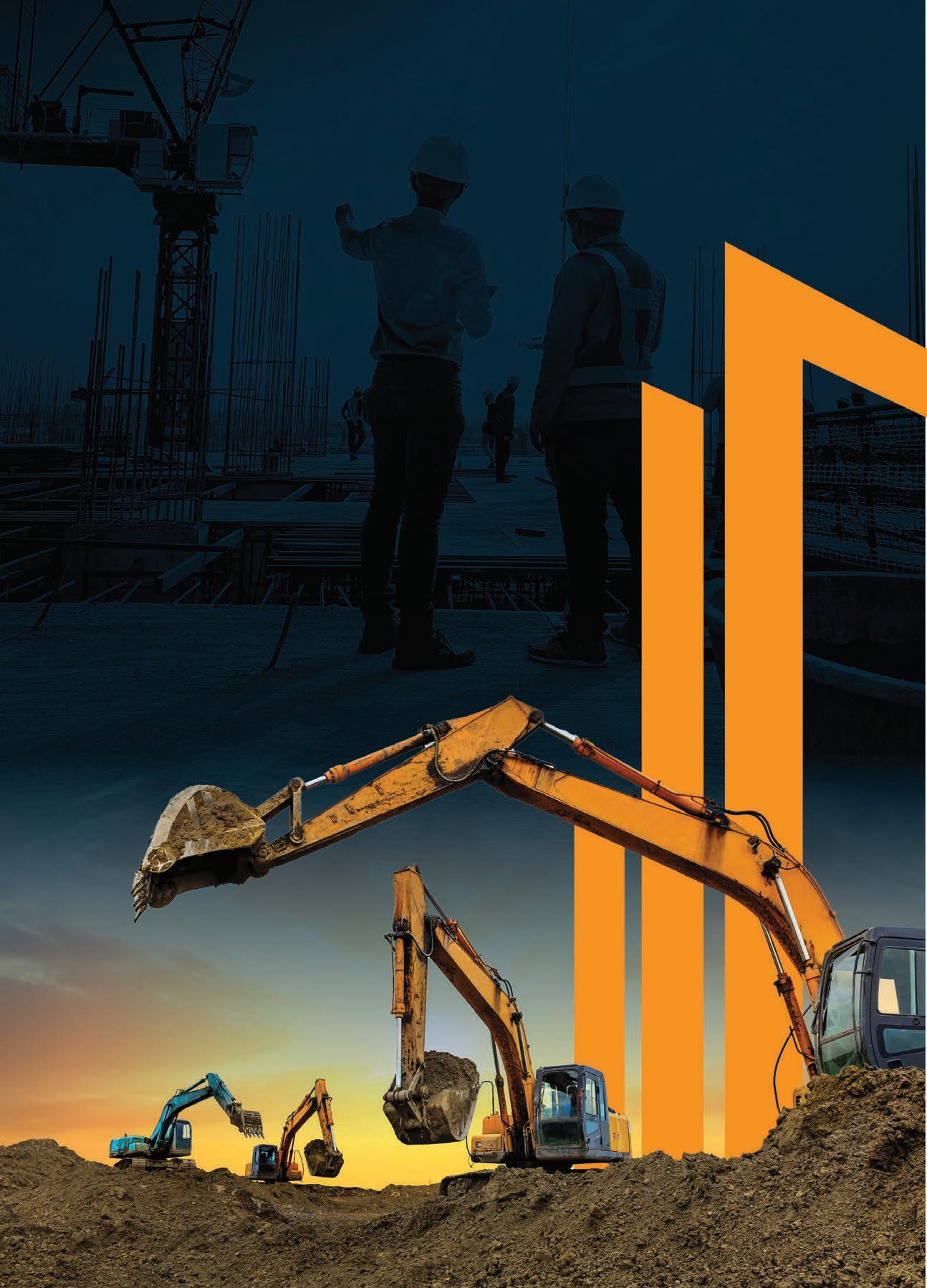

In this issue, FAE upgrades its forestry mulcher, Position Partners releases new SmartSurveyor tool, Magna Tyres expands its machinery tyre range, ShoulderMaster develops a new road repair trailer, Cat brings the 340 model excavator to Australia and expands its remote control offering, Epiroc acquires Remote Control Technologies, Liebherr upgrades excavator range, Zoomlion invests in autonomous manufacturing, Kobelco improves its supply chain with IFS Cloud, AfPA underground asset guide available, ALGA calls for improved road building standards, London’s HS2 project trials hydrogen generator for machinery charging, Vögele releases new generation of road pavers, John Deere adds new P-tier excavator models, Komatsu expands electric offering, JCB unveils its smallest telehandler, Doosan expands its mini excavator range, new Metso Outotec service centre being built, Yello Equipment opens new Newcastle branch, workplace harassment program trialled in WA mine, CCF National Earth Awards presented, HS2 project’s 2.7km-long construction waste conveyor opens, Before You Dig Australia partners with SafeWork NSW, contraction eases in the construction industry, AFPA releases new road building qualification, Annabel Crookes becomes ACA president 6–14, 44–69

As part of its investments in sustainability and productivity, Batchfire Resources has invested in an upgraded Cat dozer fleet from Hastings Deering

Komatsu’s Retrofit Kit gives excavator owners the ability to upgrade an older machine with 3D machine guidance and payload meter technology 24

Concrete provider Titan Premix needed a high capacity machine for its new Melbourne site – turning to a new Hyundai HL970 loader from Porter Group 28

Precisionscreen’s heavy-duty mobile conveyors are a flexible solution to meet a variety of applications 32

With a new mini skid steer available and business operations booming, the year ahead is looking promising for the team at Active Machinery 35

The recent delivery of a Franna MAC 25-4 crane marks the launch of Brooks Equipment’s new division –Brooks Cranes

Head manufacturer FAE has announced an upgrade to its DML/SSL forestry mulcher for skid steers that optimises the head’s efficiency and productivity when combined with 50 to 75 horsepower (37–56kW) skid steers.

The frame and push frame’s design has been redesigned to offer greater visibility in all working conditions.

The DML/SSL can now mount a rotor with robust Mini C/3 teeth or with Mini BL blades, which work with bite limiter technology. The bite limiter rotor comes with special wear-resistant steel limiters that limit the teeth’s reach so

that there is a lower power demand and a consistent working speed. The bite limiter technology also minimises rotor stalling and optimises fuel consumption.

The new DML/SSL is available with FAE’s Sonic technology, which ensures that the skid steer and the FAE mulcher are aligned by automatically calibrating the mulcher’s parameters.

Sonic continuously manages the mulcher’s hydraulic settings, for a boost in overall productivity of up to 30 per cent. The Sonic system also minimises rotor stalling and shortens recovery

time thanks to the quick recovery of the rotor’s rpm.

The new Spike Pro counter blades ensure low power absorption and a finer granulometry of the processed material. The new interchangeable and adjustable skids offer greater precision.

The optional integrated oil cooler ensures the best performance even in hotter climates.

The new DML/SSL is available in Australia in four models – the DML/SSL/ VT, DML/SSL/BL, DML/SSL/SONIC and DML/SSL/BL/SONIC – and in two widths for each model.

Position Partners has launched its SmartSurveyor – a compact device that can be used for survey-grade aerial mapping projects in combination with the DJI Mavic 2 or 3 series, as well as the Phantom 4 drone.

The SmartSurveyor can be unclipped from the drone and used as a handheld photogrammetry tool with a smartphone camera, or a survey rover to measure ground control points.

Unlike other drone mapping systems that rely on post-processed or real-time

kinematic technology, SmartSurveyor works with two or more ground control points and uses an iterative ultra-matching technique. This negates the need for an electrical connection between the camera shutter and GNSS receiver.

“SmartSurveyor transforms your drone and smartphone into advanced photogrammetry tools, with full support for coordinate and datum transformation as well as geoid models,” Position Partners RPAS

market development manager Gavin Docherty says.

“It takes just a few seconds to clip the SmartSurveyor onto a drone, or attach a smartphone for handheld applications, and users are ready to capture data and create point clouds, orthophotos and digital terrain models without any other external surveying equipment.”

Following data capture, photos and the GNSS file are transferred to a PC and run through the Agisoft UltraMatch workflow. Once accuracy is confirmed using additional check points, results are ready to be exported.

Developed by geospatial technology innovator MetaSpatial, data collected using SmartSurveyor can then be processed and managed either in the cloud or locally on a computer using MapSender software.

“SmartSurveyor also works seamlessly off the AllDayRTK subscription GNSS network service and data can be uploaded to Tokara, Position Partners’ remote access and project management solution, to overlay orthophotos onto the project map,” Docherty says.

Magna Tyres has expanded its range of mining and earthmoving tyres with three new sizes – the 775/65R29 Magna M-Terrain+, 15.5R25 Magna MA10+ and 17.5R25 Magna MA08.

The M-Terrain range was developed to perform on all terrains and for different machines.

It has now been expanded with the addition of the Magna M-Terrain+ to the range, which has been specially developed for articulated dump trucks.

The Magna M-Terrain+ has a super wide tread width and high tread depth that provides outstanding tyre wear, Magna stays. The tyre’s even area minimises vibration, resulting in improved operator comfort.

The new 775/65R29 Magna M-Terrain+ L4 size of tyre can handle up to 20,600kg (the E4 goes up to 12,150kg).

The Magna MA10+ L5 tyre range has been designed for wheel loaders, dozers and underground

transport. Such machinery requires maximum traction and the MA10+’s deep, open tread ensures traction in different environments. The new tyre size 15.5R25 can carry up to 7,100kg.

The MA10+ is constructed from puncture-resistant rubber and has a non-directional and strong tread design to maintain a high level of damage resistance.

With its extra-deep L5 design, the Magna MA08 was specifically designed for loaders. The tyre offers high levels of traction due to its massive tread blocks and aggressive, open design.

With the addition of the 17.5R25 Magna MA08, the MA08 can now also be fitted to machines that can carry up to 8,500kg. With its protected sidewall, it provides an outstanding level of cut- and damage-resistance, Magna says.

Magna tyres are available in Australia through its subsidiary Fennell Tyres International.

The ShoulderMaster SP1000 has a hopper capacity of 1.8 cubic metres, delivering a spread width of 1,600mm. Coming in at 2,000kg in weight, the trailer can carry 1,000kg of product.

It can be connected to the back of an everyday work ute that has electric trailer brake controls, making the SP1000 highly versatile, and can be used across a wider fleet of vehicles. It hosts a range of safety benefits, including a set of stairs for easy access to the hopper, flashing lights and an E-stop, bringing operator safety to the fore. The unit can also be remote controlled.

Binders are the solution to improving pavement structure and can provide improved performance when used in severe and challenging locations in particular, ShoulderMaster says.

The SP1000 is a cost-effective solution to spreading binders for pavement rehabilitation through stabilisation, improving ground crew safety and driving road repair budgets further, it adds.

Transport for NSW is already utilising the trailers to repair roads across the state. These units are also available for long- or short-term hire from ShoulderMaster.

With a more powerful engine and wider tracks, the new Cat 340 excavator offers increased production capability

Cat’s 340 hydraulic excavator, now available in Australia, provides 10 per cent better productivity compared to its predecessor – the 336 2020 model – thanks to upgrades to the engine and tracks, plus a 7.5-tonne counterweight that boosts stability.

Featuring a next-generation electrohydraulic system, Cat says the 340 boasts the best production capability in the 40-tonne class for tonnes moved per hour.

Durability has also been a focus for the design team, with reinforced structures introduced to ensure long-term durability in harsh digging, hammer applications and loading.

Under the hood, the Cat C9.3B engine features three modes to match excavator power with job requirements to best manage fuel consumption. Power mode delivers maximum power for the most demanding tasks, smart mode matches engine and hydraulic power to digging conditions automatically and eco mode minimises fuel consumption by reducing the engine speed to a constant 1,500rpm. The 340 is suitable across all environments, with the ability to operate in high-temperature environments up to 52 degrees. Fuel filter service intervals are synchronised at 1,000 hours.

Features such as Cat Product Link, which collects data automatically, and Remote Troubleshoot and Remote Flash are included as standard. Cat Payload is also included as standard, along with Grade Assist and 2D Grade with depth and slope indication. All Cat grade systems are compatible with radios and base stations from third-party tech companies.

Cat 349, 352, 374 and 395 large hydraulic excavators can now be equipped with Cat Command for Excavating. The remote-control system removes operators from potentially hazardous jobsite conditions and it reduces potential safety risks from climbing on and off machines.

The Cat Command station allows for non-line-of-sight remote control, where users can control all basic machine functions like digging, lifting and tracking. Additionally, Caterpillar exclusive machine technologies like Cat Grade with 3D for Excavators, Grade with Assist for boom and bucket, Swing Assist, E-Fence and others can be set, activated and used remotely.

The technology helps improve machine productivity on various projects like operating in unstable underfoot conditions, brownfields, shore work and demolition. It also allows production to restart immediately following disruptive processes such as blasting in quarry applications.

The Cat Command station provides non-line-of-site operation from a remote location, with distance only limited by the capabilities of the network.

The Cat Command station comfortably seats the operator in a customised ‘virtual cab’ with familiar controls and machine displays. Users can control up to five different machines, one at a time, at the same or other locations, reducing downtime for shift changes or the need to travel to the jobsite.

Touchscreen monitors offer the same machine information and access to machine setting just like in the machine. Screens mounted in front of the user provides an easy view of the excavator’s camera feeds.

By removing the operator from the cab, Cat Command for Excavating offers a solution to workforce shortages and training advantages for newer operators. It opens opportunities to those with physical limitations that prevent them from climbing into the equipment, attracting a new generation of workers, and increasing the longevity of experienced operators.

The new large hydraulic excavator models join the existing Cat Command-ready excavators (320–340) and medium dozers (D5–D7) that can be operated from the same Command station.

Batchfire Resources has expanded its fleet with four new Cat D10 dozers and four new Cat D11 dozers over the past four years

As part of its investments in sustainability and productivity, Batchfire Resources has invested in an upgraded Cat dozer fleet from Hastings Deering

Queensland mining company

Batchfire Resources has been investing in its mining assets to boost productivity, reliability and fuel efficiency.

It is achieving this through its ongoing partnership with Hastings Deering – the official Cat dealer for Queensland, Northern Territory, Papua New Guinea, the Solomon Islands and New Caledonia.

The energy coal mined by Batchfire Resources plays a crucial role in generating around 18 per cent of Queensland’s electricity needs every year. Investing in four new Cat D10 dozers and four new Cat D11 dozers over four years through Hastings Deering continues Batchfire’s strategy of upgrading its mining fleet to deliver operational and sustainability benefits.

Batchfire Resources superintendent mobile – engineering and maintenance Daniel Boal says it is a priority for the mine to invest in new machinery that allows older models to be phased out.

“There were no questions, we were going for Caterpillar dozers,” Boal says.

When looking to invest in its mining fleet, Batchfire Resources was exploring ways to reduce carbon emissions per bank cubic metre of waste and improve productivity.

“Overall, we aim to produce around 10 million tonnes of coal annually. We continue to invest in the mining fleet to ensure that we’re getting the productivity gains and sustainability benefits on site.”

Boal says investment in the new dozers was a commitment to

ensuring Batchfire’s mine operations would use more fuel-efficient machinery to help reduce carbon emissions and maintain productivity.

“The impressive reliability and performance of our existing fleet of Cat dozers was an important factor in our decision to invest in the new Cat D10s and Cat D11s,” Boal says.

“They are essentially replacing older version D11Rs and D10Rs, and we’ve seen an efficiency gain of 10 per cent on the new-style engines.”

Batchfire Resources has also installed Cat Terrain features in the new dozers to improve pit and waste dump bench control, maintain design compliance and reduce rehandling of waste – all which help reduce emissions through efficient haul truck operations and optimising material moved to uncover the energy coal.

The new machines have Cat Terrain enabled, which gives operators the information to maximise machine efficiency

The new dozers have Cat Terrain enabled, which uses high-precision guidance technologies and material tracking to help the machines work according to plan.

With onboard guidance tools and real-time feedback, Terrain for Grading gives dozer operators the information to maximise machine efficiency by monitoring coal seam location, bench heights, cycle times and volume of material cut and filled.

“They get the job done right the first time. If we put a plan in, they work to the plan, they finish the plan and its done,” Boal says.

With continued schedule optimisation, Batchfire Resources is using the D11s to undertake more cross dragline pit bulk dozing with the D11Ts.

Batchfire Resources superintendent – dragline and mine services – mining and production Matthew Scales says that Batchfire has recently reintroduced dozer push back when setting up benches for the draglines.

“That’s to optimise the dragline fully and make sure they’re efficient in what they’re doing,” he says.

“It just makes them more productive by having the D11s in front of them. We expose more coal and progress the plan a lot quicker.

“We upload mine plans into them and we’ve put ramps in recently using that system, within 30 millimeters of the designs. I mean, that’s excellent.

“It takes a bit of pressure away from having people on the ground, exposing them to additional hazards.

“Being in Biloela, our relationship with Hastings Deering Rockhampton is crucial, and with that, the product support we get.

“Our journey with Caterpillar and Hastings Deering has been a long one

with our dozers. Caterpillar dozers are a cut above, they’re always reliable, easy to work on, they always hit their AV targets,” he says.

With improved technology, equipment updates and maintenance support, the Batchfire Resources team works with Hastings Deering to maximise the performance of its Caterpillar fleet.

For more information, visit www.hastingsdeering.com.au

Hastings Deering Rockhampton is providing top quality backup for the machines on site

Epiroc has acquired Australian mining automation solutions provider Remote Control Technologies

It is the second acquisition in as many months for the Swedish mining equipment manufacturer, following the announcement that Epiroc had become the majority owner of Australian mine connectivity provider Radlink.

The agreement was first announced on October 31 but was only formalised in November.

Epiroc says the deal to purchase Remote Control Technologies (RCT) will boost its capabilities as an automation solutions provider around the world for both surface and underground rock drilling as well as underground loading and haulage.

Perth-based RCT provides automation and remote-control solutions for mining customers across Australia and in more than 70 countries.

The company’s technology is applicable for either a single machine or across an entire fleet and is manufacturer-agnostic.

RCT also provides data and information systems, fleet and machine management systems and machine protection systems.

“Automation is increasingly important for the mining industry to strengthen safety and productivity, and RCT’s advanced solutions complement Epiroc’s existing automation offering well,” says Epiroc president and chief executive Helena Hedblom.

“Together we will provide complete automation and remote-control solutions to support our customers on their journey towards optimal operations.

“We are especially pleased that Bob Muirhead, RCT’s founder and a true pioneer within mining automation, will continue in an active management role. We look forward to welcoming the strong RCT team to Epiroc.”

Liebherr has upgraded its 70–100 tonne crawler excavator range

The upgrades are part of revisions to the range that will see the new R 972, R 978 SME and R 998 SME crawler excavators replace the R 966, R 970 SME, R 976 and R 980 SME models.

Among the changes to the new excavators is a new designation, which Liebherr says is related to the operating weight of the machines.

Using the patented Liebherr Power Efficiency (PE) engine control system, the new excavators boast a significant reduction in overall energy consumption compared to their predecessors, it says. Using the PE function, the new models reduce fuel consumption by up to 15 per cent.

The new excavator range is also available with the bucket fill assist function whereby operators have additional support when using the machine by preventing the bucket from jamming when penetrating material.

The assist function also enables semi-automatic bucket filling, meaning faster cycle times, higher bucket filling levels and overall better penetration into digging material. The bucket fill assist system also results in a 10 per cent reduction in fuel consumption and a reduction in vibration.

All new Liebherr hydraulic crawler excavators in the new G5.2 and G6.2 series are equipped with the Modetronic function, which provides operators more comfort and productivity by offering assistance both when driving and during rotary motion.

Liebherr says the Modetronic

The new crawler excavator models are 10–15 per cent more fuel efficient than the models they are replacing

function enables more dynamic behaviour of the excavators when in Dynamic mode and more stability in Efficient mode.

Custom mode is also equipped and supplements the working modes with greater precision, while Fine mode allows the operator to make individual adjustments to the machine to best suit their own preferences.

Inside the cab, the excavators feature a bigger main display screen –which has grown from seven to nine inches – and foot control units ensure more precise machine movements can be performed.

As an option, a continuous chain guide is available for all models in the new range.

Individually, the R 998 SME gets a new chassis with an operating weight that exceeds 100 tonnes, along with larger track dimensions of 3,900mm and a wheelbase of 5,000mm.

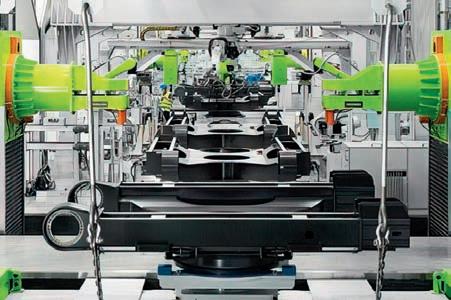

Zoomlion is automating its machine production, with new excavators being produced every six minutes

Chinese manufacturer Zoomlion Heavy Industry Science & Technology Co., Ltd. has announced that it has produced its first excavator exclusively through intelligent manufacturing (IM), where the entire manufacturing process is automated. Zoomlion’s IM is now producing excavators on average every six minutes.

Zoomlion’s Excavation Machinery Smart Park has seven workshops and 61 intelligent production lines, six of which are fully unstaffed production lines. With a 100 per cent key process data collection rate, it has fully functional IM operations from material preparation, welding, machining, painting, assembly to debugging, and is one of the most advanced IM factories in the world. The Smart Park has an annual production capacity of 50,000 units of excavators with a tonnage range of 1.5 to 50 tons (1.4 to 45.4 tonnes).

Zoomlion is utilising 5G, big data, industrial internet, AI and blockchain to build 14 lighthouse factories simultaneously and has used these technologies to reduce the production cycle time by 55 per cent.

In addition to the Excavation Machinery Smart Park, Zoomlion has built the world’s biggest tower crane IM factory, a key hydraulic components industrial park and the Yuanjiang mixer truck IM Industrial Park, producing excavators on average every six minutes, tower cranes every 18 minutes and mixer trucks every 18 minutes.

Construction machinery giant Kobelco is using IFS Cloud for greater agility and customer responsiveness

Kobelco has selected IFS Cloud to improve its supply chain, from procurement to manufacturing, sales and service management.

This major agreement will see IFS Cloud implemented for 8,000 users across Kobelco’s operations in 11 countries, starting with its home market in Japan.

Its construction equipment can be customised in the field and requires individualised management even after sale, and Kobelco found its previous platform was unable to support the required functionality without the development of a huge add-on system. IFS Cloud can handle customers’ customisations and integration with services, improving the quality and speed of service Kobelco provides to customers.

“IFS Solutions has a proven track record of supporting the core operations of global machinery manufacturers and has a high level of expertise that

IFS Cloud will be applied to Kobelco’s systems across the world, starting in Japan

contributes to the realisation of business transformations,” Kobelco Construction Machinery managing executive officer Hiroyuki Hosomi says.

“We expect it to also have the ability to achieve a high level of responsiveness to expanding global customers.”

IFS group chief operating officer Michael Ouissi adds: “Kobelco Construction Machinery is transforming to meet customer requirements through innovation, excellence, and the ability to adapt quickly to changes in demand. We are proud to partner with them on their digitalisation journey.

“IFS will deliver the next-generation enterprise resource planning capabilities and comprehensive solution set that Kobelco needs for end-to-end optimisation in today’s rapidly-changing markets where organisational agility and responsiveness are essential.”

Hidromek remains the market leader in Turkey and has sold in excess of 50,000 machines around the world through its global dealer network.

Hidromek has developed a range of machinery that has obtained an impressive list of design awards including German Design Awards, IF Design Germany Awards, Red Dot Awards, ABC Awards, Automotive Brand Contest Awards and several Good Design Awards.

Hidromek is continuously developing its existing machinery range and expanding with new releases. In the last few years a new series of excavators has been released, along with numerous new machinery models.

At the latest bauma show, Hidromek launched several new releases, including the HMK630WL wheel loader, K4-Series backhoe loader, a tracked mini backhoe loader HMK62T, HMK680MG grader, HMK235LCSR, HMK520LCHD, HMK150WR and more.

Onetrak took over the national distribution of Hidromek construction equipment in 2018 and has recently reached a milestone by delivering over 250 machines in Australia.

“2022 has been a wonderful year for new Hidromek sales,” Onetrak national sales manager Al Garcia says.

“The machines have rightly earned their deserved recognition as a high quality European manufactured product that is highly reliable and very refined to operate in any conditions.

“This, along with our commitment to customer support, has given many new customers the confidence to invest in Onetrak and Hidromek.

“It is due to the continued commitment and magnificent work that our team does both in promoting the machines and servicing the Hidromek product to the highest standard that is helping us achieve our goals.”

Onetrak managing director David Hazell gives some insight into the

“We are proud to be the sole Australian distributor for the quality Hidromek product and very grateful for the loyal support we have received from customers across Australia.

“This milestone of 250 machines sold in Australia is significant, but we are certain it will be the first of many. The Hidromek product is heavy-duty but, at the same time, very refined.

“I am pleased to say we are experiencing a considerable amount of repeat business with

happy clients and operators. At Onetrak we are very confident in the future with Hidromek and continue to invest in increased levels of parts inventory, service training and infrastructure to support this brand with our talented staff nationally.”

In addition to selling Hidromek machines, Onetrak also has Hidromek machines in the rental fleet offering various options for customers regardless of whether they are looking for short-term hire or their next equipment investment.

The Onetrak dealership network covers sales and aftersales Australiawide with branches in Victoria, New South Wales, Queensland, Tasmania, South Australia and Western Australia.

Get in touch with Onetrak today to learn more about Hidromek or to book in a demo. Visit www.onetrak.com.au or call 1300 727 520.

The LG938L wheel loader is your perfect utility machine. This all round workhorse is ideal for sand and soil yards, concrete batch plants, feedlots, material handing, farm use, waste recycling and general construction. Get ready to work with SDLG wheel loaders’ renowned versatility, fuel economy and performance.

The new year came early for Queensland’s Olympus Loaders, with its FS400 wheel loader proving so popular that units earmarked for release at the beginning of this year already sold and on their way to customers.

“It’s their reliability,” says Olympus Loaders director Simon Collins to Earthmovers & Excavators magazine.

“We’ve got a big country with a small population so we’ve been growing by word of mouth and no-one can give them a bad rap because we’ve never had failures.”

With many years of supplying loaders under his belt, having originally worked at the family business before setting up Olympus Loaders, Collins says his machinery is based around providing a value-for-money option for farmers and construction contractors across Australia.

“I spend a lot of time servicing the agricultural community, talking with the farmers, doing all the trade shows around the country, listening to what they had to say about what we need to do to make our loaders better and we just evolved as time went on,” he says.

“Different areas require different applications for the machine. So, South Australia is mostly bigger gear for the grain and then up here in Queensland there’s a lot more tree clearing and dam desilting. But the main thing is listening to the customer about what they need, what they want, and evolving the machines to have the capability to do what they need them to do.”

For construction firms looking to expand their loader fleet, Collins says the Olympus brand of Chinese-built loaders provides a cheaper option to big-name brands like Cat and Komatsu, while retaining the longevity and durability. He says the backto-basics approach of not including complicated electrics is a key selling point for many.

“We haven’t got any computer systems in them, so you don’t get the fault codes going off all the time, but we match the quality of other brands and use Cummins engines and ZF transmission, so the reliability is there,” he says.

“We’re probably a third of the price of the big main brands. Australian

farmers have tested these over the years and lot of batching plants are using our stuff as well for bulking out, as well as recycling plants for crushing concrete.

“We go right up to our 26-tonne loader that holds seven-and-a-half tonnes in the bucket for the guys in the quarries as well. We have a few quarries that are running the gear.

“For reliability we don’t get downtime with our product. They’ve been running in recycling yards for seven or eight years and we still haven’t even started selling parts yet.”

One of Olympus’ top performing loaders is the FS400, which boasts a 180 horsepower (134kW) Cummins engine. With a reinforced drive system and long wheelbase the FS400 has a large breakout force and great traction for those who want a powerful, high-performing loader.

On the inside, an enlarged cabin proofed against noise, shock and dust provides a high level of comfort

for operators, alongside robust air conditioning and joystick control. Maintenance has also been made easy with a rear-opening engine hood and a self-cleaning disc brake system.

“The FS400 comes in at 12 tonnes in weight and will lift four tonnes in the 2.4 cubic metre bucket,” Collins says.

“It comes with a quick hitch, so it’s a tool carrier. We can drop off the bucket and put forks on or long grabs – whatever the application is. We also have the ripper option at the back if you want to break up ground. A lot of guys use these for tree clearing –because it’s 180hp, it can push a stick rake very well.

“The FS400 also has external transmission coolers fitted so it will do the long, hard grinds in hot weather with no problems – it’s what they are designed to do.

“We do all the attachments as well, from stick rags to log grabs to rippers, bale grabs, forks and augers for drilling. This product’s eight years old now, so it’s been proven over the years and that’s why it’s one of our biggest sellers.”

To keep up with the popularity of Olympus’ farm and construction loader ranges, the business opened up three new dealerships in recent months – run by Equipment & Service Co. in Tamworth, Condobolin and Lake Cargelligo in NSW.

“Equipment & Service Co. have been around 60-odd years and it’s great to see these new sites up and running,” Collins says.

“With all the rain down there, things are kicking off now as it starts to dry out and everyone needs to do their repairs.”

All machinery is assembled at the Olympus Loaders headquarters in Loganholme, Queensland, where the team undertakes extensive pre-deliveries and checks before

the machines are shipped around Australia. With new units being snapped up before they’re released, Collins says it’s going to be another busy year for the business.

“We hold all of the components in China ready to build so we can custom-build a loader in 60 days in the worst-case scenario – 35 days normally,” Collins says.

“We’ve always got machines coming in. We’re top of the chain in the Chinese wheel loader market, that’s for sure.”

For more information on Olympus Loaders’ equipment, visit: www.olympusloaders.com.au

It’s time to join the digital revolution, with Komatsu’s Retrofit Kit giving excavator owners the ability to upgrade an older machine with 3D machine guidance and payload meter technology

Currently available for Komatsu excavators in the 13 to 36-tonne range, the Retrofit Kit turns older models into intelligent machines for improved efficiency and cost savings.

To showcase the advanced functionality the kit brings, Komatsu has been running a highly popular introductory offer combining the kit with its PC138US-11 and PC138USLC-11 excavator models, which Komatsu national business manager – construction Scott Berry says are the company’s biggest-selling construction machines.

“They’re a really good machine –a medium-sized excavator that you can put a breaker or bucket on and they’re big enough to fill trucks, as well as being a good size for transport,” Berry says.

“It can do everything, from rail work to any type of construction site. Even on bigger building sites they’re good as a utility machine to get in and clean up and do things that the bigger machines can’t. And they’re a pretty good size for a small contractor that just has a small truck.”

Weighing 15,500kg (PC138US-11) or 15,852kg (LC version with longer tracks), these two models have a 0.53 cubic metre bucket capacity and a 97 horsepower (72.5kW) Tier IV engine, as well as a short tail swing radius and improved fuel consumption.

“We’re all about safety, so a new feature on this machine is KomVision, which gives a bird’s eye 270-degree view from the other side of the boom, right around to over your left shoulder,” Berry adds.

“It also gives you specific camera angles so you are aware of anybody that may be near the machine.”

Included as standard is the Komtrax telematics system that provides location, utilisation and maintenance information for the machine, but Berry says there have been a lot of requests for 3D technology to also be included on machines of this size, which is where the Retrofit Kit comes into play.

Enhancing the capabilities of the PC138US-11 and PC138USLC-11

The 3D guidance technology allows for changes to design planning data to be delivered to the cab. 3D guidance can reduce rework and increase safety on site

models, as well as a wide range of other model excavators, the Retrofit Kit from Komatsu brings the functionalities of 3D machine guidance, a payload meter and access to 3D construction data to an operator’s fingertips.

3D machine guidance gives the machine operator the ability to see any differences between design data of the construction area and location of the bucket edge. As-constructed information is also collected from the machine, which can be visualised in a dashboard to allow for automatic updating of the design, while the payload meter measures the weight of soil in the excavator’s bucket.

Komastu smart construction technology consultant Marc Brook says the kit is particularly attractive in the current environment of high labour costs and skills shortages.

“In Australia, we’ve been quick adopters of this type of technology over a number of years now,” he says.

“So, it’s not necessarily new technology, but it’s continually been improved to get better and better and include aspects like the integrated payload system.

“Traditionally, surveyors or grade checkers or labourers would have to do manual surveys and mark out the site with pegs and string lines. They don’t have to do that anymore. All of the 3D design data and the line work is all presented to the operator in the cab.

“This kit helps to alleviate skills shortage issues, to make operations more effective and less limited by resources and costs.”

The system uses GNSS satellite positioning wherever you happen to be, no matter how remote, which achieves a high level of accuracy even in harsh environments, while sensors along the arm and on the bucket provides the positioning data of the cutting edge.

“Now that we have that information, it displays that position on the 10-inch

display in the cab to the operator,” Brook says.

“So, it’ll display the current position of the machine in real time against the 3D design.

“The system itself has its own Wi-Fi access point, which allows the tablet in the cab to talk to the controller and the sensors. In metropolitan areas, the kit comes with a cellular 4G/5G modem, which can be used to connect to RTK correction services. In remote areas we have the option of fitting a UHF radio.

“This connection can be used for two-way data, where design data from the engineers’ or surveyor’s computer in the office can be sent directly to the machine, so an operator is always running off the latest design data.”

As-constructed data can also be sent back at the end of a work day to show how much material has been moved.

“A lot of fleet hire companies and

construction companies that are already using this type of technology will get benefit out of this, either on their older machines or on new ones,” Brook adds.

“It’s opening up the market to people that weren’t necessarily looking at 3D guidance and payload systems, just because it was cost prohibitive before. Now, they get the benefits of 3D, which means they can move the machine around easier between jobs and out around the site and still get accurate positioning.

“It’s for new users as well. With those new applications, they can create their own simplified designs on the fly. So, when they’re waiting for design data to come from engineers or surveyors, they can actually create flat pads or simple sloping pads and stuff like that, where they can create their own surface to dig to, so that they can be effective in the times where design data is not available.

Over the past year, the kit’s functionality has been put to the test by operators across Australia, with Brook saying that the feedback has been taken on board to ensure the kit meets the needs of contractors working in this environment.

“We went through a process of ruggedisation,” he says.

“We know that Australian job sites are quite harsh environments in places, so we’ve done a lot of work to make sure that the components of the kit are robust and reliable.

“As far as the actual functionality of the kit goes, particularly due to the labour shortages in Australia, not only does having this 3D guidance functionality reduce the costs associated with traditional surveys, it also increases safety by not having to have people working near the machines, doing manual grade checking or manual surveys.

“It also allows operators to be more effective and minimises the chance of rework being required on site. If an operator is following pegs or string lines, and something happened those guides, like they were obstructed or damaged, it can lead to errors. With this system, there’s no guessing involved. Everything is presented there in real time.

“We’re always taking feedback from customers on ways that workflows can be improved, or that allow them to utilise the technology even more effectively. We’re also looking at broadening and opening up compatibility to additional sizes of machine as well as different makes and models.”

The Retrofit Kit is available now as a standalone option for customers who already own an older model excavator and are looking to upgrade, and it is also available as a factoryfitted feature on the new PC138US-11 and PC138USLC-11 machines, as well as other factory models.

For more information, visit: www.komatsu.com.au

With a new large-capacity concrete plant opening in north Melbourne came the need for a large-capacity machine to transfer aggregate around the site. Titan Premix’s new Hyundai HL970 wheel loader from Porter Group is taking on the challenge with ease

On the northern edge of Melbourne, a brand-new Hyundai HL970 wheel loader from Porter Group is getting to work loading aggregate at Titan Premix’s new ready-mix concrete plant in Epping.

Weighing in at 23,800kg and with a bucket capacity of 4.2 cubic metres, the HL970 is a step-up for Titan Premix, which was looking for a higher performance loader to handle the expanded workload, says the company’s managing director Adam Trovatello.

“We started operation in 2020, but our background has always been concrete, starting with my grandfather about 40 years ago,” he explains.

“Myself and my brother recently decided to take up the reins and set up Titan Premix in 2020. We’re proudly independent, which is our point of difference in the market.”

Supplying ready-mixed concrete to the metro Melbourne market as well as regional Victoria, the brothers also

operate a quarry further north near Kyneton, which produces crushed rock and aggregates, and two concrete production sites in Riddells Creek and Bacchus Marsh.

From the very beginning, Titan P remix and its quarry sister business have been supported with loaders, crushers and screening equipment from Porter Group, with Hyundai machinery being a firm favourite with Trovatello.

“We’ve previously bought other models, like the 770 Hyundai wheel loaders,” he explains.

“However, with our super plant in Epping, we wanted something with a bit more capacity, a bit more power, and the new HL970 certainly delivers it.

“It’s a higher volume plant, so we will be able to produce more concrete, quicker, which is delivered by our fleet of 35 agitators.”

He says that he has stuck with Hyundai machinery due to the high levels of operator comfort in the cab and the machines’ durability and

longevity, even when operating in harsh environments. With the HL970 now on board, it’s proving to be a vital cog in the Epping operation.

“On a daily basis we use the HL970 to load up the aggregate bins to produce the concrete as well as pushing out the raw material that the tippers are bringing into the site,” Trovatello says.

“It’s a crucial part of our plant –without that loader, we can’t make concrete. We needed to make sure that we had a reliable loader for the operation.”

Designed for industrial, construction, mining and quarrying applications, the HL970 meets Tier 3 emission regulations with its 280 horsepower (209kW) six-cylinder engine. With a four-speed transmission, it has a top

forward speed of 40km/h and a top reverse speed of 26km/h.

The HL970 comes with a range of features to optimise fuel efficiency and production. This includes automatic engine shut down to reduce idling, an idle engine booster that increases idle engine rpm for better operation and prompt reaction, an optional hydraulic differential lock to prevent tyre slip during operation and intelligent clutch cut off.

Smart Power Mode reduces fuel consumption by adjusting the engine speed in heavy load work like digging to provide a balance between traction force and breakout force, while an Eco Report shows inefficient operation to improve an operator’s habits.

On the safety side, the nine-camera Around View Monitoring feature provides the operator with a clear view around the machine, while the

Intelligent Moving Object Detection system detects people around the machine and analyses the images – displaying a warning sign on a monitor when detecting the danger.

Other features include an emergency stop, seat belt warning system, on-board weighing system, optional auto greasing system and the option of including Hyundai’s Hi-Mate remote fleet management system to provide diagnostic information that can be accessed remotely, including fuel level monitoring and geo-fencing.

Trovatello says that the new HL970 is fantastic, with his stand-out features being the joystick steering and personalisation of the controls. He also says the training provided by Porter Group was very useful.

“It’s comfy in there – are there are a lot of good features,” he says.

“When we’re looking at purchasing a new machine, we look at reliability and fuel efficiency and that’s one good thing about Hyundai – their machinery is always fuel efficient and they tick all the boxes.”

With the new concrete site open in Epping, Trovatello says that the future is looking bright for the business, despite a difficult start during COVID-19.

With the construction industry picking up speed again, expected population growth in Melbourne and the Victorian government undertaking its Big Build plan of infrastructure projects across the state, Trovatello says Titan Premix will continue to expand, supported by Porter Group and its machinery.

We wanted something

power and the new HL970 certainly delivers it.

A

The HL970 has been proving its worth at Titan Premix’s new site, which has only been open for a couple of months

B

Hyundai’s Hi-Mate remote fleet management system provides diagnostic information that can be accessed remotely C

Adam Trovatello says the customisable controls is a stand-out feature

“We will be expanding in the future with more concrete plants in metropolitan Melbourne,” he says.

“In the short-term we are definitely going out west – we’ve got a couple of sites planned in the inner west of Melbourne – and we are just looking to improve our current operation.”

Trovatello says the company’s ongoing work to make its operations more sustainable is also driving innovation in the business.

“We’re working to reduce our carbon footprint by developing and testing mix designs that push the limits of supplementary cementitious materials and recycled aggregates,” he explains.

“The location of the Epping site was chosen for this reason – situated inside the Repurpose It facility [which is aiming to eliminate waste and pollution through closed loop

resource recovery] we have direct access to recycled aggregate and washed sand.

“As third-generation concrete suppliers it’s our responsibility to contribute to the advancements in green concrete, while still following and believing in the same values that guided my grandfather and father through their businesses.”

Trovatello says having the strong support of a dealer who can be relied upon to keep machinery up and running is key to both keeping his business operational and being adaptable to changing times.

“We’ve been working with Porter Group since we started Titan a couple of years ago,” he says.

“They’ve been great, especially in early days during COVID – they were always there for support. And with us being such a young

company they really made sure that we had everything that we needed.

“Porter Group are very accessible and are on site at the drop of a hat if needed. Their maintenance and service are great.

“It was tough operating a business during COVID, but we are still very optimistic for the future and that’s partly due to our history, which we are very proud of. We know we can get through whatever we have to get through in tough times.

“As we move forward with our expansion plans, we’ll be bringing Porter Group along with us. We’re very, very happy with the service they provide.”

For more details on equipment available for purchase through Porter Equipment, visit www.porterce.com.au

with a bit more

Among Precisionscreen’s extensive range of Australia-built mobile screening, washing, crushing and recycling equipment is a set of mobile conveyors, running from the 10m (30-foot) SM450W through to the 30m (100-foot) SM1290 and SM12120 models.

Built in Brisbane, Precisionscreen prides itself on creating heavy-duty equipment that can stand up to the high temperatures and dusty conditions on Australian worksites.

Predominantly used for quarrying and mining applications, but also applicable for recycling and feedlot applications, the mobile conveyor range include features such as triple-sealed bearings, heavy duty conveyor belts and bespoke poly rollers with a deeper inset bearing to handle rough conditions, explains Precisionscreen chief operations officer Jonny McMurtry.

“Like all of our machines, these conveyors are built to last,” he says.

“We have customers who have high expectations, especially within the quarrying and mining

industries, so we make sure that everything that leaves our factory meets Australian standards and customers’ expectations.”

As well as having a high level of durability, Precisionscreen’s conveyors are also built with flexibility in mind – able to convey everything from rock straight from a crusher through to sand washing and wet material being transferred for dewatering.

“We predominantly supply these conveyors along the east coast,” McMurtry says.

“But, right across Australia, we have a wide range and large number of these conveyors moving different types of material.”

All Precisionscreen conveyors are mobile, so can easily be towed around a site as needed, or in some cases driven around the site, as McMurtry explains.

“Every single one of our conveyors comes on the bare minimum of a wheeled axle frame, with a track

In the middle of the range is the SM850 18m (60-foot) conveyor with a 800mm-wide belt

dolly application being offered for some of our bigger stockpilers. For some of the bigger ones, such as the 80-foot SM1090 or 100-foot SM12120, we also have the capability to include a power pack on board, so they’re self-propelled.

“A big focus for us, going into 2023, is the electric drive application. We’re getting a lot more inquiries for an electric over hydraulic drives or direct electric drive, from people looking to reduce their costs when compared to diesel. This has become more sought after. So, the volume of electric drive options we’re hoping to offer is going to increase.”

He says that this is a general trend being seen in the construction industry as attention turns towards alternative fuels and ways to cut costs, with electric versions of machines being a significant feature of the bauma 2022 show in Munich.

“Therefore, for our smaller conveyor

range, we’re starting to offer either a direct electric drive or electric over hydraulic drive, whichever the customer prefers,” he adds.

At the upper end of the conveyor range, the SM1090 (24m) and SM1290 (30m) versions have 900mm-wide EP150 heavy-duty belts, heavy-duty channel sides, Precisionscreendesigned and manufactured poly rollers, manual radial wheels, a tow bar and ground pivot, triple sealed bearings, a discharge scraper blade and are fully galvanised.

The SM1090 has an operating height of 10.28m and a discharge height of 9.5m, while the SM1290 has an operating and discharge height of 12.3m. For applications that need a higher throughput, the SM10120 (24m) and SM12120 (30m) have a 1,200mm-wide belt and a discharge height of 9.6m and 12.3m, respectively.

“These are predominantly used for bigger quarry applications where they need high volumes of stockpiles or kidney stockpiles generated,” McMurtry says.

“We’re talking a throughput of anywhere between 450 to 600 tonnes an hour. These come with a beefed-up axle that has a hydraulically-driven radial drive, which enables the operator just to hydraulically turn and create these larger kidney stockpiles for increased efficiency, as opposed to having a loader run back and forth and move material around. It’s much easier, cost effective and just good practice to have the conveyor slew round as

opposed to having a loader driving around and making stockpiles.”

A variety of configurations and attachments can further customise the conveyors to best suit whatever applications they are destined for, such as a precoater kit or weighing system.

“For all of our conveyors we offer different attachments – a popular one being a simple tumbler chute that hangs off the end of pretty much all our conveyors and allows screened material to drop straight onto the conveyor belt,” McMurtry says.

“For precoating, we have a tumbler chute with spray bars inside it, which effectively precoats the material with a precoat mix. So, it’s just a costeffective way of doing something like that. We also manufacture in-house

For heavier-duty applications, the 24m (80-foot) SM10120 conveyor has a 1,200mm-wide belt

our own load cell kits where we can digitally read or calculate how much material’s going up the belts. It might be per hour, per shift or per batch and it gives you an extra functionality and understanding about the materials being handled.”

With extensive experience building and customising equipment for the quarry, mining, recycling and materials handling industries, Precisionscreen continues to innovate its product lines to help operators get the most from their operations.

“We’re extremely proud to still be manufacturing,” McMurtry says, “These are Australian-designed conveyors manufactured and fabricated in Australia and we always have Australian operators in mind. A lot of these conveyors are built to order, so any customer preferences that there might be we can adjust to meet a customer’s demands at the point of order and at time of delivery.”

For more information on Precisionscreen’s conveyor range, visit: precisionscreen.com.au

Utility

Platinum class

36 months / 1500hrs EPTW

• Up to 500hrs

• PM Clinic / KOWAS

• Presents as new

Platinum class

36 months / 3000hrs EPTW

• Up to 3000hrs

Gold class

24 months / 1000hrs EPTW

• Up to 1000hrs

• PM Clinic / KOWAS

• Presents well

Gold class

24 months / 2000hrs EPTW

• Up to 4000hrs

Silver class

12 months / 500hrs EPTW

• Up to 1500hrs

• PM Clinic / KOWAS

• Presents well

Silver class

12 months / 1000hrs EPTW

• Up to 6000hrs

Bronze class

6 months / 250hrs EPTW

• Up to 2500hrs

• PM Clinic / KOWAS

• Presents well

Bronze class

6 months / 500hrs EPTW

• Up to 8000hrs

Construction

Mining

• PM Clinic / KOWAS

• Presents as new

• Includes Hybrid / IMC

Platinum class

36 months / 4000hrs EPTW

• Up to 3000hrs

• PM Clinic / KOWAS

• Presents as new

• PM Clinic / KOWAS

• Presents well

• Includes Hybrid / IMC

Gold class

24 months / 3000hrs EPTW

• Up to 4000hrs

• PM Clinic / KOWAS

• Presents well

• PM Clinic / KOWAS

• Presents well

• Includes Hybrid / IMC

Silver class

12 months / 2000hrs EPTW

• Up to 7000hrs

• PM Clinic / KOWAS

• Presents well

• PM Clinic / KOWAS

• Presents well

• Includes Hybrid / IMC

Bronze class

6 months / 1000hrs EPTW

• Up to 10000hrs

• PM Clinic / KOWAS

• Presents well

With a new machine and business operations booming, the year ahead is looking promising for the team at Active Machinery

Based in the south-east Melbourne suburb of Dandenong South, Active Machinery has recently added its first telescopic mini skid steer to its growing product line-up, which also includes a range of mini excavators and wheel loaders ranging from four to 23.5 tonnes.

Active Machinery brought the new AS550TS in Australia to gauge customer interest, before importing larger numbers of the units.

The skid steer is a stand-on machine, meaning the operator stands at the back unlike other conventional sit-in skid steers, and sales team member Steve Willis says the AS550TS is unlike anything he has seen in Australia to date.

“I did my research before we bought them in and I haven’t found anyone else selling the same telescopic skid steer,” Willis says.

The operator works the machine from a standing position

“We

The AS550TS is powered by a Kubota engine that produces 50 horsepower (37kW). Without any attachments it weighs in at 2.3 tonnes, putting on the heftier side when it comes to skid steers, meaning it is best suited to larger earthmoving applications.

“The horsepower is there and the reach is there, but, with this machine,

it requires a bigger trailer to carry it and take it places.

So, at the end of the day, it isn’t something that everyone needs because it’s not for the tight access jobs. But it does save you having to sit in a machine and it gives you that option if you did want to have a standon machine. It’s been great so far.”

Perhaps the most eye-catching aspect of the AS550TS is its telescopic boom that, when fully extended, can reach 3,042mm. At full extension, the machine can lift and dump 1.1 tonnes of material – a figure that is increased to 2.4 tonnes when the boom is retracted.

“It has a lot more reach than other stand-on units,” Willis says.

As standard, the skid steer is equipped with a four-in-one-bucket, making a versatile addition to any jobsite, but can also be equipped with other attachments such as rock grabs.

On the operator platform, manoeuvring the machine has been simplified, with two single-joystick operations – one that moves forward, back left and right, and another to move the boom up and down, as well as dumping the bucket.

The AS550TS is also equipped with levers on either side of the machine, which control the couplings on the respective side of the machine.

“So, if you had an attachment that required two sets of couplings, such as a rock grapple that clamps, logs and rotates, you could use that on this machine,” Willis explains.

While the AS550TS is the latest addition to Active Machinery’s product line-up, it certainly isn’t the last. The team are exploring new machines such as new sit-in skid steers and larger excavators to complement the existing range that spans 0.8–1.8 tonnes.

Active Machinery also provides service and maintenance on all its machinery across Victoria, New South Wales, Queensland, the ACT and South Australia.

For more information visit www.activemachinery.com.au

decided to bring two units in to see how they went and take them to field days.”The AS550TS is Active Machinery’s first telescopic skid steer

What a year. Even the best crystal ball was clouded. The year started with the borders opening and the inevitable wave of COVID-19 spreading across the country.

In addition, we have seen Russia invade Ukraine, the death of Queen Elizabeth II and the succession of King Charles III, three British Prime Ministers, the Beijing Winter Olympics and the world’s population reaching eight billion people.

In Australia, we have seen: a change of federal government, widespread floods, increasing inflation, eight interest rate rises, record low unemployment, high fuel and energy costs, an accelerating commitment to renewable energy and a shortage of skilled labour.

The stimulus programs designed to support Australia’s economy were starting to hit their straps. In hindsight, whilst well meaning, this could this be considered too much too quickly.

The combined effect of these domestic and international circumstances provided extremely fast-evolving challenges to industry, and their consequences have been profound. Contractors were locked into fixed price contracts whilst their input costs rose significantly faster than could have been reasonably anticipated. Without relief from their clients, it would be inevitable that the chance of survival of these companies would be diminished. This was demonstrated to be the case, evidenced by some headlining building and civil companies being forced into administration.

The inflationary pressures have put pressures on all Capital Works Programs. A lot of these programs and budgets were set on the eve of the extraordinary cost escalation.

Correspondingly to contractors, delivery authorities have had their budgets severely strained. Unlike

Long, CEO CCF QLD

contractors, these can be managed by delivering less of the program. Capital Works Budgets cannot and should not be balanced by redefining value for money as lowest price. Unfortunately, there have been examples of illinformed decisions that did this.

In Queensland, the Department of Transport and Main Roads should be congratulated on their early proactive approach to work with industry to provide relief to contractors as these challenges were evolving. However, government policy was exacerbating the issues, particularly around accelerated wage growth far in excess of underlying inflation.

The Queensland and federal government are now in budget preparation mode. The challenge is that their budgets must reflect the inflation effect and allow for escalation over the coming year and future budgets. If this is not done, there will be fewer opportunities going forward for the industry. The impact will be mostly borne by the mid to smaller end of the market.

In Queensland it is critical to ensure the industry is viable and has the capacity to deliver the combined weight of the Brisbane 2032 Olympic and Paralympic Games infrastructure and renewables program.

At this stage, it appears there is a lack of stability and believable strategy around the program of works for the Olympics Games. Many projects are on the table but the funding to support these are nonexistent. The state government insists there is a 50/50 agreement to fund the

necessary infrastructure, but I am yet to see a solid commitment from the federal government. In addition, the current state government budgets do not fully support an Olympic Games infrastructure program.

My fear is the state’s Capital Works Programs will be downgraded due to inflationary pressures and the urgent need to progress the Olympic Games infrastructure.

At present, the windfall from resource super royalties has outpaced inflationary increases on government spending. It will be interesting as to how these surpluses will be invested. Similarly, the federal government’s books are being supported by increased revenues from royalties and tax due to inflation. As noted previously, the Queensland Premier stated she felt that future federal budgets would be more favorable to Queensland. I’m hoping that these surpluses, at both federal and state levels, are invested into infrastructure. Not only the Olympic Games, but the wider infrastructure need.

Immigration will continue to increase from both overseas and interstate. The lack of housing is already a red-hot issue and unless the state government swiftly understands that its role is to facilitate a quick and economically supportive solution to the private sector the housing shortage will continue. Issues such as land availability, speed of approvals and infrastructure accessibility and support need to be promptly addressed.

My predictions for this year are that there will be some stabilisation in cost increases, a reduction in the number of capital projects for the first six months and a resumption of a more stable programs in the months thereafter.

There will be a bigger emphasis on renewable energy infrastructure construction with a parallel conversation around balancing energy production to ensure a sustainable and cheap supply, land development will be supported by high demand and there will be little progress on the delivery of Olympic Games infrastructure.

There seems to be so many moving parts that need to come together very quickly. At times, it appears that industry is operating on a parallel plane looking down on reality. Hopefully the two can come together quickly.

It was a challenging year for the industry in 2022 as it dealt with the impacts of rising interest rates. As we move into 2023, there will hopefully be greater stability, but planning infrastructure for the Olympic Games needs to be a priority

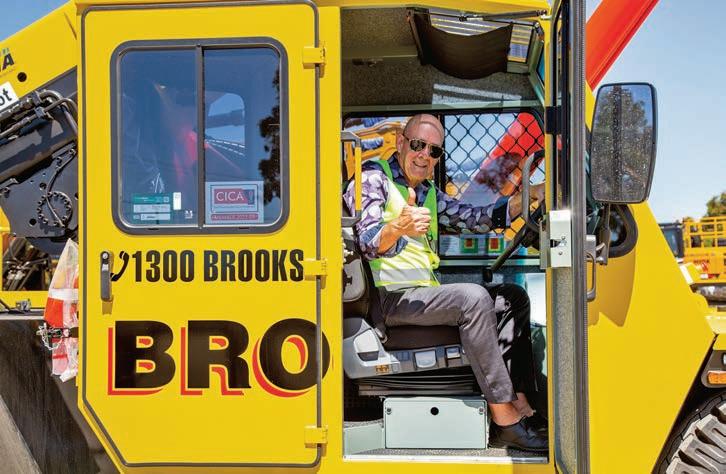

As most people who are familiar with the Brooks Hire story would know, the business was founded off the back of two un-serviceable air compressors purchased by Doug Brooks in 1979.

From there the business grew to acquire other small equipment such as pumps, generators and welders. Then, in 1982, Brooks purchased his first mobile piece of plant – a secondhand JEC crane.

At that time, Brooks Hire Service was still operating out of a tin shed in the remote WA town of Eneabba, approximately 275km north-east of Perth. Brooks tendered a total of $30,150 for the crane and won the bid. Next, he had to find a way to pay for it.

“I went and got a broker so I could borrow the money for the crane and they offered me an interest rate of 24 per cent,” says Brooks.

“Then, a few days later, they came back and said the banks wouldn’t lend me the money because I was high risk with no business experience.”

Brooks was left high and dry – he’d just won the tender and now he couldn’t finance the purchase. He scraped together about $800 and approached the broker again, this

time they came back with an offer of 27 per cent interest. “Deal,” he said. Stretched to his financial limits, he then faced the problem of how to transport the crane from Perth to Eneabba. To freight the machine by low loader would have cost $500.

“Geez, I didn’t have 500 bucks to spend on a low loader,” Brooks says.

“So, I hopped in it and started driving at first light in the morning. As I was driving, I started getting sideways on the road and I was

pointing at a truck. So, I reefed the steering wheel and came off the accelerator at the same time. Now with those cranes, as soon as you released the accelerator, you lost the hydraulic steering, so I ran right off the road.”

After a gruelling 13-hour journey, Brooks, with his trusty dog Jack on

Crusher & Screen Sales Pty Ltd (CSSH) are the IMS distributor for Australia since 2012 and have been instrumental with IMS in developing plant for Australia conditions and requirements, there has been a strong emphasis on high quality plant for blending and pugging material for the quarry, construction industry, remediation of contaminated soils and blending of recycled products. The plant has been designed with large feed hoppers and capacity to service small to large operations with manual controls that in most cases have the ability to be fully automated insuring constant and accurate blending and reducing operator errors. IMS also manufacture a large range of wheel and track conveyors with production up to 2000 tonnes per hour and up to 45 meter long and screening plants.

CSSH and IMS together continual to improve their plant with feed back from clients and adjusting or adding new plant and ideas particularly in the blending of products to make previously discarded and recycled products into a sellable item, there is a strong desire by departments to add recycled concrete and other products into construction materials to reduce waste, landfill and raw material demands.

The IMS-PM1050-16Tb Track Pugmill is now the largest selling pugmill In Australia with capacity of up to 500 TPH, available in manual adding only water / liquids or fully PLC computer controlled and recording system adding cement, lime, or most powders etc. The PLC can be controlled by an iPad in the loader operating all the functions including

client or batch mix changes, loading truck and multiple trailers direct, stopping automatically once each item had been loaded with the correct tonnes and then restarted off the remote to repeat on the next truck or trailer. The recording system displays all batchers for the day and filing into projects or client names along with a summary of the total products used for the day for management control. All reports can be sent to the office or client showing the programmed percentages of each product compared to the actual results including a graph combining all the products processed. The control system can be integrated with other IMS products including electric modular blenders and pugmills offering up to four raw materials and multiple powders and/or liquids all blended at once.

•IMS- PM1050-16TB Track Pugmill with Silo option and full automation

•IMS – BP1200-9TB Track twin hopper blender with mixer

•Rubble Master (RM) Track 22x5 three deck screen

•Rubble Master (RM) Track 16x5 two deck scalping screen

•Rubble Master (RM) Track 18x5 two deck screen

•IMS – 24-meter track stacker with loader feed hopper

• IMS – 14-meter track stacker with five-meter loader hopper with tipping grid

•IMS- 20-meter track stacker with a 1200mm wide belt can produce 900 TPH and a 300mm rock

•IMS 15-meter wheel hydraulic stacker

board, arrived safely at Eneabba at last light. The crane was soon out on hire to Allied Eneabba, where it remained on hire seven days a week for around six years. If it ever broke down, or needed maintenance, Brooks was straight out there to fix it to keep it on site and working.

Following Brooks Hire’s relocation to Perth in 1987, a further three cranes were purchased, but by 2000, all cranes were retired from the fleet. Since then, Brooks hasn’t had any cranes in its hire fleet. That is, until now.

The brand-new Franna MAC 25-4 arrived at Brooks’ Welshpool yard in mid-October and is the first asset on the books for new entity – Brooks Cranes. This model was chosen for its tried and tested versatility in a

range of difficult lifting applications.

The mobile articulated crane features a maximum lifting capacity of 25 tonnes. A unique feature of the MAC 25-4 is its patent protected Longitudinal Moment Indicator (LMI), which offers operators a dynamic real time calculation of rated load capacity.

It does this by taking into account the current boom configuration, as well as chassis articulation, pitch and roll. When operated on a jobsite over undulating terrain, the rated capacity will be updated continually, providing instantaneous information on the percentage utilisation. This means that operators are no longer required to manually calculate a reduction of rated capacity – the crane does it for them.

In addition to the Franna MAC 25-4, Brooks Cranes has also purchased

a Franna AT 22. This pick and carry model has similar key features to the MAC 25-4, but with a lifting capacity of 22 tonnes. The AT 22 is expected to arrive in the coming months.

Brooks Cranes is currently being managed by Brooks Access general manager Claire Harrison with the rest of the Access team standing behind her.

“It’s really exciting to be a part of the launch of Brooks Cranes,” Harrison says.

“By diversifying the equipment that we have on offer, we’ve really been able to better service our customer’s needs.”

Long gone are the days of appealing for finance. Brooks Hire is now the largest privately-owned construction equipment hire company in Australia. With 20 branches Australia-wide, and an ever-growing list of equipment hire categories, Brooks will continue to diversify to meet the needs of its clients.

Call Brooks Hire now on 1300 BROOKS (276 657) or go to www.brookshire.com.au and get an easy online quote.

Increasing worker safety around buried assets

The Australian Flexible Pavement Association (AfPA) has commended Transport for NSW for its adoption of the AfPA’s Guide for Locating Underground Utility Services on Profiling Projects

This guide provides information on safety procedures concerning the management of underground services, with Transport for NSW adopting the methodology for the process of cold milling – removing asphalt and concrete from a road surface – as part of its road building and maintenance activities.

The guide, developed alongside AfPA members and industry partners including energy company Jemena, is a significant milestone in roadworker safety, says AfPA.

It says work around undocumented infrastructure has previously exposed workers to extreme dangers, including gas mains and electrical hazards. The guide provides a step-by-step flow chart to help road crews minimise accidental damage of buried pipes and cables.

“The guide is a significant inclusion for the industry and now introduced into TfNSW specifications,” AfPA’s state executive director for NSW/ACT Lise Sperling says.

“It is our hope that more states will move to adopt similar measures to keep road workers safe. In states where large amounts of underground infrastructure and road work remains undocumented and unmapped below the surface, guides like this ensure that safety risk is minimised or significantly reduced in the delivery of and essential infrastructure upgrades.”

The guide can be downloaded from www.afpa.asn.au.

Position Partners named runner-up for TAFE Queensland Large Employer of the Year Award

Position Partners was named runner-up in this year’s TAFE Queensland – SkillsTech Apprentice Awards for the Large Employer of the Year award.

The company was nominated for its unique apprenticeship program, co-created with TAFE Queensland to build the right skills and knowledgebase for Position Partners field technicians.

“Our field technicians require a mix of skills and training to be able to support our customers with high precision machine control technology on heavy earthmoving equipment,” Position Partners strategic head of people & culture Bernadette Taoro Ashin says.

“We are delighted to have received recognition from TAFE Queensland at the awards night this year – it has been great to partner with them and collaborate on a progressive, tailored program that is helping to fast-track our apprentices with the skills they need on site.”

Specialising in the distribution and support of intelligent positioning solutions used in civil construction, building, mining and geospatial applications, Position Partners has

Position Partners has seven apprentices enrolled in the TAFE Queensland course

more than 350 employees across Australia, Southeast Asia and New Zealand.

The field services team supports customers with advanced survey and machine control technology used on excavators, graders, dozers and other heavy plant to accurately grade to a project design.

Position Partners has seven apprentices enrolled on the course, which incorporates a Certificate III in auto-electrical as well as communications network qualifications. The apprentices, who are employed by Position Partners across a number of locations in Australia, also benefit from a mix of online, face-to-face and on-thejob learning.

“In addition to the tailored course content, the apprentices are also benefitting from a mixed learning experience,” Ashin says.

“They learn on the job with experienced colleagues in their branches, but also alongside and from one another as a team during their time on campus.”

Speaking of behalf of Australia’s 537 councils, Australian Local Government Association (ALGA) president Linda Scott says that rebuilding roads to current standards will only cost Australian communities more in the long-term.

“In recent months, thousands of kilometres of local roads across NSW, Victoria, South Australia and Queensland have been severely damaged by flooding, and in some cases, have been washed away,” Scott says.

“ALGA has estimated the total cost of fixing and replacing these roads is in the vicinity of $3.8 billion, which is roughly the equivalent of Australia’s annual foreign aid budget.

“Considering the ongoing impacts of climate change, we can’t simply rebuild our local infrastructure – including roads, footpaths and cycleways – to current standards, we need a fundamental shift in the way we fund, deliver and maintain these assets.”

ARRB chief executive officer Michael Caltabiano says the extensive damage to large parts of the road system across several states was a major wake-up call and an opportunity to evolve the way Australia’s roads are constructed and managed to deliver more resilient outcomes.

“Moisture is kryptonite for roads

and inevitably leads to potholes,” he says.

“This year’s floods and torrential rains have caused large scale catastrophic damage to the road systems that connect communities and deliver freight. Now is the time to reassess what innovations are possible to prevent a repeat of this infrastructure emergency.”

He says that standards and materials used for constructing Australia’s road systems needed to change to improve water resistance and quicker recovery after significant rainfall events.

“Australia houses some of the smartest road technology in the world and the latest ARRB research shows many recyclables – including tyre rubber – are not only ecofriendly but create a more durable and resilient road surfaces,” he says.

“The Australian Road Research Board also has a range of the stateof-the-art vehicles fitted with lasers and high-tech equipment to measure road conditions at traffic speed. Pinpointing the issues on a road can ensure valuable maintenance dollars are spent in the right place, at the right time.”

Scott says that, while councils appreciate the significant federal government support they receive, they need an increase in Federal Roads to Recovery funding from

With increasingly severe weather causing damage to roads, the ALGA says a rethink is needed to make them more resilient in the long-term

$500 million to $800 million per year to help invest in new technologies and build more resilient roads.

“ALGA has advocated for betterment funding to be more effectively incorporated into Disaster Recovery Funding Arrangements, and we are pleased the government has indicated they are keen to progress these changes,” she says.

“While many councils are facing unprecedented flooding, others in the Northern Territory and northern Western Australia see their roads washed away every wet season, and these councils need more support to break this cycle.”

She adds that the government’s new Disaster Ready Fund would play a key role reducing damage caused by natural disasters.

“No amount of innovation can save a road that’s underwater, so it’s vital we continue to invest in flood mitigation,” Scott says.

“Allocating $200 million per year is a great first step, but we need to continue to grow this investment if we want to effectively safeguard our local towns and communities.”