COMPRESSED AIR, WHAT’S YOUR POISON? CALL 1800 800 878 OR VISIT CAPS.COM.AU TECHNICALLY OIL-FREE OR OIL-FLOODED 100% OIL-FREE NOVEMBER 2022

There are many ways you can achieve the quality of oil-free air critical to comply with relevant standards required for food and beverage manufacturing.

The food and beverage industry requires clean, dry compressed air across multiple facets of food & beverage production with varying levels of defined standards to ensure mitigation of contamination. There are multiple ways to achieve this, and CAPS is perfectly positioned to achieve our customer’s goals.

Many manufacturers use oil-lubricated compressors, which then utilise several air treatments processes downstream to clean and dry the air. This is one way, another way is to go oil-free at the point of compressing the air, which involves different compressor technology. Whichever way you go we can help.

This is often a balance between capital investment, overall efficiency and risk mitigation. Using a true- oil-free compressor, which despite its additional capital cost, the long-term benefits associated with less ancillary equipment and servicing combined with the significant reduction of risk, could be a smart investment.

LET US DESIGN THE RIGHT SYSTEM FOR YOU

CAPS, being privately owned, can search the work for the best OEM equipment available and are not tied to specific manufacturers. This is why we have been able to partner with world renowned brands such as Ingersoll Rand who lead the world in efficiency and reliability.

CAPS Australia has 42 years of experience as an Australian owned business designing and supplying bespoke compressed air systems customised for each customer’s specific requirement. With an ISO accredited in-house engineering and manufacturing division, we make sure we provide the equipment to not only meet their needs but exceed them.

caps.com.au

CAPS AUSTRALIA, YOUR COMPLETE SOLUTION FOR THE FOOD & BEVERAGE INDUSTRY 1800 800 878 CALL 1800 800 878 OR VISIT CAPS.COM.AU

NOVEMBER 2022 PLUS: Temperature Control | Plant and Machinery | Automation Australian Vintage celebrates our best regions

CEO: John Murphy

COO: Christine Clancy

Group Managing Editor (Northern): Syed Shah

Editor: Adam McCleery

Ph: (02) 9439 7227 adam.mccleery@primecreative.com.au

Design Production Manager: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Designers: Kerry Pert, Tom Anderson, Louis Romero

Sales/Advertising: Stephanie Suzuki Ph: +61 422 046 711 stephanie.suzuki@primecreative.com.au

Production Coordinator: Janine Clements Ph: (02) 9439 7227 janine.clements@primecreative.com.au

Subscriptions AUS NZ O/S 1 year subscription 99 109 119 2 year subscription 189 199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

It’s like they say, adapt or die

Copyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2019

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office 379 Docklands Drive Docklands VIC 3008

Ph: +61 3 9690 8766

enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065, Australia Ph: (02) 9439 7227

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

Editor: Adam McCleery

Editor: Adam McCleery

Sustainability will always remain a key focus area in every aspect of food and beverage manufacturing. Being more sustainable leads to a string of benefits for any manufacturer or producer, including lower overheads and in most cases better product output.

Plant and machinery are an area of food and beverage manufacturing where some of the largest gains can be made with the easiest, all be it the largest, investments. And companies which produce machinery and construct facilities for food and beverage manufacturers which we have spoken to at FBIN have all said the same thing, sustainability and efficiency is critical.

The net zero target of 2050, laid out by the United Nations, has laid out a plan for emissions to be reduced by 45 per cent in 2030, before reaching net zero in 2050.

We all eat and we all drink, and as such food and beverage manufacturing is never going any-where. While this creates a stable investment for some, it also means emphasis in sustainable practices and meeting net zero for manufacturers and producers is critical.

As one of the pillar industries of civilisation, food and beverage manufacturing takes on an important role in helping lead the way in meeting net zero.

As we near 2030, many of the initial targets set out in net zero target plans, both from the United Nations and others, will need to be met. At the very least it will give us insight into how we are tracking as a society.

Because of this, the food and beverage industry is currently undergoing rapid advancements and changes to traditional practices, but the good news is all the data is as expected, positive.

While there is no getting around the capital costs of overhauling processes or changing out certain segments as part of an ongoing change, the reduction in overheads means a return on investment is all but assured, it is only a matter of calculating the length

of time it will take.

T he future is coming no matter what, and as outlined by an ESG report in this edition, SMEs that fail to recognise the importance of becoming more sustainable, as quickly as possible, risk falling behind the pack.

The general conclusion is that as governmental investment and regulatory action increases, along with consumers are putting greater importance on sustainable manufacturing, SMEs must adapt or risk losing lucrative contracts in the future.

Future proofing is spoken of in the industry often, this is one aspect of future proofing that is of paramount importance. If you lose out to more sustainable competitors, due to a range of factors like those outlined above, then the need to future proof is likely to evaporate with time.

To truly future proof as an SME, the report outlines, is to keep up with current trends around sustainable and efficient manufacturing practices along with meeting consumer demands, including with changing tastes.

The very nature of rapid change also means greater software innovation which is already proving fruitful for the industry.

As an added benefit, many of the innovative new machines, from packaging to filling and processing, come with added adaptability, due in no small part to the innovative new software.

This is leading to an easier path to diversifying a product range and helping manufacturers and producers move into new segments of the market in an easier way.

These are all positive signs that the increased importance on sustainability, from a global perspective, will change the face of food and beverage manufacturing, future proofing it even further.

Until next month. Happy reading!

WELCOME 4 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

Request a quote Save on installation costs > up to 40% Improve ongoing operating costs > up to 20% Flexibility of production processes > 100% * these figures are based on average figures, individual results may vary. ELEMENT on/off control valves Compact, easily integrated and made for decentral automation applications. Slick, intelligent devices fulfil the demands of hygienic processes for F&B manufacturers. F&B prefers to partner with Bürkert

20

MEET

THE MANUFACTURER AVL Wines is on a sustainability journey which has also given rise to new product ranges.

AUTOMATION Bürkert continues to provide clients with the most objective advice around digitalisation and automation opportunities.

TEMPERATURE CONTROL The Paul Brady Building Group specialises in temperaturecontrolled environments and enclosures for the food and beverage industry.

PROCESSING Packserv now offers full process lines and solutions after building a strong reputation for its rental and technical solutions.

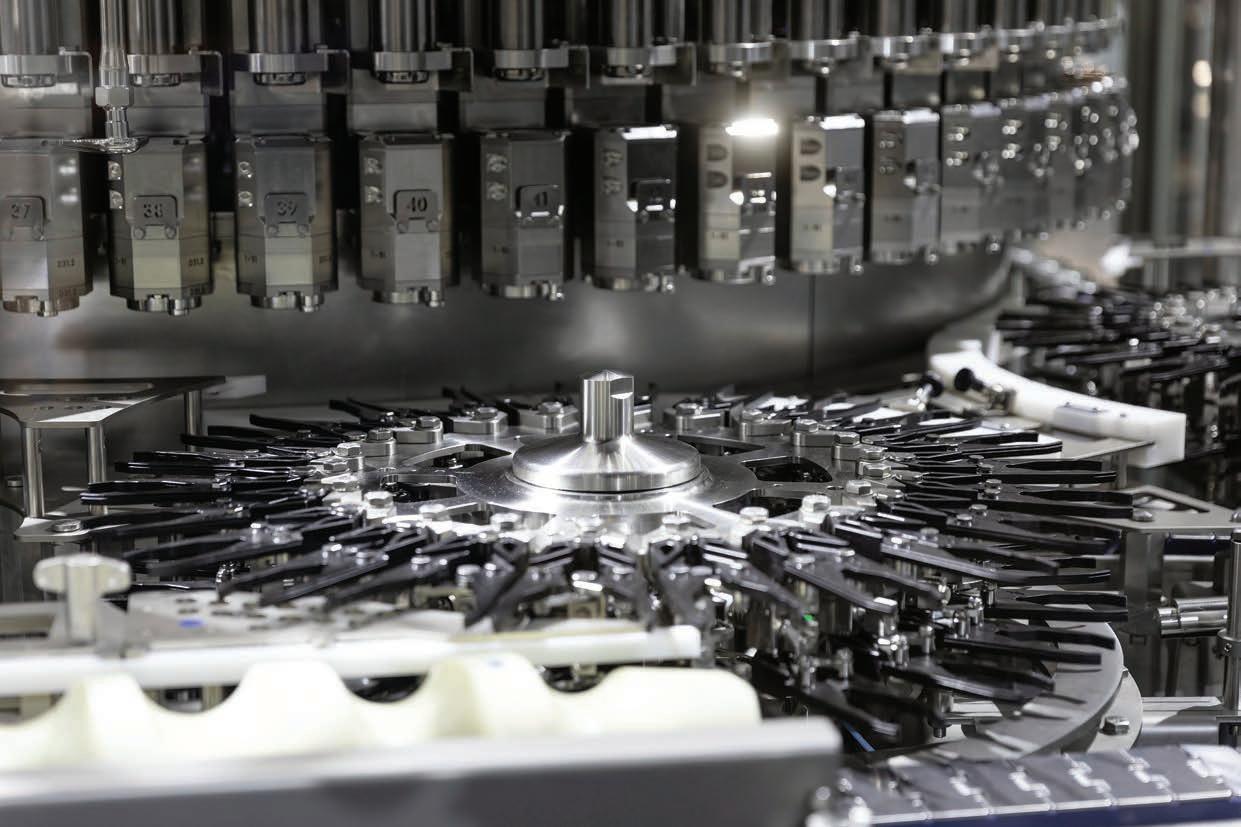

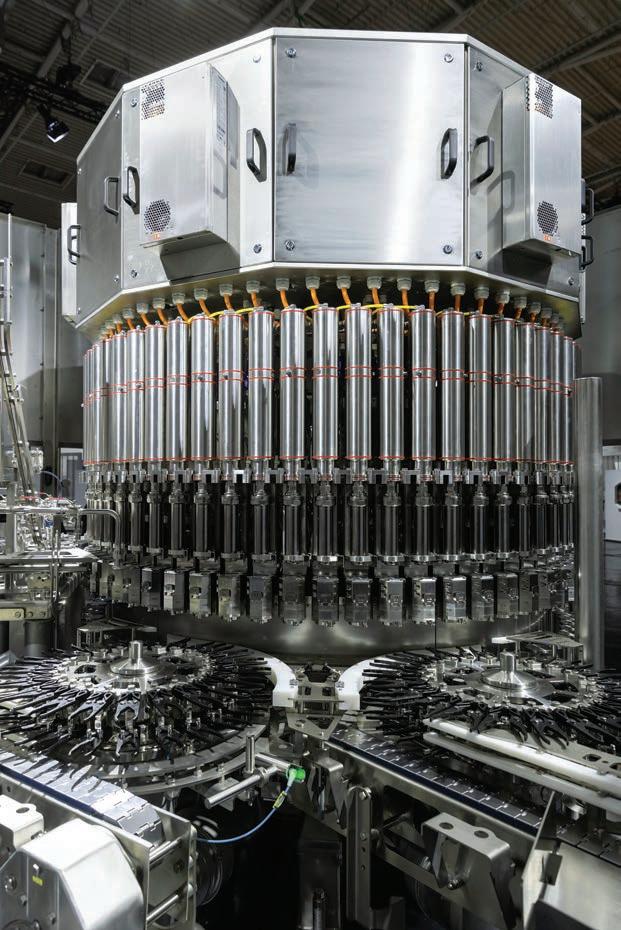

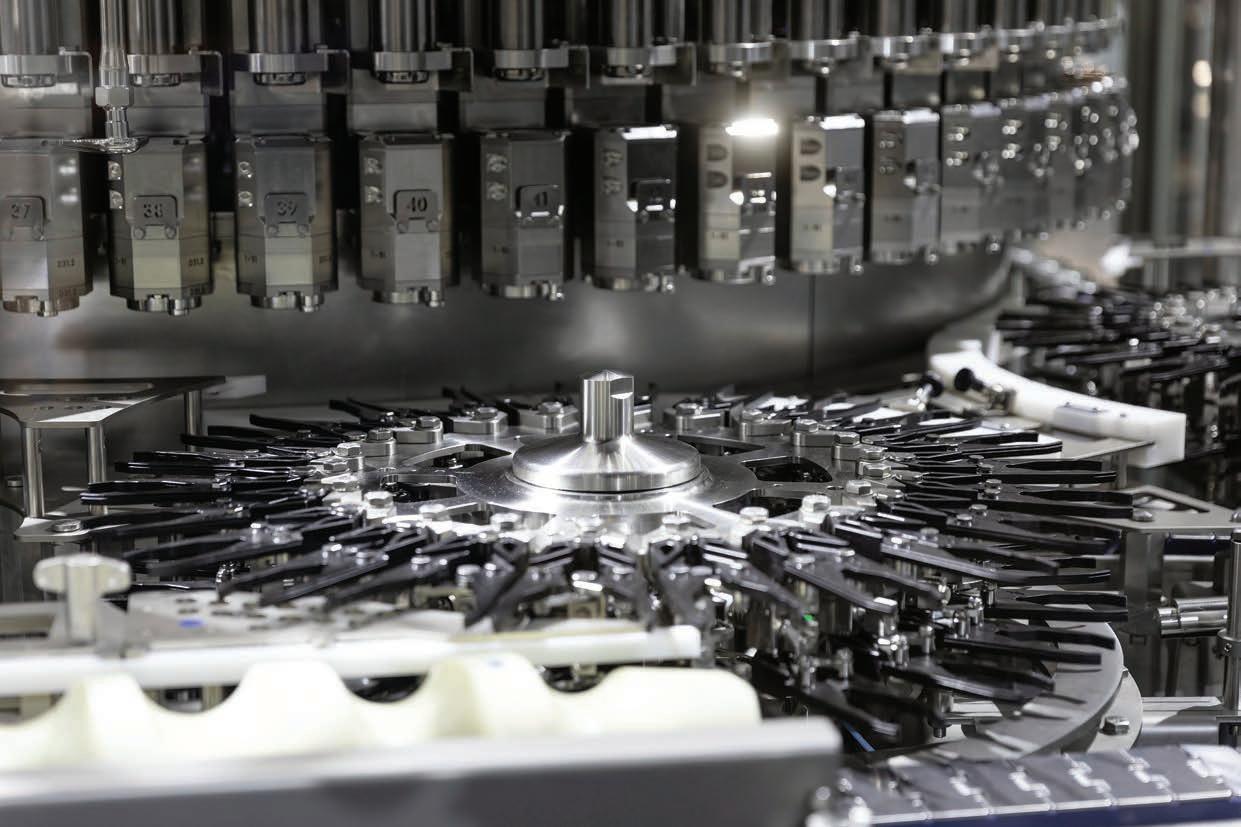

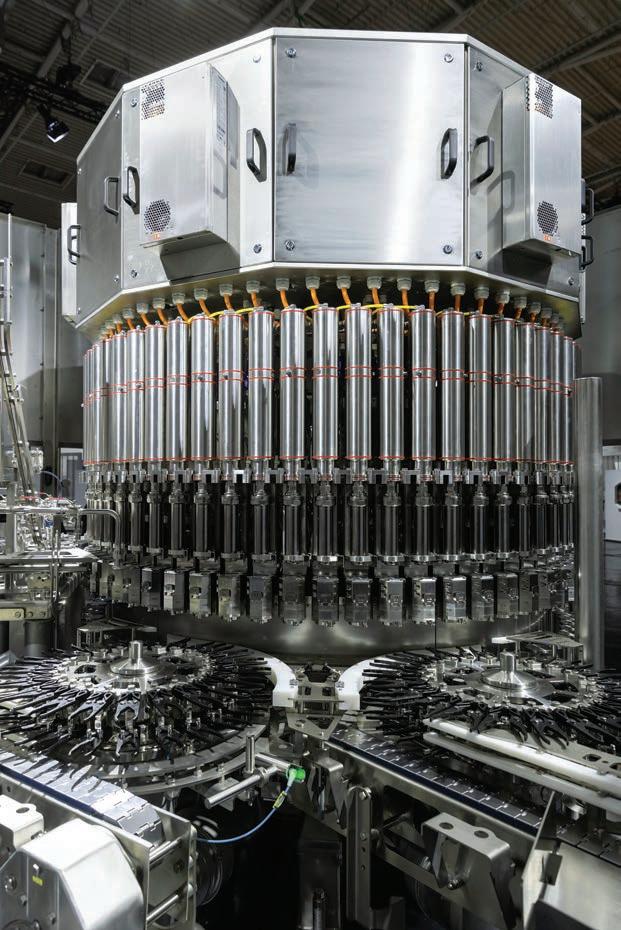

IRRIGATION Growers in the Goulburn Valley are seeing positive impacts from better irrigation supply. SUSTAINABILITY Among Krones’ suite of offerings is the Dynafill, which combines filling and crowning on a single function unit.

CONTENTS

08 NEWS

26

28 INSTRUMENTATION The John Sample Group prides itself on providing the simplest and most effective instrumentation solutions.

38

40 AIP 42 AFCCC 43 MARKETWATCH 44 NEW PRODUCTS 18 36 24 30 28 6 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

FOOD SAFETY Small to medium businesses (SMEs) that fail to prioritise sustainability risk losing lucrative contracts from governments and large businesses.

- 1• Low maintenance cost & simple operation • Advanced MAP tray-sealing technology • Competitive price - automatic tray sealer at the operating cost of a semi-automatic tray sealer • Small footprint at just 1.6mt • NO compromise on quality & product shelf-life • No air, water or vacuum pumps required • Suitable for small to medium productions • Only tray sealer in its class that can be fed from a conveyor SELECT EQUIP are the exclusive distributors of the G.Mondini Cigno. Get in touch to learn more. LET’S TALK! 1800 101 122 sales@selectequip.com.au selectequip.com.au Automatic Tray Sealer at the price of a semi-automatic just launched. CIGNO: Brand new compact tray sealer for small to medium productions Only sealer of its kind that requires no tools for changeover, small footprint, easy wash down, advanced MAP tray-sealing technology, only tray sealer in its class that can be fed from a conveyor and no compromise on quality & shelf-life Introducing... The CIGNO

World leader in tray sealing technology,

world class technology at a competitive price It’s an automatic tray sealer

operating cost of a semi-automatic tray sealer

Benefit from award-winning tray technology

G.Mondini’s brand-new release the ‘Cigno’ is

at the

Bundaberg Brewed Drinks is Queensland’s exporter of the year

Bundaberg Brewed Drinks has been named 2022 Queensland Exporter of the Year, at the Premier of Queensland Export Awards Gala, after also winning the Agribusiness, Food and Beverages category.

Queensland Premier Annastacia Palaszczuk said Bundaberg Brewed Drinks had impressed judges with their significant export success, product quality and continual range development.

“Companies like Bundaberg Brewed Drinks represent the tenacity and commitment of original Queensland family businesses, showing that products from any of our regions can grow their worldwide demand,” said Palaszczuk.

“This year I’m struck by the increasing mix of established and newly developed Queensland goods and services with successful export outcomes. The judges are always challenged by the high standard of nominations. Queensland can be very proud of each of the 2022 finalists,” she added.

A lso congratulating Bundaberg Brewed Drinks, treasurer and minister for trade and investment Cameron Dick

to develop export excellence across a diverse array of industries that take the lead on the international stage. The quality of the goods and services produced by the nominees in each award category confirms that strategy is working.”

iconic representation of the region. Today they export to over 60 countries. Returning for their 32nd year, the Premier of Queensland Export Awards recognise the businesses behind Queensland’s $100 billion export industry and elevate category winners

StrangeLove partners with Asahi Beverages

Asahi Beverages has acquired growing premium beverages company StrangeLove, which was founded in Byron Bay in 2013.

The adult soft drink, premium mixer and mineral water business was founded by James Bruce and Stafford Fox, focusing on eclectic, sophisticated flavours and local ingredients.

With products such as Tonic No. 8, Lo-Cal Yuzu, Double Ginger, and a range of premium Sparkling Waters, StrangeLove has more than doubled

in volume and revenue in the last two years to become one of Australia’s fastest-growing beverage companies.

“It is clear Australians want more sophisticated and lower-sugar soft drinks, which has fuelled demand for StrangeLove’s amazing products in recent years,” said Robert Iervasi, Asahi Beverages Group CEO.

“We are really excited about the impact that StrangeLove is going to have in restaurants, cafes, hotels and pubs.

“We expect StrangeLove to really

shake things up in the on-premise premium mixer and adult soft drink space, with a high-quality, Australianmade brand.”

Asahi Beverages’ investment in the adult soft drinks and premium mixers market comes as consumers increasingly prefer better-for-you beverages.

These categories are driving growth in Australia’s $2.8 billion soft drink market (groceries & convenience), with premium mixer sales increasing by 40 per cent in the past three years

best of the state’s exporters.

Winners in the State’s 13 award categories qualify as finalists representing Queensland in the national Australian Export Awards to be held on 24 November in Canberra, staged by Austrade. F

and adult soft drink sales up by 65 per cent off a small base.

“This deal represents an amazing opportunity to speed up StrangeLove’s mission to revolutionise the adult soft drink market with more imaginative and high-quality beverages,” said StrangeLove co-founder James Bruce.

“Asahi Beverages will help grow StrangeLove in a way we couldn’t on our own,” added Bruce.

Bruce also said the StrangeLove management team will remain in their roles at the business. F

NEWS 8 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

Editorial credit: IZWAN IS / Shutterstock.com

Winners in the state’s 13 award categories qualify as finalists representing Queensland in the national Australian Export Awards.

Kombucha manufacturing centre to bring more jobs to Victoria

The Victorian state government is backing more manufacturing jobs in Melbourne by supporting Remedy Drinks‘ new, stateof-the-art kombucha manufacturing centre in Dandenong.

Minister for Industry Support and Recovery Ben Carroll visited Australia’s largest kombucha maker Remedy Drinks’ $43 million centre in Dandenong which has created 87 new jobs.

The company has combined all its operations, including research and development, manufacturing, warehousing and distribution operations, into the new 18,000 square metre site.

“We’re proud to support local manufacturers with global ambitions like Remedy because their continued

growth means more jobs for Victorians,” Caroll said.

“Remedy’s investment in new equipment and technologies in Victoria is testament to the fact that Victoria is the home of manufacturing in Australia.”

With fermented tea drinks growing in popularity around the world, the move will boost the company’s production and exports to the United States, Canada, United Kingdom and Asia.

Remedy Drinks produces one of the world’s only kombucha drinks that can be stored at room temperature without needing refrigeration, reducing energy use and transport costs.

Victoria has the largest food and drinks manufacturing sector in Australia, valued at about $38 billion

The $43 million centre in Dandenong has already created 87 new jobs.

and employing about 72,000 people.

The state government is backing the state’s advanced manufacturers to grow and innovate through initiatives including the Manufacturing and Industry Development Fund, which supports businesses to invest in new technology and equipment and

stimulate job creation across the state.

As part of the Victorian Budget 2022/23, the government is also investing $120 million in the Victorian Industry Fund to boost local manufacturing and support the growth of businesses in key sectors like health, food production, technology and defence. F

Ultra-fast plant enzyme could advance cereal production

Researchers from the University of Adelaide have uncovered previously unknown properties in a plant enzyme that could lead to advances in cereal production, medical, and pharmaceutical industries.

enzymes are an environmentally friendly and cost-effective alternative to current methods.

Waite Research Institute.

“This was achieved by examining the binding behaviour of sugars in the

was inaccessible before,” said Hrmova.

“This means we could potentially improve the properties of the enzyme that are critical to germination and the way the roots grow, leading to higher barley yields, which is crucial in cereal production.”

Enzymes are essential to life. They significantly increase the rate of a chemical reaction without undergoing any permanent chemical change themselves. But when enzymes convert, the substances with which an enzyme operates move in and out from the enzyme at high speed.

This process inhibits the investigation of these interactions using standard experimental techniques – a problem that brought to light using this multidisciplinary approach.

Hrmova added that the work could lead to significant improvements in catalytic rates, stability, and product inhibition in the enzymes. F

NEWS www.foodmag.com.au | November 2022 | Food &Beverage Industry News 9

The discovery could lead to higher barley yields.

Mars appoints new chief science officer

Mars, Incorporated has announced the appointment of Dr Abigail Stevenson as its Chief Science Officer (CSO), a role that champions Mars’ involvement in global, cutting-edge scientific discovery.

In this role, Dr Stevenson will drive external partnerships with academia, non-governmental organisations and peers; help build the pipeline of leading science and technology talent at Mars; and provide leadership of the Mars Science Leadership Team, reporting to Nici Bush, vice president of Science and Technology for Mars.

Dr Stevenson assumes the CSO

role in October and will retain her responsibilities as vice president of the Mars Advanced Research Institute (MARI), which connects Mars with emerging science and technology to spark discoveries with the potential to reinvent the future of its business.

She will also oversee the Mars Global Food Safety Center (GFSC), a state-ofthe-art research and training facility that sits at the heart of a global network of partners and collaborators tackling the most significant food safety challenges facing the planet today.

“As the world around us continues to evolve, I am excited to be driving

discoveries that have the potential to impact not only the future of our business, but also to improve the lives of people and pets around the world,” said Dr Stevenson.

“I’m fortunate to be surrounded by some of the best and brightest scientists, researchers and professionals across the globe, and I’m looking forward to continuing our important work together.”

In her career at Mars, Dr Stevenson has overseen significant research outputs, delivering innovative solutions to longstanding food industry challenges.

She has served in multiple roles

Growing the Australian vegetable industry

he Australian vegetable industry has grown significantly by taking advantage of changes in consumer

“Growing the Australian vegetable industry by diversifying products and improving quality report shows that vegetable industry growth has significantly outpaced the overall agricultural sector over the past five decades,” said ABARES executive director, Dr Jared Greenville.

“The vegetable sector has seen growth through a shift toward higher value products and improvements in the quality and convenience of what is provided,” Dr Greenville said.

Over the period from 1969-70 to 2020-21, the nominal value of vegetable production increased by

with the Waltham Petcare Science Institute, including head of Science Communications and Engagement; and was director of the Mars GFSC from 2017 to 2020 before assuming the role of vice president of MARI. F

From 1969-70 to 2020-21, the nominal value of vegetable production increased by $4.7 billion.

Improvements in product mix and quality contributed nearly 60 per cent of that growth while general vegetable price inflation contributed 35 per cent and increased volumes 5 per cent,” said

Rising incomes and changing

tastes have shifted consumer demand towards higher quality, wider variety and improved convenience, with only a moderate increase in volumes.

“We are not eating greater quantities of vegetables, rather we are eating a wider range of higher quality vegetables,” said Dr Greenville.

The improvement in quality has come from a variety of sources, including improved packaging, greater consistency, more ready to eat products and greater year-round availability.

“An important experience of the vegetable sector has been the on-farm value created by effectively responding to changes in consumer preferences and the role that close relationships along supply chains have played,” added Dr Greenville.

“While the experience of the vegetable sector may not be fully applicable everywhere, it seems likely that for a wide range of products in major export markets a capacity to differentiate based on quality attributes will be increasingly important as consumer incomes increase and tastes evolve.” F

NEWS 10 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

Dr Stevenson assumes the CSO role in October.

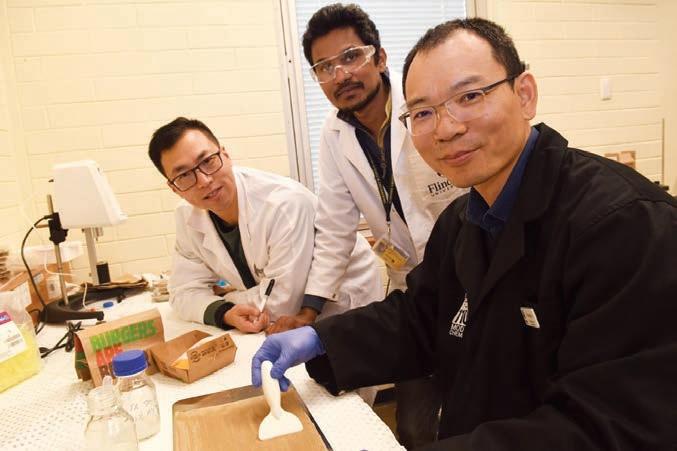

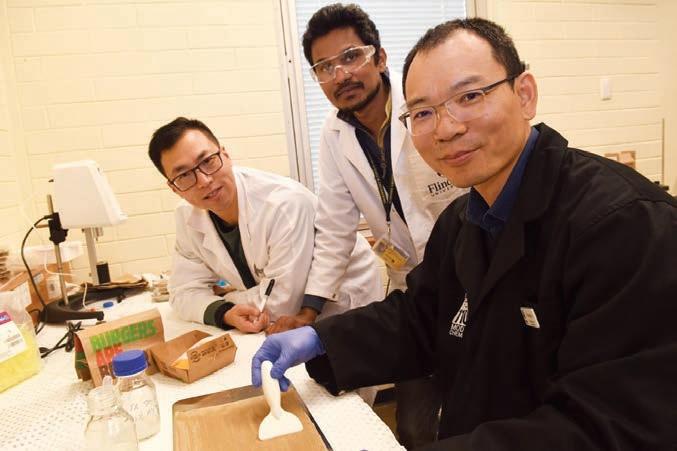

Seaweedbased wrapper provides fast-food packaging solution

Flinders University materials researchers and German biomaterials developer one•fıve are using seaweed extracts to develop nextgeneration biopolymer coating materials that could solve packaging waste dilemmas for the fast-food industry.

The new non-pollutive biomaterials are designed to replace conventional fossil-based plastic coatings used in grease-resistant fast-food packaging.

Grease-resistant paper is typically coated with plastic and other environmentally harmful chemicals, such as polyfluoroalkyl substances (PFASs), but the new prototype coating meets the functional requirements of conventional greaseresistant packaging materials while also presenting an environmentally circular solution.

The result represents a landmark achievement in creating a next-generation sustainable and ecologically responsible biopolymer.

This development – which took extracts from certain seaweeds, added modifications and formed degradable bioplastic films – has been led by Dr Zhongfan Jia, lead researcher from the Flinders Institute for Nanoscale Science and Technology and research colleague Peng Su in association with the Flinders Centre for Marine Bioproducts Development.

Biomass for the new coating formulation is made from natural polymers extracted from seaweeds that are native to the South Australian coastline – which provided a key reason why the Flinders University researchers studied it for more broad scientific application.

These extracts are transformed through a proprietary processing methodology to produce functional biopolymer sheets that can be cut or coated onto various surfaces, depending on the application. F

NEWS

The new non-pollutive biomaterials are designed to replace conventional fossil-based plastic coatings

Krones Pacific Pty Ltd, Tel: +61 2 9647 0200, E-mail: info@krones.net.au

Food & Beverage Industry News, 150 x 195 mm, Digitalisation M, CC-en91-AZ181 10/22

Coles and Bulla join forces to raise funds for food relief

Coles and Bulla have collaborated to raise funds from the sale of ice cream to help SecondBite provide the equivalent of up to one million meals for Australians facing food insecurity.

From September 28 until October 25, Coles and Bulla will donate 20 cents – the equivalent of one meal according to SecondBite – from every individual and bulk pack or tub of Bulla ice cream and Murray Street ice cream sold at Coles supermarkets.

SecondBite work with food growers, manufacturers and retailers to rescue surplus and unsold edible food that would otherwise be wasted in landfill and distribute it to local charities and non-profits around the country.

SecondBite CEO Steve Clifford welcomed the new initiative by Bulla

and Coles to raise funds at a time when many people in the community are struggling.

“This donation will really impact our ability to increase capacity, get more trucks on the road collecting food and ultimately feed more Aussies in need,” said Clifford.

Coles chief executive commercial and express Leah Weckert said Coles was pleased to join forces with two longstanding partners to introduce a new ice cream initiative.

“We know Australians love ice cream and they also want to help people in need. Through this new fundraising campaign, customers can enjoy a delicious Bulla ice cream while also helping others,” she said.

Bulla director and fifth generation founding family member James Downey said the 112-year-old business continued

to have strong family values as it has grown over the past several decades.

“We are privileged to partner with SecondBite in conjunction with Coles to support their work rescuing and

New food waste initiative to target food insecurity

Australian businesses and the Australian government can help strengthen food rescue, help feed food insecure Australians, and minimise environmental impacts of food waste, according to Stop Food Waste Australia‘s Sector Action Plan.

has been co-designed and developed

with Australia’s four biggest food rescue charities – Foodbank, OzHarvest, SecondBite and FareShare.

The plan outlines key interventions in research, policy, business

Australians.

Food rescue plays a critical role in Australia meeting its stated target of halving food waste by 2030 while also helping address the growing need for

redistributing good food to those in need right across Australia. SecondBite supports over 1,100 community food programs while at the same time reducing waste to landfill,” said Downey. F

meals for millions of food insecure Australians.

The Sector Action Plan aims to increase surplus food captured for redistribution, highlighting key initiatives for both the food rescue sector and policy-makers, primary producers, manufacturers, retailers, transport and logistics organisations and other associated parties.

Stop Food Waste Australia CEO Dr Steven Lapidge said the value of Australia’s food rescue sector cannot be understated.

“Food rescue is a unique approach to reducing food waste because it also has the fundamental co-benefit of reducing food insecurity.

“Australians continue to waste more than 7.6 million tonnes of food every year – 70 per cent of which is edible. At the same time, one in six Australian adults haven’t had enough to eat in the last year, and 1.2 million Australian children have gone hungry.” F

NEWS 12

More than 7.6 million tonnes of food is wasted in Australia every year.

SecondBite supports community food programs and helps reduce food waste.

CGA

Victoria partner for pilot project on traceability

Cherry Growers Australia (CGA) and Agriculture Victoria will partner to lead an innovative cherry supply chain traceability pilot for on-farm traceability and high-value export markets.

The project is funded through Agriculture Victoria from its Transforming Traceability program, a $11.7 million commitment to invest in the state’s traceability systems across the agri-food supply chain.

Over 2 years from 2022 to 2024, this pilot will build and protect exports by developing automated and integrated traceability systems that track the product journey from on-farm harvest through to customers. These systems will have the ability to identify products back to a carton or consignment level.

This pilot program will be conducted through a large Victorian producer and exporter, CherryHill Orchards. CherryHill will integrate the developing hardware and software technologies into their supply chain to apply this leading traceability technology to their premium cherry brands.

While on-farm traceability is well

developed in the cherry industry, it may be a paper-based system and usually ends when cherries enter export countries, preventing Australian producers from tracing their produce and leveraging the value of their brands.

GS1 traceability standards will be incorporated into the pilot, enhancing the international compatibility of these supply chains for global exports and domestic markets.

Dialog Information Technology, the technology provider for the project, will link up CherryHill’s ERP fresh produce system with two technologies – RFID farm and packing scanning and GS1 Digital Link for supply chain tracking and consumer engagement.

RAMP will provide inventory management software and RFID technology to enhance on-farm traceability.

The Australian cherry industry has a total value of $189 million and exports worth $79.5 million. At its peak, Victorian cherry growers exported almost 2,000 tonnes to over 30 countries annually at a value of $30.8 million. F

www.foodmag.com.au | November 2022 | Food &Beverage Industry News 13 NEWS

AUSTRALIAN-MADE COMPOSTABLE PACKAGING WWW.COPAR.ECO sales@copar.eco +61255656770 MADE FROM AUSTRALIAN AGRO WASTE, FOR YOUR FOOD PACKAGING SCAN THE QR CODE AND REGISTER YOUR INTEREST NOW TO GET EXCLUSIVE ACCESS TO OUR SAMPLES FOOD | FRESH PRODUCE | MEAT PACKAGING COMING SOON IN 2023

and Agriculture

The Australian cherry industry has a total value of $189 million and exports worth $79.5 million.

Lenard’s appoints new regional sales manager

Steve Smith, formerly of Coles, Woolworths, Metcash and IGA, has been appointed the Regional Sales Manager for New South Wales, Victoria and Tasmania at well-known Australian poultry company, Lenard’s.

Lenard’s chief executive officer, Harry Rumpler said they were excited to have Smith on board as the regional sales manager.

“Steve has worked for Metcash, and as a retailer so his experience will be a huge benefit to Lenard’s. [His] understanding of the independent sector will ensure our continued growth as we roll out our distribution and product strategies. We see Steve’s relationships with retailers as a key to our success,” said Rumpler.

On his new appointment, Smith commented, “Lenard’s is just a sensational product with great packaging, well-priced, extremely tasty and the fact it’s frozen-thawback means it’s easy for retailers to manage.

“Being a former store owner, I it’s a win/win.”

Hemp Foods Australia secures national distribution with Coles

Hemp Foods Australia, a subsidiary of Elixinol Wellness, has secured distribution in more than 800 Coles stores nationwide for its Functional Seed Mix range.

The newly developed range will be stocked in the health food aisle of Coles supermarkets and combines hemp seeds with other fruit, nut and seed formulations to deliver specific health benefits. The range includes a Protein Boost Seed Mix, Antioxidant Seed Mix, Gut Health Support Seed Mix, and Omega Seed Mix.

The Coles partnership is another important step in Hemp Foods Australia’s retail distribution strategy and follows a deal with Woolworths late last

year to stock its certified organic Hemp Gold Seed Oil in more than 100 stores.

“To secure national distribution with Coles for our new Seed Mix range is an exciting progression for Hemp Foods Australia and means that our brand can now be found on the shelves of Australia’s two largest supermarket chains,” said Felipe Favaro, general manager, Hemp Foods Australia.

“While we have been working hard on driving our e-commerce strategy, we also recognise the importance of bricks-andmortar sales, and we are definitely seeing more interest from supermarkets to stock our products as the mainstream appeal of hemp continues to grow,” Favaro added.

Hemp Foods Australia also expanded its partnership with Costco following

more than $3 billion by 2030.

the success of HFA’s Australian Hemp Seeds product.

Australia is being heralded as a plant-based protein powerhouse of the future, with a new report by the

the Commonwealth Scientific and Industrial Research Organisation (CSIRO) predicting that the sector could be worth between $3 billion and $9 billion by 2030. F

NEWS 14 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

locally sourced ingredients.

classics they know and love.

Steve Smith, brings experience from Coles, Woolworths, Metcash and IGA.

The plant-based protein market is predicted to be worth

C M Y CM MY CY CMY K

Refresco acquires Australian manufacturer Tru Blu Beverages

Refresco Group will expand into Australia as it enters into an agreement to acquire Tru Blu Beverages, one of Australia’s leading manufacturers of non-alcoholic beverages.

The acquisition of Tru Blu Beverages expands Refresco’s addressable market and provides opportunities to leverage Refresco’s size and scale, as well as its

track record of successfully integrating companies.

Tru Blu Beverages is a privatelyowned beverage manufacturer focused on providing non-alcoholic beverages to Australia’s largest retailers and brand owners. Tru Blu Beverages employs over 400 staff and has three manufacturing

and Perth, supported by a distribution network with warehouses in all major Australian capital cities.

Tru Blu Beverages fits into Refresco’s business model, with its wide range of beverage solutions for retailer brands and global, national and emerging brands. In addition, Refresco’s strategic ESG

accelerate its efforts of minimising the environmental impact of manufacturing processes, packaging and transport.

Refresco CEO Hans Roelofs said the acquisition is a testament to their proven ‘Buy & Build’ strategy.

“We now operate over 70 manufacturing sites globally, with just about half of those located across North America and the rest throughout Europe, offering a full range of beverage solutions to a broad customer base,” he said.

Peter Brooks, CEO of Tru Blu Beverages said, “By joining Refresco, our customers, suppliers and employees will be able to benefit from the Company’s broad capabilities, experience and expertise.

Refresco now operates over 70 manufacturing sites globally.

“Tru Blu Beverages’ leading capabilities and blue-chip customer base gives Refresco a solid entrance into the Australian market. We look forward to building an even stronger platform together.” F

Vgarden expands to Queensland

Vin Brisbane, as part of an ongoing relationship with Australia-based Cale and Daughters, which owns multiple vegan brands.

The two companies have worked together for two years to build plantbased food distribution in Australia. The new factory is scheduled for completion in 2023 and will employ 50 staff.

“Once fully established, our new facility will allow us to use locally sourced materials with a smaller carbon footprint,” said Ben Dotan, head of Innovation and Engagements at Vgarden.

“We will also investigate the possibility of exporting our products from Australia to the APAC region.”

lan Adut, CEO, Vgarden Israel said, “We are extremely proud of the partnership we have forged with Cale

delicious, nutritious foods.”

Vgarden develops, manufactures and distributes a range of products in Israel, including dairy-free cheese and spreads, vegan pastries, meat and fish alternatives, and lactose-free food.

The company is a supplier to major food chains, including Burger King and Pizza Hut. Vgarden is already a supplier to Woolworths in Australia.

Australia is a major producer of grains, pulses and legumes. With an advanced agri-research sector, Australia is poised to become a global leader in plant-based proteins.

The Commonwealth Scientific and Industrial Research Organisation (CSIRO) has estimated that Australia’s $140 million plant-based protein sector could grow to $9 billion by 2030.

Australia is the world’s third fastestgrowing market for plant-based foods.

NEWS 16 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

Australia is the world’s third fastestgrowing market for plant-based foods.

Peters Ice Cream has partnered with Australian fresh produce company, Montague, to create Rescue Pops – Plums Up, a frozen fruit sorbet stick made from rescued and repurposed Montague plums that were destined for landfill.

Rescue Pops – Plums Up sorbet sticks are naturally gluten-free, plantbased with no artificial colours or flavours and contain only 56 calories per serving.

Woolworths supermarkets have partnered with Peters and Montague to bring Rescue Pops – Plums Up to market, and will be exclusively ranging this product nationally from October in an eight-pack.

In Australia, 7.6 million tonnes of food waste ends up in landfill each year, equalling about 312 kilos per person. Much of this waste is perfectly edible but rejected due to minor blemishes and imperfections.

Stone fruits like plums are one

of the most common fruits to end up in landfill as they are prone to bruising, are highly perishable and have limited opportunities for juicing or repurposing.

According to Peters Ice Cream country head, Emma-Jane Collins, it is important for Australia’s most prominent food brands to highlight and address the issue of food waste.

According to Scott Montague, managing director of Montague, the partnership with Peters Ice Cream connected two companies with similar commitments to long-term sustainability and a keen environmental focus.

“Aligning with Peters is an exceptional opportunity for us to lead by example as we embed sustainability into every aspect of our operations,” he said.

Peters Ice Cream will also assist in closing the loop on food waste by funding 200,000 meals for Australians in need through Foodbank. F

Sorbet sticks made from repurposed plums Country managers for Japan and Korea announced

Australian Grape & Wine and Wine Australia have welcomed minister for Trade and Tourism Don Farrell’s announcement of two dedicated country managers for Australian wine in Tokyo and Seoul.

Farrell announced the appointment of Rosemary Macdonald and Suzie Chung as wine country managers for Wine Australia for Japan and Korea, respectively. They were introduced at in-market ceremonies attended by key members of the wine trade.

Japan and South Korea are two key destinations for Australian wine, currently sitting at the eighth and eleventh position for largest export markets by value respectively, and both have opportunities for growth.

“The Wine Country Manager

initiative will help Australian wine exporters diversify their markets. This is an exciting new opportunity for the industry, bringing together exporters, importers, wine experts and buyers to increase sales of Australian wine in supermarkets, restaurants and homes across Korea and Japan,” Farrell said in a media statement.

Australian Grape & Wine chief executive Tony Battaglene said he was delighted at the appointments, which are funded through the Australian Government’s Agricultural Trade and Market Access Cooperation (ATMAC) Program.

“Ms MacDonald and Ms Chung will be vitally important resources in two key markets that have been pinpointed for growth of Australian wine exports,” Battaglene said.

investment to assist in the wine sector’s strategic and long-term efforts in Japan and South Korea.” F

NEWS www.foodmag.com.au | November 2022 | Food &Beverage Industry News 17

“The Australian Government recognises the challenges facing exporters and has provided this

Peters Ice Cream, will also fund 200,000 meals.

Rosemary Macdonald and Suzie Chung as wine country managers for Wine Australia for Japan and Korea.

Carman’s announces acquisition of Fruit Wise

ustralian cereal and snack manufacturer Carman’s has announced the addition of the family-owned snacking brand, Fruit Wise, to the Carman’s family.

Carman’s has said the joining of the two businesses is a very exciting venture for their team, as it brings together a shared passion for delicious and quality

“My kids have loved Fruit Wise fruit straps for over 15 years, so much so they were the number one school lunch box request! Given how much we all loved the product, I decided to pick up the phone to see if there was any opportunity to work together.”

It’s truly a moment that I’m so proud of and I just can’t wait to watch Carman’s continue to grow.” said Carman’s founder Carolyn Creswell.

Managing director of Fruit Wise Bridget Beal said, “After speaking with Carolyn we knew straight away that this was the right move for Fruit Wise.”

“We’ve been family owned for 15 years, so wanted to make sure we were passing over the reins to someone just like Carolyn, who shared the same outlook about delicious and healthy snacking and looking after Aussie families. We can’t wait to watch Fruit Wise grow under the care of Carman’s!” Beal added.

The purchase comes after a year of negotiations.

“After a year of discussions, our unparalleled similarities and outlook on healthy snacking helped us finalise what is now Carman’s first ever acquisition.

Australian owned and made product is something Creswell holds close, which is why Fruit Wise will remain in its original home in Adelaide Hills. F

Nestlé launches NESCAFÉ Plan 2030

NESCAFÉ, Nestlé’s largest coffee brand, outlined its extensive plan to help make coffee farming more sustainable: the NESCAFÉ Plan 2030.

The brand is working with coffee farmers to help them transition to regenerative agriculture while accelerating its decade of work under the NESCAFÉ Plan.

The brand is investing over A$1.57 billion by 2030 in the NESCAFÉ Plan 2030.

T his investment builds on the existing NESCAFÉ Plan as the brand expands its sustainability work. It is supported by Nestlé’s regenerative agriculture financing following the Group’s commitment to accelerate the transition to a regenerative food system and ambition to achieve zero net greenhouse gas emissions.

Regenerative agriculture is a key part of Nestlé’s Zero Net road because

it contributes to drawing down carbon dioxide from the atmosphere and reducing greenhouse gas emissions. The coffee brand aims to contribute to Nestlé’s Zero Net commitment to halve greenhouse gas emissions by 2030 and reach zero net greenhouse gas emissions by 2050.

From farm to factory, the NESCAFÉ Plan 2030 will also build upon the brand’s actions in Australia to reach net zero greenhouse gas emissions by 2050.

In 2021, the NESCAFÉ factory in Queensland Australia transitioned to 100 per cent renewable electricity. Additionally, 100 per cent of the coffee beans roasted and blended at the NESCAFÉ factory in Queensland are sustainably grown.

Within its Australian and New Zealand operations, the brand is on track to have 100 percent of its coffee responsibly sourced by the end of 2023.

NEWS 18 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

The NESCAFÉ Plan 2030 will build upon the brand’s actions to reach net zero by 2050.

Accurate Measurement of

Kobold Instrumentation is one of the leading international instrumentation engineering manufacturers specialising in monitoring, measuring and regulating all aspects of liquid and gas applications when it comes Food & Beverage applications. Irrespective of the requirement, or the process Kobold Instrumentation will have a product to suit.

Our strength comes from high-quality distribution partners who manage installation, service, technical support & training nationwide.

Flow, Pressure, Level

& Temperature

Trusted German Engineering & Manufacturing Lubrication Management | Flow Management | Fire Suppression JSG Industrial Systems | jsgindustrial.com | 1300 277 454 Quality Engineered Systems

Adaptability is a critical aspect to modern manufacturing growth

Australian Vintage Limited, or AVL Wines, has become a clear example of how a producer in the food and beverage space can benefit from diversifying product offerings while moving towards a Net-Zero target.

Adam McCleery writes.

MEET THE MANUFACTURER 20 Food&Beverage Industry News | November 2022 | www.foodmag.com.au

Lucy Nash, AVL Wines head of sustainability, said the company prides itself on promoting Australia’s best wine regions.

Australian Vintage owns prominent wine brands across Australia including McGuigan Wines, Tempus Two, Barossa Valley Wine Company, and Nepenthe.

Australian Vintage head of sustainability, Lucy Nash, said the product portfolio of the company afforded Australian Vintage the ability to engage with consumers of all tastes across Australia, New Zealand, and the United Kingdom.

“The brands allow us to celebrate these beautiful wine regions around Australia while also bottling those and taking them to consumers across Australia and internationally,” she said.

Nash added that company exports a significant amount of product to the United Kingdom.

“We currently export our McGuigan Wines and Tempus Two brands and while these both have cellar doors in the Hunter Valley region, they both celebrate the wines of Australia,” she said.

“All our wine is made at our winery in Buronga Hill, on the border of Victoria and New South Wales, it is such an incredible site and facility. The scale of it, in the River-land’s region. It is an incredible region.”

Celebrating Australian regions is one of the key focus areas for Australian Vintage, and to do that the company

builds strong networks across some of the best the country had to offer.

“We bring in fruit from our own vineyards around the country, in the Riverland, Hunter Valley, Adelaide

Hills, and Barossa Valley,” said Nash.

“We also have some leased vineyards and purchase from some growers. We do all three methods to allow us to access the best fruit and meet market demands.”

Today, Australian Vintage crushes approximately seven per cent of the total Australian production of wine, making it one of the largest producers of its type,

“We are seeing more expansion,” said Nash.

“We are always looking at celebrating what is inherent to these beautiful regions but also exploring new varietals, especially ones that are perhaps more adaptive to changing climate conditions and consumer taste.”

Nash said putting the consumer at the heart of everything we do is an important factor in successfully reaching the market.

Nash said the company’s emphasis on listening to the consumer helps drive its innovation.

“Consumer insight drives all our brand marketing efforts and ultimately our innovation pipe-line, looking at what varietals and regions consumers are excited about and where we can serve people by meeting them where they are,” Nash added.

Australian Vintage will continue to celebrate the heritage of the brands and regions from which they come, but Nash said innovation and looking to the future was what would ensure the continued growth of the company.

One new consumer need that Australian Vintage identified, and since capitalised, was the rise in low and no-alcohol beverages.

“We are seeing a focus currently around no and low alcohol wines in the wine space,” said Nash.

“As a result, we’ve invested significantly in technology and machinery which helps us produce

www.foodmag.com.au | November 2022 | Food &Beverage Industry News 21 MEET THE MANUFACTURER

Australian Vintage Wines also exports a large amount of product to the UK.

“Consumer insight drives all our brand marketing efforts and ultimately our innovation pipeline, looking at what varietals and regions consumers are excited about and where we can serve people by meeting them where they are.”

beautiful premium wine and then spin off the alcohol to make lower alcohol, seven per cent wine, right down to a no-alcohol wine.

“We are seeing the response to that with our McGuigan zero range and in the Tempus Two zero that is launching currently.

“We are seeing the response in our McGuigan Zero range and in the Tempus Two Lighten Up and Zero range that is launching currently.

“We are seeing huge trends around moderation in consumption of alcohol and our McGuigan Zero is in the number one selling zero-alcohol wine in both Australia and the UK.

Nash said the true innovation around no-and-low alcohol was because it catered to the changing tastes of the consumer and tailoring to different drinking occasions

“That is in the wine space, but more recently we have also moved into the drink’s category,” she added.

Leveraging its world-class assets and innovative know-how, the company

recently expanded into spirits and ready-to-drink cocktails to diversify its portfolio and de-liver products that consumers are demanding.

Developed in response to global drinks trends each brand offers a distinctive point of difference - from a world-first gin to a playful sustainable spirit and high-quality cocktail convenience.

“While moving towards a more circular model in how we produce our wine packaging and create a more sustainable consumption and business model, we are also creating high-quality gin products repurposing the alcohol that is spun off from the low and no alcohol line innovation,” said Nash.

“Using a combination of traditional and non-traditional extraction and distillation methods, we just launched a beautiful gin product called Rescued Spirit Co.”

The Rescued Spirit Co range sees imperfect fruit not suitable for Australian super-markets being repurposed by Australian Vintage.

22 Food &Beverage Industry News | November 2022 | www.foodmag.com.au MEET THE MANUFACTURER

“Imperfect fruit that may not have made it into homes of people around the country, but we can utilise it to create a fresh and zesty gin blend that takes a by-product of our biggest selling line and also utilising local fruit to create something new.”

AVL Wines has vineyards across Australia’s best wine regions including the Barossa.

The company has also begun to enter the low and no-alcohol sector.

Among the brands under the AVL banner are McGuigan, Tempus Two, and Barossa Vallley.

Investment in quality machinery ensures the best possible product for AVL Wines.

“This is the first line of spirits under that brand which is exciting because it brings this ESG strategy to life and delivers on a number of those pillars,” said Nash.

The idea came about when Australian Vintage realised it had a by-product from the no and low alcohol production process which was perfectly suited to spirits, being both innovative and circular.

“We create the no and low alcohol wine, spin off the alcohol and that grape spirit is distilled with local rescued citrus fruits from the Mildura region,” said Nash.

“Using imperfect fruit that may not have made it into homes of people around the country, we can create a fresh and zesty gin blend that takes a by-product of our biggest selling line and also utilises local fruit to create something new.”

Nash also sang the praises of the innovation team

“The team have been thinking quite laterally, not only about our core product but expanding into other realms to deliver on something that serves consumer demand and gives us something new to talk about with retailers and the market,” she said.

The product diversification is a big step for Australian Vintage and signals the company’s commitment to being

more sustainable in its production processes.

“This is a signal of our transition from an established wine company into one that exists for the future,” said Nash.

Australian Vintage chief executive, Craig Garvin, said the ESG journey is an important one for the company.

“Sustainability is paramount to our success in the futures,” he said.

“It’s a critical issue but also one of the biggest opportunities of our time. It’s more than a social license, it’s a value creator and a key driver for innovation.

“Consumers want to support brands and businesses that put people and planet first and we’re seeing this in the

purchasing decision of our customers.”

The first focus area of the company’s ESG framework is centred around net zero targets and Nash said the team at Australian Vintage has set out some bold goals moving forward.

“We’ve taken this global best practice around balancing environmental and social impact,”

www.foodmag.com.au | November 2022 | Food &Beverage Industry News 23 MEET THE MANUFACTURER

Product diversification is a big step for AVL Wines and signals a commitment to meeting consumer demand.

Having facilities across multiple wine regions ensures variety of product.

said Nash.

“Alongside our financial performance, and from an environmental perspective, the number one issue is around climate change and what business can do to take responsibility for our contribution to that.

“Over the past two years we have been doing a very deep assessment of our carbon emissions to find out exactly what is the footprint of our global organisation.”

From a base year of 2021 Australian Vintage has set its net zero target date for 2040.

“That is ten years ahead of the UN 2050 deadline,” said Nash.

“We are really proud of the way we have framed our targets using the best practice climate science available now.”

is encompassing scopes one, two, and three for emissions across our entire supply chain.”

procurement strategy and how we work with partners and select like-minded business to transport our wine across the world or provide dry goods for our packaging and other materials that make up the bulk of our emissions profile.”

net zero target goal in mind.

2040.

“This is the kind of target that will impact our entire procurement strategy and how we work with partners and select like-minded business for things like transporting our wine across the world or providing dry goods for our packaging and other materials that make up the bulk of our emissions profile,” said Nash.

Nash also commended the entire team at Australian Vintage for the dedication and commitment being shown when it came to setting audacious new sustainability goals.

“Our team has embraced these ambitious targets because it helps us build a stronger framework for decision making around the future of the business,” she said.

“It’s not to say that everything we build follows the same model, but this consid-eration goes into every project moving forward to ensure we’re serving our com-munity alongside our footprint.”

Garvin also reiterated the future of Australian Vintage.

“We are on a journey, with an ambition to be net positive in everything we do,” he said. F

MEET THE MANUFACTURER

“Our targets are validated by the science-based target initiative and within that assessment criteria we not only have to set our longterm targets but a shortterm target to make sure we are on track to meet that.”

The company

has set new sustainability targets to meet net-zero by

AVL Wines has also embraced ambitious sustainability targets.

1300 007 224 | info@pbbg.com.au | paulbrady.com.au

We build food facilities from end-to-end and deal with everything in between.

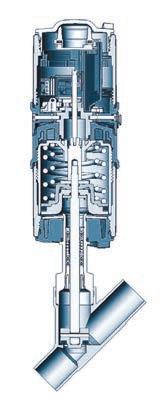

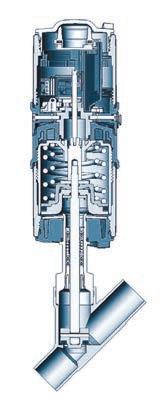

Automate valve controls in an uncomplicated and cost-optimised way

To meet market requirements and take advantage of the opportunities offered by digitalisation, machines and systems in hygienic environments and the need for automation is ever-increasing the standards for food and beverage manufacturers

Anyone who develops, produces, and installs machines for the food industry, will therefore need forward-thinking automation concepts that help keep manufacturing costs under control whilst still providing optimal hygienic standards and meeting connectivity requirements.

“Bürkert provide their customers with the most objective advice we can and offer, the most neutral solution possible in which we reduce everything to a minimum – leaving out the things they don’t need: complexity, risk and engineering effort,” said James Emerson, national food and beverage manager for Bürkert.

“This allows us then to support the food and beverage industry with intelligent, space-saving components and systems that can be quickly integrated,

scalable for changes in demand and intelligently robust for non-stop productivity.”

Digitalisation is a great opportunity to make machines and plants safer and more maintainable.

Automation does not have to be complicated. Solutions provided with simple wiring and tubing, minimal space requirements for cables, flexible digital networking and quick start-up are available and cost effective in migrating and updating sites to meet current standards and improve efficiency.

“What is most important to our customers is ‘reduced down-time’ where tens of thousands of dollars are wasted every minute,” said Emerson.

“Transparency provided through digitalised and networked systems, such as control heads on valves, gives

operators the opportunity to have programmed maintenance mapping throughout their plant, direct feedback from each valve in the field through diagnostics and overall cost savings for better bottom line results.

“That’s how digitalisation is making a big positive impact with those who are embracing transformation.”

Challenges with traditional concepts

Discrete wiring leads to a lot of effort. The challenges become visible using the example of a filling machine for food or beverage products: Various drives, flow meters, pressure and temperature sensors are required for the process. Each device has a cable connection to a discrete port of an IO module in the control cabinet.

The wiring of the machine takes a lot of time when consumer devices such as sensors or control heads exchange their signals over numerous strands in a cable, which quickly makes the installation confusing.

Tedious, error-prone installation is common with this solution, because to connect a device, it is necessary to correctly connect all 12 strands in the cable.

Cable breaks can easily occur, which are often difficult to find. The potential for errors is high, and troubleshooting is usually extremely time-consuming. This also applies to installation and commissioning in general.

Lots of cables and lots of IO cards also mean: a lot of space is required.

Control cabinets and cable racks must be correspondingly large and require a lot of floor space. Another disadvantage is that because of the large number of cables, sudden changes in voltage can cause crosstalk from one cable to another cable laid in parallel, which disrupts the process and impairs its repeatability.

AUTOMATION 26 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

Burkert provide customers with the most objective advice.

Greater security, less effort through intelligent networking

There is a better way. An intelligent networking solution reduces the number of cables to four, while only one type of IO-Link master serves all devices at the same time. All relevant data is available digitally - and significantly more parameters can be read out than in conventional solutions.

Permanent diagnostics are thus possible to ensure system availability at all times. In addition, an integrated S2 redundancy increases the availability of the system – pure safety.

Since all connectors are replaced with M12 connectors, the process of assembling electrical equipment is very fast, safe, and easy. The switch from analogue to digital devices also eliminates the need for recalibration after a certain period of operation.

Subhead: Control your system decentrally - for more productivity, improved safety and sustainability To ensure that end products are

produced with consistency and highquality, the production plant must precisely control and regulate all media at all times. Fast-switching, intelligent process valves are essential for this.

They are part of an overall concept designed and implemented as part of an objective consultation for a customised solution, just for your plant.

This results in individually planned decentralised automation solutions that ensure that the infrastructure and valve control of your systems do exactly what they are supposed to do and can be continuously monitored using numerous parameters.

How can this be achieved?

More productive thanks to intelligent control heads from Bürkert.

Decentralised automation with Bürkert means: Locally controlled process valves regulate the function of your system. The intelligence is in the control heads - a concept with many advantages. The control head

Type 8681 can also be used universally, so that process valves from different manufacturers can be easily automated with this solution.

When is decentralised automation right for you?

Consider if you need clear, flexible pneumatic control across your production facility. Would you find value in transparent processes and fast commissioning?

Could real-time, on-the-spot information for critical processes improve safety and maintenance downtime with faster reaction to mid-production faults? If these are core goals for your business, then perhaps this solution is right for you.

“Bürkert is at the forefront of decentralised control top technology with unparalleled connectivity capabilities to modern fieldbus protocols,” said Emerson.

“We’ve been assisting customers for the better part of the last decade in

upgrading, evolving, and improving their plant processes for the better.

“There is a solution for every customer, large or small and we’ve got hands on experience in helping them find the right fit for their individual challenges.”

Bürkert’s partners can take advantage of our cross-sector experience with regard to all automation concepts and fluid handling in hygienic production processes. We offer you comprehensive technical know-how as well as suitable system and product solutions for both customised and standard applications – all paired with solution-oriented consulting.

In working collectively across the food and beverage industry for more than four decades, Bürkert Australia know the challenges faced by the industry and are moving towards more sustainable, efficient solutions to help improve productivity and bottom-line results for our partners. F

www.foodmag.com.au | November 2022 | Food &Beverage Industry News 27

AUTOMATION

Burkert’s partners can take advantage of its cross-sector experience.

Reliable solutions to improve efficiency during production

Having Kobold Instrumentation’s suite of offerings included in its range of products affords JSG Industrial System the ability to offer solutions to every part of the industry. Adam McCleery writes.

The John Sample Group operates in numerous countries across the globe.

The Australian business, JSG Industrial Systems represents Kobold Australia which sells and supports the Kobold portfolio whilst lending expertise and aid across other international subsidiaries, including New Zealand, Indonesia and South Africa. It is therefore in an ideal position to help the food and beverage industry.

Instrumentation plays a critical role in so many applications and processes in food and beverage manufacturing. The companies which create and supply the technology required therefore need to be full abreast of what is going on in the industry.

Kobold’s key sales advantage is the ability to offer a full suite of instrumentation devices unrivalled in many sectors, JSG Industrial Systems is a company which requires

requirements of its clients.

“When we talk about instrumentation, that can be anything from a flow measurement device through to a level switch or a display,” said James Slowgrove, product manager – Flow & Instrumentation at JSG Industrial Systems.

“A lot of manufacturers all focus on one area; flow measurement of water or pressure monitoring in heavy industrial applications, Kobold does all of them.

“It’s a real one stop shop for all these different instrumentation devices so their range is almost endless as a result.”

As an example, Slowgrove continued, when a client contacts JSG about instrumentation, JGS’s team provide the required expertise to not just answer any query, but also present a range of other viable, and in some cases, better solutions.

“Case in point, as the technical product manager I might have an inquiry to measure or monitor the flow

of water to a baking process,” he said.

“Another inquiry may be to fill up a silo with grain and we need to find ways to best measure the amount of grain currently being stored. They go hand in hand but at the same time are very different.”

“As a result, Kobold can provide a solution for installation A and installation B with a different range of products.”

And when it comes to plant machinery Kobold offers a wide range of possible solutions.

“If I were to look at a manufacturing processing facility that makes cordial. If you know your mixture consists of part A of cordial concentrate and part B of water,” said Slowgrove.

“If it’s all automated you will need sensors to ensure you are getting the perfect mix every time to ensure the quality of the product is maintained. If something goes wrong with the line, like running out of water or the temperature goes too high, those devices that alert you are also part of Kobold’s suite of offerings.

Another example Slowgrove gave was in reference to another customer query in 2021.

The client was looking at producing new plastic moulds and were using various renewable plastics in the material makeup.

“They needed to make sure the plastic being pumped into the container was then going to be at the right temperature with the right amount of mixture,” said Slowgrove.

“When you make plastic, you often have three components, your raw material, the catalyst, and you might have a dilution of some sort”.

“In this instance we focused on the plastic line’s raw ingredient and for them to get the correct dosage they needed to make sure the plastic was being heated and maintained at a certain temperature and level.”

Because of this Slowgrove focused immediately on the process when the

Instrumentation plays a critical role in many applications and processes.

product enters the warming chamber, as an added element of instrumentation use.

“What happens down the track, especially after it has been batched out from the storage container. How far away until it reaches the next step? 10 cm? Three metres? Have they thought about what is needed to stop the warming chamber from over-filling,” he added.

“One aspect they didn’t think about was measuring the amount of material in a tank. It wasn’t too long until we started to look at level sensors for that heating chamber, this is a bit of insight into what Kobold can do”.

“It swiftly became about the level sensor and temperature probe at the same time.”

This type of expertise and insight is something JSG prides itself on providing

INSTRUMENTATION 28 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

Kobold’s key sales advantage is its full suite of intrumentation devices.

the industry.

“There are times customers will contact JSG for flow measurement devices with a certain technology in mind and we look at the application to assess if it is the best fit for the application,” said Slowgrove.

“If it isn’t then we sit down and speak with the client about why”.

“It might not meet the expectations when it comes to accuracy or hygiene. So, if the customer asked for an oval gear meter and we do some digging we might turn around and ask about pressure loss, hygiene requirements, or we might offer a magnetic flow meter to improve accuracy.”

Because of the wide range of solutions offered by Kobold, through JSG, the company can provide simple and effective solutions which result in efficiency gains and improved quality, among other benefits.

“Depending on what you’re pumping, certain other criteria might need to be met, it might be something as harmless or simple as water but something a bit more dangerous like a caustic solution,” said Slowgrove.

“That’s often used in a lot of cleaning applications, if you are running a manufacturing facility you will have tanks full of dangerous fluids.”

One example Slowgrove cited was a customer that came to JSG wanting to mitigate WHS risks and increase efficiency around the filling and monitoring of fluids in a tank.

At the time, the company had operators manually opening and closing the valves which was resulting in a level of wastage because of the very nature of manual operation in this context.

“If you have an operator manually doing a task, your accuracy will be out and that causes wastage, not to mention if they come into contact with dangerous fluids, there might be WHS risks involved also,” Slowgrove added.

“The solution here was providing them with a flow meter and a controller with specifications for a valve.

“It was a simple and basic solution but the whole purpose was to install a valve next to a flow meter and then have the wiring going to a controller where

you can measure and record.”

The result was allowing the customer to monitor the levels to an exact number.

“Once it has done so it will shut off that valve, so you get perfect, and efficient measurement of that batch,” said Slowgrove.

“For that customer, who was doing mini batches, it is a great example of how we can remove that WHS risk and improve the efficiency and made sure measurements were accurate with minimal wastage.

“That’s where automation comes into it, it is all about removing risk,

improving efficiency, with the least number of parts, and that is what Kobold do.”

Slowgrove added that in terms of meeting certifications, of which the food and beverage industry requires many, is another point of strength for Kobold.

“A large number of our products are engineered specific for a certain application,” he said.

“If you are measuring milk you want to make sure your meter has the tri-clamp fittings for sanitary connections, stainless-steel wetted materials and food grade seals.

“A lot of our magnetic flow meters can be tailor made for specific food applications.”

JSG Industrial Systems always pride themselves on providing engineered solutions with their other key suppliers, and with Kobold Instrumentation products available from Germany, it only further enhances their capability to find every customer a solution. F

Because of the critical role instrumentation plays, the selection of the right devices is paramount.

INSTRUMENTATION www.foodmag.com.au | November 2022 | Food &Beverage Industry News 29

"A lot of manufacturers all focus on one area; flow measurement of water or pressure monitoring in heavy industrial applications, Kobold does all of them. It's a real one stop shop for all these different instrumentation devices so their range is almost endless as a result."

JSG Industrial Systems is the exclusive distributor of Kobold Instrumentation in Australia.

Don’t get caught out when upscaling temperature-controlled environments

When food and beverage manufacturers experience growth and need to upscale operations, a need arises for an approach to scope, design and construction that can mitigate risks. Food & Beverage Industry News reports.

Paul Brady, owner, and founder of Paul Brady Building Group has been in the food facility construction industry for over 25 years and specialises in helping food and beverage manufacturers mitigate the risks of upscaling and meeting greater production yields.

Brady said because of the growth strategy of many of PBBG’s clients, being able to help them from scratch was critical to limiting turnaround times.

“The companies we generally do work for have grown the business quickly and have an opportunity to

obtain contracts with big suppliers, but they find themselves needing to move into a new facility,” he said.

“By nature of that opportunity, a quick turnaround time is required, which creates a lot of pressure.”

“And if they have moved into an older facility, it won’t have the accreditation specific for that type of manufacturing, so in those cases we sit down and we work from scratch.”

Brady said Paul Brady Building Group mostly specialises in brownfield sites, which is a new fit out within an existing warehouse.

“We need to take many construction, compliance, and food production elements into account but we have had clients buy a warehouse or factory and find that it wasn’t suitable,” he added.

“They might be a meat producer but have bought a facility close to residential properties which creates issues around EPA.”

“We are all about mitigating the risk for our clients and helping them find the right property to grow their business so we talk to them about future growth and how it can be incorporated into today’s design.”

There are so many things to consider when upscaling and lead times can be considerable, so being prepared and planning ahead is critical, especially in food and beverage production.

As highlighted by the seafood supplier case study, PBBG understands the need for high-quality floor finishes and the best in breed building materials, including FM approved insulated panel walls and ceilings.

“We custom manufacture our own range of insulated door systems in house. We also have exclusive distributorships for other high quality fixtures and

Paul Brady has been in the food construction industry for over 25 years.

CONSTRUCTION 30 Food &Beverage Industry News | November 2022 | www.foodmag.com.au

Among PBBG specialities is the expert ability to fit out temperature-controlled environments.

fittings that we import and insist on for our projects,” said Brady.

“We closely look at all aspects of our clients’ operations and we are able to bring into the project products/systems

that we know will work best in that environment for greater performance and longevity.”

The added focus on high-end flooring finishes has also become a

PBBG is able to help clients from the very start, helping to mitigate turnaround times.

point of pride for PBBG and is one that is of supreme importance to food and beverage manufacturers.

“We see the fall out of poor-quality floor systems and finishes that aren’t up to the demands of the production areas, so we invest in researching and installing hard-wearing floor systems.

“We import some products from Europe that we incorporate into our range.”

But one of the biggest strengths of the company is the capacity to do all the insulated panel installation by its own trained and experienced staff.

“As the principal contractor we bring in quality specialists that complement our higher build quality,” said Brady.

“By identifying with the client early on what they need to be aware of, they are more likely to avoid nasty surprises down the track,” he said. F

CONSTRUCTION www.foodmag.com.au | November 2022 | Food &Beverage Industry News 31

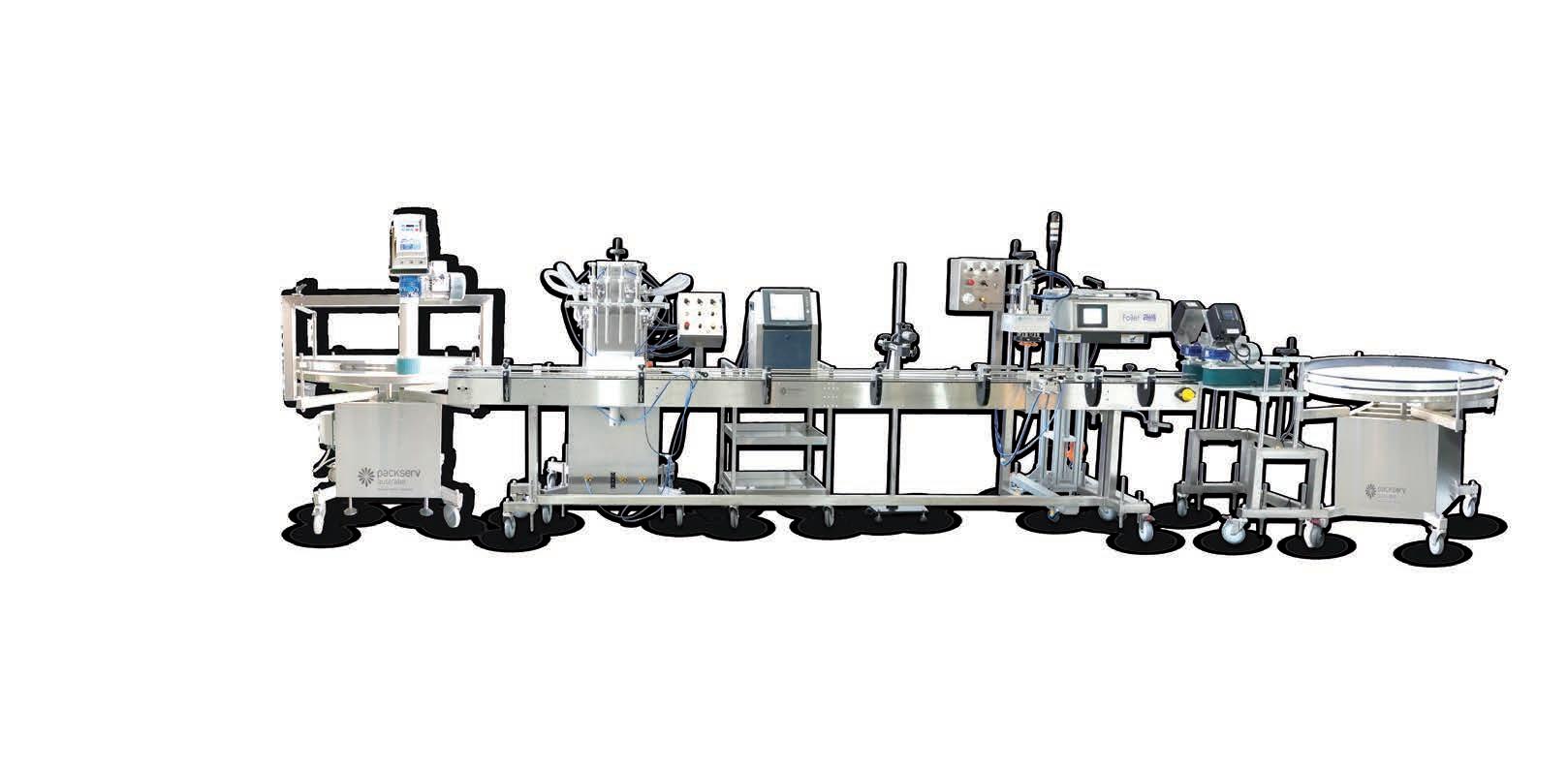

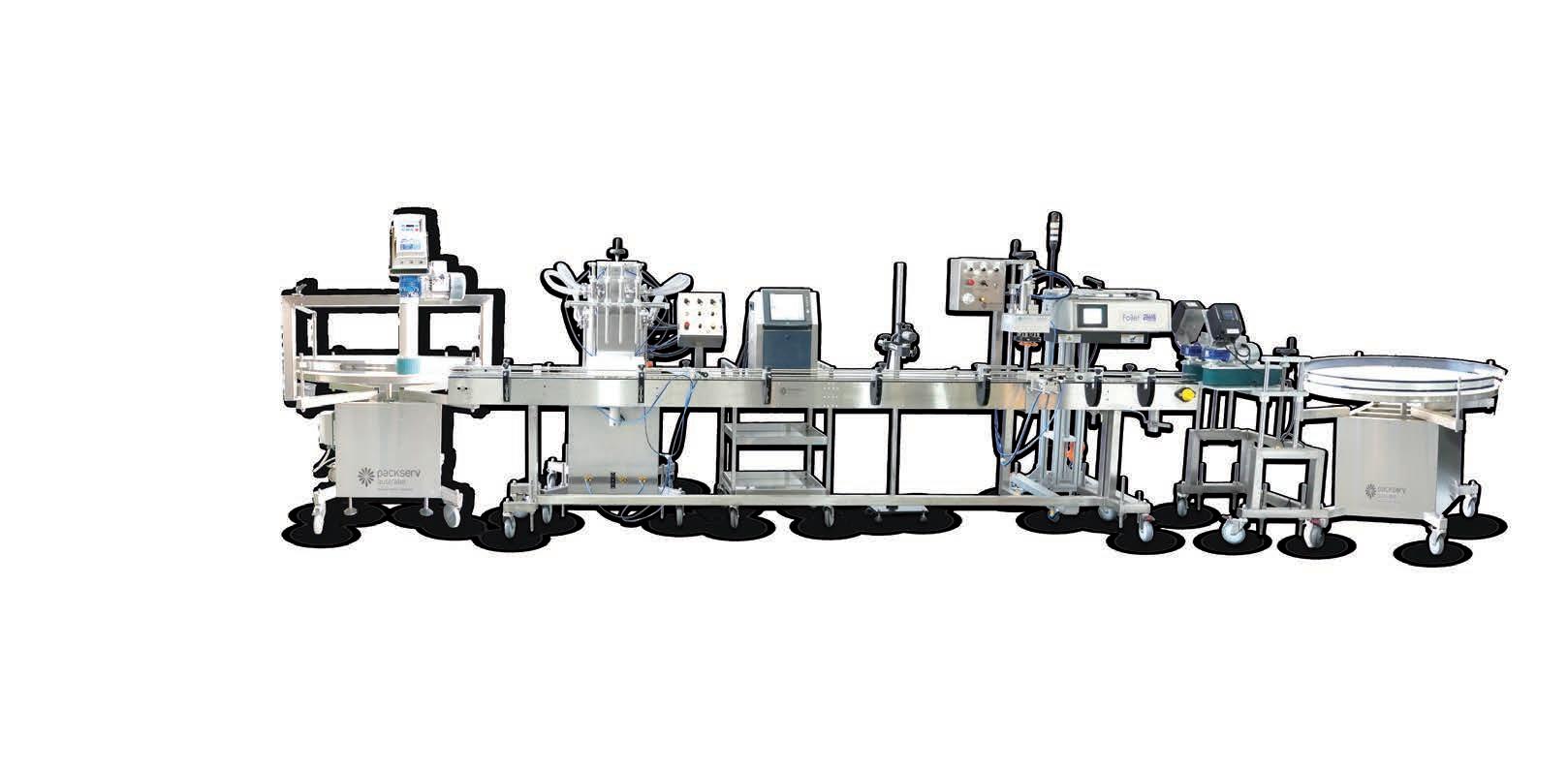

Local solutions cut

and technical service providers for the food and beverage industry, particularly SME’s.

Nathan Wardell, Packserv Australia managing director, said the company started out as a rental and technical service provider before continually diversifying its offerings.

“We began importing, distributing, and reselling other people’s machinery about six years ago and then three years ago we started designing and building our own machinery, so now we are a full-service manufacturer. Which means we can supply complete production lines and turnkey solutions.

It has been a long journey, we now have in house CAD and CNC capabilities where we can take a client’s problem, draw a solution, and be holding the finished part ready to install in very little time”.

Wardell said one of the key driving factors behind the evolution of Packserv Australia was the notion that if parts can be manufactured locally, then they should be. Not just to cut back on lead times, but making your own parts also allows rapid updates around design, which is a prerequisite for innovation,

the very real and obvious environmental cost of shipping manufactured goods from one side of the world to the other, adopting, or even aspiring to, a carbon neutral model for manufacturing can only ever be disingenuous if we

rely on imported goods. International supply chains that previously appeared so strong were revealed to be more akin to international paper chains, and wet

and machinery that creates the biggest

to keep up with the ever-increasing rate of changes in food and beverage manufacturing processes.

Packserv has several technology

32 Food &Beverage Industry News | November 2022 | PROCESSING

Packserv started as a rental and technical service provider but has continued to diversify its offerings.

Packserv grew into a full-service manufacturer with the ability to supply complete production lines.