Bearings to brilliance

Timken’s solutions keep you moving

Timken’s solutions keep you moving

• Unmatched bearing performance

• Corrosion-resistant materials

• Durable and easy to clean

• Food and safety compliant

• Lubrication-free design for easy maintenance

CEO: John Murphy

COO: Christine Clancy

Managing Editor: Syed Shah

Editor: Adam McCleery

Ph: (02) 9439 7227

adam.mccleery@primecreative.com.au

Design Production Manager: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Michelle Weston

Sales/Advertising: Stephanie Suzuki

Ph: +61 422 046 711 stephanie.suzuki@primecreative.com.au

Production Coordinator: Janine Clements

Ph: (02) 9439 7227 janine.clements@primecreative.com.au

Subscriptions AUS NZ O/S

1 year subscription 99 109 119

2 year subscription 189 199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

As our technology and innovation continues to evolve, so do the capabilities of automation. Automation technology is permeating more and more of the average person’s life, however the impact it is having on the food and beverage industry is far starker.

growth and in turn, greater output and hopefully greater profit.

T he list of advantages to employing for automation on in the manufacturing process is a long one, and one we could spend a great deal of time on, but that is what the rest of this magazine will do instead.

Copyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2019

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive Docklands VIC 3008

Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office

Suite 303, 1-9 Chandos Street

Saint Leonards NSW 2065, Australia

Ph: (02) 9439 7227

We still remember the days when many of our daily routines were still dictated by the analogue. At the checkout, the bank, in school. This remained true for manufacturing, of which many of today’s methods would look alien to those in the past. And automation is helping drive this change.

In this edition of Food & Beverage Industry News we have a renewed focus on the role of automation in the industry, from flow measurement to warehouse stackers, and so much in-between. Automation is changing the face of the industry.

Prior to the COVID-19 pandemic the perception around some automation was looked at with suspicion, for taking jobs or making certain professions obsolete. But what has been shown in recent years is the employment of automated technologies benefits both the company and its employees by allowing a re-distribution of labour across the business.

Effectively allowing the existing staff to apply their skills to other key areas, or to upskill and help grow the company quicker. Combine this with the obvious advantages of automation, great output, lower downtimes, basic risk mitigation, and the benefits to manufacturers and producers is clear.

The fact is that technology never slows and combined with the difficulty of trying to stop progress, the industry has now eagerly adopted innovations around automation without fear of its potential impact on traditional processes.

T he more widely employed these technologies are the quicker they can be improved upon, leading to faster

In other news, after the collapse of the RedCycle recycling program, industry bodies and the supermarkets themselves have committed to correcting the issues. Recycling is key to a circular economy, which is a goal of the food and beverage industry. So, seeing stakeholders looking to improve on past mistakes is a positive sign.

The food and beverage industry are in a unique position to capitalise on recycling programs, especially in the packaging sector, where materials can be used and reused to great effect. The more the industry, and key stakeholders, continue to develop recycling programs the better it will be for packaging companies working towards alternative solutions.

2D barcodes present a clear example of a modern innovation which is set to change the way manufacturers, producers, and consumers view the food and beverage market.

Fifty years after the adoption of the linear barcode, the next phase of bar coding is already proving to be a perfect tool when it comes to automating a host of aspects, including provenance, and logistics. What’s most exciting is the full potential of 2D barcodes is yet to be realised.

Automation will continue to dominate the future of industry, and society, and the food and beverage industry has already shown a keen willingness to adopt new technologies that promise risk mitigation, less downtime, great production, and efficiency. Just to name a few.

I for one look forward to what the future holds for the food and beverage industry.

Happy reading!

Printed by: Manark Printing

28 Dingley Ave Dandenong VIC 3175

Ph: (03) 9794

One of the top manufacturers of monitoring devices for many automation systems is Kobold Instrumentation, a leader in the field of instrumentation engineering globally. The KAL range is a single flow sensor/switch that is free of moving parts and consists of stainless steel for all wetted components, making it ideal for the food and beverage industry.

Our strength comes from high-quality distribution partners who manage installation, service, technical support & training nationwide. As you plan for the future, let our experience guide your success.

8

20 MEET THE MANUFACTURER

Hemp Foods Australia is riding the wave of popularity around the product.

24 BEARINGS

Timken specialises in helping food and beverage manufacturers reduce downtime with the right bearing solutions.

26 FLOW MEASUREMENT

Kobold’s KAL suite of flow meters have been developed to address key issues around pressure loss and hygiene.

28 CONVEYORS

Flexco Australia continues to provide the industry with key experts across conveyor belt technology and solutions.

30 DIGITISATION

Fifty years since the introduction of the linear barcode while 2D barcode technology continues to impress with its capabilities.

32 MANUFACTURING

The latest offering from Krones was developed with particular focus on environmental compatibility, and improved efficiency.

34 PACKAGING

Favourite Packaging’s Printed Rewind presents a string of benefits which help to drive costs down.

36 AUTOMATION

Optek photometric analysers present an ideal solution for brewers and winemakers.

38 AUTOMATION

Using Combilift’s Pedestrian stacker and automated racking systems has the capacity to maximise space.

40 WASTEWATER

Aerofloat continues to help clients with wastewater solutions.

42 COLD STORAGE

Cushman & Wakefield is hgelping to address cold storage demand.

44 BIOGAS

Eneraque are experts in converting waste gas into energy, and the technology has continued to evolve and gain in popularity.

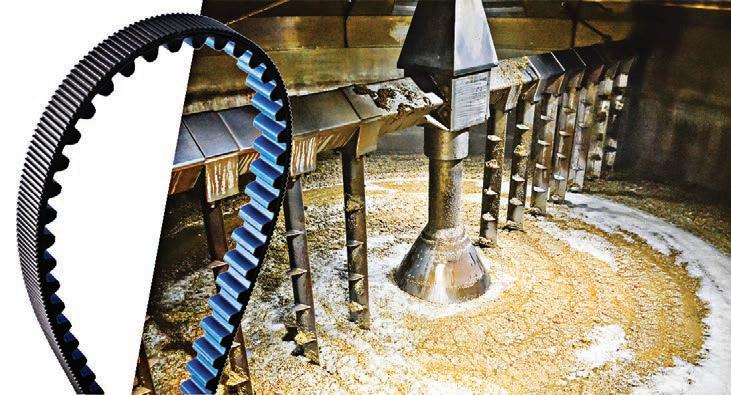

46 BELT SOLUTIONS

Brian Crouch and Rob Michaelson of Belt Solutions for Motion Australia have more than 50 years’ experience in improving production.

48 COMPRESSORS

Avoid the costly effects of air compressor links with the use of the ifm moneo platform.

50 MAINTENANCE

The 1800 HOSE VAN initiative provides mobile hydraulic repair and installation service.

52 AUSTRALIAN INSTITUTE OF PACKAGING

53 DAIRY REPORT

Kerry has announced that electricity in its Australia sites is now fully aligned to 100 per cent renewable sources.

The renewable energy strategy is one of many initiatives towards achieving Kerry’s Scope 1& 2 carbon target, which was updated in 2021 to reflect the need for bolder, more ambitious action — adopting a 1.5 degree aligned target approved by the SBTi for a 55 per cent emissions reduction by 2030, compared to its 2017 base year.

“This milestone demonstrates our commitment to investing in Australia and marks a key chapter in our journey to net zero,” said Christine Giuliano, GM & Commercial Lead for Kerry Australia and New Zealand.

“We strive to deliver to our

customers in a sustainably responsible manner, co-creating solutions to achieve a lower environmental footprint, while supporting local businesses in Australia.”

“This is a great step forward in our Sustainable Nutrition strategy towards supporting renewable energy throughout our Australian sites,” added Daniel Campion, sustainability lead for Kerry Asia Pacific, Middle East & Africa.

“It allows us to help reduce our own footprint and our contribution to our customers’ footprint, as we play our part in helping to limit global warming to 1.5° towards a better planet for future generations.”

The electricity procured through this five-year contract with Diamond Energy is linked to renewable energy certificates

The Australian Food and Grocery Council has welcomed the Soft Plastics Taskforce’s recognition of the industry-led National

Plastics Recycling Scheme as the model for the future of soft plastic packaging recycling in Australia.

AFGC CEO Tanya Barden

congratulated the Soft Plastics Taskforce, comprising major supermarkets Coles, Woolworths and Aldi, for setting out the Roadmap for restoring soft plastics recycling.

Return-tostore collection will be reintroduced as a transitional solution and the Taskforce supports the NPRS as a model for a sustainable, long-term solution to divert more plastic packaging from landfill.

AFGC CEO Tanya Barden said the Taskforce Roadmap has highlighted the importance of increasing Australia’s soft plastics recycling capacity and developing end markets for recycled packaging content.

The effects of limited markets for recycled soft plastics were made clear with the collapse of REDcycle –which collected less than five per cent of consumer soft plastics, leading to disappointment across the industry.

“The AFGC agrees that there is a crucial opportunity now to rethink

the model for soft plastics recycling in Australia,” said Barden.

The NPRS is being developed by the AFGC with funding support from the federal government and leading food and grocery manufacturers, and is now undergoing trials in Victoria, NSW and South Australia.

“The NPRS is a whole-of-supply chain plan that makes soft plastic recycling easy for consumers with kerbside collection. It has also stimulated commitments to invest in new advanced recycling infrastructure here in Australia,” said Barden.

“Manufacturers, local councils, waste collectors and processors, advanced recyclers and plastics manufacturers are united in this plan for sustainable soft plastics recycling.

“Australia’s food and grocery manufacturers are committed to growing Australia’s recycling and circular economy infrastructure. The model for a soft plastics solution exists.” F

Australian farmers and food producers will have an expanded footprint and access to more customers in Asia thanks to a major export deal facilitated by Austrade between Coles and Thai retailer, Central Food Retail.

Coles will provide the supermarket chain more than 200 products from its Coles Own Brand range, with more than 98 per cent of the offering either Australian-made or with Australian ingredients.

T he deal means more Australian farmers, agri-food and beverage producers

now have the opportunity to supply their goods to a dynamic and desirable market.

Australian Senior Trade and Investment Commissioner in Bangkok, Mr Michael Helleman said he was thrilled that the Thai people, Australian tourists, travellers and expats longing for a taste of home will have access to Australian-made food and drinks – as well as giving a boost for farmers back home.

“Australia has a hard-earned and deserved reputation for clean, green, safe and reliable agricultural produce and food products, and it is very clear there

Austrade is also supporting Coles across other markets in Southeast Asia like Singapore, Philippines, and Malaysia.

is a growing appetite for these items in Thailand,” said Helleman.

“Austrade has been supporting Coles in Thailand since 2019 with introductions to buyers for their fresh

produce, meat, and grocery products. In 2021, Austrade facilitated the introduction to Central Food Retail and it’s great to see more Australian products making their way into Asia with the help of Austrade.”

The launch of the Coles Own Brand range in Central Retail was marked at a Taste of Australia event in Bangkok.

Austrade is also supporting Coles across other markets in Southeast Asia like Singapore and the Philippines, and. A Coles spokesperson said the supermarket with thrilled to enter the Thai market. F

The Soft Plastics Taskforce has released a Roadmap to Restart, outlining the steps needed to launch a new supermarket soft plastic collection scheme, and the current state of play in the Australian recycling industry.

T he Taskforce has been tasked with developing an interim solution to restore community access to soft plastic recycling following the suspension of the REDcycle program.

Under the current plan, an initial in-store collection pilot is anticipated to launch in select stores in late 2023 – provided that REDcycle’s existing soft plastic stockpiles can be cleared prior. The new program would then be gradually rolled out nationwide next year.

W hile the Taskforce is working to launch in-store collections urgently, it is severely constrained by Australia’s limited access to domestic soft plastic recycling which can manage the “mixed polymer” soft plastics that are deposited by the public in supermarket collection bins.

At present, it would not be possible to recycle the volume of household

soft plastics collected in a supermarket program using domestic infrastructure.

Accordingly, the Taskforce has plotted out the projected gradual increase in Australian soft plastic recycling capacity over the next year.

From late 2023, the Taskforce will meet the newly available processing capacity with a staged re-introduction of in-store collections so that the volume of incoming household soft plastics does not exceed the amount that can be recycled – as occurred with REDcycle.

T he current timeline to launch an in-store collection pilot by late 2023 is contingent on the ability to clear REDcycle’s existing stockpiles of soft plastic, which Coles and Woolworths have recently been granted control of.

Should new domestic processing capacity be taken up by the estimated 12,000 tonnes of stockpiled material for at least a year, the recommencement of in-store collections will be delayed.

Accordingly, Coles and Woolworths intend to work through options to export the stockpiles to trusted recycling facilities overseas with the necessary transparency, traceability and

government approvals.

This would allow access to advanced recycling beyond Australia’s existing domestic capabilities.

that less than five per cent of consumer soft plastic was collected by the REDcycle program. F

Brunswick Aces Distillery has welcomed Gurdeep Dhaliwal as Co-Owner and Director of Global Sales, as part of the brand’s international growth strategy.

Gurdeep brings more than 15 years of experience in drinks and FMCG leadership to the role, most recently being Director of Sales On-Trade Premium Europe and India at BRITVIC PLC, growing Britvic’s premium brands, including London Essence and Mathiue Teisseire, across 35 countries.

Gurdeep will be based in the UK focussing on international growth opportunities, building on the success achieved to date in Australasia.

His immediate focus is growing the presence of Brunswick Aces’ unique portfolio of 40 per cent gin and 0 per

cent sapiir (gin alternatives) in both On and Off Trade across Europe.

Brunswick Aces co-founder and CEO, Stephen Lawrence, said Gurdeep would bring a unique skill set and fresh approach to the brand’s international growth, and be the brand’s first senior hire outside of Australia and New Zealand.

“Given Brunswick Aces unique dual offering within the gin and non-alcoholic markets, Gurdeep’s appointment will allow us to grow rapidly in some key international areas,” said Lawrence.

“Having Gurdeep on the ground in the UK will have a positive impact on our presence globally, and allow us to build stronger relationships in the market utilisng his impressive experience.

“Our existing foundations in Australasia and North America, means that we’re in a strong position to enter

the European market in 2023 and 2024, bringing a uniquely Australian offering to the region as a point of difference.”

The West Australian distillery that won two of the world’s most coveted gin awards on February 24 has set equity crowdfunding records overnight when it opened to investors during its private round.

Old Young’s Distillery became equity crowdfunding’ biggest WA raise ever, the biggest raise in Australia this financial year, and the biggest alcohol raise ever in Australia.

Old Young’s was also the fastest to $2m in WA, reaching the target after 6h 45mins. It’s $2.7 million target was achieved after 23 hours.

When the Swan Valley distillery won its massive haul at the Icon of Gin awards in London online sales for the brand spiked by 560 per cent.

‘Expressions of interest’ in its Birchal equity crowdfunding raise almost doubled from 1,722 to 3,303, with an average EOI investment amount of

$3,633, which is almost 3 x the average Birchal figure of $1,300.

According to Birchal, having EOI enquiries spike so dramatically in the back half of the campaign is almost unheard of, especially when an average campaign gets only 800 enquiries.

“Winning Craft Producer of the Year and Brand Innovator of the Year at The Icons of Gin competition in London was a definite career highlight, but to win it midway through a capital raise is biblical – I swear someone is looking after me above,” said James Young of Old Young’s Distillery.

“Setting all these records is icing on the cake of an already spectacular month. This is the first time an Australian distillery has ever won Craft Producer of the Year, and only the second time an Australian gin producer has won Brand Innovator of the year –Four Pillars winning the category in 2022.” F

The modern plant needs more than condition monitoring to ensure assets are healthy and meeting production demands.

To support a successful predictive maintenance program you need realtime streaming analytics.

ifm’s moneo is an easy to use, self service software platform that simplifies the integration of Industry 4.0 concepts into existing systems.

The in-built DataScience Toolbox enables operators and engineers to leverage their knowledge of equipment with the benefits of AI-assisted predictive analytics and machine-learning techniques. This empowers businesses to identify and remedy anomalies before they become expensive, big problems.

Wonder has announced the return of the Wonder Recycling Rewards program for a third year in a row – a fun and easy recycling program for Aussie schools to participate in.

Through a new partnership with Victorian based recycling organisation APR Plastics, Wonder is making strides in developing a circular solution for their bread bags, and creating a more sustainable future for generations to come.

APR Plastics helps Wonder in their mission of creating a circular economy for soft plastics through the use of their ‘WASTX’ pyrolysis technology that breaks down the plastic waste collected to create an oil that can be used to create new food grade plastics.

For Aussies, saving a bread bag from

landfill might seem like a small action, but it can have a huge impact on

the environment. The Wonder Recycle Rewards

program encourages Aussie schools to recycle bread bags that might otherwise go to landfill in return for points for their efforts.

Points can be redeemed on new sports equipment that kids can play with – championing active play for kids.

“At Wonder, we’ve pledged to create a better future for Aussie kids to grow and thrive in. That’s why we’re thrilled to be bringing back the Wonder Recycling Rewards program for another year giving Aussie kids a chance to do good for the world whilst having fun,” said portfolio and marketing director, Christine Fung.

“It’s fantastic to be working with Wonder to continue the development of our circular economy,” added Advanced Pyrolysis executive at APR Plastics, Logan Thorpe. F

Norco, Australia’s largest and oldest dairy co-operative, is celebrating incredible recognition after taking home not one,

but two distinguished awards at Dairy Australia’s, Grand Dairy Awards 2023.

Norco has been acknowledged as ‘best of the best’ in Australian dairy

produce by a panel of esteemed cheese and dairy judges who spooned, nibbled and sipped their way through 320 products spanning 18 different categories.

Norco Pure Jersey Milk was awarded Champion in the milk category for its product excellence and quality in creating and delivering a truly distinctive pure jersey milk.

Celebrating a third award nod is Norco’s Real Iced Chocolate winning the Champion.

Judges were not only impressed by its decadent chocolate taste credentials but also for its outstanding milk quality and freshness.

Norco general manager of Commercial & Strategy, Ben Menzies said it is a great honour to have both products awarded Champion in the most prestigious annual Australian Grand Dairy Awards.

“The Australian Grand Dairy

Awards are the crème de la crème of dairy with both Pure Jersey and Real Iced Chocolate winning their way to the top through multiple state-based competitions,” he said.

The entire team at Norco are ecstatic with the praise we have received. It’s an absolute honour to be recognised on a national scale for our talent, hard work and the positive contribution we continually give back to our industry – which is the driving force behind everything we do.

“It’s wonderful to be recognised as dairy champions and Australia’s finest but it’s also a celebration of our 100 per cent farmer owned co-operative, its people and our farmer Members.”

The Australian Grand Dairy Awards began in 1999 to recognise excellence and innovation in Australian dairy produce whilst celebrating the skilled and visionary producers behind the outstanding products. F

JBS Australia has reopened its processing facility in Cobram, Victoria, to service the growing demand for lamb, goat and mutton proteins both in Australia and overseas.

The Cobram facility will operate five days a week with a capacity to process up to 4,000 head of livestock per day.

Initially, the facility will employ 150 team members with plans to increase to 350 team members, as JBS gradually upscales production.

“JBS Australia is proud to reopen its Cobram facility to support jobs and economic growth in the local community,” said Sam McConnell, CEO of JBS Southern.

“Today’s changed market conditions and increasing demand for lamb products has allowed us to invest in this fit-for-purpose facility which will partner with local businesses and livestock producers to deliver Australian lamb, mutton and goat to domestic and

international consumers.”

JBS is investing ~$20 million in the latest processing and safety technologies to restart the Cobram facility. The facility was last operational in 2017 and has been in care and maintenance mode since, consistent with the company’s objective to re-open it once market conditions supported its sustainable operation.

As part of the Great Southern and JBS Australia businesses the Cobram

facility will focus on delivering against a range of sustainability targets including CO2 reduction, water and energy conservation and people safety.

“JBS Australia is pleased to have the opportunity to work alongside the Cobram community again. This reinforces our commitment to continually invest in Australia, our facilities, our people and local businesses,” said Brent Eastwood, CEO of JBS Australia.

The Shire of Murray’s Food Innovation Precinct Western Australia (FIPWA) has been officially opened heralding the formal start to activities in the agrifood centre. The state-of-the-art precinct- known as ‘Mereny Bidi Boodja’ which means ‘food, pathway, land/country’ in the local Noongar language- is an ecosystem

for innovation in the agriculture and food spaces. It is made up of a food and beverage production centre with a food technology facility, an Innovation Centre and a Research and Development Centre.

and has attracted further significant investment from the State Government to establish a common-use Food Technology Facility within the precinct. Anchor partners already using the precinct include:

destination for food professionals and researchers committed to advancing knowledge and production of food that is both good to eat and good for you. Murdoch University is using the facility in collaboration with the national research, industry and Government consortium, the Future Food Systems Cooperative Research Centre, for projects that help businesses to satisfy increasing demand for sustainably produced products.

• T he GrowHub, a Singapore-based innovation business supporting Western Australian food and agricultural businesses access international markets

• Spinifex Brewing Company, who champion Indigenous culture through infusing native Indigenous botanicals into craft beers.

There has been widespread business interest in the Food Innovation Precinct WA since its development and the complex is open to interested parties throughout WA, interstate and overseas from the commercial, public and academic domains to advance and accelerate agrifood, food, and beverage innovations aiming to capture new market demand. F

The four-year automated strawberry picking effort is being delivered through Hort Innovation and led by the Department of Agriculture and Fisheries Queensland (DAFQ).

Strawberries specially bred for automated picking will soon become a reality in Australia after the launch of an initiative to develop varieties that can be easily harvested by robots.

Hort Innovation chief executive Brett Fifield said recent data shows the horticulture workforce has decreased by 20 per cent over the past three years, which has resulted in 40 per cent of Australian growers adopting advanced machinery.

“The development of a sweet, rich red and aromatic strawberry that is ideal for automation will prove a game changer for growers who want to apply

new technologies on-farm,” he said.

“While harvesting strawberries using automation is not common practice yet in Australia, it will be before we know it.”

Fifield said Hort Innovation is working with tech companies and researchers on various horticulturerelated automation projects, and scoping discussions with the berry industry to identify opportunities for technology adoption is underway.

Department of Agriculture and Fisheries Queensland principal plant breeder Dr Jodi Neal said the program will reduce the time needed to pick and pack strawberries, resulting in a more profitable outcome for growers.

“It takes the same amount of time to pick a small strawberry as it does to pick a large one,” Dr Neal said.

“This breeding program is focusing

on delivering a consistent fruit size that is preferred by consumers on unbranched flower stems – meaning

that the fruit can be picked faster –either by conventional methods or through automation.” F

PepsiCo ANZ has announced paddock-to-product partnership, productivity and profitability of systems groups, with support from Mars Petcare, Kellogg, Manildra Group, Allied Pinnacle, Corson, Charles Sturt University and the Food Agility CRC.

PepsiCo sources more than 7,000 tonnes of Australian canola oil annually to make its major snack brands such as Smith’s and Doritos. The majority of the canola used by PepsiCo is sourced from regions where the Cool Soils Initiative is active.

Joining the partnership will enable PepsiCo to contribute to supporting farmers in future-proofing their farming systems, while ensuring that PepsiCo can continue to source sustainably-produced canola from these regions into the future.

The farmer-focused approach of the Cool Soil Initiative also clearly aligns with PepsiCo Positive, an initiative that guides the business on how to inspire positive change for the planet and people. F

breeding program is focusing on delivering a consistent fruit size.The Cool Soil Initiative is a paddock-to-product partnership.

The gross value of Australian fisheries and aquaculture production is forecast to rise 8 per cent in 2022−23, according to the Australian Fisheries and Aquaculture Outlook 2023 report.

The report was released at the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES) Outlook 2023 Conference in Canberra.

ABARES executive director Jared Greenville said Australia’s aquaculture sector has been driving most of this growth.

“In 2022–23, aquaculture production value is forecast to increase by 11 per cent to $2.29 billion, driven by higher production values of salmonids, tuna and abalone,” Dr Greenville said.

“Fisheries and aquaculture production is forecast to remain relatively stable in 2023–24, valued at $3.7 billion.

“From 2023–24 to 2027–28, the real total value of fisheries and aquaculture production is projected to decline by 0.7 per cent a year to $3.44 billion by 2027–28,” Greenville added.

“This reflects lower projected real prices for seafood producers and an easing of growth in the volume of Australia’s aquaculture salmonids production.”

Dr Greenville said that the value of fisheries and aquaculture product exports is expected to increase by 7 per cent in 2022–23 to $1.37 billion, then forecast to rise another 7 per cent in 2023–24, to $1.47 billion. F

Food Standards Australia New Zealand (FSANZ) has updated Safe Food Australia to incorporate the new Standard 3.2.2A Food safety management tools, which comes into effect in December 2023.

FSANZ CEO Dr Sandra Cuthbert said the updated guidance for local government and food businesses was part of a suite of initiatives developed with states and territories to support strengthened food safety in the food service and retail sector to benefit consumers and protect public health and safety.

“Food service, such as cafes and restaurants, are integral to our way of life and are vitally important to the Australian economy. Many businesses do an excellent job in providing Australians with safe food.”

“The key changes to the standard are the requirements for training for food handlers and supervisors and substantiating key actions at critical points known to manage food safety risks,” Dr Cuthbert said.

“Food businesses have 12 months to implement the changes, which come into effect 8 December 2023.”

“I am pleased federal, state and territory governments are taking a joint approach to improving food safety standards across Australia and appreciate food businesses’ cooperation in ensuring consumers continue to have high confidence in the safety practices of the food service and retail sector.”

Food businesses are encouraged to contact their local enforcement authority for further information about compliance with the new food safety standards.

The Food Policy Index, first developed and implemented in 2017, benchmarks Australian governments on their implementation of globally recommended policies to

The Northern Territory Government has a long way to go in its efforts to address obesity and create healthier food environments, according to the latest scorecard of government performance

Professor Gary Sacks from Deakin University’s Institute for Health Transformation (IHT) who compiled the most recent report said greater policy action was required by the

“While we commend the government for the steps it has taken to support Territorians to improve their diets, including ongoing improvements in the healthiness of foods in hospitals and schools, there is still a long way to go,”

“Supporting efforts to improve the

healthiness of food retail outlets in remote Indigenous communities needs to be one of the top priorities for the NT Government.”

Professor Sacks said a key recommendation was to strengthen the existing healthy food licensing and accreditation scheme and apply it to all remote stores.

“The Healthy Stores 2020 study in remote stores has shown that restrictions on price promotions and product placement of unhealthy foods and drinks resulted in 1.8 tonnes less sugar being sold from 10 stores over 12 weeks – while not impacting store profits,” said Sacks.

“If this was extrapolated out across all remote stores over a year, the reduction could be as much as 90 tonnes less sugar a year, which equates to the weight of 60 medium sized family cars.

“Modelling suggests that this reduction in sugar could result in a 10 per cent risk reduction in mortality from cardiovascular disease.” F

SweeTango displays a bright red blush over a yellow cream breaking background and is the perfect fruit to enjoy with white wine and seafood on a late summer’s evening.

This crunchy, juicy apple will be dancing off the shelves in selected Woolworths supermarkets and greengrocers nationally from 27 February.

Minnesota who crossed Zester and Honeycrisp apples using non-GMO breeding techniques. In 2009, SweeTango apples appeared for the first time on the US apple market.

Montague began trialling SweeTango apples in Australia in 2017, before presenting to shoppers five years later.

Australian family-owned, fresh produce business, Montague is presenting its first apple variety of the 2023 harvest –SweeTango.

Having made its debut in Australian supermarkets just last year, this year’s hand-picked crop is three-times the 2022 volume (over 150,000 kilograms are expected to be harvested by season end).

SweeTango was developed by

Hort Innovation is set to invest nearly $1M to assess new citrus varieties that are suited to Australian growing conditions.

Funded by Hort Innovation’s citrus levy, the $987,000 project will provide independent assessment of the horticultural performance of new citrus varieties under Australian conditions, as well as testing citrus varieties for ‘trueness-to-type’.

The assessments will take place in Dareton in New South Wales, as well as in Western Australia.

Hort Innovation CEO Brett Fifield said the project will build on previous citrus variety projects, with the aim of measuring tree attributes that are desirable for Australian growers and consumers both domestically and overseas.

“Independent assessment of new citrus varieties — under Australian conditions — means growers will be able to identify new varieties that might suit their production regions. It will also help growers be aware of key consumer valuable input from the Australian citrus citrus

It is estimated that by 2030, over 2.9 million kilograms of this variety will be distributed to the market.

“Consumer feedback on this variety has been extremely positive and renowned chef, Yotam Ottolenghi even enjoyed the apple on his recent visit to Australia and posted on his channels,” said Angela Bracken, marketing

Hemp Foods Australia is presenting the market with an alternative source of proteins and ‘good oils’ normally found in more common products like meat and fish oil, to growing success. Adam McCleery writes.

As consumers continue to become more conscious of the foods they eat, food and beverage manufacturers have had to ensure they keep up with the growing and shifting demands.

Hemp based products have become a segment of the market which has experienced a growth in popularity off the back of shifting consumer wants and needs, and better education around its benefits.

Felipe Favaro, general manager at Hemp Foods Australia, a subsidiary of Elixinol Wellness, said the health benefits associated with hemp are obvious.

“The hemp seeds are highly nutritious so once they are dehulled they have roughly 30 to 33 per cent protein content and around 45 per cent good oils, like Omega-3, 6, and Iron. If you add that together we are talking about 75 to 80 per cent of two key macro ingredients that your body needs to consume regularly,” he said.

“On the protein side of things, the hemp has all the essential amino acids, all the essential mineral acids, and these are

nutrients your body can’t produce on its own, it must come through the diet.”

As a result, hemp-based products have the benefit of being appropriate for most, if not all, diets. Opening a huge segment of the market.

“For vegans, vegetarians, flexitarians, or people who just want to reduce their meat consumption, everyone can look at hemp-based products as a good source of their protein,” Favaro added.

“Hemp ticks all the boxes. On top of this, it is hypoallergenic, meaning there are no known allergies to that source of protein.”

A nd the same, Favaro said, is true of the essential good oils.

“Fish oil is popular because of the Omega’3’s that are present,” he said.

“Hemp is an alternative to fish oil where you can intake different kinds of Omega 3’s before your body does the transformation to the more well-known Omega-3’s.”

Favaro said the strong nutritional value of hemps-based products is the key selling benefits, along with the ling list of other micronutrients present.

because it tailors to so many people. For example, if someone has an iron deficiency.

“On top of that, it is low in sugar. There are no added sugars and only six per cent carbohydrates. It really does tick

recently secured and expanded national distribution deal with Woolworths which will see its Organic Hemp Gold Seed Oil go from being in 100 stores, to 948. Presenting a clear example of the growing popularity of the sector.

the boxes for so many different diets and diet requirements. It really is a super food.”

The ease of production is another area where Hemp Foods Australia benefits from its core ingredients.

The turnaround time for a hemp crop is very short, as is the production process itself, comparatively speaking.

“It’s a minimal process,” said Favaro.

“It’s similar to the macadamia nut where we remove the outer shell and

“This new national distribution deal with Woolworths is recognition of both the quality of our organic Hemp Gold Seed Oil and the increased demand for our superior quality, certified organic hemp food products from supermarket shoppers,” said Favaro.

“We are excited that many more people across the country will now be able to enjoy the taste and health benefits of our oil.”

Favaro said the growing popularity

“On the protein side of things, the hemp has all the essential amino acids, all the essential mineral acids, and these are nutrients your body can’t produce on its own, it must come through the diet.”Felipe Favaro, general manager at Hemp Foods Australia, said the health benefits of hemp products were numerous.

Hemp Foods Australia was a Regional Finalist in the 2022 Northern Rivers Regional Business Awards.

of hemp-based products will continue to present exciting opportunities for Hemp Foods Australia.

“Our aim is to deliver the most premium, nutritional products possible to make Australians healthier, inside and out,” he said.

“Hemp Foods Australia exists to make a positive difference to people, communities and the planet.”

Being named a Regional Finalist in the 2022 Northern Rivers Regional Business Awards for the Excellence in Innovation category was another acknowledgement of the great work Hemp Foods Australia was doing with its continued growth in the market.

However, it wasn’t always so easy for the company after it launched in 1999. Since then, Hemp Foods Australia

has had to overcome the stigma which existed, and to some extent still exists, around hemp.

“We have enough farmers for existing demand after things really kicked off in 2011,” said Favaro.

“Interestingly, at that point hemp wasn’t even legal here as a food here so it was hard to get farmers, which meant we had to import from overseas.

“To help us with breaking down the stigma associated with hemp and to show that it was a safe and nutritious product, we decided to go for a certified organic product because the ACO logo is well recognised and people value what it means, and they trust it.”

“We knew that would be good for us to help break the stigma with hemp.”

Sourcing from overseas also had

the added benefit of tapping into an extensive history of hemp cultivation.

“Those certified organic farmers have been growing hemp for a very long time and because of that they have a higher yield,” said Favaro.

“And because of this they compete well with other crops, we are still a little way away from having certified organic Australian grown hemp, but that is mainly because of cost.”

The quick turnaround time of a hemp crop is another key selling point to farmers, and a benefit to manufacturers like Hemp Food Australia when it comes to keeping up with demand.

“From a farming perspective, it’s anywhere between 90 and 100 days to grow and harvest the crop,” said Favaro.

“This means it works well as an in

between crop, which works particularly well for farmers on a rotational system.

“We have two product lines; one is 100 per cent Australian grown on a conventional grade product and we have caught up with the supply and demand on that one.”

Favaro said Hemp Foods Australia will continue to grow off the back of greater awareness around the benefits of hemp, and the growth of global hemp production.

“Our aim as a company is to make a positive difference to people, communities, and planets. The way we do this is by bringing delicious, nutritious, healthy, and sustainable food products to consumers,” he added.

A key innovation from the company came last year after working closely with an industry partner.

“It is a range of functional seed mixes with hemp, fruits, seeds, and nuts,” said Favaro.

“Two years ago, we also worked without partner to do an improved version of two of our three existing products, the hemp seed oil.

“Previously we were extracting the oil from the whole hemp seed but what we started doing is extracting from the dehulled seed which produces a clearer oil with a lighter taste and colour without losing any nutritional properties.”

It’s an exciting period for hemp-based production and the future continues to look bright for the sector.

To meet the growing consumer trend and increasing interest in plant-based foods and hemp products, Hemp Foods Australia will continue to launch innovative new food products throughout 2023. F

Combilift is the perfect fit for the grocery trade industry. Safely handle goods in narrow aisles, and minimise double handling with our multidirectional forklifts, articulated reach trucks and pedestrian forklifts.

Contact Us Today

To find out how Combilift can help you unlock every inch of your storage space

combilift.com

The Timken Company has more than a century’s worth of expertise in the bearing space and the Poly-Round Housed Units have benefited from this extensive experience. Food & Beverage Industry News reports.

The Timken Company, experts in engineering, friction management, power transmission, and material science, offers a range of solutions to the food and beverage industry, including cuttingedge bearing products.

The Timken Hygienic Poly-Round Housed Units are one of these top-ofthe-line offerings from the company, promising a string of advantages for its users.

The bearing unit also has a proven

and beverage industry.

Made from corrosion-resistant materials, Hygienic Poly-Round Units are resistant to common chemical and high-pressure washdowns, meaning there are no concerns around performance in a food or beverage manufacturing space.

The product design also lends itself to food safety requirements.

Available in optically detectable blue thermoset or stainless-steel housings, this design features a solid base, smooth

USDA-accepted hygienic housed units also comply with NSF/ANSI/3-A SSI 14159-1 – 2014 requirements.

Durable and easy to clean, lubrication-free Hygienic PolyRound Plain Bearing Housed Units are engineered to meet food safety standards.

The Timken Company promises a string of benefits from its solutions, from raising productivity through the Poly-Round’s greaseless design eliminating bearing re-greasing and can outperform ball bearings in many applications. Hygienic surfaces make washdowns easier and faster.

On top of this, the Poly-Round is easy to clean but is also offered with a QuiKlean housing design which helps to avoid dead volume between the housing base and machinery, allowing washdown from all sides.

Smooth housing surfaces with laser marking also allows for effective removal of residue and reduced

The blue thermostat housing mentioned above also has the added benefit of being optically detectable. Lubrication-free Poly-Round Plain Bearings also help to lower contamination risks by using fewer

And possibly one of the most important aspects of the Poly-Round is the adaptability of the product.

The Poly-Round is dimensionally interchangeable with most insert bearings, and the housed units offer a wide variety of polymer bearing materials and housing styles to fit your specifications.

The Timken Company worked with a major manufacturer of pickles after the manufacturer was experiencing constant bearing failures and lubrication issues on

solution based on the product’s ability to incorporate lubrication into its composition, while also being highly corrosive-resistant.

After the project was completed, it was estimated the solution saved the client more than $40,000 and counting.

A nother project Timken worked on saw the company help a client save $234,000 after applying one of its solutions to oven rollers. Prior to Timken stepping in, the client was re-greasing weekly and constantly having to find bearing replacements.

Once the Poly-Round solution was applied the life of the oven roller bearings was extended from three months to 15 months, it eliminated regular maintenance requirements and drastically reduced downtime.

An example of the Timken’s corrosion-resistant products is the application of it by a large potato peeler.

The corrosive nature of potato starch required frequent washdown at the potato manufacturing facility, which interfered with lubricating grease which in turn compromised the bearing performance. Reducing bearing life to as little as one month and only as much as four months.

As a solution, a “Timken Peeler Bearing” with nonrusting, corrosion resistance components with no grease requirements was employed.

This solution led to longer bearing life, from eight to 18 months, a reduction in maintenance, and more than $8,000 in savings over two years.

These case studies are clear examples of both Timken’s expertise in food and

The Timken Company provides cutting edge bearing solutions to the industry.

Company has a proven track record of improving output, limiting downtime, and extending the life of bearings within critical manufacturing machinery, all from the right selection of bearing solutions.

Timken’s product offerings and innovations are the result of more than 120 years in the bearing space, driven by a deep research and development department and strong commitment to deliver consistent, reliable product performance tailored to customer applications and requirements.

And Timken doesn’t just install and leave the customer too it, instead a dedicated team of service engineers are on hand to represent the company’s on-site customer support, helping deliver Timken’s value proposition.

These products are exclusive to Motion, CBC, BSC, and Webster BSC throughout Australia.

to not only improve processes but save on costs.

In terms of some of the best areas for Poly-Round applications in the food and beverage industry, there are several. From modular belt conveyors to dumper pivots, horizontal mixers, chillers, freezers, and bottling machinery.

Working with the Timken

The team comprises around 100 individuals across the globe, meaning no matter where the client is, Timken can help on-site.

The service engineers demonstrate and install products and parts, provide training and consultation, and employ their expansive knowledge and mechanical skills to troubleshoot and resolve urgent issues for customers.

Additionally, service engineers provide training and consultation on operation, maintenance, and best

practices that altogether improve customer productivity.

Essentially, the Timken Company walks clients through the process to help understanding, and continues

to help customers after installation, providing a full service for customers.

These products are Exclusive to Motion CBC, BSC and Webster BSC throughout Australia F

The latest suite of electronic flow monitoring devices from Kobold, experts in industrial measuring and control devices from the area of flow, pressure, level, and temperature, promises to address key issues around flow measurement.

The KAL Flow Monitor from Kobold is a single flow sensor/ switch without any moving parts that continuously monitors the flow of waterbased fluids.

The flow monitors are designed to communicate to an oversight system, such as a PLC, to ensure the automation process operates smoothly and that any significant change to the process medium flow is identified immediately.

The process connection is available in either threaded or sanitary 3A Ti-clamp options.

– Flow & Instrumentation at JSG Industrial Systems, said the KAL product line from Kobold addresses concerns he regularly hears from within the industry.

“When it comes to food and beverage applications there’s a host of requirements that typically most operators, companies, and manufacturers look for in their products,” he said.

unscheduled breakdowns.”

“The last thing anyone wants when producing a slurry, or beer, and other things of that nature, if you are measuring it, is for component fatigue over time and a component breaking off.”

Contamination issues caused by events like this have large impacts on food and beverage manufacturers, from down time to recalls, and possible

around and over time those items can fail,” added Slowgrove.

“The reason why they fail usually has more to do with temperature and age than anything else.

“Brittle plastics might eventually just snap over time due to continual wear; gear meters might lock up and seize. When it comes to food and beverage this is particularly risky.”

By creating the KAL suite of flow measurement devices Kobold has addressed these two key issues in one shot.

“The first two main issues in food and beverage manufacturing are hygiene, ensuring what’s inserted into the production line is hygienic. The second

damage to the brand’s reputation as a result.

“Typical flow metres are generally inserted into the process line, and they

“The KAL is designed with no moving parts, so straight away we’ve addressed the second issue in the sense you don’t have to worry about ongoing maintenance or repairs down the track, it’s a set and forget device,” said Slowgrove.

The suite of KAL product offerings from Kobold promise to provide solutions to common problems associated with the installation and use of flow meters in food and beverage manufacturing processes. Food & Beverage Industry News discovered.The KAL Flow Monitor is a single flow sensor/switch without any moving parts.

“This probe is constructed with stainless steel, there’s no rubber seals, no plastic, no joints where debris can build up and cause bacteria growth."

in the sense that no moving parts means it won’t impede the manufacturing process much.”

Kobold was also focused on the hygiene risks around flow measurement when designing the KAL range.

“We talk a lot about pressure loss and when you have moving parts you inevitably interrupt the flow stream,” said Slowgrove.

“This creates some back pressure in the line which might cause issues in the greater scheme of the production line, whether that is the pump having to work harder or at the end of a long hose might not reach the right flow rate to batch.

“By having minimal pressure loss, we are ensuring all the other systems involved are not being affected by this installation of this flow meter.”

This is where the KAL helps limit contamination risks from product failures.

“With this device you don’t have to worry about that because this device is inserted into the process line with a T-intersection, so to speak, which is a little probe. This addresses the first point I mentioned about hygiene concerns,” said Slowgrove.

“This probe is constructed of stainless steel, there’s no rubber seals, no plastic, no joints where debris can build

line is completely manufactured out of one piece of stainless steel.”

The product range has also been developed with clean in place processes in mind.

“A lot of manufacturing facilities, like breweries for example, might utilise a clean in place process which means at the end of the manufacturing cycle they might flush out the line with hot soapy water or a bit of solvents, while they clean the pipes internally with a high temperature washdown.” said Slowgrove.

Typically, when you do clean in place not every product that you have in the process line can handle that and sometimes components might need to be taken out or a bypass put in.

“The KAL doesn’t require anything like that. It can handle the hot temperatures, the chemicals, and it’s allowed to be cleaned where it sits without the need of repairs or pulling it out, it’s a set

The KAL’s digitisation and automation is what allows the pieces to be set up and essentially left to their own devices. Whereas in the past not physically checking up on a flow meter could result in a failure going unseen for some time.

“A lot of businesses always look for ways to ensure their products and processes are reliable,” said Slowgrove.

“You might insert a turbine meter

www.ams-ic.com.au

and forget about it, and it could break in that time. KAL emphasises ease of use, it is all electronic wants its set up.

“In the current world of industrial automation and the 4.0 industry changes everything is becoming digital and electronic and there are fewer moving parts.”

And the fewer moving parts, along with the capacity to limit its impact on pressure flow, makes the KAL an appealing option for flow measurement.

“There’s always going to be meters with moving parts because that’s how they work. Sometimes it works well and sometimes not so much. But you must think about the bigger picture.

“If you are going to introduce new elements to an existing and sustained system you could be creating other problems. What this device is doing is alleviating that, you still have to modify the pipe to screw or clamp on the KAL, but that is it.

“We are not impeding or effecting other devices and because it’s electronic its designed to integrate into the existing system.” F

AMS have been suppliers of instrumentation and calibration equipment to all industries since 1973 representing some of the world’s leading manufacturers of the equipment in their field.

“In the current world of industrial automation and the 4.0 industry changes everything is becoming digital and electronic and there are fewer moving parts.”The KAL Flow Monitor mitigates flow and hygiene risks.

Flexco Australia prides itself in taking a hands-on approach to fully understand food application challenges related to belted conveyors and applies this knowledge to create innovative solutions to increase production yield and uptime. Food & Beverage Industry News reports.

Wright said other presses could take as long as 45 to 60 minutes to cook the belt, resulting in unnecessary downtime.

“You can imagine what that is worth for a client in terms of production time,” he added.

We saw one client at a bakery experiencing difficulties with the splice quality on an older, water-cooled press. This was very expensive and timeconsuming for the operation.

Working closely with one of our distributors, we conducted site demonstrations of the Novitool Aero Press. The in-house crew was amazed by the ease of use and short splice time. All belts on site are now joined using the Novitool Aero Press, resulting in increased uptime”.

Food Grade Belt Cleaners are another area of product expertise for both Wright and Flexco Australia, helping to create a more sanitary production process.

“We design and manufacture our own products and then work closely with end users and our distributors both in Australia and globally to ensure our products are serviced to the highest standards.”

Flexco Australia, experts in belt conveyor solutions, continues to thrive in the belt conveyor solution space because of an ability to retain key experts and present cuttingedge conveyor equipment to the industry.

The recent promotion of Adam Wright to the role of national light duty manager, Flexco Australia, is a prime example of both.

Wright has been with Flexco Australia for 12 years and in that time his expertise around conveyor solutions has only continued to grow alongside the global company. Prior to this, Wright spent 5 years in Light Duty conveyors working for an industry leading belt manufacturer.

Originally working with Flexco in the heavy-duty mining industry in Western Australia, Wright was looking for a new career challenge and was thrilled to be promoted to the LightDuty National Manager last year which includes working with the food and beverage industry.

“Just about everything you touch has been on a conveyor,” Wright said.

“It’s an endlessly fascinating space and anyone who works within it will tell you the same.”

Right off the bat Wright’s passion for the space is obvious, and an example of the type of expertise the Flexco Australia team offer its clients.

“A lot of our products, here and globally, offer solutions for the food

industry,” he said.

Among those products are the Novitool® Aero® splice presses, which are used to join conveyor belts together.

“There are two ways to join a conveyor belt together. There is the fastener, which we have food grade versions of. However, the most efficient and most food sanitary way to join a conveyor belt is with a splice press,” said Wright.

“Traditionally presses used to join belts endless were time consuming and a cumbersome process that involved using water which could lead to contamination. The Novitool Aero Splice Press range eliminates these issues by offering an air-cooled, compact press with splice times as short as 8 minutes”.

The efficiency created by belt cleaners also makes them a great process solution for food and beverage manufacturing.

Flexco offers a variety of engineered cleaners that have been designed with tensioning systems that keep constant belt-to-blade contact, creating a highly efficient system for removing food materials from the belt either at the head pulley or in a desired location on the return side of the conveyor.

“Product lost is money lost,” said Wright.

“On a conveyor system, if any product falls onto the ground, or sticks to the belt, resulting in carryback, it becomes unhygienic and costly for an operation.

Increased sanitation and reduced

product loss are what our belt cleaners deliver.”

For example, large amounts of product waste were causing major concerns for a protein producer. Not only was the operation losing thousands of dollars of product a day, but the amount time of spent cleaning excess product off the floor was keeping their maintenance team from focussing on more important tasks.

After installing a Flexco Food Grade Primary Cleaner there was an immediate drop in carryback and unnecessary maintenance time.

The ability of Flexco Australia’s conveyor solutions to improve production efficiency is another key selling point, particularly with the current labour market.

“Everybody is time poor and the lack of skilled workers in the current environment is an issue for many companies throughout the industry”, added Wright.

“The more efficient we can make the manufacturing process, the more time operators can spend doing other tasks.”

Wright said a lot of customers had started to store Flexco products on-site, particularly with how easy the installation is with a range of our products.

“The fact you can do it within minutes is leading to sites keeping spares as a back-up plan in case technicians can’t get out there in time,” he added.

In terms of digital innovation, Flexco Australia is also heavily investing in

IIoT to help future-proof and improve conveyor processes.

“We have a remote belt cleaner monitoring IIoT system which has been transforming the way mining operations maintain their conveyor system,” said Wright.

“This technology is being rolled out in other products and it’s also something we are looking to integrate into our food sector offerings in the foreseeable future.”

As an example of Flexco Australia’s ability to stay at the cutting edge of conveyor solutions was its recent win at the Australian Mining Prospect Awards,

a sector which Wright was in before moving into his current role.

Flexco Australia was awarded the Excellence in IIoT Application Award for its Flexco Elevate Belt Cleaner Monitoring Technology.

This category recognises an outstanding implementation of IIoT that enhances mining and minerals processing operations. As Wright said, many of the elements which make Flexco’s mining solutions viable, also apply to food and beverage.

“The development of the Flexco Elevate solution was driven by real-world customer challenges. We really looked to

challenge the way conveyor systems have been remotely operated, by utilizing the IIoT device” said Carl Faulkner, contract Data and digital engineering specialist at Flexco Australia.

Wright also said Flexco has some of the best conveyor solutions he has seen.

“Our headquarters in the United States just recently expanded their new manufacturing facility with spaces built specifically for engineering and R&D”, he said.

“Our facility is the most impressive I have seen when it comes to manufacturing conveyor components.

For example, we have life sized heavy and light duty conveyors that we can run 24/7 to test new products.”

Wright said this approach is what helps Flexco continue to bring cutting edge solutions to the industry.

“When we bring a product to market, we make sure we go through the proper R&D process to ensure products exceeds customer’s expectations,” he said.

“We also have a manufacturing facility here in Australia and we’re incredibly proud of our Australian manufacturing capabilities and take pride in being able to employ people from our local community to create the best product for our customers”.

This global approach by Flexco has allowed it to stay ahead of conveyor trends and technologies for over 100 years and counting. F

To learn more about the value Flexco can add to your operation, Wright and the team will be showcasing their innovative products for the food and beverage industry at FoodPro July 23rd – 26th at stand S47.

50 years after the adoption of the linear barcode, 2D barcode technology continues to gain traction across the Food & Beverage Industry. Adam McCleery writes.

The power of 2D barcodes continues to be demonstrated across the food and beverage industry, but the full potential of the technology is yet to be achieved.

GS1 Australia chief marketing officer, Richard Jones, said in its 50th anniversary year, the linear barcode would continue to have a role, but that 2D barcodes, including Datamatrix and QR codes, will gain in popularity and prominence in many areas as their full possibilities are realised.

It was April 3, 1973, when an industry-wide agreement on the use of linear barcodes was agreed, revolutionising the entire industry.

From that point forward, a simple scan at checkout connected a physical product to its core information that could be shared in stores and throughout the supply chain. Since then, GS1 standards have powered more reliable and transparent supply chains across industries.

GS1 standards and services enable trusted, complete, and accurate product

identification, as well as data sharing. Better data still means better service.

Whether online or in-store, the ubiquitous GS1 barcode (GTIN) is still the trusted foundation for retailers and brands, helping businesses large and small to uniquely identify their products.

And now the roll out and continued innovation around 2D barcodes is set to have an even greater impact on the industry, Jones said.

“I don’t want to put a ceiling on the technology because, to be honest, we still don’t know the full potential of the technology,” he said.

“The sky is the limit.”

Among some of the key benefits of 2D barcodes includes strengthening supply chain efficiency and resiliency, reliable, verifiable product information, improved consumer experiences and brand loyalty, and compliance with regulatory requirements.

Among its many advantages, 2D barcodes are able to store large swaths of information, from batch and lot

numbers to expiry dates, ingredient information, and serial numbers.

2D codes also give producers, brand owners, and retailers, new and more efficient methods for connecting to consumers. A consumer can scan the code and instantly have access to a wide range of beneficial information.

As consumer demands around sustainably sourced products, along with healthier choices, the option to present this information at the supermarket shelf could prove invaluable. Especially when it comes to promoting brand loyalty.

One great feature is how a 2D, or QR barcode, can also strengthen food safety by alerting a customer that the product is out-of-date when it is scanned at the checkout.

Woolworths and selected suppliers who are now using 2D barcodes are achieving substantial results, including boosting food safety by restricting the sale of out-of-date items and reducing food waste by up to 40 per cent.

2D barcodes enable store teams to

more quickly and easily identify if a product is approaching its expiry date and proactively mark it down, so that the product can be sold without having to be disposed

The same traceability features could also prevent recalling larger amounts of product than is required, if required. Which can also save food from unnecessarily being sent to a landfill.

The encoding of a product’s batch, lot and/ or serial number into a 2D barcode can be used to identify affected products anywhere across the supply chain, so only those products need to be withdrawn from store shelves.

All other unaffected products can be saved and remain on the shelf for sale.

The capacity for 2D barcodes to store so much information will also allow for companies to look at making changes to packaging, because all the information can now be stored on a QR code which is much smaller than a linear barcode.

Information such as storage options, recycling instructions, origin and more can be taken off the packaging, freeing

on-pack space for brand owners to use differently, or allowing them to remove excessive packaging to save costs and reduce waste.

The technology is also expected to continue, and strengthen, the fight against food counterfeiting which continues to be a thorn in the side of the food and beverage industry.

There are two main types of counterfeits in the food sector. First, food fraud, falsification and adulteration, which refers to products made from ingredients that are not of the quality claimed by the manufacturer.

Second is the falsification of a brand, protected geographical indication (PGI) or denomination of origin (PDO), which relates to falsified data either on the food or the packaging itself.

“GS1 is stepping up to the plate on this with the introduction of nextgeneration barcodes, like 2D barcodes. GS1 has also introduced new global services around verification,” said Peter Carter, director of Business Development and Innovation at GS1 Australia.

Carter said too many myths revolved around 2D codes; myths he hoped would be squashed as the technology becomes more prolific.

“One of the things that we often hear from various angles is that 2D codes aren’t safe, and I’d like to kill that myth,” said Carter.

“The fact that so many people carry mobile phones now, and QR codes have been so widely accepted, particularly in our major markets in southeast Asia, is a good sign.”

Jones echoed the sentiments of Carter stating as consumers became more aware of the 2D barcode technology the quicker it would take hold.

“I think the sign in processes during the COVID-19 pandemic did show a lot of people that 2D barcodes are more than a novelty,” he added.

Some of the other key drivers behind the continued adoption of the technology was a trade-off between cost, speed, and effectiveness.

GS1 is uniquely positioned to support the industry with all the features of 2D codes as a means of protecting product and brand quality.

Public safety, even more than brand reputation, is another key driver behind the renewed push to stamp out counterfeit food, according to Carter, but the implications are still at the front of the mind of industry insiders.

For example, consumers are quick

to point out any issues around unlisted allergens being found in a product, generally after an allergic reaction, which has led to changes at the point-ofsale with frequent allergen warnings to protect the brand’s reputation through transparency.

“When you have falsification and

counterfeiting of food in that scenario you end up with a significant long-term issue,” said Carter.

Carter said the Australian industry could learn from global markets and apply that knowledge locally to respond well to this rise in consumer awareness around the benefits of the technology. F

The greatest potential for improving stretch blow molders lies in reducing energy consumption.

The new generation’s development involved special attention to environmental compatibility and to further improving efficiency and flexibility. Food & Beverage Industry News reports.

Environmentally friendly, sustainable, and cost-effective operation: That was one of the paramount goals for this latest evolution of the Contiform.

When it comes to stretch blow molders, the greatest potential for improvement in these areas often lies in reducing energy consumption in preform heating and, of course, in lowering compressed air consumption in the blowing process.

And Krones’ research and development team have made the most of these opportunities.

They’ve shortened the distance between the heaters, made the heating space even more compact overall, and redesigned the heaters with parabolic reflectors. As a result, they’ve cut energy consumption by 11 per cent compared to the previous generation.

The team has also achieved substantial savings on compressed air.

Unlike the technology customary on the market to date, the new Air Wizard Triple air recycling system uses a three-stage compressed-air recycling process that can reduce compressed air consumption by as much as 20 percent.

But the focus on sustainability hasn’t been limited to the machine’s

operation. It also includes the materials used in the installation process.

As an example, the protective panels are made of recycled plastic.

In order to further improve total cost of ownership (TCO), the fourth generation Contiform uses a newly

scrap rate and eliminates the need for operator intervention.

But the improvements don’t end with consumption and TCO.

The new Contiform is also now even more user-friendly: It features a largescreen interface with the latest touch technology and improved visualization

The combination of AI-based software and newly developed hardware makes it possible to detect even the slightest variations in material distribution in the production of PET containers and to automatically adjust key stretch-blow-molding parameters in real time – and thus to ensure that the bottle quality meets specifications. This factor is particularly important

Ispoke with Justin Yates, managing director at Favourite Packaging recently to discuss some of their product ranges, specifically their packaging for bread, baked products

and high-volume flexible packaging for food and perishables. With operations and logistics based in Beresfield (N.S.W), the ease of transporting rolls of printed rewind

and pre-formed bread bags over less pallet space is one of the factors where Favourite Packaging’s clients benefit.

“Pre-formed bread bags and printed rewind have a significant advantage

when it comes to transport, especially the printed rewind, because it is wound tightly onto a roll. A pallet of rewind film will give you the equivalent of five or six pallets of pouches, so there is definitely a transport advantage for sure,” said Yates.

The second part of the logistics advantage offered by Favourite Packaging is their ability to have high volumes produced, hold their customer’s bread bags or rolls of printed rewind in stock and supply them on a regular, periodic basis.

Overall, these logistics offerings provide savings for Favourite’s clients in the form of reduced freight costs, cash flow management and also in inventory space.

A n exciting area where Favourite Packaging is becoming a specialist is bakeries and baked products.

“We are finding a solid foot hold in the baked goods sector, for bread that is still packed into traditional pre-formed bags, and for baked goods with printed rewind” Justin explained.

“We supply printed rewind film for packing cakes, muffins, sausage rolls, pies and similar products that are individually wrapped and sold,” said Yates “and we supply specialised pre-formed bread bags, including wicketed bread bags for bread packaging”.

R elative to the baked products, Favourite Packaging is able to provide the special packaging such as the micro perforated oven or micro-wave friendly packaging.

“For pies and sausage rolls, we supply special material with an airhole perforation so they can be cooked without having to come out of the packaging,” added Yates.

Just like any other printed rewind film or pouches, this type of baked products packaging can be printed as per brand requirements.

“One bakery customer we have who bakes bread also sells packaged muffins and lamingtons. Their cakes go into

The advantages of printed rewind when it comes to packaging high volumes of food product have been clearly defined by the work of Favourite Packaging. Food & Beverage Industry News reports.Among Favourite Packaging’s offerings are pre-formed bread bags, including wicketed bags.

the printed rewind packaging and the bread goes into pre-formed bags,” said Yates.

Favourite packaging’s specialised pre-form bread packaging presents a great productivity gain to manufacturing lines, particularly those exceeding 20,000+ order quantities on its production line, and if applied correctly the potential for unit growth is only limited by the machinery its combined with the printing, branding and best selected materials.

Printed rewind is well known to be the ideal flexible packaging solution for high volume, repetitive food and perishables packaging.

Favourite Packaging’s printed rewind film offering presents a great packaging solution which can improve productivity, economies of scale and save on overhead costs as well as providing great packaging products that fit in with brand requirements.

They can tailor the printed rewind film to suit different types of filling machines, including the speed, type of fill, type of bag, pouch or container and the type of flexible material.

“The product fill is important as

that is what decides the barrier layers to be incorporated to manage shelf life, and the print is also vital (although sometimes we supply un-printed rewind). Printing usually utilises the Gravure method, but sometimes digital or flexography methods are a good option. The main point is, printing is customised, full colour and done to our customers brand and artwork specifications”, Yates told us today.

“And to achieve the desired shelf appeal, it is invaluable that you can pretty much print what you want on the rewind film.”

Yates said because many of Favourite Packaging’s clients supply to supermarkets or retail groups (in some cases, direct to the supermarkets), customers mostly come to them with an existing design, which helps quicken the turnaround time.