reduce the burden of work-related injury or disease for truck drivers and other transport workers.”

Details of a Monash University study released in November estimate 6067 truck drivers will die and $2.6 billion of productivity could be lost over the next 10 years if the current status quo in the industry remains.

Program Lead Associate Professor Ross Iles said Driving Health had earlier found that the health and wellbeing of truck drivers in general was poor, and a system-wide effort was needed from the transport industry to help drivers be healthy and stay at work.

A $4.90 breakfast of poached eggs on toast with spinach and tomatoes is proving popular with drivers Picture for illustration only.

The Monash University report, published in The Journal of Occupational Rehabilitation estimates inaction could cost about $485 million in healthcare costs and 21,173 lost years of life due to work-related diseases or injury among truck drivers.

The last full report released in 2020 found the transport industry contributed an estimated 7.4 per cent ($122.3 billion) of gross domestic product (GDP) to Australia’s economy in 2015-16 and employed about 380,000 workers.

The latest research project estimated the work-related mortality burden among truck drivers, using modelling to simulate the Australian male working-age population (aged 15-65) from 2021-2030.

Researchers used data from the Driving Health study and other published sources to estimate work-related mortality and associated productivity loss, hospital and medication costs. All outcomes were discounted by five per cent per annum.

Modelling showed that reducing the health burden by two per cent could result in savings of $10 million in healthcare costs and $53 million in lost productivity.

“Despite the importance of the transport and logistics industry to the Australian economy, workers are at a greater risk of work-related injury or disease relative to other industries,” the researchers found.

“Our analyses highlight the health and economic consequences of poor driver health over the forthcoming decade and highlight the need for interventions to

“What this part of the project adds is a clear economic argument for supporting driver health and wellbeing,” he said.

“If the current state continues, there will be an enormous cost, not only for the individuals concerned, but also for the Australian economy.”

“The Driving Health project found there is no easy fix, but this analysis shows that even a small improvement in driver health will lead to savings of tens of millions of dollars.”

Previous research has established that transport and logistics workers have worse health outcomes than those in other industries, especially musculoskeletal and trauma-related injuries.

They also have a high prevalence of cardiovascular disease, obesity, and hypertension, which has been attributed to long working hours, poor access to healthcare, exposure to physical and mental stress and other behaviours and occupational characteristics which contribute to poor health.

The new paper found that a collective national effort was required to improve the health and wellbeing of Australian truck drivers to reduce the burden of work-related injury or disease for truck drivers and other transport workers.

“To date, there are limited studies exploring the long-term economic burden attributed to poor health among transport workers, and a clear economic argument for improving driver health would provide a compelling case for a collective effort across industry,” the researchers found.

There are at least 6067 good reasons why more needs to be done to help make truck driving a healthier profession

Study co-author Dr Caryn Van Vreden said there were some efforts underway, but they were hampered by lack of funding and policy change from the government.

“Despite efforts to improve driver health by the industry, greater input from government and regulators is needed. This includes increases in funding and changes in policy to effect lasting change,” she said.

Driving Health is a multi-stage project aiming to profile the health and wellbeing of Australian truck drivers and to develop ready-to-implement strategies to help drivers to be healthy and stay healthy at work. To date the project has explored the health burden, as well as trends in health service usage attributed to truck drivers and other transport workers in Australia.

The challenge of helping truck drivers to find better nutrition is at the heart of a pilot program being championed by the Healthy Heads in Trucks & Sheds Foundation (HHTS) that launched in September of this year.

The Nutrition Pilot Program is endeavouring to educate, raise awareness and encourage longer-term healthy eating among truck driver and was developed in partnership with Nutrition Australia.

It came in response to poor health outcomes among drivers, in particular, Monash University data that highlighted that 70 per cent of drivers surveyed did not meet the guidelines for a healthy and balanced diet.

As at November 28 – participating service stations were:

New South Wales bp Beresfield, bp Eastern Creek, bp Jerilderie, bp Marulan Northbound, bp Marulan Southbound, bp Nambucca Heads, bp Parkes, bp North Albury, bp Potts Hill.

Northern Territory bp Darwin.

Queensland bp Aratula, bp Archerfield, bp Goondiwindi, bp Paget, bp Port of Brisbane, bp Toowoomba Westbound, bp Townsville.

South Australia bp Port Augusta, bp Wingfield.

Victoria bp Dandenong, bp Energy, bp Laverton North, bp Northpoint, bp Outbound Somerton, bp Rockbank Inbound, bp Rockbank Outbound, bp Truganina.

Western Australia bp Kewdale, bp Muchea.

Healthier food, and the chance to stop and chat with other drivers are all part of the Healthy Heads in Trucks & Sheds program

The most-tested Western Star ever, the all-new X-Series is seriously tough. Boasting our legendary Star durability, the X-Series features a powerful integrated driveline, advanced safety systems, and superior comfort - even in the most rugged of applications. But talk is cheap. Experience it for yourself.

The pilot program focuses on heavy vehicle drivers. It was originally scheduled to finish at the end of 2022, but its successful uptake has seen the pilot extended into the new year.

HHTS Industry Relations and Program Management director Melissa Weller says it’s all about providing the tools for drivers to use every day.

Weller says since the launch more than 1750 healthier choice meals have already been sold to drivers, with a subsidised breakfast of $4.90 poached eggs on toast with spinach and tomato proving a popular hit among the driver’s social media pages too.

She says another plus with the popularity of this sort of meal is that drivers are ordering it, then taking a break in the truckies lounge to sit down and eat it freshly cooked, where they have access to further information if they want it, but also just some time to refresh and catch their breath before jumping back in the cab.

The aim of the program is to raise awareness about healthier food choices and the benefits they can have on both physical and mental health outcomes, without going over the top. There are hints, advice and information available for drivers, and work sites, on the Healthy Heads app that are downloadable and shareable – focused on small changes over a long time.

To accompany the health information, 29 bp service centres across Australia are offering freshly cooked healthier meals, 24 hours a day, with a menu that has had input from Nutrition Australia and attains the green tick of health.

Nutrition Australia CEO Lucinda Hancock said good food could help with both physical and mental health.

“More than three million Australians are living with anxiety or depression,” Hancock says. “Research shows that by changing the food we eat, we can have a significant positive impact on our mood and mental health.

“The pilot aims to increase the driver’s awareness of healthy eating and influence their eating behaviours more broadly. By making small changes to what we eat on a day-to-day basis, we can reap many positive health benefits.”

Weller says the long-term goal is to roll out a national program that spans across the broader logistics industry, including warehousing and distribution centres where the groups could continue to share educational information, but also, have some influence on-site canteen suppliers and increase access to healthier foods.

Rated to 60 tonne and boasting a Jost fixed turntable this 2019 Volvo FM is being sold with a full service history and 3 month / 50,000km driveline warranty.

With 450hp to play with thanks to a Euro 5 engine the truck also offers a full sleeping berth and the Volvo Automated i shift 12-speed transmission.

With a tradition of pushing the limits and setting new standards in driving innovation, the comfort, fuel efficiency and durability of this Swedish giant are worth a look.

For more information call SelecTrucks of Melbourne on 03 8373 7112.

Whatever the season demands you rely on improved Castrol RX SUPER to get things done.

Upgraded CJ-4 specification combats soot and gives critical moving parts a tougher protective layer.

New DuraShield BoostersTM giving up to 40% better protection against wear*.

Improved Castrol RX SUPER - as versatile as you are.

* average of wear parameters in industry standard tests vs. industry test pass criteria.

AAATRAILERSFLATTOP 2022,curtainside.S51. TA1149707. $92,200+GST

AAATRAILERSDROPDECK 2022,curtainside.S53. TA1149710.

$108,000+GST

AAACONCRETEPANEL TRAILER 2022,NEW,paneltrailer.S26. TA982460.

$89,000+GST

AAA45'FLATDECKTRAILER WITHPINSANDAIRBAG SUSPENSION 2022,NEW,semiwithpins. HSD553. TA811006.

$70,000+GST

AAAAAA40'3WAYLIGHT WEIGHT4.6TSKELETAL TRAILER-EBS 2022,NEW.S31. TA1038471.

$45,500+GST

AAATRAILERSFLATTOP 2022,curtainside.S52. TA1149708.

$99,000+GST

AAATRAILERS45'DROP DECK curtainside.S54. TA1149711. $115,000+GST

AAAQUADAXLELOW LOADERWIDENERWITH BI-FOLDRAMPS 2022,NEW 2.5-3.5M.S25. TA948716. $119,000+GST

AAATANDEMAXLETAG TRAILER-EBS 2022,NEW.S33. TA1051493. $47,000+GST

AAA45'LOWLOADERWITH RAMPSANDAIRBAG SUSPENSION 2022,NEW.G0011236. TA811018. $70,000+GST

AAA45'DROPDECKWITH

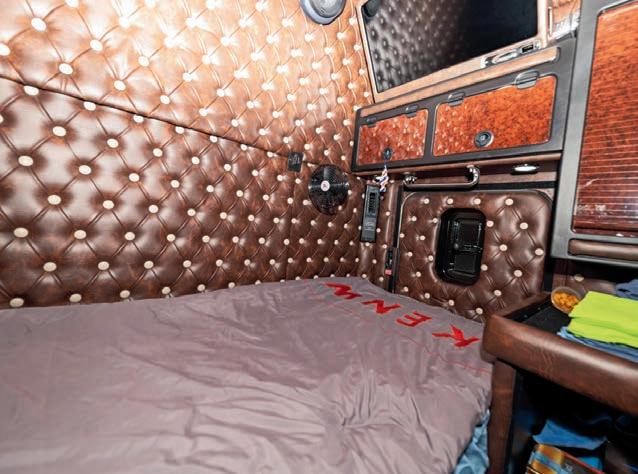

When the new model K200 landed in Australia in 2013 there was much excitement about the upgraded Cummins engine at the heart of the beast.

The classic Kenworth leather and wood styling remained in the cab, but under the bonnet, a more refined and efficient engine offered another reason to buy in.

This tipper variety, fitted with an 18 speed Eaton Fuller manual transmission, only has 726,680km on the speedo and all the kit to keep tipping for many years to come.

02 4721 7889

An MP8 engine generates 500hp that’s managed by an 18-speed Road Ranger gearbox.

The truck is being sold as a stand alone, although there’s an option to add a Hercules 2005 Super-Dog 3 axle trailer to the package for an extra $35,000.

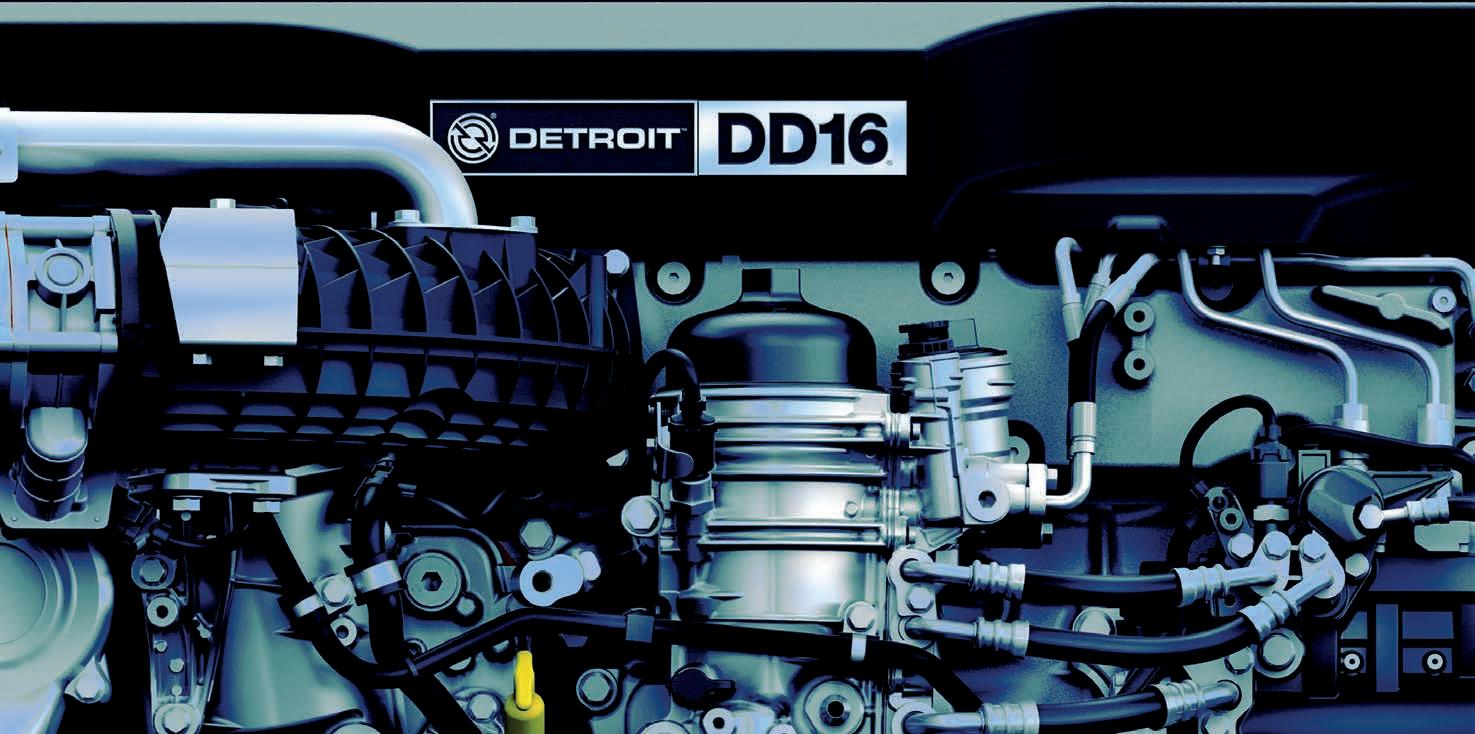

Detroit’s DD16 delivers all the power you need.

With up to 600 horsepower and 2,050 lb-ft of torque, the big bore workhorse provides efficient and dependable power and performance without compromise. Detroit’s advanced technology also means GHG17 requirements are met through innovative fuel efficiency resulting in lower emissions.

This power, performance and efficiency prowess is backed by our industry-leading warranty and extended coverage packages that ensures the highest level of support for our customers.

Combined with superior fuel economy and the absence of a midlife change out, the DD16 delivers an enviably low total cost of ownership and maximum uptime.

This is all backed by our well-established and extensive national service and support network which, together with our highly skilled factory-trained technicians, means you can count on getting the right advice when you need it.

With Detroit, there’s no compromise.

2004,the2004mackvision(sampleunitphoto)470h/p18speedg/box46/ 160diffswithxcross/locks,allon10studalloydiscwheels100%new rubber,fittedwithhightensilesheppardsteelbody4.50mx1200mm sideswithswingingtailgaterollouttarp(bodyasnew)fittedwithfull ringfeedermountsinextremlygoodcondition,revolvinglightscbradio comeswithqld/rwcreadyforrego.S170. TA1153744.

workready,justhadwheelalignmentdone,ondiscwheels, availableimmediatelycomeswithQLDRWC.S157. TA1141082.

2004,HEAVYDUTY.160-200tonrating.CAT/C16600hp,(RECENTREPAIRSTOMOTOR).18/speedMackheavy duty.Maxitorquegearbox.Onhubreductiondiffswithcrosslocks,onNewwayairbagsuspension.Allon10stud discwheels,alloy/polishedonfront,100%newrubberallround.Longrangefueltanksfitted,ptopumping combo/suitableformultitipping.Powerseats,radio/stereo/c/dplayer/CBradioetc.Heavydutyalloybullbar, recentrespraytochassis,veryclean&tidyunit.Mackmediumriseheavydutysleepercab,dieselicecoldpack fitted.Veryhardtogetthisquality&capacityunit.S129. TA1081077.

2003,18speedroadrangerg/box,CAT/C15,onNewwayairbagsuspension.Allon10studdiscwheels,Alloy/ polishedonfront.100%newrubberallround.Longrangefueltanksfitted,ptopumpingcombo/suitableformulti tipping.Powerseats,radio/stereo/c/dplayer/CBradioetc.Heavydutyalloybullbar.4x4DECKWIDENER&2x4 DOLLYASUNIT,fullyreconditioneddollyconvertor.The4x4hadrepairstobrakeswheelbearingssuspension, ramps&newHondapowerpack,itwillbeabletocarryinexcessof50tons,runningondiscwheels,comeswith qld/rwc,tyres80%+opensfrom2,50mto3,50.m.Thisisworkready.S161. TA1147863.

90tonrated,2003Volvoprimemover.14speedgearbox,volvodiffs.coupledto3x42006tagalong deckwidenerondiscwheels265x70x19.50tubeless.recentrepairsonfloatwithRWC.Complete unit.$175,000+GST+ORC.S162. TA1147864.

460hp,90tonrated4x4+2x4primemover.14speedgearbox.Allingoodcondition.Justbackfrom darwincoupledtojrm4x4dollydeckwidennglowloaderonairbagsuspension.Widensfrom2.5-3.5m. On9.75x7.50tublessdiscwheels.Newhondapowerpackforhydraulics.Coupledto2x4dollytosuit. Fullrebuildon2x4dolly..S167. TA1147865.

An automatic 2016 Fuso Rosa Bus has arrived at our Dealership. Finished in white, this bus is a ready to work. Well equipped examples such as this are often hard to comeby; especially in this condition and at an outstanding price, in addition, this vehicle comes with the following value adding features: Braun ability usa designed 363kg electric wheelchair lift, removable rear seats with the ability to seat 23 able bodied people or 19 + 1-2 Wheelchairs. T611978. TA1146549

In this issue

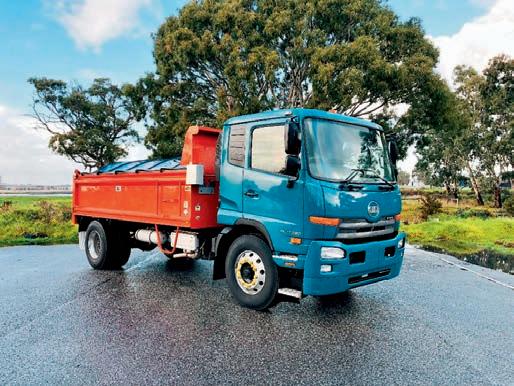

The owner of a major quarry material supplies business based in Wagga Wagga has added its first Fuso to its 14-truck fleet.

Alec Creasy, who has grown the Robbo’s Sand and Truck Hire business since purchasing it in 2013, was encouraged to switch from American-style bonneted trucks and try a Shogun by long-term contact David Warren, the dealer principal of Daimler Trucks Albury and Wagga Wagga.

Creasy says once he started to weigh up the Shogun 460’s price and the inclusive support package that came with it, the decision was straightforward.

“Ultimately, it was a business decision and when I looked at it, I realised that it was really something that I couldn’t go past,” Creasy says.

“One of the trucks I was shopping it against only has a 12-month warranty, so there is a big difference.”

The Shogun 460 comes with a manufacturer warranty that covers the truck for five years or 500,000km, whichever comes first.

Creasy decided to fit the Shogun with a body and tipper trailer made from Bisalloy steel, which is heavier but more durable than aluminium.

This way, the combination can be used for demolition cartage, which requires sturdier surfaces.

The steel body and tipper trailer weighs 500kg more than an aluminium equivalent, but the Shogun 460 combination still has a payload of 12.5 tonnes, a number that Creasy is very happy with.

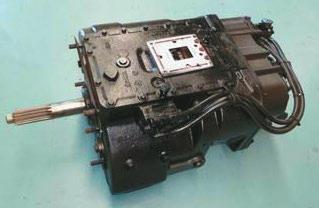

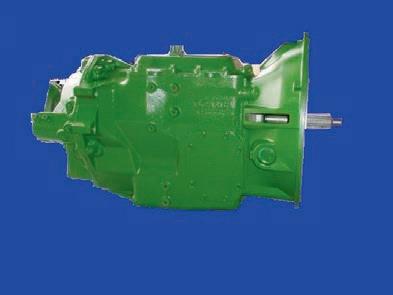

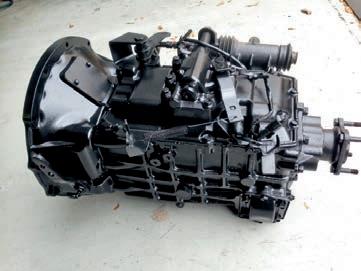

The Shogun 460 model uses an 11-litre six-cylinder engine from the Daimler Truck family, which also produces 2200Nm of torque. Sitting on the back of the engine is the latest generation 12-speed Automated

Manual Transmission, which features an easy-to-use low-speed mode.

Creasy says the Shogun 460’s engine and transmission work well together.

“The gearbox is nice and the performance is excellent. Fully loaded it will just go beautifully up through the gears, it doesn’t carry on at all,” Creasy says.

“It can turn really tight, which is very helpful in some of the sites we are getting in and out of.”

Like all Shoguns, the 460 model comes standard with a suite of advanced safety features including the latest generation Advanced Emergency Braking System (AEBS) that now uses camera and radar camera technology and completely stops for a moving pedestrian in the event the driver does not respond to an audible warning.

Radar adaptive cruise control is also standard, along with Lane Departure Warning System (LDWS), a driver airbag, Electronic Stability Program (ESP) and Hill Start System (HSS) assistance function continue.

Fuso has a full range of Shogun rigid models that are perfect for tipper bodies, as well as factory Built Ready Fighter and Canter tipper models. The Canter 815 Wide Cab Tipper and Canter 615 City Cab Tipper models can even be driven on a car licence.

Super sturdy tipper at home on the back of Fuso’s Shogun 460Robbo’s distinctive orange livery is a good match for the new Fuso The sturdy interior of the Fuso Shogun

Five Xcient Fuel Cell trucks from Hyundai will be tasked with hauling liquid hydrogen for First Element Fuel (FEF) in California thanks to a $3.5 million grant from the United States’ Environmental Protection Agency

The hydrogen trucks will replace five diesel trucks in the fleet of FEF, the largest operator of hydrogenrefuelling stations in the US.

The selection of the Xcient Fuel Cell demonstration project recognises the significant emissions reduction benefits of Hyundai Motor’s fuel cell electric truck technology.

The Xcient Fuel Cell 6x4 tractor model participating in the demonstration is equipped with a 180 kW fuel cell system and e-motor with a maximum output of 350 kW.

The tractor’s hydrogen tank can hold 67 kg of hydrogen, with the battery providing 72 kWh for a gross combined weight of 37,200 kg to deliver an average range of over 720 km per tank.

The trucks will be rolled out on a five-year schedule, with the first year forming part of a demonstration of the technology, with regular

reporting to the EPA, and the following four in a purely commercial capacity.

“Hyundai is actively engaged in setting up a carbon neutral hydrogen value chain around the world,” says Hyundai’s senior vice president and head of Commercial Vehicle Business Innovation Mark Freymueller.

“We are happy to deploy our Xcient Fuel Cell trucks in California, especially since this will help local stakeholders to decarbonise the hydrogen supply chain itself by substituting conventional trucks, which have been used to haul hydrogen – to hydrogen trucks.”

The project is led by the South Coast Air Quality Management District (South Coast AQMD), which applied for the TAG funding.

“This is where change starts. Reducing pollution from heavy-duty trucks and construction equipment brings us closer to the cleaner air that our communities deserve” says South Coast AQMD’s executive officer Wayne Nastri.

“We look forward to seeing this project come to life and deployed in Southern California.”

The EPA’s TAG program aims to

reduce air pollution in areas of the nation with the highest levels of ambient ozone and fine particulate matter (PM2.5) pollution.

Last year, Hyundai Motor also announced its NorCal Zero project, also known as Zero-Emission Regional Truck Operations with Fuel Cell Electric Trucks.

Hyundai Motor will begin operating 30 Class 8 Xcient Fuel Cell electric trucks in California starting in the second quarter of 2023. This will be the largest commercial deployment of Class 8 hydrogen fuel cell electric trucks in the US.

Launched in 2020 by Hyundai Motor, Xcient Fuel Cell is the world’s first mass-produced hydrogen fuel cell electric heavy-duty truck.

The company has already deployed 47 trucks in Switzerland where they have accumulated more than four million kilometres of driving as of July 2022.

Hyundai Motor will leverage insights from these public-private partnerships to further drive commercial vehicle decarbonisation through hydrogen fuel cell electric technology advancement.

The Land of the Long White Cloud may soon by the land of the MAN too as Penske unveils its latest trucking models

Penske New Zealand has welcomed the all-new MAN truck generation (TG) to the New Zealand market.

The introduction of the new TGL, TGM, TGS, and TGX truck ranges to New Zealand are the first MAN trucks designed from the ground up in 20 years.

With more than 167,000 hours invested by MAN Truck & Bus in the design of the all-new truck generation, MAN says drivers will realise the ultimate package.

Awaiting drivers inside the cab is a modern and streamlined experience, including the intuitive dash layout, multi-function steering wheel, advanced infotainment system, and SmartSelect navigator.

MAN’s innovative driver assistance features, such as adaptive cruise control, steering wheel airbag, cabin safety cell, emergency brake assist, lane departure warning, and more, ensure drivers have all the systems they need at their fingertips.

Delivering great efficiency and economy, MAN says the new TG takes customers further with an

economical range of engines. From the 220 hp D08 engine powering the TGL to the 640 hp D38 engine powering the TGX, MAN says its range of Euro 6 engines has the ideal solution for every application.

Utilising software to determine the optimum moving off and gearshift strategy, the Tipmatic gearbox has load and inclination detection, ‘SmartShifting’ and ‘idle speed driving’ functionalities.

Efficiency is further improved with the most powerful engine brake on the New Zealand market at 840 hp on the D38 engine.

These advanced features within the cabin and powertrain are complemented by highly reliable and fully integrated technology that delivers optimised uptime. Extended oil drain intervals and low tare weights yielding higher payload availability increase productivity and profits for customers.

All this is further backed by Penske New Zealand’s national MAN dealer footprint and MAN’s 24/365 support program,

The new eActros is expected to reach our shores next year

customised repair and maintenance packages and warranties.

“We are thrilled to welcome the all-new MAN truck generation to the New Zealand market and introduce our customers to this superior portfolio,” says Penske NZ general manager Brent Warner.

“We are offering eight different cabin configurations from the crew cab that seats up to seven to the super spacious GX cab. And the D08, D15, D26, and D38 engines are all Euro 6, delivering power that is reliable and highly efficient.

“Close attention has been paid to ensuring the specifications are ideally suited to our New Zealand conditions, including tyre and diff ratio selections to optimise performance and economy for our unique terrain.

“We’re also excited to be offering, for the first time, a down-line factory 8x4 model specifically for New Zealand.

“We look forward to hearing the thoughts of our existing MAN customers and our new customers as they step into this truck generation and experience it for themselves.”

while offering a weight advantage of 185kg over the previous generation DD15 in the legacy Western Stars.

Offering 500-600 hp and 1,8502,050 lb-ft of torque, the DD16 is engineered for greater reliability than ever before.

The engines both meet the latest GHG-21 fuel economy standards, conforming to the US EPA-10 emissions standard, as well as being ready for the pending Australian ADR80/04 regulation.

The engines are paired wth the DT12 automated manual transmission which has been subjected to 56 million kilometres of testing.

There’s more than just new chassis and body work on the new X-Series trucks launched with much fanfare by Western Star last month.

Underneath the bonnet, and in the cab, Detroit has contributed a new series of engines and cutting-edge technology in the form of the Detroit

Assurance suite of safety systems, Detroit DT12 automated manual transmission, and Detroit Connect vehicle services.

The DD13 Gen 5 offers 450-525 hp and 1,550-1,850 lb-ft of torque and is designed to deliver exceptional fuel economy and high performance

Available in DT12-OV and DT12-OVX variants, the 12-speed transmission boasts rock-free and off-road functions in addition to the on-highway focused economy and performance modes. It also includes a power launch feature and has side and rear power take-off (PTO) capabilities.

Penske’s Sean McLean with the trophy recognising the group’s 70 year partnership with Allison Transmission

McLean said the Allison products had been a part of the Penske business for a long time.

“It was an honour to be recognised for our milestone at the conference,” McLean said.

“The first in-person regional gathering since 2019, it was a valuable opportunity to connect with other distributors and to obtain updates on Allison’s current and future products as well as aftermarket support opportunities and initiatives,” McLean said.

“I felt privileged to accept this recognition on behalf of Penske Australia and our current and former employees who have dedicated years to supporting the Allison product and our customers.

When the distributors of the Allison Transmission portfolio of products across the Asia Pacific finally got together face to face after two years without a conference, the team at Penske were recognised for their 70 years of support for the brand.

Since the days of Detroit Diesel Australia, and MTU Detroit Diesel Australia, now known as Penske, the group has been making use of Allison Transmission products across Australia. Penske general manager of Dealer Capability and Technical Services Sean

“As Australia’s longest-serving Allison distributor, we have a well-established customer support network that delivers superior service that complements the high performance of the Allison on- and off-highway products we distribute.

“We look forward to continuing to extend our strong relationship with Allison for many years to come.”

Seven decades of excellence recognised

Back in 1939, UD Trucks founder Kenzo Adachi embarked on a 3000-mile odyssey to prove the ultimate dependability of the brand’s new vehicle.

Now, more than 82 years later, UD Trucks Australia is heading off on an Adachi-San inspired lap of the Australian continent.

UD Trucks says the dependability and reliability of the UD brand in Australia was established long ago, so as a result this journey is instead focused on the people and the faces that have become a part of the UD family since its inception.

Following Australia’s fabled Highway 1, the fully loaded UD Quon CW25 360 will circumnavigate the country, stopping in to visit customers and dealers over the course of the 15,000-kilometre journey.

“We feel that the quality of the UD product speaks for itself,” says Lauren Pulitano, vice president UD Trucks Australia.

“However, the Australian UD story is so much more than a tough dependable truck.

“UD customers and dealers around the country have been key to our success over the past nearly five decades, so this trip is both a homage to Adachi-San as well as a celebration of customer success and partnership.

“This is also a fantastic opportunity to showcase the comfort, economy and connectivity of the UD Quon.”

The team set off on their journey at the start of November, and they expect the Lap of the Map tour will encounter all the extremes in terrain and temperature that the Australian continent is renowned for.

From the towering forests of East Gippsland and Southwest WA to the searing heat of the Pilbara and the Kimberly, from bustling capital cities to dusty Wheatbelt towns.

Isuzu Australia reached the achievement of once again bettering its alltime truck sales record, attained just last year, with two months left in the calendar year, the company said it was thrilled to announce.

Despite economic and supply chain disruptions, Isuzu Trucks enjoyed a record-breaking year in 2021, setting a new high watermark of 10,175 truck deliveries at the end of December.

That trend has continued unabated with Isuzu’s internal sales figures indicating that the 10,175 mark was surpassed in mid-October 2022, producing yet another all-time sales record for the nation’s number one truck brand.

Isuzu says sales highlights include finishing September 2022 with 9,642 sales year-to-date in a 32 per cent increase in volume on this time last year.

Truck Industry Council market figures say Isuzu has increased market share, with now 29.9 per cent of all trucks sold bearing the Isuzu badge.

Playing a starring role in the unrelenting sales success is Isuzu’s

4,500 kg Gross Vehicle Mass (GVM) light-duty models, including the NLR, NLS, NNR, NPR and NPS variants.

“As an indicator of how well these models are being received by Australian businesses, we can see that in the month of September 2021, Isuzu delivered 310 units. Compare that to the same time this year and we’ve delivered 572 trucks,” IAL head of sales Les Spaltman says.

Other models that continue to strike a chord with Aussie workers include Isuzu’s newly updated 6x2 and 6x4 F Series range, including FVM & FVL, FVZ and FVY variants.

“We’ve worked hard to ensure that these models are continuing to tick the box for all manner of business operations, and especially in that freight and logistics task, which is in huge demand at the moment,” Spaltman says.

“We’ve raised the bar when it comes to safety, comfort and user experience across our medium and heavy-duty range, so it’s great to see consistent sales performance in this model group across the last 12 months.”

Keep an eye out for the distinctive UD as it rolls across the country. Follow the journey on TikTok and Facebook.

#UDtruckslapofthemap

UD Trucks is stepping back in time as it takes its UD Quon on a historical lap of Australia

Isuzu has smashed all previous sales records as it powers towards the end of the year

The Hyundai brand will complement the dealership’s existing offering of Iveco’s range of trucks with light duty cab-over models that will open a new market for the company’s services.

Hyundai has already gained a foothold in the WA transport industry and this new appointment is expected to accelerate the company’s development in the rapidly expanding last-mile delivery sector.

In particular, the factory-fitted steel trays, flat decks, Pantech, fridge, freezer and tipper bodies will overcome major delays in local bodybuilding availability.

Supply-chain opportunities aside, the Korean-manufactured bodies have a solid reputation for high quality and durability and can handle everything from 3 to 12 pallets and temperature from -20C to 4C.

The Allison 6-speed full auto transmission, which is available in the Mighty range up to and including the EX9, has certainly supported the growth of the brand in Australia.

Not to be outdone, ZF will provide a full automatic 8-speed transmission option on Pavise from mid-2023.

Hyundai also offers a five year 300,000km warranty as standard on both Mighty and Pavise models.

Hyundai’s General Manager Daryl Thornton says the new appointment reflects Hyundai’s longterm commitment to expanding the company’s range around Australia.

“Western Australia is a very important part of that expectation. AV Trucks are a good fit with our

Hyundai brand values and that’s important.

“As 65 per cent of our sales are with repeat buyers or referrals from existing owners, it’s good to know we’re working with an experienced team who understand the value of a customer.

“Our volume has grown 30 per cent on average year-on-year since 2019 and we know AV’s will take the brand to a new level in WA.”

AV Trucks was established almost four decades ago the dealership is still family owned.

Since opening it has represented Western Star, UD, MAN and International trucks for the broadest range of on and off-road applications, up to and including road-trains.

It has provided expert advice and services to countless truck owners and operators, matching their requirements for new trucks, used trucks, truck servicing, truck accessories and more.

Dealer principal Russel Davies said the entire team welcomed the opportunity to represent Hyundai to its extensive customer base.

“We are excited to expand our reach into the biggest sector of the truck market. The Hyundai product’s outstanding quality allows us to compete on equal terms with the three already established brands,” says Davies.

The business is strategically located in Redcliffe, with the Tonkin, Great Eastern, Roe and Leach highways in easy reach.

Presently AV Trucks provides new Iveco and used truck sales, allbrand maintenance and parts, and a fabrication workshop, together with the parts and warehousing facility.

As the new WA dealer for Hyundai Trucks, AV Truck Services brings a highly valued reputation of quality and customer service to the Hyundai brand. It’s in-house finance facilities and quality maintenance services are also recognised industry-wide for adding value for customers by minimising whole-of-life costs.

The sales team are experienced in developing corporate truck solutions for any size operation incorporating purchase/lease, fleet service contracts, buy-backs, insurance, and sub-contractor entitlements.

The workshop offers after hours bookings, 24/7 emergency service, electrical/aircon on-site plus multicombination access and the AV Trucks parts operation delivers multi-brand products and approved after-market options too.

The most familiar names in the transport industry - products from Alcoa, Meritor, Castrol, Caterpillar, CSA, Dana, Donaldson, Eaton/Fuller, Engel, Exide, Hella, Hendrikson, Horton, Lelox, Reddog, Stemco and Timken, to name a few, are all on-site.

The company supports a range of workshop services when customers require urgent, on-site rectification. Critical parts are supplied from Perth by air when required, and an ethos of maximising customer’s up-time underlines planning and response.

A

Truck leasing company TR Group has continued to expand in Australia, building on three decades of business in New Zealand.

In 2019, TR Group took its first step into Australia and the company has grown its fleet size from 1,300 trailers to 1,800 heavy commercial vehicles available for short and long-term hire.

In the subsequent three years, TR Group has also added new branches, from the original in Melbourne to locations in Brisbane and Newcastle, with more to come.

In New Zealand, TR has 4,500 lease vehicles in a fleet of 6,000 and is looking to get a long-term lease fleet of similar size up and running in Australia.

TR Group’s Australian expansion plans ramped up on September 1, 2022 when TR Group signed its first electric vehicle lease deal in Australia with Mainfreight. The group says this milestone with Mainfreight is a double win, as the five-year fully maintained leases are for two SEA Electric 816 - 300 85 EVs.

Mainfreight is a long-term rental customer of TR, both in New Zealand and Australia, so the two businesses were delighted to extend their relationship to long-term leasing.

As part of its sustainability initiative, Mainfreight has put the two units into its Melbourne and Sydney Metro fleets. These trucks are rated to 8.5-tonnes and specified with a 138kWh battery driving a 1,500Nm motor.

TR Group also offers other fuel alternative vehicles for rental and lease in line with its strong commitment to sustainability and reducing carbon emissions.

TR Group’s national sales and accounts manager Rick Halliwell says: “This lease is historic for TR Group, and we hope the first of many to come.”

Volvo’s push for a fossil fuel free future continues in earnest with news the European giant has now started using fossil-free steel in its manufacturing process

Fresh from launching factory production of heavy-duty electric trucks in September, Volvo is continuing to push the boundaries when it comes to reducing carbon emissions.

Its latest experiment involves the production of a number of electric trucks featuring steel created using fossil-free electricity and hydrogen from Swedish steel manufacturer SSAB.

Volvo Trucks senior vice president of Product Management Jessica Sandstrom says the trucks are all part of a strategy to lower the impact Volvo’s business has on the climate.

“Our journey to net zero emissions includes both making our vehicles fossil free in operation and over time fully replacing the material in our trucks with fossil-free and recycled alternatives,” Sandstrom says.

The SSAB steel is made by using a completely new technology resulting in a significantly lower climate impact that Sandstrom says is an important step towards a net-zero emissions value chain.

Among the customers that will have fossil-free steel in some of their electric trucks from Volvo are Amazon and DFDS, courtesy of the transport company Simon Loos, Unilever.

“At Amazon, we are on the way to make all of our operations netzero carbon by 2040,” says Andreas Marschner, vice president Transport Services Europe at Amazon.

Green fuel, green skin. Volvo is taking a zero emissions approach wherever it can

“We need partners like Volvo to make this transition happen.”

For logistics business DFDS the intent is similar.

“DFDS is committed to our green transition and to deliver greener transport and logistics solutions,” Niklas Andersson, executive vice president of DFDS Logistics Division said.

“Any step in the green transition of logistics brings us closer to a carbonfree society and we are therefore happy to learn that some of our new electric trucks soon to be delivered are also produced with fossil free steel,” Anderssson says.

The first steel produced with hydrogen is being used in the electric truck’s frame rails, the backbone of the truck upon which all other main components are mounted. As the availability of fossil-free steel increases, it will also be introduced in other parts of the truck.

Today, around 30 per cent of the materials in a new Volvo truck come from recycled materials. Also, up to 90 per cent of the truck can be recycled at the end of its life.

Volvo says fossil-free steel will be an important complement to the traditional and recycled steel used in Volvo’s trucks. It aims to achieve net zero greenhouse emissions by 2040.

lease deal between TR Group and Mainfreight is set to have a positive effect on emissions

When it comes to putting food on the tables of South Australians, the Wightman family has backed Scania trucks to help them get the job done, including the purchase of five new vehicles delivered in November

Wightman Transport, which is contracted to a major logistics chain to deliver groceries for supermarkets in South Australia, now has a fleet of 37 Scania trucks, ranging from refrigerated pantech A-B triples, B-triples and B-doubles as well as a number of Scania rigids for last minute deliveries.

“Doug Wightman started his business in 1964 with a contract to deliver for a supermarket chain and we continue that business today, albeit now as a subcontractor,” Peter Starke says.

That 58-year relationship must be one of the longest in SA, if not Australia, and it is at the core of the family-owned business, that employs not only Peter and his wife, Meredith, but also son Josh as general operations manager and daughter Jess in payroll and accounts.

“We deliver reliability for our customer and their customer, and Scania is a key element of that reliability,” Starke says.

Starke says that the fleet is almost entirely Scania as he has traded five older European trucks for five new R 620 V8 prime movers.

He says the new trucks will be charged with pulling larger combinations including road trains and A-B triples where possible, using

fewer trucks to move more freight for greater productivity and efficiency when it comes to fuel burn.

“Our SA routes take us to the Iron Triangle, to Broken Hill as well as Berri and Mildura, Mount Gambier and Melbourne, and we run as many trailers in combinations as we are allowed to those locations.

“On an average day we’ll be sending out 100 plus loads – local and regional – which includes deliveries to local supermarkets across South Australia.

“In our peak we can efficiently move up to 200 plus pallets to and from the Iron Triangle, this includes tomatoes out of Sundrop Farms.”

Wightman’s has been buying Scania trucks since 2014 when open book contracting came in with their key client.

“We had other European trucks, but only Scania could provide a G 440 4x2 with air at both ends which allowed us to get deliveries into underground loading bays at supermarkets,” Starke says.

“That truck is still working today, with around 700,000 km on it, and it has been brilliant.”

The Wightman fleet also includes a 2018 R 560 V8 which has clocked up 1,000,000 km with the only work outside of standard servicing required so far being the fitting of a new water pump.

“We’ve had some six-cylinder G 500s, but our preference is for the V8s,” Starke says.

“Fuel is a key element of our business planning and ensuring

we run as efficiently as possible is important. Where we can we’ll backload produce such as tomatoes, blackberries, and grapes from around South Australia and Victoria. Even with a backload we can average 1.9-2.0 km per litre as a triple with the V8s,” he says.

The business also makes use of Scania’s fleet monitoring capabilities to report all truck movements and driver behaviour.

“We had Scania driver trainer Kylie Shire down to go through the trucks with the newer drivers to explain the onboard tech and how to get the most from the engine with the best fuel figures,” Starke says.

“Thanks to the monitoring we can, for example, see who uses the power mode for the gearbox when the economy mode should be used, and we can pull them up on it. The training and the monitoring had a massive impact on the driver scoring, as well, and we’re very proactive about reinforcing the training messaging about efficiency,” Peter says.

“This isn’t just about the boss being paranoid about fuel burn, but also, we need to be able to show our customer and theirs’ how safely our drivers are performing, no excessive overspeeding, etc. I have an employee who checks every logbook entry against the monitoring system trip report to ensure there are no anomalies. That’s how we can show our client that we are meeting their requirements for safe and courteous driving.

“Our trucks are on the road all day

six and a half days per week, the drivers are paid well, so there’s no incentive to speed.”

Starke says the drivers spend a long time behind the wheel, driving long distances, and he’s found the Scania set up helps to keep them comfortable.

“One of my guys who came (reluctantly) from an American truck said he’d never go back to it after driving the Scania,” he says.

“One of the guys I share a yard with has American trucks and he’s looked at the Scania bunk and commented on how much bigger his trucks are, but today so many drivers sleep in motels, so the bunk area is not an issue.”

Peter’s trucks are serviced by Scania at Wingfield in Adelaide and there’s a standing booking for a truck to be serviced overnight on Tuesdays and Thursdays.

“The management there know how important it is for us to get the trucks in and out quickly,” Peter says.

Wightman’s is also a loyal customer of Haulmark Trailers and Peter pays tribute to the efforts of Mark Crossling, James, and Joe there for keeping their trailers services and repaired.

“We have two trailers a day in at Haulmark for servicing. We service trailers every 35,000 km, and they never let us down.”

Looking into the future Starke sees an increase in awareness of environmental issues and says he will be moving to Euro 6 emissions.

“I’ve seen a Scania R 660 V8 and that looks like it will be our next specification. I already have a Limited-Edition R 650 V8 in the fleet.

“With the new batch of five trucks, truck Number 1 honours the founder of the business Doug Wightman. His original truck was a Fuso and was painted red and white, and our new one will be running as a B-double or road-train on the Adelaide to Mildura run, under the control of one of our leading drivers.”

Scania’s Wingfield account manager Tim Jensen says the relationship with Wightman Transport was an example of working together to deliver great results.

“Wightman Transport is a great example of how Scania can not only

deliver excellent product that’s right for the application, but also a series of additional services that assist the business to run as efficiently and productively as possible,” Jensen says.

“Peter and Josh have grasped the advantages of the whole Scania offer. We are delighted to deliver five new V8s and look forward to continuing a long running relationship with this very high-profile fleet.”

Transport Women Australia (TWAL) has announced its Driving the Difference scholarship winners for 2022.

Now running for four years, TWAL – together with its sponsor Daimler Truck Australia Pacific – provides this opportunity annually to women in the transport and logistics industry who want to either advance their career or to enter the industry.

The range of courses selected by candidates in 2022 has been the most varied since the inception of the Driving the Difference scholarship program.

TWAL says the quality of applicants has been extremely high

since the beginning, making the task of selecting scholarship winners a difficult one.

“This year was the hardest year of judging that we have had so far, and it is always disappointing that you cannot award them to everybody,” says TWAL chair Jacquelene Brotherton.

“However, we have six very worthy candidates who will be presented with their certificates at end of year functions in the city closest to them.”

The successful applicants for 2022 are:

• A insleigh Bilato, Adelaide

• Brooke Tran, Perth

Saul Bosch was named the Young Professional of the Year at the Chartered Institute for Logistics

and Transport in Australia (CILTA) Awards recently, ahead of finalist Calvin Sham. In a deep talent pool,

A Elle Tandy, Forbes, NSW

B Joana Feiteira, Sydney C

Nichole Speers, Wollongong, NSW

• E llen Tandy, Forbes, NSW

• Nichole Speers, Wollongong, NSW

• Joana Feiteira, Sydney

• Sally-Ann Eather, Sydney

“All the candidates provided outstanding applications and courses that will assist them in advancing within our industry and contribute to the future of all women as leaders. TWAL and Daimler are very proud to support women as female participation continues to grow in the industry,” Brotherton says.

“Leadership skills and careers are enhanced by programs such as these, and the opportunity that the scholarship provides, being awarded the Driving the Difference scholarship means that those successful applicants can undertake a course of study that might otherwise be out of their reach.”

Winners received a certificate and a uniquely designed trophy

the Professional Women in Logistics and Transport award was won by Heather Jones, with Catherine Lou, Kara Cheung and Shannon Fleming all being finalists.

In a two-company pool, TransEco edged out HVCCC for the Innovation in Freight Movements award, while Nortans won the Industry Safety Award ahead of finalist Flyone.

In the final two awards, Keolis Downer won the Passenger Transport Operator award, while Flyone won the Reducing Carbon Footprint award for its work in the space.

A recent Power Torque online opinion article (“An Industry with an Image Problem”) provides ample food for thought.

It made the point that the importance of road transport to the health of the economy still goes unrecognised by most people, as is the level of professionalism amongst truck drivers.

While it’s fair to say that any industry involving big bits of machinery interacting with people inside smaller pieces of machinery comes in for its share of criticism, I believe the road transport industry is held in a higher regard than many of us realise.

I base that on evidence.

In February, NatRoad undertook national research of 1000 Australians aged 18 and above, mostly from outside of our industry, to evaluate how they saw our industry.

It was the first research of its kind in many years.

It found that 98 per cent of Australians regard road freight as an essential industry, while 99 per cent consider it important to the economy.

Unsurprisingly, people in Regional Australia have the highest regard for road freight with 38 per cent saying it was ‘very important’ compared to 29 per cent of metropolitan respondents.

That’s no shock because trucks are the lifeblood of smaller communities and people in the bush are used to sharing roads with 18-wheelers.

Clark, CEO of the National Road Transport AssociationAsked about environmental issues that concern them, Australians ranked road freight lowest from a list of eight.

Eight-in-ten say truck drivers are considerate and drive well around other road users.

Some 40 per cent of Australians know someone who drives either a small, medium, or large truck (or more than one category).

These drivers are very much a part of the fabric of their communities.

COVID-19 did many things but a positive is that it made the broader community sit up and take notice when supermarket shelves was devoid of toilet paper or Mum’s prescription was unable to be filled by the local pharmacist.

It made people not involved in road transport understand we are an essential service.

I don’t want to take too much exception to my fellow columnist’s article. One point very well made was that the vast majority of truckies are highly-professional, well-trained individuals who are “doing their

best to get the job done properly and regard themselves as performing a valuable service to society”.

Point taken, but I don’t agree with the assertion that our sector could do with an awareness-raising, PR campaign. The issue here isn’t about fixing our image but highlighting the things that will make young people want to join us.

Interestingly, the Federal Government is drawing up a National Action Plan to address the national shortage of teachers.

One of its ideas is a $10 million PR and ad campaign to “raise the status and value the role of teachers”.

Just like the teaching profession, we have a personnel shortage.

We need more young people and women and they need to know that that driving heavy vehicles is a resilient and rewarding profession requiring high skill levels.

It’s not just about the image of trucking and public perception.

You can’t attract more women if rest stops don’t include female facilities or are not set up in a way that makes all people feel safe.

Right across the board, we also need national consistency in licensing and competency.

Being able to drive a heavy vehicle shouldn’t just be about holding a piece of paper (or plastic) after you’ve spent a specified number of hours being the wheel.

We’re often described as an industry that’s hidden in plain sight and I understand that sentiment.

It’s often convenient for governments to pay us lip service because we’re diverse, disconnected and represented by many voices.

There’s one thing we all agree on: Setting high standards and keeping them there are minimal requirements if we want to remain relevant.

There’s more challenges to finding new drivers than a perception by some that it is a tough industry to work in

rotten

In just a few short years, people could be booking a private chartered aircraft from an app on their phone and fly up to 700 kilometres away, for a cost similar to present day commercial air ticket prices.

And the aircraft will be electric.

The engaging possibility was made to CILTA delegates by Korum Ellis, founder of FlyOnE sustainable aviation, who said he was on a mission to electrify aviation in Australia at the CILTA International Conference in Perth recently.

“I aim to import the world’s best electric aircraft, build Australia’s electric aviation charge node network and lobby for policies to support decarbonisation of aircraft operations with new technologies and systems of energy management,” Ellis says.

“Fortune favours the bold. Modern aviation is completing the longest test cycle to date of how not to succeed at powered flight, having finally determined that fossil fuels are not an acceptable energy source for the future of aviation.”

Ellis says the electrification of existing air transport operations presented air transport operators and users two significant benefits.

“The first is a massive reduction in toxic emissions. Most small two to six seat aircraft use 100LL aviation fuel.

The LL stands for low lead,” he says.

“What a lot of people don’t know is that 100LL aviation fuel is still quite toxic, containing 0.875 grams of tetra-ethyl-lead per litre. The toxic effects to humans of 100LL aviation fuel include damage to organs through prolonged or repeated exposure from inhalation, skin irritation, drowsiness, dizziness, developmental delays, neurological changes and irritability.”

Ellis says electric aircraft are just like electric cars, as they do not emit exhaust fumes.

“The aircraft carries no liquid fuel but rather, is powered by on-board batteries charged with electrical energy,” he says.

“The second significant benefit of switching from AVGAS to electric is a spectacular reduction in the cost of operations.

“Cessna have produced more than 30,000 - 150 and 152 aircraft. They are one of the most popular trainer aircraft in the world.

“A Lycoming engine Cessna 152 consumes about $50-$60 of fuel per hour of flight. The comparable electric aircraft, the Pipistrel Electro, consumes around $6 of electrical energy per hour of flight.

“But it’s not the reduction in energy costs that offer the greatest economic

benefit. The absence of a combustion engine removes a great deal of the mechanical service costs of operating an aircraft.

“No more fluids, filters, hoses, or spark plugs means faster, safer scheduled service and maintenance checks. The day-to-day operating costs of an electric aircraft are around 1/10th of an equivalent combustion aircraft. The lifetime service and maintenance costs are less than half.

“Most of the wear and fatigue that occurs with a traditional airframe is due to vibration from the engine. Electric powered aircraft are vibration-free and made from high quality composite materials, with the hull one solid piece with no seams or joins or rivets to work loose.

“So, our engineers have an easier time checking the aircraft for wear at the regular service intervals.”

And then there’s the noise, or lack of it. The aircraft is inaudible from the ground.

“This will open up the opportunity for flexibility on noise abatement restrictions around populated airports,” Ellis says.

He says the massive cost savings of electric aircraft operations would also open up what is currently a small niche in aviation services in the micro charter.

Four-to-six seat aircraft charters for routes of 20-400km will radically reduce in cost.

Ellis says there’s no doubt that there was still a long way to go to see a meaningful change in the decarbonisation of aviation. And electric aircraft won’t solve all the world’s emissions problems.

“But the change has begun. New transitional technologies are already taking hold and as we build and grow Australia’s electric aviation charge node network, we can reach more of the population, connecting regional centres and metropolitan areas with decarbonised affordable on-demand air transport,” he says.

The Australian Livestock and Rural Transporters Association (ALRTA) has supported a single national approach to heavy vehicle licencing, including a shift to competency-based training and assessment.

In a recent communication to the industry the ALRTA articulated 26 recommendations in response to reform proposals contained in a consultation regulatory impact statement published by Austroads.

ALRTA National President Scott McDonald says that a uniform national heavy vehicle driver competency framework has the potential to deliver safer drivers, sooner.

“The current age and time-based licencing system denies eager young people a viable pathway into a driving career. In the majority states and territories, a person is not eligible to drive our most productive freight vehicles until they are 24 years old,” McDonald says.

“By that time, most have pursued other career opportunities or settled into lifestyle patterns incompatible with the road transport industry.

“ALRTA is strongly supportive of the proposal to offer alternative licence progression pathways. By focusing on training relevancy, practical skills development, accumulation of real-world driving experience and more rigorous competency assessment, we can deliver better drivers faster compared with the current licencing system.”

McDonald says this would be a good outcome for road safety as well as business productivity and career development. He made the point that a better system should not add time and complications.

“Requiring all in-house driving supervisors to obtain a formal qualification, or introducing too many new licence classes, would similarly introduce unnecessary learning and progression barriers.

“A better system does not need to be more complicated.”

Austroads has developed a new framework for smart motorways that focuses on human capabilities

Austroads says it has developed new guidelines to support road managers in better managing smart motorways.

The guideline focus is on the human resource capabilities which are required to support smart motorway operations across all phases of a motorway lifecycle.

‘Smart motorways’ is the term used to describe motorways that have information, communications and control systems incorporated in and alongside the road.

These technology-based systems are deployed to actively manage traffic flows and improve road capacity and safety, as well as deliver other important outcomes for road users such as better travel reliability and real time traveller information.

“The guidance will help agencies plan to better utilise existing infrastructure assets and identify the optimum resources for operating smart motorways,” says Amy Naulls, Austroads transport network operations program manager.

“The guidance will assist road managers to develop detailed policies, processes and procedures to improve smart motorway operations.”

The guidelines are founded on a suggested capability framework which can be applied to a wide range of different operational scenarios and situations. The framework is linked to currently available training material

The push is on to find the best people to work with smart road technology

and describes the knowledge, skills and abilities needed to perform tasks across all business functions and levels of organisations.

The business functions include infrastructure planning and design, responding to unplanned incidents, and the process of integrating design, planning and ongoing operations in delivering the required motorway performance outcomes.

A Smart Motorway Classification Model (SMCM) is introduced as an optional tool that could be used by transport agencies to guide discussions on business capabilities.

The SMCM will enable users to understand typical smart motorway operating characteristics, including technology features that may be used and typical operational outcomes to be achieved.

“Motorway operations can be challenging and high-pressure work environments, where staff must be adaptable to rapidly changing situations. Staff also need to be open to ongoing learning on how to optimise the opportunities which come from new technologies,” Naulls says.

“These guidelines provide an approach to help road managers foster a culture of innovation and facilitate learning.”

The ALRTA says the industry should focus on implementing the new heavy vehicle licensing scheme to encourage younger drivers to enter the workforce

The National Heavy Vehicle Regulator (NHVR) has released a Discussion Paper seeking industry input to help shape the future of the Performance Based Standards (PBS) scheme – ensuring it continues to lead and promote innovation in the Australian heavy vehicle industry.

NHVR CEO Sal Petroccitto says the Performance Based Standards 2.0 Discussion Paper primarily focuses on opportunities to reduce regulatory, administrative and cost barriers for industry and promote innovative approaches to heavy vehicle safety and productivity.

“The PBS scheme, which now has more than 15,400 combinations operating across the country, has played a significant role in transforming road freight transport in Australia,” Petroccitto says.

“The scheme puts safer, more productive vehicles on our roads

– allowing more freight to be moved in a safe way with fewer truck movements.

“As the freight task keeps growing and we continue to be challenged by driver shortages, it is essential that we do everything we can to improve accessibility to safer and more productive heavy vehicles and encourage innovative approaches to move goods.

“The Discussion Paper has a strong focus on working with road managers to open up increased access for PBS vehicles, so they can operate on the same networks as their conventional equivalents, provide certainty of access for these vehicles, and eliminate the need for permits.

“It also provides a pathway for PBS vehicles to exit the PBS scheme into the ‘as-of-right’ fleet, as we have recently delivered through the

The director of a New South Wales waste company has been ordered by the Parramatta court to comply with an Enforceable Undertaking (EU) voluntarily entered into with the National Heavy Vehicle Regulator (NHVR), following a breach of the EU conditions.

NHVR acting executive director Statutory Compliance Belinda Hughes says the director failed to undertake three safety initiatives within 12 months, as required under the EU.

“The court issued the director an order to comply with the EU conditions within

12 months, as well as a Conditional Release Order for a period of two years,” Hughes says.

“If the director doesn’t comply with the court order, they may be prosecuted again and risk a more severe penalty.

“The NHVR offers EUs as an alternative to prosecution because they provide real safety benefits for the transport industry and the community. If a company or person doesn’t comply with the conditions in an EU, the NHVR will hold them accountable.”

If the accused does not comply with the

National Class 3 20m Long 3-axle Truck and 4-axle Dog Trailer Mass and Dimension Exemption Notice.”

The NHVR’s preferred option presented in the PBS 2.0 Discussion Paper comprises three key components that will:

• ensure PBS vehicles remain at the forefront of innovation through the dynamic management of PBS Standards

• create a ‘lifecycle’ for a PBS vehicle from initial concept through to exit from the PBS scheme for common and mature design concepts

• expedite end-to-end approval processes through opportunities for third parties – such as, assessors, certifiers and manufacturers – to support delivery of regulatory functions.

“The Discussion Paper provides a comprehensive review of the PBS scheme and is designed to be a consultative process. We know there is a lot to consider, so we’ll be holding a series of webinars in early 2023 to provide the chance to discuss your views and provide feedback,” Petroccitto says.

“The work undertaken through PBS 2.0 will inform the Review of the Heavy Vehicle National Law.”

To read the Discussion Paper, register for a webinar or find out how to submit your views, visit www.nhvr.gov.au/pbs2-0 and submit a written submission before February 17, 2023.

The NHVR is calling for industry input into shaping the future of the PBS scheme

court order, the NHVR says they may be prosecuted again for failing to comply with a court order.

Parramatta Court orders waste company director to comply with NHVR Enforceable Undertaking (EU)NHVR is asking for operator feedback on the clarity of its safety notices

The trophies were ready for the big night

The last list of finalists have been announced ahead of the HVIA National Awards

The Heavy Vehicle Industry Australia (HVIA) has revealed its remaining finalists for its Eastern region ahead of its Gala Awards dinner in late November.

Along with major sponsors NTI and Truck Assist, HVIA has announced the finalists for five awards.

For the Safety Innovation award, MAXSAFE Anti Rollaway – Protecting People and Property is a finalist for its active safety solution. Wheely-Safe is the second finalist for the award with its wheel loss sensor solution.

When it comes to product innovation, Enveero is one of four finalists alongside Jamadillo – PT Blueboys TM. Airtec Corporation is a finalist for its SmartOBM digital product, while STEMCO’s SVT Gate Reader device rounds out the finalists for the Product Innovation award.

Penske Australia has been named as a finalist for the Community Leadership award through its Outback Futures organisation.

For the Wurth Australia-sponsored Apprentice of the Year Award, Hunter Tapping of Brown and Hurley is named as a finalist, alongside Simon Flynn from Brown and Hurley Kyogle.

Cummins South Pacific’s Lachlan Waser has also been named, with Cummins Wetherill Park’s Simon Axisa joining Kai Underhill from Haulmark Trailers and MaxiTRANS’s James Cohen-Campbell as finalists for the prestigious award.

For the final Peter Langworthy Award, Smedleys’s Dion Simms has been named as a finalist for his leadership in the industry.

The Heavy Vehicle Industry Australia (HVIA) and the National Heavy Vehicle Regulator (NHVR) have agreed that the HVIA will organise a webinar that will allow the allow members to engage with the NHVR and seek clarity on what can and can’t be done under the existing Class 3 truck and dog notice.

On September 28, the NHVR released the new Class 3 truck and dog notice, which enabled 20m long 3-axle truck and 4-axle dog trailers to gain mass and dimension exemptions.

This notice was the first of a series of notices the NHVR is planning to allow proven PBS designs to be used without needing to go through the PBS approval process.

Unfortunately, the HVIA says the publication of the notice has raised many questions from operators who have found the notice confusing and who have in turn sought clarification from trailer manufacturers and PBS assessors.

In response to the confusion over the notice, HVIA approached the NHVR to see if it could clarify how the notice will work in practice.

The HVIA says the NHVR is also keen for suggestions from industry on how to refine the notice to make it simpler and easier to understand and implement. This will also assist the NHVR in preparing future notices.

The HVIA recently approached the NHVR to clarify the Class 3 notice for truck and trailer set ups

A total of $15 million in emergency funding is to be fast tracked to eight councils in central and western NSW for urgent road repairs to restore access to flood-impacted areas.

Deputy premier and minister for regional NSW Paul Toole says the funding will allow councils to start repairing critical infrastructure and support future recovery works.

“Restoring road access as quickly as possible is critical to ensure the supplies, support and equipment needed to recover from this disaster can get where it’s needed,” Toole says.

“With harvest underway, we also need to ensure roads are up to the task of carrying the additional truck and heavy machinery to get this crop off and to receival sites.

“This cash is being directed straight to councils which, with their detailed knowledge of their local region and roads, are best placed to identify those critical priority areas.

“Natural disaster-declared councils will still be able to submit their Natural Disaster Funding Recovery claims once those damage assessments are complete.”

Thousands of kilometres of road network are in need of fixing and repair after the recent flooding in NSW and Victoria

Nationals minister for regional transport and roads Sam Farraway says it’s critical to start the repair and recovery process as soon as possible to reconnect communities and the state’s supply chain.

“Regional NSW relies on an accessible road network, which is why I worked with Transport for NSW to ensure emergency funding is in bank accounts of councils today,” Farraway says.

“We will come back from these floods stronger, and I will be raising with the federal government the need to expand the Betterment Program currently in place for councils in northern NSW to the west.

“Our natural disaster funding needs to allow councils to rebuild their infrastructure to be more resilient against natural disasters to keep communities connected.”

The eight councils to receive the fasttracked funding are Cabonne, Cowra, Forbes, Lachlan, Moree Plains, Narrabri, Parkes and Walgett.

Additional councils which have also been impacted by the floods may be eligible to receive advance funding and will be evaluated on a case-by-case basis.

There’s hope a new pavement material might put an end to persistent potholes

“One of the biggest challenges facing repair crews using traditional repair methods is the need to wait until the road is dry before being able to fill a pothole. The prolonged wet weather also increases the risk of the same pothole re-forming,” NSW metropolitan roads minister Natalie Ward says.

The Australian Flexible Pavement Association (AfPA) says it welcomes a new trial by the New South Wales government in response to road damage caused by extreme weather events in the state.

The trial aims to test ways of fixing rising rates of potholes in record time using cold mix asphalt, allowing for faster drying and application in wet weather conditions. The method has become useful in combatting flooding events.

The NSW government estimates that since March this year there have been more than 152,000 potholes filled, including almost 18,500 in Sydney roads alone.

The AfPA says innovations like this remain one of its key strategic priorities as it continues working alongside government to ensure that the latest improvements in technology, resilience and sustainability are at the forefront of infrastructure.

“We’ve been using a new cold mix product on some of our worst potholes and it has already produced outstanding results – our road crews haven’t needed to refill a single pothole since they started using this product.”

AfPA CEO Carlos Rial says: “We always welcome the introduction and adoption of road maintenance innovations into government projects.

“Given the frequency and devastation of flooding events across the state and the country more broadly, there is a clear need to trial new solutions which keep our infrastructure safer for longer.

“We applaud the NSW government’s commitment to keeping the state safe and moving and look forward to continuing to work alongside government to deliver these urgent maintenance projects.”

The NSW government is putting $15 million in emergency funding towards fixing flood-wrecked roadsA pavement association has praised the NSW government for trying a new road maintenance product to protect against flood damage

The opening of Daimler Trucks Dubbo represents a strengthening of support for the Central West region of New South Wales.

Backed by Dubbo local businessman Chris Gibson, the new centre features a sizable team led by general manager Damian Brewer.

Daimler Trucks Australia Pacific president and CEO Daniel Whitehead says he is pleased Daimler Trucks Dubbo team has joined the network.

“We are really excited that Chris and his team are committed to supporting Daimler Truck customers in the Central West region of New South Wales,” Whitehead says.

“They have a lot of experience putting the customer first and we know they will be a valuable addition to the Daimler Truck network in Australia.”

Brewer says he is thrilled the dealership is now open.

“We have drawn together a strong team to ensure that we can support our local Daimler Truck customers and every single one of us is excited to get started,” he says.

“We have a lot of knowledge and a lot of enthusiasm and are committed to providing the support that

customers from our region need to get on with their work.”

Chris Gibson says Daimler Trucks Dubbo provides important coverage.

“There has been a gap without a Daimler Truck dealership in the area for a while, so we know Daimler Trucks Dubbo will be well-received and play an important role for our customers,” Gibson says.

“We are a local business and are committed to a long-term presence with Daimler Trucks Dubbo.

“Our customers can now be assured that our whole team is committed to help them operate their business in the best way possible with class-leading trucks and unbeatable service.”

NatRoad

The National Road Transport Association (NatRoad) says Victoria’s revised approach to allowing heavy vehicles leeway with curfews is a step in the right direction.

The Victorian government has introduced a planning exemption as part of its return to COVID normal settings.

The exemption allows deliveries of essential goods to premises one hour before and one hour after times specified in any planning permit condition.

This measure is in place now and will be trialled for up to 24 months with comment invited from industry and local government.

NatRoad says a recent contracts bill passing into law shows the pendulum is swinging towards operators

The passing of unfair contracts legislation into law in November is good news for the road transport industry, the National Road Transport Association (NatRoad) says.

CEO Warren Clark says NatRoad is pleased that the Treasury Laws Amendment (More Competition, Better Prices) Bill 2022 has been given Royal Assent.

“It has been a long road, and this sends a clear message to big corporations that the pendulum has swung back to small operators,” Clark says.

The new law prohibits the use of unfair contract terms in a standard form consumer or small business contract and creates new civil penalties for anyone trying to do otherwise.

It also gives courts more power to make orders to void, vary or refuse to

enforce part or all of a contract, and it will expand the class of contracts that the law applies to.

“The changes aren’t perfect and the

“This is a win for common sense and will help ensure supermarket shelves remain stocked and pharmacies have medicines they need,” NatRoad CEO Warren Clark says.

“It is a fact that supply lines remain under stress and that’s been exacerbated by the recent East Coast floods.

“It makes no sense for truck drivers to miss delivery cut-off times by a few minutes and have to wait until the following day.”

Clark says national research commissioned by NatRoad shows that 58 per cent of Australians are aware of curfews and six-in-ten would consider their removal if the pay-off was improved delivery of goods.

Victoria restored its curfews in August following their suspension during the pandemic.

new law won’t take effect for 12 months to give businesses the chance to adjust,” Clark says.

“There are still nuances in the law that operators will need to take into account and we are urging our members to seek advice if they have questions.

“But we are in a much better place than we were a year ago and we are grateful that the federal government brought on the legislation.”

Clark says a contract NatRoad has seen required the operator to find a five per cent “productivity” saving each year during the term of the contract. The operator’s tenure could be ended, without cause, on a month’s notice, but the contract is for a five-year term.

“That’s one example of an onerous and one-sided contract that we hope will be extinct as the law comes into effect,” Clark says.

says it is welcoming of the flexibility in truck curfews occurring in VictoriaChanges to curfew rules on key Victorian transport routes have been welcomed by NatRoad NatRoad CEO Warren Clark

From December 1, Performance

Based Standards (PBS) vehicles will be able to use a broader range of tyres, enabling the PBS scheme to better support and promote the next generation of smarter, safer and more productive vehicles.

The National Heavy Vehicle Regulator (NHVR) says the new approach will remove the restrictive and outdated tyre requirements that created unnecessary costs and allow PBS operators to use any brand and model of tyre, as long as it meets relevant PBS Standards.

NSW regional transport and roads minister Sam Farraway says the introduction of the PBS generic tyre approach was a significant development in supporting greater industry productivity and delivering improved economic benefits.

“At all levels of government, we have a responsibility to ensure the heavy vehicle industry can meet the country’s growing freight task,” Farraway says.

“PBS vehicles allow more goods to be delivered with fewer vehicles in a safe and sustainable manner –offering productivity improvements of 15 to 30 per cent compared to their prescriptive counterparts.