14 minute read

GETTING ANIMAL WELFARE RIGHT

from Diesel November 2020

by Prime Group

There have been many initiatives in recent years aimed at improving animal welfare in the livestock transport industry. Tim Giles visits a groundbreaking training course which is getting the message out to people working in this sector.

The entire supply chain for the livestock industry has a responsibility to ensure animals suffer minimal stress throughout – from handover from the stock owner to the transport operator and then to the saleyards manager, livestock agents, stock persons and abattoir personnel.

Goodiwindi Regional Council were hosts to a new initiative’s pilot program, alongside Frasers Livestock Transport and the Queensland Trucking Association, with the aim of improving transport practice.

Not only has there been increased emphasis on animal welfare from authorities over time, but the livestock industry is realising that poor practice in handling live animals results in a lower performance by those animals, when being prepared for the abattoir. Improving the practice is in overall interest to the livestock transport industry, as it will eventuate in a win-win situation. The animal welfare advocates will see an improvement and the livestock industry will see improved productivity per animal.

Surveys have shown that poor practice in handling animals results in increased health issues, such as injuries, feet issues, bruising and animals not feeding properly. Increased mortality rates have also been identified in groups of animals which have not been treated in the best manner. Plus, at the end of the long supply chain, poor animal handling practice leads to a lower quality meat on the table of the consumer.

A series of livestock transport workshops were held at the Frasers facility in Goondiwindi recently and drew a number of personnel who work with animals in the supply chain to learn from the experts about efficient handling of stock.

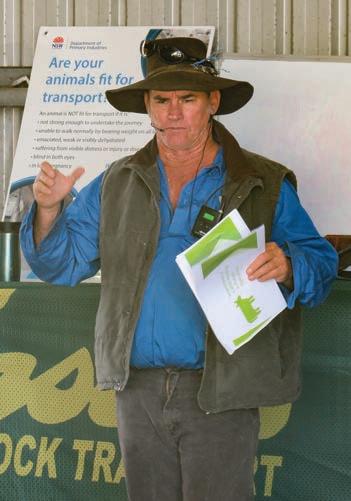

The mentor brought in by the workshop was Tom Shephard, a well -known stock handling expert, whose life’s work has been in improving the human to livestock

The mentor brought in by the workshop was Tom Shephard, a well -known stock handling expert.

interface.

Those attending were reminded that producers will use livestock transport companies that they trust to handle their livestock in the best way. Poor animal welfare practices may well result in a loss of business for the livestock transporter who does not keep up to speed with the latest animal welfare guidelines and protocols.

On average, livestock will travel over 500 km from the farm gate to the eventual processor. This journey can involve numerous stops and transfers between feedlot, saleyards and vehicles, especially when there are different livestock loading regulations across state borders.

Demand for beef continues to rise and industry has to work hard to keep its efficiency up to the levels which will enable it to handle the task as it grows. This has led to the increasing use of high productivity combinations to haul animals around the country. These larger combinations present challenges for the saleyards, abattoirs, feed-lots and livestock transporters when the task of loading a number of trailers is taking place.

Precise rules around animal welfare can be hard to define as there are different perspectives in the food supply chain. However, most of the rules can be boiled down to the fact that those who are handling the animals have a responsibility for their care and must insure they are free from distress and are content.

The globally recognised standard for animal welfare is often talked about in terms of five freedoms. These include freedom from hunger and thirst, freedom from discomfort, freedom from pain, injury or disease, freedom to express normal behaviour and freedom from fear and distress.

Apart from the ethical considerations and legal requirements, the customer expectations on the issue of product quality is also very important when talking about animal welfare. This was the message which was brought home by Tom Shephard when talking to livestock handlers during the course.

Setting out all of the details of how to handle animals in a book of rules is not the best way to get the message across to those working with animals on a day-to-day basis. This is why the series of courses have been organised around this issue.

The important part of the training involves some hands-on experience while being mentored by Tom Shephard. There is a mob of cattle in the yard for trainees to work with as Tom guides them through the process of minimising stress and worry for animals being shifted.

During the day, Tom goes deeper into the psychology of the cow and the psychology of the relationship between livestock and human beings, instinctively perceived by cows as predators. He outlines technical information about the eye line and vision of the animals and how moving into different parts of the cattle’s vision will induce different behaviour on the part of the animal.

Many of these factors are well known to people who handle cattle in their line of work, but his explanations give an empirical value to some things which people working with cows already know by instinct. He goes into detail about how herding animals have evolved as prey and that the basic instinct driving most of their behaviour is to escape.

There was also a discussion about the social order within a group of cows. He discussed how when animals are being moved about they end up forming into groups and those groups have to re-establish their social order before they can function normally.

Throughout his talk, Tom constantly goes back to the assertion that the calmer an animal is then the more responsive it is to handling, if that handling is done correctly. Cattle are also very aware of their personal space and different types of cattle have different personal spaces, this area can also vary with the number of cattle in the group.

He also goes into the point of balance, which is somewhere just behind the animal’s shoulder. If a human being is at that point of balance, the cattle will remain calm and be easier to control. Move in front of the point and the cow will slow, go behind and it will speed up.

One of the most important aspects of this point is the distance away from the animal. Come too close and the cow will feel pressured, closer and it will want to run away, and closer still, it will turn and fight.

Getting into the subtleties of working with animals, Tom discusses how people can develop their relationship in a situation which can often be fraught for the animals. He recommends looking clearly at the eye and learning how to read the animals expected behaviour from that eye to eye contact.

Talking to the participants, many of whom have been work handling cattle for some time, they appear to be getting reassurance from the material they were being given. In some ways it showed them that what they have been doing, in the main, is right. It also gave them an explanation about how some of the things that they are doing actually work from the animal’s point of view.

Furthermore, the session showed some of the mistakes they can make in a situation

and explained to them, simply, how they

The important part of the training involves hands-on experience with a mob of cattle.

can improve their performance, as well as how to get better behaviour from the animals that they are handling on a day-today basis.

This masterclass in the moving of a mob of cattle from one yard to another, or onto a vehicle with minimal stress occurring for both the cattle and for the handlers ,seemed to give those taking part a much better understanding of why they do the things they do and what things they should avoid doing.

It is events like this one in Gondiwindi which will help in the cultural change which is needed throughout the livestock industry. The excuse that, “This is the way we always used to do it,” is no longer applicable. The knowledge is there to help improve welfare and the overall productivity of the livestock industry. More initiatives like this and more government funding, which helped set the workshop up, will not only improve welfare outcomes but also business outcomes for those involved in transporting cattle.

TAKING THE HYUNDAI MIGHTY TO THE NEXT LEVEL

The introduction of an Allison automatic transmission has taken the Hyundai Mighty to new heights, with the truck now able to compete toe-to-toe with its strong Japanese competition.

The light duty truck market in Australia is completely dominated by the big three Japanese truck makers, Isuzu, Hino and Fuso. These three brands set a very high standard to which any serious contender in this market sector must aspire and, to a certain extent, exceed.

This is the task that Hyundai trucks has decided to take on. Examples of the light duty trucks from South Korea have been around for some time, but numbers and market penetration have been limited. Hyundai declared its intentions to become a more important voice in the truck industry when it introduced the heavy duty Xcient last year. This was not the action of a fly-bynight truck importer, but instead, a brand making a serious attempt at credibility.

Now, Hyundai have overcome one of the problems which was holding the brand back from selling large numbers in the Australian light duty market, namely, the lack of an automatic transmission with credibility. By introducing an option for the Hyundai Mighty to be fitted with an Allison automatic transmission, the market should become much more open to suggestions from the Hyundai brand.

The Hyundai Mighty does come in four separate models. There is the EX4 with a GVM of 4.5 tonnes, the EX6 with a GVM of 6.5 tonnes, the EX8 with a GVM 7.8 tonnes and the EX9 with a GVM of 8.5 tonnes. This selection of models fit into the four main categories of the light duty segment, without offering a complete range across all of the options at this size and weight.

The Mighty range is powered by the 3.9 L Hyundai engine which comes in two power options. One is the 140 hp(103 kW) engine with maximum power available at 2700 rpm, and the other is available at 170 hp (127 kW) with maximum power at 2500 rpm. Maximum torque of 392Nm (289 ft lb) is available at 1400 rpm on the lower power rating, whereas it is available at 608 Nm (448 ft lb) on the higher horsepower engine.

When it comes to transmissions, there is a five speed synchromesh manual gearbox at the lower hp rating and a six speed synchromesh box at the higher power. The important factor behind this test drive, however, is the use of the 1000 Series Allison automatic transmission in these trucks. When an Allison auto is fitted the engine will always be the more powerful of the two options.

Previous experience with these Hyundai trucks has shown that the basic design, driveline and finish of the Hyundai product is a match for its competitors in the market. This test, which was conducted in and around the suburbs of Brisbane was essentially to assess how well the installation of a fully automatic Allison has been done, and how much it improves the performance of this truck.

Trucks in the light duty segment 15 years ago only ever offered a basic manual gearbox. But times have changed, and the fact that trucks are generally working in metro areas in very busy traffic, combined with a lowered skill level of drivers, has led to the growing preference for a fully automatic transmission in this sector.

In fact, the Allison has grown in popularity all the way across the light duty and medium duty sector of the truck

market. There is still a part of the market, which is extremely price sensitive and will always choose the cheaper manual option, but the improved performance of the latest generation of Allison autos and the reduced maintenance costs associated with an automatic gearbox protecting the driveline has won many truck buyers over.

Chosen for this particular test was the Mighty EX6, fitted with the refrigerated body which is also a Hyundai product. The complete vehicle is imported directly from Korea with a Hyundai refrigerated body already fitted.

The truck was fully loaded and taken through a particularly hilly route in order to test the mettle of the Allison and its installation. When looking at a truck which will be doing this kind of work, the ease of use and the ability to handle all of the situations which may arise in a day’s work have to be assessed. This truck has to be easily driveable for someone who’s only previous experience will have been driving a car.

This is where the Allison comes in, it is a transmission designed to cope with the stresses and strains of hauling a reasonably heavy mass around, but also to be simple to use for the driver. They need simply to be able to get into the truck, hit the accelerator and go, and then press the brake in order to slow down and stop, and that’s it.

Climbing into the truck, it does feel quite familiar. This looks like a welldesigned interior with a modern looking dashboard and up-to-date controls. The steering wheel does feel quite small but is extremely modern with a vast array of buttons available. This is the latest trend from the heaviest trucks down to the

The quality of the fridge body fitted was good, with the Hyundai badge stamped into the metal on the top corners of the box.

lightest, a confusing array of switches available to the drivers thumbs as they rest their hands on the steering wheel.

The experience of starting up the truck and setting off down the road is reassuring. This truck has a solid well-finished feel. The steering is positive and accurate, the pedals are well positioned, with a responsive feel.

In recent years, we have become used to the Allison transmission hitting all the right notes in its installation, and it is no different here. The truck is always in the right gear and able to cope with everything thrown at it. Some of the road junctions in the Western Brisbane suburb of Bardon can be quite tricky, especially in a manual truck.

A T-junction on a steep climb with a stop sign requires good handbrake and clutch control, when the truck is fully loaded. This truck sailed up and around the corner without missing a beat, we expect no less from the Allison 1000 Series, these days.

The communication with the rest of the truck works well. The driver simply

The steering wheel does feel quite small but is extremely modern with a vast array of buttons available.

activates the engine brake and the Allison immediately goes down one or two gears to get the rpm levels up to the point where the engine brake can actually be effective, and not just make a different engine note.

In terms of manoeuvrability, the trucks scores well, with a neat turning circle, comparable to anything else in the market and vital for a truck like this to get into tricky loading and unloading situations.

The price premium which has to be paid for the Allison transmission option will be a disincentive for some buyers. Sharper pricing would up the percentage of operators who opt for the auto transmission. The more the merrier in this case, the more customers who are impressed by the Allison fitment, the more word of mouth will get around about the overall quality of the Hyundai Mighty.

Looking at the truck driven on this test, it comes over as an altogether effective package. The fit and finish of the truck is excellent. The performance of all of the systems is a match for any of the opposition. The quality of the fridge body fitted was good, with the Hyundai badge stamped into the metal on the top corners of the box.

Hyundai seem to have got the product right. Someone looking to buy a light duty truck and testing this Mighty side by side with a N Series, 300 Series or a Canter would be able to put this truck into the same category.

The difference would be in the next step the Japanese truck makers are currently making, as they up the ante on state-ofthe-art safety and electronic systems. This, of course, comes at a price and maybe Hyundai can exploit the gap in costs with this truck. Or, we might see just how sophisticated the Koreans can get?