6 minute read

HINO IS PUSHING THE ENVELOPE

by Prime Group

With the introduction of the updated 300 Series range, Hino is pushing the envelope on what light duty truck buyers can expect as standard on a truck that they buy.

Hino has delivered a new level of features and performance at the lower end weight range with the release of its 300 Series light duty truck. The new range features what Hino terms as SmartSafe – a comprehensive safety package with advanced driver-assist technology that takes an active focus in protecting the life of drivers, passengers and other road users.

This launch continues a number of initiatives which Hino has taken in recent years to stay ahead of the game. The truck maker has long been the number two in sales in the Australian truck market and continues to outrank its rivals, especially Isuzu, at every new iteration of its models.

As we saw with the new 500 Series last year, Hino has access to all of the latest sophisticated safety systems from the Toyota catalogue and is introducing state-of-the-art safety systems to keep the models ahead of all of their Japanese rivals in electronics sophistication.

The kind of equipment now being included in a small Hino truck is comparable to the kind of safety system we are seeing fitted in the latest top of the range European heavy duty prime mover, where the development costs of such systems can be absorbed into the cost of a much more expensive bit of kit.

“Hino SmartSafe includes a PreCollision System (PCS) with Autonomous Emergency Braking (AEB), Pedestrian Detection (PD) and Lane Departure Warning System (LDWS), in addition to the already extensive list of standard safety features such as Vehicle Stability Control (VSC) and Reverse Camera,” says Daniel Petrovski, Manager of Product Strategy for Hino Australia.

“At Hino, we have lifted the bar in regards to the standard safety specifications that Australian customers should expect from a Japanese-built truck. Starting in 2011, the Hino 300 Series was the first Japanese-built light duty truck to include the life-saving feature of VSC.

“Similarly, Hino was also the first Japanese manufacturer to offer VSC and PCS in the medium-duty market, with the launch of the new 500 Series Standard Cab in early 2019. It should come as no surprise that we have continued with this trend, by introducing Hino SmartSafe and choosing the most comprehensive safety package available for our new 300 Series models.”

The Pre-Collision System has a forward facing camera and radar to detect potential collisions with another vehicle, or a pedestrian. It continuously scans the road in front of the truck and is particularly useful in avoiding nose-to-tail collisions.

The PCS detects the vehicle ahead and an algorithm continuously calculates risk of a collision and will warn the

driver both audibly and visually if a collision is deemed to be likely. In the eventuality of the driver not reacting to the warning, PCS can apply emergency braking to reduce speed and avoid a collision.

Other safety features include dual SRS airbags, four-wheel ventilated disc brakes, and UN ECE R-29 cab strength certification.

The inclusion of this safety suite does up the ante in this sector of the truck market, but from the outside, the trucks look little changed with an update on the grille giving the game away, hiding the fact that there is a lot more going on under the skin.

IMPROVED PERFORMANCE As Hino releases the new 300 Series Light duty truck, there is also an improvement in performance from the new trucks, with a new model being introduced for those looking for even more oomph. Hino claims to offer Australia’s most powerful Japanese-built light duty truck range and this claim has been further advanced with the

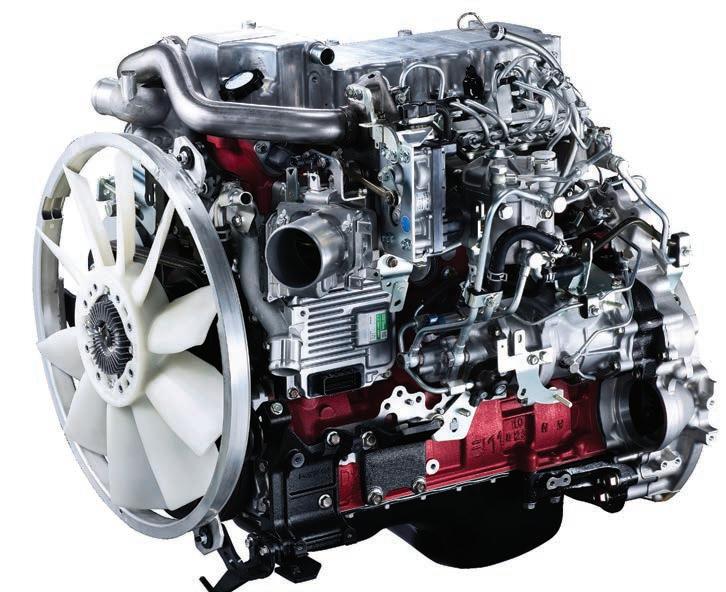

The 721 is fitted with the five litre J05E-UJ engine with 205hp (151kW) on tap with 600Nm (442 ft lb) of torque.

introduction of the new 721 model.

The 721 is fitted with the 5-litre J05EUJ engine with 205hp (151kW) on tap with 600Nm (442 ft lb) of torque. This power unit is matched to the six-speed double overdrive automatic transmission, with a towing capacity of 3.5 tonnes.

The range also includes the current 4-litre N04C engine which puts out 150hp (110kW) of power, with torque rated at 420Nm (310 ft lb), also available coupled with the automatic transmission. This is the engine choice in the 616 models, which come in standard, wide and crew cab variants. These models can also be specified at a car license GVM of 4.5 tonnes or a light rigid licensed 5.5-tonne GVM. If the 616 model is specified with the manual option, also a six-speed double overdrive box, the power rating available is higher at 165hp (121kW) with 464Nm (342 ft lb) of torque on tap.

There are also four models available as a hybrid. Hino is still the only truck supplier of this technology in Australia and the company is set on persisting with it. The four models are the 616 standard and wide cabs, the 716 wide cab and the 916, which has a GVM of 8.5 tonnes, taking it into medium duty truck territory.

Technical changes to the hybrid system have seen the engine go to Euro6 emission levels by using improved fuel injection, EGR, a DPF and SCR. The battery in the new truck is around 25kg lighter than the last generation. Hino does not expect to increase the numbers sold, which currently run at around 50 per year.

On the new hybrid, the common-rail injected engine produces 150hp and 470Nm of torque, which is delivered, in combination with the electric motor, from as low as 1000rpm.

“When maximum torque is available at such low rpm, fuel use is minimised,” says Daniel. “The revised automated

Inside the cabin the driver now has access to the multimedia unit introduced by Hino in the 500 Series launch last year.

transmission is now a six-speed instead of the five-speed in the previous model and is coupled directly to the electric motor.

“The additional gear and the wider ratio spread enable the engine to spend longer in its most efficient rpm, resulting in maximum driving efficiencies. The hybrid system continuously seeks to supplement the diesel power delivery with electric power into the driveline. It is constantly switching between diesel engine drive only; a combination of both electric motor and diesel engine drive; and can also use electric drive only in certain situations.”

Inside the cabin the driver now has access to the multimedia unit introduced by Hino in the 500 Series launch last year. This includes a 6.5 inch touch screen which gives the driver access to the high level of functionality available.

The system can be connected to four cameras, as well as a full suite of radio, music streaming and phone connectivity. The system runs on the Android platform and many apps are currently available. More should come on stream in the future, which can run or monitor various functions in the truck or for the driver. These include items like connections to tyre pressure monitoring systems. Further options can be expected to appear in the next couple of years.

Overall, most of the changes to the 300 Series introduced this time around by Hino are little more than an update. However, it is the introduction of a comprehensive suite of cutting-edge safety systems which tells us this is more than just a facelift. It is a statement of intent from the Japanese truck maker.

These changes also make this new model launch a likely precursor to many truck launches we may expect in the future. It is likely that the number of changes in the hard metal of a truck will become less important, while a major step forward may simply be upgrading electronic hardware, or software. Or even improved integration and co-operation between existing systems.