Renewables apprenticeships

The national program powering Australia’s clean energy workforce

The national program powering Australia’s clean energy workforce

The PVS-10/33 is built to give you complete flexibility.

FIMER’s new three-phase solution is ideal for homes and commercial and industrial applications and comes with a full 10 year warranty as standard.

Fuseless design with 1,100VDC maximum DC input voltage, high power density with up to 10% extra AC output power and a choice of 2-4 MPPT with a built-in DC isolator.

Advanced communication are built-in such as dynamic feed-in control and free monitoring via the Aurora Vision platform and EnergyViewer app.

Order the PVS-10/33 today in one of its six power sizes for your next project and get the performance, flexibility and reliability you require.

Chief Executive Officer: John Murphy

Managing Editor: Mike Wheeler

Editor: Gavin Dennett gavin.dennett@primecreative.com.au

Business Development Manager: Juanita Farrington, +61 434 792 225 juanita.farrington@primecreative.com.au

Client Success Manager: Karyssa Arendt karyssa.arendt@primecreative.com.au

The good news keeps coming for the clean energy industry with the 2022-2023 financial year being a record for renewable energy generation in Australia. Renewables comprised 36.8 per cent share of energy produced in the National Electricity Market (NEM), representing a rise of 3.5 per cent, up from 33.3 per cent share during the previous 12-month period.

This news is coupled with the nation’s coalfired power dropping to 57 per cent generation for the financial year, its lowest share this century and the lowest since the National Electricity Market was formed in 1999. Gas generation contributed just 5.2 per cent to Australia’s national grid, its lowest share since 2006.

While this upward trend of clean energy in Australia is welcome, we still have a long way to go to reach 82 per cent renewable energy produced across the nation by 2030. Current projections have us lagging behind where we need to be so hopefully the current financial year can deliver a greater boost in investment in utility scale wind and solar, which endured a lull at the beginning of 2023.

Among the many policies and initiatives introduced by the Federal Government in the past 12 months to help chart Australia’s course towards becoming a clean energy superpower, the New Energy Apprenticeships Program has been one of the most welcomed by the renewables sector. Addressing the skills shortage the industry faces, the program is attracting new apprentices into the clean energy space and providing incentives for workers and their employers to get onboard with our energy future. You can read about it in this issue’s cover story on page 36.

Also in this issue is a feature on the vital role of the construction industry on the path to net zero (page 26); a report on the success of the NSW Peak Demand Reduction Scheme (page 28); insight into how electric vehicles hold the key to community energy (page 34); and EcoGeneration ’s annual solar inverter guide, which provides installers with important information and the latest innovative products in the market (page 42).

Gavin Dennett EcoGeneration editor

Follow EcoGeneration on LinkedIn

EcoGeneration acknowledges the Cammeraygal people, traditional custodians of the land on which this publication is produced, and we pay our respects to their elders past and present. We extend that respect to all Aboriginal and Torres Strait Islander people today.

Production Manager: Michelle Weston

Head of Design: Blake Storey

Art Director : Julitta Overdijk

Subscriptions: T: +61 3 9690 8766 subscriptions@primecreative.com.au

Published by: PRIME CREATIVE MEDIA PTY LTD

ABN: 51 127 239 212

379 Docklands Drive Melbourne VIC 3008, Australia

T: +61 3 9690 8766

www.primecreativemedia.com.au

www.ecogeneration.com.au

Cover images: (Main) 1st footage/Shutterstock. (Inset — left to right): APsystems; Panya7/Shutterstock; Owlie Productions/Shutterstock

EcoGeneration is printed on Lumi paper which is PEFC-certified and manufactured in an ISO 14001-certified mill. Lumi paper also contains premium white waste paper, reducing matter going into landfill. This magazine is available to interested parties throughout Australia and overseas. The magazine is also available by subscription. The publisher welcomes editorial contributions from interested parties, however, the publisher and the Editorial Board accept no responsibility for the content of these contributions and the views contained therein are not necessarily those of the publisher or of the Editorial Board. The publisher and the Editorial Board do not accept responsibility for any claims made by advertisers. Unless explicitly stated otherwise in writing, by providing editorial material to Prime Creative Media, including text and images, you are providing permission for that material to be subsequently used by Prime Creative Media, whole or in part, edited or unchanged, alone or in combination with other material in any publication or format in print or online or howsoever distributed, whether produced by Prime Creative Media and its agents and associates or another party to who Prime Creative Media has provided permission.

Average net distribution 6616

Period ending September 2021

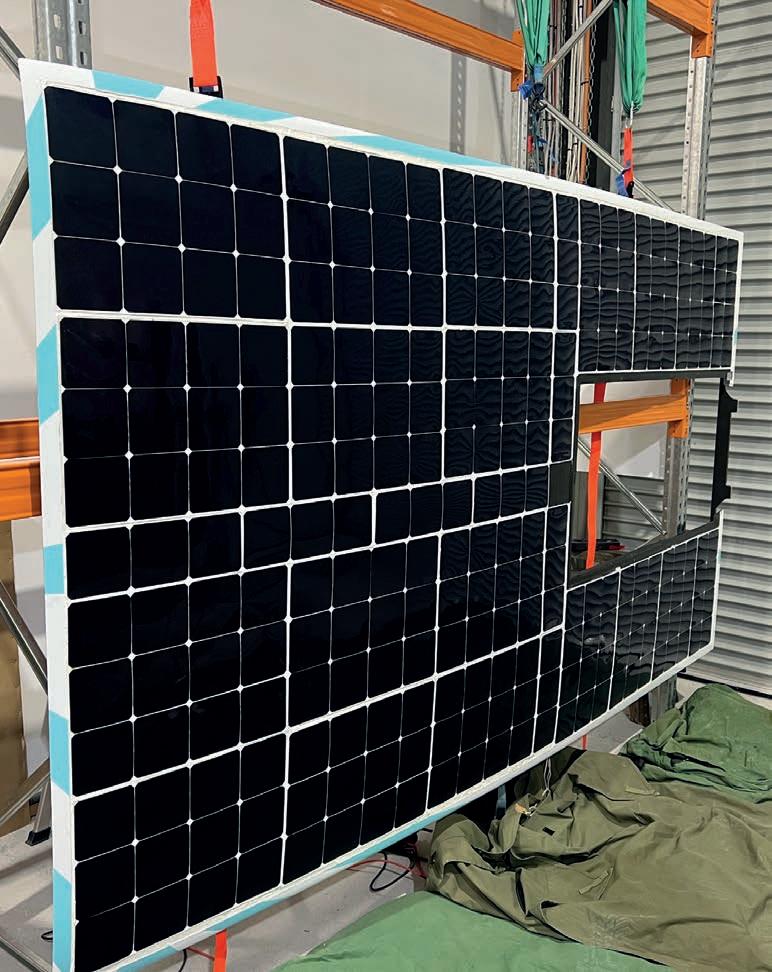

Excellent balance between power, size and weight

Power Range is up to 440W with size of 1762 x 1134mm and weighing 21.1kg

n type i-TOPCon technology

With 210mm innovative platform

Excellent Mechanical Performance

With dual glass structure

Outstanding reliability and safety

Designed for extreme weather conditions and reduced risk of micro crack from handling

Lower degradation

1% 1st year degradation,

0.4% annual power attenuation

High system compatibility

99% compatibility with mainstream inverters

NSW electricity transmission operator Transgrid has released an energy roadmap that outlines the $16.5 billion investment required for the state to transition to a cleaner and cheaper electric future.

The “System Security Roadmap” outlines Transgrid’s plan to grow the NSW power system to 100 per cent instantaneous renewables in the grid during the next decade.

The transmission operator is engaging in a major low-emissions works program across three pillars:

• Energy reliability: Investing $14 billion to build a 2500km energy superhighway of essential transmission lines and infrastructure to connect new large-scale renewable energy and storage to the grid, integrate five renewable energy zones, and expand transmission interconnection between regions and states.

• System security: Deploying $2.2 billion in technologies and services to maintain grid security without coal generation.

• O perability: Changes to analytical and operational capabilities and capacity, including a $300 million investment to strengthen Transgrid’s technology tools, workforce and training.

“Modernising the energy grid to bring down energy prices requires us to build enormous amounts of new transmission to connect renewable generation in record time,” says Transgrid CEO Brett Redman.

“The only way to bring down energy prices

is to deliver cheaper renewable energy as soon as possible. Transgrid must build and operate the backbone of this new grid while ensuring the safety, reliability and security of our existing 13,000km transmission system.

“With more than 80 per cent of coalfired capacity in NSW expected to retire and 28GW of new renewable and storage capacity coming online in the next 10 years, we must urgently accelerate investment in all areas of the energy transition.”

Transgrid’s new energy superhighway includes the EnergyConnect, HumeLink and VNI West projects.

“There will be no transition without transmission, however the enormity of the task and the challenges we face must not be understated,” says Redman.

“We must embrace innovation, invest in technology, develop a larger and more skilled workforce, and strengthen our capabilities if we are to achieve a rapid transition to a low-emissions energy system providing clean, affordable and reliable electricity to Australians.”

The 2022-2023 financial year was a record for renewable energy generation in Australia, comprising 36.8 per cent share of energy produced in the National Electricity Market (NEM), according to data from OpenNEM.

This figure represents a rise of 3.5 per cent, from 33.3 per cent share for the previous 12-month period.

The record share for clean energy comes as the nation’s coalfired power dropped to 57 per cent generation, the lowest share this century and the lowest since the NEM was formed in 1999.

Of the 207 terawatt hours (TW/h) of energy produced on the NEM in 2022-2023, 77TW/h emanated from renewable sources, with wind contributing 13 per cent, rooftop solar 10 per cent, hydro 7.6 per cent and utility scale solar 6.1 per cent.

Gas generation contributed just 5.2 per cent to Australia’s national grid, its lowest share since 2006.

Coalfired power was also at a record low. In the 2022-2023 financial year, brown coalfired power fell to 15.1 per cent share in Victoria, while black coalfired power fell to 42.5 per cent NEM share in Queensland and NSW.

Despite these encouraging figures, Australia remains at risk of falling short of its renewable energy target of 82 per cent by 2030.

In 2022-2023, 8.5TW/h of renewable energy was added to the NEM, but it is well short of the 16TW/h the Australian Energy Market Operator says must be added annually to remain on target to hit the 2030 goal.

Australia’s fleet of zero-emissions heavy vehicles is set to expand in the next two years with Countrywide Hydrogen and Walkinshaw Automotive Group signing a binding agreement to develop hydrogen-based trucks and prime movers for the domestic market.

Local renewable hydrogen company Countrywide Hydrogen is targeting its first production of the green fuel in 2025 and had been seeking a partnership with a heavy

vehicle manufacturer to deliver zero-emissions fuel cell trucks to the Australian market.

The partnership with Victorian-based Walkinshaw Automotive Group will see the companies develop vehicles to run on hydrogen as the nation phases out diesel-fuelled haulage.

Currently, left-hand-drive fuel cell trucks are available in the Australian market, but there are no right-hand-drive heavy vehicles on offer — a gap in the market the two

companies aim to fill.

“The partnership with Walkinshaw will fast-track the introduction of hydrogen fuel cell trucks across Australia,” says Countrywide Hydrogen managing director Geoffrey Drucker.

“It follows our agreement to supply green hydrogen trucks to 7R Logistics to transition their Tasmanian fleet from diesel to zero-emissions fuel cell trucks.

“This project complements the Federal Government’s goal to rebuild the nation’s manufacturing, especially where it has a positive clean energy impact.”

The partnership goal is for Countrywide Hydrogen to build the vehicles and Walkinshaw Automotive Group to supply the Australian market. The two parties will also explore the possibility of importing left-hand-drive fuel cell trucks to convert them to right-hand-drive.

Walkinshaw Automotive Group is currently delivering 70 similar conversions a day in the 4WD ute category, with RAM and Silverado makes.

The companies are also exploring the option of securing truck bodies to be fitted with Toyota fuel cells and electric drive trains.

“At Walkinshaw Group, we are constantly looking to use our expertise to expand our range,” says Walkinshaw Group managing director Joel Stoddart.

“We are excited about the opportunity to collaborate with Countrywide Hydrogen to determine the potential for development of hydrogen-based truck and prime movers for the Australian market.

“We are also thrilled the opportunity could extend through exports to other right-hand-drive nations such as New Zealand and South Africa.”

The Victorian Government has awarded $1 million funding to Yarra Valley Water to expand its food-waste-to-energy facility in Lilydale, in Melbourne’s western fringe.

The facility is set to open in 2024-2025, and this latest funding boost will ensure a second generator can be constructed. Once operational, the site will generate more than 12,900MW/h of electricity per year — approximately 35 per cent of Yarra Valley Water’s energy needs, or enough to power around 2200 Victorian households. It will also divert 55,000 tonnes of commercial and industrial food waste from landfill every year.

The Lilydale facility uses anaerobic-digestion technology to create energy, and the funding comes via the Victorian Government’s Waste to Energy — Bioenergy Fund, which is committed to delivering $10 million in grants to support the development of innovative bioenergy projects.

It is delivered by Sustainability Victoria under the Victorian Government’s “Recycling Victoria: A New Economy” policy, which is part of a $515 million investment to transform the state’s waste and recycling industry.

“Investing in food-waste-to-energy production is central to our commitment to support Victoria’s transition to a circular economy, reduce waste and minimise our carbon footprint,” says Yarra Valley Water managing director Pat McCafferty.

“Having a second generator will increase the power output

of our Lilydale facility, nearly doubling our export to the grid. It also means we can continue to operate uninterrupted if one generator has any issues.”

Yarra Valley Water has also been granted $175,000 to enhance electricity generation infrastructure at its bioenergy facility in Wollert (pictured above) in Melbourne’s outer north.

“This funding will play a vital role in expanding our capabilities, allowing us to divert even more food waste from landfill and generate clean energy to power homes and facilities,” says McCafferty.

The Clean Energy Council is proposing significant rule changes to give investors and developers of renewable generation and storage greater certainty when connecting to the grid.

The proposed rule changes have been submitted to the Australian Energy Market Commission to provide improved investment certainty to a process that, historically, has created delays for renewable investors and developers.

The submission addresses concerns over costly delays and complexity that have affected a significant number of projects — such as solar, wind and batteries — connecting to the grid.

The Clean Energy Council says the Australian Energy Market Operator (AEMO) and network service providers have worked constructively with industry to address these issues, however further reform is needed to provide greater certainty and clarity.

“Every Australian has a stake in getting this right and helping bring clean, affordable new power generation to the grid efficiently,” says Clean Energy Council chief executive Kane Thornton.

“Currently, some generators face open-ended delays to connection and unmanageable risks, creating a culture of uncertainty for renewable investors.

“If this adds to cost, if this causes delays, and if this discourages investment, it is Australian homes and businesses that ultimately suffer when it comes time to pay their power bills.”

The Clean Energy Council and AEMO have been working with networks and industry leaders to improve the connection process as part of the Connections Reform Initiative.

The initiative aims to achieve a consistent and predictable connections process that delivers repeatable outcomes; reduces rework and improves efficiency; and creates a collaborative working model between industry, AEMO and network service providers.

“Our aim is to make the connections process for new utility-scale renewable generation and storage work better for everyone,” says Clean Energy Council policy director of market, grid and investment Christiaan Zuur.

“It’s been a real eye-opener in terms of demonstrating a different way to make change in the National Electricity Market. Goodwill from AEMO, networks and industry has allowed us to work as equals and find common sense solutions to previously intractable problems.”

The Sydney Opera House has become one of the first UNESCO World Heritage listed buildings to receive a globally recognised 6 Star Green Star rating for sustainability and efficiency.

Australia’s iconic performing arts building has been retrofitted with operational technology from Honeywell Building Technologies that increases performance and reduces its environmental impact through reduced carbon emissions.

The 6 Star Green Star rating from the Green Building Council of Australia comes from continued improvement in the Sydney Opera House’s sustainability performance, including:

• Installation of technology to monitor indoor air quality and relative humidity.

• Integration of more than 20 subsystems to improve energy efficiency, safety and water usage.

• Innovations including electricity spot-price monitoring, extraction fan control in non-air-conditioned areas and monitoring of cold room doors that remain open for too long.

• Automated outside air control through real-time air quality data from the Bureau of Meteorology.

• Installation of more than 60 water meters and 800 electrical meters.

“Sustainability is in the Sydney Opera House’s DNA,” says Sydney Opera House CEO Louise Herron AM. “Architect Jørn Utzon incorporated

sustainable design into the fabric of the building in the 1960s.

“As we approach our 50th birthday later this year, we continue to look for ways to build on this legacy by embedding sustainable thinking into everything we do.

“Thanks to long-term support from Honeywell, Sydney Opera House is working harder and smarter than ever before.”

The Honeywell Buildings Sustainability Manager software platform provides improved visibility of energy use and Scope 1 and Scope 2 carbon emissions. Honeywell has tailored the system to the unique requirements of the performing arts building, while leveraging existing systems such as the building’s pioneering seawater cooling system.

“Sydney Opera House takes a thoughtful and deliberate approach to minimise its impact on the environment while providing a world-class experience for its occupants,” says Billal Hammoud, president and CEO of Honeywell Building Technologies, which offers operational solutions and services in more than 10 million buildings worldwide.

“The Honeywell team which services and supports Sydney Opera House closely collaborates with its engineering and sustainability teams to ensure building systems are performing efficiently.”

Australia’s rooftop solar is doing the heavy lifting in the fight against rising power bills and charting the net-zero course as large-scale renewable energy investment slows, writes Clean Energy Council chief executive Kane Thornton.

Australia has been a world leader in rooftop solar for years. We have the highest solar radiation per square metre of any continent so there is an enormous opportunity to harness that energy for the nation’s clean energy transition. The Clean Energy Council’s “Clean Energy Australia 2023” report shows rooftop solar installations are already leading the way.

However, the findings of the Clean Energy Council’s “Renewable Projects Quarterly Report” for Q1 2023 make for sobering reading. They show that levels of investment in utility scale wind and solar have slowed dramatically.

While larger utility scale projects under construction equated to $1.3 billion in value in Q1 2023 – nearly double the volume from the same point in Q1 2022 – no new large-scale renewable generation projects reached financial close during this period.

The number of projects reaching financial close is a leading indicator for the renewable energy pipeline, and it’s worrying to see the figures significantly drop. Hopefully this is a one-off and not a trend.

Investment in large-scale clean energy projects has slowed at a time when it needs to accelerate. Even at 2022 levels of investment, Australia was not installing new capacity quickly enough to reach its stated target of 82 per cent renewable energy by 2030 so these financial results are concerning.

While we work to resolve the headwinds and blockages facing the large-scale sector, rooftop solar and batteries can play a key role in leading the transition. As revealed in the “Clean Energy Australia 2023” report, rooftop solar accounted for 25.8 per cent of Australia’s renewable energy generation in 2022 – its highest level yet.

Predictions in the latest Integrated Systems Plan publication from the Australian Energy Market Operator suggest that by 2050, more than half of homes in the National Electricity Market are likely to have rooftop PV systems, totalling 69GW capacity. Distributed storage will complement that generation significantly, representing almost three-quarters of dispatchable capacity in megawatt terms by 2050.

Australia has an opportunity to double down on rooftop solar and battery storage. With power prices still high, driven by the country’s reliance on fossil fuel generation, it not only makes environmental sense for consumers to switch to clean energy but financial sense.

Latest figures from the Clean Energy Regulator in its “Quarterly Carbon Market Report” show the payback period for solar PV systems – the point after which the amount saved on your bill outweighs system installation cost – has been trending downwards during the past six years,

aided by component price reductions and improved installation efficiency.

While COVID-19 and associated supply chain issues caused a blip in this trend, increasing energy prices driven by higher wholesale costs have seen the payback period continue to decline, making rooftop solar increasingly attractive to consumers.

Enhancing the Small-scale Renewable Energy Scheme (SRES) could be a way to accelerate the uptake of rooftop-scale generation and storage. Given the falling cost of rooftop PV and expected decreases in batteries, expanding SRES could be a low-cost policy lever providing major payback.

We know SRES works. Along with the Renewable Energy Target, no policy has delivered as much abatement, given as much certainty, and unlocked as much investment as SRES.

One option could be to extend SRES beyond 2030. It could also be expanded to cover small-scale battery installations, which could help consumers take direct action to keep down power bills. It benefits other customers, too, as batteries do a lot to keep network costs down, which ultimately flows back to all consumers in the form of lower bills.

These policy approaches could be introduced quickly, and there’s reason to believe the benefits would far outweigh associated costs.

More work needs to be done to explore what an expanded SRES might look like. However, we think it shows real promise as a way to accelerate the transition and lower consumer bills.

“With power prices still high, it not only makes environmental sense for consumers to switch to clean energy but financial sense.”

In the meantime, as an industry, we need to focus on how we can push the market forward through regulatory reform. Priorities to help the distributed energy resources (DER) sector grow could include:

• A clear handover of accountability of the DER Implementation Plan from the Energy Security Board to the newly formed Energy Advisory Panel.

• Establishment of a National Technical Standards body that leads a consistent oversight of standards.

• Development of market and price signals that reward owners of rooftop solar and batteries for using their stored energy to provide system-wide services.

The myCEC program is another way the Clean Energy Council is supporting the rooftop solar and battery industry. It offers access to our technical support and resources to help raise standards across the sector.

We launched myCEC in June 2023 for no cost to all Clean Energy Council-accredited installers and designers for an initial period of seven months. The launch coincided with the release of a subscription-based service, opening the same information to everyone across the industry. Once we know the result of the Clean Energy Regulator’s accreditation provider tender, we will share further details on how this affects accreditation and myCEC.

The myCEC platform provides expert support from industry veterans; assistance with standards and requirements; the ability to supercharge skills through deep dives and learning resources; and business essentials such as discounts and benefits.

Now, more than ever, the industry needs technical advice to ensure it is well equipped for the complex regulations, standards and technologies that will continue to shift in the coming years. By supporting the rooftop solar and battery industry, we are guiding Australia’s clean energy transformation, which must continue irrespective of the performance of the large-scale sector.

While we hope and believe large-scale investment will pick up again, we should be doing all we can to support Australia’s world-leading rooftop solar and battery industry in the meantime.

Kane Thornton has more than a decade of experience in energy policy and leadership in the development of the renewable energy industry. His column is a regular feature in EcoGeneration, where he analyses industry trends and explains the impacts of federal and state renewable policies on the energy sector.

Photo: Halfpoint/Shutterstock

Photo: Halfpoint/Shutterstock

“Enhancing the Small-scale Renewable Energy Scheme could be a way to accelerate the uptake of rooftop-scale generation and storage.”

The Federal Government is establishing a Net Zero Authority to ensure Australia’s renewable future is fair and inclusive for all.

By Gavin Dennettto attract new clean energy industries. • Help investors and companies engage with net-zero transformation opportunities.

The authority will focus on regions and industries that have traditionally powered Australia’s economy as they adapt and transform to the net-zero agenda. It will work with state and territory governments, unions, industry and First Nations groups to help key regions, industries, employers and communities manage the transformation to a clean energy economy.

The Climate Council says the national Net Zero Authority will be crucial to ensure everyone gets to share in Australia’s projected era of clean energy prosperity.

“The national Net Zero Authority can provide important leadership and coordination for this shift.”

The Clean Energy Council has also long advocated for a national Net Zero Authority as an essential building block to Australia’s renewables future.

“A Net Zero Authority will safeguard worker support, ensure regional employment and enrich education in the sector and beyond,” says Clean Energy Council chief executive Kane Thornton.

“It is a vital piece of the puzzle as we shift towards a cleaner, more prosperous economic future for all Australians.

“The clean energy transition can be transformative for Australia’s regional communities, providing low-cost, renewable energy to consumers and long-term employment pathways in the clean energy sector.

As part of the 2023-2024 Federal Budget, the Australian Government announced it is establishing a national Net Zero Authority to steer the agenda for workers, industries and communities in the nation’s transition to net-zero emissions.

Back in May 2023, the government recommended the Governor-General commence the authority’s responsibilities by 1 July, 2023, through an interim Executive Agency in the Department of the Prime Minister and Cabinet.

With the government plotting Australia’s course to becoming a clean energy superpower, the national Net Zero Authority will:

• Support workers in emissions-intensive sectors to access new employment and skills.

• Coordinate programs and policies to support regions and communities

“Australia’s global allies and trading partners are forging ahead with the transition to net zero and it makes perfect sense for Australia to get in the game,” says Climate Council CEO Amanda McKenzie.

“Taking strong action now is the best way to ensure Australia captures growing markets for clean energy and low-emissions products, to power the next era of our national prosperity.

“There is no doubt Australia’s path to net zero requires transformative change. The Climate Council has been advocating for a national authority to oversee Australia’s rapid clean energy transformation.”

The Climate Council is also urging the Net Zero Authority to take an active role in coordinating and agreeing on realistic closure dates for all Australian coalfired power generators.

“Communities in regions where fossil fuels are being phased out, and those in Renewable Energy Zones, need a voice as well as clear plans and strong investment to guide the transformation of their local economies and industries,” says McKenzie.

“A Net Zero Authority with dedicated funding and a long-term mandate will ensure the appropriate level of coordination, durability and leadership necessary to achieve a genuinely just energy transition.”

The World Wide Fund for NatureAustralia also welcomes the announcement of the national Net Zero Authority.

“Coordinated, long-term planning is needed to ensure no worker or community is left behind as we move to power our domestic energy needs with renewables,” says Cam Crawford, WWF-Australia’s energy transition manager.

“The Federal Government’s commitment to legislate an independent, statutory Net Zero Authority will support workers and communities affected by the transition and help deliver much-needed education, skills training and new jobs in a renewables nation.

“This must include communities that have previously relied on fossil fuel jobs, regional communities, and First Nations communities, and we must build a world-leading renewables industry that benefits our environment, communities and the economy.”

Photo: Christiane Lach/Shutterstock

The Federal Government’s Guarantee of Origin certificate scheme is helping drive Australia to a low-carbon economy as the nation embraces its renewables future, writes Clean Energy Regulator chair David Parker.

Australia’s ambitions of becoming a global renewable energy leader have taken a step forward following the Federal Government’s $38.2 million investment in delivering a world-class Guarantee of Origin (GO) certificate scheme.

The Department of Climate Change, Energy, the Environment and Water

(DCCEEW) is working with domestic and international stakeholders to design the scheme, and the Clean Energy Regulator will administer it once it is legislated to help drive the transition of Australia’s economy to low-carbon products. Announced as part of the 2023 Federal Budget, GO is expected to commence in 2024 and will be a game changer in developing new markets for

renewables and low-emissions products.

The Guarantee of Origin scheme will track and verify emissions associated with hydrogen and other low-emissions products, and provide an enduring mechanism to certify renewable electricity. Certificates will show where a renewable or lowemissions product has come from, how it was made and its lifecycle carbon intensity.

Photo: PomInPerth/ShutterstockAt its heart, the scheme is about providing markets with high-integrity emissions information about products to help them operate efficiently. Information published on a GO certificate will support renewables and hydrogen investment and improve access to markets for low-emissions products.

In the April edition of EcoGeneration, I discussed how Australia’s long-term transition to clean energy is supported by renewable energy certificates issued and regulated by the Clean Energy Regulator. The proposed renewable GO certificate will build on the effective and highly regarded Large-scale Generation Certificate (LGC) framework which ends in 2030.

The seamless continuation of certification post-2030 through renewable GOs will allow the industry to keep reaching long-term power purchase agreements and maintain a market for renewable electricity.

The GO scheme will enable producers to seek premiums for goods that produce lower emissions. Many companies are willing to pay for credible low-emissions claims. This has already been demonstrated in the growing voluntary demand for existing renewable energy certificates and Australian Carbon Credit Units by businesses. Extracting a green premium improves the economics of new lowemissions projects and will draw forward investment and emissions reduction.

The GO certificate will also facilitate acceptance of Australian products worldwide. With countries and regions increasingly establishing criteria around the emissions associated with imported products, we need a way of showing that our goods qualify to access markets.

The GO certificate will accompany cargos leaving Australian ports to provide trading partners with assurance of the lifecycle emissions of the product.

The Australian Government is already actively working with international bodies, standards organisations and trading partners to make GOs internationally recognised.

The benefit of a national certificate scheme is it can reduce regulatory burden and establish GO as a source of truth for government incentives, market transactions and private schemes. Several government schemes at national and state levels are now being developed to incentivise hydrogen, and they are using GO as the foundation of the emissions claims. I am encouraged to see the NSW and Western Australia hydrogen production targets have identified GO as the foundation of their schemes.

By providing consumers with information to choose energy and products produced from renewable sources, the GO scheme raises the public’s awareness of the environmental impact of their energy consumption.

This helps to foster a societal shift towards more sustainable behaviours.

Corporations are now looking hard at reducing not only their emissions but the emissions of their inputs (Scope 2 and Scope 3 emissions). GO certificates can provide a far more robust and systemised way for companies to understand their upstream emissions footprint and make choices to switch to products with lower emissions intensity.

The benefits from a GO certificate only come if the information is trusted and transparent. Without credible claims, the pace of transition to decarbonise our economy will slow.

Further, the GO scheme will reduce opportunities for greenwashing. Increased public reporting on the data-rich GO certificates will help consumers and stakeholders understand claims in detail.

Fortunately, the foundations of the GO scheme are built on Australia’s existing world-class carbon accounting schemes, including the National Greenhouse and Energy Reporting Scheme, administered by the Clean Energy Regulator. These schemes provide a rich source of data that allows us to undertake data matching and compliance cross-checks.

I am confident we can deliver a scheme that is robust and transparent. I am also excited the Clean Energy Regulator has been offered the opportunity to deliver another scheme that will help drive the transition of Australia’s economy to a lower carbon future.

David Parker AM has been chair of the Clean Energy Regulator since July 2017. With a career spanning more than 25 years with Commonwealth Treasury, he has worked across financial sector liberalisation, tax reform, macroeconomic forecasting and policy, competition policy, energy policy and international economics.

“At its heart, the scheme is about providing markets with high-integrity emissions information about products to help them operate efficiently.”

Demand response and energy management are critical components to ensure reliability of the rapidly evolving electricity sector. GridBeyond’s latest white paper, “Decoding Demand Response” shows how grid programs are key to reducing business costs and supporting the transition to a greener future in Australia.

While discussions around climate change often focus on green mobility – for example, renewable energy and net-zero carbon targets – they frequently overlook the question of how to prepare the electricity grid for structural changes in supply and demand that accompany these initiatives. The phasing out of coal and gas plants, and their replacement with renewables, creates volatility in electricity prices.

In the Clean Energy Council’s “Clean Energy Australia Report”, released in April 2023, it notes more than 5GW of new renewable energy capacity was installed in Australia in 2022, and that renewable energy provided 35.9 per cent of Australia’s total electricity generation that year, up from 32.5 per cent in 2021. While this growth in renewables is clearly welcome from a climate change and sustainability perspective, one of the impacts of intermittent generation on the power system is increasing volatility in energy costs.

Wholesale electricity prices in the National Electricity Market averaged $93/MWh during the December 2022 quarter, dropping 57 per cent from the September quarter ($216/MWh) but remaining well above the Q4 2021 average of $52/MWh.

Demand response allows electricity consumers to take an active role in grid balancing by adapting their consumption profile to help keep the grid stable. Flexible consumers who respond to grid balancing events can save money or even generate revenue from the grid operator, partially offsetting their electricity bill.

Increasingly higher optimisations can be achieved when the consumer has other types of assets such as a battery and/or solar PV generation at their consumption access point. These additional assets provide flexibility for moving away from high prices of electricity, or even for choosing when to consume electricity from the grid.

Let’s consider a hypothetical scenario involving a manufacturing facility located in Victoria. The facility has annual energy consumption of 10,000MWh and recently implemented a renewable energy system comprising a 2MW solar photovoltaic system and a 1MWh battery storage system. It is also part of a microgrid connected to an industrial load of 1MW. The average electricity price is $0.27/kWh, and the

facility incurs demand charges ranging from $15/kW to $20/kW based on the time of day.

To estimate its potential cost savings and revenues, we can analyse cost savings from reduced grid electricity consumption:

• The solar PV system generates 12MWh of electricity per day (2MW x 6 hours).

• The industrial load consumes 24MWh of electricity per day (1MW x 24 hours).

• The facility’s total daily electricity consumption is 36MWh (12MWh + 24MWh).

• With the battery storage system discharging 1MWh per day, the daily electricity consumption from the grid becomes 35MWh (36MWh minus 1MWh).

• The daily cost savings from reduced grid electricity consumption amounts to $9450 (35MWh x $0.27/kWh).

“Demand response allows electricity consumers to take a role in grid balancing by adapting their consumption profile to help keep the grid stable.”Through demand response, businesses can voluntarily reduce electricity consumption in exchange for financial benefit.

Cost savings from avoiding demand charges:

• Assuming the facility’s peak demand occurs for one hour each day and reaches 3MW.

• Without the microgrid, the facility would face demand charges of $15/kW x 3MW, resulting in $45,000 per month.

• By utilising the battery storage system and industrial load in the microgrid, the facility can reduce its peak demand by 1MW.

• Consequently, monthly cost savings from avoided demand charges equal $21,600 ($15/kW x 2MW x 720 hours per month).

Revenues from excess electricity generation:

• A ssuming the solar PV system generates 12MWh per day, but the facility only consumes 10MWh per day.

• The surplus electricity can be sold back to the grid at $0.10/kWh.

• The daily revenue from excess electricity

generation amounts to $200 (2MWh x $0.10/kWh).

Total estimated monthly cost savings and revenues from this microgrid installation example would be $37,050 ($21,600 + $9450 + $200 x 30 days). It is important to note these figures are approximations, and actual savings and revenues depend on several factors such as installation specifics, energy prices, demand charges and geographical location.

The integration of battery storage and solar PV systems alongside participation in demand response services offers businesses an innovative solution to mitigate energy price risks. By generating electricity, reducing grid dependence and storing excess energy, businesses can significantly reduce energy costs and enhance energy efficiency.

Investing in these technologies promotes energy independence, reduces carbon footprints and contributes to a sustainable future. Considering these benefits, battery storage and solar PV systems emerge as crucial investments for businesses aiming to hedge against energy price risks and maintaining competitiveness in an ever-evolving market.

Corporation

The Clean Energy Finance Corporation (CEFC) has announced its first major injection of capital in more than a decade, with the Federal Government allocating $20.5 billion to contribute towards Australia’s energy grid infrastructure, and the establishment of two funds to stimulate clean energy opportunities.

The CEFC was established in 2012 with a capital allocation of $10 billion from the government. Australian Parliament recently passed the Treasury Laws Amendment (2022 Measures No. 4) Bill 2022, which locks in a further $11.5 billion in capital, allowing for an additional $9 billion to be added for future initiatives.

This government funding will contribute to ongoing CEFC investment across renewable energy, emerging cleantech and hydrogen.

The $20.5 billion capital will contribute to the creation of three new CEFC investment priorities: • $19 billion allocation to help deliver

received its

the Rewiring the Nation program, with investments including high-voltage transmission, long-duration grid storage and electricity distribution network infrastructure.

• $1 billion allocation to create the Household Energy Upgrades Fund, providing discounted consumer finance to increase sustainability in Australia’s housing sector.

• $500 million allocation to establish the Powering Australia Technology Fund to support clean technology projects and facilitate the development, commercialisation and uptake of clean energy technologies.

“This is significant support by the Australian Government and Parliament for our work as Australia’s ‘green bank’ in investing on behalf of all Australians in our low-emissions future,” says CEFC chair Steven Skala.

“The Rewiring the Nation program, Household Energy Upgrades Fund and Powering Australia Technology Fund

substantially expand the role of the CEFC. New large-scale investment in priority grid infrastructure projects complement our existing work in transforming our energy system and bringing the benefits of decarbonisation to key sectors of our economy.”

From 2012 to the end of 2022, the CEFC made lifetime investment commitments of $11.7 billion. After repayments and returns on its investments, the “green bank” had $4.6 billion available for ongoing investment from its original $10 billion funding allocation. This latest funding boost represents a seismic shift in its renewables investment potential.

CEFC CEO Ian Learmonth says the additional capital will enable the CEFC to make a significant contribution to the achievement of net-zero emissions by 2050.

“We expect to make substantial gridrelated investment decisions within the next 12 months,” he says. “While these transactions are often large and complex, we must move quickly to invest in the expansion and augmentation of our grid and related infrastructure to deliver on Australia’s net-zero objectives.

“Analysis from the Intergovernmental Panel on Climate Change provides an important reminder of the scale of the climate challenge and the urgency to accelerate meaningful action this decade. In Australia, this means transforming our energy system to low-cost, low-emissions renewables, backed by large-scale energy storage and a modernised two-directional grid, connecting distributed generation with industrial, commercial and residential power users.

“At the intersection of this revolution in low-emissions energy generation and distribution is government and private sector capital, delivered via tailored investment models that leverage considerable market momentum towards sustainable green investment opportunities.”

Photo: ymgerman/Shutterstock.comThe Clean Energy Finance

has

biggest investment boost in more than a decade as it ramps up project work on the path to net zero. By Gavin Dennett

By Jeremy Chunn

By Jeremy Chunn

Australians have a love affair with utes. Now a trio of former tech executives aims to make the nation’s favourite set of wheels cleaner by converting petrol and diesel utes into electric.

Like many great ideas, it was incubated by the watercooler when Roev founders Robert Dietz, Noah Wasmer and Paul Slade worked in the cloud division of technology giant Atlassian.

“We used to chat about things we were interested in outside of work,” Dietz tells EcoGeneration. Cars and energy management were two topics, but it was Wasmer who turned words into action by converting a 1967 VW Kombi and Land Rover Defender Perentie to electric.

Classic car conversions are an investment in passion – the Kombi conversion cost

Wasmer $70,000 – but Dietz says Roev is pitched squarely at economic rationalists.

“We realised if we were going to have any impact at scale, it wasn’t going to be in the classic car industry,” he says. Instead, the trio started to think about EVs as batteries on wheels, capable of complementing residential solar systems and providing grid services.

“It makes sense that if you can leverage your vehicle for that, it’s a cost-effective way of doing the dual-duty purchase,” says Dietz.

As true techies, they scaled up the idea to a business proposition that would target fleets of utes, including Toyota Hilux and Ford Ranger that are the first and third top-sellers in Australia, respectively.

“We realised that is a prime area

for us to dive into,” says Dietz.

Classic cars are easy to convert, but it is a totally different proposition doing it for today’s vehicles. New cars have between 50 and 75 computers, commanding features such as anti-lock braking, airbags, suspension, traction control, emissions control and cruise control. All of that intelligence is coordinated in a “CAN bus” system, or controller area network hub.

“The engine is the heart of a vehicle,” says Dietz. “If you yank it out, the dashboard will light up like a Christmas tree.”

Dietz says the goal for the Roev team is to convert a modern vehicle in one day.

“You’d drive in, drop out the ICE [internal combustion engine] drivetrain and pop in this kit – think about IKEA-simple installation – and then take out the vehicle,” he says.

Roev’s research is finding that few fleet vehicles cover more than 50km a day. The short-range conversion kits the company is looking at installing can cover 240km.

“That’s one of the reasons we targeted

fleets,” says Dietz. “On average, consumers drive 30km a day and fleets do 50km so on a per-vehicle basis you can have more impact going after fleets.”

Amortisation of fleet vehicles usually sees book values written down to zero after three years. A conversion – from $47,990 for 2WD to $57,990 for 4WD, depending on battery capacity – will be balanced against the capital expenditure of a replacement vehicle and operating expenditure savings in fuel (between $5000 and $9000 per year, says Dietz) and the cost of charging.

Approximately 250,000 utes were imported to Australia in 2022. Roev is also eyeing other international markets south of the equator, such as South Africa.

“We’re hoping the kit is going to be reproducible enough that we can set up in other regions fairly quickly,” says Dietz.

The company won’t share details of the technology that may be dropped into utes, but it is working with a third-party engineering consultant to zero in on optimal solutions, with production expected in early 2024. Two vehicles are already on the road displaying Roev branding.

So far, prospective customers are favouring a 4WD configuration, with higher mileage and a larger battery than the cheaper 2WD option. It’s a preference that appears irrational to Roev, but Dietz says they’re learning a thing or two about the psychology of buyers.

While a pocket of drivers is hesitant about giving up on ICE vehicles, Dietz has also found many of them simply love their brands. For them, the electric vehicle experience involves a leap of faith, from levers and buttons to a touchscreen interface. One customer described it as favouring “sameyness” so when a driver jumps in a conversion he or she knows where everything is.

“That will alleviate some of that resistance to change,” says Dietz. “Then when they hit the accelerator, especially when going up a hill and there’s that instant torque, you move from somebody questioning it to it putting a smile on their face.

“As soon as they feel a Hilux with an EV engine in it, it gets across their face and they start getting giddy.”

“When drivers hit the accelerator, you move from somebody questioning it to it putting a smile on their face.”Roev has big ambitions to convert Australia’s beloved utes into electric vehicles. Roev is targeting the electrification of Australia’s fleet vehicles. One of two Roev utes on the road displaying the company’s branding.

As millions of solar panels reach their end of life in the next decade, innovative Australian companies are using technology to recover materials and avert them from landfill.

By Chris RyanWhat goes up must come down. That’s an emerging problem for the Australian renewable energy industry, with millions of photovoltaic panels installed on roofs and erected at solar farms across the country.

With solar panels reaching their end of life at around 25 years, what happens to them after they are retired is a significant issue. Sustainability Victoria estimates more than 100,000 tonnes of solar panel waste

could end up on the scrapheap by 2035.

It’s a daunting figure that plays into reservations about a solar revolution, with sceptics seizing on images of overflowing landfills and cluttered warehouses. But where some people warn of a looming environmental disaster, a range of innovators see an opportunity.

One company looking to turn the flood of used solar panels into a stream of revenue is Solar Recovery Corporation (SRC).

“We’re going to get hundreds of thousands of materials out of end-of-life solar panels,” says Rob Gell, sustainability advisor at SRC. “The downstream process upcycles everything to create new value and generate new manufacturing for Australia. [It is a matter of] revaluing the materials. You still have governments talking about ‘recycling solar panels’ but that’s not it. We are a materials recovery company working in the circular economy, trading commodities.

“Someone is going to do something smart with the silicon – take it to nano-silicon and make it into a battery. We are working with the Australian Aluminium Council – they’re going to take our frames. Because they will have a continuous stream of this stuff, they will make it into higher-value aluminium ingot and we’ll get higher prices.

“We also have high-quality HDPE [highdensity polyethylene] coming out of panels, and we are talking to a smart company that has new structural recycled plastic. We’re going to do ‘downstream upcycling’.”

SRC will use technology from La Mia Energia, an Italian consortium with a decade of experience recovering materials from end-of-life solar panels. Their patented clean technology claims to capture more than 99 per cent of materials from the panels without using crushing, chemicals, thermal processing or pyrolysis techniques.

AGL Energy has signed a memorandum of understanding with SRC for a feasibility study into establishing a PV materials recovery facility in Victoria’s Latrobe Valley as part of the company’s commitment to repurposing AGL Loy Yang as Latrobe Valley Energy Hub.

“They understand where the industry is headed and they’re going to build renewable energy hubs,” says Gell. “They will get into battery and solar panel manufacturing, and see us as a cornerstone because we’re going to recover the materials that go into those new manufacturing processes.”

SRC isn’t the only player in the market,

which is a good thing because there will be plenty of used solar panels to go around.

“I reckon if we have 100 machines installed by 2050, it will only be 10-15 per cent of the market,” says Gell.

Another company seeking to give solar panels a second life is Elecsome.

“We have a pilot facility in Melbourne where we used it for research purposes, proving the process and system flow and validating the byproduct,” says Elecsome director Brendan Lloyd. “Now we are transitioning to a factory that can process one panel every minute.”

Elecsome will recover precious metals such as copper, silver and aluminium, as well as professional-grade silicon, which is valuable to the semiconductor industry. The company has cooperative research programs with RMIT and the University of Melbourne, and has developed intellectual property (IP) of these processes.

“We’re keeping the process a little bit quiet to protect the IP, but it will be up

and running in August 2023,” says Lloyd. “We will have a grand opening and walk people through the process.”

One development Elecsome is happy to talk about is Solarcrete, a nano-engineered concrete aggregate produced from sand fines. Developed with their partners over four years, it allows concrete manufacturers to save 50-80 per cent of precious and limited river sand typically used in these products.

“Cement is one of the largest commodities currently around the world just for construction,” says Lloyd. “We are solving the problem of needing to mine natural environments. We view it as modern-day mining.”

Lloyd is excited about the role his company can play in a clean energy future.

“We are at the leading edge with technology when it comes to replacing coal and gas,” he says. “We want to do the best from a global-warming perspective, but why wouldn’t we want to evolve to something even better for a green and sustainable future?”

“The downstream process upcycles everything to create new value and generate new manufacturing for Australia.”Photo: nevodka/Shutterstock Precious materials can be extracted from used solar panels.

The construction sector’s embracing of technology will play a crucial role as Australia embarks on the building of nationwide renewable megaprojects.

By Rob BryantWhen the Federal Government’s whole-of-economy Long Term Emissions Reduction Plan was announced in 2021, former Minister for Industry, Energy and Emissions Reduction Angus Taylor acknowledged it was “technology not taxes” that would serve as

its backbone. Progress has since been made by the construction sector to steer Australia towards achieving net zero by 2050, however the clock is ticking and more must be done to avoid falling short of the target.

The journey to net zero is a mammoth change-management undertaking for

companies and nations. To achieve Australia’s ambitious net-zero goals, the government and private sector will need to turbocharge the pace of energy infrastructure while compressing costs.

The construction industry will be a key player in this process, needing to execute

accurate and affordable bids; managing megaprojects swiftly with full environmental, social and governance compliance; and minimalising risk to budget and schedule when pace and cost are under sharp focus. This is no easy ask in today’s constrained supply chain and labour shortage environment.

The Long Term Emissions Reduction Plan’s technology investment roadmap includes three pillars: priority low-emissions technologies such as hydrogen and solar, emerging technologies such as reduced methane livestock feed, and infrastructure for deploying low-emissions technologies. Australia has recently moved to address a problem other nations are grappling with while leading the decarbonisation charge: delivering and storing clean energy is a logistical problem because the pace of solar and wind deployment outpaces transmission deployment.

In 2015, China erected 57-storey energy efficient skyscraper Mini Sky City in just 19 days. In 2022, a 75km stretch of highway in India was built in five days. New York’s Empire State Building went from design to opening in 20 months, and was built in one year and 45 days in 1930 and 1931. To build the clean infrastructure needed to meet climate targets, organisations must radically shorten development and construction timelines.

Contractors aiming for massive renewable energy infrastructure projects will be unable to win bids or deliver with efficiency if they are still using manual project management processes. Many renewable projects are first-of-their-kind projects on a unique scale, creating a sharp learning curve in the industry.

There is a major lack of benchmarking around building pipelines or windfarms compared to what exists for building tunnels and bridges. Forward-thinking renewable construction firms are leveraging tech for dynamic, adaptable benchmarking, resulting in less wasted time, materials and labour. As an industry reluctant to lean into the digital transition, failure to recognise the role of technology could mean disastrous consequences for profitability and the planet.

Open, interoperable tools are key to encouraging and enabling open and collaborative project management models. They provide a single source of truth to keep all eyes on the same project data. Replacing traditional siloed, sequential project delivery methods with agile and collective approaches will drive leaner and faster development. The development and preconstruction stage is when digital solutions can make the most potent impact in unearthing efficiencies that keep projects on time and prevent surprises.

Contractors such as AG Coombs are using building information modeling – used on the International Convention Centre Sydney

– to produce precise virtual models that construction, engineering and procurement teams can see. This translates into fewer changes throughout the build while reducing potential rework that results in wasted materials, time and money.

A single source of truth in renewable construction project data makes a complete real-time view of projects possible, saving significant time when generating and distributing reports, and making important decisions. Construction management tech can help prevent delays and costly surprises when, inevitably, field issues or scope and design changes pop up.

Global management consultancy McKinsey reports onsite productivity can be increased by as much as 50 per cent by implementing a cloud-based control tower that assembles accurate data in near real time that is backwards looking and predictive. By automating scheduling, resource allocation, contracts, procurement tasks and communications, infrastructure project managers can reduce delays and cost overruns.

Australia’s audacious vision to reimagine its decarbonised energy grid will be at risk if electricity transmission deployment doesn’t catch up with electricity generation, and megaproject stakeholders can’t deliver on time and to budget.

Policymakers have set goals and launched incentives but successful execution of a sustainable, efficient and resilient renewable future requires a cooperative effort from the public sector, clean energy generators, clean energy transmitters, communities and other private sector stakeholders.

“To build the clean infrastructure needed to meet climate targets, organisations must radically shorten development and construction timelines.”

Rob Bryant is executive vice president, Asia Pacific and Japan, at construction project management software company InEight.Australia’s construction industry has a major role to play in the nation’s decarbonisation goals.

The NSW Peak Demand Reduction scheme has completed its first summer compliance period and comfortably met its targets.

By Rod WoolleyFollowing the completion of the first summer compliance period of the NSW Peak Demand Reduction Scheme (PDRS), from 1 November 2023 to 31 March 2023, the first-year targets of four million Peak Demand Certificates (PRCs) are likely to be comfortably met.

PRC registration in NSW is significantly increasing month-on-month. Eligible energy retailers will need to purchase certificates to meet their annual individual liable demand.

The first-year PDRS target in 2022 was just 0.5 per cent, but it will rapidly increase annually to 10 per cent by 2030. By reducing electricity demand at peak times, the scheme will reduce the risk of power outages and decrease pressure on NSW wholesale electricity prices. Participating

household and business bill savings of $1.2 billion are predicted from 2022 to 2040.

At a recent ESIA seminar, the NSW Government explained how Peak Reduction Certificate (PRC) vintages work. Some PRCs can be “forward created” during the life of an implementation. This means they are created upfront and assigned various vintages in relation to when capacity can be made available (see Chart 1 below).

For the second summer, it is anticipated more activities will be eligible for PRCs, in addition to the current ones, which are commercial and residential refrigeration and air-conditioning, and commercial and

industrial hot water heat pumps. Public consultation on new methods is expected in mid-2023. Technologies being considered to include in the next NSW Government PDRS Rule are demand shifting (water heaters and pool pumps); demand response (air-conditioning); consumer batteries; commercial and industrial technologies; and behavioural demand response.

At the ESIA seminar, certificate creator National Carbon Bank of Australia shared early learnings in residential air-conditioning, including that a little return can go a long way. PRC revenue represented only an additional 20 per cent in financial incentives, yet client installations increased by 55 per cent per month on average. The average number of Energy Savings Certificates (ESCs) per installation also increased by 23 per cent as the additional incentive enabled customers to replace their larger and more costly ducted systems.

Engineering services firm and certificate creator Energy Conservation shared several case studies on commercial hot water and refrigeration at the recent ESIA seminar. For example, a supermarket upgraded its baseline equipment – a remote multi-deck open meat case. The upgrade equipment was a low Energy Efficiency Index, four-door, remote multideck meat case. The certificate incentive stack included 91 ESCs worth $2821 (at $31 each) plus 1118 PRCs worth $2515 (at $2.25 each). The incentive provides an offset to upgrade cost up to a material $5336.

Electricity bill savings are around $1510 per year, calculating a simple payback

period under four years. Further bill savings are being achieved as the supermarket is saving on space heating because cold air no longer seeps storewide. Previously, additional heating was needed for customer comfort at the site.

It is game on for the rollout of peak demand reduction incentives across Australia under the National Energy Performance Strategy (NEPS) provided the Federal Government is prepared to build on the success of the Victorian and NSW energy savings schemes, and now NSW’s world-first PDRS. This is what is needed for transformative change before 2030. ESIA considers that the $1.6 billion committed in the Federal Budget

in May 2023 might not mobilise the volume of upgrades anticipated for a few hundred thousand households.

What Australia needs is a National Energy Savings Scheme (NESS) including a peak demand reduction incentive that mobilises industry to drive millions of household and business upgrades. This much-needed transformative measure will address the biggest barrier to energy efficiency: reduced customer costs at point of sale.

We weren’t expecting transformative strategy from the Federal Budget. But we are expecting transformative measures in NEPS, which has been through consultation and for which we await the government to respond later in 2023.

A new report from professional services company EY outlines the potential for Australia to become a clean energy superpower, but it won’t happen without targeted action.

By Dr Steve Hatfield-Dodds

By Dr Steve Hatfield-Dodds

New research from the EY Net Zero Centre kicks the tyres on the idea that global action on climate change creates prospects for Australia to emerge as a renewable energy superpower. In the report, “Seizing Australia’s Energy Superpower Opportunities”, it reveals the potential for Australia is significant – and it’s ours to lose.

EY’s modelling of the energy superpower dividend shows it would lift the value of Australian economic activity by $65 billion a year – or $1800 per person – in 2050 if we get it right. This is a 2.3 per cent GDP gain and a 1.5 per cent lift in wages. EY considers these numbers conservative, and real-world benefits would likely be larger.

However, dollars are only one aspect of the prize.

Heavy industry has a central role in the global shift to a low-emissions, high-income world. Rising incomes and living standards, particularly in Asia, will see demand for minerals, metals and other heavy industry outputs double by 2050. But this needs to happen while greenhouse gas emissions

fall 70 per cent or more during the same timeframe.

Australia is well positioned to capitalise on this growing global demand for clean sources of minerals, metals and other energy intensive commodities. The report identifies three areas where Australia has an advantage, underpinned by costcompetitive renewable energy at scale and abundant minerals and natural resources:

• Clean low-emissions heavy industry, including producing green iron (initially using gas and then hydrogen) as an input to electric arc furnace (EAF) steelmaking. Green iron is a global game changer for clean steel, allowing zero-emissions EAF to scale up by providing an alternative to using scrap metal as an input.

• Lithium, copper, nickel, cobalt and other critical “new economy” minerals, including initial processing opportunities. The report argues Australia can also leverage increasing attention to friendly supply chains.

• Hydrogen for use within Australia, including as an input to other exports. Examples include metal production, chemicals such as ammonia, and fertiliser. EY’s view is that the physics of hydrogen will tilt markets towards local use. While Australia can be competitive in hydrogen-based energy exports,

EY considers the scale of these markets will be limited on the demand side for at least the medium term.

However, Australia’s potential advantage is not automatic or absolute. While the shift to net zero could create new strengths, existing weaknesses and watchpoints remain, including labour costs and project approvals processes.

Australia has no room for complacency, and effort is required on three fronts to fully capture this opportunity.

First, Australia needs to rise to the challenge of delivering near-zero emissions electricity as a crucial step in the wider energy transition. This is complex, especially managing the risk of unanticipated coal retirements while adding the firming and storage required for a system based on variable renewables. But the challenges are well understood, and policies are evolving rapidly.

Second, major new facilities will require competitively priced, world-class infrastructure. Planning, resourcing and pricing new infrastructure is always challenging given their monopoly characteristics.

Third, substantial innovation is needed to reduce non-energy emissions and incubate commercially attractive new technologies. Policy and business leaders will need to lean

more heavily on innovation than has been necessary in the past. Well targeted research and development is the price of entry, particularly where international efforts do not meet our distinctive needs.

Fully capturing the transformative clean energy superpower opportunity will require Australia to get technologies out of the lab and demonstrated in the real world. Partnerships and risk sharing between government and business will also be crucial.

Australia has been conflicted about climate change. We recognise the nation is more exposed to climate change impacts and risks than most high-income nations. However, Australia’s old-economy advantages in fossil fuel exports have at times constrained our willingness to take decisive action.

However, those days should be behind us. Australia can make a distinct contribution to meeting global needs, creating new jobs and income streams from clean energyintensive products while supporting the transition to net-zero emissions. We can do well while doing good.

“Australia is well positioned to capitalise on global demand for clean sources of minerals, metals and other energy intensive commodities.”Dr Steve Hatfield-Dodds is an associate principal at EY Port Jackson Partners and research leader at EY Net Zero Centre.

As the digital world becomes increasingly swamped with data, it poses a significant environmental and security risk, presenting unique challenges for organisations seeking to achieve their sustainability goals.

By Matthew Hurford Matthew Hurford is managing director and vice president, ANZ, at NetApp.

Data is often called the “oil of the digital era”, a valuable resource driving innovation and economic growth in Australia’s digital-first landscape. However, according to global market intelligence firm IDC, just 32 per cent of data available to enterprises is ever put to work.

IDC’s research indicates the remaining 68 per cent is not used. Most of it is siloed across different teams, in conflicting formats, or being “zombie projects” that serve no purpose beyond what they were created for.

This has led to the concept of “data minimalisation”. It is thought to be a means to tackle data bloat and inherent environmental costs. It also addresses security risks associated with lax data retention practices.

Reducing the environmental impact of data storage has become a challenge for organisations looking to achieve sustainability credentials. Managing environmental impacts is increasingly key to KPIs and board-level commitments to environmental, social and governance (ESG).

Data minimalism has emerged as a systematic and effective strategy to tackle inefficient and wasteful data accumulation. Organisations are cutting costs and making significant strides towards meeting sustainability goals by adopting data minimalism as the cornerstone of a data strategy.

Adopting practices to cut data wastage and streamline storage can help

organisations achieve the following benefits:

Comprehensive visibility: A thorough understanding of the volume, nature and location of data helps organisations manage it effectively. Visibility across on-premises and cloud environments is essential.

Categorisation and prioritisation: Once organisations have achieved data visibility, the next step is categorising and prioritising it. Distinguishing between necessary and unnecessary data is key to meeting governance and sustainability standards.

Cloud migration and optimisation: Cloud-based solutions enable organisations to effectively explore data migration and tiering opportunities. Cloud providers often prioritise energy-efficient infrastructure architectures, offering scalability and flexibility while cutting the carbon footprint of data storage.

Data compression and deduplication: Organisations can boost storage efficiency by using these techniques. This allows IT teams to remove redundant copies and compress data, drastically reducing their

footprint and allowing consolidation of storage infrastructure.

NetApp conducted a recent study of tech executives across Australia and New Zealand. The company found that 62 per cent of those executives are developing cloud systems specifically with sustainability goals in mind. Despite Australia’s net-zero ambitions, this result is lower than our Asia-Pacific neighbours, who

prominently feature sustainability in their cloud strategies.

According to IDC, spending on sustainability initiatives promoting big data and analytics adoption in Australia and New Zealand is expected to reach more than $13 billion by 2026. There are significant data storage costs across on-premises and the cloud. That’s before accounting for the increasing importance of environmentally sustainable outcomes. This means effective data management must be top of mind for organisations.

It is clear sustainability initiatives are a priority for the Federal Government.

The creation of the Net Zero Authority will assist in Australia’s clean energy transition and hitting net-zero emissions by 2050.

The government has also acknowledged the environmental cost of data storage. A new tax break for SMEs (small-tomedium enterprises) was announced in the 2023-2024 Federal Budget for the electrification of cooling and heating systems, including data centres. Amid current economic uncertainty and the ongoing energy crisis, there is an unprecedented opportunity to overhaul data management strategies and build a greener future. Using data minimalism approaches, organisations across Australia and New Zealand can continue to establish and develop a digital presence and innovate while placing sustainability at the core of their approach.

“Organisations are making strides towards meeting sustainability goals by adopting data minimalism as the cornerstone of a data strategy.”

By Brian Innes

By Brian Innes

Australia’s state and federal governments are committed to funding and installing community batteries that absorb and store excess power generated by residents’ and businesses’ solar panels for local use when the sun goes down.

In April 2023, the Federal Government committed to funding $200 million for the installation of 400 community batteries across Australia. In the lead up to the Victorian election in November 2022, the state government promised $42 million for the installation of 100 batteries. The newly formed Labor Government in NSW has also made community batteries the centrepiece of its $1 billion NSW Energy Security Corporation.

Community batteries, which are roughly the size of a large car, store approximately 500kW hours of energy – enough to support around 250 homes. They also help stabilise the grid, providing energy security to remote communities affected by power cuts during natural disasters.

The concept of individual households and

businesses returning excess solar power generated by rooftop panels is not new, but feeding that power into a local neighbourhood battery – subsidised by the government – is a recent phenomenon.

At first blush, government support for a concept to increase the use of renewable energy seems like a great idea. However, they are spending money on batteries the private sector is installing anyway.

These aren’t big batteries sitting next to the local footy oval, as envisaged by state and federal governments under the community battery model. We’re talking batteries in electric vehicles attached to the sides of homes or inside office buildings and factories that are charged by solar panels. These behind-the-meter batteries can fulfil the same role as community batteries.

The flawed community battery program involves state and federal governments investing hundreds of millions of dollars into electricity networks to build something that, in most instances, does not need to be built. Australia would be better off telling those networks to stay away from

small-scale batteries powering community microgrids and adopting a distribution system operator (DSO).

The traditional DSO model worked when the electrical system was designed for one-way power flow – typically connecting fossil fuel power stations to households and businesses. It was not anticipated consumers would become producers of energy, feeding excess power into the grid.

DSOs are entities responsible for distributing and managing energy from new private generation sources to consumers. This is the role energy networks should be playing.

The DSO model has been successfully adopted in the UK energy market. It uses smart meters that allow bidirectional reading of energy flow to and from homes, and real-time communication, providing up-to-date visibility into network operation. This helps to better control voltage, faults and flows at macro and local levels. Without this, the grid is less efficient and less reliable.

Under this model, Australian energy

Australia’s federal and state governments have thrown their support behind community batteries, however encouraging higher EV uptake across the nation is the more practical solution.Photo: Avigator Fortuner/Shutterstock

networks should be managing the power system, contracting with people who are battery specialists and focusing on fixing network problems.

If our governments want to utilise excess renewable energy generated by households and businesses, they should invest in the uptake of EVs. The April 2023 announcement by the Federal Government of $40 million support for discounted loans on EVs is a great example.