5 minute read

SUSTAINABILITY

SUSTAINABILITY Sustainability at core of Cookers Bulk Oil’s business

Cookers Bulk Oil not only supplies high-quality cooking oils to the food and beverage industry, it also recycles used oil for other industrial uses.

While food safety is first and foremost a priority, conscientious consumers are increasingly calling for products that also meet rigorous environmental standards.

For nearly 20 years, Cookers Bulk Oil has placed sustainability at the core of its operations. The company has made it its mission to minimise its impact on the environment at every step of the supply chain. This is not just a case of making sure it reduces the amount of waste it creates, but that its running operations are also made as sustainable as possible.

With this in mind, the company provides a complete oil management solution across the broader food services industry. Its diverse customer base ensures it is able to service small to medium businesses, right through to major corporations, with high-quality cooking oils that meet industry standards. This includes an array of outlets that serve the food and beverage industry, such as restaurants, casual dining, cafes, takeaway, hotels and fast food establishments.

The two major products sold by Cookers are canola oil and a premium frying oil branded XLFRY Oil. In addition to a suite of other products, the company is able to manufacture blends that can suit the needs of individual customers.

The businesses’ lifecycle solution sees it source fresh Australian oil that meets industry standards. It delivers the oil via a fleet of trucks, which also pick up used oil that is converted into other, reusable commodities, such as biodiesel.

Garry Nash, general manager of sales at Cookers Bulk Oil, said the business initially started out with a focus on kitchen efficiencies. Over time, Cookers Oil increased its scope with recyclable solutions for oil management as sustainability became a focus for procurement.

“It’s really important for our customer base that they not only know where their oil has come from, but also where it’s going,” said Nash.

“When we pick up customers’ oil, they know that it’s coming back to our depots to be refined and given a second life in the biodiesel industry. That full circle approach helps a business understand and implement best practice.”

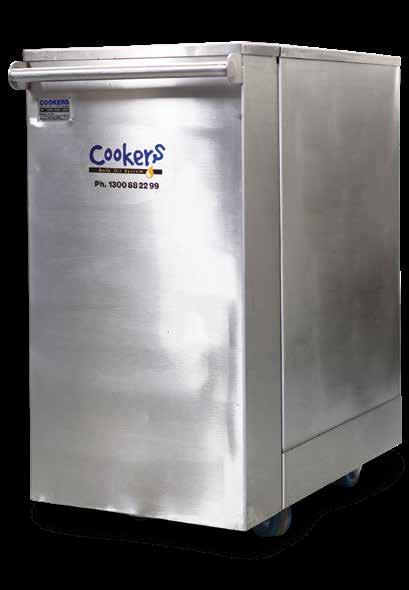

The company works with Australian oil manufacturers to refine products locally. One of the company’s key offerings is the use of storage units instead of tins, preventing 300 tins from ending up in landfill for each truck of oil delivered. Nash said that there are a couple of benefits to this outcome – less impact on the environment, plus cost savings by not having to pay gate fees at the local landfill.

“Procurement teams in this day and age want a more sustainable approach to how they deal with their oils,” he said. “So, the fact that our model removes packaging and tins of oil from the supply chain is a really big tick.”

Each delivery is accompanied with a certificate of analysis to support traceability for customers. Food service organisations are supplied with purpose-built storage units and a business development manager to meet their requirements.

“We batch track every drop of oil that we deliver knowing the date we delivered it, what the product was and what the batch was, all the way back to when we received it.”

Cookers’ key point of differentiation in the food market is that it holds Safe Quality Food (SQF) accreditation for oil supply in Australia. SQF is a globally recognised food safety program that reinforces its commitment to safety standards in the industry.

Nash said SQF holds Cookers to a high account for its product traceability

– an issue that has become topical with product recalls. He says product dilution is also another food industry issue that Cookers seeks to alleviate with transparent processes, as the company allows unannounced audits.

“Our business policy is our doors are always open to our customers and that means

if they were to knock on the door unannounced, our warehouses can be walked through and viewed by anyone at any time and that is a requirement of SQF,” he said.

“It’s one thing to have a Hazard Analysis and Critical Control Points (HACCP) certification, but we feel that SQF is one step above that.”

Cookers also holds an International Sustainability and Carbon Certification (ISCC). ISCC covers comprehensive sustainability requirements to monitor greenhouse gas emissions and ensure products are traceable and produced in an environmentally responsible manner.

The used oil that returns to the depots is decrumbed, dewatered and heat treated to create a finished product sold off into biodiesel.

The company ensures its own operations are sustainable by harvesting and reusing rainwater at its sites, measuring and analysing its greenhouse emissions and using a wind turbine at its head office to supply 30 per cent of its factory power needs.

“We don’t just talk about sustainability, but live it and breathe it as a business ourselves,” Nash said. Nash also said that Cookers offers a national footprint with nine depots across Australia and the same service model and offering available around the country.

He said that Cookers Bulk Oil will continue to evolve its business to ensure it keeps pace with the ever changing industry practises and expectations.

“We think the amount of experience we have in the industry, and the investment that’s gone into the business to attain the certifications we do have, ensures customers can be comfortable that we will look after their oil management,” Nash said. F

Cookers Bulk Oil can manufacture oil to suit a customer’s needs.

Quality Products. Experience you can TRUST.

PERFORMANCE DRIVEN. PERFORMANCE PROVEN.

When you’re looking for reliability in your Feedlot, look no further than Carlisle ® V-Belts. Carlisle Cogged Vee belts are designed to last longer in your mill to ensure maximum uptime and minimise breakdowns. These Cogged Belts are made of EPDM and feature large, round bottom cogs which can last up to 2-3 times longer than a conventional V-Belt. Carlisle belts are proudly made in the USA by Timken.