MEET THE INDUSTRY FIRST MINOTAUR DL550.

GET IN TOUCH WITH YOUR LOCAL DEALER TO LEARN MORE ABOUT THE INNOVATIVE HYBRID DOZER LOADER AND ADD ANOTHER CASE TO THE FAMILY.

MEET THE INDUSTRY FIRST MINOTAUR DL550.

GET IN TOUCH WITH YOUR LOCAL DEALER TO LEARN MORE ABOUT THE INNOVATIVE HYBRID DOZER LOADER AND ADD ANOTHER CASE TO THE FAMILY.

LEARN MORE

Get a true edge on the job site with the Lippmann 1200j Heavy Duty Mobile Jaw Crusher. With a 1905mm deep jaw chamber, this go-to crusher tackles the toughest applications in mining and aggregates. Rely on the 1200j for smooth operation and maximum throughput as Lippmann engineers have optimized the material flow and jaw chamber design for high productivity.

In this issue, Zoomlion has opened its Melbourne HQ, MPS will supply Astec machinery, Kubota opens Victorian parts warehouse, CJD Equipment opens Rockhampton branch and John Deere announces the next generation of SmartGrade for small dozers, plus much more! 6 –8, 56–72

CJD Equipment highlights how reduced tail swing Volvo excavators bring efficiency to the fore Fechner Brothers has found Cat FirstCut Cutting Edges to be a game changer for its dozer McCloskey’s new compact crushing range is now available at 888 Crushing and Screening Equipment

The Cat Fuel Edge Program promises that customers won’t exceed an agreed fuel burn level

A Onetrak showcase of the Tigercat 6900 horizontal grinder saw an impressive turnout Cobra Equipment Sales is now offering GNSS on its Shantui graders

Colbrook Industries explains how to choose the right drum mulcher

Case Construction Equipment’s Minotaur DL550 is the first compact dozer loader of its kind 26 Onetrak found the ideal solution for Sofos Civil Contracting with a Hidromek excavator 28 Brisbane Mini Excavator Sales has welcomed fresh stock of two new Sunward skid steer loaders 30

Coopers Final Trim has been recognised with an award for its dedication to its field of expertise 32

Editorial & Design

Editor Cat Fitzpatrick

catherine.fitzpatrick@primecreative.com.au

Journalists

Darragh Bermingham, Jackson Haddad

Contributors

Damian Long, NAWIC

Managing Editor Andrew Hobbs

Art Director Daz Woolley

Kinsela 0422 635 778

Liew 0421 474

“We capture data of your site then analyse this data to implement a customised solution tailored to your site’s requirements.”

Andy Oliveira - CJD Sales Manager - Site Solutions

Ability to manage multiple sites and projects from one portal

Brand Agnostic

Ability to change guidelines on site for vehicles, routes & zones

Zoomlion has officially entered the Australian earthmoving equipment market, holding a grand opening of its headquarters in Melbourne

Zoomlion Australia & New Zealand officially opened the doors to its Melbourne HQ in late October.

Located in the south-eastern suburb of Mount Waverley, attendees were shown a selection from Zoomlion’s wide product portfolio, including a range of excavators, skid steer loaders, articulated boom lifts, mobile cranes and truck mixers.

Zoomlion says its new facility is designed to be more than just a headquarters; acting as a hub for innovation, customer support and growth. The facility will be integral to providing service, spare parts and training to the local area.

“Zoomlion is looking to bring our manufacturing excellence to Australia, backed up by our specialised local service, spare parts and operational teams,” Zoomlion Australia and New Zealand general manager Lion Li says.

New partnerships were celebrated on the day, with six businesses signing letters of intent to acquire machinery valued at approximately $22 million.

“We are excited about the future and look forward to collaborating closely with our partners to drive continued

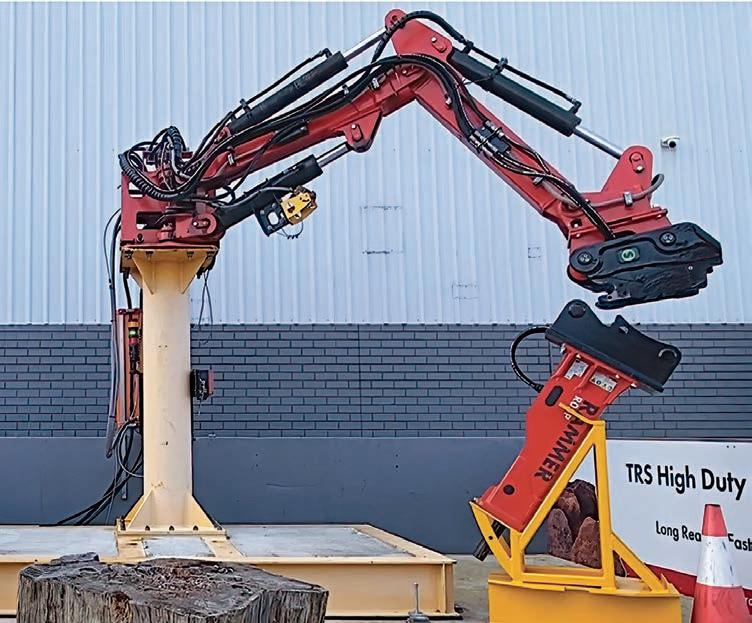

Mineral Processing Solutions will now supply Astec Material Solutions fixed and modular plant, equipment, parts and servicing throughout Australia

modular crushing, fixed screening and washing equipment and systems, as well as material handling (Telestack) and breaker technology (BTI) products to all states and territories.

A ribbon-cutting ceremony was held to mark the grand opening of

success and growth in Australia and New Zealand,” Zoomlion says.

“Together, we are shaping the future of construction, earthmoving, and industrial equipment solutions in Australia, New Zealand, and the broader Oceanic region.”

Zoomlion has plans to open multiple branches across Australia, with plans for further expansion in the first quarter of 2025.

strong partnership over the years.

“In June, we announced that MPS would take over distribution of Astec fixed and modular equipment in NSW, with other eastern states to follow later,” he says.

“This new network will enable us to deliver parts more efficiently, reducing downtime and enhancing the operational efficiency of businesses.

“The MPS team’s extensive local market knowledge and experience in mineral processing – supported by Astec’s innovative technologies and manufacturing capability – has made MPS the perfect partner to deliver outstanding products and service.”

, Astec Australia has announced an expansion to its dealer agreement with Mineral Processing Solutions (MPS) to include its construction materials product lines in Queensland, Victoria and Tasmania.

Under the terms of the new agreement, MPS will distribute all Astec fixed and

Astec’s regional managing director David Smale says Astec and OPS Group (MPS’ parent company) have forged a

MPS already has a strong presence on the east coast, with depots in Goodna (QLD), Rutherford (NSW) and Laverton (VIC).

The company also has branches in Darwin, Perth and Adelaide.

Kubota Australia has officially opened the doors to its ‘state-of-theart’ parts warehouse in Victoria.

After working with a third-party logistics provider for eight years, Kubota has centralised parts operations, bringing control back in-house to streamline efficiency, service and speed.

The new 17,000sqm facility houses 130,000 unique part storage locations and has a 14.6m ridge height for smarter, more space-efficient inventory management, it says.

Located in the western suburb of Ravenhall, the facility is situated near Melbourne Airport and Kubota’s head offices in Truganina.

“With this cutting-edge warehouse, we’ve consolidated operations from three separate, third-party facilities into one, and we’re already starting to see the

benefits,” Kubota Australia general manager for service, parts and quality assurance Chris Nielsen says.

“This is about giving our dealers and customers direct access to people who know these products intimately.”

Kubota adds that the facility has delivered impressive results, reporting a first-time picking accuracy rate of 99.5 per cent.

Kubota Australia’s Ravenhall warehouse is now the central location for all national parts distribution. Customers can make an order for specific parts through their local Kubota dealer.

new

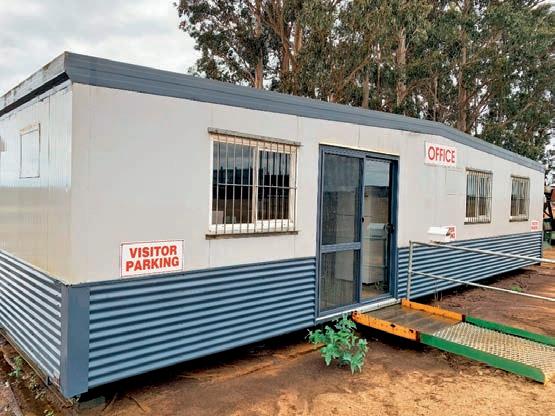

CJD Equipment’s Rockhampton branch is expected to open in December. Image: CJD Equipment

CJD Equipment’s Rockhampton branch will open in December, with customers set to benefit from a local authorised service and parts agent BRANCH OPENING

CJD Equipment has announced that it will be opening a new branch in Rockhampton, QLD, with it scheduled to open its doors in December.

The national distributor for Volvo Construction Equipment (Volvo CE) and SDLG Construction Equipment says it purchased the Rockhampton-based facility to provide a greater level of support to its customers in the surrounding area.

“This new facility marks a significant step in our commitment to providing high-quality equipment and exceptional service to our valued customers in the region,” CJD says.

“With the advent of advanced services, cutting-edge technology, and new developments in electromobility, CJD Equipment recognises that the time is right to expand our presence in the region.

“Our new Rockhampton branch will ensure we can deliver these innovative services and solutions directly to our customers, enhancing their experience and meeting their evolving needs.”

for

Local customers will be able to benefit from CJD’s partnership with Volvo CE authorised service and parts agent REO Heavy Equipment Repairs.

CJD says this partnership was formed many years ago with Russel and Doreen Ostwald. New owners Kelvin and Kelly Bath purchased REO Heavy Equipment Repairs in 2015, with CJD maintaining a strong relationship ever since.

“They have consistently demonstrated the dedication and excellence that have come to define REO Heavy Equipment Repairs, and we would like to take this opportunity to express our gratitude for their steadfast support of the Volvo brand and our customers over the years,” CJD says.

“Once we are open in Rockhampton, we are eager to invite the community to visit our new branch and experience our commitment to the region firsthand.” =

John Deere launches next generation of SmartGrade on dozers and announces Trimble partnership

Available now on small dozer models, John Deere has released its next generation of SmartGrade, available in both Leica and Topcon solutions.

John Deere says the next generation of SmartGrade helps customers to easily complete grading tasks and supports new operators to hit target grade more quickly and efficiently. No daily setup or calibration is needed at the start-up of the machine. When issues arise, customers and dealers can easily troubleshoot their machine with wireless data transfer and remote display access integration through the John Deere Operations Center.

“Since its introduction to the construction market in 2016, SmartGrade has been a proven solution that enables our customers to get jobsites to grade quickly and accurately,” John Deere product marketing manager Matt Costello says.

“Now, as we build upon this technology with the rollout of the next generation of SmartGrade, starting with our small dozer line-up, customers will benefit from improved and expanded capabilities that help increase user confidence and productivity. We are confident that any customer looking to improve their day-to-day

operations will greatly benefit from implementing SmartGrade on the jobsite.”

The split screen capabilities on the new G5 10 touchscreen display allows the operator to see jobsite plans and the selected grade management option simultaneously, helping enhance operator flexibility. In addition, machine calibrations can be done easily through the monitor in the cab.

The 450, 550 and 650 P-Tier dozer models come equipped with upgradable technology solutions that allow machine capabilities to grow with business or jobsite needs. Therefore, customers can select the solution that best suits their needs, including the adoption of EZ Grade with electro-hydraulic (EH) controls, Slope Control, SmartGradeReady with 2D grade control or 3D SmartGrade with Topcon or Leica.

The new SmartGrade-Ready with 2D grade control option comes prewired for SmartGrade with Leica and Topcon. This option brings in the new John Deere G5 display that has Slope Control and easy plug and play laser capabilities.

The next generation of SmartGrade is now available as a factory option or through field kit solutions on all 450, 550, and 650 P-Tier dozers already in the market.

John Deere has launched the next gen SmartGrade on its small dozer models. Image: John Deere

Trimble partnership

John Deere has also announced a new strategic partnership with Trimble. In the future, the Trimble Earthworks Grade Control technology will be integrated with the John Deere SmartGrade platform.

“Our mission is to help our customers maximise their productivity and profitability, especially when it comes to incorporating valuable technology solutions into their equipment fleets,” John Deere vice president, earthmoving production systems & engineering Jerred Pauwels says.

“Our partnership with Trimble presents a tremendous opportunity for our customers to access Trimble’s advanced technology ecosystem. Paired with the power and performance of the John Deere construction equipment line-up with SmartGrade, our customers will be able to make productivity gains, at the jobsite and beyond.”

Trimble technology, enabled through John Deere SmartGrade machines, will be available for purchase on select John Deere construction equipment models in the future.

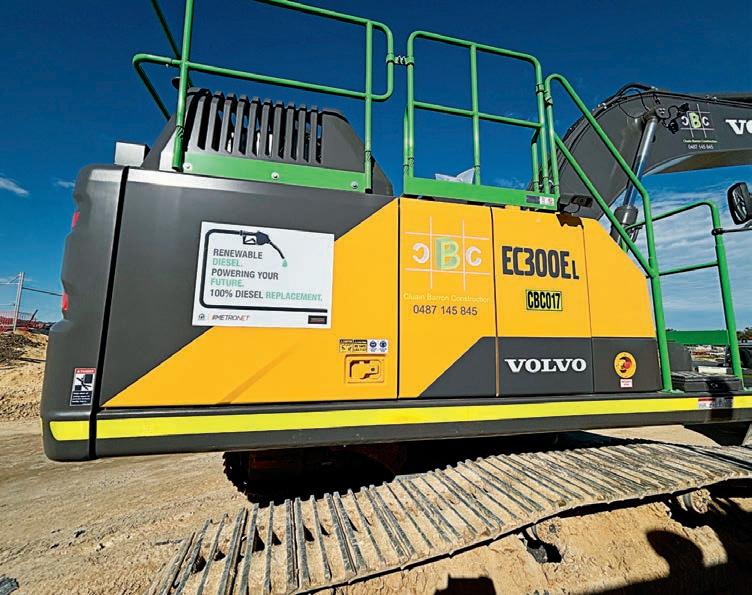

CJD Equipment highlights how reduced tail swing Volvo excavators bring productivity to the fore in tight spaces

Volvo excavators are revolutionising the construction industry with their innovative short-swing designs. These compact machines address a growing need for powerful equipment that can operate effectively in confined spaces, making them ideal for urban construction projects and tight work sites.

The construction industry is experiencing a significant shift towards these short-swing excavators, with their rising popularity driven by several factors including urbanisation, space constraints and the need for more efficient and environmentally friendly equipment.

As cities expand and develop, construction sites become increasingly restricted. These machines are ideal for working near existing structures such as buildings, fences and walls, allowing operators to be precise and cautious in their excavation work.

Volvo’s range of excavators, including models like the ECR145E, ECR235E and ECR355E, offers exceptional manoeuvrability without compromising performance or stability.

The company’s cutting-edge excavator technology is boosting productivity in challenging environments, with features like the Volvo Co-Pilot system enhancing operator efficiency and safety.

Reduced tail swing excavators have gained significant traction over the past decade. These machines allow operators to work up against structures and obstacles without restricting rotation, minimising the risk of contact with surrounding objects. This design not only helps to prevent damage to existing structures but also reduces machine downtime and keeps the equipment in better condition. The ability to work in tight spaces without compromising performance has made reduced-tail swing models increasingly popular among contractors.

Volvo Construction Equipment offers a comprehensive range of short-swing excavators designed to meet the diverse needs of construction projects. These machines are engineered to

The reduced tail swing design makes Volvo excavators ideal for tight workspaces

work efficiently in confined spaces without compromising performance or stability.

The ECR145E, ECR235E and ECR355E models offer the power and performance needed for demanding tasks for medium to large-scale projects.

These excavators are well-suited for applications that must operate on the side of roads or in areas with many obstacles. They provide flexibility with a short swing radius without compromising power, lift capacity or balance.

All Volvo excavators come with advanced features that enhance productivity and efficiency. The password-protected attachment management system allows storage for up to 20 attachments, enabling operators to preset the correct hydraulic flow and pressure inside the cab.

This system ensures optimal performance from various attachments, increasing machine versatility. By offering a wide range

of short-swing excavators, Volvo ensures the operator has access to the right machine for their specific project needs – whether in urban environments or tackling heavy infrastructure work.

The optional Volvo Co-Pilot system offers operators real-time information and guidance, and tools to achieve precise depth, slope, and alignment requirements.

There are three operational modes:

• a 2D mode for tasks like site levelling and slope profiling

• a n in-field design mode using GNSS and RTK navigation for centimetre-specific accuracy

• a 3D mode for large-scale infrastructure projects, allowing direct import of project designs.

This advanced system enhances precision, productivity and safety during excavation, making it a valuable feature for operators working with Volvo excavators, including the ECR145E, ECR235E and ECR355E models.

Volvo excavators are not just about power; they significantly impact economic performance and environmental sustainability within construction projects.

These reduced-tail swing models maintain renowned fuel efficiency through advanced hydraulic systems. The reduced fuel consumption translates into lower expenses and aligns with stringent emissions regulations, while maintaining performance.

Volvo excavators are designed to deliver value throughout their lifecycle. They are built to withstand tough applications, which also reduces the frequency of replacing parts, while Volvo’s CareTrack telematics system maximises uptime and reduces repair costs.

By combining durability with advanced support services, Volvo ensures a solid return on investment through enhanced operational longevity.

Volvo CE is committed to reducing its environmental impact through innovative engineering practices.

The company has a 30 per cent reduction target for CO2 emissions from product use by 2030 and a target of 50 per cent reduction in CO2 across operations by 2030. These lead to an overall goal of Volvo achieving net-zero greenhouse gas emissions by 2040.

With Stage V-compliant engines at their core, featuring diesel particulate filters and oxidation catalysts, Volvo’s commitment extends beyond compliance; the company actively seeks ways to minimise ecological footprints across all operations.

Volvo excavators are making waves in the construction industry by offering a perfect blend of power, efficiency and environmental responsibility.

With their short-swing designs tailored specifically for urban environments alongside zero-tailswing capabilities that redefine operational boundaries, these machines change how projects are executed across various sectors.

Advanced features like the Volvo

Co-Pilot system combined with Stage V engines boost productivity and positively impact environmental sustainability efforts within construction practices today.

The economic benefits of Volvo machinery are clear: improved fuel efficiency leads directly toward lower operating costs while ensuring better returns on investment over time, due largely to the durability built into each model produced by this leading manufacturer within heavy equipment sectors worldwide.

Investing in Volvo means investing in a future where construction becomes more efficient while remaining environmentally conscious – a win-win scenario!

For more information on CJD Equipment and Volvo excavators, contact your local CJD branch today or visit: www.cjd.com.au

The 36.6-tonne ECR355E is the largest in the Volvo range of tracked reduced tail swing excavators

Earthmoving contractor Fechner Brothers has found Cat® FirstCut™ Cutting Edges to be a game changer for its dozer

Dozer operators are bound to come across tough-to-penetrate materials, such as compacted, rocky or frozen soils, so it’s important that when they do, they’re well equipped to push past them.

Cat FirstCut™ Cutting Edges, which slice through materials rather than using unnecessary force to break them up, is an ideal solution.

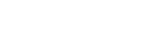

Compatible with D6-D8 dozers equipped with Semi-U (SU) blades, Cat FirstCut Cutting Edges are

designed with a sharpened and forward-protruding digging angle, providing a cleaner cut.

Cat® dealer, Hastings Deering, adds that Cat FirstCut Cutting Edges reduce the need for ripping because they slice the materials as the blade passes through.

Made from DH-3 steel, Cat FirstCut

The cutting edges slice through materials rather than breaking them up

Cat FirstCut Cutting edges are compatible with D6-D8 dozers equipped with Semi-U blades

Cutting Edges have an increased wear life and breakage resistance compared to standard Cat options.

This type of steel also eliminates the need for mid-life flips, resulting in reduced downtime and operating costs.

“As the standard cutting edges wear out, they need to be pulled off and flipped upside down,” Hastings Deering aftermarket solutions consultant Mitchell Vella says.

“However, Cat FirstCut Cutting Edges are made from a harder metal with a more aggressive cut, where there’s no need for mid-life flips.”

As an edge eventually wears, operators can identify when it needs replacing through the integrated wear-life indicator.

Specific grooves are designed on the side of the Cat FirstCut Cutting Edges, notifying the operator how long is left before it starts wearing into the blade structure.

In addition to the productivity benefits, Cat FirstCut Cutting Edges are also suited for final trimming due to the level cut that they provide.

For earthmoving contractor Fechner Brothers this ground engaging tool has been a gamechanger on its Cat D6R XL dozer.

winwithcastrol.com.au/rollupandwin

AU residents 18+ only. Between 12:01am AEST 1/9/24 & 11:59pm AEDT 30/11/24, spend required amount in 1 transaction on any Castrol product or lubricant ($200 - $1,299.99 for Prize Pool 1, or $1,300+ for Prize Pool 2), from participating Castrol outlets (excl online), visit www.winwithcastrol.com.au/rollupandwin & fill out entry form incl. receipt upload and select a roller door on screen to see if you have provisionally won an instant prize. Max 1 entry per qualifying purchase and per itemised receipt. Keep original itemised receipt/s. Prize Pool 1 prizes: 100x Castrol Reignite Cooler Packs ($100), 10x Castrol WAECO Icebox ($300), 100x Castrol/Frank Green Bottle ($100), 30x Castrol Laptop merch ($100), 10x Wanderer Quad Fold Beach Cart ($200), 50x Castrol Eftpos Giftcards ($100) & 10x Signed Framed Tickford Racings Polos ($750). Prize Pool 2 prizes: 20x Weber Baby Q ($568), 20x Makita 18V brushless 2pc kit combo ($800), 10x Castrol Branded Bar Fridges ($1k), 10x Apple iPhone 15 256GB Midnight Black ($1,700), 10x Samsung 65” Q70C QLED 4K Smart TV ($1,895), 10x PS5 Bundle ($1K) & 10x Gran Lattissima Automatic Capsule Coffee Machine Black ($649). See

Fechner Brothers

Servicing the Scenic Rim Region of South-East Queensland, earthmoving contractor Fechner Brothers has been family-owned since 1962.

Run by Steven Fechner, the company specialises in a multitude of areas, including constructing and maintaining dams, drains, soil conservation works, excavations and levelling, as well as carparks and roads.

Steven has been using the Cat FirstCut Cutting Edges on his D6R XL dozer and has been blown away by the product – he couldn’t be a bigger endorser.

“My immediate thought was just wow,” he says.

“It blew me out of the water how productive and how easy it was to use.”

Working with hardened claybased soil, the Cat FirstCut Cutting Edges proved critical to slicing through the material.

“It’s the only edge that will carve out this hard clay, like butter,” he says.

“At this stage, there’s nothing that comes close to FirstCut in terms of its dig ability.”

Steven Fechner has been running the Cat FirstCut Cutting Edges on his D6R XL dozer, and says nothing comes close for dig ability

Further emphasising its productivity capabilities, he says the dozer is now pushing approximately 11-15 per cent more dirt when using the Cat FirstCut Cutting Edges.

“It’s ridiculous how productive it is, I feel like I’m doing the work of two dozers with the Cat FirstCut,” Steven says.

“It’s the first time in a long time that dozing has made me smile.”

Due the forward-protruding digging angle of Cat FirstCut Cutting Edges, Steven has been able to reduce his fuel consumption by nine per cent.

This is because the machine is slicing through the soil rather than pushing, which Hasting Deering’s Vella says is more beneficial for the dozer.

“With Cat FirstCut Cutting Edges, Steven’s dozer doesn’t have to push as hard, so it’s not overworking,” Vella says.

“The product also allows dirt to funnel in towards the blade, capturing more material with a reduced fuel burn – leading to increased productivity.”

When Steven first approached the Hastings Deering team, he had some initial queries about how Cat FirstCut Cutting Edges would be fitted onto his dozer.

This is because he already had a stick rake attachment, so the Hastings Deering team got to work and made some slight modifications to ensure that the Cat FirstCut Cutting Edges would work well with the existing setup.

“At Hastings Deering, it’s not just about giving the customer a product,” Vella says.

“It’s about really supporting the customer to ensure the product is supporting their overall business.”

Steven can attest to this, having been a long-standing Hastings Deering customer.

“You can’t go wrong with Hastings Deering,” he says.

“I like the products, support and the people, it’s the whole package.”

For more information on the Cat FirstCut Cutting Edges, visit www. hastingsdeering.com.au

Now available at 888CSE, McCloskey’s new compact crushing range is designed to have the same power of a full-sized plant, but also be easily transported

In the mobile crushing and screening industry, McCloskey International has long stood at the forefront, renowned for its range of high-performance equipment.

Now, with its new compact crushing range, McCloskey distributor 888 Crushing and Screening Equipment (888CSE) says that McCloskey machinery represents the future of mobile crushing – smaller, smarter and stronger.

Compact, powerful and designed to exceed the needs of operators across the globe, 888CSE says these new solutions are ready to rival anything on the world market.

McCloskey’s compact crushing range consists of two machines, the I4cR and the I3cR, with both crushers engineered to pack the power of a full-sized crushing plant into a compact, easily transportable package.

888CSE adds that these machines deliver significant flexibility, with onboard screening and recirculating conveyor options, making them a great choice for various applications in recycling, demolition and small to mid-sized quarry operations.

One of the key advantages of McCloskey’s compact crushing range is the use of diesel hydraulic technology, which 888CSE says offers easier servicing capabilities for many contractors operating similar equipment.

This focus on user-friendly maintenance ensures that operators can spend more time crushing and less time dealing with costly downtime.

At approximately 42 tonnes, the McCloskey I4cR might not seem like a ‘compact’ machine by traditional standards, but this crusher is proof that size isn’t everything.

It is a fully contained crushing, screening and stockpiling plant, with all closed-circuit options included. Its design means the plant can be deployed quickly and easily in a variety of settings, offering an impressive performance-to-size ratio.

For contractors seeking a robust solution that can handle demanding jobs while maintaining efficiency, the I4cR ticks all the right boxes.

Despite its compact size, the I4cR delivers superior output, processing a range of materials with the power and precision that McCloskey is known for.

888CSE says its user-friendly features and portability make it an ideal choice for operators who require mobility without sacrificing capacity or quality.

McCloskey I4cR might not seem compact at 42 tonnes, but can be deployed quickly and easily in a variety of settings

McCloskey’s I3cR is suited to small to mid-size recycling operations and small quarry owners who need an easily transportable machine

Even more compact than its larger sibling, the McCloskey I3cR weighs in at just 27 tonnes.

This crusher is perfectly suited to small to mid-size recycling operations and small quarry owners who need a high-performing, easily transportable machine.

The I3cR is packed with all the features needed for a complete closed-circuit crushing operation, including onboard screening and recirculating conveyors.

Its compact dimensions do not compromise its capabilities, as it offers the same advanced McCloskey diesel hydraulic technology as its larger counterparts, ensuring reliable and efficient performance in even the toughest conditions.

The machine’s compact frame and lightweight design allow it to access sites that other crushers simply cannot reach, 888CSE says.

Beyond the technical prowess of these machines, McCloskey Compact Crushing plants benefit from the unmatched support and service provided by 888CSE.

With extensive industry expertise and a commitment to customer satisfaction, 888CSE ensures that McCloskey equipment performs at its best, offering operators peace of mind and optimum uptime.

For more information on McCloskey’s compact crushing range, visit 888cse.com.au or call (08) 9550 6388.

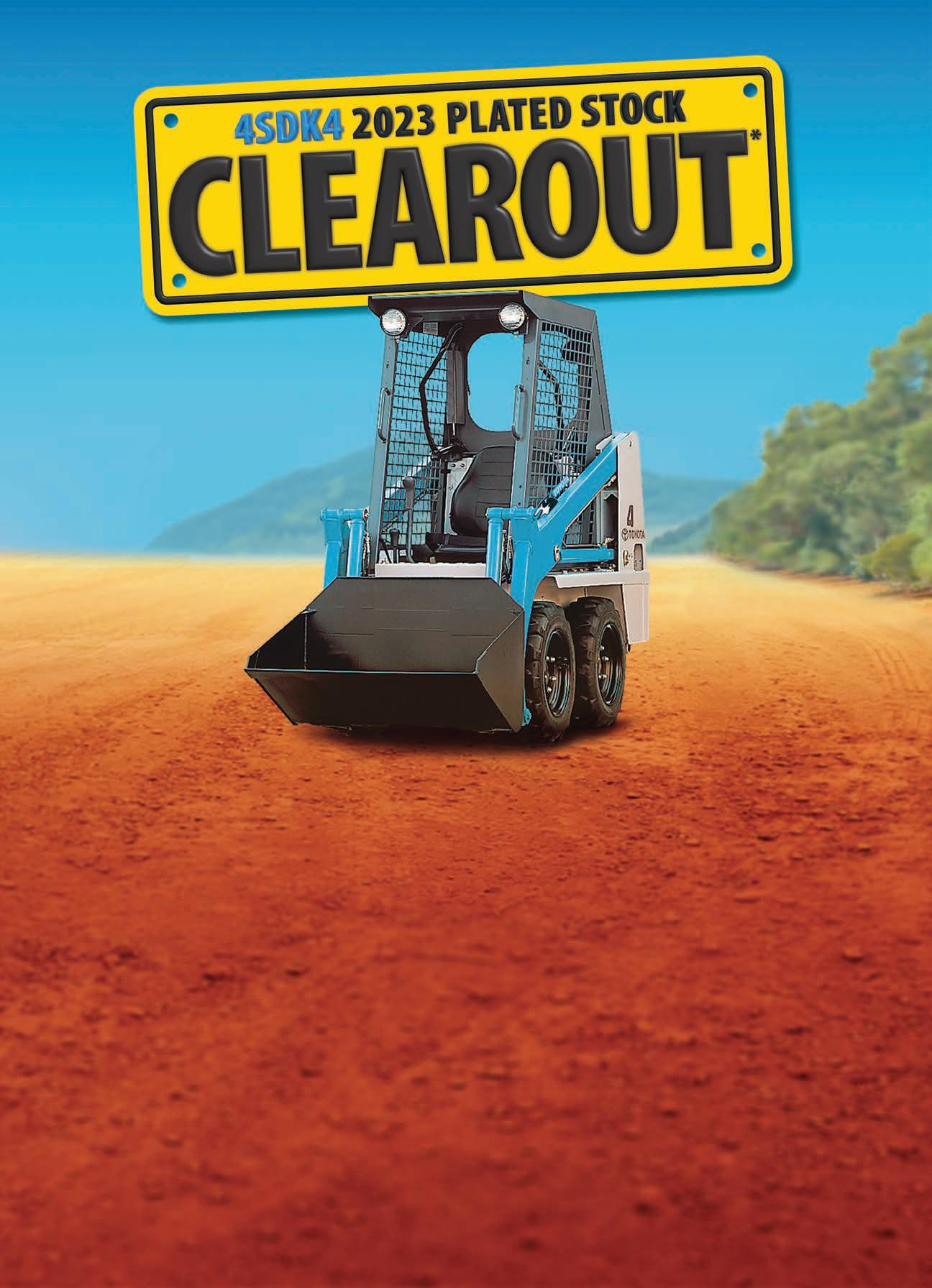

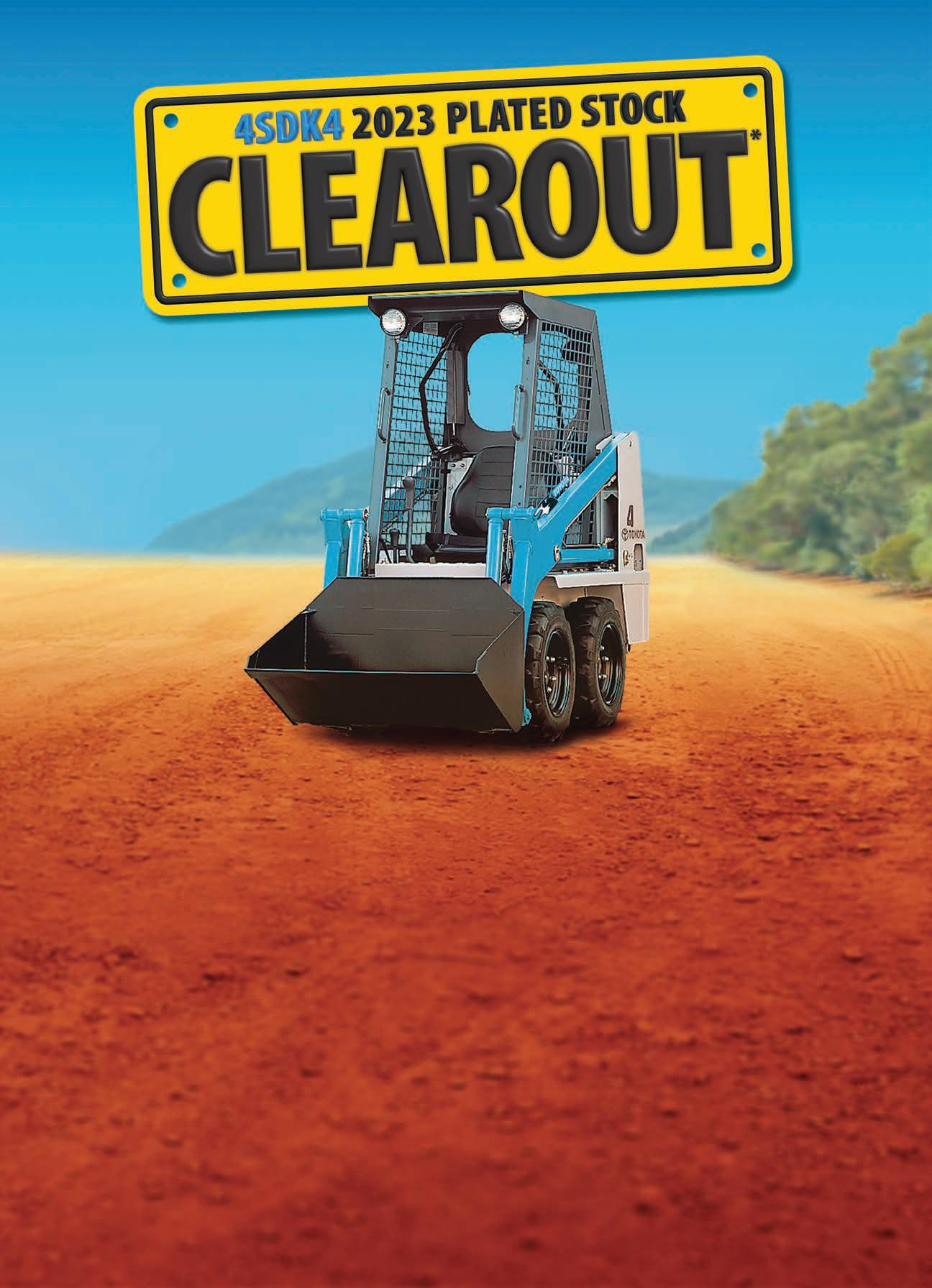

As the smallest pup in the Toyota Huski skid steer loader range, the 4SDK4 is compact in size, yet strong enough to handle the toughest jobs. With a 320kg operating load its nimble size makes limited access applications possible, and it's ideal for many industries due to it being lightweight and towable.

Right now you’ll score a great Toyota deal across new 2023 plated Huski 4SDK4 skid steer loaders, currently in stock. Plus you’ll also enjoy a discount of $1,500 on 2023 plated 4SDK4 skid steer loaders ordered before 31st January 2025*. To take advantage of this offer contact your local Toyota Material Handling branch today.

*Fixed discount of $1,500.00 applies to orders made on new 2023 plated 4SDK4 skid steer loader floor stock ordered between 1st November 2024 and 31st January 2025 and delivered prior to 30th June 2025; available to private buyers only. Offers

The Cat® Fuel Edge Program promises that customers won’t exceed an agreed fuel burn level, and if they do, a dealer will provide a parts credit

As Caterpillar continues to release new products into the Australian marketplace, great gains have been made in fuel efficiency and advances in product and technology.

With fuel consistently at or near the top of customers’ annual operating expenses, it doesn’t really matter if the price of diesel is going up or down. Any savings that are made in the area of fuel consumption go straight to the customer’s bottom line, and the improvements made will pay off down the road when the cost of fuel inevitably rises.

What makes Cat® machines stand out from the crowd is not just the immediate impact these innovations have on the customer’s bottom line in terms of reduced operating costs, but the fact that the company stands behind the claims it makes in terms of fuel efficiency.

There is proof of this in the Cat Fuel Edge Program, which entitles customers who purchase a qualifying Cat machine, with Cat VisionLink® enabled, to a parts credit if their new machine consumes more fuel per hour on average than its committed Fuel Consumption Threshold for the duration of the program.

Eligible Cat machines will have their fuel consumption monitored by Cat dealers, and a report will be sent quarterly to show the average fuel consumption in litres per hour

compared to the threshold given at delivery.

If the machine has consumed more, a parts credit will apply at the agreed value per litre over the threshold – it’s that simple.

Machine fuel consumption can be viewed on the website vl.cat.com or on the VisionLink mobile application.

As an example, Cat’s Next Gen Excavators offer up to 25 per cent reduced fuel consumption when compared against previous models.

A parts credit will be offered if the new machine consumes more fuel per hour on average than the committed Fuel Consumption Threshold

Customers who purchase a qualifying Cat® machine with Cat VisionLink® enabled are eligible for the program

Caterpillar says this is not a bold claim – but rather a promise and statement the company is standing by, which is why the Cat Fuel Edge program exists.

Caterpillar has identified the Fuel Consumption Threshold as the rate of fuel consumption (expressed as litres per hour) considered to be representative of the expected fuel burn or consumption rate (in typical Australian operating conditions) for that model of a qualifying machine.

Fuel is often the number one operating cost. The productivity and efficiency of Caterpillar’s new models are critical to finishing jobsites on time and with proper margins.

Give your business an edge with the Cat Fuel Edge Program. Contact Cat dealers now for more information or visit cat.com/fuel-edge-au

NSW/ACT: WesTrac 1300 881 064

VIC/TAS: William Adams 1300 923 267

Western Australia: WesTrac 1300 881 064

QLD/NT: Hastings Deering 131 228

South Australia: Cavpower 08 8343 1600

NZ: TERRA 0800 93 39 39

Customers had the opportunity to witness the impressive grinder in action

A Onetrak showcase of the Tigercat 6900 horizontal grinder saw an impressive turnout of customers from across Australia, all eager to discover the capabilities of this new machine

Forestry machinery manufacturer

Tigercat and authorised Australian dealer Onetrak introduced the 6900 horizontal grinder to the Australian market in early October.

During a two-day event at Treescape Richlands in Brisbane, Queensland, customers had the opportunity to witness this impressive machine in action, with Onetrak and Tigercat representatives showcasing the innovative design

and features of the new grinder.

Each day featured a brief history of Tigercat and the journey to developing the 6900 horizontal grinder.

This was followed by an in-depth walkthrough led by Tigercat’s product specialist from the US, Aaron Murray, who boasts 26 years’ experience working with grinders.

It also featured a question and answer session with customers.

The event culminated in the muchanticipated live demonstrations, where the 6900 was fed tonnes of timber by a Hidromek HMK145 17tonne excavator.

Onetrak expressed its gratitude to Treescapes for providing the venue and timber for processing, with the 6900 tackling several tonnes of timber over the two days.

The company highlighted the event as an excellent opportunity to interact directly with Tigercat representatives, customers and Onetrak sales and technical representatives.

Nothing beats first-hand feedback and an exchange of ideas in a relaxed and welcoming setting. An enjoyable time was had over a BBQ lunch and drinks.

Tigercat is a Canadian company, established in 1992. Owner Ken MacDonald had branched out and wanted to build his own machines.

Currently, the company employs over 2,000 people and has 30,000 Tigercat machines operating in the market.

Tigercat’s history is rooted in a unique background – it has developed machines designed to perform in some of the most

challenging applications in the forestry sector.

All the steelwork and fabrication are completed in-house.

“Everything you see here that’s yellow and black is all our own; our own track frames and chassis for example,” Tigercat Australasian district manager Glen Marley says.

This specific unit marks number 53 since Tigercat started the grinder company, and there are currently 55 units of this model working in the market already.

When it comes to supporting Australian customers with this machine, Tigercat itself has four dedicated field staff members working full time across the country.

Combining this extraordinary commitment with Onetrak’s national network of fully equipped service facilities, field service trucks and

parts professionals means Onetrak, and by extension Tigercat, have customers covered, wherever they might be working.

Onetrak also had a large contingent of its team present for the week, starting with the aftersales and product support members flying in from all areas of Australia representing all seven branch locations.

Tigercat and Onetrak emphasise that they have a comprehensive and experienced parts and service system in Australia, making sure the Tigercat 6900 horizontal grinder is well supported to ensure the success of their customers.

The attendees at the launch event provided positive feedback, making note of thoughtful details in the overall design and the robust performance and construction.

One customer from the Central Coast highlighted the convenience

of operating certain hydraulic functions without needing the entire machine to be running, also remarking on its impressive throughput.

Several customers also commented on how quiet the machine was, especially considering the volume of material it processed, and mentioned that dust production was minimal.

Overall, the feedback on Tigercat’s new 6900 horizontal grinder has been outstanding, Onetrak says.

If you have an interest in this machine, reach out to Onetrak sales staff and they can run through its capabilities, as well as providing video and photographs from the demo days.

Contact Onetrak on www.onetrak.com.au or phone 1300 727 520.

Cobra Equipment Sales is now offering GNSS capabilities on its Shantui graders, improving jobsite efficiency by automating blade control

Over his 40 years in the industry, Cobra Equipment Sales founder George Nason has seen significant changes in machine automation.

A key example of this is the installation of global navigation satellite system (GNSS) capabilities on motor graders.

“In the old days, you’d have a surveyor on site taking levels from a datum point and then putting pegs in the ground,” Nason says.

“You’d peg out the desired width and height of the finished road, and there would be people manually checking all the heights across the road.”

He adds that these operations were quite complex, because measurements constantly needed to be checked. But now with GNSS, the work is made much simpler.

Using GNSS, Nason says a signal will be sent to a grader, regulating the blade’s height and angle.

All an operator has to do is drive the grader down the road and everything that would normally be done manually will now be done automatically.

“GNSS makes the work a lot easier and more precise,” Nason says.

“Your time on-site is probably saved by 50 per cent – if not better.”

Some of the other added benefits include reduced fuel costs, machine wear and hours on the grader, due to less rework taking place.

This can all be achieved through Shantui Equipment’s range of graders, available from authorised dealer and distributor Cobra Equipment Sales.

Under a deal with well-known European brand Leica Geosystems, GNSS capabilities are integrated in the Shantui graders prior to their leaving the factory.

As an authorised dealer and distributor of Shantui Equipment, Cobra Equipment Sales is now offering this capability on its Shantui machines, either factory-fitted or retrofitted onto older machines.

“We’ve got a Shantui grader in stock without GNSS, but we can fit a GPS system to it locally, which would basically be the same,” Nason says.

For any job that requires precision measurements, Nason says GNSS is the way to go.

This can include roadworks, subdivision works and building pads.

“It’s basically machine control and it saves a lot of time in all general civil works,” Nason says.

“Having these intelligent motor grader products coming directly from the factory means it’s already fitted on for you.”

Compared to other brands, Nason says the Shantui-branded GNSS is much more competively priced –including the grader itself.

Although Cobra Equipment is focusing on GNSS and GPS for graders, Shantui has also developed these systems to be integrated on bulldozers and excavators.

Using a similar concept to graders, GNSS and GPS support precision digging tasks on an excavator.

With these systems, the operator doesn’t have to manually check the

GNSS systems can make grader work much easier for operators.

Image: Shantui Equipment

digging depth as the excavator will present this information in the cab.

Again, emphasising the time saved with this technology, Nason says the machine will work more efficiently than it usually would.

Through Cobra’s partnership with Shantui, Nason has had the opportunity to visit the OEM’s factory headquarters.

On his most recent trip, Nason got to experience GNSS firsthand.

“The last time I was there they had the system set up on a D5-sized dozer,” Nason says.

“It’s very easy for the operator, you just get in the cab and the system does all the work. You’re basically just driving the dozer, and the blade does everything.”

Seeing the demonstration for himself, Nason says the dozer did all the levelling by itself and made the work much more efficient. This also means less-experienced operators can carry out work that would usually require more thorough training.

“It’s getting harder to find seasoned operators with the training required to know what they’re doing,” he says.

“With GNSS and GPS, you could put a less-experienced operator in the cab and tell them what to do –the system will do it for them.”

Cobra Equipment Sales currently has two different models of Shantui graders in stock, which Nason is happy to source GNSS for.

The first grader model weighs 6,300kg, without rippers/scarifiers/ front blade, and has a 3,050mm blade, while the largest model weighs 18,500kg without rippers/scarifiers/ front blade, and has a 3,965mm blade.

“We can supply the GNSS and GPS on the Shantui graders and excavators,” Nason says.

“If someone wants this system on their machine, it’s not a problem.”

For more information on Cobra Equipment Sales’ Shantui machines, visit www. cobraequipmentsales.com.au or call (07) 3379 9419.

Colbrook Industries takes a deep dive into the different Diamond Mowers drum mulchers available for Australian customers

Determining which attachment is the right one for specific jobs is a conundrum that operators regularly come up against.

Drum mulchers are essential to those involved in land clearing, vegetation management and roadside maintenance, but with various models available, it can be hard to determine which one is best suited for a job.

Offering machinery for industrial vegetation management, Colbrook Industries is frequently asked which of its drum mulcher is best suited to specific applications.

Each type of drum mulcher is engineered to suit different machines and applications and comes with its own advantages, so to make the selection process easier, Colbrook looks into the different Diamond Mowers drum mulchers available.

Drum mulchers

As the sole Australian dealer for Diamond Mowers products, Colbrook says there are two common types of drum mulcher attachments – depth control (DC) and open drum (OD).

Colbrook offer a range of sizes and options for skid steers, compact track loaders (CTLs), and excavators.

Skid steer and CTL drum mulchers are available in OD or DC and come in three sizes, 50” (127cm), 60” (152cm) and 72” (182cm).

Excavator drum mulchers are available in either 30” (76.2cm) or 50” (127 cm) for machines from 4.5t to 10t.

All Diamond Mowers drum mulchers have multiple teeth options, with the unique ability to be able to mix and match to optimise tooth layout for optimum productivity for each application.

The Diamond Mowers DC and

OD drum mulchers are different mulching heads from the ground up.

Key differences between DC and OD drum mulchers revolve around their operations and applications.

For example, Diamond Mowers’ OD models infeed area and entire processing chamber has been designed for the most efficient reduction of material, producing a smaller end product than conventional open drum models, while allowing heavy ground engagement for maximum productivity.

In comparison to the OD open throat design, DC has a closed throat which pushes larger material into the teeth, creating mulch in front and inside the processing chamber.

OD models are more efficient when mulching smaller materials into a slightly larger and stringier product, also grinding stumps and incorporating mulch into the ground when running the carbide tooth.

Compared to OD, the DC models make the most of sharp steel teeth in high-production environments with limited ground engagement.

These drum mulchers are more appropriate for users who take down larger materials and prefer a fine, aesthetically pleasing mulch.

The DC drum with its depth control rings allows operators to efficiently work through large material, achieving optimum results and efficiently using the carrier’s power.

ODs are designed for a variety of heavy-duty mulching tasks, they are ideal for large clearing land jobs for agricultural use, infrastructure development and habitat restoration.

The ODs are designed to be run with carbide teeth, making it perfect for handling rough and rocky terrain,

however engaging with more of the cutting tooth, this drum mulcher offers maximum productivity through its larger bite size.

As bushfire season approaches, Colbrook says OD drum mulchers are essential for those in rural environments looking to manage vegetation and reduce fire risk.

OD drum mulchers are also particularly effective for clearing tree limbs and overgrowth around roadways and powerlines.

Since these areas are regularly maintained, vegetation growth is typically not extensive, so an OD drum mulcher is often preferred for these tasks.

DCs are especially productive when processing large-diameter material.

They feature a closed throat design and sharp steel teeth that push trees and brush onto the rotor.

The teeth then cut and reduce the size of the material before it enters the processing chamber.

Colbrook says the helical tooth pattern is modelled after a vacuum brush to feed material efficiently toward the drum’s centre, while DC rings limit bite size for optimal infeed.

This style of drum mulcher is suited to large-scale brush clearing, undergrowth removal and vegetation management projects with limited ground contact.

Due to its sharp teeth, DC drum mulchers can remove trees and larger material with speed.

Colbrook says they are particularly effective for processing hard or fibrous wood, such as eucalypt, making them more efficient than ODs.

To help select the right drum mulcher for your machine and application, Colbrook says to consider your specific carrier power, type of vegetation and desired finished product.

For more information on Diamond Mowers’ drum mulcher offering, visit www.colbrookindustries.com. au or call (03) 8369 6610.

TheTerexMDSM4133SplitTrackisidealforscreeningfromlightmaterialtorecycling demolitionwaste.

INSTOCK&AVAILABLENOW.030124_1. TA1211054.

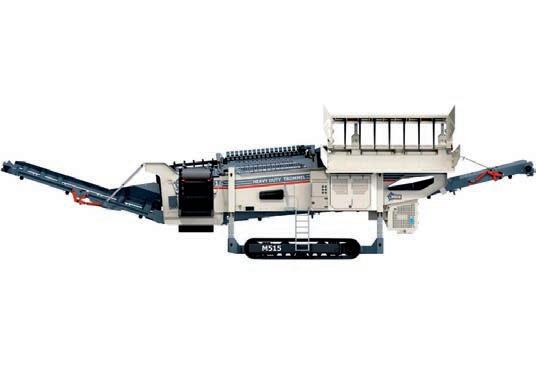

TheTerexMDSM515HeavyDutyTrommelexcelsatcraftingRipRapandreclaiming rocksentangledwithclayandotheradhesivematerials.

INSTOCK&AVAILABLENOW.070224-1. TA1209482.

TheTerexMDSrangeofmobileconveyors are designedtoworkinconjunctionwiththe entirerangeofTerexMDSHeavyDutyTrommels.

INSTOCK&AVAILABLENOW.030124_3. TA1210853.

TEREXMDSM412MOBILETRACKTROMMEL

TheTerexMDSM412MobileTrackTrommelisperfectforscreeningeverythingfrom lightweightmaterialstorecyclingheftydemolitionwaste.

INSTOCK&AVAILABLENOW.0702/24-2. TA1209481.

TEREXMDSMT15HHIGHLEVELFEEDER

TheTerexMDSMT15HHighLevelFeeder,combinesthehighlyversatilefeedersystem andstockpilingconveyor.

INSTOCK&AVAILABLENOW.240524_3. TA1223335. POA

TEREXMDSMT24TRACKEDCONVEYOR

TheTerexMDSMT24TrackedMountedConveyorissuitedtoaggregateandquarrying applications.Highlymobileandbuilttolast!

INSTOCK&AVAILABLENOW.040124. TA1210854. POA

GetatrueedgeonthejobsitewiththeLippmann1200jheavydutymobilejaw crusher. Witha1905mmdeepjawchamber,thisgo-tocrushertacklesthetoughestapplications.

INSTOCK&AVAILABLENOW.211223_4. TA1211051.

TheLippmann300cisaheavydutyconecrusherwithaninnovativematerialflowthat maximizescapacityandthroughputwhiledeliveringhighqualityproduct.

INSTOCK&AVAILABLENOW.201223. TA1211053.

2023,TheAggredryDewateringWasher,acombinationwetscrewanddewatering screen,canbeusedanywhereafinematerialwashermightbeused.

INSTOCK&AVAILABLENOW.090524_3. TA1222479.

The1060jisdesignedtomaximizeoutputofhighqualitymaterial,withaheavyduty buildandhighqualitywearpartsandcomponentstominimizedowntime.

INSTOCK&AVAILABLENOW.201123_3. TA1203346.

Whenmobilityandtoughnessmatter,countonthe400c.Thismobileconecrusherplant wasspecificallydesignedtotakeonthemostabrasiveandtoughestmaterials.

INSTOCK&AVAILABLENOW.241123_1. TA1203349. POA

TheSuperiorTSSA150Conveyorispound-for-poundthestrongest,safestandmost productivetelescopicstackerontheplanet.

INSTOCK&AVAILABLENOW.S647. TA1105133.

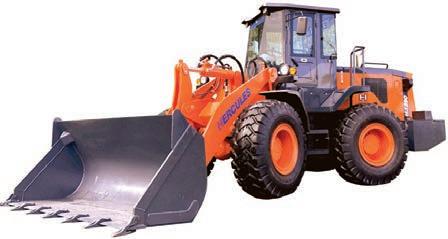

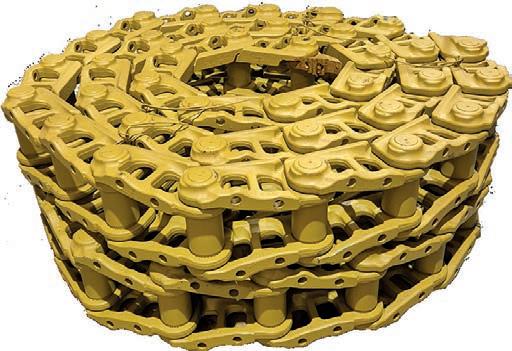

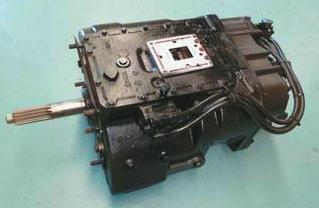

Combining the power of a dozer with the agility of a wheel loader, Case Construction Equipment says its Minotaur DL550 is the first of its kind

The all-new Case Minotaur DL550 has established an entirely new category in the construction equipment industry – the compact dozer loader.

Merging the robust performance of a dozer with the agility of a loader, Case says the Minotaur creates a versatile and powerful tool designed to transform the job site.

The Minotaur DL550 stands out with its fully integrated C-frame, delivering genuine dozer capabilities along with the finesse and precision of a loader. This unique combination ensures that the Minotaur can handle everything from heavy-duty dozing to delicate fine grading with ease.

The addition of an industryexclusive integrated ripper and the machine’s compatibility with hundreds of attachments make the Minotaur stand out for its versatility and functionality, Case adds.

Able to carry out dozing, grading, loading and ripping works, the Minotaur thrives in an array of different applications – including land clearing, roadwork, trenching, storm cleanup, landscaping, utility work and even trail blazing.

Case Construction Equipment says innovation of its product range is driven by what customers are looking for to make their jobs quicker and easier, with the Minotaur DL550 the end result of extensive research and development that has involved those on the ground in real-life applications.

Backed by 29 patents and over 10,000 hours of rigorous field testing, Case’s team conducted multiple customer clinics and countless operator evaluations, continuously refining the product based on user feedback.

Case says the Minotaur delivers unmatched productivity whether it is ripping, dozing or loading. With intuitive controls and a comfortable cab, the operator is provided with a seamless experience in dozer or loader mode.

Long days on the jobsite can become more manageable with the Minotaur’s operator-centric design.

The fully sealed and pressurised

The Case Minotaur DL550 merges the capabilities of a loader and a dozer into one machine

rollover protection system/falling object protection system level one enclosed cab provides a quiet and comfortable working environment.

Features like a ventilation system with integrated heater, air conditioning and an AM/FM Bluetooth radio with USB port ensure operators stay comfortable and focused throughout their shift.

The Minotaur’s fully chassisintegrated C-frame, equipped with the same blade featured on the Case 650M dozer, has 11.7 tonnes of drawbar pull to ensure smooth and efficient dozing, while its vertical lift path and 2,495kg rated operating capacity make it a highly capable site loader.

“The Case Minotaur DL550 represents a leap forward in construction equipment capabilities, embodying innovation, power and a customer-centric design,” Case says.

“Transform your operations and elevate your productivity with this revolutionary compact dozer loader from Case Construction Equipment.”

For more information, head to your nearest Case dealer or visit casece.com.au

An industry-exclusive integrated ripper provides greater versatility

CATERPILLAR

140M3

2015,AccugradeReady, AirConditioner,Air SuspensionSeat, Beacon,Lighting, Mirrors,MoldboardSize -14',OnlineOwner's Manual,ProductLink, Pushblock,Radio-AM FMRadio,RipperMulti-Shank,ROPSEnclosed,Scarifier. N9D00466. TA1232534. $381,700

CATERPILLAR

972M

2021,AirConditioner, AutoLube,Beacon, Bucket,Fire Extinguisher,Lighting, Mirrors,OnlineOwner's Manual,ProductLink, Protection12Months 1500HrsEPP,RadioAMFMRadio,Ride Control,ROPSEnclosed,Weight MonitoringSystem. M8W20255. TA1213828. $456,500

CATERPILLAR

AP600FLRC

CATERPILLAR

730-04LRC

2020,AirConditioner,Air SuspensionSeat,Am FmRadio,AutoLube, CustomerValue Agreement(Cva)24 MonthsHDAdvantage, EROPS,Lighting,Online Owner'sManual, ProductLink,Protection 12Months1500hrsEpp. RearView Camera,Tailgate. 3F300510. TA1173354. $577,500

CATERPILLAR

930K

2019,AirConditioner, AutoLube,Beacon, Bucket,Hydraulic Coupler-Quick,Fire Extinguisher,ForksPallet,Lighting,Mirrors, OnlineOwner'sManual, Protection12Months 1500HrsEPP,Ride Control,ROPSEnclosed,Weight MonitoringSystem. P3K00732. TA1232292. $324,500

2018,3DGradeControl -Capable Beacon Generator

OnlineOwner'sManual ProductLink

Screed,ExtensionsHydraulic SonicGradeSensors WashdownTank. JA600105. TA1205008. $183,700

962M

2017,AirConditioner Counterweight Lighting Mirrors

OnlineOwner'sManual ProductLink Radio-AMFMRadio RideControl ROPS

SteeringType-Wheel. EJB00947. TA1223308. $313,500

CATERPILLAR AP300FLRC

2021,CustomerValue Agreement(CVA)24 MONTHSHD ADVANTAGE HEATEDENDGATE OnlineOwner'sManual PRODUCTLINK ProtectionREMAINING FACTORYWARRANT 36/3000PREMIER. YES00126. TA1186026. $247,500

CATERPILLAR

326-07

2019,3DTopCon System AirConditioner AuxiliaryHydraulics BoomCheckValve IncludesTiltMudAnd1 GPBucket OnlineOwner'sManual Protection12Months 1500hrsEPP StickCheckValve. MFJ00134. TA1185595. $275,000

For a huge range of new and used Cat® parts visit CatUsed.com today.

A family-owned civil contractor business wanted a machine that was efficient and eye-catching – a machine that would make it stand out from the crowd. Onetrak and Hidromek provided the answer

When Sofos Civil Contracting managing director Michael Emerzidis wanted to expand the contracting side of his business, he didn’t want to add just any machine to his fleet. He wanted an excavator that would make Sofos Civil stand out from the crowd, a conversation starter, a point of difference.

He found exactly what he was looking for, thanks to Hidromek and Onetrak.

Sofos Civil Contractors was originally founded in 2013 under the name Costless Plant Hire and specialises in demolition, excavation and civil construction services.

With two decades of experience, the company previously played a pivotal role in a larger family enterprise before embarking on its own journey.

Currently engaged on a project in Sydney, the business is preparing a site for a brand-new, four-storey split-level home. This has included demolishing the old house and carrying out rock excavation for the building, swimming pool and onsite stormwater detention tank. Once the groundwork is complete, the construction of the new home will begin.

Managing director Michael Emerzidis was impressed with the machine’s sturdiness and spacious cab

Emerzidis says his team is committed to delivering excellence and maintaining the company’s reputation for high-quality workmanship. The team works closely with architects, engineers and clients to ensure that every aspect of the preparation for this project meets the highest standards and client expectations, he adds.

When Emerzidis made the decision to expand the contracting side of

Sofos Civil Contractors turned to Hidromek’s HMK145 as it expanded its contracting business

his business, he turned to Onetrak and Hidromek.

Although he had operated most excavator brands in the industry, ranging from 1.8t to 50t, he had yet to experience a Hidromek machine. His first encounter with Hidromek was in 2023 at the Onetrak stand during the Diesel Dirt and Turf Expo. Impressed by the machines’ appearance and the knowledgeable, approachable Onetrak team, Emerzidis began to consider a return to contracting.

Over the next six to seven months, he researched the capabilities of the HMK145 and thoroughly examined the many reviews and awards it had received.

By this stage Emerzidis was completely taken by the appearance of the machine and was suitably impressed by its capabilities. He was looking for a point of difference that would gain recognition and start conversations, and he felt the look of the Hidromek would spark that attention.

In his own words: “Give me a reason not to buy it!”

After researching the capabilities of the HMK145, Emerzidis was completely taken by the appearance of the machine and its capabilities

Rent-to-buy opportunity

And so, the process began for the purchase of the HMK145. Sofos Civil took advantage of Onetrak’s rent-tobuy option and took delivery of the machine in June this year.

Comparing the HMK145 to other machines he has operated, Emerzidis says he was impressed with the spacious and comfortable cab, as well as the Hidromek machine’s sturdiness.

“I value the counterweight balance and the sense of security it provides,” he says.

“The excavator is also wellbuilt and strong, including the underbelly, and with a great pump flow it has excellent hydraulics in comparison to other excavators in this class.”

Emerzidis believes the Hidromek machines are well thought out and one of his favourite features is the convenience and safety aspect of

Emerzidis’s father, who has 35 years of experience in the industry, also appreciated the design and quality of the machine

the siphon hose for refuelling.

He also noted the machine’s capacity for easy maintenance, with easy access to change oils and filters and to work on the hydraulic motor, as well as easily visible grease points.

“I think they have done a really good job of ticking all the boxes, it is really well thought out and crafted,” he adds.

Emerzidis revealed that his father, who has 35 years of experience in the industry, also appreciated the design and quality of the machine.

Another key point of difference for Sofos Civil was the Onetrak team.

From the start, Aaran Hayden, Onetrak’s local territory manager, made a strong impression on Sofos Civil with his friendly demeanour

and quick responses. The entire Onetrak team at the DDT also stood out for their approachability.

Emerzidis mentioned that he prefers to invest in family-operated businesses, reflecting his own background. Having downsized his operations to better serve smaller clients, he prefers to support companies that truly value his business.

Sofos Civil believes Onetrak has put a lot of effort into creating a strong brand identity that reflects its products, including Hidromek.

“The synergy between Onetrak and Hidromek is evident,”

Emerzidis says.

“For a relatively new brand in the Australian market, having a patient and dedicated team including the likes of Aaran and Brad [regional manager NSW and QLD], who promptly follow up and treat you with respect, is crucial.

“As Onetrak continues to grow, maintaining excellent customer service and accessibility become increasingly important,” he adds.

“The rent-to-buy option offered is incredibly beneficial and adds value to Onetrak’s offerings.”

Emerzidis says he is pleased to endorse this from his consulting perspective.

He has already had many people stop him to ask about the excavator and so far the Hidromek HMK145 is doing exactly what Sofos Civil had hoped it would.

Contact Onetrak if you would like to know more about the Hidromek range and what it could do for your business. Visit www.onetrak.com. au or call 1300 727 520.

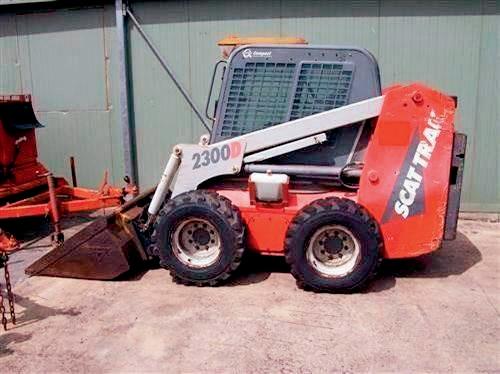

Brisbane Mini Excavator Sales has welcomed fresh stock of two new Sunward skid steer loaders, with a special offer available for eager customers

Queensland’s exclusive supplier of Sunward equipment, Brisbane Mini Excavator Sales (BMES), has a variety of new earthmoving machinery at its Brisbane-based yard.

Two of its latest additions are the 2024 Sunward SWL3220 and SWL2820 wheeled skid steer loaders.

These compact yet powerful loaders are the perfect running mate for a mini excavator, sales executive Steven Ragenovich says.

“A lot of our customers like to pair these machines up with 3.5-tonne excavators as a combo unit,” he says.

“They’re great little machines, wellsuited for site cleanup, back filling and levelling.”

Power and size are the main two differences between the skid steer models, offering more optionality, depending on the job requirements.

The 3220 weighs in at 3,450kg (3.5 tonnes) and has a rated operating capacity of 1,100kg (1.1 tonnes), while the 2820 is 2,830kg (2.8 tonnes) and comes with a 750kg (0.75-tonne) rated operating capacity.

Both Sunward machines are powered by a genuine Kubota engine, with the 3220 offering 73 horsepower (54.6kW) and the 2820 producing 56hp (41.7kW).

As standard, the skid steer pair comes with a hydraulic 4-in-1 bucket, a rollover protection system and falling object protection system

cabin, integrated air conditioning and high flow hydraulics.

The ability to use high-flow attachments is also a key selling point, so if a customer needs to use a more powerful trencher, for example, they can quickly fit it on with the multi-fit quick hitch.

“Any Digga or Norm Engineering attachment will fit straight onto these machines,” Ragenovich says.

Thanks to the multi-fit quick hitch,

attachments can be quickly swapped out to suit the task at hand – providing enhanced versatility.

From running a mixer to an auger or a variety of buckets and blades, these machines offer a number of different possibilities.

Ragenovich adds that another key selling point of the skid steer duo is the 3,000-hour/three-year comprehensive factory-certified warranty (conditions apply).

“We’ve got plenty of these machines in stock at the moment and we’re doing a special offer for our customers,” he says.

“If you purchase any Sunward 2820 or 3220 skid steer, you’ll get complimentary Digga pallet forks and a Digga spreader bar.”

To make sure you don’t miss out on this special offer, head to www. brisbaneminiexcavators.com.au or call (07) 3807 4333.

Specialising in final trim work for road construction, Coopers Final Trim has been recognised with an award for its dedication to its field of expertise

Coopers Final Trim director Luke Cooper has been operating and specialising in motor graders for the best part of 15 years, but never did he think he’d win an award for his everyday work.

To his surprise, his business was named as the winner of the excavation and demolition category at the Australian Trades Small Business Champion Awards earlier this year.

The awards aim to shine a spotlight on the different trades and small businesses that keep the nation functioning, and Coopers Final Trim does this quite literally.

Established in 2021, the Newcastlebased business specialises in final trim work for road construction and infrastructure projects in the Hunter region.

Cooper first worked as a grader operator for a leading civil construction contractor, gaining expertise over a decade with the machines that he now uses daily.

“Once you get any good at operating a grader, you can never get out of them,” he says.

When the opportunity came to implement this expertise into a business of his own, he seized it.

Now as the director of Coopers

Final Trim, the business offers wet hire motor grader services.

It also used to provide dry hire, but has since shifted its focus solely to wet hire, with Cooper operating a single SmartGrade John Deere 672GP.

“This transition has allowed us to maintain the highest level of quality, ensuring that the machine is used to its full potential,” he says.

Compared to standard graders that focus on bulk earthworks, Cooper’s final trim work is responsible for achieving detailed accuracy when fine-tuning road surfaces.

“Our clients have strict specifications that we must meet,” he says.

“This is critical in road construction and similar projects where precision ensures long-term stability and performance.”

Coopers Final Trim has varying clients, including civil construction companies, councils and private developers.

In road construction projects, Coopers Final Trim helps to prepare the base and surface layers, ensuring a smooth and level surface.

Depending on the project requirements, Coopers Final Trim has the capacity to work on both public and private roads and is more than willing to take on projects across New South Wales (NSW).

This flexibility allows the business to meet the needs of varying clients throughout the state, with a focus

CATERPILLARD5K2XL 2019,4,500hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrservice,workshopreport..S1201. TA1225199. $249,900plusGST

CATERPILLARD8RSERIES2 2003,11,500hrs, SUtilt,CAT4Cylinderripper,servicedwith workshopreport.S1197. TA1225194. $369,900plusGST

CATERPILLAR259D3 2021,1,850hrs,4in1 bucket,250hrservice,verygoodtracks..S1200. TA1225198. $94,900plusGST

KOMATSUD61EX 2018,5,800hrs,6wayblade, MSripper,TopConwired.S1067. TA1163362. $309,900plusGST

CATERPILLARD5K2XL 2018,2018 CATERPILLARD5K2XL233.233. TA1166133. $258,390inc.GST

CATERPILLAR12M3 2015,2015 CATERPILLAR 12M3239.239. TA1166139. $362,890inc.GST

CATERPILLAR12M3 2016,Graderwith4,950hours. 14ftblade,joysticksteering,Autoshift,Lightpackage, soldwithMSripperandpushblock.This12M3Grader willbesoldclean,detailedandservicedwithour comprehensiveworkshopreport.S1013. TA1139678.

CATERPILLARD6K2XL 2017,4,900hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrserviceandworkshopreport..S1199. TA1225197. $269,900plusGST

KOMATSUD39EX-24 2021,1,200hrs,6wayblade, 95HP,MSripper,suitnewbuyer.ThisD39EX-24willbe soldclean,detailedandservicedwithour comprehensiveworkshopreport..S1108. TA1173489. $274,890IncludingGST

JOHNDEERE450K 1400hrs,6wayblade, sweeps,screensandMSrippertobefitted. S1063. TA1163359. $229,900plusGST

CATERPILLARD6TLGP 2017,6,590hrs,ARO wired,6wayblade,tankguarding,Conventional undercarriage,rearscreen.Soldwith250hr serviceandworkshopreport.S1165. TA1198871. $419,000plusGST

CATERPILLARD6TXL 7,150hrs,VPAT,ARO wired,nextgenMSripper,goodU/C.Soldwith 250hrserviceandworkshopreport.S1198. TA1225196. $439,900plusGST

on delivering accuracy down to the millimetre.

Cooper recently demonstrated this versatility on a 12-month project in Armidale, NSW – a five-hour journey from home.

Providing final trim services for the Armidale Regional Council and Transport for NSW, Cooper helped upgrade the Waterfall Way scenic route – a 185km drive that links Coffs Harbour and Armidale.

Cooper worked Monday to Friday every week on the route that passes through rainforest, river valleys and waterfalls, including the New England and Dorrigo national parks; only returning home on weekends.

“I wouldn’t have been able to do the project without the support of my wife at home,” he says.

This all shows the commitment he has to his clients and his business.

John Deere

Coopers Final Trim has always had experience with John Deere graders, previously offering a 772GP for dry hire services, and now solely focusing on wet hire with the SmartGrade 672GP.

When asked why the business chose John Deere over other brands, Cooper says it came down to its advanced technology and reputation for reliability.

One of the biggest selling points for him was John Deere’s mastless Local Positioning System (LPS).

“This system provides precise positioning, even in areas where GPS signals are limited or obstructed by buildings or trees,” he says.

LPS offers millimetre-level accuracy, an essential for meeting

high client standards in fine grading.

“The mastless design significantly improves the grader’s usability and visibility,” he adds.

“Without a pole mounted on the side of the blade, as seen in other brands, the grader is far easier to manoeuvre and operate effectively.”

Cooper also emphasises the premium circle feature.

“This enhances blade control, making it perfect for the final trim work we specialise in,” he says.

“This level of precision is essential for meeting our clients’ strict specifications.

“I’m currently working with 0 to 10mm specifications, which can’t really be achieved with GPS, so the LPS comes in pretty handy.”

This combination of the LPS system and the premium circle

The business is responsible for achieving detailed accuracy when fine tuning road surfaces

ensures his SmartGrade 672GP can achieve precise results on any project, with results within 0–5mm.

“As technology in the industry has advanced, we’ve kept pace by using the most up-to-date equipment, to provide our clients with the best results possible,” he says.

Coopers Final Trim is looking to expand its grader fleet in the future.

To help fulfill this, the awardwinning business is searching for skilled grader operators to match the level of precision its clients expect.

When asked about winning the excavation and demolition category at the Australian Trades Small Business Champion Awards, Cooper says it came as a shock.

“My wife and I went to the awards to see what it was all about, it was very surprising to end up winning,” he says.

“It was an unreal night and was great to get the recognition for the work we have put in.

“Hopefully we can get back there next year.”

For more information on Coopers Final Trim, please call Luke Cooper on 0402 169 592 or email luke@ Coopersfinaltrim.com

MCCLOSKEYR155

2018,16'x5'twodeck,apronfeeder,readyforwork condition.SM177. TA1203700. $295,000+GSTExMSCdepot

MCCLOSKEYJ50V2

2018,1270x735jawopening,Catengine,magnet,sidebelt 54tonne.KM83. TA999690.

$490,000+GSTEXDepot

MCCLOSKEYR70

Doubledeck,CatC4.4(130hp).SM330. TA1227402. POA

MCCLOSKEYJ50V2

2019,1270x735jawopening,Catengine,wellmaintained andregularlyserviced.KM91. TA1232332.

$620,000+GSTExKingIsland

MCCLOSKEYS130

2019,14'x5'doubledeck,Catengine,15'hopper.SM225. TA1198773.

$290,000+GSTExMSCdepot

MCCLOSKEYS190

2020,20'x5'twodeck,100mmgrid,readyforwork condition.SM237. TA1203702.

$345,000+GSTExMSCdepot

MCCLOSKEYI3CR diesel/hydraulicpowered,adjustableimpactapron 27,500kg.KM138. TA859307. POA INSTOCK

MCCLOSKEYJ40

1016x610mmjawopening,Catengine,magnet,sidebelt 37tonne.S167. TA1227406. POA

CPB Contractors is on the team delivering the Main Road South and Victor Harbour Duplication projects in SA as part of the Fleurieu Connections Alliance project

CPB Contractors has been visiting schools in South Australia to create awareness about career opportunities across the industry.

The company has been trusted to deliver some of Australia and New Zealand’s most complex critical infrastructure projects and has been delivering for its clients and communities for more than 90 years.

CPB Contractors says it is committed to engaging with school students to create awareness about the career opportunities across industry and says that showcasing its major, city-shaping projects is key to that work.

In March this year, CPB Contractors’ school engagement program sparked excitement in South Australia.

Excited students from Old Noarlunga Primary School in SA got a taste of the construction world thanks to a visit from the team delivering the Department for Infrastructure and Transport’s

Fleurieu Connections Alliance (FCA) project – one of the state’s largest road projects.

The visit aimed to spark interest in STEM fields and showcase the diverse opportunities in the construction industry.

Justin Redelinghuys, CPB Contractors alliance project director, says students of all ages enjoyed the day – which consisted of interactive activities, presentations and a guided bus tour of the project.

“CPB Contractors has an established school engagement framework which we’re really proud to bring to local schools in the community while we deliver the Fleurieu Connections Alliance project,” Redelinghuys says.

“By fostering a passion for STEM and an interest in construction early on, we hope to inspire future generations of skilled professionals.”

CPB Contractors is delivering the Main Road South and Victor Harbor Duplication projects as part of the

CPB Contractors visited Old Noarlunga Primary School in SA in March to highlight career opportunities and showcase projects

FCA alongside Aurecon, GHD and the Department for Infrastructure and Transport.

The duplication of Main South Road involves duplicating approximately 10 kilometres from south of Griffiths Road, Seaford to Aldinga.

This includes the addition of two new lanes in each direction, as well as the widening of shoulders and the construction of new median barriers.

The duplication of Victor Harbor Road involves duplicating approximately five kilometres between Main South Road, Old Noarlunga, and Main Road, McLaren Vale.

This includes the addition of one new lane in each direction, as well as the widening of shoulders and the construction of new median barriers.

In May, CPB Contractors teamed up with students in SA to help preserve and celebrate traditional Kaurna culture, as part of the FCA project.

Led by CPB Contractors and its Alliance partners, the FCA project is delivering innovative cultural immersion workshops to foster cultural understanding and leave a lasting legacy in South Australia.

Under the guidance of local Kaurna artists from Aboriginal Urban Design, the workshops give students the opportunity to learn about the traditional history, symbols and

stories of the region.

They also cover practical skills such as how to grind and mix ochre paint, which participants then utilise to create visually striking cultural poles.

Measuring two to five metres tall, these striking poles will become permanent fixtures within the four rest bays along Main South Road’s shared-use path.

Once complete, the rest areas will incorporate traditional carvings, seating and interpretive signage to tell the story of Kaurna culture in that specific location.

CPB Contractors says it is committed to engaging with school students

Redelinghuys explains that this cultural project is part of the FCA project’s broader Kaurna Indigenous Urban Art strategy.

“This strategy will see larger art installations on overpasses and other structures along the Main South Road and Victor Harbor Road Stage 1 Duplication projects,” he says.

“These installations will carry themes of fishing and the sea, holding significant meaning for the Kaurna people of the Fleurieu Peninsula.”

Over 100 students from four local primary schools have already participated in this innovative program, contributing to the preservation and celebration of Kaurna culture.

CPB Contractors hope the program will spark interest in STEM fields and showcase opportunities in construction

2012 CATERPILLAR 140M B9D Machine #ZM009053

$161,800 + GST

2013 JOHN DEERE 670G 653850

2021 CATERPILLAR 336LC GDY

2023 CATERPILLAR 320 ZBN Machine #ZM009056 Machine #ZM009074

$236,300 + GST

$400,000 + GST

2023 CATERPILLAR 320GC DKJ

$218,000 + GST 1999 KOMATSU D65EX12-62862

+

$272,800 + GST

2023 CATERPILLAR 950GC M5K

#ZM009084

$328,000 + GST

2023 BOBCAT S510 B5K211192

+ GST

The Rookwood Weir project team moved more than 800,000 cubic metres of soil and poured 131,000 cubic metres of concrete before construction was completed in November 2023

The Rookwood Weir project, a collaboration between Sunwater, Acciona, GHD and McCosker, has been named Queensland Project of the Year at the recent 2024 Engineers Australia Excellence Awards.

The awards, which recognise Queensland’s most innovative engineers and engineering projects, were held at voco Brisbane City Centre on September 12.

Engineers Australia says the major infrastructure development “demonstrates excellence in engineering and social responsibility”.

“The project has delivered significant environmental benefits through innovative design improvements, reducing the need for excavation.

“The Alliance construction model fostered collaboration, with a strong focus on safety, well-being and mental health.

“The project also promoted Indigenous and female employment, offering apprenticeships and supporting local agriculture.

“Recognised with an ‘Excellent’ rating from the Infrastructure Sustainability Council, the Rookwood Weir project sets a benchmark for

sustainable, world-class projects in regional areas.”

Local winners will go on to represent their division at the national awards’ gala dinner on November 21 at Brisbane City Hall.

Located 66km southwest of Rockhampton, the Rookwood Weir provides Central Queensland with an additional source of water for its agriculture, urban and industrial needs.

After plans to build the weir received federal government approval in February 2017, the Queensland government-owned Sunwater partnered with designer GHD and construction joint-venture partners McCosker Contracting and ACCIONA to build the weir.

The project team moved more than 800,000 cubic metres of soil and poured 131,000 cubic metres of concrete before construction was completed in November 2023.

The project contributed more than $270 million to the Central Queensland economy and is expected to create approximately 500 full-time and seasonal jobs to support agriculture growth.

Rookwood Weir provides Central Queensland with an additional source of water for agriculture, urban and industrial needs. Image: Rookwood Weir

The Rookwood Pier Project team was also recently presented with the 2024 Australian Construction Achievement Award.