MARCH 2024

INGREDIENT INNOVATION

MARKET DRIVEN ON THE RISE

MARCH 2024 PLUS: Traceability | Packaging | Logistics

CEO: John Murphy

COO: Christine Clancy

Managing Editor: Syed Shah

Editor: Adam McCleery

Ph: (02) 9439 7227 adam.mccleery@primecreative.com.au

Design Production Manager: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Michelle Weston

Sales/Advertising: Stephanie Suzuki Ph: +61 422 046 711 stephanie.suzuki@primecreative.com.au

Production Coordinator:

Salma Kennedy

Ph: (03) 9690 8766

salma.kennedy@primecreative.com.au

Subscriptions AUS NZ O/S

1 year subscription 99 109 119 2 year subscription 189 199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

Understanding the vital role of ingredients

ICopyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Cover

Image: Quality Stock Arts - stock.adobe.com

Head Office

379 Docklands Drive

Docklands VIC 3008

Ph: +61 3 9690 8766 enquiries@primecreative.com.au

http://www.primecreative.com.au

Sydney Office

Suite 303,

1-9 Chandos Street

Saint Leonards NSW 2065, Australia

Ph: (02) 9439 7227

Printed by: Manark Printing

28 Dingley Ave Dandenong VIC 3175

Ph: (03) 9794 8337

Editor: Adam McCleery

ngredients are the building blocks of every food and beverage product.

They are not just components added for flavour or texture but play a crucial role in determining the quality, safety, and nutritional value of the final product. Understanding the importance of ingredients in food and beverage manufacturing is essential for producing products that meet consumer expectations and regulatory standards.

The quality of ingredients directly impacts the overall quality of the product. Whether it’s fresh produce, grains, spices, or flavourings, using high-quality ingredients ensures consistency and enhances the taste profile of the final product. Manufacturers must source ingredients from reputable suppliers who adhere to strict quality control measures to prevent contamination, spoilage, or adulteration.

On top of this, ensuring the safety of food and beverage products is paramount in manufacturing. Ingredients must comply with regulatory standards and guidelines set by food safety authorities.

Manufacturers need to trace the origins of ingredients, conduct thorough testing for contaminants, and adhere to labelling requirements to provide consumers with accurate information about allergens, additives, and nutritional content

Consumers are also becoming increasingly concerned about the nutritional content of the foods and beverages they consumer.

Ingredients play a crucial role in determining the nutritional profile of a product. By incorporating wholesome ingredients rich in vitamins, minerals, and essential nutrients, manufacturers can create products that contribute to a balanced diet and support consumer health and wellness goals.

Ingredients are instrumental in defining the flavour

and texture of food and beverage products.

From natural sweeteners and spices to emulsifiers and thickeners, each ingredient contributes to the sensory experience of the final product.

By leveraging a diverse range of high-quality ingredients and innovative flavouring techniques, manufacturers can create products that resonate with consumers and drive success in the market.

Balancing ingredients to achieve the desired taste, aroma, and mouth feel requires precision and expertise to meet consumer preferences and market trends.

In a competitive market, innovation is key to staying ahead of the curve and experimenting with new ingredients or incorporating unique flavour combinations allows manufacturers to differentiate their products and capture consumer interest.

Whether it’s introducing exotic fruits, plantbased alternatives, or functional ingredients with health benefits, innovation in ingredient selection drives product development and market growth.

And with increasing awareness of environmental and social issues, consumers are demanding transparency and accountability in sourcing practices.

Manufacturers that prioritise sustainability not only contribute to environmental conservation but also enhance brand reputation and consumer trust.

The importance of ingredients in food and beverage manufacturing cannot be overstated. From ensuring quality and safety to enhancing flavour and nutritional value, ingredients are the foundation of every product.

Until next month, happy reading!

WELCOME 4 Food &Beverage Industry News | March 2024 | www.foodmag.com.au

COMPLETE SOLUTIONS FOR FOOD & BEVERAGE

Australia’s leading specialists in oil-free compressed air, gas and power generation, CAPS has been servicing the food and beverage industry for over 44 years.

As an independent company with the flexibility to search globally for the best technology, we work alongside world-renowned partner brands like Ingersoll Rand, Mitsubishi, AIRMAN and many more to deliver purpose-built systems designed to match your needs.

With ten branches nationwide and 24/7 service for maintenance and emergency breakdowns, CAPS Australia leads the industry in service and solutions.

ISO

CALL 1800 800 878

OR VISIT CAPS.COM.AU

GENERATORS SERVICING & SPARE PARTS

GENERATORS POWER

POWER

NITROGEN

CLASS 0

AIR

TREATMENT

OIL-FREE

AIR

8 NEWS

20 MEET THE MANUFACTURER

24 TRACEABILITY

GS1 continues to work closely with the industry on providing tailored, real-time information.

26 PACKAGING

COPAR’s fibre packaging developments go from strength to strength.

28 INGREDIENTS

Earlee Products provides a strong source of locally sourced ingredients.

30 LEVEL MEASUREMENT

The VEGAPULS 42 is expertly tailored to hygiene-sensitive industries such as food and beverage manufacturing.

32 PACKAGING

Tetra Pak’s product offerings are making strong inroads into ready-to-drink coffee sector.

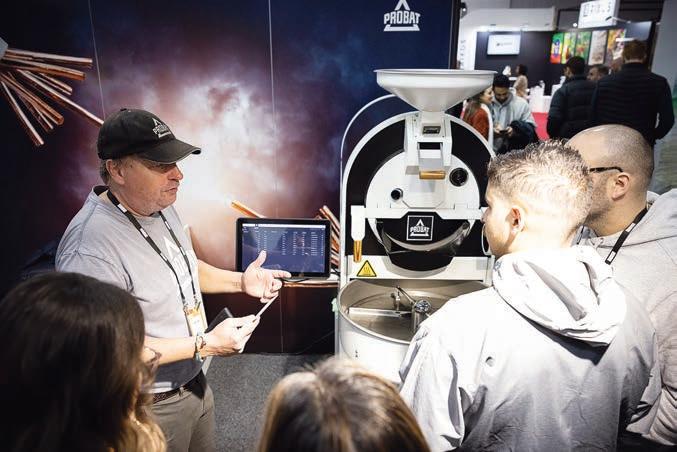

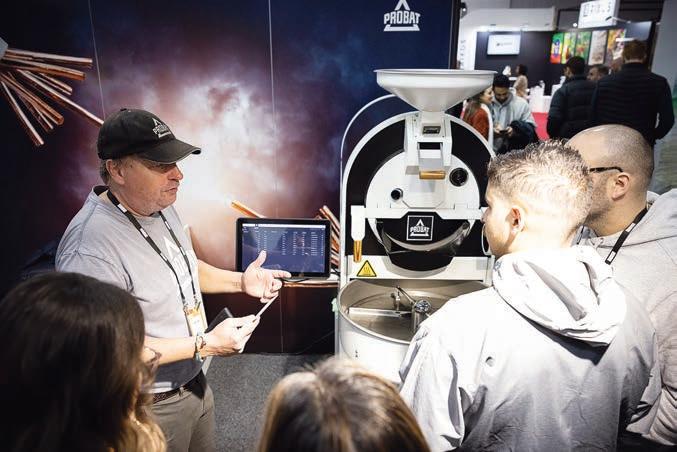

34 MELBOURNE INTERNATIONAL COFFEE EXPO

This year’s MICE event will host a series of educational conferences for attendees.

36 LOGISTICS

Scully RSV’s long-term partnership with Rum City Foods demonstrates the company’s ability to help growing companies in ever changing conditions.

38 LOAD HANDLING

The food and beverage industry has begun to realise the benefits of Combilift’s electric Combi-CS Pedestrian Stacker.

40 INGREDIENTS

Angel Yeast’s yeast protein offers a string of benefits as an alternative to traditional protein ingredients.

42 ACCC

The Australian Competition & Consumer Commission has been tasked with looking into supermarket pricing.

44 AIP

The Australian Institute of Packaging announces winners of WorldStar Student Awards.

Equipped with our patented multi-position tiller arm the Combi-CS offers safer operation, maximum operator visibility and narrow aisle performance. The tiller can be turned to the left or right, allowing the operator to remain at the side, providing full visibility of the load and forks, while maintaining full steering control, enabling greater awareness of their surroundings which enhances overall safety. Standing to the side of the stacker eliminates the risk of being trapped or crushed while allowing the Combi-CS to operate in very narrow aisles.

46 INDUSTRY OUTLOOK

A newly released Rabobank annual outlook has found Australia’s agricultural sector is “moving confidently into 2024”.

6 Food &Beverage Industry News | March 2024 | www.foodmag.com.au CONTENTS 20 28 32 38

Pedestrian reach stacker with Combilift’s patented multi position tiller arm

• Benefit from the safe, space saving and efficient handling of products without the need to use a ride-on forklift.

• Patented multi-position tiller arm turns to enable operation from either side of the stacker.

• Safer operation, maximum operator visibility and narrow aisle performance.

• Full visibility of the load and forks, while maintaining full steering control.

combilift.com

COMBI-CS Capacity 1,000 kg - 2,000 kg Lift Height 2,500 mm Engine Type Electric Machinery Type Pedestrian Stacker

Coles launches 846 new recycling drop off points

Australia’s official governmentbacked battery recycling scheme B-cycle, is pleased to welcome Coles to the scheme, adding 846 recycling Drop off points across the country.

The partnership marks a major moment for the scaling-up of the B-cycle scheme with 5000+ B-cycle drop-off points now available across the country and present in every major supermarket – making safe battery recycling easy and accessible for all Australians.

90 per cent of used batteries currently go to landfill, causing environmental impact and wasting precious resources. While recycling rates are improving across Australia, there is a long way to go.

The addition of Coles to the national recycling scheme means more people are now able to bring their used loose handheld batteries to the clearly marked recycling

bins located at the front of each store, meaning valuable minerals and materials are not wasted, but used again and again.

Coles general manager of sustainability, Brooke Donnelly, said batteries are one of the fastest growing waste problems in Australia, and this initiative not only helps to address the challenge but also advance our transition to a circular economy.

As one of the nation’s fastest-growing waste streams, B-cycle has shifted consumer behaviour, seeing an increase in battery recycling among all Australians by over 30 percent.

Since the launch of B-cycle in 2022, collection of used batteries for recycling has almost doubled, creating positive impacts for people and our planet, as well as helping grow Australia’s onshore recycling industry capability. F

Victorian food manufacturers drive record food and fibre exports

Anew report shows Victoria is Australia’s flagbearer for international food and fibre sales, with booming exports boosting jobs and putting the state within reach of achieving a strategic goal years ahead of schedule.

Minister for Economic Growth

Tim Pallas visited Remedy Drinks in Dandenong South to release the 202223 Food and Fibre Export Performance Report, which shows Victoria is Australia’s largest food and fibre exporter by value – accounting for 24 per cent of the national total.

In another stellar year for Victorian farmers and food manufacturers, the state achieved an increase of 7 per cent in export value, taking the total to a record $19.6 billion.

That is just shy of the Victorian Government’s ambitious target of reaching $20 billion a year in food and fibre international sales by 2030, pledged in the 2020 Agriculture Strategy when sales stood at $14.5 billion.

Grain was our largest export in 202223, increasing by 26 per cent to reach $5.6 billion in value, while meat was the second largest at sector $4.5 billion.

Remedy Drinks continued to be an outstanding performer, with the kombucha brand contributing to a 12 per cent increase in Victorian beverage exports. Remedy grew its exports by 40 per cent in 2022-23, increasing its workforce by 30 people. The company created in a Melbourne kitchen in 2012 now exports to more than 20 countries.

The state’s trade agency Global Victoria has supported Remedy’s growth – the company took part in three trade missions last year including the China International Import Expo where it was one of 49 Victorian exhibitors.

Food and fibre exports increased in the majority of Victoria’s key markets in 2022-23, led by China, Japan and the US, and inroads continued to be made in other strategic markets including Singapore, South Korea and Indonesia.

Food and fibre exports increased in the majority of Victoria’s key markets in 2022-23.

NEWS 8 Food &Beverage Industry News | March 2024 | www.foodmag.com.au

The partnership marks a major moment for the scaling-up of the B-cycle scheme.

Image: Farknot Architectstock.adobe.com

Image: VICHIZHstock.adobe.com

PepsiCo promotes ANZ CEO

P“Kyle has identified new growth platforms that have enabled portfolio and channel expansion, as well as stronger capabilities including marketing transformation and demand acceleration. With a people-first approach, Kyle has also personally invested a significant amount of time into talent development, empowering teams and facilitating growth opportunities,” said Tan.

PepsiCo has also made two new general manager appointments to support Faulconer’s promotion.

eCommerce.

Horley has also been instrumental in driving ‘better for you’ product innovation and partnering with customers in this space to deliver more choice to Australian consumers.

Stephan Anderson, current chief financial officer for PepsiCo ANZ has been given the additional title of general manager, ANZ Beverages. Anderson will lead the finance functions across ANZ Foods and Beverages and will also be responsible for the entire ANZ Beverage business. F

to COPAR's Australian wheat straw packaging, precisely replicating your packaging with our custom solutions.

www.foodmag.com.au | March 2024 | Food &Beverage Industry News 9 NEWS

Food Service & Hospitality Ready to Eat Fresh Produce Meat and Poultry HealthCare Our Packaging is Designed for Our Australian production scheduled to commence in April 2024 Keep it Safe Keep it Sustainable Keep it Australian Custom Packaging Solutions

Transition:

your

Our New Australian Wheat Straw Packaging with NO ADDED PFAS +61255656770 sales@copar.eco www.copar.eco Get Your Sample Pack: Be First to Try Our Wheat Straw Packaging AUSTRALIAN Made - Sourced - Owned Wheat Straw Butter Tubs Hot o the PressOur new Sustainable Packaging Solution Image: PepsiCo

Faulconer moved from the United States business to join PepsiCo ANZ as CEO in November 2021.

Seamless

Convert

plastic packaging

Sydney Markets Limited announces Peter McBride as new chair

Sydney Markets Limited announced the appointment of Peter McBride as its new chair of the board of directors.

Peter McBride, an internationally renowned agribusiness leader, will commence his role in January, 2024. He succeeds John Pearson ASM, who retired in 2023 after serving as Chair of SML for almost 19 years.

Mr McBride joins Sydney Markets with extensive leadership experience. He is the current Chairman of Fonterra Co-operative Group Limited, a Director of Sequal Lumber Limited, and is a member of the New Zealand China Council and the Zespri Global Supply Advisory Board.

His previous governance roles include being a Director and then Chairman of Zespri international – the world’s largest marketer of kiwifruit, selling kiwifruit in more than 50 countries – and a director of the New Zealand International Business Forum.

Peter’s proven track record of delivering shareholder value and international agribusiness experience make him an ideal leader for our next phase of growth. His appointment reflects our commitment to excellence and innovation in serving the Australian community.

Mr McBride says he is honoured

to serve the shareholders of an iconic Australian institution.

“I’ve spent a significant amount of my governance career in agribusiness,

particularly large exporters and cooperatives. As a result, I have deep empathy with the shareholders of Sydney Markets and understand that the markets are an extension of their businesses.

“I look forward to working alongside shareholders and my fellow directors to bring the transformative change that is required to ensure the continuation of Sydney Markets’ legacy.”

This significant appointment marks a new chapter for Sydney Markets Limited as it continues to play a pivotal role in Australia’s agricultural supply chain and community markets. F

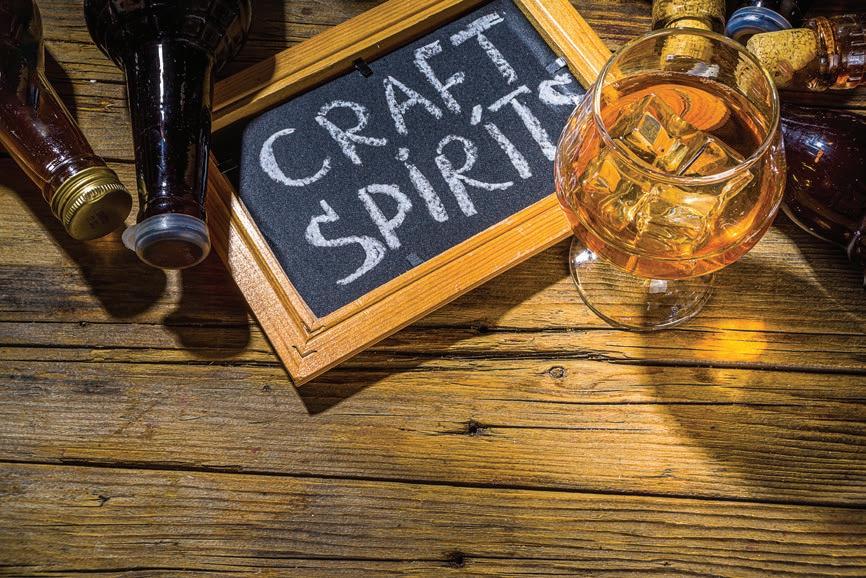

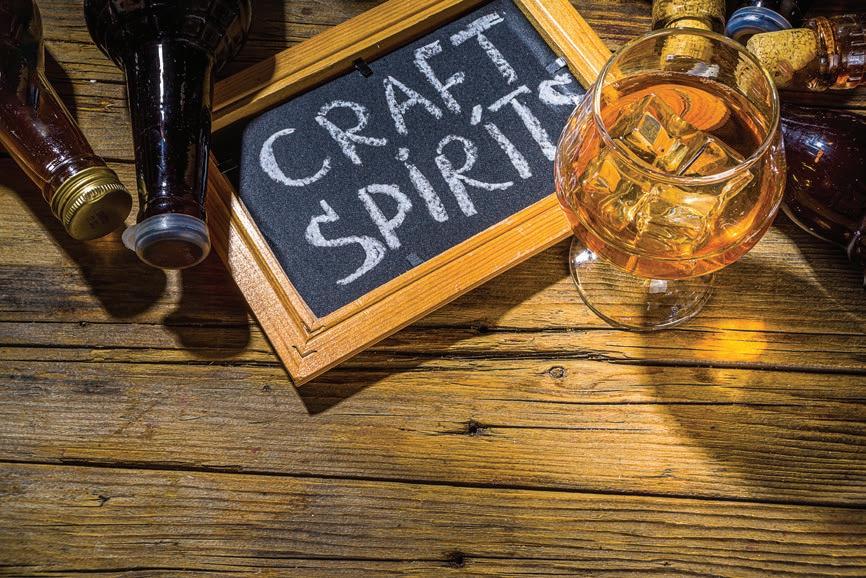

Worldwide sales of craft spirits set to reach $342.75bn by 2033

ACraft Spirit Market is expected to achieve a valuation of $342.75 billion by the conclusion of 2033.

The market is anticipated to experience a substantial Compound Annual Growth Rate (CAGR) of 29 per cent from 2023 to 2033.

Craft spirits, encompassing domestically manufactured alcoholic beverages, are crafted through distillation and fermentation techniques. Typically produced in limited quantities, often below 750,000 gallons, their production requires individuals to hold a distiller’s license specifying production capacity and emphasizing independent operation.

Regulatory oversight is provided by a major player in the alcoholic beverage industry, and in the United States, certification for craft spirit production involves label approval by the Alcohol and Tobacco Tax and Trade Bureau (TTB).

The global demand for craft spirits has witnessed significant growth, spanning ethnic premium, superpremium, and flavoured varieties, capturing the interest of consumers worldwide. This heightened demand acts as a driving force for the expansion of the craft spirit market. The

renaissance of craft spirits has led to the introduction of innovative products, establishing their unique presence with packaging designs that evoke quality and handcrafted sensibilities.

Millennials, driven by a preference for unique and authentic experiences, are inclined to explore and experiment with various flavors and types of distilled liquors. This trend has resulted in a surge in demand for new and unconventional offerings in the craft spirits market.

“Growing desire for craft spirits, surge in craft distilleries, and an uptick in disposable income are propelling market growth. Furthermore, the millennial demographic, possessing significant purchasing capabilities, is expected to be a driving force in the market over the coming years,” said a Fact.MR analyst.

The market comprises both global and local participants. Prominent market leaders emphasise strategies like innovation and the introduction of new products in retail to enrich and expand their product line-up within the market. F

NEWS 10 Food &Beverage Industry News | March 2024 | www.foodmag.com.au

ccording to market research and competitive intelligence provider Fact.MR, the Global

The market comprises both global and local participants.

Image: Sydney Markets

Image: ricka_kinamotostock.adobe.com

This significant appointment marks a new chapter for Sydney Markets Limited.

Apple juice concentrates market forecasted to reach $11.92bn

According to market insights provided by Fact.MR, a renowned market research and competitive intelligence provider, the global apple juice concentrates market is anticipated to reach a valuation of $6.95 billion in 2024.

The market is poised to witness a steady growth with a projected Compound Annual Growth Rate (CAGR) of 5.5 per cent between 2024 and 2034.

Apple juice concentrates, known for their versatility, have become a prevalent ingredient in a wide range of food and beverage products. The rising consumer inclination towards natural and healthier beverage options is fuelling a robust demand for apple juice concentrates on a global scale.

Noteworthy within the market is the ongoing trend of continuous product innovation. Leading manufacturers are actively engaged in developing organic and non-GMO variations of apple juice

concentrates. Additionally, they are exploring novel flavours and blends to cater to the diverse preferences of consumers.

The key segments highlighted in the Apple Juice Concentrate Industry Research Report include growing consumer awareness and an increasing demand for clean-label products. Manufacturers are responding to these trends by placing a strong emphasis on environmentally friendly and transparent supply chain practices in the production of apple juice concentrates. This reflects a broader industry commitment to sustainability and responsible sourcing.

Key Takeaways from Market Study

• T he global apple juice concentrate market is forecasted to reach $11.92 billion by the end of 2034.

• Apple juice concentrate sales in the United States are predicted to rise at a CAGR of 4.9 per cent from 2024 to 2034.

Leading apple juice concentrate companies are focusing on continuous product innovations and forming strategic alliances.

• Preference for organic products and a rich culinary culture is generating lucrative opportunities for apple juice concentrate producers in Germany.

• Demand for apple juice concentrates in Japan is estimated at a market value of $179.60 million in 2024.

• Organic apple juice concentrate sales are projected to reach $4.56 billion

by the end of 2034.

Leading apple juice concentrate companies are focusing on continuous product innovations and forming strategic alliances to stay competitive. Product differentiation, sustainable practices, and agility in responding to market trends are key factors shaping market competition. F

NEWS www.foodmag.com.au | March 2024 | Food &Beverage Industry News 11

Image: nata_vkusideystock.adobe.com

VIC launches grants program to showcase regional food and beverage producers

Regional towns across Victoria are being called on to get creative and show off their locally produced food and drinks as part of the Victorian Government’s $1 million Regional Activation Grants Program.

Minister for Agriculture Ros Spence today opened the first round of grants under the new program, inviting Regional Tourism Boards, food and fibre groups, and regional bodies to apply for funding.

Grants of up to $70,000 are available to hold local events that showcase local food and beverages in the regions where they are produced.

Minister for agriculture, Ros Spence, said, “we’re empowering local producers to promote Victoria’s wonderful variety of locally sourced food and drinks and

celebrate the unique stories behind every product.”

“These grants will help foster a rich appreciation for Victorian produce and encourage consumers to shop in their local region and build a connection with local producers.”

This new initiative aims to shine a light on the high-quality food and beverages produced in Victoria’s regions and connect local producers with l ocal consumers.

Events may include vibrant farmers’ markets, immersive food and beverage festivals, or collaborative tasting sessions, directly engaging local communities with producers.

Victoria’s food and drinks sector is world-class, and these grants will support greater appreciation for locally

sourced products and strengthen the community’s connection with the creators behind the goods they value and enjoy.

Businesses involved will also have their products showcased on the VIC Grown website. The webpage serves as a

producer profiles.

Victoria’s agricultural sector generates more than $20 billion for our economy each year and is Australia’s biggest producer of dairy, sheep meat, and horticulture. F

100 Coles dairy farms share in $1.45m worth of grants

Coles is supporting sustainability in the dairy industry, announcing that 100 Coles dairy farms around the country will share in $1.45m in grants as part of the newly developed Dairy Farm Sustainability Accelerator Fund.

Grants of up to $50,000 have been awarded to Coles’ direct sourcing dairy farmers to drive innovation and fund projects which invest in animal welfare, solar energy, and infrastructure improvements.

Coles general manager Dairy, Freezer and Convenience Brad Gorman, said Coles wanted to give its direct sourcing dairy farmers opportunities to invest in research and projects which boosted sustainable farming and drove innovation.

Under its direct sourcing model, Coles directly contracts with farms in

Victoria, southern New South Wales, South Australia, Western Australia, and Tasmania to supply more than 490 million litres of milk each year for Coles Brand Fresh milk and some Coles Brand cheese.

“There are dozens of impressive, farmer-led projects that will focus on reducing greenhouse gas emissions, improving soil nutrients and quality, water management, biodiversity and

To date, the CSDDG has invested more than $3.78m in on-farm initiatives.

the impact of these initiatives,” said Gorman.

“We look forward to working with our farmers and learning how much of a difference these projects will make to their operations and to the environment as they evolve and establish.”

Coles dairy farmers and grant recipients Benjamin and Melissa Holloway will use the funds to help install an 80kw solar roof system on their farm in Victoria’s southwest.

The new 80kw system will be a significant addition to the Holloways existing roof solar system, providing their farm an extra 106,000kw a year in clean, renewable energy.

To date, the CSDDG has invested more than $3.78m in on-farm initiatives, including farmer education and training, and improving herd health and milk quality F

NEWS 12 Food &Beverage Industry News | March 2024 | www.foodmag.com.au

Image: fotopicstock.adobe.com

Victoria’s agricultural sector generates more than $20 billion for our economy each year.

Image: Coles

9/11 confirms sale of its bottle shops to Coles Liquor Group

Federal Group, owners of 9/11 bottle-shops, announced that Coles Liquor and 9/11 have agreed to a transaction that will see Coles Liquor acquire twenty 9/11 stores located in Tasmania.

The transaction incorporates both hotel attached and stand-alone 9/11 stores. Federal Group’s Vantage Hotel Group will continue to own and operate the 12 current hotels.

Managing director of the Federal Group, Greg Farrell, said that the transaction would allow the Group to focus on re-investing in their wider business and hospitality and tourism assets, including award winning hotels, tourism resorts and casinos.

“Federal Group is proud of the way it has built the 9/11 business over the last 15 years and the legacy that we will pass on to Coles Liquor,” said Farrell.

“9/11 has become an iconic Tasmanian business providing convenience, quality service and an

extraordinary range of local, national, and global products to Tasmanians.

loyal staff, suppliers and partners for their support over the past 15 years in building 9/11 into the fantastic business that it is. You should all be very proud.”

Liquor on terms no less favourable than what they currently hold.

Coles Liquor chief executive, Michael Courtney said the business was keen to expand its network in Tasmania

“We’re looking forward to continuing on the great 9/11 legacy by supporting local suppliers and the community and providing great value and excellent service,” said Courtney F

Vegetable growers buffer rising costs

Newly released data in the Australian Horticulture Statistics Handbook reveals Australian vegetable growers produced 3.59 million tonnes of vegetables in 2022-23 with a production value of $5.83 billion.

Coinciding with a period marked by severe weather events and major increases in farm input costs, the handbook shows production volume was down only three per cent compared to the previous year.

While the $5.83 billion overall production value – an increase of 5.4 per cent compared to the previous year represents a record high in dollar terms, this was offset by a six per cent increase in CPI over the same period.

As a further indication of the financial pressures confronting many vegetable growing businesses, the four per cent increase in fresh supply wholesale value from $5.91 billion to $6.17 billion represents a decline in real terms.

The Australian Horticulture Statistics Handbook, released by Hort Innovation, quantifies the value and volume of all major vegetable and fruit crops produced in Australia, including exports, and also includes imports.

“This handbook is an important data source that helps growers and other supply chain stakeholders make informed business decisions and better understand the bigger picture in the Australian horticulture sector,” said AUSVEG CEO Michael Coote.

“Australian vegetable growers continue to supply more than 98 per cent of the fresh vegetables sold domestically and employ tens of thousands of people.

This data again demonstrates the critical role the nation’s vegetable growers play, not only in providing the nation with produce, but also in terms of its major contributions to the national economy.

“These contributions have occurred despite the severe weather events, labour shortages and supply chain issues that

have affected production volumes of many vegetables. These challenges have also impacted growers’ profitability, with both the overall and fresh

wholesale production values of many common commodities down on the previous year, both in year-on-year and actual terms. F

NEWS www.foodmag.com.au | March 2024 | Food &Beverage Industry News 13

Image: Barillo_Picturestock.adobe.com

Image: AUSVEG

9/11 employees will be offered employment with Coles Liquor on terms no less favourable than what they currently hold.

The figure is an increase of 5.4 per cent compared to the previous year.

Asia’s foodservice landscape is transforming with AI

Technology is fast emerging as a crucial tool for the everchanging foodservice landscape in Asia by seamlessly transforming the dining experience of customers into a futuristic affair.

Players in the foodservice sector, especially quick-service restaurants (QSR), are deploying innovative artificial intelligence (AI) tools to enhance customer experiences as well as improve operational efficiencies to boost their bottom line in a highly competitive environment, says GlobalData, a leading data and analytics company.

“ There is a growing adoption of digitalization tools, including mobile apps and self-service kiosks, as well as innovative engagement initiatives such as delivery platforms, to improve customer experiences,” said consumer lead analyst at GlobalData, Parthasaradhi Reddy.

“Tech-savvy Asian shoppers, often

the Gen Z and Gen Y customers, appreciate the convenience of hightech attributes and smartphone/app compatibility. This is concurred by 31 per cent of Asian millennials in a recent GlobalData survey wherein they

admitted finding high-tech attributes to be essential, while 26 per cent of Gen Z respondents stated the same.”

“McDonald’s China, for instance, is testing RFID technology aimed at reducing the time required for

Cadbury Australia plans to halve virgin plastic

Australia’s food and beverage brand Cadbury has signed a deal with global packaging leader Amcor, to source 1000 tonnes of post-consumer recycled plastic to wrap its core Cadbury chocolate range, accelerating the company’s ambitions to reduce its virgin plastic needs.

In 2022, Cadbury announced it had sourced 30 per cent (on a mass balance basis) of the plastic needed to wrap its 160g to 185g Cadbury Dairy Milk family blocks produced in Australia from recycled materials.

With its latest purchase, Cadbury aims to use 50 percent (on a mass balance basis) recycled plastic for its wrappers across its chocolate blocks, bars and pieces range produced in Australia. This will be equivalent to halving its virgin plastic needs to wrap those products.

stocktaking, thus improving supply chain competency. Yum China, on the other hand, rolled out an innovative app leveraging AI to provide insightful recommendations to customers while simultaneously being senior-friendly with an easy-to-use interface.”

“While third-party delivery services have already seen a rise in penetration across the foodservice landscape, the next few years will be significant for improvements in the dining space, thanks largely to new and innovative technologies,” said account director at GlobalData Singapore Tim Hill.

“The integration of technology is designed to boost the evolution of Asia’s foodservice industry, overhauling every aspect, including food preparation, customer interaction, ordering, dining, and delivery experiences for both customers and outlets alike. Technology can also help alleviate logistical challenges such as labour shortages in the industry.” F

The roll out of recycled material is expected to begin in Q1 of 2024, starting with blocks and expanding into bar lines such as Cherry Ripe, Crunchie and Twirl as well as pieces wrappers for Roses and Favourites.

This announcement comes shortly after Cadbury’s custodian, Mondelēz International, shared its longer-term vision to recycle plastic waste on home soil, partnering with Amcor to invest in Licella to fund the construction of one of the first soft plastic advanced recycling facilities in Australia.

The new facility in Melbourne, managed by Advanced Recycling Victoria (ARV), is scheduled for completion in 2025 and will initially process around 20,000 tonnes per annum of end-of-life plastic, with plans to scale up to 120,000 tonnes per annum. F

NEWS 14 Food &Beverage Industry News | March 2024 | www.foodmag.com.au

The roll out of recycled material is expected to begin in Q1 of 2024, starting with blocks and expanding into bar lines.

Image:

wolfhound911stock.adobe.com

The technology can also help alleviate logistical challenges and labour shortages in the industry.

Image: velirinastock.adobe.com

Winners revealed at 2024 Australian Dairy Awards

Tand the Royal Agriculture Societies.

The annual awards acknowledge

The event saw Victoria’s Berrys Creek gourmet cheese oak blue claim

the Grand Champion Cheese title and Queensland’s artisan gelato shop Milani Minus Eight Degrees crowned as Grand Champion Dairy, for its peanut caramel gelato.

The winning champions represented each Australian state across categories such as cheese, ice cream, milk, yoghurt, butter, and gelato.

The rigorous judging process was conducted by a panel of expert judges comprising of dairy experts, cheesemongers, retailers, chefs, food experts from across the country.

World renowned cheese expert and Australian Grand Dairy Award chief judge Russell Smith, said this year’s entries are testament to the innovation and creativity of producers, and Australia’s high-quality dairy.

“Each year we expect to taste

exceptional dairy products. Year after year, our expectations are exceeded. The class of products presented saw winners and finalists from across the nation – showcasing the breath of excellence Australian dairy has to offer,” said Smith.

Yue Lin, winner of the Grand Champion Dairy product for a second year in a row, and owner of Milani Minus Eight Degrees, Market Square Sunnybank said he has spent the better part of 10 years perfecting his craft.

Meanwhile, winner of the Grand Champion Cheese product and owners Barry Charlton and Cheryl Hulls from Berrys Creek Gourmet Cheeses said the award was a welcome surprise.

The Awards saw 380 entrants across 18 categories judged on flavour, aroma, texture, body, and visual appearance to determine the finest products. F

Gippsland Dairy yogurt products now made with 44 per cent less plastic

Chobani Australia, the company behind Gippsland Dairy, has released new sustainability focussed packaging for its Gippsland Dairy 160gram products reducing the plastic per unit by almost half.

The removal of the product’s lid is part of Chobani’s commitment to Australian Packaging Covenant Organisation (APCO) and the 2025 National Packaging Targets (the 2025 Targets), including to reduce unnecessary or problematic plastics, and follows the earlier removal in 2023 of the embedded plastic spoon as part of Victoria’s ban on single-use plastic cutlery.

Once all Gippsland Dairy 160gram products transition to the new packaging, Chobani is set to remove 95,000 kilograms of plastic from its business in 2024 and reduce greenhouse gas emissions associated with sourcing and transporting the packaging (lids and spoons) through its supply chain and to

retailers.

The transformation of the product’s packaging is a key milestone in the company’s progress against the 2025 Targets, which form a crucial part of its sustainable packaging roadmap.

Chobani‘s general manager ESG & General Counsel, Tim Browne, says that Chobani is proud to have executed this change in line with its 2025 Target commitments.

The innovative new packaging design also maintains the signature Gippsland Dairy 160gram pot look and feel by replicating the former black lid through the product’s artwork.

The pot will now feature a black band around the circumference of the pot’s top, emulating the lid to ensure consumers can easily spot the distinctive product on shelf.

Chobani’s new 160gram Gippsland Dairy packaging will be available in all leading supermarkets nationally from February 2024. F

NEWS 16 Food &Beverage Industry News | March 2024 | www.foodmag.com.au

The winning champions represented each Australian state across categories such as cheese, ice cream, milk, yoghurt, butter, and gelato.

The innovative new packaging design also maintains the signature Gippsland Dairy.

Image: Dairy Australia

Image: Chobani Australia

Calls for a tax on soft drinks misguided

The Australian Beverages Council, National Retail Association and the Australian Association of Convenience Stores have rejected a call for a tax on soft drinks, labelling it a misguided measure that won’t address obesity and hit those households that can least afford it.

“The tax is a misguided attempt to address complex problems like obesity with a simplistic, quick fix that lacks real world evidence it has any discernible impact on weight,” said Geoff Parker, CEO of the Australian Beverages Council.

“Consumption of sugar from drinks

“The introduction of any sugar tax will have significant impacts on small and family businesses, from retailers to farmers and particularly in rural and regional areas of Australia. Tax policy should not be made up without consultation, without any significant economic impact analysis, including whether it will achieve its goals and how it would affect businesses.”

In 2018 the Australian Beverages Council along with the nation’s largest non-alcoholic drink companies announced Australia’s first Sugar Reduction Pledge – a commitment to reduce sugar across their portfolios by 25 per cent from 2015 to 2025. As of 31 December 2022, pledge signatories had reduced sugar across portfolios by 18 per cent. This significant progress shows an industry that is responding with speed and scale to Australians’ desire for more choices with less sugar. F

NEWS &Beverage Industry News 17

foodmag.com.au PLUS: Traceability Packaging | Logistics MARKET DRIVEN ON THE RISE INGREDIENT INNOVATION Food & Beverage Industry News is distributed nationally to more than 6,210+ subscribers, while the website has more than 50,000+ unique views every month. It is the food and beverage industry’s one-stop-shop when it comes to the latest products, services and technologies in this space. Visit our website and subscribe to get your print and digital editions in additon to our free daily newsletters today! To book contact Stephanie Suzuki now stephanie.suzuki@primecreative.com.au 0422 046 711 Image: Denysstock.adobe.com

Australians will now have access to recycling instructions on qualifying paper cups thanks to a recent partnership between the APCO’s Australasian Recycling Label (ARL) program and Simply Cups.

Simply Cups, acknowledged as an alternative destination under the ARL program, has introduced a distinctive drop off only logo on qualifying paper cups. This logo directs consumers to recycle their paper cup at one of more than 1,500 collection points across Australia.

The ARL is an on-pack label that provides consumers with easy-tounderstand instructions about how to responsibly dispose of all parts of a product’s packaging. The evidencebased label clearly identifies if an item of packaging belongs in the kerbside recycling, general waste bin or can be recycled by following a simple instruction.

APCO and Simply Cups launch new ARL logo Food waste fighters unite under new banner

Paper cups pose a significant recycling challenge in regular Australian kerbside collections due to their waterproof lining. Away-from-home programs like Simply Cups are now recognised as alternative destinations for paper cup disposal under the ARL.

These programs play a crucial role in managing packaging not accommodated by regular collection systems in Australia and/or New Zealand. Following collection, Simply Cups partners with reprocessesors who use innovative technologies to transform the used cups into new products like roads and lightweight concrete slabs, diverting them from landfill.

Australian businesses selling proprietary paper cups can leverage the drop off only logo to promote cup recovery through the Simply Cups program, subject to APCO and ARL membership, and cup eligibility confirmed through a PREP assessment. F

The two key organisations spearheading the Australian fight to end food waste, Fight Food Waste Cooperative Research Centre and Stop Food Waste Australia are coming together under a new brand ‘End Food Waste Australia’.

The AFCCC has worked closely with these organisations for the past five years and welcomes the new entity and its programs to halve food waste in Australia by 2030 in line with the National food Waste Stragegy and United Nations goals.

The new entity’s CEO, Dr Steven Lapidge said that under its new a cohesive brand, public communication will be enhanced, and collaborations

Through the founding organisations which are now merging, Australia has developed one of the world’s largest

public-private partnerships dedicated to ending food waste.

Achievements thus far include comprehensive research into consumer food waste behaviours and identifying technologies for transforming unavoidable food waste into new resources.

End Food Waste Australia has a host of research partners, including the APPMA, Food Bank, and KPMG.

Every year in Australia, 7.6 million tonnes of food waste end up in landfill. Which is enough to fill the Melbourne Cricket Ground ten times over and costs the economy $36.6 billion annually.

Achieving Australia’s target to halve food waste by 2030 will take 23 high impact interventions to be fully implemented and an investment of $2 billion of new money. F

NEWS 18 Food &Beverage Industry News | March 2024 | www.foodmag.com.au

Australian businesses selling proprietary paper cups can leverage the drop logo to promote cup recovery.

Food waste currently costs the Australian economy over $36 billion a year.

stock.adobe.com

Image: dmf87

Image: Stefan Redelstock.adobe.com

Australia’s Largest Dedicated Fleet of Refrigerated Transport Solutions .

Scully RSV provides top-quality refrigerated truck and trailer solutions for delivering produce to regional businesses across Australia. From short and long-term hire options, new and ex-fleet sales, and customisation services, all backed by cutting-edge technology and dedicated customer service to help your business thrive.

1800 728 559 www.scullyrsv.com.au Info@scullyrsv.com.au AUSTRALIA WIDE

QUALITY RELIABILITYFLEXIBILITY SERVICETECHNOLOGY Temperature Monitoring System GPS Tracking

Australian liquor manufacturers, Sunshine & Sons, took home multiple awards at the highly coveted World Vodka Awards as the manufacturers continue to make inroads into the market. Adam McCleery writes.

Australian vodka named World’s Best by World Vodka Awards

Su nshine & Sons, born out of the creative vision of Queensland friends, has evolved into a flourishing spirit manufacturing enterprise, garnering global recognition.

Matt Hobson, co-founder of Sunshine & Sons, said the origin of the idea came when he spoke with a close friend about business opportunities presented to them.

“A great friend, and now co-founder of the business, Michael Conrad, and I started to discuss the idea for the company in 2018,” he said.

“Michael was a founding director of the largest independent brewery in Brisbane, and I had been working in the airline industry with a large airline.

“We first collaborated professionally on a branded beer for the airline, using a brand I created within the airline and with the beer provided by Michael and that was my first insight into the possibilities.

friends that they worked well together on developing and launching an alcoholic product.

“It really marked not only the success of our collaboration, but it also showed investors the viability of doing such

“The genesis of the idea took shape as a brand being firmly connected to the Sunshine Coast and making highquality spirits. Our vision is to really create an identity for the definitive Queensland white spirit brand.”

“The feeling of getting a concept from concept to a brand in hand was very fulfilling was exhilarating.”

The feedback from their employers was positive and demonstrated to the

brands,” said Hobson.

“It really opened a whole new conversation with the airline, driven by innovation, albeit a very small circulation of product but cutting edge.

“The branding was extended onto an aircraft that still fly around Australia today.”

It was from that moment when both men knew they were onto something with their collaborative ideas and decided to take it further.

“That lit the fuse for me and started me looking into what I could do in the space myself,” said Hobson.

“My view was I couldn’t do it on my own so me and Michael started discussing ideas and our main genesis was wanting to manufacture Australia’s finest rum.”

Hobson said the genesis of the business idea was to create something in Queensland which he felt had been

20 Food &Beverage Industry News | March 2024 | www.foodmag.com.au MEET THE MANUFACTURER

Sunshine & Sons was awarded the title of World’s Best in the coveted World Vodka Awards in the UK.

Images: Sunshine & Sons

lacking, while highlighting the region at the same time.

“By July of 2019 when we executed the deeds to form the business, we wanted to put into place an iconic Queensland white spirits brand,” he said.

“Effectively becoming a house of brands rather than a single brand, which tends to be the norm with craft spirits in Australia.

“The genesis of the idea took shape as a brand being firmly connected to the Sunshine Coast and making highquality spirits. Our vision is to really create an identity for the definitive Queensland white spirit brand.”

From that moment on, Sunshine & Sons was born.

Hobson also said he felt many Queensland distillers are ‘late to the

party’ when it comes to premium white spirits.

Situated amidst the lush rainforests of the Sunshine Coast hinterland, with the iconic Big Pineapple as its neighbour, the company crafts its renowned Sunshine & Sons range of spirits. Drawing inspiration from the unique flora of the region, the team concocts distinctive flavours for their brands.

operations stand their impressive Tasmanian artisan pot stills, Maria and Sarah, each with capacities of 6,000 and 2,500 litres respectively.

Commissioned in January 2020 according to head distiller Adam Chapman’s exacting specifications, these stills epitomise the company’s commitment to excellence.

www.foodmag.com.au | March 2024 | Food &Beverage Industry News 21

Located in the Sunshine Coast hinterland, Sunshine & Sons embrace local ingredients to form unique tastes.

Sunshine & Sons manufacture a variety of premium spirits with the help of head distiller, Adam Chapman.

Matt Hobson, Sunshine & Sons co-founder, said a major goal of the business was the embrace premium white spirits.

The business also helps to promote agritourism for its local region.

“We were very lucky getting Adam on the team. He is a very well-known winemaker and had been the founding and head winemaker of his own label at Queensland’s largest winery,” said Hobson.

“He joined us in 2019 when we set about building a distillery focused on producing nuanced, aromatic, and flavoursome spirits.

“We had equipment designed by Adam in collaboration with the still makers, and to our specifications.”

Hobson said right from the outset ambitions for the company were high.

“We also invested at scale; we didn’t start small. Our pot stills are 2,500 and 6,000 litre capacity and made from premium Australia copper ore milled to perfection in Germany,” he said.

“Our scale and ambition from the start has been to develop multiple big brands within our business, and we have a great team that is helping to achieve that.”

Crafted with precision from premium German copper, Maria and Sarah were meticulously designed to impart stunningly complex flavour profiles to the spirits they produce.

For Sunshine & Sons, maintaining premium quality across its product line is paramount.

This pursuit begins with securing the best distillers for the task at hand.

of the first major milestones of Sunshine & Sons, who also distil gin and vodka in several different offerings, from added tastes to pouches for airline consumer use.

“Unfortunately, Australia does not have a large reputation around its rum which proceeds it,” he said.

“We have our two big players, but it doesn’t necessarily excite the international pallet and the dark spirit connoisseurs

“Our scale and ambition from the start has been to develop multiple big brands within our business, and we have a great team that is helping to achieve that.”

Sarah and Maria, affectionately named by the team, represent the epitome of craftsmanship and innovation. Their creation underscores the company’s dedication to allowing the coast spirit to shine through in every sip of their spirits.

Hobson said the goal of developing and producing a premium rum was one

tend to lean into premium whiskey as the reflection of Australian aged spirits.

“Our rum brand is now Australia’s only certified organic aged spirit and we really leaned into that as we knew it was a great opportunity while rum became a bit more premium within Australia.”

The Sunshine & Sons team didn’t

just want to make rum to a premium global standard, but also aims to do so with its vodka and gin and has already done so with its vodka product.

The distillers achieved a significant milestone by winning gold for Australia and being named the World’s Best by the prestigious World Vodka Awards. Competing against vodkas from more than 20 countries, their success highlights the emergence of ‘new world’ vodkas outperforming those from traditional producing nations like Poland, Sweden, and Canada.

The judging process involved evaluating vodkas across four categories: pure neutral, varietal, botanical, and flavoured. Among the global winners selected, Sunshine & Sons Original Vodka has made the cut and will vie for the title of the World’s Best in its category.

Hobson said one thing that helps Sunshine & sons vodka stand out from the competition is the use of grapes, instead of

22 Food &Beverage Industry News | March 2024 | www.foodmag.com.au MEET THE MANUFACTURER

grain, a rarity in the vodka market.

“Adam’s background in wine has really helped us hone and develop some beautiful flavours and aromas that have been delighting consumers,” he added.

land to add uniqueness to the products.

This recognition adds to Sunshine & Sons’ recent accomplishments, including their partnership with Australia’s newest airline, Bonza, where their spirits have

“Our rum brand is now Australia’s only certified organic aged spirit and we really leaned into that as we knew it was a great opportunity while rum became a bit more premium within Australia.”

“We have gone from zero to 100 in no time. Building, designing, manufacturing, and installing in that time frame is almost unheard of at the scale we have achieved.”

On top of this, the Sunshine & Sons vodka undergoes a unique filtration process using ancient volcanic rock from the region, imparting a distinct minerality and floral pepperiness.

Which is one of the ways Hobson and his team utilise the surrounding

become a popular choice.

With their Original Vodka being a top seller at surf clubs and liquor retailers nationwide, they are poised for further growth, including expanding into export markets and participating in events like AusTrade in London.

Moreover, Sunshine & Sons aims to promote the Sunshine Coast’s food and agritourism sector, collaborating with local organisations to showcase the region’s offerings on a national and global scale. F

Maintaining

MEET THE MANUFACTURER

premium quality across its product line is paramount for the Sunshine & Sons business.

Sunshine & Sons has already been recognised with awards for its premium product offerings.

Transforming consumer engagement in the food and beverage industry

Providing tailored, real-time information from various sources has become increasingly important in the food and beverage industry. Food & Beverage Industry News reports.

In the ever-evolving landscape of the food and beverage industry, a global trend is reshaping the way brands and consumers interact. It’s no longer just about the exchange of products; consumers now demand a richer experience that goes beyond transactions.

Today’s consumers crave more information, personalisation and an immersive brand encounter that mirrors their identity.

This begs the question: How can consumers easily access this vital information, especially when standing in front of the physical shelf in a store? And how can brands make the most of this trend?

Next wave of digital transformation

time information from diverse sources, meeting consumers wherever they may be. The solution lies in an already existing tool—the QR Code. Not just any QR Code, but a GS1-powered QR Code, also known as a 2D barcode.

While traditional QR Codes are often limited to a single purpose, such as a promotional offer, GS1-powered QR Codes can execute multiple functions. They can seamlessly transition from showcasing manufacturing processes and recycling instructions to delivering personalised brand messages and exclusive offers.

Picture a barcode that can connect consumers to a product’s entire journey in real-time, offering business visibility from manufacture to distribution across the supply chain and in the near future,

consumers, granting almost limitless access to brand and product details. Through a simple scan of a single on-pack symbol using their phones, consumers can explore material composition, production origin, sustainability, nutritional facts, allergen information and much more.

Leveraging New Insights

GS1-powered QR Codes serve as a powerful tool for brands to extract invaluable insights. By tapping into these analytics, brands can tailor offers, and exclusive deals based on consumer preferences, purchase history or location.

Fostering loyalty through engaging promotions, surveys, and gamified purchase experiences.

The integration with a brand’s

features like two-way instant feedback.

In addition, brands gain the ability to track the who, where and when of QR Code scans globally. This wealth of information provides essential insights for refining business strategies and making vital improvements.

Why GS1-powered QR Codes?

The next generation QR Codes adhere to GS1 standards, ensuring consistency, interoperability, and accuracy in data exchange, globally.

The good news is that updating to GS1-powered QR Codes doesn’t require an extensive overhaul of business processes and systems. By incorporating a GS1 Digital Link into existing QR Codes, products transform into gateways for immersive brand

GS1-powered QR Codes seamlessly integrate across industries, languages, and systems, facilitating tasks like inventory management, supply chain tracking and consumer engagement.

The scan of a code becomes an opportunity to engage consumers in unprecedented ways—driving connections, delivering personalisation, and creating immersive experiences.

One barcode, infinite

From product identification to traceability, marketing campaigns to inventory control, GS1-powered QR Codes unlock endless possibilities for brands ready to embrace the future of qr-codes.

24 Food &Beverage Industry News | March 2024 | www.foodmag.com.au TRACEABILITY

Images: Panuwat/AdobeStock

The global QR code trend is reshaping the way brands and consumers interact.

Diverse and flexible range of alternative-packaging

COPAR’s extensive research and development into fibre-based packaging is helping the company make inroads in the push for a more sustainable industry. Adam McCleery writes.

Focus on recyclable and more sustainable packaging only continues to intensify as we get ever closer to critical sustainability and efficiency targets for industry, and alternative packaging technology is meeting the demand.

Sustainable Packaging Innovator, COPAR, has worked tirelessly to develop new fibre-based packaging to replace non-recyclable or less sustainable packaging.

COPAR’s work with wheat straw has resulted in an extremely viable packaging alternative which continues to prove its flexibility by being developed for multiple sectors, both wet and dry.

COPAR’s International Business Director Vishnu Ramasamy, who is also the founder and director of Hexcore, has worked closely with the UK and European industries, which in turn has helped the continued development of the company’s alternative packaging offerings.

“We meet with brands and show them our products and they are able to ask us if we can meet particular needs for

their sectors, which helps us learn and further our research and development,” he said.

As well as the in-depth consultation, COPAR has developed a strong research partnership with the University of Newcastle, which helps bring the company’s packaging ideas into reality.

“The University of Newcastle and our customers are invaluable in helping to drive our product development,” said Ramasamy

“This has great potential for us. The food and hospitality industry is one of the heaviest users of plastics so the impact this fibre-based packaging could have is very important.”

On top of this, COPAR has manufacturing capabilities to immediately put into practice any new concepts or ideas, again creating great flexibility in approach. This benefits customers greatly, as the food and hospitality industry’s needs are so varied.

“As a manufacturer we can play with the properties of the product to help give customers exactly what they want,” said Ramasamy.

“We can change chemical and physical properties. Every product has

Ramasamy said the proliferation of polystyrene packaging, which has traditionally been used in these two sectors, presents a great example of the positive impact replacement packaging can have on the circular economy.

“If you are looking at the United Kingdom and European markets, where I predominantly work, there is a ban

an extremely viable and flexible

PACKAGING 26 Food&Beverage Industry News | March 2024 | www.foodmag.com.au

Wheat straw presents a string of benefits as a source of alternative, recyclable packaging.

COPAR’s work with wheat straw has resulted in

packaging alternative.

of polystyrene packaging in the food sectors especially for take away,” he added.

“Policies are driving the market to look for alternatives and paper-based has been an area where some people have focussed.”

As well as government policy, cost is another major area of importance to businesses.

“Paper-based packaging is quite expensive though, but our pricing is up to 20 per cent cheaper in comparison to paper-based packaging,” said Ramasamy.

And on top of its affordability, fibrebased packaging also offers flexibility in design, meaning COPAR can help any customer achieve the desired result, whether for a wet or dry product.

“At COPAR, we can make fibrebased packaging in the same shapes as existing polystyrene packaging,” said Ramasamy.

“That is not the same in the case of paper, which is also routinely coated in PFAS materials, unlike our fibre-based packaging.

“And our product is mainly preferred by service restaurants because it does the same job as polystyrene but with a more sustainable fibre-based option.

“This is one of the main reasons why our product is succeeding, especially around pricing. Pricing will always play an important role.”

Colin Farrell, business development manager, COPAR, echoed Ramasamy’s comments.

“The reason why you can’t just use paper is because you can’t achieve that moulding like you can with fibre-based

COPAR’s extensive research and development has led to a string of innovative packaging designs for the food industry.

packaging. For the shelf life of this product, the design helps,” he said.

“For example, with our sausage packaging we have moulding that makes it perfect for the product, which is something you just can’t achieve with paper.”

That flexibility in design is clearly demonstrated with the packaging prototypes COPAR has developed for the meat sector, which requires specific packaging requirements.

“Meat is something that is interesting for us, and we have been getting lots of interest from stakeholders. We are looking at 46.6 million order inquiries,” said Ramasamy.

COPAR have also developed an alternative butter tub, with Ramasamy saying the company recognised products which are routinely bought by consumers should be the ones receiving more sustainable and recyclable packaging as soon as possible, to help cut down on land fill.

“We are working with a large dairy company in Europe to develop fibrebased butter tubs. In testing, it works perfectly well and achieves the desired result,” said Ramasamy.

“What happens with paper packaging for butter is a high chance of the packaging being damaged and exposing the product. Fibre-based can avoid contamination risks.”

The size or the global butter market alone presents even greater opportunities for COPAR and dairy manufacturers.

“This butter tray alone is about 6 billion pieces per year in terms of market size,” Ramasamy added.

“This type of packaging can also be used on other products such as soft cheeses, and these are products that are bought regularly by almost the entire customer base.

“Being able to use fibre-based packaging would really cut down on non-recyclable packaging going into land fill.”

Ramasamy said the extensive research and development done by COPAR is a major reason the company has developed what it believes is not just a viable packaging alternative, but one which can have a hugely positive impact on the environment.

“This shows the capabilities of what COPAR has achieved in terms of research and development,” he said.

“We have pushed ourselves as a company and are catering to the entire food and hospitality industry.

“We are even designing products for the horticulture market now too.”

Ramasamy’s innovative work with paper and fibre-based packaging has been in-valuable for COPAR and their latest findings have given rise to a great opportunity for the packaging specialists.

“This proves COPAR’s capabilities, we are progressing and developing at a rapid rate both existing and new markets,” he said.

“Customers are a big driving factor for us and help influence our research and development.

“We also invest heavily in sample products for customers. We have 3D printers and a design team. All of this helps to make the process faster and more direct.”

Ramasamy said the expertise that COPAR team possesses also creates a valuable asset for the company, and by extension, its customers.

“We can transfer our own knowledge with what we get in feedback, all of which in-forms our decision making. This helps create a global approach for the brand,” he said. F

PACKAGING www.foodmag.com.au | March 2024 | Food&Beverage Industry News 27

rangizzzstock.adobe.com

Image:

Sourcing ingredients locally brings host of benefits

Earlee Products is seeing first-hand the positive flow-on effect of sourcing ingredients locally. From addressing consumer demand to ensuring a better supply of product. Food & Beverage Industry News reports.

Ethe food industry, with technical expertise to help customers achieve the best outcomes when it comes to product quality, safety, compliance, and better food outcomes every time.

Earlee Products continue to build a reputation for developing innovative new solutions for food manufacturers looking to value add.

The range of products within the product range include dry premix blends (sausage and burger meals, dry rubs and glazes, injection systems, sprinkles, yield extension systems), Butter discs, Stuffing cores, Anti-microbial products, sauces / wet marinades, Baconvenience.

The success of Earlee’s product development initiatives and progress is to understand both customer needs and market needs.

Each customer has their own requirements whether it be functionality, nutritional targets, specific ingredient

“Country of origin has become very important to consumers and retailers,” said Lea Reid, research and development manager, Earlee Products.

“Supermarkets want to maximise the number on that sliding bar scale for the consumers to see.

“And with the current environment with freight and shipping delays, it is in our best interest to use Australian ingredients to avoid those delays, which can be up to as much as six weeks.”

Australian Native ingredients

A current trend driven by consumer demand is the inclusion of Australian Native ingredients in foods.

Australian natives are increasingly featured on restaurant menus, food magazines and televised cooking shows.

A lot of consumers want to try the different flavours and reap the reported natural health benefits of

is experiencing a shift, with native Australian ingredients becoming an increasingly popular choice.

Australian native ingredients, once overlooked, are now sought after by chefs and food manufacturers worldwide. Australia is host to many native crops; however, sustainability and continuity of supply plays a key role in product development.

Earlee’s product development technologists understand this consumer demand and trend and we work with Australian native suppliers to understand the supply, availability, and sustainability of ingredients.

Once a supply has been secured, the creative fun can begin.

Some of the Australian native ingredients that have recently been incorporated into products include Saltbush, Lemon Aspen, Mountain pepper leaf, Davidson Plum, and finger lime.

ingredients not only brings new tastes but also helps in preserving the country’s rich culinary heritage and supports Australian small and developing businesses including indigenous businesses.

Provenance of Australian ingredients

Provenance of Australian native ingredients are also important to consumers and retailers.

A strong aspect of research at Earlee Products is exploring ingredients native to Australia and establishing provenance information and narration around such. Supplier relationship is key in defining the provenance of ingredients.

Some ingredients with strong provenance narrative within Australia which appeals to consumers and retailers is Australian honey, native ingredients, sugar, garlic, salt, and some pepper varieties.

INGREDIENTS 28 Food &Beverage Industry News | March 2024 | www.foodmag.com.au

Earlee Products continue to emphasise the benefits of sourcing ingredients locally.

Images: Witristock.adobe.com

Clean label claims

Consumers and retailers are scrutinising labels more so than ever before. Earlee’s development process uses ingredients that are easily identifiable and achieve the desired outcome with the motto of less is better.

“Retailers and consumers are increasingly looking for more clean label products, the lesser ingredients on the label the better. Especially around preservatives and alike,” said Reid.

Sauce concentrates which is a range of products that are currently being expanded, taste authentic as they do not rely on acidulants for preservation, instead the development finesse focuses on refrigeration and specifically selected ingredients for preservation. Secondary preservation is not required.

The development of clean label products uses natural physical and culinary aspects of ingredients rather than the overuse of starches and hydrocolloid thickeners to achieve consistency.

Earlee Products have developed a clean label injection system for water retention and succulence in processed meat products. This is appealing within the current market.

Earlee Products strives to provide

non-allergenic products.

There are also a range of natural flavours at our fingertips, for example, umami, yuzu, fried onion, and matcha.

Country of Origin – Australian ingredients

“The last thing we want to do is tell our customers we can’t deliver because of a delay in one vital ingredient,” said Reid.

To avoid this, locally sourced ingredients are critical, while also addressing the demands of consumers looking to support local. By doing so, the manufacturer and retailer are able to address several areas of concern for some consumers. Including:

• Satisfies consumer and retail demand

• R educed freight from abroad

• R educes environmental impacts from excessive shipping

• Supports Australian economy and local businesses

• R esponsiveness and quick turnaround from order to delivery is achieved through minimal delays in transport

• R educed packaging

Brett McMullen, general manager, Earlee Products, said the impact of COVID-19 on international shipping and logistics has had a long-term flow

on effect when it comes to provenance of ingredients, beyond supporting local.

McMullen said as many brands found themselves with stock and ingredients shortages, those who were able to source locally were also able to remain on the shelves. Which had a positive impact for the brands.

“It was the consistency of supply which really helped them,” he said.

“The providers who are able to ensure their offerings were on the shelf garnered some loyalty from consumers. Even if they switched to it during the COVID19 pandemic. The product won them over and they may have stuck with it.”

This demonstrated that consumers were willing to switch allegiance to other brand’s products if the circumstances were right, which bleeds over to provenance and quality of ingredients supply.

Low sodium, low sugar claims

Consumers are always on the lookout for ingredient labelling that has reduced sugar and sodium content.

With this in mind, Earlee’s product development team have a range of ingredients within their palette.

Finding alternative to boost flavours include yeast extracts, natural flavour

enhancers to enhance the perception of saltiness without the addition of sodium.

A strong supplier relationship is crucial in staying abreast of ingredient options and availability.

Earlee Products continues to build a strong reputation for developing innovative new solutions for food manufacturers looking to value add with premium elements without a huge capital investment.

Lea Reid, Research and Development manager, Earlee Products, said it was a critical part of the company’s approach, and success, to intrinsically understand the needs and goals of customers.

“The first part of delivering ‘the brief’ is accurately understanding it. No two briefs are the same and each customer comes with their own unique requirements,” said Reid.

“We at Earlee Products, are all about building close relationships with our customers and understanding on a deeper level what our customers want to achieve and how they envision the end product to be.”

Accurately understanding the goals and needs of customers’ is always a critical part of Earlee Products’ approach and success in the food and beverage manufacturing space. F

INGREDIENTS www.foodmag.com.au | March 2024 | Food &Beverage Industry News 29

The impact of clean label products is another area where Earlee Products encourages manufacturers to lean into.

Images: TensorSparkstock.adobe.com

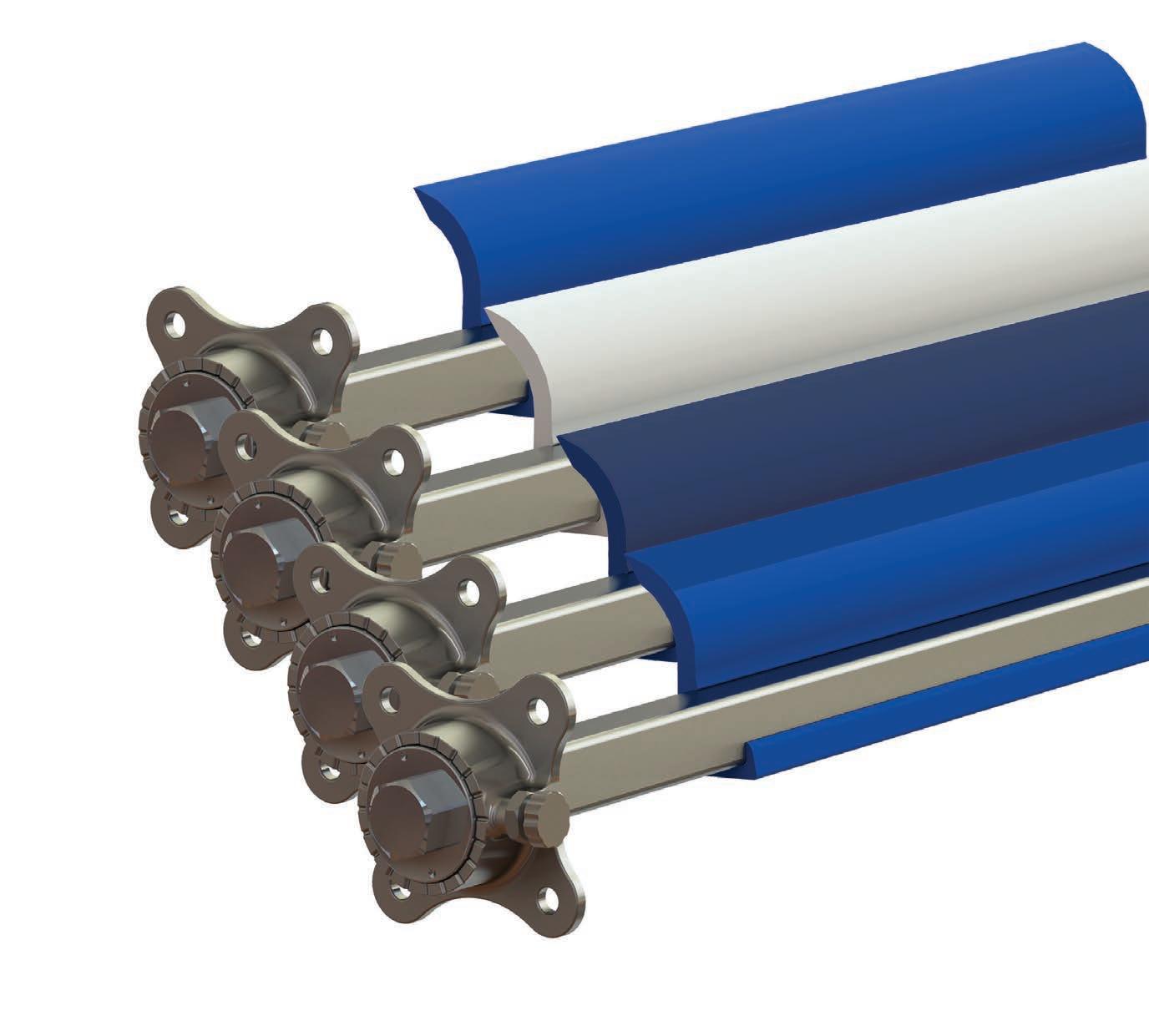

VEGAPULS 42: Helping advance non-contact level measurement

The VEGAPULS 42’s innovations stand out, particularly in hygiene-sensitive industries such as food and beverage manufacturing, Food & Beverage Industry News reports.

VEGA, a stalwart in measurement technology with over 30 years of industry experience, further solidifies its position as a one of the leaders in radar technology with the VEGAPULS 42.

This addition to VEGA’s radar level portfolio epitomises compactness, communicativeness, and user convenience. The innovative solution is designed to streamline operations in fast-paced industrial environments, offering enhanced functionality and ease of use.

With the VEGAPULS 42, VEGA continues its commitment to delivering cutting-edge technology that meets the evolving needs of modern food and beverage manufacturing processes.

Leveraging an in-house developed radar chip renowned for its wide dynamic range and versatility, VEGA brings top level expertise to factory automation for industries characterised by strict hygiene standards, such as food and beverage manufacturing.

“Our customers can rest assured that they’re in good hands with us for all their applications,” said VEGA product manager Marvin Moser.

“This requires us to proceed with the greatest care. For that reason, we’ve carefully integrated cutting-edge technology into all the main functions of this sensor. At the same time, we’ve consistently refrained from ‘overdesigning’ the sensor.

“That means it has also been stripped of everything that makes it unnecessarily expensive and technically over-complex.”

With its versatile features and cutting-edge technology, the VEGAPULS 42 is poised to help reshape how liquids and bulk solids are measured in both simple and moderate applications. Making it ideal for manufacturers of any size.

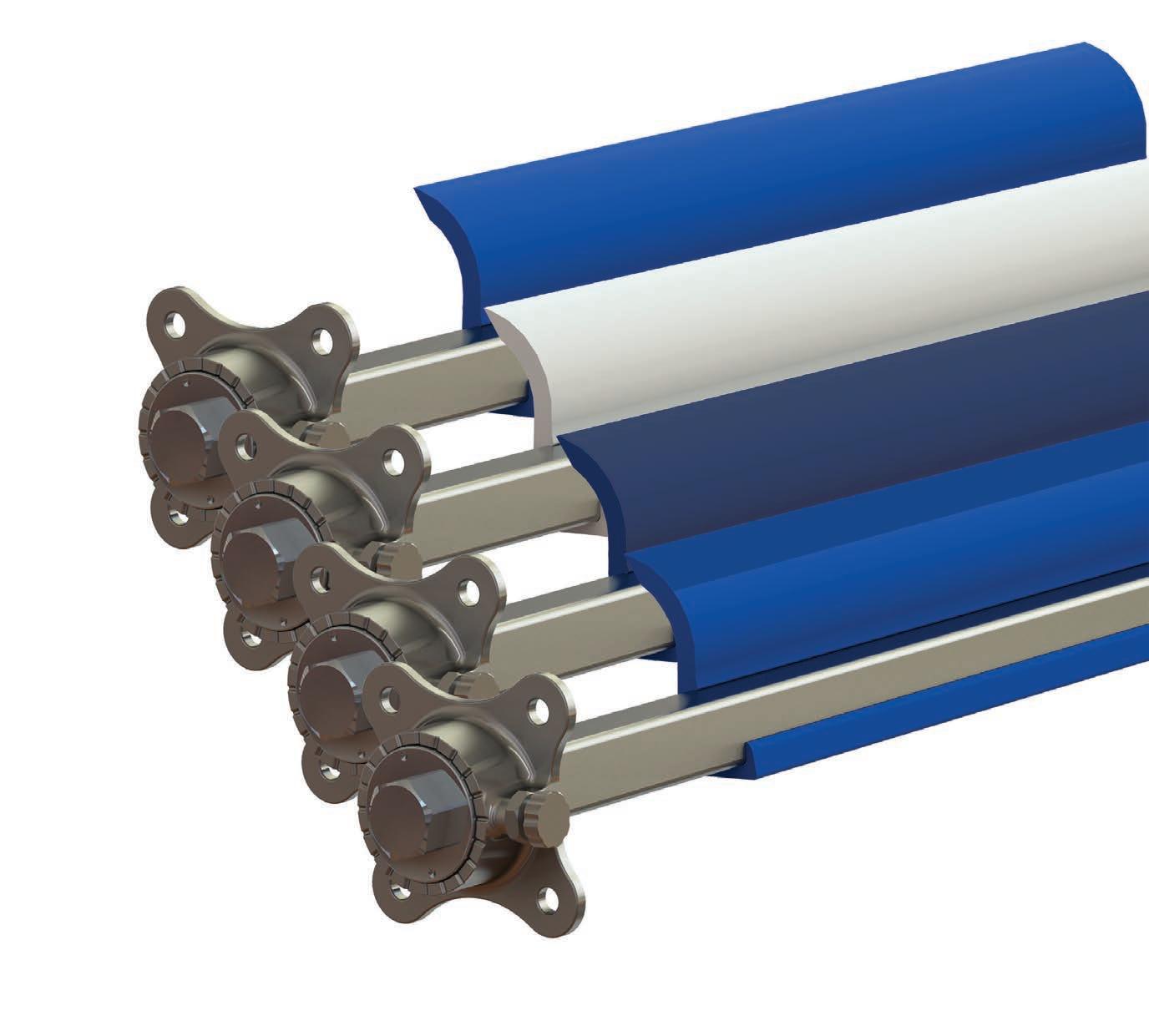

At the heart of the VEGAPULS 42 lies its unique “3/4 thread” universal connection, boasting compatibility with G1” hygiene adapters.

One of the standout features of the

VEGAPULS 42 is its compatibility with a range of interfaces, including IO-Link, PNP/NPN, and 4-20 mA (active).

Designed to seamlessly integrate with IO-Link, the VEGAPULS 42 radar level sensor represents a significant advancement in measuring tasks within factory automation. Offering expert interaction of speed, simplicity, and affordability, this sensor addresses the intricate needs of modern industries with finesse.

This adaptability also ensures seamless integration into existing control systems, empowering users with continuous digital data transmission capabilities, which is invaluable to food and beverage manufacturers.

Furthermore, the sensor’s hygiene approval underscores its suitability for applications where cleanliness is paramount, providing peace of mind

to food and beverage manufacturers.

With a measuring range of up to 15 meters and the ability to withstand temperatures of up to 150°C, the VEGAPULS 42 caters to a diverse range of applications, including cyclical production, dosing processes, and downstream operations such as conveyance and filling systems

This design not only streamlines installation processes but also minimises stock-keeping requirements, offering a practical solution for industries seeking efficiency without compromising on quality.

Another key advantage of the VEGAPULS 42 is its intuitive coloured 360° status display, which can be easily adjusted to suit the specific requirements of the user.

This feature not only enhances visibility but also helps to simplify

monitoring, which in turn helps operators to assess levels with precision

In addition to its user-friendly interface, the VEGAPULS 42 also boasts maintenance-free operation, thanks to its non-contact 80 GHz radar technology.

This ensures reliability and longevity, minimising downtime and maximising productivity, an invaluable asset in industries where every minute counts.

By enabling continuous level detection without direct contact with the product, the sensor remains resistant to process and ambient conditions, which helps increase reliability.

As manufacturing processes evolve to meet the demands of the digital age, the VEGAPULS 42 radar level sensor provides a solution that can keep up.

Its streamlined configuration prioritises simplicity, making it the preferred solution for standard applications where complexity only hinders efficiency.

Whether it’s monitoring liquid levels in a food processing plant or managing bulk solids in a pharmaceutical facility, this sensor is more than up to the task with high levels of efficiency and accuracy in hygienic applications.