This impact crusher boasts the best ratio of weight to throughput capacity, combined with equipment perfectly matched to each application, promising maximum flexibility. The operator can also monitor the status of the machine without leaving the cab.

The M515 Track Trommel is perfect for cleaning dirty material and can handle rocks up to 800mm in size. It comes complete with fold out stockpiling conveyors and is ideal for moving around the quarry and from one site to the next.

TradeEarthmovers

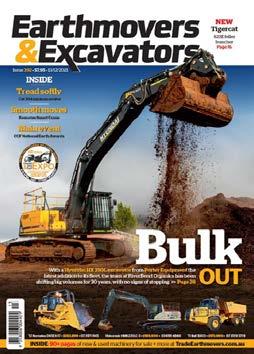

In this issue, Porter Group adds Bergmann site dumpers to its offering, Topcon Positioning Systems releases new laser range, Komatsu acquires GHH Group, a Vermeer trencher makes short work of NBN installation, Volvo CE releases two new electro thermo-controlled fixed screeds and makes plans to display its new DD25 Electric asphalt compactor at CONEXPO, Holcim drives production with Komatsu iSite, Bobcat and Manitou Group release new telehandlers, Metso Outotec to supply plant to WA mine, Diamond Mowers releases new mulcher, Hexagon buys Projectmates, new program pushes for more women working in construction , CIMIC selected for Rio Tinto earthworks project, new vocational training councils announced, latest infrastructure market capacity report flags key challenges, Wirtgen milling machines used in huge airport renovation, resource projects report shows turn towards clean energy, Doosan unveils new name and JCB to supply engines to Powerscreen 6–14, 42–69

For Darwin’s AKJ Services, used machinery from Makin Traks is helping support the business as it builds its presence in the Northern Territory

a suite of mini excavators running from 1.3–6 tonnes, Toyota Material Handling Australia’s Huski range represents excellent reliability and a high breakout force, all

Editorial & Design

Editor Cat Fitzpatrick

catherine.fitzpatrick@ primecreative.com.au

Journalist

Anthony Wingard

Contributor

Charlie Bliss, Damian Long, Johnathan Trask

Art Director Daz Woolley

Managing Editor

Andrew Hobbs

Advertising Brand Sales Manager

Greg Messenger 0429 187 751 greg.messenger@primecreative.com.au

Account Coordinator

Paul McQuillan 0422 049 958 NSW Ben Coleman 0466 545 664 QLD Emily Schlegal 0466 317 555

Hydraulic

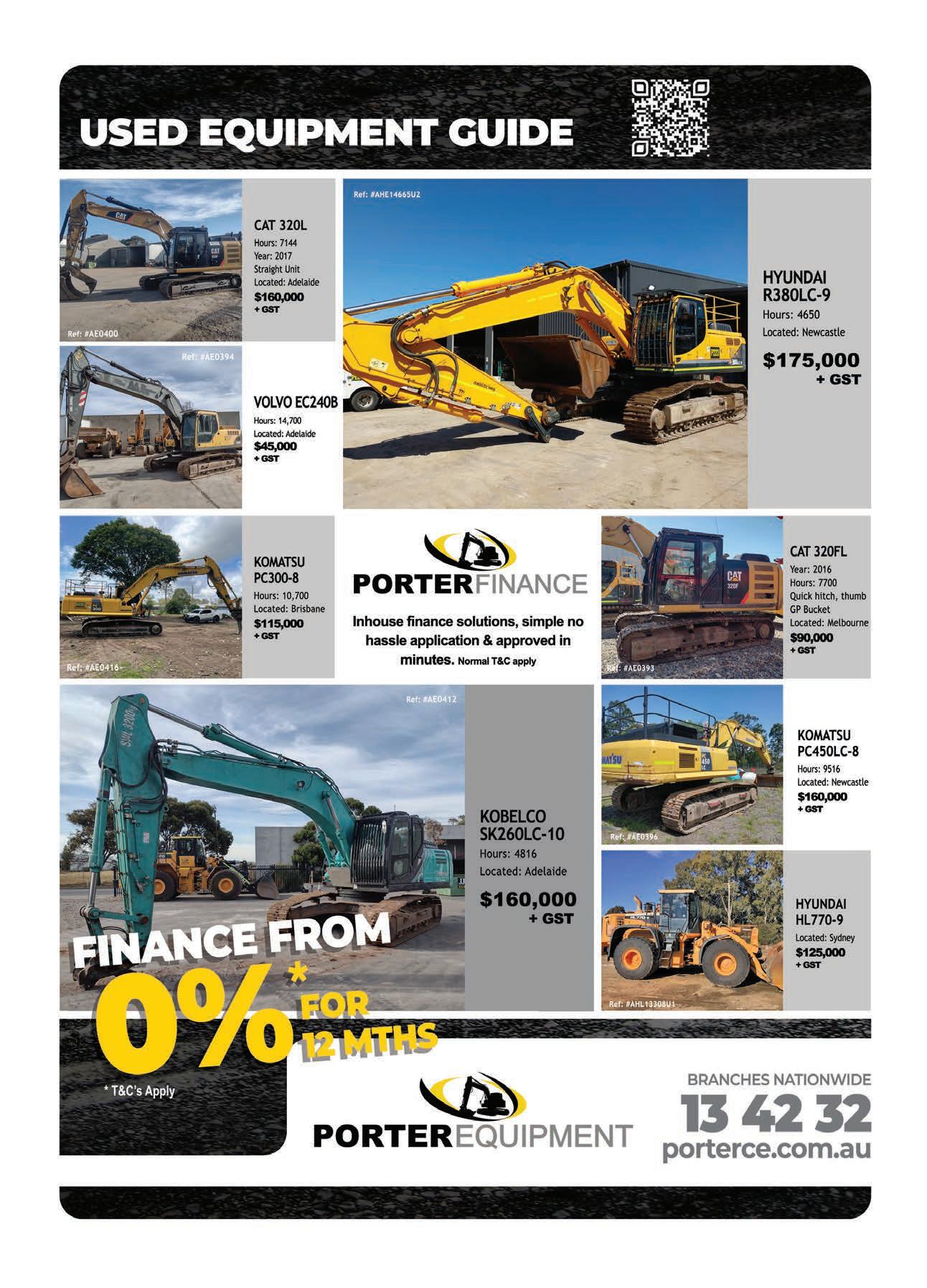

Bergmann site dumpers meet critical demand in Australia, new importer Porter Group says

Porter Group will stock wheeled and tracked dumpers up to 25 tonnes across Australia, New Zealand and the Pacific after signing a new deal with Germanowned Bergmann.

“Bergmann have a demonstrated history of producing reliable and innovative earthmoving solutions for over 60 years,” Porter Group says.

“Designed to cater to a wide range of requirements on the most diverse construction sites, Bergmann dumpers combine high transport performance, driver comfort and maximum operational safety.”

Porter Group chief operating officer Darren Ralph says the products will be available for sale and rental across Australia and New Zealand.

“The Bergmann dumpers integrate perfectly into our well established and extensive range of new equipment,

completing our line-up of premium off road dump trucks,” he says.

“With options ranging from one tonne to 35 tonnes, tracked or wheeled, diesel or electric, this product fills a critical demand in our region.”

Porter Group says its initial Bergmann product offering will consist of the following models:

C810 – This nine-tonne swivel site dumper is ideal for small to medium sites, Porter says. The compact and agile model comes with a fully airconditioned cabin, reversible operators’ station/seat, rear axle suspension and 360-degree camera views for optimum safety.

C815 – The C815 wheel dumper shows that efficient work, crosscountry mobility, travelling comfort and safety are compatible, Porter says. This 12-tonne 4WD high flotation articulated dumper also features a fully airconditioned cabin, reversible operators’ seat and 360-degree cameras.

C912 – Bergmann’s 10-tonne tracked dumper does its job even on rough terrain. Featuring two hydrostatic power trains with constant full power and optimal weight distribution with any load, the C912’s hydraulic parking brake offers a guaranteed secure hold even on extreme inclines – making practically any terrain accessible.

C828 – Working conditions underground are tough. In addition to a high transport capacity in confined conditions, maximum operational safety and efficiency are required.

The Bergmann C828 is a 25-tonne, 4WD tunnel truck with articulated axle, 260 horsepower (194kW) engine and a high payload. Its rotatable operator’s console allows a forward speed of 40km/h and a reverse speed of 35km/h, with optimum visibility.

Available in single or dual grade, the HV series replaces popular SV models, with enhanced features and connectivity options

Topcon Positioning Systems has released a new range of grade laser levels, the RL-HV series. Designed for all manner of construction applications and building trades, the HV series replaces the popular RL-SV series laser levels and comes in either single or dual grade models. New to the HV series is the ability to remotely control the unit using a smartphone. Users simply connect the

laser level to Topcon’s Laser Manager app, available on both iOS and Android devices, to adjust slope and laser level settings, or perform calibration checks.

“The HV series is ideal for contractors and tradies needing a versatile laser that can be used for horizontal, vertical, single or dual grade applications,” Position Partners building business executive manager David Gentle says.

Position Partners is Topcon’s partner for laser levelling and positioning solutions in Australia.

“With control of the laser in the palm of your hand using the new Laser Manager app, customers can set up position and slope, change rotation speed, or switch working mode quickly without needing another remote control in their pocket.”

Position Partners supplies Topcon laser levels throughout Australia via a network of value-added resellers and hardware stores.

“We have more than 300 stores stocking the premium Topcon laser levelling ranges right around the country,” Gentle says.

ACQUISITION

GHH’s mining equipment will join Komatsu’s equipment offering

Komatsu has announced plans to acquire German mining equipment company GHH Group

Komatsu today announced that it has entered into an agreement to acquire GHH Group GmbH, a manufacturer of underground mining, tunnelling and special civil engineering equipment headquartered in Gelsenkirchen, Germany.

Founded in the 1960s and currently part of the German-owned Schmidt Kranz Group, GHH supplies loaders and articulated dump trucks for mid-seam mass mining, narrow vein and lowprofile market segments.

“We are very excited about this acquisition as it represents a great opportunity for Komatsu to expand its offerings for underground mining equipment and accelerate new product development through synergies with Komatsu’s existing team and product offerings,” Komatsu president and CEO Peter Salditt says.

“By adding GHH’s factories and rebuild

facilities in key markets in Europe, South Africa, India and Chile, we also aim to strengthen production and service capabilities for our customers.”

Komatsu and GHH will work together to expand Komatsu’s offering for underground mining equipment and increase customer access to products in new territories.

“GHH is excited to be able to start a new journey with a strong player in the mining world.

“ This opens huge doors for our people and our products to develop further and grow beyond what we could have hoped for,” GHH Group CEO Dr Jan Petzold says.

“This is the next logical step in becoming a true global player and we look forward to becoming part of the Komatsu family.”

The official close of the acquisition is projected for the first half of 2023.

CR produces advanced ground engaging tools

Epiroc to acquire CR and Mernok Elektronik to expand its digital solutions for mining

Epiroc has agreed to acquire CR, an Australia-based provider of advanced ground engaging tools (GET) and related digital solutions, mainly for the mining industry.

With this acquisition, Epiroc is expanding its offering of essential consumables and digital solutions.

CR is headquartered in Brisbane and operates globally. The company’s products include cast lips, teeth and protective shrouds installed on mining buckets and loaders.

Its digital solutions include, among other offerings, the real-time GET loss detection system GET Trakka and the Titan 3330 payload management system. The solutions strengthen safety and productivity and preduce delays in mining operations. CR’s GET offering covers both surface and underground mining.

“This acquisition will expand our offering of innovative and high-quality consumables and digital solutions that strengthen customers’ productivity and safety,” Epiroc president and CEO Helena Hedblom says.

Epiroc is also in the process of acquiring Mernok Elektronik (Pty) Ltd, a South African company that provides advanced collision avoidance systems for mining companies. With this acquisition, Epiroc will strengthen its position as a world-leading provider of automation and safety solutions for mining operations, it says.

Mernok Elektronik is headquartered in Pretoria, South Africa. The company designs and produces proximity detection technologies and collision avoidance systems of the highest level (EMESRT Level 9) applicable for either a single machine or an entire mixed fleet of machines regardless of manufacturer or type of equipment.

The systems significantly reduce the risk of vehicle accidents, strengthening operator safety as well as productivity, the company says.

Both acquisitions are expected to be completed in the first half 2023.

Volvo wheel loaders will now be safer thanks to a new collision system

Volvo Construction Equipment (Volvo CE) has introduced an automatic braking feature across several wheel loader models to assist operators working in reverse.

The Collision Mitigation System (CMS) has been launched by the manufacturer, which says it is the first of its kind from any original equipment manufacturer (OEM) and has been specifically designed for wheel loaders, given the machines spend up to 50 per cent of their time being driven in reverse.

The system assists operators working in reverse by identifying when there is a risk of collision via sensors in the loaders that automatically applies service brakes when the machine approaches obstacles; alerting the operator to take further action.

Brakes will be activated for two or three seconds, Volvo CE says, which slow the machine prior to impact or giving the operator enough time to intervene and either stop the machine or avoid the obstacle.

CMS will be developed in-house by the Volvo CE team and will be a factory-fit option available on the L110H/L120H with OptiShift, L150H, L180H, L220H, L260H and L200H High Lift wheel loader models. Volvo CE global product manager Lars Eriksson says the company hopes to minimise worksite collisions.

“We at Volvo CE continue to proactively develop intelligent solutions which not only mitigate the consequences of accidents but strive to avoid them all together.

“This new collision mitigation system is one important part of our work to reduce the risk of accidents and help fulfill our commitment towards zero accidents.”

Volvo CE says the CMS does not replace safe operator behaviour and will be available on machines globally.

The HX series replaces the previous DV+ series and includes Easy Drive, high performance data, many comfort features and sustainable operation, as well as the Smart Compact digital compaction assistant.

Designed for asphalt compaction, the HX 70i model (7t/55.4kW) and HX 90i (9t/74.4kW) achieve high surface outputs on large construction sites. The pivot steering shows its strengths with a large turning angle, large track offset and four different steering modes.

Along with intelligent drive control with automatic reversing. The seat also turns automatically in the direction of travel when reversing.

The glazed cab includes a camera system with two monitors so views to the front and rear are always visible regardless of seat position. The cab floor’s glass window allows for viewing the drums.

With the digital compaction assistant Smart Compact, Hamm automates setting of each drum, while a revised dual-circuit additive mixing unit for the combination rollers saves water and increases the range, as the sprinkling system at the front and rear are controlled separately. Water and additive can be sprayed separately or as a mixture.

For spreading surface courses, Hamm has improved chip spreaders in its range for the HX series: the HLS 150 line spreader (760L) and HLS 170 line spreader (960L), as well as the HDS disc spreader (750L, with a spreading width 8m).

The Smart Compact compaction assistant can be used in the rollers of the HX series. The system decides compaction automatically and individually for each drum –whether to compact with vibration and big or small amplitude, with oscillation, or statically.

The driver then only has to enter whether a base, binder or asphalt surface course is to be compacted. The assistant evaluates data about the condition of the asphalt, optionally incorporating local weather data from an integrated weather station.

The engines work at a lower speed of 1,500–2,000 rpm, which reduces fuel consumption as well as noise and exhaust gas emissions. The automatic engine stop automatically switches the engine off after an extended period of inactivity. Up to 15 per cent of fuel is saved by switching off the vibration or oscillation as soon as it is no longer useful.

The HX series rollers are available with 7t (HX 70i) and 9t (HX 90i) operating weight. Among the nine total versions are models with two vibrating roller drums, an oscillation and a vibrating roller drum as well as combination rollers. Here, the vibration and oscillation drums are made as a split or non-split drum depending on the model.

Usually when it comes to hearing about the earthmoving, resource management and construction projects taking place in Australia, the focus is either on what’s happening in the more populous states or over in the mines of WA.

However this time we’re heading up north to the tropical climes of Darwin and the Indigenous-owned and operated business AKJ Services, which has been sourcing high quality used earthmoving equipment from Daz Scale, the owner of Sunshine Coast’s Makin Traks.

Established in early 2018 by local Larrakia woman Jesse Risk, AKJ Services has been building its reach and reputation as a highly respected, client-focused construction company servicing Greater Darwin and beyond, with an emphasis on being a local voice for the Northern Territory civil industry and providing career development opportunities for Larrakia people.

Speaking with Earthmovers &

Excavators magazine today is AKJ Services director Antal Reti, who has been with the business since its inception. He says AKJ Services is predominantly a civil contractor that does defence, subdivision and roadworks.

“We’re 100 per cent Larrakia-owned and operated and we’ve seen quick growth in the civil and defence sectors,” he says.

“We now employ around 45 people and operate around the Greater Darwin area and down to Katherine. We just won a subdivision contract out at Galiwin’ku, which is an island about 500km away, so we’re starting to spread our wings a bit more.”

With the business looking to grow its workload, AKJ Services turned to the expertise of Makin Traks, which supplies used machinery and attachments both in Australia and internationally from its base in Yandina. A specialist

primarily in Cat dozers, Makin Traks also supplies Komatsu, John Deere and other brand dozers, graders, excavators and track loaders as well as new rippers and stick rakes.

“We needed good quality used machines so got hold of Daz,” Reti says.

“First we got a dozer, a couple of graders, a roller and a loader. Daz has been really good with helping us get what we need.”

The fleet is now made up of a variety of brands, with a Komatsu 2018 D65 dozer, a 2013 Cat 140M2 motor grader, a Cat 140H grader from about 2006, a Dynapac 2010 smooth drum roller and a Cat 930G loader from 2007.

“We’ve been working with Daz for around 18 months,” Reti says.

“The relationship’s been very good – Daz is approachable, trustworthy, says it how it is with his

machines and his contacts over in the US have helped him get good quality used machines over to Australia, which has obviously helped us in a market where it’s difficult to get resources and machines.”

Reti says that good stock and clear communication were vital to the process of buying used machinery, along with honest information about the state of the used machine and any potential issues. Finally, of course, is a fair price. Reti says Makin Traks covers these bases so he can trust in the quality of the machines.

“The 140M2 grader was a very clean machine from the US with just 7,000 hours on it and was in a really good condition,” he says.

“The Komatsu dozer also had only around 2,000 hours on it and Daz was able to throw on the rippers. He had all that stock there that made it easy to customise the machine to what we wanted and needed.”

Reti says that having a good source

of used machinery made sense for the business, where a machine may be busy one month and then not be used the next.

“If you’re going to run something 24/7 all day every day, you’d obviously be looking for a new machine with warranty,” he says.

“The used machinery we bought you could run 24/7 because they had low hours, so we wouldn’t be worried about issues, but, overall, this is more cost effective.”

Looking ahead for 2023, he says that there is plenty going on in Darwin, which is great news for AKJ Services as it aims to position itself to

be a key contractor in the territory. “We’re looking towards our development and doing more projects in and around Darwin in that subdivisional space and expanding and getting more resources,” Reti explains.

“The industry is very busy in Darwin at the moment, it’s very good.”

For more information on used machinery for sale, call 0402 940 490 or visit: www.makintraks.com

Epiroc is on the verge of creating the world’s largest autonomous mine in Western Australia with early indications suggesting higher productivity than conventional mines

A project set to convert nearly 100 mining haul trucks to driverless operation is entering its final phase from March this year, Epiroc says.

The mining productivity partner is working with WA iron ore mine Roy Hill and automation specialist ASI Mining to deliver the autonomous haulage system (AHS) project, which will see 96 haul trucks converted to autonomous operation.

Since 2020, the three parties have collaborated across a two-year testing phase to develop an autonomous haul truck solution in Australia, which Epiroc says is interoperable and scalable across original equipment manufacturer machinery within the mining sector.

Ten haul trucks have been converted using ASI Mining’s Mobius traffic management system and on-board automation systems, which allow them to communicate with other vehicles as well as a Remote Operations Centre in Perth.

Throughout the verification phase, the trucks have met the desired safety and productivity measures – including higher productivity rates than conventional haul trucks, Epiroc says.

Following the initial testing, the progressive expansion of the AHS project will see autonomous truck numbers grow in 2023. The fleet will comprise of 54 Caterpillar and 42 Hitachi machines, in addition to the 200+ ancillary vehicles that will interact with the trucks.

Epiroc president and chief executive Helena Hedblom says she is now looking forward to completing the project.

“The team working on this is doing a fantastic job, and we are now looking forward to collaborating with Roy Hill in ultimately achieving the world’s largest autonomous mine.”

A Victoria-based civil engineer has enlisted the help of a Vermeer trencher to bring the National Broadband Network to regional Australia

When Ikon Civil’s Anthony Mlandenich was tasked with preparing trenches for the National Broadband Network (NBN) alongside roads and other tight places, he opted for a Vermeer machine instead of an excavator to do the job.

He chose the RTX750 ride-on trencher from Vermeer, which has 75 horsepower (55kW).

“The RTX750 ride-on trencher was the perfect machine for the job. It’s a great all-rounder, and it fits in tight places which is great for digging alongside roads,” Mlandenich says.

“When comparing it to an excavator, it can dig 300–400m of trenching in the same time an excavator does 100m. Our productivity is through the roof.”

Despite its productivity, the RTX750 boasts the smallest footprint in its class, meaning it excels in tight and narrow spaces. Its array of attachments is suited to many applications and is also equipped with an integrated system display, which allows operators to view machine diagnostics and functions such as engine rpm, alternator voltage,

fuel level, engine hours and engine coolant temperature.

The trencher is also cleaner and straighter than an excavator for trenching, providing Mlandenich with a better base for the installation of the NBN infrastructure.

Mlandenich says that the in-field performance of the trencher was matched by the customer service provided by Vermeer.

“Jim from Vermeer Australia was instrumental in the decision to buy the trencher. He was always there, helping me to understand everything and make the right decision,” Mlandenich says.

“It’s a solid and good-looking machine, but the exceptional customer service I received is what sealed the deal.”

On the verge of buying another machine from Vermeer, Mlandenich says the decision will be an easy one.

“I’ll be calling Jim in the next few months. I’ve got my eye on a skid steer to help with backfilling.”

Volvo CE has released the MB122 and VTD121 electro thermocontrolled fixed screeds for its large tracked pavers

Electrically heated fixed screeds by Volvo CE have now been introduced to make large-scale paving even more cost-effective and to boost the productivity and efficiency of major road projects.

The MB122 and VTD121 electro thermo-controlled fixed screeds for Volvo CE large tracked pavers produce speedy, consistent and evenly spread heating from a single source of power.

Powered by a 55kVA on-board generator, there is no longer a need for customers to refill gas bottles to heat the screed, as would normally be required with gas heated screeds. The result is a fast start-up, maximum uptime and a more efficient work site.

These fixed screeds are now available on the Volvo P6820D ABG, P7820D ABG and P8820D ABG models and benefit from an expansive paving width of 2.5–13m.

They have been designed to lay everything from hot asphalt through to dry concrete and cement-bound materials, all the way to railway ballast and graded mineral mixes.

The new electric heating function enables a start-up in just 40 minutes. Precise thermo-controlled heating is achieved with an automatic temperature adjustment and individual temperature sensors per section.

The new vibratory and double tamping fixed screeds deliver up to seven per cent more compaction than

The screeds are designed to lay everything from hot asphalt through to dry lean roller-compacted concrete and cement-bound materials

with a single tamper and can achieve a 98 per cent Marshall density, substantially reducing rolling work requirements and associated costs.

Vario extensions, with an extension range of 0.75m on each side, allow the screed to extend or retract as needed in order to adapt to irregular edges, while manual or hydraulic end gates are an optional feature to control flow of material on either side.

The new on-board diagnostic function helps to check the condition of the heating bars and detect if and where a replacement is needed. Uptime is also secured with easy screed assembly and straightforward maintenance.

The possibility for an easy lift of screed sections is supplied through two central lifting eyes per section, while an integrated hose and cable routing provides a clear path for assembly. In addition, hydraulic connecting points and easily accessed electric connections, as well as service points and tamper bars that are within easy reach, makes assembly and maintenance quick and easy.

We are experts in the delivery of parts to the industries that move, build and power our world.

earthmoving.supplies

1300 315

With a suite of mini excavators running from 1.3–6 tonnes, Toyota Material Handling Australia’s Huski range represents excellent reliability and a high breakout force, all in a compact package

Having been available to the Australian market for three years, the Huski mini excavator range from Toyota Material Handling Australia (TMHA) has proven to be a popular draw for contractors across the country, who have already experienced the high quality and reliability of Huski skid steers.

The Huski mini excavator range is made up of seven models, running from the 1.3-tonne M-13K through to the six-tonne M-60U, tailored to contractors needing access to confined spaces on the job site, with the majority achieving zero tail swing.

“The largest numbers of mini excavators sold globally are within the 1.5 to 1.8-tonne machine range, so the 1.6-tonne M-16U is our biggest seller,” TMHA product manager – construction equipment Matt Meddows says.

“The 1.6, 2.2 and 2.8-tonne Huski machines have been the most popular in the market to date.

“The 2.2-tonne machine is really in a class of its own as, realistically, it’s as capable as a 2.5-tonne machine. However, it still falls under the towing capacity of three and a half tonnes,

which is a big thing for customers. They want the biggest machine possible, but they only want to tow it with their ute – they don’t want to be buying a truck to tow it as well.”

The M16-U has a variable track width that reduces to just 990mm, providing access to the tightest of spots, and the smaller models have a removable canopy for entry into low-access spaces such as garages. The larger 5.5-tonne and six-tonne machines have an air-conditioned cabin for larger outside jobs.

“The base core machine for both the M-55U to M-60U models are identical, so they have the same undercarriage, cabins and engines – the six-tonner just has a larger counterweight and a different style boom,” Meddows says.

“The five and a half-tonner has a conventional boom, which has that dogleg shape. On the six-tonner it’s more of a European-style boom where that dogleg bend has a joint, which straightens it out.

“That’s a very common feature to see throughout Europe and on wheeled excavators. So, when you’re focusing on the six-tonne machine

over the five and a half-tonner, you can have tighter swing access because you can bring that boom a lot closer to the cabin.”

This style of boom means that, if an operator is in a tight access point, they can still lift a full bucket of material and turn within the width of the machine. This provides greater versatility, a longer reach and a deeper dig depth – plus, it makes the M-60U the only mini excavator available in Australia that has a variable angle boom.

From the 1.6-tonne machine upwards the machines are factory-fitted with quick-hitch piping and second auxiliary piping, which means that the machines can be run with a tilt hitch with no additional piping.

The 2.8-tonne machine and above also have a floating blade for backfilling and grading as a standard feature.

“The 5.5-tonner and the six-tonner come standard with safety valves, both on the boom and dipper arms,” Meddows adds.

“When it comes to the six-tonner there’s two boom segments plus the dipper arm – all of those have safety valves or anti-drop valves fitted from factory. A lot of a lot of job sites these days, even though they’re not necessary, are requesting those. To locally fit that type of stuff is very expensive, so bringing it in from the factory as a must.”

When asked if there are plans to expand the mini excavator range further with electric versions of the models, Meddows highlights that the Italian manufacturer TMHA works with to produce the Huski range is currently working on a prototype electric 1.8-tonne model, so there possibly could be a version appearing in the country in the future.

However, he emphasises, thorough testing will need to be undertaken to ensure it meets contractors’ requirements in Australia.

“There has definitely been interest in electric machinery from customers so, if this prototype turns into a production machine, we will probably bring a couple in and test them with customers,” Meddows states.

“Before we do anything with any new models, we bring in machines and we get customer evaluations done on them. Prior to bringing in the

mini excavators we had nine in the country, for two years, which were operating all over with customers.

We get their feedback from this process and made changes as required. This meant that the original machines that were brought into Australia as a test machine were completely different to what our final product is and is tailored to meet the customers’ needs.

“The whole Huski name is reliability. It doesn’t matter what products we bring under the Huski banner, we want these to meet the same values that our skid steer does, so reliability and durability is 100 per cent necessary.”

He explains that, with 18 branches around the country, TMHA has customers with footprints that extend deep into the bush, where temperatures can hit over 50 degrees, so the Huski machines need to be able to handle that type of environment.

“We have excavators in the Pilbara and north Queensland in the tropics and we haven’t seen issues with any of them, so we’re happy with the reliability of all the machines so far,” he adds.

“It comes down to reliability and our name in the industry. We have a very good name with our skid steers and that’s where we’re hoping to expand our reach with the mini excavator range.

“A lot of our customers have the combo of a skid steer from TMHA and an excavator from another manufacturer. When they go to replace that one, we want them to think: ‘Well, my skid steer has been really good, I want both of them to be the same brand.’

“We have multiple customers in Sydney that got rid of their one of their excavators and bought a Huski excavator to match the skid steer on their truck.”

With a range of bucket options available, TMHA says these mini excavators are suitable for a wide range of applications, from construction and mining to forestry and landscaping across Australia.

“We have stock in most of our major capital city branches across the country and we are competitive in pricing,” Meddows adds.

For more information, visit: www.huskiconstruction equipment.com.au

Volvo’s A40G Articulated Hauler is optimised for efficiency. Featuring intelligent systems from Volvo such as CareTrack, MATRIS and the On-Board Weighing System, the smart design of the A40G offers more capacity with reduced fuel consumption, so you can move more for less.

“We’ve been buying Volvo machinery since 2006. Their dump trucks are probably the most popular and well-respected in Australia.”

These are the words of Markwell Group managing director Gavin Markwell, who in May last year welcomed two A40G articulated haulers into his hire fleet, where they’ve been busy proving their worth on subdivision, mining and earthmoving works across Markwell’s vast area of operations.

Now in its 43rd year of operation, Queensland’s Markwell Group runs a fleet of over 90 earthmoving machines across its demolition, recycling, crushing and plant hire operations.

“We’re based in Townsville and work throughout north Queensland with a mixture of excavators, dump trucks, graders, skid steers, loaders and crushing plants,” Markwell explains.

“We work from north of Brisbane to Weipa and over to Mount Isa in a big arc, as well as some occasional work in Papua New Guinea.

“We’re working on about 20 sites at the moment – some might have one machine while others have half a dozen. We primarily work all round

north Queensland for councils, local government departments and developers and we do a lot in quarrying and mining. For example, we’re crushing at Moranbah currently, as well as at a gold mine in Georgetown – those are two of the largest jobs we have at present. We’ve also got two crushers down in NSW.”

One of the largest privately-owned earthmoving, mining, quarrying, crushing and demolition contractors in north Queensland, Markwell Group has been involved with everything from crushing 200,000 tonnes of road base for the Bruce Highway upgrade to demolishing bridges and removing asbestos.

As to why he chose the A40G haulers to add to his dry and wet hire fleet, Markwell says they are a reliable option with parts availability and local support from CJD Equipment.

“We were deciding between the A40G and the A45G and, because a lot of our work is shorter-term work, it’s easier to move these machines around. We decided on the Volvo after moving from another brand because of the lack of parts and lack of support.”

Having been on the market since 2017, CJD Equipment Mackay regionals sales manager Jarrad Bennett says that the response from customers to the A40G model has been fantastic.

“I would suggest that the A40G is the market leading articulated hauler. It’s a highly recognised and sought-after machine,” he says.

“Reliability, productivity and safety are the three key reasons for this. They’re extremely reliable and productive when it comes to fuel efficiency and cycle times. Plus, they rarely break down – the uptime is just exceptional.”

Bennett points to the onboard weighing and mapping system, known as Haul Assist, as being a key safety feature for operators.

“Haul Assist allows the machine to load and unload safely. The onboard scale system within the chassis won’t let you unload the machine if there is the potential for it to tip over.”

The 40-tonne payload is also a major draw for customers

“Markwell Group use their machines

in civil applications, so roadworks and highway construction, but the A40G is also suitable for mining and quarrying, especially when transporting material over long distances.

“The machine is very comfortable to operate. The cab is operatorfriendly with a positive pressurised system. This is a key benefit for operators working in very dusty environments, as it stops dirt from infiltrating the cab. The way that the articulation is set up provides a smooth articulation system, which is good for minimising driver fatigue.”

Operator feedback

Markwell says feedback from operators hiring the haulers from Markwell Group has been very positive, particularly around the visibility from the cab.

“They’re definitely reliable – they don’t break down,” Markwell adds.

“As we’re a plant hire company, we’re always looking for more equipment to satisfy our customers’

needs – we can’t have a fleet of ageing machines.”

Having worked with CJD Equipment since 2006, Markwell says the support he’s received over the years, with the quality of the machinery on offer, means it’s been a long-running and positive relationship.

“CJD are good to work with – if you have an issue, they resolve it in a timely manner. They always have excellent product.”

He says the two A40G haulers are just the latest in ongoing machinery purchases the Markwell Group will be making, with significant work planned for this year.

“This last year has been very

busy, and we expect this year to be busy as well. There’s a fair bit of work coming through for North Queensland, so hopefully we get a share of that,” he explains.

“We’re probably going to expand our concrete recycling facility and to get that more efficient and busier.”

For more information on the Volvo CE range offered by CJD Equipment, visit your local CJD branch or cjd.com.au.

In this business, the show must always go on. And that’s why you can count on Deere’s 1050K Crawler Dozer, with its suspended doublebogie undercarriage, to put in a rock star performance. When you’re cranking out over 40 hours a week in the cab, a comfortable operating environment isn’t just an option – it’s a necessity. And with the right features at hand in the right places, it makes it easier for you and your crew to enjoy getting the job done, however long it takes. Add a rock star to your line-up, today.

D-LOCK TILT COUPLER

• Up to 180° of tilt

Virtually maintenance free Compact design to improve machine performance

No greasing or lubrication required

Dual pin lock – Locks both front and rear pin in the event of loss of engagement force

• No unwanted movement

• No pins or bushes to wear out

• Fully guarded hoses

• Actuator only has two moving parts and is triple sealed

• Simplified connections and controls

D-LOCK COUPLER

• Picks up multi pin centres

• Picks up multi pin diameter 140 class and above

• Locks front pin in event rear pin is not engaged

• Additional safety built in with heavy duty compression spring, preventing primary lock releasing in the event of loss of engagement force

• Prevents implement swinging on front pin in event of loss of engagement forces

Features apply to both standard

Up to 180˚of tilt

To see the full range of Doherty attachments, contact the Doherty team.

P 1800 057 021 | E sales@dohertydirect.net WWW.DOHERTYDIRECT.NET

D-LOCK TILT COUPLER

D-LOCK TILT COUPLER

With over 40,000 new alternative part lines in stock at its 20 acre premises in Toowoomba in southeast Queensland, Tilly’s Crawler Parts’ undertaking to provide an online sales platform for its customers across Australia was never going to be a small project.

The commitment of the team to constantly innovate and provide the very best in customer service saw this come to fruition in late 2022.

The Tilly’s Crawler Parts story began in 1924 and continues with the third generation of the Tilly family, now renowned as an Australian family-owned company with global reach. The Tilly’s team ships quality earthmoving and excavation parts both nationally and worldwide.

Tilly’s long-standing mantra of ‘right part, right price, right now’ will never be more relevant than it is now, with the ability for customers to place an order at any time of the day or night and know that it will be processed the next business day. Understanding that machinery downtime means loss of income for its customers is key in the constant development of the supply chain and d istribution process.

A streamlined process for applying for an account with Tilly’s ensures that new customers can quickly and easily find the product they are

looking for, sign up for an account and have the order actioned, all within two business days.

Account holders will then have the ongoing ability to access previous orders, reorder items simply and quickly, and maintain their account details online. Pricing benefits may also apply based on purchase history.

“Our ability to deliver on our brand promise is becoming even more refined as we constantly work to improve our service offering,” Tilly’s general manager Lance Hinrichsen says.

“That improvement now sees the implementation of new software, which is increasing efficiency and productivity across the entire company. This is a substantial investment in Australian-developed ERP software and one which Tilly’s believes will have multiple benefits for the future.”

The development of the online platform has included the monumental task of photographing and cataloguing more than 30,000 parts by the Tilly’s team. The initial roll-out includes a selection of Tilly’s quality alternative undercarriage range, from track groups to idlers, rollers, sprockets and track adjusters suitable for dozers up to D9 and excavators up to 30 tonnes, with multiple other categories being continually added. This new iteration of the wellknown and respected Tilly’s brand makes Tilly’s your number one choice for earthmoving parts and equipment.

You can find out more by contacting the team for a chat on 07 4633 6000 or take a look at the extensive range at www.tillys.com.au

eldersrealestate.com.au

Highly profitable, all-inclusive Civil Business, Land, Infrastructure and Accommodation Village.

Major provider of Civil works across the Gulf and Cape Region. Established over 20 years. Strong relationships with key industry customers, QLD Govt agencies, Ergon Burke, and Carpentaria shires, Road Tek, Mining and Rural Earthworks.

Incorporating Norwest Consolidated, Norwest Civil Pty Ltd and Norwest Village. Unique opportunity to purchase a walk-in walk-out operation, in time for the 2023 season.

Land, Improvements, Plant and Equipment included in sale. Services include: road works, precision work, bulk earthworks, dam construction, earthmoving, drainage, Earthen water tank rectification, Airstrips using a large range of equipment graders, loaders, dozers, scrapers, excavators, water cartages and more.

Norwest Consolidated; Norwest Civil Pty Ltd –2000m2 workshop, parts storage, accredited washdown facility and oil separation plant. On-site office. Transportable site camps included. Adjacent property includes on-site accommodation as well as a separate 3-bedroom manager’s home. Zoned Industrial.

Norwest Village – Quality workers’ accommodation in the heart of Normanton. 28 rooms, fully A/C, commercial kitchen, dining, outdoor recreation. Equipped laundry, WIFI and board room. On-site managers home. One residential block with Home, one residential block with storage shed, modern living area and one residential vacant block.

Normanton is central to the lower gulf region and is serviced by road and air. The expanding mining industry supports growth for this business, currently operating in the agricultural and public services sectors.

Auction Tuesday 28th February, 11:00am

If not sold prior to the Auction

Venue Brisbane

Chris Atkinson 0429 342 944

Chris.atkinson@elders.com.au

Elders Mareeba

Alison Ross 0417 847 950

alison.ross@eldersrealestate.com.au

Elders Katherine eldersrealestate.com.au/300P105564

Perth’s Dayrell Stone has welcomed a new Hyundai HL970 wheel loader to its fleet – the latest in a long line of Hyundai loaders that keep getting better and better

Just before Christmas last year a new Hyundai HL970 wheel loader was delivered by Porter Group to Perth’s Dayrell Stone, at its site in the northern suburb of Landsdale. It joins a mixed fleet of machinery, including five other Hyundai loaders, eight Hyundai excavators and an Ammann smooth drum roller.

“I started doing limestone blocks back in 1990, servicing the limestone builders and developers, and, from that, I branched out into doing earthworks and earthmoving,” Dayrell Stone owner Frank Mignacca says.

“I have a lot of gear with Hyundai and they have supported me over that period.”

Working mostly in the Perth metro area servicing developers, the HL970 wheel loader is the latest in a long line of Hyundai wheel loader models that the company has used over the years.

“Previous to getting the 970 I’d been running 770s, and this is my

fifth Hyundai loader,” Mignacca says.

“It’ll mainly be working on bulk earthworks, so either on a screen or bulk filling trucks.”

When asked what it was about the Hyundai brand that appealed, Mignacca says that the loader models “have been getting better and better each year – extra capacity, bigger bucket size, better fuel capacity. That is why we decided to try the 970.

“The operators love the machine –it’s very comfortable and quiet, with plenty of power, and is operatorfriendly. We’re also getting very good fuel economy out of the machine. Hyundai is very reliable.”

Machine features

Hyundai’s new HL970 wheel loader is a 23,800kg machine with a bucket capacity of 4.2 cubic metres, suitable for a wide range of operations from construction and earthworks through to quarrying and mining. The Tier III engine generates 280hp (209kW) for a high level of production efficiency.

Porter Group territory manager –Western Australia Matt Milner points to the suite of safety features as also being a draw for machinery buyers.

“The AAVM [All Around View Monitoring] system is a camera system that surrounds the machine and provides visibility from different working angles,” Milner says.

“This system gives the operator a 360-degree view so they can see their surroundings from above as well.

“There’s also the radar system called the Intelligent Moving Object System – similar to what’s in a car –where, as you’re backing up, it sounds an alarm and shows you warnings of people and objects coming into your path.

“These are some of the biggest features when it comes to the majority of new machines we’ve sold.”

Milner also points to a range of improvements in the cab that enhance ease of use and comfort. There is an improved air conditioning system that has had adjustments for ease of maintenance and the cab is fully soundproofed. The seat and arm rests are also fully adjustable and implements are controlled through an electro-hydraulic control level to minimise operator fatigue.

“There are also some fuel-saving aspects that are also a big draw for customers,” Milner adds.

“With the increasing fuel prices, everyone is looking to save whatever they can at the moment.”

This includes a Smart Power mode that adjusts engine speed in heavy working conditions, electrohydraulic control, a hydraulic differential lock option that prevents tyre slip and intelligent clutch cut off. An engine idle booster increases idle rpm for improved engine reaction, automatic engine shut down and an eco-report that shows the loader’s inefficient operation status to improve an operator’s working habits.

Another upgrade has been the addition of the onboard weighing system to Hyundai’s HiMate diagnostics system, giving an operator access to various weighing functions on the seven-inch (17.8cm) touchscreen monitor.

“What we find is once people move

over from another brand to Hyundai and find out how reliable the machines are, it’s that reliability that brings people back to buying more,” Milner says.

“The new updated HL970 model is so much better than the previous model. So, I think Dayrell Stone started out with dash 7s, they’ve had dash 7As, the dash 9 series and now into what we call the 900 series. They’ve had three previous models before that machine, so they’ve seen the transition.”

Porter Group

The relationship between Mignacca and Porter Group has been running for many years, with the financing option being a strong feature.

“We’ve been getting great support from Porter Group,” Mignacca says.

“We first started work with a Hyundai branch that wasn’t Porter Group’s but, since they took it over, they’ve been good to deal with because they have financing for the machines,” he says.

“They’ve financed a lot of the machines and it’s a lot easier to sell the machine back to them. They also give good warranties – up to 8,000 hours and they’re giving good buybacks on the machines.”

Milner adds that the financing option means Dayrell Stone gets a better resale price for the machines when it upgrades to newer models.

“We work together to try and get

them the best cost of life through using our financing and our warranty,” he says.

Mignacca also points to the aftermarket service and parts availability.

“Porter Group have been very good, very reliable, and they’ll chase the parts down.

“With dealers, you’re looking for the backup, reliability, the availability of parts and the financing. Porter Group have been a one-stop shop.

“We’ve still got about five loaders of other brands that we’ll probably roll over and get all Hyundai.”

Milner says parts availability is looking strong at the moment now the market is returning back

We’ve been getting great support from Porter Group

A

Dayrell Stone has been working with Porter Group for many years, sourcing a range of Hyundai excavator models through the dealer B Porter Group’s financing for the machines has been a key benefit for Dayrell Stone

C

The

D

The All Around View Monitoring provides a working view around the entire machine

to more normal operation after the COVID-19 pandemic.

“We’re pretty much back on top of all of parts now – we’ve got new parts people and plenty of parts in stock,” he says.

“The market overall for work is fairly strong. Normally, December and January are our two quietest months, but we haven’t seen any slowdown. We’ve actually been busier this December and January than we have for years, since the last mining boom.”

For more details on equipment available for purchase through Porter Equipment, visit www.porterce.com.au

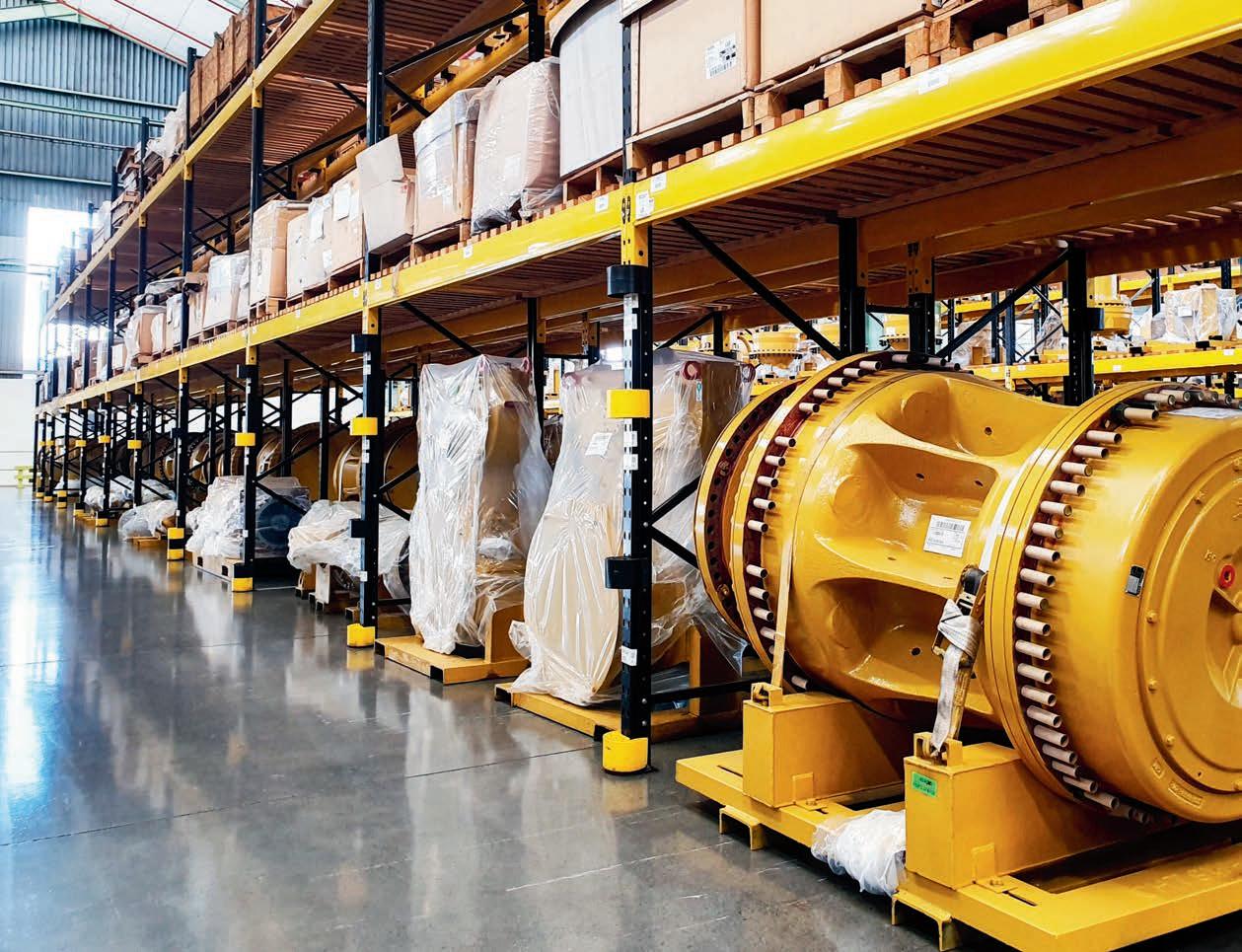

It’s going to be a busy year for Brisbane-based Components Only as it continues to broaden its horizons into machinery parts and further scale its international supply chain capabilities

With a global reach and specialising in mining componentry, Components Only is a Brisbanebased business now in its ninth year of ensuring that it has the right component at the right time for the right customer.

Set up by Adrian Vinnicombe, Daniel Fedder and Ben Hailes in 2014, the three directors have expanded Components Only’s reach beyond Australia’s shores to include offices in Chile and Mongolia.

Hailes, the company’s director for sales and marketing, says the genesis of Components Only came from identifying an opportunity to create an online marketplace for heavy earthmoving components.

“We knew that there was a supply of components in the market that people just didn’t have access to, or understand where they could get them from,” he explains.

“Now, we have a team of 35, with our head office in Milton, Brisbane and branches in Mount Thorley in the Hunter Valley, Welshpool in Perth and then Mackay in Queensland,

as well as the international offices in Santiago in South America and Ulaanbaatar in Mongolia.”

By leveraging component supply chains from around the world, Components Only focuses on hard-to-find components for a wide range of heavy earthmoving equipment, but primarily large mining machines, with the top four brands of Caterpillar, Komatsu, Hitachi and Liebherr being extensively supported.

“We have been specific with the equipment and components we support, supplying miners with stock across their major mining machines. In the instance of haul trucks as an example, we support the 830E-1AC and 930E1-AC trucks from Komatsu, 785D, 793F, 795F, and 797 series trucks from Cat, Hitachi’s EH3500, EH4000 and EH5000 model haul trucks and, most recently, Liebherr’s T282C and T284 trucks.

Market knowledge

Although Components Only supplies a range of aftermarket

components, its focus is on finding and supplying genuine components and ensuring stock is available when the customer needs it.

To assist in the management of the supply chain and what is required at any given moment, Components Only has a propriety software system called Markets Manager.

“This is an inventory and asset management system that allows us to track, on a very granular level, the frame hours and the component history of global mining fleets,” Hailes explains.

“Driven by data, this provides us the ability to service our customers with the products they require when they require them. It’s an area that we’re currently commercialising at the moment, having carved that out as opportunity within the market.”

This is just one aspect of

CATERPILLARD6K2XL 2015,with7,500hours.VPAT6 wayblade,HDstickrake,HDtreespear,MSripper, sweepsandscreens.ThisD6K2XLwillbesoldclean, detailedandservicedwithourcomprehensiveworkshop report.S1016. TA1143552. $239,900PlusGST

JOHNDEERE672G 2015,graderwithonly4,950hrs.6X6, 17.5tyres,frontscarifierorpushblock,MSrippertobe fitted.14 ft blade,autoshifttransmission.This672G Graderwillbesoldclean,detailedandservicedwithour comprehensiveworkshopreport.166. TA1138802. $319,900Plus.GST

JOHNDEERE672G 2016,with6,200hours.6×6allwheel drive,MSripper,scarifiers,Pushblock,New17.5tyres, reversingcamera,14ftblade.This672GGraderwillbe soldclean,detailedandservicedwithourcomprehensive workshopreport.143. TA1128935. $315,900PlusGST

CATERPILLARD6K2XL 2018,withonly2,700hours.6 wayblade,AROwired,14ton,135HP,sweeps,MSripper andscreenstobefitted.ThisD6K2XLwillbesoldclean, detailedandservicedwithourcomprehensiveworkshop report.95. TA1123096. $274,900PlusGST

JOHNDEERE450K 1400hrs,6wayblade,sweeps, screensandMSrippertobefitted.S1063. TA1163359. $229,900plusGST

CATERPILLARD5KXL 2010,4,500hrs,6wayblade, Sweeps,screens,MSripper,stickrake.S1065. TA1163361. $204,900plusGST

CATERPILLAR12M3 2016,Graderwith4,950hours.14ft blade,joysticksteering,Autoshift,Lightpackage,sold withMSripperandpushblock.This12M3Graderwillbe soldclean,detailedandservicedwithourcomprehensive

CATERPILLARD6TXL 2012,with8,900hours.SUtilt blade,sweeps,rearscreen,HDtankguarding,MSripper. ThisD6TXLwillbesoldclean,detailedandservicedwith ourcomprehensiveworkshopreport.S1006. TA1139666. $299,900PlusGST

KOMATSUD61EX 2018,5,800hrs,6wayblade,MSripper, TopConwired.S1067. TA1163362. $309,900plusGST

CATERPILLAR140M3 2016,Graderwith6,500hours. EROPS,AROwiredwithCrossslopeandGradecontrol, Accumulators,A/C,Heat,17.5tyres,Pushblock,MS ripper,14ftblade.This140M3willbesoldclean,detailed andservicedwithourcomprehensiveworkshopreport. S1041. TA1153267. $339,900PlusGST

CATERPILLARD6HXL SUtiltblade,Sweeps,rearscreen, MSripper,nearnewundercarriage,greatworking machine.S1044. TA1156033. $179,900plusGST

Components Only’s growth strategy, with the launch last July of its Earthmoving Supplies business expanding its reach into parts and consumables that in Hailes’ words “build, move and power the world”.

“What that will allow us to do is to serve a far broader market that extends to civil, construction, agriculture and marine,” Hailes says.

“When it comes to components, people rebuild mining machinery, but they rarely rebuild civil. So, this new business is built around how we target sectors that we would not have otherwise serviced.

“What sets us apart is our global reach, being able to support our customers with a timely supply of components and parts. Miners are continually constrained with the availability of options and we work with them to provide solutions that increase the continuity of their operations.”

Hailes says that, despite the challenges, mining remained active during the pandemic, presenting unique complexities relating to supply with shipping activity constrained and the costs of logistics rising sharply.

“I think we’ve all got to be grateful that the market is returning to normality,” Hailes says.

“However, regardless of market conditions, if we look at the world’s focus with going green, it’s apparent that if there’s no mining there are no resources and no net zero. This means that, right now, the market is extremely busy and we don’t see

demand coming off anytime soon. In fact, it’s getting busier.

With the Earthmoving Supplies side of the business getting into its stride and a lot of energy spent on making sure the business can scale efficiently, Hailes says the group of companies has a very positive outlook for growth in 2023.

“People are a key part of our operations and having the right people aboard the bus is really allowing us to continue that growth, both in terms of the Markets Manager software, but also with Earthmoving

Supplies, which is the key focus for us in 2023,” Hailes says.

“One the biggest impacts COVID19 had was on our ability to grow internationally. For us, it’s as much about managing risk as it is generating revenue and, particularly when creating new outposts overseas, it’s about being present to manage the relationships in those regions.

“With the effects of COVID-19 far less than during the peak of the pandemic, our focus in 2023 is the continued expansion of our international footprint.

“Expanding internationally is a prudent strategy for our business and provides us with the ability to further diversify our revenue, resource exposure and companies that we deal with.

“The growth of our business has been extremely robust, and 2023 looks like it’s going to be a great year.”

For more information, visit: www.componentsonly.com

Utility

Construction

Platinum class

36 months / 1500hrs EPTW

• Up to 500hrs

• PM Clinic / KOWAS

• Presents as new

Platinum class

36 months / 3000hrs EPTW

• Up to 3000hrs

• PM Clinic / KOWAS

• Presents as new

• Includes Hybrid / IMC

Platinum class

36 months / 4000hrs EPTW

Mining

• Up to 3000hrs

• PM Clinic / KOWAS

• Presents as new

Gold class

24 months / 1000hrs EPTW

• Up to 1000hrs

• PM Clinic / KOWAS

• Presents well

Gold class

24 months / 2000hrs EPTW

• Up to 4000hrs

• PM Clinic / KOWAS

• Presents well

• Includes Hybrid / IMC

Gold class

24 months / 3000hrs EPTW

• Up to 4000hrs

• PM Clinic / KOWAS

• Presents well

Silver class

12 months / 500hrs EPTW

• Up to 1500hrs

• PM Clinic / KOWAS

• Presents well

Silver class

12 months / 1000hrs EPTW

• Up to 6000hrs

• PM Clinic / KOWAS

• Presents well

• Includes Hybrid / IMC

Silver class

12 months / 2000hrs EPTW

• Up to 7000hrs

• PM Clinic / KOWAS

• Presents well

Bronze class

6 months / 250hrs EPTW

• Up to 2500hrs

• PM Clinic / KOWAS

• Presents well

Bronze class

6 months / 500hrs EPTW

• Up to 8000hrs

• PM Clinic / KOWAS

• Presents well

• Includes Hybrid / IMC

Bronze class

6 months / 1000hrs EPTW

• Up to 10000hrs

• PM Clinic / KOWAS

• Presents well

Earthmoving machinery owners and operators are being encouraged to keep on top of maintenance of their machines’ hydraulic systems, with Continental Australia national business manager

Scott Weston saying that regular inspections of hydraulic hoses and fittings are key to safe earthmoving operations, and noting that failure to employ such maintenance methods can result in massive costs for business owners.

While operators utilising rental fleets are usually required to record rigid maintenance schedules, contractors and operators who own their machinery could do a better job to prevent machine downtime, he explains.

Weston recommends that rigid maintenance schedules are employed.

“Ensure that parts are replaced [by] reputable manufacturers who offer matched and validated hydraulic assembly solutions. This will ensure a safe operating system whilst reducing the susceptibility of premature failure,” he says.

Inspecting hydraulic hoses and fittings is not an arduous process, according to Weston, who says it is simply up to each operator and contractor to find out what maintenance schedule suits them best, but he adds that it is vital to

maintain a firm schedule, whether that means checks are performed daily, weekly or fortnightly.

While checking hoses may not be a timely or difficult practice, the consequences of not checking machinery hydraulics may prove costly. Figures indicate that over half of all incidents that cause downtime on mining equipment are due to hose failures.

Weston says the ramifications can range from a simple hose replacement all the way up to a major failure.

“If you end up cavitating a pump or damaging cylinders, it’s going to be a significant cost. Not only to change and repair the damaged part but it’s also the downtime of that machine,” he says.

“You may even miss your project deadlines and then you’re up for additional costs for being late.

“Even to replace just one hose assembly, you could lose hours of the machine’s uptime while it’s not operational and then you have to call out a hose doctor or someone to replace the hose assembly.”

Continental, perhaps best known as one of the globe’s top tyre manufacturers, was first established in Germany in 1871. Continental boasts over 150 years of experience in

the industry and is a leading heavyduty industry manufacturer thanks to its wide range of products used across the earthmoving, construction, mining and manufacturing sectors.

Continental’s knowledge and expertise in hydraulic hose manufacturing and fluid conveyance allows it to deliver the most innovative and highest quality products on the market. Extensive problem-solving experience across multiple industries and applications enables Continental to share innovations over the entire product offering, resulting in unexpected solutions and advanced improvements in situations where others can’t.

Continental pushes the boundaries of what is possible and constantly solves tomorrow’s most challenging problems – today and every day.

In essence, Weston says Continental has something for every type of application that requires hydraulics.

“It’s all the different applications, whether that is on the boom, on the attachment or for the drive system. We have equipment to cater for all those applications,” he says.

For earthmoving applications, the high-performance Continental hydraulic hoses are most suitable. The standard hoses provide safe transportation of mineral oil, oil and water emulsion-based hydraulic oils for use onsite lifting, digging and transporting material.

Continental crimp fittings also provide maximum coupling retention through extensive design and impulse testing, which ensures a leak-free system and decreases the likelihood of premature failure.

Continental and its partners are also able to provide first-fit and replacement solutions through various methods, with hose assembly kits, hydraulic workshop equipment and portable crimp solutions.

For more information, visit www.continental-industry.com, email aus.ep@continental.com or call 1300 Rubber (1300 782 237).

This year, my hope is that there is a return of some normality to life and business conditions. I am hoping that normality includes the stabilisation of supply prices, improvement in lead t imes and availability of the supply chain, improvement in the availability of labour, interest rate increases stalling and a drier year –all resulting in a return to sustainable profit margins.

The Bureau of Meteorology’s modelling is suggesting a breakdown of the La Niña event and a possible return to El Niño conditions throughout the year. Whilst the probability of high rainfall decreases under these scenarios there is still some uncertainty. We need a break, so fingers crossed that the numbers fall our way.

Unfortunately, the headwinds will continue into this year but will hopefully be more manageable.

Inflationary pressures have put a strain on infrastructure programs. The dilemma is how to manage budgets in the light of an increasing need for more infrastructure to be delivered.

An easy solution would be to deliver fewer projects. In Queensland the demand for infrastructure development is outstripping delivery. This is due to the current and projected population growth and a slowing of new projects.

Considering our ageing population is signalling a further increase in international migration, it would seem the demand for infrastructure is only going to increase.

Added to this is the infrastructure required for the Brisbane 2032 Olympic and Paralympic Games and the renewable energy infrastructure to be delivered by 2030 to 2035.

The release of the last November’s report from the Clean Energy Council paints a depressing scenario

regarding our current pace of delivery of renewables to meet 2030 targets. The rate of renewable energy infrastructure has dropped below the required level and an acceleration of projects is required.

Chris Bowen, the Federal Climate Change and Energy Minister, has estimated that Australia will need to install 22,000, 500-watt solar panels every day for eight years in addition to 40 wind turbines every month. An additional 10,000km of transmission lines need to be installed to meet federal government targets.

It was reported in the Australian Financial Review by Dylan McConnell, a renewable energy and energy system analyst at the University of New South Wales, that to meet the federal government’s 82 per cent renewables target by 2030, the rate of development needs to double and almost quadruple for the hydrogen superpower scenario.

Queensland has committed to being a hydrogen producer. In addition, the Queensland government has committed to building pump hydro storage facilities.

There seems to be growing resistance on environmental and ecological grounds to deliver some of this infrastructure, as exampled by Chalumbun Wind Farm cutting half the proposed turbines, Mackay’s pump hydro flooding a town and a general resistance to increased overhead transmission lines. These delays are adding to the urgency to accelerate renewable energy projects.

This acceleration and volume

of renewable projects, coupled with the demand for transport and other civil infrastructures, will not help the inflationary, supply and labour pressures we have been experiencing. There is no doubt that the problems China is facing with COVID-19 will add to the supply and cost issues.

So how do we tackle this dilemma?

There is no doubt that governments will need to increase their budgets for infrastructure. Considering the debt they are carrying, there is little room for large increases. The private industry will need to play a larger part in financing and delivering infrastructure.

The industry will need to deliver more for less. This is possible, but reform of the planning, design, procurement and delivery of infrastructure projects needs to be implemented immediately. These reforms should be supported from other productivity-enhancing policies such as industrial relations.

Planning needs to be streamlined to reduce barriers and speed up the process. Designers need to be incentivised, through better renumeration and liability sharing, to explore and embrace innovation in their designs. Whilst designs are procured at lower cost, the designer wears all liability for its designs and the boundaries of true innovation will not be challenged. This is needed to provide cheaper and better performing infrastructure.

Standard specifications, which are prescriptive, need to be performancebased. Where prescriptive specifications are required, standardisation across jurisdictions should be forced wherever possible.

The procurement process needs to be quick, with tenders being easy to price and risk adequately shared.

Collaborative contracting is the tool to link all this together.

The light at the end of the tunnel is there will be sustained high level of opportunities for the foreseeable future. Interest rate increases will abate. Fuel prices will be stable. China’s COVID19 wave will subside. Collaborative contracting will continue to evolve, providing a path for a better way of doing business, and the year should be drier. Unfortunately, the demand on materials, plant and labour will continue to make delivering projects difficult.

The significant demands for new infrastructure and renewable energy mean that greater investment is needed, and quickly, by the government

18 MAY 2023

Royal International Convention Centre, Brisbane, Queensland

Hear from key speakers including Demographer, Bernald Salt AM, QIC Chief Economist, Dr Matthew Peter and much more!

Visit

Book via www.ccfqld.com/events

HEMS ticket includes entry to the TruckBrisbane Show! Australia’s biggest showcase of everything

Civil Construction

All conference tickets include a free pass to the show! BRISBANE SHOWGROUNDS

18 - 21

Over the past year, Le Roi has been expanding its Service Line undercarriage range with high quality and affordable undercarriages and parts, catering for machines in the 13–45 ton (11.8–40.8 tonne) range.

Le Roi Machinery Parts managing director Ziane Gouicem explains that Le Roi has been supplying Berco aftermarket parts in Australia for the past two years.

“This service line is an outsourced product, mainly from China and Korea, but it’s designed by Berco and the quality is Berco,” Gouicem says.

“All parts that are made in Asia are shipped to the company’s warehouse in Italy and go through quality tests before they are then sent over to us, so you can rely on the quality of the product.

“This outsourcing strategy means that costs can be minimised, meaning that we can provide a high-quality product at a competitive price.”

Alongside the undercarriage service line, Le Roi also supplies a

variety of chains, sprockets, shoes, rollers and engine parts for all of the big manufacturers.

“We cover Cat, Komatsu, Hyundai, Hitachi, Doosan – most of the brands in the market,” Gouicem explains.

“Berco is an OEM [original equipment manufacturer] for a lot of major brands – Hitachi, Komatsu, Liebherr, John Deere –you name it. It’s the main supplier for all John Deere products. For aftermarket undercarriages, Berco is number one.”

Quality is key to the service line’s popularity, he adds, as well as Berco supplying a diverse range that has a high level of durability.

After Le Roi experienced severe delays in being able to ship new parts from Italy during the COVID-19 pandemic, Gouicem says that the focus has been on building up the stock available in Australia of the most common items and stocking them in warehouses in major cities. This led to the opening last year of the company’s Melbourne

warehouse, with a Sydney warehouse in the works.

“We had delivery issues for sure during COVID, and for some parts we had to wait for six, seven or even eight months just to get them produced and then shipped over. So, we’ve been building our stock in Australia and, now, we have warehouses in Perth, Melbourne and Brisbane, with plans for one in Sydney for 2024,” Gouicem says.

With expenditure in the industry forecast to grow by 80 per cent by 2030, he adds that the service lines will be further expanded as well to give customers access to an even wider choice of aftermarket parts.

“Over the past two years our customers’ reception to the Berco line has been very positive,” he says.

“The Service Line is designed by Berco, the quality is Berco, but with a very competitive price, as well as good availability.”

For more information, visit: leroiparts.com

ITR Pacific is looking to expand its mini undercarriage installation team across Australia – making the replacement of parts as simple as a phone call

ITR Pacific has outlined plans to expand its mini undercarriage installation team to more corners of Australia as the company looks to capitalise on a successful 2022.

Currently, the installation team operates only in southeast Queensland, where it is responsible for the onsite fitting of parts, including rubber and steel loader tracks, for excavators and skid steers of eight tonnes and below.

The installation team also offers rubber pad fitments and other undercarriage parts such as sprockets and rollers.

The Queensland team has two service vehicles for onsite fittings, however ITR Pacific national product manager of mini undercarriage Chris Yared says that an expansion of the team will happen in the near feature.

While no concrete deadline for the expansion has been established, ITR Pacific hopes to grow the installation team at its existing branches around the country in Sydney, Melbourne, Adelaide, Perth and Mackay.

Yared says the benefit of the mini undercarriage installation team lies in its ability to fit parts in an efficient manner – something that sets them apart in the market.

“Our success in Queensland has always been based on us offering a quality undercarriage product and then we back it up with quality tradesmen to fit the part and we do it in an efficient amount of time,” Yared says.

“It means customers save their

time having to drive to us, which sometimes can be two or three hours away. If we can do it in an efficient manner, then we’ll make sure we can get that product to the customer as quick as we possibly can without them having to leave their site, meaning they can keep working.

“When we get there, you know that it’s going to be fitted correctly and you’re not going to have any problems with any of the gear.

“Some operators that aren’t as experienced can sometimes take hours at the extreme end because they may not know what they’re doing and that obviously costs time and money.”

Yet, despite the efficiency of the installation service technicians, ITR does not charge for travel. Instead, one simple cost-effective fee is given for each class of machine.

“We know that, because of our proficiency in this product and service, we’re confident that you will get the right thing, it will last, it will do its job and you won’t pay an arm and a leg for it,” Yared says.

The future expansion of the mini undercarriage installation team across the country follows the acquisition of Queensland-based undercarriage specialists DTN Equipment in July 2020.

DTN Equipment was a pioneer of efficient undercarriage installation. With over three decades of experience in the earthmoving and diesel mechanic sectors, DTN offered what Yared calls a “difference

ITR Pacific has an extensive range of undercarriage parts available

in the market”, whereby the company would deliver and fit parts throughout southeast Queensland. The sale and integration of DTN into ITR’s business meant the latter could offer the same service, with vehicles capable of completing several fitments in different locations within the one day.

“To cover that geographical space and still being able to get all of the guys back here is our real advantage,” Yared says.

“The fact that the boys can go to a site and do a job in, at maximum, one hour some days and then move onto the next job – I don’t think other companies have the same level of proficiency.”

The planned future expansion follows a strong 2022 calendar year for the brand, with the ITR USCO group selling over 79,000 rubber tracks through its global network of distribution networks.

A stringent process of quality control measures means all rubber tracks supplied by ITR meet the high standards set for performance and reliability, which includes a 24-month warranty on excavator rubber tracks and a 12-month warranty on compact track loader and multi-terrain loader rubber tracks that protects owners against manufacturing defects.

The success of the strict quality control process process has meant that less than 0.25 per cent of all rubber tracks produced within the last two years have reported faults.

When it comes to undercarriage parts, ITR boasts one of the most comprehensive ranges on the market which includes components such as shoes, rollers, track chains, idlers and segments. All steel undercarriage parts are manufactured by the company’s Asian manufacturing facilities, with all production – from the design of parts to the choice of material – managed entirely in-house by the team at ITR.

To find out more about ITR Pacific’s full product offering and services call 1300 820 214 or visit www.itrpacific.com.au.

At Caltex, we are committed to providing the most advanced premium industrial lubrication technologies available for every kind of operation - from mining to agriculture, power generation to construction, trucking to global marine. No matter what challenges you might face, the journey will be Smoother, Better, Together with Caltex.

Talk to your local distributor or find out more about Caltex fuels and lubricants. www.caltex.com/au/business-solutions

The DD25 Electric is a zero-exhaust emission compact double-drum asphalt compactor which will be unveiled at CONEXPO 2023 in March – and is expected to be available in select markets from Q1 2024.

The compactor has been designed for small scale compaction projects including street repairs and patching, parking lots, driveways, municipalities and rental houses.

The newest addition to Volvo CE’s lineup of electric machines, the DD25 Electric is the first Volvo CE-produced electric machine designed specifically for the asphalt industry.

“As a global leader in construction

solutions, delivering premium products and services, we not only have a responsibility to reduce our carbon footprint, but we are committed to leading the way and providing real-life solutions for our customers that will help them meet their own sustainability goals,” Volvo CE North America vice president product management and productivity Ray Gallant says.

“We are proud to expand our portfolio of electric machines and extend our offering to the road segment.”

The electric driveline of the DD25 Electric is based upon the

architecture and components found on Volvo CE’s ECR25 Electric compact excavator and L25 Electric compact wheel loader.

The machine comes with an integrated on-board charger that enables charging from 0 to 100 per cent in as little as three hours depending on AC power level. With an optional off-board DC fast charger this can be achieved in little over an hour.