t has been a big 12 months for Australia’s offshore wind industry. On the back of the nation’s first offshore wind zone announcement in waters off Victoria’s Gippsland region in 2022, comes the unveiling of plans for an official wind zone off the coast of the NSW Hunter region. This announcement, in July 2023, cements the Federal Government’s commitment to fast-tracking wind energy production.

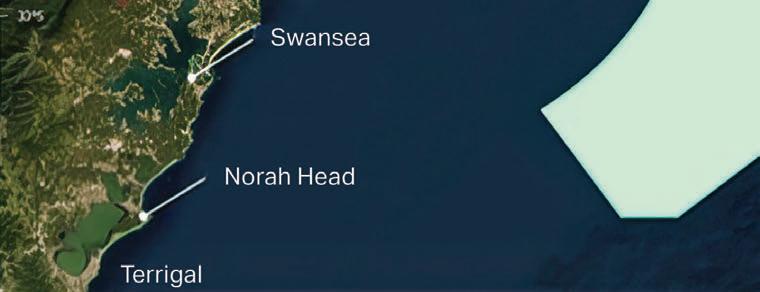

The declared offshore wind zone 20km off the coast of the Hunter region will cover 1800 square kilometres between Swansea and Port Stephens, with potential energy generation of 5GW. This location is an important pillar to support one of Australia’s industrial heartlands.

Australia is a nation with an abundance of sun and wind so it makes sense we maximise these natural resources for solar and wind energy as part of national ambitions to become a renewables superpower.

While the announcement of large-scale renewable energy projects is always exciting for Australia’s future, it is important we maintain momentum to remain on track to meet legislated emissions targets of 43 per cent by 2030, and 82 per cent renewable energy by the same year. As Clean Energy Council chief executive Kane Thornton explains in his regular EcoGeneration column (page 14), there have been some bumps in the road in 2022 as the nation accepts that 240 per cent expansion in annual new generation from 2026 to 2030 is required to meet these targets. However, our commitment remains strong.

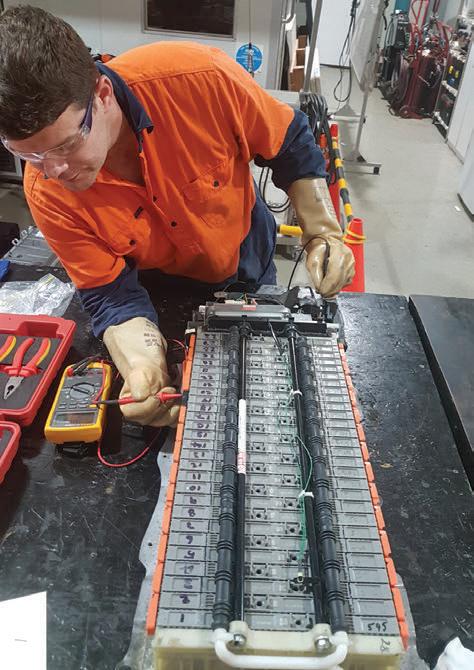

As Australia’s uptake of electric vehicles rises, mechanics and auto electricians face challenges adapting their skill-set and knowledge. Neil Beveridge from Albury-based renewables training organisation Skillbuild explains how he is delivering practical courses that offer expertise to ensure mechanics are up to speed on how to service EVs. Read more on page 40.

Also in this issue is a feature on the role of data centres in achieving net-zero emissions (page 28), and how the Clean Energy Council’s new myCEC service is helping the solar industry to keep on top of regulations and reducing compliance concerns.

Finally, in the solar inverter guide in the August issue of EcoGeneration, we mistakenly left off our thanks to David Tolliday from Holmesglen Institute for his time and expertise in compiling the information and writing the feature.

Gavin Dennett EcoGeneration Editor

Follow EcoGeneration on LinkedIn

EcoGeneration acknowledges the Cammeraygal people, traditional custodians of the land on which this publication is produced, and we pay our respects to their elders past and present. We extend that respect to all Aboriginal and Torres Strait Islander people today.

Chief Executive Officer: John Murphy

Managing Editor: Mike Wheeler

Editor: Gavin Dennett gavin.dennett@primecreative.com.au

Business Development Manager: Juanita Farrington, +61 434 792 225 juanita.farrington@primecreative.com.au

Client Success Manager: Karyssa Arendt karyssa.arendt@primecreative.com.au

Production Manager: Michelle Weston

Head of Design: Blake Storey

Designer : Kerry Pert

Subscriptions : T: +61 3 9690 8766 subscriptions@primecreative.com.au

Published by: PRIME CREATIVE MEDIA PTY LTD ABN: 51 127 239 212 379 Docklands Drive Melbourne VIC 3008, Australia

T: +61 3 9690 8766

www.primecreativemedia.com.au

www.ecogeneration.com.au

Cover images: (Main) Shutterstock (Inset — left to right): Skillbuild, Schneider Electric, Dynamic Ratings

EcoGeneration is printed on Lumi paper which is PEFC-certified and manufactured in an ISO 14001-certified mill. Lumi paper also contains premium white waste paper, reducing matter going into landfill. This magazine is available to interested parties throughout Australia and overseas. Themagazine is also available by subscription. The publisher welcomes editorial contributions from interested parties, however, the publisher and the Editorial Board accept no responsibility for the content of these contributions and the views contained therein are not necessarily those of the publisher or of the Editorial Board. The publisher and theEditorial Board do not accept responsibility for any claims madeby advertisers.Unless explicitly stated otherwise in writing, by providing editorial material to Prime Creative Media, including text and images, you are providing permission for that material to be subsequently used by Prime Creative Media, wholeor in part, edited or unchanged, alone orin combination with other material in any publication or format in print or online or howsoever distributed, whether produced by Prime Creative Media and its agentsand associates or another party to who Prime Creative Media has provided permission.

Average net distribution 6616

Period ending September 2021

Excellent balance between power, size and weight

Power Range is up to 440W with size of 1762 x 1134mm and weighing 21.1kg

n type i-TOPCon technology

With 210mm innovative platform

Excellent Mechanical Performance

With dual glass structure

Outstanding reliability and safety

Designed for extreme weather conditions and reduced risk of micro crack from handling

Lower degradation

1% 1st year degradation,

0.4% annual power attenuation

High system compatibility

99% compatibility with mainstream inverters

LEARN MORE

is with FIMER’s PVS980-58 central inverter solution.

To power your utility-scale PV plant for reliable energy yields you need equipment that can stand the test of time.

The FIMER PVS980-58 5MVA central inverter solution is built for long-term performance. With the plug and play skid solution, you can expect maximum yields for more than 25 years and hit peak performance right away. The end result is reduced LCOE for longer.

Power your lasting performance with the FIMER PVS980-58 5MVA.

Australia’s first zero-emissions emergency services vehicle has been unveiled at the Australasian Fire and Authorities Conference in Brisbane, Queensland.

Volvo Group has supplied the green logistics vehicle to the ACT Emergency Services Agency, and it will be used for operational support to fire and rescue teams in the national capital.

The Volvo FL Electric is a solid and nimble truck designed for urban and city environments.

“This is a significant milestone for the ACT,” says ACT Minister for Police and Emergency Services Mick Gentleman. “Transitioning emergency services operational support vehicles to zero-emissions vehicles is a crucial step to achieving our government’s nation-leading target of net-zero emissions by 2045.”

ACT Fire & Rescue has welcomed the new truck as part of the department’s commitment to a cleaner and greener future.

leadership and innovation in the design and delivery of this vehicle.”

Volvo Group Australia president Martin

King Island’s transition from dependence on diesel to a renewable energy future has taken another step forward with the opening of a 1.5MW solar farm.

Owned and operated by Hydro Tasmania, the 5000-panel solar farm on the picturesque Bass Strait island, between Tasmania and Victoria, spans six hectares and cost $3.35 million to build.

“During the past 10 years, we’ve slashed diesel consumption on King Island by 50 per cent [through renewables projects],” says Hydro Tasmania CEO Ian Brooksbank. “That saves 2.1 million litres of diesel and cuts carbon emissions by 5700 tonnes a year.

“The solar farm will save an additional 300,000 litres in diesel and 800 tonnes in carbon emissions annually, delivering greater reliability in electricity supply for local homes and businesses.”

processes, the first vehicle is expected to go into operational service in and around the ACT in early 2024.

The first wind farm was installed on King Island 25 years ago, and subsequent expansions and technology advances have made the island an Australian innovator in hybrid renewable energy systems.

“King Island has become a renewable energy blueprint for isolated off-grid communities in Australia and around the world, and it continues to lead the way,” says Brooksbank.

“This type of hybrid, renewable energy system is a model for the national electricity market. How we integrate wind, solar and storage, while reducing fossil fuels and maintaining grid stability, is an important lesson as the nation transitions to renewable energy.”

Hydro Tasmania aims to achieve net-zero Scope 1 and Scope 2 emissions across its organisation by 2025.

Australia’s first zero-emissions emergency services vehicle on display at the Australasian Fire and Authorities Conference in Brisbane.

The Victorian Government is phasing out gas usage across the state, with a new policy requiring residential dwellings built after 1 January, 2024, to be all-electric.

Victoria has the highest usage of residential gas in Australia, with 80 per cent of homes connected. However, the state government is committed to reducing its dependence on the fossil fuel and embracing its electric future with new regulations to residential planning permits.

All new public buildings – such as schools, hospitals, police stations and government offices – that have not already reached the design stage will also become all-electric, effective immediately.

Victorian Minister for Energy and Resources Lily D’Ambrosio says the ban on gas in new homes will help the state reach its emissions reduction target of 75-80 per cent by 2035 and net zero by 2045, as well as easing cost-of-living pressure.

“The cost of living for Victorians is getting bigger,” she says. “Gas bills are absolutely eye watering.

“Going all-electric will save a new homeowner $1000 off their energy bills each year. If they’ve got solar panels, it will save them $2200.”

The Energy Efficiency Council endorses the Victorian Government initiative to reduce its dependence on gas, which contributes around 17 per cent of Victoria’s emissions.

“All-electric homes are good for Victorian families,” says Energy Efficiency Council CEO Luke Menzel. “They are cheaper to run, healthier to live in and help lower emissions.”

Analysis by consumer group Renew reveals that building an all-electric home could reduce household energy bills by 35 per cent.

“With interest rates sky high, if used to help pay off your home loan, these bill savings from going all-electric could slash two years off an average 25-year mortgage in Melbourne,” says Menzel.

“Given upfront costs of building an all-electric home are comparable to building a home with a gas connection, it makes going all-electric a no-brainer. It is a big

Transgrid is preparing to deliver a major overhaul of Australia’s electricity transmission network. It has signed a $100 million contract for the supply of high-voltage equipment as the nation transitions to a clean energy grid.

The transmission operator in NSW and ACT has signed the contract with ZTT Australia to supply 17,500km of high-voltage conductors as part of its Powering Tomorrow Together program that includes the rollout of major projects such as HumeLink, VNI West and EnergyConnect.

“We continue to build our global supply chain to secure the specialised kit needed to build the future clean energy grid and ensure competitive and efficient delivery of the Federal Government’s energy plans,” says Transgrid CEO Brett Redman.

“Transgrid has finalised a $100 million contract with ZTT Australia to supply 17,500km of high voltage conductors – enough to stretch from Sydney to Dublin. We are also finalising a separate contract with another Australian company to supply other locally produced conductor elements.”

The Powering Tomorrow Together

program bundles procurement for major projects and enables Transgrid to purchase materials such as substation equipment at a lower cost, enabling limited resources to be used across multiple projects. It is supported by a $400 million Federal Government underwriting as part of the Rewiring the Nation program.

“Transgrid is investing $16.5 billion in transmission infrastructure in NSW during the next decade to accelerate the Federal Government’s vision,” says Transgrid’s executive general manager, delivery, Craig Stallan. “Our major transmission projects involve a long shopping list for big kit, and we are competing with Europe, the US and UK to secure highly sought-after slots on production lines.

“The new conductors will be used on HumeLink and VNI West. By securing supply now, we can deliver projects faster and cheaper for consumers.

“It is also reducing risk as we compete with other energy companies and nations to secure critical, large-scale equipment, materials and skilled labour to deliver the projects Australia needs.”

Five decades of commitment to sustainability of the planet have taught us one thing above all else: to be non-conformists Because the only way to heal the relationship with our planet is to question everything. Starting with who the key players should be in this unstoppable process of energy transition. So INGETEAM wants to lead a dream team made up of millions of people. Real people, like you, who want to be part of the solution and not part of the problem. Part-time heroes and heroines who share the daunting task of fighting for the future of humanity, every single day. Thank you for being part of a team that’s truly unique.

Tuning in to the news in recent times reminds me of the history of clean energy and the naysayers who always said, “It can’t be done.”

They said it couldn’t be done when John Howard set the original 10 per cent Renewable Energy Target (RET) at the turn of the century. They said the 20 per cent RET couldn’t be achieved by 2020, yet we smashed that. They said one million rooftop solar systems would shut down the grid. Today, there are more than 3.5 million of them on Australian roofs.

There have always been naysayers, but clean energy progress in Australia and worldwide continues regardless.

Emissions reductions of 43 per cent, and 82 per cent renewable energy, by 2030 are ambitious targets. But they set up Australia to become a global clean energy superpower, fundamentally modernising

our economy and energy system.

At the Clean Energy Council, we recently commissioned a report from Green Energy Markets, which reveals that achieving the 82 per cent target will require a 240 per cent expansion in annual new generation from 2026 to 2030.

For that to happen, Australia must double down on its abundance of natural, renewable resources and not be distracted by debates about extending the life of fossil fuels, or a role for nuclear energy, as is currently popular. These are distractions.

Fossil fuels are finished – Victoria’s decision to ban gas connection in new homes from January 2024 is a good example – and nuclear is far too costly, time-intensive and untested.

At the Australian Clean Energy Summit, in July 2023, we were blessed with a fantastic

line up of speakers from government, industry leaders, analysts and experts. We were pleased to find there is widespread enthusiasm for extending Australia’s RET, something we have long called for.

Australia’s previous RET was met in 2020 and it is phasing out. No single policy has propelled forward the industry as much. The benefits of an extension would be enormous. While state governments have stepped into the breaches, we still need a national policy mechanism to help us reach the 82 per cent target.

Consumer uptake of rooftop solar in Australia has been built off the back of the successful Small-scale Renewable Energy Scheme (SRES) program. Not only has SRES helped reduce upfront costs associated with the purchase of rooftop solar, it has built strong compliance requirements.

At the Clean Energy Council, we are proud of the role we have played in building robust i nstaller and product accreditation programs, and running the New Energy Technology Code of Conduct (NETCC), which was replaced by the Solar Code of Conduct in early 2023. These schemes are a critical part of the regulatory framework that helps drive better behaviour from the industry and ensures customers are treated fairly and honestly.

The Clean Energy Regulator is currently undergoing a tender process for the installer accreditation program. The Clean Energy Council has not applied to continue in this role, assuming there is another body that can perform this important, but arduous, task.

However, our strong support for installers continues. This takes the form of the myCEC program, a subscription service providing technical support, learning resources, business benefits and much more. This service provides critical support to installers in understanding and

navigating growing complexity and demands as they install systems. We need more installers, and myCEC is designed to encourage and support them in the industry.

The Clean Energy Regulator’s latest small-scale technology certificates report shows that rooftop solar capacity installed in Q1 2023 was 21 per cent higher than in Q1 2022. The rooftop solar industry in Australia is world leading, and evidence suggests it will continue to drive the country’s clean energy transition.

The Australian Energy Market Commission (AEMC) and the Australian Energy Regulator (AER) are currently undertaking several policy reviews that are exploring ways to unlock value in making

energy generated from rooftop solar more flexible and valuable by creating markets and providing incentives for consumers to move their energy to different parts of the day when the system has spare capacity. These reforms are important to unlocking new revenue streams and incentivising households to take up solar.

Consumer confidence in any industry is essential. The rooftop solar industry in Australia has built significant social licence with communities by delivering power bill savings. These benefits are there for all to see – clean energy is the best way to reduce energy bills in the short-term and long-term.

The Clean Energy Council is carefully considering how we can leverage an expanded SRES program to better support customers in the future. The focus needs to be on how to encourage more orchestration of rooftop solar and storage. However, that needs to be driven by consumers who make informed choices and have trust in the installation process and the quality of products.

At a time when the large-scale clean energy sector is wrestling with how best to engage and work with communities on bigger projects – although large-scale projects are a more difficult sell, have longer lead times and fewer immediately visible benefits – rooftop solar continues to bring crucial generation to the grid.

It’s no secret commitments to large-scale clean energy projects slowed in early 2023. Just 0.4GW of large-scale projects were committed in the first half of 2023, which is a long way short of the 5GW per annum we need.

But we must not forget we have the best combination of wind, solar and water resources anywhere in the world. For the first time in our history, we have wall-to-wall governments supporting clean energy. Australia has built a strong, vibrant industry, led by remarkable progress in the rooftop solar and storage sector.

This is the time to embrace the challenge and prove the naysayers wrong again.

Kane Thornton has more than a decade of experience in energy policy and leadership in the development of the renewable energy industry. His column is a regular feature in EcoGeneration, where he analyses industry trends and explains the impacts of federal and state renewable policies on the energy sector.

Leading suppliers in Australia’s clean energy sector will recognise the market opportunities the recent Safeguard Mechanism reforms have created.

The facilities covered by the emissions legislation will increasingly need to source clean energy technological solutions, large and small, to achieve and surpass the Federal Government’s emissions reduction targets.

The Safeguard Mechanism has been in operation since 2016. However, for 2023-2024, the system has been tightened to drive down emissions in Australia’s industrial sector.

The Safeguard Mechanism applies to facilities that emit more than 100,000 tCO2-e of covered emissions in a financial year. It covers Scope 1 emissions – including direct emissions from fugitive emissions –and emissions from fuel combustion, waste disposal and industrial processes such as cement and steel making. Scope 2 emissions, such as those associated with electricity sourced from the grid or from hydrogen produced offsite, are not covered under the mechanism.

Approximately 28 per cent of Australian greenhouse emissions come from facilities

covered under the mechanism from sectors of the economy including mining, oil and gas extraction, manufacturing, transport and waste.

Earlier in 2023, Federal Parliament passed reforms to the Safeguard Mechanism, which came into effect on 1 July and apply to the 2023-2024 compliance period. The reformed Safeguard Mechanism will contribute to Australia’s goal to reduce greenhouse gas emissions by 43 per cent below 2005 levels by 2030, and to reach net zero by 2050.

The mechanism requires and incentivises Australia’s largest industrial facilities to

be issued to facilities that do not exceed their declining baselines. The structure of these incentives means those who reduce emissions faster and at the lowest cost will be rewarded. The first SMCs are likely to be issued in early 2025 to facilities whose emissions are lower than their baselines in the year to June 2024.

SMCs may be on-sold for financial benefit or retained for use against a future liability.

Facilities that don’t have commercially available emissions reduction opportunities have options to meet their baselines. Facilities could choose to bring forward capital investments, and doing so will reduce emissions and generate SMCs. They may borrow a portion of their baseline from a future compliance year, apply for a Multi-Year Monitoring Period (MYMP) or purchase and surrender SMCs or Australian Carbon Credit Units (ACCUs).

To promote accountability and transparency, facilities will be required to publicly justify their use of offsets if they use ACCUs equivalent to 30 per cent or more of their baseline to meet their obligations.

I believe the reformed scheme will stimulate demand for large-scale and small-scale clean energy solutions. Many Safeguard facilities are remote and have onsite electricity generation that could be transitioned from diesel to firmed renewables.

Other potential changes may include the electrification of industrial processes, or the production of renewable-electricity based “green” hydrogen to displace the use of natural gas for heat-based processes.

The economic incentives are now in place for facilities to seek cleaner energy solutions. The mature and innovative Australian clean energy sector is well placed to supply Safeguard facilities with the solutions they are looking for.

reduce their emissions to help meet these targets. It aims to deliver more than 200 million tonnes of abatement by 2030. This is equal to taking two-thirds of the nation’s cars off the road during the same period.

The reforms introduce a declining emissions limit – called a baseline – that facilities are required to stay below each year. The baseline of each facility will lower by 4.9 per cent annually through to 2030. Some trade-exposed facilities, such as cement manufacturing, may apply for flexibility to secure a reduced baseline

decline rate if they meet a cost-impact metric test. New facilities will have their baselines set to tighter international best-practice emissions-intensity levels.

The reforms also introduce Safeguard Mechanism Credit units (SMCs), which will

The Clean Energy Regulator (CER) administers the National Greenhouse and Energy Reporting (NGER) scheme and Safeguard Mechanism. CER oversees facility registration, reporting and obligation management. Information about covered Safeguard facilities are available at cleanenergyregulator.gov.au.

for financial years commencing on

after 1 July 2023

Transmission operator Transgrid has carried out its bushfire prevention operation ahead of a predicted hot and dry summer in Australia.

With Australia bracing for a long, hot summer, Transgrid has undertaken its annual bushfire prevention program to help protect communities from natural disaster.

The transmission operator in NSW and ACT has carried out hundreds of hours of helicopter inspections, aerial imagery, 3D laser scanning, thermographic surveying, vegetation management and network maintenance across thousands of kilometres of transmission lines as part of its bushfire prevention operation.

“Transgrid has completed its comprehensive annual bushfire prevention program as we prepare for what is likely to be a potentially severe bushfire season,” says Transgrid’s executive general manager of network, Marie Jordan.

“We take the risk of bushfires very seriously and the safety of our people and local communities is our priority. That’s why we have ensured a high level of preparedness across more than 13,000km of transmission lines.

“Transgrid uses best-practice asset management and network safety management systems to reduce bushfire risk and potential impacts to local communities and the environment.”

Transgrid’s 2023 bushfire safety management program includes:

• A 3D laser aerial survey of easements across the entire network using LiDAR technology to identify vegetation growing too close to transmission lines.

• An extensive vegetation management program with on-the-ground teams assessing and mitigating potential vegetation encroachments.

• Helicopter inspections and aerial imagery of the network to physically assess the condition of transmission towers and lines.

• On-the-ground teams carrying out network inspections and maintenance to avoid potential bushfire hazards.

• Thermographic surveying of substations to identify and address required asset upgrades.

“These aerial surveys and inspections involve 500 flying hours and have enabled our teams on the ground to proactively respond to potential bushfire hazards, including vegetation management and tower and line maintenance,” says Jordan.

“About half of our maintenance expenditure each year relates to mitigating bushfire risk, including ongoing and comprehensive vegetation management to maintain our easement corridors.

This is conducted with asset inspection programs and rectification works to ensure the safe operation of our network.

“Transgrid works closely with the NSW Rural Fire Service and local Bush Fire Management Committees comprising landholders, land managers, fire authorities and community organisations.

“During bushfire season, we work very closely with fire authorities to provide safe and secure access to our easements for firefighters, including de-energising transmission lines if required.

“Our focus is on prevention first. That’s why our network planning, design, construction, operation and maintenance takes bushfire risk into account every step of the way.”

NSW Rural Fire Service Commissioner Rob Rogers says preventative bushfire action ahead of the predicted hot and dry summer is essential work.

“As we move out of a period of incredibly wet weather, the risk of serious bush and grass fires is returning to NSW,” he says.

“Transgrid’s commitment to preparedness is an important part of ensuring our people are in the best position to protect communities across the state when fire threatens.”

Dynamic Ratings provides an affordable way to increase the reliability of your power supply. Monitoring for renewable energy assets is an easy way to extend the life of your asset, offset risk, and keep your workplace safe.

▪ Extend the Life of Your Assets

Excessive and harmful harmonics can significantly decrease the life of your transformers. Online monitoring is an affordable way to give you better visibility into the condition of your assets to extend the asset’s life.

▪Offset Risk

Replacing assets can be time consuming and costly if an unexpected problem occurs. Monitors evaluate and measure the asset’s performance to improve site uptime and generation availability.

▪ Monitor Your Renewable Assets

Dynamic Ratings provide online monitoring solutions for transformers, circuit breakers, switchgears, distributed assets, and more.

The recent Australian Clean Energy Summit in Sydney provided a platform for leaders in the renewables space to progress the industry into the future.

The future of Australia’s renewables industry was in focus at the Australian Clean Energy Summit in Sydney on 18-19 July, 2023. Hosted by the Clean Energy Council and run in conjunction with the Energy Next exhibition at ICC Sydney, the conference was a platform for industry leaders to share their sustainability and renewable energy vision. Across the event’s two days of keynote speakers and networking, attendees gained insight into the ideas, innovations and policies driving Australia’s ambition to becoming a clean energy superpower. Presentation topics included decarbonising Australia’s industrial sector; large-scale hydrogen; First Nations engagement in the renewables industry; the importance of small-scale renewables; the transition away from oil and gas; offshore wind power; and growing the clean energy workforce.

The annual Australian Clean Energy Summit gala dinner was a highlight of the event. Hosted by Walkley-award winning journalist Jan Fran, the evening incorporated the 2023 Clean Energy Council Awards, in which the renewables industry’s high achievers were honoured.

The dinner’s guest speaker was prominent lawyer, academic, land rights activist and founder of the Cape York Partnership, Noel Pearson.

Another feature of the summit was the Women in Renewables Luncheon on the opening day. The theme was mentoring, with prominent clean energy industry leaders speaking about the role of women supporting each other and fostering vocational relationships.

The event was introduced by the Clean Energy Council’s director of workplace development, Dr Anita Talberg, and featured panellists including session chair Victoria McKenzie-McHarg, strategic director, Women’s Environmental Leadership Australia; Ruby Heard, director, Alinga Energy Consulting; and Romilly Madew, chief executive officer, Engineers Australia.

“Mentoring is a big part of our professional lives and in a small purpose-driven industry such as renewables in Australia it can become a really important part of our personal lives,” Dr Talberg told attendees. “This year, the Clean Energy Council launched its Women in Renewables Mentoring Program. We connected 40 industry leaders with 40 aspiring and emerging leaders who identify as women.

“The driver for our work in this space is the staggering statistic that the

representation of women in our industry, which sits at 39 per cent across the whole industry, drops to 32 per cent in senior management roles, and just 19 per cent at board level.”

In chairing the onstage panel, McKenzieMcHarg stressed the importance of mentoring in fostering an industry where more women are in leadership roles.

“The evidence is abundantly clear that more women in decision-making roles equals better outcomes for the environment, climate change and clean technology,” she said. “If we want to see the scale of the energy transformation that everyone is exploring at this conference, we need to see women in senior leadership roles. That is across politics, government, business and community sectors.”

A highlight session on day one of the summit was “Shining light: The massive role of small-scale renewables in the clean energy transition”. This session was chaired by Jenny Paradiso, co-founder of solar and battery storage company Suntrix. The keynote speaker in this session was Warwick Johnson, Clean Energy Council board member and founder of solar analytics company SunWiz.

The focus was on the role of rooftop solar and batteries in doing much of the heavy lifting in Australia’s clean energy transition. However, it was noted that households will need to prepare for greater PV system sizes – from the standard rooftop system size of 6.6kW to 26kW – as full electrification of

homes and vehicles takes hold.

“6.6kW has been the habit of the solar industry,” said Johnson. “From research I have seen, households follow the recommendation of their retailer. But we will see significant upgrades as people realise what they have is not enough and they embrace things such as electric vehicles.”

Focus was placed on collaborative relationship building between industry and training organisations at day-two session, “Attract, train, retain: Industry partnerships to support the clean energy workforce”. With the ongoing skills shortage in the renewables sector, there is growing need

for collaboration between industry and training organisations to offer portable entitlements and transferable upskilling opportunities.

“The clean energy industry is in huge competition with every other industry in Australia,” said NSW Electricity Infrastructure Jobs Advocate Mark Apthorpe. “There are so many infrastructure projects happening around the country and as an industry, employees need to be the most valuable assets.

“There is an opportunity for collaboration between players we have not seen before. As we move to a new world of energy, there is an opportunity to go to a new world of managing people and working collaboratively.”

The 2023 Clean Energy Council Awards honour the individuals and organisations excelling in Australia’s renewables industry.

The Clean Energy Council celebrated high achievers of the renewables industry at the Australian Clean Energy Summit in Sydney on 18 July. The 2023 Clean Energy Council Award winners were announced at a gala dinner during the two-day event at ICC Sydney.

The awards recognise leaders who are contributing to Australia’s clean energy transformation. They honour individuals and organisations across categories including Outstanding Contribution to Industry, Collaboration, First Nations Engagement and Participation, and Diversity and Inclusion.

The Outstanding Contribution to Clean Energy Award went to former NSW Minister for Energy and Environment Matt Kean. This award honours an individual’s impact towards accelerating Australia’s transition to clean energy. During his time as state energy minister, from 2019 to 2021, Kean delivered the 20-year Electricity Infrastructure Roadmap, the biggest renewable energy policy in Australia’s history.

“Leadership is doing more than showing up,” said Clean Energy Council chief executive Kane Thornton. “Leadership is taking risks to have an impact even if it comes at the expense of your own role or position.

“Championing a progressive set of energy and climate policies in the Liberal Party, Kean argued that the centre of Australian

politics needs to reclaim its voice in the political debate. His leadership helped break through the partisan political barriers that plagued our sector for years.”

The Collaboration Award recognises an organisation, individual or group that has worked to build consensus and progress a reform that benefits Australia’s clean energy industry.

For 2023, it was presented to Supply Solar for its work recycling and repurposing solar panels. Addressing Australia’s major problem of 450,000 tonnes of used PV panels being destined for landfill by 2040, the company has formed a relationship with the Ministry of Defence to export secondhand panels abroad.

The First Nations Engagement and Participation Award recognises an individual or organisation that demonstrates outstanding positive engagement with First Nations communities.

The 2023 recipient is the First Nations Clean Energy Network for its groundbreaking work giving First Nations peoples a voice in Australia’s clean energy transition.

The organisation – which was featured in EcoGeneration’s cover story in April 2023 – works with Indigenous communities to develop clean energy engagement and activities. It also works with policymakers to develop strategies to ensure the nation’s clean energy transition is equitable.

There were joint winners of the Diversity and Inclusion Award, with Hydro Tasmania and RES taking the gongs.

Lucy Aird commenced with Hydro Tasmania in 2017 and is recognised for leading an inclusive and accessible culture across the business.

“Championing a sustainable future isn’t just about renewable energy,” she said upon accepting the joint award. “It is about addressing social inequalities and investing in opportunities for people to succeed.”

RES is the world’s largest independent renewable energy company. It has been honoured for its establishment of a global “affinity network” covering the five dimensions of diversity: age, disability, gender, race and LGBTQI+.

Thornton said the 2023 Clean Energy Council Awards recognise outstanding work to fast-track Australia to a clean energy future.

“Our sector is navigating the greatest transformation of our economy since the Industrial Revolution,” he said. “This year’s award winners lead the way, delivering the benefits of clean, low-cost renewable energy for Australia’s success and prosperity.”

Australia’s clean energy industry gathered in Sydney on 18-19 July, 2023, for the annual Energy Next exhibition. Co-located under one roof with the Clean Energy Council’s Australian Clean Energy Summit, the events attracted the renewables sector’s innovators and thought leaders for two days of knowledge sharing and exploration of the nation’s clean energy future.

Powered by All-Energy Australia, in partnership with the Clean Energy Council, Energy Next at ICC Sydney focused on the latest renewable energy and energy management technologies and solutions from suppliers across solar, energy storage, electric vehicles and energy monitoring software.

In 2022, around 1500 attendees passed through the doors during the two-day event, but in 2023 this same approximate number of people visited in the first day alone, helping cement Energy Next as a premium renewables expo.

The overriding themes were collaboration, creativity and critical thinking on Australia’s path to net-zero emissions. These messages were communicated through keynote speakers and technical sessions with experts who discussed the latest issues and areas of growth for the industry across PV

innovation, electric vehicles, digitisation, hydrogen, energy data, offshore wind, microgrids and storage.

Solar installers and designers attending Energy Next benefitted from the educational Solar Masterclass sessions, where technical experts presented on a range of issues relating to standards, compliance and the latest developments in the PV industry.

“The Solar Masterclass sessions provided a great platform to engage installers on industry requirements,” said Gary Edgar, technical services SME at the Clean Energy Council. “They provided a great platform to engage installers on industry requirements.

“Energy Next is a good base for products and new technologies for consumers to consider, and it has been a great place for the Clean Energy Council to connect with the industry.”

Energy Next also served as an urgent call for action from the clean energy industry and government to accelerate the uptake of renewables to meet Australia’s target of 43 per cent emissions reduction by 2030.

“We need to decarbonise rapidly,” said Dr Nicole Kuepper-Russell, deputy CEO of solar company 5B, during her address at the event. “We need to electrify everything and deploy at enormous scale, well beyond the Industrial Revolution.

“Australia needs 80 terawatts of power and 60 times more terawatts on the ground by 2030. However, there are major challenges: labour is becoming scarce, with an ageing population. Large-scale solar farms are in highly remote sites; materials are scarce and land is scarce. We urgently need to think creatively about how we achieve these goals.”

Energy Next returns to Sydney in July 2024

The NSW Hunter region has been announced as Australia’s second offshore wind zone, maximising the nation’s abundance of wind to produce renewable energy, writes Gavin

Dennett.

Dennett.

Australia’s offshore wind industry is fast-tracking the future with the Federal Government unveiling an official wind zone off the coast of the NSW Hunter region.

Following the 2022 announcement of Australia’s first offshore wind zone in waters off southeast Victoria’s Gippsland region, this latest development cements the government’s commitment to maximising the nation’s abundance of natural wind to produce clean energy.

The Hunter region is one of Australia’s heavy industrial heartlands. Combined with its offshore region in the Tasman Sea featuring strong, consistent winds, it is an ideal location for turbines to produce large volumes of renewable energy while supporting future onshore manufacturing.

The declared offshore wind zone covers 1800 square kilometres between Swansea and Port Stephens. It is positioned 20km from the coast in the north and 35km from the coast in the south. Its potential energy generation is 5GW, enough to power local industries and an estimated 4.2 million homes.

“The Hunter is undergoing significant economic change, and the prospect of creating new job opportunities for decades to come through a new offshore wind industry is a game changer,” says Minister for Climate Change and Energy Chris Bowen.

“This declaration opens the door for a new industry in the region, which could create more than 3000 construction jobs and another 1560 ongoing jobs.”

The Climate Council endorses the rubber stamping of the Hunter offshore wind zone,

which brings Australia a step closer to being a renewable energy superpower.

“Offshore wind will be a key pillar of Australia’s future renewable energy mix,” says Dr Madeline Taylor, Climate Councillor and senior lecturer at Macquarie University’s School of Law. “The Hunter offshore wind zone will fill another piece in the puzzle in decarbonising Australia’s energy system as we continue switching away from carbon-intensive fuels.

“As one of the windiest places on earth, Australia should be cashing in on those solutions and creating a prosperous and sustainable future.

“Australia holds the potential to generate up to 5000GW of electricity from offshore wind using a combination of fixed and floating infrastructure. It is endowed with some of the richest and most diverse renewable energy resources. The right investment and planning in offshore wind is Australia’s golden ticket to a clean energy future.”

Climate Council CEO Amanda McKenzie says wind power is an essential ingredient in Australia’s renewable energy mix.

“We have a huge opportunity to seize our potential and get more renewables such as offshore wind online as we work to dramatically slash our emissions this

decade,” she says. “Wind energy is one of the cheapest ways to add new electricity supply in Australia, especially as power prices continue to bite.

“Ramping up the renewables rollout will bring us closer to lower power bills and less harmful carbon pollution. We must maintain this momentum if Australia is to become a renewable energy superpower.”

The parameters of the Hunter offshore wind zone were established following two months of public consultation with local communities, local industry and sea users. The area is smaller than the original proposed zone, with stakeholder feedback resulting in amendments to enable safe management of shipping and other sea industries.

Offshore infrastructure will be limited to a height of 260 metres to ensure aviation safety.

“The Albanese Government has listened to community feedback and revised the offshore wind zone to ensure it coexists with whale migration, bird and sea life, and our shipping industry,” says Member for Newcastle Sharon Claydon.

“This is an important part of a suite of measures which will position Newcastle and the Hunter as a clean energy hub, including a $100 million investment to ensure

hydrogen readiness at Port of Newcastle.”

Leading Australian energy developer Oceanex and international energy company Equinor welcome the news of Australia’s second offshore wind zone.

“We’ve seen firsthand the incredible transformation the Hunter economy is undergoing with the need to rapidly decarbonise local industry,” says Oceanex CEO Andy Evans.

“This announcement is an unprecedented opportunity for the Hunter to benefit from an innovative new industry that will grow rapidly to be a cornerstone of the Australian energy market.

“Developing a multibillion-dollar clean energy industry here will spearhead the Hunter’s economic transformation and ensure its skilled workforce and industrial capacity continues to deliver prosperity well into the 21st century.”

Oceanex first announced plans to develop its Novocastrian Offshore Wind Farm off the Hunter coast in 2020. Two years later, the company partnered with Equinor to bring the project to life once the offshore wind zone was green lit from the Federal Government.

The project will utilise modern floating wind generation technology and will be located more than 20km offshore to access strong and consistent winds.

With data centres comprising up to two per cent of global energy use, their operators must become resource stewards on the path to net zero, writes Joe

The global energy sector is a major contributor to emissions output, but its demand is currently outpacing supply of renewable energy. In Australia, demand is growing, with development exceeding 183,000 square metres in 2023. Data centre storage needs have led to $3.8 billion investment in Australia in the past 12 months. Globally, it is close to $13 billion investment.

It is incumbent on data centre owners and operators – whose industry is responsible for one to two per cent of global energy use – to focus on energy efficiency and environmental sustainability. With independent research commissioned by Schneider Electric revealing just 33 per cent of sustainability decision makers at colocation providers say their organisation has a strategic sustainability plan, it is clear the industry is only just starting its collective journey in this space. However, there is a path forward. By creating an action plan based on

a holistic measurement framework, and leaning on modern technology, businesses can accomplish sustainability goals and turn them into competitive advantages.

Energy use is just one measure of sustainability. Data centre operators that wish to turn sustainability into a competitive advantage should consider energy use as one part of a holistic plan.

Understanding a data centre’s impact on the environment requires measuring greenhouse gas emissions; water use; waste production; land and biodiversity footprint; and energy consumption. By adopting standardised metrics within those sustainability categories, data centre operators will gain a thorough view of how their entire value chain impacts the environment.

With metrics in place, organisations can create action plans to mitigate data centres’

environmental impact. This will help operators reduce their negative impact on the environment and achieve operational efficiency. Leveraging cutting-edge software tools to help ingest and analyse data to these ends will ensure ongoing sustainability practices.

Each data centre is one part of sprawling hybrid IT infrastructure that spans edge deployments and smaller regional data centres. Any failure at data centre level can cascade to impact the entire IT ecosystem.

Limiting failure requires carefully monitoring and measuring the performance of various support systems, such as cooling and energy generation. A software management system that measures the output and performance of every piece of infrastructure supporting the system is the only way to corral the

complexity of data centre deployment and realise operational efficiencies.

For example, data centre infrastructure management (DCIM) platforms allow operators to monitor, manage, plan and model physical IT infrastructure, even when it comprises thousands of devices spread across sites around the world. DCIM solutions

help simplify management of complex hybrid IT architectures.

These solutions ingest and analyse data in real time, providing insight into everything from device health to environmental impact for a holistic view of data centre operations.

Using software to develop and maintain a green action plan does more than increase sustainability efforts. Sustainable operations manage resources in efficient ways, including increased agility and fuel innovation. Such innovation improves customers’ experience and helps create a digital culture that attracts the best candidates. Creating a sustainable IT infrastructure has a ripple effect on an organisation’s bottom line, as well as the environment.

The data centre industry requires vast resources to fuel its boom. Only through careful planning and measurement can operators become thoughtful stewards the industry needs to flourish.

As the global energy crisis grips the world, companies such as APsystems are developing new technologies that can benefit Australia.

During the ongoing global energy crisis, solar technology continues to nurture the hope of implementing a carbon-free world where energy is accessible to as many people as possible.

According to Solar Power Europe, the European Union (EU) added a recordbreaking 41.4GW of solar power in 2022. This new capacity is equivalent to the power needs of 12.4 million European homes. Annual EU solar power growth has increased by 47 per cent, from 28.1GW, in 2021.

The company mission for microinverter manufacturer APsystems shares this vision of the world where innovation pushes the limits, creating new applications and accelerating energy transition. With more than 3GW of microinverters delivered worldwide, and customers in more than

100 countries, the organisation provides multi-module microinverters utilising cutting-edge technology.

Microinverter systems bring many benefits to residential rooftop systems. APsystems’ products eliminate shading issues. Through their installation flexibility, energy production can be maximised and users can rely on a safe system.

Since the start of the conflict between Ukraine and Russia, Europeans have braced for the possibility of widespread power cuts. The already strong demand for residential solar energy has accelerated since the Northern Hemisphere winter of 2022.

In Germany, the deployment of microinstallations for balconies has increased. This type of application – favoured by local legislation authorising direct injection of up to 600W from solar energy into a home’s electrical network – helps families reduce their energy bill while covering the energy needs of their appliances.

These microinstallation systems allow families to fight against energy shortages without having to make substantial investment up front. APsystems’ dual microinverters are suitable for such applications, and there is strong demand for them in Germany.

On the back of this demand, APsystems has introduced a range of microinverters that are simple to use due to integrated wi-fi technology that allows a direct connection with a user’s internet router. The company’s range of microinverters was launched in Germany in June 2023.

As uptake of microinverters increases for residential and commercial rooftops, site owners of large projects are realising their potential. In Terneuzen, Netherlands, a large-scale residential solar conversion has utilised APsystems’ inverters. Combining rooftops and cladding, this 88kWp project features 110 of the company’s DS3 microinverters, switching 22 gas-powered apartments to clean electricity from solar, including for hot water and heating.

“It was decided to connect every home to 10 solar panels – together these provide 4000W to each residence,” says the project’s installer, Erik de Zwart, from Zonnepaneel Zeeland. “However, space was lacking and the roof offered limited capacity. That’s how I thought about completing the solar-powered roof with a cladding project for 20 panels which, according to our calculations, was the optimum size of the installation.

“But then a new challenge arose – how would we divide the panels among the residents in a fair way? We chose the ideal mix, with each house receiving 10 panels, some on

the east and a few on the south and west. This way, every home is guaranteed a minimum yield.

“Connecting all the panels with different orientations together with a string inverter would not have worked. The flexibility offered by the DS3 dual microinverters from APsystems assured every home would get an optimal solar power generation package to cover its boiler and heating.”

Commercial and industrial solar Converting unused parking spaces into solar energy carport stations across supermarkets in France was debated in the country’s National Assembly in 2022. In December the same year, it was legislated that outdoor car parks of more than 1500 square metres must be equipped with photovoltaic structures by 2028.

At the end of 2022, APsystems introduced the QT2, its second generation of native three-phase quad microinverters. The car park legislation in France illustrates how the

Since 2007, the CEC has supported installers and designers with expert technical advice and resources to help them meet standards.

Now, we’re making these services available to others in the industry with a myCEC subscription.

Whether you're a salesperson looking to learn more about technical aspects, an inspector who needs detailed interpretations of standards, or you simply want industry updates and relevant offers, find out what myCEC can do for you.

ACCREDITED INSTALLERS AND

cleanenergycouncil.org.au/mycec

commercial and industrial (C&I) solar segment is evolving, paving the way for a new generation of rooftop solar systems, which leverage advanced communication and conversion technologies at an affordable price. Many buildings only consider the use of microinverters for large rooftops when a shading problem exists. There is a common belief it is too expensive compared to string

BENEFITS for less than $1/day

From bitesize essentials to standards deep-dives, find resources to help you get the job done right.

Have your say on the issues that matter to you through regular polls, industry opportunities and our Industry Reference Group.

inverters, but this is not true. A native three-phase microinverter, such as the QT2, guarantees phase balance while connecting four modules of 500W to 600W per device.

For a 100kW installation, it would require the installation of only 25 microinverters, which guarantee optimum production from each of the PV modules independently without any impact on the panel next to it. APsystems understands the cost of cleaning the panels – frequently needed for this type of installation with string inverters – is now less of a priority since each panel operates independently, benefitting project owners.

Because microinverters produce more power while requiring minimal maintenance, the small upfront cost is largely offset by a lower levelised cost of energy (LCOE) during the life of the system.

Microinverters also present many advantages compared to string inverters, including greater flexibility when fitting a roof with different angles or orientations, and accommodating other roof obstacles or limited space. Safety is also maximised because there is no high voltage DC on the roof, an important concern for a building such as a school or supermarket car park.

It is also a good way to raise users’ awareness of the project as production of each module is accessible online and free of charge on the real-time monitoring portal with the possibility of observing the equivalent tonnes of CO2 avoided.

Generating clean energy from solar-powered roofs, cladding or carports is a growing trend, but the next step is the ability to store that energy for use at other times. This is driving the next wave of product innovations APsystems will launch on the market under the APstorage brand.

APstorage is already introducing the SEA range, its first generation of smart power conversion systems (PCS) with an ELS battery charger solution.

Based on APsystems’ innovative Module Level Power Electronics technology, the ELS 3K or 5K PCS provide a modular, single-phase AC coupling energy storage solution for residential solar.

Together with compatible low-voltage LiFePO4 batteries, including APstorage batteries, it becomes

the ideal AC coupling storage solution for residential PV applications.

The system can store from 5kWh to 20kWh for households. With automatic energy management features, system owners can choose between a back-up function, self-consumption and peak valley time modes to secure critical loads during power outages and maximise energy savings.

APstorage’s LAKE1000 will complete the company’s mobile power storage solutions range in 2023 with its 1kWh capacity, which is tailored to meet the charging needs of various small home appliances such as a microwave, coffee machine or notebook for several hours.

There are many other innovations on the horizon for APsystems’ product portfolio to make solar energy accessible for everyone.

For more information, visit apsystem.com.au.

Abra Base Metals Mine turned to Pacific Energy to guarantee reliable clean power at its remote site in Western Australia.

clean energy solutions at scale.

Abra Base Metals Mine is a high-grade lead-silver mine being constructed in the Edmund Sedimentary Basin, in the Gascoyne region between Meekatharra and Newman, in Western Australia, approximately 1000km northeast of Perth. It is majority owned by Galena Mining Limited, which has a 60 per cent share in the site.

The mine’s lead-silver resource is 230 metres below the surface. Exploration drilling has identified the potential of copper-gold mineralisation directly below the currently defined lead-silver mineralisation.

site’s energy requirements. The company has supplied two 4.6MW (4565kVA) FIMER PVS980-58 central inverters that are guaranteed to deliver high performance in the harsh Western Australian desert, where temperatures can reach 50 degrees Celsius.

The mining industry is a critical pillar of the Australian economy. It has an essential role in the nation’s ambition to become a clean energy superpower. With wind and solar megaprojects rolling out during the next decade, the sector is providing the resources to ensure infrastructure gets built.

The mining industry is synonymous with its carbon footprint, however it is taking steps to reduce its emissions. With Australia committed to a 43 per cent reduction in emissions by 2030, and net zero by 2050, mining is innovating to become cleaner and greener.

This is where renewables entities such as FIMER Australia can assist. With a history of solar-inverter excellence, the Italian-based company can help support mining heavyweights to deliver

Due to the remote nature of the mine, Galena Mining has sought to establish an onsite hybrid thermal and renewable power station to ensure reliable energy, lower the mine’s operating costs, and reduce its carbon footprint.

The off-grid power station was completed in 2022 and is operated by Pacific Energy. It is a 21MW fully integrated system combining a 6MWac solar farm, 2MW battery energy storage system (BESS) with a 10MW highefficiency/low-emissions gas generation plant and 1100kl LNG storage and re-gas facility.

The solar farm – which features 15,024 mono-facial 460W panels that provide 30 per cent of power to the site – and BESS system were designed and constructed by Pacific Energy.

In mid-2021, FIMER was engaged by Pacific Energy’s renewables division to provide a 8.8MVA solution to meet the mine

“We have been extremely impressed with the capability and responsiveness of FIMER’s local and global product team throughout the project, specifically the product selection process and commissioning of products,” says Daniel Jackson, Pacific Energy’s managing director – renewables. “Their level of communication provided us with comfort that our requirements have been met and we could meet our project milestones.”

FIMER’s PVS980-58 inverter performs in harsh environments, including extreme summer heat. It is durable and equipped with electrical and mechanical protection to provide reliable service life of at least 25 years.

“FIMER’s PVS980 inverters have proprietary technology using self-contained, two-phase thermo-syphon heat exchangers,” says Jason Venning, country manager at FIMER Australia. “These are totally passive and provide high performance with a low-pressure drop, with an efficiency equivalent to liquid cooling and with the simplicity of an air-cooled system. This enables the inverters to be installed in high temperatures while still providing reliable performance.”

For more information, visit fimer.com/anz.

In August 2022, the US Government announced the Inflation Reduction Act, a landmark legislation passed by Congress that commits A$520 billion into programs and funding to accelerate the North American nation’s transition to net zero.

The legislation is a win for global emissions reduction and the health of the planet. However, given the size of the US economy, there are major ramifications as the worldwide renewables landscape has become more competitive.

For a nation such as Australia that harbours achievable ambitions to be a clean energy superpower, it is essential to enact a coordinated response to the Inflation Reduction Act to ensure it doesn’t get left behind.

To help combat increased renewable energy competition from the US, the Federal Government committed $4 billion to the advancement of Australia’s electrification and growth of the domestic hydrogen industry in the 2023-2024 Federal Budget. This big spending on clean energy is a direct response to the Inflation Reduction Act

For international companies with a renewables footprint in the US, the Inflation Reduction Act is a shot in the arm for research and manufacturing. Spanish company Ingeteam, which has 5000 employees stationed in 21 countries around the world, has been boosted by government support in the US.

Ingeteam is a leader in renewable generation across wind, solar and hydroelectric; in energy storage solutions; in green hydrogen; and in the electric vehicle charging space. The company has operated in the US since 2008, and has a manufacturing plant in Milwaukee, in the northern state of Wisconsin.

The site has manufactured more than 4000 generators for the wind energy sector and supplied 4GW of solar and energy storage inverters for the US market. An additional 1.1GW of awarded contracts for solar and energy storage are in execution stages and scheduled to be installed by the end of Q1 2024, totalling more than 5.1GW of utility scale installed capacity for the company.

In August 2023, US President Joe Biden toured the Ingeteam plant during a visit to Milwaukee. He met with staff and viewed the

processing facility where generators for the wind energy sector, solar and energy storage inverters, and EV chargers are produced.

During the visit, Biden was welcomed by Alex Belaustegui, Ingeteam’s corporate development director; David Solé, Ingeteam’s managing director; and Mark Obradovich, Ingeteam’s US director.

Thanks to incentives from the Inflation Reduction Act, US orders of wind turbine generators from Ingeteam are expected to double in the next year.

In May 2023, Ingeteam announced its Milwaukee plant will manufacture electric vehicle chargers for the North American market. This plan is a direct response to the US Government’s announcement to develop a national network of 500,000 electric vehicle chargers.

Ingeteam’s production capacity of EV chargers in the US will exceed 13,000 units per year. These chargers will range from 7.5kW to 420kW and production is expected to commence in the first half of 2024. For more information, visit ingeteam.com.

As the sixth-largest country on Earth by area, Australia is a sprawling land mass comprising many climate zones. From the desert centre and tropical north, to the snowfields and temperate east and south, it is a nation of extremes with seasonal variations.

Due to these environmental contrasts, there are varying conditions in which Australia’s electric vehicles operate. At the highest and lowest ends of the temperature scale, it can be essential to precondition vehicles prior to use for maximum performance, energy efficiency and driver comfort.

Preconditioning allows users to pre-heat or pre-cool an EV’s cabin before each journey, ensuring less of the vehicle’s stored energy is used for these functions. By preconditioning an EV while it is still plugged in, it ensures power for these functions is used from the grid or solar, increasing the vehicle’s range when hitting the road.

In winter, preheating an EV refers to the use of external power from the charger – or the power supply from the car battery if need be – to heat the battery before starting the car so it reaches optimal discharge working temperature.

The battery life of EVs is shortened in winter, and in extreme cold vehicles can be difficult to start. Therefore, the battery needs to be preheated to power the car.

The heating technology of an EV battery varies according to the vehicle. A battery comprises the positive electrode, separator, negative electrode, organic electrolyte and battery shell.

The organic electrolyte conducts ions between the positive and negative electrodes of the lithium battery, which is the guarantee for the lithium-ion battery to obtain the advantages of high voltage and high-energy density so the low viscosity of the electrolyte makes for the movement of lithium ions. If the viscosity is high, it will form internal resistance, thereby preventing the movement of lithium ions.

When the temperature is low, preheating the battery can increase activity of the electrolyte inside it with the change in temperature so the charging and discharging performance is improved. This preheating helps meet the power demand of the vehicle.

When the temperature is below -25 degrees – not an issue in Australia, but certainly in parts of Europe, Asia and North America – the lithium electrons freeze, resulting in failure to start the car. In such cases, vehicle charge time is

Preconditioning an electric vehicle prior to use ensures it is ready to roll in all conditions, which reduces battery stress and range anxiety, writes Gavin Dennett.

extended to warm the battery in preparation for use.

The most common EV preheating systems are PTC preheating, electrothermal film preheating, cold preheating, phase change material preheating, heat pipe preheating, thermal and AC preheating. No matter what kind of preheating system is used, the most important aspect is electrothermal conversion.

Most EV users charge their car during the off-peak time at home, usually at night. In some winter cases, when drivers are in a hurry to use their car in the morning, they have to spend time warming it up. There are vehicles available with pre-heating functions, however if that power comes from the battery, it can reduce battery life and create range anxiety.

However, if the preheating can be sourced via the EV charger, the battery is preserved. This function is available in all Shenzhen ATESS Power Technology Co (ATESS) EV chargers available in Australia.

Founded in 2017, ATESS is a global supplier of solar energy storage and EV charging solutions. The company offers a range of EV chargers at the forefront of technological advancements.

When users charge overnight with ATESS, the EV charger remains connected to the car to reach the set preheating time, and the energy required for preheating comes from the charger. The preheating power for the in-car environment is also provided by the charger, which improves user experience. For more information, visit atesspower.com.

“Preconditioning allows users to pre-heat or pre-cool an EV’s cabin before each journey, ensuring less stored energy is used. By preconditioning an EV while it is still plugged in ensures power is used from the grid or solar, increasing the vehicle’s range.”The portfolio of ATESS EV chargers, which ranges from 7kW to 400kW, and has AC and DC charging stations for home and public applications.

course, and now we strip down a few vehicles and do training in EV conversion projects. We are also doing diagnosis, repairs, fault-finding, disassembling and reassembling – fully stripping down and rebuilding individual components, then putting them back together.”

For mechanics and auto electricians who don’t have experience working with electric vehicles, the Skillbuild course is opening a world of learning in a rapidly evolving segment.

With Australia’s uptake of electric vehicles accelerating, the nation is facing a shortfall of skilled auto electricians, mechanics and repairers who are adept at working on what’s under EV bonnets.

For auto electricians who were trained on traditional combustion engine vehicles, the working components of an EV are different to what they are accustomed. Identifying a hole in this clean energy space, Albury-based national registered training organisation Skillbuild is offering students EV training courses.

The course is for auto electricians and mechanics who want to depower and repower hybrid and electric vehicles. Delivered by electrician and heavy diesel mechanic Neil Beveridge, the Skillbuild course offers education in EV charging, maintenance and servicing.

The course covers safely depowering hybrid and electric vehicles, servicing and repowering the battery system. It allows participants to access manufacturers’ manuals and work on an EV.

“We discovered there are not enough technicians in Australia,” says Beveridge.

“In conjunction with an overseas company, we have developed virtual reality and augmented reality, with online training, to get in the market so students can get their head around the way EVs work.

“In 2025, EVs are going to become bidirectional compatible so they can feed homes and feed back into the grid, which bleeds into renewable energy training.

“With auto technicians on the EVs, we started with the repower-depower safety

“Coming from a mechanical background, I know mechanics have been left unchecked in the industry in regards to upskilling,” says Beveridge. “Vehicles have changed so much since they were first invented. Pistons still go up and down, fuel goes in and burns, but we have tweaked a few systems, and in many respects, mechanics have been left to figure it out.

“However, this is a revolutionary change. We no longer have the engine and fuel, and are dealing with electronics, which is a whole new field for mechanics.”

Initial interest in the Skillbuild EV training course has been from the private market, predominantly car enthusiasts with a thirst for knowledge on how EVs work.

“These people are saying, ‘We don’t know

Huge numbers of new electric vehicles are hitting Australia’s roads, but the nation’s auto electricians and mechanics currently lack the know-how to service them. Skillbuild is addressing this problem, writes Gavin Dennett.Skillbuild students receive electric vehicle safety theory at the Sydney Training Centre.

what we don’t know, and we don’t know what we need to know.’ We are basically trying to teach them to be pseudo electricians.”

From a legislative standpoint, there are still many grey areas to work through.

“Governments are still trying to tweak legislation to figure out what works,” says Beveridge. “There are existing conflicting rules and regulations with regards to if the electrics are on a house, unqualified people would not be able to touch it. But because it is on a vehicle, mechanics can touch it unrestricted. This is mainly because when EV standards were written, voltages were not as high. But things have changed.

“It’s a slightly messy area at the moment that we’re trying to navigate our way through. It is a bit of a minefield. Government has been really receptive to change, but they are a bit slow to move because when they commit, they want to ensure they commit to the right thing.”

The problem facing the industry is that EVs are already on the road and are coming to Australia every week. Therefore, more of this training is needed to bring the auto industry up to speed.

“We do training for electricians with EV charging, and are already doing training for auto technicians on how to diagnose problems, repairs, fault-finding and depower-repower, but there is enormous potential to roll it out in a more systematic fashion,” says Beveridge. “When policy catches up, the expectation is it will be part of the learning curriculum for mechanics.

“The rollout of EVs is still in its early stage in Australia, but with plans across the nation to increase fleets during the next few years, it’s going to be an interesting navigation. There are thousands of mechanics across the country who are going to need to know this stuff.

“This is the first time we have had vehicles and homes meshed. Some of these vehicles are capable of powering a house, yet you have a mechanic who has to repair it because it’s on wheels. An electrician usually deals with things that plug into a house, with all their standards. It’s going to be a really interesting hybrid between the two industries.”

For more information, visit skillbuild.edu.au.

Dynamic Ratings is an Australian owned and operated business that provides condition monitoring products and services to the renewables industry. Based in Melbourne, it has been in operation for 25 years, and has a team of industry experts internationally, with offices in the US and UK.

The company’s global reach helps it leverage experience and cutting-edge technology to produce solutions for the evolving needs of its customers. It is passionate about extending the life of renewable assets, and by utilising real-time data, it provides awareness of high-voltage electrical equipment, including transformers, circuit breakers and switchgear.

According to Dynamic Ratings, condition-based monitoring is a way for renewable assets to increase workplace safety; reduce unexpected failures; reduce unplanned outages; gain visibility of asset conditions; increase load and overall safety; and nurse aged or critical assets.

Wind and solar energy operations have long been confined to a short design life based on current technologies. In many cases, decisions about what to do with assets come down to the economics of long-term maintenance costs and equipment failure risks. Condition-based monitoring

technologies help renewable generation providers offset risk, extend asset life and reduce the cost of repowering a facility.

The amount of renewable assets connected to the grid has quadrupled during the past decade, and the renewable-energy sector is a lucrative space for investors. Dynamic Ratings aims to shift the status quo of operations and maintenance (O&M) providers, system designers and energy users towards a culture of maximising the lifespan of electrical assets.

With wind and solar energy operations working within the parameters of a 15-20year design life based on turbine and panel technologies, power purchase agreements (PPA) structures and tax incentives, decisions to repower or dismantle renewable energy operations often come down to the economics of long-term maintenance costs and equipment failure risks.

By implementing condition-based maintenance technologies into renewable generation, energy providers can offset risk, extend the life of assets, and reduce the cost of repowering a facility.

Best practices for O&M indicate that investments in proactive maintenance are key. Continuous monitoring systems are an efficient means of collecting data to achieve maintenance goals and keep a power plant

running as efficiently as possible.

Online monitoring systems not only provide critical data for assessing the long-term health of electrical equipment, they reduce downtime and lower maintenance costs. Online monitoring allows operators to deploy condition-based maintenance and direct resources to known issues rather than introducing potential problems by performing unnecessary work. It also reduces unplanned outages and maintenance durations, keeping power and revenue flowing.

In solar applications, the cost of vegetation maintenance and keeping PV panels clean can account for as much as one-third of

O&M costs. Wind facilities require more maintenance and repair activities, whereas the maintenance requirements for solar tend to lean towards site maintenance. This can lead to the idea that solar O&M costs are less than wind when viewed on a kWh basis, however their electrical maintenance costs are similar and provide equal benefits to extending the life of equipment.

Renewable applications are still the new kids on the block when it comes to the electrical world. In a system designed for stepping down power from transmission voltages to distribution levels, data is available to determine the useful life calculations for utility transformers. Absent of rich data sets, it becomes important to begin gathering this data early in the life of a renewable asset.

Asset owners have increasingly relied on independent service providers or selfperforming maintenance work, however the cost of maintenance contracts has increased. As a result, investors are increasingly looking for wind and solar farms that have implemented computerised maintenance and asset management systems.