In construction, the challenges are constant. We’re committed to helping you find the right solutions as you work toward sustainability in achieving environmental and business goals.

Over the last decade, we have reduced CO2 emissions by 30 to 45% on some of our core construction products. Over a year, this means those machines now emit about 20 to 30 metric tons less CO2 * And, this is just one of the ways we’re working to help you make your job sites more sustainable and profitable.

Wherever you are on your sustainability journey, we’re ready to help. Contact us today or visit Cat.com/Sustainable-Choices

Editor Mike Woof

Publisher Geoff Hadwick

Editorial Team

David Arminas, Guy Woodford, Liam McLoughlin, Alan Dron, Munesu Shoko

Sub-Editor Kevin O’Shea

Sales Team

Graeme McQueen, Philip Woodgate, Fulvio Bonfiglietti, Monica Colleoni

Designers

Simon Ward, Andy Taylder

Liebherr has won an innovation award for its novel R9XX H2 prototype excavator, manufactured at the company’s Colmar facility. The machine is powered by an internal combustion hydrogen. This clean-burning concept produces mostly water vapour from the tailpipe, ensuring low emissions. The

CO2

machine from manufacturing to decommissioning is estimated to be around 70% lower than for a conventional machine.

The special H966 power unit was developed at the engine facility in Switzerland and is based on conventional technology adapted for the purpose. The port fuel injection

(PFI) and direct injection (DI) systems are said to ensure

hydrogen-fuelled engines is scheduled to commence in 2025. The H966 engine features six cylinders and a fourcylinder H964 unit is also in development. The machine has a 50tonne operating weight. www.liebherr.com

To demonstrate its expanding range of connected machinery, Hitachi Construction Machinery (Europe) (HCME) is showcasing a Zaxis-7 ZX210LC-7 medium excavator with a 3D machine control solution from Leica Geosystems. The control solution has been fitted in HCME’s factory in Amsterdam as part of the new Hitachi Customised Solutions platform.

Adding Leica Geosystems machine control technology to the ZX210LC-7 is said by HCME to increase efficiency on the jobsite while lowering running costs. It also enables work to be completed on time, on specification, and on budget, safely and sustainably.

From simple slope grading to blind and submerged cuts, the machine control solution

is said to provide operators with an easyto-use system to rapidly excavate to the reference design. This ensures more uptime and operator satisfaction.

The partnership between HCME and Leica Geosystems, part of Hexagon, brings numerous benefits to customers, the companies say. Both the machine and system are covered by HCME warranty and undergo extensive testing to ensure optimum machine calibration.

In addition, customers can choose from several options through their authorised Hitachi dealer and will benefit from a simplified purchasing and delivery process. The financing for both the excavator and the additional Leica Geosystems machine

control technology can be combined in a single package. Thanks to this partnership, customers will also benefit from Leica Geosystems’ hands-on training upon machine delivery. The Leica Geosystems solution is designed and proven to work optimally with Hitachi excavators, improving their lifetime value when OEM-fitted.

HCME Solution Linkage manager Ryo Kurihara says: “By taking advantage of a factory-fitted Leica Geosystems solution, operators can start work immediately after machine delivery.

“By delivering customised solutions such as this, we aim to become their first-choice solutions provider.”

www.hitachicm.eu

Bell Equipment is offering a special narrow version of its B30E truck for use on-road. The machine has narrower tyres than the standard model, giving it a width of just under 3m. This allows it to be used on-road, with customers also able to specify it with a full package of road equipment such as suitable mudguards, lighting and licence plates.

The same six-cylinder Mercedes diesel rated at 260kW that meets Stage V/Tier 4 Final emissions requirements is fitted to the special narrow variant as to the standard machine and this also drives through the same six-speed Allison transmission. The payload also remains the same at 28tonnes, though the dumpbody is revised to keep it within the 3m width limits. The machine offers a top speed of 50km/h and is equipped with an automatic retarder, while the dumpbody retains its heating kit to ensure efficient tipping with sticky materials. The machine has been developed to meet the needs of those earthmoving contractors or quarry firms that sometimes have to move machines on road.

www.bellequipment.com

Increased compaction forces are delivered by the new HC series soil compactors being introduced by Hamm. The new models are said to generate up to 15% more centrifugal force

Operating weights range from 11-25tonnes while engine power outputs range from 85160kW. However, new ECO modes ensure more

operate in partial load mode unless more output is required, saving fuel.

The cabs are larger and more comfortable, with even lower vibration levels for the operator than on the earlier models. A wide array of options is available including an automatic engine stop system and a dozer blade, while CR variants with reinforced drums for use on rocky ground will be available in due course.

with the latest machine control systems from the leading suppliers, to suit customer preference. www.hamm.eu

Caterpillar is piloting four battery electric prototype machines for the construction sector – two excavators and two wheeled loaders.

The electric prototypes are the 301.9 mini excavator, 320 medium excavator, 950 GC medium wheeled loader and 906 compact wheeled loader. The machines are powered by Caterpillar battery prototypes and include an onboard AC charger. Cat says it also plans to offer an offboard DC fast charging option. All four models feature Caterpillar’s dedicated blue branding for electric machines.

In addition to construction, Cat says the 22-tonne 320 excavator is suitable for quarrying operations. It utilises five 600V Cat lithium-ion batteries which

provide a total of 320kw/h electric power. Thierry Brasseur, Caterpillar medium wheeled loader product and applications specialist, said that this enables up to six hours operation before recharging is required, depending on the operation. More demanding operations such as trenching will have a shorter period before recharging is necessary.

The 19.7-tonne GC wheeled loader is suitable for secondary operations in quarrying and uses four Cat 300V lithium-ion batteries for a total of 256kw/h electric power. It takes around one hour to recharge.Both the 320 medium excavator and 950 GC medium wheeled loader can use DC fast charging.

Liebherr is offering the upgraded version Generation 8 version of its TA230 Litronic ADT. Empty vehicle weight is 24.6tonnes while load capacity is 28tonnes. Power comes from a six cylinder, Liebherr diesel, which features exhaust gas aftertreatment to meet the Stage V emissions requirements. The 12litre diesel delivers 265kW and is said to be responsive and economical on fuel, allowing a top speed of 57km/h. The 18.1m3 capacity dump body is made from hard wearing steel for long life, with a profile that allows efficient dumping. Maintenance of the truck is said to be eased due to grouped service points. Aimed at use in the earthmoving and extraction sectors, the truck is rugged and durable according to Liebherr. A specially modified version is also available for use in tunnelling projects. The design has been proven in use and won a Red Dot design award.

www.liebherr.com

Cat construction industries

group president Tony Fassino commented: “It’s important we meet customers on their sustainability journey today with a variety of solutions including machines that run on renewable

fuels or technology that increases fuel efficiency, as well as supporting them into the future as we power our next generation of machines.”

www.caterpillar.com

• Fully electric drive and vibration • 1 Shift = 1 charge • Zero-emission

• Ecodrop and Ammann Servicelink • Energy recuperation = extended operation

• Advanced battery pack with long life cycle, high capacity and optimal safety

• 100% Traction control for performance on difficult terrains

Komatsu has unveiled the 20tonne class PC210E electric hydraulic excavator equipped with a Proterramanufactured lithium-ion battery system. Since January 2021, Komatsu and US-based Proterra have been jointly developing electric medium-sized hydraulic excavators and have been conducting PoC (Proof of Concept) tests on advance research machines at customers’ construction sites. The PC210E is scheduled to be introduced

to the Japanese and European markets in the

Komatsu notes that hydraulic excavators are the most versatile type of construction equipment, and the mid-size class is used in a wide range of jobsites and applications, mainly in earth excavation and loading operations, requiring power and durability to withstand heavy-load work.

The PC210E model is said by the manufacturer to optimise the entire body

control system by capitalising on Komatsu’s proprietary coordinating technology. It

ion battery technology which has a proven track record for use in heavy-duty and commercial vehicles deployed in various components, such as the hydraulic pump, controller, and electric motor for work equipment operation.

www.komatsu.eu

With its new range of medium-sized products consisting of the 11tonne e12 excavator, the 1,000litre load capacity es1000 swing loader, the 6tonne ed6 dumper and M-Power, its onsite high-power battery charging solution, Mecalac says it is helping to revolutionise urban construction sites and definitively paving the way for intelligent, clean and silent construction sites.

Climate change and the resulting need to reduce CO2 emissions has become a major global challenge of the 21st century. In recent years, many construction equipment manufacturers have presented electrical products to limit CO2 emissions. However,

Italy-based Perlini is launching the new DP265WD dump truck for the quarrying, mining and public works sectors.

Referred to by the manufacturer as “the little one” in its range, the 26.5tonne truck features new control electronics, modern GPS monitoring and electronic weighing systems.

The width of less than 3m allows for road transport without the need for special transit permissions or escorts. The vehicle’s features include a brake retarder system with oil-bath brakes, oil-pneumatic suspension, and a Stage V Scania DC09 engine and an Allison 4430ORS

transmission with updated electronics. The DP265WD also features a new digital electronic system which enables real-time monitoring of all system parameters, including remotely.

The onboard GPS available in the new dump truck connects to the vehicle’s power supply and constantly collects the status of its main parameters including position, speed, direction, panel status check on/off, progressive mileage and hours of panel on. It then transmits them via GPRS to a web monitoring platform. www.perlinidumpers.it

Mecalac notes these alternatives only provide a very partial answer, as the offer is currently mostly limited to small machines (eg 1.5tonne mini excavators) that tend to only assist larger diesel-powered machines.

Mecalac states that the need for mediumsized machines on urban construction sites is not yet met. With very limited autonomy (mostly between 1.5-4 hours), they do not allow a full day of work onsite between two battery recharges. Companies and operators are used to combustion-powered machines, thus the switch to electric vehicles is not seamless.

www.mecalac.com

Komatsu’s Utility equipment is designed, manufactured and supported to meet the same industry-leading standards as our construction and mining industry machines. Versatile and easy to transport, with precision controls and simple maintenance features, our Utility performers are the right choice whenever you need

Fayat discussed the Fayat Group’s current performance

ALL OUR LIGHT EQUIPMENT WILL BE ELECTRIC IN FIVE YEARS “

Fayat Group president Jean-Claude Fayat discussed the firm’s business developments with Mike Woof

The Fayat Group has come a long way since it was

Business growth has thinks this will grow to nearly

Despite the strong machine the construction machinery

autonomous machines in the that there remain too many autonomous machine prototypes is increasingly an important

www.fayat.com

Ammann has developed an effective technology for introducing RAP into the asphalt mix with its innovative RAH100 recycling system. According to the firm, this is capable of producing mix containing up to 100% recycled materials. Ammann says that the quality of the mix is high, despite the use of RAP. The key advance that allows the use of RAP in such a high percentage has been the development of a gentle heating process. The firm recognises also that using up to 100% RAP in the feed is dependent on the availability of quality material as well as efficient logistics with regard to its retrieval and storage. For applications where lower quantities of RAP are to be used in the feed, Ammann also offers the RAH50 and RAH60 dryers, which have maximum usage of 50% and 60% RAP, respectively. In addition, the firm offers the RAC system, which can handle up to 40% RAP in the feed.

All Ammann recycling systems are able to produce high-quality mix with 100% virgin aggregate if so desired.

www.ammann.com

Wirtgen says that its latest WR recyclers/ stabilisers are more efficient due to the development of the new Resource Efficiency System.

This increases the degree of automation in the overall process, boosting working efficiency.

In addition, the new VARIO injection bar for binding agents allows the user to regulate the injection pressure of water and bitumen to achieve more homogeneous distribution in the mixing chamber.

The Resource Efficiency System combines an automatic steering system and digital project site documentation in a single app, improving the cost-effectiveness and resource-efficiency of soil stabilisation and

recycling operations. The satellite-based guidance system allows precise and efficient completion of project tasks and steers the machine with precision measured in centimetres on the basis of a previously calculated reference cut and a predefined overlap of adjacent cuts. At the same time, location-specific parameters are recorded to generate a database for site analysis and documentation.

Parameters such as working width and depth, distance and area worked and fuel consumption are recorded. The system is scalable, which means that other machines such as rollers and compactors involved in the process can also benefit from the data. www.wirtgen-group.com

Vögele is offering four new mini road pavers able to pave widths from 0.25-1.8m. There are four models offering a choice of tracks or wheels as well as the choice of diesel or electric power.

The four compact models share many features and the tracked MINI 500 is available with diesel power or as an e variant, with battery electric drive. Similarly, the MINI 502 wheeled model is offered with a choice of diesel power or as the battery electric e variant. The machines are suitable for use in small-scale construction projects that include constructing cycle and pedestrian paths, paving between railroad tracks

as well as repair work in small inner-city sites.

The standard screed working width is 0.8m and it can be enlarged up to 1.35m hydraulically. The minimum paving width can be reduced down to 0.25m, while the width can be built up to a maximum of 1.8m using bolt-on extensions.

The new Vögele MINI series has been developed in partnership CM, an Italian company that will also build the machines for Vögele.

www.voegele.info

Dynapac claims high compaction efficiency for its revamped 8tonne CG2300 twin drum asphalt roller as well as the new CG3300 machine for the 9tonne class. Both models now benefit from the firm’s VI technology, with a key feature being the addition of the innovative SEISMIC system first developed for the company’s soil compactors.

Among the features of the new Dynapac CG3300 VI are its latest generation VI operating station, interface, electric system, and ECU software. Additionally, the Dynapac CG3300 VI will come with a new style for forks, beams, and frames.

After comprehensive testing and adjustments to a hot asphalt mix, similar results were achieved with the novel SEISMIC technology in asphalt compaction

as in use for soil compaction. Benefits include reduced vibration power and energy consumption by 20-30%, and a 7-9% fuel consumption reduction. In addition, noise levels are reduced due to lower frequency and there was an overall reduction in the number of passes depending on the application. The generation VI CGs will also be available as combi versions with a split drum front and rubber wheeled rear. The new operator station for the CG3300 VI station offers full seat rotation, making it possible to turn the seat and steering module all the way around for visibility. The machine has an electric steering wheel and an instrument panel that is said to be easy to understand.

www.dynapac.com

Swww.sumitomokenki.com

Ease of control is a key feature of the BW 154 and BW 174 pivot-steered tandem roller from BOMAG. The machines are fitted with the latest myCockpit system, a new generation control offering a choice of three operating concepts. Operators have a choice of touchscreen, rotary pushbutton switch or classic joystick controls.

The touchscreen allows full control over functions. Touchscreen operation meets the need for digitalisation, though the rollers can also be operated using the rotary pushbutton on the control lever.

The operator can configure default settings and operate and control all functions using the touchscreen. A driver can set individual user profiles and switch to default settings. There is also a preset profile for the truck driver when loading the machine for transport.

High visibility allows the drivers to watch

the drum surface and see if the spraying system is working correctly.

The BW 154 and BW 174 tandem rollers are available in several variants and with a wide range of equipment. They offer working widths of 1.5m or 1.68m and operating weights of 7.1tonnes and 9.8tonnes. Three compaction systems are offered: Asphalt Manager 2, vibration, or the split drum oscillation TanGO4. The Asphalt Manager system has been simplified and regulates amplitude as well as compaction direction. This allows it to achieve optimum compaction quality with minimal passes.

The Asphalt Manager system allows the operator to concentrate on the rolling pattern and other machines working alongside, as well as being suited to compacting lowtemperature asphalt.

www.bomag.com

One of the latest – and painted specially in green - Sealmass M5 asphalt sealers is about to roll off the assembly line at Massenza. This one will not be the usual red but will be in NATO green, says Diego Massenza, general manager of the company.

This example of the proven Sealmass M5 is headed to Sigonella Airport in Sicily to be used by the Italian army for melting sealing compound and applyiing it into cracks and joints. Thanks to its thermal oil heating system for both the melting tank and hand lance, the sealant is kept hot and liquid until the very last application point. It works even with very high viscosity compounds.

The drive wheel has a variable 0-4km/h speed and there is a hydraulically operated steering system controlled by joystick. Meanwhile, the melting tank has a capacity around 500litres with hot oil coils on top for melting and a stirrer with paddles driven by an hydraulic motor.

www.massenza.it

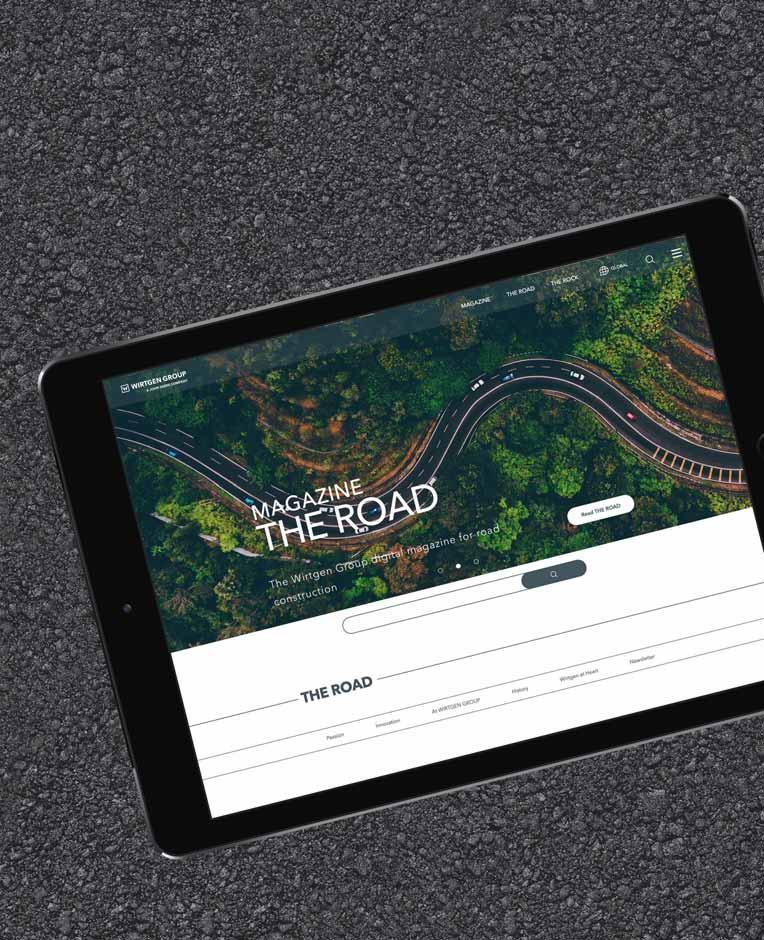

Wirtgen Group chief sales officer (CSO) Domenic Ruccolo spoke with Mike Woof

Uthe Wirtgen Group a few years ago and has now integrated the road machinery business into its operations. The company sees a healthy future for the road

invested heavily in research and development as well as manufacturing. Wirtgen Group

John Deere perspective we have Like many other leading is looking to meet future Wirtgen. Addressing climate change and sustainability are looking at new power systems. Electric drives and alternative fuel and power systems are an increasingly important area for development in the construction machinery sector. New electric equipment has been added to the Wirtgen range as Ruccolo machines and we have more coming.”

Electric power will be a key system across the range of John Deere earthmoving equipment and Wirtgen road

machines. That John Deere

providing the ability to meet the challenges of electric power technology. Ruccolo said. “They specialise not only in battery technology but also in charging technology.”

New systems will be developed for use with the construction machines onsite

superchargers and mobile charging solutions.”

Having an in-house battery supplier will be of enormous road machines from Wirtgen. make batteries along modular

machine installations. At the be ruggedised to cope with tough working applications in markets such as construction or quarrying. John Deere will have 26 electric products in the range Wirtgen machines.

Simple details such as charging connections are

OUR INVESTMENT IN TECHNOLOGY IS EXTREMELY HIGH JUST NOW “

“The adaptors are going to be universal. There are chargers that are going to be mobile and others that are going to be stationary.”

“Full battery electric power is not going to be the solution for everything. Hybridisation is biofuels and hydrogen.”

Alternative power sources are a key focus for John Deere (as well as the Wirtgen Group) as part of a wider programme aimed at improving sustainability and reducing the carbon footprint of the company

“Our investment in technology is extremely high just now.”

presence at bauma 2022 saw the history.

where a lot of the innovation is taking place.” And he said that over time most of the world will follow the lead set by Europe with regard to sustainability.

The acquisition of Wirtgen by John Deere has brought a

“We have equipment that varies greatly in size. “We can be as

vertically integrated as possible. development in the John Deere space that can be leveraged within Wirtgen.”

Wirtgen was a privately held German company and is now owned by a public US

Deere and Wirtgen has been twothe Wirtgen Group.”

A notable change has been seen with the use of John Deere engines in several of the road machines. “Where it makes

While both John Deere and Wirtgen have wide product lines there is zero product overlap. The two brands are now being sold alongside each other for some markets and John Deere the Wirtgen stand at bauma 2019. And The Wirtgen Group is now marketing the John Deere wheeled loaders with the other markets.”

www.wirtgen-group.com

Doosan has given a world premiere to its new 4x4 articulated dump truck (ADT). The new 4x4 version of the DA45-7 ADT complements the company’s standard, popular range of 6x6 ADT models, including the 28tonne DA30-7 and 41tonne payload DA45-7. The 4x4 DA45-7 aims to compete with 40tonne class rigid dump trucks (RDTs).

In Doosan’s new 4x4 ADT, the front truck and cab unit is the same as in the original 6x6

made on the rear dumper unit only. Featuring a ZF EP8-420 transmission, the 4x4 DA45-7 is a two-axle ADT with twin wheels at the rear, and with a dumper section like that on RDTs in the 40tonne class.

“With superior operation on poorer roads, smoother surfaces and steeper terrain, the aim of our new 4x4 machine is to challenge RDTs in the 40tonne class, by providing a dumper product that delivers much more than RDTs,” says Beka Nemstsveridze, Doosan’s ADT

One of the key products that Keestrack is presenting is the completely redesigned Keestrack I4e tracked mobile reversible impact crusher with an advanced diesel-electric drive.

Thanks to the RIC, or Reversible Impact Crusher, this machine is very flexible in the secondary and tertiary crushing of rock and recycling building materials, for example, asphalt. The specific design of the reversible horizontal impact crusher with a large variable crushing chamber, powerful rotor and electronically monitored hydraulic gap adjustment allows feed sizes of up to 250mm and ensures consistently high-quality

end products of up to 0-2mm in closed circuit.

Secondary and tertiary crushing can be now combined in one highly mobile solution. This makes the I4e a real alternative to mobile cone crushers or vertical impact crushers, especially with regard to its outstanding production capacities from 100-250tonnes per hour.

According to Keestrack, the system offers lower wear, better quality of the end products (grain shape) and significant energy savings in typical applications such as sand production.

As with other Keestrack large crushers, the drive unit with its 447kW diesel engine and

Matec unveils world’s biggest filter press

product manager.

As well as performing better in conditions that are tough for RDTs, the new 4x4 DA45-7 ADT has a width of less than 4m to avoid the need for special

a better turning radius than a comparable RDT. The shorter turning radius and the design of the rear dumper unit, which is

heavy rocks, provide particular advantages in the mining and tunnelling industries. www.eu.doosanequipment.com

Matec Industries is showcasing a prototype of the eye-catching

‘Twin Freccia Rossa’ – the world’s biggest filter press. The first full-production 50m-long, up to 380-plate and 600t/h machine is set to be snapped up by a Turkish iron ore mining customer. The Italian company says its innovative machine combines the efficiency of two machines into a single product with exceptional performance, offering faster sludge feeding and cake discharge time. The patented ‘Twin Freccia Rossa’ is said to reduce customers operating costs and allows production to continue during maintenance times. the cutting-edge filter press can be equipped with 25 to 50mm standard or membrane plates. “All our customers are asking us for two filter presses in one machine,” says Matec Industries CEO Matteo Goich.

www.matecindustries.com

300kVa generator is designed as a removable drop-off module. Electric drives for the crusher, with 160kW of power, feeders and conveyor belts as well as

the system hydraulics enable particularly cost-efficient and emission-free plug-in network operation.

https://keestrack.com/en

McCloskey International has unveiled the latest entry into its jaw crusher line in the European market, the heavy duty J4. The crushers are particularly suited to aggregates, construction and demolition recycling, and site preparation.

The crushing and screening equipment manufacturer says the J4 builds on the robust features of the existing product range, with a line-up of features aimed at

durability across applications.

Designed to withstand the toughest conditions worldwide, the J4 delivers high production due to its jaw chamber design

The large 1060mm x 700mm jaw opening accommodates large feed sizes, contributing to higher production in material processing.

RM has launched the new H50X hybrid screen, which can run on diesel or fully-electric power.

As a hybrid variant, RM says the machine can be operated fully electrically to notch up zero emissions. It adds that, in addition, the screen delivers impressive modularity and versatility.

“It’s a whole new conception of doing a scalper,” said Gerald Hanisch, founder and CEO of the Austrian head-quartered RM Group. “It is not only electrified, it has all kinds of features – the mobility, the versatility, the simplicity and the energy.”

RM says that both the RM5H50X hybrid screen and

the RM J110 jaw crusher –which will make its debut at Conexpo in March 2023 – have incorporated countless ideas and customer requests to redefine the application options of processing equipment.

RM says the use of a hybrid machine brings a 25% reduction in fuel costs compared to a diesel-direct crusher or a hydraulic screen, and combining them into one machine train increases the savings even further.

The company says that, when a diesel-direct crusher drives the new RM hybrid screen, the customer saves up to 33% on fuel. In combination with an RM

The material path is enhanced with the 1064mm x 4247mm grizzly pan feeder under the hopper that allows for better sizing of material with a variety of mesh options. Options of either a short pan feeder to suit the pre-screen or a double deck grizzly pre-screen are available, ensuring suitability and better sizing of material based on the application.

https://mccloskeyinternational.com

hybrid crusher, which drives the RM hybrid screen, the savings potential reaches up to 50%. In addition, if only one engine is running because the crusher is

driving the screen, the customer only has to refuel and service one engine, effectively saving fuel time and money.

www.rubblemaster.com

Epiroc is presenting a demonstrator of its firstever tophammer battery-electric drill rig, the SmartROC T35 E. The Swedish manufacturer describes the landmark rig as an important step in the shift towards zero emission drilling in surface mines and quarries all over the world.

Based on the design of Epiroc’s well-proven SmartROC T35 surface drill rig and drawing on the company’s experience in developing underground battery rigs, the SmartROC T35 E comes with a range of smart features,

and is said to deliver high safety, reliability, and performance – in a quieter working environment.

The SmartROC T35 E rig is equipped with both a battery and an electric cable, which improves flexibility considerably. You can choose to drill with the most suitable alternative for the location and occasion. It also allows for quick and smooth transportation in and between sites. www.epiroc.com

TURNKEY COMPLETE PLANT

QUICK INSTALLATION

MODULAR SYSTEM FOR ALL SECTORS

Kleemann is premiering its mobile impact crusher

MOBIREX MR 130(i) PRO. The latest member of the Wirtgen Group brand’s PRO line, the extremely powerful plant is used as a primary and secondary crusher in natural stone and recycling and meets high environmental standards. Local emission-free operation is said to be possible thanks to the model’s E-DRIVE diesel-electric drive with the option of external power supply.

When it comes to high performance and great

130(i) PRO is said to be in its element. The Kleemann PROLine system can process up to 600 t/h of material, meeting the requirements in the highperformance range. The high output is made possible by the crushing unit with a heavy rotor and a 250kW drive in screening. The Continuous Feed Systems’ (CFS) continuous feed control is said by Kleemann to ensure consistently high utilisation.

The Kleemann MOBIREX MR 130(i) PRO impact crusher mobilises its energy fully electrically with the innovative

E-DRIVE drive concept. Thanks to the external power supply, the system can be operated locally without emissions This ensures low energy consumption per tonne of end product. Furthermore, due to the electric drive, hydraulic oil

is only required for setting and set-up functions. This minimises the risk to the environment and further increases the sustainability of the MOBIREX impact crusher.When the MR 130(i) PRO is operated via the diesel unit, the performance

and load-dependent fan is said and low noise emissions. The formation of dust is also said to be greatly reduced by water spraying at all relevant points. www.wirtgen-group.com /kleemann

bearing screenbox with the ability to switch to a two-bearing setup in less than three hours, making the Chieftain 1700X one of the most versatile units of its size on the market.

The high-performance Premiertrak 330 jaw crusher and Chieftain 1700X three-deck incline screen are standout models for Powerscreen.

The Dungannon, Northern Ireland-based Terex brand, a major global supplier of mobile crushing, screening and conveying equipment to the quarrying, mining, construction and recycling

sectors, has a strong relationship with German strategic partners, Kölsch and Christophel.

The Premiertrak 330 boasts a two-piece grizzly feeder which allows better material flow towards the chamber.

User benefits include track mobility for a quick set-up time, and variable crusher speed that allows the operator to fine tune the

machine and maximise output.

The Powerscreen Chieftain 1700X is a mid-sized tracked mobile screen aimed at end users requiring high volumes of finished products in applications including topsoil, coal, crushed stone, recycling, iron ore, sand and gravel. User benefits include a quick set-up time, drop down tail conveyor and the patented four-

Commenting on Powerscreen’s key relationship with distributors Kölsch and Christophel, Joe Cassidy, Powerscreen International sales director, said: “Both companies have been representing the Powerscreen brand for many years and offer an extremely professional service to end users of our equipment across the country. We are strongly committed to the German market and look forward to continued success and growth in the region.”

Jürgen Kölsch is a familyrun business with over 20 years industry experience. It offers tailormade solutions in new machines, a rental and used equipment to meet the exact needs of its customers.

The company prides itself on aftermarket support and has an extensive service and parts offering which spans across Southern Germany.

SBM Mineral Processing says its innovative REMAX 600 track-mobile impact crusher

one cycle. With a feed capacity of 600t/h, the new machine can accommodate material feed sizes up to 900mm and a maximum

total weight of 75tonnes depending on the equipment.

Triple wind sifting and the separator with longitudinal discharge as an option – which SBM says is a novel feature in highly mobile impact crushers –

are said to ensure the high purity recycling applications.

SBM stresses that the new REMAX 600 serves as a technology platform for the fully automatic production monitoring and control that it

The environmental and commercial gains to be had from utilising innovative waste recycling operations is a key theme for CDE.

The Cookstown, Northern Irelandheadquartered global provider of sand and aggregate wet processing solutions for the natural processing and waste recycling sectors, is highlighting the role of its technology in supporting the circular economy and zero waste agenda.

As the construction sector continues to adjust to the restricted availability and high cost of raw materials, CDE demonstrated the potential benefits of processing construction, demolition and excavation (CD&E) waste.

On October 26 and 27, senior CDE figures were joined by several of the company’s European customers for a series of round table discussions on the future of recycling. Before that, as part of the bauma exhibitor forum on 24 October, Eunan Kelly, CDE’s head of business development for North West Europe, delivered a lecture on the topic of Creating valuable in-spec products from CD&E waste

Speaking ahead of his lecture, Kelly said: “In the current economic and social climate, with materials costs rising, resources depleting, and regulations calling for the adoption of sustainable solutions, we should look to the technology of today to produce the sustainable construction materials of tomorrow; how CDE’s waste recycling solutions in their trademark blue can support the industry to transform CD&E waste into certified, in-spec sand and aggregates.”

Materials shortages and their rising costs are not entirely symptoms of the pandemic, but they have been exacerbated by it and have become more acute, CDE’s business development manager for the DACH region, Christoph Baier, explains.

“Every day we continue to extract our fast-depleting natural resources to support rapid urbanisation and our modern, technological lifestyles. Essential to this is sand, the second most consumed natural resource after water and the most consumed solid material on earth.” www.cde.com

is currently developing in cooperation with researchers of the Montanuniversität Leoben, Styria.

Based upon an innovative sensor system and video technology, powerful communication and IT networks, as well as technological innovations such as the automatic gap adjustment, SBM says that

its way into mobile processing

It adds that the ‘autonomous crusher’ will help users and operators with all decisions,

operation, assure optimum product quality at all times, as well as make an important contribution to save energy and costs during crushing.

The autonomous crushing R&D project has been running for two years and features interdisciplinary teams from the Leoben chair of mineral processing and SBM research departments. The project aims to make the decisive step from today‘s already extensively monitored and optimised crushing to autonomous fully-automated production by means of “intelligent” self-learning mobile crushers.

Ammann

Ammann is taking a long-term view with regard to developing new technology for the construction industry. Developing zero emissions and low emissions technology for one of its strategies.

The company recently introduced a number of electric machines to its range and Schneider commented that emissions restrictions mandated by the government, work in tunnels indoors, or city centres with noise restrictions. He added that such electric power solutions are mainly for handtools and compact machines, like plates and rammers, trench rollers and light tandem rollers.

One of the key launches for Ammann has been the new eARX 26-2 Tandem Roller, which showcases Ammann’s to Schneider. He said that this model highlights how there are several key considerations with electric-drive machines, such as powerful batteries that enable extended operation and how charging needs to be fast and easy for the crew. He said, “The machines need to be user friendly and need built-in managers successfully integrate

To meet market demands, Schneider said that Ammann’s new eARX 26-2 light tandem roller features a fully-electric drive that can operate for up to 18 hours, and sometimes beyond, without recharging. Key is the advanced 48V battery pack with a capacity of 600Ah/31.5kWh. The pack’s

innovative LiFePO4 technology provides individual protection for each internal battery cell, resistant and increasing safety.

According to Schneider, the roller’s technology provides extended operation, and the demands on the machine, an eARX26-2 can operate up to 18 hours without having to recharge. This means the machine must only be charged once/typical working day, usually at the end of the working shift.

Schneider said that hydrogen fuel is suitable for machines weighing 7tonnes and more and for construction sites, where electricity is not available. However, he cautioned that the technology is still not costto be in place for use in compaction equipment or other 2027.

Alternative fuels for asphalt plants are also an issue that gas shortages and particularly as Schneider explained. He utilise alternative fuels that for a very good alternative to the ‘classic’ type of fuels commonly

The classic examples include light oil or heavy oil as well as waste oil or kerosene. However, in addition to these, more sustainable fuels include LPG, natural gas, coal dust (in Germany mainly), wood dust (in Scandinavian countries mainly) and hydrogen. A key point according to Schneider is that all these burners can utilise

THE

traditional fuels, easing the minds of some plant owners.

The choice today is driven mainly by the cost and availability, in many areas due

Schneider said Ammann can support a customer’s conversion to more environmentally friendly solutions.

immediate response to the situation. Existing plants can be of multiple fuel types. That limits their reliance on traditional sources.

Regarding the use of recycled materials, Ammann is using advanced technology and ever-improving knowledge to ensure quality. All asphalt materials are 100% recyclable and transformable into new asphalt pavement without any

Schneider. He said, “In Europe, a very high percentage of the available amount of RAP is used in the production of new asphalt mix. The availability of this material and knowledge about how to manage and treat it is continually improving. As quality and availability improve, rising energy costs and the strong demand for crude oil products have encouraged the use of a high content of reclaimed asphalt in hot and

The use of RAP lessens the environmental impact at a time when there is a need for more sustainable products. Clearly, the highest possible reuse of task for all future generations. Ammann is a market leader in asphalt plant technology RAP, both from environmental and economic perspectives.

“A properly designed and well manufactured asphalt mix, produced with a high percentage of RAP, performs equally or even better than a said Schneider.

Meanwhile, other technologies are also playing key roles for the future, with

construction and becoming prevalent in plants and machines.

Schneider said, “Essential to plant digitalisation is the as1 control system. Sometimes the control system isn’t given its proper due in the digitalisation process – and even its role in sustainability. Many times those of us in the industry think of tangible, visible solutions when it comes to RAP utilisation and other processes. Yet the as1

Our innovative technologies are changing the ways to detect and treat eye diseases, build cities, and produce the food needed to feed our world. We’re creating solutions that make a positive impact now and finding new paths to a better, more sustainable future. Healthcare Agriculture Infrastructure

Ammann says that its prototype eAPX 68/95 3D Vibratory Compactor areas.

eAPX 68/95 prototype has an

As the journey toward a more sustainable construction industry gathers pace, Bobcat is expanding its electric mini excavator range with the launch of its new E19e.

The 2tonne battery-electric machine features the same profile, external dimensions and offers comparable performance as the popular diesel-powered E19 mini excavator, more than 10,000 units of which have been sold globally.

With a width of just 98cm, the new E19e model is ideally suited for indoor applications where space is at a premium.

“The E19e is a perfect fit for applications such as indoor and outdoor demolition, landscaping

in narrow trenches and areas

can steer the eAPX 68/95

motors mean that the machine ironphosphate

and infrastructure activities, as well as other tasks that necessitate night-time work or low noise levels. The machine, therefore, fits the bill for rental companies and contractors alike,” says Miroslav Konas, mini excavator product manager at Doosan Bobcat EMEA.

Featuring a 3.5-hour battery capacity, the E19e comes with a superfast charger, which allows for opportunity charging during work breaks, thus maximising uptime onsite.

Doosan Bobcat CEO Scott Park says the launch of the E19e confirms Bobcat’s commitment to helping the industry meet

FAE presented its first road planer, the RPM/SSL. FAE is gearing up for production now for the 1,650mm-wide machine specifically made for skid steer loaders.

With its 600mm-wide planing width, it is ideal for municipalities that need to carry out small repaving projects along

any urban road. It is also efficient for repairing the hard shoulders of major roads and motorways.

Standard equipment includes a mechanical tilt system of 8°, independent hydraulic skids control and a maximum working depth of 250mm. The RPM/SSL weighs in around 1,170kg.

www.fae-group.com

its environmental, social and governance (ESG) targets. “The move toward a more sustainable construction industry is well underway with a clear roadmap ahead to deliver zero-emission

equipment fit for the future.

Battery electric products form a major part of this ambition, and we remain at the forefront of the global rollout,” concludes Park.

https://www.bobcat.com/eu/en

Komatsu is unveiling its prototype electric compact wheeled loader, which has been designed and built together with Moog, precision control components and systems. Moog’s Intelligent electric system includes an and steering electric cylinders, power electronics, system control computer, battery, and battery management system. The integrated control system connects and coordinates the actions across the machine, while the all-electric actuators and motors drive the machine’s traction and loading system, controllability.

“To achieve our CO2

carbon neutrality by the end

suppliers to accelerate our electric machine development,”

“The machine built together with Moog combines the

the joint testing will show the machine.”

The companies are testing the electric loader jointly to prove that it can achieve a new

companies will show that the

The prototype’s intelligent is designed to be connected and automation-ready. The system has the sensing and automation while the integrated with built-in tools to coordinate precisely control torque,

www.komatsu.com

Hitachi Construction Machinery (Europe) (HCME) says it is meeting the growing need for emission-free equipment and strengthening its commitment to the creation of a sustainable future with the launch of a 5tonne batterypowered excavator.

As well as zero exhaust emissions, the debut Hitachi-branded model in this class is said by the Japanese off-highway machine giant subsidiary to deliver lower noise levels, enhanced efficiency, exceptional performance in confined spaces, and fewer maintenance requirements and less downtime than conventional models.

The new ZX55U-6EB is said to operate with exceptional manoeuvrability in confined spaces, as it has inherited the short tail swing of the diesel-powered ZX55U-6 model. It also

provides equally high levels of performance.

Customers will be able to work on a diverse range of projects with the ZX55U-6EB, including urban construction sites, residential building and waste material handling projects – wherever the environment is a priority.

Customers can choose between batterypowered operation, using 39kWh lithium-ion batteries, and wired operation, which allows the machine to work while charging from a CEE 400VAC 3-phase power source. Utilising both methods allow operators to use the ZX55U-6EB to work productively and continuously throughout their working day, while enjoying the comfortable cab with air conditioning as standard.

www.hitachicm.eu

Simex is widening its range of planer attachments with the introduction of the new PL 2000 model. This shares technical features with the existing PL 1000, PL 1200 and PL 1500 models, but is larger and more powerful.

The previous top-of-the-range model from the firm was the PL 1500 model, with a 1.5m-wide drum. However, the new PL 2000 features a 2m-wide drum, making it the largest planer attachment currently on the market for use with compact loaders.

The unit is said to be highly durable and is able to cope with tough operating conditions. The quality of the milling drum is said to be high due to the use of robotic welding during manufacture, which ensures a rugged and durable tooth holder offering both longevity and performance.

www.simex.it

The new Mecalac MCL range includes six models, from 1.74 -2.85tonnes, four models with long boom as standard, fit the needs of the agricultural segment, while two models with short boom, fit the needs of construction customers.

MB Crusher has launched the new mid-sized MBHDS220 shafts screener shovel bucket.

The Italy-based manufacturer says the bucket is suitable for use with loaders and excavators for groundworks and agricultural applications.

Alessia Valerio, responsible for product growth and content at MB Crusher, said that the

MB-HDS shafts screener range, bringing the line-up to six sizes.

The MB-HDS523 bucket, the biggest in the range, is suitable

for quarrying applications. Valerio said the company is seeing a lot of demand for its smaller buckets in Italy and the rest of Europe, while many customers in Asia and the US are moving towards the larger models.

www.mbcrusher.com

Latest from MEILLER is a range of new generation three-way tippers designed to cater for all weight classes. Dubbed TRIGENIUS, the range is a radical redesign of the predecessor line. In every weight class, from the light D202 tipper body for 3.5tonne vehicles to the

large D428 for four-axle vehicles with an overall weight of 41tonnes, functionality, operation and handling are the same.

The modular design and the increased use of bolted connections facilitate numerous individual adaptations to meet

varied customer requirements, meaning numerous options can be retrofitted at a later stage.

All TRIGENIUS three-way tippers are based on a modular system, have a new, uniform operating concept across all series. Ergonomically designed components shorten operating cycles and make for efficient operation and handling. The clever design of the TRIGENIUS reduces weight while the use of highstrength steel increases loading capacity.

Strategic cooperation with all European commercial vehicle manufacturers enables easy harmonisation between the vehicle chassis and the MEILLER superstructure. A close exchange between MEILLER and truck manufacturers enables the tipper maker to respond rapidly to new market requirements.

www.meiller.com

The MCL2’s diminutive size and wheel motor transmission allow it to move with agility. The smallest machine in the MCL range but with maximum performance, it has all the features of the big ones. Its modern and ergonomic operator’s station protected by a canopy is also available in a cabbed version.

The MCL4 is said by Mecalac to offer an excellent compromise between compactness and performance. With its 18.4kW engine, it is also the ideal machine for rental fleets that want a durable and high-performance machine. Its low transport weight also allows the machine to be transported on a road trailer.

Offering the best of the MCL4 but with even more power, the MCL6’s 36kW motor allows it to reach and maintain high speeds on the road. Its high hydraulic flow and its speed of execution are said to allow it to considerably increase the productivity on worksites.

Power, high dumping height and lifting capacity are the key words that guided the design of the MCL8. Mecalac says the machine is at ease in all circumstances whether it is for loading, handling or driving hydraulic attachments.

The MCL4+ / MCL6+ are short arm versions to meet the specific needs of different applications, especially in the construction sector, offer an increased tipping load. All MCL machines are available in three versions: canopy, canopy with foldable top, or cab, and all with a wide selection of attachments. w www.mecalac.com

As part of its “Innovation for Green” strategy, XCMG is unveiling its XCA60-

hybrid all-terrain crane. With a maximum lifting capacity of 60tonnes and a boom length of 48m, the crane’s 115kWh high-capacity, onboard battery provides emission-free lifting

operations. Both AC and DC charging options are available,

operation. The hybrid engine, which provides up to 400kW power, is for moving the crane between jobsites. Braking and coasting energy is recovered, thus reducing fuel consumption

by more than 40%. One of the major talking points is the winch servo control technology, which automatically manages the winch during telescoping

operation time by up to 40%.

“Targeting carbon peaking by 2027 and carbon neutrality by 2049, XCMG is continuously

upscaling its research and development as well as manufacturing capabilities to spearhead the development of alternative power solutions,” according to Jianshen Liu, vice president of XCMG and general manager of XCMG Import and Export.

www.xcmg.com

Manitou Group is adding to its range of compact offering with the commercial launch of the MT 625e, its first 100% electric compact telehandler.

The MT 625e, with a capacity of 2.5tonnes and a height of 6m, is said to deliver the same performance as its comparable internal combustion counterpart. Fitted with a 25 or 33kWh lithium-ion battery, the model reduces maintenance by 56% and noise by 12%.

Perfect for indoor or city centre use, the MT 625e, like all the other models in the Manitou compact telehandler range, benefits from the new Safety Pack, which is designed to protect the operator and the site teams, as well as alerting fleet managers to any highrisk behaviour.

“Key features of the Safety Pack include harness detection and identification of obstacles around the machine’s chassis. A ‘lighting’ pack ensures the utmost safety for platform loading and unloading operations with a number of lights positioned on the platform to maximise visibility,” explains Arnaud Boyer, vice president of Marketing and Product Development at Manitou.

The first commercial units will be shipped to the global market by mid-2023, confirms Laurent Bonnaure, executive vice president at Manitou.

www.manitou.com

Moving the cab from the middle of the rotary telehandler to the front has made life easier for an operator of Magni’s new RTH series.

By moving the cab forward the operator has better vision when travelling on roads, as well as around construction sites. This also helps when positioning the vehicle’s stabilisers, especially in rough terrain.

Inside the cab, along with the latest Combi Touch Screen incorporating the Magni LLD –Load Live Diagram – the operator now has better knowledge of where the load is positioned. In addition, this is helped by the use of more glass in the cab to make visibility a key feature of the RTH series. Entering the cab is easier thanks to a new positioning of the steps. www.magnith.com

With four new electric mobile elevating work platforms (MEWPs) models, Manitou Group is accelerating the roll-out of its ‘Oxygen’ low emissions range.

The 100% electric line – which comprises the 200 ATJe, 160 ATJe, 180 ATJe 160 ATJ+ e rough-terrain platforms – is part of a larger rollout of seven electric models.

With a working height of 20m, the 200 ATJe roughterrain platform is available with four-wheel steer for greater manoeuvrability. The machine is equipped with a basket that can now take 250kg of load, 30kg more than the two-wheel drive counterpart. Apart from zero

reduced total cost of ownership (TCO). Customers can expect a 50% reduction in maintenance costs compared with the internal combustion version.

With a working height of 16m and 18m respectively, the 160 ATJe and 180 ATJe see their capacity increased by 50kg, with a basket that can take a total

Sinoboom is introducing its SPA33HJ hybrid spider lift in the European market.

The model was developed in collaboration with spider lift specialist, Falcon Lifts. The arrival of the SPA33HJ in Europe follows the conclusion of a wide-ranging partnership agreement between Falcon Lifts, specialist manufacturer of large spider lifts, and global mobile elevating work platform (MEWP) maker, Sinoboom. The partnership follows extensive research and cooperation during the past 12 months, during which time Sinoboom launched own-branded spider lifts built by Falcon into the Chinese market.

“The agreement is part of Sinoboom’s commitment to providing its global customer base with a complete range of MEWPs. We expect the combination of Falcon high-quality design with Sinoboom’s worldwide customer base and after sales support to make this a great success,” says Susan Xu, CEO of Sinoboom.

www.sinoboom.com

weight of 250kg. The 160 ATJ+ e, the biggest platform in the range, comes with a 400kg capacity.

With these new products, Arnaud Boyer, vice president of Marketing & Product Development says Manitou is range of 100% electric roughterrain platforms from 16m to 20m.

“The acceleration of our electric development allows solutions across our platform ranges, as well as on our telehandlers. We will continue to extend this energy to other ranges in accordance with the objectives of our CSR roadmap,” says Boyer. www.manitou.com

For bridge construction, PERI is introducing the continuously developed VARIOKIT VIL Incremental Launching Facility. The system is internal and slab formwork for bridges using the incremental launching method.

The optimised shuttering and striking mechanism of the slab formwork via Roller Dropheads releases the formwork more quickly for time-critical work in the construction sequence

the cross-swivel head, the slab props of the mobile VIL Slab Formwork solution can also be folded up easily and do not have to be moved by hand. During the moving process, Roller Dropheads automatically bring the formwork back into the concreting position.

The SC-135 Tiger is Soilmec’s top-of-the-range piling rig and is designed to be productive and reliable while minimising downtime and maintenance costs.

The machine is a Tiger type equipped with the HDD system platform with drums on the machine. To allow perfect movement of the hydraulic and mud hoses in the different working radius, the drums are installed in series and are aligned with the cathead. The SC-135 Tiger is equipped with a Caterpillar C27 engine capable of delivering 708kW while offering low emissions and fuel consumption. The machine features automatic and independent control of the radiator fans and the optimised air flows, allowing operation in

Importantly, the incremental launching system formwork. The distance between the cured concrete and the formwork is produced directly by means of a mechanism and thus, in the case of steep web walls, does not have to be moved in a horizontal direction as part of an additional work step.

Another advantage is that the clamping points of the trough formwork can be used for anchoring, thus reducing the number of lost components.

The clamping holes of the wall formwork can be used for anchoring the wall supports. The wellthought-out anchoring procedure reduces costs: required.

www.peri.com

With its new iONTRON eMixer, Putzmeister is paving the way for environmentally friendly concrete transportation.

Based on a SANY electric chassis, the iONTRON eMixer is 100% electrically powered, confirms head of product management Markus Frasch. No carbon emissions are released during operation - whether during the journey or when working on the construction site.

“The 315kW e-motor offers great torque and virtually silent operation. This means that the eMixer can drive without restrictions – even in places where strict noise regulations apply. This offers a competitive advantage when tendering for construction projects with strict environmental protection stipulations,” says Frasch. www.putzmeister.com

extreme temperatures and severe work cycles. Reliability is ensured by the double hydraulic system, with lines dedicated respectively to the excavation module and the base machine by the high pressure filters dedicated to each return line. As with other Soilmec equipment, safety, ergonomics and accessibility were among the cornerstones in the design of the SC-135 Tiger. A system with eight cameras optimises safety around the machine. This machine weighs over 200tonnes but has been designed along modular lines with single load transport weights of a maximum of 45tonnes for ease of transport.

The SC-135 Tiger is available with the new Soilmec SH-35 excavation module. With an

operating weight of 30-38tonnes, the SH-35 is assembled on a frame that allows for a wide range of panel thicknesses, from 650-1500mm. It benefits from

a new mud pump, hydraulic compensators with improved flow rate and new hydraulic fittings connecting the motors.

www.soilmec.com

Doka says it recently reached a milestone towards sustainability

formwork supplier in the industry to provide transparent emissions data for 6,000 products.

Doka had pledged that it will be carbon-neutral by 2040 as it addresses one of the most pressing issues in the global construction industry. By

focusing on decarbonisation and the circular economy, the company says it has already

towards achieving this goal.

Last summer, Doka introduced the Product Carbon Footprint to help customers make more environmentally responsible purchasing decisions, explained Robert Hauser, chief executive of Doka. “Sustainability and

Micro-Soilmec is expanding its micropiling rig offering with the introduction of the new SM-22 model as well as the electric SM-13e, the first of a new range of electric models with zero emissions.

The SM-22 is the biggest rig in the SM line and is an evolution of the PSM-1350 and SM-20 models, retaining the efficiency of the earlier machines. The machine was developed with kinematics capable of guaranteeing a variety of angles and positions in different construction site conditions and with different drilling methods. Power comes from a Cummins B6.7 diesel, available in a Stage V version.

The machine has two fixed stabilisers

digitalisation are two of the most powerful market of our global growth strategy. With the calculation of the Product Carbon Footprint, we empower our sector to make environmentally conscious product selection decisions.”

The Product Carbon Footprint details each product’s CO2 emissions.

The company reviewed the

Less weight and better performance are the prime features of Paschal’s new NeoR formwork system for smaller projects.

Because it combines the benefits of the company’s proven modular universal formwork and the LOGO.3 wall formwork system, NeoR can be used universally, making it ideally suited for construction of foundations, beams, columns and walls.

The formwork panels of the NeoR lightweight formwork have a maximum weight of just 41.3kg on the element 90cm x 150 cm. It can easily be assembled and moved in pairs and smaller panels solely onsite by hand without a crane or other

in the rear and two extendable hydraulic stabilisers in the front, rotating and pivoting, for stability in difficult conditions. The machine is equipped with opening hydraulic cages, ROM and SPM operating modes and all accessories to ensure accessibility, visibility and safety. The Soilmec SM-22 is versatile due to its modular design and can be easily configured in different combinations. It can be used for single rotary, double rotary, top-hammer and vibro-rotary applications to perform consolidations, micropiles and anchors with different drilling technologies, direct circulation, reverse circulation, DTH, CFA, and jet grouting.

www.soilmec.com

composition and raw material requirements for each item’s manufacturing, the delivery methods to the worldwide distribution centres and branch processes, as well as end-of-life recycling.

The cradle-to-grave approach allows Doka to detail each product’s carbon footprint over its entire life cycle.

www.doka.com

transport aids. At the same time, the NeoR lightweight formwork boasts significantly higher fresh concrete pressure absorption of 50kN/m² - an improvement on the Modular system’s 30kN/m².

A further advantage of the new formwork system is the low overall height of only 7.5cm, which ensures particularly low storage and transport volumes. NeoR can also be assembled in both upright and sideways direction so there is no need for a second system of different dimensions, making a client’s investment in formwork go further.

www.paschal.com

For any bridge construction worldwide – you can at all times rely on PERI.

For over 50 years, PERI has been a competent partner of numerous construction companies and contractors all over the world. In the field of bridge construction, PERI’s formwork and scaffolding systems as well as PERI’s engineering expertise point the way ahead in the today’s construction industry. These solutions positively influence construction procedures and thereby improve the results on the construction site. PERI engineers constantly strive to optimise construction procedures and to take advantage of remaining efficiency potential.

Learn more about PERI systems and solutions on our website.

www.peri.com

Liebherr is launching six new unplugged machines for piling and lifting

the LRH 100.1 and LRH 200 piling rigs, the LB 25 and LB 30 drilling rigs and the LR 1130.1 and LR 1160.1 crawler cranes. These new models follow on electric drilling rig, expanding the range considerably.

The battery-powered units

quiet in operation, suiting them to duties in noise-sensitive areas such as urban locations. The battery is charged using a conventional electric supply. Operation can continue while charging. In order to change

The Flydeck system from Pilosio simplifies and speeds up the assembly of suspended scaffolding and structures more safely. Importantly, because it is an under-bridge suspended system, there is no need to stop bridge traffic or close lanes. The system consists of 25cm or 45cm aluminium or steel lattice girders connected by patented pins and spring pins.

The girders are installed using the Flyrail rail. The cantilevered girders of the Flydeck surface are supported by the Flyrail rail, while the operator arranges the surface and anchors it

In response to the growing importance of environmental protection in construction, Putzmeister is introducing its iONTRON hybrid truckmounted concrete pumps. The range is available in 20-40m class sizes. The models comprise the 20m

class BSF 24-4 and BSF 28-4, the 30m class BSF 36-4, as well as the 40m class BSF 42-5 and BSF 47-5. Markus Frasch, head of product management, says Putzmeister’s patent-pending solution for integrating a plug-in hybrid in the hydraulic

to battery operation, the user simply removes the plug while performance remains unchanged. All six models are now available in both conventional and batteryoperated versions with identical performance. The LRH 100.1, LB 25, LB 30, LR 1130.1 and LR 1160.1 were previously available with diesel power only but are now too. The LRH 200 however is brand new.

The LRH 200 closes the gap between the proven LRH 100 and LRH 600. A 200kWh battery pack ensures that the unplugged models can operate in battery mode for 4-5 hours in average pile driving applications. Optionally, it can be upgraded to 400kWh for 8-10 hours of operation.

The new design of the LRH 200 extends the range of applications. In addition to piling, the machine can auger, full displacement and down-the-hole drilling, as well as for soil mixing work. A torque of 250kNm provides the power.

www.liebherr.com

in full safety.Loading capacity is up to 150kg/m² with tie-rods every 6m² and loading capacity up to 300kg/m² with tie-rods every 4m². The result is a perfectly horizontal plane for workers in any situation where a suspended solution is needed.

Furthermore, with the use of the Flyrail beam for mounting the Flydeck table, work can be undertaken without difficulty and in complete safety. With this solution, Pilosia says that pillars and pier-caps can be encircled and continued in the next span.

Importantly, there is no limitation in width, length or load capacity. The system is modular and uses beams and scaffolding decks of any make, model, shape and size.

https://pilosio.com

pump train is not just environmentally friendly, but also saves fuel, space and weight. There is virtually no limit to its possible uses, as the 92kW electric motor easily covers typical applications in electric mode.

www.putzmeister.com

equipment come too close, the

up to 50m and within this, can

“You can see on a toolbox

Using the new Trimble Roadworks Paving Control Platform version 2.10 is said to boost the accuracy and efficiency of asphalt paving work.

The system now benefits from Horizontal Steering Control and is offered on Vögele Navitronic asphalt pavers. The addition of Horizontal Steering Control and automatic screed width control is said to be a major step ahead in operator assistance for users of Vögele pavers.

The system can be used to steer Vögele asphalt pavers automatically and also controls the screed width. The steering and screed functions follow a 3D

design, which is programmed into the system. According to Trimble, this is the most advanced 3D paving technology the company has developed so far.

Providing auto steering and screed control allows for higher quality paving while also meeting high accuracy requirements and boosting productivity at the same time.

As the system controls these functions, the operator has more of a machine supervisory role and will be less fatigued than with using conventional systems.

Other improvements from the system include waste reduction and improved jobsite

www.leica-geosystems.com

sustainability. The system also allows users to estimate material quantities more accurately before work starts as well as consuming

during the

process, delivering major cost benefits.

www.trimble.com

CM Labs showcased its new Vortex simulator training and assessment solutions for articulated dump trucks, compact track loaders, and telehandlers The new releases from the Canadian firm all run on the immersive Vortex Advantage and the entry-level motion-enabled Vortex Edge Max. Both simulators are deploying CM Labs’ full catalogue of earthmoving and lifting equipment, including the recent release of their boom truck simulation training pack.

In addition, attendees were able to experience CM Labs’ newly expanded excavator simulator training pack, which includes

tiltrotator and jackhammer attachments. This training pack integrates with the Trimble Earthworks Grade Control Platform, now available with the dozer and motor grader training solutions. During operator training sessions, all information is captured by the simulator and pushed to an Instructor Operating Station (IOS). The IOS supports trainers with objective reporting on key metrics related to safety violations and efficiency, which provides valuable insight into the operator’s true capabilities.

www.cm-labs.com

Topcon says that its new

Data on the compaction

Leica Geosystems, part of Hexagon, says that its Leica iCON gps 160 package is a next-generation construction Smart Antenna with features that increase productivity for stakeout and measurement applications on the jobsite.

The Leica iCON construction portfolio offers a broad range of Smart Antennas to suit all applications according to the firm. The Smart Antennas are said to be able to withstand challenging site conditions. The units integrate with all Leica iCON construction instruments and controllers as well as the iCON field software for precise, real-time verification.

The iCon gps 160 is a versatile solution for various applications. It can be used as a base station, a rover or for machine guidance. The Leica iCON gps 160 is an improved version of the successful Leica iCON gps 60. The result is a smaller, more compact GNSS antenna with additional features and a larger display for ease of use.

www.leica-geosystems.com

www.topconpositioning.com

Indeco, one of the first construction attachment manufacturers to embrace digital transformation and 4.0 technology, is demonstrating its new Indeconnect remote monitoring system.

Indeconnect, using the Internet of Things and 4G technology, runs through sensors mounted on the various attachments. The cloud-based web platform is accessible from a mobile app or a PC.

The system allows a machine operator or fleet manager to consult the data

transmitted in real time by each installed device to see hours of work done, working position in space, hydraulic oil temperature, ambient temperature and GPS location.

According to Indeco, an Italian manufacturer of hydraulic breakers, this makes it possible to monitor productivity, control the operation of equipment, increase safety, predict and plan maintenance and manage any rented equipment.

https://indeco.it

Topcon is now offering a machine control package developed for use with compact equipment such as mini excavators and skid steer loaders. The package comes with a screen in the cab as well as a survey pole, allowing users to make simple site surveys and then load data directly into the machine. John Downey from the firm commented, “It’s aimed at use with small contractors or for utilities works.”

Productivity and quality can be improved using the system as operators can work closely to job specifications, allowing jobs to be completed more speedily and without a need to carry

Doosan is launching its new generation XiteCloud ‘all-in-one platform’ for smart construction under the company’s ‘Powered by Innovation’ banner. In 2019 in South Korea, Doosan introduced the Concept-X, unmanned automated and integrated control solution for construction, quarrying and mining sites. XiteCloud is the first stage in commercialising Concept-X.

Doosan says the launch of the new-gen Xitecloud platform is part of the further expansion of its business portfolio into the field of construction site management, to complement its existing operations in manufacturing and sales of construction equipment.

With XiteCloud, a customer can manage

multiple tasks such as surveys, terrain analysis, machine purchases, equipment operation and construction management on a single platform. Doosan says this reduces construction costs and saves time, while increasing work accuracy, which in turn raises productivity. XiteCloud is also claimed to allow customers to manage multiple projects on a single platform, accumulating and managing data that can be utilised for future decision-making/business.

The platform introduces a range of new solutions that form part of the XiteCloud, covering many aspects of construction management, including XiteCore, XiteFleet, XiteAnalyst, XiteSIM, XiteSafety, and XiteAuto. www.doosan.com

www.trimble.com

out reworking. The system allows work data to be recorded accurately from jobs such as repairs to utilities, meeting the latest requirements for digital records of work carried out. Downey commented that digital workflows are mandatory in Japan for all construction works for example. The system has been available for six months in Japan and he said that it is proving popular with smaller contracting firms due to the need for accurate digital recording of job data.

www.topconpositioning.com

John Deere Power Systems is introducing two new engines, the JD14 and JD18, which have been designed from the ground up. These engines have capacities of 14litres and 18litres respectively and meet Stage V and Tier 4 Final emissions requirements for Europe and the US.

Engine specialist from commented, “The 14 and 18 are the next generation of engines from us. They’ve been developed with a focus on serviceability and have the latest

diagnostics.” He explained that that the diagnostics

predictive maintenance capabilities, catching potential faults before they develop and in maintenance costs while also preventing unplanned downtime.

He said, “We have our telematics gateway and if you opt in, the dealer is able to call you even before you know there’s an issue.”

Meanwhile, the wiring harnesses are all external to

the engines making them easier to maintain and also less vulnerable to damage. Customers are also able to

aftertreatment package for the

required and a further reduction in maintenance costs. These engines are biofuel capable and on HVO.”

www.deere.com

Berco, a global producer and supplier of undercarriage components for many of the world’s main manufacturers of tracked earthmoving machinery, has launched Berco Aftermarket.

Berco says the new company exclusively serves the aftermarket requirements of construction machinery worldwide, except for North America. This region will be covered by Berco of America, a standalone company 100%owned by Berco.

Piero Bruno, chief executive of Berco, says the quality and performance of the company’s many components found in original equipment machinery will now be available for the replacement parts industry.

At the same time, Berco Aftermarket plans a significant extension of its current product portfolio – far beyond the existing

Service Line – to include many other undercarriage-related components. As part of this strategy, the new company is running its recently opened 12,000m² warehouse in the northern Italian city of Bologna.

There, Berco Aftermarket will be partnering with Gruber Logistics, a transport company with expertise in moving heavy loads and special cargo worldwide. www.berco.com

As part of the company’s enterprise strategy to support customers during the energy transition to a lower-carbon future, Caterpillar is developing 48V, 300V and 600V batteries for the off-highway industry.

Leveraging expertise across the US construction, quarrying and mining equipment giant’s global network of technical centres in the US, UK, China and India, the programme focuses initially on battery solutions for equipment used predominantly in industrial applications.