8 Up Front Pilequip

Pilequip launch a range of rubber shock absorbers and customers are impressed.

14 CICA CEO report

Brandon Hitch discusses the conference.

16 Impor tance of having the right insurance cover

UAA go the extra mile for WA contractor.

22 Liebherr at bauma

Liebherr launches new all terrain at bauma.

26 Grove at bauma

Grove launches new GMK4070L at bauma.

30 Comansa at bauma

Comansa launches new hydraulic luffing jib crane.

32 Tadano at bauma

Tadano launches AC 4.070-2 70t capacity all terrain.

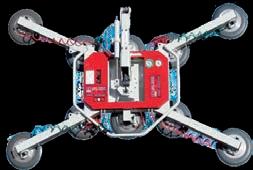

37 Bet ween Hook and Load

Our regular feature focusing on the importance of the lifting equipment sector.

38 LEEA

Justin Boehm looks back at 2022 and discusses what we’ll see from LEEA in 2023.

41 Andromeda

Andromeda continues to develop products for a broad range of applications.

44 Crosby Group

Crosby Group takes home LEEA award.

46 Bremco

Australian designed, engineered and manufactured lifting equipment, from start to finish with Bremco.

50 Pacific Hoists

Taking a look at the new M-series from Pacific Hoists.

56 RUD

RUDs offering for the lifting sector.

59 Lif ting Victoria

New name but same great service.

62 Patterson Cranes

The Jekko mini crawlers an asset.

66 Tutt Bryant Heavy Lift and Shift

Impressive bridge replacement from the team at TBHL&S.

70 Surf City

Surf City Cranes invests in new Liebherr all terrains.

75 Cranes 4 Hire

Turning to Pace Cranes and Maeda proves to be a game changer.

78 Terex flat top

New city class tower crane released by Terex.

80 Tadano straight boom

Advantages of Tadano vehicle loading cranes over knuckle booms.

83 Walz Group

Two new TIDD pick and carry cranes delivered to Walz.

86 Fred Blake Cranes

Fred Blake Cranes invest in brand new Grove GMK 3060L-1.

90 Centur y Cranes

Century Cranes continue to grow the fleet with Liebherrs.

94 Lif t of the Month

What our industry does best.

34

Sennebogen at bauma

Sennebogen launches all electric 50t capacity telescopic crawler.

36 Liebherr at bauma

Liebherr launches new duty cycle crawler.

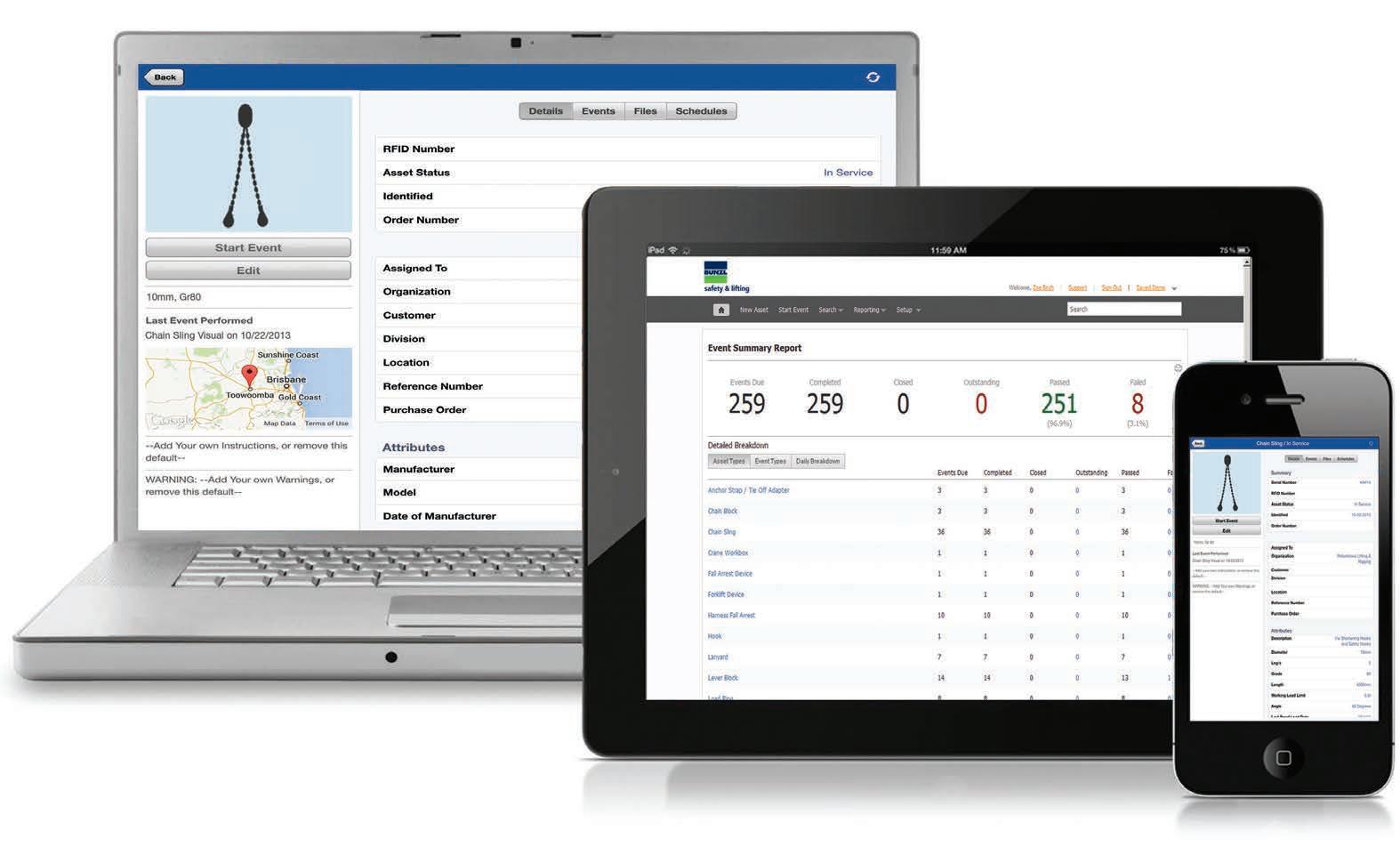

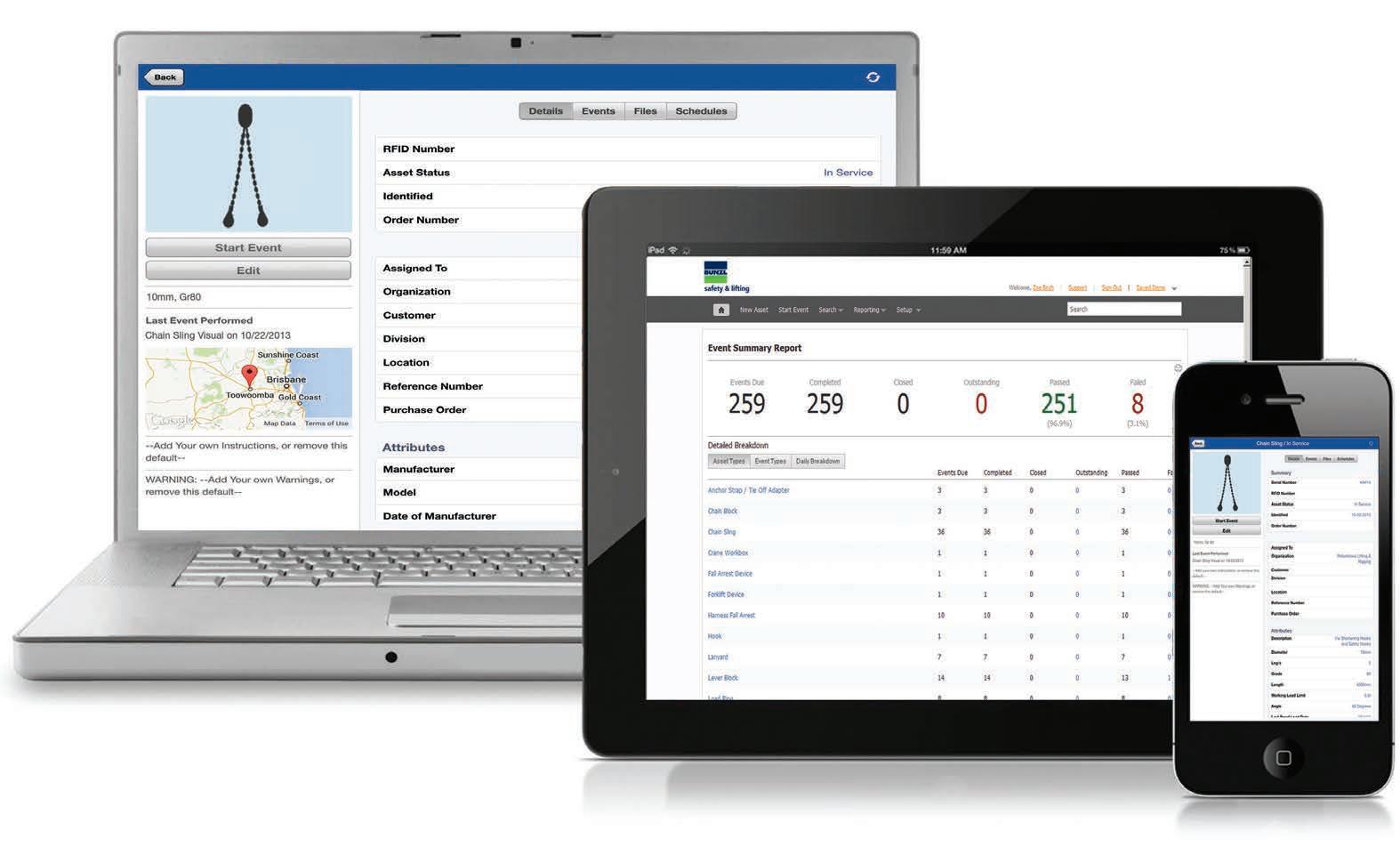

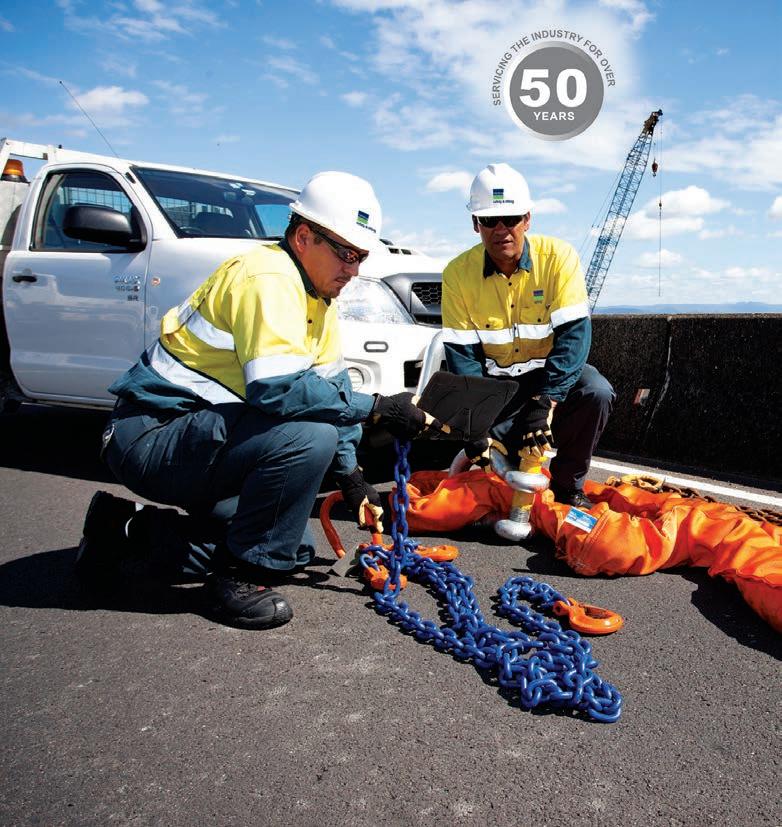

52

Bunzl

Bunzl reaffirms its commitment to the heavy lifting sector.

54 LEEA awards

LEEA Australia and New Zealand take home award.

FROM

Published by:

IN THIS ISSUE THE TEAM AT CRANES and Lifting is delighted to bring you insights from bauma, the world’s largest trade fair for the construction and crane sectors. In terms of exhibition space, bauma is the leading trade fair for construction machinery, building material machines, mining machines, construction vehicles, construction equipment and every type of crane.

More than 3,100 exhibitors from around 60 countries presented their innovations and products on 614,000 square meters of exhibition space - the equivalent of 86 football pitches.

We highlight numerous products released by the crane manufacturers and you can expect to see these new models being offered over the coming months.

The team at Cranes and Lifting thanks

products Liebherr manufactures.

This issue also includes a look at the importance of rigging equipment with our regular Between Hook and Load feature which also includes a review of the recent LiftEx event organised by the Lifting Equipment Engineers Association.

A selection of crane hire companies discuss the reasons for purchasing the cranes they do and the projects they have been completing with them. Tutt Bryant Heavy Lift & Shift emphasises the importance of planning complex lifts where there is no room for error.

As always, the team at Cranes and Lifting has worked hard to bring this content to you, we hope you enjoy the read.

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766 www.primecreativemedia.com.au

CEO John Murphy E: john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy

E: christine.clancy@primecreative.com.au

Group Managing Editor (Northern)

Andrew Hobbs andrew.hobbs@primecreative.com.au

Editor Simon Gould E: simon.gould@primecreative.com.au

Journalist Joshua Farrell E: Joshua.farrell@primecreative.com.au T: 0420 298 087

Business Development Manager Emily Schlegel E: emily.schlegel@primecreative.com.au T: 0466 317 555

Client Success Manager Glenn Delaney E: glenn.delaney@primecreative.com.au

Art Director Bea Barthelson

Advertisement Designer Lee Mawdsley

Imaging Assistant Paul Breen

Subscriptions

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be re produced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

www.cranesandlifting.com.au

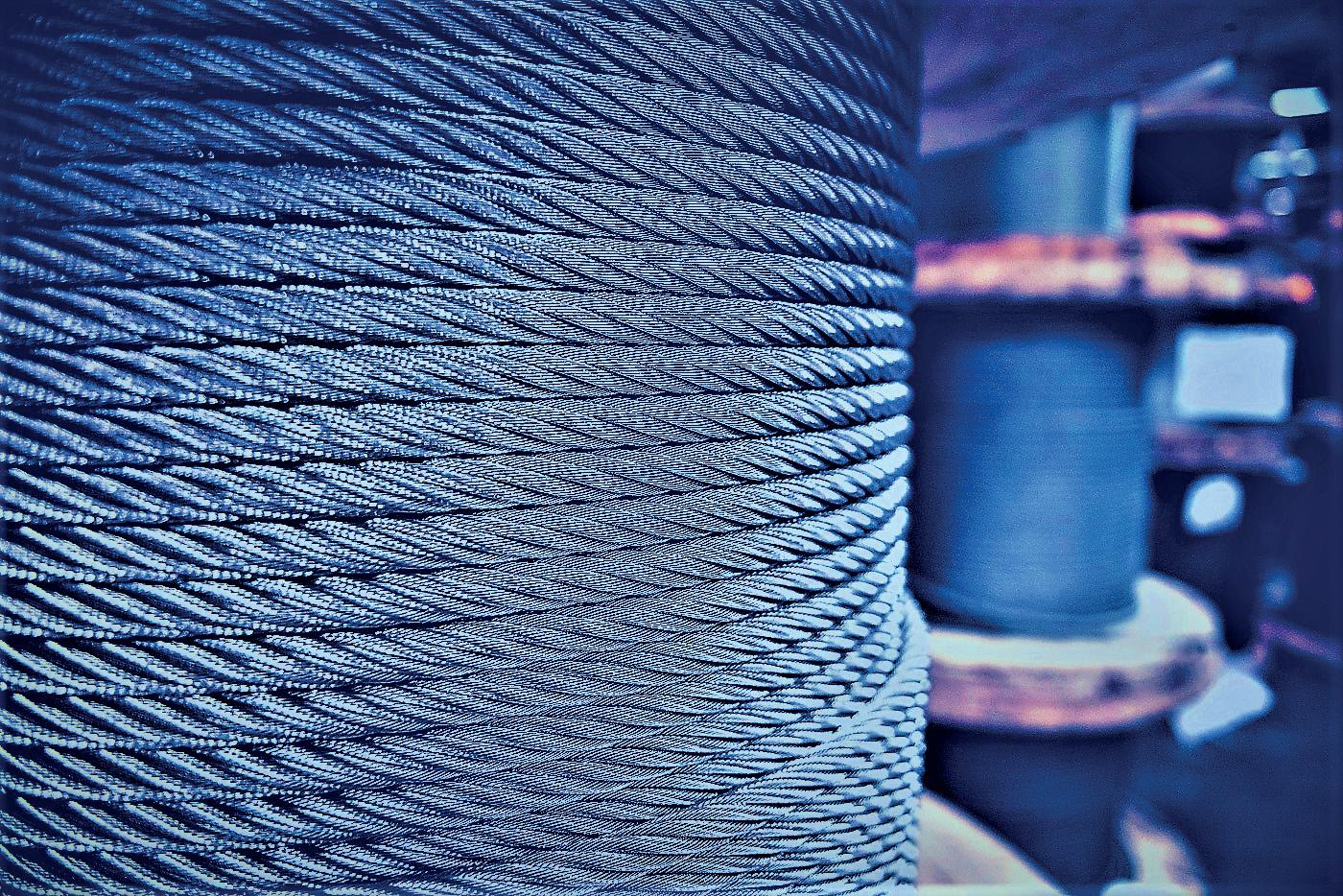

Pilequip’s range of Tünker rubber shock absorbers are taking the shock out of piling for leading civil construction and piling organisations.

MITCHELL MARINE CONSTRUCTIONS specialises in waterfront and marine construction. Matthew and his brother Chris Mitchell have over 30 years of combined experience in the sector. They started Mitchell Marine Constructions three years ago. Matthew and Chris explain more about the business and how closely it works with piling equipment specialist, Pilequip.

“Mitchell Marine Constructions specializes in marine construction. We find ourselves involved in a variety of projects including the construction of wharfs, bridges and boat ramps. More recently and following the floods in Brisbane, we now find ourselves working in the residential side of the construction sector and this work includes the demolition of existing pontoons and piles and fabricating and installing brand new ones.

“We manage a lot of work commercially as well, and this is for Brisbane City Council, MSQ, Port of Brisbane, and in early October we sent a crew to Sydney to work on the new Fish Markets development. We work up and down the East Coast of Australia, but primarily we’re based in Brisbane,” said Matt.

Chris discusses the capabilities of the Mitchell Marine Constructions fleet.

“We own a crane barge which is called ‘The Flea’. It’s a small but really versatile barge on the water, and it can be pushed with a tin boat. We own two work punts and what you call a pusher boat which is like a small tug.

“We’ve also just hired a piling barge, which is 45m by 14m and this has 120t Kobelco crane on it. Our driver for this piece of kit has been in the marine construction industry for 30 plus years. We’ve got riggers, dogmen, bridge and also wharf carpenters. We have a crew that varies from six to 10 guys and we ramp up when we need more resources especially when we win some of the bigger jobs,” said Chris.

“It’s a pretty versatile crew in terms of the marine construction industry and it is hard to get guys with experience on the water, but all our guys are well equipped and confident about working in and around the water and on barges and with cranes and all that,” he said.

Matthew goes on to discuss the piling

equipment supplied by Pilequip and the relationship he has with National Sales Manager David Hopkins.

“Piling is a big part of what we do, and the use of vibratory hammers and hydraulic hammers are essential in our trade. We use Pilequip for all this equipment. We currently have got a 1223 ICE vibratory hammer on hire, which is a smaller vibrator, but ideal for the residential market. It’s compact, not too big and not too small, and it’s a really good hammer for the smaller steel piles.

“We have a job coming up and we’re going to hire a 6t or 7t Dawson hydraulic hammer. We generally always use Pilequip for our pilling equipment requirements. They provide a great service and we have good relationship with David Hopkins, the National Sales Manager. We currently have a brand new vibratory hammer on hire which is ideal,” said Matthew.

Mitchell Marine Constructions was recently involved on a project which involved a vibratory hammer being attached to a hydraulic all terrain. Normally an application most crane hire companies will say no to because of the damage the vibrations can do to the crane. Chris explains how they were able to circumvent this problem.

“The Tünkers range of rubber shock absorbers was new to us, and we used it recently on a project in Grafton, where we were installing some piles with the vibratory hammer. Because we were using a hydraulic all terrain, if we hadn’t had the Tünkers rubber shock absorber we couldn’t have done the job to be honest.

During the testing, the Tünkers rubber shock absorbers reduced the vibration by up to 93 per cent.

“The majority of crane hire companies we’ve dealt with, will not let a vibratory hammer operate on a hydraulic all terrain because of the damage the vibration can cause to the main boom and the structure of the crane.

“But we introduced the Tünkers rubber shock absorbers, which David had sent up to Grafton, to Wicks and Parker the crane hire

company we used. We installed four piles, two steel piles and two fiberglass piles, and the Tünkers range of rubber shock absorber took the shock out the vibration and worked a treat,” said Chris.

“It’s the first time we’ve ever used Tünkers rubber shock absorber and it’s the first time we’ve ever had a vibratory hammer on a hydraulic all terrain, and the

end result was great. There was minimal vibration and Wicks and Parker were happy and said they’ll be happy to hire a crane for a vibratory hammer application any time as long as there’s a Tünkers rubber shock absorber fixed to the crane.

“In terms of our projects, a hydraulic all terrain is ideal compared to mobilizing and setting up a lattice boom crane, which takes days and costs a lot of money, you can just get a hydraulic all terrain on site much quicker and more cost effectively,” he said.

Pilequip’s David Hopkins explains more about the impact vibration has on a crane and how the Tünkers rubber shock absorber helps to negate the problem.

“Piling is a big part of what we do, and the use of vibratory hammers and hydraulic hammers are essentially in our trade. We use Pilequip for all this equipment.”

“There are, typically, two types of vibratory hammers. There’s a Static-Moment Vibratory Hammer and a Variable Moment Hammer. The biggest issue with the StaticMoment hammers is when you turn them on, they spin through the low frequency until they get to their peak frequency. When it’s moving through the low frequency, it starts to shake. It’s a bit like an off-balanced frontload washing machine. When it’s a little bit off balance and starts to spin slow, it starts to jump around, but once it gets up quite fast, it quietens down.

“When it starts and stops, we get those really big shock load vibrations going up into the crane. It’s not good for the computers. It’s not good for any componentry on the crane itself and some of the crane OEMs state in their literature that they need to have shock absorber when using vibratory equipment,” he said.

“It’s not just the start and stopping of the equipment. There are heavy vibrations even at the peak frequency, particularly if you’re pulling up on the vibratory hammer, you’re still getting quite a lot of vibration going up through the crane line and into the crane. We found the Tünkers shock absorbers eliminate up to 75 per cent of that shock load vibration and up to 93 per cent of peak frequency vibration.”

Pilequip tested the shock absorbers in its yard, on its crane a 75t capacity crawler. They engaged VMS Australia, a specialist vibration monitoring company, to measure the vibration. VMS put up four different measuring points on the crane. Above the hook, at the top of the jib, midway on the boom, and in the cab.

“We tested the shock absorbers on a Static Movement Hammer, an ICE 32NF and we also tested a Variable Moment Hammer, a PVE 28VM. A Variable Moment Hammer doesn’t have that start and stop shock as I mentioned earlier. So essentially it doesn’t start vibrating until the frequency is high. But as soon as you start pulling on that vibrator, you get that same peak frequency vibration going up through the crane. That doesn’t change whether it’s variable moment or a normal frequency hammer.

“As I have said the Tünkers rubber shock absorbers reduced the vibration by up to 93 per cent. Obviously, there are huge

Anyone that owns a crane and is planning to put a vibratory hammer on it, utilising the Tünkers rubber shock absorbers seems to be a fairly straight forward business decision

benefits for crane companies considering this product. I’ve spoken to customers operating cranes and computer systems can’t handle the vibrations. It keeps resetting or it keeps getting errors.

“Obviously, the absorbers will help prevent wear and tear on the crane. I’ve spoken to customers who have got a crane down because they started a big StaticMoment Hammer, the ropes were jumping around all over the place and this caused damage to a point where they couldn’t operate it anymore, they had to fix it,” said David.

Anyone that owns a crane and is planning to put a vibratory hammer on it, utilising the

Tünkers rubber shock absorbers seems to be a fairly straight forward business decision to make says David.

“They’re relatively inexpensive to either rent or buy, when compared to the cost of a crane or fixing the damage vibration has caused your crane. It’s the unknown damage that needs to be considered. I don’t know if there’s any studies on the impact of long-term use of a vibratory hammer on your crane, but you can only assume that it would be significantly less when we’re talking about the vibration reduction that these shock absorbers can achieve,” he said.

Matthew was impressed with the Tünkers rubber shock absorber performance.

“The performance of the shock absorber was pretty amazing, and I’d say it definitely reduced the level of vibrations by around 70 to 80 per cent. It’s changed things from our point of view, we can now quote a lot more jobs knowing we can use one of these absorbers with a piece of vibratory equipment on a hydraulic all terrain. We’ve now got the proof because

we’ve completed a project with it and Wicks and Parker were happy, so it’s a massive win,” said Matt.

Another fan of the Tünkers range of rubber shock absorbers Paul Wood from Fitzgerald Constructions. Paul is Plant Supervisor and has been with the organisation for 25 years.

For more than 30 years, Fitzgerald

Constructions Australia have been providing civil engineering and concrete construction services to numerous industry sectors including bridge construction, building construction, civil construction and infrastructure, marine construction transport and remedial concrete.

Paul explains a bit more about his role within the organisation.

“I’m a plant superintendent and look after all the cranes, piling barges and equipment we run. We operate 40 plus marine vessels, 30 plus crawler cranes, and driving piles anywhere from 457 cm diameter to two and half metre diameters. Our crane fleet includes 20t capacity Frannas through to 600t capacity crawlers. The crawlers are mainly Kobelco and Manitowoc.

“Fitzgerald Constructions operates in a range of industries including the marine, concrete and civil sectors and we building anything from bridges to tunnels and wharfs. Currently, we are building the biggest multi-compartmental silo in the world, Lorimer Street in Port Melbourne. It’s 78 metres high and being constructed of slipform concrete,” said Paul.

Fitzgerald Constructions has a close relationship with Pilequip which dates back many years.

“Pilequip has always been fantastic with service and pricing. We have hired a lot of gear from Pilequip over the years and they will hire gear from me occasionally. We have also purchased a number units from them and their backup and support is second to none. Their mechanics are factory trained, they are highly skilled and knowledgeable. I rate the team at Pilequip very highly,” said Paul.

David Hopkins introduced Paul to the Tünkers range of rubber shock absorbers.

“Dave called about the Tünkers rubber shock absorbers and gave me a week’s free trial, and I really liked them. I think they’re a great innovation, they are simple to use and really effective. I am in the process of matching the right size of shock absorber with our equipment. The shock reduction built into the Tünkers rubber shock absorbers is fantastic. I’m extremely impressed and so were our crane operators,” said Paul.

“As I have said the Tünkers rubber shock absorbers reduced the vibration by up to 93 per cent. Obviously, there are huge benefits for crane companies considering this product.”

For over 30 years Pace Cranes have offered premium quality equipment to the Australasian market with a dedicated and unrivalled service, supported by specialist technical advise across the full range of equipment sold.

Mini Crawler Cranes

Crawler Cranes

Electric Cranes

Mobile Cranes

Telescopic Crawler Cranes

Mini Crawler Cranes

Crawler Cranes

Electric Cranes

Mobile Cranes

Telescopic Crawler Cranes

Modulift, the market-leading manufacturer of modular spreader beams, was recently involved in an exceptionally heavy load test in Dubai.

Two MOD 1000 spreader beams were used in a crucifix configuration to perform the test, with each beam lifting a load of 990 tonnes, and the remaining load being supported directly by the crane hook.

The project was a collaboration between several specialist equipment suppliers across the world, with 600T & 500T P-6043 Green Pin shackles provided by Royal Van Beest; wireless load links, load pin shackles and T24 electronics from Load Monitoring Systems; and 110MT & 50MT Waterbags, Cable Laid Grommets & Round Slings manufactured by Liftek International.

spreader beams

Sarah Spivey, Managing Director at Modulift, said: “It’s encouraging to see our beams being used as part of such a demanding project, a real testament to the quality of our products. The MOD 1000 is ideal for this type of lift due to its relatively low self-weight.

can work at maximum capacity.”

All products within the Modulift Spreader Beam range are compliant with ASME, BS and DNV standards. Capacities range from 6 - 3000t and can be re-used without the need to re-test or re-certify even when dismantled and re-configured, wherever the lift is, anywhere in the world.

Our

are specially designed to provide a lightweight solution so that cranesTwo MOD 1000 spreader beams were used to perform the load test The Modulift spreader beams were used in a crucifix configuration

“It’s encouraging to see our beams being used as part of such a demanding project, a real testament to the quality of our products.”

WITH THE THEME OF ‘LEADING THE WAY ’ CICA National Conference 2022 looked ahead to the future of our industry, explored new technology, and innovations in crane operations.

We shared a fabulous three days in Adelaide, and it was great to be back together again for a face-to-face conference, being able to reconnect with old friends, and network with new ones.

Attendees were treated to informative speakers, workshops and delightful opportunities to network and enjoy the food and wine for which South Australia is renowned. This year

the Year’ entries, and I congratulate all who entered, your entries were complex and showcased the tremendous and intricate lifts being done all over this great land. The ‘Lift of the Year’ Awards are Australia’s premier crane lifting excellence awards, recognising and rewarding outstanding planning, teamwork and execution. I encourage you to keep the 2023 awards in the forefront of your minds, when planning lifts over the next nine months, and I would also like to thank Cranes and Lifting for their sponsorship of these awards.

Brandon Hitch(UAA) were this year’s platinum sponsor, and it’s fair to say that an event of this calibre wouldn’t happen without the valuable support of UAA, and the support of all the sponsors. Thank you to our fabulous speakers, delegates, sponsors and exhibitors for supporting the 2022 CICA Conference and our industry. We look forward to re-connecting with you in Perth in 2023.

Once again Sue and her team from WISE Connections worked hard to organise, plan and deliver a wonderful conference experience, and a special shout out and thanks to Cheryl Woodhart, Jeff Wilson, Karli Sutherland, Peter Koschel and Susan Stagg for giving of your time to put together the conference program.

The CICA AGM saw the election of a new CICA President and with that, I would like to thank Tom Smith, the outgoing CICA President for his invaluable contribution. During Tom’s tenure as president, CICA has seen incredible growth and strategic and operating improvements. CICA has really benefitted from Tom’s leadership and vision. They say that you can tell a lot about a person by the way he handles lost luggage, and tangled Christmas tree lights, but the tests of the last three years, make those minor annoyances, pale in comparison. The difficult COVID days, marked by lockdowns and evolving restrictions are thankfully behind us, but very fresh in our memories. Throughout the most trying days, Tom’s character and exemplary leadership shone through. He unwaveringly put the needs of others and the needs of CICA ahead of his own, and I really appreciate his commitment, guidance, selfless leadership and friendship.

I hope you enjoy this issue of the magazine and wish you and your loved ones a happy and safe Christmas. We look forward to working with you in 2023 for a safe and progressive crane industry.

Hitch

CONTACT

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170

Phone: 03 9501 0078 Fax: 03 9501 0083 Email: admin@cica.com.au Website: www.cica.com.au

Brandon Hitch

Chief Executive Officer

03 8320 0444 04 2822 8048 ceo@cica.com.au

Paul Arztenhofer

Membership Engagement/ Business Development Specialist 04 9093 9274 paul@cica.com.au

Alice Edwards Technical Project Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran

CraneSafe and CrewSafe Technical Advisor 048 800 4274 pat@cranesafe.com.au

Damien Hense

CICA Road Policy Advisor

03 8320 0460 04 8800 7575 damien@cica.com.au

Jed Kenwright Road Technical Engineer 04 3955 6867 jed@cica.com.au

Julie Turner

CICA Executive Assistant / Office Manager/Vic Secretariat Direct: 03 8320 0411 Email: julie@cica.com.au

Shane Coupe CraneSafe & CrewSafe Administration Officer Phone: 03 8320 0455 Email: shane@cica.com.au

Michelle Verkerk

Marketing Communications Officer 040 493 8714 michelle@cica.com.au

For information, please visit our website or call the CICA office.

When JD Rigging had an incident with its new Liebherr LTM 1230 5.1, managing director Jack Walsh turned to UAA for help. The response from UAA and that of other parties was immediate and designed to get the crane back and operating as soon as possible.

There were two stages to the process including the recovery of the crane and the assistance required from Liebherr when the crane was back on its wheels.

JD RIGGING HAS BEEN OPERATING IN PERTH for close to 25 years. Specialising in heavy lift crane hire in tilt up and precast concrete construction. JD Rigging has grown in line with the exponential growth of its mining clients during the resources boom.

JD Rigging provides a range of services including erecting concrete tilt panels, erecting steel structures, shutdowns, heavy lifting and specialised crane services, heavy equipment recovery, panel layouts, lift Studies and consultative project planning with clients.

Jack Walsh is the Managing Director of JD Rigging and he’s been in this line of work for over 35 years.

“We do a fair amount of panel lifting work in and around Perth and some heavy lifting for clients in various industry sector including resources. We cater for these markets with heavy lift cranes including two Grove GMK5220 220t capacity all terrains and the brand new Liebherr LTM 1230 5.1,” said Jack.

JD Rigging has been insured by UAA for the last eight years explains Jack. He also confirms how quickly George Grasso, UAA Group CCSO - Chief Claims and Services Officer, and the team at UAA responded to a recent incident.

“We’ve been with UAA for about eight years and before that we were with Wesfarmers. We’ve never had a big claim that we’ve had to go to UAA with, so I really didn’t know what they were like and what to expect. I thought we going to be just another number, until we had this incident with the brand new Liebherr tipping over. The incident was nobody’s fault, just one of those things; soft ground which nobody knew was there, it can happen to anyone,” said Jack.

“After going through four boxes of tissues, I heard from our contact at UAA who said George Grasso, UAA Group CCSO - Chief Claims and Services Officer was coming over to Perth. He had other business to attend but he said he would catch up and have a look at our problem. I spent a day with George, and to be perfectly honest, it was the best thing I have ever done. I have never felt so relieved and happy with a person to deal with in all of my life.

“There was no nonsense with George, he said, ‘Jack we’re right here to back you’ and when someone like George has your back, I tell you, I’d go the extra mile for him any day. I put the boxes of tissues away, and we got back to business,” said Jack.

Both Jack and George visited the Liebherr workshop where they met with Richard Gulpis and the team.

“Liebherr were really helpful and we’re now waiting on Germany to ship some parts required for the repairs. It’s not a big drama, but it’s just the inconvenience of not having the crane and not making any money with it. It’s also financially painful because we are still having to make the repayments on the crane. It’s a lesson for everyone to ensure you have the right levels of insurance including the loss of revenue cover.

“George is working with us to try and get the crane back on the road as quickly as possible, through Germany and UAA, which I really was surprised at because I didn’t think they would help us so much,” said Jack.

looking for support from us, for someone get to site, and what could we offer in support. So, I got in touch with young Brayden Lawrence, one of leading technical hands, and he headed to site to offer his assistance wherever it was required,” said Richard.

“The early stages of the recovery were quickly underway. Like we always say, we are not lifting specialists, we’re specialists in repairing cranes when they break down. At the end of the day, the lifting side of things is done by the customer, and we’re there to support and that’s essentially what Brayden did,” said Richard.

Brayden worked with the guys on site and saw no problems in the way they planned to manage the recovery. He also examined the machine and prepared a quick assessment of the damage he could see. So, in the background there two stages to the process. There was the recovery of the crane and the assistance required from Liebherr when the crane was back on its wheels.

Richard Gulbis is Liebherr’s Regional Service Coordinator for Liebherr Mobile Cranes in WA. He explains how Liebherr handled JD Riggings’ crane incident and how responsive a crane OEM needs to be when a customer is in trouble.

“It was first thing on a Saturday when I received a call from Stefan De Silva, Sales Manager, WA/SA Mobile Crane Division Australia & New Zealand. Stefan had received a call from Jack Walsh saying there’d been an incident and could I give Jack a call. I returned Jack’s call within half an hour and understandably, he was in a state of panic.

“Obviously, I’d seen no pictures or anything by this stage, and Jack was just

“Brayden was working directly with their crane operator and the supervisors, and they had recovered the crane by the Sunday. By this time, we’d identified a few damaged axle components, and there was no way the crane was going to be driven back in this condition, the damage was too severe. Luckily, the two main damaged components were an axle strut and a suspension cylinder and Brayden ordered those parts,” said Richard.

“All this was done with good will towards the customer, because you want to support the customer in these difficult situations. The last thing the customer needs is you asking for a purchase order. We contacted Matt Clark in spare parts who confirmed everything was available. To make the situation a little easier for the technician on site and to demonstrate

our

“There was no nonsense with George, he said, ‘Jack we’re right here to back you’ and when someone like George has your back, I tell you, I’d go the extra mile for him any day. I put the boxes of tissues away, and we got back to business.”

spare parts support to Jack and his team, Matt decided to quickly jump into a ute and deliver the parts directly to Brayden. This allowed the repairs to be conducted in a much more efficient time frame,” said Richard.

“There were a number of calculated risks in driving the crane back. I had a question regarding the condition of the engine. We needed to know how long crane had been on its side with the engine running? Oil starvation always needs to be considered, but we checked the oil, and we had a listen to the engine, and everything sounded okay. We replaced the spare parts that needed replacing, and we managed to get the crane back. It arrived in the Liebherr yard on the Sunday evening,” said Richard.

With the crane being brand new it was still covered by the warranty, says Richard.

“I don’t think there’s any doubt insurance companies would prefer to repair a crane which is brand new. If it were five or a 10-year-old crane, maybe the repairs go out to tender, but because it was such a new crane, UAA Groups’ CCSO - Chief Claims and Services Officer George Grasso said, ‘It’s going to come to you guys. It’s as simple as that. We want the repairs to be right, and we want the warranty to still be valid for the remainder of the crane’s warranty period,’” said Richard.

MCT Equipment is UAA’s preferred repairer thanks to its hugely experienced team, its industry-leading expertise across a diverse range of mobile lifting equipment, and its commitment to innovation and efficiency.

MCT will soon host a 5000m2 facility in Henderson, with almost a third of the facility dedicated to workshop space. The workshop houses one of WA’s largest teams of specialist mobile lifting equipment technicians and has the capacity for the team to complete up to eight major works at any one time. These works regularly include UAA insurance claims and range from large structural repairs to minor repairs. The new facility boasts the ability to accommodate overhead cranes, which allows MCT to minimise turnaround times

and costs, without compromising quality or safety.

MCT’s customer satisfaction can be accredited to the team’s efficient workmanship and the savings that are passed on. As a privately owned company, the team is able to make fast in-house repair decisions to hasten the insurance claim process.

The relationship between UAA and the MCT team goes back more than 10 years, with MCT valuing the partnership we have formed during this time. The long-term relationship is reflected in the strong, solid workflows across the entirety of their business, and is particularly noticeable in the workshop’s refurbishment section. MCT looks forward to continuing the successful partnership with UAA long into the future.

UAA AND MECON INSURANCE WA Martyn Shirley is UAA’s Regional Manager, Central and West and he has been with the organization for 15 years.

“The crane sector is a large part of our portfolio, but we also insure earthmoving equipment, concrete pumps, drilling contractors, road making equipment, aerial access equipment in fact most types of mobile plant.

of mine work. This work including shutdowns, servicing of equipment and the number one priority for a crane hire company is the safe operation of the crane and this is generally the result good lift studies and planning before the work has started. Planning has to be a major responsibility when operating in a highrisk environment,” he said.

Martyn discusses the Western Australian team and how claims are managed. He also confirms how the merger with Mecon Insurance will impact the WA market.

“We have a team of eight here in the WA operation and we are all underwriters and business development managers. Claims are handled by our specialist WA claims team based in Newcastle, the birthplace of UAA. The merger between UAA and Mecon is exciting. We complement each other because Mecon is in construction insurance and insure the actual construction side of the industry, and we insure the plant, so they go hand in hand, and we dovetail nicely into each other’s activities.

“MCT’s customer satisfaction can be accredited to the team’s efficient workmanship and the savings that are passed on. As a privately owned company, the team is able to make fast in-house repair decisions to hasten the insurance claim process.”

“The crane sector has been a fundamental pillar for UAA over the years and we insure most of the large crane hire companies here in Western Australia. But servicing an industry like the crane sector has its challenges and maintaining a profitable book due to high volatility and claims costs for cranes, is a major one. When cranes go wrong or when they are involved in incidents, they are very expensive pieces of equipment to fix,” said Martyn.

“The crane sector in WA is resources driven and cranes are involved in a lot

“We are fitting out new office accommodation which will enable to the two teams to come together under then one roof which is exciting for everyone. This will enable to teams to work even more closely together which will ultimately see our customers benefit from a more comprehensive and responsive service when it comes to insurance,” said Martyn.

In July of this year, Underwriting Agencies of Australia and MECON Insurance announced they had agreed to merge the businesses. Daniel Joiner is MECON Insurance’s State Manager for Western Australia and has been in the role since 2015.

Daniel originally started at MECON Insurance in 2013 as an underwriter in

the Melbourne office as a construction underwriter before transferring over to Perth to manage MECONs newest branch. Daniel explains how the business has grown in WA and how the merger is going to benefit customers.

“We’ve seen significant growth over the last few years due to an increase in the number of construction projects throughout WA and continued with the Government investment into the industry during the ‘COVID pandemic period’. Because MECON is based in the state, we can remain engaged with the changes throughout the construction market in Western Australia. Although our connection with builders remains entirely through insurance brokers, we work with our broker partners to provide flexible insurance solutions for builders throughout the construction sector whose projects range from owner builders, small to medium businesses taking on speculative projects, to larger commercial, residential and civil builders requiring annual policies.

“Over the years that MECON has been in Perth, we have seen Perth and Western Australia grow immensely, and I take much enjoyment that we have been involved in the expansion in some small way,” said Daniel. “Being a construction underwriting agency in Perth has allowed us to be involved with many major and exciting projects within WA, such as certain portions of Perth Stadium, Elizabeth Quay and more recently Busselton Jetty redevelopment”

With the merger with UAA, MECON has moved its mobile plant portfolio across to the UAA team to manage.

“UAA is the best in the market for mobile equipment, and I know that our existing portfolio is in great hands being managed by Martyn and the UAA team. This will allow our team at MECON to focus on our core strength, which is construction insurance. From that point of view, the merger has been great, and it’s gone hand in hand with what we’re looking to achieve as a business,” said Daniel.

The WA team at MECON is experienced and customer-focused.

“We have a team of seven based in Perth, managing business from WA as well as business from South Australia and the Northern Territory. We have built a formidable team with what I consider to be the best construction underwriters in the state, our underwriters actively engage with our brokers and are passionate about finding the best solutions for our mutual clients” said Daniel.

The teams at MECON and UAA are planning to physically join forces and will be moving into the same office.

“Our new offices are currently in the process of being fitted out. Due to both MECON’s and UAA’s Perth-based team’s rapid expansion, joining offices was the most logical solution, however, we will still operate as two brands, one family”.

“Martyn (UAA WA State Manager) and I have a solid relationship. We share a good level of banter and have been mates for some time before the merger. One of the most surprising things which came from the merger was how well our teams get along and how similar our company cultures are. We are looking forward to exploring the obvious synergies that the merger brings, and offering a more comprehensive service to our customer base,” said Daniel.

Knightcorp is seen as a market leading Insurance broking firm. The team at Knightcorp approaches business with customer centric values and passion. A key business objective is to create a company where professionals can thrive and be their authentic selves. This has resulted in a culture where clients feel completely secure and valued through strong relationships and stand-out personalised service. We have a national portfolio of customers across Australia with our head office being based in WA where the company was founded.

Knightcorp has been servicing the insurance and risk management needs of customers in the Civil, Mining and Construction industry for over 13 years, we are very familiar with Small and

Large Mobile Plant Fleets and are very experienced with providing strong solutions In this sector, we have a combined industry experience in excess of 60 years and are experts in this field.

The Knightcorp team has vast experience in dealing with clients within the Crane industry sector, whether you are an owner, operator or are in the crane hire business, they understand the sector and are able to help customers of all sizes and complexities says Bernie of Norwest Crane Hire.

“Our decision to partner with Knightcorp Insurance Brokers for all of our insurance needs has been a great decision for our company, they understand the Crane Industry very well and always deliver great solutions and professional service. The Crane sector and the contracts within it can change so quickly and it was important to us that we had an insurance partner that understood this and could come on our journey with us. The construction industry also comes with a lot of risk and potential insurance claims, Knightcorp have always been in our corner and they are a team we have been able to rely on.

When next considering your insurance broking partner we would recommend you get in contact with the team at Knightcorp.”

The Knightcorp team has an in-depth understanding of crane hire agreements and are able to assist with the insurances clauses found in industry contract reviews. From a claims handling perspective, they understand that if a client suffers damage to its fleet, there is a need to act quickly and

Throughout the process, UAA has been cooperative and keen to see everything resolved - getting that crane out of the yard and back to work as quickly as possible

effectively to begin the process. Our large network and high level of claims services is a significant part of the difference Knightcorp make to our customers.

Recovering, assessing and repairing a crane is an intricate and costly operation that involves all parties working closely together and Knightcorp’s expert claims team is the perfect conduit to ensure this process happens seamlessly between all parties involved.

Over the years, Knightcorp has found UAA to be a great supporter of insurance

for plant & crane fleets, with a product that consistently performs. Knightcorp continuously finds UAA policies have special benefits that can be negotiated. Their breadth of cover is amongst the best in the market.

UAA’s team are realistic, commercially minded, technically proficient and always approachable. Their claims service is consistent and knowledgeable, which reflects positively in reaching a favourable, fair and reasonable outcome for our UAA clients.

“UAA’s team are realistic, commercially-minded, technically proficient and always approachable. Their claims service is consistent and knowledgeable, which reflects positively in reaching a favourable, fair and reasonable outcome for our UAA clients.”

When the grounds of Messe München become the centre of the construction machinery industry for seven full days, bauma is finally taking place again.

A TOTAL OF AROUND 3,200 EXHIBITORS from 60 countries (2019: 3,684 exhibitors from 63 countries) and more than 495,000 visitors from over 200 countries (2019: 627,603 visitors from more than 200 countries) came to Munich for the world’s leading trade fair for construction machinery, building material machines, mining machines, construction vehicles and construction equipment held from October 24 through 30. The proportion of international visitors was around 50 percent.

The top 10 exhibitor countries were, in this order: Germany, Italy, Turkey, Great Britain and Northern Ireland, the Netherlands, France, the U.S., Austria, Spain and China. The share of international exhibitors was nearly 65 percent.

Stefan Rummel, the CEO of Messe München responsible for the event, is pleased: “This bauma has again stoked enthusiasm and fascination! After the world fundamentally changed following the last bauma, we’re really thrilled that bauma 2022 demonstrates the trade fair remains a powerhouse of the construction-equipment industry thanks to our customer’s great variety of innovations, good business deals and many visitors from all over the world.”

INDUSTRY EXPECTATIONS GREATLY

And this is because bauma displayed its usual strength even in these unsettled times, as Domenic Ruccolo, CSO of Wirtgen Group and Senior Vice President of Sales, Marketing and Product Support for Global Construction Equipment at John Deere confirms: “The WIRTGEN GROUP’s joint trade show appearance with John Deere was a resounding success. The interest in our company and our innovative and sustainable products was simply overwhelming. Our participation in the industry leading trade fair bauma was the most successful in the history of the WIRTGEN GROUP.” Steffen Günther, a member of the Board of Directors of Liebherr, also expresses his satisfaction: “bauma proved to be a very successful trade fair for us. We generated a lot of enthusiasm among the large audience. The conversations were outstanding. We’re already looking forward to the next bauma trade fair now.” Fred Cordes, Chairman of the Management Board at Zeppelin (CAT), adds: “bauma was long overdue — as demonstrated by the overwhelming rush of visitors to our booth and the extraordinary interest in Cat construction machinery and Zeppelin services.”

And in terms of business deals as well, bauma proved once again it is THE platform for the industry. Alexander Greschner, Chief Sales Officer at Wacker Neuson Group, says: “Visitors flocked to our stand, and we had a lot of very good discussions. From the very first day we were able to achieve sales success on the same level as 2019 and beyond.”

Alexander Schwörer, owner of PERI, had a similar experience, saying: “The entire team was very keen to see how the trade fair would develop in these difficult times. But even after the first day it was clear to see that this bauma would be a complete success. What’s particularly noteworthy to mention is the quality of the conversations we had during the week of the trade fair: They were exceptional in all respects. And something I certainly want to mention: We signed a number of very attractive contracts right at the trade fair. In short, bauma 2022 more than exceeded our expectations.”

These are assessments the co-CEOs of Messe München, Stefan Rummel and Dr. Reinhard Pfeiffer, like to hear: “In these challenging times, bauma has sent a strong signal to the trade-fair sector: Industries need precisely such in-person events like bauma where everyone can directly experience products and hold personal conversations.”

But bauma did not just showcase its strength as a business platform; the trade fair also lived up to its leadership claim in setting topics for the event. Franz-Josef Paus, Managing Director of Paus Maschinenfabrik GmbH and Chairman of the bauma Advisory Board says in summary: “We’re very satisfied with how bauma went. The trade fair was enormously popular among our customers and guests. Digitalization and automation are topics that dominate the trade fair, and this trend is irreversible.”

Joachim Schmid, Managing Director of the Construction Machinery and Building Material Association of the German Engineering Federation (VDMA) echoes this, saying: “The exhibitors are offering solutions to address current challenges related to CO2 neutrality as well as tackling the issue of skilled worker shortages with automation and digitalization. This is the future.” The next bauma will be held in Munich from April 7–13, 2025.

At bauma, Liebherr presented a new all terrain that takes the combination of mobility, economy and performance to a new level. The LTM 1100-5.3 offers a powerful 62-metre telescopic boom and carries up to 16.9 tonnes of ballast with a 12-tonne axle load on public roads.

economical mobility worldwide, as it can travel with an axle load of only 9 tonnes. For this reason, Liebherr will present the new LTM 1100-5.3 under the slogan ‘The master of all roads’. It is the second crane in the Liebherr range to feature the new LICCON3 control system.

In the all terrain section of the Liebherr stand at bauma, two mobile cranes visibly stood out. They both feature a new driver’s cabin and crane cab, new paintwork and the LICCON3 control system – the previously unveiled

LTM 1110-5.2 and the all-new LTM 1100-5.3.

When designing the LTM 1100-5.3, Liebherr focused above all on lightweight construction to allow as much ballast as possible to be carried with a 12-tonne axle load; and to achieve the lowest possible axle loads by reducing ballast. In addition, the new crane was designed with a long, strong telescopic boom in mind.

Even in countries where mobile cranes with a 12-tonne axle load are permitted

on the roads, crane operators have been demanding cranes which can be driven with low axle loads and total weights by simply removing the ballast. These models deliver major benefits when it comes to obtaining licences and route permits. In addition, day-to-day circumstances often require reduced weights, such as when driving over bridges and in inner cities.

When it comes to flexible axle loads, the new LTM 1100-5.3 sets unprecedented standards. With 0.8 tonnes of ballast, it reaches a total weight of 44 tonnes with axle loads of 9

The new Liebherr LTM 1100-5.3 mobile crane offers a new level of combined mobility, economy and performance.

tonnes. With 4.4 tonnes of ballast, it can travel with 10 tonnes of axle load and a total weight of 48 tonnes. With an axle load of 12 tonnes, the new 100-tonne crane can carry up to 16.9 tonnes of counterweights. At 75 per cent of the maximum ballast of 22.5 tonnes, this is a new record for mobile cranes worldwide. This allows the new LTM 1100-5.3 to perform the majority of its jobs as a taxi crane without additional ballast transport. Even with maximum ballast, the axle loads of 13.4 tonnes are low and evenly distributed across all axles. The new LTM 1100-5.3 has a narrow width of

2.55 metres – an additional advantage when driving on roads and construction sites. It is the first 5-axle mobile crane worldwide based on this narrow design.

At 62 metres, the telescopic boom is two metres longer than the next most powerful Liebherr 5-axle machine, the LTM 1110-5.2. In addition, a 9.5 to 16-metre folding jib is available which, as an option, can also be adjusted hydraulically between 0° and 40°. This enables the LTM 1100-5.3 to achieve hoisting heights of up to 76 metres and radii of up to 64 metres. Other options include a 2-metre assembly jib and a side-folding rooster sheave, which offer additional flexibility in use.

The new 100-tonne crane offers extra safety, flexibility and lifting capacity thanks to the VarioBase® variable outrigger system. Greater flexibility on the construction site is also provided by the standard VarioBallast®, which allows the ballast radius to be adjusted between 4.0 and 5.1 metres.

The third generation of the LICCON (Liebherr Computed Control) system relies on proven control features, but also includes a completely new software package and programming language as well as a faster databus, significantly more storage space and more computing power. Crane operators who are familiar with the previous control system

will

“When designing the LTM 11005.3, Liebherr focused above all on lightweight construction to allow as much ballast as possible to be carried with a 12-tonne axle load; and to achieve the lowest possible axle loads by reducing ballast.”

quickly and easily get to grips with the new version, as the recognition value is very high. Proven hardware components, such as the mobile operating and display unit BTT, have been adopted. The touchscreen function on the new large display in the superstructure cab means that it is now even easier and more comfortable to control. The way in which the information is shown has also been revised and simplified. In addition, LICCON3 cranes are prepared for telemetry and fleet management as standard. In the future, crane contractors will be able to view and evaluate all the relevant data using the MyLiebherr customer portal.

As a result of the high synergy effects involved, Liebherr is launching the new driver’s cabin at the same time as the

LICCON3 control system. The modern design features premium materials and timeless lines as well as delivering a whole host of improvements for the crane driver. These include the new multifunction steering wheel, side roller blind on the driver’s door, improved instruments and modules as well as new displays. Additional convenience is offered by options such as a central locking system with remote key and the “Coming and Leaving Home” function.

A completely new, modern automatic heating and air-conditioning system in the driver’s cabin and in the crane cab, which features an adapted design, ensures a high level of comfort. A sun sensor detects strong sunshine and automatically adjusts the heating settings.

The lighting packages for the crane cab, the superstructure, the rear of the

vehicle, the front headlights and the telescopic boom as well as the lattice fly jib have been optimised and can be operated with LEDs. The benefits of LED technology include a longer service life and superior lighting performance.

The innovative DynamicPerform coupling module is installed in the new LTM 1100-5.3. It ensures virtually wear-free starting and manoeuvring without overheating for the modular ZF TraXon gear unit, because it transmits the engine output via an oil-cooled clutch plate pack. The friction heat generated when starting is dissipated in the clutch oil and supplied to the vehicle’s cooling system via an oil/water heat exchanger. Crane operators thus benefit from greater efficiency and lower maintenance costs.

Off-road, powerful, robust. With maximum safety thanks to VarioBase as standard and automatic outrigger levelling as well as global load tables to ANSI, EN, GOST and AS. The safe choice – even for beginners! www.liebherr.com

Mobile and crawler cranes

Mobile and crawler cranes

The Grove GMK 4070L offers the strongest load charts and at 60m, the longest boom in its class.

To strengthen its four-axle all-terrain crane line-up, Grove unveiled the GMK4070L at bauma. The 70t capacity GMK4070L offers the strongest load charts and the longest boom in its class at 60m. At its full 60m length the crane is able to lift an impressive 4.4t, while at 49m owners will be capable of picking loads of up to 8.3t. When working at its maximum radius of 46m, the GMK4070L will lift 1t.

UP TO 78M OF MAXIMUM TIP HEIGHT IS available when the 60 m main boom is paired with its 15 m swingaway jib option. These are capabilities more commonly associated with 100t cranes and allow the new model to take on jobs that would typically require larger cranes.

“The Grove GMK4070L offers improved engineering design and adopts several latest technologies to deliver a new level of performance, operation, serviceability, and fuel efficiency,” said Andreas Cremer, vice president of product management for mobile cranes at Manitowoc. “It’s a crane that will be a true game changer, surprising many customers with just how much more a 70 t all-terrain crane can achieve.”

Offering unmatched versatility, the GMK4070L will give owners a host of options for travel. At a configuration of 16.5t per axle, the crane will carry an impressive 17.8t of counterweight, just shy of its full 19t complement. In situations requiring 12t per axle, it will carry up to 13.3 t, while at 45.8t for NSW Level 4 GVM, it will be able to travel with 11t of counterweight while for 10t per axle configurations it will be able to travel with 5.3t of counterweight.

A Telma retarder packaged in the carrier design will reduce the risk of overheating and overall wear and tear on the conventional service brake system. The frictionless, maintenance-free Telma braking system remains effective even after the engine is switched off, or when the gearbox is in neutral, ensuring full braking power is available, regardless of the crane’s speed.

The new high-visibility carrier cab offers the best levels of protection in line with European ECE R29-3 regulations, ensuring exceptional security in frontal impact, roof, and rear wall strength. Power for both the carrier and the superstructure will come from a single 320 kW (430 HP) Mercedes Benz OM470LA 6-cylinder diesel engine. Compliant with Euromot 5/Tier 4 Final requirements, this clean, efficient engine is approved for use with HVO Diesel, for customers looking to

“Also making life easier for the operator is Manitowoc’s Crane Control System (CCS), which supports both setup and lifting.”

further reduce their CO2 emissions or meet tight environmental jobsite requirements. The engine’s ECO mode can be used in conjunction with the transmission’s Fuel Saver mode, for unbeatable fuel efficiency.

The GMK4070L will be one of the first Manitowoc cranes to offer the exciting new Grove CONNECT™ digital platform that provides owners with real-time access to fleet data. Through Grove CONNECT™, fleet managers can get instant insights into the crane’s performance with just a couple of taps on a screen. Service technicians are supported with remote, optimized troubleshooting, reducing the frequency of onsite trips and strengthening preventative maintenance programs.

The optional MAXbase feature helps users reduce setup time at the jobsite and give them a wider choice of outrigger positions. With this option, the crane becomes an ideal choice for confined spaces or projects where obstacles are preventing setup in the preferred location. The productivity-enhancing MAXbase allows the crane’s four double hydraulically telescoping outriggers to be easily extended to a range of symmetric and asymmetric positions. This maximizes flexibility and enables lifting work to continue in less-than-ideal environments.

Also making life easier for the operator is Manitowoc’s Crane Control System (CCS), which supports both setup and lifting. Using its Boom Configurator feature, the operator can select the optimal arrangement of the seven-section MEGAFORM® boom with TWINLOCK® dual-pinning system.

During bauma 2022, the Spanish tower crane manufacturer presented its innovative model, the all new LCH300.

COMANSA EXPANDS ITS RANGE OF LUFFING jib cranes with the launch of the LCH300, its first hydraulic model, with a maximum load capacity of 16 tonnes and reach of 60 metres.

The LCH300/16 t is available in various versions: embedded, supported on bases of 6 or 8 metres, or movable. The crane can be assembled with 2.5 x 2.5m tower sections. Its modular jib has a reach of 25 to 60 metres, with configurations every 5 metres. It has a minimum working radius of 4 metres and a minimum radius of 9 metres when out of service.

It has manual transmission combinations of 1T (direct pulling) and 2T. The maximum load capacity is 8t with the 1T configuration and 16t with the 2T configuration. The

maximum load at the jib end is 3,400 and 3,150kg, respectively.

Its 1t configuration can reach the 60m boom with a 2t configuration reaching a maximum 55m.

The luffing moves the jib and counter jib jointly by a hydraulic cylinder at the cathead and jib hinge assembly. The hydraulic pump unit is located on a movable platform in one piece.

From the cabin there is direct visibility of the lifting mechanism of between 50kW (standard) and 65kW (optional). Thanks to the Effi-Plus technology, it is possible to increase the speed of the lifting mechanism without affecting consumption, which allows loading cycles to be considerably reduced,

thereby improving the productivity of the crane.

The design of this new rotating part - jib, cathead and counter jib - as well as the mechanism, cabin and hydraulic unit platforms, optimises the transport of this model, which may be supplied by 8 trucks or containers.

This new luffing jib crane from Comansa incorporates the award-winning CUBE Cab (L or XL) with Split type air conditioning. The cabin platform, like the lifting and hydraulic unit platforms, can be transported in a single piece.

Now, with the incorporation of the LCH300 hydraulic model, the luffing mechanism is optimised to offer even greater performance and an efficient assembly, as well as reduction of the radius when out of service.

from Comansa incorporates the award-winning CUBE Cab

conditioning. The cabin platform, like the lifting and hydraulic unit platforms, can be transported in

With a main boom length of 50 metres, the crane can lift a good 7.1 tonnes at a radius of 12m.

WHEN DEVELOPING ITS NEW AC 4.070-2 all terrain crane, Tadano made sure to pursue some extremely ambitious goals: “To put it simply, we wanted to bring to life a powerful and cutting-edge 70-tonne crane that would deliver the best performance on the market in as many axle load configurations as possible. And to put it plainly, that’s exactly what we did,” explains project manager Sascha Scholler, who was responsible for the development.

Among the various impressive characteristics, one stands out in particular: The AC 4.070-2 can transport its sizeable maximum counterweight of 11.9 tonnes by itself while staying within an axle load limit of 12 tonnes, and it can still manage an impressive 4.4 tonnes when the axle load is reduced to 10 tonnes instead. Needless to say, this makes the AC 4.070-2 an extremely flexible and versatile

taxi crane. And there are also the lifting capacities, which are just as impressive: For example, with a main boom length of 50 metres, the crane can lift a good 7.1 tonnes at a radius of 12 metres, and this goes up to a total of 7.3 tonnes at a radius of 10 metres. “No other crane in its class can reach these lifting capacities,” Sascha Scholler underscores with a glint of pride in his eyes. Among other things, this means that the Tadano AC 4.070-2 is the perfect assist crane for erecting large lattice boom crawler cranes, as well as an outstanding crane for residential and functional building construction projects. Moreover, the crane’s extremely compact design only helps to boost these advantages even further: With a total length of 11.7 metres, a width of 2.55 metres, and a traveling height of 3.8 metres, it is the most compact four-axle

unit of its class on the market.

The boom solution also plays a crucial role in the AC 4.070-2 crane’s versatility: Tadano offers two extensions for the crane’s 50-meter main boom – a swingaway jib with a length of 6.5 metres and a double folding swing-away jib with a length of 16 metres, making it possible to reach a system length of up to 66 metres. In addition, there is also an optionally available runner.

It goes without saying that the new Tadano AC 4.070-2 would not have been complete without the highly coveted IC1 Plus control system, which determines the crane’s lifting capacity for every boom position as a function of the superstructure’s slewing angle. Moreover, the way these

Tadano continues its innovation campaign with the launch of the most powerful 70t capacity all terrain on the market.

computations are carried out directly in the cab means that the lifting capacity for a specific radius is no longer limited to the lowest value for a pre-calculated 360° lifting capacity, but is instead determined in real time. As a result, the AC 4.0702 is always able to take advantage of the maximum lifting capacity available to it, and the advantages provided by this system literally deliver invaluable support for lifts over the outriggers. And when used together with the Flex Base, an outrigger system that comes as standard and features outriggers that can be extended to any point within their available range, this enables the crane to take care of jobs that would normally be the exclusive purview of larger cranes. In fact, the Flex Base can be used to extend the outriggers in asymmetrical configurations instead of predefined extension positions, making it possible for crane operators to get the outriggers as close to obstacles as possible and use the maximum possible outrigger spread in any scenario. After this, all the IC1 Plus has to do is to incorporate every single centimeter of outrigger extension into determining the lifting capacity.

The AC 4.070-2 can transport its maximum counterweight of 11.9t by itself while staying within an axle load limit of 12t.

In addition to the Flex Base, the innovative Tadano IC-1 Remote telematics solution for location-independent crane and fleet management is also available for the AC 4.070-2. This cloud solution provides remote access to all relevant crane data from anywhere, enabling online troubleshooting by Tadano Support.

Another highlight behind the new AC 4.070-2 is the one-of-a-kind Tadano Surround View System, which features a separate monitor in the carrier cab that provides 360° visibility and graphically shows the maximum possible extension lengths for the outriggers and the counterweight tailswing radius from a bird’s eye view perspective. Accordingly, Tadano Surround View makes it significantly easier to optimally position the crane at work sites without the need for additional personnel. The system also provides assistance on the way to the work site by making it easier for crane operators to notice pedestrians and cyclists. For example, the area to the right of the crane, which traditionally does not have the greatest visibility, is highlighted on the monitor when the turn signal is activated.

The AC 4.070-2 can also be equipped with another Tadano innovation at the factory: With a special transportation cradle and the required hydraulic connections, the four-axle unit is optionally prepared for work with the ESTA-award-winning E-Pack. This feature is an electro-hydraulic system that comes with an integrated 32-kW electric motor that makes extremely quiet zero-emission crane operation possible. The E-Pack can be used to carry out all AC 4.070-2 crane functions without any negative impact on the corresponding maximum lifting capacity. Not only that, but other performance characteristics are comparable to those achieved with operation with a diesel engine in many work areas, expanding the range of applications of the AC 4.070-2 to indoor projects and cleanrooms, for example. On top of this, the costeffective single-engine design allows for climate-friendly crane operation thanks to its compatibility with various alternative diesel fuels, such as HVO. The use of these fuels generates fewer emissions and makes operating the crane more environmentally friendly. The AC 4.070-2 shares these advantages with a number of other units, including Tadano models AC 4.080-1 and AC 4.100L-1, which feature a drive train that is virtually identical – this is also part of Tadano’s current shared component strategy, which is intended to provide customers with standardized controls and easier maintenance options.

With the new AC 4.070-2, Tadano is once more introducing the most compact crane of a class while raising the bar in many areas with the best lifting capacities out there. Thanks to comprehensive standard equipment and a flexible range of accessories, the new four-axle machine is a particularly versatile representative of its class, and technical highlights such as the IC1 Plus, Flex Base, Surround View, and E-Pack prep package are sure to make it an extremely attractive option for many crane service providers.

The Sennebogen 653 E Electro Battery, has a powerful 130 kW electric motor instead of the diesel engine, powered by a lithium-ion battery in the uppercarriage.

THE NEW 653 E ELECTRO BATTERY 50T capacity battery-powered crane combines the benefits of battery technology with the proven advantages of the telescopic crawler crane design. This means you work completely emission-free and retain maximum flexibility thanks to the Dual Power Management system.

The 653 E Electro Battery is the first battery-powered telescopic crawler crane in the range.

Especially in inner-city areas, environmental requirements are becoming increasingly stringent in Europe, and these are increasingly including construction machinery. Sennebogen already has two battery-powered material handlers in its material handling product portfolio.

During bauma Sennebogen presented the 653 E Electro Battery, its first batterypowered telescopic crawler crane.

Thanks to sales partner Van den Heuvel working closely with Dutch crane rental companies and construction companies, the valuable market requirements from the progressive Dutch market have now been factored into in a development partnership and a 50t telescopic battery-powered crane has been developed in collaboration with the dealer. With coordinated battery technology and analog charging management, this crane is perfectly adapted to applications in the construction industry thanks to the collaboration.

NEW, BATTERY-POWERED VERSION OF THE SENNEBOGEN 653 E

The battery-powered version of the 50-tonne SENNEBOGEN 653 telescopic

crawler crane, the 653 Electro Battery, has a powerful 130 kW electric motor instead of the diesel engine, powered by a lithium-ion battery in the uppercarriage. The high-quality, liquid-cooled battery system, which is particularly durable and has already proven itself on- and off-road under the toughest conditions, has a capacity of 210 kWh and is connected to an intelligent battery management system (BMS). Depending on the type of use, the crane operates in battery mode for up to 14 hours. For charging, the machine simply needs to be connected to a standardised 32 A CEE industrial socket, which is usually available on any construction site.

Thanks to the 22 kW on-board

charger, there is no need to invest in additional charging stations. The integrated power electronics also ensure a particularly smooth motor start-up that is gentle on the mains power grid.

The machine’s Dual Power Management system guarantees maximum mobility and uninterrupted work, all with the same performance as usual. Like the SENNEBOGEN battery-powered material handlers, 817 and 825 Electro Battery, the electric crane can continue working whilst charging from the power grid. As soon as the machine is connected, the mains power is used for the lifting operations, while excess energy is simultaneously used to recharge the batteries.

In the future, you will not only continue to benefit from the flexibility of the telescopic crawler crane itself on the construction site, which is characterized by unique off-road capability and maneuverability – even with a load on the hook – but will now combine this with the technological advantages of state-of-the-art battery technology. The crane’s hydraulics have basically remained the same, but the control of the battery-powered machine has proven to be even more sensitive due to the more directly acting torque, which customers and crane operators find very pleasant.

The 653 Electro Battery is not only free of fossil fuels such as diesel and engine oil, but also works noticeably more quietly and with less vibration than its diesel-powered counterparts. When generating energy from renewable energy sources, the battery-powered crane also saves more than 23 t CO2 per year in single-shift operation. In addition to the positive CO2 footprint, the machine also has a further significant advantage - it requires less service work, as maintenance procedures such as engine oil changes are completely eliminated.

The new 653 E Electro Battery 50t capacity battery-powered crane combines the benefits of battery technology with the proven advantages of the telescopic crawler crane design.

benefit from the flexibility of the telescopic crawler crane itself on the construction site, which is characterised by unique off-road capability and maneuverability – even with a load on the hook – but will now combine this with the technological advantages of state-of-the-art battery technology.”

“In the future, you will not only continue to

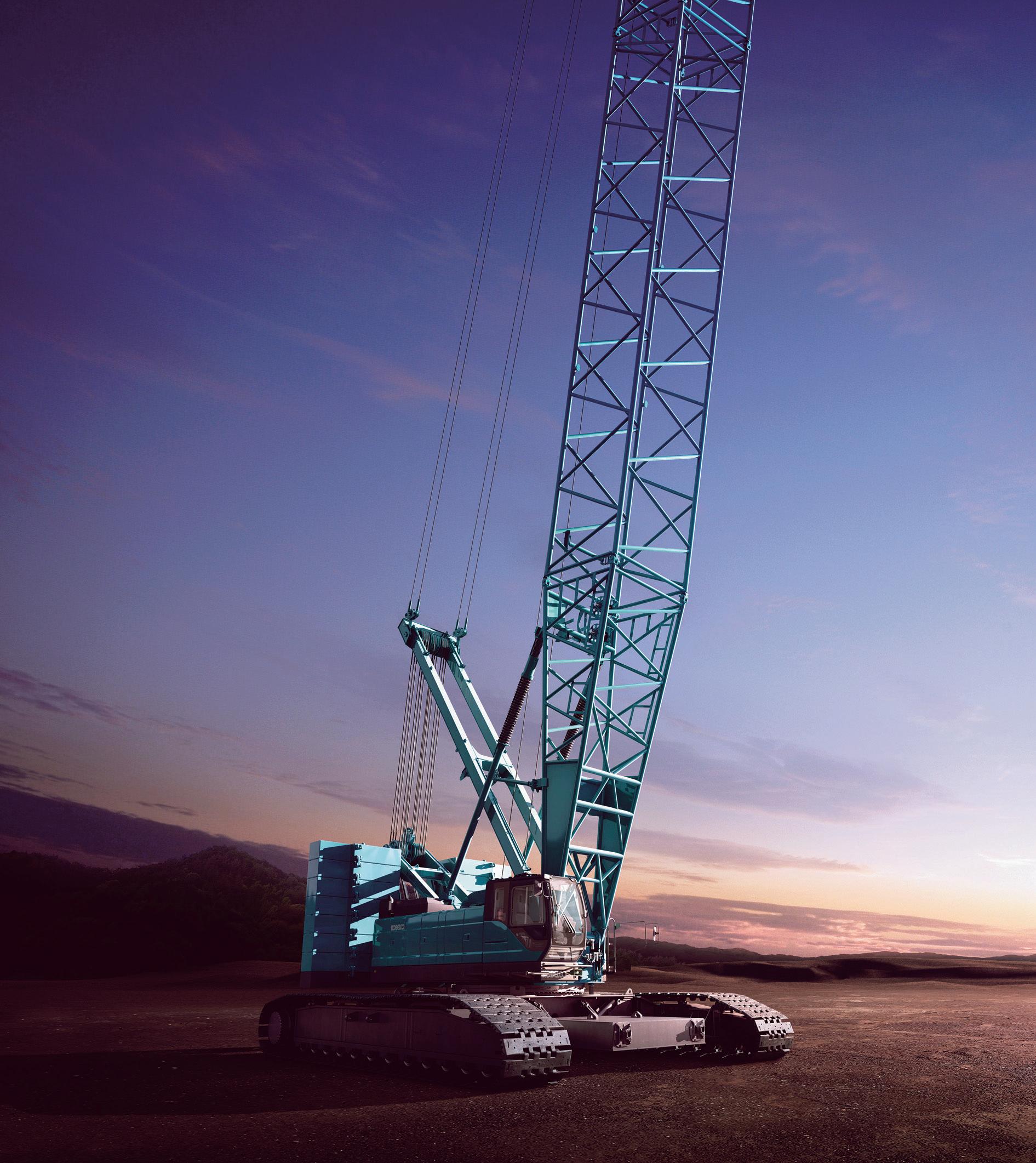

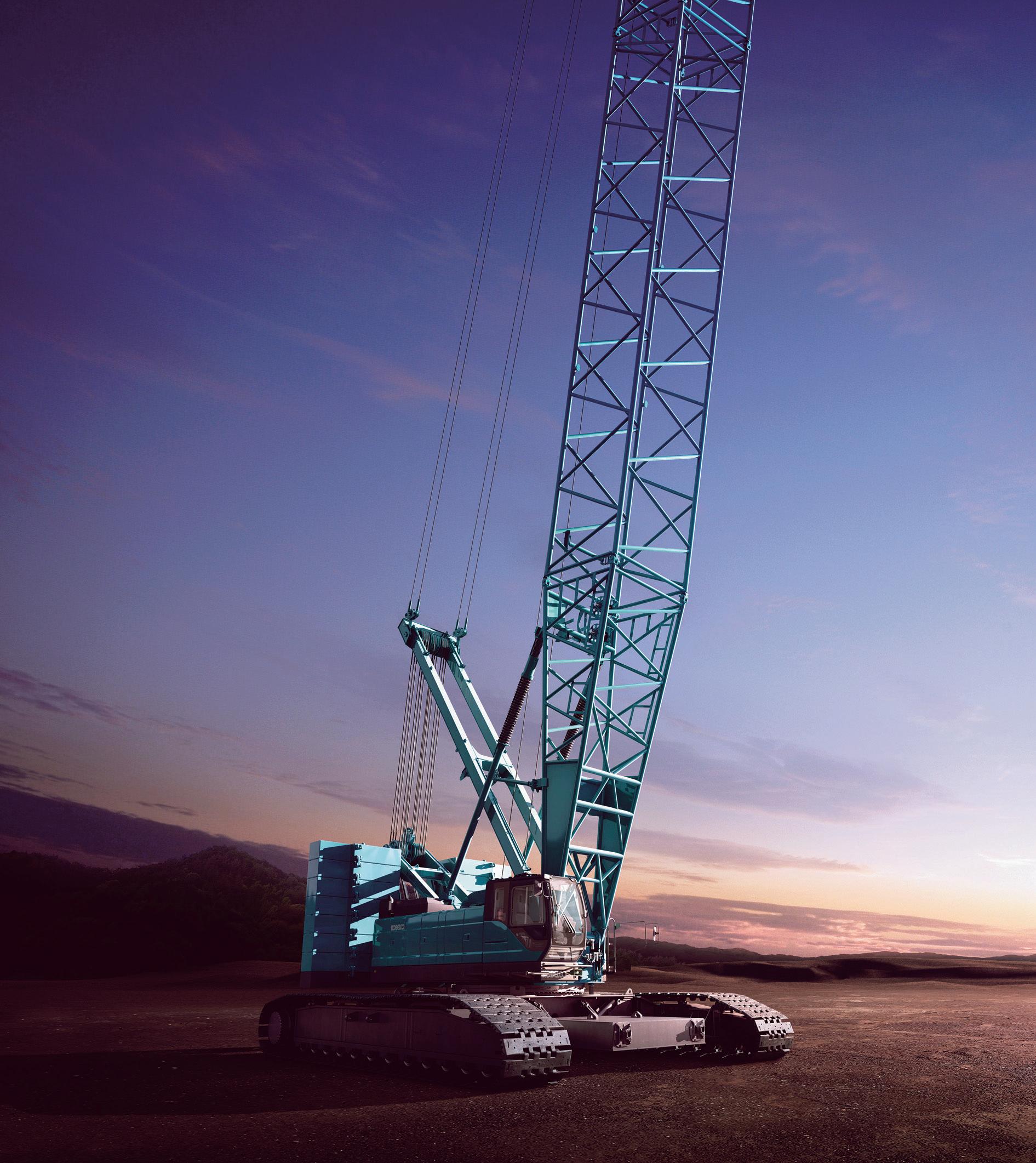

The new Liebherr HS 8070.1 is versatile, flexible and compact

Liebherr launched the new all-rounder duty cycle crawler crane, the HS 8070.1. The new cycle crawler is particularly suited for material handling, deep foundation work and lifting work. It features a modular counterweight system for various applications and a new A-frame system for dynamic operations.

VERSATILE, FLEXIBLE AND COMPACT:

these attributes are combined in the new duty cycle crawler crane HS 8070.1. It represents the all-rounder qualities of Liebherr’s HS series and is equipped for an especially wide range of applications. Thanks to the new design it can be individually fitted depending on the application and customer requirements.

Liebherr revealed the latest generation of duty cycle crawler cranes at bauma. The machine has a lifting capacity of 70 tonnes and is the first choice for a multitude of applications: material handling, deep foundation or lifting work.

Using the new jack-up system, the crawlers can be easily disassembled for transportation, so reducing the transport weight to less than 35 tonnes. The platforms and railings must no longer be removed before transportation.

Instead of a single counterweight, the new model is fitted with a modular system. Thus, the customer can mount the counterweights individually as required, depending on the operation. Further, the boom of the HS 8070.1 is compatible with the HS 8100.1. Therefore, customers can use attachments such as the slurry wall grab HSG 5-18 on both machines and install thicker slurry walls with a more compact machine.

As opposed to the fixed system, the new floating A-frame system ensures higher performance in dynamic applications. It also simplifies and speeds up the assembly and transportation of the machine. The userfriendly design extends to the tank neck, which is easily accessible via a platform on the uppercarriage - a perfect example of the modern and individual design strategy.

What a year it’s been so far. It feels like 2022 has been a thrilling rollercoaster ride, with dizzying highs and out of control lows and as things progress, we’re heading through the last bends, travelling at an alarming pace towards 2023.

AS WE STEAM TOWARDS THAT FINISH line, it’s good to reflect on the achievements and progress that LEEA has made over this past year. Bursting out of the pandemic was probably not on many people’s radar, but we had different ideas at LEEA. We put into action a number of new and exciting initiatives, both in this region and globally.

LEEA is a global association, and we have members in 80+ countries and gather expertise from our membership across all manner of industries throughout those countries. They share their knowledge with us, which helps shape our global industry best practice guides. This global connection was evident at the dinner for the LEEA Awards 2022 where we welcomed 250 guests from across the world during the two days of LiftEx in Aberdeen. At this event the LEEA Australia and New Zealand Regional Council was awarded – Member of the Year 2022, as a collective group. This was an outstanding reward for a group that I am most fortunate to be able to work with and on behalf of. They are exceptional industry leaders who dedicate their time to progressing LEEA’s global best practice agenda and assist in shaping products and services specifically for our local members. I thank the eight regional council members for making my role so rewarding and highlight them publicly for their contribution.

These members are:

• Steve Flint (Chair) – The Rigging Shed

• Adam Thompson – Stenhouse Lifting

• A ndy Campbell – Bunzel Safety

•

•

•

•

•

I was fortunate enough to attend LiftEx in Aberdeen, Scotland where thousands turned out to see the latest in products and services relevant to the Lifting Equipment Industry. As part of the event schedule, I had the opportunity to speak with a group of senior school students

from local Aberdeen High Schools. This engagement formed a part of a promotional program to build interest in learning more about the huge range of opportunities available to them in the lifting industry locally and around the world and, I highlighted the many prospects they would have available to them in this region. These students were invited to come along and learn more, engage with industry professionals and interact with global companies and organisations as part of the “Think Lifting” campaign which introduces

school ages students to the great industry in which we work.

Also during my time in the UK I spent a week with colleagues at LEEA HQ in Huntingdon. There I had the chance to reconnect after 3 years and this opportunity afforded me a closer look at LEEA’s brand new online learning platform prior to the official launch at LiftEx. This new platform is state of the art and gives our learners greater flexibility to learn at their own pace, in the office, on the road, on PC, Mobile or tablet. Additionally, the use of an offline study capability with auto-sync updates (once back online), means that learners can study literally anywhere at any time. Our team has been working overtime on ensuring this new system is second to none and I can happily say we’ve delivered on an incredible piece of work for the benefit of our members and the broader industry.

Tailing into the new learning platform is the brilliant new LEEA TEAM Card. The TEAM Card is a way to quickly and easily identify a qualified and capable LEEA trained Lifting Equipment Testing Inspection

and Certification professionals. The new TEAM Card is NFC enabled, which when tapped against a mobile phone – links straight to the TEAM Card database, showing all credentials, is updated automatically and doesn’t need to be re-issued. The TEAM Card is a way for end users to be certain that their equipment is being inspected by a true industry trained professional, quickly and easily in any location. We look forward to promoting this as the best way to ensure lifting equipment inspections are being carried out be suitably qualified people.

Finally, in March 2023 our members and end users will be able to see all our new services in action, as we will host our very own LiftEx event and exhibition in Darling Harbour, Sydney. This will be our first event since

before the pandemic. We’re looking to celebrate with a showcase of innovative products and services that highlights our industry. One that is incredibly important to so many supply chains throughout the world. As highlighted at the LEEA Awards in Aberdeen in October, Australia is a world leader in safety in the Lifting Equipment Industry and this is an ideal opportunity for our members to be rewarded for their commitment and dedication to this industry. The event will span two days, with a major portion highlighting our work for members, but giving an insight as to what the key business drivers, pitfalls and highlights business should be watching for in 2023. I look forward to welcoming our members and guests to the event and we will make further announcements closer to the event.

“Tailing into the new learning platform is the brilliant new LEEA TEAM Card. The TEAM Card is a way to quickly and easily identify a qualified and capable LEEA trained Lifting Equipment Testing Inspection and Certification professionals.”

The Lifting Equipment Engineers Association (LEEA) is established across t he world as t he leading trade association for all t hose involved in t he lifting industry. Trust t he professionals, always insist on a LEEA member.

LEEA member near you visit www.leeaint.com or email mail@leeaint.com

The recycled mats are tough and durable, perfect for difficult work.