NOVEMBER 2019

Is your facility ready for Industry 4.0?

WorldClass ClassFacility FacilityConstruction Construction World Talkto toTotal TotalConstruction Constructiontoday todayto tosee seehow howwe we Talk canassist assistwith withensuring ensuringyour yourfacility facility&&services services can areable ableto tocope copewith withyour yourmove moveinto intoautomation. automation. are

NOVEMBER 2019

PLUS: Construction rules and regulations | The rise of plant proteins | Lean manufacturing

EXHIBITION SPACE NOW ON SALE 1ST - 3RD A P R I L 2 02 0

ME LBO U R N E CO NV ENT I O N & E XHI BI T I O N C ENT RE SU PPORT I N G S P O NS O R S

ASS O CI AT I O N PA RT N ER S

CONFE RE NCE SPONSORS

WELCOME

Why food labels offer essential info

L

CEO: John Murphy Publisher: Christine Clancy Group Managing Editor (Northern): Syed Shah Editor: Mike Wheeler Ph: (02) 9439 7227 mike.wheeler@primecreative.com.au

Design Production Manager: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey Designers: Kerry Pert, Madeline McCarty Sales/Advertising: Luke Ronca

Editor: Mike Wheeler

Ph: (03) 9690 8766 luke.ronca@primecreative.com.au

Production Coordinator: Janine Clements Ph: (02) 9439 7227 janine.clements@primecreative.com.au

Subscriptions AUS NZ O/S 1 year subscription 99 109 119 2 year subscription 189 199 209 For subscriptions enquiries please email subscriptions@primecreative.com.au

abelling of food and beverages can be a nightmare for manufacturers, especially in an age where allergens seem to be increasing and a lot of perishables are being imported. Australia has a pretty good record when it comes to labelling, but it pays to be vigilant. In this issue of Food & Beverage Industry News we talk to the AIFST’s Fiona Fleming who gives some insights on how to make sure manufacturers are keeping up to speed with local labelling requirements. Imagine producing a 20-year-old malt whiskey overnight. Or, how about if almost every house has a 3D food printer in their kitchen ready to produce that late night snack at the push of a button? These are some of the ideas that are spruiked by KPMG’s Trent Duvall in our story

that mainly looks at plant-based proteins but also covers some of the latest trends coming to the fore. As he mentions in the piece, food and beverage manufacturers need to look at who is calling the shots these days, and it may not be who you think it is. On the back of its story on rules and regulations in our last issue, Total Construction offers up some more, in-depth information on the subject. Company director, Bill Franks, gives some practical hints and insights when it comes to building a new facility or renovating a brownfield site. There’s plenty of other great stories in this issue. Have a great month. Mike Wheeler

INSIDE Copyright Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2019 Articles All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format. Head Office 11-15 Buckhurst St South Melbourne VIC 3205 Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au Sydney Office Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065, Australia Ph: (02) 9439 7227

40

24

30

4 NEWS

28 ROBOTICS

40 F&B AWARDS: PROFILE

18 SAFETY

30 DRIVE TECHNOLOGY

44 MARKETWATCH

20 SUSTAINABILITY

32 PACKAGING

45 DAIRY REPORT

22 BUILDING PLANT

34 AIP

47 NEW PRODUCTS

24 CONSUMER

36 LEAN MANUFACTURING

26 AUTOMATION

39 BELTS

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175

Ph: (03) 9794 8337

www.foodmag.com.au | November 2019 | Food&Beverage Industry News 5

NEWS

Action to protect native fish ahead of hot, dry summer

Murray Cod is just one species that will benefit from the initiative.

T

he Federal Government is working with the states to protect the Murray–Darling Basin’s native fish ahead of an expected hot and dry summer. Minister for Drought, David Littleproud, released the Native Fish Emergency Response Plan. Make no mistake, we are likely to see fish deaths this summer,” Littleproud said. “We’re facing another hot summer with very little water flowing through our rivers. This plan will give the MDBA and the states vital tools to help protect fish populations. The Federal Government has money put aside for fish-death prevention measures and environmental water holders will replenish areas on red alert, where they can.

“Fish deaths are common during summer but what we saw last year were a major wake-up call about the impact of the drought on our rivers. After the Vertessy Review, we have put an emergency plan in place. “The plan will see more activity in high risk areas, with aerators, fish relocated and algae blooms watched closely. “The last Northern Basin environmental watering program refreshed waterholes and fish refuges although there is little environmental water left. “NSW emergency measures have seen fish relocated so they survive this summer and re-populate the rivers when conditions improve. “The Commonwealth is also bringing government officials and experts together this month to

6 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

coordinate plans and identify areas at high risk of fish deaths. “Communities too have their part to play and we also ask the community to report river conditions and fish deaths to help with fish relocations and recovery. “We want native river fish such as the Murray cod, silver perch and golden perch to have the best chance of surviving this summer. “We want healthy and thriving fish populations in our rivers during drought and in the good times.”

Background Under the Native Fish Emergency Response Plan, the Commonwealth Government will: • Provide emergency funds from the Emergency Contingency Fund

to help states manage urgent and extreme fish death events, with $300,000 set aside. • Provide available Commonwealth environmental water to mitigate fish deaths. • Support the coordination of emergency response activities and sharing of resources. • Maintain a database of significant fish deaths events. • Contribute to water quality monitoring programs to identify areas at risk. In return, the states will: • Identify and monitor high risk sites for fish deaths. • Identify priority refuge areas for native fish. • Prepare on-ground emergency response plans for priority species and areas.

NEWS

Brownes Dairy switches to plant-based renewable packaging B rownes Dairy will replace its existing milk cartons with an Australian first, a carton package made entirely from plantbased, renewable materials in a new sustainable packaging move. Tetra Rex Bio-based package is the world’s first fully renewable beverage carton, with the protective layers derived from sugar cane. “There is a lot of emphasis on the importance of recycling, but less of a focus on how we can make products more sustainable from the beginning. Brownes Dairy wanted to improve the sustainability of our packaging across the entire lifecycle of our products,” said Brownes Dairy CEO, Tony Girgis. The bio-based packages offer a more sustainable alternative to the standard milk cartons, reducing the reliance on fossil based polyethylene plastic in the lining. “Brownes Dairy scoured the planet

in search of the best sustainable packaging on the market. Making the switch to a protective layer derived from sugar cane is not only better for the environment, but our consumers can trust the package is made from a renewable source that has a lower carbon impact to climate change,” said Girgis. Brownes Dairy will switch 25 of its milk carton products to the new sustainable packaging - about 17.8 million milk cartons per year. “We have done the due diligence on this packaging format to ensure our product quality, freshness and food safety are fully maintained,” said Girgis. The Brownes Dairy white milk, cream and CHILL range will all be packaged in a Tetra Rex Bio-based pack. “Across the industry, we have seen almost all flavoured milk products move to bottles, but Brownes Dairy has made the conscious decision for its

Brownes Dairy will switch 25 of its milk carton products to sustainable packaging. CHILL range to remain the ‘King in Cartons’,” said Girgis Tetra Pak has delivered more than half a billion renewable packs since the bio-based package was first introduced in dairy by Finnish brand Valio in 2015. Brownes Dairy will be the first company in Australia to integrate the renewable cartons across its entire milk carton range.

“Consumers globally are concerned about protecting the planet, with research showing people of all ages believe businesses should take responsibility for their impact on the environment. At Brownes Dairy, we wanted to support the global movement by looking at packaging across its entire lifecycle, from source to end of life,” said Girgis.

www.foodmag.com.au | November 2019 | Food&Beverage Industry News 7

NEWS

Blockchain whiskey released William Grant & Sons’ existing data sources, cask types, filling dates and bottling dates are all tracked. Consumers can trace the origins of their whisky via an innovative web experience, which is individually tailored to each bottle. By scanning a QR code, users are presented with a visual history of their whisky, produced using digitally created art generated by blockchain data unique to the drink’s journey. Blockchain technology also allows Ailsa Bay to gather data from existing and potential customers, using mobile location services to correlate where the whisky is being purchased and consumed to maintain brand protection. James Macrae, brand ambassador or Ailsa Bay, said, “Innovation is a key part of the William Grant & Sons business. We’re constantly looking to evolve our offering and learn new things in order to push the boundaries within the drinks industry.

Consumers can trace the origins of the whiskey using blockchain.

W

illiam Grant & Sons’ premium whisky brand, Ailsa Bay, has launched the world’s first-ever blockchain whisky in partnership with specialist blockchain technology company arc-net. Ailsa Bay aims to transform whisky through experimentation, technology, precision distilling and data driven methods. Its whisky is unique as it undergoes a micro-maturation process in small Hudson whiskey casks. Ailsa Bay’s use of blockchain captures the full distilling and manufacturing process, allowing customers to track their whisky from source to store; ensuring authenticity and traceability. Blockchain is a list of registers, or “blocks” which contain information about the previous block and transaction data between them. It acts as an open ledger, and this ledger is managed publicly rather than controlled by one party, meaning stored information can’t be changed or tampered, to track authenticity. For Ailsa Bay, blockchain data is collected from parent company

Blockchain is used to capture the whiskey’s distilling process.

8 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

“We’re doing something now that we hope will set the bar for the future experience of spirits, and we look forward to seeing how other brands follow suit as innovation within the industry continues to develop in the next few years.” The concept of using blockchain for whisky emerged from William Grant & Sons’ inaugural Hackadram event that was held last year, in which start-ups and innovation specialists were invited to use their expertise to shape the future of the company’s spirits. The adoption of blockchain is the latest innovation for Ailsa Bay. It joins other innovative processes, including ‘micro-maturation’, where the spirit is added in small bourbon casks for six to nine months for rapid and intense maturation, and unique taste measuring labelling, displaying both the Phenol Parts per Million (PPM) and Sweet Parts per Million (SPM); bringing a new way of thinking to a traditional drink.

NEWS

Consumer demand expected to boost cheddar cheese market

Cheddar is said to be being preferred over natural cheese in several snack preparations.

T

here has been a shift in consumer preferences towards various types of nutrient and protein-rich foods that also promise healthy substitutes to everyday consumable products. Cheddar cheese is a multipurpose food product that has been used in the food industry in numerous applications. The availability of cheddar cheese in the bakery sector and food product companies is increasing as it is a basic ingredient in most of the food preparations requiring cheese. This has boosted the demand for cheddar cheese in the global market. Increasing consumption of cheese in various types of cuisines is also anticipated to boost the overall production of cheddar cheese in the food industry. Cheddar cheese is increasingly being preferred over natural cheese in several bakery and snack preparations. This has also led to increased consumption and hence production in the global market. Furthermore, growing consumer demand for cheese-based

breakfast products is also expected to lead to a rise in the utilization of cheddar cheese in different breakfast products. A study on cheddar cheese by Fact.MR found that cheddar cheese fanatics are always experimenting with food and manufacturers are coming up with new varieties of food items. The trend of fine gourmet, cuisine and luxury culinary items has inspired manufacturers to innovate their products in order to cater to the taste preferences of consumers. As a result, the development of block cheddar cheese is expected to trigger a mass demand for cheddar cheese especially in hotels, restaurants, and cafes. A growth in the demand for gourmet and artisanal cheese products is a key factor which is likely to boost the cheddar cheese market in the long run. The expansion of online and retail outlets resulting in the easy obtainability of cheddar cheese is anticipated to create lucrative opportunities for manufacturers in the coming years. European and North American

markets are moving towards a saturation point, so manufacturers of cheddar cheese are looking for regions that will present them with versatile opportunities in the future. The growing cheddar cheese market in Latin America will open a plethora of opportunities for market players to capitalise on. Europe is the largest consumer of cheese in the world. Several varieties of cheese are available in the region and the application of cheddar cheese is also widespread in the food industry in Europe. Asia Pacific Excluding Japan (APEJ) is the third largest consumer of cheddar cheese and related products in the world. With the growing acceptance of Western culture in the region, the food habits and taste preferences of people are also increasing at an extensive rate. In spite of the growing disposable income of people in the region, consumers still look for inexpensive food options. As a result, the demand for cheddar cheese is increasing in several countries in APEJ. The study also

found that Japan is slowly emerging as one of the lucrative markets for cheddar cheese with the trend of mild snacking increasing in the region. With the trend of drinking gaining traction in Japan, having light snacks especially cheddar cheese has increased considerably as a home trend. The Middle East and Africa are anticipated to present manufacturers of cheddar cheese with new and lucrative growth prospects. As the governments in these regions are looking to generate revenue from other sources apart from oil reserves, a variety of industries are emerging as highly profitable options. For instance, in September 2019, Arla Foods a Scandinavian dairy products company will scale up its commitment to develop a sustainable dairy sector in Nigeria. This study underlines key opportunities in the cheddar cheese market and finds that the market would exhibit growth at a value CAGR of – three per cent during the forecast period.

www.foodmag.com.au | November 2019 | Food&Beverage Industry News 9

NEWS

Compostable cucumber wrap from BioBag World A fully compostable shrinkwrap for cucumbers has been developed in South Australia and is set to launch onto international markets. The compostable wrap is manufactured by BioBag World Australia and took 12 months to develop in partnership with South Australian produce and packaging businesses IG Fresh Produce. It was launched in September as an environmentally friendly alternative to the traditional polyethylene plastic wrap and has already generated export interest from Qatar and South Africa. IG Fresh executive director George Antonas said he was approached by South Australian independent grocer Drakes Supermarkets to develop a compostable fruit and vegetable wrap to replace traditional shrink-wrap. Antonas said the product was being used exclusively on cucumbers sold at Drake’s 38 South Australian supermarkets until October 16, after which it’d be available for a wide range of purposes. “JP Drake put the challenge to us and so we gave them product exclusivity for the first four weeks,”

Antonas said. IG Fresh produce is a fruit and vegetable wholesaler located in Adelaide. Antonas said a potential investment partner from Qatar had travelled to Adelaide for the product launch with Drakes. He expected to begin exporting cucumbers dressed in the compostable wrap to Qatar by the end of October, with exports to South Africa and Europe to follow. The bioplastic film is made from a compostable resin called Mater-Bi that uses substances obtained from plants including non-genetically modified corn starch. While there are other compostable products on the market, Antonas said creating a 100 per cent industrially compostable cucumber wrap required a unique process. “That’s where Scott Morton’s expertise came into it – because it’s heat shrunk onto the cucumber. There’s plenty of compostable products out there but this one is for a specific purpose,” Antonas said. “There’s a big push to make all single use packaging compostable. So, you buy a cucumber, you peel off the wrapper and you put it in your greens bin and you know it’s not going to

The cucumber’s bioplastic cover is made from compostable resin. add to landfill and that sort of thing. Plastic has its place but not for single use, it just creates too much waste.” According to Antonas, the cucumber compostable wrap has the potential to be used on all fruit and vegetables, and BioBag World Australia director Scott Morton agrees. “The potential is endless. It’s improving all of the time. I see it as a direct replacement for plastic,” Morton said. Norway-based BioBag has six factories and 20 market or distribution partners around the world, producing over one billion bags a year.

Morton said BioBag was also working on a non-shrink-wrap compostable product that could replace plastic cling films. He said the cucumber wrap developed in South Australia could also be distributed in major global markets including the United States. “We’re trying to enhance the current cucumber wrap. It’s not quite suitable yet as a cling wrap alternative,” he said. “We’re developing a new product that’s more for the international market. That’s a product that will especially keep fruit and vegetables fresh.

SIA happy with state of fisheries S eafood Industry Australia (SIA), the national peak-body representing Australia’s commercial fishing industry, is delighted that for the sixth consecutive year its solely Commonwealth managed fisheries are in great shape and being fished sustainably. The release of the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES) “Fishery status reports 2019” highlights the quality of Australia’s Commonwealth fisheries management. “This is great news and is unprecedented internationally,” SIA CEO Jane Lovell said.

“The ‘Fishery status reports 2019’ provides an evaluation of 96 Australian commercial fish stocks. “This positive report card given for the sixth consecutive year to Australia’s solely Commonwealth managed fisheries is the ultimate endorsement that Australia continues to be a leader in world class seafood and sustainability. “Australians should be proud of their seafood industry which provides fresh, high-quality seafood, year-round. “As fishers, our priority is the ocean. We advocate the health, sustainability, and future of our ocean. It’s our livelihood and the future livelihood of generations to come.”

10 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

The SIA’s CEO Jane Lovell.

NEWS

Developing new processes for new ingredients C rispy roasted crickets were recently served in a sushi restaurant in London, reigniting the discussion about integrating insects into consumer diets. However, less thought has been given to what industry will have to do to handle these new food types. New ingredients that have been incorporated into diets in recent years include quinoa, avocado and kale. These new food products, with mass consumer appeal, are even more important when they use ingredients that are nutritious and environmentally sustainable. However, the sudden increase from low to large volume production can be an issue when a food product emerges to mass popularity. Scaling up production and processing food that suddenly and rapidly grows in popularity can be a daunting task. Improperly controlled mass production can cause

inefficiencies to spiral out of control, or for unknown issues to come to the forefront. For example, the massive global increase in demand for avocados forced the Kenyan government to ban the export of the fruit as there was not enough to supply local needs. The increase in demand for new ingredients or products also raises the need to implement proper applications for handling new ingredients. In the case of the crickets, most food manufacturing processes are built to deter insects and prevent them from contaminating the food. As such, if insect-based foods were to grow in popularity, new processes would have to be developed to ensure proper cleanliness and hygiene levels. When a product is in high demand and supplies run low there is also the potential for food fraud to come into play. This is dangerous, with potentially

fatal consequences for the end consumer, because the product may have been tampered with, contaminated, and may not be fit for human consumption at all. To combat these potential issues, producers that are handling new exotic products should ensure that they have measures in place so that operations managers have full control and oversight over their facility. Systems such as ABB’s Manufacturing Operation Management (MOM) can help keep track of products as they move around the production line and beyond. The MOM software can give products digital passports allowing producers to accurately tell when the product was produced and exactly what it has come into contact with during production. MOM’s can also help speed up the implementation period of new products because operation managers

will have more in-depth information regarding their system, allowing them to effectively prepare for using a new or unique ingredient. Being able to effectively prepare production lines for the introduction of a new ingredient is immensely helpful for producers, especially with the mass adoption of plant-based diets, meaning that more producers will begin introducing animal-free alternatives into production lines. Having the level of control brought by a MOM system will cut down on the time required to begin production. While insects may not have soared in mass consumption just yet, as people become more interested in what is in their food it is likely that new ingredients will come to the forefront. Preparing for these changes by increasing control will help businesses remain ahead of trends and increase their product security, one crispy cricket at a time.

Marbett: So Many Ways to Accessorise. Engineered to perform in high-speed and high-sanitation applications, Marbett® Conveyor Components help extend chain life and provide highly flexible, smooth running conveying conditions. Many products within Rexnord’s complete portfolio of conveyor components are available in plastic and stainless steel to address a wide range of requirements. Chain Guide • Wear strips • Corner tracks • Return rollers

Product Handling • Guide rails • Roller guides • Clamps and brackets

Frame Support and Leveling • Support bases • Articulated and fixed feet • Connecting joints

Specialty • Modular roller transfer plates • Return rollers • Shaft collars

Contact Rexnord today to learn more about Marbett Conveyor Components. sales.australia@rexnord.com or Tel 02 4677 6000

|

www.rexnord.com

www.foodmag.com.au | November 2019 | Food&Beverage Industry News 11

NEWS

New director appointed to Jenkins Group Board

Lachie Johnstone has been appointed to Jenkins Group board.

J

enkins Group has announced the appointment of Lachie Johnstone to its Board of Directors to further strengthen its position as a key industry player throughout Australasia’s horticulture post-harvest industry. Jenkins Group provides an extensive range of labelling, packaging and handling systems to the horticulture industry across

New Zealand and Australia via its two subsidiaries – Tauranga-based Jenkins Freshpac Systems and NSW-based J-Tech Systems. Johnstone has extensive links within New Zealand’s primary sector and will now join five other board members to guide Jenkins Group through the current innovation and expansion phase. Johnstone is well positioned to help guide Jenkins Group through these changes. He holds a B.Com from the University of Auckland and is the current chair of Farmlands (New Zealand’s largest farmer-owned rural supplies co-operative), as well as Wellington’s Centreport and Centreport Properties. He is a director of the C. Alma Baker Trust NZ and is the deputy chair of the Board of Governors at Auckland’s King’s College. In addition to these governance roles, Johnstone has private investments and commercial involvement in New Zealand’s agricultural and logistics sectors. He

has been at the helm of Farmlands for the past 16 years but will step down at the end of 2019, Johnstone is looking forward to sharing his experience and observations from other industries with Jenkins Group. “I enjoy primary sector and am particularly interested that the Jenkins Group is in the innovation space. It’s an exciting time in the horticultural sector, notwithstanding the likes of environmental challenges and shortages of labour. Our aim should be to bring together solutions that help our customers to solve complex problems,” said Johnstone. Having been exposed to many different industries has helped Johnstone shape his governance expertise over the past two decades, he said. Jenkins Group chair Harry Cranefield says the board is delighted to have someone of Johnstone’s calibre and breadth of knowledge join the team. “His overall farming experience, and his experience at governance

How to better manage animal disease threats A ustralia will be better prepared to manage significant animal biosecurity threats, such as African swine fever (ASF), through a new comprehensive online field guide for emergency animal diseases. Head of biosecurity, Lyn O’Connell, said the guide will help vets with early detection, diagnosis and control of exotic and emerging infectious diseases in livestock. “Early identification and reporting is critical to minimise the devastating impact that these diseases can pose for our animals,

industries, jobs and environment,” O’Connell said. ASF and foot and mouth disease (FMD) could wipe out industries, jobs, impact on trade and availability of the Australian produce we all enjoy, so we need to be as prepared as possible because the threat is real, said O’Connell. “Australia’s vets are vital for biosecurity. If the unthinkable happened and a significant animal disease was to hit our shores, our vets would play a key role in managing and minimising the risks. “This guide will help vets identify emergency animal diseases

12 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

in the field, ensure they consider priority diseases when conducting diagnosis and take appropriate action when they suspect signs of a biosecurity threat. The disease list included in the guide will be reviewed and updated to address emerging threats so the country is best placed to manage them as they arise. “We have some of the best vets in the world and this gives them another tool to improve the work they do in protecting Australia from deadly animal diseases.” The guide is in addition to a range of measures in place to

level, means he has a lot to add to Jenkins Group board. He brings that primary sector involvement and insight which is what we were looking for,” said Cranefield. “We specialise in the handling, labelling and packaging of horticultural products post-harvest and that includes everything from the orchard gate right through to the end consumer at the supermarket. Lachie is uniquely placed with a lot of skills and experience in different parts of that supply chain and will help us look towards the future.” Recent times have seen strong growth for Jenkins, in July the Group invested in Hawke’s Bay based CR Automation, which specialises in mechatronics and automation control systems for a wide range of industries including horticulture. Jenkins has also commenced a new joint venture with US company Van Doren Sales, Global Pac Technologies, to market and support the Robotics Plus apple packing systems across the globe.

better manage animal biosecurity threats. This includes increased intervention measures at our borders, testing of intercepted meat produce for ASF and FMD, as well as stronger enforcement approaches for biosecurity breaches relating to meat products. A roundtable was recently held between leaders, scientists and governments to discuss the actions needed to keep African swine fever out of Australia. A simulation exercise will also be held later this year to test our disease response capabilities to make sure we’re as prepared as we can be.

NEWS

DuPont launches dairy-free protective cultures for plantbased fermented products YM Vege is designed to prevent spoilage in plant-based beverages.

D

uPont Nutrition & Biosciences has announced a new ingredient – Holdbac YM Vege – as the latest addition to DuPont’s Danisco Holdbac line of protective cultures, known for their ability to extend shelflife and secure the quality of products by holding off yeast and mold spoilage – all without use of synthetic preservatives. Now, Holdbac YM Vege brings this effective and label-friendly spoilage prevention to plant-based, fermented foods and beverages, at a time when customer demand in this space has never been higher. “The industry has seen enormous growth for fermented plant-based products in recent years, driven by higher numbers of flexitarian, vegetarian or vegan consumers around the world. These shifts in diets are driven by a number

of factors, including the search for improved health that comes with a plant-based diet, ethical choices toward foods with lower environmental impact and which are deemed better for animal welfare, and switching to dairy alternatives for lactose-intolerant consumers,” said Eve Martinet-Bareau, global product manager, cultures for plant-based fermented food and beverages. “DuPont Nutrition & Biosciences has been working with customers for decades as consumer demands for plant-based options have increased, and we are constantly looking for ways to innovate in this space,” added Martinet-Bareau. “For example, in May 2018, we launched a new cultures line – Danisco Vege Cultures – especially designed for fermented plant-based

products, helping customers attain desired taste and texture profiles in a wide variety of plant-based dairy alternatives and beverages.” However, with that demand came certain challenges for producers of fermented goods, including the need to: • gain market share in the fastgrowing plant-based food sector; • consistently ensure high-quality products with the desired taste and texture, particularly across regions with differing consumer preferences; • secure that quality throughout a product’s shelf-life; • address the fast-growing demand for friendly labelled consumer products; • make a substantial contribution to the sustainability of the food and beverage sector; and • provide consumers with

products that improve their health and wellbeing. “As more consumers look for fermented food and drinks, our Holdbac YM Vege cultures will help our customers meet that demand.” This innovative new ingredient also offers customers the ability to make a significant difference in terms of environmental and social impact through reduced food waste and plant-based alternatives. The potential impact is massive: DuPont has estimated that if just five per cent of the global yogurt market is replaced with plantbased alternatives made with Danisco Vege and Holdbac YM Vege cultures, the carbon dioxide emission saving would theoretically be as high as 3,000,000 tons annually. This would be roughly equivalent to 1,700,000 EU-based cars off the roads. “We are thrilled to add Holdbac YM Vege to our range of plant-based and sustainable offerings,” said Mikkel Thrane, global sustainability lead for DuPont Nutrition & Biosciences. “We look at our environmental footprint through the lens of the UN’s Sustainable Development Goals (SDGs), and we are proud to say that this culture supports at least three – SDG 3 (good health and well-being), SDG 12 (responsible production and Consumption) and SDG 13 (climate action). Holdbac YM Vege is helping us facilitate the transition to a healthier and more environmental-friendly diet.” This transition to a healthier diet for people and the planet has been lead by DuPont’s expertise in microbiology, food protection and fermentation, as well its commitment to developing and offering more sustainable ingredients for customers.

www.foodmag.com.au | November 2019 | Food&Beverage Industry News 13

NEWS

Toby’s Estate partners with Califia Farms with oat milk Q In the US, oat milk is the number two dairy alternative after almond milk.

uite a few Australians are choosing plant milk over dairy including a new player in the market – oat milk. Toby’s Estate has teamed up with Califia Farms to offer oat milk to its café customers nationwide. “With compelling health, ethical and environmental benefits, it’s no wonder more people are turning to plant-based diets. When it comes to coffee, they’re now looking for more options than just soy and almond and so we knew

we had to listen to our customers,” said Jody Leslie, Toby’s Estate general manager. After a launch in the US, Califia Farms recently launched its new Oat Barista Blend in Australia and now Toby’s Estate is the first specialty coffee roaster who will soon be distributing it to its café network across Australia, starting with NSW. According to Dan Kaplan, national business manager for Califia Farms Australia, in the US, oat milk is the number two dairy alternative

in coffee shops after almond milk and it looks like Australia is headed in the same direction. “Oat milk is not only dairy free and not a nut milk, but it’s free from soy and made from a sustainable grain, which makes it an appealing option for consumers,” said Kaplan. Califia’s Oat Barista Blend is made from whole rolled oats and is unsweetened with no added sugar, gums, dairy or soy. It also has half the amount of natural sugar than other oat milk brands.

Carlsberg moves to create paper beer bottle C arlsberg Group is trying to create the world’s first “paper” beer bottle made from sustainably sourced wood fibres that is both 100 per cent bio-based and fully recyclable. Carlsberg has unveiled two new research prototypes of its Green Fibre Bottle, which are the first “paper bottles” to contain beer. Carlsberg also announced it has been joined by other global companies that are united in their vision of developing sustainable packaging through the advancement of paper bottle technology. These developments are a continuation of Carlsberg’s sustainable packaging innovation journey and a key part of its sustainability programme, Together Towards Zero, including its commitment to zero carbon emissions at its breweries and a 30 per cent reduction in its full value chain carbon footprint by 2030.

(PEF) polymer film barrier. These prototypes will be used to test the barrier technology as Carlsberg seeks a solution to achieve their ultimate ambition of a 100 per cent bio-based bottle without polymers. Myriam Shingleton, vice president group development at Carlsberg Group, said: “We continue to innovate across all our packaging formats, and we are pleased with the progress we’ve made on the Green Fibre Bottle so far. While we are not completely there yet, the two prototypes are an important step towards realising our ultimate ambition of bringing this breakthrough to market. Innovation takes time and we will continue to collaborate with leading experts in order to overcome remaining technical challenges, just as we did with our plastic-reducing Snap Pack.”

Two new prototypes

Carlsberg kicked off the project to develop a bottle made from sustainably sourced wood fibres, the “Green Fibre Bottle,” in 2015 alongside innovation experts ecoXpac, packaging company BillerudKorsnäs, and post-doctoral researchers from the Danish Technical University, supported by Innovation Fund Denmark. These combined efforts

The two new research prototypes are made from sustainably-sourced wood fibre, are fully recyclable and have an inner barrier to allow the bottles to contain beer. One prototype uses a thin recycled PET polymer film barrier, and the other a 100 per cent bio-based polyethylene furandicarbonxylate

New partners onboard

14 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

Carlsberg’s “paper” beer bottle is made from wood fibres. have resulted in the emergence of Paboco, the Paper Bottle Company – a joint venture between BillerudKorsnäs and bottle manufacturing specialist Alpla. Carlsberg will now be joined by The Coca-Cola Company, The Absolut Company and L’Oréal in a paper bottle community – launched by Paboco. The community unites global companies and experts with the vision of advancing sustainable packaging, offering highquality products while reducing their environmental impact. Shingleton said, “The work with our partners since 2015 on the Green Fibre Bottle illustrates that this kind of innovation can happen when we work together. We’re delighted that other like-minded companies have now joined us as part of Paboco’s paper bottle community. Partnerships such as these, ones that are united by a desire to create sustainable innovations, are the best

way to bring about real change.” “We’re driven by our constant pursuit of better, to create more sustainable packaging solutions that help people to live more sustainable lives. Sometimes that means completely rethinking how things are done – pushing the boundaries of existing technologies and overcoming technical challenges as they present themselves.” Gittan Schiöld, interim CEO of Paboco said, “It is all about the team! We are collaborating across the value chain, sharing the risks and are united in our vision that the paper bottle will become a reality and fundamentally change this industry for good.”

A constant pursuit of better Carlsberg’s focus on sustainable packaging innovations is not new. In 2018, the Danish brewer launched a number of packaging innovations including recycled shrink film, greener label ink and the innovative “Snap Pack,” which replaces the plastic wrapping around its six-packs with a solution that instead glues cans together. Carlsberg’s packaging improvements are part of its long-standing progress of betterment and innovation, including developing scientific breakthroughs such as pure yeast and the pH scale.

NEWS

Matilda founder returns to brewery

Phil Sexton will help develop a new Matilda range of beer.

A

ustralia’s original craft brewer Phil Sexton is returning to the label he founded more than 35 years ago to reinvigorate the country’s original craft beer. This will see Sexton partner with Carlton & United Breweries, which fully acquired Matilda Bay in 1990, to build a new small-batch brewery in country Victoria that Sexton and his team will run. The brewery will be in Healesville in the Yarra Valley, an hour east of Melbourne, and will have a pub attached. It will exclusively develop and brew a new Matilda Bay range and some Matilda Bay classics such as Redback and Dogbolter. Sexton said the timing was perfect to re-launch Matilda Bay and

help craft beer reach its potential in Australia. “Restoring Matilda Bay to its rightful place as Australia’s leading craft beer is unfinished business for me,” he said. “I want to grow craft beer by showing people how special good small batch beer can be. “I founded Matilda Bay in 1983 to give drinkers beautiful craft beer. And as the original craft brewery, it still has a special spot in the consciousness of Aussie beer lovers. It’s the right label to finish what I started and reaffirm what artisanal brewing should stand for: sessionable, flavourful beers that stand the test of time.” Sexton is one of Australia’s leading brewers and winemakers. In addition to Matilda Bay, he founded Little Creatures and launched Giant

Steps and Innocent Bystander wineries. He said sustainability is a critical part of the new project, with solar panels supplying power and all waste to be recycled. The brewery will use pristine Healesville water. “This is also about creating a beautiful new attraction in the town I love and live in,” he said. “There is something special about drinking great small-batch beer where it’s brewed.” CUB CEO, Peter Filipovic, said, “Phil will oversee everything from brewery construction to brewing and marketing. He is a craft beer visionary who revolutionised Australia’s beer landscape. There is no one in the world more suited to delivering this venture than him. “We’re meeting the changing needs of consumers by creating

beautiful new beers in pristine surroundings that live up to Matilda Bay and Sexton’s original vision. We couldn’t be more excited about this opportunity and we know beer drinkers will love it.” The Matilda Bay brewery and pub will be built on the site currently occupied by Giant Steps winery and restaurant, which, in addition, is owned by Sexton. Construction is expected to start in coming weeks and the brewery is expected to be operational by the end of the year. More than 20 new jobs will be created. The current Giant Steps site will close Sunday. Tasting will re-open immediately at a new site in Healesville and the winery will re-open soon, with more details to be announced in coming months.

www.foodmag.com.au | November 2019 | Food&Beverage Industry News 15

NEWS

Australian and Chinese meat sectors sign MoU

A MoU signed between China and Australia is the result of 18 months of discussion.

A

new Memorandum of Understanding (MoU) between the Australian and Chinese meat sectors highlights the importance of China to Australian industry and underlines a commitment to collaboration on both sides, according to Australian Meat Industry Council CEO, Patrick Hutchinson. The MoU is the result of 18 months of preparations and discussions that were initially kicked off at the China International Meat Industry Week that was held in 2018. Hutchinson signed The China Australia Red Meat Agreement (CARMA) MoU with the China Meat Association in Chengdu,

China today on behalf of the Australian Meat Industry Council, Meat & Livestock Australia and the Australian Meat Processor Corporation. “China is the biggest export market for Australian meat, and maintaining and enhancing our relationship with this critical partner is essential for the future of our industry. This MoU serves to reinforce the strong value our sector places on the relationship and our great respect for China as a very important trading partner,” he said. In the year to August, Australia has sent more than 172,000 tonnes of beef, 45,000 tonnes of lamb and 39,000 tonnes of mutton to China,

16 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

with a total market value of close to $2 billion. “The aim of this MoU is to establish long-term and formal cooperative relations, strengthen effective and practical food safety processes and enable bilateral exchanges around technical knowhow, marketing, and research and development investment. Ultimately, the MoU will help secure trade outcomes that are beneficial to all parties.” The longer-term aims of the CARMA include development of both sides’ red meat industries, an enhanced supply chain for Australian meat into China, and working to streamline product specifications and

labelling requirements. “Demand for Australian meat products continues to grow in China and this MoU is another step towards securing and growing this important relationship. I extend my gratitude to the China Meat Association, Meat & Livestock Australia, the Australian Meat Processing Corporation and my own team at AMIC for all their hard work in creating this agreement, and I look forward to continuing to work towards the best outcomes for our industry.” Under the terms of the MoU, a working group to help implement the goals of the CARMA will be formed to initiate the cooperative program.

NEWS

Unilever announces new commitments for packaging waste U nilever has announced that by 2025 it will eliminate more than 100,000 tonnes of plastic packaging and collect and process more plastic packaging than it sells. The company, which owns brands like Lipton, Ben & Jerry’s and Walls Ice Cream, has announced new commitments to reduce its plastic waste and help create a circular economy for plastics Unilever has confirmed that by 2025 it will: • Halve its use of virgin plastic, by reducing its absolute use of plastic packaging by more than 100,000 tonnes and accelerating its use of recycled plastic. • Help collect and process more plastic packaging than it sells. This commitment makes Unilever the first major global consumer goods company to commit to an absolute plastics reduction across its portfolio. Unilever is already on track to achieve its existing commitments to

ensure all of its plastic packaging is reusable, recyclable or compostable by 2025, and to use at least 25 per cent recycled plastic in its packaging, also by 2025. “Plastic has its place, but that place is not in the environment. We can only eliminate plastic waste by acting fast and taking radical action at all points in the plastic cycle,” said company CEO, Alan Jope. “Our starting point has to be design, reducing the amount of plastic we use, and then making sure that what we do use increasingly comes from recycled sources. We are also committed to ensuring all our plastic packaging is reusable, recyclable or compostable. “This demands a fundamental rethink in our approach to our packaging and products. It requires us to introduce new and innovative packaging materials and scale up new business models, like re-use and re-fill formats, at an unprecedented speed and intensity.”

Unilever’s commitment will require the business to help collect and process around 600,000 tonnes of plastic annually by 2025. This will be delivered through investment and partnerships which improve waste management infrastructure in many of the countries in which Unilever operates. “Our vision is a world in which everyone works together to ensure that plastic stays in the economy and out of the environment. Our plastic is our responsibility and so we are committed to collecting back more than we sell, as part of our drive towards a circular economy. This is a daunting but exciting task which will help drive global demand for recycled plastic,” said Jope. Since 2017, Unilever has been transforming its approach to plastic packaging through its “Less, Better, No” plastic framework. Through the initiative, Unilever has explored new ways of packaging and delivering products – including concentrates, such as its new Cif

Eco-refill which eliminates 75 per cent of plastic, and new refill stations for shampoo and laundry detergent rolled out across shops, universities and mobile vending in Southeast Asia. Better plastic has led to pioneering innovations such as the new detectable pigment being used by Axe (Lynx) and TRESemmé, which makes black plastic recyclable, as it can now be seen and sorted by recycling plant scanners, and the Lipton “festival bottle”, which is made of 100 per cent recycled plastic and is collected using a deposit scheme. As part of the initiative, Unilever has brought to the market innovations including shampoo bars, refillable toothpaste tablets, cardboard deodorant sticks and bamboo toothbrushes. It has also signed up to the Loop platform, which is exploring new ways of delivering and collecting reusable products from consumers’ homes.

Unilever is committed to cutting its plastics footprint.

www.foodmag.com.au | November 2019 | Food&Beverage Industry News 17

SAFETY

The importance of food and beverage labelling The AIFST’s Fiona Fleming talks about some of the problem areas when labelling food and beverage products.

Consumption of food allergens can have life-threatening consequences.

F

ood labelling – it can be a minefield. In an era of food allergens, many imported products, as well as a bevy of health and safety regulations, food and beverage manufacturers have their work cut out for them to make sure they create products that meet a wide range of food regulations. It’s something not lost on Fiona Fleming who is the managing director of the Australian Institute of Food Science and Technology (AIFST), which is the body for food industry professionals who work in many different fields within the food and beverage industry.

Fleming knows that food labelling can be a difficult subject to navigate, especially for those just starting out in the industry. What are the main issues surrounding food labelling? Correct labelling of imported foods and declaration of food allergens provide significant challenges, according to Fleming. Australia does appear to be the food allergy capital of the world, with Melbourne leading the way. There is no single reason for this, more a myriad of causes – peoples’ diets have changed, more sufferers are reporting their allergies and,

18 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

in the case of Melbourne, some researchers believe low levels of vitamin D contribute due to the city’s cooler climate and children spending less time outdoors in the sun. Whatever the reason, consumption of a food allergen can have fatal consequences for those who are allergic to that food or foods. For someone with a severe allergy, exposure to the allergen can cause a life-threatening reaction called anaphylaxis which affects the whole body, often within minutes of exposure. “They key allergens of concern in Australia and New Zealand are

egg, milk, peanut, fish, crustacea, peanuts, soybeans, sesame seed, tree nuts, wheat and other gluten containing cereals, and lupin,” Fleming said. “These are required to be labelled when present in a food under the Australia New Zealand Food Standards Code. And just to add to the confusion, both for those on the ground in Australia and those wanting to import food products, allergens required to be labelled in one country might not always be required to be labelled in another.” For example, in Europe, mustard

SAFETY

MANDATORY REQUIREMENTS - THE BIG 11 1. Name of food 2. Name and address 3. Lot identification 4. Allergen declaration 5. Ingredient list 6. Date marking 7. Storage and usage instructions 8. Nutrition information 9. Characterising ingredients 10. Country of origin 11. Quantity marking

and celery are allergens that must be labelled, whereas in Australia they are not on the list of food allergens required to be labelled. “Any ingredient that is in a food product has to be labelled, and it is up to the importer to ensure that foods they bring into Australia and New Zealand have the correct allergen declarations to comply with ANZ requirements,” Fleming said. “Australian and NZ manufacturers have gone further with labelling following best practice guidance developed by the food industry. For example, allergen names are highlighted in bold text in the ingredient list which helps consumers when purchasing products.” Food allergens are not the only important piece of information that needs to be put on food labels. There are 11 key points food and beverage manufacturers have to include (see box story). For imported foods, all of this information is required to be provided in English, meaning labels must be translated accurately and completely. Failure to include all of the information can potentially result in a costly product recall and injury to consumers. Importers of foods into Australia have to be responsible and realise that ignorance of local labelling laws is no excuse if the correct information is not available to the buying public. There is an overriding premise in law that ignorance of law is no defence. “All food companies have an obligation to know the regulations under which they must operate, and they have an overriding obligation to provide food that is safe and suitable,” Fleming said.

“Accurate food labelling is important for ensuring food safety, and ignorance of the labelling requirements is no defence.” First and foremost, manufacturers tend to initially concentrate on the product itself. Is it tasty? How much will it cost to produce? Where can we source the ingredients? Can we outsource the manufacturing of our product, or can we set up our own manufacturing facility? Once a manufacturer gets their head around what is involved in crossing the t’s and dotting the i’s, correct labelling can sometimes be intimidating and time consuming. But there is help available. Fleming is the first to acknowledge that there no easy route to labelling food and beverage products. “Food labelling is quite complex,” said Fleming. “I do recognise that it is very hard to start up a food manufacturing enterprise because sometimes companies don’t know where to go to find the information they need. “There are certainly organisations that provide training in food labelling. If you are in NSW, for example, you can go to the NSW Food Authority’s website where there is a lot of good information

for starting a business, and they have some basic information around requirements for food labelling.” The final piece of advice Fleming would give is with regard to preservatives and additives in food products. They, too, have to be approved for use, and labelled as part of the ingredient listing on products. “Australia is a small country, population wise, and we import a lot of our products,” Fleming said. “It is important to remember that just because something is approved to be used in a food product overseas, it doesn’t mean it’s been approved to be used here. It can be challenging negotiating the regulations, but it is very important for companies to be aware of the requirements and put steps and processes in place to ensure they have the information and knowledge they need to ensure their products are fully compliant. “I know that sometimes information is not easy to find, but there are also food consultants out there who can assist. The AIFST website has a page that lists members who are consultants and provide this sort of assistance to food companies.” There are also tools available to food manufacturers developed by the

food industry to assist with collection of information and labelling. For example, the Product Information Form, or PIF, is an industry-agreed questionnaire developed by the food industry, for the food industry, in Australia and New Zealand. The PIF allows companies to include a variety of information about food products and ingredients in a single document that meets information needs for legal and regulatory compliance in Australia and New Zealand, in a standardised manner. The PIF is an industry tool that can improve company efficiency and reliability in managing product specification and other related data when applied across the sector. With respect to allergen management and labelling, the Allergen Bureau has a comprehensive website and tools available to assist with allergen risk assessment and labelling (http:// allergenbureau.net). “At the end of the day, as a food manufacturer, whether big or small, Australian or not, you have an important role in ensuring that consumers continue to enjoy a variety of safe and nutritious food that will contribute to their wellbeing,” Fleming said. F

Consumers need to know they can trust the information on food labels.

www.foodmag.com.au | November 2019 | Food&Beverage Industry News 19

SUSTAINABILITY

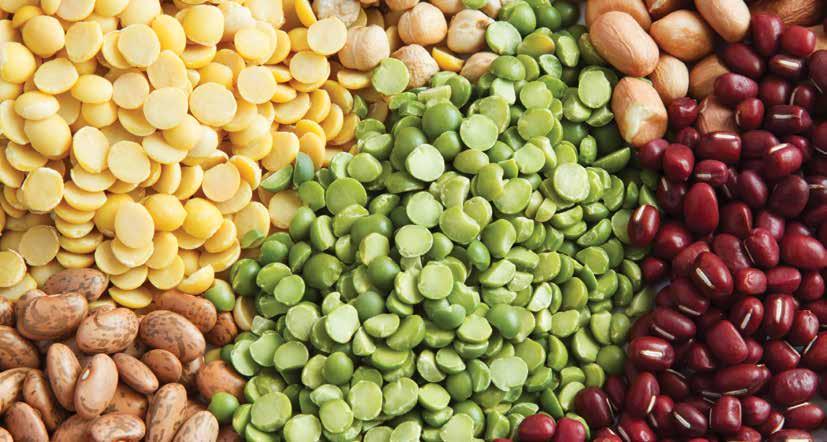

Plant-based proteins are starting to make huge inroads into what has traditionally been the purview of meat.

The rise and rise of plant-based proteins Today, the consumer owns the narrative of what food and beverage manufacturers are producing. Food & Beverage Industry News explains why.

A

ccording to Trent Duvall, 20 years ago the food and beverage processors and manufacturers controlled the narrative in relation to what foods and drinks were consumed by customers. Then, it shifted to the retailers. Today, it is consumers that are running the show. And if you are a manufacturer of food and beverage goods, it’s advisable that you sit up and take notice of your customers like never before. Duvall is the national sector leader, consumer and retail for KPMG, and was speaking to group of food and beverage primary producers at the FoodTech event held mid-year in Brisbane. Consumers are becoming more discerning with regards to the healthiness of food, how it is packaged, and its effect on the environment, he said. Not only that, but his main

point was that plant-based proteins are going to have a big impact on the food panorama over the next decade. And Duvall is no vegetarian/vegan evangelist – he is a proud omnivore and likes nothing better than to tuck into a nice, juicy steak. However, he said the landscape is changing, with an anecdote from a recent trip to the US reinforcing the shift. “We went to Disneyland’s Adventure World, which was also home to the California Food and Wine Market Spring Fair,” he said. “There were stalls everywhere – different foods and produce. We walked past a stall that had this beautiful-looking burger patty with guacamole on top. I had to have one. For five minutes, myself and my wife and kids lined up to pay for one of these sliders – and they were to die for. Imagine the best burger you’ve had, the oil coming

20 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

down the side of your hands. I looked across at my 10-year-old son – his was gone in a flash – nothing but a little bit of avocado left on the side of his face. Perhaps the best slider I’ve had. It turned to be a plant-based slider. First time I’ve had one. And it was fantastic.” Part of Duvall’s brief is to spot coming trends. He counsels those in the food and beverage processing and manufacturing space who are putting their company’s value chain together to respond to these trends and create opportunities for their companies. While plant-based proteins are gaining popularity, there is still an issue getting the average punter to buy into the trend. Duvall gives the example of New Zealand’s Hell Pizza franchise, which released to market a burger-flavoured pizza. For the first four days it flew off the shelves – the

market couldn’t get enough of them. They were selling out. Hell Pizza then announced that the meat wasn’t beef, it was made from plant-based protein. “Social media went into meltdown, because people were saying to the company, ‘how could you lie to us?’” said Duvall. “There was no lying per se, it was just a burger-flavoured protein. We are going to see the same things coming through in the Australian market and they are going to be marketed as being better for you and less processed. And they are better for you in terms of less fats and higher protein content per gram.” Not to be outdone, Domino’s in Australia has announced an exclusive partnership with a Queensland manufacturer to create plant based “meat” for its pizza toppings and plan to be the first pizza chain in Australia to launch alternate meat pizzas.

SUSTAINABILITY

Importantly they will be lower in saturated fat and higher protein than the comparable meat pizzas. Long-term consumers of existing products need not fear that their favourite food or beverage will be disappearing any time soon. The market for meats and processed foods is still strong. What Duvall is pointing out is that the younger generation of consumers is causing a change in the market and it behoves processors and manufacturers to be aware of these changes if they don’t want to get left behind. He cites the example of Shreddies, a popular cereal from Canada and the UK that was first produced in 1939, and was available in Australia. “The packaging has now been changed – not only does it say ‘wholegrain’ in the top corner of the packet, it’s also now says ‘vegan’,” said Duvall. “So why is vegan important to our kids? It’s not. They don’t know that. But it is important to the mum that is buying it. Shreddies is repositioning itself in the market.” And to reiterate the point, Meat and Livestock Australia (MLA) also know that customers – again primarily the younger generation – will be the ones making choices about what they will be consuming. MLA’s marketing campaign is concentrating on animal health and welfare, environmental sustainability and nutrition. The three questions mentioned in the MLA’s current marketing campaign are: • W hat’s the consumer talking about? • W hat does the consumer want? • How do we market to that? The consumer is now the centre of attention. They are now digitally and data enabled and they’re the ones that are influencing trends, said Duvall. “The consumer is influencing the government by what they say on social media,” said Duvall. “They are influencing the manufacturers by what they want and it is influencing the retailers and how they are going to get it. And it is about what is good for them. However, what is good for one consumer might be different from the other.” One of the more interesting trends that Duvall talked about was the introduction of molecular alcohol – not one for the purists. Rather than distilling, makers of alcoholic beverages are using this technique to create a beverage quickly, compared to traditional methods. “A 20-year-old malt whiskey can

Trent Duvall said the younger generation of consumers are starting to call the shots in the food space. be reproduced almost overnight,” said Duvall. “Same with vodkas, same with gins. That is where technology’s going. Will the consumer buy it? Maybe. Maybe not. Maybe a consumer likes that fact their whiskey has been distilled or aged for 20 years. Others might be interested in the newer version because of the price point, or because it is a different style of product they see as being good for them.” “Big and small companies are doing different things to drive innovation to meet what the consumer demands and needs,” said Duvall. And another technology that has been mentioned recently in Food & Beverage Industry News (September issue) is 3D printed food. Duvall

compared 3D printing technology to where Nespresso coffee machines were 10 years ago. “In the space of a couple of years, with the product positioned at the right point, Nespresso has made its way into many homes,” he said. “You go back 10 years, nobody would have thought to put a Nespresso machine in their house. There has been a rapid change in how we consume coffee. Printing your food using a pod and having a machine that can do that in every house is probably not that far away.” The last point Duvall wanted to make on coming trends was to do with the state of

consumers themselves. There are those who are more carnivore than vegetarian, while most people lie somewhere in the middle. However, he said that there is a growing number of flexitarians, those who generally engage with eating plant-based foods, but still include meat in their diet. “They are people like me who like meat but will try a lot of alternatives,” he said. “And it might be part of my diet because generally it might be good for you. There has been an acceleration of change in terms of the products that are coming to our supermarkets in the last year. In the last six months alone it has rapid. Those different alternative proteins and foods are rapidly changing. In 12 months’ time, there will be a proliferation of those types of products in the market.” F

The Incredible Burger is just one example of vegetarian proteins that are becoming popular. www.foodmag.com.au | November 2019 | Food&Beverage Industry News 21

BUILDING PLANT

Getting the specifications right for an F&B build Total Construction’s Bill Franks gives the low-down on pitfalls food and beverage processors and manufacturers can fall into when building or renovating a plant.

F

or food and beverage facility owners, navigating compliance requirements when building or renovating a new building can be tough at the best of times, especially in a constantly changing regulatory environment. Bill Franks is a founding shareholder of food and beverage construction specialist Total Construction and is also member of the Australian Institute of Building. He has been involved in the industry for more than 30 years, and has some interesting insights on how some of these pitfalls can be avoided, especially for some of the smaller, up-and-coming food and beverage enterprises. “Whereas a big multinational company has a team of people checking compliance, if you’re a mum-and-dad business, or own an industrial unit where you want to produce food for sale, you don’t have access to that kind of resource,” he said. “For starters, it’s important to understand which regulations you need to comply with. A commercial building comes under the Building Act and National Construction Code (NCC); what was known as the Building Code of Australia.” A couple of regulations in particular, can cause issues because people don’t know some of the minute details – the fine print – that can be hidden in the regulations. “For example, Section J (energy efficiency) of the NCC, along with essential fire services, have been catching people out for a number of years now,” said Franks. “Plus, with the ‘Access to Premises’ standard, a minor addition or alteration to a commercial building can now involve some serious upgrades to services like water, electricity and insulation just to mention a few.” Franks adds that, while a lot of people know that buildings require fire sprinklers, there are other accessories that need to be added, too. “For example, water pressures

Safety and the dissipation of food odours need to be considered when building or renovating a food and beverage plant. have changed, and sprinklers now require water storage tanks and a set of pumps, which can sometimes cost around a half a million dollars.” Then there is disability that needs to be added to the mix of potential changes some sites that are being renovated. In some cases, councils will require a lift to be installed, doorways and corridors widened and disability amenities added to satisfy current building codes. Other considerations that need to be considered when planning to convert a brownfield site into a food and beverage facility include the noise and odour impacts. Many councils insist on obtaining noise and odour statements as part of the any submission. Although the consultant fees to produce these statements can be relatively low, the resulting adaptions to the building

22 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

can be significant. In one instance a client was required to install 6.2m high exhaust flues to ensure that odours from their cooking processes were dispersed effectively and not impinge on neighbouring residential properties. “You may say that is fair enough,” said Franks, “however, the residential properties were almost a kilometre away, yet the odour report indicated that with the right conditions the cooking odours could travel that far.” Any new facility in the industry will need to comply with a Council’s Health Department requirements, so this means effective drainage, washing and waste disposal areas need to be well-defined to comply. Generally, to accommodate new drainage runs and wash areas in brownfield sites, a company needs to cut into the slab. Also, depending on

the amount of drainage required, the existing slab could end up looking like “swiss cheese”. These drainage runs will then need to be reinstated and pinned back into the existing slab. In some instances, combining this with set down areas for any freezers, it can be cheaper to lay an entire new slab. Apart from Council and NCC requirements, brownfield sites can also have issues with the roof weight capacity, as the majority of industrial units available are only designed to support roofing sheets and not much else. To enable the roof to support numerous services and insulated panel ceilings etcetera, the roof structure generally needs to be strengthened – sometimes dramatically. Then there is another set of key criteria in deciding on premises to convert – power and gas availability.

BUILDING PLANT

Again, the majority of industrial units only have access to approximately 100amps supply and no gas feed. Food and beverage facilities can require in excess of 500amps and a reliable gas supply to effectively run their operations. The time and cost associated with upgrading and installing these feeds can be exorbitant, and have caught out many proponents, causing delays in establishing operations. So, what can you do to make sure your building ticks all the boxes? “The first thing is to establish the scope of the development, then work out where it might be non-compliant and if your budget stretches to bringing it up to standard,” said Franks. “You can find a copy of NCC online, but it can be difficult to make sense of it if you’re not a lawyer or building professional. My advice would be to get a report from a building certifier and engage an appropriate food and beverage builder to advise. By enlisting the services of professionals, you can avoid a host of problems in the future. “The key to ensuring you mitigate risks in your project is to involve your builder early in the process commonly known in the construction game as

early contractor involvement or ECI.” According to Franks, having a builder involved during the scoping and design stage can allow critical cost items in any build/fit out be identified and alternatives discussed. “For instance, you may have a plan to construct a mezzanine level in your operations, this although perfect for the intended process flows can be extremely costly to construct,” he said. “Sometimes, a client cannot see the forest for the trees so to speak – they are so intrenched in their business that they only see one aspect of the project – being to increase efficiencies in their production.” Involving a builder with process engineering capability in the food and beverage industry, such as Total Construction, can allow a different set of eyes to see the requirements and suggest alternatives to the building layout that just don’t reduce the need for costly building works, but can improve the process flow overall.

How ECI works to develop an achievable budget. First, a site investigation is carried out by the builder on the existing and proposed facilities to detail and identify all services required and what

is available at the new site (power, gas capacities). It is important to note that to increase power or gas supply to a site can be very costly to the project and create delays. Another area that needs consideration in the case of an existing building to be fitted out is the structure’s integrity. Having to strengthen this to cope with the additional weight of fit out and services can often blow out project costs. Then a workshop is carried out with all stakeholders to identify required efficiencies, confirm proposed outputs and flag any potential limitations. As part of this workshop, all production processes are mapped and detailed for both the existing and proposed operations. A list is made of the capacities and dimensions of all equipment both existing and new is developed. This helps to identify all utilities and services that are required. It also sets the benchmark for power and gas requirements at the proposed site. This process helps identify potential bottle necks in current processes and helps highlight any potential hygiene requirements in the new fit out. Getting all this data captured is critical in maximising

efficiencies of the new facility. A review of the buildability of the facility is done and sketch design layouts are completed to optimise process flows to best fit the client’s objectives. A building/fit out SWAT analysis is carried out and build/ fit-out costs are derived. Through close consultation between the builder and client, this process allows savings to be identified early on in the design and layout of the facility. A detailed design including all services and requirements is then developed and put to the market for live market costing. This will give the client a firm understanding of what they can get for their dollar. Finally, this is where working to a budget comes in – once the ideal building and fit out costs are established it is possible to derive further reductions in the overall project spend through rationalising the design. This includes, but is not limited to, reducing the number and sizes of rooms, freezer/cool room capacities and locations, and finishes in the design. This can be done while keeping future expansion capability intact in the design and maintain the client’s required production output for the new facility. F Planning needs to start at the beginning otherwise unnecessary cost overruns can occur.

www.foodmag.com.au | November 2019 | Food&Beverage Industry News 23

CONSUMER

Show me the honey – Nature Nate’s arrives in Australia Nathan Sheets has spent almost two decades building his brand with a philosophy that it isn’t just about the bottom line. Food & Beverage Industry News explains. Making honey started out as a hobby for Nathan Sheets. Now it is his full-time job.

T

urning your hobby into a full time job would be a dream for many people. And turning that dream into a multi-million dollar business would be like winning the lottery. You could argue that is what happened to Nathan Sheets, the CEO of Nature Nate’s Honey Co., a US-based company that produces raw and unfiltered honey. Now, Sheets is making a foray into the Australian market. “When I got married in 1996, my wife Patty said we needed a hobby,” said Sheets. “She was thinking gardening or antiques, but I was thinking bees. We started keeping one hive in my parents’ backyard because we lived in an apartment. I would also go and help the guy who I got the hive from with his 100 beehives on the weekends. He had started a honey company in 1972 – the North Dallas Honey Company – which would eventually become

Nature Nate’s. I then started getting up at 4am to help distribute his honey because he had cancer and needed help delivering to the 20 stores that stocked his product. “Then I started going down to his house and helped bottle the honey. In 1997, I took over the business.” However, Sheets wasn’t ready to go full time just yet. He decided to take up an offer to become a missionary and spent the next 12 years visiting 88 countries doing this work. He sees this time as formative in terms of how he wanted to run the company he now owns. In 2010, he went full time so that now, nine years later, he has more than 85 full-time staff at the company’s headquarters based just north of Dallas, Texas. Like any business, in order to grow, the company needed to expand. Australia was always going to be on Sheets’ radar. “I chose Australia because we had

24 Food&Beverage Industry News | November 2019 | www.foodmag.com.au

some relationships with people down here,” he said. “That opened up the door for us. Personally, I’ve always loved Australia. I’ve always been fascinated with Australia and I love to fish, and you guys have great fishing.”

Australian standards Nature Nate’s has teamed up with Woolworths to launch the product in Australia. How did he find the local market compared to the US? “Australian standards and regulations are pretty similar to what we have in the US,” he said. “I have found that the actual honey in Australia to be cleaner than what we have in the US, which is awesome.” As with any foray into a new market, there are teething issues however, the overall experience has been good. Sheets noticed there is an issue with traceability. In order to deal with any suspicions or any negative impact that might occur with regard