said Nathan.

“For our team, the shift to the Liebherr unplugged range will be simple - with the same systems throughout – the only

difference from other Liebherr crawlers is how it is powered.

“On a typical day, the crane can be operated for eight hours without the need to be charged. Although charging instead of refuelling may be unfamiliar to some operators, it is expected that the plant hire industry will move towards electrification and embracing this change will become second nature.

“The recommendation is to work with the crane plugged in for the battery’s

customised solutions for each situation. For example, Select is currently working with a client who will have the crane plugged in 24/7 for maximum operation, so we are creating crane pads for the area it will be working in.”

FEATURES OF THE LR 1250.1 UNPLUGGED

The Liebherr LR 1250.1 unplugged won the European Association of Abnormal Road Transport and Mobile Cranes (ESTA) Awards of Excellence in 2021. This is recognised as the leading award event for the European crane and heavy-lift industry. During the online event, Liebherr-Werk Nenzing GmbH won the top award in the category ‘Innovation Manufacturer’. The LR 1250.1 unplugged – the world’s first battery-powered crawler crane was the award-winning product.

The LR 1250.1 unplugged is driven by an electric motor with a power rating of 255 kW. There are no compromises at all regarding its performance of the unplugged crane when compared with the conventional version, and it has a maximum lifting capacity of 250t.

The blue accent in the colour composition, which lends the distinctive look to the unplugged series, symbolises the electric solution representing an advanced technology. The unplugged cranes achieve the best possible combination of operator

longevity and to produce a higher output. Cranes of this size typically work in one area, and with the correct setup it can easily operate whilst plugged in,” he said.

Select expects the LR 1250.1 will run just as well as its diesel equivalents. It already has electric and hybrid plant and equipment in the fleet, and they provide their diesel counterparts a run for their money.

“We know that there will be some challenges with accessing electricity to recharge the crane batteries in remote locations. However, we are confident that we can work closely with clients and create

benefit, efficiency, and environmental sustainability.

The model is emission free and a has a very low noise level. That is a huge advantage in areas sensitive to noise, and also for the people working on the jobsite.

The crane can be recharged on a conventional jobsite electric supply (32A, 63 A) in 4.5 hours and optionally with 125 A in 2.25 hours. The capacity of the battery is designed for 8 hours lifting operation. In accordance with its name, the crane can be operated with or without a cable, hence the ‘unplugged’, thanks to the battery-electric drive design.

IN FOCUS / SELECT PLANT AUSTRALIA 28 / CAL June 2023 www.cranesandlifting.com.au

“On a typical day, the crane can be operated for eight hours without the need to be charged.”

The crane provides great flexibility operating either plugged or unplugged.

+61 2 8811 3500 | www.btstech.com.au 142-146 Magowar Rd Girraween NSW 2145 Australia BEAVER TECHNOLOGY SERVICES PTY LIMITED FS603922 For more information, log onto www.btstech.com.au or contact: sales@beavergrp.com.au MITIGATING THE RISK MOBILE FALL PROTECTION for Crane, Heavy Machinery & Mobile Plant Equipment AIRHOOK AIRDOCK AIRSTAIR BTS Member

RAISING THE EXPECTATION

The Magni rotating telehandler delivered by MCT equipment has been a game changer on a number of major civil projects recently for Calroc.

30 / CAL June 2023 www.cranesandlifting.com.au

IN FOCUS / MCT EQUIPMENT

The team at Calroc has been so happy with the Magni telehandler it has ordered a second.

CALROC’S MANAGING DIRECTOR LIAM McKinney will take delivery of his second Magni RTH7.26 next month and he’s not shy about telling Cranes and Lifting Magazine why.

Calroc is a leading formwork, reinforcement and concreting specialist, servicing the Mining and Minerals, Civil Infrastructure and Specialist Precast Sectors across Australia.

“In our line of business, this machine is a game changer”, Liam commented.

“From a safety perspective, we’re not relying on hand signals or radio communications. My operators are standing next to their loads, using the remote to lift and land the loads with pinpoint accuracy,” he said.

As a contractor, providing precast solutions for a major Perth rail project, Calroc is benefiting from the improved safety, efficiency and versatility of the Magni RTH7.26 on the worksite.

“The boys have access to a large crawler crane onsite but if the lifting capacity is within its limits, they are going with the Magni every time because it’s quicker, easier and so much more accurate,” added Liam.

McKinney concedes that it’s not a replacement for every lifting machine, but reinforces that if you think differently, and set up your site in the right way, the versatility you get from your Magni Rotator allows for unparalleled capabilities.

“Why are we getting a second machine? Put it this way, we’ve had that machine [the Magni RTH] for a few months, and it’s already done 700 hours. It’s in operation 4-8 hours a day on this site and we’re committed here for another 12 - 18 months,” Liam said.

“I have my team demanding the Magni on other projects and with the safety and efficiency benefits it’s delivering onsite, it’s a no-brainer for Calroc.

“The Magni Rotating Telehandler’s reach, within a small footprint, is the innovation behind its versatility.

“The Magni RTH’s variable outrigger reduces the working footprint, making it ideal for working in tight spaces. This combined with its lifting capabilities is seeing it outperform a city class or rough terrain crane in most situations.”

Instead of hiring a city class or rough terrain crane to have a boom capable of reaching the right areas, the Magni is getting into tight areas to get the job done,” he said.

MCT Equipment is Australia’s leading alternative lifting provider. MCT’s Sales Manager, Danny Blazeski spoke about the Magni and what makes it a standout.

“The Magni RTH’s variable outrigger reduces the working

footprint, making it ideal for working in tight spaces. This combined with its lifting capabilities is seeing it outperform a city class or rough terrain crane in most situations,” Danny said.

The Magni’s load moving indicator (LMI) is also delivering on lifting compliance, according to Danny.

“With the LMI system fully compliant with crane regulations, the operator can see where they are within

June 2023 CAL / 31 www.cranesandlifting.com.au

The ability to use the Magni with a remote has been important to improve safety on site.

Platinum Sponsor:

the load range chart at any point. As the boom moves in and out the load chart is updating live, giving you complete comfort and control of your load,” added Danny.

The Magni RTH is said to be the smoothest rotational telehandler on the market and this is in part due to its partnership with Liebherr who provide state-of-the-art slew rings and drive gears to Magni.

“When you buy into Magni you’re getting a manufacturer that values tier 1 componentry,” said Danny.

“Dana Spicer axles, Bosch / Rexroth pumps and Volvo engines. Magni focuses on manufacturing the machines and all attachments in-house. They take the best of tier 1 manufacturing for these machines, making the Magni extremely reliable and extremely smooth to operate.”

REGISTER NOW!

IN FOCUS / MCT EQUIPMENT

The telehandler is often used on site to save having to use the larger crawler crane.

Calroc backs the think different, lift different movement with MCT and Magni.

The Magni RTH7.26 is the machine raising the roof when it comes to rotational telehandlers.

With a lift height of 87ft and multi-accessory capabilities, this tough, high-performance rotating telescopic handler is doing the job of multiple machines.

I have my team demanding the Magni on other projects and with the safety and efficiency benefits it’s delivering onsite, it’s a no-brainer for Calroc.

- Calroc Managing Director, Liam McKinney

MCT Equipment has exclusive distribution rights for Magni in Western Australia and Northern Territory. Magni, where innovation is at its best. Get in touch with us today & reach new heights by adding one of our class leading machines to your fleet.

Magni RTH7.26 under full remote control with

and auto-levelling to provide full capacity load for

Call us: (08) 6500 3460

The RTH7.26 in operation lifting a section of truss screed into position on a bridge deck from the road below.

single operator

this operation.

“

MANITOU GROUP ANNOUNCES ALL NEW QUADRUPLE DROP

Manitou Group has announced its plans to release four new products - light, sustainable, heavy duty and manoeuvrable machinery that is soon set to target Australian shores.

FRENCH MANUFACTURING GROUP

Manitou has announced the launch of its newest models: the all-electric MT625e Electric Telehandler, a compact lift truck that runs 100 per cent off electricity; and the Ultra-Light Manitou (ULM), an ultra-light telehandler designed to specifically target three different areas; profitability, safety, and comfort.

Presenting at Conexpo, Arnaud Boyer, vice president of marketing and product development, said the announcement is a continuation of the growth of telehandlers offered internationally which commenced in 2019.

“With 14 models now on offer, we are strengthening our position in a

market with very high potential for Manitou Group,” he said.

“We will continue to extend electrification to other ranges in accordance with the objectives of our CSR roadmap.”

Boasting a capacity of two and a half tonnes in tandem with a height of six metres, the MT625e provides a performance level matching its internal combustion counterpart, whilst also offering a 56 per cent reduction in maintenance fees because of its lithium-ion battery, which comes in either a 25 or 33kWh capacity.

Ideal for indoor applications, downtown or building renovation, the MT625e benefits

34 / CAL June 2023 www.cranesandlifting.com.au IN FOCUS / MANITOU GROUP

Manitou’s MT625e Electric Telehandler, an electrified machine suitable for indoor applications, downtown or building renovations.

Manitou’s new heavy-duty telehandler series enables heavier loads operating on all types of terrain.

from the optional operation safety system and harmony on-board display for safe and easy operation.

The Manitou ULM, on the other hand, provides the lightest and most compact option on the market, providing customers with optimal versatility and transportation.

Coming in two different options –both 1.49m wide, 1.92m tall and with a lifting height of 4.3m – the ULM 412 H and ULM 415 H hold lifting capacities of 1.25t and 1.5t respectively, with both maintaining a transportable weight of less than three tonnes.

The first of the three pillars driving the release of the ULM - profitability - comes in due to its light weight and easy transportability. Providing reduced transportation times and - because its interface can be quickly navigatedmuch more user productivity, it also operates as an all-terrain vehicle thanks to an oscillating rear axle, a wide range of tyres, and a 29cm ground clearance.

The machine holds additional features such as a stop and start option, allowing a reduction of $10 per hour due to reduced machine depreciation, fuel consumption and preventive maintenance.

Equipped with an unobstructed 360-degree view in the cabin, the ULM telehandler is designed to provide even more comfort and safety to its users, according to product manager Camille Rouvrais.

“We worked with our design office to find an innovative solution that provides even more safety and comfort,” she said.

“We replaced the roof grille with a transparent, shock-resistant polycarbonate window, which complies perfectly with the requirements of the FOPS standard”.

On top of these are visibility improvements to the operator’s lateral view, a much more flexible positioning of the joystick on a floating armrest, and two vents being placed on the windshield for optimal demisting.

Furthermore, the ULMs offer three different steering modes: two-wheel for high-speed traveling, four-wheel for

navigating tighter areas, and crab mode for lateral manoeuvres.

Additional to the MT625E and ULMs, Manitou has also announced brand new ranges for its electric rotative telehandlers, with two new models encompassing six different versions, whilst also adding a new range of heavy-lifting telehandlers.

The electric range of rotative telehandlers, the MRT 2660e series from its recent VISION+ range, holds a loading capacity of 6 tonnes and a lifting height of 26 metres. Possessing a 700 V/65 kWh lithium-ion battery ensures the model can operate just as well as its internal combustion counterpart –especially in more hostile climates such as Northern Europe.

With charging requiring just four

hours and 30 minutes thanks to an onboard 11kW charger as well as a 22kW charger topping up the battery in just two hours and 15 minutes, a second battery can also be added to boost the MRT’s range by a further four hours.

On the other hand, the new heavylifting telehandler range presents an improved design for safer handling of bulkier loads on all types of terrain.

With weight capacities ranging from nine to 33 tonnes and a working height of up to 12 metres, practicality and safety have also been enhanced with easier access to the driver’s cabin provided via wide non-slip steps, and a new Manitou JSM joystick featuring the ability to accurately detect and respond to the operator’s hand for safe operation.

June 2023 CAL / 35 www.cranesandlifting.com.au

The ULM, a light option offering customer’s transportability and versatility.

The MRT2260e, an electrified, all-climate rotative telehandler.

REDUCE YOUR EMISSIONS, RAISE YOUR STANDARDS. Scan this QR code, or visit www.oxygen.manitou.com to discover the new Oxygen ranges with the new Manitou Oxygen range of 100% electric mobile elevating work platforms, fixed and rotative telehandlers.

HYDROGEN’S TIME TO SINK OR SWIM

Presenting at ConExpo 2023, JCB unveiled internationally the fruits of its labour in the net-zero sector over the past three years, paving the way for the rest of the world to follow suit.

FOUNDED IN THE UK IN 1945 AND STILL bearing the acronym of its founder Joseph Cyril Bamford, agriculture and construction manufacturing powerhouse JCB creates machines for consumers in industries ranging all the way from defence through to waste and recycling.

It’s little wonder then, with an internal target of zero carbon emissions in construction and external pressures from European carbon regulations, that the multinational corporation switched its attentions to how it would conduct business in a net zero environment.

One group of engineers, two prototypes and an A$188.5 million investment later, and the results were laid bare for all to see at ConExpo

2023, the world’s biggest construction exposition in Las Vegas.

JCB formally introduced its superefficient hydrogen engine on the stage at the International Fluid Power Exposition (IFPE), held alongside ConExpo 2023.

“The JCB engineering team has made enormous strides in a short space of time to develop a hydrogen internal combustion engine,” said JCB Chairman Anthony Bamford. “As the first construction equipment company

JCB has made a commitment to growing its hydrogen division.

to develop a fully working combustion engine fuelled by hydrogen, I’m delighted we are now able to present this technology on the international stage.”

Already focusing its attentions on providing electric and battery powered technology on smaller machines like the 525-60E telehandler, Bamford says JCB felt larger machines required an alternative that would leave them unencumbered by the constraints of a constant recharge.

June 2023 CAL / 37 www.cranesandlifting.com.au JCB / IN FOCUS

“The JCB engineering team has made enormous strides in a short space of time to develop a hydrogen internal combustion engine.”

Because of their power usage, larger cranes and excavators that work multiple daily shifts would require larger batteries – and it is precisely because of their constant usage that they would not possess the necessary downtime required to charge.

“Hydrogen also offers a potential solution to the challenge of batteries on larger machines,” he added. “It allows for fast refuelling and is a mobile fuel solution, allowing fuel to be taken to the machine.”

JCB has been operating a few prototypes since July 2020, namely

in its backhoe loader and Loadall telescopic handler machines.

It was this success that inspired the company to then invest a further A$188.5 million into the hydrogen engine program.

“The JCB engineering team has gone back to first principles to completely re-design the combustion process to work for hydrogen,” said Bamford.

“In doing so they’ve secured JCB’s place in history as the first construction equipment company to develop a fully working combustion engine fuelled by hydrogen and

engines in telehandlers landing on Australian shores, the path forward to a net-zero future is becoming ever so clearer, with JCB indicating that anything can be achieved with the right amount of care, technical ability, and investment.

“The unique combustion properties of hydrogen enable the hydrogen engine to deliver the same power, the same torque, and the same efficiency that powers JCB machines today, but in a zero-carbon way,” said Lord Bamford.

“It is a technology which is cost effective, robust, reliable, and well known throughout not just the construction and agricultural industry, but the whole world.”

38 / CAL June 2023 www.cranesandlifting.com.au

“The unique combustion properties of hydrogen enable the hydrogen engine to deliver the same power, the same torque, and the same efficiency that powers JCB machines today, but in a zero-carbon way.”

2 Heland Place Braeside VIC 3195 | 1300 686 626 | sales@gleason.com.au | www.gleason.com.au All terrain, crawler crane, tower crane, rough terrain and truck crane Dealer for: New Cranes Include: New Zoomlion ZCT900V 90 tonne Hydraulic Boom Crawler

As standards change and increased safety practices are highlighted, BTS received requests to talk about products from the crane industry.

THE RISK

BEAVER TECHNOLOGY SERVICES (BTS),

is a company holding 60 years of experience providing Australian businesses with practical and innovative product solutions for Industrial Fall Protection applications,

We started out in the late 1970’s operating as the market leader within the lifting and materials handling market, which was the main focus until 2010. Beaver Technology Services saw a requirement for “fit for purpose” height safety products and evolved to become a company focussed directly in engineered height safety and specialised lifting solutions, as BTS’ Marketing & Project Manager Aaron Hatch explains.

“Originally Beaver came to the market supplying lifting equipment below the hook, including chain slings, lifting slings and shackles,” says Aaron. As the focus on safety became increasing stronger, BTS look at at ways we could offer a better product that wasn’t just another close enough is good enough offering.

Having joined the company as of late November 2022, Aaron boasts two-and-ahalf decades worth of industry experience related to safety and below the hook safety. Whilst a lot of his experience surrounds mobile cranes, it also resides in tower cranes and general construction with lifting and the height safety.

Working for various companies in lifting systems to the construction industry, the more recent years saw him switch to the safety and safe lifting side of things.

“I have worked across numerous height safety and lifting manufacturers across Australia all of which were apart of CICA which BTS has recently joined,” Aaron said.

“Joining CICA, the leading body in Australia for crane-industry representation, provides a perfect opportunity for BTS to showcase their awareness of an everincreasing focus on safety in the crane sector also providing a safer, smarter way of offering devices for below the hook within the industry,” he said.

40 / CAL June 2023 www.cranesandlifting.com.au

With extra scrutiny being placed on workplace safety in working at heights, solutions are now required to combat the challenges of keeping a work site safe in the crane industry. Fortunately, Beaver Technology Services and their range of height safety products provide just the answer.

mobile fall protection space range from fixed to mobile equipment the suits all areas of the crane industry from new to maintenance.

BTS’ AIRDAVIT

BTS’ AirDavit is an exciting development by the company, a permanent fixed articulated anchor point, with a working anchor point height of 5.7m and available in single and twin arm configuration providing ideal coverage for overhead fall protection. This is ideal for workshops or to assist in the use of working on transport during the loading and unloading process.

BTS AIRHOOK TRAILER