Control costs with a Cat® Customer Value Agreement

As any professional in this industry will tell you, topquality equipment is the backbone of our projects, the driving force behind progress, and the embodiment of innovation. But what truly sets an outstanding manufacturer apart from the rest is their commitment to providing comprehensive after-sales support. It’s an aspect of the game that is cherished and, in some cases, esteemed even more than the machines themselves.

Why is after-sales support so crucial in the earthmoving industry? It’s because these robust machines, despite their cutting-edge technology and sturdy construction, are subject to a rigorous and often unforgiving environment – especially in Australia. From navigating treacherous terrains under the scorching sun to enduring relentless workloads, the wear and tear on these powerful machines can be substantial. It’s here that the true worth of a manufacturer comes to light.

The willingness of a manufacturer to stand by their dealers and customers, not just during the initial sale but throughout the lifespan of the machinery, speaks volumes about their dedication to customer satisfaction and their belief in their products. So, it’s no surprise to hear that the standard of after-sales support on offer can heavily influence a buyer’s decision when choosing a brand.

It’s a story I hear time and again about our friends on the cover: Caterpillar. In our cover story, we learn more about the manufacturer’s dealer-driven Customer Value Agreements, which are designed to help customers get the most out of their Cat® machinery – whether it’s one machine or a fleet of 100. We also hear from long-time Cat advocates on either side of the country: Heath Shipard of Perth’s HAS Earthmoving, who has just added a Next Gen Cat 306 CR Mini Excavator to his

fleet; and Clay Badenoch of Gold Coast-based Baden Civil, where a brand-new compact radius Cat 325 excavator is helping give his operators room to move on crowded urban worksites.

Sydney’s Solution Plant Hire has also jumped on board the zero-swing train, and National Sales Manager Sam Townsend explains why a LiuGong 915FCR – with its combination of a compact frame and impressive digging power – was the right choice for his business.

One place where space is certainly no issue is at Western Quarries, just outside of Ararat, a few hours west of Melbourne. Here, the team’s machinery fleet is Volvo through and through, including their recently acquired (and Australia’s very first) 50-tonne EC550E crawler excavator. Nearby, we also check in with Styles Civil – a young, enthusiastic family earthmoving business from Melbourne’s north with a taste for Kobelco mini excavators.

Quite a range, to be sure. But one thing that ties all these stories together is the next-level support provided by the passionate teams representing these OEMs –before, during, and most crucially, after the money’s down.

EEM also speaks to businesses across the country about what they’re doing to take their after-sales support to the next level, whether they’re supplying telehandlers, lubrication solutions, pumps, or anything in between.

While you’re here, you can also feast your eyes on some of the latest and greatest coming out of Germany, with deep dives into Liebherr’s TA 230 articulated dump truck and Wacker Neuson’s WL110 wheel loader.

Happy digging!

Leon Cranswick Editor

Finlease

record of establishing long term relationships with clients, finding them the best finance solutions to support their business growth. The company’s goal is to make the finance process simpler for businesses so they can focus on what they’re good at.

Ann has been the Manager of Allied Earthmovers Association for the past 19 years bringing many years’ experience into the role. After gaining business qualifications and managing a retail shopping centre in Sydney CBD, Ann first started her career in earthmoving when she joined the long-established family business in Penrith, which specialised in Caterpillar graders and dozers. Working in a male-dominated industry, Ann brings a different aspect to the Association. She has met many people in the industry and knows what the owner operator needs, from the importance of paperwork to machine availability. It’s an industry she respects and is proud to be a part of.

Earthmoving Equipment Magazine is published bimonthly by Prime Creative Media Pty Ltd.

CEO John Murphy

COO

Christine Clancy

Sales Director Bradley Buchanan Editor Leon Cranswick leon.cranswick@primecreative.com.au

Brand Manager KahChi Liew kahchi.liew@primecreative.com.au 0421 474 407

Production Editor Michelle Alder michelle.alder@primecreative.com.au

Art Director/Design

Daz Woolley, Cat Zappia Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au

Website www.earthmovers-magazine.com.au

Copyright Earthmoving Equipment Magazine is owned by Prime Creative Media and published by John Murphy. All material in Earthmoving Equipment Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in Earthmoving Equipment Magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head Office 379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au

www.primecreative.com.au

Sydney Office Suite 3.06, 1-9 Chandos Street Saint Leonards NSW 2065, Australia

P: +61 2 9439 7227

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

Free Delivery

Australia wide.

Whelans Group Investments is a family owned and operated construction business in Eastern Victoria. The business currently operates 90+ pieces of Cat® equipment, including skid steer loaders, compactors, excavators, dump trucks, motor graders, and dozers.

Across Victoria, Whelans Group is contracted to deliver a wide variety of projects including earthworks, roadworks, drainage works, civil construction, heavy mining applications, major highway re‐alignments, railway works, sub‐divisions, and residential construction.

Customer Value Agreements (CVAs) help Cat machine owners focus on their business and keep their machines at work on the jobsite.

As the General Manager of Whelans Group, John Dick knows better than anyone the value of CVAs for their business and how the tailored agreement ensures their machines are kept in top working order and deliver a hassle-free ownership experience.

“It allows us to focus solely on our production on the ground,” says John. “Knowing that Caterpillar have our machine’s best interests at heart also gives us confidence that we’ll meet project timelines.”

And should the unexpected arise, their Cat dealer is on hand and ready to provide machine support and guidance through the standard Cat warranty and Equipment Protection Plan.

A Cat CVA provides customers with access to expert support.

“Better yet,” says Robert Selby, Caterpillar Aftermarket Services Representative, “it provides customers with access to expert

support when they need it. Cat CVAs are available in a range of plans – from a total maintenance and repair contract, through to planned maintenance parts, which are delivered directly to you.

“By structuring the right agreement with your Cat dealer, you can lower your total operating costs to maximise your investment. Customers can take out a CVA at any time, whether this is

when they purchase the machine or down the track, and CVAs can cater to one machine or an entire fleet.”

“Our relationship with our Cat dealer and the ease of doing business is paramount to our success,” says John. “We save time with our CVA because we can focus on logistics,

delivery, and other issues, knowing full well that our machinery will be ready to go when we need it.

“And that means, with our CVAs, I can keep costs under control,”

Cat Dealer Representative, Gary Zarth, agrees.

“We help control their costs so Whelans can focus on their business,” he says. “Genuine Cat parts are delivered right on schedule, with clear instructions to ensure planned maintenance is done accurately, while the Equipment Protection Plan offers troubleshooting,

diagnostics, and repairs for newer machines. “Cat VisionLink® and dealer monitoring also provides real time data in-feed, meaning customers can monitor everything from machine health through to production without needing to leave the worksite.”

Understanding that different customers will have different requirements, needs and budgets, Caterpillar does not have a ‘one size fits all’ solution with its CVA product, instead letting customers design a solution with their

Cat Customer Value Agreements are available in your dealer territory. Contact your local Cat dealer:

their operation.

To find out more about Cat Customer Value Agreements, speak to your local Cat dealer or visit cat.com/cva-au

Developed for Cat® D6-D8 Dozers equipped with semi-u blades, Cat FirstCut™ Cutting Edges provide superior penetration in the toughest digging conditions.

• Through-hardened DH-3 and thicker DH-2 steel provides balanced and increased wear life.

• Load faster and increase payload mass with reduced track slip.

• Slice through soil instead of breaking it up, and with less ripping. Ready to make the first cut? Contact your local Cat dealer or visit cat.com/cuttingedge-au

In a tight job market, employers are always looking for ways to stand out and attract the best candidates. But what elevates an employer to a true employer of choice – one where people don’t just take a job, but stay, grow, and thrive?

Colin Shaw, Komatsu Australia’s Executive General Manager, People and Strategy, says it starts with getting recruitment right – but it goes much further.

Komatsu Australia has won several awards for its HR focus and the positive experience its people enjoy at work. Most recently, it was named in the 2023 AFR BOSS Best Places to Work List.

“Komatsu Australia is always proud to be recognised for our commitment to creating an environment that empowers employees to grow, excel, and achieve their personal and professional goals,” Colin says. “We really do believe that a supportive and positive work environment is critical to our success.”

He believes people will join a company for a job that pays well, offers good conditions, and provides opportunities to learn new skills. But the best employers want to do more than just get people through the door.

“We want our people to feel truly valued, to see real rewards for their commitment and to be able to achieve their goals both in and outside of work,” he says. “We want people to feel like they can bring their whole selves to work.

“We’ve put a strong focus on what really makes for a good workplace, from the basic elements like great facilities to addressing some of the less visible challenges, like creating career pathways for women and other underrepresented groups, giving our people time to do the things that matter to them, and walking our talk on topics like flexible working, bullying, and all the other things that can make the difference between a great day at work and one that is not so great.”

Getting it right, right from the start

Komatsu’s award-winning Apprentice Development System has revolutionised the way apprentices and trainees are trained and developed in the industry. It has earned widespread recognition, including receiving Silver for Large Employer of the Year and Silver for Employing Australian Apprentices at the National Training Awards in 2022.

“The way our system is designed means that by the time our apprentices complete the program, they’ve achieved a competency level that would take about another year of experience for apprentices trained in conventional programs,” Colin says. “It really supercharges our apprentices’ careers and helps them reach their potential.”

The apprentice program is managed through the Komatsu Training Academy, which has two state-of-the-art, purpose-built education centres in Brisbane and Perth, giving the

company a strong presence on both the east and west coast.

“Our facilities offer a highly interactive and technologically advanced learning environment, and our workshop labs are specifically designed to deliver hands-on training for both construction and mining class machines, ensuring that students gain practical skills and experience,” Colin says. “Our training facilities also incorporate a number of simulators, so trainees can safely learn on a range of machines – from small utility machines, right up to an ultra-class heavy excavator.”

The company currently has over 300 apprentices in training on the west coast and more than 200 on the east coast and plans to build the total to more than 600 in the coming year.

Almost half the current WA apprentices are women and Komatsu selects apprentices based on potential, not age – a few years back they had a 47-year-old apprentice, and in the current intake there are apprentices in their 30s.

“Flexibility for us isn’t just about how you structure a work day, it’s about how you think about what makes a good apprentice, or a good mechanic, or any other role,” Colin says.

Komatsu also recognises the importance of equipping apprentices with important life skills, such as mental health awareness, public speaking, road safety and fatigue management, drug and alcohol awareness, and a variety of business skillsets.

The Komatsu Training Academy gives apprentices an incredible start to their careers, but it also supports continued training and upskilling for their people at every level.

“A big focus of the academy is upskilling people in their current roles, whether that be in leadership and management, operator skill proficiency development or customised technical training,” Colin says. “We offer a mix of fully accredited courses and modules, along with purpose-designed operator, technical and management training.

“Both our training academies are backed by expertly skilled trainers aimed at building the workforce of the future. A lot of our training and courses focus on autonomous methods or using technology like Komatsu’s Smart Construction offering. The technology they’re learning about will ultimately help operators become more precise and accurate, and lead to better productivity on-site.”

Komatsu Australia recently doubled its annual training investment to $12 million to drive greater impact for apprentices, industry, and the economy.

Families at Komatsu

Colin says it’s important to recognise that Komatsu’s people have responsibilities outside of work.

“We understand the impact that happy and healthy families have on our people, and our community,” Colin says.

“If we can make it easier for our people to balance working with having children and raising their families, then of course we should. It means our people are happier and it means we’re able to keep those incredible employees who might otherwise feel they need to step out of the workforce to pursue their personal goals. It’s a win-win.”

The new Families at Komatsu replaces the company’s paid parental leave scheme and is a much broader program designed to provide benefits and support to all types of families, so everyone can thrive in the business’s inclusive culture.

Key elements of the program include 16 weeks of paid leave for the primary carer of a new baby, plus four weeks of bonding leave for the secondary carer; plus, special paid leave for our people who experience miscarriage or stillbirth. There is also a structured return to work program to make it easier to come back into a role, and ongoing access to flexible work arrangements.

“We’re really proud of this comprehensive program which really is about our people’s wellbeing,” Colin says.

Inclusive means everyone, every day Komatsu has led the industry by putting diversity and inclusion on the agenda. The brand has won a range of awards in relation to its Say Again? program to address casual workplace sexism, and for its industry-leading training programs.

“We are always looking for opportunities to highlight the benefits diversity can bring to our organisation and address the barriers that may

hold us back,” Colin says. “We’re doing very well in our entry level roles, with goals of 30-50 per cent women, compared with an industry benchmark, which is less than a third of that.

“We’re also making inroads on increasing female representation further up the corporate ladder, by thinking more openly about what the key skills are in some of our leadership roles, to enable us to recruit from a wider pool of applicants. That means, for instance, that we don’t just look to people with a technical background – which typically means men in our industry – for roles where the key skills are around communication.”

Komatsu has partnered with the Western Sydney Wanderers women’s football team as part of its diversity and inclusion program.

“The strategies that the Wanderers are implementing echo our business strategies here at Komatsu,” Colin says. “We are both focused on creating an environment that offers

equality and opportunities for women because we understand and know the unique value they can bring our workforce and teams.”

Komatsu supports its people to do the things that matter to them, through initiatives like the Live Your Dream program, which provides $10,000 grants for employees to support a notfor-profit organisation or charity of their choice.

Colin says the program is one Komatsu is proud to deliver for its employees.

“This initiative helps our people to support the causes they care about,” he says. “It gives them an opportunity to do something special that they normally don’t have the provisions to do outside of work.”

To find out more about Komatsu, and available career opportunities, head to www.komatsu.com.au/careers

Sandwiched between the 13-tonne 313 and the 18-tonne 317, the 15-tonne Cat® 315 and the 315 GC excavators are the latest addition to Caterpillar’s small excavator line-up.

Due to their compact radius design, both machines are suitable for use in a wide variety of jobs and industries such as grade work, slope work, trenching, loading, and utility work.

“Caterpillar has redesigned every aspect of the 15-tonne excavators to deliver better performance and better match customer needs just as we did with the 20-tonne machines,” says Cat Excavator Product Specialist Teo Yibin.

“And we’ve given the customer more choices, allowing them to choose their emissions preference as well as technology options.”

Like many other larger Next Gen Hex range, the 315 and 315 GC have the option of a Tier 4F engine, or a Tier 3 Engine that does not require diesel exhaust fluid.

The new fuel-efficient Cat C3.6 engine powers these two Next Gen small excavators, giving improved performance over the previous 315 F model. Both engine choices are backed by the Cat Fuel Edge program, giving customers certainty on their biggest operating cost.

This is available with the purchase of a qualifying Cat machine – with Product link™ enabled – from any participating Cat dealer. If the machine burns more than the committed fuel consumption threshold, the dealer will provide a parts credit.

“The compact design gives operators the confidence to dig, swing and dump in spacerestricted jobsites,” Teo says. “The 315 is eight per cent more productive than the previous model, giving improved fuel efficiency, while the 315 GC can save up to 15 per cent fuel consumption over the previous model.

“New Smart Mode operation automatically matches engine and hydraulic power to working conditions for maximum productivity

applications.”

The advanced hydraulic system of the 315 and 315 GC excavator provides the optimum balance of power and efficiency to increase productivity over the 315F L. Its new electronic hydraulic valve delivers significant efficiency. A 10 per cent higher swing torque makes working on slopes and around the jobsite much more efficient, and the drive system easily navigates tough ground conditions and slopes with 14 per cent more drawbar pull.

“Both machines are suitable for much more than just utility work or on residential sites,” Teo says. “These machines are right at home on even large infrastructure jobs and loading trucks. The new electronically controlled hydraulics have made for both faster control response and better controllability.

“To the customer, the benefit with the 315 GC model is that you’re getting F-Series levels of performance, but at a lower price point while still getting the big maintenance savings, big fuel savings, and electro-hydraulic controls. The 315 GC is the new standard model that is reliable, comfortable and productive. It is ideally balanced to deliver performance, maximise operator productivity and offer the lowest cost per machine hour of performance.

“But for customers looking for a 10 per cent boost in swing torque that elevates efficiency when working on slopes and moving around the jobsite, check out the 315 excavator with technology options like the very popular Cat Grade with 3D.”

Delivering superior performance and bestin-class productivity for 15-tonne excavators, the Cat 315 comes standard with a host of productivity enhancing technologies to increase operator efficiency by up to 45 per cent. Standard Cat Payload provides on-thego weighing and real-time payload estimates, so operators can deliver precise load targets every time to improve loading efficiency. Using VisionLink Productivity, Payload and other jobsite data can be used to remotely analyse and manage production targets across multiple jobsites.

Critical operating data such as fuel usage, idle time, CO2 emissions and fault codes are tracked by VisionLink to help boost fleet management efficiency.

“There is also a range of additional factoryfitted options to increase productivity and expand grading capabilities for the 315,” Teo says. “Grade 2D automatically guides digging depth, slope, and horizontal distance to quickly and accurately reach desired grade. Increasing safety when excavating in confined spaces, the new 2D E-fence keeps the front linkage within a predefined work area to avoid hazards on the jobsite as well as standard cab avoidance.

“For advanced grade demands, Cat Grade with 3D includes an additional 10-inch highresolution touchscreen monitor featuring powerful graphics, and customisable 3D views bring the job-site design to life, giving operators the ability to hone in on the right perspective. And there is a range of other intuitive embedded features to help them be more productive.”

The new Cat GRADE with 3D system allows operators to quickly create in-field 2D and 3D designs if a job-site design is not available.

“This enables customers to utilise Cat GRADE with 3D on smaller projects to build designs such as swale drains, trenches, pads, basement cuts, and finishing,” Teo says. “The in-field design can use the cutting edge as a survey tool, or operators can input the exact plan, elevation, and profile of the design, which helps improve work quality and prevents rework.

“The factory 3D option also means operators can start work quickly and safely with no need to install or remove 3D

system components, and eliminating cable connections adds to the reliability.”

Cat GRADE with 3D systems come with the option of single or dual GNSS receivers, securely mounted to provide real-time position and heading of the machine.

“But there are some customers that do not need the added technology features for the work they do,” Teo says. “Why pay for something you will never need? If you’re in the market for a machine that gives you a solid performance with the benefit of lower up-front acquisition costs, lower owning and operating costs, and unmatched dealer support, then check out the 315 GC.”

Both Cat 315 and 315 GC operators will experience a new, 13 per cent larger cab designed with improved ingress/egress to boost comfort and productivity. The full-sized cab offers a low-profile design plus large front, rear, and side windows with narrow cab pillars to offer 40 per cent greater visibility compared to F Series small excavators, enhancing safe operation.

“We take safety seriously at Caterpillar,” Teo says. “The standard rear-view and right-handsideview cameras further improve visibility of the operating environment. Owners can also upgrade to 360-degree visibility to easily see objects and personnel around the excavator in a single view.”

Teo says advanced viscous mounts significantly reduce cab vibration compared to previous models, reducing operator fatigue.

“Improved sound suppression lowers interior noise levels to improve operator comfort,” he says. “Operators can make hands-free calls through the new standard radio’s Bluetooth connectivity for personal devices. It’s really cool.”

These two models also lower maintenance costs by up to 25 per cent, making them the right fit

for rental, municipal, and general all-around excavating applications that require dependable performance and low operating costs.

The 315 and 315 GC feature a host of design upgrades that simplify maintenance to deliver up to 25 per cent lower costs than their F-series counterparts. The excavator’s new hydraulic oil filter delivers improved filtration and a 50 per cent longer change interval at 3000 hours. New anti-drain valves keep the hydraulic oil clean during filter replacement to improve system longevity.

“Operators can now conveniently track filter life and maintenance intervals through the incab LCD monitor – it’s a no brainer,” Teo says. “All daily maintenance checkpoints, including engine oil, are easily accessible from ground level, making it safer.”

Cat S∙O∙S system on these machines allows for quick and easy extraction of fluid samples for analysis, simplifying maintenance.

“With more standard technology at better price points, a wider range of machines to better match applications, and huge reductions in fuel consumption and maintenance costs, the Next Generation excavator range delivers a better bottom line for all customers,” Teo says.

Currently the 315 and 315 GC come with three-year Equipment Protection Plans on powertrain, hydraulics and technology including a 3.99 per cent Finance rate up to 60 months for purchases made before 30 September 2023.

Contact your local Cat dealer now

NSW/ACT: WesTrac – 1300 881 064

VIC/TAS: William – Adams 1300 923 267

Western Australia: WesTrac – 1300 881 064

QLD/NT: Hastings Deering – 131 228

South Australia: Cavpower – 08 8343 1600

NZ: TERRA – 0800 93 39 39

Lifting capacities 5000kg

Reach 26 metres

Continuous rotation of the turret

ASCS security system with 10.1’’ display Tilting cab with inclination up to 20°

Multi-position stabilisers

125 kW/170 hp engine

Hydrostatic transmission with management system

Lachlan Connors, Sales

Australia’s industrial sector has long been upheld by a workforce of senior specialists, many of whom boast decades of experience. While this means that the industry is rich with knowledge, it also indicates that a large number of employees will be retiring over the next decade. With the majority of industrial insiders being around 50 years old, the sector will likely experience a shortage of skilled workers in the next 10 years. This leaves businesses to take action in attracting, teaching and retaining the next generation of industrial employees.

As a longstanding industrial business, Pickles knows the importance of acquiring the next industrial workforce in the next few years. Not only is it important to start developing the future wave of industrial workers to keep Australia’s industry progressing, but it needs to be done now so the newcomers can take advantage of the wealth of knowledge offered by their predecessors. Empowering the next generation benefits the entire sector, as vendors too would be greatly impacted if the industry was suddenly barren of the skilled workers needed to conduct the buying and

selling of industrial assets. That’s why Pickles has invested considerable time and resources in sourcing the industrial leaders of tomorrow. Using recruitment, cadetship, training, development and mentorship, Pickles aims to uplift newcomers and ensure a strong future for the industry.

For Nathan Heymans, NSW OEM Manager, industrial management comes naturally. After liaising with Pickles through his roles in the OEM dealer network, the opportunity to progress came about through his internal connections. Having built strong relationships with Pickles executives, Nathan was referred for a role with Pickles Industrial.

Now three years into his Pickles career, Nathan is taking industrial management to the next level with his fresh perspective on the industry. At 33 years old, Nathan is one of Pickles’ youngest industrial managers and is one of the freshest leadership talents in the business. Nathan is part of a new generation of industrial enthusiasts who are currently

coming up in the business. This new wave of insiders will need to shepherd the industry into the future, and Nathan believes the only way this can be done is by soaking up as much knowledge as possible from the senior industrial experts at Pickles.

“There is so much to be learned from the industrial guys at Pickles,” he says. “Some of them have been in the industry for 30 plus years – you just can’t buy that kind of insight. I soak in as much knowledge as I can while I can, and I’m lucky that they’re so willing to help.”

While keeping one foot rooted in the knowledge of his predecessors, Nathan keeps his head towards the future of the industry. Nathan’s career is developing during huge industry changes, as digitisation sweeps the used asset marketplace.

The 20s have led Pickles to reorganise and innovate their offerings in a digitally led way. As the industry and Australia changes, the youngest Pickles leaders have rallied to push the business into the future. For Australian auction houses, it appears that the era of the in-person auction has passed, with most sales

ExecutiveIndustrial, NSW,

believes employees do well at Pickles if they are motivated, have a hunger to learn, and are willing to admit mistakes.

now being conducted online. Pickles’ youngest employees are the loudest advocates for this digital auction revolution, with online auctions drastically improving sales results.

These changes have been hard to swallow for those who miss the atmosphere of inperson auctions. For industrial predecessors, the industry has changed drastically over the last two decades. Sales have gone from handshakes at the pub, to completely online transactions. In 2023, the landscape of Australian industry has changed and so has Pickles.

Entering the industrial sector is an extremely lucrative business, albeit a daunting one to enter. For young Australians, getting a foot in the door can be the hardest part. For new industrial talent, there are a broad range of career pathways available to choose from, like starting as a cadet, sales coordinator or an assistant. Getting started is the most important thing to Pickles senior leaders, who believe in investing in their employees, building a broad

range of skills to create well-rounded experts over time. Meaning, newcomers simply need to get a foot in the door to be offered all the opportunities in the world.

For those interested in cadetship, Pickles offers traineeships for graduates, or those undertaking study. The two-year programs allow new starters to train with industry leaders and learn a variety of skills including asset valuing, auctioneering, sales techniques, project management and insolvency handling. After completing training, Pickles offers the candidate a role within the business that is suited to the individual’s skills and preferences.

For those interested in starting a new career but aren’t completing studies, there are a range of job opportunities available across Pickles’ 27 Australian locations. A large majority of Pickles’ senior executives climbed the ranks after starting in branch-based roles and honing their knowledge and skills over many years. So, for new entrants to the industrial sector, getting started in any role at any facility could mean the opportunity of a lifetime.

There is a wealth of opportunity afforded to recruits by Pickles, a sentiment which is echoed by some of Pickles Industrial’s most promising young talent. When asked about their advice for those wanting to join the industry, Nathan Heymans, Alex McAvoy, and Lachlan Connors had plenty to share:

“Just give it a crack! It’s a very rewarding career path for those who are just willing to give it a go.” Nathan Heymans, NSW OEM Manager - Industrial.

“Industrial is a very rewarding and exciting industry to be part of. Pickles invests in their staff, with a range of opportunities provided to develop and advance within the business.” Alex McAvoy, Vendor Payments Team Leader - Industrial.

“As long as you are motivated, have the hunger to learn and are willing to admit mistakes, you’ll do well.” Lachlan Connors, Sales Executive - Industrial NSW.

For more information on Pickles cadetship programs or job opportunities, head to: www.pickles.com.au/about/careers

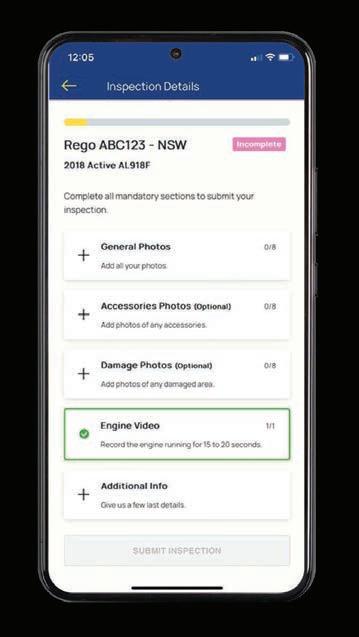

Need to offload your used trucks and machinery? DIYinspect is a self-inspection app powered by Pickles. Asset owners can simply download the app, complete an in-app inspection and receive an offer to purchase equipment. Start the process anywhere, at any time.

Why use DIYinspect?

DIYinspect helps customers sell their assets with ease and in their own time and space. By conducting remote inspections, sellers can maximise their time and return on their assets.

Customers receive data-led offers to purchase, eliminating the expense and hassle of conducting in-person asset inspections.

Sellers can offload a range of equipment including trucks, buses, excavators, and loaders.

Head to DIYinspect.com.au for more information, or simply download and get started!

The entire process only takes 15 minutes and you simply follow the steps below to get started.

STEP 1

Download DIYinspect from the App Store or Google Play

STEP 2

Register a business account using your information incl. your ABN

STEP 3

Select the asset type you want inspected

STEP 4

Upload information, notes, photos and videos of your equipment

STEP 5

Submit your DIY inspection and we’ll get back to you within 48 hours!

If you’re looking for an edge in tough conditions, you’ve found it. Cat® FirstCut™ Cutting Edges deliver superior penetration in all soil types –tough and compacted, rocky or frozen – leading to bigger blade loads and less ripping.

The patented design of the shallower angle of the intermediate edges, has a sharpened and forward-protruding profile. This carefully focuses the machine’s energy on slicing through the soil rather than breaking it up, resulting in up to 35 per cent* larger payload mass and up to 17 per cent* improvement in productivity.

And because the blade penetrates the ground that much easier, the tracks stay fully engaged with the ground, helping to reduce track slip. So even when you push harder, your undercarriage stays pinned to the ground, helping to make your components last longer.

The patented edge design of Cat FirstCut Cutting Edges features matching end bits that

direct material toward the centre of the blade, resulting in better load retention and smaller windrows.

The intermediate edges and end bits of Cat FirstCut edges are sharper than traditional DH-2 plate cutting edges, with the end bits and intermediate edges being cast DH-3 steel. This is purposefully designed to tackle tough terrains. And while the centre cutting edge is traditional DH-2 steel, it is thicker than the standard cutting edge to match the thickness of the Cat FirstCut edges, meaning no mid-life flip.

Cat FirstCut Cutting Edges are interchangeable with traditional cutting edges, so blade modifications are not necessary because they use the same hardware as traditional systems. Drilled and tapped holes are provided on all components, so you can safely lift the parts into place during installation and removal.

The on-plane cutting edge system of Cat FirstCut Cutting Edges means there’s no more trade-off between dig productivity and finish dozing capability: it is designed to provide both. Better yet, its service life is the same as the standard Cat Cutting Edges without mid-life edge flip. How? The system is designed to have equal wear material as standard Cat Cutting Edge systems with DH-3 steel. This means you can expect the same or even more wear life hours without the need to flip the edges and replace the end bits at mid-life.

Every machine owner knows just how expensive blade damage can be. If cutting edges are not replaced at the right time, wear continues into the supporting structure underneath and eventually, the base edge will need to be replaced. That’s the

kind of cost every business can do without.

Cat FirstCut Cutting Edges have built in wear indicators, so you know when you are approaching end of life. Plus, they offer two times more wear life* than standard Cat Cutting Edges, and with no mid-life flip required.

For long-lasting edges and superior penetration in the toughest conditions, choose Cat FirstCut Cutting Edges.

If you’re ready to make the first cut or to find out more about Cat FirstCut Cutting Edges, speak to your local Cat dealer or visit cat.com/cuttingedge-au to find out more.

• Up to 35 per cent* increased payload

• Up to 17 per cent* productivity improvement

• 2 x more wear life*.

The Finlease team breaks down some common myths around equipment finance, and how a skilled broker can help separate the fact from the fiction.

With over 30 years of experience financing both vehicles and equipment for a diverse range of clients in many industries, Finlease has the expertise to debunk some common misconceptions about equipment financing.

If you’re a solid company with good trading results, the interest rates available at present ranges from 7-8 per cent, depending on the asset and term. If you’re paying more than this, it may be a case of what your provider would like to charge you, as opposed to what is actually available in the market.

Although interest rates have essentially doubled in the past six months, the effect on the actual monthly payment for equipment and vehicle finance has been much less than for home loans.

We’ve seen circumstances where the interest rate quoted is not actually reflected in the monthly payment. The problem here is that unless you have a finance calculator to work it out, you’re none the wiser. There are plenty of online calculators where you can check –including one on the Finlease website.

Take heed – unless you actually check, there’s really no way of knowing, so it’s worth spending five minutes online to ensure you’re getting what you have been told.

There are plenty of competitive financiers who will finance used machines at good interest rates. Often, there are significant savings to be made by going down this track. Yes, there are extra steps in the finance process, including an inspection of the asset, but these are easily arranged. Care needs to be taken to ensure that the asset being purchased is not currently either under finance or under a GSA (fixed and floating charge). This is easily checked through a company search on the vendor.

That may be the case with your bank, but there’s plenty of other competitive financiers out there who will finance vehicles and equipment at good rates without the need for financials.

Where assets are being upgraded, there are ‘no financials’ policies that can finance replacement equipment up to $500,000.

We’ve heard plenty of times people saying: “I use my bank because brokers are more

expensive”. This is simply not the case and easily tested by obtaining finance quotes so you can compare the monthly finance costs. Larger broking firms place large volumes to market ($900 million per annum in our case), driving substantial discounts.

Any decent broker should be looking for a 20-year relationship and will act in a manner to ensure that. Brokers should have plenty of feedback from clients on independent review websites, such as Product Review and Google.

Money is a raw material, no different to fuel. It must be accessed in the easiest, cheapest manner, backed by good service. In a world where margins are tight, it’s more about the leftover than the turnover, so it’s essential to keep all costs under control – including finance costs.

A good equipment finance broker will gladly help give you clarity around the options available to your business.

At Finlease, we pride ourselves on taking the BS out of equipment finance to ensure you talk to an expert who has your best interests front of mind.

For more information, visit: www.finlease.com.au

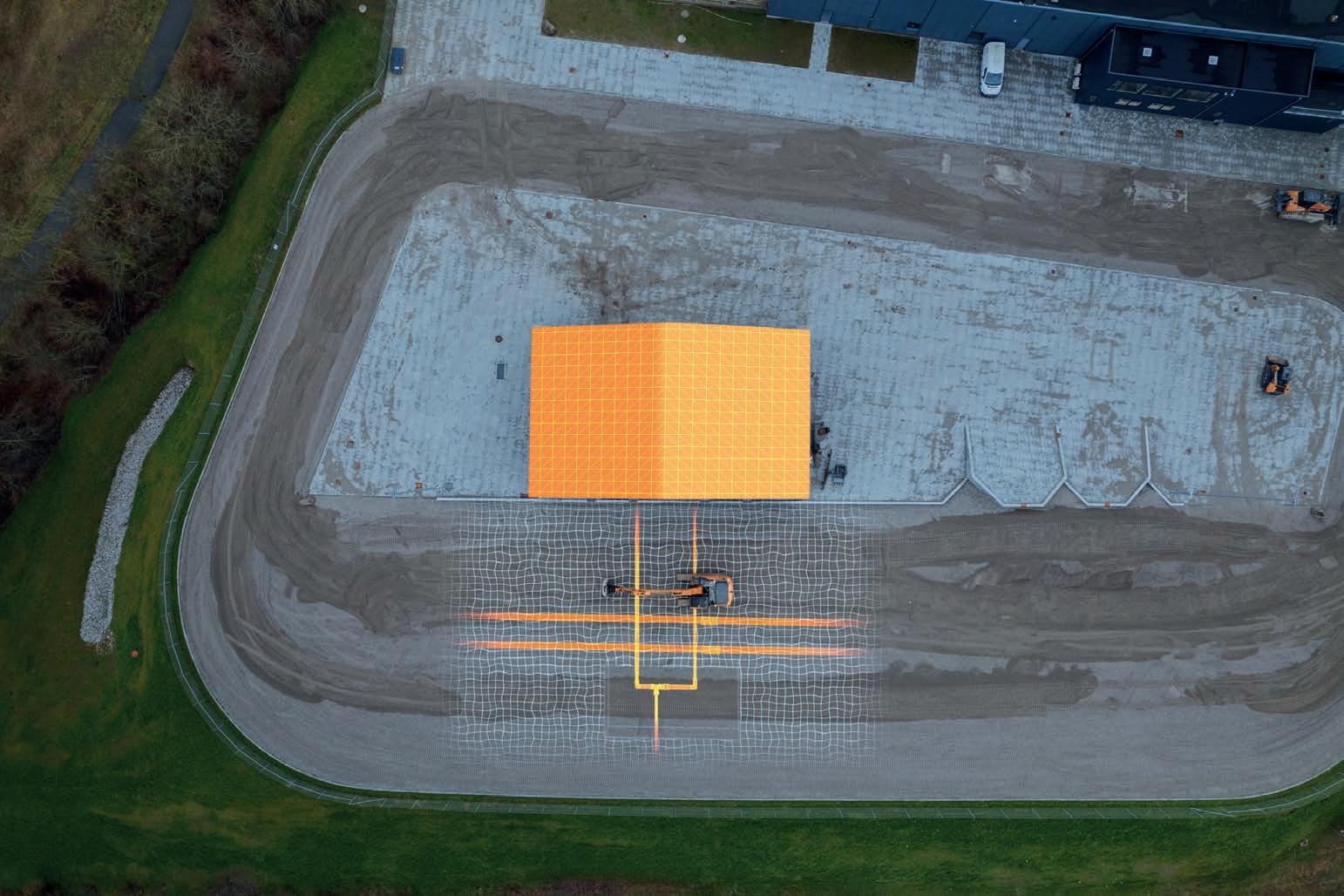

Leica Geosystems and Xwatch Safety Solutions team up to bolster jobsite safety. The novel integration interconnects excavator height control, slew control, and safety awareness in a promising stride towards reducing heavy construction incidents.

With every passing year there are more demands – from workers, company boards, and governments – to improve safety on worksites. So, it’s no surprise that Leica Geosystems, a Hexagon subsidiary, and UKbased manufacturer Xwatch Safety Solutions Ltd., are joining forces to redefine construction site safety.

This collaboration marks an important stride in transforming the hazardous realm of heavy construction, an industry that consistently records high rates of severe injuries and fatalities globally.

The partnership's driving force is to interconnect Leica's advanced 2D and 3D machine control and safety awareness solutions with Xwatch's cutting-edge excavator machine control technology. Bridging these technologies aims to enhance safety for all jobsite personnel, whether they're operating heavy equipment or working around it.

Harnessing years of experience and outsidethe-box thinking, Xwatch is taking a fresh approach to worksite safety solutions with its XW series safety system, which features:

• Height control

• Slew control

• Rated Capacity Indication (RCI).

All of these are aimed at monitoring and accurately restricting excavator movement using ‘feather touch’ proportional hydraulic control.

“The integration of our XW series directly into Leica Geosystems MC1 ecosystem is a global first and a true revolution in safety,” says Dan Leaney, Director of Sales and Operation at Xwatch.

The combined technology offers a costeffective solution, incorporating state-of-the-art hardware technology from the automation sector.

Brad Mullis, Leica Geosystems’ Product

Manager for Safety Awareness Solutions, shares in this enthusiasm, highlighting the importance of protecting assets, infrastructure, and – most significantly – human lives.

“Through the integration of our Leica PA80 with Xwatch XW series, we aim to provide solutions that protect assets and infrastructure – but most importantly ensure people always get home safely to see their families after a hard day’s work,” Brad says.

One of the key features of the partnership is the integration of the Leica iCON PA80 and Xwatch XW series into the popular Leica MC1 machine control platform. This move makes it possible for users to run a new safety

awareness solution directly on their existing machine control system. The safety awareness solution can be applied to a range of heavy equipment, from dozers to excavators, that use the Leica MC1 system.

“With the integration of Xwatch into Leica MC1, we are now not only able to alert the operator but are able to proportionally slow down and stop a machine when a wearable device is detected in a configurable zone,” Brad says.

“In addition, by leveraging the Leica ConX cloud solution, comprehensive logs can be downloaded and distributed for analytics within contractors’ existing management processes.”

Furthering this commitment to safety, Dan

says Xwatch has also integrated the Leica PA80 personal alert solution into its controller. “This takes safety to a whole new level,” he says. “The wearable device worn by the field personnel can link with all machines on site creating greater awareness and a much safer working environment.”

Plantforce Digital Manager, Dale Hawkins, represents a growing number of contractors already making use of both technologies. He expresses the company's pride in being the first plant hire company in the UK to use the Leica Geosystem fitted semi-automatic excavator.

“At Plantforce we pride ourselves as being innovators in our field,” Dale says. “This combined safety solution with a reliable, easy-to-use system and an excellent aftersales service is why we have the confidence in Xwatch and Leica Geosystems products to enhance our commitment to safety.”

With this partnership, Leica Geosystems and Xwatch are leading the charge in changing the face of safety in construction. This groundbreaking integration of technologies represents a major stride towards a safer working

environment and promises to be a gamechanger for the earthmoving industry.

Your local Leica dealer Leica Geosystems products are solely distributed in Australia through machine control and positioning specialists C.R. Kennedy.

Based in Port Melbourne, C.R. Kennedy has a national network of more than 260 staff across branches in Melbourne, Brisbane, Adelaide, Sydney, Hobart, Perth, and Cairns.

For more information, visit: www.survey.crkennedy.com.au

At just 1,720mm, the new 245XR has a 40% shorter tailswing than the conventional 220X, making it ideal for work in confined urban sites and highways. Despite having reduced tail swing, the 245XR still boasts one of the biggest, most comfortable, quiet and easy to operate cabs on the market, while our proven Tier 4 Final DIESELMAX engine and selectable swing smoothing as standard provide optimum performance in any application.

The NTI team explains why consolidating insurance is a simple way to avoid many business and financial complexities.

Taking out broad coverage with one insurer is the best way to get your claims paid out quickly, without arguments about policies, disputes between insurers, or long delays.

NTI’s solution is called Transport Pack. Transport Pack rolls up to three policies into one, provides market-leading cover and is backed by NTI’s expert team to ensure your claims are resolved quickly.

Consider the following scenario: a driver or unloader deposits powdered concrete into the wrong silo at the receiver’s yard.

There are three potential losses: damage to the unloaded products, damage to any product already in the silo and the cost of repairing or rebuilding the silo. It’s a single incident, yet each loss could be covered by a different policy type or under a Transport Pack policy:

“We’ve seen these kinds of circumstances many times,” says Alex Sawtell, NTI’s National Liability Product Manager. “Different insurers administer cover for liability around loading and unloading goods from a vehicle differently.

“Some people put it under a motor liability component – as we do at NTI. Others may put it under a public liability cover instead.

“If you take the wrong combination of policies, you might find you have no loading and unloading cover at all, which is a significant exposure.

“It’s important to ensure those kinds of gaps are covered. Our Transport Pack policy can protect operators against all these incidents if all sections are selected. They’re designed to ‘dovetail’, so there’s continuity of cover.”

Another example of a potentially complex claim is when a piece of plant equipment, like a skid steer or an excavator, is driven on the road and hits another vehicle.

“If it’s registered and allowed to be driven on the road, there’s a lot of nuance to it,” Alex says. “If it’s being used to dig, scrape or lift –whatever its intended purpose is – then it’s no longer a Motor Section 2 liability; it becomes a public liability claim.”

But claims can be thorny, as Alex explains: “If there’s an issue around crossing an active roadway and you cause some property damage, there could be a fight between your liability insurer and your motor insurer as to who responds.”

Bundling your insurance with a single provider is a simple way to avoid many complexities.

“With Transport Pack, if you have liability and motor/plant cover together, it doesn’t matter when you cross the verge onto the

road and start driving or stop driving and start digging,” Alex says.

“You’ll have a seamless cover designed to give you end-to-end protection against a property damage event that could arise.”

While he recognises cost is a factor in insurance buyers’ decision-making, Alex stresses the importance of considering the overall coverage provided and ensuring customers are fully protected instead of using multiple insurers solely based on price.

“As an industry, we want to ensure customers are informed and able to make decisions to ensure they are fully covered,” he says.

“Looking at the loading and unloading example again, say the motor and public liability policies were with different companies.

“There could be argy-bargy between the two insurers on trying to split costs and trying to determine who owned the liability. All that does is cause consternation and delay in handling the claim.

“Whereas if they’re all with us, not only are you minimising those gaps, you’re also putting us in a position where we can say, ‘The correct home is here’. We’ll quickly and easily determine that for you.

“Then we’ll ensure the claim is paid efficiently and there are no problems down the track because another party thinks they do or don’t have an obligation under the claim

or try to recover money.

“I think there’s a lot of value in that.”

Another area of potential conflict is clean-up after a crash. If policies are held with different insurers, they must decide who’s liable for the clean-up and organise a crew to attend and remediate the site.

“There’s potentially an obligation on the tow operator or whoever has come to the accident scene to clean it up and remove whatever’s there,” Alex says.

“But then again, you might get stuck with the bill or have to put a surety down until your cargo insurer comes to the party.

“But for the accident clean-up teams who work on our behalf, as soon as they hear it’s an NTI job, they know they’re going to get sorted out, they’re happy to do the job, and it removes some of the stress from the client.”

With a national network of repairers, tow operators, clean-up crews and other specialists, an expert in-house claims team, and some of the best policy wordings in the business, NTI’s Transport Pack offering is hard to beat.

“Our wordings are well-known, wellregarded and tend to have the broadest cover,” Alex says. “They also tend to have lots of additional benefits that are greater than, or don’t even exist in, our competitors’ products.

“Ultimately, it means NTI can get you back to business and back on the road sooner. And isn’t that what insurance is all about?”

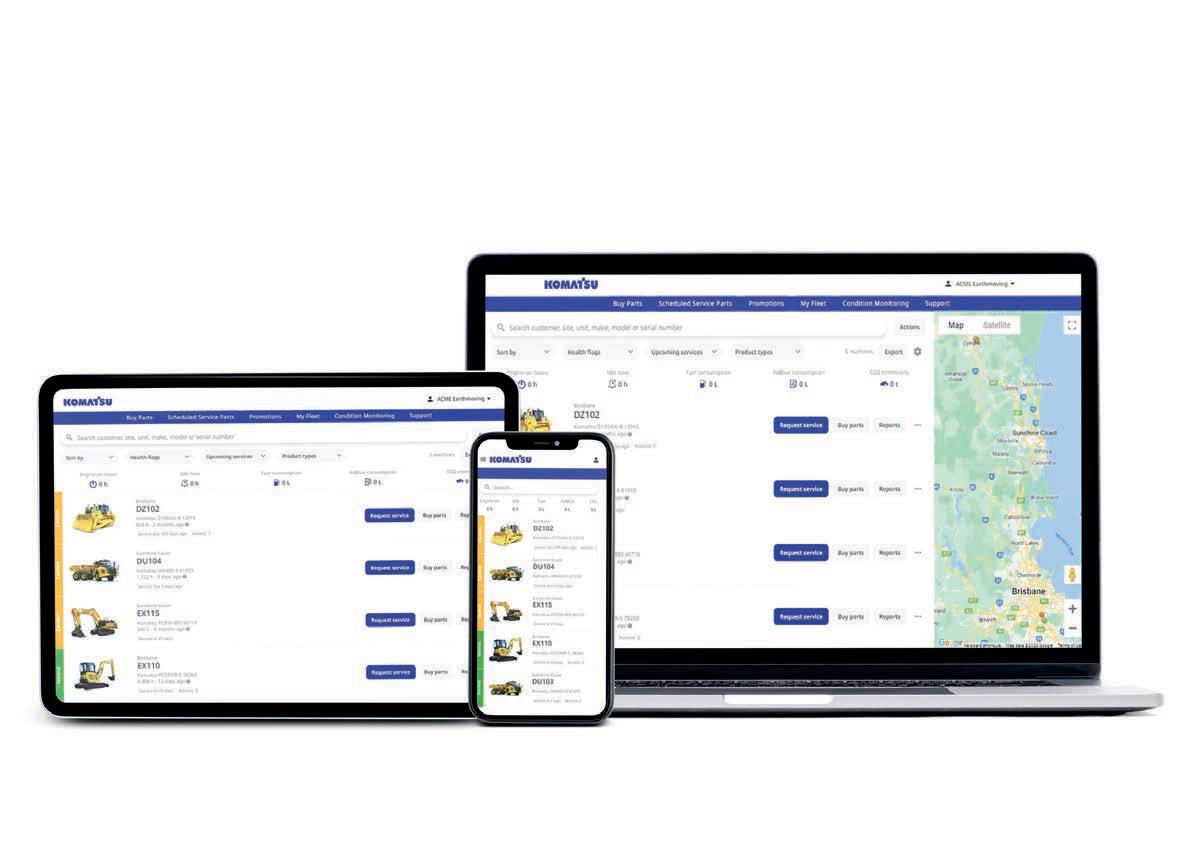

very best contractors – the most successful ones – are extremely good at managing their logistics, enabling them to reduce their costs. Once it was all about the machines, but we are increasingly seeing a demand from customers for insights from telematics and data.

This is where VisionLink is so useful. Whether it’s helping contractors to manage their workflow, schedule maintenance or assign tasks – you name it, VisionLink is ready for it. Importantly, VisionLink was developed in close consultation with dealers and customers, and feedback was incorporated every step of the way.

your business with the integrated full-fleet management solution you’ve been looking for. The platform’s new, intuitive interface will help you manage your entire fleet efficiently, regardless of manufacturer. Whether your equipment is owned, leased, or rented, you’ll now have access to data to make better informed asset management decisions.

No matter how big or small your fleet, VisionLink® provides your business with the insights it needs to take action. Its updated interface reduces complexity and provides the right combination of features, so you can improve fuel efficiency, reduce idle time, and keep machines healthy, all leading to greater profitability. Better still, it’s available for mixed fleet management. Read on and you’ll discover from both experts and customers how VisionLink puts the power of knowledge in your hands.

Over time, Caterpillar customers have become increasingly technology savvy. Business is moving too quickly for you to afford to be left behind, and our customers understand that the key to better management of operations is having access to more insights. Indeed, the

“Before VisionLink, our equipment management was very reactive. VisionLink has really improved our maintenance program, reduced planned downtime, and maximised efficiency.”

USA.

“VisionLink has allowed us to expand our company and grow our fleet. We’re able to see fuel usage, idle time versus working time, what equipment is being utilised the way we designed it, and what is being underutilised.”

The number one request we received time and again was to make this new interface more intuitive and easier to use. We recognise that when you’re on the jobsite, you are focused on getting the job done safely – on time and on budget. You need to have complete confidence that the data you’re receiving is one hundred per cent right. This is never more important than when bidding for jobs. Being accurate is the “secret sauce”, especially when overquoting can lose you a job and underquoting can cost you the shirt off your back. The beauty of VisionLink is that it makes all the data from previous jobs available for the next, allowing you to learn as you go.

We appreciate that technology adoption is a journey. That’s why we’ve packaged VisionLink to grow as you do. Our advice is to start training your people now because we’re only getting started. With VisionLink, the sky is the limit.

Asset tracking? Maximising machine uptime? Optimising utilisation? New VisionLink provides

VisionLink is cloud-based, making it accessible from your desktop, tablet, and mobile device. It allows users to stay up to date on key metrics, such as asset location, fuel level, idle time, and more. Easy-to-use dashboards allow for asset management by groups and geofences. Plus, by defining access levels for personnel, you get to decide who can and cannot edit settings and configurations. That way, customised reports can be generated and sorted automatically to facilitate tasks such as identifying underutilised equipment.

VisionLink also consolidates my.cat.com, the Cat® app, and the previous version of VisionLink applications into one centralised solution for easy fleet management. It also offers streamlined subscription levels designed to reduce complexity and provide the right combination of features for businesses of any size.

VisionLink continues to offer core telematics data standard with every machine to answer important questions about assets. That includes daily machine location, utilisation, fuel usage, maintenance reminders and integration with Caterpillar’s extensive digital ecosystem. Bring the power of knowledge to your business. To find out more visit www.cat.com/visionlink or contact your local Cat dealer.

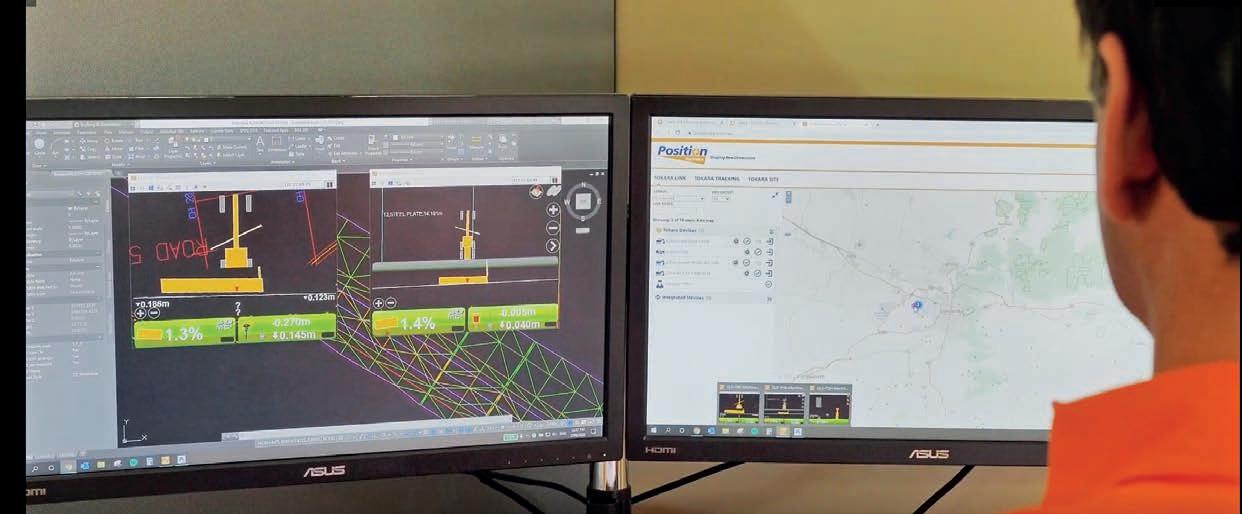

We’re experts in connected, supported solutions across mixed fleet.

• Topcon technology for every machine

• Tokara remote management for every asset

• Position Partners support for every project

If it’s got a cutting edge, we can measure it.

Australian Earth Training’s Scott Lidster takes a closer look at the WesTrac Institute’s post trade training offering.

In this month’s edition of Industry Training, I thought I’d move out of the dirt and into the workshop to shine a light on the people who keep our diesel mechanics on top of their game and across the rapid advancements of our machine’s engines, systems, and components –post trade trainers!

Believe it or not, once an individual has completed their chosen apprenticeship, the training does not stop. It’s just the beginning.

To gain more insight into post trade training, I reached out to the great folk at WesTrac, the Cat® dealer for NSW, ACT, and WA. They put me in contact with their Post Trade Trainer James Peters at the WesTrac Institute to gain a greater understanding of what underpins his skills and knowledge and to look behind the scenes of a typical day.

James started his apprenticeship in the mining industry 20 odd years ago in the Hunter Valley. After completing his apprenticeship, he did his time with various contractors before landing a full-time position at a coal mine. It was there that James was given the opportunity to become a crew trainer, a role he quickly realised he had a knack for.

As it tends to happen, a pathway started to present itself for James. He enjoyed what he did, being a mechanic, but he also genuinely enjoyed imparting his knowledge onto others.

That set him on the path to gaining his Certificate IV in Training and Assessment (TAE40116) and seeking out casual work at a local Registered Training Organisation (RTO),

where he honed his craft and embraced the challenge of teaching people new skills. Each class, like each learner, had its own unique challenges and learning styles.

James told us he was stoked to have landed a role with WesTrac about one year ago. He now gets to combine his passion for training and learning with new technology. Not to mention, he gets paid to talk as well as meet new people – tick!

A typical training day involves James coming in early to set up his classroom, reviewing the training material, and double checking his audiovisual equipment before the students arrive. At the start of the course, he does a brief introduction where he asks what his students would like to take away from the course and outlines the structure of the day.

Like any good trainer – and after attending enough dull training sessions himself – James puts himself in his students’ shoes by realising the importance of keeping his classes fluid and interactive, limiting “death by PowerPoint” as best he can. His classes are like a big discussion where learners are encouraged to share their experiences and knowledge.

After completing the theory component, he’ll then take his class out to the onsite WesTrac workshop where they get hands on experience in a practical environment, applying what they’ve just learned.

James says the most rewarding part of his role is seeing the students leave happy, having gained new knowledge from the course. He

also hopes to have made a meaningful impact on their career development.

The WesTrac Institute is an RTO offering nationally recognised training packages for apprenticeships alongside short industry courses and safety and equipment operator training.

The institute’s focus is on ensuring customers are ahead of the curve regarding new developments with Cat equipment, and providing course participants with the skills and knowledge to service, repair, and diagnose mobile equipment and systems.

The WesTrac Institute offers a large range of post trade courses and can develop custom options to meet customer needs. Some of their most popular courses include:

• Applied Failure Analysis 1 & 2

• Hydraulics (Basic to Advanced)

• Engines (Basic to Advanced)

• Transmissions (Basic to Advanced)

• Electronic Technician (ET) Sensors & Schematics

• Scheduled Oil Sampling (SOS)

• Emission Control Systems (Tier IV)

• Air Conditioning

• Electrical Systems

• Machine Electronics

• Fuel Systems.

If you’d like to learn more about WesTrac Institute’s courses, visit: www.westrac.com.au/training/courses

OTR Australia supply earthmover, agricultural, truck, bus and light vehicle tyres and rims from 6” through to 63” in diameter, to blue chip mining, civil contracting, road transport companies, agricultural dealerships and end users.

We maintain a healthy inventory of new and used earthmover tyres of critical sizes and have the ability to custom manufacture Australian Made wheels in 1 of our 10 locations Australia wide.

SALES PHONE 1300 791 672

For any enquiries please visit www.otraustralia.com

Are you wondering how best to harness your personal LinkedIn profile to support your brand or business? The Hardman Communications team talks us through five key tips for social media success.

We all know how powerful LinkedIn can be to enhance your professional brand, expand your network, and support your business goals. By strategically leveraging your individual LinkedIn profile, you can also position yourself as an asset to your organisation, attract business opportunities, and foster meaningful connections.

But where do you start? Below we share five ways to effectively leverage your personal LinkedIn profile to support your business objectives and drive success.

1. Craft a compelling personal brand

Take the time to optimise your profile by creating a professional headline that showcases your expertise and aligns with your professional goals. The headline should be a captivating summary that highlights your skills, accomplishments, and a unique selling point in 220 characters or less.

Don’t forget to include a quality headshot that reflects who you are and portrays you best in a professional sense.

2. Showcase your professional achievements

Your LinkedIn profile is an opportunity to highlight your professional accomplishments and demonstrate your credibility. Use the experience section to showcase your career progression, milestones, and responsibilities. Sell yourself by including metrics, project successes, and include portfolio samples where you can.

3. Cultivate strategic connections

It’s called a LinkedIn network for a reason. Make it a rule of thumb to add all professionals

you connect with, whether it’s colleagues, industry influencers, potential clients, or thought leaders relevant to your industry. Add a personal note to all connection requests and engage in meaningful conversations to foster those relationships.

4. Engage and contribute meaningfully You’ve built a LinkedIn network, so make sure you keep them engaged and show you’re active. Share industry insights, thought leadership articles, and relevant news updates to position yourself as a knowledgeable professional with your finger on the pulse. Regularly engage with others’ content by commenting, liking, and sharing too.

5. Influence with longform content

LinkedIn articles allow 120,000 characters

– compared to a post that is limited to 1300. Articles provide the opportunity to establish yourself as a thought leader, reach a wide audience, and build personal branding. Regularly share articles that are relevant to your industry, and offer valuable insights, actionable tips, and thought-provoking perspectives that will position yourself as that go-to person for insights, attract connections, and unlock new opportunities – whether that be for business or personal growth.

Your LinkedIn profile holds so much potential to support not only your personal goals, but your business goals as well. Don’t neglect it –keep your profile fresh, your network engaged, and you’ll see the difference.

Need help updating your LinkedIn profile? Let us know at hello@hc.net.au

A LEGACY THAT WORKS. FIND A

When it comes to wheel loaders, trust the LiuGong expertise. With 60 years of experience in making wheel loaders, LiuGong prides itself on reliability and durability. Get your projects done on time and on budget with LiuGong’s top selling line of wheel loaders.

The relationship between Sydney’s Sitex Rentals and STM Trucks & Machinery stretches back more than three decades. EEM chats to Sitex Director Jon Arnot to learn how the businesses continue to help each other grow and thrive.

These days, you’d be hard pressed to drive past any major civil works site in the greater Sydney area without catching a glimpse of a Sitex Rentals logo emblazoned across the boom of an excavator or the body of a dump truck.

And for a business that started in 1997 with just five machines, that’s evidence of something done right.

Now one of Sydney and the South Coast’s largest excavator hire companies, and with more than 500 pieces of equipment in regular operation throughout New South Wales, Sitex has well and truly ingrained itself into the fabric of the state’s construction sector. From government road, rail, and utilities projects to commercial housing, the business has become one of the go-to heavy machinery rental businesses for tier one contractors across the state.

For Director Jon Arnot, this is the reward for a business built on dedication to customers, and on being well attuned to the industry it serves.

“We’ve always aimed to go slowly with the flow, and build the business up as we go. And while you do have to change and evolve on the fly, it’s also important to have a three-tofive-year vision ahead of you. You need to understand market trends and be prepared for changes, but also be patient and not rush into anything – it’s about finding that equilibrium.”

But for Jon, one key element that will never change is a simple one: doing the right thing by customers. And it’s right there in the Sitex company motto: “the answer is always yes”.

“That attitude is embedded into the whole staff,” he says. “From account managers to administration staff to the mechanics to the painter. It gives customers the confidence to

keep coming back to Sitex.”

And when your customer base is made up of busy tier one contractors working on some of the country’s biggest and most complex projects, this means providing reliable machinery that’s ready at the drop of a hat.

“Whether its excavators, dump trucks, rollers, or track loaders, we supply plant that’s ready to go straight to work on site the moment it’s delivered,” Jon says. “All safety paperwork is completed by our internal compliance officers at Sitex. So, when a machine arrives, there’s no delay in getting it up to spec – the paperwork is done and dusted, and it can just start digging.

“There’s nothing worse than paying to hire a machine for a day, only to have it sit in a compound for four hours while it gets inducted. That’s why we do all that internally before a machine goes out the gate.”

Sitex’s commitment to keeping its finger on the industry’s pulse has recently seen the business take delivery of several new 35-tonne and 38-tonne Kobelco excavators – machines Jon says are on the larger side of Sitex’s typical offering.

“A lot of the major projects in NSW at the moment are demanding larger machines, where we’ve typically specialised in the lower-tomedium side,” he says. “But increasingly, we’ve had to have more of these larger machines to help our customers and support their growth.”

Jon says that whenever Sitex is in the market for any new Kobelco gear, there’s one dealer that will be receiving that call: STM Trucks & Machinery.

“We’ve been buying Kobelcos ever since STM became their NSW dealer – about 15 years ago,” he says. “But my family and I have had a longterm relationship with STM founder Michael Gerace and his team, going right back to when I was a boy.”

The Sitex fleet now includes around 100 Kobelco excavators, ranging from 1-tonne to 50-tonne machines.

“We use Kobelco excavators for two main reasons,” Jon says. “Firstly, they offer great reliability, efficiency, and value for money. Secondly, because of our long-term relationship with STM.

“They make any purchase very easy, and they’re very willing and flexible. They’ll go over and about for you, whether you’ve got 10 machines or 100.

“That’s key for any company buying earthmoving machines – you’ve got to have that confidence in your dealer. And of course, you’ve got to have the backup support.

“It’s not just about taking the order – STM will look after you the whole way through the journey.”

(L-R) Ryan Brown, Sitex; Jon Artnot, Sitex; Mark Morris, STM; Jon Deayton, Sitex. Jon says Sitex's 12-tonne D'Avino dumpers are easily transportable. The latest additions to STM's Kobelco excavator fleet.For Sitex and STM, that journey is one with no end in sight.

“We rotate our machines frequently,” Jon says. “We’re always refreshing our fleet, and we always go back to Kobelco and STM. We’ve had a lot of other dealers and suppliers knocking on our door – and while it’s good to have a bit of a mix of machines and brands to offer clients, 90 per cent of our excavator fleet is Kobelco.”

Despite the size of this Kobelco fleet, Jon says Sitex’s parts turnover and warranty claims are kept to a minimum.

“As a hire company, we understand everyone’s human,” he says. “Everyone knows that when you hire a machine, the care factor is a little bit less than if they owned it.

“But the Kobelcos are able to withstand the harsh treatment of the rental industry, which is a huge compliment to the machines.”

Thanks to STM, Sitex has also recently added D’Avino dumpers to its fleet, which Jon says have become a bit of a hit with customers.

“We have the little 7-tonne front tip dumpers, as well as 12-tonne dumpers,” he says. “They are proving to be very good in the industry.

“D’Avino as a brand is breaking new ground in the Australian market, and some of our clients were initially a bit sceptical about hiring them. But since we’ve had the four 12-tonners in the fleet, we almost never see them – so that says something. Our customers have said they’ve been reliable and extremely versatile.

“Transportation-wise, they’re not oversized either – they’ll fit on a tilt tray, which is very handy.”

Jon says the decision to take a punt on D’Avino – a lesser-known brand in Australia – wasn’t made lightly. But the Sitex team’s relationship with STM played a big part.

“Our trust in STM was about 80 per cent of the reason, because we knew we’d have their backup support and service,” he says. “And the rest is the fact that D’Avinos are Italian-made machines, and you always get good quality coming out of Italy. With those two factors combined, we figured we’d have a recipe for success.”

Jon says this is also indicative of one of STM’s strongest attributes: that the team can be trusted to do the research and the legwork necessary before engaging with a new brand.

“They won’t just take something on for

purely monetary reasons,” Jon says. “They’re not going to put their name to a product that’s not suited to the Australian market.

“They’ll look five to 10 years into the future. Whether it’s a European, Chinese, or Japanese machine, STM will look deeper to find out what kind of backup support they’re going to get from the manufacturer before they take the dealership on.”

For Jon, this dedication is all part of why Sitex and STM have enjoyed such a mutually rewarding relationship.

“Having STM partner with us along the way from day one has been an integral part of Sitex’s growth,” he says. “Without that support from all areas and departments of their business, we probably wouldn’t be where we are today.”

For almost half a century, STM has made it possible for businesses across NSW to power up – supplying and servicing quality trucks and machinery to meet the demands of any job.

Starting out in a single shed in the 1970s, we know what it takes to build a business – and are passionate about helping you grow yours. Today, our family owned and operated enterprise is proud to offer a multi-site, modern service, with a team of more than 120. We care about giving every customer the best experience possible – with a wide range of trusted brands, flexible finance, spare parts, repairs and personal service.

We may have come a long way from that shed, but our family commitment to quality remains. Whatever your size, whatever your budget, STM is your one stop shop – with everything to keep your business moving.

Allied Equipment Sales draws on more than four decades of expertise to supply reliable used earthmoving equipment to Australian construction, mining, and quarrying catches up with Director Mitchell Smith to learn more.

Mitchell says Allied Equipment Sales focuses on a handful of trusted brands, including Caterpillar, Komatsu, Hitachi, John Deere, and Volvo.

“Our biggest movers are Cat wheel loaders from 966s through to 988Ks, Cat dozers – D8s through to D10s, as well as motor graders, skid steers, and telehandlers,” he says.

“We like to carry quite a broad range – it’s about being able to have a variety of options for our customers.”

Drawing from a combined 100+ years of industry experience, Allied Equipment Sales has become a trusted name in used equipment – at first in its hometown of Perth, and now increasingly across the country.

“My father’s had control of the business since 1990,” Mitchell says. “And I joined the company myself in 2014 after working in the field as a diesel fitter for 10 years.”

Working his way up from operations to sales in another part of the business, Mitchell then shifted to retail sales with Allied Equipment Sales. From here, he grew with the business,

moving into international purchasing, and eventually the role of Director.

Mitchell has continued to help facilitate the growth and reach of the business, from WA to the east coast, and beyond.

“The east coast has continued to be a large growth region for us,” he says. “We’ve seen our Penrith branch grow to the point where it’s now making up well over a third of our total revenue in sales.

“We’re now looking to continue expanding in NSW to enable us to provide the kind of service offering that we do in Perth. We’re investing into our property there with workshop facilities so we can provide customised spec build-ups, equipment repairs, and reconditioning.”

This side of Allied Equipment Sales’ operation has previously only been available to customers at its Perth branch. But Mitchell says with so many of the business’ blue-chip clients operating nationally, customers have come to expect the same level and availability of service from coast to coast.

“Growing our NSW facility is a big focus for us right now,” he says. “We’ve recently appointed

a very talented young man out of the industry to assist managing this location, and he’ll be tasked with helping us grow that service segment on the east coast as well.”

All about the people

Mitchell attributes Allied Equipment Sales’ steady growth to its people-first approach, combined with its strong family business roots.

“Our business is built on people and their relationships with suppliers and clients,” he says. “So, we want to bring in the right people who are willing and keen to grow with the business, and be mentored by some of our senior staff – some of whom have been in the industry for more than 40 years.

“We want to help people grow their careers, while also providing that flexibility that a family business can. Here, they’ve got trusted relationships with the senior people in the business, as well as the board.”

Additionally, Mitchell says having senior staff sitting in on board meetings helps ensure everyone has a deeper understanding of the business, where it can improve, and where the next potential growth areas are.

“We try to understand everyone’s perspective, because people all have different views and different ideas,” he says. “And if you’re going to employ people and not listen to them – you’re asking for trouble, really.

“Our approach has always been to give our people a sense of ownership over what they do – and that’s been paying dividends for us.”

To learn more, or to explore the range of equipment currently available for purchase, visit: www.alliedequipmentsales.com.au

Dieci Australia’s brand-new flagship facility in Prestons, NSW, demonstrates a business ready to step into a new era. CEO Pat Italiano tells EEM what this means for the company, its dealers, and a steadily growing customer base.

This year, Italian equipment manufacturer Dieci is celebrating 25 years in the Australian market. And with Dieci Australia having just opened its new flagship facility in New South Wales, the milestone couldn’t have come at a better time.

“Compared to the rest of the world, Australia is a small market in the construction machinery space. So, for a business to be here for 25 years is something to be proud of,” says Dieci Australia CEO Pat Italiano.

Combined, he says, the milestone and the new facility in Prestons represents a step into a new era – one centred around a renewed focus on reliable service and backup support customers can trust.

When Pat and his team came on board in April 2019 – rebranding the business to Dieci Australia in the process – he understood the quality represented by Dieci’s range of Italian-