THE ENERGY STORAGE BOOM

How we’re leading it and what’s next Energy Networks’ Andrew Dillon on CYBER SECURITY

Ivor Frischknecht of ARENA talks DISTRIBUTED GENERATION

MACHINE LEARNING PREVENTING POWERLINE BUSHFIRES

How we’re leading it and what’s next Energy Networks’ Andrew Dillon on CYBER SECURITY

Ivor Frischknecht of ARENA talks DISTRIBUTED GENERATION

MACHINE LEARNING PREVENTING POWERLINE BUSHFIRES

SPEED. PRECISION.

LOCAL PRODUCT SUPPORT.

THE VERMEER PD10

SOLAR PILE DRIVER IS YOUR SPRINGBOARD INTO LARGE SCALE SOLAR.

[ Speed ] Designed from the ground up for solar array installation, the PD10 brings cycle times down to unprecedented lows.

[ Precision ] Laser or optional GPS guidance and an innovative hammer design means outstanding accuracy, less pile damage—and less rework.

[ Local product support ] Get your project underway with the peace of mind that only the backing of a truly nationwide dealer support network can offer.

Contact your local Vermeer product specialist to learn more.

PD10 SOLAR PILE DRIVER. GET EQUIPPED.

The sector has seen a few major developments recently with progress on the National Energy Guarantee (NEG) taking a step forward after the COAG Energy Council agreed to progress to the final design stage.

ABN: 36 426 734 954 PO Box 1763

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au

energymagazine.com.au

info@energymagazine.com.au

ISSN: 2209-0541

The industry has long advocated for a national energy policy to bring muchneeded stability to a sector undergoing so much change, and the NEG represents a viable step forward. While there are still questions to be answered, like many in the industry I’m looking forward to reading the final design when it’s released later this year.

We’ve also seen funding announced for several projects that are supporting the implementation of renewable energy, from new wind farm projects in NSW to Hydrogen Energy Supply Chain pilot projects in Victoria’s Latrobe Valley, and solar farms in Queensland.

In our conversations with the industry about the energy trilemma, two factors constantly come up as being critical to the solution – distributed generation and energy storage.

This edition takes a closer look at these topics, with ARENA’s Ivor Frischknecht exploring the impact of decentralised consumer energy assets, and what we can expect as the uptake of rooftop solar and batteries continues to increase. We’re also focusing on the huge influence that energy storage technologies are having on the grid and the way we think about electricity networks. There are a wide variety of storage projects currently in Australia, or planned for the future, from Tesla's Hornsdale Power Reserve battery, to Snowy Hydro pumped hydro, and the introduction of smaller companies with new technologies.

Energy magazine has continued its relationships with key industry associations, so in this issue you will find contributions from ARENA, Australian Energy Council, the Energy Policy Institute of Australia, Standards Australia, Energy Networks Australia, the Climate Council, AEMO, The Clean Energy Finance Corporation (CEFC), and companies like Snowy Hydro Limited, among other key players.

From within the industry we’ve also been contacted by a number of people with positive feedback about Issue One of Energy magazine. We’re excited to be able to fill a need for news and in-depth analysis of the most pressing issues in the energy industry, so please keep your thoughts and suggestions coming.

This issue will be distributed at events including the Australian Energy Storage Conference and Exhibition and Energy Networks 18, so I look forward to catching up with some of you in person to hear about how you have been taking advantage of current opportunities and keeping up with the sector’s rapid rate of change. Chris

Ivor Frischknecht was appointed inaugural CEO of ARENA in August 2012. Ivor is widely acknowledged as an expert and innovator in the rapidly evolving energy industry. He leads ARENA’s efforts to accelerate the commercialisation and integration of renewable energy into Australia’s energy system, as well as playing a leading role in transforming the electricity sector.

Ivor brings decades of private sector experience to ARENA, particularly involving smart investment in clean technology startups and growth companies. Before joining ARENA, Ivor was responsible for clean tech investments at venture capital firm, Starfish Ventures, which manages $400 million primarily on behalf of Australian superannuation funds.

Before that he was CEO and investor in the clean tech sector in Silicon Valley, California. Ivor has degrees in law and economics from the University of Sydney, and an MBA and Public Management Certificate from the Stanford University Graduate School of Business.

Chief

Sarah was appointed as the new CEO at the Australian Energy Council in March 2018, having worked as its General Manager of Corporate Affairs since January 2016. Sarah is a corporate and government relations professional with more than 10 years’ experience working with policy and regulatory frameworks across the resources and energy sectors. Previously, she was the Chief of Staff to the then Minister for Industry, the Hon Ian Macfarlane, and prior to that worked as a senior policy adviser to the Prime Minister (energy, resources, environment, agriculture and communications). Sarah has also worked for the industry – between 2008 and 2013 she worked in AGL’s Corporate Affairs team as Head of Government Affairs (and for some of that time also headed up its Community Engagement team). Sarah began her career as a corporate lawyer and has a Bachelor of Arts/Law from the University of Melbourne. She also worked as a policy adviser in the Howard Government.

Paul Broad was appointed Managing Director and Chief Executive Officer of Snowy Hydro Limited in July 2013. Before being appointed as a Director, Paul was Chief Executive Officer of Infrastructure NSW, AAPT, PowerTel, Energy Australia Sydney Water and Hunter Water.

Chief Executive Officer, Energy Networks Australia

Andrew Dillon is an experienced energy sector executive, most recently as the General Manager Corporate Affairs at AusNet Services, owners of electricity transmission and both gas and electricity distribution networks in Victoria.

Prior to AusNet, Andrew was General Manager Corporate Affairs at Energy Supply Association of Australia, worked in Corporate and Government Affairs at TRUenergy (now EnergyAustralia) and was a Senior Ministerial Adviser. He is also a Director of Goulburn Valley Water. Over two decades Andrew has worked in many parts of the energy industry as well as in government and consulting. He was appointed the Chief Executive Officer of Energy Networks Australia on 20 November 2017.

Ian Learmonth joined the CEFC as its CEO in May 2017, after previously serving as an independent member of the CEFC Executive Investment Committee. Ian has more than 25 years' experience as a financier and investor, working across clean energy and major infrastructure projects, as well as social impact investments.

He joined Social Ventures Australia (SVA) in 2011 to establish its Impact Investing business and raised SVA's first Social Impact fund in 2012. Ian structured and launched Australia's first Social Impact Bond and was also instrumental in establishing a dedicated Social and Affordable Housing fund with large super fund HESTA.

Previously an Executive Director of Macquarie Group for 12 years, Ian has investment banking experience in Sydney, Hong Kong and London. He established and led various businesses, notably European renewable energy and carbon credit investments, as well a cross-border structured finance and asset financing in Asia and Europe.

As NERA CEO, Miranda is a strategic leader at the forefront of innovation and collaboration within the Australian energy resources sector. It is a role she is passionate about, bringing together the country’s best minds from technology, research and enterprise, all with the aim of building a more sustainable and efficient energy resources sector.

With more than 20 years’ experience in strategic policy, risk management and stakeholder engagement, Miranda has a great understanding of the challenges being faced by the sector – one of the country’s biggest economic contributors and employers. Her interest in transformative and disruptive thinking, coupled with her significant industry experience, ensures NERA plays a vital role in leading the future of the energy resources sector. Miranda has overseen NERA since its inception in 2016 and prior to appointment as CEO, Miranda was the Director Environment, Safety & Operational Performance for APPEA, Australia’s peak oil and gas representative.

David Blowers has extensive experience developing both energy and broader public policy in both Australia and the UK.

He has spent the past three years as the Energy Fellow for the Grattan Institute, providing analysis and commentary on Australia’s electricity and gas markets, as well as on climate change policy. Prior to working for Grattan, he spent three years working on energy and earth resources policy for the Victorian State Government.

Megan is a Senior Executive with over 20 years’ experience in consulting, government, energy and water utilities, leading business strategy, growth and transformation. Prior to joining ERM Power in 2016, Megan was Director-General for the Queensland Department of Tourism, Major Events, Small Business and the Commonwealth Games. She has previously held senior executive positions in strategy and finance with Energex, United Energy and PricewaterhouseCoopers, and non-executive director roles on the boards of GOLDOC (the 2018 Commonwealth Games Organising Committee), Tourism and Events Queensland, Unity Water and Urbis.

As the CEO of CitySmart, Brisbane’s sustainability agency, Megan built the startup business and led it for six years. Megan is a member of Chief Executive Women and a former Telstra Queensland Business Woman of the Year, and named as an AFR 100 Women of Influence.

The COAG Energy Council has agreed to progress to the final design stage for the National Energy Guarantee (NEG), following the presentation of a detailed proposal by the Energy Security Board (ESB).

The ESB presented a high level design of the Guarantee to the COAG Energy Council on 20 April 2018 following a two month consultation process and the review of more than 150 submissions received from a broad range of groups and individuals.

The design of the NEG will now be finalised with the aim for it to be completed by the next COAG Energy Council meeting scheduled in August 2018.

Alongside the design document prepared by the ESB, the Commonwealth Government has prepared a document on the design elements that are its responsibility – setting the emissions target under the Guarantee, the treatment

of emissions-intensive trade-exposed industries and the role of external offsets.

Federal Minister for the Environment and Energy, Josh Frydenberg, said the decision by the COAG Energy Council was “a big step forward in delivering a more affordable and reliable energy system as we transition to a lower emissions future”.

“Backed by an unprecedented cross-section of business, industry and community groups, the Guarantee is a technology neutral energy policy that will drive the right investment in the right place and at the right time to secure Australia’s energy future,” Mr Frydenberg said.

“Modelling undertaken by the Energy Security Board (ESB) shows that wholesale electricity prices will decrease by 23 per cent under the Guarantee, flowing through to households and businesses.

“The Guarantee is only one element of the Turnbull Government’s comprehensive plan for a more affordable and reliable energy system. It complements practical actions such as our agreement with energy

ARENA will provide $370,000 in funding for a feasibility study into a ‘virtual microgrid’ for the Latrobe Valley. The $775,000 project will be led by Brooklyn-based energy company LO3 Energy and focuses on the feasibility of creating a ‘virtual microgrid’ across up to 200 dairy farms, over 100 household consumers and around 20 other commercial and industrial customers in the Gippsland region.

A ‘virtual microgrid’ is a local marketplace of connected energy users who can buy and sell electricity within a localised area.

The virtual microgrid will incorporate solar PV, battery storage, smart appliances and enabling technologies combined with the LO3 Exergy peer-to-peer energy trading platform which uses blockchain

technology to allow participants to securely buy and sell locally produced renewable energy.

This marketplace would allow Gippsland farmers to take greater control of their energy use, providing the opportunity to sell their solar power back to the grid, delivering savings on their energy bills.

Participants would be linked in an IoT-based marketplace while using AusNet’s distribution network. Participants would have a combination of solar, battery and smart devices to generate and store energy, and manage usage.

Farmers would be able to participate at no upfront cost through loans provided by the Sustainable Melbourne Fund, repaid through council rates.

The study is expected to be completed by the end of 2018, and if successful the pilot microgrid could be rolled out in Gippsland in 2019.

retailers to offer millions of customers a better deal on their power bill, new laws to stop the networks gaming the system and the work we have done to ensure more gas for the domestic market before it is shipped offshore.”

APPEA, the Australian Energy Council, the Clean Energy Council and the Energy Efficiency Council all welcomed the COAG Energy Council’s in-principle support for further consultation with stakeholders on the design of the National Energy Guarantee as a sensible way forward.

Energy Efficiency Council CEO, Luke Menzel, said the next several months will be critical as the detailed design of the NEG is hammered out.

“A strong pro or anti-NEG position is premature at this point as there is still so much detail to be worked through. What is positive is seeing Australia’s energy ministers engaged in a constructive process focused on resolving questions that have plagued policymakers for well over a decade.”

The project involves a consortium of partners including AusNet Services, Sustainable Melbourne Fund, Dairy Australia and Siemens.

ARENA CEO, Ivor Frischknecht, said the feasibility study would be the first step in transitioning one of Victoria’s primary agricultural regions towards renewables, and would be the first trial of a blockchainbased virtual microgrid in Australia.

“With significant increases in distributed energy resources across the network, there is an emerging opportunity to optimise these systems through orchestration.

“The ‘virtual microgrid’ concept brings an alternative approach to these solutions where the control remains with the customers, rather than retailers, who can choose to opt in depending on the current prices and energy types, or their willingness to provide demand response,” Mr Frischknecht said.

SGB MY Sdn Bhd is part of the SGB-SMIT Group of Companies in Germany, and commenced its production early 1996 in Nilai, Malaysia. The SGB Group of Companies is one of the world’s leading manufacturers of distribution, power and cast resin transformers, with 100 years of experience in manufacturing high-quality transformers.

SGB Malaysia manufactures:

• Oil distribution transformers up to 5,000 kVA

• Cast resin transformers up to 6,300 kVA

• Power transformers up to 50 MVA.

SGB MY plays an important role in the transformer industry, both in Malaysia and the export market within ASEAN, SAARC, Australia and the Middle East.

The Federal Government will invest $50 million into a world-first Hydrogen Energy Supply Chain (HESC) pilot project in Victoria’s Latrobe Valley.

The pilot project will turn brown coal into hydrogen as Australia continues to diversify its energy sources.

The pilot will create over 400 direct and indirect jobs, and is an initial step towards a commercial-scale hydrogen supply chain to diversify energy sources. Hydrogen energy is currently used in cars, electricity generation and industry.

The four-year joint federal, state and industry project will demonstrate the feasibility of turning brown coal from the abundant reserves in the Latrobe Valley into hydrogen to be exported to Japan.

A commercial HESC project has the potential to add more than $8 billion to Australia’s economy.

“We are not only creating a new industry and jobs in the Latrobe Valley and Port of Hastings, but building local skills in a future global hydrogen industry, estimated by the Hydrogen Council to be worth $2.5 trillion in 2050,” Prime Minister Malcolm Turnbull said.

“Our CSIRO hydrogen and energy experts will be working with their Japanese counterparts, maximising the exchange of scientific knowledge created from the pilot, including in carbon capture and storage.

Mr Turnbull said the project builds on the long-standing trade relationship between Japan and Australia on energy and resource commodities.

“Investing in this feasibility pilot is a down payment on our future economic

prosperity and security. We now embark on four critical, groundbreaking years.

“The world-first Hydrogen Energy Supply Chain pilot project is significant for the cutting-edge science and technology it uses, for the potential it represents for Australian industry in hydrogen production and export, and for the jobs it will create.”

The Australian and Victorian Governments are providing a combined $100 million in funding to the $496 million pilot project, co-funded by a Japanese consortium — led by Kawasaki Heavy Industries (KHI) — and the Japanese Government.

The project is being delivered by a consortium of large Japanese and Australian companies, including Kawasaki Heavy Industries, J-Power (Electric Power Development), Iwatani Corporation, Marubeni and AGL.

Platinum Sponsor:

August 20-23, 2018

Gold Coast Convention and Exhibition Centre

Queensland, Australia

Join fellow colleagues from several Oceania nations and abroad for the inaugural damage prevention industry conference to educate stakeholders on damage prevention and safe excavation. A showcase of best practices and international learnings for damage prevention efforts on underground assets and essential infrastructure.

Gold Sponsor:

Founding Sponsors:

3 Industry-Specific Streams

Featuring 30 Sessions Focusing on:

• Damage Prevention Endeavors

• Dial Before You Dig Initiatives

• Utility Location Practices

Supporting Organisations:

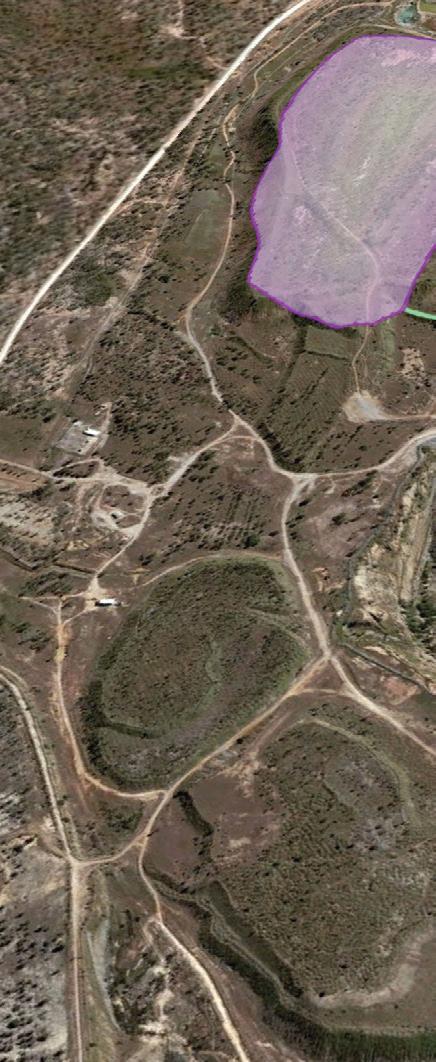

Genex Power has signed a deal to secure the land option to develop a wind farm project up to 150MW as stage three of its Kidston Renewable Energy Hub in North Queensland.

Genex signed the binding heads of agreement with local landholders with the exclusive option to develop stage three of the project, with the new wind farm (K3-Wind) set to become the world’s first solar, wind and pumped storage hydro technology project.

The project is expected to benefit from naturally elevated topography along an escarpment of approximately 21km in length.

According to the company, the project area could be developed into a wind farm of up to 150MW, and connect into the National Electricity Market via the proposed new 275Kv transmissions line

at Kidston to be developed as part of its stage two project.

The K3-Wind Project represents the company’s fourth project in its development pipeline.

In combination with the existing stage one solar and planned stage two solar and hydro projects, the proposed K3-Wind Project could provide inversely correlated generation which could enable the dispatch of firm clean renewable electricity 24 hours a day, seven days a week.

Genex will now undertake a detailed feasibility study to assess and determine the technical and economic feasibility of constructing and operating a wind farm of up to 150MW at Kidston which will include a full assessment of the wind resource at the project site, transmission requirements, capital and operating costs, and firming up of anticipated capacity factors.

The Federal Government’s Cooperative Research Centres (CRC) program has received $90 million in funding to secure its research program until 2025.

The CRC program will be co-funding Future Fuels CRC with $26.25 million over its proposed seven year research program.

The Future Fuels CRC will undertake research and development to transition Australia’s energy infrastructure to a low-carbon economy using fuels such as hydrogen and biogas.

Collaborating with over 60 companies, six universities, the energy market operator and two regulators, the CRC will develop solutions for current infrastructure and equipment to use these new fuels today and well into the future.

Future low-carbon fuels offer the potential to store and deliver reliable,

clean and affordable energy through both new and repurposed equipment. The CRC will be researching across three integrated programs.

The first program will look into the future fuels technologies, systems and markets. It will address technical, policy and commercial barriers to the increased utilisation of future fuels and aims to accelerate development of production technologies and end use applications.

The second program will address the issues around safety and social acceptance of new and changed fuels, so industry can more effectively design, build and operate projects needed to deliver Australia’s energy needs now and in the future.

The final program focuses on the infrastructure itself. It studies the effect that future fuels introduction will have on existing and new infrastructure.

These programs are all supported by an extensive education and training program.

In addition to training up to 50

industry-ready PhDs, the CRC will deliver seminars, conferences and training for industry and the wider community.

NERA Chief Executive, Miranda Taylor, said additional investment in future fuels research and development is critical to ensure Australia successfully and sustainably transitions towards a lowcarbon economy.

“A decarbonised energy future cannot be achieved without supporting Australia’s traditional energy resources sector and leveraging Australia’s global competitive advantage, existing infrastructure, assets and technology into a smart, high value and sustainable domestic energy sector that can reliably meet Australia’s future energy needs."

Australia’s gas network businesses will contribute $8 million towards the venture, in addition to investing in trials that will demonstrate how hydrogen technology can be used in Australia’s existing gas networks. Research is expected to begin in July 2018.

The Albany Visitor Centre in Western Australia has been chosen as the location for the University of Western Australia’s (UWA) Wave Energy Research Centre, making it one step closer to becoming a global leader in marine renewable energy.

The announcement comes after the State Government awarded $3.75 million to UWA to establish a marine energy research hub in Albany to drive offshore research and innovation.

UWA Vice-Chancellor Professor, Dawn Freshwater, said the university was pleased to play a key role in the project and work with government and industry leaders to expand the state’s knowledge

of renewable wave energy.

“With our abundance of wave, wind and solar energy, Western Australia is ideally positioned to be at the forefront of renewable energy research and technology,” Ms Freshwater said.

“The Wave Energy Research Centre will undertake world-class research to support the growth of the entire marine renewable energy sector.

“Research will be undertaken across a range of areas including offshore engineering, oceanography, marine biology, marine planning and management with potential impact on marine policy and law, commerce and economics.”

The Wave Energy Research Centre will become ingrained in the Great Southern community and continue to work closely

with UWA’s Oceans Institute and industry partners to support the development of a wave energy industry in Albany and across WA.

“The university is already a global leader in offshore engineering with world-class geotechnical and hydrodynamic laboratory facilities at the Crawley campus,” Ms Freshwater said.

“By connecting these facilities to our Albany campus, we will be well placed to expand into a variety of marine research programs and to coordinate innovative research.”

State Government funding for the centre will be provided over four years and bring together more than 30 researchers from UWA.

AGL has committed to building a 252MW gasfired electricity generation plant to replace the Liddell Power Station.

The commitment represents an estimated investment of up to $400 million and would comprise flexible, fast-start generation capable of delivering rapidly dispatchable peaking and firming capacity into the National Electricity Market.

AGL is assessing sites for the project near AGL’s Newcastle Gas Storage Facility. This power station will consist of 14 reciprocating engine units capable of generating 18MW of capacity each. Construction on this project would be targeted to complete during the 2022 calendar year.

AGL Managing Director and CEO, Andy Vesey, said AGL is committed to supporting the orderly transition of Australia’s electricity generation capability to modern, clean and reliable energy supply.

“That’s why we gave seven years’ notice of when we intend to close the Liddell Power Station at the end of 2022, and we

are pleased to commit today to build the power station near Newcastle.

“AGL has now committed ahead of schedule to stage one of our NSW Generation Plan submitted to the Federal Government and the Australian Energy Market Operator (AEMO) in December 2017.

“In addition, we continue to assess the potential to develop a further 500MW of gas-fired generation capacity as part of stage two of that plan and are inviting commercial and industrial customers to provide their long-term demand commitments to enable AGL to progress this project.

“AEMO has confirmed that our plan addresses the capacity shortfall that may occur as a result of Liddell closing, and we remain committed to working with AEMO to deliver on that. This is in addition to our generation projects already under construction: 210MW of gas-fired generation in SA and, through the Powering Australian Renewables Fund, 653MW of wind farms in QLD and NSW.”

Mr Vesey said electricity generation is undergoing an increasingly rapid transition to lower-cost, clean energy, renewable and storage technologies. This requires the complementary development

of flexible, dispatchable gas-fired technology, as well as policies to support these developments.

“We are optimistic that the proposed National Energy Guarantee (NEG) will provide sufficient policy certainty to enable market participants such as AGL to invest with even greater confidence in cleaner, more reliable and more affordable energy generation.”

Stage one of the plan comprises projects required to meet AGL’s committed customer needs: the 252MW power station near Newcastle, a 100MW efficiency upgrade to AGL’s Bayswater Power Station, an agreement for AGL to offtake 300MW of solar capacity from Maoneng Australia’s Sunraysia solar project, the conversion of a Liddell turbine into a synchronous condenser, and up to 20MW of demand response capacity.

Stage two comprises projects required to meet AGL’s potential uncontracted commercial and industrial customer demand, and stage three involves further development that may be required if no other market participants invest in new generation prior to Liddell closing. Both stages two and three are subject to Board approval.

The Northern Territory Government has removed the moratorium on hydraulic fracturing, following an extensive, independent and robust 18-month inquiry which found the risks associated with unconventional gas development can be mitigated to acceptable levels or removed entirely.

The government has accepted the key finding of the Scientific Inquiry into Hydraulic Fracturing in the Northern Territory, that any risks associated with onshore gas development and hydraulic fracturing can be managed through effective regulation.

APPEA NT Director, Matthew Doman, welcomed the government’s decision but warned the manner and timeframe in which it implemented the inquiry’s 135 recommendations would be critical in determining the commercial viability of the industry.

“If they are to be implemented, they must be addressed within the next six months to ensure the industry can be on the ground exploring in the 2019 dry season,” Mr Doman said.

“Businesses, contractors and workers in the Territory are counting on the quick ramp up of the gas industry to get the Territory moving again. Explorers are ready to resume their activities as soon as the government gives the green light.”

Jemena also welcomed the announcement and intends to progress its plans to extend and expand the $800 million Northern Gas Pipeline (NGP).

This work is expected to create around 4,000 jobs across northern Australia, with early estimates placing the cost of the project at around $3–4 billion.

Jemena’s Managing Director, Paul Adams, commended the Territory Government’s decision, noting it had commissioned a thorough review into unconventional gas development that included broad and frequent consultation with the community. Mr Adams said the NGP will be completed in late 2018.

by Sarah McNamara, CEO, Australian Energy Council

by Sarah McNamara, CEO, Australian Energy Council

Electricity is critical to our well-being and the functioning of a modern economy. The grid in Australia has been described as one of the biggest machines on earth. It is a machine that is going through an unprecedented level of change and as a result we are seeing the way that power is generated and delivered is changing quickly. The industry is facing both policy and investment challenges which must be either managed or resolved as a matter of urgency.

Akey driver of the investment challenge is the rolling series of closures of older coal-fired generation.

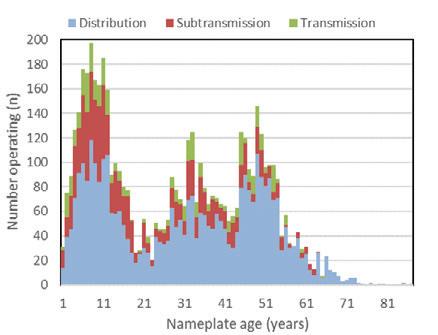

The Australian Energy Market Operator’s timeline of plants that are retiring or reaching 50 years of service (see Figure 1) illustrates the steady departure of coal generation plants from the National Electricity Market (NEM).

This capacity will be replaced by newer lower emissions technologies, including new large-scale renewable generation. What differentiates this generation is that it is not a like-for-like replacement. We will continue to need plants and technology that are dispatchable – or put another way, plants that can be turned on or that can increase output to balance supply and demand.

It will also require significant new investment. Exactly how much depends on a range of factors including technology costs, changes to carbon and energy policies, the timing when older plants retire and more.

Unsurprisingly, it gets more challenging to make a meaningful estimate the further into the future we look. The price of technologies, particularly renewables like wind and solar, have fallen quickly and made previous assumptions redundant. New coal is now more expensive per megawatt hour than new wind and solar, this is even after renewables have been backed up by technologies like peaking gas-fired power stations.

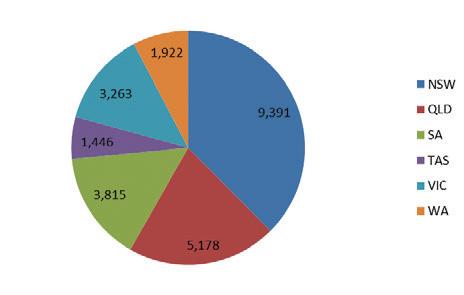

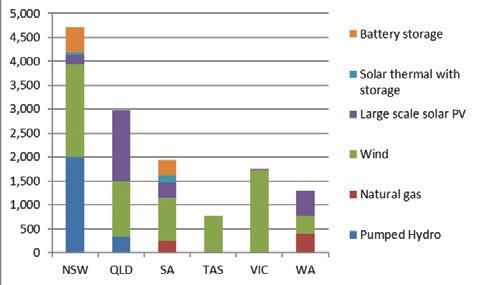

To get a better sense of the investment challenge, the Australian Energy Council recently commissioned Newgrange Consulting to look at the likely costs, as well as the possible mix of generation that we might see to 2030.

That report estimates that around $25 billion in investment will be needed to 2030. The largest proportion of investment is expected to go into new wind farms (51 per cent), followed by pumped hydro, large-scale solar and battery storage. The

remainder of the investment is expected to be made in solar thermal and gas-fired power plants.

These shares are predictions based on projections of relative technology costs assuming the market is allowed to choose the best way to meet customers’ need for reliable supply and the Commonwealth’s emissions target for the sector. If the market is distorted or policy settings remain uncertain, costs will be higher.

Additional investment is likely to be required to develop the transmission and distribution networks to deliver the electricity to homes and businesses. It is anticipated that substantial amounts will be spent by households and businesses on rooftop solar, battery storage and other distributed energy resources, and additional spending will be required to maintain existing electricity system assets.

Generation is more sensitive than other types of electricity infrastructure investment to the kind of stop-start policy that we have seen in Australia for more than a decade. The National Energy Guarantee is the sixth iteration of a proposed national energy policy.

It currently has the support of Federal and State governments, and the Energy Security Board appointed by those governments must now work through the detail of how the scheme would work in practice. That consultation will be concluded by August, at which point the Federal Minister will seek the support of the state and territory governments to proceed to implementation.

Industry is keen to see an end to the policy uncertainty of the past decade in order to stabilise investment signals. The uncertainty does not just impact higher carbon emitting forms of generation like coal-fired plants. The Newgrange report notes that the return on a renewable generator can also be affected by policy uncertainty, as it does not have clarity on the treatment of its competition, the more emissions intensive generators.

Where the new investment takes place is largely expected to be proportionally in line with current demand – except for South Australia, which is expected to attract more investment than its demand would suggest (because it is attractive to wind and solar investors) and Victoria which is expected to have less.

Unsurprisingly, 90 per cent of the new generation build will be in the NEM covering the eastern seaboard states, South Australia and Tasmania. The largest amount of new capacity will be in New South Wales, followed by Queensland and South Australia.

The expected capacity across the different states of the NEM and WA’s Wholesale Electricity Market (WEM)1 is 13,431MW as shown below (note the smaller grids in northern WA and NT were excluded).

The NEM is designed to balance supply and demand. The wholesale price indicates when supply is scarce and in this way works to encourage the development of new capacity to meet demand.

While there are still state-owned generators alongside private investors in the NEM, the market depends on attracting private investment capital. Private investors need confidence that they can achieve a return from their assets over the life of their investment.

The Newgrange report concludes that investment cannot be taken for granted, and that policymakers need to understand the value of stability to the sector. The industry will continue to advocate for a national energy policy to be put in place to deliver that much-needed stability and enable it to focus on the critical transformation of the sector that lies ahead.

¹ Source: Newgrange Consulting

by Robert Pritchard, Executive Director, Energy Policy Institute of Australia.

by Robert Pritchard, Executive Director, Energy Policy Institute of Australia.

There is much community dismay at Australia’s failure to meet its power system needs. Intermittent, renewable power sources, such as wind and solar, have increased their share of the energy mix. However, governments are only beginning to understand the implications of this for energy policy.

The power system must be able to respond to changes in supply when the wind doesn’t blow or the sun doesn’t shine. Why? Because we have to keep the lights on, the schools open, the trains running and the factories operating. At the same time, we have to ensure that the power system remains affordable.

Keeping the lights on at an affordable cost requires a technology-neutral approach to energy policy – an approach that caters for all possible solutions without prejudice to, or predisposition against, any single option.

Technology neutrality must be embraced as the core principle of modern energy policy. There are two reasons for this: first, because it allows for the deployment of both intermittent and dispatchable power; and second, because it optimises the operation of the power system at the lowest possible cost.

Australia’s lack of energy policy certainty has two causes: the first is an insufficient understanding of power system technology; the second is excessive politicisation of the policy debate.

Decisions affecting the electricity sector, rather than being directed by a clear policy framework, have been made on an ad hoc basis in response to, and sometimes in ignorance of, a range of issues that are not so often spoken about, such as how we plan our cities as populations grow, what are the changing energy needs of our transportation and other infrastructure, and what new technologies are available to us.

More overtly, over the past ten years, the two main drivers of energy policy have been the increasing cost of electricity and, even more emphatically, environmental concerns over climate change.

Australian policy has now come to be driven by the risk of blackouts, a risk that is likely to continue as older coal-powered

stations are retired and the lost capacity is not replaced, potentially creating a cliff over which the entire power system could fall.

Policymakers have failed to provide an effective, apolitical mechanism for consideration of the energy mix and emissions reduction targets.

The major explanation for policy uncertainty has been the effective failure, for over a decade, of the Commonwealth and the states to articulate and debate the range of practicable, technology-neutral options for the energy mix for Australia, and to seek industry and community guidance.

One discussant at a recent Energy Policy Institute meeting quipped that technology-neutral in Australia means anything that doesn’t have nuclear or coal in it.

The Finkel Review of the Future Security of the National Electricity Market in 2016/2017 promised relief for a while. However, its fate and future direction is being mainly driven by the competing

interests of the Commonwealth and the states. The contrast might be made with a country like Japan, which regularly listens to industry and indicates to the market what new power generation infrastructure needs to be planned.

Policymakers have also failed to outline a truly technology-neutral approach to achieving Australia’s emission reduction targets.

To achieve significant reductions in emissions within the time-frame set by governments, and without also harming GDP, it will be necessary to continue relying for some time on natural gas and coal and to utilise carbon capture and storage technology. As well, there has been almost no discussion about the nuclear power option in Australia; either in public or in government.

There is increasing community frustration with governments about the lack of proper debate on technology options and inattention to the core principle of technology neutrality.

by Megan Houghton, Executive General Manager Energy Solutions, ERM Power

by Megan Houghton, Executive General Manager Energy Solutions, ERM Power

Big data is changing the way industries manage, analyse and leverage information, and is playing an increasingly important role in shaping the way businesses use and optimise their energy.

Data science can reshape the energy sector in the same way it is transforming financial services and health, where data scientists have built models for credit scoring and risk modelling and algorithms in the trading and medical fields for years.

Twenty years ago, no one would have predicted the reality of accessing financial advice from virtual robo-traders via our smartphones or using machine learning algorithms to detect and track health conditions like heart or respiratory disease.

Just as data science has transformed these sectors, it’s opening new doors in energy management in Australia right now.

Why is this so important?

With continued high energy costs a reality for businesses, along with the transition to renewables and locally generated and managed energy, what’s required is a fundamental shift in the way we think about and use energy, and, importantly, how we realise the potential of an avalanche of data being captured and delivered through multiple sources.

It’s widely acknowledged that the energy sector has been slow to recognise and harness the opportunity and power of data to transform business productivity and enhance customer value.

As a retail energy business, ERM Power has always been data rich and data driven. As the second largest retailer to commercial and industrial customers in Australia, we have a unique perspective on the needs of large energy users.

The increasing complexity of the industry and the proliferation of offerings and suppliers is challenging territory for businesses to navigate. Data can play a pivotal role in energy productivity by helping businesses make evidence-based decisions that can enable them to save money, reduce consumption, improve sustainability or generate revenue from their energy assets.

Data is core to determining the best energy management solutions and the right approach for a business’ sector, size and operations. There is a clear value in investing in data science and digital capabilities to stay ahead of the game.

Just as the health sector turned to data science models for diagnoses to solve health problems, the energy sector is increasingly using big data sets to diagnose the health of buildings and plants to solve their energy problems, in ways that consider the challenges and opportunities on both the supplyside and the demand-side of the energy equation.

An investment in big data and analytics can help businesses to make accurate, targeted and prioritised decisions around their energy productivity.

The amount of big data sets available from businesses own usage and those publicly available has grown exponentially with the Internet of Things. IoT’s ability to turn otherwise ‘dumb’ devices into digital intelligence, combined with faster WiFi and mobile networks and cheaper cloud-based storage options, is making the data science opportunity even bigger. In particular, IoT has the ability to deliver large amounts of real-time data, which has massive implications for the sector.

The utility sector is one of three sectors, alongside manufacturing and transportation, expected to spend the most on IoT worldwide in 2018, and this $73 billion spend will be dominated by smart grids for electricity, gas and water. A further

¹ The Internet of Things explained: what the IoT is, and where it’s going next. Zdnet.com

$92 billion is expected to be spent on cross-industry IoT areas like connected vehicles and smart buildings, air conditioning and security systems.1

Globally, the digitisation of the utility industry is occurring across the entire supply chain; through the network, via meters and into buildings, plants and equipment.

Real-time connectivity to what’s happening behind the meter is critical to enabling a data-led approach to energy management.

For example, with increasing deployment of ‘behind-themeter’ energy resources like renewable power systems, grid-synced generators, battery storage and automated demand management solutions, IoT devices can be used to collect data from these resources and combined with existing data sets from utility electricity meters and weather data and market data.

Data scientists can use these new combined data sets to build very rich and accurate data models that can predict the impact of proposed energy efficiency or demand management projects, both from an energy productivity and financial point of view. These models are particularly well suited to multi-site business environments, as they identify issues across the portfolio, then prioritise actions based on a financial business case.

They find the best prospects for each site, whether it’s solar, battery storage, power factor correction or another energy efficiency solution. They draw on data from historical use, meters, individual equipment and tariffs, as well as using external weather and solar radiance data for each site to forecast future energy consumption and costs.

ERM Power uses models like this to simulate different solutions over multiple time periods to work out the optimal combination from a cost and payback perspective, while also considering the impact of different tariffs and other efficiency measures for businesses.

As an example, demand flexibility, which relies on accurate, real-time data, is increasingly important for organisations driving an agenda of improved energy productivity. It enables organisations to reduce power consumption at different times when wholesale prices spike or there are constraints on the network. As the grid incorporates more renewable energy, modelling demand flexibility and taking action will be even more important.

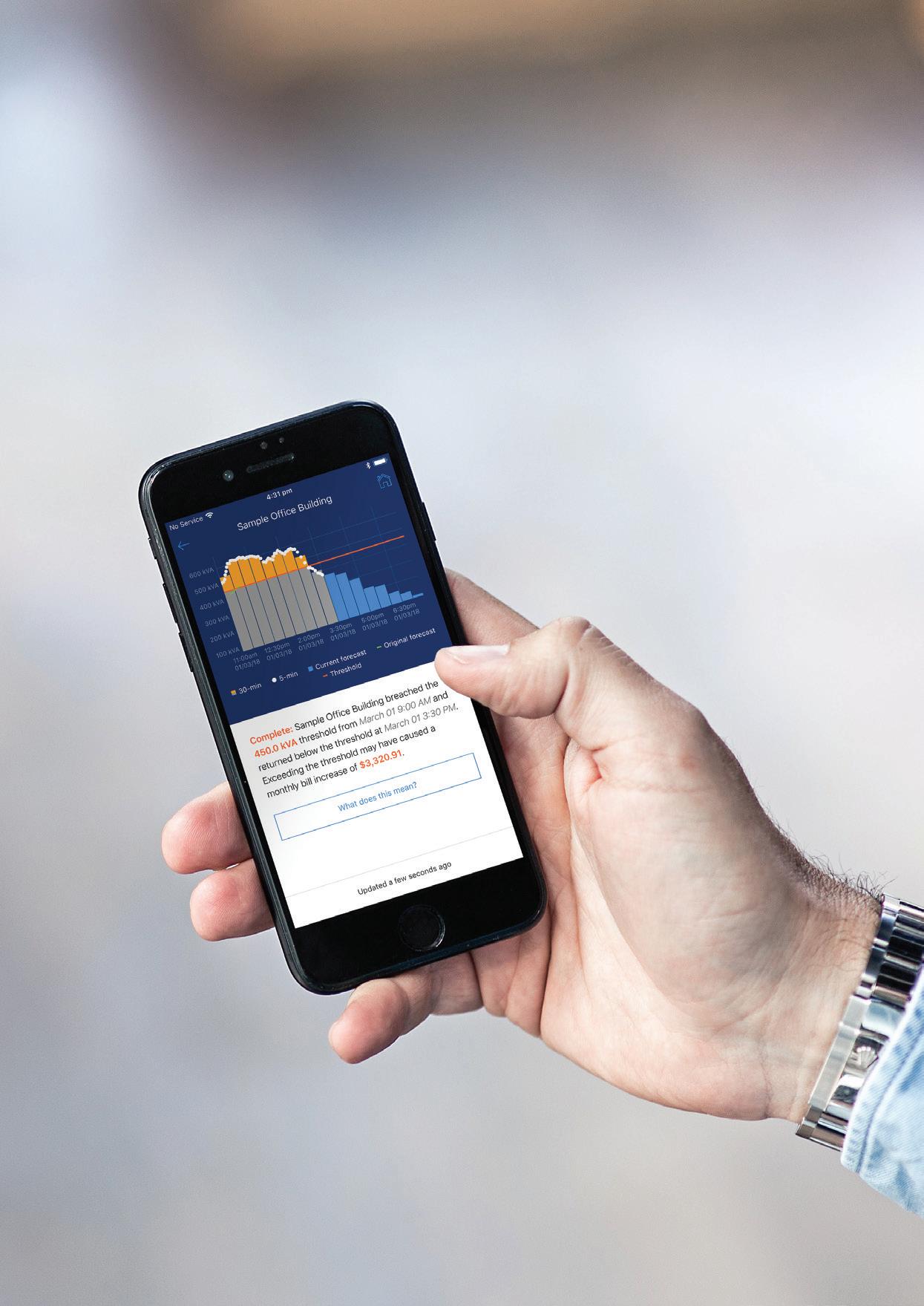

Modelling and data visualisation are being used to create user friendly products like smart apps and dashboards that turn the otherwise complex energy data into something that’s simple, easily digestible and actionable. At ERM Power, design thinking methodology sits at the heart of new product development to ensure capabilities and tools are in line with user needs.

Using data science and machine learning technology, ERM Power has developed a predictive forecasting and notifications smart app. Relatively new to market, the ERM Power app can predict a spike in an organisation’s energy usage and advise them in advance so they can take action to reduce or defer consumption. Real-time data feeds the results back to customers via the app - they can immediately see the results of their actions or inaction and understand the cost implications.

With more connected things than people in the world now and the number still growing exponentially, IoT and big data will undoubtedly lead to far more automation in the way energy is consumed and managed behind the meter.

As more businesses install their own infrastructure behind the meter, whether it’s solar, embedded generation or other new technology, this will create even more meaningful data sets that can be incorporated into modelling. New types of sensorequipped devices will provide more granular data, with the potential to drive more accurate outcomes for businesses with very little human interaction.

The two-way connectivity that these devices will enable will change the way organisations view and manage their operations in the future. For example, machines may run when prices are favourable, and demand is low, or when businesses are generating their own energy to reduce consumption from the grid. This is a clear example of automation driving energy optimisation in business.

Data is continually and rapidly transforming the future of energy management. The opportunity for Australian business is to harness its power to create a sustainable, competitive advantage.

By Ivor Frischknecht, Chief Executive Officer, Australian Renewable Energy Agency.

By Ivor Frischknecht, Chief Executive Officer, Australian Renewable Energy Agency.

In the decades to come, it is increasingly clear that much of the future will be ‘behind the meter’. Or to be more precise, the future is going to be distributed.

Even the phrase ‘behind the meter’ is antiquated, as it draws a line between the customers and the rest of the energy system. It frames the whole electricity system from the perspective of the traditional industry players — the retailers and the networks — instead of from the customer’s point of view.

What’s behind the meter all depends after all on which side of the meter you are standing on and which way you’re facing. From the Australian household’s point of view, the whole electricity system is ‘behind the meter’ – not the other way around.

If millions of Australian households and businesses continue to invest in their own solar and battery storage systems, this vast array of decentralised consumer energy assets could create enormous headaches for the electricity market, its operator, regulator, retailers and networks. It also creates opportunities.

In the last decade, Australians have embraced rooftop solar so enthusiastically we are now the biggest rooftop solar adopters per capita in the world. Ten years ago, there were just 14,000 rooftop solar units across Australia.

Today, nearly 1.8 million Australian households now have solar panels on their rooftops, accounting to 6.4GW of generation capacity.

And that is only increasing. Rooftop solar installations hit a new monthly record in the March quarter just passed with 127MW installed, up 56 per cent from the same time last year. Rooftop solar installations are running at an annualised rate of more than 1300MW. An estimated 1GW of rooftop solar was installed across Australia last year alone. For the first time, rooftop solar throughout Australia generated over 1000GWh in December last year.

The uptake of rooftop solar PV among commercial and industrial customers is also increasing apace with businesses outstripping residential customers.

In the next two decades, AEMO has forecast that rooftop solar will grow by at least 10,000MW, which equates to a fifth of all of Australia’s existing generating capacity.

By 2040, according to some current forecasts, 25 to 40 per cent of Australia’s generation will be coming from solar PV on the rooftops of households and businesses. To put that in perspective, at present, rooftop solar generation accounts for just three per cent of our generation.

While grid-scale generation will always be needed, this increase in solar PV and other distributed energy resources (DER) represents a huge disruption to the National Electricity Market, and a huge challenge for the electricity system to grapple with.

On the other hand, it also represents a huge, untapped

opportunity to make these DER work for the system, rather than against it.

For example, it leads to a situation where demand for electricity — which was once highest in the afternoon — becomes very peaky, where demand is very low during the day while the sun is shining and suddenly demand spikes once the sun goes down as all of the rooftop solar is no longer available.

Thanks to compulsory registration schemes, we can track where rooftop solar is installed but we don’t have visibility on how much electricity they are generating. Rooftop solar cannot currently be monitored or coordinated. We can’t optimise their output the way we can with grid-scale assets.

Home batteries present an even greater challenge. With home batteries, we don’t even know where they are in the system or how many of them there are, let alone what they are doing and we can’t control them externally.

In the coming decade, the cost of residential batteries is expected to plummet. If forecasts are accurate, the global cost curve of batteries will continue to fall as their size and capacity increases – much like computers have become smaller, faster, smarter and less expensive.

If residential batteries become cheaper and more efficient, we can expect a large number of Australian households to adopt them – particularly those that already have solar on their roofs. Last year alone, the number of Australian households installing home batteries more than doubled, from 1566 in 2016 to 3763 in 2017. And this is just the beginning.

Apart from storage, there are other technological innovations that are coming that will change the way we use electricity in our homes and businesses. More Australians will be driving electric vehicles that they charge in their homes. The Internet of Things will allow appliances to be automatically optimised for energy efficiency, and smart thermostats and smart pool systems will become the norm.

In a future where millions of Australian households have solar PV on their rooftops, home battery systems and smart appliances all capable of working together, these assets will not only change the way we use electricity but will also necessitate that we change the way we think about the system.

If we don’t enable these assets to be monitored and optimised, it creates the potential for a future Australian electricity system with limited visibility, lots of instability and the need for lots of new network infrastructure to balance this. This would in turn lead to even higher network costs than Australians are already paying for.

While those lucky enough to afford their own rooftop solar and

storage would experience cheaper energy costs and would be largely self-sufficient in the grid, this could be at the expense of others who cannot afford their own solar and storage who would bear the cost of network upgrades built into their power prices. All of this can be avoided however.

There needs to be a massive enablement of rooftop solar, batteries and controllable loads so they deliver benefits back to the system as a whole, with participation on a voluntary opt-in basis. This will include ways to sensibly manage demand, including incentivising the use of demand side resources as happens in other countries from Texas to Taiwan.

If consumer energy assets can be orchestrated and optimised so as to work harmoniously, distributed energy resources could save consumers money on their power bills, reduce the need for network infrastructure, help deliver grid stability services and inject dispatchable power back to the grid when and where it is needed.

To deliver this, there are certainly technical challenges to overcome. However, this shift to distributed energy also creates commercial issues and regulatory challenges.

We need incentives for people to allow access to their solar and battery storage devices and appliances. We need commercial and business to benefit from integrating into the system. We need new business models to drive this innovation so it is seamless and automated. We need new market rules to allow these unregulated assets to be valued as part of the energy mix.

Retailers could become the future orchestrators of consumer energy, but at the moment their existing business model is to sell electricity to customers.

Networks also have an important role to play, but existing networks make money through regulated returns from expenditure on grid infrastructure.

In the US, cable companies are becoming new consumer energy enablers. In Australia, it is conceivable that this “energy enabling” might be done by telecommunications companies, or it could be a service offered by tech giants like Google, Amazon and Apple who are moving into home automation technologies.

Already, ARENA is supporting a wide range of studies and pilot projects that look at how to optimise consumer energy.

In South Australia, AGL is already rolling out their virtual power plant project involving 1000 AGL customers in Adelaide, by aggregating 1000 batteries in 1000 households and businesses.

Earlier this year, Simply Energy announced a $23 million project in Adelaide, with $6 million in ARENA grant funding to create a virtual power plant consisting of 1200 households totalling 6MW of capacity, and a further 2MW of demand response from commercial businesses.

This will involve installing subsidised Tesla Powerwall 2 batteries in households with existing rooftop solar, which will then be coordinated and aggregated. This virtual power plant will also involve the ARENA-funded Greensync’s deX platform and the South Australian Power Network.

In Victoria, ARENA is also supporting a feasibility study into a “virtual microgrid” for the Latrobe Valley. US-based energy startup LO3 created and manages the Brooklyn Microgrid, and would look to create a local energy marketplace of 200 dairy farms, 100 households and 20 other commercial and industrial businesses in Gippsland.

This “virtual microgrid” would see these customers install solar and storage, and would allow them to buy and sell their renewable energy locally using blockchain-based peer-to-peer energy trading platform Exergy.

Last summer, ARENA and AEMO also kicked off a three-year trial of demand response. This trial is funding 10 pilot projects to deliver 200MW of demand response emergency reserves across three states in NSW, Victoria and South Australia.

Most of these pilot projects are trialling paying energy consumers — both commercial and industrial customers and residential customers — to be on standby to conserve energy during extreme peak demand events, such as a summer heatwave. All participation in these schemes is voluntary and all businesses and residential consumers benefit from their involvement.

Beyond this trial, ARENA has also funded a Sydney boutique energy retailer Pooled Energy to trial smart pool system technology in 5000 swimming pools across NSW, which uses cloud-based software and sensor-based control systems to optimise backyard swimming pools so they can be turned into controllable loads.

In March, ARENA announced a $12.5 million DER funding initiative. Under this initiative, ARENA has called for pilot projects to look at improving network hosting capacity and for studies to look at improving orchestration and integration of high levels of consumer energy.

It is too early to say which of these new business models or new technologies might ultimately be the best way to enable and integrate distributed energy, but one thing is certain; we cannot afford to ignore the customer side of the equation.

In a future where the customer side of the system has a huge role to play in delivering supply and managing demand, our current industry-centric view of the system has to change.

Instead, we need to think about the energy system holistically – and that includes finding ways for customer’s household solar, batteries and appliances to be utilised for the benefit of the system as a whole.

SBetween 2005 and 2015 the value of the electricity grid – the poles, wires and substations that transport electricity from generators into our homes and businesses — increased by $40 billion in real terms. This 70 per cent increase was a major reason electricity bill increased so much over the same period. But while the value of the grid ballooned, our use of the grid grew only modestly. So why all this extra spending on infrastructure? This is the question that the latest Grattan Institute report, Down to the wire, tries to answer.

pending on network infrastructure is important. When consumers start using more electricity during peak periods – as has happened with the widespread adoption of air conditioning – the existing networks need to expand. When new houses and suburbs are built – as is happening as Australia’s population booms –new infrastructure is needed to connect these households to the grid. And as infrastructure ages, it needs to be replaced.

But our report found, even after taking these factors into account, that network businesses spend up to $20 billion more on infrastructure than was needed. And most of this excess spending occurred in just two states: up to an extra $11 billion in New South Wales and up to $7 billion in Queensland.

There are a number of reasons.

First, expected increases in peak demand never materialised. Everyone

thought electricity demand would continue to grow in line with economic growth. But in 2009, electricity demand began to fall and then flatline.

Second, network businesses that are owned by state governments can have different incentives than a privately-owned business. Publicly-owned businesses may prioritise local procurement over cheaper foreign options. They may, under pressure from their political masters, give priority to making the system even more reliable, rather than seeking to provide electricity at the lowest cost.

That’s what happened in NSW and Queensland. In the middle of the 2000s, the governments of those two states imposed strict reliability standards on their network businesses. They did so in response to some high-profile blackouts and safety concerns, which had attracted a lot of media attention.

As a result, network businesses had to build a lot more stuff to strengthen their networks. Eventually, some of the reliability standards were either removed or eased. But not before the damage was done.

The network businesses had already spent up big – and consumers in NSW and Queensland were left with the bill. Consumers in NSW, in particular, have paid an awful lot of money for a quite-limited improvement in reliability.

Of course, politicians want to take action when blackouts occur, as we have seen recently in South Australia. No one wants to be left holding the baby when the lights go out. But immunity from reliability problems doesn’t come for free.

Grattan’s Down to the wire report shows a common link between the businesses that overspent; they were all publicly owned. This fact does not ‘prove’ that private is better than public; there are a range of factors that together resulted in network businesses overspending. Nonetheless, the evidence suggests privatisation of the electricity businesses in Victoria and South Australia has benefitted consumers in those states.

The businesses in Victoria and South Australia have spent less, maintained decent reliability and kept network costs down, compared to the publicly-owned businesses to their north. That’s why our report recommends the privatisation of remaining publicly-owned network assets.

But even if the businesses are privatised – and this seems unlikely – there is still the issue of what should be done about that $20 billion of unnecessary spending.

The excess investment has made grid-based electricity more expensive than it should be. That will drive more consumers to get off the grid and on to solar power and other off-grid alternatives. And that in turn will mean those consumers who remain wholly reliant on the grid will need to pay still more for their grid-based service.

Only by making sure that the price of grid-based electricity reflects its true value can policymakers ensure efficient investment decisions are made and equitable outcomes achieved.

To this end, we proposed that, where government still owns the network business, they should write-down the value

of their assets in line with the overspend. This would not create sovereign risk: as owners, the government can do pretty much what they want to their businesses without creating sovereign risk for privatelyowned businesses.

Nor would it require changing the regulatory framework, which could impact on other network businesses in the National Electricity Market.

electricity consumers a rebate

In the case of the recently privatised, or partly-privatised, NSW businesses, the state government doesn’t have such luxury. Changing the value of a privately-owned business creates all sorts of sovereign risk.

So instead, we recommend that the NSW Government pays all electricity consumers a rebate commensurate with the savings consumers would receive had a write-down of the assets occurred. In both cases – for the publicly-owned and privately-owned network businesses – consumers would get a reduction in their bills.

The problem of networks ‘gold-plating’ is not new. But it’s time to draw a line under the problem. Either governments act,

or they choose to accept that the excess costs are locked in for consumers.

As for the electricity grid itself, it faces greater challenges.

The grid is likely to remain vital to our future electricity needs. But the way it is used is changing, and how the grid will look in future is a big unknown. Electricity generation is becoming more distributed, more individuals are using the grid to both buy and sell electricity, and some are fleeing the grid altogether.

Working out how we build the right electricity infrastructure in the right places will be vital if we are to avoid a repeat of the massive overspending of 2005 to 2015.

IPS-SYSTEMS™ is a fully integrated and comprehensive Enterprise Asset Management (EAM), Asset Performance Management (APM), Network Model Management and Mobile Solution, specialised for the global electricity industry, with large and ever expanding technical libraries of assets, technical data and analytics.

With big data and the IoT transforming the way asset information is managed in the digital age, more and more organisations are looking at implementing advanced EAM software to ensure assets operate more efficiently and with minimal disruption.

By setting up a dedicated EAM platform, utilities can monitor and analyse the real-time condition of their assets, offering more informed decision-making and opportunities for preventative maintenance, and asset life extension. With concerns about aging assets and the cost of replacement, utilities are seeking maximum cost efficiency and return on their assets.

IPS-ENERGY’s Asset Performance capability is world-leading, with highly advanced software and analytics to accurately assess asset health and predict asset lives, undertake what-if analysis, and capex and opex optimisatio n.

Highly-intelligent asset, configuration management for protective relays and IEDs (a must-have for high level of power system security, reliability and flexibility), is just one of our key differentiators.

Another one is our CIM XML, Topology and Network Model Manager functionality, which provides you with one centralised set of validated system network model data, for multiple users to implement in:

» Network planning

» Network analyses

» Asset management and more.

Our new state-of-the-art Mobile Solution (IPS-MobApp), has both online and offline capability, and leading-edge dynamically-changing work tasks and action lists, based on field data collection and instant asset analytics, providing superior predictive maintenance capability, as well as voice recognition, machine learning asset nameplate and condition photo recognition and analysis.

According to Gartner, the world’s leading IT research and advisory company, utilities looking for a product tailored to an engineering focus on physical characteristics should consider IPS-SYSTEMS in their shortlist.

IPS-ENERGY Australia Pacific is the Australian branch of IPS-Company Group, a global organisation headquartered in Munich, Germany, that specialises in EAM and APM for electrical power utilities.

If you would like to have more information or see a demonstration of IPS-SYSTEMS™ software and analytics and IPS-MobApp solution, please contact us at any time as per details below and/or come to see us at Booth No. 27 at Energy Networks 2018

For more information and product specifications, visit www.ips-energy.com, call +61 3 9042 8081 or email info.au@ips-energy.com

The dragonfly is a creature of intrigue, its appearance and behaviour fascinating to many cultures and civilisations. Universally, the dragonfly symbolises power and poise through its ability to move in all six directions at amazing speeds with graceful agility. The name dragonfly has its source in the myth that dragonflies were once dragons, thus the genus name ‘odonata’ meaning ‘tooth’. The espionage group ‘Dragonfly’, infamous for its attacks on energy security systems, has resurged to take some vicious bites.

Late last year, Symantec reported that Dragonfly, suspected to have its roots in Russia, was targeting Europe and North America’s energy sectors in a new wave of cyberattacks. The group, in operation since at least 2011, re-emerged as “Dragonfly 2.0”.

Issues relating to cyber security are generally considered by the public to be a financial services and privacy concern: credit card fraud, identity theft etc. What many people never think about is an attack in the energy space. A compromised grid could bring a city (or country) to its knees if essential infrastructure and services are cut such as water, electricity, gas supplies, hospitals, transport.

Recent global events have forced the doomsday scenario to the fore with politicians and sector leaders speaking publicly with unprecedented candour and immediacy.

Putin’s recent warning to Great Britain was stark; there are incumbent “consequences” to be suffered for the Syrian airstrikes. In response, Britain’s Foreign Secretary, Boris Johnson, raised the alarm, saying an imminent cyber backlash could see Britain’s vital services affected.

“You have to take every possible precaution, and when you look at what Russia has done, not just in this country…

attacks on critical national infrastructure –of course we have to be very, very cautious indeed.”

Mr Johnson warned that cyberattacks undermine “civilised values”, fearing that hackers could force electricity blackouts and cripple the grid. A few weeks prior, an industry taskforce was announced to draw up a strategy to restore the grid in the event of a nationwide power failure triggered by a cyberattack.

Ciaran Martin, Director of the National Cyber Security Centre (NCSC), the public face of UK spy agency Government Communications Headquarters (GCHQ), confirmed that Moscow’s attempts at hacking into the UK’s energy network over the last year was part of a larger effort seeking to undermine the international system’s critical infrastructure, suggesting it is a matter of when, rather than if.

Jeremy Fleming, GCHQ’s Director, launched a blistering attack on the Kremlin, simultaneously warning that the online threat from Moscow was ill addressed at peril.

“The Russian Government widely uses its cyber capabilities. They’re not playing to the same rules, they’re blurring the boundaries between criminal and state activity.

“To stay ahead, to match the pace of technological change, we are investing in deploying our own cyber toolkit. It’s one

that combines offensive and defensive cyber capabilities, to make the UK harder to attack, better organised to respond when we are, and able to push back if we must.

“We may look to deny service, disrupt a specific online activity, deter an individual or a group or perhaps destroy equipment and networks.”

The threat posed by Dragonfly isn’t just a threat for European countries; the United States has been on cyber threat alert for some time, particularly since the allegations of Russian interference in the 2016 Presidential election.

In the energy sector, the North American Electric Reliability Corporation (NERC) set up the Electricity Information Sharing and Analysis Center (E-ISAC) in 1999. Originally focused on physical security, in recent years E-ISAC has greatly broadened its remit to provide unique insights, leadership and collaboration, particularly on high impact low frequency (HILF) events.

An ongoing challenge is the unknown nature of what each attack may involve; a coordinated attack could be a combination of physical and cyber threats, and this underlines the need for a collaborative, cross agency approach. E-ISAC has undertaken four biennial GridEx grid security exercises.

GridEx is an unclassified public/ private exercise designed to simulate a coordinated cyber/physical attack with operational impacts on electric and other critical infrastructures across North America and beyond, in order to bolster preparedness, resilience and reliability.

Cyberattacks in our space have been foreseen. A 2015 survey of 625 IT executives in the US, UK, France and Germany found that 48 per cent thought a cyberattack on critical infrastructure, including energy infrastructure, by the year 2018 resulting in loss of life, was likely.

Our new Minister for Law Enforcement and Cyber Security, Angus Taylor, warned that in our efforts to thwart the Dragonfly, businesses, agencies and departments mustn’t entrench silos even further, but should collaborate and share.

"The key in cyber, like most areas, is speed and that means you've got to share information in a collaborative way.”

At March’s Senate committee examining the digital delivery of government services, Australian Signals Directorate (ASD) Director-General, Mike Burgess, berated department heads for being secretive when it comes to cyber security.

"There is a possibility that those who aren't taking this seriously don't ask for our help. That would be a risky strategy for any chief executive.”

Last year, Australia launched a national $230 million cyber security strategy, led

by attorney general George Brandis, with particular attention on the energy sector. Securing critical infrastructure assets in partnership with industry was a key focus.

"With increased foreign involvement, through ownership, offshoring, outsourcing and supply chain arrangements, Australia's national critical infrastructure is more exposed than ever to sabotage, espionage and coercion," Mr Brandis said.

While legislative steps have been put in place to protect critical infrastructure, what is industry doing to protect its assets?

The Finkel Review’s examination of the future of Australia’s National Electricity Market (NEM) recommended a heightened emphasis on cyber security, with an annual report considering the NEM’s cyber security preparedness.

The review also recommended an Energy Security Board (ESB) that would coordinate whole-of-system monitoring of security, reliability and planning. The ESB was established in late 2017 and espousing collaboration, works with key agencies including the Australian Cyber Security Centre, the Critical Infrastructure Centre, the Department of Defence, ASD, ASIO, and Prime Minister and Cabinet.

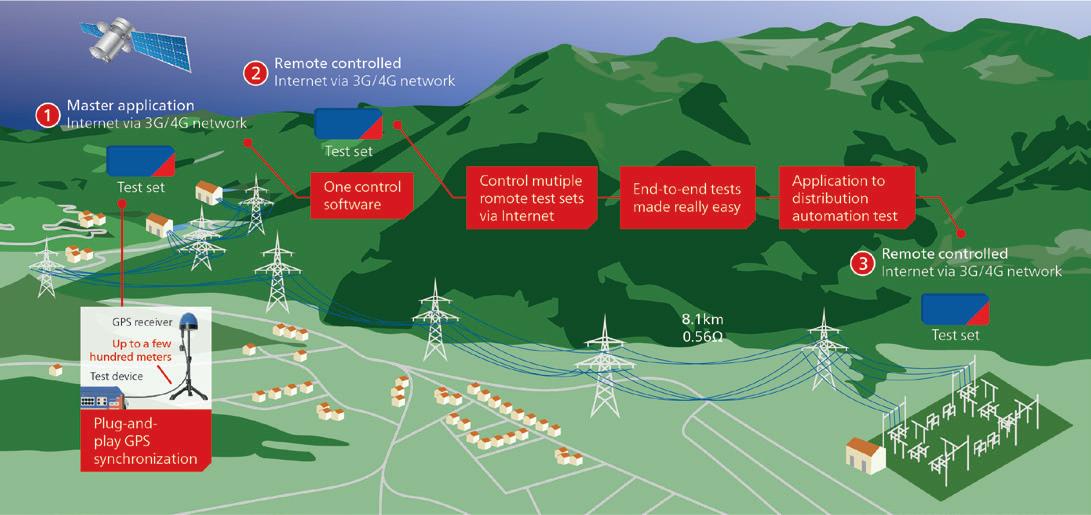

The Federal Government and AEMO have ultimate responsibility for the sector’s response to cyber threats, however, Energy Networks Australia has designed programs to complement and add value to those work streams.

Energy Networks Australia’s cybersecurity program is, together with our members, reviewing networks’ resilience and capacity, with a final report expected in June 2018. Litmus, the independent consultant leading the study is utilising the internationally recognised US Department of Energy’s Cyber Security Capability Maturity Model (C2M2) assessment tool.

Networks are collaborating with AEMO (which has ultimate responsibility for our nation’s grid security) to ensure the findings of our program can be used to inform the Cyber Security Industry Working Group (CSIWG) and mitigate threats.

Networks are also working with Standards Australia to undertake a review of technical standards and international protocols. A future roadmap will consider the most appropriate technical cyber standards for Australia.

Examining how our nation’s information and technology planning matches up with international standards will complement the Cyber Security Industry Working Group task to develop a holistic cyber security framework for Australia.

Energy Networks 2018’s June conference will take a deep dive into cyber security and leaders in our sector will share how we can best protect our assets.

The adage about an ounce of prevention being worth of a pound of cure is apt in relation to cyber security; the strongest insect repellent we have to stymie the Dragonfly is continued information sharing, timely communication, cross agency working and agile, expedient solutions.

by Louis Brailsford, Energy Advisor, The Climate Council

by Louis Brailsford, Energy Advisor, The Climate Council

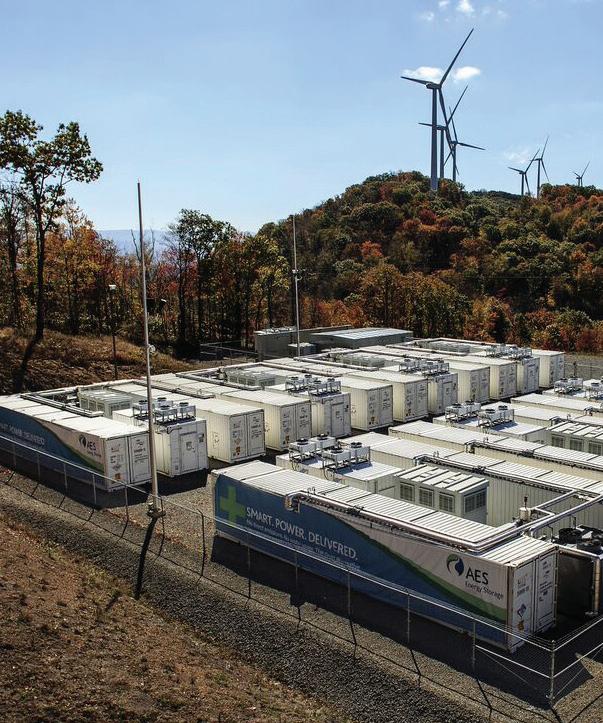

Australia is currently enjoying an energy storage boom. In 2017, Australians installed more energy storage (batteries, solar thermal and pumped hydro) than any other country in the world, with 246MW of power capacity added to the grid, according to a GTM Research report released recently.

Australia was also second in the world for energy capacity (MWh) added, just behind the United States. To cap it all off, Australia was number one globally for household storage installations. Australia’s love affair with the technology is growing in leaps and bounds, with no signs of slowing down.

The combination of high electricity prices, the falling costs of renewable energy and batteries, and supportive state government policies have turned Australia into a world leader on energy storage in the space of just a few years.

Australia has very high electricity prices. Between 2007/8 and 2015/16, Australia’s electricity prices were driven up by over investment in the poles and wires of the electricity network. High gas prices, lack of competition and policy uncertainty have also played a role in Australia’s high electricity prices.

The high cost of electricity has meant that new technologies, particularly batteries, are becoming competitive with established technologies more quickly than they otherwise would. Grid-scale batteries are already competitive

with peaking gas power stations, as has been recently demonstrated in California, where solar and batteries are beating out gas to provide electricity during peak periods at the lowest cost.

The high cost of electricity has been one of the main drivers behind the rapid uptake of household solar. Household solar in Australia has reached over 6,000MW – over twice the size of Australia’s largest coal-fired power station.

With many Australian homes now generating some of their own electricity, many households are

considering installing batteries as well. In 2017, over 20,000 households installed batteries – three times the total for 2016.