ISSUE 141 | APRIL 2024 OFFICIALLY ENDORSED BY SOLAR INSTALLER PAGE 26 PAGE 28 PAGE 40 Australia’s greener future Critical role of social procurement Guardian of the solar power New lease on life Extending the life of industrial electronic assets – pg 22

Have you got the procurement & supply chain expertise to deliver your renewables projects? We do.

We can help you:

Build the right supply chain

Deliver on your ESG commitments

Enable high performance procurement

We are a specialist Asia Pacific procurement and supply chain consulting firm, part of Bain & Company. We deliver an integrated end-to-end procurement transformation offering.

DO YOU KNOW A DRIVER OF CHANGE?

Our team are highly experienced in delivering procurement, supply chain and social impact for infrastructure and renewable energy projects, including wind, solar, hydrogen, hydro and transmission.

Thurs 20 June, 2024

WOMEN IN INDUSTRY NOMINATIONS ARE NOW OPEN.

Our experienced team of 150+ procurement and supply chain professionals, provide organisations with practical, hands-on advice and delivery support.

Now is your chance to nominate an industry leader who you believe is advocating for positive change and deserves to be recognised.

Find out how we can help you take your project from design, to delivery and operation.

The Women in Industry Awards recognise outstanding women leaders from across Australia’s industrials sector.

Justin Sara, Director ArcBlue justin.sara@arcblue.com.au

arcblue.com/energy-naturalresources

+61 401 252 770

womeninindustry.com.au PROUDLY SUPPORTED BY Australia PROUDLY PRESENTED BY MHD upply

4 | ecogeneration April 2024 www.ecogeneration.com.au REGULARS From the editor ......................................................................................................................6 News in brief ..............................................................................................................................8 Industry update with Kane Thornton ......................................................... 16 Greener horizons for the sunshine state ............................................ 20 THE SOLAR INSTALLER Akcome: Designed to shine 38 Guardian of the solar power ............................................................................... 40 Unlocking the potential of commercial solar ..................................42 Say goodbye to power outages .................................................................... 44 ATESS unveils ‘worry-free’ off-grid solution .................................... 46 Solar news ................................................................................................................................48 Solar Accreditation Australia confirmed as new accreditor............................................................................................................ 50 CORE market wrap .........................................................................................................52 Equinix unveils 1MW rooftop solar system ......................................... 54 Like us on Facebook facebook.com/EcoGenMag 18 56 54 30

The accreditation provider for installers and designers .....18 Rejuvenating industrial electronic assets ........................................... 22 Taking Australia into a greener future ....................................................26 Redefining social procurement and licence...................................... 28 Publisher first to use paper-wrapping mailing machine 55 Exploring the winds of change ........................................................................ 56 Be here and be part of the future ................................................................ 58 ELECTRIC VEHICLES Australia’s electric vehicle juncture ................................................... 30 Plug into the future ............................................................................................... 32 Embracing the future of electrive vehicle fleets .................... 34 Contents ISSUE 141 | APRIL 2024

FEATURES

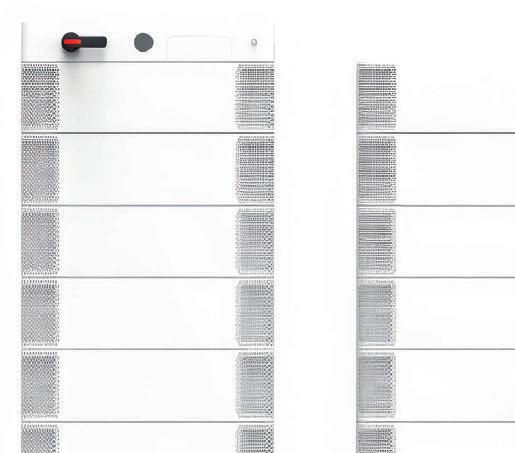

Growatt New Energy Australia Pty Ltd au.growatt.com 1800 476 928 australia@ginverter.com Reliability

Inverter Supplier Residential Inverter Supplier

Inverter Supplier

To enable everyone to benefit from sustainable energy PV

Hybrid

SustainabilityAll-Scenario Solutions SMART ENERGY FOR A REEN FUTURE

From the editor

Welcome to the April edition of ecogeneration. This issue focuses on Australia’s rising demand for electric vehicles (EVs) necessitates the rapid growth of charging infrastructure, from commercial road transport to home charging stations, and everything in between.

With a focus on EV, ecogeneration takes a deep dive into the industry by speaking with Daniel Bleakley, Senior Energy and Technology Transition Advisor at Next System about how in comparison to many countries, Australia lacks nationwide incentives for purchasing new EVs.

Despite the hard truths of Australia’s EV industry, Bleakley said we should not be discouraged, with recent data showing Australia’s EV market slowly growing.

EV sales more than doubled in 2023 to 87,217 vehicles, capturing 7.2 per cent of the total market, according to the Federal Chamber of Automotive Industries. When including hybrids, electrified models accounted for an impressive 16.2 per cent share.

This momentum has continued into 2024, with EVs achieving a record 9.6 per cent market share in February.

Recognising this shortage of expertise in EV, Holmesglen has launched a specialised EV charging infrastructure course, tailored for the Australian market, and based on local standards. The course equips licensed electricians with the knowledge and skills necessary to design, install and commission EV chargers.

February was also a month of change, with the Clean Energy Regulator (CER) announcing Solar Accreditation Australia (SAA) as the new installer and designer accreditation scheme operator supporting the small-scale Renewable Energy Scheme (SRES).

SAA now replaces the Clean Energy Council (CEC), which served in this role for the past decade, with the official transition period now underway.

SAA is an independent and accountable body which aims to enhance standards, transparency, and accountability in the solar energy sector. Accredited installers and designers under SRES must transfer to SAA by June 2024 to maintain eligibility for small-scale technology certificates. The transition incurs no fee, and existing CEC accreditation expiry dates and fees are honoured.

Happy reading!

Molly Hancock ecogeneration Managing Editor

Follow ecogeneration on LinkedIn

ecogeneration acknowledges the Cammeraygal people, traditional custodians of the land on which this publication is produced, and we pay our respects to their elders past and present. We extend that respect to all Aboriginal and Torres Strait Islander people today.

Chief Executive Officer: John Murphy

Managing Editor: Molly Hancock molly.hancock@primecreative.com.au

Assistant Editor: Fred Zhang

Business Development Manager: Nick Lovering, +61 414 217 190

nick.lovering@primecreative.com.au

Client Success Manager: Karyssa Arendt karyssa.arendt@primecreative.com.au

Production Manager: Michelle Weston

Head of Design: Blake Storey

Designer : Kerry Pert

Subscriptions : T: +61 3 9690 8766 subscriptions@primecreative.com.au

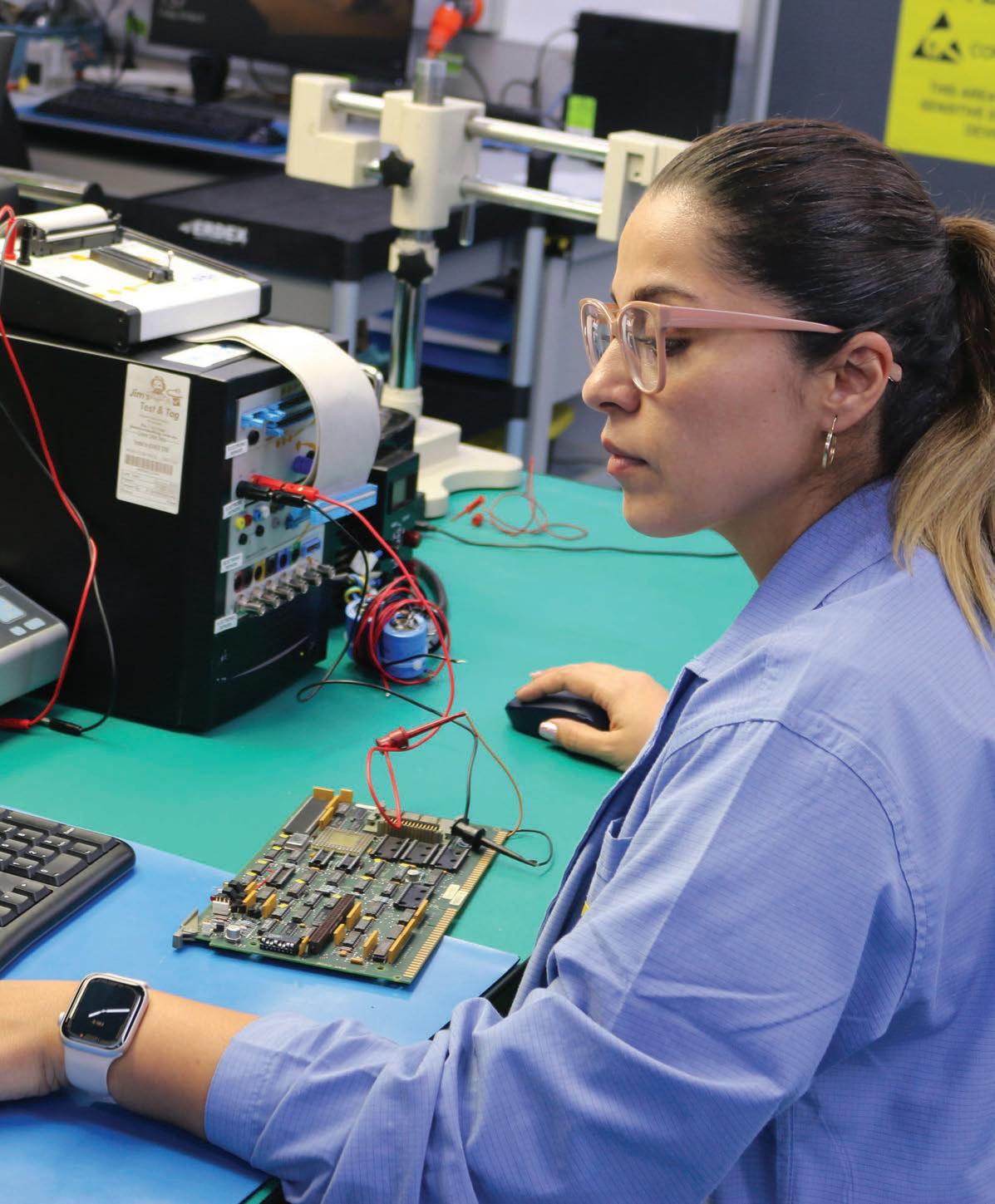

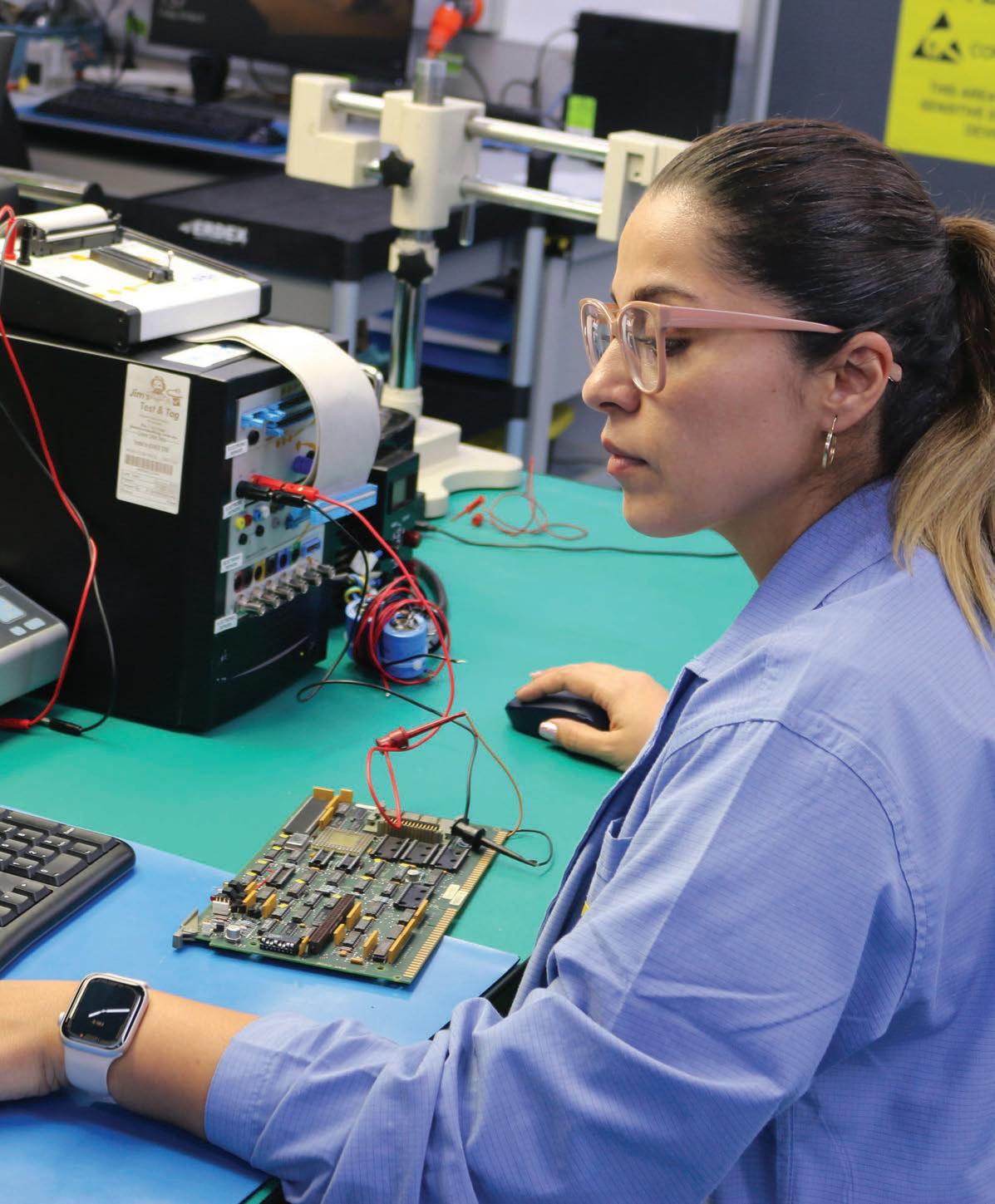

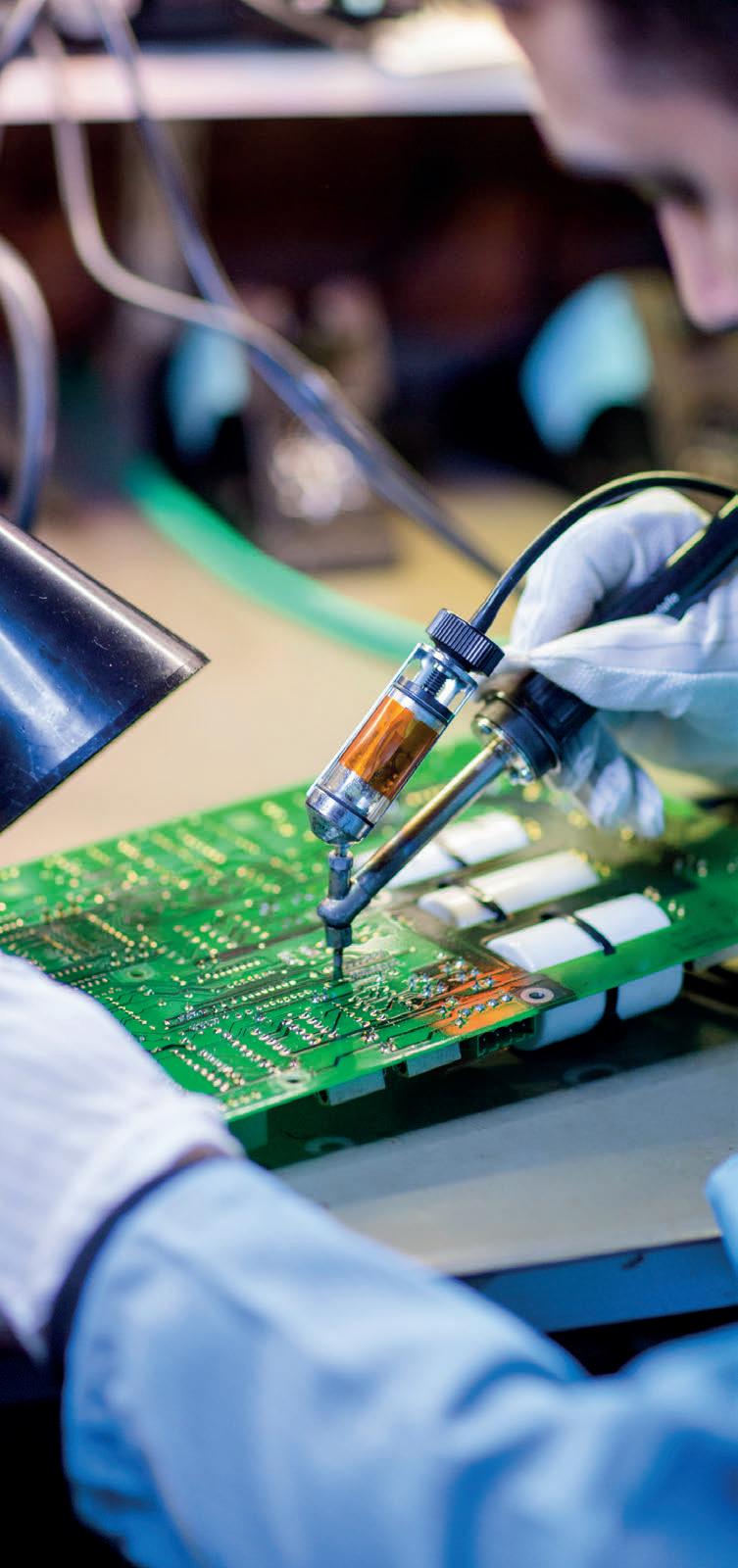

Cover image: (Main) Rom-Control.

ecogeneration is printed on Lumi paper which is PEFC-certified and manufactured in an ISO 14001-certified mill. Lumi paper also contains premium white waste paper, reducing matter going into landfill. This magazine is available to interested parties throughout Australia and overseas. Themagazine is also available by subscription. The publisher welcomes editorial contributions from interested parties, however, the publisher and the Editorial Board accept no responsibility for the content of these contributions and the views contained therein are not necessarily those of the publisher or of the Editorial Board. The publisher and theEditorial

For the latest industry news, sign up for the FREE WEEKLY NEWSLETTER and check out our website at ecogeneration.com.au

Average net distribution 6616 Period ending September 2021

stated otherwise in writing, by providing editorial material to Prime Creative Media, including text and images, you are providing permission for that material to be subsequently used by Prime Creative Media, wholeor in part, edited or unchanged, alone orin combination with other material in any publication or format in print or online or howsoever distributed, whether produced by Prime Creative Media and its agentsand associates or another party to who Prime Creative Media has provided permission. www.ecogeneration.com.au Published by: PRIME CREATIVE MEDIA PTY LTD ABN: 51 127 239 212 379

Drive Melbourne

3008, Australia T: +61

Board do not accept responsibility for any claims madeby advertisers.Unless explicitly

Docklands

VIC

3 9690 8766 www.primecreativemedia.com.au

SOLAR INSTALLER New lease on life life of industrial –6 | ecogeneration April 2024 EDITORIAL

Affordable, Reliable, Durable Embrace the Future, A Safer Choice hoymiles.com Microinverter Expert Open Energy for all

News in brief

Australia’s first indigenous engagement guide for renewables industry unveiled

The Clean Energy Council (CEC) and KPMG have jointly launched Leading Principles: First Nations and Renewable Energy Projects, marking the first comprehensive national guide on meaningful engagement, consent, participation, and benefit-sharing with First Nations people in Australian renewable energy projects.

Co-authored with the First Nations Clean Energy Network, the guide operationalises the network’s Aboriginal and Torres Strait Islander Best Practice Principles for Clean Energy Projects.

CEC Chief Executive Officer Kane Thornton said the guide’s purpose is to uphold the rights of First Nations peoples and enhance community outcomes.

“Australia’s clean energy sector has identified the need for stronger engagement and relationships with First Nations peoples,” Thornton said.

“We are proud to partner with the First Nations Clean Energy Network and KPMG to forge a path ahead for Australia’s clean

energy industry to work hand in hand with First Nations communities.

“With proper practices in place, the essential work of the energy transition will not only accelerate Australia towards achieving its targets but provide First Nations Australians with an opportunity to be heard and play a crucial role in a defining economic shift for the country.”

Leading Principles: First Nations and Renewable Energy Projects outlines expectations for industry and provides key considerations at each project stage, promoting stronger relationships and engagement with First Nations communities and groups.

First Nations Clean Energy Network coChair Karrina Nolan stressed the guide’s role in placing the rights, interests, and aspirations of First Nations peoples at the forefront of Australia’s clean energy transformation journey.

“The guide provides a new template for

governments, industry and First Nations communities to work together towards the shared goal of more affordable, reliable and sustainable energy for all,” Nolan said.

“Meaningful engagement with First Nations communities leads to energy partnerships, equity and ownership opportunities stands to maximise community support for projects, increase opportunities for local employment and businesses, and deliver stronger outcomes for sustainability and energy security.

Nolan added that the rights, interests and aspirations of First Nations peoples must be front and centre to achieve a just clean energy transformation. She said this will ultimately minimise risks, costs and delays for renewable energy projects being planned, developed and operated on country.

“And it’s something which must be done in partnership with industry. This guide can help with that,” she said.

Rio Tinto inks Australia’s largest renewable energy deal

Rio Tinto, one of the world’s biggest mining companies, has inked Australia’s largest renewable power purchase agreement (PPA) to date.

The 25-year PPA will see Rio Tinto acquire 80 per cent of the electricity from Windlab’s forthcoming 1.4 gigawatt (GW) Bungaban wind energy project to supply its Gladstone operations in Queensland.

Rio Tinto said the agreement solidifies its position as the largest industrial purchaser of renewable power in Australia. The Gladstone operations include the Boyne aluminum smelter, Yarwun alumina refinery, and Queensland alumina refinery.

Still early in its development, the Bungaban project is set to be constructed and operated by Windlab at a site about 40km from

the town of Wandoan, and 290km south-west of Gladstone.

The Windlab agreement follows Rio Tinto’s recent PPA with European Energy Australia at the Upper Calliope solar farm, where the mining giant announced it will buy all electricity from the 1.1GW solar farm located 50km south-west of Gladstone.

Once operational, the combined 2.2GW of renewable PPAs with Windlab and European Energy could potentially slash carbon emissions by five million tonnes per year, constituting 10 per cent of Queensland’s current power demand.

In a statement, Rio Tinto Chief Executive Officer Jakob Stausholm emphasised the importance of large-scale renewables development.

“This agreement with Windlab builds on our momentum in our work to repower our Gladstone operations and provide a sustainable future for heavy industry in Central Queensland,” Stausholm said.

“The task remains challenging, but we have a pathway to provide the competitive, firmed power our Gladstone plants need, and we are continuing to work hard with all stakeholders, including the Queensland and Australian Governments, on getting there.”

“Competitive capacity, firming, and transmission, are critical to developing a modern energy system that can ensure more large-scale renewables development in Queensland and help guarantee the future of Australian industry.”

Construction of the Bungaban project is scheduled for late 2025, with the aim of becoming operational by 2029.

8 | ecogeneration April 2024 www.ecogeneration.com.au

The guide’s purpose is to uphold the rights of First Nations peoples and enhance community outcomes.

Rio Tinto’s agreement solidifies its position as the largest industrial purchaser of renewable power in Australia.

Image: edojob/stock.adobe.com

Image: Ruslan Batiuk/stock.adobe.com

NEW TECHNOLOGY, NEW PROJECTS, NEW IDEAS

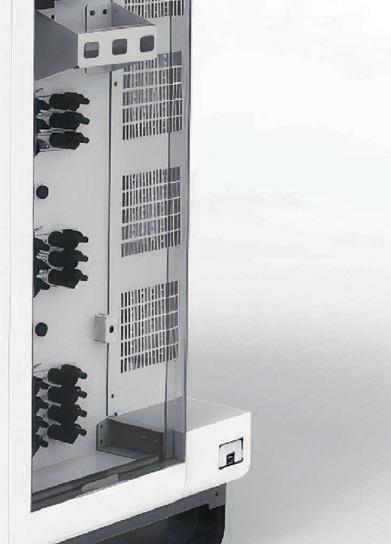

ELECTRONIC EQUIPMENT NEW LIFE FOR YOUR INDUSTRIAL

Rom-Control has been successfully repairing and refurbishing industrial electronic equipment, irrespective of function, make, model or age since 2007.

Imagine working with an expert that can do this at half your OEM replacement costs, backed by 2-year warranty! Now you can.

Our team of highly specialised & knowledgeable electronics engineers will repair and refurbish your industrial electronic equipment like:

•Variable Speed Drives and Servo Drives

•Programmable Logic Controllers

•Human Machine Interfaces

•Power electronics

•Inverters, converters

•Numeric controls

In industries like:

•Solar & Wind farms

•Mining

•Oil & Gas

•Light & Heavy Rail

•Shipping & Ports

•Food & Beverage

Start the journey to lower YOUR maintenance and capital expenditure and contact us now!

www.rom-control.com.au1300

766 287

Swinburne drives innovation in road-embedded EV charging

Swinburne University of Technology has been granted $3 million to integrate dynamic wireless charging technology into roads, allowing trucks and buses to charge wirelessly as they travel on highways.

The primary focus of the project is on electrifying heavy vehicles, presenting a solution to the challenge of ensuring sufficient charge for these vehicles with heavy loads over long distances.

According to Professor Mehdi Seyedmahmoudian, the leader of the project, the seamless integration of dynamic wireless charging systems into road infrastructure sets the stage for a transformative shift in the heavy vehicle industry.

“This collaborative effort is a perfect example of our shared vision for a sustainable transportation ecosystem that can significantly reduce our environmental footprint,” Seyedmahmoudian said.

The project anticipates significant benefits, not only for the environment but also for the efficiency and safety of the transport sector. By electrifying heavy vehicles, Australia could potentially save $324 billion by 2050, as Swinburne University of Technology said in a statement.

Funded through the Australian Government’s Cooperative Research Centres Projects (CRC-P) Grants scheme, the $8.2 million prototype for embedding advanced wireless charging infrastructure on regional roads is a collaborative effort involving ACE Infrastructure, SEA Electric, Fleet Plant Hire, Royal Melbourne Institute of Technology, Siemens, ARRB Group, and Net Zero Stack.

Queensland’s Wambo Wind Farm set to double in size

The Queensland Government has announced its plans to nearly double the capacity of the Wambo wind farm project in the southwest region of the state.

The expansion of the Wambo Stage 2 project will see the addition of 41 turbines to the existing 42-turbine farm in Jandowae, resulting in a total energy production of 506 megawatts (MW) by 2026.

These turbines, towering at 247m, are among the largest onshore wind turbines in the nation.

Queensland Minister for Energy and Clean Economy Jobs Mick de Brenni said the state’s abundant wind resources are attracting growing global interest, creating jobs and economic opportunity for the state.

“Queensland has the cheapest power of any state in Australia thanks to our nationleading cost-of-living relief support and growing renewables base – and today’s announcement will help keep it that way,” de Brenni said.

“Major industrial energy users are seeking low emissions power to decarbonise their production and the Miles Government is delivering, because that’s good for the economy and good for jobs.

“Queensland has been the world leader in rooftop solar, are now we are building world-class wind power thanks to partnerships between publicly owned energy companies like Stanwell, and Cubico Sustainable Investments.”

The Queensland Government, through its Queensland Energy and Jobs Plan, aims to reduce household power bills by about $150 per year and small business costs by approximately $1495 annually by 2032, with the assistance of projects like Wambo Stages 1 and 2.

Additionally, wholesale prices are expected to decrease by around 15 per cent by 2040 as the state transitions to renewable energy.

The Wambo wind farm is a collaborative effort between publicly owned energy company, Stanwell Corporation, and global sustainable developer, Cubico. Stanwell will own 50 per cent of the energy produced, with the remaining power purchased from Cubico under a 15-year agreement.

Doubling the size of Wambo is anticipated to contribute significantly to the state’s goal of achieving 70 per cent renewables by 2032, with the added benefit of stimulating the local economy.

The construction phase is expected to create around 200 direct jobs and up to 500 indirect jobs, providing a substantial economic stimulus during the multiyear build.

Foundations for the first wind turbines of Wambo Stage 1 are already underway, and construction of Stage 2 is scheduled to commence in mid-2024.

Commercial operation of Stage 1 is expected by 2025, with Stage 2 following in 2026, creating an additional eight ongoing jobs.

10 | ecogeneration April 2024 www.ecogeneration.com.au

The QLD Government will double the capacity of the Wambo wind farm project.

The project aims to enable trucks and buses to charge wirelessly as they travel on highways.

Image: piai/stock.adobe.com

NEWS IN BRIEF

Image: vencav/stock.adobe.com

With 12GWh of Battery Energy Storage in development, Pacific Green is focused on playing a crucial role towards achieving the worldʼs net-zero emissions target.

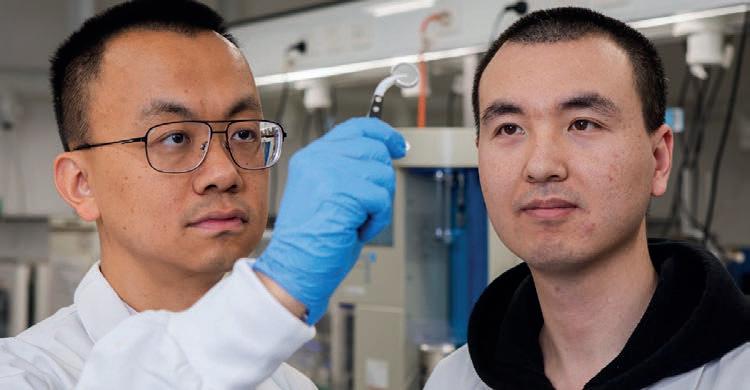

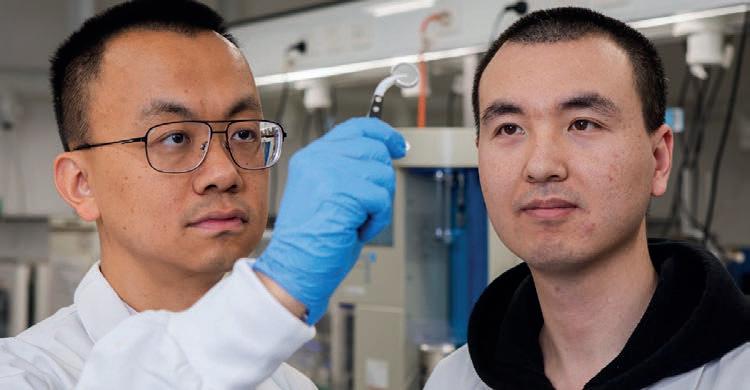

University unveils recyclable water batteries

Researchers at RMIT University, along with global industry collaborators, have developed recyclable “water batteries” that address safety concerns associated with traditional lithium-ion batteries.

The team focuses on aqueous metal-ion batteries, utilising water instead of organic electrolytes to prevent the risk of fire or explosions. Lead researcher professor Tianyi Ma highlighted the eco-friendly aspect of their batteries, emphasising the ability to safely disassemble them for materials reuse or recycling.

“What we design and manufacture are called aqueous metal-ion batteries – or we can call them water batteries,” Ma said.

“Addressing end-of-life disposal challenges that consumers, industry and governments globally face with current energy storage technology, our batteries can be safely disassembled, and the materials can be reused or recycled.”

According to RMIT, the simplicity of the water battery’s manufacturing process makes mass production feasible, using abundant and less toxic materials like magnesium and zinc.

The team prevented dendrite growth by coating battery parts with a protective layer of bismuth and its oxide.

As a result, the water batteries demonstrated a longer lifespan comparable to commercial lithium-ion batteries, making them suitable for high-speed and intensive real-world applications.

The energy density of the water batteries is closing the gap with lithium-ion technology, with a recent magnesium-ion water battery achieving an energy density of 75 watt-hours per kilogram (Wh kg-1), approaching 30 per cent of the latest Tesla car batteries. The goal is to further increase energy density by developing new nano materials for electrodes.

Professor Ma sees magnesium-ion water batteries as potential replacements for

A $14m to boost Aussie-made batteries

The Albanese Government has allocated $14 million to Powering Australia Limited to establish the Powering Australia Industry Growth Centre, in order to help Australian businesses manufacture renewable energy technologies locally.

The Powering Australia Industry Growth Centre program, spanning from 2023-2024 to 2026-2027, is a key component of

lead-acid batteries in the short term (one to three years) and lithium-ion batteries in the long term (five to 10 years).

“Magnesium is lighter than the alternative metals, including zinc and nickel, has a greater potential energy density and will enable batteries with faster charging times and better capability to support power-hungry devices and applications,” Ma said.

The in-depth study, Synergy of dendrites-impeded atomic clusters dissociation and side-reactions suppressed inert interface protection for ultra stable Zn anode, was originally published in Advanced Materials.

the Australian Made Battery Plan is aimed at boosting domestic battery manufacturing to boost job creation and economic prosperity.

The program will support local businesses in the development and adoption of renewable technologies, with a focus on batteries.

Objectives include facilitating connections between critical minerals producers and renewables manufacturers, fostering collaborations between government, research institutions, and industry, addressing battery regulatory barriers, and supporting First Nations businesses through a dedicated advisor.

According to the government, this initiative aligns with its broader support for the renewable technology industry, encompassing projects like Powering Australia, Rewiring the Nation, and a Future Made in Australia.

Minister for Industry and Science Ed Husic said the potential for batteries, renewables, and low-emissions technologies to create jobs and enhance Australia’s economic resilience in a statement.

“Batteries, renewables and other low-emissions technologies offer huge opportunities for Australian industry to create jobs and the sovereign capabilities critical to our economic success,” Husic said.

“This $14 million investment is targeted support to grow Aussie know-how in these emerging areas.

“It aligns with what we’re doing with our $15 billion National Reconstruction Fund, which has renewable and low-emissions technologies as one of its priority investment areas, once again demonstrating how government linking up policies can better support Australian industry.”

12 | ecogeneration April 2024 www.ecogeneration.com.au

Professor Tianyi Ma (left) and Dr Lingfeng Zhu in the team’s lab at RMIT University.

Image: malp/stock.adobe.com

The program aims to help Australian businesses manufacture renewable energy technologies locally.

NEWS IN BRIEF

Image: Carelle Mulawa-Richards, RMIT University

A $140m grant for Pilbara Hydrogen Hub

The Federal Government has finalised a $140 million agreement with Western Australia to establish the Pilbara Hydrogen Hub.

This hub aims to be a significant centre for hydrogen production and export, potentially serving as an international gateway for Australian-made green steel and iron.

The project is expected to generate nearly 1000 direct and indirect jobs, spanning various professions such as builders, concreters, electricians, plumbers, fitters, and technicians.

Construction on infrastructure, including roads and intersections, will commence this year, with the hub expected to be operational by mid-2028. The planned pipeline could facilitate hydrogen production of around 492,000 tonnes annually, contributing to the decarbonisation of existing ammonia production on the Burrup Peninsula.

The $140 million investment, split equally between the Commonwealth and WA Government, will not only support hydrogen exports and renewable energy production infrastructure but also establish a Clean Energy Training and Research Institute. This institute aims to provide practical, jobfocused training in renewable energy and hydrogen for Pilbara residents, including First Nations peoples.

According to Western Australian Premier Roger Cook, the hub was a key part of his government’s plan to turn WA into a

NT–Japan partnership boosts renewable economy

The Northern Territory (NT) Government has signed a memorandum of understanding (MoU) with the Japan Bank for International Cooperation (JBIC) to support eco-friendly projects and boost the local economy.

The MoU establishes a platform for ongoing discussions between the NT and JBIC officials, specifically focusing on financing energy and infrastructure projects.

This collaborative effort extends to a diverse range of sectors, including oil and gas, carbon capture, critical minerals infrastructure, hydrogen, ammonia, renewable energy, and sustainable aviation fuels.

The strategic engagement opportunities facilitated by the MoU position the NT Government and interested stakeholders to showcase the Territory as a dependable supplier of liquefied natural gas (LNG), critical minerals, hydrogen, and solar energy.

global clean energy powerhouse.

“When it comes to producing and exporting world-leading products at a global scale, WA leads the way,” Cook said.

“This project will be WA-produced hydrogen on Asia’s doorstep, helping to strengthen and diversify our economy for the future.”

Minister for Climate Change and Energy Chris Bowen said in a statement that the hub would ensure the Pilbara’s future as a major energy producer and exporter.

“This hub will bring a new clean energy industry to the Pilbara, supporting the region’s world-class industries well into the future,” Bowen said.

“WA is already a global mining and export powerhouse, and it’s now primed to become a world-leading hydrogen supplier as well.”

Kevin Michel WA Member for Pilbara added that the hydrogen hub means hundreds of potential long-term local jobs for the region.

“Developing a hydrogen industry in the Pilbara means more jobs and a strong future for our local communities,” he said.

According to the Federal Government, by 2050 Australia’s hydrogen industry is anticipated to generate $50 billion in additional GDP and create over 16,000 jobs in regional Australia, including WA.

NT Chief Minister Eva Lawler emphasised the significance of the MoU, highlighting its role in attracting new investments in resource extraction, mineral processing, and carbon capture and storage.

“By signing an MoU with JBIC, the Territory Labor Government is attracting new investment into resource extraction, mineral processing and Carbon Capture and Storage,” Lawler said.

“This is supported by a strong industry development focus, that underpins

traditional sectors such as agriculture, mining and energy, maritime and tourism, to help grow local Territory business and jobs.

“There are clear opportunities to expand our relationship with our largest trading partner, to grow our economy and achieve net zero.”

The value of NT exports to Japan surged by 27.3 per cent to $7.7 billion in 2022-23, propelled by increased commodity prices and exports of metalliferous ores and metal scrap.

www.ecogeneration.com.au April 2024 ecogeneration | 13

The partnership will focus on financing energy and infrastructure projects.

The $140 million investment is split equally between the Commonwealth and WA Government.

Image: sticker2you/ stock.adobe.com

NEWS IN BRIEF

Image: gpointstudio/stock.adobe.com

WA offshore wind zone consultation opens

Consultations have been officially launched for the proposed Bunbury offshore wind zone, which will unlock thousands of renewable energy jobs and provide cleaner, cheaper energy for Western Australia.

The wind zone, strategically positioned 20km off the state’s coastline, spans an expansive 7674 square kilometres.

According to the Federal Government, the wind zone situates itself strategically to harness high-speed winds from the Indian Ocean, taking advantage of its close proximity to major energy consumers and the potential to generate a substantial 20GW of offshore wind power.

The consultations are open until May 3, 2024, with community information sessions

scheduled to run between March 19-21.

The anticipated development of the Bunbury zone is expected to yield a significant number of skilled and wellcompensated jobs, covering a spectrum from engineers and technicians to cable installers and administrative positions.

Proposed initiatives are expected to adhere to stringent criteria, including a commitment to utilising components manufactured in Australia and providing detailed engagement plans with local suppliers, aiming to stimulate economic benefits such as direct job creation and training opportunities.

Chris Bowen, Minister for Climate Change and Energy, said offshore wind energy not

only means new job opportunities across Western Australia but would also provide much-needed energy security.

“Offshore wind will be a critical new clean energy industry for Western Australians as electricity demand increases, helping to provide thousands of jobs along the way,” Bowen said.

“The Albanese Government is committed to genuine consultation on offshore wind –that’s why we want communities, industry and businesses to have their say on an offshore wind area off Western Australia from the very beginning.

“We encourage everyone to put in a submission and attend a community consultation session.”

14 | ecogeneration April 2024 www.ecogeneration.com.au

NEWS IN BRIEF

Image: PictMotion/stock.adobe.com

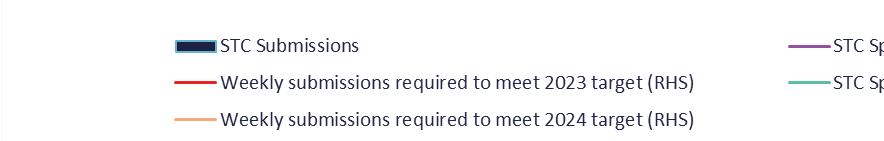

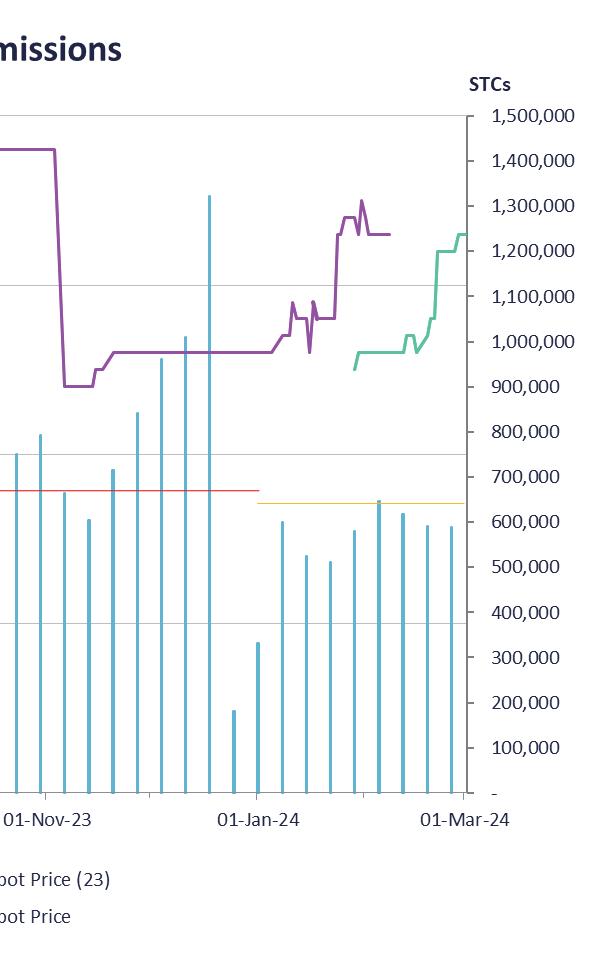

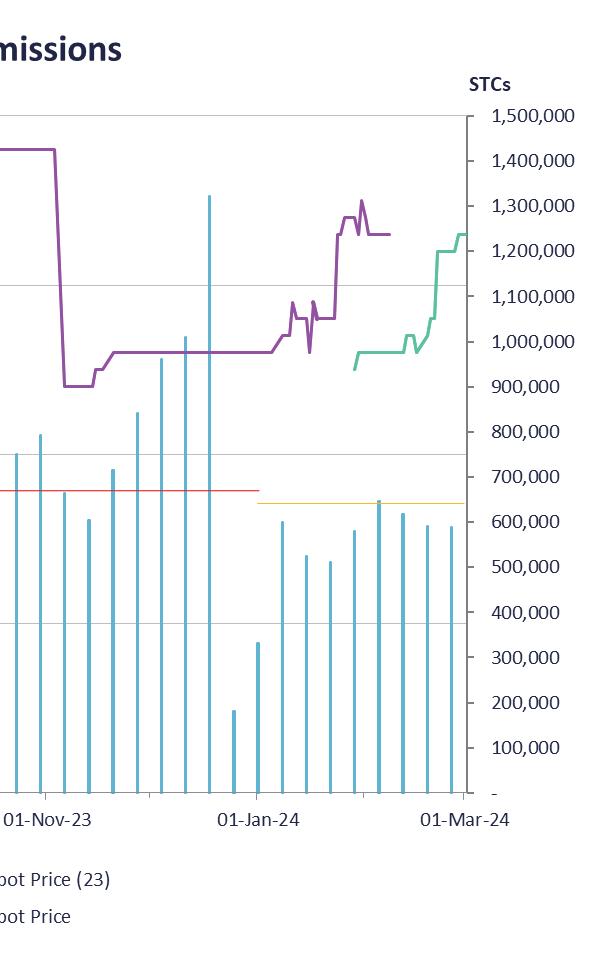

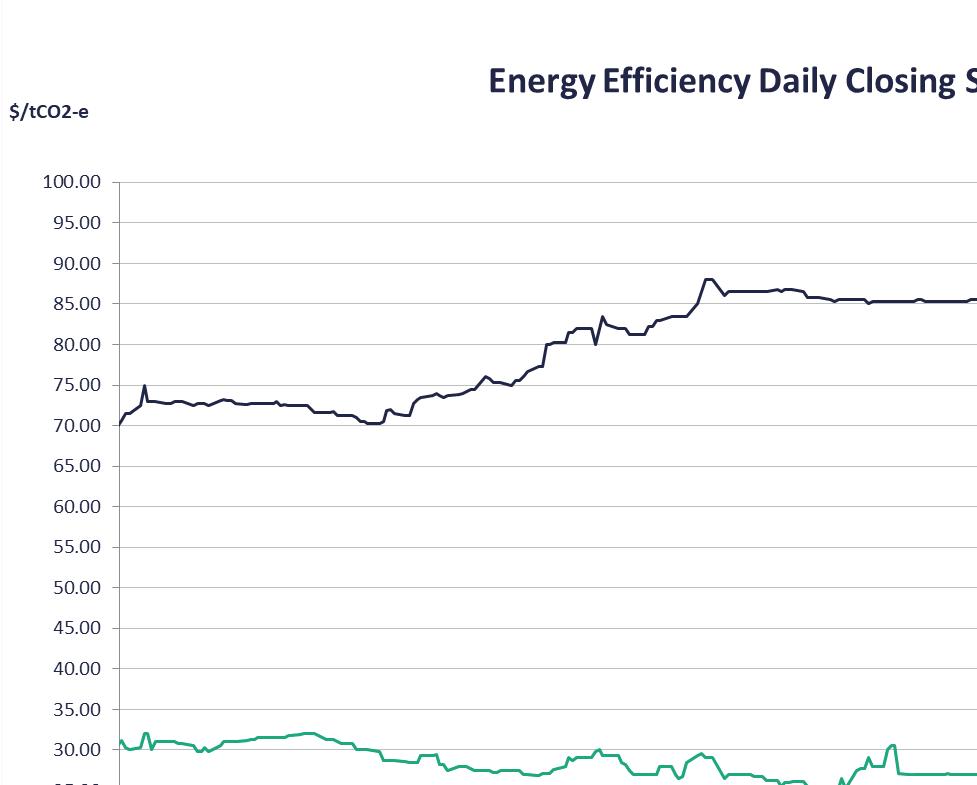

Revealing the state of the sector

With a positive set of results for rooftop solar and record-breaking figures for investment in utility scale storage, 2023 was another strong year for renewable energy in Australia. However, a slowdown in new financial commitments to large-scale renewable energy generation is cause for concern, writes

Kane Thornton, Chief Executive of the Clean Energy Council.

What a difference a year makes.

This time last year, I wrote about a mixed report card for Australian renewables; positive numbers in several areas backed up by a wave of increasingly positive political sentiment.

Reflecting on 2023, we saw very positive fi gures across rooftop solar and energy storage, but the slowdown in new fi nancial commitments to utility scale generation projects is cause for concern.

I believe clean energy has the policy settings and positive momentum to boom over the next few years as we progress toward the Federal Government’s target of 82 per cent renewable energy by 2030.

The Clean Energy Council released the 2024 edition of the ‘Clean Energy Australia’ report in mid-March, revealing the state of the sector and providing vital statistics and trends.

Total generation capacity added in 2023 reached 5.9 gigawatts(GW), substantially up from 5GW in 2022, and not far off the record of 6.3GW in 2021. That was comprised of 3.1GW from rooftop solar and 2.8GW from utility scale projects – 1.9GW of large-scale solar (up from 841 megawatts [MW] in 2022) and 942MW of wind (down from 1.4GW in 2022).

While rooftop solar didn’t quite reach the record-setting heights of 2021, it was still a

stellar year, with 337,498 solar systems installed across Australia (up from 315,499 in 2022).

These encouraging numbers demonstrate the value Australians see in rooftop solar and the benefits it brings, not just to the country’s decarbonisation effort, but to their energy bills and energy independence.

Dawn of the battery age

One area that saw an unexpected and welcome boom was utility scale storage. Investment in big batteries broke the billion-dollar mark for the fi rst time in Q2 2023, that record had already been broken and by Q4, making 2023 the

16 | ecogeneration April 2024 www.ecogeneration.com.au

INDUSTRY UPDATE | CEC CHIEF EXECUTIVE

The Clean Energy Council has released the 2024 edition of the ‘Clean Energy Australia’ report. Image: ArgitopIA/stock.adobe.com

strongest ever year for new fi nancial commitments in the large-scale storage space at $4.9 billion, including hybrid projects with storage elements ($4.7 billion for storage-only projects).

That is a 157.9 per cent increase on 2022, which reached $1.9 billion in new fi nancial commitments to large-scale storage. The combined capacity of large-scale storage projects reaching fi nancial commitment in 2023 totalled 3949 MW/9905 MWh.

It is difficult to pinpoint a single reason for this upturn in battery fortunes. In truth there are many reasons, including the improving scale and cost of battery solutions, higher wholesale prices and ancillary services revenues.

This level of new commitments is a clear signal that investors and developers are comfortable with the risks and strong business case for these solutions and are increasingly optimistic about their role in Australia’s future energy mix.

Utility scale generation slows

While fi gures for capacity added from generation projects in 2023 were up on 2022, which is a huge positive, the status of the investment landscape for large-scale generation projects is concerning.

Large-scale projects have been facing a complex and challenging landscape for new investment decisions, including a constrained grid, slow planning and environmental assessment processes in some jurisdictions, higher costs, and tighter markets for equipment and labour.

There was only $1.5 billion of new fi nancial commitments to large-scale

generation projects in 2023, significantly down on $6.5 billion in 2022, and no new wind projects reached fi nancial commitment (compared to six in 2022). This is a disheartening situation that needs to be addressed, and clearly the driving factor behind the Federal Government’s welcome decision to expand the Capacity Investment Scheme late last year.

In its ‘Renewables 2023’ report, the International Energy Agency reined in its growth forecast for renewables in Australia “due to continued policy uncertainty following early achievement of its LargeScale Renewable Energy Target (RET)”. The expanded Capacity Investment Scheme is intended to be the big policy-driver that replaces the RET, and if implemented correctly will hopefully give the large-scale sector the acceleration it needs.

In its ‘Draft Integrated System Plan’ released in late 2023, the Australian Energy Market Operator forecast Australia would need to install at least 6GW of utility scale generation annually if it was to reach the Federal Government’s target of 82 per cent renewables by 2030. The 2.8GW of largescale capacity added in 2023 is a good start but clearly well short of where we need to be, and the investment landscape must pick up if that number is to be dramatically increased.

Planning ahead

The fall in new investment commitments in utility scale generation is a leading indicator of the levels of new projects that will be competed and commissioned in the years ahead. So, despite the strong policy response from the federal and many state governments in 2023 (and early 2024), the levels of new large-scale generation coming online over the coming year is likely to be slower.

These are the topics and issues that will be the main focus of the clean energy industry throughout 2024.

The Clean Energy Council runs a series of essential industry events each year, and chief among those is the Australian Clean Energy Summit (ACES) in Sydney in July.

This is a jam-packed two days of discussion and debate that will be crucial to our industry going forward – a chance for industry leaders to connect with their peers, government, market bodies, community and regional leaders, and the fi nance sector.

Last year’s event was the biggest and most fully rounded we have hosted, and there is every reason to believe it will be even better this year, particularly given how pivotal the next decade will be for renewables in Australia. Join us in July to be part of the clean energy conversation and discuss the best ways forward for the industry

CEC CHIEF EXECUTIVE | INDUSTRY UPDATE

Kane Thornton has more than a decade of experience in energy policy and leadership in the development of the renewable energy industry. His column is a regular feature in ecogeneration, where he analyses industry trends and explains the impacts of federal and state renewable policies on the energy sector.

www.ecogeneration.com.au April 2024 ecogeneration | 17 Renewable Energy Training RTO: 0416. IHE: PRV12129. CRICOS Provider Code: 00012G. Multiple start dates available throughout the year at our Moorabbin campus. Scan the QR code to find out more, or call 1300 639 888 to apply now. Gain new skills for growing opportunities in the renewable energy market. Electricians and engineers interested in upskilling or gaining accreditation can tailor their training to suit their career goals at Holmesglen Institute’s Renewable Energy Centre of Excellence. Industry experts deliver our nationally accredited renewable energy short courses with online and face-to-face hands-on practical workshop sessions. You can study: •Grid Connected PV systems•Battery Storage•Stand-Alone Power Systems

The

accreditation

provider for installers and designers has changed

The Clean Energy Council reflects on its time as the solar accreditor, and the Clean Energy Regulator’s rigorous application and evaluation process to approve Solar Accreditation Australia for the role.

On 29 February, the Clean Energy Regulator (CER) approved Solar Accreditation Australia (SAA) as the new installer and designer accreditation scheme operator under the Small-scale Renewable Energy Scheme (SRES).

How did the CER choose SAA?

The CER undertook a rigorous application and evaluation process to approve SAA.

After operating as an administrator for over 16 years, the Clean Energy Council (CEC) chose not to apply to be an accreditation scheme operator and its services have now ceased. The CEC deeply considered how its technical experts can support the industry amid complex and competing priorities, including standards changes and regulatory reforms.

How is the CEC supporting the transition?

Over the past few months, the CEC has worked closely with the CER and SAA to ensure a smooth handover for the benefit of accredited installers, the rooftop solar industry, and consumers. A successful transition is crucial and the CEC remains committed to supporting the industry.

Important information for installers and designers

Scope of accreditation:

• The SAA is now responsible for the accreditation of electricians who design and install small-scale solar, wind and hydro systems incentivised by the SRES

• The SAA will accredit battery installers

Make the switch:

• If you haven’t transferred your accreditation, you can visit the SAA website (saaustralia.com.au) and apply to transfer by 29 May or before their CEC accreditation expires, whichever is earlier

• Accredited persons must transfer to the SAA by 29 May to maintain accreditation and remain eligible under the SRES

Access to the CEC installer portal:

• You will continue to have access to the CEC installer portal until May. To allow time to access any details, you may need to transfer your accreditation

• myCEC access offering technical information and support has been extended until July, free of charge

18 | ecogeneration April 2024 www.ecogeneration.com.au CLEAN ENERGY COUNCIL | ACCREDITATION

CEC reflection

The CEC is proud of the role it has played in building robust installer and accreditation programs, alongside administering the New Energy Tech Consumer Code (NETCC) program for retailers, and product listing program for manufacturers.

The rooftop solar industry in Australia is world-leading and over the past 16 years the CEC team has played a critical role in upholding the regulatory framework to drive best practice and improve industry behaviour to ensure customers are treated fairly and honestly.

Together with the industry, it has been building significant social license with communities as they benefit from savings on power bills.

Transitioning out of the role of administering accreditation allows the CEC to focus on strong advocacy for the solar industry, as well as increased support for installers to ensure they have

access to quality training, that they are kept up to date on latest industry developments, and that they feel supported to navigate the complex industry standards and requirements.

www.ecogeneration.com.au April 2024 ecogeneration | 19

ACCREDITATION | CLEAN ENERGY COUNCIL

Pallavi Guha, Clean Energy Council Director, Regulation Industry Programs and Advisory Services.

The CER undertook a rigorous application and evaluation process to approve SAA.

Image: Clean Energy Council. Image: Beton Studio/stock.adobe.com.au

Greener horizons for the sunshine state

The future of Queensland’s energy sector is brimming with endless clean, green potential. ecogeneration takes a look at the current renewable projects in the state.

Renewable energy isn’t just good for the environment; it’s also a booming economic force, creating jobs, attracting investments, and stimulating regional development. ecogeneration explores the major renewable energy projects in Queensland.

MacIntyre Wind Farm Precinct

The MacIntyre Wind Farm Precinct, built by Acciona, is situated in the South-West of Warwick, Queensland, Australia, on land primarily utilised for sheep farming. The location was chosen for its consistent wind exposure, making it a suitable resource for the development of the wind farm.

With a planned capacity of 1026MW, the wind farm will feature 180 Nordex Delta wind turbines. This makes the project the largest onshore wind farms globally.

On January 2024, project developer Acciona Energia and contractor Holcim announced they completed the pouring of MacIntyre Wind Farm’s concrete foundations for its 162 wind turbines, marking a significant milestone in the 923MW project.

The construction of MacIntyre Wind Farm Precinct began in 2022, with the wind farm expected to become fully operational by 2024.

The total investment in the MacIntyre Wind Farm Precinct is $1.96 billion. Beyond economic contributions, the wind farm aligns with Queensland’s decarbonisation strategy and climate change mitigation efforts.

According to the Queensland Government, the project is anticipated to result in a Community Enhancement Program, strategically delivering added value to the

local region over the project’s life cycle. It is also expected to provide significant economic activity across the Goondiwindi, Southern Downs, and Toowoomba Regional Council areas. Local spending during construction is projected to exceed $500 million.

Steven Miles, Queensland’s Premier said once operational the MacIntyre Wind Farm Precinct is expected to generate enough renewable electricity to supply about 700,000 Queensland homes.

“The MacIntyre Wind Farm Precinct is set to provide up to 400 local jobs during construction, with an additional 240 jobs for the construction of the 64km transmission line, and 14 fulltime jobs once in operation,” Miles said.

“Acciona also expects its local spend during construction to exceed $500 million, which is great news for the Southern Downs, Goondiwindi, and Toowoomba communities.”

Western Downs Green Power Hub

Situated near Chinchilla in the Western Downs region of Queensland, the Western Downs Green Power Hub is located 22km southeast of Chinchilla. The site spans 1500 hectares in Barunggam country, 300km northeast of Brisbane.

The Western Downs Green Power Hub is a 460 MW solar farm project developed by Neoen, a French renewable energy producer.

When complete, it will add 400MW of renewable energy into the grid with Queensland Government owned energy generator and retailer CleanCo signed up to take 320MW.

The project, utilising 72-cell bi-facial solar

modules, incorporates advanced tracking systems to efficiently follow the sun. It also includes a battery with an energy storage capacity of up to 200MW.

Western Downs Green Power Hub’s solar farm is projected to become operational in 2023, with the battery component scheduled to commence operations in 2024.

With an estimated investment of $600 million, the Western Downs Green Power Hub is anticipated to deliver an annual economic benefit of around $32 million to the Queensland economy.

Additionally, the solar farm is expected to offset approximately 864,000 tonnes of carbon dioxide emissions annually. The project’s electricity generation, exceeding 1080GWh per year, will power around 235,000 homes.

Last Christmas, CleanCo announced its collaboration with Coles to provide 95 per cent of the latter’s electricity needs in Queensland.

According to Tom Metcalfe, CEO of CleanCo, the renewable energy generated by the Western Downs Green Power Hub will supply some of CleanCo’s biggest customers including Coles and BHP.

“Projects like these complement CleanCo’s portfolio of fast ramping, flexible gas and hydro generators to provide our customers with 24/7 reliable clean energy,” Metcalfe said.

“We are proud to support renewable energy projects like the Western Downs Green Power Hub that deliver great local employment opportunities and economic outcomes in regional Queensland.”

“The renewable solar energy generated here

20 | ecogeneration April 2024 www.ecogeneration.com.au QUEENSLAND REGION REVIEW

Ariel view of a solar farm.

Image: Frankie/ Stock.adobe.com

in Queensland’s Western Downs will contribute to the long-term sustainability of Queensland industries and communities, helping them to thrive in a net zero future.”

CQ-H2 Hydrogen Project

The Central Queensland Hydrogen Project (CQ-H2) is located near Gladstone, which has been identified as the hub for strategic development. The region possesses attributes conducive to global participation in green hydrogen production, including a deep-water port, expansive space for expansion, and robust electricity and gas transmission infrastructure.

Led by Stanwell Corporation, the project aims to produce 200 tonnes of renewable hydrogen per day by 2028, scaling up to an impressive 800 tonnes per day by the early 2030. The venture incorporates advanced technologies to facilitate the large-scale production of green hydrogen.

The CQ-H2 project anticipates substantial economic and environmental advantages. At its peak, it is poised to generate over 8900 new jobs, contributing $17.2 billion in hydrogen exports and adding $12.4 billion to Queensland’s Gross State Product over a 30year lifespan. The project aligns with Queensland’s commitment to becoming a renewable energy superpower.

In December 2023, the Australian Renewable Energy Agency (ARENA) announced that CQ-H2 and five other applicants had been shortlisted for a $2 billion Hydrogen Headstart Program. This represented a total electrolyser capacity of over 3.5GW, making CQ-H2 among the largest renewable hydrogen projects in the world.

Mick de Brenni, Queensland’s Minister for Energy and Clean Economy Jobs said CQH2 would bring new jobs in manufacturing and help the agricultural sector to decarbonise.

“Over time, eliminating fossil fuels from Queensland supply chains and replacing them with clean energy means our agricultural jobs will remain safe in a carbon emissions conscious marketplace,” de Brenni said.

Pioneer-Burdekin Pumped Hydro Project

Situated in the South-West of Warwick, Queensland, the Pioneer-Burdekin Pumped Hydro Project is set to become the largest pumped hydro scheme globally.

Proposed in two stages to reach completion by 2035, the project aims to deliver 5GW of clean, reliable power supply and storage.

The innovative pumped hydro technology acts as a giant water battery, using electricity

to pump water from a lower reservoir to an upper reservoir during periods of low energy prices. This stored energy is released when needed, generating hydroelectricity through turbines.

The construction activities of PioneerBurdekin have commenced, with a planned completion timeline by 2035.

Awarding over 3000 jobs during construction, the Pioneer-Burdekin project plays a pivotal role in the $62 billion Queensland Energy and Jobs Plan. It is expected to provide 24/7 clean and reliable power, generating 5000MW for 24 hours, equivalent to about half of the state’s peak usage.

According to Queensland Hydro, the investigation phase is well underway at its proposed Pioneer-Burdekin Pumped Hydro Project site.

“Works such as geotechnical drilling help us to avoid, minimise, and offset potential adverse impacts to local ecosystems and the environment,” Queensland Hydro said in a LinkedIn post.

Minister de Brenni said the PioneerBurdekin Pumped Hydro Project is the cornerstone of the Queensland Energy and Jobs Plan and will be the largest pumped hydro scheme in the world.

“This mega pumped hydro project will act like a giant battery, and when connected to our Queensland SuperGrid, will underpin the reliability of our publicly owned grid by storing the energy generated by our renewable energy zones,” de Brenni said.

“It’s regions like Mackay that are at the centre of this Queensland’s renewable energy transformation – which will unleash new industrial jobs in hydrogen, renewables, manufacturing, and critical minerals.”

Townsville Region Hydrogen Hub

The Townsville Region Hydrogen Hub is Queensland’s latest major renewable energy project, announced only in January 2024.

Located in North Queensland, it is considered a key investment by the Federal Government,

with up to $70 million allocated for the development.

The initial stage of the hub aims to produce 800 tonnes of green hydrogen annually, catering to local industry and zero-emissions transport. The facility includes a 17.6 MW domestic production unit integrated with renewable energy generation and battery storage.

The hub plans to scale up to approximately 3000 tonnes for domestic use and exceed 150,000 tonnes for export.

Construction of Townsville Region Hydrogen Hub is slated to commence in the coming year, with a targeted completion in 2026. Its initial commercial operations are expected to begin in 2027.

The project is anticipated to create a minimum of 200 direct job opportunities during construction, benefitting local electricians, plumbers, fitters, and concreters. Ongoing roles in technical and engineering capacities will contribute to sustained regional employment.

The hub aligns with Australia’s renewable energy ambitions, offering green hydrogen for local use and export.

With a combined investment exceeding $137 million, including up to $70 million from the Commonwealth, the initiative signifies a collaboration between Australia and Germany, leveraging German hydrogen technology expertise and Australia’s potential as a renewable energy leader.

According to Prime Minister Anthony Albanese, renewable hydrogen is a game changer, opening the door to green metals, green fertiliser, green power and supporting industrial decarbonisation.

“The whole world needs renewable hydrogen, and regional Australia is ready to provide it,” Albanese said.

“With its port, expertise in exports and access to Queensland’s abundant solar resources, Townsville is ideally placed to help power the world with Australian renewable energy and create jobs in regional Australia.”

www.ecogeneration.com.au April 2024 ecogeneration | 21 QUEENSLAND REGION REVIEW

Engineers examining wind turbines.

Image: Martin Barraud/Caia Image/stock.adobe.com

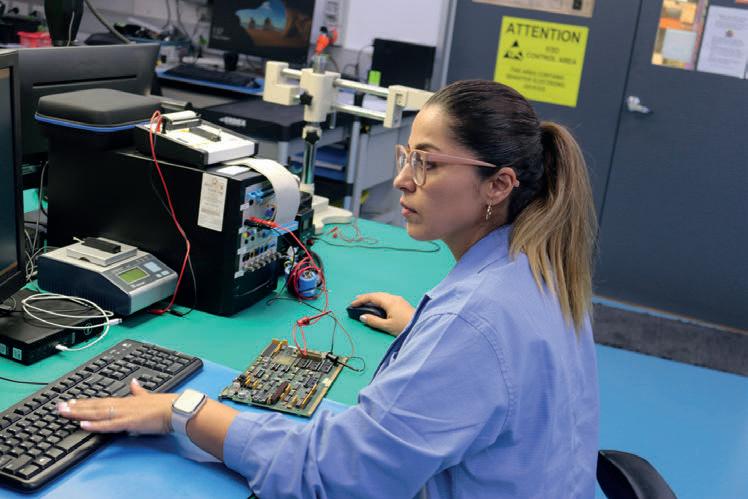

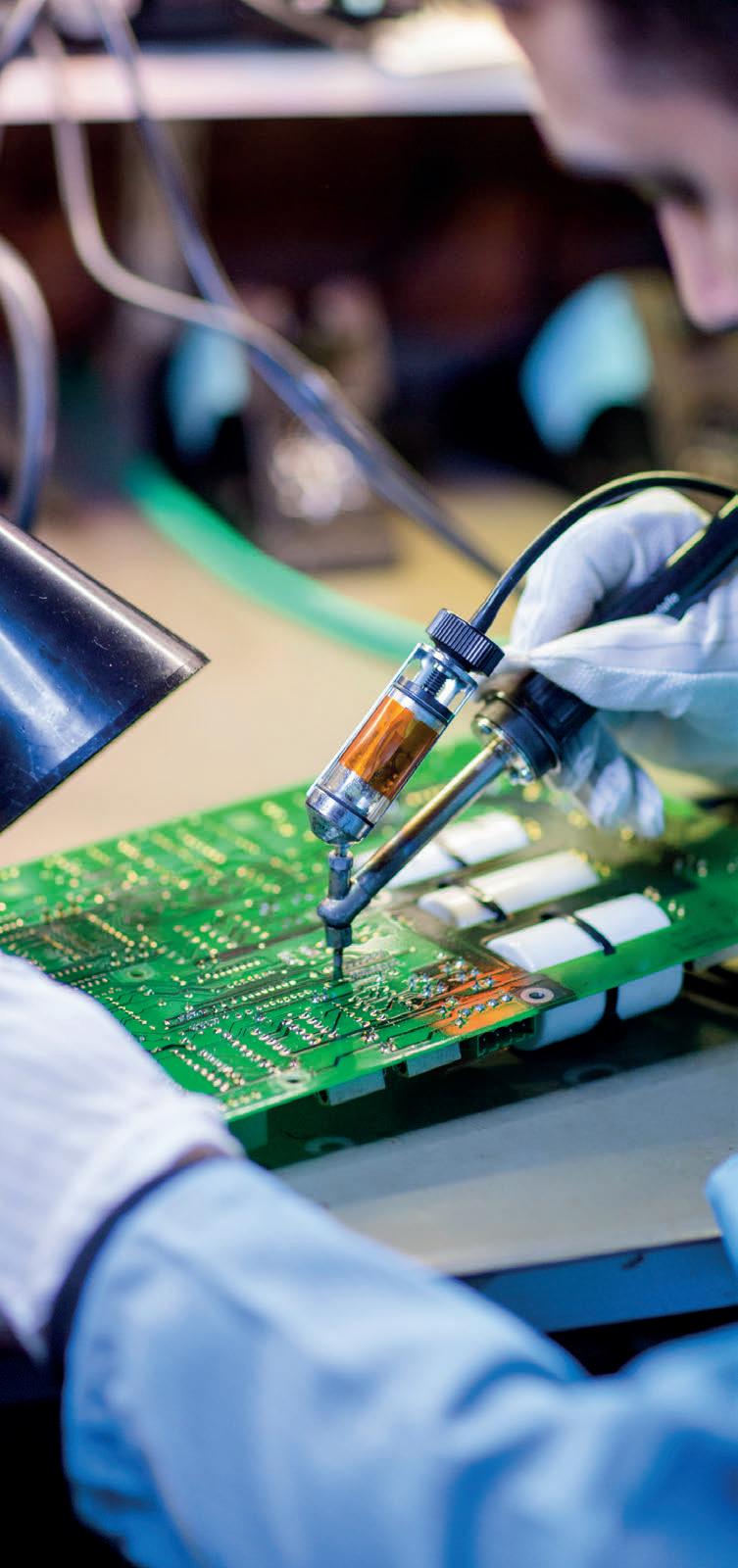

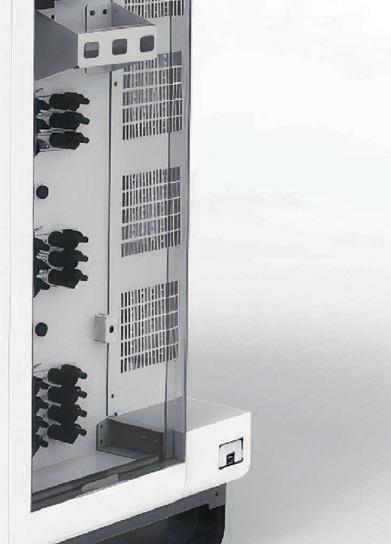

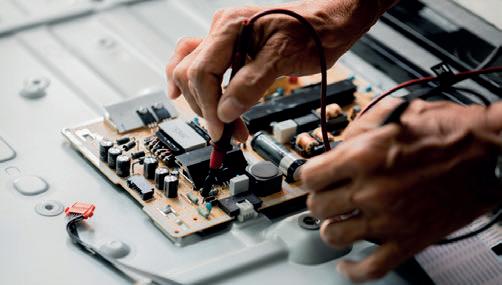

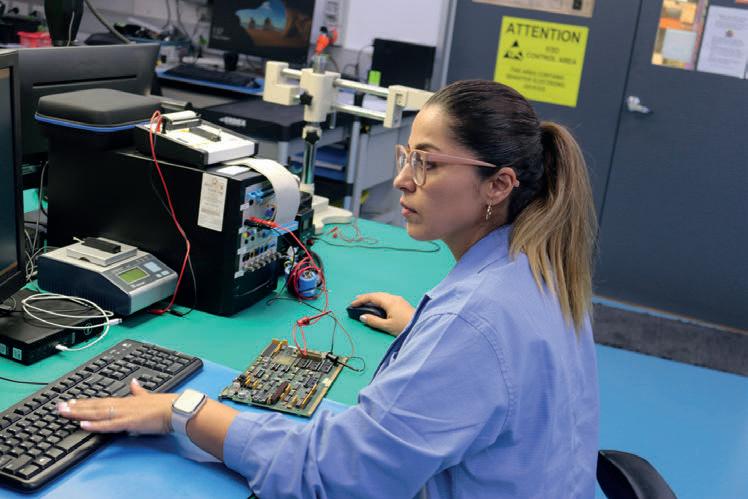

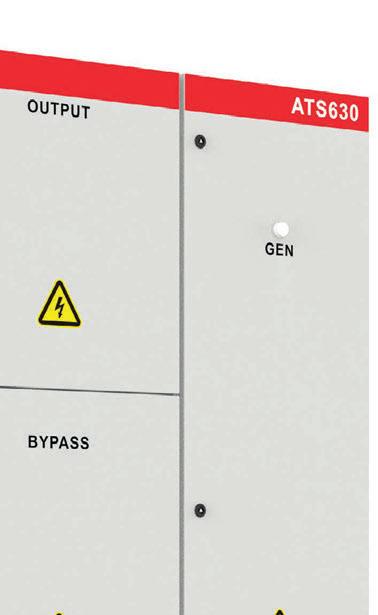

Rejuvenating your industrial electronic assets

As Australia sails towards a greener future, the industry faces a significant challenge, but Rom-Control is confident its solutions will improve equipment life and reliability

The maintenance and repair of ageing electronic equipment represented major concerns for many businesses operating in various industries, as obtaining a spare part from overseas when facing a breakdown caused by the failure of electronic equipment can result in long waiting periods and high costs.

This is where Rom-Control, an Australianbased electronic engineering company, steps in, offering innovative and sustainable solutions that are revolutionising the way the industry approaches equipment lifecycle management and obsolescence, while also contributing to the reduction of CO₂ emissions.

Established in 2007, Rom-Control has carved a niche for itself as a leading provider of repair and refurbishment services for

22 | ecogeneration April 2024 www.ecogeneration.com.au COVER STORY | ROM-CONTROL

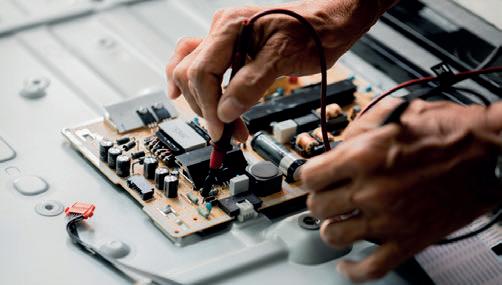

Rom-Control engineer diagnosing an electronic device.

Rom-Control’s engineers have developed specialised techniques to diagnose and repair equipment.

Images: Rom-Control

industrial electronic equipment.

With a team of highly skilled engineers and a success rate of 98 per cent, the company has garnered a reputation for excellence, serving more than 1000 clients across Australia, New Zealand, and the Asia-Pacific region.

At the helm of Rom-Control is the founder Michael Horovitz, a veteran in the field of process control, electrical engineering, and consultancy. His extensive experience in industries such as power generation, chemical manufacturing, and food and beverage maintenance and engineering has given him a unique perspective on the challenges faced by companies relying on electronic equipment to drive their production activity.

“I realised there was a gap in Australia, where we don’t manufacture much equipment locally,” Horovitz said.

“When companies purchase equipment with process control systems, eventually the electronics will fail. As the original equipment manufacturers (OEMs) cease to support old equipment, we offer a plug-and-play solution by repairing and refurbishing the failed modules at a fraction of the cost of buying new equipment.”

Rom-Control’s approach to repair and refurbishment is ground-breaking. Unlike

traditional methods that rely heavily on schematics and documentation from OEMs, Rom-Control’s engineers have developed specialised techniques to diagnose and repair equipment without such resources.

This allows them to work on a wide range of equipment, including power electronics and renewable energy components such as converters and inverters, control systems,

variable speed drives, and more.

One of Rom-Control’s most significant achievements is becoming an approved supplier for Vestas, a leading European manufacturer of wind turbines.

This partnership has opened doors for Rom-Control to receive repair jobs from various wind farm operators and maintenance providers across Australia, even though the farms under their control comprises of equipment manufactured by other than Vestas

“Our engineers understand the functionality, fault-find and repair different electronic circuits at component level,” Horovitz said. “We build customised testing rigs for each brand to simulate real-life conditions and ensure our refurbished units perform as intended.”

The company’s commitment to sustainability and extending the lifespan of electronic equipment is exemplified in a recent project with a major pharmaceutical company.

The client had a control system from the 1980s that was still operational but an upgrade was not feasible under the current financial constraints. Rom-Control was approached and asked to provide a solution that would ensure the equipment would be in a solid position to continue being used for another 10 years.

Rom-Control offered its proactive refurbishment service, auditing the entire system, identifying critical components, and refurbishing or replacing them on a rotational basis.

This approach enabled the client to keep the system running for another 10 years without costly replacements.

www.ecogeneration.com.au April 2024 ecogeneration | 23 ROM-CONTROL | COVER STORY

The Rom-Control team.

Rom-Control Managing Director Michael Horovitz.

“It’s hard to estimate the exact savings, but we potentially saved them millions compared to the price of purchasing a new system,” Horovitz said.

Rom-Control’s approach to quality control is equally impressive. All components used in the repair and refurbishment process are brand new and tested thoroughly before installation.

The company has invested in specialised equipment to detect counterfeit parts, ensuring that only genuine components are used in customer equipment.

In addition, Rom-Control has established relationships with various component manufacturers around the world, allowing them to quickly source parts, even for obsolete equipment.

As the renewable energy industry continues to evolve, Rom-Control is wellpositioned to meet the anticipated surge in demand for repair and refurbishment services. The company’s systems-based approach and flexible business model allow for scalability, while continuous investment in training and advanced testing equipment ensures that its workforce remains ahead of the curve.

“Our core strength lies in our ability to repair any electronic equipment at the component level, regardless of brand or intended function,” Horovitz said.

“As long as there are electronics involved, we can provide cost-effective repair solutions to extend the lifespan of the equipment sustainably.”

In an industry that has traditionally relied on a “replace and discard” approach, RomControl’s solutions offer a feasible and costeffective alternative. By extending the lifespan of electronic equipment and reducing waste, the company is not only contributing to the bottom line of its clients but also promoting a circular economy and minimising the environmental impact of the renewable energy sector.

“For decision-makers in the renewable industry, partnering with Rom-Control represents a strategic investment in sustainability, cost savings and operational efficiency,” Horovitz said.

With its unique expertise, cutting-edge techniques, and commitment to quality, Rom-Control is poised to play a pivotal role in shaping the future of the renewable energy industry, one repaired component at a time.

For more information, visit rom-control.com.au/contact-us

and repair equipment.

24 | ecogeneration April 2024 www.ecogeneration.com.au COVER STORY | ROM-CONTROL

Rom-Control’s engineers have developed specialised techniques to diagnose

#AllEnergyAU

all-energy.com.au

23 -24 October 2024

Melbourne Convention and Exhibition Centre

Australia’s Largest Clean Energy Event: Your gateway to a clean energy future.

Electrifying Days 2

11,563 Unique Visitors in 2023

400+

Industry Leading Exhibitors

400+ World Class Speakers

With an expanded EV and infrastructure zone, meet leading exhibitors such as Tesla, Sungrow, SMAPEE, BYD, Delta, Sonnen, Growatt, SMA, Goodwe & more. Registration for All Energy Australia opens in July and is completely FREE. This also includes access to All Energy 365, your year-round education hub. LEARN

MORE

Taking Australia into a greener future

As Australia forges ahead to a net-zero future, the need for innovative and scalable renewable energy solutions has never been more pressing.

At this key transition point on the path to a clean-energy future, Pacific Green, a global leader in the renewable energy sector, has entered Australia with a mission to accelerate the netzero transition worldwide.

With a long track record in the UK, where the company has successfully delivered one operational battery park totalling 100 megawatt hours (MWh) and has another 375MWh facility under construction, Pacific Green has set its sights on the growing Australian market.

“We are positioning Pacific Green to become one of the largest battery park developers in the Southern Hemisphere,” Pacific Green Australia Managing Director and Chief Executive Officer Joel Alexander told ecogeneration

Pacific Green is targeting more than 12GWh of battery energy storage capacity across four global markets; Australia and Italy remain hotspots for significant pipeline expansion, with the company also seeking to recharge its origination portfolio in the maturing UK market, as well as taking its first steps into the nascent Polish market.

Leading the charge in Pacific Green’s Australian ventures are two ground-breaking projects: the Limestone Coast Energy Park in South Australia and the Portland Energy Park in Victoria.

The Limestone Coast Energy Park, a mammoth 1.5 gigawatt-per-hour (GWh) battery facility, will be located adjacent to the South East Substation, a critical interconnector between SA and Victoria. This strategic positioning will not only provide

vital grid stability and security but also enable the energy park to serve as a backup power source, ensuring uninterrupted energy supply to both states.

The Portland Energy Park in Victoria, poised to become the largest battery energy storage system in Australia and Asia at 1GW/2.5GWh, will play a pivotal role in supporting existing and proposed renewable energy projects within the state’s Southwest Renewable Energy Zone, as the nearby Alcoa smelter accounts for approximately 10 per cent of Victoria’s energy demand.

The significance of these large-scale battery storage projects cannot be overstated, as they hold the key to enabling a more stable and reliable renewable energy grid moving forward.

“Our battery parks will provide relief

26 | ecogeneration April 2024 www.ecogeneration.com.au PROEJCTS | PACIFIC GREEN

against wholesale volatility and contribute to overall peak price reduction, ” Alexander said.

To underline the point, Alexander cited modelling from Cornwall Insights Australia, which suggested that the Portland Energy Park could result in 3.8 per cent reduction in wholesale energy costs for Victorian households alone.

Moreover, these battery facilities will act as catalysts for increased renewable energy generation, enabling solar and wind farms to remain online during periods of low or negative pricing by providing a constant load for charging the batteries.

“Where our battery can soak up more solar and wind, and those solar and wind farms can stay online to support the transition to netzero, that’s a really positive outcome,” Alexander said.

Pacific Green’s success in Australia is underpinned by its ability to leverage international expertise and resources from its global operations.

The company’s UK team brings vital knowledge in corporate finance and project bankability, ensuring each project meets the stringent criteria required to secure nonrecourse project financing.

This expertise, coupled with Pacific Green’s strategic partnership with leading battery manufacturers in China, including a

dedicated team of over 30 employees in Shanghai, provides a competitive edge in supply chain management, quality control, and timely delivery of project-critical equipment to site.

Navigating the complexities of developing and constructing large-scale renewable energy infrastructure projects is no small feat, but Pacific Green is well-equipped and ready to handle the challenge.

One of the most significant challenges lies in navigating the complexities of grid connections and power systems.

“The Australian market is experiencing a lot of activity at the moment, and the power system studies required to achieve GPS (generator performance standards) are complex and time-consuming,” Alexander said.

To address this issue, Pacific Green is leveraging proven technologies and fostering open and transparent relationships with network operators, helping to ensure compliance with technical characteristics and timelines.

Another area in which Pacific Green takes particular pride is its collaboration with traditional owners. In the case of the Portland Energy Park, the company has worked closely with the Gunditjmara people, redesigning aspects of the project following site visits and consultations.

“We believe in engaging with key stakeholders and community members as early in the planning process as possible,” Alexander said. “In turn, this leads to a really positive outcome for not only Traditional Owners but also the broader community.”

Community engagement is a cornerstone of Pacific Green’s approach, with the company hosting dedicated community information

sessions to engage with community members and discuss feedback from local residents.

“There’s an overwhelming sense of support across both communities,” Alexander said. “We are committed to being open and transparent with each of our communities regarding what we’re doing, why we’re doing it, and articulating the community benefits of each project.”

Among these benefits is the creation of regional employment opportunities, with Pacific Green committed to engaging local contractors, suppliers and businesses where possible. The company is currently in the process of determining work packages that will offer opportunities ranging from hospitality and accommodation to site works and groundworks.

Pacific Green’s commitment to Australia’s energy transition extends far beyond the construction of battery storage facilities. The company is dedicated to fostering a sustainable future through strategic partnerships, community empowerment, and innovative solutions.

By collaborating with indigenous communities, local businesses and industry experts, Pacific Green ensures its projects contribute not only to a cleaner energy future but also create long-lasting positive impacts on the communities they serve.

With a global footprint and a track record of success, Pacific Green is poised to play a pivotal role in propelling Australia towards its net-zero targets. As the nation embraces a future powered by clean, sustainable sources, the company is leading the charge towards a greener, more resilient Australia.

For more information, visit pacificgreen.com/aus

www.ecogeneration.com.au April 2024 ecogeneration | 27 PACIFIC GREEN| PROJECTS

Inside Pacific Green’s Richborough Battery Energy Park located in the UK.

Images: Pacific Green

Pacific Green aims to become one of the largest battery park developers in the Southern Hemisphere.

The critical role of social procurement

Establishing and maintaining ‘social licence’ is critical for Australia’s ability to deliver our massive renewable energy project pipeline. Social procurement is the fundamental vehicle that will deliver on and demonstrate the positive social, economic and environmental impacts that will underpin the achievement of ‘social licence’ through our energy transition.

From solar to onshore and offshore wind, batteries, hydrogen, transmission, and everything in between, there are enormous opportunities in renewable energy. However, the speed and scale of energy investment needed in Australia to reduce its dependence on fossil fuels and meet the targets is challenging.

According to Chris Newman, Managing Director at ArcBlue Consulting, the complexity of a diverse and evolving regulatory environment is challenging for all involved, and more work is needed.

“To establish common approaches across different renewable sectors and jurisdictions,” he said.

The increasing competition in the global supply chain highlights the critical importance of building local capacity, investing in procurement and supply chain expertise and early planning.

“Australia is not the only country in the world who are working hard to try to transition our economy and we don’t yet have the strength of local manufacturing. We’re competing with other buyers who are often doing bigger projects and are closer to the suppliers in Asia, Europe, and North America,” Newman said.

Achieving social licence

A key challenge for consideration is how to achieve social licence in regional communities, enabling the delivery of critically required infrastructure, and addressing workforce shortages and supplier capability gaps.

“Renewable energy projects are often promoted as environmentally friendly and socially responsible alternatives to traditional energy sources,” Newman said.

“Maintaining a social licence reinforces this image and aligns with the values of environmentally conscious consumers. Governments and regulatory bodies are increasingly considering community attitudes and social acceptance when granting permits

and approvals for renewable energy projects.

“By demonstrating strong social backing for projects, they are more likely to navigate regulatory processes smoothly, reducing the risk of delays or legal challenges. Investors recognise that community buy-in has a huge impact on the success of a project and its financial viability and will view a project more favourably if it can demonstrate strong social support and acceptance in the community.”

For Newman, “social licence is shaped by how a proponent plans, builds and manages infrastructure, as well as the perceived impacts and opportunities associated with the project”.

“Social licence is critical to the success of renewable energy projects, and building acceptance and support for each project will be fundamental to establishing and maintaining community support for the broader renewable energy transition,” he said.

“It is important to acknowledge that the social licence for a project is not uniform among all stakeholders. Different groups may

hold varying perceptions and levels of support. Hence, understanding that social license exists on a continuum rather than a simple binary assessment is crucial.”

Establishing social licence can be more challenging for renewable energy projects. These projects are being largely developed in regional Australia where they are subject to intense local scrutiny, and unlike traditional infrastructure projects such as roads, rail, and hospitals, the direct benefit to the affected communities is less clear.

“A genuine commitment to social licence requires an understanding of stakeholder perspectives, a strategic approach and proactive engagement. Best practice involves establishing a comprehensive framework in a place-based approach for and with the community that is communicated, measured, and reported on through the lifecycle of the project(s),” Newman said.

The importance of social procurement

While the importance of achieving social

28 | ecogeneration April 2024 www.ecogeneration.com.au SOCIAL LICENCE | ARCBLUE

Image: Studio-FI / stock.adobe.com

Social procurement is the fundamental vehicle that will help deliver future renewable projects.

licence is gaining traction, there is still a misconception that social licence should focus only on community consultation, land holders and issue management. While these are vital concerns, there needs to be a broader focus on maximising and demonstrating the specific achievement of local, economic, social and employment impact through the delivery of these projects.

“Social impact assessment processes have told us that achieving sustainable local economic employment, and broader positive social impacts are critical drivers for community acceptance and the achievement of social licence,” Newman said.

Social procurement is becoming increasingly well integrated into publicly funded infrastructure projects across Australia, yet it is inconsistently applied and not well understood in the renewable energy sector.

Social procurement is not only setting targets and requirements for suppliers, but a comprehensive approach is also needed to establish a shared commitment to a collaborative social impact framework between the proponent, key contractors, and partners.

Social procurement needs to be integrated at each stage of the development process, ensuring social and local economic objectives form part of detailed planning in the scope, feasibility, and design stages.

In the delivery and operation stages, the achievement and demonstration of social and local economic impact is vital. Strategies and action plans need to be resourced and executed with a consistent focus on

measurement and reporting, management of community expectations, and communication about the project’s activities and social and local economic impacts.

“Social procurement enables the integration of service delivery plans and goals such as Aboriginal participation, workforce development, inclusive employment, and local and social benefit supplier engagement to maximise the demonstrable benefit to the community,” Newman said.

There is also a critical opportunity to leverage and integrate community investment schemes to support local partners in delivering or enhancing workforce and local supplier programs that will create a long-term legacy for the community.

As Australia ramps up its efforts to meet the country’s decarbonisation and sustainability targets, hundreds of renewable energy projects are reaching a critical stage in their developments.

The speed and scale of development requires a national commitment to social procurement. This will not only underpin the social licence that is so critical to this transition but will ensure we take advantage of this unique opportunity to deliver a sustainable positive legacy for the communities where these projects are taking place.

Engaging in three ways

Established in 2013, ArcBlue is a specialist Asia Pacific procurement and supply chain consulting firm, part of Bain & Company. ArcBlue is experienced in delivering procurement, supply chain and social impact

for infrastructure and renewable energy projects.

One of ArcBlue’s key areas of expertise is in delivering social impact, working with governments, proponents, and head contractors, at all levels of the supply chain and key local partners and stakeholders in three distinct ways:

• Organisational policy and strategy –integrating a commitment to achieving social value through all aspects of organisational practice.

• Place-based approaches and programs - bringing stakeholders together to strengthen local eco-systems that can help deliver on the promise of social procurement. This includes the design and delivery of place-based collaborative programs such as Q-Seed to drive local economic development and address disadvantage through local and social procurement, and inclusive employment.

• Project solutions – integrating the achievement of social value into all aspects of a project from design and planning through to implementation and operations. Working with both private and public sector organisations who are delivering major projects to implement practices to actively target, support, grow and measure inclusive employment, and local and social procurement outcomes.

For more information, visit arcblue.com or contact Chris Newman, +61 412 318 384, or chris.newman@arcblue.com.au.

www.ecogeneration.com.au April 2024 ecogeneration | 29 ARCBLUE | SOCIAL LICENCE

Image: ArcBlue

Social procurement needs to be integrated at each stage of the development process.

Australia’s electric vehicle juncture

As global adoption of electric vehicles rapidly accelerates, spurred by ambitious climate policies and lucrative industry incentives, Australia finds itself at a critical moment in time.

While Australia has lagged in implementing comprehensive Federal Government incentives compared to other major economies, this deficit paradoxically highlights the enormous opportunity before it.

Daniel Bleakley, Senior Energy and Technology Transition Advisor at Next System spoke with ecogeneration about how in comparison to many countries, Australia lacks nationwide incentives for purchasing new electric vehicles (EVs).

“However, this gap represents a greenfield space for impactful policymaking to rapidly accelerate our EV transition,” Bleakley said.