HMI Comfort Panels

The increasing volume of data in manufacturing and new possibilities for interaction between human and machine are leading to extensive changes in the field of industrial visualisation. Thanks to the new SIMATIC HMI Unified Comfort Panels from Siemens, users are assured the capability to implement innovative operating concepts that make sense for their operations.

CEO: John Murphy

COO: Christine Clancy

Managing Editor:

Syed Shah

Editor: Adam McCleery

Ph: (02) 9439 7227

adam.mccleery@primecreative.com.au

Design Production Manager: Michelle Weston

michelle.weston@primecreative.com.au

Art Director: Blake Storey

Designers: Kerry Pert, Tom Anderson, Louis Romero

Sales/Advertising: Stephanie Suzuki

Ph: +61 422 046 711 stephanie.suzuki@primecreative.com.au

Production Coordinator: Janine Clements

Ph: (02) 9439 7227

janine.clements@primecreative.com.au

Subscriptions AUS NZ O/S

1 year subscription 99 109 119

2 year subscription 189 199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

Copyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2019 Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

11-15 Buckhurst St

South Melbourne VIC 3205

Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office

Suite 303, 1-9 Chandos Street

Saint Leonards NSW 2065, Australia

Ph: (02) 9439 7227

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175

Ph: (03) 9794 8337

safety and hygiene have always been, and will always be, a critical foundation for the food and beverage industry.

The risk of contamination is a constant threat to any producer and manufacturer, so much so that entire sectors of the industry are devoted to constantly improving ways to protect food and beverages during and after the production process, even after the point of sale.

Every element of the production process presents contamination risks, and contamination presents a huge financial and reputation risk to companies in the industry.

Many of the experts, stakeholders, and key decision makers I’ve spoken to all reinforce how important it is for their companies to invest in technologies which not just improve food safety and hygiene today, but as far into the future as possible.

New solutions are constantly appearing and being implemented successfully by the industry but contamination, and recalls, will remain a constant threat to the production of food and drinks.

As a result, the companies committed to improving these processes are constantly innovating through cutting edge research and development.

The wide breadth of the food and beverage industry and the products therein present a challenge to these companies, requiring them to create flexible solutions because no two food and beverage manufacturers will necessarily require the same solutions.

This creates a specialist approach to every element of food safety and hygiene which in turn can give confidence to producers and manufacturers when they look to invest in newer solutions.

In this edition of Food & Beverage Industry News we speak to some of these companies about how they approach food safety and hygiene and what solutions

continue to prevail, and which have emerged as critical new elements in the field.

From flooring solutions to digital solutions, producers and manufacturers must remain vigilant in their approach to guarding against the risk of contamination.

Perhaps one of the key drivers behind investment in these solutions is the impact of a contamination event.

As some experts lay out, the follow-on effect a product recall can have on a company’s bottom line, and its brand reputation seems reason enough to research carefully and then invest in the best suited food safety and hygiene solutions and protocols.

Then there is the element of employee safety and hygiene. Personal Protective Equipment (PPE) is another area which every producer is keenly aware of.

Tweaks to something as seemingly minor as the choice of glove material, is proving to have a positive impact and the same is true across all PPE. The continued improvement in materials, based on feedback from within the industry, is leading to improved PPE and improved hygiene on the production floor.

Food scientists are also having a significant impact when it comes to the world of food safety and hygiene, helping to formulate new methodologies and practices. This input is proven to help improve both output and overheads, among other positives.

Meanwhile, packaging has always played an important role in food safety and hygiene and this will continue to increase as new materials emerge in the market. These new materials must meet or exceed the same standards as the leading materials of today if food safety and hygiene is to improve with it.

Until next month.

Happy Reading.

Every

Where to Buy

08 NEWS

Kraft Heinz continues to build strong relationships with Australian fruit growers.

20 DIGITISATION

The new SIMATIC HMI Unified Comfort Panels promise new innovations.

The Vintner Reserve hose range from Continental is perfect for the beverage industry.

24 PPE

Nitrile gloves are becoming increasingly popular in the food and beverage industry.

26 FLOORING

Allied Finishes produced the perfect solution for a meat manufacturer

Etihad Cargo is opening a new cold chain hub in Abu Dhabi.

How to overcome the challenges of detecting and stamping out bacteria.

ELISA Systems’ next generation gluten test kit now has added features for the food industry.

34 SENSORS

Making digitisation easier with the IIoT platform from Moneo.

HACCP Australia’s team of expert food scientists continue to shape the organisation’s approach.

Heat & Control are helping to educate the industry around the advantages of the CEIA metal detection system.

40 PACKAGING

COPAR is seeing first-hand the continued growth of fibre-based packaging in the food and beverage industry.

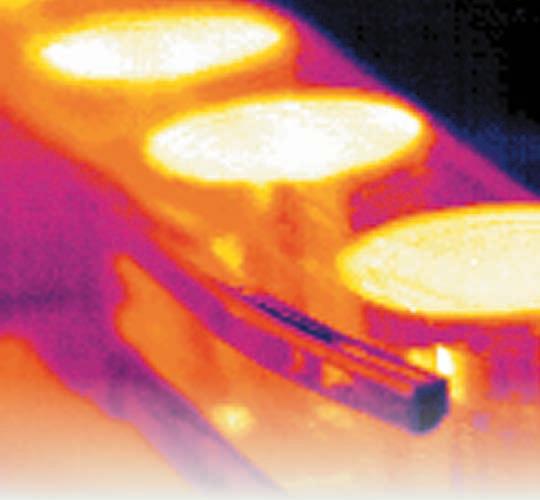

The FLIR A-Series can tackle the most complex remote monitoring objectives.

The Regal Rexnord LF600 and LF600TAB conveyor chain promises massive benefits

is partnering with the beef industry to trial a new feed supplement that greatly reduces methane emissions from cattle, which could lead to a step-change in the sustainability of Australian beeffarming.

Coles is collaborating with Mort & Co Grassdale Feedlot in Queensland on Australia’s largest commercial feedlot trial of the feed supplement Bovaer. DSM, the developer of Bovaer, is a partner in the trial.

The trial will study how effectively Bovaer reduces methane production in feedlot cattle, thus providing a better understanding of the sustainability of beef farming in Australia.

A recent study of 20 cattle funded by

Meat and Livestock Australia revealed that Bovaer, which is added to cattle feed at the rate of just a quarter-teaspoon per day, reduces methane emissions by

between 60 to 90 per cent.

9,800 cattle will form part of the trial, and Coles will provide grading data to be analysed. Specialised cattle

veterinarians and researchers Bovine Dynamics will produce a research paper outlining the findings of the study to be then published in a scientific peerreviewed journal.

The cattle will be fed at Mort&Co Grassdale Feedlot and processed at the Teys Australia Beenleigh processing plant, Queensland.

International studies have already shown Bovaer – which is broken down as part of the natural digestive process of the animal – to be successful in reducing methane emissions. This trial will be the first in Australia to test the feed supplement in a real-world, large-scale commercial feedlot of industry size and scale. F

Group has launched its retail media arm, MixIn by Endeavour, which offers suppliers the opportunity to promote their products through its extensive store and hotel network as well as its digital assets.

MixIn by Endeavour will be run by experienced advertising executive Lachlan Brahe, who was appointed head of retail media in May this year. Sales manager Steve Jones and operations manager Rhiannon Hart will join him along a team of sales specialists and media strategists.

The in-house capability, which sits within Merchandising, has been 12 months in the works. Advertising opportunities include tasting programs, in-store digital screens and radio, as well as sponsored product listings and display advertising placements across the

different brands’ websites and apps.

Suppliers will also have access to a self-service platform, where they can easily set up digital campaigns that will run on a variety of advertising placements with just a few clicks.

Endeavour Group operates a network of retail drinks and hospitality businesses, with over 10 million average monthly website and app visits. Its portfolio of brands includes BWS and Dan Murphy’s, as well as Australia’s largest portfolio of hotels.

“We offer Australia’s largest connected drinks ecosystem, which means we can leverage customer insights to deliver great campaigns for our suppliers and help them reach customers in meaningful ways in their most sociable of moments,” said Endeavour Group general manager of merchandise transformation Bree Coleman.

MixIn was launched to promote Endeavour Group products.

Theactual drop in Australians’ spend on dining out during the pandemic is revealed for the first time in a new report released today by the Australian Foodservice Advocacy Body (AFAB).

In 2019, Australian households spent 37.2 per cent of their food and non-alcoholic beverage budget on eating-out, as opposed to eating-athome, which was among the highest in the world.

By the end of 2021 this had dropped to just 13.7 per cent.

AFAB’s State of the Foodservice Industry Report 2022 is the first definitive report of its kind, covering industry trends by stakeholder groups, facts about Australia’s foodservice market, the size of the sector,

foodservice distribution and consumer behaviour.

It was compiled using extensive quantitative as well as qualitative research and data tracking series by AFAB founding member Food Industry Foresight (FIF), as well as data collated from AFAB members, the ABS, and other government and industry bodies.

The report also includes the new Foodservice Confidence Index, or FSCI, which takes the pulse of the market each quarter.

The AFAB FSCI for the second quarter of 2022 shows, not surprisingly, that overall confidence levels among foodservice operators are at their lowest since 2017, with the exception of pubs and function caterers.

F

Inan Australian scientific first, the local innovators at Magic Valley have created a cultivated lamb meat prototype, completely free from animal byproducts. The scientific milestone comes at a time when more than a third of Australians are considering new ways to reduce their animal intake.

The team of highly qualified scientists at Magic Valley are successfully working towards transforming the future of large-scale protein production and removing animals from the supply chain.

Their prototype – initially created in the form of burgers and tacos – looks and cooks just like real lamb yet has the potential for an even healthier nutritional profile, showcasing what is possible for the future of cultivated meat products.

To create the prototype, a small skin biopsy was taken from Lucy the lamb,

who is happily residing in a field in New South Wales. The cells from Lucy were then grown in Magic Valley’s Melbourne lab where they are made into cultivated meat products.

The process used by Magic Valley takes the skin cells and turns them into stem cells called induced pluripotent stem (iPS) cells. The iPS cells can grow in an unlimited and scalable way and can also be made into muscle and fat –the main components of meat. This is the first time, anywhere in the world, this technology has been used to make a cultivated lamb product.

In just 18 years, it is predicted that cultivated meat will comprise more than a third of the $1.8 trillion global meat market2, and while talks of alternative meats have been bubbling away under the surface for some time now, Magic Valley’s prototype has broken the mould of possibility.

F

MarsWrigley Australia has announced a $25.5 million investment into its Ballarat factory to boost local manufacturing capabilities and drive consumer-led innovation.

The funding will occur over 12 months and will enable the company to better respond to consumer demands across its Bitesize Portfolio, which includes brands such as M&Ms, MALTESERS, and PODS.

The new funding builds on the $67 million invested by the company over the last two years in its Ballarat factory as part of its continued commitment to Australian manufacturing. The new investment will also help future-proof Mars’ local operations by improving its raw cocoa and melted chocolate production, driving its local sustainable

packaging efforts, and creating greater operational efficiencies.

Mars Wrigley Australia has been manufacturing locally in Ballarat for over four decades.

Andrew Leakey, general manager at Mars Wrigley Australia said, “We have a commitment of making the majority of our product portfolio here in Australia, and we are cementing this further by unlocking greater capabilities to create new consumer-led product innovation whilst accelerating our sustainable packaging focus locally.

This new round of investment will support this ambition by improving our domestic processing and manufacturing capabilities and continue our long and proud legacy of manufacturing in Ballarat.”

Leakey also explained that as one

The new funding builds on the $67 million invested by the company over the last two years.

of Australia’s largest snacks and treats manufacturers, Mars Wrigley strives to respond to evolving consumption habits and new consumer trends in the market.

“This latest investment will allow us to bolster our production capabilities

for our Bitesize Portfolio, which will be critical to our growth over the coming three years. We see substantial opportunities in this space, with a number of exciting projects currently underway,” he added. F

Globalwine company AVL Wines has launched its ESGguided sustainability roadmap and journey to Net Zero 2040.

The ASX-listed company behind pillar brands McGuigan, Tempus Two, Nepenthe and more, is committed to an ESG strategy that encompasses environmental impact and climate action, alongside social iWmpact initiatives to support communities and good corporate governanc.

The announcement, as the company releases its FY22 results, is an intentional shift to a more balanced and transparent approach.

AVL Wines has set an ambitious climate target – informed by current climate science – to achieve Net Zero carbon emissions by 2040 across the entire value chain.

Taking an evidence-based approach to achieving Net Zero, AVL Wines has set a long-term target to reducing Scope

1, 2 and 3 emissions by 2040. In the near term, the company will reduce absolute scope 1 and 2 emissions 42 per cent by 2030 and reduce scope 3 emissions 52 per cent.

AVL Wines chief executive

Craig Garvin says the ESG journey is important, and he is pleased to be

announcing not only the positive financial results but the company’s progress on environmental and social impact.

Emission interventions within the company’s industry-leading Net Zero target include 100 per cent transition to renewable energy sources, addressing

downstream transportation emissions and innovating around sustainable packaging solutions to meet 2025 National Packaging Targets.

From a social impact perspective, AVL Wines is committed to engaging and nourishing the communities in and around the company.

Australian

Dairy Farmers (ADF) welcomed a decision by Federal Environment Minister Tanya Plibersek not to halt development of a $4.5 billion urea fertiliser production plant in Western Australia’s Pilbara region.

Minister Plibersek’s decision supports fertiliser manufacturing in Australia – which helps dairy farmers deal with soaring costs of farm inputs – and preserves ancient rock art by First Nations people on the Burrup peninsula.

“We congratulate Minister Plibersek on finding a path forward. Development of the site can now proceed having already received approval from the relevant state authorities,” said ADF president Rick Gladigau.

ADF has been advocating for the importance of shoring up Australia’s fertiliser production directly to Minister Plibersek and has lobbied for exploration and development of fertiliser production in Australia. ADF supported the

previous Government’s pre-election decision to award major project status to the urea fertiliser project in the Pilbara. Dairy farmers rely on fertilisers, including urea, to produce pasture and fodder to feed their cows and produce

Environment Minister Tanya Plibersek will not halt development of a $4.5 billion production plant.

milk. Fertiliser prices are more than double their pre-pandemic level.

The fluctuating price of natural gas – a key input in urea production –means urea prices are on a rollercoaster with no end to the volatility in sight

for the dairy industry, Australia’s fourth largest agricultural industry.

Australian dairying is a $13 billion farm, manufacturing and export industry that employs 43,000 Australians and feeds millions every day. F

Australian Dairy Farmers (ADF) has secured a federal grant of $814,000 to improve price transparency, product traceability and efficiency across the dairy supply chain.

With the grant, ADF will produce a framework for the dairy industry that lays out what technology and systems need to be deployed to track and trace produce and price through the supply chain.

“We thank the Federal Government for this grant. It’s an opportunity to not just improve traceability, but also build transparency and trust within the dairy industry. This is a significant industry reform initiative. It ensures that a reform of the supply chain will continue under the leadership of ADF,” said ADF CEO David Inall.

“As part of the project, we will be conducting an audit of existing traceability systems and processes, as well as mapping the critical price and financial transactions as product moves through the supply chain. This will help us identify the gaps and barriers in the industry’s current traceability practices based on the Australian Dairy Traceability Guideline released in September 2021.

“We’ll then use this information

to develop a technology and systems roadmap to indicate the most efficient and integrated approach to track and trace product and price through the supply chain. This positions us to deploy real time price and product monitoring tools and capture data more effectively.

“The guidelines set out a common language for traceability. Now we’re using that language to determine which technology and systems will lead to more effective and transparent tracking across the supply chain.”

The grant is part of the Australian Government’s Improving Market

Australian Dairy Farmers secured a federal grant of $814,000.

Transparency in Perishable Agricultural Goods Industries Program that aims to tackle bargaining power imbalances in these industries by improving market and price transparency. This project has been developed in collaboration with the Australian Dairy Products Federation and Dairy Australia. F

announced that Chris Rowe will become its acting chief financial officer (CFO) to replace current CFO Marc Rivers who is leaving the Co-op at the end of 2022.

Chief executive Miles Hurrell said that Rowe has worked for Fonterra since 1988. He has undertaken a number of commercial and finance leadership roles and is currently the Co-op’s group finance director.

“Chris is a highly competent leader, who has considerable knowledge of the Co-op and the management of its physical and financial portfolios, as well as its mergers and acquisitions,” said Hurrell.

“I am pleased that Chris has agreed to act as our CFO, and he will continue to provide strong direction and leadership while we continue our recruitment process for a permanent CFO. The recruitment process for a permanent CFO is well underway and I hope to announce the successful candidate in the coming months.”

Chris will join the Fonterra Management Team as the Acting CFO from 1 October 2022, and current CFO Marc Rivers will move into the role of Strategic Advisor to the CEO from 1 October 2022 until his departure from the Co-op. F

Cheese Limited (ASX: BGA) has announced its full year audited results for the financial year ended 30 June 2022. Bega Group revenue exceeded $3 billion with the company recording normalised earnings of $180.1 million and statutory earnings of $149.9 million.

The company generated net operating cash flow of $158 million and reduced debt by $60 million to $265 million.

“It is testament to the knowledge, experience and capability of our team and the strength of our business that we have managed the supply chain and market disruptions created by the COVID-19 pandemic, record flooding and associated transport challenges and the global impact of the war in Ukraine while delivering a successful integration of Bega Dairy and Drinks, continued growth of our branded business, a right sizing of our dairy nutritionals business

and a solid financial performance including a net debt reduction of $60 million,” said Bega executive chairman Barry Irvin.

The first full year of ownership of Bega Dairy and Drinks is reflected in the growth of the branded segment of the Bega Group with revenue growth of 63 per cent to $2.5 billion, external revenue in the bulk segment which largely consists of dairy nutritionals and ingredients benefited from higher commodity sales prices with revenue totalling $529 million.

The importance of both segments of the business was well demonstrated in FY2022 with the company able to respond to historically high international dairy commodity prices which assisted in offsetting the impact of increased costs across the supply chain and a very disrupted convenience and food service market in Australia.

Scientistsfrom NTU Singapore’s Food Science and Technology (FST) programme have developed a technique to cultivate a fungi-based food product that could serve as a healthier, better tasting, and greener alternative to plant-based protein.

The fungi used to cultivate the product is grown from a base of nutrientrich common food waste, which infuses the fungi with more essential nutrients, such as protein, iron, and amino acids. This makes them more nutritious than ingredients commonly used in plantbased alternative meat, such as peas, chickpeas, wheat gluten, and soy.

The cultivation of the NTU-developed food product would also offer an opportunity to reuse common food waste and byproducts of agriculture and the food and beverage industry, such as soybean skin, wheat

stalk, and brewers’ spent grain, a by-product of the beer-making industry.

To scale-up their fungi-cultivation method, the NTU team, which also includes PhD student at NTU’s FST programme Miss Malsha Samarasiri, is collaborating with The FOODBOWL, part of New Zealand Food Innovation Network, a national network of open access food processing facilities supported by the New Zealand government to help food businesses and startups globally innovate, scale up and commercialise new products –ultimately to international scale.

Besides playing an advisory role to startups, the researchers at NTU’s FST programme hope to develop their product to further boost its nutritional profile, as well as reduce food waste. They also hope to commercialise their solution by the year 2024. F

The cultivation would offer the opportunity to reuse common food waste byproducts.

TheEntrepreneurs’ Programme and the Australian Institute of Packaging (AIP) have invited SMEs to participate in the Sustainable Packaging SMART Project, to help improve sustainable packaging practices.

Developed by the Entrepreneurs’ Programme, the project is available to eligible SMEs with revenues between $1.5 to $100 million ($750,000 for Northern Australia).

It will provide SMEs with access to industry networks, expert resources and up to $20,000 (matched) grant funding to progress their sustainable packaging goals and help meet the 2025 Sustainable Packaging targets. It also offers up to 12 months direct individual business assistance along with collective,

peer group knowledge and skill development activities.

Sustainable packaging ensures that the design provides the lowest possible environmental impact compared to existing or conventional packaging. Sometimes achieving the lowest possible environmental impact can be challenging, particularly when balancing various environmental criteria with other functional and commercial considerations.

This support will help businesses navigate the new ways packaging needs to be designed.

Businesses are turning to sustainable packaging for many reasons, including to meet the 2025 Sustainable Packaging targets, corporate social responsibility, reducing

The Sustainable Packaging SMART Project will help improve sustainable packaging practices.

their carbon footprint, reducing unnecessary packaging and waste, increasing sales — and because retailers and consumers are demanding it as a key global movement.

Each event will be hosted via Zoom. Whilst these events are focused on regions, eligible businesses are encouraged to register an EOI from anywhere in Australia.

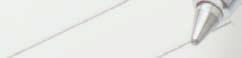

Produce Supplies

in Severnlea will soon feed more mouths thanks

to funding from the Queensland government’s Rural Economic Development (RED) Grant scheme.

Minister for Agricultural Industry Development and Fisheries, Mark Furner, said that Queensland produce providers growing alongside demand is critical to ensuring long-term sustainability and good jobs across the industry.

“The Southern Downs is home to some of the best crops in Australia,” Furner said. “The more summer vegetables we can produce and consume on home soil, the better. That’s why projects like this to increase capacity and boost efficiency through infrastructure upgrades are so important. This expansion won’t just benefit the industry, but the entire Southern Downs community through local job creation.”

The first three rounds of the RED Grants Program have seen funding of $10 million.

“We’re excited to share our more than 45 years of experience in the

TheXXXX Brewery in Milton will see an expansion in production, with leading brewer Lion set to invest nearly $5 million to enable mass production of seltzers and ready-to-drink adult beverages at the iconic site.

XXXX sales director Patrick Donohue said the XXXX Brewery is a Queensland icon, having stood proudly on Milton Road for nearly 145-years.

“It is an integral part of Lion’s brewing network – producing the vast majority of Lion’s portfolio of household name beer brands, including XXXX, Hahn and James Squire,” said Donohue.

“The beer and alcohol beverages market continues to evolve, as do consumers’ tastes and preferences. It is important that we innovate and set the brewery up for long-term success.

“We are pleased to announce that

we are looking to produce most of our portfolio of seltzer brands, including global sensation, White Claw, at the XXXX Brewery.

“Mass production of seltzers and RTD beverages requires bulk ethanol storage, and so we will lodge a development application with Brisbane City Council in the coming weeks to build a new facility on the current site to ensure we’re doing this in the safest way possible.

“This represents a significant investment in the site and builds on our decade-long registration under state planning laws protecting the existing use of the brewery from encroachment from other development, which was extended in 2019.”

As part of our application, XXXX will conduct a period of community consultation, which will commence later this year.

horticulture industry as we expand our enterprise,” Wallaroo Produce Supplies managing director John Patane said.

“The expansion will generate 12 direct full-time jobs and employ even more during the construction phase. Many of these ongoing jobs will be longterm, skilled positions that we hope we can fill within our own community to boost the local economy.”

Wallaroo Produce Supplies is one of 16 businesses approved in the fourth round of the RED Grants program, with total funding of just over $3 million. Overall, these 16 projects are expected to create more than 217 direct long-term jobs across regional Queensland.

The initial three rounds of the RED Grants Program have seen funding of $10 million over three years to support more than 30 projects which have created 1,800 jobs across regional Queensland. F

XXXX will conduct community consultation later in 2022.

Kraft-Heinz continues to build its diverse portfolio of brands, including Golden Circle, into products that are recognised for quality and ethical production. Adam McCleery writes.

Australia, Kraft Heinz have multiple manufacturing locations, including Echuca for Heinz Infant and Heinz Baked Beans, Seven Hills for Saxa Salt, Gravox gravy, Fountain sauces, and F. Whitlock & Sons, Wagga Wagga for Hamper corned beef, and finally Northgate for Golden Circle.

The Northgate site is the only one within Australia canning pineapples for Golden Circle and as a result of the

growing popularity of the product Kraft Heinz has been forced to engage with more producers to meet demand.

“Our relationship with Australian farmers is essential and is at the core of who we are,” said Michael Joubert, Kraft Heinz senior vice president of operations, Asia Pacific.

“We try to be as clean as possible when it comes to agriculture, so we are talking a lot about food science. We work with a network of growers,

for instance with pineapple, it is a big product for us and Australian love Golden Circle pineapples.”

“We just realised we are not growing enough pineapple, so we started to recruit more growers.”

The company sent a team to visit different pineapple producers across Australia to speak about the Kraft Heinz strategy on growing together.

“We sent our team to farms to speak with growers about why it is good to

work with us as a partner. We also invited them to our factories to share our strategy on how we grow together and through that we have more pineapple,” said Joubert.

“Last year we used about 18,000 tonnes of pineapple in golden circle and this year we expect more than 20,000. This goes into our pineapple juice. This relationship is essential, we see it as a partnership.”

“In New Zealand we have families

of growers who have worked with us for more than 50 years. We cultivate strong relationships.

The The Northgate Factory is also a lighthouse factory for Kraft Heinz’s Manufacturing Excellence system (KHMS) - focusing on training, upskilling, and empowering line operators to solve problems and improve performance.

The factory is people focus with regular engagement surveys and targeted action plans, KHMS people committee, celebrating diversity.

All of this plays a critical role in the Kraft Heinz commitment to food safety.

“Food safety is non-negotiables and is about systems, compliance, and rigour. We have high level of training and the Kraft Heinz Management System, which is the same in all our facilities around the world,” said Joubert.

“We work with partners, do audits, have tight specification, and we have several processes. Manuals describing

In 2021 Kraft Heinz used over 18,000 tonnes of pineapple for its Golden Circle brand.

everything we do, from calibration to sanitation and everything else in between, at the end of the day we try to be as automated as possible.

“For example, we have X-Rays on all of our lines to make sure every product is individually checked to make sure there is no foreign material.”

The company also has training in place to make sure all staff are competent and up to speed on everything they need to know.

“We are a very people driven company and we are value based with ownership at the centre of everything we do, this is in the context of manufacturing, it gives us the freedom to act individually and hold yourself accountable and be the owner of your own product,” said Joubert.

This hands-on approach always pays dividends when it comes to being part of a large chain in manufacturers, producers, and retailers.

“And we are part of an integrated supply chain which means we work

upstream with our suppliers, and we have dedicated food safety quality team that works upstream,” said Joubert.

“Food safety and quality is at the heart of everything we do and is a constant obsession and it starts with our consumers.

“That is who we work for, so we need to make sure we deliver consistent taste day in and day out.

“We have a set of platinum rules we share with our partners and we except people to adhere to them in order to maintain our product’s reputation.”

Joubert said all of this played an individual role in cultivating the Kraft Heinz values.

“We have six values and ownership is an important one,” he said.

“We always strive to do better every day and do something new and different; we are very people driven and value our people.

“We also demand diversity; it is one of our values. We want diverse people in this business, and we must reflect

The company also works closely with consumers to introduce new tastes.Kraft Heinz senior vice president of operation, Asia Pacific, said the relationship with Australian growers was key.

the communities we operate in, gender, race, sexual orientation, this does not matter to us. It is all about the person. Everybody’s welcome at our table.”

Joubert said the company always aimed to do the right thing, in terms of compliance, food safety, quality, and every other important aspect of food and beverage production.

“That’s Kraft Heinz in a nutshell,” he said.

“We sell provenance and highquality products that are locally grown, Australian pineapple being one of our key products in Australia.”

Joubert said along with the popularity of the Golden Circle range in Australia, the Heinz sauce range had also continued to grow in popularity.

Despite the popularity, he added, Kraft Heinz is always looking to innovate and create new products for

consumers.

“We launched a range of baked beans last year and they are completely different to any baked beans you’ve tried,” he added.

“People want to try new tastes, so we are constantly bringing new ingredients and working with our R&D team to bring new innovations to the market.

“It is about guaranteeing you will get on your plate something that tastes amazing, and that you can trust.”

On top of this continued innovation around product taste and look is changes

and innovations around efficiency and sustainability as a food and beverage manufacturer.

“We have made bold commitments because we all feel passionate about sustainability,” said Joubert.

“Our commitments started with energy and water in 2019 and decided we would reduce our water and energy consumption by 15 per cent as a first step before 2025 in all our Australian and new Zealand factories which we are on track for.

“We also ran a big initiative in July

where all the factories had a competition to see who could reduce the water the most within a month.”

Kraft Heinz also has some large targets set out for further into the future.

“We’ve started to talk about carbon more recently and have a target of Net Zero emissions by 2050. That is a big goal, and we are working towards also making more packaging compostable and recyclable.,” said Joubert.

A change to a Golden Circle product was a good demonstration of this commitment.

“We recently just changed our Golden Circle cordial bottle, it was a PVC bottle which wasn’t recyclable, we instead have switched to PET two years ago and it’s lighter and less plastic goes into the environment and its completely recyclable.” F

“We are a very people driven company and we are value based with ownership at the centre of everything we do, this is in the context of manufacturing, it gives us the freedom to act individually and hold yourself accountable and be the owner of your own product.”Kraft Heinz has also looked at alternative packaging for its Golden Circle cordial range.

Thenew SIMATIC HMI Unified Comfort Panels, from Siemens, promises users the capability of implementing innovative operating concepts, suited to their operation, both today, and in the future thus creating a new level or ease of use.

Steven Sischy, automation, and drives business manager for APS Industrial, reports these new comfort panels are a ‘break from tradition’ for the digital solution’s provider.

“If you look at the product itself, it is completely different, as Siemen’s are normally very conservative with their outlook,” he said.

“This is a brand-new design based on the latest technologies in the marketplace. It looks like an iPad, completely rounded, and is a breakaway from the normal grey colour. There is also a neutral look option without the Siemen’s logo.”

Sischy said that Siemen’s longstanding reputation played a key role in the success of new models being released.

“The pedigree has been built up and it’s a slight change in product portfolio as it lends itself to many different applications,” Sischy added.

“An edge-based app could include

power monitoring, AI, and machine learning. If we look at from a future proofing standpoint, it allows us to add new features going forward.”

Natively, the panel consists of all the pre -existing features but with some noticeable additions.

“Currently there is the option of pay per use apps, but that’s still in its infancy. You will however first need it certified and approved resulting in income from the application’s use around the world.”

Another new feature is the integration of alerts directly to a smart watch.

“All these functionalities are app based, and use push alerts, so any downtime caused by stoppages will immediately alert maintenance” said Sischy.

“Due to the direct connection to the device, you can diagnose the problem which in turn gets the machine back online quicker than it otherwise would have if you had to be onsite.”

The product also has a high RT Rating, and the user can successfully use the tablet while keeping their safety gloves on.

“In the past single touch would not be as reliable, if water droplets, and alike, would get onto it. Multi-touch is not

susceptible; you can use different liquids or chemical gloves directly on the app without being removed. If you look at something like cold room, or CIP, you can utilise these directly onboard.” said Sischy.

feature which Sischy said needed to be highlighted.

“As an example, say you have a 15-inch screen, and decide you want to

of a smartphone, if in use. We can cater to any size according to the users’ needs, no matter what you develop on it.”

The panel’s Totally Integrated Automation (TIA) has also undergone improvements over previous generations.

“If a customer has TIA Professional, unified data, is a part of that package. There is no additional cost as there is no need for additional components,” said Sischy.

“All the security, everything we know about TIA Version 17 is incorporated into this product,”

The advantages of remote access have also been doubled down on, with the latest generation of Siemens comfort

“We know who the user is, and remote access can be defined by manufacturers or plant managers,” said Sischy.

“We have pdf readers and viewers directly on this, and as a result can store manuals into it.

“It’s the programming environment that is used for all Siemens PLC’s. It’s a single software package. Everybody is used to TIA, this is just an additional extension.”

Other new features include the ability to look at a movie, a wave file, or pdf viewer, and the installation of barcode scanners to the product.

And in terms of security, the default settings are moving towards two-factor

The SIMATIC HMI Unified Comfort Panels, from Siemens,Vintner Reserve beverage hose has been a staple of industrial hosing in the beverage industry, particularly wine and beer, for many years.

This longstanding popularity is backed by a strong reputation as an industrial hose which can withstand the day-to-day rigours of beverage manufacturing.

The Vintner Reserve industrial hose is manufactured with premium materials designed to meet, and exceed, hygiene standards. This is demonstrated by the hose’s FDA/USDA certifications, conforming to the 3-A Sanitary Standard 18-03.

Continental national business manager, Scott Weston, told Food & Beverage Industry News that the Vintner Reserve hose already has a strong reputation in the beverage industry, but the company was always eager to promote its benefits.

Weston said the long range of advantages provided by the Vintner Reserve hose, especially for breweries and vineyards, meant the product mitigated many risks associated with other hose solutions.

“The product is lightweight and easy to clean and those two features tie into a lot of the product’s benefits,” said Weston.

“But perhaps the biggest advantage of our Vintner Reserve is that it’s both crush and kink resistant.

The crush and kink resistance has already proven its worth within the beer and wine sectors, Weston said.

“When you think about the application of the product, it’s really used to transfer beer and wine but in plant operations, so when the hoses are

running between big vats and silos with forklifts running over them, things like that,” he said.

“We always sell this based on its crush resistance and that’s because of the monofilament reinforcement. Instead of being steel.

“If its steel, once you crush or kink it then it never goes back to its original state, and you can also have rusting issues if any of it is exposed. This product doesn’t have either of those risks as a composite material.”

In-house joiners and other additions to the hose also make for ease of application on-site, including around the cleaning process.

These include ContiTech crimp specs. Rubber rings are also available to extend the life of the investment and ensure correct hygiene.

“From a clean perspective and quality control is important and this product is able to undergo clean in place procedures,” said Weston.

“Also, it’s manufactured on a special chrome mandril to ensure it is as clean as possible from the manufacturing plant versus a traditional hose where it can be done on a steel mandril.”

The ease with which the Vintner Reserve can be cleaned has always been another critical part of the product’s offering, especially in an environment where everything needs to be clean, such as breweries and vineyards.

“The cover is made from materials that are easy to keep clean while also being non-marking. Which means when it’s dragged around the workshop floor it won’t leave behind any rubber marks and that’s great especially if you do tours of your brewery,” Weston added.

Another critical part of the Vintner Reserve’s selling point revolves around the products ability to prevent other contamination.

“Then it’s really the other key parts are around discolouration of your finished product. It won’t cause that because of the tube and the impact on taste and odour is non-existent, it’s the quality we guarantee on our product,” said Weston.

And in terms of safety, Continental’s Vintner Reserve has a four-to-one working pressure, as opposed to the

that added safety net,” ” said Weston.

Which is a key point for the Vintner Reserve, doubling down on the product’s benefits ensures its longevity and a string of associated benefits as a result.

“Vintner is popular within the beverage industry and people will likely know this one by name, but we are always eager to get the message out there and reinforcing the benefits of the Vintner Reserve,” said Weston.

“Now is the time where we get a lot of queries direct into vineyards, they start producing in the next two to three

The Vintner Reserve industrial hoses from Continental have a proven track record in both breweries and vineyards. Food & Beverage Industry News reports. Continetal’s Vintner Reserve beverage hose has become a staple in the beverage industry.

Allied Finishes continues to present a variety of solutions for the food and beverage industry, which requires flexible options when it comes to food safe industrial flooring. Adam McCleery writes.

Allied

Finishes was approached by a long-term client for a flooring solution at one of its chicken meat processing facilities after expressing satisfaction with the company’s earlier work at other sites.

An Allied Finishes spokeswoman said the project was interesting because Allied Finishes generally work as a more high-end supplier of flooring solutions.

The Allied Finishes client decided to go with the company again to ensure a long-term solution, with long term reliability.

“The client wanted peace of mind in knowing the floor wasn’t going to fail on them in a short period of time,” said the spokeswoman.

“Which is a smart choice because you want the investment to last a long time and be easy to clean and maintain.

“We got the go ahead a week before we started, and it was turned around within a month. It ran throughout the month of August and that was a key advantage in using us, we have the ability to turn around large jobs in a short time frame.”

The area for the job was a 1020 sqm in size and consisted of change rooms, production rooms, and an anteroom.

“We had to make sure our solution

complied with food safety regulations, which all of our SteriFloor products do. As the flooring had to be easy to clean and highly durable, we decided to go with our SteriFloor Stä rke flooring solution.”

SteriFloor Stärke is a two component, solvent free, low viscosity, heavy-duty protective floor coating suitable for a range of commercial and industrial applications.

With the inclusion of coloured pigment, SteriFloor Stärke flooring provides an aesthetically pleasing appearance, with high strength chemical and abrasion resistance, allowing for easy cleaning.

SteriFloor Stärke is free from any potential carcinogens or mutagens and will not taint foodstuffs.

SteriFloor Stärke conforms to both the BRCGSFS and SQF food safety standards, ensuring you meet any audit requirements. SteriFloor Stärke contains no VOCs (volatile organic compounds) and is highly suitable for food and beverage manufacturing facilities.

“We were required to also adhere to workplace health and safety requirements, which we are well versed in doing, that involves the slip resistance

of the floor and ensuring its safe for people to walk on, particularly when its wet,” said the spokeswoman.

“The requirements were the floor being sealed and a non-slip surface and coving was required in the anteroom and change rooms.”

Expansion joints were also required throughout the facility to ensure the floor won’t crack in a couple of months’ time. Coving was also used in change rooms and also had to comply with food safety regulations as well.

“We recommend SteriFloor Stärke and have used it at this client’s other sites, and it’s proven to be very successful,” said the spokeswoman.

“It’s a two-component protective floor coating and it’s one of the hardest wearing floor solutions with multiple layers that stand up to the challenges of food processing sites.

“It’s ideal for this type of facility and they went with a maze yellow colour with a heavy non-slip finish, and this is probably critical in a meat processing facility where there a lot of fats and

liquids on the floor,” said the spokeswoman.

The project was turned around quickly and with minimal impact on the production process.

“It is a solutions that is long-lasting and easy to clean,” the spokeswoman added.

Another point of pride for Allied Finishes is the ability to meet customer needs.

“One of the key reasons they turned to us is the fast turnaround,” she added.

“It was completed over multiple stages over workdays and that was to the client’s request, they needed someone there to get it done fast and we answered to that, and they were impressed with the final result, as they have been for all of their projects.”

The spokeswoman said the longterm relationship with the client and quick turnarounds on projects were all excellent indicators of Allied Finishes ability to meet market demands for flexible solutions which need to meet a host of standards. F

After having to put the project on hold due to the COVID-19 pandemic, Etihad Cargo is almost set to open a new cold chain facility in Abu Dhabi. Adam McCleery reports.

and safer,” said Panza.

Despite being in a post pandemic world, Etihad learnt critical lessons from the unprecedented events, which are helping inform the company today.

“The late Winston Churchill is credited with saying, “Never let a good crisis go to waste,” and Etihad Cargo learned many lessons during the pandemic,” said Panza.

“The COVID-19 crisis highlighted how critical an agile and flexible approach is when providing emergency solutions. As countries locked down, borders closed and supply chains were disrupted, the world increasingly relied on air cargo for necessities, such as food, fresh produce and pharmaceuticals, including vaccines.

“Throughout the pandemic, the cool chain supply chain remained robust, driven by strong segment demand and the efforts of governments around the world to ensure the continuous supply of pharmaceutical and perishable products.”

Cargo continues to invest heavily in its products and infrastructure as part of a company promise to provide its customers with the best possible logistical solutions.

Fabrice Panza, manager global cool chain solutions, commercial division, said the newest state-of-the-art cool chain facility at the company’s Abu Dhabi hub was proof of this commitment.

Prior to the opening of our cool chain facility in our Abu Dhabi hub, Etihad Cargo handled an average of 38,000 tonnes of perishables under our dedicated FreshForward product, of which 42 per cent is fruits and vegetables and 15 per cent is flowers—our top commodities every year—and a further 11,000 tonnes of pharmaceutical and healthcare products via our dedicated pharmaceutical transportation product, PharmaLife,” said Panza.

“Following the launch of our new

cool chain facility, we will have the capability to accommodate additional 50,000 tonnes, doubling our cool chain storage capacity in our hub in Abu Dhabi.”

The 3,000 square-metre facility comprises the latest technology and features, including RFS loading docks with levellers, high-speed roll-up shutters, insulation, and floor work for faster and more efficient loading with stricter temperature controls, increased storage space, additional build-up and breakdown zones for improved production workflows and upgraded cool chain facilities for Etihad Cargo PharmaLife handling and storage operations.

The new facility will also feature new x-ray screening for police and customs inspections within a fully temperaturecontrolled environment and new dedicated thermal covers.

The new cool chain facility will officially launch on 26 October.

“Etihad Cargo’s customers will benefit from our expanded IATA CEIV Fresh and Pharma-certified cool chain products—FreshForward and PharmaLife— as we continue to provide world-class end-to-end temperature-controlled solutions for the transportation of perishables and pharmaceuticals across our global network,” said Panza.

Being IATA CEIV Fresh certified demonstrates Etihad Cargo’s compliance with Perishable Cargo Regulations (PCR), ensuring food safety and a reduction in waste, which in turn reinforces trust among our customers and enables us to implement best practices across the cold supply chain.

“Our new cool chain centre will also provide smoother transfers to Etihad Cargo’s FreshForward truck fleet when products need to be delivered in the UAE or be handed over to the consignee at Abu Dhabi Airport, making the end-to-end journey of perishables easier

Demonstrating this was Etihad Cargo’s 14 per cent increase in transportation of perishable goods in 2021.

“In 2022, we achieved a 46 per cent increase in revenue for our PharmaLife product,” said Panza.

“From our new cool chain facility in Abu Dhabi, Etihad Cargo will continue to work closely with customers and partners to ensure the smooth, efficient, safe, and on-time delivery of perishables.

Panza said achieving this goal relied heavily on transparency between parties involved.

“And the provision of accessible and accurate information at every step of perishable cargo’s journey,” he added.

“We monitor and control external conditions and have robust contingency plans in place to mitigate the risks associated with temperature and other external factors so we can ensure perishables arrive at their final destination in perfect condition.”

Etihad Cargo also had to endure the impact of the pandemic while in the

midst of planning its new cool chain facility in Abu Dhabi.

“Plans to expand our cool chain capabilities and develop a new state-ofthe-art cold chain facility commenced back in 2018,” said Panza.

“While the COVID-19 pandemic delayed our plans, we are delighted to announce the new cool chain facility will officially open its doors on 26 October.”

Panza said the location of the site also created a host of advantages for clients.

“The country has a dynamic and active cool chain and supply chain ecosystem, and there is strong collaboration between regulatory bodies and business entities with the shared goal of future-proofing the industry and further establishing the emirates as a global cool supply chain hub,” he said.

“Our hub in Abu Dhabi is unique in that it is in the perfect location to offer a bridge between not only Asia and Europe but also, further afield, the USA and Africa. Etihad Cargo’s network currently offers cargo capacity to 79 destinations across Europe, Asia, Africa, Australia, and the Americas with 564 weekly rotations.

“We also operate charter flights and utilise an extensive road feeder service network to service demand across non-network destinations. We remain committed to expanding our network and adding capacity to address our

customers’ requirements.”

The facility is also capable of storing a huge range of products which require differing environments.

“To meet the requirements for transporting dangerous goods in frozen and deep-frozen conditions, PharmaLife provides premium tailored solutions to handle temperaturecontrolled conditions from -80 to 25 degrees Celsius via the carrier’s portfolio of leased active and hybrid

“Etihad Cargo also utilises traditional containers that meet standard temperature requirements, from 2 to 8 and 15 to 25 degrees Celsius.”

The flaws highlighted by the supply chain breakdown of the last handful of years also informed the industry on the best ways to safeguard the supply, and cool chain, into the future.

“The flaws of the cool chain exposed over the last couple of years

last of data, incomplete data, data that has not been digitised and cannot be shared effectively and what we do with the data we gather,” said Panza.

“More than ever before, consumers are demanding increased traceability and traceability from the perishables supply chain.

“This traceability is also essential to maintaining food safety and operational efficiency, so it is vital carriers are able to track a product’s journey from production through to processing and distribution.”

Etihad Cargo ensures perishables are delivered in the best condition possible through processes that provide visibility and offer robust traceability and tracking.

Through the adoption and utilisation of digital traceability, Etihad Cargo works with clients to help them validate the authenticity of product safety, provenance and health or sustainability claims.

“The technologies we use and processes we follow ensure the data we collect, track and share give unrivalled visibility across every stage of perishable cargo’s journey,” said Panza.

And to address concerns of sustainability, Etihad Cargo has implemented several initiatives to make the transportation of perishables more sustainable, including the introduction of specialised thermal covers and the replacement of traditional unit load devices (ULDs) with lighter-weight ULDs, enabling

Food producers face a raft of difficulties when it comes to detecting and stamping out bacteria. Vendart are experts at finding the right solutions. Food & Beverage Industry News reports.

Herewe discuss the difficulties facing food producers in detecting bacteria and residues on food production surfaces, the shortcomings of the most common detection methods and how food producers might benefit from using impedance flow cytometry to close the gaps that cultural methods and ATP testing leave behind.

Impedance flow cytometry is a technology which uses electrical impedance to detect, count and characterise cells. Imagine a flow channel through which particles, suspended in solution, are flowing between two electrodes. Electrical currents are flowing at low and high frequencies and any object passing between the electrodes will introduce a change to the current. It is this flow change that impedance flow cytometers are calibrated to detect.

Bacteria have unique electrical properties which acts as a fingerprint for impedance flow cytometers to distinguish bacteria from other particles. Bacteria have a non-conductive shell and core which prevents the electrical field from penetrating the intact cell membrane at low frequencies, but at higher frequencies cells are similar to conductive particles.

Five gaps in your environmental monitoring program

1. V iable but non-culturable (VBNC) microorganisms

In general, bacteria in the VBNC state are alive but do not multiply and are therefore unculturable.

Researchers have concluded that bacteria that enter the VBNC state (for a variety of reasons including starvation, incubation temperature, oxygen levels etc.) can be resuscitated and return to a culturable state, and therefore become potentially pathogenic again. Moreover some pathogenic bacteria require a host to grow and need only to survive in food until ingestion to cause illness in humans. VBNC bacteria should be of concern in food manufacturing.

2. A naerobic & microaerophilic bacteria

Several pathogenic bacteria have special growth requirements regarding oxygen and temperature and many of these species are responsible for common foodborne illnesses. Of the anaerobic group a Clostridia species such as C. botulinum is responsible for the foodborne illness known as botulism, often transmitted through canned, oxygen-poor food in which C. botulinum can thrive. Campylobacter species is an example of a thermotolerant bacteria which infects every other chicken, on average, making poultry meat one of the most common causes of food poisoning.

The “great plate count anomaly” is the term we use to describe the observation that microscopic cell counts are significantly higher than corresponding counts of colony forming units (CFU) on agar plates. Different growth conditions and types of media promote the growth of different microorganisms, but we are unable to successfully cultivate all the microbes that we’re able to

see under a microscope.

4. Psychotrophic bacteria

Psychotrophic bacteria can grow at temperatures as low as 0 °C with optimal growth occurring above 15 °C. Given that these microbes can proliferate at refrigeration temperatures, they are especially problematic for foodstuffs and beverages like raw meat and milk stored at low temperatures for long periods. Psychotrophic bacteria are adulterants which can significantly diminish the quality and shelf life of food and lead to serious illness. For example, the robust Pseudomonas species are most often responsible for spoilage in vacuum packed chilled meat.

Most bacteria can form biofilms a nd researchers have suggested that the complex structure of mixed biofilms renders them more stable and resistant to disinfectants. Biofilms that form on food processing equipment and other food-contact surfaces act as a persistent source of contamination, threatening the overall quality and safety of food products and possibly resulting in foodborne diseases as well as economic losses. Spoilage microorganisms are known to be responsible for almost a third of losses in food supply chains, making biofilm prevention and control a priority in the food industry.

Each of these five cases presents a difficulty in detecting bacteria and residues on food production surfaces.

Options for bacteria detection for food

producers are limited.

• W hile visual inspection is a prerequisite, it is not a sufficient means of verifying proper cleaning. Even if a surface has no apparent residue, this does not mean that a sanitiser has effectively reduced the microbial level on the surface.

• Traditional agar plates take days to deliver results and, because most bacteria are unculturable, only limited bacteria species can be detected using this method. If a plate count has no growth, it might be deemed sterile, but this is not correct as there are many reasons why microorganisms might not grow on a plate (VBNC, anaerobic, stressed to name a few).

• A naerobic bacteria can grow on classic agar plates but this process requires carefully controlled oxygen levels.

• Vital staining and microscopic methods can quantify VBNC bacteria but are time-consuming and require special equipment.

• Adenosine triphosphate (ATP) can be thought of as the “energy molecule” found within all living cells. ATP tests indirectly indicate the presence of food residues or (potentially) microorganisms but do not directly detect bacteria. Certain environmental conditions can elicit faulty ATP test results; changes in temperature can impact reaction times; light can make it difficult to obtain correct readings and disinfectants can interfere with the reaction. Most foods leave behind residue containing large amounts of ATP - about 10 millions time more than the amounts contained within bacterial cells. Any ATP generated by bacteria in an ATP test will be

greatly overshadowed by the greater amount of ATP left behind by any food residues. Practically this means that ATP systems cannot be used to assess microbial contamination in food processing facilities.

The shortcomings of these most common detection methods, such as plating and ATP are well documented. So what can food producers do to close the gaps that cultural methods and ATP testing leave behind?

Impedance flow cytometry brings considerable advantages to food producers looking to verify their food safety and cleaning programs: the fast and separate quantification of bacteria and residue particles, the sensitivity of the method, and the robustness of the device. Another advantage is their portability; light, small and batterypowered for operation in the field at critical control points.

CytoQuant is easy to use. A test begins by swabbing a predefined area of the surface to be tested. The swab is placed inside a tube containing a proprietary conductive solution.

After shaking the swab kit to suspend the bacteria, the user inserts it into the device. Two needles penetrate the bottom of the tube, connecting the liquid to the flow system in the device. The solution is introduced into the flow system and is passed by the electrodes in the flow cell. After 30 seconds, the device produces separate results for bacteria and particles.

The CytoQuant mobile flow cytometer enables the immediate, on-site verification of cleaning and disinfection procedures in food production facilities or other areas where hygiene is crucial. By directly quantifying bacteria and residue particles on surfaces without the negative influence of disinfectants or temperature, it provides substantial advantages over ATP devices, while the 30 second time-to-result makes it a perfect enhancement to hygiene programs that already use cultural methods. Considering the huge potential of impedance flow cytometry, it may at some point come to be regarded as equal to or even replace cultural methods as the standard in cleaning verification. This would amount to a true revolution in the field. F

Food & Beverage Industry News reports that the latest gluten test kit from ELISA Systems is the first to reliably detect both native and deamidated gluten, in an easy-to-use way.

Theimportance of improved gluten detection in ELISA test kits continues to grow as the incidence of coeliac disease also increases. There’s currently no cure for the chronic digestive and immune disorder and as a result people with the condition are forced to avoid gluten. To cater for this, food manufacturers are entering the gluten-free market at an increasing rate.

ELISA Systems is a company which prides itself on being at the cutting edge

of allergen test kit development. Its upcoming Generation 3 Gluten test kit, ESGLT3-48, promises a feature not yet seen in other testing kits.

“Coeliac disease affects many people and there is no cure, so our aim is to protect the consumer and have a kit that can detect gluten in as many forms as possible,” said Karrin Ryan, ELISA Systems’ quality manager and scientist.

The newest gluten kit from ELISA Systems still reliably detects the three native grains: wheat, barley, and rye,

but the added benefit of the Generation 3 Gluten kit is its ability to also detect deamidated gluten.

“When there’s combined heat and acid in the production process it can cause deamidated gluten. Deamidated gluten may also be added as a functional ingredient as it is more water soluble, thus enabling it to be used as an emulsifier in a wide range of products.”

Previously these residues had a way of going largely undetected, or underestimated, which in turn

ELISA Systems’ quality manager and scientist Karrin Ryan said the kits contain all new features.

ELISA Systems are set to launch a new gluten test kit to the market.

especially with its toxicity to coeliac disease sufferers.

“Other test kits on the market are unable to effectively detect these residues. We wanted to make sure we developed a kit that could, because these residues are still toxic to coeliac sufferers,” said Karrin.

Using a muesli bar as an example, the new test kit can be used at any stage of the manufacturing process. This means the test kit user can perform testing as they require.

“Manufacturers can test all the raw ingredients that go into that muesli bar,” said Karrin. “They can also use swabs to test the equipment being used in production, and they can test their final product as well. Testing can be done at any stage of the process.”

Protection against gluten contamination is critical for manufacturers within the sector. The impact of product recalls on food and beverage manufacturers is a constant concern, so improved testing

As well as detecting the three native grains, the kits also detect deamidated gluten.

to avoid recalls is good for both the manufacturer and the consumer.

“A large percentage of product recalls are due to food allergens that aren’t declared. It is really important that manufacturers are testing their products and making sure they’re safe because it will cost companies if they have to recall products, both directly and due to brand damage,” said Karrin.

“We focus on helping protect the consumers who have food allergies by helping the manufacturers ensure labelling laws are followed when it comes to declaring allergens.”

“It’s about protecting both the consumer and the manufacturer.”

Karrin said continually improving test kits was critical with the growing number of manufacturers entering the sector who produce both gluten and non-gluten products.

“We want to make sure manufacturers aren’t missing anything in their products,” she added.

“There are many manufacturers with both gluten-containing and

gluten-free ranges, which may use the same processes and machinery. To ensure the safety of their gluten-free ranges, testing needs to be completed in a fast, reliable way.”

The Generation 3 Gluten test kit has been designed with ease-of-use in mind. “Other methods use longer extraction procedures with solutions containing hazardous compounds which are unpopular with customers,” said Karrin. “Our new test kit has a short assay time and it’s a simple, shorter extraction procedure as well. Whether testing in-house or using a third-party laboratory, a faster turnaround time is created by having a one-step extraction procedure that can be performed safely without a fume cabinet.”

The ease of testing is important with the prevalence of gluten across just about every sector of food manufacturing.

“It’s potentially everywhere, to be honest,” said Karrin.

“The deaminated gluten being used

as an emulsifier means it can be used in a wide range of products. Things like pasta sauces, recipe mixes, even vegan vegetable sausages. You see a lot of products with added wheat protein. There are a whole range of industries which need to be vigilant.”

The ELISA Systems team remains dedicated to constantly innovating new and improved products, such as the Generation 3 Gluten test kit, allowing the industry to be prepared for the future.

“Our team focuses on research, and we constantly make sure we are keeping up to date with new products and monitoring industry trends. We work hard to have the right antibodies and extraction procedures for the best detection in order to meet customer requirements and produce high-quality, easy-to-use kits,” said Karrin.

“In terms of timelines, we look to improve and launch our kits to meet customer demand as it occurs. The new Generation 3 Gluten Kit will be available from November 2022.” F

beverage producer can exceed millions of dollars of costs along with a big hit to the brand’s reputation, which means processing equipment can’t afford to faulter.

It’s impossible to create a machine, or piece, that can promise 100 per cent success for 100 per cent of the time, external factors must be factored in. In addressing this, ifm offers sensor and measurement technology to the industry as an added layer of protection against processing and machine failures.

Catching a fault or poor quality product in the process before stock goes to the consumer is the best way to avoid any unforeseen contamination risks.

The IIoT platform moneo from ifm promises to make digitisation easy, which in turn will help keep on top of the data being produced by key process

production process.

In order to obtain the important information from the shop floor, reliable connection of the sensors to the IT infrastructure is essential.

Moneo, the powerful IIoT platform, effectively and efficiently bridges the gap between the two worlds, thus enabling an easy entry into the digital evolution.

Moneo’s modular concept provides a selection of different, easy-to-handle applications that can be linked together. From sensor parameter setting to key process data capture and evaluation to condition monitoring, moneo thus offers all the features of future-proof IIoT software.

However, you alone decide which applications are required and activated in each individual case. It’s as easy as that. In other words: moneo is great - without ever exceeding the size you

processing is possibly the most critical part of food and beverage manufacturing for its ability to circumvent potential hazards and product issues.

“ifm often talk of Moneo and how it plays a decisive role in quality and food safety, especially with most production processes being automated,” he said.

“With the automated side, this is where our sensors kick in. They must be of the highest hygienic quality and made of food grade stainless steel. During the washdown process, every part of the sensor needs to be cleaned without any food residue which can grow dangerous pathogens.

“Sensors play an important element with these processes, for example separating, homogenising, pasteurizing, filling, bottling,

canning, packaging, conveying, all these things are important and these processes for us is where sensing technology comes into its own space.”

As part of this, ifm has come up with a new motto to guide its latest campaign, to ‘protect what’s important’.

“Because if you can monitor the product as it’s being made, from a quality aspect, you protect the product through the automation sensing technology,” said Thornton.

“The narrow tolerances in food safety means you try to protect against impurities and a product that is out of specifications even a little, it may be visually or aesthetically wrong, but the risk is when it becomes dangerous through a hygienic problem with the product which can lead to recalls.”

Thornton said the impact of product recalls on manufacturers and producers were heavy, and in some cases hard to bounce back from in any decent amount of time.

“The worst thing before even losing production and downtime, is the hit to brand reputation,” he said.

“As soon as you end up with a recall you have damaged your reputation, so we aim to provide product security and surety. The security is on the quality side and the surety is on the

branding side because you know once you package this, and it has been monitored the whole way through.”

The sensors are also critical for the clean down processes as they have the capability of helping to ensure the hoses, and other equipment washed down, doesn’t contain any leftover contaminants that could then end up inside the packaging.

“The cleaning processes are critical. Then the measurement is done, and after the pipe looks clean is when you can start running your product again,” said Thornton.

“The thing is to make sure the cleaning is finished and once you’ve made your product, the cleaning starts again.”

I fm can also add a layer of Moneo software into the process to create an even stronger system.

“The Moneo software is an area which we are really focusing on because it gives us another layer or product surety because it’s not just saying let’s put automation in,” said Thornton.

“ We also use software to monitor it. This monitoring is the part that is important because it can be exported to dashboards. It gives quick alerts and alarm notifications in real time, which is critical.” F

Our products are made from agro-waste that is locally sourced from Australian farmers

safety has always been one of the most, if not the most, important factors in food manufacturing and as technology advances, so do the capabilities of expert food scientists.

HACCP Australia, a leading food science organisation specialising in the HACCP Food Safety Methodology, is one organisation with a strong and storied history in the sector.

Since 1998 HACCP Australia has helped the Australian food manufacturing industry improve its processes, and by extension, its output and overheads, through the use of its team of high-ranking food executives and experts.

Martin Stone, executive director at HACCP Australia, said the decades of experience in the organisation, backed with industry leaders and food science experts, made HACCP Australia a great resource for the food manufacturing industry.

“We built the company in 1998 and we are an organisation of food scientists with a great deal of experience in the food industry. “We help people develop, implement and certify, Food Safety Management Programs, typically using the HACCP methodology,” he said.

Food safety, is the area of main concern for Stone and the HACCP Australia team, who are constantly working to incorporate the best training

“We work with clients as diverse has hospitals, breweries, people that manufacture pickles, coffee roasters, in fact, you name it and we have had involvement with those sectors.”

and consultancy from emerging, and existing, techniques and methodologies.

Mr Stone also has concerns about high levels of food waste in processing and the community. “There’s an awful amount of food waste and it’s something we would like to reduce, but there is balancing act between food safety and food waste, in some ways,” said Stone.

“We have a great many years of expertise within this organisation and one key thing about us is all our employees have been working in the industry for many years in managerial and operation roles.