Know yourSafe Working Areain real time! FRANNA LAUNCHES GAME CHANGING SAFETY INNOVATION Patent Pending FEATURES Official Media Partner Two Way Cranes on the moveFocus on Telehandlers SANY rough terrains

We’re just as passionate as you are about cranes and we are focused on giving you the support and services you need to keep your cranes lifting.

OUR CUSTOMERS’ SUCCESS DRIVES OUR SUCCESS. It’s Simple SCAN TO VIEW OUR FULL PRODUCT RANGE ©Tadano Ltd. 2022. Tadano is a registered trademark of Tadano Ltd. or its subsidiaries

10 Up Front Terex Franna launch Safety Radar system.

15 CICA Presidents R eport Welcome to the CICA National Conference and Exhibition.

16 CANZ Conference and Exhibition

Review of the Crane Association of New Zealand Conference and Exhibition.

20 Tutt Bryant and Cranecorp Joint Venture complete infrastructure project.

30 Pilequip

New Piling Lifting Device from Pilequip.

34 The Crosby Group The Crosby Group purchase KITO.

36 MCT Equipment MCT discusses its firm belief in bringing quality products to Australia such as the Magni telehandler

40 Manitou Manitou is excited to launch its new range of telehandlers.

48 Construction Equipment Australia CEA has taken delivery of its first rotating telehandler in Australia.

52 Skyreach Skyreach highlights the quality products offered in its rental fleets.

54 Billing Crane and Grove New Grove to Billing Cranes.

57 Cranecorp Cranecorp Australia, an imposing force in Western Australia.

ownsville Cranes and Tadano Outstanding performance from

SANY rough terrains

New rough terrains from SANY.

ace Cranes

Mini crane hire specialist takes Liebherr on the hook.

XCMG is excited to gain provisional oval for the world’s largest capacity all terrain crane.

Manitowoc upgrades successful lattice boom crawler range.

www.cranesandlifting.com.au IN THIS ISSUE

25

48

LONGER, STRONGER, AND MORE COMPACT. and the most compact carrier design in the • • loadcharts •Access tight building sites, city centers and indoors with unmatched compactness • Increased safety and flexibility with MAXbase variable outrigger positioning •Lower fuel consumption through latest Cummins engines with ECO Mode • Manitowoc Australia www.manitowoc.com Western Australia WATM Crane Sales &Service Queensland New Zealand TRT Australia TRT NZ trt@trtaust.com.au trt@trt.co.nz LEVEL ACCESS MAXbase Equipped The NEW GMK3060L-1 delivers excellent reach NEW GMK3060L-1

WELCOME TO THE NOVEMBER EDITION OF CRANES AND LIFTING MAGAZINE.

THERE ARE PROMISING SIGNS THAT surging construction costs and inflation, which is making projects unviable will ease next year. Global weakening in demand will soften prices, helping calm inflation in the wider economy, according to recent forecasts from consultancy Rider Levett Bucknall (RLB).

Construction cost growth should slow from 11.5 per cent this year to 5.5 per cent in calendar year 2023 in the Gold Coast alone, while in Melbourne it will halve from 8 per cent to 4 per cent and drop from 6.9 per cent to 3.9 per cent in Sydney, the quantity surveying firm’s International Report Q2 2022 forecasts show.

The figures, come on top of observations that prices of materials were starting to stabilise, is a hopeful sign for many across construction.

Home-building costs, along with record petrol prices, were one of the key drivers of the jump in Australian consumer inflation to 6.1 per cent. New dwelling prices leaped 20.3 per cent yearon-year.

The RLB numbers more closely reflect the pressures in non-residential and commercial-scale apartment construction.

Six months ago, the consultancy predicted 5 per cent cost inflation for

the Brisbane market in the current year – now it expects 10.5 per cent. At the time of its last report it forecast 3 per cent tender price growth for Melbourne, a figure it has since revised up to 8 per cent. Lead times for some products sourced from overseas had blown out to 16-20 weeks from their traditional 8-10week duration, the consultancy said.

The crane sector will be watching this development with interest.

As always, the team at Cranes and Lifting has worked hard to provide a November edition which we hope will prove to be an interesting read for everyone. You will see how Two Way Cranes is approaching training with a return to traditional ‘on the job’ mentoring. You will also learn how the venture south is faring. Mini crawler cranes remain as popular as ever and we introduce a relative new comer to the hire market. We also focus on the role of one of the construction sectors workhorses, the Telehandler.

As always, the team at Cranes and Lifting magazine hope you enjoy the read.

Published by:

Simon Gould Editor, Cranes and Lifting

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

CEO

John Murphy

E: john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy

E: christine.clancy@primecreative.com.au

Managing Editor

Andrew Hobbs

E: andrew.hobbs@primecreative.com.au

Editor

Simon Gould

E: simon.gould@primecreative.com.au

Journalist

Joshua Farrell

E: Joshua.farrell@primecreative.com.au T: 0420 298 087

Business Development Manager

Emily Schlegel

E: emily.schlegel@primecreative.com.au T: 0466 317 555

Client Success Manager

Glenn Delaney

E: glenn.delaney@primecreative.com.au

Art Director

Bea Barthelson

Advertisement Designer Lee Mawdsley

Imaging Assistant

Paul Breen

Subscriptions

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

6 / CAL November 2022 www.cranesandlifting.com.au FROM THE EDITORIAL TEAM

The jewel for your fleet

The LTM 1150-5.3

Capable of carrying nine tonnes of ballast with an axle load of 12 t, together with a powerful 66 m boom. That reduces the number of transport vehicles required. Global mobility and convenience thanks to ECOmode, ECOdrive, Hillstart Aid and VarioBase. It does not get more economical than that! www.liebherr.com

Mobile and crawler cranes

Mobile and crawler cranes

REGIONAL ACADEMIES RE-SIGN PARTNERSHIP WITH UNIVERSITY OF NEWCASTLE

The Hunter (HAS) and Central Coast (CCAS) Academies of Sport have announced the re-signing of a ground-breaking tri-partisan partnership with the University of Newcastle, further strengthening the importance of a ‘Pathway to Enrolment Program’ for regional athletes.

Partnering with the University of Newcastle, HAS and CCAS have established a ‘Pathway to Enrolment Program’, an initiative that has shown great success in familiarising families and young athletes with campus life and education options into the future. In what has been termed as ‘ground-breaking’, all three parties are now closely aligned with the sole objective of providing world class opportunities to future students and a pathway to the elite athlete program at the University.

Through the exclusive education partnership with HAS and CCAS, the University of Newcastle is supporting the dreams of high school athletes and preparing them for a career after sport. The partnership offers the opportunity for high school students to engage with the University of Newcastle to explore the pathways, flexible study options, scholarships and support available to student-athletes.

The University provides the Academies with a major point of difference to other partners, including support through sports science testing, integrated learning for postgraduate students and direct access to the Exercise and Sports Science facility at its Central Coast campus. The partnership will enable access to facilities across the Callaghan and Central Coast campuses, which will be used for education seminars with worldclass presenters and cooking classes run by nutritionists.

Each year, HAS and CCAS provide hundreds of regional and rural-based athletes, ranging in ages from 10 to 18, the opportunity to access national and international standard training and development programs within their regional bases.

As a long-time supporter of elite sport development, this partnership will allow the Academies to strengthen their position in Australia’s elite athlete pathway and provide greater educational opportunities for regional-based athletes.

B rett O’Farrell, Chief Executive officer of HAS and CCAS stated, “This partnership is much more than providing world class sporting facilities to young, regional athletes, it’s about providing a pathway to education and creating a strong, job-ready future generation. The development of pre-elite sportspeople we believe, must include a holistic approach with appropriate leadership and

careers advice. We thank the University for the long-term support and share their passion in guiding our athlete’s pathway, both in their chosen sport and their education journey.”

Professor Kent Anderson, Deputy Vice-Chancellor Global of the University followed, saying “We know that athletes make great students, and we want to attract these students to study with us – helping them to balance the demands of their sport with study at the University of Newcastle.

“The Academies have been developing and supporting athletes for many years right across our regions to succeed in their sport and we’ve been doing the same, but with students. We’re very proud of our partnership and we can’t wait to see athletes come through the Academies and combine their achievements on the field, court, track or in the pool with success studying at our University.”

www.cranesandlifting.com.au INDUSTRY NEWS 8 / CAL November 2022

L to R Kent Anderson, Ian Robilliard (CCAS), Dianne Allen, Brett O’Farrell (HAS)

FRANNA LAUNCHES GAME CHANGING SAFETY FEATURE

TEREX FRANNA HAS JUST RELEASED a new software feature, called Safety Radar. Safety Radar has a patent pending on the design and methodology behind it. The functionality of Safety Radar is based on the limitation that, until now, Franna pick and carry cranes have been displaying to the operator the rated capacity of the crane and the load at singular point in time. Mike Atherden, Principal Engineer at Terex Franna explains more.

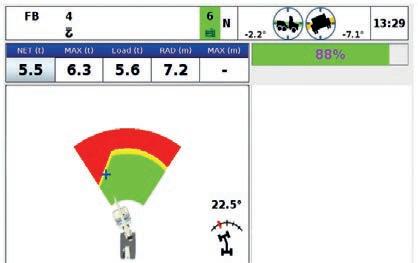

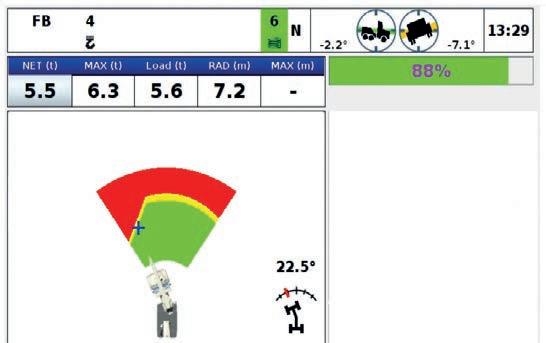

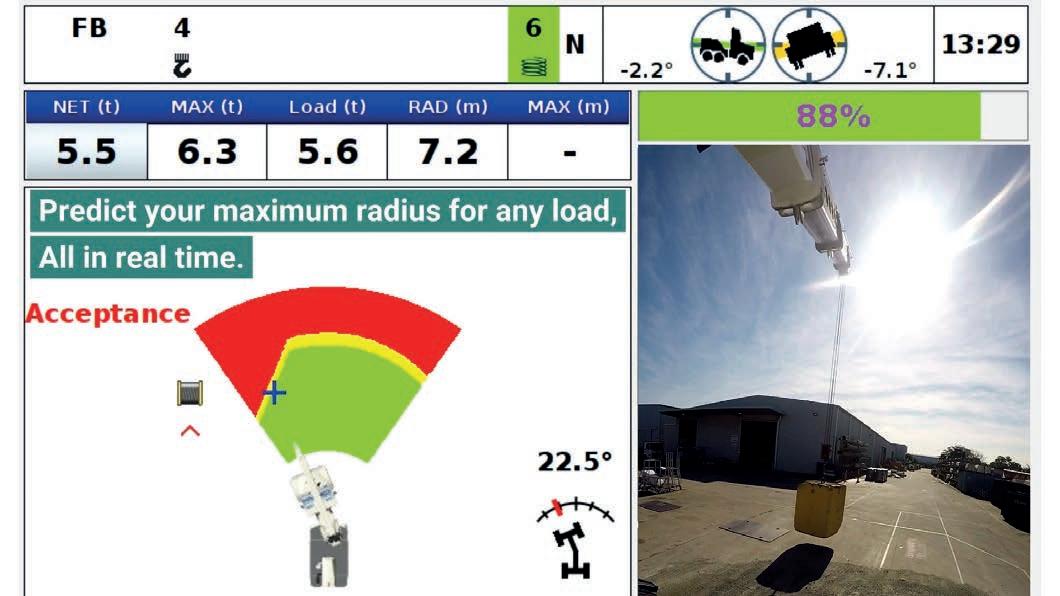

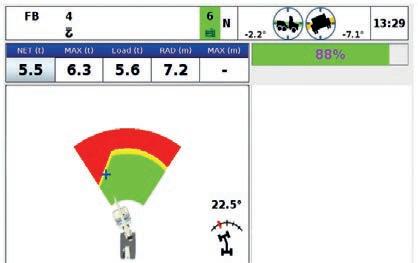

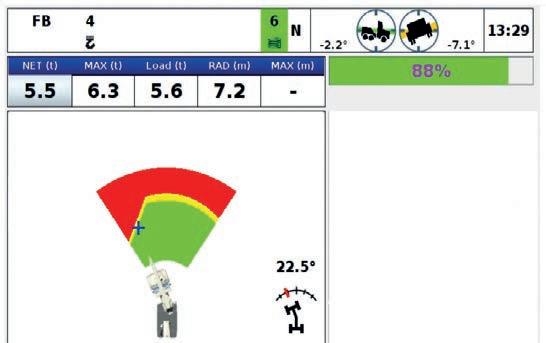

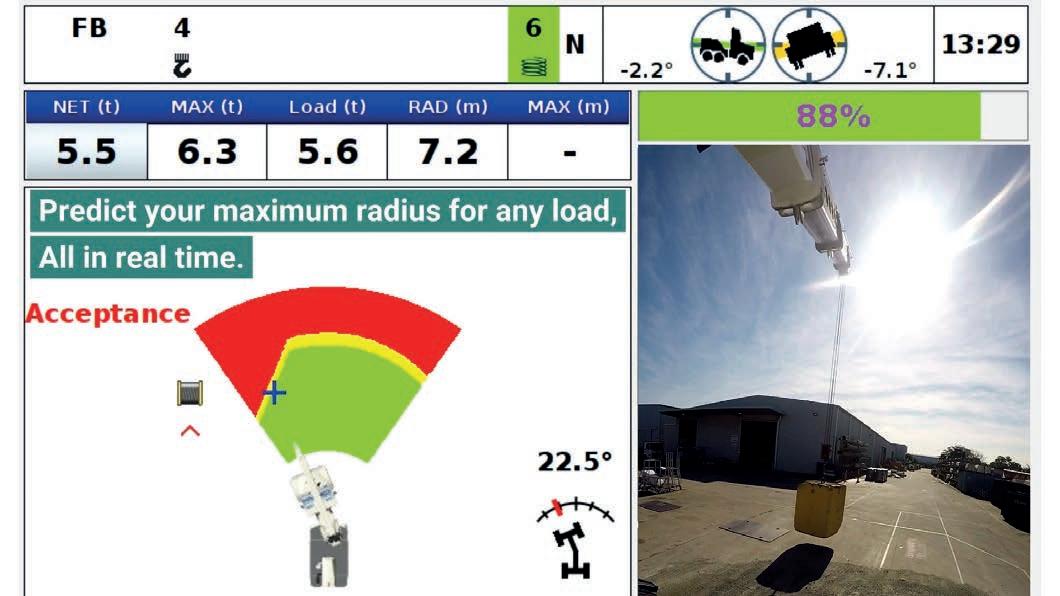

Unlike conventional Load Moment Indicators (LMI) which only tell you the percentage of rated capacity for the current lifting position, Franna’s Safety Radar shows the operator a simple and clear visual radar map of the safe working area for the load being lifted and most importantly for the actual working environment of the crane i.e. front/rear and side slope. It will help to predict the safest options for the next stages of the lift.

“When you’re operating a crane, you need to be thinking about what your next move is and this is where Safety Radar comes in. We wanted to design a simple visual display which shows the operator what is going to be the next correct move. The display element we’ve designed shows the complete safe working area of the crane, including articulation and radius for the particular configuration, and the system dynamically adjusts for pitch and roll,” he said.

All Franna operators would have a general understanding that the rated capacity drops off as radius is extended, when the crane is

articulated and when the crane is positioned across a slope with the load on the downhill side. But what is really hard to predict is when the crane is limited by or approaching a side tipping condition, based on the real life working conditions.

“The display consists of areas of green, yellow, and red, corresponding to the standard crane ‘Christmas tree lights’ or warning lights that are given by the Load Moment Indicator (LMI) system, which are very familiar to operators. The green band represents zero to 90% of rated capacity, the yellow 90% to 100%, and the red being overload, or over 100% of rated capacity,” said Atherden.

With Safety Radar, Terex

surface undulations that have to be negotiated. As the display dynamically updates, it gives the operator an understanding of what the next move should be. If the operator has options in how to get from point A to point B, Safety Radar helps determine which

Franna is hoping to change the way operators utilize the information being presented, such as when the crane starts to pick up the lift. The operator sees the green safe working area instantly adjust on the display, dynamically updating to show any areas of the working area that the operator should not approach.

When it comes to the next step of the lift, with the pick and carry crane mobile and moving the load from point A to point B, there’s typically quite a number of twists or turns and

With Safety Radar, Terex Franna is hoping to change the way operators utilise the information being presented, such as when the crane starts to pick up the lift.

UP FRONT / FRANNA 10 / CAL November 2022 www.cranesandlifting.com.au

Safety Radar is a new software feature designed by Terex Franna to assist with pick and carry crane lifting operations. It is unique as it operates in real time.

“Terex Franna sees Safety Radar, as a game changing development in the pick and carry sector, and we don’t use the term lightly.”

Franna’s Safety Radar shows the operator a simple and clear visual radar map of the safe working area for the load.

move is going to be the safest.

“There would be circumstances, particularly involving articulation and side slope, where the operator may have an option to go one way, which might move the crane closer towards the red area of the display element, or another option that moves you deeper into the green area of the display element, keeping the crane’s operation more stable and safe,” said Atherden.

“Keeping the crane in the green area will ensure operator can perform the lift safely. Safety Radar provides a different level of understanding by calculating a whole working area, not just the one point the crane is currently at. Even the most experienced operator couldn’t predict the safe working area like the system can calculate.”

“Another way of explaining

Know yourSafe Working Areain real time!

November 2022 CAL / 11www.cranesandlifting.com.au

The display element we’ve designed shows the complete safe working area of the crane, including articulation and radius for the particular configuration.

Safety Radar’s functionality is to say it is predicting what the crane’s response to the current load and working environment would be if radius is increased or the articulation is increased with the current configuration. Terex Franna sees Safety Radar, as a game changing development in pick and carry sector, and we don’t use the term lightly,” he said.

Most people in the crane industry would know that Terex separated from Demag in 2019. Prior to that separation, the design and engineering team at Terex Franna had been working closely with Demag’s in-house software team. This collaboration was part of the development process for the Franna AT40.

“At that point in time, we were faced with a decision, we either had to outsource our software support for the AT40, or start up an in-house software team to continue to develop the AT40 and move forward in the software space,” said Atherden.

“The decision was taken to do the latter, to create software as a core element within the engineering group at Franna. The Safety Radar development started as an idea to better present information to the operator.

“There are similar concepts in the field, in the slew crane space for example, but Safety Radar has been specifically designed for Frannas and

executed by our in-house Australian software team for the AT40, then we shared with Robway Safety Pty Ltd to implement our patent into the MAC25 and AT22 machines. The display’s working area dynamically updates for pitch, roll, articulation, load, boom angle, and boom length,” he said.

The Terex Franna design and engineering team has been working on the project in earnest since 2020.

UP FRONT / FRANNA 12 / CAL November 2022

Safety Radar went through some iterations internally to maximise the performance and understand what could and couldn’t be achieved.

“Once we were happy we had got the concept to a certain level, we ran a pilot program with a couple of customers. The customers came to our Terex Franna operation here in Brisbane and we fitted the Safety Radar software to their machines. We then let them go in the field and monitored operator feedback.

“Franna can only do so much in the confines of a structured testing environment, and nothing beats a ‘real world’ pilot program where operators are using it on a daily basis to perform their general lifting duties,” said Atherden.

The feedback has been very positive. The customers that we’ve

discussed Safety Radar with and the operators we’ve given it to, have come back and said, “It’s fantastic, we can’t believe how we have been operating without it.” And even people that aren’t in the operational space but are more in the fleet management are saying, “It really gives a new dimension in terms of safety for this type of machine, allowing the operator to really plan their next move more effectively and safely”, he said.

Safety Radar will be standard to all AT40 machines, as well as MAC25 and AT22 machines and will be available for retrofit to these existing crane models in the field which are fitted with our Dynamic LMI system.

“We are planning a public launch of the system at The Crane Industry Council of Australia

National Conference and Exhibition in November. And we’re targeting a release date of early 2023”, said Atherden.

Terex Franna has prepared a marketing video which helps owners understand how the Safety Radar system works. In the video, you are able to see the AT40’s in-crane computer with the new display element on the left-hand side and then an overlay section of a GoPro looking out the front of the crane, showing the operators perspective. The video highlights the way the Safety Radar changes under different operating conditions, including the initial lift, operation on a side slope and articulating on a slope.

Check it out on the Franna website: www.franna.com.au.

www.crewsafe.com.au

CrewSafe is the standardised VOC assessment tool for the Australian crane industry.

CrewSafe provides machinespecific, impartial, peer assessment with documented evidence of competency.

ENGINES/ GEARBOXES DIFFERENTIALS/ TRANSFER CASES BARE/GLAZED CABS UPPER AND LOWER SERVICE EXCHANGE HYDRAULIC CYLINDERS BOOM SECTIONS/ FLYJIBS BEN BADEN SERVICES PTY LTD | PH (02) 9679 8333 | 43 HOLBECHE ROAD ARNDELL PARK 2148 MECHANICAL STRUCTURAL PAINTING MACHINING AND LINE BORING ENGINE AND TRANSMISSION OVERHAULS CASAR WIRE ROPE DISTRIBUTOR BEN BADEN SERVICES NO DOWNTIME! MOBILE CRANE REPAIRS COMPONENTS EXCHANGE PROGRAM DRY HIRE AVAILABLE WHILE YOUR CRANE IS BEING REPAIRED!

Tom Smith – President

Ben Pieyre – Vice President Danny Adair – Director Danny Black – Director Andrew Esquilant – Director Marcus Ferrari – Director David Solomon – Director Bart Sutherland – Director

CICA OFFICE

Brandon Hitch Chief Executive Officer 03 8320 0444 0428 228 048 ceo@cica.com.au

Paul Arztenhofer Membership Engagement/Business Development Specialist 0490 939 274 paul@cica.com.au

Alice Edwards Technical Project Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran CraneSafe and CrewSafe Technical Advisor 0488 004 274 pat@cranesafe.com.au

NATIONAL CONFERENCE AND EXHIBITION WELL ON TRACK

Welcome to the November issue of Cranes and Lifting magazine.

AMIDST A TIME OF VARIOUS INTERNATIONAL and local economic uncertainties, I am pleased to report that the 2022 CICA Conference is as certain as can be. The program committee have fine-tuned an excellent and informative selection of topics to ensure that the sessions

Damien Hense CICA Road Policy Advisor 03 8320 0460 0488 007 575 damien@cica.com.au

Jed Kenwright Road Technical Engineer 0439 556 867 jed@cica.com.au

Julie Turner CICA Executive Assistant / Office Manager/Vic Secretariat Direct: 03 8320 0411 Email: julie@cica.com.au

Shane Coupe CraneSafe & CrewSafe Administration Officer Phone: 03 8320 0455 Email: shane@cica.com.au

Michelle Verkerk Marketing Communications Officer 0404 938 714 michelle@cica.com.au

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170 Phone: 03 9501 0078 Fax: 03 9501 0083 Email: admin@cica.com.au Website: www.cica.com.au

will add value and be of interest to everyone attending. CICA has received an overwhelming number of ‘Lift of the Year’ entries, and we appreciate the contribution of Cranes and Lifting magazine who are the sponsors of the ‘Lift of the Year’ Awards.

Underwriting Agencies of Australia (UAA) are this year’s platinum sponsor. CICA is very appreciative of UAA’s tremendous support, and the support of all the sponsors of this year’s CICA Conference.

I am sure you’ll agree that the October issue of Cranes and Lifting magazine was quite remarkable. The magazine has grown in both quality and readership, and I congratulate Simon and his team for their ongoing commitment to our industry and to this publication.

By all accounts, the recent branch meetings and Annual Branch Meetings were well attended and well run. Thank you to the outgoing executive teams, your efforts and leadership have been crucial, and you leave your branches in good shape. I would also like to welcome the new executive, putting your hand up for a role as a volunteer member of your team requires vision, commitment and promises to be an incredible growth experience. CICA would not exist but for its volunteers.

I can speak from experience when I say that November is a great time to visit Adelaide and I look forward to catching up with you during the many networking opportunities during the CICA Conference.

Thank you for your support and interest, stay safe.

Tom Smith CICA President Managing Director – McKay United 0439130567

www.cranesandlifting.com.au November 2022 CAL / 15

For information, please visit our website or call the CICA office.

CICA president Tom Smith.

CICA PRESIDENT’S REPORT

CANZ CRANE CONFERENCE 2022

16 / CAL November 2022 www.cranesandlifting.com.au THE CRANE ASSOCIATION OF NEW ZEALAND

Sarah Toase, CEO of the Crane Associaiton of New Zealand gets the conference underway.

“Delegates also travelled from Australia, Germany and Japan to attend the conference and do business with our members now that confidence has returned in the status of New Zealand’s borders.”

November 2022 CAL / 17www.cranesandlifting.com.au

Thousands of tonnes of liftng capacity was on display.

and off-site which demonstrated the benefit of being face to face. Exhibitors who were new last year returned having initiated business relationships with members and keen to develop further leads.

CELEBRATING EXCELLENCE

Its highly regarded industry awards were held on the final evening at the gala dinner. These awards recognise the incredible work and collaboration taking place in the New Zealand Crane Industry.

So much is to be gained simply by entering the awards as the reflection needed on the entrant’s success and challenges is rewarding in itself.

Delegates also benefit as the finalists for the Project of the Year and the Lift of the Year present their entries for everyone to experience, learn from and be inspired by.

• Training Company of the Year

NZ Crane Hire

• L eader of the Year

Stuart Hindley, Major Oak Safety Training

• People’s Choice Award

As always, the Crane OEM panel was very interesting for delegates.

IN CONCLUSION

The commitment of the industry in attending and supporting this event through sponsorship increased significantly this year. It is heartening to see this support

18 / CAL November 2022 www.cranesandlifting.com.au

THE CRANE ASSOCIATION OF NEW ZEALAND

Sir Graham Lowe (“Lowie”) opened the conference with an incredible keynote speech which was very well received by attendees.

P.A.

For over 30

Cranes

Australasian

with a

Mini Crawler Cranes

Crawler Cranes

Electric Cranes

Mobile Cranes

Telescopic Crawler Cranes

Duty Cycle Cranes

Mini Crawler Cranes

Crawler Cranes

Electric Cranes

Mobile Cranes

Telescopic Crawler Cranes

Duty Cycle Cranes

Glass Lifting Devices

Tracked Carriers

Crawler Cranes

Knuckle Boom Cranes

Construction

Equipment Pty Ltd (Pace Cranes)

was established in 1987 to provide the construction industry with an independent Australian owned and operated

crane

sales, crane service and crane

spare

parts organisation.

years Pace

have offered premium quality equipment to the

market

dedicated and unrivalled service, supported by specialist technical advise across the full range of equipment sold.

Electric Pick & Carry Cranes

Glass Manipulators Bi-level Multi Loaders pacecranes.com.au +61 2 9533 5411 sales@pacecranes.com.au

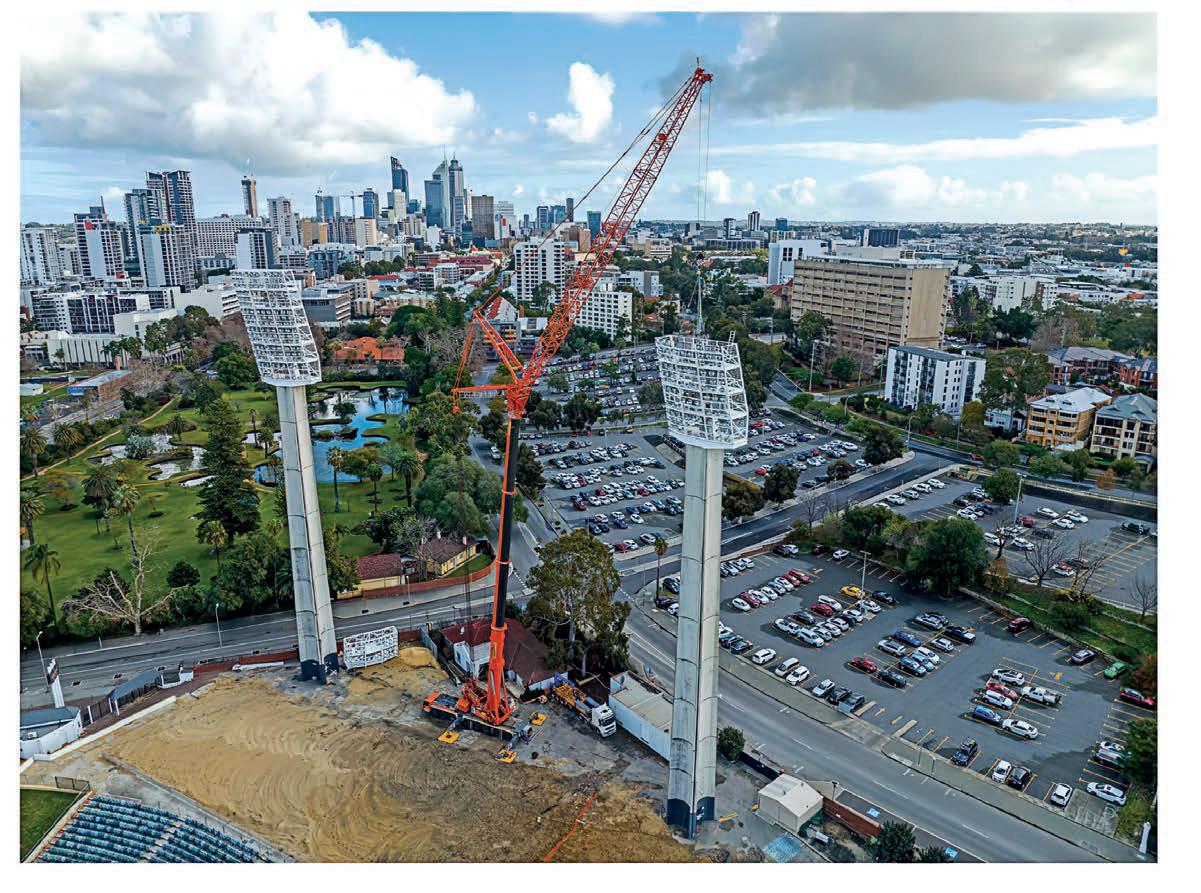

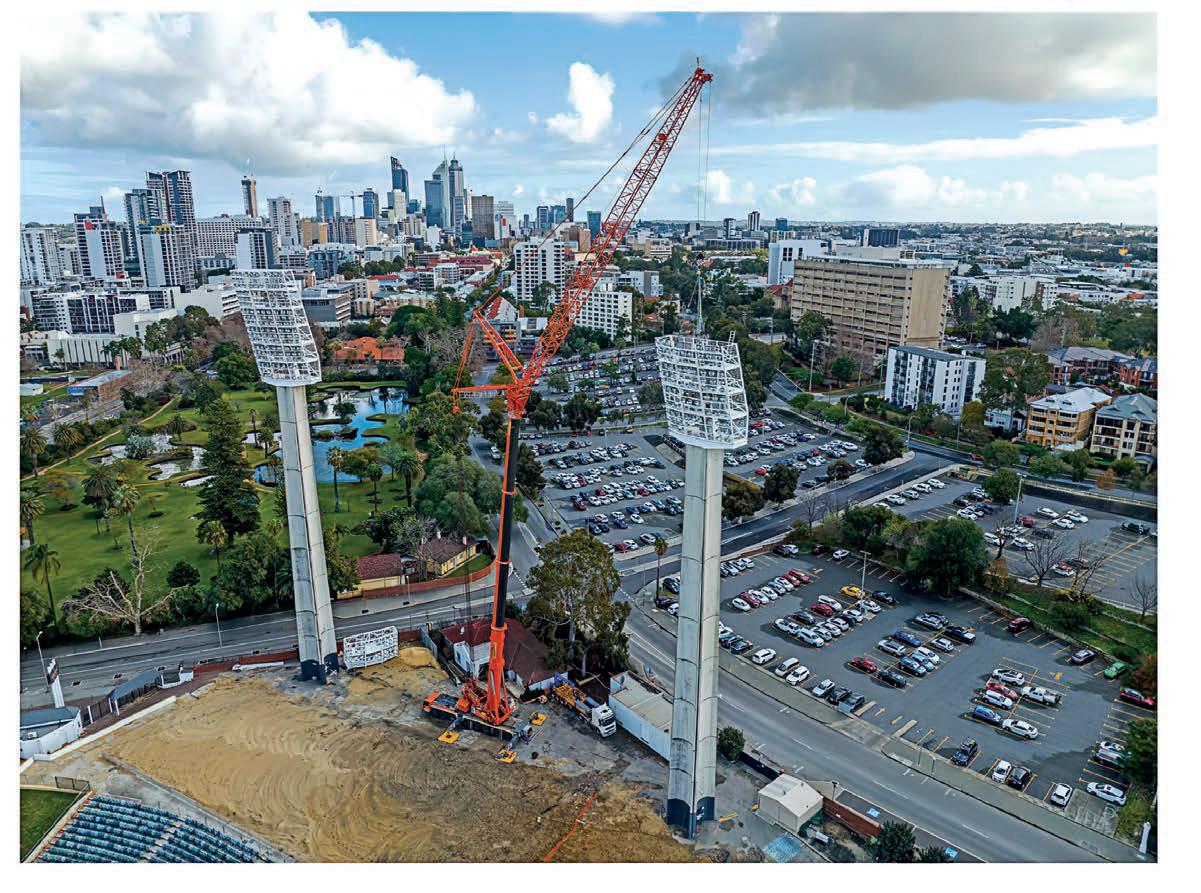

LEACH HIGHWAY AND WELSHPOOL ROAD INTERSECTION UPGRADE

The Covid19 pandemic has had a global impact on many people’s lives, not only physically but also financially. To cope with the crisis, many institutions have closed their doors or reduced their staff. Despite the challenges, the Western Australian government is committed to completing major infrastructure projects that will alleviate the difficulties faced by road users.

THE LEACH HIGHWAY AND WELSHPOOL

Road Interchange upgrade was proposed to enhance Western Australia’s second most dangerous and congested intersection, which had more than 200 crashes between 2015 and 2019. To realise the proposed concept, local WA companies BG&E Pty Ltd, Georgiou Group Pty Ltd, and Golder Associates Pty Ltd allied. The Leach Welshpool Alliance (LWA), as they are known, was awarded a $93 million contract for the interchange upgrade. [1]

SCOPE OF WORK AND CHALLENGES

Part of the interchange upgrade was to install sixteen bridge beams for Bridge 1883 consisting of two spans and eight beams per span. The maximum weight of the beam is 200 metric tons with a length of 45m, which would require a decent size of crane to handle the operation. Simultaneous project executions had affected the availability of the cranes in the country and bringing in cranes from overseas would have been an expensive approach. With these limitations, the LWA had sorted

multiple options to satisfy the constraints and deliver the project on time.

OUR METHODOLOGY

Tutt Bryant Heavy Lift & Shift (TBHL&S) a renowned heavy lift contractor and crane provider, proposed an installation methodology with the use of a crawler crane with a variable positioning counterweight (VPC). With this proposal, the crane would only be at two positions, pick and carry the beams and install them in the final position. This method would

TBHL&S proposed two sets of self-propelled modular transporters (SPMT), in which beams were received simultaneously and the succeeding beams were ready after the preceding beams had been installed.

IN FOCUS / TUTT BRYANT HEAVY LIFT & SHIFT 20 / CAL November 2022 www.cranesandlifting.com.au

November 2022 CAL / 21www.cranesandlifting.com.au

TBHL&S

installation methodology involved the crawler crane with a variable positioning counterweight (VPC).

“Through the Cranecorp Tutt

Bryant

Joint Venture, a

Demag AC300-6

300 metric ton capacity telescopic all terrain was provided from the Cranecorp fleet along with several riggers to assist with the MLC650 as part of the joint venture.”

not only save the crane from having several positions, which would necessitate some groundwork, but also increase the number beams installed to fulfil the deadline. The delivery of the bridge beams from the current offload locations to the crane’s pick-up position was another part of this project.

TBHL&S proposed two sets of self-propelled modular transporters (SPMT), in which beams were received simultaneously and the succeeding beams were ready after the preceding beams had been installed. TBHLS also introduced the use of a rigging spreader to expedite the installation of the beams and as a result, it saved additional costs associated with employing assist cranes to handle the rigging tackles.

EQUIPMENT SOLUTION

The proposed solution delighted the LWA, and the contract was given to TBHL&S. The crane that was suggested and was the only crane available and could handle the operation is the Manitowoc MLC650 with VPC-MAX and a maximum rated capacity (MRC) of 650 metric tonnes. Due to its size, the first challenge was the suitability of the assembly location. It was extremely tight and congested, with the live traffic that could not be disrupted as per main road guidelines. To save the traffic, TBHL&S devised an assembly strategy in which only crane parts needed were brought on site that day. Through the Cranecorp Tutt Bryant Joint Venture, AC300-6 a 300 metric ton capacity all terrain crane

was provided from the Cranecorp fleet along with several riggers, to assist with the MLC650.

The assembly was completed three days ahead of schedule, boosting the alliance’s confidence in the TBHL&S heavy lift team and the Tutt Bryant Cranecorp Joint Venture. The delivery of the rigging spreader was another important hurdle that was critical to the project’s success. Due to lack of option, TBHL&S decided to create their own, which will serve as an asset for future projects. The rigging spreader was finished and transported to site two days before the scheduled lift with the assistance of a local fabrication firm.

PROJECT COMPLETION

Only one weekend was set for the transport and installation operation. The roads were closed on Friday night, and the installation completed by Sunday evening, with the road re-opening at 05:30 on Monday morning. To meet the requirements, TBHL&S with the support of the Cranecorp Tutt Bryant Joint Venture provided two separate crews working day and night shifts.

The sixteen bridge beams were successfully transported and installed by the TBHL&S team ahead of the schedule. The crew managed to reduce and create a working solution that avoided any delays of the transit of the beams towards the pick-up position, thanks to their skill and experience in handling these operations. Numerous progress meetings and risk management were held to ensure that all viable solutions and hazards were explored and managed. The ability of the ground to bear the stresses exerted by the massive crane required collaboration between the LWA, TBHL&S and Cranecorp Tutt Bryant Joint Venture teams. The engineering team of TBHL&S developed 3D models to ensure that clashes were avoided.

Reference: [1] Cabinet D 2022 Media statements - Local contractor to deliver Leach Highway and Welshpool Road upgrade Mediastatements. wa.gov.au

22 / CAL November 2022 www.cranesandlifting.com.au IN FOCUS / TUTT BRYANT HEAVY LIFT & SHIFT

The Manitowoc MLC650 with VPC-MAX has a maximum rated capacity (MRC) of 650 metric tonnes.

Follow us on: brisbane | sydney | melbourne adelaide | perth tuttbryant.com.au1300 658 888 Peter Lawgall0411 256 388Peter.Lawgall@tuttbryant.com.au Philip Chadwick0457 510 097Philip.Chadwick@tuttbryant.com.au CR-250RV L : 9,165mm W : 2,745mm H : 3,368mm 24,000kg 25t x 2.8m (6.7m Boom) 6.7 ≈ 29.0m (6 sections) 5.3m, 8.2m (2 sections) 7˚ ≈ 60˚ 6.0m (5 sections) 54km/h MS-230D 1.0m 2 positions (high/low) Compact and Versatile High Performance CITY RANGE Crane

A NDR OMEDA I NDU ST R IES PT Y LTD Plaited & Woven Division Ph. 02 6760 3773 andromedaindustries.com.au SUPERFLEX STEEL SLINGS • manufacturing • infrastructure • construction • shutdown Australia’s leading manufacturer of high quality cable and lifting slings such as our very own cable and Steel Flat woven slings. Featuring aluminium or steel ferrules. Slim tapered under loads. GIVE YOURSELF A LIFT FROM THE BEST IN THE BUSINESS • mining • LNG ops Flat Woven Slings

TWO WAY CRANES ON THE MOVE

“WE’VE RECENTLY INTRODUCED SOME youngsters into the business. I refer to them as the next generation and we have had success pairing them with experienced crew members, where they can watch, listen and be mentored on the job.

“On the radio, they listen and watch the operator work with the crew and really understand what is happening. This is how I learned. It’s a hands-on approach and a very important aspect to their training, not just sitting in a classroom learning from a textbook.

“I think this approach is more practical than theory. Theory can only give you a basic cover, but the practical experience on site provides you with life experience of what the industry is really all about. For me and my teams, that’s better training and I’m a prime example of it and so are many other in the industry,” said Frank.

“We just had another youngster start

and he’s a motor mechanic. He’s done his trade and now he wants to get into the crane industry. I said, “Go get your Dogging and Rigging tickets and we’ll put you through a training program here,” he said.

Frank explains how the experienced team members are responding to the

and enthusiastic from the start. The response out in the yard to him has been unbelievable.

“One of my experienced Franna drivers said, “Mate, I want to work with this bloke, he helps me really enjoy my job, and I love showing him what needs to be done and how we do

training and mentoring of the new generation.

“We are handpicking the experienced guys for the mentoring roles and the response has been really good. Take Dylan Ross for example, he just walked into the yard one day, scaffolder by trade and was just happy

it at Two Way Cranes.” The operator has had a boost in his confidence, and he is enjoying the job more because of Dylan’s personality and positive approach to everything. When you see him, he’s just smiling,” said Frank.

Jason Jordan has been in the crane industry for 18 years. Over this time,

IN FOCUS / TWO WAY CRANES November 2022 CAL / 25www.cranesandlifting.com.au

With a renewed focus on bringing youngsters into the business, renewing the crane fleet and expanding operations, Two Way Cranes Managing Director, Frank Zammit is happy with where the business is currently sitting.

“Theory can only give you a basic cover, but the practical experience on site provides you with life experience of what the industry is really all about.”

The Two Way Cranes Wollongong operation recently completed a heavy lift with three AT40s.

he has held various roles within a number of Sydney’s leading crane hire companies before joining Frank Zammit and Two Way Cranes six years ago. His job title might be Allocator but watching Jason at work, it is quite apparent he is the focal point of the business, central to everything that happens every day, and night.

Jason talks about his role at Two Way Cranes

“Job titles don’t mean much to me, I’m just here to help Frank run Two Way Cranes”.

Jason spends his working day managing an ever-changing schedule of customer bookings, crane movements and ensuring the right personnel move with the cranes.

“It’s like you have a huge mental jigsaw puzzle in your head and you are constantly moving the pieces to ensure you have the right ones in place at any given time. We operate a tracking system, so you can see at a glance where everything is and when you get an urgent job, you are on the phone to the crews giving them the instructions so as soon as they finish the job they are on, they are onto the next,” he said.

Jason discusses one major frustration he faces on a day to day basis

“I couldn’t count how many inductions the crews do, it’s a major issue for the industry. As a business we absorb the costs and make the crews available which leaves us short. Then we find certain personnel are inducted on certain sites, cranes are inducted on certain projects, it’s an ongoing issue and gets very difficult that way. You could spend a couple of hours juggling things around just to make it all happen, it’s very time consuming. And unlike the good old days, every

builder and project have a different set of requirements” he said.

During his six years, Jason has seen a lot of change within the Two Way Cranes business

“When I started working with Frank, we had between 25 and 30 crew and around 14 cranes. Today we have a fleet of 47 cranes and our team is in excess of 100. I’ve had a couple of people in here to help over the years, but the pressure of the job isn’t for everyone. Personally, I don’t look at it as pressure, it’s more of a puzzle that has be solved every day. We just

make it happen,” he said.

“Sometimes it is logistically impossible and we can’t help that, but most of the time, it takes a bit of effort and patience, and everything goes to plan, and we make it happen,” said Jason.

“We’re not only just managing the yard, we also have to manage the information from the supervisors, manage what cranes are going where and what’s on site and what’s not on site, anything to resolve the situation,” he said.

“Sometimes you got to be an open

IN FOCUS / TWO WAY CRANES 26 / CAL November 2022 www.cranesandlifting.com.au

“The Wollongong operation is starting to move and is gaining some really good traction. We opened the yard almost early two years ago and for the first 15 months, it was chugging along. But today it really has some traction.”

Two Way Cranes likes the fact that the Franna AT40s are strong lifters.

ear for the crews in the yard, as well. We are mindful that this type of work can be stressful, there can be long hours, which can lead to difficulties in relationships and that type of thing. So, we are always here to listen and to make sure everyone is OK, and if they are not, they have the confidence to put their hand up and say so,” said Jason.

Frank goes on to explain that young women have also come forward and expressed an interest in working in the industry.

“Riarna Anderson who we had working within the office, showed a genuine interest in getting her Dogging ticket, now she is working and learning on the cranes I have at Garden Island and the customers couldn’t be happier with her. “

Frank goes on to discuss the Wollongong operation and how it

has been performing.

“ The Wollongong operation is starting to move and is gaining some really good traction. We opened the yard almost early two years ago and for the first 15 months, it was chugging along. But today it really has some traction.

“I was in the yard for a toolbox in late September and we have 11 full time employees, and it really feels like a crane yard now. I haven’t been spending much time there as I’ve got Scott Slender who is the allocator and Sash Vujic the project manager running it and they are doing a really terrific job.

“We brought some new employees on board, and they are all locals, and we are getting people approach us and wanting to join the operation,” he said.

“There are eight cranes permanently based in the yard and I feel like we need

more. I’m going to put a dolly crane down there. We’ve already got a 250t all terrain, so we’ve got a solid base. There’s a Franna AT40 permanently based there as well. I’ve got another two AT40s on order. We probably need another 40t and 60t capacity all terrains there as well. So yes, it’s taken almost two years, but the Wollongong operation is self-sufficient,” said Frank.

Frank goes onto discuss the Sydney operation.

“The Sydney operation is headed in the right direction. Anyone that knows me, understands I am very focused on the Two Way Cranes’ brand and everything it stands for and we are seeing that the brand getting noticed.

“We are getting comments from new customers saying they see Two Way Cranes branded utes or a Two Way crane, or a truck. Everyone sees Two

November 2022 CAL / 27www.cranesandlifting.com.au

The Two Way Cranes’ Sydney operation is growing not only from the recruiting of trainees but it is also attracting experienced crane staff as well.

“The good thing about the business today is we’ve been receiving enquiries from ex Gillespie Cranes employees. Some of them left prior to me purchasing the business, or they decided not to come across to Two

employees join us and that’s a big positive for the business, I feel. They’ve been watching what’s happening, they have been talking to the existing guys, they went off to try something different and now they’re willing to come back. I’m wrapped with that,” said Frank.

Frank goes on to discuss how he is expanding the Two Way Cranes fleet with new purchases.

“I feel really positive. As I’ve said, I have good people around me. It’s been hard work, but we are here now.”

this has got to continue. There’s still significant construction to come with the planned metropolis which is going to be huge. You can’t have a new international airport with nowhere to go. This means there’s a lot of infrastructure to go in and it’s all in my backyard,” he said.

“I feel really positive. As I’ve said, I have good people around me. It’s been hard work, but we are here now.”

28 / CAL November 2022 www.cranesandlifting.com.au

Two Way Cranes’ Dylan Ross, Jason Jordan and Riarna Anderson.

Continuing the legacy...

SYDNEY –

37 Cox Place, Glendenning NSW 2761 02 9622 8830 02 8887 7888

WOLLONGONG

5 Resolution Drive, Unanderra NSW 2526 02 4272 5224

twowaycranes.com.au

HEAD OFFICE

www.cranesandlifting.com.au30 / CAL November 2022 IN FOCUS / PILEQUIP PILEQUIP INCREASES PILING PRODUCTIVITY WITH NEW PILE LIFTING DEVICE The Pile Lifting Device is a winch system that is hydraulically powered and controlled by the existing vibro hammer system.

Pilequip recently introduced a range of Pile Lifting Devices (PLD) to their vibratory hammer packages, which are designed to increase the productivity of cranes during the installation of piles during the construction process. David Hopkins, National Sales Manager Pilequip Australia explains more.

The Pilequip PLD allows you to pitch the pile with the vibro hammer.

do it separately with a separate crane or remove the vibro from the hook, which can make the whole process a bit tedious.

“You take the vibro hammer, lay it down, lay all the hoses down, take it off, then go over, pick your pile up, place it, then let go of that. Then come back over to your crane and hook it up, then lift it up, get your hoses out, get all the hoses right, come back over, line the pile up.

“That all just takes time. But with the PLD, it’s all in one movement. The PLD comes down, picks up the pile, the winch is turned, pile goes onto the vibro hammer which places the pile and starts to drive. You’ve got less crane movements, which is a massive advantage for any piling site,” he said.

Compared to the cost of hiring a vibro hammer, a hiring a PLD is not going to cost a significant amount.

“We are still working out what that rental price will be, but it’s going to probably add $1,500 to $2,000 a week to

“The PLD comes down, picks up the pile, the winch is turned, pile goes onto the vibro hammer which places the pile and starts to drive. You’ve got less crane movements, which is a massive advantage for any piling site.”

your rental which isn’t really a significant cost. We are not sure how much time it could save a customer, we’ll see when these units arrive.

“A conservative number, I’d say maybe 30 per cent in terms of time savings. That $2,000 really becomes insignificant on a weekly basis. We are going to have initially two lifting devices in the fleet, one for the bigger vibros, so our ICE 1412, 82NF, and PVE 70VM, with a 20t lifting capacity. And on our smaller ICE 55NF vibro, and PVE 40VM which has a capacity of 10t swl.

The PLDs are Manufactured and shipped from the Netherlands, from Pilequip’s parent company Dieseko which is the same company

manufacturing Pilequips’ ICE & PVE vibratory equipment. The PLDs is an additional piece of kit for the vibratory hammer.

There are similar products, but none with an independent winch system.

“The only other product, that I’m aware of, on the market relies on the auxiliary line of a crane. So you’d have obviously your main line with the vibro, but then a secondary auxiliary line to come down and to pull the pile up. So no, I don’t believe there to be a system that exists that uses the same winch system that we have, which is integrated into our power pack, so it all can be independently controlled by the operator of the vibro,” said Hopkins.

IN FOCUS / PILEQUIP 32 / CAL November 2022 www.cranesandlifting.com.au

The big advantage of PLD system, is that it allows the user to either eliminate a second crane, or eliminate all the off-hook time that comes with having a single crane and a vibro hammer.

THE CROSBY GROUP TO COMMENCE CASH TENDER OFFER FOR ALL OUTSTANDING SHARES OF KITO CORPORATION

Completion of regulatory clearances marks a key step in agreed combination process announced by both companies. The business combination of The Crosby group and Kito corporation will be to create a global provider of comprehensive lifting solutions.

THE CROSBY GROUP, A LEADING PROVIDER of lifting and rigging solutions, and Kito corporation, a leading manufacturer of material handling equipment with 90 years of experience in the development and production of hoists and cranes, today announced that they have secured all regulatory clearances for their business combination and that the Crosby group will commence a cash tender offer to acquire all outstanding shares of Kito corporation for JPY 2,725 per share on September 26.

The cash tender offer price represents a premium of 64.3 per cent compared to Kito corporation’s undisturbed closing share price on May 13, the last trading day before the transaction was originally announced.

The cash tender offer will commence on September 26 and the transaction is expected to close in Q1 2023, following the settlement of the cash tender offer and the

completion of the squeeze out period.

The proposed combination will bring together the complementary capabilities, geographic footprints, and product portfolios of two industry-leading companies to better serve customers, team members, and communities. Well positioned to accelerate growth through investments in its products, people, and facilities, the combined company will bring customers a broader portfolio of products, globally, and provide increased levels of service, support, and training.

Robert Desel, CEO of The Crosby Group, said, “the receipt of regulatory clearances and commencement of the cash tender offer are key milestones as we work toward the completion of our business combination with Kito corporation and thus the creation of a global provider of comprehensive lifting solutions.

“Pairing our highly complementary product portfolios gives our global customer base

IN FOCUS / CROSBY GROUP 34 / CAL November 2022 www.cranesandlifting.com.au

“Pairing our highly complementary product portfolios gives our global customer base access to a broad range of lifting and material handling solutions from one trusted source, together we will create compelling value for our stakeholders globally.”

access to a broad range of lifting and material handling solutions from one trusted source, together we will create compelling value for our stakeholders globally. Kito corporation shares our core values of safety, reliability, and innovation, and we look forward to completing this process.”

Yoshio Kito, the CEO of Kito corporation said, “We are pleased to have received the necessary regulatory clearances. We believe this combination creates excellent value for all stakeholders, and we are excited to build upon a combined business to better serve our customers, team members, and communities. This combination will allow us to grow as a global business and provide our customers with expanded, best-in-class product offerings, with the same dedication and support to which they are accustomed.”

SMBC Nikko serves as the tender offer agent as well as lead financial advisor, Mizuho Securities USA LLC acted as financial advisor, and Kirkland & Ellis LLP and Mori Hamada & Matsumoto acted as legal advisors for The Crosby Group. Debt financing is being provided by UBS Investment Bank, KKR Capital Markets, Sumitomo Mitsui Banking Corporation, Mizuho Bank, and ING Capital. Nomura acted as financial advisor and Nishimura & Asahi acted as legal advisor for KITO CORPORATION.

The 3t and 25t are just some of the products the Kito corporation provide.

November 2022 CAL / 35www.cranesandlifting.com.au

The Magni telehandler has an impressive reach of 22 metres and a six tonne capacity.

IN FOCUS / MCT 36 / CAL November 2022 www.cranesandlifting.com.au

WHAT DO YOU GET WHEN YOU COMBINE A CRANE AND A TELEHANDLER? A MAGNI.

With sights firmly set on being the premier provider of innovative mobile lifting equipment for Australian mining, construction, and agriculture industries, MCT Equipment scours the globe for ground-breaking solutions for its customers.

ONE SUCH GAME-CHANGER IS THE market-leading 3-in-1 rotating telehandler (RTH) from Italian mover and shaker, Magni. A Magni RTH is not your average telehandler, it is so much more. Functioning as a 360° rotating telescopic handler, rough terrain crane, and aerial work platform, it is the ultimate in versatility and flexibility. It replaces the need for three separate machines, saving both time and money.

Able to service many applications with a single piece of machinery, its attachments are easily interchangeable and include buckets, clamps, forks, hooks, platforms, jibs, winches, and more. All models of the RTH (with lifting capacities from 4,000kg to 13,000kg) are equipped with an RFID automatic attachment recognition system and patented Q-Fit Quick Connect system to ensure safe pairing.

The RTH offers outstanding manoeuvrability with its front axle, 4-wheel drive, and crab steering settings, and compact outrigger footprint. Bolstering its ability to effortlessly lift and move in tight, hazardous spaces is its remote operation capabilities.

The remote control allows the machine to be remotely operated from the ground or from a distance, with the same functionality as the cab. This in turn improves visibility and efficiency, reduces the number of operators required for the task,

The Magni has a range of attachments that can be added.

and mitigates potential risk. As a bonus feature, the remote control uses Bluetooth and can be used all over the world without limitations.

MCT Equipment and Magni have synchronised their business

models in more ways than one, but a significant common thread is their pursuit of innovation. Whilst Magni strives for endless improvement through technology and quality, the team at MCT lives by their promise

November 2022 CAL / 37www.cranesandlifting.com.au

“Able to service many applications with a single piece of machinery, its attachments are easily interchangeable and include buckets, clamps, forks, hooks, platforms, jibs, winches, and more.”

to “think different, lift different”. MCT has found that opportunity to provide a new and unique solution in the Magni RTH.

The Magni RTH is effortless, intuitive, versatile, and reliable. Furthermore, it is one of the safest machines on the market, thanks to its patented load control system that detects the risks of overload during use and inhibits further usage. With incredible lifting capacities and dizzying telescopic expansion and

reach, they are a masterpiece in craftsmanship. Scan the QR code to watch how impressive the RTH is in action.

See for yourself why MCT Equipment’s range of Magni telehandlers is leading the way. Book a demo today by simply scanning this QR code!

For further information, contact our experienced team today by calling 08 6500 3460 or visiting https://mctequip.com.au.

IN FOCUS / MCT

Australia’s Most Respected & Reliable Crane Dealer 2 Heland Place Braeside VIC 3195 | 1300 686 626 | sales@gleason.com.au New Zoomlion ZCT900V 90 tonne Hydraulic Boom Crawler Gleason Cranes proudly partner with the following global brands: Zoomlion, Mijack, Ormig and Beta With Gleasons well-earned reputation and commitment to quality, every imported crane is brought up to Australian Standards and backed by a full parts and labour warranty. Gleasons are now taking orders on the newest series of Zoomlion’s Hydraulic Boom Crawlers, with a ZCT300V5 and ZCT600V in stock now New and Used Cranes Imported Cranes “The remote control allows the machine to be remotely operated from the ground or from a distance, with the same functionality as the cab.”

These

•

•

•

•

•

•

A MAGNI TELEHANDLER

machines are in a league of their own, pushing the boundaries of what's possible in the world of telehandlers and heavy machinery. This is NOT your average telehandler. MCT EQUIPMENT HAS EXCLUSIVE DISTRIBUTION RIGHTS FOR MAGNI IN WESTERN AUSTRALIA AND NORTHERN TERRITORY. What do you get when you combine a crane and a telehandler? IN FOCUS: MAGNI RTH 7.26

The RTH 7.26 is a touch, high performance & world leading rotating telescopic handler.

Maximum Lifting Height of 25.7m, with variable outriggers for greater safety and manoeuvrability.

Programmed to provide the best possible lifting capacities with “live” dynamic load charts.

Leveling system on tyres added safety and performance.

RFID tag system for automatic recognition across a huge range of attachments available.

The Swiss army knife of the Construction Industry, this is true 3 in 1 machine and is NOT your average telehandler. Book a FREE Demo Find out more

INTRODUCING THE MANITOU VISION+ ROTATING TELEHANDLER RANGE

Manitou continues its impressive development of telehandlers with the new range of Rotating telehandlers, the Vision Plus range. Featured here, the MRT-X 2260 Vision+ has a maximum lifting height of 22 metres and a capacity of six tonnes, and a number of models in the range including a 35 metre, 7 ton unit, it is an impressive piece of machinery entering the Australian market.

The MRT-X Vision+ range is very versatile and each model can be fitted with various attachments.

IN FOCUS / MANITOU 40 / CAL November 2022 www.cranesandlifting.com.au

MANITOU IS A COMPANY WITH a rich history. It was started in Western France by Marcel Braud in 1958. He envisioned the original machine and created it by inverting the layout of a farm tractor and adding a lifting mast and hydraulic steering. From this early concept and humble beginnings, Manitou has grown astronomically and has sold over 500,000 machines across the globe.

The all new Vision + Range of Rotating telehandlers is expected to be well received by the numerous industry sectors in Australia including the construction and crane industries.

From the ground up, the Vision plus range has been redesigned

Manitou MRTs can be remotely controlled. The operator can remotely setup the machine on outriggers and automatically level it to maximise lifting capacity.

and boasts a total of 21 new patents. Manitou’s Matt Szady explains more.

“We have the new engine supplier in Yanmar and you will see this brand being installed across a large number of models in the Manitou range. The Yanmar power plants have proven to be super-efficient and deliver more power and Torque then previous models with some units in the range now using Yanmar able to generate 50% more torque whilst being 10% more fuel efficient,” Szady said.

The Vision plus range has seen a complete redesign of the machine to improve it specifically for applications in the tough working environments found particularly in the construction and resources sectors.

“We have changed the type of steel

used and the treatment it receives to improve the anti-corrosion capabilities. We have used a higher yield, 700 megapascals (MPa) steel which has allowed us to get the extra tonne of capacity, one meter of lift whilst not raising the overall weight of the machine,” Szady said.

This machine has been designed to improve the safety and visibility for the operator. The visibility through to the forks, the corners and above have been vastly improved. The roof grid above the driver’s head has been precisely angled to improve the visibility of the operator improving safety, efficiency and made handling loads at height a breeze.

“30 per cent of reported

November 2022 CAL / 41www.cranesandlifting.com.au

telehandler incidents in Victoria comes from people getting in and out of the cabin so with the introduction of the Easy Step Cab into the Vision Plus range, this is sure to help minimise these incidents. The whole top deck of the Vision Plus range is now walkable even when slewed out and features access and egress steps on all sides of the machine meaning the operator never has to jump off the machine to get around, once again lowering the chance of injury,” Szady said.

The driver focus is not simply kept to the safety, the comfort of the driver is vastly improved in this machine as Szady explains.

“It does not take a genius to realise that a glass box the driver sits in can get hot, so with that, the designers have taken phenomenal steps to improve the ability for the cab to be cooled. The shape of the cab has been designed to allow air to flow more effectively around the

cab and operator thus allowing the system to work more efficiently, lowering the power needed thus reducing the operating costs without sacrificing operator comfort,” he said.

“This development is something that started in the agriculture sector and we have brought this across to our construction machines. This is the benefit of working in a number of industries, lessons can be learned and developments can be shared between them.”

The Vision plus range has been designed with longevity in mind, whether that be using nitrogen to

cut the steel as opposed to a laser to eliminate corrosion during the production process and a paint finish with a greater weather o meter rating of 800 as opposed to the previous 600.

The build of the machine is not the only part vastly improved, the technology available to the operator is impressive. The pop-up display provides numerous fail safe options, the screen will flash amber or red and recognise the task that is being performed incorrectly to notify the driver a change must be made.

The display tracks the boom position on the screen, it also shows the load chart and what the capacity

“The shape of the cab has been designed to allow air to flow more efficiently around the cab thus keeping it cab cooler and allowing the system to not have to not work as hard therefore lowering operating costs without sacrificing operator comfort.”

is at each point on each angle. The machine can simulate lifts after the parameters have been set to simplify the task for operators.

“The feedback from long term users of these machines is that they can often replace four or five guys on site simply by being there, they can then be redeployed in different areas of the site or allow companies to operate a greater number of sites, it is just infinitely capable of doing multiple tasks with a vast array of attachments” he said.

In most cases, owners will take delivery of their MRT and include a winch and basket but the true benefit of a telehandler on site is its versatility. Manitou offer a wide range of attachments including buckets, jibs and concrete mixers just to name

“We are excited for this machine to be launched in Australia, we believe it fits the market really well and we look forward to feedback from customers,” he said.

IN FOCUS / MANITOU 42 / CAL November 2022 www.cranesandlifting.com.au

The MRT panoramic cabin offers classleading visibility, comfort, and ease of operation with a large 12.1” touch screen.

MANITOU

The NEW Manitou Rotating Telehandlers are now available in Australia. With a lifting capacity of up to 7 tons and a lifting height of up to 35m the MRT is a 3in1 concept and can be used as a telehandler, a crane, and a mobile elevating work platform with our wide range of attachments. Visit manitou.com to find your nearest dealer for sales, parts and service.

REINVENTES THE ROTATING TELEHANDLER MRT VISION RANGE

MERLO ROTATING TELEHANDLERS SHOW STRONG PEDIGREE

STM Equipment have represented the Merlo range of telehandlers since 2019, with the company believing this telehandler to be one of the most versatile on the market.

STM STARTED IN 1976 AS A DEALERSHIP for international harvesting equipment. From the outset the business was focused on sales, but also support, in terms of investing in service and parts availability. STM was also a truck and commercial vehicle dealer.

Gino Cassaniti is the Operations Manager for STM Equipment and he explains more about the diverse nature

of client’s serviced by the business.

“Our clients range from sole traders, who can be owner operators of equipment and small contractors, right through to large farmers, multinational transport businesses, large civil construction businesses and contractors, as well as major hire and mining companies.

ROTO 50.26SEE PLUS is one of

The Merlo has the capability to be used a smaller version of a pick and carry crane.

IN FOCUS / STM EQUIPMENT 44 / CAL November 2022 www.cranesandlifting.com.au

the fresh Merlo models to enter the Australian market and is an impressive piece of machinery.

The Roto comes with a five tonne lifting capacity and a lifting height of 26 metres and with five boom sections. It is powered by a four cylinder diesel engine producing 125 kilowatts and 170 horsepower.

The Roto’s are the only models on the market to offer active hydropneumatic suspension on the axles, for maximum safety and optimal driving comfort. This solution eliminates the pitching motion when taking curves, for greater stability.

The cab is level II FOPS and ROPS certified, designed to maintain the maximum level of ergonomics while ensuring excellent protection for the operator. Merlo is the only company on the market that offers a vertical cab tilting solution designed to ensure operating comfort and perfect visibility of the load.

Merlo’s patented Adaptive Stability Control System is capable

of recognising the attachment being used and measuring the magnitude of the load being handled, in order to maximise the speed of the hydraulic movements without any risks to the operator’s safety. Customers can simultaneously check all the operating parameters in real time and see at which point the safety system will intervene by slowing down and stopping any problematic movements.

The boom on the Merlo consists of a double “C” profile in high-strength steel with welds made along the neutral bending axis. The hydraulic hoses and electrical wires positioned inside the boom with a ‘cartridge’ system, to protect against any possible impacts and easy extraction in case of maintenance. The L-shaped runner blocks are made of composite material

to maximise efficiency and reduce impact and wear on the sliding surfaces. The Merlo boom solution can offer:

With the self-stabilisation device, which comes standard on all ROTO models, the operator can simply press a button to initiate the machine’s automatic frame stabilisation and tilt correction procedure, this allows operators to reduce setup times, maximise safety and simplify the machines use.

Compared to market standards, the frame is characterised by small dimensions, allowing to minimise the overall floor space occupied by the machine. Furthermore, it is equipped, on the outside, with an exclusive steel belt (made from a steel section bar).

Designed to maximise structural strength and ensure excellent torsional

November 2022 CAL / 45www.cranesandlifting.com.au

“The Roto comes with a five tonne lifting capacity and a lifting height of 26 metres and with five boom sections.”

It comes with a range of attachments for any challenge.

strength, the underside of the body is completely secured by steel sheets, in order to protect all components from possible impacts during off-road driving.

The chassis is completely walkable. This solution, combined with the ladder applicable to the chassis itself, allows the user to climb on and off the vehicle in any situation, thereby facilitating the work processes.

The attachments, which are designed and manufactured at the Merlo Group facilities, are the real operational tools used by Merlo telehandlers, and are designed to bring out the machines’ performance and versatility in different operational situations.

• A Pl atform to be used as a EWP

• A bucket to be used as a loader

• Forks to be used as a forklift

• Jibs of various kinds to be used as a Crane

The patented recognition of the attachments and the effective Tac- lock hydraulic locking system allow for quick tool changes to be performed, with the operating parameters being configured automatically for maximum safety.

Cassanti explains what makes the Merlo brand one of the leaders in the telehandler market.

“Worldwide, the Merlo brand is recognised as the original telehandler and like STM Equipment, Merlo still operates as a family business. With

the Italian flair in terms of design, engineering and manufacture, it is an extremely versatile product.

“The development of the ROTO began as a result of market demands and is typical of the continual evolution Merlo seeks throughout its range of products. The Merlo design team is focused on introducing state of the art technologies for new machines of similar dimensions and weights to previous ranges, thus providing superior performance, greater ease of use and higher levels of safe operation,” he said.

T he hydrostatic transmission guarantees high performance, millimetric precision, and excellent braking capacity, by increasing the engines’ “engine braking” effect.

Although the team at STM Equipment have grown over the years to become a major force in the industry, they have not forgotten the traditional business values that have served the business well explains Cassaniti.

“Versatility is the ‘name of the game’,” said Cassanti. “With a telehandler, you can have up to seven machines in the one unit, and of course, you will save in capital expenditure as well as running costs,” Cassaniti said.

These models feature engines with power ratings ranging from 75 to 170 horsepower, which, in accordance with the original Merlo design concept, are installed in a longitudinal direction on the right side of the frame to ensure maximum accessibility to the components during maintenance operations.

“This customer focus has enabled the business to grow to what you see today, a multi brand dealership with a strong focus on customer support located in a purpose-built eight acre facility at Smeaton Grange,” he said.

“Anyone can sell equipment to the right buyer. The key to building a business involves providing the right levels of support to that customer and growing with their business.”

“We don’t see our customers as a number, we see them as partners in the business. We have facilities in Sydney, Wollongong, Canberra and Bathurst. This means we are capable of providing a wide services across a diverse range of industries,” he said.

IN FOCUS / STM EQUIPMENT 46 / CAL November 2022 www.cranesandlifting.com.au

“With a telehandler, you can have up to seven machines in the one unit, and of course, you will save in capital expenditure as well as running costs.”

The basket is a great addition to the machine allowing it to be used as an EWP.

STM FOR ACCESS

For almost half a century, STM has made it possible for businesses across NSW to power up – supplying and servicing quality trucks and machinery to meet the demands of any job.

Starting out in a single shed in the 1970s, we know what it takes to build a business – and are passionate about helping you grow yours. Today, our family owned and operated enterprise is proud to offer a multi-site, modern service, with a team of more than 120. We care about giving every customer the best experience possible – with a wide range of trusted brands, flexible finance, spare parts, repairs and personal service.

We may have come a long way from that shed, but our family commitment to quality remains. Whatever your size, whatever your budget, STM is your one stop shop – with everything to keep your business moving.

SYDNEY / WOLLONGONG / CANBERRA WWW.STM.COM.AU 02 4728 7500

EQUIPMENT EQUIPMENT

FIRST JCB ROTATING TELESCOPIC HANDLER ARRIVES IN AUSTRALIA

JCB CEA IS THE NATIONAL DISTRIBUTOR of the JCB brand in Australia and is a part of the overarching CFC group. With branches in Brisbane, Sydney, Melbourne, Adelaide and Perth along with 56 dealers around the country, they have a strong offering in Australia.

JCB in the UK was one of the pioneers of the telescopic handlers when it developed its first in 1977 and still lead by way of innovation today with these products. It has just released its new range of telescopic handlers meeting the new AS10896 standard creating a safer platform for its customers.

Wes Henshall is the general manager for Queensland and the Northern Territory and explains why these telehandlers are so important on Australian sites.

“What we have always found with telehandlers is they are always first on

site and last off it, they have multiple tools giving them incredible versatility,” he said.

“JCB continues to be number one in this space due to the JCB engines impressive fuel efficiency, in house transmissions with 6 speeds and a lock up torque converter and ride control, in house cylinder rams and more,” Henshall said.

JCB’s 5.5-26 rotating telescopic is an exciting addition to the Australian market, it has a 5.5t lift at 600mm load centres with a maximum height of 26 metres, Henshall explains more.

“The new machine just landed in Queensland and has lasted just 4 weeks on the floor with it going straight out the door to a precast concrete facility.

“It runs a lot of the same componentry as previous models, the difference for us and the important thing to note when a new machine is

released, is that JCB actually makes the whole telehandler. We make the boom, the ram cylinders, the engines, the transmission and the axles.

“We have a complete understanding of all of the components and users can be confident in their use of the range, particularly if they have other JCB products,” Henshall said.

The roto is the first rotator telehandler JCB has released, having the ability to turn 360 degrees means it has been redesigned and now allows it to reach 26 metres in the air which is eight metres more than previous models.

“We use the same switches, dials and even door handles across our range, this ensures the machines are simple to use, even though this is a fresh product in Australia the JCB DNA is woven all the way through it,” he said.

The engine in the new Roto’s is a

48 / CAL November 2022 www.cranesandlifting.com.au IN FOCUS / JCB CEA

JCB is one of the pre-eminent manufacturers of construction equipment globally, they have used this experience and understanding to bring the first iteration of the rotating telehandler the company has produced to Australia.

4.8 litre JCB ECOmax t4F producing 108 kilowatts and 560 Nm of torque. The four in line diesel is connected to a Bosch Rexroth two-speed hydrostatic providing drive to all four wheels ensuring the telehandler is able to find its way through any site with confidence.

“By having these universal engines, it means if they have an issue, we have full control of the machine and a deep understanding of how it works. The same engine is used in our backhoes and our telehandlers, so it has been well tested and is well understood by technicians and users,” he said.

The low boom design offers maximum visibility which can be further enhanced with optional camera kits providing protection for

those working both in and around the machine.

Operators can have the confidence to handle any load thanks to the full load management system with configurable envelope limits for working in confined spaces.

JCB’s automated technology gives one-touch auto deploy, stow and level of the outriggers, whilst still allowing for full hydraulic function. Speed profiles allow the operator to set the speed of each hydraulic service for ultimate controllability, allowing the operator to focus fully on the lift.

JCB is making this machine even more versatile than previous models, really shaking up the telehandlers in Australia.

“With this machine, we have brought it to the country with the first JCB certified man basket, this means now the machine can be used as an EWP, they can put a crane jib on it, pallet forks and a bucket, it is impressively versatile,” Henshall said.

JCB has designed and developed in-house a full range of aerial work platform baskets for use with its 14-20m telehandlers. There are three

November 2022 CAL / 49www.cranesandlifting.com.au

“What we have always found with telehandlers is they are always first on site and last off it, they have multiple tools giving them incredible versatility.”

Whilst the new JCB has been completely re-designed, it has many of the familiar hallmarks of other JCB’s.

The transmission in the JCB gives it a strong off road capability to tackle any challenge on site

The new models have an extra eight metres of reach.

“The telehandlers are sensational at accessing tight areas, as Australian sites shrink in size they will become more and more important as many pick and carry cranes will be too big.”

platform options, depending on the model, with capacities of 365kg, 500kg and 1,000kg. The smallest basket is a 2.4m fixed design, while the two larger models offer extending decks from 2.2m to 4.4m and a 180° slewing function.

Henshall explains how Australian construction sites fail to maximise the use of its telehandlers and how Europe shows the direction many sites will head in the near future.

“In Australia we are so behind Europe in the use of telehandlers simply due to the space we have on site in comparison. In Europe they are the first on site, they will unload the truck

when they arrive, lifting pallets and equipment to height, then when the job is finished, they put a bucket on it and they can clean up the site,” Henshall explained.

“The telehandlers are sensational at accessing tight areas, as Australian sites shrink in size they will become more and more important as many pick and carry cranes will be too big,” he said.

Henshall says that the uniform nature of the JCB components coupled with an extensive network lower the instances of long downtimes for repairs.

“With JCB CEA we offer Sales, Service, Parts and Used Equipment

from all locations and a NDC based out of our Sydney facility. We are a familyowned business with family values which makes us easier to deal with day to day and allows us to be more flexible,” he said,

“Rurally we have dealer support, so no matter where you are you can keep your machines going, whether that be the mines in Western Australia to a site in the heart of Sydney.

“We also find through the range of JCB products is the commonality of parts and service and accessories making the whole of life cheaper for the end user,” Henshall said.

The rotating telehandler comes with 500 hour service intervals, and impressive fuel economy to lower costs when it comes to running the machine.

Many in the industry will watch the arrival of the new Roto telehandler closely to establish whether it can stand up to the rigours of Australian sites.

50 / CAL November 2022 www.cranesandlifting.com.au IN FOCUS / JCB CEA

From the world’s leading manufacturer of telescopic handlers with 40 years of experience, the new JCB Roto combines the reach and lifting capability of a crane with the manoeuvrability of a telehandler and the access capability of a mobile elevated work platform. With a 20.5m maximum lift height and 5500kg lift capacity the Roto boasts the industry’s best-in-class load chart, and the 160 l/min variable displacement pump gives smooth multi-functional control. The automatic levelling ensures the stabilisation of the Roto is quick and safe, while the 2-Speed Hydrostatic drive enables smooth control of the Roto at all times. For more information on the new JCB Roto Telescopic Handler please contact your local dealer www.jcbcea.com.au or call 1300 522 232. ALL NEW! JCB ROTATING TELESCOPIC HANDLER PROVIDING ROUND THE CLOCK VERSATILITY

SKYREACH HAS A SOLUTION FOR ANY CHALLENGE

Skyreach was started in Geebung in Brisbane in 1994 by our current Managing Director Rod Leech. Since then, the business has gone on to become is a true pioneer of the Access Hire Industry. Today Skyreach specialises in height access equipment including Elevated Work Platforms (EWP’s), Telehandlers, mast climbers and forklifts.

JAMES NIGHTINGALE IS THE PRODUCT and training specialist for Skyreach and he explains what has helped the company become the success it is today.

“When Skyreach was started, there were very few companies providing this type of equipment in Australia and the vast majority of machines in the market were second hand units sourced from the US,” Nightingale said.

“Skyreach started purchasing brand new machines that provided the highest level of safety, as well as ease of use and versatility for the operators,” he said.