FEB/MAR 2017

WWW.FOODMAG.COM.AU

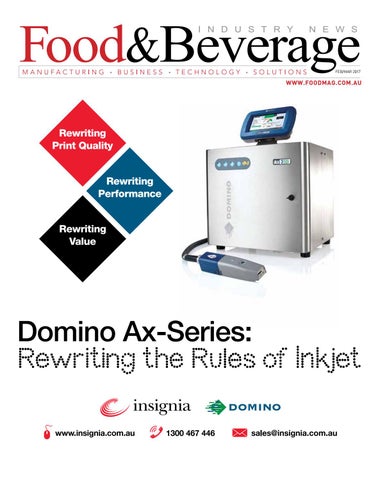

Rewriting Print Quality Rewriting Performance Rewriting Value

Designed by Customers, Engineered by Domino Rewriting Print Quality

Perfect drops every time Higher resolution text and 2D codes Inks for the toughest substrates

Rewriting Performance

29% Faster Ideal for High Speed serialisation Designed for the factory of the future Service free operation

Rewriting Value

Optimised fluid management systems, reducing waste Minimum operator intervention

The best way to improve your products is by listening to your customers. That’s exactly what Domino did. They learned from your coding experiences and studied the regulatory, environmental and supply chain pressures you face. They deconstructed Continuous Inkjet as we’ve known it for the past four decades - before rebuilding it as a better, faster, more responsive and cost-effective technology. Experience the Domino Ax-Series and rethink Continuous Inkjet.

AND 410 T S T A S U VISIT

FEB/MAR 2017

WWW.FOODMAG.COM.AU

OPTIONS FOR GMO-FREE Print Post Approved 100007267

LABELLING IN AUSTRALIA PLUS: The year ahead for F&B | AUSPACK 2017 | New products

Low-cost level measurement. Radar sensor for water management. Reliable level measurement in water treatment facilities, pump stations and rain overflow basins. Open channel flow measurement and water level monitoring.

VEGAPULS WL S 61 ▪ Measuring range up to 8 m

▪ Can be used outdoors without restriction ▪ Flood-proof IP 68 housing

▪ Operation via Bluetooth with Smartphone, tablet or PC

Further information: www.vega.com/wls61

Phone 1800 817 135

WELCOME

Welcome back, Vegemite?

I

Managing Director: John Murphy Managing Editor: Branko Miletic Ph: (02) 9439 7227 branko.miletic@primecreative.com.au

Editor: Matt McDonald Ph: (02) 9439 7227 matthew.mcdonald@primecreative.com.au

Art Director: Michelle Weston michelle.weston@primecreative.com.au

Designers: James Finlay, Blake Storey, Sarah Doyle

Sales/Advertising: Sonia Bonner Ph: (02) 9439 7227

Editor: Matthew McDonald

sonia.bonner@primecreative.com.au

Production Coordinator: Kristina Peric Ph: (02) 9439 7227 kristina.peric@primecreative.com.au

Subscriptions AUS NZ O/S 1 year subscription 99 109 119 2 year subscription 189 199 209 For subscriptions enquiries please call Gordon Watson: 03 9690 8766

Copyright Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2016 Articles All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format. Head Office 11-15 Buckhurst St South Melbourne VIC 3205 P: +61 3 9690 8766 enquiries@primecreative.com.au http://www.foodmag.com.au Sydney Office Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065, Australia

n mid-January Bega Cheese purchased most of Mondelez International’s Australian and New Zealand grocery products for $460 million. The deal included Vegemite. In other words, the iconic product would be returning to Australian ownership. For many, this was great news. Dick Smith, who has long campaigned to return Vegemite to local hands and released his own product Ozemite as a locally-owned alternative, called it “wonderful for Australia”. One main point behind the sentiment, obviously, is that local ownership means that profits (and jobs) generated by Vegemite will stay in this country. It will help contribute to the health of not just the local food industry, but the broader economy. Fine, but doesn’t that argument hold for all products. Why the focus on Vegemite? Under Mondelez ownership, the product was made in Port Melbourne so job losses were not an issue. According to Bega, it will continue to be made there so not much will really change as a result of the sale. Why no campaign to place all local manufacturing in local hands? Because of the product’s cultural significance. I would argue that the main reason people are so happy about the Bega deal

is more about sentiment than the Australian economy. Vegemite can be found in an amazing 90 per cent of Australian homes and there is a justifiable urge to keep it as ‘ours’. Vegemite has spent most of its nearly 100 year history in foreign hands, however it’s difficult to think of a time when it wasn’t clearly Australian. Culturally, it’s always been ‘ours’, because nobody else wants a bar of it. For example, in 2011 then Australian Prime Minister Julia Gillard visited a US high school with President Barack Obama. Answering a question, Gillard tried to explain our weird obsession with the spread, while Obama was happy to have a dig and said he hated it. All this, while it was US-owned! Announcing the deal, Bega Cheese’s Executive Chairman, Barry Irvin, mentioned the heritage values of the product and called it “strategically important and company making”. In other words, it was a sound business decision. While we can welcome the deal, it’s hard to believe sentiment had much to do with it. And it’s hard to believe that Vegemite has ever been under any threat in Australia. Matthew McDonald, Editor

INSIDE 18

12

26

Average Net Distribution Period ending Sept ’15

5,316

6 MERGERS & ACQUISITIONS 8 FOOD & BEVERAGE INDUSTRY AWARDS

Printed by: Manark Printing

10 2017 - THE YEAR AHEAD

28 Dingley Ave Dandenong VIC 3175

Ph: (03) 9794 8337

12 V IC MANUFACTURING SHOWCASE

14 MELBOURNE INTERNATIONAL COFFEE EXHIBITION

28 ON THE SHELF

16 GMO FOOD

32 COMPANY PROFILE

18 AUSPACK 2017

34 NEW PRODUCTS

30 MOTORS & DRIVES

26 MANAGEMENT www.foodmag.com.au | Feb/Mar 2017 | Food&Beverage Industry News 5

MERGERS AND ACQUISITIONS

Strong finish to 2016 bodes well for deal activity in 2017

By Ben van der Westhuizen and David Baveystock

C

orporate activity in the food and beverage industry was unexpectedly high in December 2016 and January 2017 with several substantial transactions announced during this period.

Acquisitions announced Date

Target Name

Acquirer

Sector

Deal Value

22 Nov 16

Temptation Bakeries

Private Investors

Baked goods

Undisclosed

30 Nov 16

Leader Group

Patties Foods

Prepared meals

Undisclosed

5 Dec 16

Avocado Ridge orchards and packing operations

Costa Group

Fresh produce

$50 million

11 Dec 16

Green’s Foods (43.5%)

Raphael Geminder

Biscuits & snacking

$24 million

19 Jan 17

Mondelēz Australia Grocery Business

Bega Cheese

Packaged foods

$460 million

The standout transaction in the quarter was the acquisition of the Mondelêz Australia Grocery Business by Bega Cheese for $460 million. The Mondelêz grocery business includes iconic Australian brands such as Vegemite, ZoOSh salad dressing and sauces and Bonox spreads. The Mondelêz grocery business has an estimated 31 per cent share of the $550 million spreads category in Australia. The baked goods and prepared meals sector saw two transactions with Temptation Bakeries and New Zealand-based Leader Group both sold. Raphael Geminder, the chairman of Pact Group, acquired 43.5 per cent of

Green’s Foods from CVC for approximately $24 million. Geminder is now the largest shareholder in Green’s Foods. Costa Group has acquired the Avocado Ridge orchards and packing operations in central Queensland in a joint venture with Macquarie Agricultural Funds Management.

Listings on the ASX Date

Entity name

Capital raised

Issue price

16 Dec 16

Murray River Organics

$35 million

$1.30

3 Jan 17

Bubs Australia

$5.2 million

$0.10

5 Jan 17

Winha Commerce and Trade

$8.5 million

$0.35

Murray River Organics was the most substantial IPO, listing on the ASX on 16 December 2016 after raising $35 million as part of the IPO process. 2017 is shaping up to be a dynamic year across the food and beverage industry with strong interest in the industry from both trade investors and financial investors. Ben van der Westhuizen (left) and David Baveystock are directors of Comet Line Consulting, an advisory business that specialises in acquisitions and divestments within the Australian food & beverage industry. For more information visit www.cometlineconsulting.com.au.

How many suppliers does it take to build your entire snack line?

You don’t get ahead of the curve without rethinking the conventional.

Learn more at tnasolutions.com

or visit us at AUSPACK booth 85.

Snack on that.

6 Food&Beverage News | Feb/Mar 2017 | www.foodmag.com.au Food & Beverage Industry SK SS 210x122.indd 1

19/12/2016 17:14

Ingenious solution, cabinet-free

Exactly

More flexible and efficient automation with IndraDrive Mi With IndraDrive Mi, the intelligent drive system, you relocate the entire drive technology from the control cabinet directly into your machines. That saves space, sharply reduces the wiring costs up to 90 % and optimizes your energy balance. Thanks to the integrated motion logic, complex motion sequences can be achieved right at the drive level. The IndraDrive Mi is a fully-equipped automation system, with a wide variety of certified safety functions and multi-protocol interface. Put the intelligence of this system to use in your modular machine concepts as you start your journey into Industry 4.0. IndraDrive Mi

To find out more, please contact: Bosch Rexroth Pty Ltd Phone: (03) 9580 3933 Email: mel@boschrexroth.com.au Visit: www.boschrexroth.com

FOOD & BEVERAGE INDUSTRY AWARDS

Nominations open for Food & Beverage Industry Awards Tables are available and nominations are now being taken for the 2017 Food & Beverage Industry Awards. In its 14th year, the awards will be held on Monday 17th July, 2017 at the picturesque Doltone House Hyde Park in Sydney.

T

he food and beverage industry’s premier awards night showcases excellence in the food and processing industry, as well as highlighting some of the great innovations and products that have been produced over the past year. In the past, a diverse range of products have taken away gongs in what is a highly competitive market. Past winners have included the likes of Morlife, Summer Snow, Soma Organics and Marvella Superfoods. This year there are 10 categories up for grabs including the prestigious Best of the Best award. Last year

there were more than 77 finalists in 13 categories with the Best of the Best award going to the Sydneybased Protein Bread Company. It is not only a great opportunity for companies to spruik their latest products and services, but also one of the few times they can kick back and relax with their peers and discuss the latest developments in one of the most innovative industries in Australia. Once again our Platinum sponsor will be Flavour Makers, whose flavour creations have been boosting our tastebuds for almost 25 years.

A company that is dedicated to improving the quality and taste of Australian foods, Flavour Makers is now a global brand whose love of food is evident with a product range that tantalises the taste buds. We also welcome on board a new sponsor - Creative Food Solutions, one of Australia’s culinary entrepreneurial experts. Whether you’ve had success in exporting, have developed cutting edge technology for the food processing industry, or eco-friendly packaging or an idea that helps sustain resources, we want to hear from you. To nominate simply visit our website: foodmagazineawards.com.au. Nominations close on Monday, April 24, with finalists announced on Monday, May 1 2017. Last year's MC, Larry Emdur with some of the winners.

8 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

AWARDS WILL BE PRESENTED FOR THE FOLLOWING CATEGORIES: ¥ ¥ ¥ ¥ ¥ ¥ ¥ ¥

Beverage of the Year Ingredient Innovation Food Exporter of the Year Ready Meals Food Safety Equipment & Material Innovative Technology of the Year Heath Foods Sustainable Manufacturer of the Year ¥ Meat, Poultry & Smallgoods ¥ Paddock to Plate ¥ Best of the Best

THE YEAR AHEAD

What’s in store for F&B in 2017? Once again 2016 was a less than spectacular year for Australian manufacturers. And once again the food and beverage sector was an exception to this trend. Matthew McDonald takes a closer look at what’s in store for the industry’s top performers in 2017.

F

ord’s gone and Holden and Toyota will soon follow suit. Industries like steel, petroleum and aluminium are in decline and Prime Minister Malcom Turnbull’s attempt to rally the nation with his call to ‘innovate, innovate, innovate’ failed to set the nation on fire during last year’s election. So, while things aren’t crumbling around us, it isn’t exactly easy to get excited about Australian manufacturing. We seem to be stuck with a slow decline of about 2 to 3 per cent a year. But it’s not all bad news. Food and beverage makers have many reasons to be happy about where their sector is headed in 2017. “Food and beverage manufacturers have remained resilient to factors affecting other manufacturing industries in Australia,” Nick Tarrant, Senior Industry Analyst with IBISWorld told Food & Beverage Industry News.

For example, we are blessed by our proximity to key export markets in the Asia Pacific. Also, because perishable items like butter and other dairy products can’t be easily transported from overseas, demand for such goods is fairly constant.

The Winners Late last year, as featured in our sister publication Manufacturers’ Monthly, IBISWorld compiled a list of Australia’s top 100 manufacturing companies for 2016. As we move into the new year, it is worthwhile to take a look at the food and beverage makers on that list and consider where they are headed in 2017. Australia’s largest integrated cattle and beef producer, Australian Agricultural Company (AACo) was one welcome addition to the list. And the success of the company (which is said to be the nation’s oldest continuously operating business) is expected to continue. According to Tarrant, it should grow at a rate of 38

per cent over the coming financial year to reach $781 million. “A lot of that is due to growing sales revenue due to high demand for [its] beef produce in the USA and South Korea,” said Tarrant, adding that AACo is positioning itself as a premium producer on international markets and that the company is part of a trend in which manufacturing industries are increasingly relying on Australia’s natural resources. Fellow beef producer Teys Australia (a Cargill joint venture) is in the same boat. Last year, with help from the high demand for beef, strong cattle supply and good weather conditions, the company was able to increase its stock production and increase its revenue by 21.7 per cent.

Dairy The year, 2016 was a pretty torrid year for the dairy sector. Fonterra and Murray Goulburn (MG) both found themselves cast as major villains (not just by suppliers, but

by the wider community) when they retrospectively cut their farmgate milk prices and instantly put many dairy farmers into debt. As a result, many accused the two co-operatives of incompetence or worse, with the attitude of many being “how could they let things get so out of hand”. Whatever the case, the root cause of the crisis was global oversupply and subsequent low milk prices. “[Milk prices] kind of bottomed out a couple of years ago so the worst of it seems to be over,” said Tarrant. He said that he expects MG revenue within the milk and cream processing sector to decrease by 6.4 per cent in the coming year to $475.5 million, while Fonterra revenue in that sector is expected to fall by 2 per cent to $260.8 million. Despite these problems, MG and Fonterra remain two of the mainstays of the Australian food and beverage industry. Pointing out that milk and cream processing is worth about

Beef producers such as Australian Agricultural Company and Teys Australia are among a number of companies whose success relies on Australia's natural resources. 10 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

THE YEAR AHEAD

$2.2 billion, Tarrant said the fact the sector is so reliant on export markets means that slight downturns in demand can negatively affect it. However, he maintained that a lot of the problems are short term. “A lot of them can be due to changing policy or looking to purchase more locally made produce. It can be affected by change in the Australian dollar as well,” he said.

AUSTRALIA'S TOP 10 FOOD AND BEVERAGE MANUFACTURERS OF 2016 (Courtesy of IBISWorld. The full manufacturing list appeared in Manufacturers' Monthly.)

1. 2. 3. 4.

Fonterra Co-Op Group Coca-Cola Amatil Lion Nathan National Foods Teys Australia - A Cargill Joint Venture 5. Devondale Murray Goulburn 6. Ingham's 7. Treasury Wine Estates 8. Carlton & United Breweries 9. Nestle 10. George Weston Foods

“There is strong demand for milk from places like China where it sells for about $8 a litre…[and] free trade agreements as they are introduced sets up opportunities for milk producers to export.” He said that as MG and Fonterra become more vertically integrated, streamline their costs and get more efficient distribution methods going both should be able to recover. The other big player in the sector, Warrnambool Cheese & Butter is expected to see revenue grow by 43.8 per cent in 2016/17 to reach $653 million. “A lot of that is not necessarily organic growth,” explained Tarrant. “They acquired Lion Dairy & Drinks. They’re a cheese business, so they’re also becoming more vertically integrated and trying to consolidate their supply chain. And they’ve also got a Japanese joint venture.”

Beverages According to Tarrant, in the current year the beverage sector is growing by 2.2 per cent (which is the second strongest growth for a manufacturing sub-division).

PROCESSES AND PACKAGING LEADING TRADE FAIR

“Most of that is to do with the strength of Australian wine production,” he said. “Revenue for the wine production industry is expected to grow by 7.1 per cent in the current year to reach $6.2 billion. A lot of that is to do with strong export growth. The industry is recovering from a wine glut where there was some structural over supply for about a decade due to lower grape prices and the sharp entrance of a lot of wine producer into the Australian industry.” But, he added, strong export demand from Asian markets combined with poor harvests in Chile and Argentina have meant an undersupply for exporters. This, in turn, has seen Australian wine makers picking up that slack. On top of that, Australia’s clean green image hasn’t hurt. Australian wine is seen as high quality. When asked to nominate a top performer in the wine industry, Tarrant pointed out that our wine industry is quite fragmented, with a lot of small producers. “The biggest is Treasury Wines [which owns Penfolds, Wolf Blass, Yellowglen, and others]. It’s expected

to grow by 7.4 per cent in the current year but that’s roughly in line with the industry average.” Beer manufacturing, on the other hand, is expected to decline by 0.7 per cent over the five years to 2016/17, to $4.2 billion. “Although beer consumption has been declining in Australia over that period, there’s been a shift to premium beers, craft beers, beers that are low in carbs or foreign labels. That’s kind of negatively affected companies like Carlton United Breweries are focused more on their traditional staples like VB, Carlton Draught, etc.,” said Tarrant. “Other companies like Lion, a subsidiary of Kirin which produces Tooheys, XXXX, James Boag’s, etc., have looked to acquire more craft beers to respond to that trend. They own Little Creatures and White Rabbit. Although they’re expected to decline by 1.3 per cent this year, the outlook for them as they transition towards more craft and premium beers is positive.” IBISWorld 03 9655 3800 www.ibisworld.com.au

HONESTY YIELDS THE JUICIEST

FRUITS

NICOLAS LECLOUX CMO TRUE FRUITS

Barth Trade Consulting Australia Pty. Ltd. PO Box 6009 _ North Sydney _ NSW 2059 Suite 18 _ 122 Arthur Street _ North Sydney _ NSW 2060 Tel: +61 (2) 9955 5515 _ Fax: +61 (2) 9955 5516 info@fairsltd.com _ www.fairsltd.com

www.foodmag.com.au 2017 | Food&Beverage Industry News 11 2017-01-02 interpack 2017_Australien_true fruits_210 x 122_Food & Beverage Industry| Feb/Mar News_4c_5469

VICTORIAN MANUFACTURING SHOWCASE

Food sector innovation at Ballarat A large audience gathered at the Victorian Manufacturing Showcase in Ballarat to hear from business leaders about challenges and opportunities in emerging growth sectors, writes Hartley Henderson.

K

ey factors considered central to success in today’s changing manufacturing environment included an ability to adapt, the development of a competitive risk-taking culture, and exploiting collaboration with other companies and universities. Also highlighted was the critical role of strong leadership, involvement of employees in seeking new ideas and productivity improvement, and recognising the importance of consistently delivering quality added value products for clients. True Foods is an Australian owned family business that was established in 2001 as a specialist manufacturer of flat bread products. In 2011 the company purchased a major production facility in the Victorian regional town of Maryborough which consists of 27 acres with 3 acres under roof.

True Foods Director, Mark Thurlow, says the company has experienced enormous growth in its production capabilities, now employs some 250 people, and has an annual turnover of around $50 million. “We have grown to become the largest Australian-owned manufacturer of Tortilla Wraps, flatbread products, and bakery snacks such as crumpets and pikelets, and this is supported by a supply chain that distributes significant volumes of shelf stable, ambient and frozen products nation-wide,” he said. “Innovation is a driving force in our success and we continue to invest in new capabilities and capacity to bring innovative new products to market for our customers, which range from large multi-national supermarket brands and international franchise groups to weight-loss companies and health food chains.

12 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

“Our culture of innovation is aimed at finding unique solutions across the entire value chain from new product development, to purchasing of raw materials, and finding new production and supply chain efficiencies. We are always looking to invest in new capabilities that are synergistic with our existing purchasing, production and supply chain efficiencies. “The focus on innovation is backed by an R&D team that is equipped for rapid prototyping to help us quickly focus on a clients’ specific brief, and our multiple production lines have all been modified to make slightly different products. This in turn means that the company has some of the broadest capability in Australia to offer a range of products, with or without inclusions, and to make multiple health claims. “We are constantly increasing

the range of products we offer, and because of our ability to run segregated production lines, allergen-free, gluten-free, organic, Kosher or Halal products can be effectively processed. “It is people that make a business and development of a loyal culture and a highly reliable workforce is essential. We have established a diverse management team with backgrounds in food manufacturing, food technology, logistics management, corporate finance and marketing, and a key feature of the company’s culture is to encourage and listen to employee ideas.”

Collaboration benefits Thurlow says great emphasis is also placed on collaboration, communication and the sharing of ideas, both internally, with suppliers, and with valued customers.

VICTORIAN MANUFACTURING SHOWCASE

“For example, True Foods enjoys a wonderful working partnership with the team at Laucke Flour Mills, with significant collaboration on many of the technical aspects of flour right across the supply chain – from sourcing grain, to developing technical specifications, right through delivery and final use in our facility,” he explained. “Both companies have invested considerable time to better understand the requirements of the other, and through this transparent and collaborative approach we have built significant trust. “Through their hands-on approach, world-class equipment and technical knowledge, we have developed a flour that consistently meets our specialised needs, and we continue to work on cross-seasonal strategies. “Actively engaging with our partners at all levels is a central feature of our operations. This includes identifying emerging trends and working with our partners to develop market leading products, achieving supply chain efficiencies, and utilising lean manufacturing to drive costs out at all levels of our production process.” According to the General Manager of Laucke, Peter Cobb, locality is a key factor in enabling strong collaboration between Laucke and True Foods. “We are positioned at Bridgewater on Loddon, which is only about 40 minutes by road from True Foods in Maryborough,” he said. “This assists many areas of collaboration, including in product development because we are able to instantly run samples from our laboratory to True Foods and thereby help our client to keep ahead of the game. “Close geographic location also applies to logistics where collaboration with another partner, CVT Transport, which is located in Maryborough, provides very fast and reliable delivery of the main bulk ingredient flour in specialised tankers from Laucke storage containers to True Foods, where the flour is blown into their bulk storage facility. “In this way, raw materials supply is managed in an extremely efficient and reliable manner to give True Foods comfort in its scheduling, which in turn also benefits effective scheduling at Laucke.

“Strong collaboration is providing the flour to end user requirements how each other’s factories operate. a strategic advantage by enabling in niche markets, which includes the Information is shared openly including differentiated supply options to be supply of specialty flours such as between CEO’s, production schedulers offered to ensure the management of certified organic, and differentiates the and planners, and often across both quality as well as efficiency in delivery company from big multinationals. organisations by people of equal of tailored products to our client. “At the planning stage we work job function.” “We have developed a flour specific closely with True Foods product Laucke to True Foods requirements to ensure development team and are also able 1300 133 331 that it goes through its automated plant to provide ideas and feedback on www.laucke.com.au in a certain way, ensuring for example marketing and sales strategies for that the correct amount of water is specific products. True Foods absorbed by the Food flour and between Laucke CC-en24-AZ227 & that Bev.specific Ind. News,“The 150 relationship x 192 mm, Craftmate, 01/17 1800 497 277 requirements for consistency are met.” and True Foods is multi-tiered and www.truefoods.com.au Cobb says Laucke is able to tailor there is an understanding about

AUSPACK 2017 Sydney, 7 – 10 March Stand 330

Craftmate #GermanBlingBling #Craftmate

We do more.

CC-en24-AZ227_01-17.indd 1

www.foodmag.com.au | Feb/Mar 2017 | Food&Beverage Industry 24.01.17News 10:2413

MICE 2017

MICE 2017: Bigger and better Asia Pacific’s largest specialty coffee show, the Melbourne International Coffee Expo (MICE), is set to take off from 30 March to 1 April this year, with virtually all exhibitor space being filled. Not only will visitors get to see the latest in coffee making and marquee competitions (ASCA’s line of coffee championships), but exhibitors and sponsors will also once again get a shot at cementing their positions in the market. Syed Shah gives the lowdown.

F

rom the food and beverage sector, MICE will feature an array of equipment suppliers, dairy processors, packaging manufacturers, technology suppliers and other stakeholders who will be looking to use MICE as a key meeting point for new business opportunities. To date, MICE is Asia Pacific’s largest specialty coffee show. Last year’s event featured 120 exhibitors and attracted 9,213 people – record numbers for the show. This year’s event looks to host a similar number of exhibitors and potentially exceed the previous attendee count. Of those visitors, 34 per cent were café owners, 20 per cent were coffee roasters, and 20 per cent were baristas. What’s more, 38 per cent

of last year’s attendees reported they had come to recommend or appoint suppliers.

Exhibitor highlights Event favourites from previous years will return once again in 2017 with the likes of the Melbourne Coffee Week, the MICE Product Innovation Awards; the Royal Agricultural Society of Victoria Australian International Coffee Awards; Sensory Lab Brew Bar; Roasters Alley; and Origin Alley. Here is some of our top picks: Detpack Form and function unite in Detpak’s full range of food and beverage packaging solutions.

Together with beautiful design, the range of packaging solutions offered by Detpak, including the café and coffee ranges, overcome the many technical challenges of insulation, maintaining freshness, and sustainability. We’re coffee packaging specialists and we work with you to understand what your business needs are in order to meet your individual requirements – from technical specifications, to deciding sizes and developing brand and design. Detpak’s packaging solutions and printing ability will showcase your products, grow your brand, and support your business. We’re looking forward to meeting you at stand #103.

Jet Technologies Whatever your packaging requirements, Jet Technologies can be relied upon for expert advice and support from start to finish, on trays, packaging bag solutions, filling and sealing machinery, lidding materials, closures and adhesives. Their staff are industry experts, with the knowledge and practical knowhow to provide premium quality products, along with outstanding customer service. Jet Technologies offers a range of packaging solutions developed for the specialty coffee industry including world-leading vertical form fill seal machines, premium flexible printed packing and one-way degassing valves. Visit Jet Technologies at stand #71 at MICE2017.

Building the momentum In an industry with ever increasing interest in coffee production from seed through to the brew, there will be a series of training rooms that will provide industry-recognised education, in all aspects of coffee preparation from espresso through to filter. With the event just around the corner and anticipation reaching a fever pitch, Show Director Simon Coburn is bullish about this year’s event with many new developments in the world of coffee that will be showcased. “MICE will showcase incredible new products and equipment for the coffee and cafe industry, For the food and beverage supply chain, this event shouldn’t be missed,” he said. Secure your position at MICE2017 today, contact event.organiser@ primecreative.com.au or call +61 (0)3 9690 8766. For tickets or more information, visit internationalcoffeeexpo.com. 14 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

COMMERCIAL Brands you can trust

GMO FOOD

Telling the market you’re GMO free Putting aside the arguments for and against GMO food, the fact is that many consumers give it a big thumbs down. As Matthew McDonald writes, food makers stand to benefit from establishing that their products are GMO free.

C

onsumers all want food that tastes good, is good for them and doesn’t cost too much. More and more, consumers are also hoping that their food is produced efficiently and with factors like the environment and global food security in mind. Supporters and patent owners of genetically modified (GMO) foods claim such products can potentially address these issues right now. Even so, many Australian consumers don’t want to eat them. The reason is simple. As multiple National surveys have proven, they don’t want to eat them because they don’t trust them. The fears surrounding GMO food are many. While they may often be overblown, most have not been conclusively refuted by the scientific community. The public health effects of GMO foods in areas like increased herbicide usage, allergens and antibiotic

resistance may be slim, yet they have not been 100 per cent refuted. Despite all the best intentions, testing and legislation the whole story of GM, biodiversity and the intrinsic value of organisms is not set in stone. So consumers are cautious. “If you put two products side by side and they look the same, smell the same but one’s labelled as certified non GMO and the other one is a maybe you’ll probably sell more of the certified non GM,” Martin Stone Director of HACCP Australia and GMO-ID Australia told Food & Beverage Industry News. Stone argues that it makes good sense for food makers to establish their products as Non-GMO. GMO-ID Australia offers businesses in Australia and the Pacific Non-GMO certification, which allows them to do just this. As Stone explained, the company also counts those who want to export

to GMO sensitive markets, such as Europe and the UAE amongst its clients. The aim of the Non-GMO programme is to provide businesses with independent, third-party certification verifying that their production and handling systems, identity preservation systems, quality systems, and internal controls result in food eligible to be called Non-GMO. In addition, all clients certificated against the Non-GMO standard are listed on a directory which is used as a tool to connect buyers with suppliers and help clients raise their industry profiles.

GMO food in Australia So how much GMO food are we consuming in Australia? “That’s a very difficult question to answer,” said Stone. “It’s uncertain.” “There’s a few different routes of GMO consumption in Australia. The

first of those is legally approved GMO foods which are grown as crops and then highly refined and turned into some sort of food ingredient.” He explained that, where all traces of the DNA have been removed in the refinement process, the products do not legally have to be labelled as GM. “A good example is canola oil. There’s a great deal of GMO canola grown in Australia that’s turned into oil and then consumed. We don’t know exactly how much of this refined GMO material is used from both domestic and international sources.” “The second route is where there’s a legally approved GMO product and that’s consumed whole or in a form that is not so highly refined. In that case it needs to be labelled.” As mentioned, there are very few if any such products consumed in this country. “It’s almost pointless putting GMO soy on the market where you have to label it because people wouldn’t buy it,” said Stone. The third route includes illegal products which are mostly grown overseas. The amount of such foods in this country is almost completely unknown. “…European regulatory sources indicate that there’s a great deal of GMO rice floating round in the Chinese market and papaya out of Thailand is contaminated heavily with GMO papaya. So if you’re eating dry papaya in breakfast cereals or things like that it could well be there. These are illegal GMO products which have escaped into the market place,” he said. Pointing to the number of GMO food applications currently before FSANZ, Stone said the GMO food market is growing. Applications include those for things like corn, soy, potatoes, wheat, sugar beet, and rice.

Testing Testing is a key part of the certification process offered by GMO-ID. 16 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

GMO FOOD

In simple terms, genetic modification involves cutting a piece of DNA that bears a particular trait from one organism and inserting it into the DNA of another (target) organism. “…you can imagine that DNA is a strand or a string. Basically when you make these GMO products you cut that string somewhere... You take out a little bit of it and then you replace it with a little bit of something else,” said Stone. “When you put that additional genetic information in there there’s the join between the two ends of the string and at the join typically marker genes are found. And you can search for those marker genes which tell you that something (you don’t know what) but something has been put into the DNA strand at that particular point,” said Stone. Polymerase Chain Reaction (PCR) tests are used to do this. These involve firstly isolating and then multiplying DNA up to a level that makes it possible for DNA technicians to look for specific markers which tell them that the product is genetically modified. “With legal genetically modified

product that’s a relatively easy task because when you have a legal product, these are typically patented by large companies so you know what to look for…like a formulation if you like,” explained Stone. “The illegal GMO products are a little bit more difficult but they still carry some classic markers that the DNA technicians looks for.” PCR tests are accurate (down to about one part per million) and digital PCR testing, which is likely to soon be possible, should deliver Limits of Detection of around one part per billion.

Identity preservation Apart from testing products to determine whether or not they are GMO free, the certification process also involves identity preservation. Given the complex global supply chains involved, this is crucial. As Stone put it, identity preservation means “…you know what’s happened to it, you know where it’s been, you know what it’s been mixed with and stored with and stored alongside all the way through the supply chain.

Oxygen Analysers, Relative Humidity Sensors and Meters, Dewpoint Measurement

“So you can guarantee that what started off as non-GMO finishes as non-GMO in the product that you use here in Australia.” Considering that GMO foods are common in some parts of the world, identity preservation has to be robust. For example, in the US, a large amount of GMO Corn and GMO soy is grown. These crops yield many products used as ingredients by the food industry such as dextrose and proteins. “If you are using a dextrose type product out of America then it’s had every opportunity to become infected with genetically modified material so you need a very good identity preservation system to be able to prove and control the non-GMO status,” said Stone. Finally, asked if other non-GMO claims not involving certification by GMO-ID or a similar organisation can be trusted, Stone was adamant. “They can’t be,” he said. “You see it around a bit actually, where people have put non GMO in a small star or something similar on the label. That’s based on the fact that probably their ingredient suppliers don’t trigger the labelling

U.V Absorption Conductivity pH / ORP Colour

AMS Instrumentation & Calibration Pty Ltd Analytical Process Division

requirements from FSANZ in this country. “We take a lot more thorough look at the whole process …so if you find that a product that is claiming to be non GMO actually does contain GMO material almost certainly it will be a self-declaring product, a non-certified product.” GMO-ID Australia 02 9956 6911 gmoid.com.au

Martin Stone, Director of HACCP Australia and GMO-ID Australia.

Head Office: Unit 20, 51 Kalman Drv Boronia VIC 3155 Ph: 03 9017 8225 Fax: 03 9729 9604 NSW Ph: WA Ph: QLD Ph: SA Ph:

02 08 07 08

9911 9201 3387 7221

6615 0984 7706 2205

www.ams-ic.com.au sales@ams-ic.com.au

Oxygen Analysers, Thermal Conductivity Analysers, NDIR Analysers, Multigas Analysers, OEM Analysers

Industrial Water Analysers and Liquid Analytical Products (pH, Conductivity, ORP, Dissolved Oxygen, etc) www.foodmag.com.au | Feb/Mar 2017 | Food&Beverage Industry News 17

AUSPACK 2017

SMART PACKAGING AT AUSPACK 2017 Australian companies exhibiting at AUSPACK are using intelligent packaging to develop experiencerich marketing campaigns, provide information on nutritional content, and provide a platform for authentication, traceability, and brand protection.

S

mart packaging – which encompasses both active and intelligent packaging – is seeing rapid technological advancement on a global scale. While active packaging is a relatively mature market, intelligent packaging is in a high growth phase, spurred by printed electronics, the Cloud and the Internet of Things, which combined create a new frontier for packaging manufacturers. Intelligent packaging technologies incorporated or embedded in a pack (like codes and tags) provide a means to access information, check authenticity, monitor product conditions, receive and store data as well as deliver messages to customers, shippers and brand owners. An important application for Australian manufacturers is proving product provenance and authentication, particularly for those exporting into Asian markets where

counterfeiting is rife and where consumers seek assurance that a product is genuinely Australian. For example, packaging equipment supplier Result Group (Stand 38 at AUSPACK 2017) has partnered with IDlocate, a traceability and anti-counterfeit solutions provider, to deliver a consumer-facing authentication platform which enables unique QR coding systems to be printed on packaging. By scanning the code with any smart phone or hand-held device, consumers have direct access to a range of data in real time — including growing information, ingredient details, promotional offers, export origin and serving suggestions. Benefits to brand owners include the ability to check supply chain and distribution without needing thirdparty feedback, and the capability to understand consumer-buying

behaviour first hand, plus being able to build product-relevant custom content and share it with consumers instantly. In another exciting addition this year, AUSPACK 2017 will be the place to experience bleeding-edge innovation and technology developments that are shaping the processing and packaging

The show has teamed up with augmented reality specialist Omniverse Foster Packaging, to deliver a unique direct marketing experience for the show.

industry’s future. The show has teamed up with augmented reality (AR) specialist Omniverse Foster Packaging, to deliver a unique direct marketing experience for the processing and packaging industry trade show. “It’s a physical-to-virtual promotion, taking potential visitors ‘beyond the box’ into an immersive experience of what AUSPACK has to offer,” says Anne-Marie Mina, event executive at Exhibitions & Trade fairs, organiser of AUSPACK. “We’re excited to bring this exclusive experience to our audience, to demonstrate how AR can transform packaging into a dynamic marketing tool that is set to revolutionise the industry.” Show organiser Exhibitions & Trade Fairs (ETF) has also pulled out all the stops to bring AR to the show floor in the form of interactive AR signage, a trade exhibition first in Australia. See the following pages for a floor plan of AUSPACK 2017 and profiles of several key exhibitors. WHERE: Sydney Showground, Sydney Olympic Park WHEN: 7 - 10 March, 2017

18 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

SMC Australia | New Zealand

SMC offers automation solutions for food and beverage customers As the global leaders in pneumatics and industrial automation with a 40% local market share, SMC offers a range of over 12 000 basic components available in over 700 000 variant forms. With products designed and developed specifically around the requirements of customers in the food and beverage industry, SMC caters to the hygienic and safety standards demanded by these applications. With the largest sales and engineering force in the business, we bring you global insights into best practice from all over the world. Contact SMC for high quality, low cost and rapid delivery of your pneumatic and

positiv/graffictraffic/F&B/0217

automation requirements.

70

311

700

502

92

92

50

440

79

98

120

233

A&D Weighing & Inspection

AAA Packaging Supplies

AB Autopack

ABB Australia

AccuPak

AccuWeigh/AccuPak

Adept Turnkey Vision Systems

ADM Packaging Automation

Aerofloat Wastewater Treatment Specialists

Allpack Adhesive Tapes Co

AmbaFlex Spiral Conveyor Solutions

Anderson Wholesale Packaging

67

86

75

114 117 118 121 123

85

74

68

57

47

152

151 153 160 162 164

140

144

115 116

88

76

207

125 95

Dongguan Guilai Printing Co Dongguan Hing Shing Adhesive Product Co

264

deluxe enviornmental technology (shanghai) Co Department of Industry, Innovation and Science

321

Datalogic Automation

736

Dandong Mingcheng Environmental Protection Products Co 289

747

Crafers Group

Dansensor- Pryde Measurement

51

587

24

Stand

69

48

CPS

CP Packaging Industry Co / CP Poly-Industry Co

Contech & Flexmove Systems

Exhibitor

154 158

130

134

103 102 101 100

73

40

25

122

Stand

Cafe

54

39

38

34

124 125 126 127 128

104

92

31

21

17

20 22 24

99 98 97 96 95 94

84

72

53

29

13

82

64

630

80

71

61

51

3M

Exhibitor

70

60

50

27

28

26

18

59

49

149

120

700

701

600

601

603

Guangzhou Biaoji Packaging Equipment Co

Guangzhou Keshenglong Carton Packing Mahine Co

Guangdong Tengen Printing Co

Grip B Innovations Co

Green Packaging Material (Jiangyin) Co

Grain Tech

Gongguan Encolors Packing Co

GMD INNOVATION

GLOBAL PACKAGING

Fulun Packing Manufacture

Exhibitor

119

89

79

502

400

402

300

301

200

201

606

607

127

375

784

251

376

389

126

750

229

489

Stand

610

710 712

621

422

321

220

Cafe

721

626

631

530

430

330

226

570 366

MAGNATTACK GLOBAL

54

754

241

116

276

310

466

487

53

717

330

618

75

Stand

Machine Knives Aus

Linco Food Systems

Lighthouse Systems

Liaoning hengyue printing and packaging co

Leuze electronic

630

331

230

636

536

541

440

340

337

236

640

641

540

240

660

560

460

360

750 752 754

751

650

450

350

260

Qingdao Huahongxing Plastic Co

Qimarox

Q&L Packaging Machinery Co

PSE

Proseal Australia

ProPak Events

Propac Industrial

Prior Packaging

Print & Pack Australia

Pressco Technology Inc

Pouch Direct

Polytij

POLYLAYERTECH SRLS

677

34

236

575

420

673

47

267

307

681

295

201

663

151

Stand

760

661

662

262 263 264 265

251 253 255 257 259 261

PKN PACKAGING NEWS + FOOD & DRINK BUSINESS

Exhibitor

744 748

747

646

550

446

451

346

351

250

231 233 235 237 238 239 241 245 247

728 730 732 734 736 738 740

Leussink Engineering

LD Packaging

LACHENMEIER / BLISS & REELS

Label Power

Kuka Robotics

Krueger & Salecker

KRONES PACIFIC

Koelnmesse

Kockums Bulk Systems

Exhibitor

717

614 618 620

617

520

510

320

216

420

611

310

311

210

410

411

306

307

206

229

Sydney Showground, Sydney Olympic Park

207 209 211 212 217

702 704 706

205

Exhibitors Listings

672 677

670 671

673 678

570 572

675 676

674

573 574

474 473

375 376

373 374

294

293

788 784 785 782

470 472

372

273

271 272

789

781

688

689

575

475

378

297

289

681

587

589

591

581

487

589

488

481

389

381

288

104

40

Taiwan Hon Chuan TECHIK INSTRUMENT (SHANGHAI) CO

676

Synthetic Packers Pvt

162 540

Synergy Packaging

102

210

118

617

472

611

668

Stand

Suzhou Tipack Co

Suzhou Lucky Time Pack Materials Co

SUPERIOR PUMP TECHNOLOGIES

Sunshine Packaging Solutions and Services Limited

Sunlea Label Printing Co

STAINLESS TANK & MIX

Spraying Systems Co

Solutionpack Machinery (M) Sdn Bhd

Exhibitor

List accurate as of 24/01/17

Cafe

669

666 665

668 667

566

466

366

266 267

277 276 275 290 291 292 295 296

Meeting Rooms

31

669

566

220

701

154

748

89

661

Case Packing Systems

CDE Design Solutions

CGP COATING INNOVATION

Chart Inc

Chellsons

Cheng Fong Plastics Co

CLARIANT SOUTH EAST ASIA

CONCETTI Group

CONFOIL

712 748 245 601 240

Enterline Packaging Solution Environmental Control Products ErgoPack Australia Eriez Magnetics Ernest Fleming Machinery & Equipment

607

Filling Machines Australia

Fujian Henglong Plastic Industrial Co

Fromm Packaging Australia

FPC INDUSTRY CO

foshan Wilpac Packaging Machinery Co

710

560

789

117

670

94

Foshan BAOPACK Packaging Machinery Co Foshan Shunde Shengshi Qunli Packaging and Printing Co

260

231

FOOD & BEVERAGE INDUSTRY NEWS FOODMACH

689

Flo-gineering

732

80

FILLER SPECIALTIES

Fletcher International

71

209

Fibre King

Fenghua Sanyang Trading Co

76

530

FANUC FB Propak

510

Fallsdell Machinery

84

28

EMRICH PACKAGING MACHINERY

ESKO AUSTRALIA

160

216

612

114

212

Stand

Elliott Automation

ELETTRIC 80

EASYPRINT

Dongguan Zhiteng Plastic Product Co

Dongguan Kaidi Adhesive Technology Co

Exhibitor

Media Partner

550

CAMA AUSTRALIA (CAMA GROUP)

706

BCDS Group

751

29

Barry-Wehmiller Australia

C21 SYSTEMS

626

Axelent Automation & Safety

20

760

AVIAN Granulator Group

CS Machinery Co

68

Automaint Solutions

134

450

AutoCoding Systems

Busch Vacuum Pumps and Systems

67

Australis Engineering

25

360

Australian Wrapping Company

BluePrint Automation

122

Australian Institute of Packaging

460

660

AUSPOUCH The Australian Pouch Company

Biotec Solutions

541

Aurora Process Solutions

300

257

Aupacific Co

BioSteam KHD Belt Cleaning

481

ATS Applied Tech Systems

728

646

Asafe Australasia

290

744

Approval Laboratories

Biofiba Pallets

60

APPMA

Beagle Pack

Stand

Exhibitor

702 621 96

KHS Pacific KIEL INDUSTRIES King Garden Paper Product Co

261

Joseph Lee & Co

620

230

Johns Adhesives / Beardow Adams

KENENG LIMITED

411

49

237

373

381

475

320

17

86

446

410

704

782

650

JMP Engineering

Jinri Beverage Machinery

Jiaxing Mingyue Packaging Materials Co

Jiangsu Zhongtai Packing Machinery Co

Jialong Group

Jet Technologies

J.L. Lennard

ITW Zip-Pak Australia

Intralox

Integrated Machinery / Sinolion

insignia

Inside FMCG

Innopack Suzhou Co

IndustrySearch. com.au

581

262

InControl Hygiene Industry Update Media

721

206

140

69

121

610

665

ifm efector

Icon Equipment International

Hybrid Software

Hot Melt Packaging Systems

Hong You (Changzhou) Package Co

Honey and Fox / Wool Cool

HIGHFINE ENGINEERING

678

Hewlett Packard

72 291

Heat and Control HELEE GROUP

115

288

238

573

Stand

Haver & Boecker

Hastings Data Loggers

Hangzhou Qunle Packaging Co

H&H INTERNATIONAL CORP

Exhibitor

372

600 346 730

Phillro INDUSTRIES Pilz Safe Automation

636

48

99

402

PharmEquip

PerForm-MeypackKliklok

Perfect Packaging

Peking Ynnovation Packaging Material Co

Paksmart Machinery

785

247

PACKWEIGH EQUIPMENT PAKEA

39a

297

378

153

738

144

474

27

272

430

Packsize

Packovation

Packline Solutions

Packaging Council of New Zealand

PACKAGING AND FOOD

ORIENTAL PACKING

OMS Australasia

Omniverse Foster Packaging Group

OFS

Nupac Industries

603

NOVACART S.p.A NSK Australia

226

688

277

674

Nordson

NETZSCH Australia

NDA Engineering

NATIONAL WEIGHING

662A/B

149

Narrowtex Australia/ Absortech

667

Multiplex Packaging SDN BHD

640

740

470

21

734

59

235

641

366

Stand

Multipack

Minipack International

Minipack International Food Division

Millsom Materials Handling

Milliken Chemical

Metro Plastic Manufacturer SDN BHD/Malaysia

Matthews Australasia

Martor Australia

Makum

MAGNATTACK™ Global

Exhibitor

57 675

SMI S.p.A

666

340

61

572

574

97

128

123

49

271

100

101

781

520

250

18

752

259

74

73

266

293

205

331

422

301

451

164

38

306

130

788

292

Stand

SMC Pneumatics

Smalte Conveying

SKY Softgel Co (KOREA)

Sick

SI Instruments

Shrinath Flexi Pack

SHENZHEN BULL PACKAGING MATERIAL CO

Shantou Linghai Plastic Packng Factory

Shantou Dachuan Machines Co

Shanghai Jornen Machinery Co

Shanghai Grepack Packing Machinery Co

Shanghai Acepack International Trade Co

SG Global Packaging Co

SEPAK INDUSTRIES

Selpak

Scott Automation & Robotics

Schur

Sabre Medical Packaging

ROXSET HEALTH + SAFETY FLOORING

Romheld Automation

Rockwell Automation

Robotic Automation

Robot Technologies - Systems Australia (RTA)

Robatech Gluing Technology

RMR Process

RML Engineering

RK ROSE + KRIEGER

Rhima Australia

RETAILQUIP

RESULT GROUP OF COMPANIES

REGETHERMIC

Recopak Machinery

Qualicaps Co

QLM LABEL MAKERS - LABEL PRINT SYSTEMS

Exhibitor

Zhongshan TO-U Intelligent Equipment Technology Co

ZANASI - MAKE YOUR MARK

Youngsun China

YISHUI BORUI PACKING PRODUCT CO

YII LEE ENTERPRISE CO

XWPACK Co

Xinle Huabao Plastic Machinery Co

Xiamen Xinanxing Import And Export Co

Xiamen Ameson New Material Inc

WRH Global Australia

WORKFLOW

What's New In Food Technology

Wells Hygence and Defectable Products

WELLMAN PACKAGING

Weifang Parkson Pack Co

WEDDERBURN

Walls Machinery

VPET Plastic Co

Visy

Viking Food Solutions

UV Solutionz

TXM LEAN MANUFACTURING

TRONICS

Toyota Material Handling

Total Pack Australia

tna

TITAN PACKAGING

TINCO

TigerPak Packaging

Tianjin Zerpo Supply Co

Thriving Enterprises

THERMAL RIBBONS AUSTRALIA

The Pouch Shop

The Le Mac Australia Group

Tech-Long Packaging Machinery Co

Exhibitor

103

294

631

263

22

672

265

239

211

82

589

158

473

351

671

13

400

255

62

606

253

591

26

88

152

85

614

217

350

124

273

119

337

275

374

Stand

AUSPACK 2017

Stand 410 - insignia This year, insignia will be showcasing all three models of the newly-released Domino Ax-Series printers at AUSPACK.

B

ased in Queensland, insignia is a national label manufacturer and distributor of international thermal printing and coding solutions, with close to 50 years of experience in the industry. The company manufactures a range of prime product labels, blank labels, barcode labels and laser labels, and has two state-of-theart press rooms in Brisbane and Melbourne. It distributes leading brands such as Datamax-O’Neil, Zebra, Bixolon, Intermec, Carl Valentin

AX550i and Domino. These brands cover some of the best global products for desktop and portable printers, as well as coding, marking and labelling automation equipment. insignia will be showcasing Domino Printing Sciences’ recently launched Ax-Series, a range of continuous ink jet (CIJ) printers that are optimised for demanding industrial packaging environments. In developing this new series, Domino has rewritten the rules of coding and

marking by revisiting the underlining science behind CIJ and introducing its own innovations. This has resulted in a comprehensive reengineering of the technology that the company believes will reset customer expectations of productivity, quality and cost of ownership. “Starting from the ground up, our team of research scientists, engineers and designers set about reinventing the CIJ printer,” said Nick Plaister, Domino’s CIJ product director. “We broke down all the components of CIJ and started from scratch with the smallest detail, discovering things about coding that no one ever knew. So now every code is the highest possible quality which means fewer rejects, less downtime and improved operator efficiencies.” The Ax-Series includes the Ax150i, Ax350i and Ax550i. The main features of the Ax150i include use of the i-Pulse system, a new generation of precision ink drop technology leading to gains in ink usage, droplet accuracy and placement at traditional print speeds, as well as CleanFill technology to eliminate the risk of spillage or mess, and QuickStep software to deliver flexibility and ease of operation. The Ax350i also utilises the i-Pulse system, as well as the Machine Readable Codes (MRC) and Optical Character Recognition (OCR) systems, which enable the printer to rapidly print messages and multiple line codes at rapid speeds and reduce rejects. The Ax550i is supplied in a tough, stackable cabinet made from marine grade stainless steel that is not only dust tight, but can withstand powerful

22 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

Ax350i

water blasting during heavy duty cleaning. It also utilises i-Pulse, MRC and OCR systems. With all models, constant automatic monitoring and control of the ink condition through Domino’s Quality Management Module (QMM) ensures the ink is always optimised for the i-Pulse print head and promptly informs the operator when an ink, makeup or Service Free i-Tech filter

Module (ITM) change is required. Furthermore, traditional ink shelflife is significantly extended and the number of operator interventions is substantially reduced, with both factors significantly contributing to enhanced levels of Overall Equipment Effectiveness (OEE). insignia 1300 467 446 www.insignia.com.au

Ax150i

WORK DIFFERENT

GO BEYOND ERP WITH SAGE

Intelligent Business Management Software

www.sage.com/au

AUSPACK 2017

Stand 57 - SMC Taking the static out of manufacturing environments

S

MC Pneumatics will be showcasing its range of ionizers at AUSPACK 2017. Static is problematic in the manufacturing environment. Static causes dust and this in return comes with its own set of problems. From dealing with the nuisance of products clinging to each other, plastic sheets not separating property to managing possible damage to electrical products. There is also the real hazard of a possible fire which can be caused by a spark in a chemically sensitive environment. SMC Pneumatics is able to offer a solution to these ‘every day’ manufacturing problems by means of the three different types of ionizers available from their product range. When working with plastics you often have an unwanted but unavoidable charge of electricity. There are various options of ionizers available depending on the application and the environment. The bar type is equipped with nozzles which generates charge and air then blows the charge onto the application. This could work in a PET environment for example. It would also be suitable for lamination and web printing. The bar type

Ionizer bar type with electro static sensor varies in length and performance options. The nozzles can be equipped with condition monitoring and therefore easy maintenance and replacement of the nozzles are not a problem. The unique thing about the SMC ionizer is that it can be ordered in a variant which is equipped with a sensor. The sensor has a feedback device which is able to determine if a positive or negative charge is required, and then it will generate accordingly. The charge relates back to a voltage so that the unit can measure the charge. This is communicated back to ionizer

fan type ionizer

24 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

and ionizer will generate ions to balance out the charge. An option without a sensor is also available. In this case the unit will generate alternate charge which ‘bombards’ the application with positive and negative ions until it neutralizers the application. This would however be a less energy efficient option. A great example of this application can be found at a dairy PET manufacturer which uses this type of solution to assist them in managing the static generated when the bottles come off the plastic injection moulding station and onto the shrink wrapper. The static makes the products difficult to handle by clinging to the feeding mechanism of the shrink wrapper. The bar type ionizer will be deployed to combat this problem. The ionizer is also available in two other variants. The fan type would generate a charge

and blow it over the affected area. This would work very well especially in an area where polystyrene is involved. The nozzle type consists of a single nozzle and is for concentrated applications where a single area needs to be neutralized. The air supply is blown onto area that is required. With 50 years of commitment to the Australian manufacturing economy, this Japanese owned company has offices in a total of 81 countries, the company boasts more than 12 000 components in their product range and an international market share of 36 per cent. The Australian market share of SMC is at around 40 per cent. It is investments in R&D and new products such as the ionizer which has seen this Japanese multinational win the Forbes Innovation Prize for a third time. SMC www.smcworld.com

Nozzle type ionizer

Stand 730 - Pilz

XT TION E N RA E EN

G

Whether you need packaging or processing machines with an elementary function range, machines with multiple functions or interlinked plant and machinery you can turn to Pilz for your automation needs.

A

t Pilz’s AUSPACK stand you will be able to see firsthand the full complement of product innovations and safety services available. Pilz has recently released a number of new products & services so make sure your drop in and meet the team. As one of its main focusses in the sensor area, the company will be launching its second generation light curtains. Cost-effective and simple to install, these products ramp up the advanced technology features. They deliver strong connectivity with plug and play convenience. In addition, Pilz will showcase PASvisu, its recently released visualisation software. Suitable to run on mobile phones, tablets and so forth, this software allows users to connect to their machines and visualise statuses, inputs, safety functions, and so forth. A simple wireless solution,

according to the company, it represents its first real ‘Industry 4.0 ready’ to be made available on the market. As always, visitors to AUSPACK will also be able to catch up with members of the Pilz services staff. These days, more and more customers are approaching the company seeking bespoke engineering solutions. Whereas historically such solutions were usually taken care of in-house, now the company offers turnkey engineering capabilities to clients. Pilz offers a high-end automation and machinery consultancy. The company can help customers make their machinery more efficient, faster, and safer. So come on down to Stand 730 and meet the Pilz team! Pilz www.pilz.com.au

Visit us at

AusPack 2017 Stand 730

See the light. Pilz has recently released its new range of PSEN Light Curtains which include its second generation Cat 3 & Cat 4 compliant Light Curtains. This means Pilz now has a comprehensive range of light curtains and accessories that can support a large variety of applications in any plant or factory. Benefits of PSENopt II at a glance; u Come with a huge variety of functionality & programmability u Large selection of lengths and widths, including a slim line version u Highly robust for protection against shock, collision and vibration u User-friendly diagnostics via LEDs to reduce downtimes u Rapid and simple assembly, installation and commissioning

Melbourne • Sydney • Brisbane • Auckland

Ph: 1300 723 334 Ph: 03 9560 0621 Fax: 03 9574 9035 www.pilz.com.au safety@pilz.com.au www.foodmag.com.au | Feb/Mar 2017 | Food&Beverage Industry News 25

MANAGEMENT

Disruptive manufacturing is now a good thing Disruption is not just a symptom of the major changes going on in manufacturing. In all likelihood, it will also be its saviour.

T

o say that the global manufacturing industry is undergoing an era of profound upheaval (or disruption) would be an understatement. Disruption can come in many forms, such as pressure from cheaper Chinese imports or even currency fluctuations, all of which have impacted on global manufacturing over the past two decades. For its part, Australia’s manufacturing sector has also suffered from a disruptive economic climate throughout that time.

Disruption in the form of IoT Across multiple industries the Internet of Things (IoT) is causing a far-reaching form of disruption in all areas, especially in the manufacturing sector. The IoT is fast becoming one of the most disruptive forces that the Australian, and indeed the global, manufacturing sector has faced. The modern manufacturing plant floor is a hub of technology, sensors, electronic controls and automated equipment. These interconnected devices drive compliance, efficiency, quality and will cause the most disruption. Fast, efficient and flexible computerised machines are provided

with instructions for the exact requirements for each product at each moment of production. This is a fullscale transformation of the old-style “economies of scale” approach that drove mass-produced consumer goods. Connected tools and machines are a key aspect of these changes. Take an IoT-enabled torque wrench in the assembly of a complex part, as a simple example. When connected to specific Cloud applications, a torque wrench can capture the torque applied to a specific part, as well as information like the specific wrench that was used, when that wrench was last calibrated and the employee(s) who used it. Faults can be detected in real time, and even when they’re missed, the Cloud applications can trace every part affected back to the root cause. Quality and speed are the first things that will be improved in such a hyper-connected environment, which leads to an improved customer experience. This same level and depth of visibility won’t stop when the product leaves the plant. Smart products will not only interact with the customer in new ways but will also be able to stay in contact with the producer for better long-term performance,

maintenance and support. Quality issues not only get service attention, but can (and do) influence future product design. Sensorconnected smart technology via the IoT brings processes and products together into a new ecosystem for added customer value. Compliance is also a major headache to many manufacturers, IoT solutions are being used to streamline compliance with company and government regulations, from collecting and analysing data remotely, to making sure that machinery is being used effectively. Utilising sensors allows staff to immediately detect potential problems and ensure that any issue that may affect quality or safety issues are promptly dealt with well before they arise.

How disruption helps What is mainly transformative about the IoT is the changing nature of the products that companies will make and how they will be made. Smart, connected products are generating new value in ways we couldn’t imagine even five years ago – from reduced costs of production to improved efficiencies in areas like service and innovation, opening up new landscapes for invention and growth. To compete, differentiate, and win in this new IoT world, companies must recognise the transformative (again, disruptive) power of the IoT – and be ready to collect, analyse and capitalise on the information (data) now being generated by customers, suppliers and the products themselves.

Thinking outside the box A study from the Economist Intelligence Unit found 87 per cent of leading executives from across the globe have had operations with out-ofdate infrastructure. New technologies that can identify issues with infrastructure before they occur will be needed by companies 26 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

to put them on a firm footing for the future. IoT enabled solutions will help companies improve efficiency, extend the life of assets, reduce the risk of failure and improve the ability of businesses to meet customer expectations and demand.

Exploiting benefits of IoT with business managment software In order to capitalise on all the benefits of the IoT, the implementation of new technologies in ERP, or next generation business management solutions, is the best way for manufacturers to improve and increase their efficiencies. Manufacturers need to understand that improvements in efficiencies will only come when they think ‘outside the box’ and embrace the notion that disruptive technologies are not only good for their business, but will also help improve the outcomes in a sector that is in a continual state of flux. However, getting the right solution is half of the battle and experience suggests that success is down to procuring the right software.

Be ready for IoT with Sage X3 Sage X3 has been designed to support complex organisational deployment and reporting structures, in order to simplify management across multiple facilities, companies or business units and geographic regions. With built-in functionality for manufacturing, distribution and services tasks, Sage X3 can be customised to accommodate a range of rules and processes. For the requirements of the IoT, Sage X3 is scalable and is designed to adapt to the needs of large volumes of data, making it simple to manage a global business while at the same time navigating the new universe that is the IoT. Sage 137 243 www.sage.com/au

NOMINATIONS NOW OPEN 11 MAY 2017

MELBOURNE WWW.ENDEAVOURAWARDS.COM.AU

ON THE SHELF

1

2

3

4

5

6

1 - Hip Chips

2 - Backburner IPA

From the company behind Australia’s favourite, popcorn brand, Cobs Popcorn, comes a new chip range, Cobs Hip Chips. Made from 100 per cent Australian whole grain corn, potato and rice, Hip Chips are made without using vegetable oil, which often masks the flavour.

The Lord Nelson Brewery has released Backburner IPA, an experimental seasonal ale as it celebrates its 30th year of brewing and the 175th birthday of the pub whose name it bears.

Manufacturer: Cobs Fine Foods Packaging: 90g foil bags Website: www.cobs.com.au

Manufacturer: The Lord Nelson Brewery Packaging: 375ml cans Website: www.lordnelsonbrewery.com

Manufacturer: Connoisseur Ice Cream Packaging: 1 litre tubs Website: www.connoisseuricecream.com.au

4 - Blended Malt Scotch whisky

5 - Brownies & Lemon Drizzle Squares

6 - Premium Tea

Chivas Regal Ultis, the first blended malt Scotch whisky from the House of Chivas uses only five of the distiller’s most precious, signature single malts from Speyside in Scotland, and represents the style and diversity of this renowned region. Manufacturer: Chivas Regal Packaging: 700ml bottle Website: www.chivas.com

3 - The Brooklyn Ice Cream Collection Connoisseur has partnered with world famous OddFellows Ice Cream Co. in New York to create The Brooklyn Collection, a range designed to take people on a journey to four Brooklyn neighbourhoods.

Fibre One Chocolate Fudge Brownies and Lemon Drizzle Squares are tasty snacks that allow you to fill up without filling out. At just 90 calories per square, they are also naturally high in fibre and lower in fat.

The range consists of four varieties: English Breakfast, Earl Grey, Green Citrus and Peppermint. The English Breakfast sticks to traditional roots of full-bodied flavour and the Earl Grey delivers a strong floral aroma with a well-structured and creamy body.

Manufacturer: General Mills Packaging: Boxes of five (120g net.) Website: www.fibreone.com.au

Manufacturer: Boutea Packaging: Net 40g box Website: www.boutea.com

28 Food&Beverage Industry News | Feb/Mar 2017 | www.foodmag.com.au

ON THE SHELF

7

8

9

10

11

12

7 - Organic Coconut Water

8 - Wizz Fizz Fizza Ballz

9 - Perfectly Pure Mash

Those who love the taste and hydration properties of fresh coconuts but not the inconvenience of cracking the whole fruit are in for a treat with Oqua Organic Coconut Water.

An exciting addition to the iconic and muchloved Wizz Fizz range, this on-the-go treat with a chewy sherbet centre is made with all natural colours and flavours, providing a fizzy taste sensation with every bite.

Made with 100 per cent real sustainably grown potatoes, sourced fresh from the field, nothing but potato goes into Maggi Natural Mashed Potato. With not an additive or allergen in sight, the Mashed Potato offers chefs a quick, nutritious side dish alternative.

Manufacturer: Ceres Organics Packaging: 1 litre boxes Website: www.ceresorganics.com.au

Manufacturer: Fyna Foods Australia Packaging: 43g net bar Website: www.fyna.com.au

Manufacturer: NestlĂŠ Professional Packaging: 2kg box Website: www.nestleprofessional.com.au

10 - Sweet Bites

11 - Focus Drink

12 - Gelista Premium ice-cream

Sunny Queen Australia has launched a ready to serve, egg-based sweet snack that has all the indulgence of a sweet treat but with less of the naughtiness.

Australia’s first focus drink, Shine+, has launched across the country. This part of a new class of beverages formulated for one purpose - to maintain levels of focus, concentration and mental performance.

Premium ice-cream and gelato manufacturer Gelista has released two new flavours in its 570ml consumer jar range, Almond Milk and Coconut with Raspberry Swirl. This expands the existing range to eight flavours: five dairy and three non-dairy.

Manufacturer: Sunny Queen Australia Packaging: Cartons of 120 x 20g Website: www.sunnyqueen.com.au

Manufacturer: Shine+ Packaging: Boxes of seven x 110ml bottles Website: shinedrink.com

Manufacturer: Gelista Packaging: 570ml jars Website: gelista.com.au

www.foodmag.com.au | Feb/Mar 2017 | Food&Beverage Industry News 29

MOTORS & DRIVES

Goodbye control cabinet! Cabinet-free drive technology enhances productivity throughout the entire value stream. Bosch Rexroth outlines five requirements of the future.

Q