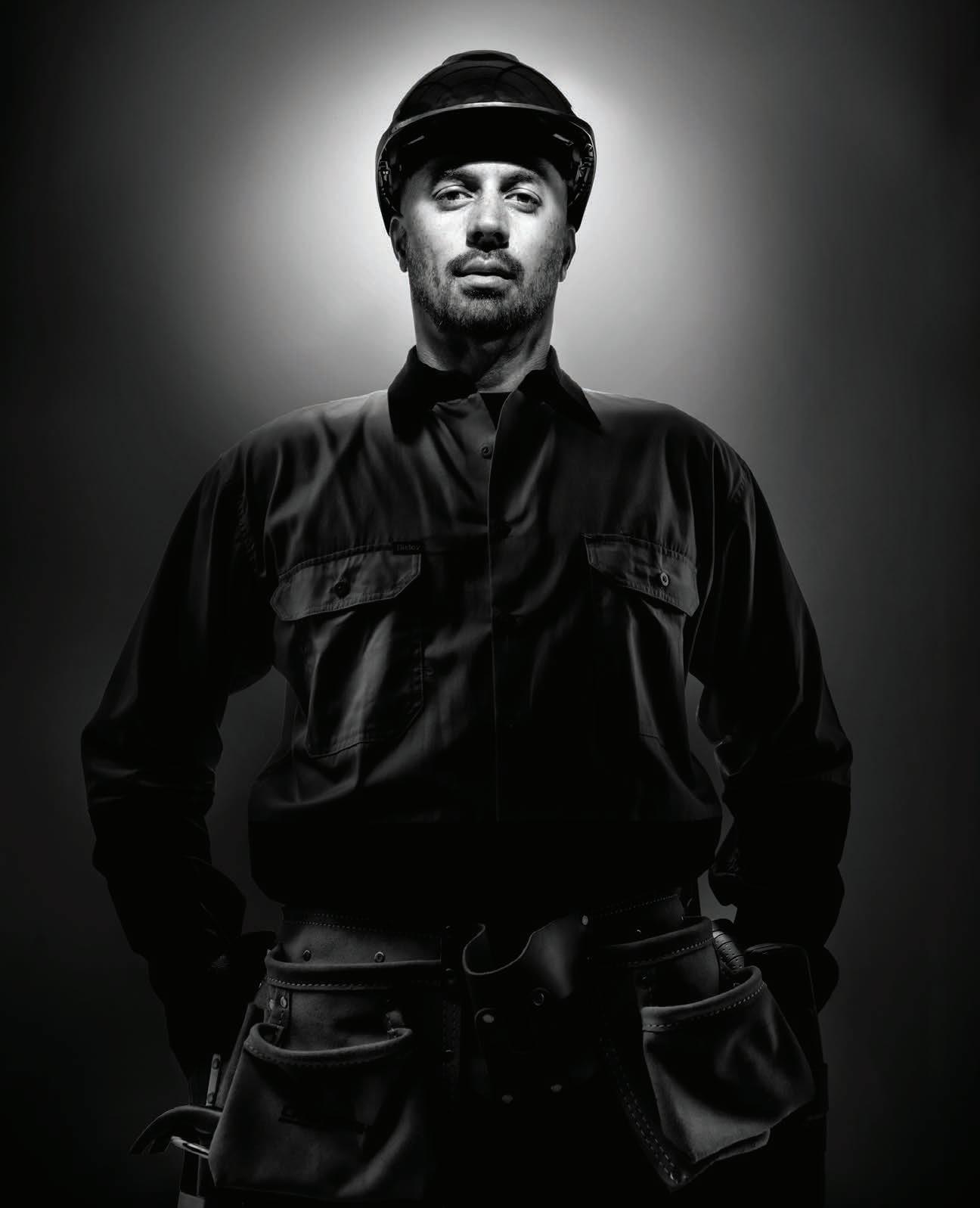

In this issue, FAE announces the release of three new shredders, RDO Equipment to relocate Toowoomba workshop, Volvo Construction Equipment invests in electric hauler range, Thwaites displays electric dumper, Position Partners awarded Rajant Kinetic Mesh premium partner status, Kennards Hire acquires Top End Access Hire, Trimble researches autonomous construction site technology, Engcon tiltrotator system made available for Doosan excavator, ASV unveils new mulcher range, Position Partners opens new Rockhampton branch, CIFA launches new electric cement pump, SA survey shows appetite for shorter work week , UNSW Sydney invents hybrid engine retrofit system , NSW government releases new construction industry Bills, NSW undertakes new pothole fixing trial , website launches to tackle workplace harrassment , wall-building trial utilises used construction machine tyres, TAFE Queensland awards recognise construction industry apprentices 6–14, 48–65

Batchfield Resources increases handling capabilities with a new Cat 994K from Hastings Deering

Ascot Demolition relies on crushing and screening equipment from MSC to handle the load

With a busy business handling large volumes of construction and earthmoving waste on the Gold Coast, JGI Quarry’s relationship with Porter Group ensures that its equipment is up to the task

FAE’s new RPL/SSL, RPM/SSL and RWM/ SSL shredders work with skid steers between 60 horsepower (45kW) and 120hp (89kW) and add further depth to FAE’s construction range.

The units are based on cold planer technology, FAE says, where the road’s surface is scraped and cut by the impact of special teeth that are attached to the rotor.

It also has a layout that is specifically designed to increase performance and reduce vibration.

The RPL/SSL and RPM/SSL models are primarily designed for surface preparation before resurfacing roads with new asphalt or concrete, or to simplify excavation operations.

The RWM/SSL model, equipped with a disc rotor, aims to ensure targeted

excavations for laying electrical, water, gas and fibre optic conduits.

Many of these uses will apply to farmers, in addition to the primary target market of construction workers.

The RPL/SSL works with 60–120hp skid steers, can mill up to seven inches (18cm) deep and is available in 45cm, 60cm and 75cm widths.

The RPM/SSL is designed for skid steers between 75–120hp, can work area up to 10 inches (25cm) deep and 24 inches (61cm) wide.

Both models have self-levelling skids and tilt to ensure optimal results, including on uneven surfaces.

They are designed for ‘plug and play’ pairing with leading skid steers and have a high-visibility design to ensure no visual interference from the cabin.

FAE’s other model – the RWM/SSL –is compatible with 75–120hp skid steers and can create channels up to 20 inches (51cm) deep and with modular widths of three, four or five inches (7.5–13cm).

The depth indicator allows precise depth management and self-levelling penetration skids allow the working depth to be kept constant.

It also has ‘plug and play’ compatibility with leading skid steers and include teeth specifically designed for concrete and asphalt road surfaces.

The manufacturer says the range will become available in 2023.

Construction on the new facility will commence by the end of the year, with completion expected by early 2024.

RDO Equipment, the distributor for brands such as John Deere and Vermeer, says the development is part of the company’s strategy to provide world-class

facilities across key regional locations, with Toowoomba earmarked as a pivotal location within regional southeast Queensland.

The dealership will hold a range of construction, agriculture, turf and utility equipment.

“We’re extremely excited to be building a new state-of-the-art workshop and dealership in this key distribution hub,” RDO Equipment chief executive Phil Canning says.

“Our new location in the Aatlis Precinct, with large, modern facilities and conveniently situated for surface and air transport, will place us in an optimal position to continue to offer our customers the service they need now and well into the future.”

The new building will also house support staff that are currently located away from the branch, with RDO Equipment saying around 50 of its employees are based in Toowoomba.

“We’re very pleased to have attracted such a significant national business like RDO Equipment,” FKG Group manager –development Jack Gardner says.

“This contributes to the creation of continued growth and job opportunities for the region.”

announces release of three new asphalt shreddersRDO Equipment is set to move its Toowoomba workshop to a new state-of-the-art facility The three new shredders will be available from next year An artist’s impression of the new RDO Equipment Toowoomba dealership to be based in the Aatlis Precinct, expected to be completed by early 2024 RELOCATION

Volvo Construction Equipment has announced that it will invest approximately A$50 million into its production facility in Braas, Sweden.

The investment will see the factory developed between now and 2027 in order to produce a larger range of articulated haulers with varying powertrain types to reflect the shift in demand towards more sustainable power sources for equipment.

Production capacity at the Braas plant will also be extended to broaden the range moving forward, with the addition of new buildings and equipment to the 45,000 square metre site.

Volvo CE says investment will be made in automation and ergonomics as well, to both reduce the need for employees to engage in repetitive tasks and create safe working environments.

The decision to invest in the Braas facility was made by Volvo’s board of directors and forms part of the company’s long-term focus in driving

industry transformation to combat climate change.

Volvo CE has built a prototype of the world’s first articulated hauler powered by hydrogen fuel cells – the Volvo HX04 – which Is the focus of testing at the moment.

Braas site manager Jonas Lakhall says the investment will benefit Volvo, its customers and the climate.

“The transport and construction industry is undergoing a transformation with, among other things, an increasing number of electrified vehicles,” Lakhall says.

“This investment will enable us to adapt and extend our production facility so that we can offer a broader range of machines – with different powertrains –to our customers and help them meet their emission reduction ambitions.”

DUMP TRUCK

UK manufacturer Thwaites showed off a new electric three-tonne dumper at bauma 2022

Thwaites displayed an advanced concept machine and says a version will be made available to the market in 2023.

Earthmoving Equipment Australia is the Australian distributor for the brand.

“As the demand for cleaner alternative fuel sources grows, we are keen to ensure we offer a quality product that delivers for our customers, their clients and the environment,” Thwaites general sales manager Andy Sabin says.

Four 5.75kWh lithium-ion (dry-cell) batteries, operating at 48V, are fitted.

The electric drive dumper has a similar unladen weight when compared to the diesel/hydrostatic version. The main battery pack and driveline components now sit low in the rear chassis, lowering the centre of gravity when compared to the hydrostatic drive machine, further improving machine stability.

Critically, the battery pack will complete a full eight-hour shift of normal site operation from a single charge.

The standard on-board 3.4kW battery charger can charge the pack fully in eight hours. Optional off-board chargers rated at 7kW (single-phase) and 22kW (threephase) have charge times of four hours and two hours respectively.

“Available for both the UK and export market, the machine will provide for the rental market, a cleaner, quieter, alternative, giving contractors options to use the machine in more urban refurbishment settings,” Sabin says.

“In addition, the new all-electric dumper is compliant with the growing number of authorities and bodies that operate low emission zones.”

Volvo CE is investing heavily in electric construction technologyVolvo Construction Equipment is focusing on expanding its electric hauler range ELECTRIFICATION

Position Partners has announced an upgrade to Premium Partner status by industrial mobile network communication provider Rajant. The agreement will see Position Partners continue to grow the reach of Rajant Kinetic Mesh solutions across Australia, New Zealand and Southeast Asia for mining and other industrial sectors.

“The Position Partners team has been highly engaged with Rajant solutions since joining the partner program in 2019, winning Fastest Growing New Partner at our Australian summit in 2021,” Rajant APAC sales director Troy McKay says.

“We’re delighted to announce their achievement of top tier distributor status and look forward to working together for the benefit of mining customers throughout the region.”

Position Partners has successfully deployed Rajant Kinetic Mesh solutions for customers in the Pilbara, Bowen Basin and Hunter Valley. With a commitment to providing reliable, fully mobile wireless communications in the most challenging industrial environments, Rajant Kinetic Mesh solutions are designed to meet requirements for mobility, speed, ruggedness and operational complexity.

“Rajant solutions are renowned for their reliability and ability to support the latest developments in Internet of Things, machine-to-machine communication and autonomy,” Position Partners’ mining business manager Andrew Granger says.

“We’re honoured to be awarded premium status for Rajant solutions. With our 350-strong team, diverse skill set to deploy a wide range of machine and operational technology platforms and backed by local Rajant experts Madison Technologies, we are well placed to support customers with any network requirements.”

This is the first Access-specific branch for Kennards Hire

An Australian family-owned and operated equipment hire company, Kennards Hire’s new branch will provide an extensive range of height and lift solutions equipment, ranging from forklifts to telehandlers. It is also home to the largest boom lift available in Australia.

“Kennards Hire is excited to be carrying on an already amazing legacy started in Darwin by Top End Access Hire,” Kennards Hire area manager Trent Torrens says.

“We’re lucky to have the experienced staff from their team join us to continue the great experience and service customers are used to.

“This is the first Access-specific branch for Kennards Hire and its specialised equipment range will cater to the growing infrastructure developments and needs in the Northern Territory.

“The availability of the 180ft Genie boom lift is industry-changing. We’re

confident this will be a very soughtafter piece of kit.”

Torrens, who has over 12 years of experience working with Kennards Hire and over 30 years within the hire industry joins the team alongside branch manager Lisa Bretherton, assistant branch manager Wally Drescher, mechanic Dave Whelan and drivers John Bretherton and Patrick Bretherton. The team is also lucky to have live-in mascot, Ava, a five-month-old Great Dane puppy, owned by Lisa Bretherton.

Having entered the Northern Territory market in 2011, the company’s latest acquisition expands Kennards Hire’s ever-growing network to five branches across the region and will support the growing population and construction activity anticipated over the coming years in the Top End.

The new branch is located at 898 Stuart Highway, Pinelands, Northern Territory, 0829.

Trimble and Exyn Technologies, a developer of autonomous robotics, have announced a collaboration to explore the use of autonomous construction surveying technology.

The solution will integrate Boston Dynamics’ Spot robot, the ExynPak powered by ExynAI and the Trimble X7 total station.

“The integration of autonomous surveying technology into a construction workflow has groundbreaking potential,” Trimble vice president of technology innovation Aviad Almagor says.

“It can improve operational efficiency and transparency throughout the build lifecycle while also transforming worker safety for potentially hazardous data collection.”

The robot can sense and avoid obstacles, with the ExynPak supporting level 4 autonomous exploration missions without requiring the robot to ‘learn’ about its environment beforehand. A surveyor simply defines a 3D volume for a mission and the integrated robotic solution handles the complexities of self-navigation without needing a map, GPS or wireless infrastructure.

The integration of the Trimble X7 provides high-speed, highaccuracy 3D laser scanning to capture the state of the environment. The captured data can be uploaded

to the Trimble Connect collaboration platform and shared as a map with project stakeholders for further analysis, including a comparison to Building Information Models and previous scans to monitor quality and progress.

In a separate collaboration, Trimble and printer manufacturer HP are integrating Trimble’s latest robotic total station with HP’s new SitePrint robotic layout solution to autonomously undertake the layout process for indoor construction projects.

The two companies say this autonomous solution will help address the shortage of skilled workers in the construction industry, delivering an autonomous layout workflow faster than

traditional methods. Augmenting the contractors’ work, SitePrint can avoid obstacles and print lines and complex objects with pinpoint accuracy and consistent repeatability. In addition, text printing capabilities bring additional data from the digital model to the construction site to prevent errors.

“The integration of Trimble Ri and HP SitePrint can transform the layout process on complex construction sites with pinpoint accuracy, and in a fraction of the time,” Almagor says.

“This is an opportunity for layout contractors to improve accuracy and productivity and handle more projects with the same size of team.”

HP vice president and general manager of large format printing Daniel Martínez adds: “Technology adoption and increased digitisation can help construction firms bridge this productivity gap.

“HP has played a key role in bridging digital and physical worlds with print solutions for architects and engineers over the last 30 years. With the integration between HP SitePrint and Trimble Ri, we can make it easier than ever for layout professionals to bring an idea to life on site, while also enabling increased digitisation of the construction industry as a whole.”

The Trimble and HP collaboration is looking to produce an autonomous solution for site layout

Engcon’s third generation tiltrotator system will be introduced in Doosan’s new DX225LC-7X excavator.

The DX225LC-7X was unveiled by Doosan in August of this year and is a fully-electric hydraulic excavator that features a factory provided 2D machine control and the latest technology from Doosan.

As part of the tech offering, the machine is also Engcon Ready, meaning it can easily be equipped with the MIG2 Grips and third generation control system DC3.

Engcon’s DC3 system and machine controllers interact via controller area network (CAN), which allows for data to be exchanged between the two systems at high speeds, meaning a deeply integrated solution is available to the operator.

Engcon control system product owner Fredrik Eklind says the collaborative system will result in higher productivity and flexibility for users.

“The deep integration allows Engcon and Doosan to create a better operator experience,” Eklind says.

“It allows the operator to get an overview and configure the functions of the MIG2 Grips directly in the Doosan machine display.

“The high accuracy Engcon rotation and tilt sensors are also directly integrated with the Doosan semi-automatic machine control solution, weighing and assist features without the need for a third-party sensor installed in the attachment, making it truly integrated with the machine.”

Stephanie Dieu from Doosan Europe’s excavator division says the manufacturer is glad to partner with Engcon and says it will lead to shortened lead times when in operation.

“With the technologies combined the customer can see both improved productivity and flexibility. Shortening lead times is something that both Engcon and Doosan have been working on over many years, and with the DX225LC-7X being Engcon Ready the upgrade is quicker than ever.”

ASV has unveiled its latest line up of high-performance mulchers

The updated mulchers, which were part of a larger line up announcement that also included snow attachments and a six-way dozer blade, were unveiled to the public at the Equip Exposition in Kentucky in October.

ASV says the mulchers are compatible with its Max-Series RT135F and RT75HD posi-track loaders but are able to be fitted on other major brands’ track loader models.

ASV attachments product manager Frank Gangi says the updated mulcher models are designed for year-round performance.

“These new attachments allow operators to seamlessly transition from dirt and landscaping work in the summer to snow clearing in the winter,” Gangi says.

“Our machines are designed for all seasons and conditions and that includes our attachments.”

The new mulcher attachments are offered in a standard drum or depth control series for both the RT-135F and RT-75HD.

The standard drum can be used

ASV’s new mulcher attachment range is suitable for all conditions

across most applications and features carbide teeth, while the drum’s heavyduty frame makes it the best option for operators requiring a versatile mulcher suitable for all conditions.

The depth control series is outfitted with knives that are better suited for fibrous vegetation applications. The depth control technology on these mulchers allows the machine to process the tough material in a single pass and create a consistent bite for a clean, finished look.

When used with the RT-135F and RT-75HD loaders, the new mulcher attachments help achieve maximum power and productivity, ASV says. The plug-and-play nature of the mulchers means they can be productive in applications such as forestry mulching, land clearing, trail development and right-of-way work.

A release date for the mulchers in Australia is not yet known.

Position Partners has opened a new branch in Rockhampton

The new base will support the building construction, civil, mining and survey sectors in the region with access to local sales and support.

Position Partners’ new Rockhampton facility follows the opening of another branch in Townsville in May this year. Together, the two branches have made a commitment to supporting customers throughout the state.

“Our customers are based and/ or win work throughout the state of Queensland, so we are committed to being there to support them whenever and wherever they need us to be,”

Position Partners Queensland regional manager Harry Katsanevas says.

“There’s a strong pipeline of work in the central and northern areas of the state, and with bases now in Brisbane, Townsville and Rockhampton we’re ready to help customers with leading technology backed by great service.”

Position Partners specialises in the distribution and support of positioning and machine control technology across the earthmoving, mining and civil construction sectors. Its systems help surveyors and engineers make more accurate designs.

David Irons, who has recently joined Position Partners and is based in Rockhampton, is optimistic about how fleet management systems, high precision machine guidance, Rajant Kinetic Mesh networks and other platforms and technology such as survey drones can be used in the region.

““I’m looking forward to growing the business in the local area – Position Partners has some unique and powerful and a large, experienced support and services team,” he says.

Concrete systems manufacturer CIFA showcased its new K42E truck pump at bauma, the latest in its fully electric range of concrete machines.

“The Energya brand has been a revolution for the sector ever since its launch in 2013, presaging such current concerns as the importance of electrification for sustainability, automation and connectivity,” CIFA CEO Davide Cipolla says.

“Indeed, these have become prerogatives for all CIFA machines – by using the digitisation of management systems and remote monitoring (CIFA Vista). We are proud to have been pioneers in a traditional sector such as the concrete industry, which is becoming aware of the need to change and adapt in an evolving global situation.

“The concrete sector has three approaches to achieve the objectives of the 2030 Agenda: the introduction of low-impact materials and processes, durability of the equipment and the reduction of CO2 emissions on site. CIFA has been on the right track for many years and has taken a further step forward with Energya K42E.”

Energya K42E is a powerful truck pump that can operate in full electric mode without compromising

performance. The boom extends for up to 42 metres and consists of five sections, with the last two made from carbon fibre to reduce the machine’s weight.

The K42E system uses a 30 Amp Hour cell battery pack to power two Rexroth electric motors, the first of which drives the hydraulic pump to move the boom and open the outriggers while the second drives the pumping unit (with a closed circuit and maximum capacity of 160 cubic metres/hour at 80 bar) and other services.

If the job requires higher performance than the batteries can provide, the new Energya pump can be connected directly to an electrical outlet on site. The system will then cut out the batteries and power the electric motors directly (a 40-metre power cable is included).

This means the system will continue to operate with the diesel engine of the truck switched off and therefore without emitting exhaust gas and noise. In the case of a complete lack of electrical sources, an emergency system allows you to connect the K42E to the truck’s power take-offs and therefore use the engine to complete the work and close the boom and outriggers.

Carved by a lifetime of hard work, Rokbak articulated haulers are built to perform. Day after day. Decade after decade. From the heat of the desert to the cold of the arctic, you can rely on Rokbak.

Contact your local dealer for more information.

Hydraulic Steels Australia already boasts the largest range of hydraulic steels in the country, but the grand opening of its new headquarters in Brisbane is set to catapult the business to even bigger heights.

While the new facility has been operating since late 2020, it was formally christened on October 14 this year, opening its doors to valued customers and business partners.

The company specialises in supplying the hydraulic cylinder repair and hydraulic cylinder manufacturing industries. Steels used are suitable for most types of hydraulic applications and are compatible with most original equipment manufacturer (OEM) machines in sectors including earthmoving, construction, mining and agriculture.

The new facility, located on Ashover Road, Rocklea, in Brisbane’s south, features over 4,000 square metres of warehousing, 12 bandsaws and, in founder and managing director Stephen Holt’s words: “15 of the most wonderful hardworking and resilient staff members.

“The move to Ashover Road was a real team shift but it has now become a large operation. And here we are today with operations both in Brisbane and Melbourne.

“It has certainly been a steep climb, but it has also been extremely rewarding.”

The warehouse at Hydraulic Steels features a large range of chrome

plated steel bars for the hydraulic sector, including medium to high tensile and induction hardened steel. A range of honed and unhoned cylinder tubes, CDS line tubes and special hydraulic steels are also available including a range of hollow bar, bright bar and 4140HT.

Hydraulic Steels is the exclusive distributor for Cromax bars and tubes in Australia and New Zealand, which are developed by European steel manufacturer Ovako.

The vision for Hydraulic Steels began in 2007 when Mr Holt – then working for a different local metals company – envisaged a landscape where a specialised company could offer chrome bar and precision

steel tubes businesses operating particularly with hydraulics.

“The response at the time was ‘why would you do that... that will make you go broke’,” he says.

But Mr Holt held to his beliefs, he and his wife Terea brought the dream to life after trading various steels in the early 2010s enough capital was raised for the idea of stocking chrome bar and chrome tubing, and it slowly began coming to fruition.

Hydraulic Steels’ formative years were confined to a corner of a warehouse belonging to another local business where Mr Holt stocked one rack of hardened chrome. While small in stature, the business began supplying local customers with specialised chrome bars for hydraulics.

The coming years saw Hydraulic Steels continue to grow, with more sizes in the stock range and an upgrade to its warehouse facility, which had moved to Randolph St in Rocklea. The facility featured 2,200 square metres of warehouse, four new bandsaws and a truck.

In 2019, the brand opened its first interstate facility, located in Dandenong South in Victoria.

A specialised warehousing system is helping Hydraulic Steels Australia provide top level service to its parts customersHydraulic Steels features Australia’s largest stock range of hydraulic steel bars Warehouse staff utilise Zebra scanner guns to locate and dispatch chrome bars quickly

“The goal was to service customers in the southern and western states of Australia quicker,” Mr Holt recalls.

To minimise time between receiving and shipping orders, Hydraulic Steels has developed a specialised system that underpins much of the business’ recent success.

The RTP system makes it easier for customers to order chrome, tube and special other hydraulic steels, and easier for the workforce at Hydraulic Steels to source, cut and ship orders as required.

To do so, Hydraulic Steels has partnered with transportation and logistics solutions specialist Zebra to implement a fleet of scanning guns used by staff in the warehouse. The guns are capable of scanning QR codes, which are added to each bar of steel that passes through the warehouse.

“If you scan the code, we can know every item that is in each particular location in the warehouse. Behind that though, there is a lot of information as well,” developer Jeremy Ferrett says.

“We can see the purchase order it came in on, the certificates that are

attached to it. You can also do a lot of inventory management with these devices as well.

“It’s a good way of being able to make sure that we keep track of stock, know exactly where it is, and contributes to being able to fulfill orders and get stock out the door quickly.”

The RTP system was developed after Mr Holt and Mr Ferrett discussed implementing better digitations methods for the company and optimise business turnaround.

“We wanted to work out how we would deliver customer outcomes that were fast, accurate and with all of the traceability information that was required,” Mr Ferrett says.

“To meet the requirements of quick dispatch and fulfilment of orders, you’ve got to know where things are. Each of the users out in the warehouse have their own individual ID cards and PIN numbers, so we also know who has executed each task.”

Hydraulic Steels general manager Brock Nason, who joined the business in March 2020 and oversees the day-to-day operations, says the RTP system has helped improved the speed

of order fulfillment.

“Improving our systems was a big focus for us – customer orders, purchasing, procurement, inventory, ordering, fulfilment, dispatch – and we want to provide real time feedback to our customers and give our team proper inventory data which they have access to,” Mr Nason says.

“We have the ability to access this data 24 hours a day because it’s a cloud-based system. If a customer has internet access and a phone or a tablet, we can take an order.

“I believe it’s lifting Hydraulic Steels to new heights with this technology. It’s customised to our requirements and it’s an advantage over our competitors.”

As the business heads into the future, Mr Ferrett outlined greater business-to-business integration through a customer portal and a more streamlined supplier integration portal as two ways forward.

For more information on the range of chrome bars and other hydraulic steel, including Cromax, visit hydraulicsteels.com.au.

Improve your efficiency and move more for less with Volvo’s A45G Articulated Hauler. This machine features 100% off-road performance, proven Volvo technology, excellent fuel efficiency and increased payload - contributing to sustainable operations, year after year.

ITR’s Italian-made repair parts are synonymous with high quality – and they are available Australia-wide

ITR Pacific is part of the USCO ITR Group – the world’s largest aftermarket supplier of parts for earthmoving machinery.

With branches in Brisbane, Mackay, Sydney, Melbourne, Adelaide, Perth and Kalgoorlie, an extensive geographical footprint of warehousing and workshops in the Australian market and industry experts in each region, ITR Pacific can offer a superior customer experience across undercarriage, ground engaging

tools, repair parts, rubber tracks and tyres.

The unparalleled range held locally, and support from the Group, means ITR Pacific can confidently sell into all sectors of the Australian market, including mining, construction, plant hire, agricultural and forestry industries.

ITR Pacific carries a full range of parts across all main product categories for excavators, dozers, loaders, graders and scrapers.

USCO ITR is recognised as

an industry leader worldwide. Headquartered in Italy, all research, engineering, quality control and corporate affairs of the group are managed and controlled within this facility to deliver a high-quality and consistent product throughout the global supply chain.

Manufacturing facilities are located throughout Europe, South Korea, China and the United States to deliver the best value to ITR Group’s aftermarket and original equipment manufacturer (OEM) customers.

Distribution structures, established in barycentric positions with respect to the target markets, ensure widespread, efficient distribution of the ITR product range. Thus, optimised lead times and reduced logistics costs are a strategic part of the offer the Group proposes, from competitiveness through to aftersales service.

A wide range of aluminium loading ramps are available

Thanks to careful design, technological innovation and strict process controls, ITR repair parts have always been synonymous with high quality since 1989. The 100 per cent USCO ITR owned and controlled ITR Meccanica is the production centre for this product category.

Within ITR Meccanica’s 12,000 square metre facility are produced over 50,000-line items compatible with most makes of earthmoving machinery, including Caterpillar and Komatsu.

These include various types of gears (sprockets, hub gears, crown wheels and pinions), loader frame pins, bogies parts, brake callipers, equaliser bars, worm wheels,

suspension groups and track tensioning. However, the flagship line manufactured within ITR Meccanica is its gear pumps.

Producing 60,000 pumps each year, including oil and transmission pumps, high-pressure hydraulic pumps, water, and fuel transfer pumps, ITR has all your bases covered, no matter the size or brand of your machine.

ITR Meccanica prides itself on the high level of research and development, state-of-the-art equipment and strict quality control measures that it employs when producing its parts – which means that the end user can have confidence in the quality and durability of their pumps.

Every single pump produced by ITR Meccanica has a unique serial number that is linked to a technical sheet showing the tests conducted and technical specifications to provide transparency and accountability throughout the process.

In addition to pumps, ITR Meccanica also produces an extensive range of frame and body components for all major brands, including Caterpillar, Komatsu, John Deere and Volvo.

From equaliser bars and track guides to trunnion caps and bearings, pins, bushes, wear strips, bearings and minor and major bogies – everything you need to replace original equipment manufacturer parts can all be found in one place. They are designed to provide extended life to a machine’s frame and ensure exceptional traction, even in the roughest of conditions.

Moving outside of the machines to their transport between sites, ITR Meccanica manufactures over 700 models of aluminium loading ramps, built for small to mediumsized mini excavators, compact machines and utility machines, both wheeled and tracked.

All ITR production facilities in Italy and abroad follow a stringent internal test procedure for their products. However, the Modena facilities conduct additional sample testing on its components from each site to ensure the highest possible quality control, managed by a highly qualified team using the most technologically advanced test equipment.

The well-established quality of its components has resulted in USCO ITR becoming partners with numerous OEMs for the supply of original spare parts.

For more information on the wide range of aftermarket parts available in Australia contact ITR Pacific on 1300 820 214 or visit the website at www.itrpacific.com.au

A new medium sized excavator and a tracked skid steer are both set to be added to the Sunward range, distributed by Lynfield Mini X.

The pair of machines will be added to the product line-up for the business, which is the distributor for Sunward products in Victoria, South Australia and Tasmania.

The new additions at Lynfield Mini are the results of the efforts of Lynfield manager Jayden Lynch, who was one of the half a million attendees at bauma 2022 last month, where he finally got the opportunity to meet and mingle with many of Sunward’s top brass from its European ranks.

And while the vast expanses of the Neue Messe München exhibition halls could never be a substitute for the home comforts of Altona North on Melbourne’s outer suburbs where Lynfield Mini X is found, Lynch says the chance to fly

to Germany and meet Sunward’s staff was a fantastic experience.

“Meeting the big bosses and the whole European edition was great. It was good to see how they are performing over there and obviously that will have a flow-on affect for their plans in Australia,” he tells Earthmovers & Excavators magazine.

“Germany has 17 Sunward dealers and there’s a lot more across Europe as well. In Europe, Sunward is kicking ass, so that’s really good for me.

“Bauma is huge. It is massive and it was a massive eye-opener for me.”

Part of Lynch’s bauma experience was seeing Sunward’s new 15-tonne excavator firsthand.

The SWE 155UF-2PB is Sunward’s first zero-swing excavator in its class and features a short radius, stand boom and two-piece boom. The

machine is compliant with European Stage V emissions standards and comes with a diesel particulate filter.

Sunward says the SWE 155UF-2PB is distinguished by its compactness, with a tail swing radius of 1,490mm and high stability. The machine is powered by a 90kW (120hp) 2,200rpm Cummins engine and hydraulics sourced from KYB.

Operators have the option of purchasing the excavator with different boom options – a standard boom, a monobloc boom or a twopiece boom and can be equipped with three different arms depending on user needs.

Sunward has also paid close attention to the cab, giving it a modern design with a larger interior space, next-gen touchscreen display, comfort seat, Sunward Smart Fleet remote troubleshooting system and a GPS system as standard.

Mini X is expanding its Sunward offering with a new 15-tonne excavator and skid steer joining the ranksThe Sunward SWE155UF excavator will soon be available

“It has all of the bells and whistles including a new electric keyless start. It also has a new dash that has a big 10-inch screen, which is cool,” Lynch says.

Fresh from its debut in Munich, Lynch says the 15-tonne excavator will arrive in Australia by early 2023.

Australians will also have the option of Sunward’s compact track loader offering in the form of the SWTL4538 skid steer.

Having dominated Sunward sales in Europe over the past year, the SWTL4538 has finally touched down in Australia, with units available now.

“We sold wheeled skid steer loaders, and they were a really big hit, but this is our first track loader,” Lynch says.

“The whole European market has first dibs of the Sunward product, so we had to wait a little while, but now we’re happy we can offer them in Australia.

“Having a wide range of machinery is great and, right now, stock levels are ready for customers. We have about 15–20 units ready and two containers arriving in late November. Up until Christmas, we have about 25 new units rolling in.”

Sunward says the SWTL4538

offers excellent performance with outstanding drawbar power thanks to the suspended undercarriage system and the tracks. The CTL thrives in rough terrains such as mulch, rock and dirt and is easily manoeuvrable in small spaces.

The track loader is powered by a Kubota engine that delivers 55.4kW (74hp) of power at 2,600rpm and also features 3,385kg of breakout force (bucket). At just 1,950mm wide and

This is Sunward’s first zero tail-swing excavator in its class

with a small lightweight frame, it can still be transported behind a small vehicle.

For more information about Lynfield Mini X and the Sunward machinery range visit www.lynfieldminix.com.au

With a busy business handling large volumes of construction and earthmoving waste on the Gold Coast, JGI Quarry ’s relationship with Porter Group ensures that its equipment is up to the task

Words Cat Fitzpatrick Images Warren AitkenLocated just off the M1 in the Gold Coast suburb of Oxenford, JGI Quarry is an earthworks supplier and recycler that accepts construction, demolition and other earthmoving waste material and converts it into new building products.

Having been operational for four years, the site is based on an old river stone quarry, so non-contaminated excavated material is also used to rehabilitate the old river stone extraction pit.

“Basically, we take soil, sands, fills, concrete and asphalt from earthworks and construction sites and recycle them into products for reuse as road bases, aggregates, sands, soils and Class A fills,” JGI quarry manager Dan Faux explains.

“It’s a good location that we are on for incoming materials from the Gold Coast, because it’s quite a trek up to Brisbane otherwise. There was just a bit of a hole in the area where there wasn’t anybody else servicing those needs.”

Alongside being a convenient waste disposal point for contractors, Faux says that the popularity of using recycled construction materials has also been increasing in recent years, partly due to changing specifications making these products easier to use, but also the possible cost savings.

“I’ve been recycling concrete for around 20 years, so I’ve definitely noticed that trend over the last four or five years,” he says.

“There’s been a shift in specifications with quarried material and recycled materials originally being classed as different substances, but they’ve combined them now, so JGI mainly exports road base and drainage aggregates from the site.”

On the quarry site is a range of machinery sourced from Porter Group – three HL770-9 wheel loaders, two HX350L excavators, various pieces of Sandvik crushing and screening equipment and a new Ammann ARS170 roller.

Faux, who has been working in the industry for decades and has worked his way through a fair amount of machinery in that time, is explicit that backup service and parts availability are key to his decisionmaking process when purchasing new machinery.

“There’s no point having a cheap machine if the dealer can’t service it or you can’t get parts for it – it’s worthless to you,” he explains.

“Can a dealer support the machines that they’re selling? That’s the key.”

Faux first contacted Porter Group to bring in a couple of HL770-9 wheel loaders – a machine that he has been a fan of for many years, having run a fleet of them at a previous employer.

“I love my 770s, I think they’re fantastic,” he says.

“They’re cheaper, they move more tonnes, they give you way fewer headaches – why wouldn’t you buy them? To me, it’s just the right-sized machine.

“We get a lot of little landscape trucks and blokes with trucks and

trailers, so it’s not a case of putting a bigger loader in to move more and more tonnes of material coming into the site. There is a limit for us as to the practicality and size of a loader, so it’s important that they’re zippy for us and they’ve got good control.”

The three HL770-9s currently on site cover sales duties, stockpiling, feeding the crushing plant and loading trucks with the recycled material; with Faux saying he’s usually looking for a daily throughput of 2,500 tonnes.

“The 770 is a particularly goodsized machine. It’s small enough to still be zippy but big enough to still handle a pretty decent volume per day. Looking at the dollar-pertonne being moved per day it is more efficient when compared to other brands that I have run previously. They are a bit light for face duties on blasted quarry rock or unprepared ground, but other than that they can do everything else.

“I’ve had very few troubles with any of the ones I’ve owned. They’re

good on fuel, they’re comfortable, reasonably productive and the parts are quite cheap.

Porter Group supports them really well. They know those machines inside and out so, if there is an issue, they fault-find quickly. It’s also the little things, like the fact that they’ve got scales on already, so you don’t have to buy scales separately.”

Breaking down the larger pieces of construction and demolition waste delivered to the site and moving the stocks of soil and sand around are the two HX350L excavators, each fitted with either a pulveriser attachment or a bucket.

“One is crushing concrete down to remove the steel out of it in the recycling side of the operation,” Faux says.

“It’s a three and a half-tonne attachment, so the fact that these Hyundai machines can stand up to it is to their credit, they handle it quite well.

“On the earthworks side, if we’ve got any site works that need doing, we use the other excavator. So, loading topsoil or sand into the screening plants.”

He says that a stand-out feature for himself and his operators is the top-down view provided by Hyundai’s Advanced Around View Monitoring (AAVM) system. This provides all-round vision through nine camera feeds and comes as standard on the HX range supplied by Porter Group.

“It’s pretty handy, when you’re in a tight situation, to have that top view and be able to make a judgement call as to whether you’re going to miss,” he says.

“They’re also more comfortable than the previous series, with a better seating position. They’re a bit larger in the cabin and the aircon works better.

“One thing I do like about the HX, which is superior to other machines, is that they walk quite fast in the travel mode, so I find that quite handy for what we’re doing.”

The HX350L excavator has a maximum high travel speed of 6.4km/h and a maximum low travel speed of 3.5km/h.

“It’s a decent-sized site we’re on, and they noticeably walk quicker than other machines that I’ve had,” he adds.

“Travel’s never the most comfortable thing to do in an excavator, so it’s good to get it over with quickly.”

Alongside the excavators is a suite of Sandvik crushing and screening equipment, comprising a Sandvik QI341 impact crusher, QJ341 mobile jaw crusher, QA441 three-deck mobile screen and QA451 twodeck screen. These produce JGI’s range of export products, including sand, 5–75mm crushed natural and recycled rock, crusher dust, roadbase, topsoil, mulch, fill materials, concrete blends and larger rocks.

“We bought the QI341 with the expectation of doing 70 tonnes an hour and it seems to be sitting at around 120 tonnes an hour, so it’s

noticeably better than we were expecting,” Faux says.

“It’s only a little impact crusher and we’re primary feeding it with concrete, which is pretty much the worst thing you can do to any crusher – it’s extremely brutal on it. But it’s holding up alright – it does what it needs to do, and it does it well.”

The simplicity of the two-deck screen particularly stands out as well, along with standard features such as having a speed adjuster for every belt.

“It’s also the simple things, like the bearings being SKF. I can pull the part number off the side of it and go to any bearing shop and buy that part. As time goes on, more and more manufacturers are phasing that out.

“That’s what I do like about the Sandviks – they don’t have over-thetop stuff that’s not required, which invariably fails and is beyond the realm of an average fitter to work out what’s wrong.

“And the throughput’s there – they do the tonnage they need to do.”

We have saved a favourite till last, with Faux thoroughly pleased with one of the newest pieces of machinery on site – the Ammann ARS170 17-tonne single drum roller.

This soil compactor has a new cab design that provides 360-degree visibility, while the no-rear-axle design improves stability.

After years of seeing rollers get stuck when compacting the material being backfilled into the lake on site, Faux can’t praise the ARS170 highly enough.

“I’m particularly pleased with that little thing. It’s very mobile,” he says.

“We receive a lot of fills and they all need to be compacted and laid down. But people don’t bring us good fill, they bring us the stuff that nobody wants. So, having a roller that can traverse difficult material is really handy. It makes a big, big difference for us.

“The previous rollers that we’ve had here on site – they were always getting bogged and it was

Dan Faux says the 770s stand out for being zippy

The simplicity of the Sandvik QA451 two-deck screen is a strong feature

Demolition and construction site waste is crushed and recycled

One of JGI’s HX350Ls crushes down concrete to extract the metal

They noticeably walk quicker than other machines that I’ve had

problematic to try and compact the ground. Eventually this one came in and just shone – we love it. We push everything out with a swamp dozer and it goes where the swamp goes. It’s made a huge difference for us.

“It doesn’t matter how bad the ground is, this one will just walk straight through it. I think it’s because it’s got traction control between the drum and the rear wheels and it has a float mode. So, whenever we get stuck, we put it in float mode and it just climbs out, it’s quite incredible. We’ve been hiring rollers on and off for ages and nothing’s come close to this.”

Faux also points out that the cab is particularly comfortable, and the variable range of vibration frequencies offers a high level of versatility – suiting the particular work that JGI is doing, which is filling material into a lake.

“Other rollers were either hitting the ground too hard and punching through, or they were vibrating too fast in the low mode and bringing the water up to the top,” he says.

“What we’re trying to do is to put a crust across the top and compact the material. When you’re only half a metre above the water, you don’t want that water to come up because then you’re in the lake.”

With the mixture of Hyundai, Sandvik and Ammann machinery all

running smoothly on site, Faux says the relationship with Porter Group has been vital to making this happen.

“Porter Group are really good,” he says.

“The fact that they have the crushing and screening gives us good buying power and they’re really good with the Hyundai gear – they know it inside out.”

The high level of aftersales service has also been a major positive for JGI, he explains, with Porter Group’s service team usually heading out on the same day if any problems arise.

“They’re there when you need them to be, so the service on that side is fantastic,” Faux says.

“The relationship is great – they’re far better than any other dealer I’ve had to deal with. That’s why we chose to buy the roller from them. The reason we bought the Sandvik equipment from them was because we’d had a good run with the Hyundai here and it just made sense.

“Looking ahead to next year, we’ll be probably picking up another loader from Porter Group and replacing the two-deck as it comes to the end of its service life. We’ll probably end up trying to use Porter Group for water truck/ Moxie-type stuff as well.”

For more details on equipment available for purchase through Porter Equipment, visit www.porterce.com.au

It doesn’t matter how bad the ground is, this one will just walk straight through it.

Productivity in Australia’s construction sector has not improved across the past 30 years, a report from Australian Constructors Association (ACA) says.

The report – Disrupt or Die –outlines how the industry has stagnated in terms of its productivity.

Construction productivity, it says, is lower today than it was in 1990 which is a result of a sector that is stuck in the past and has failed to adapt to contemporary practices and technologies.

Considering the Australian construction industry is responsible for employing almost one in 10 of the country’s working population and contributes seven per cent of the national GDP, the report paints a worrying picture of a sector not only treading water but regressing in its efforts to be more productive.

In all, the poor productivity achieved by the construction sector, which is Australia’s fourth largest industry, costs the economy $47 billion each year, the ACA says.

Disrupt or Die was derived in 2020 by the ACA, which commissioned BIS Oxford Economics to investigate productivity in the construction industry since 1990.

ACA chief executive Jon Davies outlines the problems faced by the industry that were brought to light in the report.

“Over the last 30 years, almost every other industry has advanced, yet Australia’s construction industry has gone backwards,” Davies says.

“Construction productivity today is lower than it was in 1990 and the industry is out of touch with the next generation of workers, who no longer view it as an industry of choice.

“Workers do not want a job in an industry where the hours are long and disputes are commonplace, Excel spreadsheets are considered the height of tech and little focus is placed on the impact we are having on the environment.”

Australia’s construction industry boomed in 2014 when resources were at their most available.

However, since then, productivity has decreased 16.5 per cent from the 2014 levels at such a rate that productivity performance is now 1.8 per cent lower than in 1990. That means the construction industry yields an average growth rate of -0.1 per cent.

Other laborious industries in Australia such as manufacturing, transport and other selected industries such as agriculture, forestry, mining and waste services have all grown over the past 32 years, some of which are 33.6 per cent more productive than construction.

While there are many culprits which the ACA has outlined to be at fault for the current state of the industry, the biggest opportunity to improve productivity lies in fundamentally improving how projects are procured, delivered and governed, it says.

These so-called ‘white-collar’ activities are responsible for the

A new Australian Constructors Association report has looked into why productivity isn’t improving in the construction industry

Utility

Platinum class

36 months / 1500hrs EPTW

• Up to 500hrs

• PM Clinic / KOWAS

• Presents as new

Platinum class

36 months / 3000hrs EPTW

• Up to 3000hrs

Gold class

24 months / 1000hrs EPTW

• Up to 1000hrs

• PM Clinic / KOWAS

• Presents well

Gold class

24 months / 2000hrs EPTW

• Up to 4000hrs

Silver class

12 months / 500hrs EPTW

• Up to 1500hrs

• PM Clinic / KOWAS

• Presents well

Silver class

12 months / 1000hrs EPTW

• Up to 6000hrs

Bronze class

6 months / 250hrs EPTW

• Up to 2500hrs

• PM Clinic / KOWAS

• Presents well

Bronze class

6 months / 500hrs EPTW

• Up to 8000hrs

Construction

Mining

• PM Clinic / KOWAS

• Presents as new

• Includes Hybrid / IMC

Platinum class

36 months / 4000hrs EPTW

• Up to 3000hrs

• PM Clinic / KOWAS

• Presents as new

• PM Clinic / KOWAS

• Presents well

• Includes Hybrid / IMC

Gold class

24 months / 3000hrs EPTW

• Up to 4000hrs

• PM Clinic / KOWAS

• Presents well

• PM Clinic / KOWAS

• Presents well

• Includes Hybrid / IMC

Silver class

12 months / 2000hrs EPTW

• Up to 7000hrs

• PM Clinic / KOWAS

• Presents well

• PM Clinic / KOWAS

• Presents well

• Includes Hybrid / IMC

Bronze class

6 months / 1000hrs EPTW

• Up to 10000hrs

• PM Clinic / KOWAS

• Presents well

overseeing of construction projects –something which the ACA describes as a “significant wastage of skilled resources”.

For a while contracts have been a race to the bottom, with the lowest upfront cost often winning out, even though it may not be the best value. That concept is outdated, not sustainable and is focused only on the short-term, the ACA says.

And while time and cost are obviously important components of value, assessed value should also include additional outcomes, ACA says, namely increasing innovation, productivity and environmental sustainability as well as improving industry culture and sovereign capability.

“There is significant wastage of skilled resources through inefficient tender processes, but the bigger problem is the myopic focus on selecting the lowest price at the tender box to the detriment of all else,” Davies says.

“The lowest bid at the tender box is a completely false economy and is the direct cause of the adversarial contracting environment in which we now find ourselves.

“All too often, procurement

processes encourage competition on willingness to price and accept unquantifiable risk rather than ideas to deliver improved project outcomes.”

The ACA also raised other issues that hinder productivity, such as the long hours worked by construction workers and the need to evolve towards utilising more advanced technological solutions.

Paramount to the Disrupt or Die report was an outline of how best to disrupt the sector and make it more productive.

The ACA called on the various levels of government – the largest infrastructure client in Australia – to play the role of the disrupter in chief and encourage state governments to procure projects to maximise productivity, promote training and upskill the workforce.

To do so, the Future Australia Infrastructure Rating (FAIR) has been developed to rate government-funded projects against key reform areas. All projects undertaken by government agencies would be given a rating that is published.

If implemented, the ACA has also

proposed that the FAIR system could be included in the next National Partnership Agreement as a requirement for all projects funded by the federal government.

Other recommendations outlined by the ACA to improve productivity performance in the industry include a better adoption of digital technologies, increased collaboration of contracts, streamlined design review process and a greater use of enterprise delivery models that increase innovation and improve engagement.

To fully address the productivity issue currently plaguing the construction industry, government, industry and unions must come together and collaborate, the ACA says.

“The industry cannot afford to continue down the path of slow incremental change,” Davis says.

“It is time to fundamentally disrupt how it operates to ensure we have sufficient workers delivering infrastructure that Australia can afford.

“Everyone has a part to play, including contractors, but it is the government, if it chooses to, that has the biggest power to disrupt.”

Productivity and innovation are being hindered by inefficient tender processes

has strongly voiced concern regarding the government’s amendments to the Secure Jobs Better Pay Bill and has called for the Senate to block its passage

multi-employer bargaining, it has no place in our industry. Our industry is amongst the highest paying and certainly does not fit within the government’s Bill criteria of applying to low-paid industries.

Those who have had to navigate the industrial relations laws in this country know that the application of these laws have been shaped by various court interpretations of legislation over the years.

It takes expert experience to adequately ensure compliance with the laws and establish agreements with the workforce. If it is not correctly addressed, the consequences for employers can be quite catastrophic.

The federal government introduced the Secure Jobs Better Pay Bill 2022 to Parliament in November. The Bill proposes changes to workplace relations relating to bargaining, job security, gender equity, conditions, protections, compliance and enforcement.

There are several concerns regarding this Bill. The federal government had preempted changes prior to the election regarding the abolition of the Australian Building and Construction Commission (ABCC), which Civil Contractors Federation (CCF) has opposed.

However, there are a number of additional amendments to the Fair Work Act and others that were not foreshadowed. The Bill is large and very complex and to fully consider its impacts and unintended consequences significant time should be dedicated to consultation.

This did not occur and effectively industry has had less than a month to consider these issues and respond.

The main concerns were the abolition of the ABCC and the introduction of multi-employer bargaining.

Damian Long, CEO CCF QLD

The federal government’s reasoning for abolishing the ABCC was: “This would ensure that workers in the building and construction industry have the same rights as other workers in relation to enforcement of the Fair Work Act.”

In other words, the Fair Work Ombudsman (FWO) could provide the same service to the building and construction industry as it does with all other industries. The problem with this reasoning is that it ignores four of the Royal Commissions, being the:

• Winneke Royal Commission 1982

• Gyles Royal Commission 1992

• Cole Royal Commission 2031

• Heydon Royal Commission 2015.

These Royal commissions found that, in the building and construction industry, there was fundamental lack of respect for the law and threats of physical violence were common in the workplace.

It is for these and other reasons that the establishment of an independent regulator with additional powers to regulate the building and construction industry was recommended.

Multi-employer bargaining is another term for collective bargaining or pattern bargaining. Whilst there is an argument for low-paid and non-dynamic industries to adopt

The reach of what would be considered common interest in deciding which employers would be grouped to collectively bargain is concerning. It is possible that parts of the supply chain could be caught in this net to the detriment of individual enterprises.

Regardless of the collective industries’ concerns and objections, the government’s industrial relations legislation subsequently passed the House of Representatives after the government made several amendments.

One amendment the government made was to redefine the meaning of ‘building and construction’ and remove the multi-employer bargaining exemption from civil construction. This puts the IR Bill at odds with the Building and Construction General On-site Award 2020.

This amendment was rushed and clearly the impact of this amendment has not been thought through. It is inconceivable how civil construction is not considered with building and construction when the two industries are intertwined.

The responsibility lies with the Senate to reject the Bill following its rushed passage through the House of Representatives. It is a Bill that in its current form, would implement major and regressive changes to Australia’s workplace relations arrangements that would set us back decades and damage the economy.

CCF supports an effective industrial relations framework that enhances productivity by minimising workplace and workforce disruptions, however, the Secure Jobs, Better Pay Bill 2022 falls far short of meeting this objective. Rather, it would act as a drag on productivity which is one of the key problems facing the civil construction industry.

In a pit near Calbe, a town in central Germany, around 5,443 tonnes of gravel is removed daily by earthworks specialist Erdbau Schrader.

Gravel extraction began at the site around 30 years ago and is expected to continue for another three decades. Currently navigating this tough terrain, travelling up and down steep inclines to unload around two kilometres away, is a Rokbak RA30 articulated hauler, the latest addition to Erdbau Schrader’s fleet.

“We chose Rokbak because of its reliability and the priceperformance ratio, as well as the hauler’s ability to cope with our long, heavy off-road operations,” Erdbau Schrader managing director Ines Schrader says.

“We also wanted to ensure that our experienced operators would be able to work with maximum comfort.”

Erdbau Schrader was founded in April 2011. The company specialises in removing overburden for gravel extraction and renaturation, utilising its machines at several locations near its bases of Staßfurt and Brumby. Erdbau Schrader already owned four Terex TA300s – which it bought before Terex Trucks rebranded to Rokbak in September last year.

In July, the company added the RA30 to its fleet, purchasing the machine from Rokbak dealer

Klarmann-Lembach. Three other articulated haulers are working alongside the RA30 at the pit.

“The Rokbak RA30 is a strong, reliable and high-performing machine – which is exactly what Erdbau Schrader needed,” explains Klarmann-Lembach salesman Thomas Keil, who recently visited the Calbe site with Rokbak to see the RA30 in action.

“Our confidence in the Rokbak brand and the haulers is such that, when we were approached, we could assure our customer that the RA30 was the ideal addition to their fleet.”

Erdbau Schrader’s articulated haulers move at full power five days a week, 6am–4pm. Materials from the site are transported over sandy and spongy ground for two kilometres before being unloaded at a railway loading station.

Able to transport a payload of up to 28 tonnes, the RA30 has a maximum engine power of 276kW (370 horsepower), a heaped capacity of 17.5 cubic metres and a maximum torque of 1,880Nm @ 1,400 rpm.

Routine maintenance is as quick and efficient as possible, keeping service time and costs to a minimum. Furthermore, the factory-approved parts are backed by a two-year/6,000-hour warranty – one of the most comprehensive

guarantees in the industry.

Operational comfort is also at the forefront of the RA30 design. A spacious, ROPS/FOPS compliant, pressurised cab with excellent heating, ventilation and air conditioning (HVAC) keeps the operator comfortable and focused.

The RA30’s EP320 transmission comes with eight forward gears and four reverse gears and features a top speed of up to 55km/h, high overall gear ratio spread, equal ratio steps between gears and optimised gear shifting with partial load shifts.

All of this means that the RA30 offers lower fuel consumption with smoother gear shifting and higher levels of operator comfort as well as faster cycle times and reduced carbon emissions.

The RA30’s long life transmission fluid increases the length of time between oil maintenance intervals to 4,000 hours. This helps customers achieve increased productivity and uptime, as well as lower cost per tonne.

“The RA30’s transmission strikes the perfect balance between efficient power, effective gearing and weight distribution, allowing the hauler to move more loads quicker,” Rokbak customer support manager for Europe Thomas Schmitt says.

“The RA30 is simple to operate and easy to maintain, it delivers low total cost of ownership with a fuel-efficient performance and high productivity – so it’s no wonder the Erdbau Schrader team are so happy with it.”

Queensland coal mining company

Batchfire Resources is committed to responsibly developing the Callide Basin’s resources while reducing its environmental impact and carbon footprint, so optimising mobile machinery to lower fuel emissions and increase operational efficiencies is an ongoing priority.

Batchfire’s long-term partnership with Hastings Deering has supported the business’ strategy of phasing out older machines and upgrading its pre-strip-mining fleet.

With nearly 100,000 hours on the clock, Batchfire Resources recently retired the original Cat 994 wheel loader to bring in a brand new Cat 994K, which is customised for runof-mine (ROM) coal operations.

This new model has already achieved excellent results, generating 150 per cent more material movement without increasing carbon emissions thanks to the new model’s larger and stronger design, which offers higher payload and horsepower.

Batchfire Resources superintendent mobile – engineering and maintenance Daniel Boal says that the investment in new machinery was to ensure a more sustainable and efficient ROM operation.

“This journey started in 1993 – the old 994 has pretty much been in service the whole time. The way Caterpillar build things, they are

Improvements include greater visibility

made to last; they’re built for a longterm investment. It was an easy decision in the end to go for the new 994K loader,” Boal says.

“On a ROM, what you need is a reliable loader. It’s probably one of the most critical parts of the mine.

“We’ve got 500 more horsepower in the new 994, so we can work more quickly and efficiently.”

The new 994K was customised with a 40 cubic metre bucket, increasing capacity from the old loader’s 16-metre bucket.

“There’s a huge difference in payload. It used to take us 10 buckets to load a 789 truck on the ROM. With the new 994K, we can do that in four,” he says.

Batchfire Resources is seeing a reduction in emissions, alongside increased productivity and a lower cost per tonne on the ROM.

The safety and comfort of

operators is a key priority for Batchfire. These employees will benefit from the new model’s higher cab position, lower sound level environment and seat air suspension features.

“It’s a beautiful piece of machinery, the cab’s wonderfully comfortable and spacious and the machine itself delivers great performance and power,” Batchfire Resources operator trainer and assessor Adam Burling says.

Caterpillar has worked to improve the wheel loader models to provide a safer work environment for operators, including adjustments to machine access, visibility, operator comfort and a powered access system.

The Cat 994K has been designed and built with the highest standards of operator safety and comfort.

Visibility features that help to provide a safe work environment for operators and other staff on the work site include the higher cab position that delivers improved visibility while loading and the Cat Detect feature that enhances operator awareness around the machine.

“It’s not just the reliability with Cat machinery – what Caterpillar and Hastings Deering do especially well is the support that you get. If you do have an issue, Hastings are there,” Burling says.

For more information visit www.hastingsdeering.com.au

With help from MSC Group and its range of McCloskey plant equipment, Brisbane’s Ascot Demolition has been able to expand its footprint and offer more services to its customers.

The family-owned and operated business began around two decades ago, primarily in the area of what its business name suggests – demolition – but has since grown to include a plethora of other services.

From site remediation and bulk excavation to earthmoving jobs such as civil contracting and rock breaking, the services offered by Ascot Demolition are almost endless.

Director Gareth Golding, whose own experience in demolition and earthmoving spans back to his youth, says the business prides itself on being a one-stop shop for customers.

“As we’ve developed, more of our work falls under civil earthmoving than demolition as you’d normally think of it,” Golding says.

“If I incorporate the demolition and earthmoving aspects all in one, we save the hassle of a demolition company coming in. The big benefit to our customers is being able to offer a one-stop shop.

“It makes us incredibly competitive with cost and time with what we’re doing now.”

Golding says the ability to offer both demolition and crushing and processing services onsite is far more friendly to the environment as well –removing the need for trucks to haul processing material offsite.

“More and more people are looking towards soil remediation and concrete crushing and processing onsite, as opposed to taking it offsite and getting it removed and replaced,” he says.

“It’s becoming more cost efficient now to do it on site and certainly more environmentally friendly as well.

“On a job we are currently doing at the moment we are saving thousands of truck movements coming in and out of the job. We’re turning the site into a far better product than what it was before.”

Having operated a second-hand McCloskey J50 jaw crusher for many years, Golding and the Ascot Demolition team decided to

Ascot Demolition’s Gareth Golding says the I44Rv3 is “very impressive”

update its crushing and screening equipment, enlisting the help of MSC Group and its CEO Kirwan Barr.

The investment means Ascot Demolition is running plant that, for the most part, is less than two years old. This means that the machinery is more sustainable than the older gear, with most running AdBlue to lower emissions onsite.

Among the equipment purchased from MSC Group are two J50 heavy duty crushers, an I44Rv3 high production impact crusher and a R155 high energy durable screener.

Golding says the J50 is used primarily for concrete processing and crushing, which is made easy thanks to its 1,270mm x 735mm single toggle jaw, which McCloskey says is the widest in its class. The J50 also features an integrated hydraulic folding hopper and heavier flywheels – the latter helping deliver maximum productivity.

The R155 durable screener is put to work sizing and separating material or aggregates for making road bases. The screener can also be used for processing, Golding says, given it guarantees a uniform product.

Ascot Demolition uses the I44Rv3 impact crusher for processing rocks and other material. McCloskey says the I44Rv3 allows operators to produce a crushed and screened final product all within the one machine as it combines the productivity of a full screening and recirculating system and a 45-inch (114cm) impactor.

“We can also put concrete through the I44Rv3, but that’s mainly on a secondary run. It does make a very nice product and it is a very impressive piece of machinery,” Golding says.

Together the machines have become a staple for Ascot Demolition, with the business serving the Brisbane and Gold Coast regions from the company’s Stapylton base.

While the business has long moved on from its roots in Ascot – a suburb in Brisbane’s north – a recent job there saw Golding and the team return. The McCloskey machines were tasked with processing and screening 120,000 tonnes of material.

For Golding, the appeal of the McCloskey equipment is simple –with the newer and more sustainable technology and quality of parts used the standout features.

“The quality of the machine is very

good. They are very well thought out and they’re very ergonomic.

I believe their productivity is second to none when you think about tonnes per dollar and what they’re producing and what we can make with it,” he says.

“The machines themselves are very well set up. I’m impressed by how you can set the jaw now. Gone are the days where you’d have someone up there looking at the jaw

working the levers – now you can fine-tune the telemetry of the jaw and the feedback is phenomenal.”

Equally, it was the team at MSC Group who made the purchase worthwhile for Golding.

“All of the team there are the best people that we deal with in the industry. Their commitment to service and everything else just far exceeds their commitment to generating sales,” he says.

“These guys care about what they do and they care about their product and that reflects back to what they are doing. We wouldn’t go to anyone else. The quality of the McCloskey products is exceptional.”

MSC Group is a wholly Australian owned company that commenced in 1986. It is the sole authorised distributor for the complete product range from McCloskey International across the eastern states of Australia, as well as Papua New Guinea and the Pacific Islands.

MSC Group is based out of Cleveland, Queensland, with branches in Newcastle and Melbourne.

For more info, visit msc.net.au

three most common mechanisms in the same period were being hit by moving objects (23 per cent), vehicle collisions (17 per cent) and slide or cave-ins (17 per cent).

“The Agency also looks at other characteristics of these fatalities that can assist in educating employers about the types of hazards prevalent in their industry and provide valuable information as they embark on their own WHS risk assessment,” Safe Work Australia says.

Safe Work Australia has released its Key Work Health and Safety Statistics Australia 2022 report, which analyses work-related fatality and serious injury data in Australia for 2021.

And there is some great news –Australia’s work-related fatality rate has decreased by 35 per cent over the past 10 years, and there’s been a huge 57 per cent decrease in the fatality rate from a peak in 2007.

However, in 2021, there was still a total of 169 workplace fatalities in Australia – the vast majority being men working in areas of machinery operation, labouring and trades. With the highest numbers recorded in NSW and QLD, men between the ages of 45–64 are those who are at the highest risk of death at work.

Speaking with Earthmovers & Excavators, Safe Work Australia says that, while the decrease in fatality rate over the years is great to see, any workplace death that occurs is obviously a tragedy.

“As part of the Australian Work Health and Safety Strategy 2012–2022, work health and safety [WHS] system stakeholders committed to reduce the incidence of work-related death, injury and illness,” it says.

This is being achieved through: • a n improved and reformed work health and safety framework

• i ncreased work health and safety awareness

• i mproved quality of workplace controls, resulting in reduced exposure to work-related hazards causing death, injury and illness.

“Safe Work Australia has also developed and maintained a growing evidence base, which is informing policy and practice in an ongoing way,” it adds.

So, what is happening? Vehicle collisions were the most-recorded cause of death in the workplace, with the transport, postal and warehousing industry recording the highest number of deaths at 52, but agriculture, forestry and fishing having the highest fatality rate. Six deaths were recorded in mining and 24 in construction in 2021.

“Our data shows that, in 2021, 38 per cent of fatalities were caused by vehicle collisions, and 96 per cent of worker fatalities were male,” Safe Work Australia says.

“These trends are consistent over time and partly reflect the demographic profile of workers in certain high-risk industries.”

In the construction industry, the three most commonly-seen mechanisms causing worker fatalities between 2017–2021 were falls from a height (31 per cent), being hit by moving objects (16 per cent) and being hit by falling objects (15 per cent). In the mining industry,

“For example, the Agency looks at fatalities involving a vehicle more broadly. This accounts for 70 per cent of worker fatalities and includes vehicle collisions as well as fatalities resulting from workers [being] hit by moving vehicles (e.g., as pedestrians) or being hit by falling objects from vehicles (e.g., when loading/ unloading material or equipment).

“Safe Work Australia has released national guidance relevant to vehicle/ traffic management and safety in the workplace. We will continue to work with our stakeholders to increase awareness and promote safety both in and around vehicles.”

Again, improvements have been seen in the area of serious injury claims, with a drop of 17 per cent seen in the decade 2010–2020.

Looking at the 130,195 serious injuries claims lodged in 2021, people aged 60–64 had the highest frequency of injury, with body stressing accounting for 37 per cent of claims. Falls, trips and slips was the second most frequent, accounting for 23 per cent.

Body stressing covers injuries or diseases caused by stress placed on muscle, tendons, ligaments and bones, with non-powered hand tools, appliances and equipment the most likely cause.