CSIRO CEO Larry Marshall on the pathway to zero emissions

renewable energy: managing solar waste Cleaning up

QUEENSLAND TAKES

hydrogen to the next level

ISSUE 14 · June 2021 · www.energymagazine.com.au

Non-contact voltage and current measurements, through a clamp.

The Fluke 377 FC & 378 FC clamp meters. The newest members of the FieldSense™ family.

• Test faster and safer. Get simultaneous non-contact voltage and current measurements with Fluke FieldSense™ technology

• Power quality indicator to detect equipment or power line issues (378 FC Only)

• Complete 3-Phase voltage and current tests in 3 quick steps

Learn more:

fluke.co/377FC-378FC

Cover highlights our focus on wind energy in this issue, with features on the pathway to zero emissions, accelerating Australia's clean energy journey, and the ways in which we can give aging turbines a new lease of life.

For this issue, I’m writing my Editor’s Welcome off the back of two fairly large events for the energy industry – the launch of the Federal Budget for 2021-22, and the Smart Energy Conference and Exhibition.

Unsurprisingly, each of these events offered pretty different takes on where the future for the energy industry lies.

The Federal Government used the Budget to double down on its commitment to a gas-fired recovery from the COVID pandemic; while also earmarking $1.2 billion for emissions reduction.

And while that is a sizable contribution, many in the industry have described this year’s Budget as being full of “missed opportunities” when it comes to the inevitable transition to renewable energy.

Meanwhile, at the Smart Energy Conference and Exhibition – which kicked off the morning after the Budget was handed down – the focus has shifted away from policy somewhat, and towards the innovation that is happening within the industry, and that will drive the industry forward when federal energy policy will not.

In particular, Professor Martin Green – widely regarded as the “father of PV”

– discussed the way solar prices will evolve in the years to come, sharing his prediction that in the next few years we can expect to see power purchase agreements worth one cent per kilowatt hour.

With prices like that, it’s clear to see that this transition is happening, and will continue to happen at pace, with or without policy support.

Over the past couple of months a number of announcements from within the industry have served to remind us of this: the early closure of Yallourn; the release of Victoria’s game-changing Climate Change Strategy; a raft of hydrogen project announcements; and more big battery developments.

The other thing that gives me faith that the transition will continue to gather pace is you, the readers of Energy Magazine. It’s my job to understand the content that you engage with week in and week out, and consistently, that is stories about the evolution of this industry.

I can see how excited you are for change, and I know how passionate you are – let’s keep pushing forward to create the energy industry we all want to see.

Laura Harvey Editor

1

ISSUE 14—JUNE 2021 WELCOME EDITOR’S WELCOME Leading Energy Storage For when you need proven battery technology with guaranteed performance Evaluating your energy storage battery return on quicker payback on your capital outlay. Delivering fast, effective installation and commissioning. Once you’ve chosen the right system for your business, we’ll install We offer the latest energy storage battery technology coupled with a range of system-level guarantees, giving you absolute peace of Part of the Pacific Green Technologies Group Green Approach Technologies delivers industry can provide a full review commissioning service, Grid Scale / Co-Located Commercial & Industrial + www.energymagazine.com.au CSIRO CEO Larry Marshall on the pathway to zero emissions QUEENSLAND TAKES hydrogen to the next level renewable energy: managing solar waste Cleaning up Monkey Media Enterprises ABN: 36 426 734 954 C/- The Commons, Office 1, 36–38 Gipps St, Collingwood VIC 3066 P: (03) 9988 4950

(03)

Published by We’re keen to hear your thoughts and feedback on this issue of Energy. Get in touch at info@energymagazine.com.au or feel free to give us a call on (03) 9988 4950. June 2021 ISSUE 14 Editor Laura Harvey Associate Editors Imogen

Eliza Booth Contributing Editor Michelle Goldsmith Design Manager Alejandro Molano Designers Jacqueline Buckmaster Danielle Harris National Media and Events Executives Rima Munafo

Thompson Marketing Associate

Sud Marketing Assistant

Di Paola Publisher Chris Bland

F:

8456 6720 monkeymedia.com.au info@monkeymedia.com.au energymagazine.com.au info@energymagazine.com.au ISSN: 2209-0541

Hartmann

Brett

Radhika

Stephanie

2 FUTURE ENERGY 14 Taking hydrogen to the next level: Queensland’s Hydrogen Taskforce 18 Nuclear for net zero: facing the realities of a carbon constrained world 22 Committing to change: time for energy users to embrace clean energy 24 Australia’s clean energy journey: accelerating the transition FUTURE ENERGY 28 7 steps to maximise battery return on investment 30 Future Energy: pathways for Australia’s energy transition 32 Giving new life to aging wind turbines INDUSTRY INSIGHT 10 The pathway to a zero-emissions electricity sector by 2035 14 28 10 NEWS 4 AGL CEO quits “effective immediately” 4 EnergyAustralia gains new leader 6 SA-NSW Interconnector gains ElectraNet’s commitment 6 Hydrogen MOU signed for Gladstone 8 $160 million for Victorian Big Battery 8 Report: coal power plants unviable by 2025 EACH ISSUE 1 EDITOR'S WELCOME 64 FEATURES SCHEDULE 64 ADVERTISERS’ INDEX CONTENTS June 2021 ISSUE 14 www.energymagazine.com.au

CONTENTS 3 ENERGY NETWORKS 34 State governments need to work together to plan renewable energy policies 38 This price is definitely not right 34 EVENTS 59 Making a difference in the energy transition ASSET MANAGEMENT 60 Lighting the way for a responsible and respectful energy transition 59 60 WASTE-TO-ENERGY 50 Turning leftover food and grease into power 50 SAFETY AND TRAINING 52 Polarity app makes for safer work practices 56 Unveiling the hidden risks in power system earthing 58 The safest way to measure voltage 52 STORAGE AND SOLAR 40 Waste not, want not: preparing for Australia’s solar waste problem 44 Rays the roof: accommodating home solar and batteries into the grid 48 Charging to export solar: will it send the system backwards? 40 www.energymagazine.com.au June 2021 ISSUE 14

AGL CEO QUITS “EFFECTIVE IMMEDIATELY”

AGL Managing Director and CEO, Brett Redman, has resigned after almost 15 years with the company, including the past two-and-a-half years as CEO.

The resignation came less than a month after Mr Redman announced AGL’s plans to separate into two business units – New AGL, focused on retail and renewables, and PrimeCo, the new home for AGL’s existing gas and coal generating assets.

The timing, and the fact that the decision became “effective immediately”, has led to much speculation of a difference of opinion between the AGL Board and Mr Redman regarding the best path forward for the soon-to-be split organisation – which Mr Redman was the architect of.

The official line has been that Mr Redman is simply moving on because he believed he could not make a long-term commitment beyond the proposed structural separation; and that the board agreed it was appropriate to put in place alternative leadership arrangements now to facilitate the separation.

AGL’s current Chairman, Graeme Hunt, has been appointed Interim Managing Director and CEO effective immediately, and will step down as Chairman. Mr Hunt will lead AGL throughout the process of planning for the structural separation, which is continuing, and includes consideration of the appropriate long-term leadership of the two proposed new businesses. Non-Executive Director, Peter Botten, has been appointed as Chairman, also effective immediately.

Mr Hunt said, “I wish to thank Brett on behalf of the board and all of AGL’s people for his service to the company.

“Over his time as CEO, Brett has returned the company to growth in its customer base and stabilised relationships with key stakeholders at a time of unprecedented uncertainty in energy policy and market conditions.

“In addition, the structural separation strategy Brett has sponsored gives AGL the opportunity to make material progress in our role in the energy transition.

“I look forward to working with the rest of the leadership team to deliver a successful outcome for AGL’s shareholders and all stakeholders as we drive this process to its completion.”

Mr Redman said, “After almost 15 years with AGL, I am proud of the contribution I have made to growing Australia’s largest multi-product energy retailer, assembling Australia’s largest electricity generator and founding Australia’s largest renewable investment fund.

“I am also pleased to have established the case for the structural separation of the business. The timing of my departure will enable the leadership team to be established to execute upon the separation strategy and lead the business into its next chapter.”

Mr Botten said, “I am honoured to be appointed Chairman of AGL. I want to add my thanks to Brett for his service to the company and to recognise Graeme for agreeing to take up the role of Interim CEO while we work through this important period.

“This will provide important continuity of leadership for the business and certainty for our people and shareholders while we work through the considerations of structural separation and establish a platform for future success.”

While Mr Redman’s resignation was effective immediately, he will remain available to the board of AGL until the end of his notice period, which concludes on 21 October.

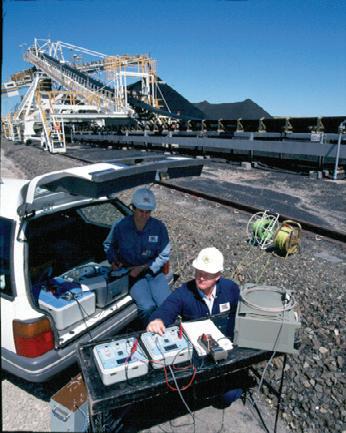

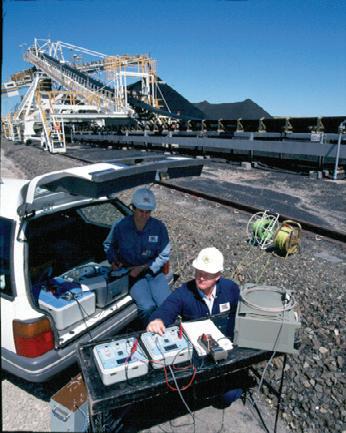

ENERGYAUSTRALIA GAINS NEW LEADER

EnergyAustralia has appointed Mark Collette to be its new Managing Director, effective 1 July 2021, following current Managing Director Catherine Tanna’s decision to retire after seven years at the helm.

The leadership change was announced just a week after fellow big-three organisation AGL announced its CEO was moving on, but the announcements couldn’t have been more different.

In EnergyAustralia’s case, Chairman Graham Bradley AM and Ms Tanna couldn’t be more pleased with the new appointment.

“Succession planning began two years ago, and we’re thrilled that an internal candidate has been appointed following a comprehensive domestic and international recruitment process,” Mr Bradley said.

“Mark is a highly experienced executive who has played a pivotal role in positioning EnergyAustralia to navigate the complexities of the energy transition.

“Under Mark’s leadership we will continue to pursue opportunities as we build a modern energy business that helps keep the lights on.”

Mr Collette joined EnergyAustralia in 2003 and since then has led the Customer, Energy, Trading and Corporate Strategy

and Development teams. He is a director of the board of the Australian Energy Council, a former director of the Australian Financial Markets Association, member of the Reliability Panel and holds degrees in Aerospace Engineering, Business Administration and Economics.

Mr Collette succeeds Ms Tanna, one of Australia’s most respected leaders, credited as being one of the first in the industry to commit their business to become carbon neutral by 2050.

“I would like to take this opportunity to thank Catherine for her tremendous achievements and for developing a firstclass team,” Mr Bradley said.

“In her trademark authentic and approachable style, she built a culture that enables people to do their best work.

“Before COVID-19 changed the world of work, Cath had already encouraged progressive ways of working for EnergyAustralia’s people.

“She is also a passionate and genuine supporter of a range of social issues including diversity and inclusion, Aboriginal and Torres Strait Islander reconciliation and workplace giving.

“That an internal candidate succeeds her is testament to the investment she made in people.

“She is widely respected by the people of EnergyAustralia and although she will be missed, we understand she feels that it’s the right time to pass the baton.”

Mr Collette said he is honoured to become EnergyAustralia’s next Managing Director and is particularly looking forward to bringing to fruition recently announced initiatives.

“I thank the board for this opportunity and am committed to carry on the work to build a thriving business capable of delivering momentous projects, such as Australia’s first four hour, 350MW utilityscale battery by 2026,” Mr Collette said.

Ms Tanna said that she is delighted that her successor has been appointed from within EnergyAustralia’s ranks.

“Developing leaders has been a priority and I’m so pleased that this has enabled us to deliver a leadership transition that best suits our business,” Ms Tanna said.

NEWS 4 June 2021 ISSUE 14 www.energymagazine.com.au

“Run with us – Your partner in Plastics”

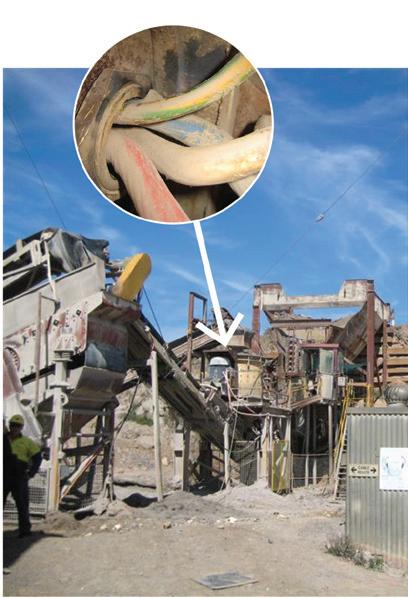

All Australian Supplied Electrical Cable Cover is manufactured in accordance with AS4702-2000 and is independently tested, by TUV Rheinland Australia

Unique rounded edging of the Cable Cover ensures maximum installer safety and reduces the risk of injury

100% Recycled Plastic

Notched Pallet allows web hoist to be safely fed through the coil and ensure safe offloading of larger coils

Gas Protection Covers available in a range of sizes

The Corrugated Cable Cover, is a patented product, manufactured under License

Thicknesses range from 3mm to 10mm, Widths available from 100mm up to 600mm

Standard Slab Length available in 1.2, and 2.1 Metre

Standard Coil Lengths are 10 Metre, 15 Metre, 20 Metre, 25 Metre and 150 Metre

Both Plastics Extrusions Thailand, and AGC Plastics, are 100% Australian owned and ISO accredited Companies

The product is continuously checked during the production cycle to ensure the surface finish, size, weight and impact strength are to the required specification

In-Line Printing allows for product batch and manufacture date for identification and tracing

Maintain strict control over all our procedures so as to maintain the highest quality of both product, and service to our customers

+61 432006775 rory@agcplastics.com.au

for further information.

Contact Rory Livingston AGC Plastics Pty Ltd 38 Sarton Road, Clayton Victoria, 3168 Australia www.agcplastics.com.au AGC Plastics has a number of quality distributors in Australia, as well as internationally. Please contact us

ELECTRICAL CABLE COVER

AS4702-2000

INTERCONNECTOR GAINS ELECTRANET’S COMMITMENT

The proposed SA-NSW Interconnector is a step closer to the final approval stage, with ElectraNet submitting its commitment to proceed with the project to the Australian Energy Regulator (AER).

ElectraNet Chief Executive, Steve Masters, said ElectraNet’s Board has resolved to commit to proceed with the South Australian section of the project, subject to the AER awarding incremental regulated revenue commensurate with the capital and operating costs of the project.

ElectraNet is continuing to work proactively with the AER to progress the project through its last regulatory approval, with a final determination anticipated in the coming weeks. Following the AER’s determination, ElectraNet would then enter its Final Investment Decision phase for the project.

When it released its preliminary position in December 2020 on the contingent project application for Project EnergyConnect, the AER indicated that the board resolution from ElectraNet as part of its application should fully reflect the contingent project trigger event.

“The board’s resolution fully satisfies the final contingent project trigger event requested by the AER to enable it to make a formal determination under the National Electricity Rules,” Mr Masters said.

“This is an important project for the national electricity grid and is a priority project for ElectraNet, the Australian Energy Market Operator (AEMO) and many other stakeholders.

“We look forward to concluding the regulatory approval process to support the timely delivery of the project in the interests of

electricity customers across the National Energy Market (NEM).”

In addition to the commitment to proceed with the project, ElectraNet has provided the AER with its latest review of the economic assessment of Project EnergyConnect considering recent announcements linked to the NEM.

“ElectraNet is mindful of the rapid pace of change across the NEM and the importance of the project delivering the expected benefits for customers,” Mr Masters said.

“We have modelled and considered the potential impact on the project’s benefits from recent policy and market developments –which were not included in AEMO’s 2020 Integrated System Plan – and have concluded that overall, the project benefits are likely to be higher than previously forecast.

“In fact, our latest economic assessment shows that, when combined, these recent market developments increase the expected benefits of the project by between $190 million and $440 million (present value) compared to the $1.9 billion previously reported in September 2020.”

Independent analysis shows Project EnergyConnect is expected to deliver net annual savings of around $100 for a typical household in South Australia and up to around $60 for a typical household in New South Wales – it will drive competition in the wholesale electricity market by connecting more, low-cost generation to the grid and support the ongoing transition to a lower carbon emissions future.

HYDROGEN MOU SIGNED FOR GLADSTONE

Ahistoric Memorandum of Understanding (MOU) has been signed with a Japanese multinational for a new hydrogen ecosystem in Gladstone.

Sumitomo Australia, Gladstone Ports Corporation (GPC), Gladstone Regional Council (GRC), Australian Gas Networks (AGN) as part of the Australian Gas Infrastructure Group (AGIG), and CQUniversity Australia (CQU) have joined forces to explore opportunities to develop a hydrogen ecosystem in Gladstone.

The ecosystem will initially pursue domestic offtake and mobility solutions before moving to enable large-scale export.

GPC Acting CEO, Craig Walker, said Australia’s National Hydrogen Strategy and Queensland’s Hydrogen Strategy set a vision for a clean, innovative, safe and competitive industry that benefits all Australians.

“Australia is uniquely positioned to be a world-class hydrogen energy generator and exporter,” Mr Walker said.

“With an exceptional port and the ability for the region to develop an abundance of clean energy, Gladstone is positioned to be Australia’s leading hydrogen export location by 2030.”

Gladstone Region Mayor Matt Burnett said he welcomes the development to the region, supporting the scale up from domestic generation and utilisation, to large-scale generation and export.

“From a community perspective this is great news for our region,” Mayor Burnett said.

“We are perfectly positioned to establish Australia’s first hydrogen ecosystem, and we have five parties that are fully committed to seeing this through to fruition. Gladstone has an excellent track record for development – the early opportunities in domestic gas offtake and mobility are very exciting.”

The MOU, signed at the Gladstone Entertainment Convention Centre, sets out a three-phased plan, commencing in 2021, with the key end goal by 2030 to see hydrogen exported from Gladstone to the world.

Yoshikazu Ishikawa, Managing Director of Sumitomo Australia, said the three-phased approach allowed tangible milestones, positioning Gladstone as an industry leader in hydrogen utilisation and technology.

“Sumitomo Australia is pleased to be working with an esteemed group of stakeholders who share our common vision of a Hydrogen Ecosystem in Gladstone.

“Uniquely positioned with a world-class port, exceptional solar radiance, skills, knowledge and technology, Gladstone is a strategic location with significant hydrogen potential to benefit both Australia and Japan.”

AGIG’s CEO, Ben Wilson, said, “We are proud to build on our existing partnership with the Queensland Government on Hydrogen Park Gladstone to bring us further closer to our vision to convert our gas networks and cities to renewable hydrogen.”

NEWS 6 June 2021 ISSUE 14 www.energymagazine.com.au

SA-NSW

OsmoFume

Wood Utility Pole Preservative System

Using OsmoFume to protect your wood poles from internal decay provides benefits to your utility infrastructure through added resiliency and extended asset life.

OsmoFume meets the rigorous performance and toxicity criteria established by the Australian Pesticides and Veterinary Medicines Authority (APVMA Reg. No. 88348/120987).

First dazomet-based wood pole fumigant commercially available in Australia. Dazomet provides superior long-term benefits when compared to a diffusible rod.

Proprietary, stick design provides a controlled dose and sufficient space for a copper accelerant, like Hollow Heart CB Wood Preservative (APVMA Reg. No. 90556/129272). ®

(08) 9300 2950 | enquiries@logsys.com.au | logsys.com.au/osmofume an company

$160 MILLION FOR VICTORIAN BIG BATTERY

The Federal Governmentowned Clean Energy Finance Corporation (CEFC) is providing $160 million for the construction of Neoen’s 300MW/450MWh Victorian Big Battery (VBB).

The VBB is set to help strengthen grid security, drive down power prices and support the integration of more renewable energy into the grid.

CEFC CEO, Ian Learmonth, said, “Energy storage supports cost-effective, reliable, clean electricity and is a key component of Australia’s transition to a low emissions economy.

“This project is a world-class example of how utility-scale batteries can help electricity networks support a higher penetration of renewable energy.

“The VBB will improve grid security by providing extra capacity during the peak summer months.

“It will also contribute to the dispatchable resources needed to underpin the increasing share of renewable energy that will make up Australia’s future energy mix.”

Under the System Integrity Protection Scheme (SIPS) contract Neoen has signed with AEMO, the VBB will unlock up to an additional 250MW of peak capacity on the existing Victoria to New South Wales

Interconnector. The extra power flowing between the states during the peak summer season will deliver support to the grid at critical times.

Independent analysis by PWC found that the SIPS process could deliver total benefits of more than $220 million to Victorian consumers in the next eleven years, including savings on power bills.

If gross savings and AEMO costs for the battery are passed on to consumers, the Portland aluminium smelter stands to save about $1 million a year on its electricity bills, while the average industrial Victorian electricity consumer could save about $280,000 a year.

Federal Minister for Energy and Emissions Reduction, Angus Taylor, said the project would give Victorians confidence in their state’s energy system.

“All Australians need access to reliable and affordable power, which is why the Morrison Government is focused on keeping the grid secure,” Mr Taylor said.

“After the challenges of COVID-19, this is more important now than ever to support jobs, families and businesses in Victoria.”

Lily D’Ambrosio MP, Victorian Minister for Energy, Environment and Climate Change, said, “The Victorian Big Battery is an important part of the largest modernisation of the grid in our state’s history.

“It will create jobs and drive down energy prices, while supporting our transition to renewable energy.”

Xavier Barbaro, Neoen’s Chairman and Chief Executive Officer, said, “We are thrilled to be building our second big battery in Australia.

“The Victorian Big Battery once again demonstrates the value of innovative solutions that Neoen is proud to be pioneering.

“At 300MW, it will be one of the largest batteries in the world, taking our total capacity in operation or under construction in Australia to over 1.8GW, and bringing us one step closer to our global target of 5GW by the end of 2021.”

REPORT: COAL POWER PLANTS UNVIABLE BY 2025

The Institute for Energy Economics and Financial Analysis (IEEFA) and Green Energy Markets have released a new report which indicates that several coal power plants in the National Electricity Market (NEM) are likely to be financially unviable by 2025.

Several of the 16 coal power plants in the NEM will be financially unviable and at least one is likely to face closure several years sooner than planned due to coal plants’ poor flexibility and inability to adapt to a rapid influx of renewable energy, according to the report.

Tracking the announcements of proposed wind and solar projects, authors Tristan Edis and Johanna Bowyer found previous estimates of future power supply from renewables in the NEM to be understated.

A huge amount of renewable energy supply is expected to be added to the NEM. From 2018 to 2025, new wind and solar plants will add 70,000GWh of extra supply – which equates to New South Wales’ entire electricity consumption.

By 2025, it is forecast that the installed renewables capacity will include 8GW of utility-scale solar, 12GW of wind, and 22GW of rooftop solar*.

“The market is facing a tidal wave of new supply, much greater than anything government authorities or market analysts forecast or even contemplated just two years ago,” Mr Edis said.

“The supply added from 2018 to 2025 equates to over a third of the entire demand in the NEM, and more than eight times the annual generation of the Liddell coal-fired power station in NSW.”

Ms Bowyer said this extra supply will lead to a collapse in output from many of the existing fossil fuel generators.

“They will be displaced because wind and solar have no fuel cost and typically bid into the market with prices close to zero,” Ms Bowyer said.

“We predict that gas power station output will fall by 78 per cent and coal output by 28 per cent by 2025 compared to 2018 levels.

“The extra competition from wind and solar plants will also have a deflationary impact on wholesale electricity prices, as more expensive gas and coal generators will be needed far less.

“While prices will be more volatile, on average they are likely to return back to the kinds of levels that prevailed in 2015.

“This is because the extra supply from renewables is several times greater than that lost from the closure of Hazelwood, Northern and Liddell Power Stations.”

*This forecast excludes any additional supply expected from the NSW Government’s Infrastructure Roadmap.

NEWS 8 June 2021 ISSUE 14 www.energymagazine.com.au

THE NEXT STEP IN BATTERY TECHNOLOGY

Zenaji AEON, Lithium Titanate Batteries allow you take full advantage of your home solar installation, delivering the best lifespan and performance on the battery market.

Available from R&J Batteries and distributors across Australia. Talk to the experts on how Solar Storage can work for you.

// 1300 769 282 // rjbatt.com.au/store-locator

YEAR W ARRANTY

20

THE PATHWAY TO A ZERO-EMISSIONS

ELECTRICITY SECTOR BY 2035

by Dr Larry Marshall, Chief Executive, CSIRO

by Dr Larry Marshall, Chief Executive, CSIRO

For years now, the industry has been puzzling over the path towards zero emissions. Here, CSIRO Chief Executive Larry Marshall weighs in, outlining the research his organisation has conducted into how the industry needs to transform.

June 2021 ISSUE 14 www.energymagazine.com.au 10 INDUSTRY INSIGHT

www.energymagazine.com.au June 2021 ISSUE 14 11 INDUSTRY INSIGHT

My son recently completed a school project on solar energy. I was astounded at his literature review.

At the one end were articles claiming coal would always be cheaper than renewables and renewables would never deliver stable, reliable energy. At the other were articles claiming renewables have been the cheapest source of energy for a decade and are stable because the wind blows when the sun doesn’t shine.

Unfortunately, neither are entirely true. You’d be forgiven for not knowing who or what to believe.

CSIRO recently released our GenCost report for 2020-21, which we produce each year with the Australian Energy Market Operator to assess electricity generation and storage costs.

We work with a range of real-world industry players to provide a data driven, scientifically researched model that projects the cost to generate electricity for new power plants in Australia, including coal, gas, wind and solar.

We also project future changes in costs based on our CSIRO technology roadmaps, and the progression and impact of technology advancement in areas like storage.

I want to share some of our findings here to help separate myth from fact.

But first, some context.

CSIRO has analysed and projected energy futures for more than two decades, and we are working with the Australian Government and industry to catalyse the transformation of our energy sector.

It’s one of the biggest industry shifts we’re likely to see in our lifetimes, and we want to get it right.

Over those two decades, we have forecast and tracked the reduction in cost of key types of utility-scale power generation, including renewables, and more recently the development of battery storage options (including our own UltraBattery which has been helping stabilise the United States power grid in Eastern Pennsylvania).

For much of this time, a system called LCOE (Levelised Cost of Electricity) has been the methodology for a consistent comparison between technologies and costs.

While a useful starting point, due to its relative simplicity, it fails to account for the associated ‘system’ costs of different technologies, and in particular, non-dispatchable renewables such as wind and solar. This is a critical factor to be addressed as our grid transforms itself.

Many studies have claimed cost parity for renewables with coal and gas over the last decade, but have typically excluded the costs associated with grid stability and security – a big issue in Australia where we have vast distances and sparse populations.

With the stage now set, let’s talk about our GenCost report, which is in its third year of publication.

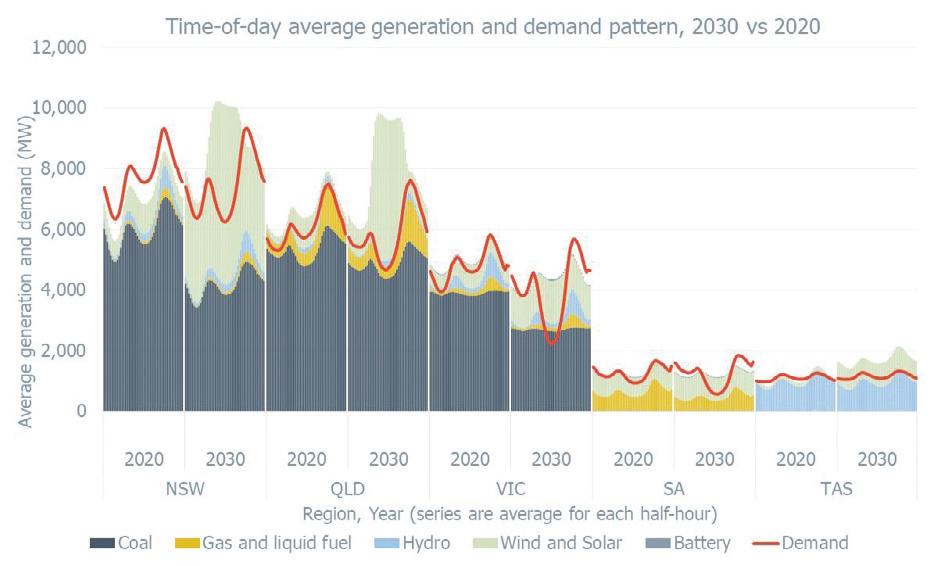

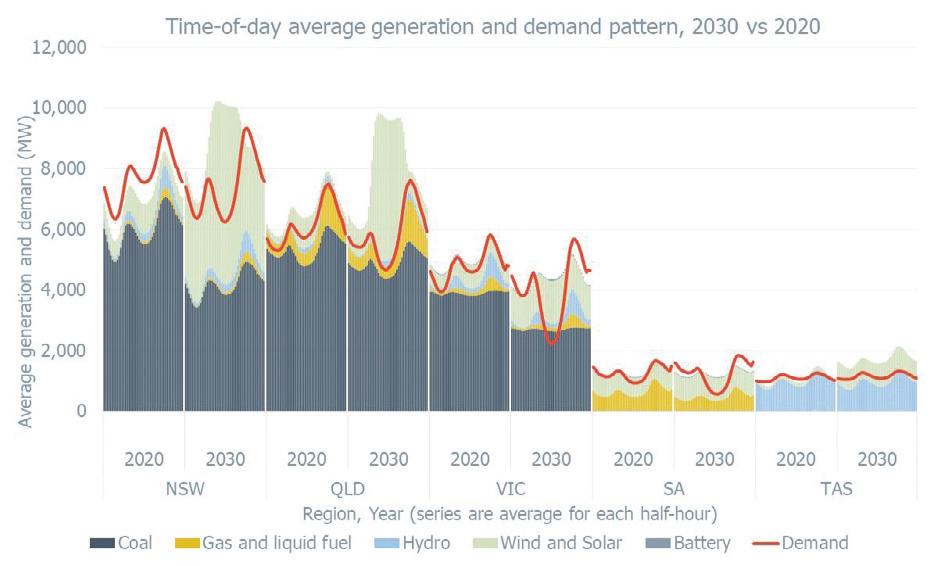

Large-scale solar and wind becoming cost competitive with gas

This year we focused on improved representation of system integration costs – moving beyond LCOE to consider how the mix of energy technologies integrate, plus the need for (and cost of) balancing technologies like storage.

While we have tried to incorporate system costs in a very simple form in the past, this time we explored more effective ways to estimate and account for system impacts.

For the first time, we started to see large-scale solar PV and wind becoming cost competitive with gas on a ‘system’ basis.

Our previous GenCost report found that renewables were and continue to be the lowest cost new-build technology, but when we added the cost of storage, some gas generation was available at comparable cost.

But in this report, we clearly see that by 2030, if large-scale solar and wind are deployed at up to 60 per cent share – even with storage and grid integration costs – they will be significantly more competitive than gas across all plausible future gas prices.

While this is excellent news, this does not mean we should abandon gas – quite the contrary.

Keeping gas in the mix will allow for a faster transition

Existing gas plants are cheaper than new builds and are well placed to provide the flexibility and dispatchability we need as we add more variable renewables to the grid.

CSIRO’s Australian National Outlook, which projected what Australia could look like out to 2060, mapped scenarios to limit global warming to 1.5 degrees Celsius.

Generally, that goal requires a zero-emissions electricity sector by 2035, because other sectors are harder to reduce. To reach that, we will need around 75GW of variable renewables in the energy system, which is about 5GW of new variable renewables generation capacity installed each year.

Australia has already demonstrated it can deploy 5GW of variable renewables per year, and almost every state has tens of gigawatts of projects in the planning phase.

June 2021 ISSUE 14 www.energymagazine.com.au 12 INDUSTRY INSIGHT

That puts Australia in a great position to reach our goal and contribute to global emissions reduction.

Keeping gas in the mix will allow for a faster transition, because it is around 30-50 per cent lower in greenhouse gas emissions than coal, and offers a pathway to gradually introduce hydrogen to further reduce emissions.

Coal still the cheapest existing electricity source for the time being

Looking across the spectrum at some of the other findings from GenCost, today existing brown coal is still the cheapest electricity source, followed by existing black coal and existing gas.

While this is broadly true, there are different markets at play here. Gas rules the evening peak period, and solar is substantially impacting the market share of coal in the daytime.

But we will soon see this start to shift as around 80 per cent of gas and coal assets reach their end of life and are retired over the next 20 years. This will happen quite naturally, driven by market forces, and does not require government intervention.

Over the same period, the cost of storage will continue to come down, and it will become more attractive to build variable renewables either integrated with their own storage or installed elsewhere in the grid.

And they won’t need some form of carbon pricing to help them.

GenCost shows that renewables plus integration costs are already lower than all other options for new generation, with or without a carbon price.

But to be realistic, it will take at least a decade, if not more, for wind and solar generation capacity to grow to reliably produce enough power to reach what coal does today.

In the meantime, we will need gas to cover the gap, and buy us time to build the renewable generation capacity and storage we need.

We can’t go renewable without storage

By 2030 we expect Australia will be at around 50 per cent renewables, with some states such as South Australia exceeding that by a significant margin.

This means energy storage will be critical, because we can’t go 100 per cent renewables without storage.

We’ll need different solutions depending on the situation and geography.

In general, batteries work well for short durations (hours not days) and lower loads, while pumped hydro is designed for much longer periods. Snowy 2.0, for example, has the capacity to

provide 175 hours or more than seven days of stored power – a true workhorse.

Each has their pros and cons, but we’ll need both to power Australia’s transition to renewables. Fortunately, we’ll have time to build them.

By 2030 we expect grid integration costs to be low enough that renewables will be clearly the lowest cost option, and we will power on to 100 per cent renewables over the next two decades.

Hydrogen is another storage option we are developing that combines the best of batteries and pumped hydro. The beauty of this option is that it can be made and consumed here, and exported in bulk to help our neighbours.

Fuel for industry and growth

But electricity production is only one third of our energy demand – the lion’s share is used by industry.

Despite our passion for solar and wind, we still need fuels for industry, for heating and transport. Australia must have low-cost energy to give our industries a globally competitive edge.

Solar and wind can simply not deliver power fast enough (literally high current over a short time) to support our industrial processes.

If you’ve ever tried to boil your billy with your car battery while camping, you’ll know that it takes a good 30 minutes and flattens your battery while fuel (LPG) does it in minutes.

We need solar and wind, but we also need a low to zero emissions fuel for industry. That fuel will be gas in the short term, and hydrogen over the longer term as we transition.

Australia has some unique challenges – our geography and population size means we have the world’s longest and least interconnected electricity grid.

But we also have the world’s largest penetration of residential solar, which is consumer-led and continues to grow. And we have a world-class science sector innovating in low-emissions technology.

Australian science invented the low-cost solar cell design that is used around the world today.

We invented futurefeed, which almost eliminates emissions from cattle – the world’s third largest emitter if they were a country.

And we invented the hydrogen cracker to enable a liquid renewable fuel for transport and industry.

We have the power to make sustainability profitable. To reduce the emissions – but not the profits – from our industries.

It’s not a matter of policy or politics, it’s simply a matter of performance.

Science can deliver that profitability, and industry will leap. That’s how we will change the world.

www.energymagazine.com.au June 2021 ISSUE 14 13 INDUSTRY INSIGHT

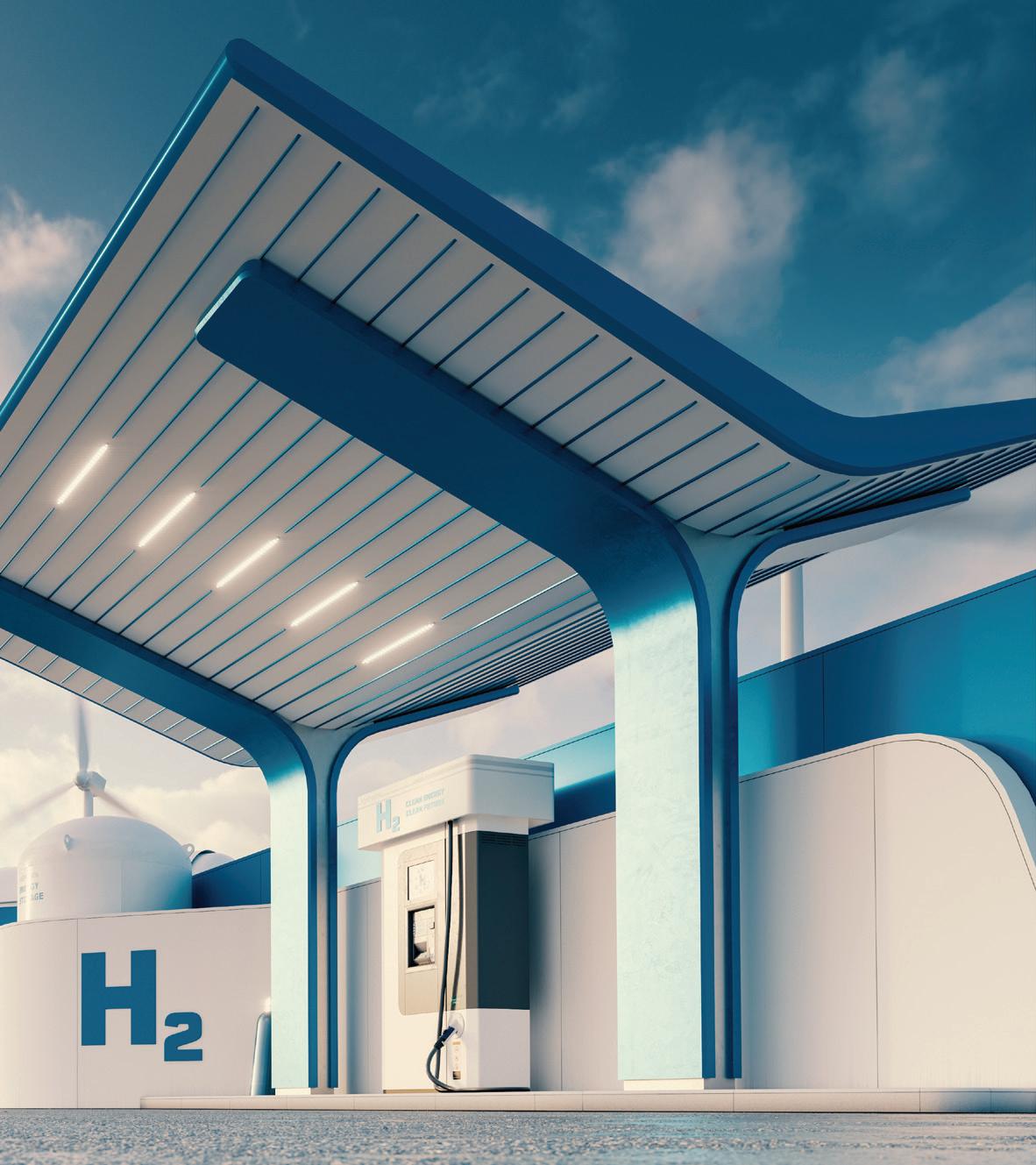

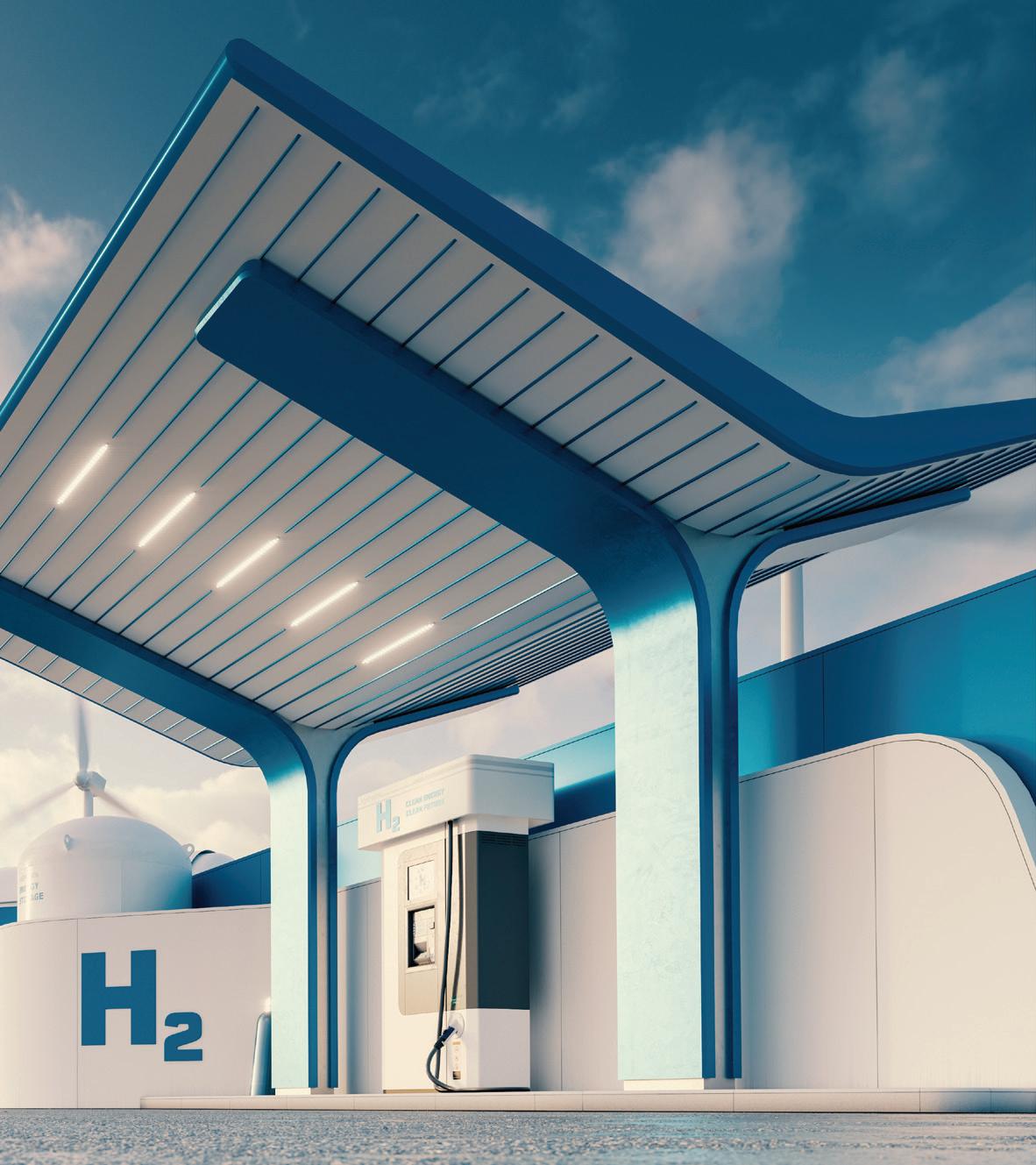

TAKING HYDROGEN TO THE NEXT LEVEL: QUEENSLAND’S HYDROGEN TASKFORCE

June 2021 ISSUE 14 www.energymagazine.com.au 14 FUTURE ENERGY

by Eliza Booth, Associate Editor, Energy Magazine

www.energymagazine.com.au June 2021 ISSUE 14 15 FUTURE ENERGY

Hydrogen is the hottest topic in the energy industry right now, and no one is more bullish on this new technology than the Queensland Government, which has just announced the establishment of a specialised Hydrogen Taskforce, tasked with fasttracking the establishment of a sustainable hydrogen supply chain for the state. Energy magazine spoke to Mick de Brenni, Queensland Minister for Energy, Renewables and Hydrogen; and Chair of the Hydrogen Taskforce, Professor Peta Ashworth, about how the Taskforce is helping to establish Queensland as a leader in hydrogen and renewable energy generation.

The seven-person Hydrogen Taskforce – announced on 11 March 2021 – brings together industry, academic and public sector leaders to create Australia’s first dedicated hydrogen development team, led by Professor Peta Ashworth, Director of the Andrew N. Liveris Academy for Innovation and Leadership, and Chair in Sustainable Energy Futures at The University of Queensland. Mr de Brenni told Energy that the Taskforce is currently underway with its first objective – delivering a work plan that will map out Queensland’s hydrogen journey.

“The Hydrogen Taskforce symbolises our genuine commitment to establishing a renewable hydrogen supply chain out of Australia, led by Queensland,” Mr de Brenni said.

“We have some of Australia’s leading public servants as part of the Taskforce. Their first deliverable is going to be setting out a work plan for how Queensland can meet the opportunities that are set out before us, and also to meet our responsibilities internationally.

“We know that we are incredibly well-placed in terms of our abundance of renewable energy. We want to leverage the growth in renewable energy that we’ve seen in Queensland with around $8.5 billion in investment already, and a further 60GW of projects on the books as part of our renewable energy zones.

“The Taskforce really will ensure that the livelihoods of Queenslanders and their lifestyle is front and center in the thinking when it comes to the policy directions that our government establishes to meet that opportunity, and to respond to that global responsibility.”

Mr de Brenni, who made history as Australia’s first minister for hydrogen, said he wanted to ensure that the work plan for the Taskforce is focused on ensuring the state can deliver on the nation’s hydrogen potential with Queensland at the helm.

“I think it's reasonable to assume that this work plan will be iterative. It will need to be agile and we want to be able to respond to new opportunities as they arise. But we've got a pretty good handle on some of the key things that will need to be incorporated into that.”

The perfect place for hydrogen

There’s no doubt that Queensland is a prime position for renewable energy generation with its abundance of sun, wind, water and significant investment in renewables, as well as its publicly-owned asset base, which will be integral to producing and exporting hydrogen.

Mr de Brenni said that there has already been significant investment in Queensland’s renewable energy zones, including the

announcement of the State Government’s $500 million Renewable Energy Fund in 2020.

“I think it's important that we note and recognise that Queensland is very well-placed to apply strategic policy settings in the energy sector, because Queenslanders own their energy system. They own the generation, the transmission, the distribution, and when it comes to exporting commodities like renewable hydrogen around the world, Queensland has owned their ports as well,” Mr de Brenni said.

“Match that with the abundance of sunshine and access to water, there is probably nowhere else in the world where the opportunities to deliver renewable hydrogen commercially at scale are as good as they are here in Queensland.

“Not only will that benefit the emissions reductions objectives of other nations, it'll also help us continue to drive down electricity costs here in Queensland. We've seen the last three years an almost eleven per cent decline in prices. The forecast for the three years ahead is for a further 14 per cent decline in prices. What that means is that if we can deliver continued downward pressure on prices through renewable energy supported by a hydrogen manufacturing sector, that we think that we can significantly grow Queensland-based manufacturing, particularly in our regions, and support the sustainability of our resources sector. So this is very key to the economic development of Queensland.”

Professor Ashworth said that while hydrogen is not new, clean hydrogen presents an amazing opportunity for countries across the world to decarbonise and assist them in reaching their emissions reduction targets. With the cost of generating renewable energy coming down, allowing the sector to build at scale, the future of hydrogen is looking brighter than ever, however Professor Ashworth said that lining up a supply chain is key to ensuring the success of hydrogen production and exporting.

The role of the Hydrogen Taskforce

For Professor Ashworth, the role of Chair of the Hydrogen Taskforce was slightly daunting at first, but she also saw it as a real opportunity for change and growth for the state and hydrogen production.

“My passion is around, ‘how do we overcome the challenges of climate change mitigation in a way that is fair for all society’. I've been working in that research for a long, long time, so I thought this was actually a really nice addendum to that.”

Professor Ashworth said that the first milestone for the Taskforce will be to get the work plan completed, however that would only be the beginning of the coordination of resources that would need

June 2021 ISSUE 14 www.energymagazine.com.au 16 FUTURE ENERGY

to be done. Professor Ashworth said that ongoing coordination across community, industry and government is key to successfully establishing a hydrogen supply chain in the state.

Among that coordination is collaborating with the broader Queensland community, industry and governments to look at what opportunities are on the table right now, where future opportunities lie, the different regulatory approvals or changes that may need to be made, and the precincts that will be able to best facilitate hydrogen projects in the future.

“[Professor Ashworth] has been talking to me about one of the critical roles of the Taskforce, which is supporting collaboration. If we can get that regulatory environment right, and see further collaboration, I think that's going to be key to meeting our nation's objectives,” Mr de Brenni said.

“A lot of commentators have asked me about, well, who should be first? Should it be Queensland or Victoria or South Australia, or Tasmania? Well, I think ultimately this is an opportunity for our nation. Queensland just thinks that we have a lot to offer and can make a significant contribution to that. So I think there are a few policy spaces across government, or across our national landscape, where the level of collaboration is as strong as it is in the development of a hydrogen supply chain.

“Whether it's government corporations or academia, everybody's in lockstep in terms of the end goal. The job for the government and the job for the Taskforce is making sure that we can get there in a way that supports outcomes for Queensland, primarily, but for Australians generally.

“I fundamentally think there's enough demand for renewable hydrogen across the world that there are going to be places in Australia, including Queensland and other states, that will be able to partake in the development of the supply chain and may contribute to export. However, our intent is to ensure that the supply chain is led out of Queensland.”

Mr de Brenni said that fundamental to establishing the Taskforce was ensuring that the work undertaken in the hydrogen space was done in an optimal fashion to deliver the best outcomes for everyone. This is why the Hydrogen Taskforce is so important – to ensure that the proper planning, upskilling, education and supply chains have been established so they can be deployed when the time comes.

“There is a significant amount of effort and investment being applied by universities, by local governments, by federal governments, by other state governments, by commercial partners and our trading partners. But the responsibility of the State Government is to ensure that we have an environment in which that effort can be applied in a way that delivers the best outcomes,” Mr de Brenni said.

“By way of example, we know that one of the challenges we need to overcome is having a workforce that is ready to deliver this for us. So we've invested in two hydrogen training centres; one for gas fitters, one for electricians. Construction of one is underway. The final design work for the other is nearing completion.

We will invest in the training and development of our young Queenslanders. So we're investing in a TAFE and a high school in Townsville and Gladstone respectively.

“It's being able to pull those levers and ensure that that piece is being worked on, so that when the call comes that we need thousands of Queenslanders ready with their tools to build this infrastructure, they will have the skills that they need. We will have done the precinct planning to ensure that they go to the right place. We’ll have prepared the port so that it's ready to take the ships. We’ll have prepared the transport infrastructure. We’ll have deployed this resource into our fleets and our domestic pipelines into residences, so that Queenslanders get the benefit of that already.

“It's really about ensuring that the planning leads to the optimal outcome, that we've got the workforce ready to go, and that the Taskforce drives an environment of collaboration. “

The future of hydrogen

Looking to the next twelve months, Mr de Brenni said there are several milestones the Taskforce would like to reach to advance the state’s hydrogen generation.

“Here in Queensland, especially, we would like to be implementing our work plan. In the short term, we expect to see some initiatives that are well-developed and in market, including gas blending into domestic residential pipelines,” Mr de Brenni said.

“We expect to see some fleet on the roads, and potentially on water. We expect to see a resolution of trade competencies and workforce training getting underway."

Professor Ashworth also agreed, saying that implementing the Taskforce's work plan is top priority for the short to medium term. In addition, Professor Ashworth highlighted the need to connect with communities and regions to identify where opportunities lie for different components, as well as initiating and facilitating crucial skills training that will be essential to the future of hydrogen generation in Queensland.

“I think giving comfort to communities that this is a long-term goal, and where they will fit within that to give them clarity about their future. Obviously as we transition, there'll be different communities affected in different ways so if we can provide that security, I think that's a good start.”

As for those within energy utilities who may be looking at how they can incorporate hydrogen into their existing business models and take advantage of the opportunities hydrogen presents, Professor Ashworth said that collaboration is key to successful integration.

“If there's questions that are emerging, I'd say reach out to the Taskforce because this is a two-way street as we move forward.

“This is where collaboration is key as well as public and private partnerships, working with government, working with industry and also the research components. That's what I think we're seeing hydrogen bring together.”

www.energymagazine.com.au June 2021 ISSUE 14 17 FUTURE ENERGY

NUCLEAR FOR NET ZERO: FACING THE REALITIES OF A CARBON CONSTRAINED WO RLD

by Benjamin Heard and Jonathan Armstrong, Frazer Nash Consultancy

While countries around the world are laying down their targets for achieving net zero emissions, Australia is still yet to commit to a net zero timeline. But pressure is mounting, and according to Benjamin Heard and Jonathan Armstrong, we need to face the reality that nuclear energy should be part of the transition to net zero in Australia.

The expression net zero has swiftly become a global rallying cry that has taken a firm hold at the highest levels of policy.

It is an elegant, scientifically-robust concept, focused on an outcome – emit no more greenhouse gas than we can remove. Given global emissions of carbon dioxide alone from combustion of coal, oil and gas are around 33 billion metric tonnes per year, the emphasis must be on the “zero”. We cannot plausibly remove or store emissions on that scale – we must in fact halt emissions on that scale. This requires technologies, processes and systems of social organisation with zero climate impact that enable people to continue to live in health, safety, security and reasonable prosperity. There is no cap under which we can trade, no bureaucratic attempt to ration the global atmospheric commons. There is a single goal, relevant to all, that can be reached through the development and scaling of solutions which mean cleaner air and advantageous re-industrialisation.

No wonder net zero is proving itself to be politically durable. However, challenges lie ahead. Popular focus remains on our power grids, which are only responsible for about a third of Australia’s national emissions. Transport, along with industrial processes and direct combustion, are responsible for more than 53 per cent of emissions. Agriculture, waste and fugitive emissions account for 13 per cent. We have limited examples of near-zero carbon power grids worldwide, and no economy-wide examples merging zero-carbon power, transportation and industry. It is a race into the broadly unknown.

Understandably, Prime Minister Scott Morrison emphasises a need for confidence in how net zero can be achieved and with what technologies. Whilst well-endowed with raw renewable energy potential, Australia is immensely dependent on consumption, import and export of fossil fuels. We also maintain legislative prohibitions against the use of nuclear technologies.

June 2021 ISSUE 14 www.energymagazine.com.au 18 FUTURE ENERGY

Our major trading partners, who are lining up behind net zero, have nuclear technologies in the frame. The United Kingdom, United States and Canada are all making accelerated efforts for a new generation of indigenous small modular reactors. China’s recently announced expansion plans, to a 300GW sector, has left analysts in no doubt of their intentions. These technologies offer clear technical advantages in reliability, firm capacity and scalability that set them apart from weather-dependent power generation. Crucially, they are also direct providers of net zero heat. This is essential for powering industrial processes, including a new hydrogen economy.

The potential role of hydrogen is becoming more broadly understood, as a direct fuel, a vital ingredient to industry, and a path to synthetic transport fuels. But the scale required remains unappreciated. Consider Australia’s imports of fossil oil – approximately 2,400PJ per year. If Australia’s entire current wind and solar capacity was redirected to committed hydrogen production, we might make in the order of three per cent of the energy in our oil imports as hydrogen. If we use only that which is presently curtailed supply (the excess that occurs when wind and solar is in relative plenty), our hydrogen production potential falls to a small fraction of one per cent of current oil imports.

This is confronting. Net zero is arguably unachievable in Australia through continuing incremental growth in variable renewable supply, and creative sponges for the excess. We must build our thinking backwards from the outcome. Net zero means creating

and sustaining an interlinked system of energy creation, industrial production and energy supply that will dwarf the existing electrical supply capacity, with massive-scale production of zero-carbon electricity and heat at its heart.

From that back casting view, the role for advanced, hightemperature small modular reactors (SMR) becomes clear. A fit-for-purpose size that can connect to the existing grid, SMRs offer full-time production of electricity and heat. This supports hightemperature steam electrolysis – a more efficient and productive path to hydrogen production. Positioned as multi-purpose devices, SMRs will support the further cost-effective integration of variable renewables, while maximising production of hydrogen and synthetic fuels, and ensuring best, economical use is made of all storage capacity in the grid. Their synchronous generation, which can run day long in a net zero industrial system, will maintain the essential system grid security currently under threat from the departure of Australia’s coal sector. Viewed from the essential systems perspective, SMRs are a benefit multiplier on the road to net zero.

However, those benefits are inaccessible to Australia under current policy settings. Policies can, ultimately, be changed quickly. But the acquisition and deployment of new technologies, while possible to accelerate, cannot be rushed.

Australia’s approach to offshore renewable energy is a case in point. While not prohibited, we have no extant sector, and we cannot have one that is producing power tomorrow, or even

www.energymagazine.com.au June 2021 ISSUE 14 19 FUTURE ENERGY

next year. Australia is developing the legislative and regulatory settings that will enable benefits from those technologies in years and decades to come, while ensuring smooth integration with social and environmental needs and expectations. A like-minded attitude is required for SMRs.

Technologies can only flourish in the context of capabilities. In capabilities, Australia has a reasonable foundation for future use of SMRs, but serious work ahead. Global developments in SMRs are swiftly overtaking the Australian status of “watching brief” expressed in the 2019 Energy White Paper. A pivot is required, from “watching brief” to roadmaps and action plans, if we are to have a timely inclusion of these solutions to take us to net zero.

Australia’s trading partners and competitors are quickly setting the industrial ground rules for the rest of this century – net zero, technology-inclusive industrialisation with a clear role for nuclear technologies.

It is beyond Australia’s reach to alter this, but it is well within our reach to benefit from it. That needs a systems thinking approach, working backward from a future state, to prepare and deliver full-scale re-industrialisation. The conversations that link policy with engineering need to happen early. It is a race to the top, and like any race, you need to be in it to win it.

About the authors

Based in Adelaide, Jonathan Armstrong is Director of International Business, serving on the Board of Frazer-Nash. He started his career in the UK’s civil nuclear industry, where his roles included leading a major project to increase the enrichment of the UK’s nuclear fuel, leading teams providing specialist technical support for in-reactor fuel behaviour and authoring safety cases requiring the highest level of experience. He has also run a clean energy start up in the UK and founded Frazer-Nash’s operations in Scotland. In 2015 he relocated with his family to Australia to lead Frazer-Nash’s international business. Jonathan studied physics at Edinburgh University and is a Companion and Engineering Executive with Engineers Australia.

Ben Heard is a Consultant with Frazer-Nash, and also the Founder of the environmental NGO Bright New World. Australian-born and raised, he holds a Masters in Sustainability and a professional background in climate change related work. Formerly anti-nuclear, Ben is wellknown for his evidence-based reappraisal of nuclear technologies considering the need to address climate change. He has since become a globally recognised advocate for the use of nuclear to address our biggest challenges, including presentations at COP21 in Paris (2015) and organised protests at COP23 in Bonn (2017). He completed PhD studies in 2017 including the highly-cited paper Burden of Proof, and joined Frazer-Nash in 2018. He has featured in 60 Minutes, and the international documentary film Juice: How Electricity Explains the World.

June 2021 ISSUE 14 www.energymagazine.com.au 20 FUTURE ENERGY

A small modular reactor.

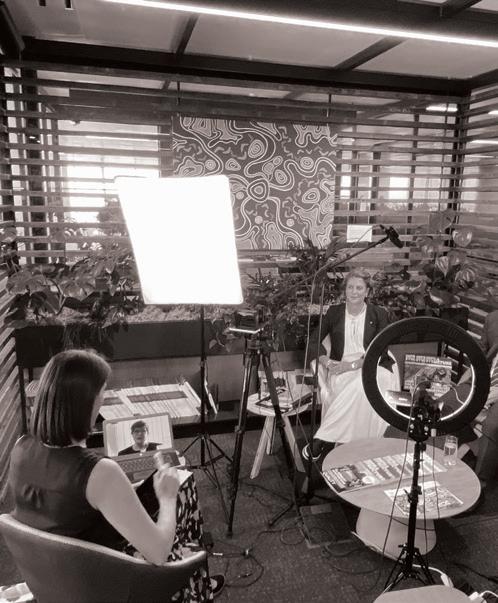

Looking for a complete solution for online events?

Combining our experience in publishing, live events, digital marketing and video production, Monkey Media has the capability to deliver a range of online events for your organisation.

Specialising in the energy, infrastructure and utility sectors, we combine our expert knowledge in these fields with our behind-the-scenes knowhow to help you deliver your events in a range of online formats.

We work closely with our partners to understand why and how you want to connect with your audience online, and can recommend the right solution to help you cut through and achieve the high levels of audience engagement and participation you’re looking for.

Some of the online events we can help you deliver include:

Webinars

Virtual conferences

Awards nights

Round tables

Online learning

Hybrid virtual/live events for a complete online event solution

9988 4950

03

www.monkeymedia.com.au/services/custom-virtual-events/

COMMITTING TO CHANGE:

TIME FOR ENERGY USERS TO EMBRACE CLEAN ENERGY

The global pandemic provided many of us with the chance to pause and reassess traditional ways of doing things. As we emerge from the crisis, it’s time for energy users large and small to firmly commit to the benefits clean and alternative forms of energy can provide.

Although greenhouse gas emissions improved in 2020 due to travel bans and economic slowdowns resulting from the COVID-19 pandemic, the United Nations highlights that climate change continues to affect every country on every continent.

The UN Secretary-General has proposed a raft of climate-positive actions for governments to take in the process of rebuilding their economies and societies in the years ahead, aimed at triggering long-term systemic shifts to change the trajectory of CO2 levels in the atmosphere.

While the UN’s goal remains to reduce global emissions by 50 per cent by 2030, the Australian Government has committed to a net zero goal “as soon as possible”, and preferably by 2050.

The transition will require bold, forward-thinking policies at both a state and federal level, backed by targeted government spending.

Henry Anning, Chief Executive Officer of ResourceCo Energy Systems, said the recent announcement of funding support for recycling and clean energy manufacturing projects under the Modern Manufacturing Initiative (MMI) is encouraging.

Acknowledging the pace of change required in the energy sector in Australia, Mr Anning said the release of a defined roadmap for the advancement of the industry is a significant step forward.

“It really marks the beginning of a collaborative, long-term clean energy strategy framework, bringing industry experts across the sector together to drive a positive transition.

“Assisting Australian manufacturers be more competitive, resilient and build scale in the global market will be critical to achieving sustainable outcomes.”

The Federal Government’s Recycling and Clean Energy National Manufacturing Priority roadmap, released in April 2021, highlights that investor and market appetite for clean energy in Australia and around the world is undeniable, but Australia is yet to convert this into large-scale manufacturing opportunities.

The domestic supply chain for clean energy components remains underdeveloped and adoption of clean energy for

industrial manufacturing is still in its early stage as a proposition, especially in heavy manufacturing processes.

Mr Anning agrees demand for alternative energy solutions is a common barrier, however, he believes the industry is at the cusp of making real progress – a position supported by the announcement of the closure of the Yallourn Power Station four years earlier than planned.

“As more of our very old, expensive and polluting coal-fired power stations begin to close, the demand for cleaner, greener solutions will very quickly ramp up.

“It is encouraging that governments and industry are working together to intensify efforts to position Australia as a global hub for renewable energy.

“We need continued collaboration between governments, investors, manufacturers and their customers to enable, shape and create markets for renewable energy – green products.”

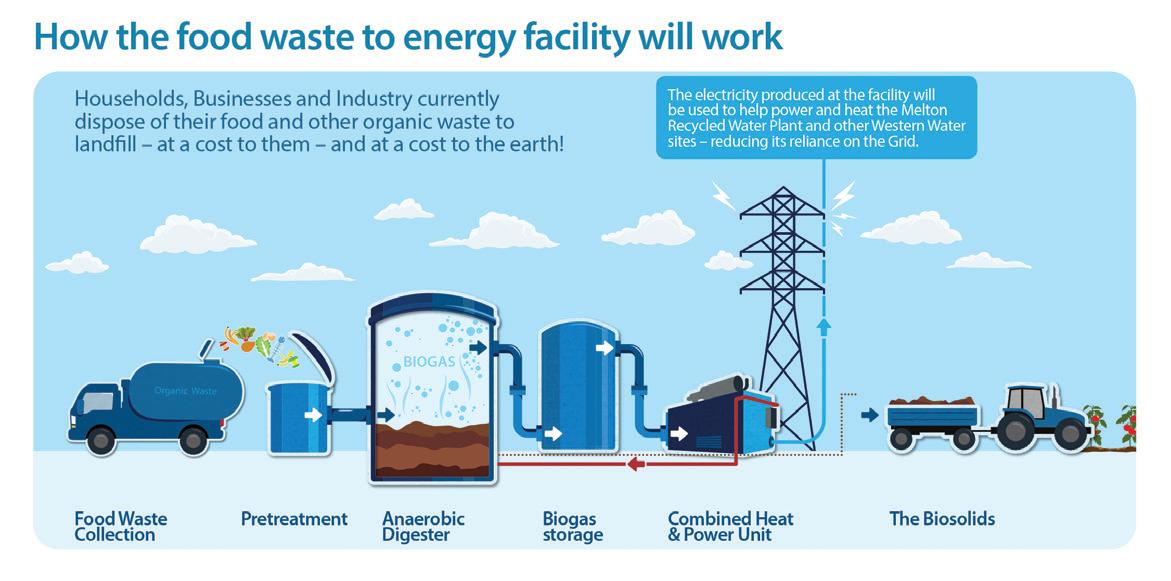

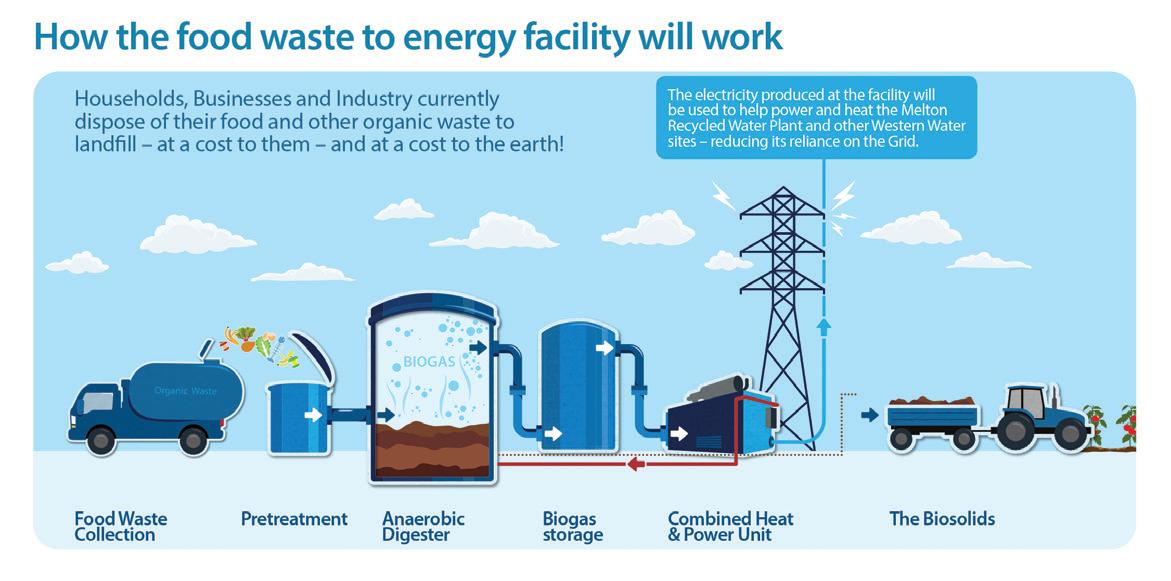

As a company, ResourceCo is a leader in the development of waste-from-energy plants, which deliver strong environmental and economic outcomes by repurposing materials otherwise destined for landfill, to generate clean energy.

ResourceCo Energy manufactures processed engineered fuel primarily from waste timber materials, but also previously nonrecyclable plastics, cardboard, paper and textiles.

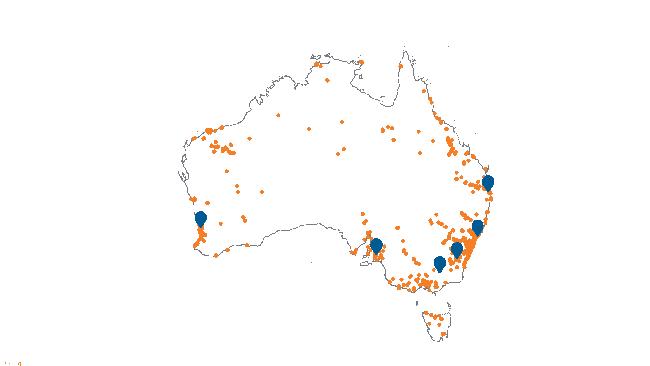

“It’s time for large-scale business to see alternative energy as a viable alternative to expensive, emissions generating fossil fuels,” said Mr Anning. “We’re continuing to progress some interesting and ambitious new projects across our national footprint, which bares testament to the evolving opportunity.”

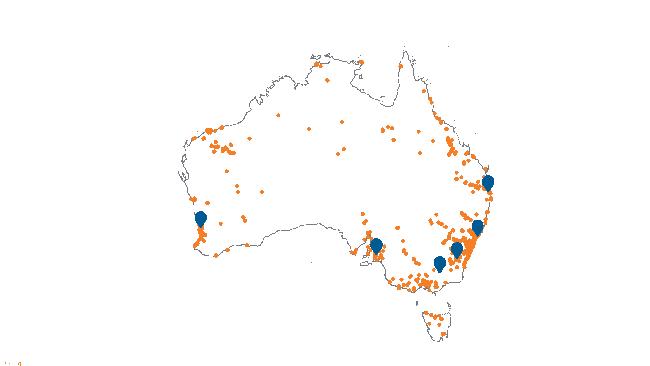

That optimism is matched by an expansive capital investment program – the biggest in the history of the company – with new plants planned for Sydney, Perth, Brisbane and the Pilbara this year.

“We’re solidifying our commitment to make progress for real change and to play our part in progressing Australia’s transition to a circular economy.”

June 2021 ISSUE 14 www.energymagazine.com.au

22 FUTURE ENERGY SPONSORED EDITORIAL

TOMORROW’S SOLUTIONS. TODAY

AUSTRALIA’S CLEAN ENERGY JOURNEY:

ACCELERATING THE TRANSITION

2020 marked new ground for the Australian renewable energy industry, with a string of records for the rate of uptake of renewable energy across the country. The Clean Energy Council's recently-released Clean Energy Australia report has revealed that over a quarter of Australia's electricity supply now comes from renewable energy sources, and that we are now well on our way to achieving our clean energy transition goals. In this extract from the report, we take a closer look at the progress made by the industry over the past 12 months.

Australia’s clean energy transition accelerated again in 2020 as wind and rooftop solar set new records, battery storage came of age, and the hydrogen sector continued its rapid development.

This all points to Australia realising its potential as a clean energy superpower.

The Australian renewable energy industry has come a long way in the past five years. In 2016, just 17 per cent of the country’s electricity came from renewables, and the majority of this was due to New South Wales and Tasmania’s long-serving hydro systems.

Fast forward to 2020, and more than 27 per cent of Australia’s electricity came from clean energy sources, with wind and rooftop solar leading the way. This

represents a massive transformation that makes Australia’s electricity system cheaper, more reliable and, most importantly, cleaner.

But the best news is that the shift is showing no sign of slowing down.

An enormous amount of new clean energy capacity was added in 2020 as both the rooftop solar and wind sectors set new annual records. Emerging technologies also made rapid progress, with several major utility-scale battery announcements and considerable investment in renewable hydrogen building strong momentum for these exciting new technologies.

Much of this progress was driven by state and territory governments, which introduced a number of world-leading renewable energy policies and targets in 2020. However, the states and territories’ progressive energy policies only served to

June 2021 ISSUE 14 www.energymagazine.com.au 24 FUTURE ENERGY

highlight the ongoing failures at the federal level, where arguments about government support for gas and coal overshadowed some genuinely positive developments.

These included the continued growth of clean energy jobs, with the industry employing more than 25,000 Australians in 2020, and the hundreds of dollars that households and businesses saved on their electricity bills due to the recent influx of new renewable generation. These are just a small sample of the benefits of renewable energy, and there is enormous potential for more in the coming years as the industry continues to grow.

First though, the industry will need to overcome ongoing grid connection and transmission challenges, which continued to plague renewable energy developers in 2020. While the market bodies made some progress on resolving these challenges

throughout the year, much more work and investment is required to ensure that Australia’s clean energy transition can continue unimpeded.

The COVID-19 pandemic meant that 2020 was a difficult year for many Australians, but the renewable energy industry continued to provide hope that Australia’s other great challenge – climate change – is being addressed. The industry’s incredible progress over the past five years is just the beginning of a long and challenging journey towards our vision of a clean energy future.

The Australian renewable energy industry’s record-breaking run continued in 2020, despite the impacts of the COVID-19 pandemic. The growth of Australia’s renewable energy industry showed no sign of slowing in 2020 as increased support from state and territory governments saw

numerous records set across the large- and small-scale sectors.

The industry passed a significant milestone in 2020, with more than a quarter of the country’s total electricity generation coming from renewable sources for the first time.

Renewables were responsible for 27.7 per cent of total generation in 2020, an increase of 3.7 percentage points compared to 2019. Much of this increase was due to the small-scale solar sector, which added more than 3GW of new capacity in 2020 to record its fourth-straight record-breaking year. This brought the sector’s share of Australia’s renewable energy generation to 23.5 per cent, pushing it past hydro into second place for the first time.

The large-scale sector contributed almost 2GW of new capacity in 2020 as

www.energymagazine.com.au June 2021 ISSUE 14 25 FUTURE ENERGY

immediate health crisis abated, the focus turned to economic recovery and the opportunity to stimulate the economy by accelerating the clean energy transition. Rather than grasping this opportunity, the government opted for a “gas-fired recovery” that included a threat to build a government-owned 1,000MW gas-fired power station in New South Wales.

However, pressure on the government to increase its emissions reduction ambitions began to grow towards the end of 2020 following the election of Joe Biden as US President and several of Australia’s major trading partners adopting a net zero emissions target by 2050.

The challenges associated with grid connection and transmission continued in 2020 as the need for additional investment in transmission capacity to allow more renewable energy connections became more urgent. However, the announcement of renewable energy zones by several state governments should help to ease pressure on the grid, as will Federal Government funding for some key transmission projects to help unlock additional renewable energy resources.

The battery storage sector rose to prominence in 2020, with 16 utility-scale batteries under construction at the end of 2020, representing more than 595MW of new capacity. This will increase significantly in the coming years, following the announcement of several major utility-scale batteries throughout the year, including several projects that will again make Australia home to the world’s largest battery. Australian households installed 23,796 small-scale batteries with a combined capacity of 238MWh in 2020.

32 projects were completed around the country. While the majority of these projects were large-scale solar farms, representing 893MW of new capacity, the wind sector accounted for the bulk of new generation, adding 1,097MW throughout the year. This was a new record for the sector, comfortably surpassing the 837MW record set in 2019.

A further 76 large-scale wind and solar projects were under construction at the end of 2020, representing more than 8GW of new capacity and employing over 9,000 Australian workers. Of these projects, 49 were large-scale solar farms, 21 were wind farms, three were bioenergy plants, while three were hybrid plants producing at least two different types of renewable energy.

The expansion of Australia’s large-scale renewable energy industry is being led by state and territory governments, who made considerable new commitments to the industry in 2020. The New South Wales

Government’s Electricity Infrastructure Roadmap was the most ambitious renewable energy policy released during the year, promising to deliver 12GW of new transmission capacity to facilitate the construction of three renewable energy zones across the state.

Tasmania passed a major milestone in 2020, becoming the first Australian state to source 100 per cent of its electricity from renewable sources. The Tasmanian Government has now set a 200 per cent renewable energy target by 2040, which is the world’s most ambitious target for renewables.

South Australia passed its own significant milestone in October 2020, when 100 per cent of its electricity came from solar for one hour; the first time this had been achieved by a jurisdiction as large as South Australia anywhere in the world.

Federal politics was dominated by the COVID-19 pandemic in 2020. As the

Several noteworthy steps were taken in 2020 to develop Australia’s emerging renewable hydrogen industry. The most significant of these was the technology's inclusion in the Federal Government’s Technology Investment Roadmap. The states and territories also upped their investment in renewable hydrogen, committing millions of dollars to various pilot projects and new initiatives throughout the year.

Small-scale renewable energy

Despite the COVID-19 pandemic, the small-scale solar sector showed no sign of slowing down in 2020, as more than 3GW of new capacity was added to Australian rooftops.

The small-scale solar sector recorded its fourth-straight record-breaking year in 2020, easily surpassing 2019's record of 2.2GW of new capacity. The 378,451 systems installed in 2020 was also a record, overtaking the previous best set back in 2012.

June 2021 ISSUE 14 www.energymagazine.com.au 26 FUTURE ENERGY

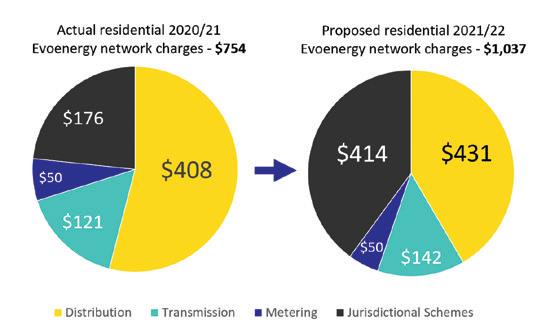

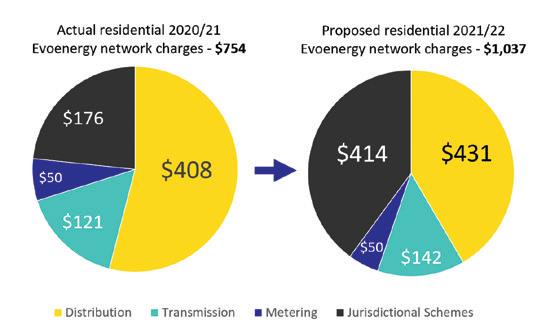

WHAT MAKES UP YOUR POWER BILL, 2019–20 Generating electricity $556 Poles and wires $579 Electricity company costs $98 Environmental costs $104 CLEANENERGYCOUNCIL.ORG.AU/CLEANENERGYAUSTRALIA THE CONSTRUCTION BOOM FOR LARGE-SCALE RENEWABLE ENERGY PROJECTS* * From 2017 to 19 March 2021 ANNUAL ELECTRICITY GENERATION IN 2020 Coal 62.0% Renewables 27.7% Gas 9.9% RENEWABLE GENERATION BY TECHNOLOGY TYPE Wind 35.9% Large-scale solar 10.9% Hydro 23.3% Small-scale solar 23.5% Bioenergy 5.0% Medium-scale solar 1.4% Liquids 0.1% Waste coal mine gas 0.4% 388 Megawatts $2019m Investment 1861 Jobs 0 Megawatts $0m Investment 0 Jobs 2955 Megawatts $5064m Investment 3584 Jobs 3612 Megawatts $5600m Investment 4194 Jobs 1962 Megawatts $3441m Investment 2594 Jobs 64 Megawatts $119m Investment 272 Jobs 1414 Megawatts $2395m Investment 998 Jobs

CLEAN ENERGY AUSTRALIA 2021

The industry’s success was seen right across the country as every state and territory besides Tasmania – which recorded its second-best ever year – set a new record for installed capacity. New South Wales was Australia’s small-scale solar leader in 2020, adding 927MW of new capacity, followed by Queensland with 787MW and Victoria with 559MW.

Victoria’s 2020 performance is particularly notable considering that its entire small-scale solar industry was forced to shut down for almost two months in mid-2020 due to the state’s devastating COVID-19 outbreak.

The household battery sector continued to grow in 2020, with 23,796 batteries with a combined capacity of 238MWh installed throughout the year. Unsurprisingly, the states with government-backed battery installation support schemes saw the most installations, with South Australia, New South Wales and Victoria leading the way.

The remarkable growth of the Clean Energy Council’s Approved Solar Retailer program continued in 2020 as more governments made it mandatory for companies to sign up to the program to participate in their solar schemes. By the end of 2020, the program had grown to 1,141 participating companies, an increase of 66 per cent on 2019.

The Solar Retailer Code of Conduct was re-authorised by the Australian Competition and Consumer Commission in 2020, with a number of minor amendments made to bring it up to date and in line with industry developments. This will allow the gradual transition of signatories to the New Energy Tech Consumer Code (NETCC), which was authorised by the Australian Competition Tribunal in September 2020. The NETCC will eventually replace the Solar Retailer Code of Conduct to include solar, battery energy storage systems, electric vehicle charging products, energy management systems and software, and other emerging products and services for homes and businesses.

The number of Clean Energy Council accredited installers also grew strongly in 2020, increasing by 17 per cent to 7,713. The program has seen remarkable growth alongside the solar industry, with the number of accredited installers surging by more than 3,000 over the past five years.

Large-scale renewable energy

When the extent of the COVID-19 pandemic first became apparent in the early months of 2020, there were some

dire predictions about the prospects for the large-scale renewable energy industry.

However, the sector was able to ride through most of these challenges, completing 32 projects with a capacity of almost 2GW throughout the year. A further 76 large-scale renewable energy projects were under construction at the end of 2020, representing more than 8GW of new capacity and employing over 9,000 Australian workers, often in regional areas. Of these projects, 49 were large-scale solar farms, 21 were wind farms and three were bioenergy plants.

A further three were hybrid plants, producing at least two different types of renewable energy. Despite making up just over a quarter of all projects under construction, the wind sector is responsible for over half of the new capacity, with more than 4GW of new wind generation currently being built.

The utility-scale battery sector saw a number of significant developments in 2020. The most notable of these was the expansion of the Hornsdale Power Reserve to 150MW/194MWh, which will allow Australia’s biggest battery to provide additional grid support services such as inertia to help stabilise the grid.

An additional 16 utility-scale batteries were under construction at the end of 2020, representing more than 595MW of new capacity. Several new major project announcements in 2020 provided a further

boost to the sector, including a 300MW battery in Victoria, Western Australia’s first large-scale battery, and a plan to install a mammoth 1.2GW battery in New South Wales’ Hunter Valley.

The development of Snowy 2.0 and the Battery of the Nation hydro projects continued to make steady progress in 2020. Snowy 2.0 received state and federal environmental approval during the year and a $125 million transmission investment from the Clean Energy Finance Corporation, putting the project on track to begin construction in 2021. In Tasmania, the Battery of the Nation named its first pumped hydro site, while Marinus Link – the interconnector that is a critical component of the project – received a $94 million commitment from the Federal Government.