PLUS, THE MAXAM AGRIXTRA RANGE DELIVERS MINIMAL SOIL COMPACTION, A COMFORTABLE RIDE AND IMPROVED TRACTION WHICH SURPASSES ALL AGRICULTURAL TYRE EXPECTATIONS. WHEN PACKAGED WITH ONE OF THE BEST WARRANTIES IN THE INDUSTRY, THE AGRIXTRA DELIVERS THE PERFORMANCE YOUR FARM DESERVES!

TO SEE THE COMPLETE RANGE VISIT

12 Review: The Dieci Agri Plus 40.7 PS Evo2 boasts fine lines and good looks – but our reveiwer finds it’s a true workhorse

19 A rmour Group introduces four-inone Stewart trailer to suit Australian mixed farmers

23 Brisbane Mini Excavator Sales is expanding its heavy duty range of graders and dozers

27 Bourgault grows local range by adding 4420 DKD deep knife drill

31 Newly customised dozers, graders and wheel loaders further show what Dixie Holdings can offer

20 Addressing staff shortages and tackling economic challenges were key topics at this year’s TMA conference

32 Tractor sales were steady in June as the government’s instant asset write off ended, TMA’s Gary Northover says

35 John Deere offers strategies to help farmers select the right piece of haymaking equipment

39 John Shearer’s Mk4 Universal seeder bar meets today’s farming

Editorial & Design

Editor Lincoln Bertelli

lincoln.bertelli@primecreative.com.au

Journalist Will Krawczuk

Contributors Gary Northover, Trevor Whittington

Art Director Daz Woolley

Managing Editor Andrew Hobbs

ISSN 1449-6399

needs thanks to a variety of improvements

43 Farmgard brings Rolland’s Rollforce 5517 muck spreader to field days and local market

49 The Orsi product range – available through Clark Equipment - offers mowers, mulchers and more

6 New data shows the prospect of both El Niño and an Indian Ocean Dipole is impacting crop forecasts

8 Australian farmland prices have risen strongly, according to ABARES data

8 I nterest rates remain steady on Regional Investment Corporation farm business loans

10 CSIRO launches national soil data and information tool for farmers and industry

60 Upgrades to Lemken’s front tanks and applicator systems to boost efficiency

61 New hopper and traction control system for Pottinger cultivator range

62 Deere acquires precision spraying company Smart Apply

63 Mazda upgrades BT-50 SP and Thunder utes

64 New generation Mitsubishi Triton ute launched

Advertising

46 ifm’s Moneo system works like a smart watch to help its user make sense of a wealth of farm data

54 Monash University professor Chao Chen discusses the opportunities which ‘cobots’ provide in farming

52 WAFarmers CEO Trevor Whittington asks if Australia can find the capital to channel new opportunities to use technology in agriculture

4 Editor’s note

58 Calendar of upcoming events

84 Nanometre perfect

A NCA’s new CNC control system guarantees a smooth finish

84 Global winners

Jungheinrich wins at IFOY awards

85 All-rounder

Kaeser’s Mobilair compressors are efficient and dependable

Regular readers will notice a few things are different in this edition – most notably the physical size.

The decision to move to an A4 format is intended to make the magazine easier to hold and therefore read, as well as providing the chance for a refreshed format and design.

One thing has not, and will not, change though – and that is our commitment to providing quality content for farmers, contractors and the wider agricultural industry.

New products and technology have always been a focus of Farms & Farm Machinery ’s content, and this will of course remain.

Beyond just reporting the news though, we recognise the importance of your farming businesses getting the most out of both your land and people to ultimately increase farm revenue.

This is why we are putting an increased focus into explaining how these extra efficiencies can be found, and supplementing this with customer testimonials and independent machinery reviews.

Dieci’s Agri Plus 40.7 PS Evo2 telehandler is the subject of this month’s review and was put through its paces to show how it can be an asset to farmers.

Australia is also gearing up for several major field days and with this comes the opportunity for new products to be launched and showcased.

We have highlighted a few which will be on display at AgQuip; including the Stewart VT6100 four-in-one trailer from

Armour Group, the Rolland Rollforce 5517 muck spreader imported by Farmgard, and Bourgault’s 4420 DKD deep knife drill.

We shine a spotlight on other products including Clark Equipment’s Orsi range, John Shearer’s Mk4 Universal seeder bar and some John Deere machinery which Dixie Holdings has customised to meet specific needs.

Speaking of John Deere, in this issue the company offers strategies to help farmers pick the most suitable haymaking equipment.

New technology including ifm’s Moneo system is explained, while we look at topics such as farmland prices and the impact of a predicted El Niño event in our relocated industry news section.

Farms & Farm Machinery also attended the Tractor & Machinery Association conference last month, where topics included an economic outlook and discussion around current industry challenges.

The farming industry always faces unique challenges and these often require unique solutions.

This magazine might be slightly smaller in the hand, but our desire to help inform the industry about how to solve these

Lincoln Bertelli

With

The prospect of an El Niño and an Indian Ocean Dipole is denting Australia’s crop forecasts for the year ahead, according to new data

All things being normal, a CSIROdeveloped forecasting service says Australia’s 2023 national wheat harvest will be 2.4 tonnes of wheat grown per hectare – a median calculation that sits above the 15-year national average.

Wheatcast, a part of the CSIRO’s Digiscape Future Science Platform, notes that the median yield prediction it set is below that of 2021 – a record year for wheat yield but is well above that of 2017 – considered an average year for wheat yield.

The platform developed the forecast based on current plant-available soil water levels and current weather data, compared to records from the past 30 years, from 202 testing sites across Australia.

But it concedes there is some uncertainty about the forecast, acknowledging the predictions do not account for extreme weather events or pest or disease outbreaks.

According to the Australian Crop Report, developed by the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES), those weather conditions pose “a significant downside risk” to the 2023-24 winter cropping season.

ABARES says it is likely an El Niño event, which results in below average rainfall, will develop across much of eastern Australia this year – while a positive Indian Ocean Dipole could exacerbate its effect

– supressing winter and spring rainfall across the country.

“Rainfall in El Niño and positive Indian Ocean Dipole years is generally below average in both winter and spring in Australia,” the report says.

“Therefore, rainfall could be insufficient to restore depleting soil moisture required for plant growth.”

Due in part to this lower predicted rainfall, the Australian Crop Report forecast total Australian winter crop production would fall by 34 per cent to 44.9 million tonnes in 2023–24 following three consecutive record production years.

Wheat production was forecast to fall 34 per cent to 26.2 million tonnes, reflecting an expected fall in yields and slight fall in expected area planted to 12.8 million hectares.

Barley production is also forecast to fall, down 30 per cent to 9.9 million tonnes, despite an anticipated 4 per cent rise in area planted. Canola production is also forecast to fall by 41 per cent for year, to 4.9 million tonnes.

ABARES Executive Director Dr Jared Greenville said rainfall in northern and southern cropping regions in Western Australia, northern New South Wales, northern Victoria and parts of southern and Central Queensland had been lower than average, with soil moisture levels low.

“Winter crop production is expected to decline to 3 per cent below the 10-year average to 2022–23 of 46.4 million tonnes and yield prospects are forecast to be below average due to the expectation of below average rainfall for winter and spring,” he says.

In line with this, wheat export volumes are forecast to fall by 29 per cent, to 21 million tonnes in 2023-24 – a figure that is still 15 per cent above the 10-year average to 2022–23, due to steady demand from South-East Asia and East Asia.

Canola and barley export volumes are also forecast to fall this year, due to lower production.

But in happier news, the risk of a mouse plague was significantly reduced, Greenville says, due to growers carrying out successful baiting campaigns early.

“On a more positive note, high crop prices, good seasons and record farm cash incomes over the last three years mean many growers will stay in a strong financial position despite the fall in production,” he added.

“Despite the decline in production and weather events, national planting to winter crops in 2023–24 is set to remain historically high in 2023–24 at 23.3 million hectares, 6 per cent above the 10-year average to 2022–23 and summer crop production in 2022–23 remains above average but below last season’s record.”

The average per hectare price of broadacre farmland has almost doubled over the last three years, increasing by 93 per cent from 2020 to 2023.

That’s according to the Farmland Price Index, produced by the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES).

ABARES executive director Jared Greenville says the increase in prices likely reflects a combination of factors including low interest rates in previous years, recent good commodity prices and seasonal conditions, and increased demand for land in general.

“Farmland is often used to secure lending, so increases in value can both

improve equity and drive investment,” he says.

Median farmland prices have grown most in the high rainfall zone, increasing by 125 per cent over the last three years to almost $9,000 per hectare.

Price growth in the wheat-sheep zone was also strong, increasing by 80 per cent over the same period to $3,465 per hectare.

Coming off a lower base, the average price of pastoral zone farmland increased by 130 per cent since 2020 to reach $1,528 per hectare in 2023.

Greenville says this is the first release of the ABARES Farmland Price Index online tool, which uses CoreLogic data

Rates on Regional Investment Corporation (RIC) farm business loans will remain steady for the next six months, the organisation has confirmed.

The variable interest rate will remain at 4.52 per cent on all concessional farm business loans – including AgriStarter, Farm Investment, Drought and AgBiz Drought – until 1 February 2024, while the Plantation Loan will remain at 4.07 per cent.

RIC interest rates are variable and reviewed every six months, bringing certainty to RIC customers that any change will be effective on 1 February and 1 August each year.

RIC chief executive John Howard says RIC concessional loans play a vital role in strengthening Australian agriculture and in helping farm businesses manage their risk.

“RIC concessional interest rates remaining on hold at 4.52 per cent will be welcome news for thousands of RIC customers across Australia, providing much-needed breathing space, greater

certainty to manage cash flow and stability to strengthen their long-term financial position,” he says.

“One of the key benefits of RIC loans is interest rates are reviewed every six months and are based on the average of the Australian Government 10-year bond rate, not Reserve Bank of Australia (RBA) cash rate movements. So now, RIC loan interest rates have proportionally become even better.”

The RBA has increased its cash rate 12 times - up by 4 per cent since May 2022. In comparison, during the same period, RIC concessional loan rates have moved twice, with an increase of 2.21 per cent.

“RIC loans have saved our customers an estimated $105 million in interest repayments in FY2021-22 alone,” Howard says.

“Our latest research shows four out of five RIC loan customers have greater confidence in the future and profitability of their farm business.”

“We are pleased to help farm businesses set up, invest, recover, and prepare

Median farmland prices have grown most in the high rainfall zone

and a stratified median approach to make its findings – with quarterly indexes and more detailed regional estimates yet to be developed.

“The Index utilises a robust and effective method developed by ABARES ensuring estimates reflect market conditions,” he says.

“Through an innovative and simple to operate dashboard on our website, users can gain valuable insights into market trends, access reliable information on the value of their farmland assets and track annual changes over time,” he says.

“Users can make price comparisons between farming zones or download data for their own analysis.

ABARES’ new Farmland Price Index can be found at www.agriculture.gov.au/ abares/data/farmland-price-index

for potential severe business disruption including drought, floods or bushfires for a more sustainable, thriving regional Australia,” he says.

Farm businesses with a concessional RIC loan benefit from no application fees, no ongoing management fees and no extra or early repayment fees.

RIC loans have a 10-year term with interest-only repayments over the first five years, followed by principal and interest repayments for the remainder of the loan term.

Australia’s national science agency, CSIRO, has launched a new tool that will help Australia sustainably manage a critical natural resource which sustains lives and livelihoods.

Now live and available for use, the Australian National Soil Information System (ANSIS) brings together soil data from across Australia, connecting multiple data sources to provide access to nationally consistent soil data and information.

It will equip farmers, policy makers and researchers with the data and information they need to better manage, restore, and protect Australia’s soils.

ANSIS project lead at CSIRO, Peter Wilson, told attendees of the Soil Science Australia conference in Darwin that the new System is an important step forward for the sustainable management of soils in every part of the country.

“Soil is the backbone of our food security, and it is critical that we manage it effectively for climate change adaptation and economic and environmental prosperity to support national and global agrifood priorities,” Wilson says.

“Until now, it’s been exceptionally difficult to find, access, integrate and compare soil data.

“This new system brings together all this information providing easy access to soil data and information that will underpin the effective management of soil.”

ANSIS will be a valuable tool for farmers and farm advisors, allowing them to compare the condition of their soil with other soils in their region; monitor how their soil has changed over time; and inform opportunities for change or improvement in land management practices.

Governments and industry bodies will be able to use data and information through ANSIS to support the development of effective policies to ensure our soil is sustainably used and enhanced for future generations, and to inform policy decisions in areas such as drought resilience, climate adaptation, natural capital accounting and biodiversity conservation.

Australia’s National Soils Advocate Penelope Wensley says the launch of the new national soil information system was an exciting development.

“It represents a major advance in implementation of the National Soil Strategy,” she says.

“Good data, available in a consistent, accessible form, is essential for better understanding and management of Australia’s soil.”

More productive healthy and resilient soil can provide multiple benefits for farmers

Wilson says ANSIS will enable researchers to better understand the way our soil works, its role in climate change adaptation and mitigation, and the impacts of humans on this valuable natural resource.

ANSIS is supported by funding through the Australian Government National Soil Strategy (Department of Agriculture, Fisheries and Forestry) in collaboration with CSIRO and partner organisations.

ANSIS will provide data and information to enable improved soil management

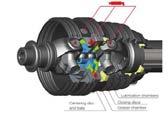

The Dieci Agri Plus 40.7 PS Evo2 boasts fine lines and good looks – but make no mistake, it’s a true workhorse

Words Ash Santilla Images Lincoln Bertelli

Sometimes it’s the first impressions that stay with us.

Of course, we want to know everything about a machine: the specs, the power and durability and functionality.

However, does style and finesse come into the equation when we are talking about a pure agricultural workhorse?

In the case of the Dieci Agri Plus 40.7 PS Evo2 it is undeniable.

On first inspection, one is immediately drawn to the lines and good looks of this machine, then when we look a little closer, we find out why this telehandler is at the top of the food chain in its range for the end user.

Designed in Montecchio Emilia, Italy, the machine is perhaps even slightly over-engineered, using extremely robust pivot points with a chassis boasting one-piece sheets down each side of the machine – giving it inherent strength and durability.

While some other machines offer a singular grease bank as standard, this is an optional extra on the 40.7, as Dieci has identified that many agriculturists don’t feel the need for the bank as an extra add on, as most of the grease points are easily located for ease of maintenance.

It is possible on the machine to go one step further than that and option a

Torque converter with PowerShift Evo 2 shuttle with electric control 400/70x24”

Crab Steering, Singular Grease Bank, Automatic Greasing System

full electronic system whereby it’s set by timer and regulates the greasing system as required in use.

This workhorse is powered by a 93kW / 125hp FPT engine and has 7.06m maximum lift height with a load capacity of 4,000kg.

It has an easy dumping rotation of 146 degrees which is specially designed to increase the operating angle, particularly useful when dumping with the boom raised.

The telescopic boom is supported by Dieci’s patented Single Compensation Cylinder, located inside the lifting ram, which ensure that the load on the boom is always balanced.

As far as steering modes are concerned, the machine is electronically set up for easy use from inside the cabin, with a 4-in1 ergonomically designed joystick with integrated forward and reverse.

There is option of front steer only, but the operator can also choose crab steer, so that all four wheels move in opposite directions, to enable diagonal travel. When working near a wall or trying to stack into a shed in tight confines, there is also an option for all wheels to move in the same direction so the whole machine crabs sideways.

Another important feature of note is the self-aligning system where the operator can press a button and as the wheel is turned, it will then tell the operator when the machine is in a straight-ahead position.

The entirely electronically controlled,

ecological and high-performance FPT engine, combined with the Evo2 transmission, transmits all the required power with reduced consumption to the Agri Plus 40.7 PS Evo 2.

The other beautiful thing about not having complicated engine or a canvas electronic system, there isn’t the need for a diagnostic tool to troubleshoot mechanical or hydraulic issues that may arise.

The machine will give the operator error codes on the dashboard for some of the common faults, enabling them to consult the operators’ book for those code, so they can do exactly what is needed to sort out the problem.

With an extensive dealer network and technical support hotline, one can very easily get help over the phone if needed.

The hydraulic pump on the Agri Plus 40.7 is a variable type of displacement pump for power steering and movements which has a capacity 180 L/min, with a

• Robust pivot points and 146 degree dumping rotation

• Sleek lines and improved visibility from the cabin

• Highly manoeuvrable, with PowerShift transmission and optional crab steering

• Grease Bank and system available as optional extra

A

Operator comfort has been considered

B

The cabin features a 4-in-1 joystick

C

Inside the Agri Plus 40.7’s engine

D

Dieci’s distinctive yellow design

E

The telehandler is set up for easy use

F

Dieci’s Single Compensation Cylinder

G

The maximum lift height exceeds 7m

maximum operating pressure of 25.0 MPa (3626 psi), helping to maximise manoeuvrability in all applications.

The transmission on the Agri Plus is a torque converter with Power Shift Evo 2 shuttle with electric control, including

inching with electronic pedal for controlled forward movement. When it comes to the transmission, the gearbox boasts six forward gears and three reverse gears with electronic control.

Agricultural lug type tyres are fitted as standard, with 460/70xR24 giving the machine a relatively low centre of gravity aiding in stability when lifting loads at height.

Inside the cab of the Agri Plus, the design centres around comfort for the operator for extended periods of operation.

Soundproofing, adjustable steering wheel height and depth, electric windows, storage compartments, along with six air conditioning vents and an ergonomic seat, are just a few of the standard features inside the cab.

Visibility from the cab is unparalleled

in the Agri Plus with the design of the engine hatch being curved downwards toward the base, so the view is minimally obstructed on the working side of the machine.

Whether style and design are attributes favourable to the operator in an agricultural scenario is arguably up to

the individual, but most surely reliability, engineering and performance must be.

The Dieci 40.7 PS Evo2 has both in spades. Italian flair mixed with a workhorse-like operating system designed for ease of use, comfort and serious engineering surely place this telehandler a cut above the rest in the market.

watch the

Scan to find out more!

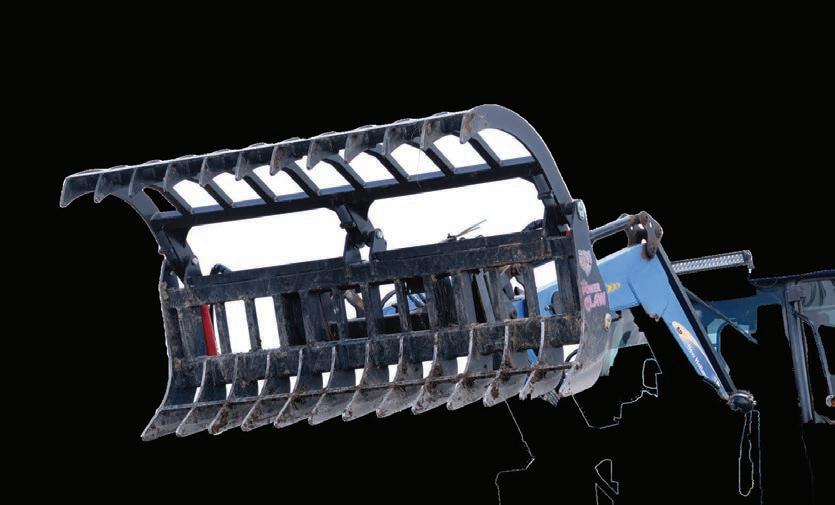

Australia’s most useful attachment!

Turn your Tractor, Telehandler or Skidsteer into a multi-task machine! Stick Rake, Grapple, Grab, Clamp & More!

Models to suit tractors 45hp to 250hp, telehandlers & skidsteers

Widths from 1.5m to 2.4m wide

Combines the functionality of multiple attachments into one!

High tensile steel tines!

The Rata Field Wave Subsoil Aerator crushes compaction and aerates the subsoil, allowing nutrients and water to go deep, naturally accelerating pasture and crop growth.

Grow More Grass

Save Money & Fert

Remove Compaction

Better Water Absorbsion

P: 1800 962 022

E: sales@rataequipment.com

W: www.rataequipment.com

“The best piece of equipment I ever brought!”

Enjoy the productivity gains that come with John Deere’s Mower Conditioners and Balers. With a broad range of equipment to suit your specific needs underpinned by John Deere’s trusted reliability and quality, you can confidently expect to maximise uptime, enhance performance, and drive efficiencies across your operation. So, if you want to get more done in a day and do it better, talk to your local John Deere dealer today.

The latest models of Stewart trailers – designed in Australia and made in Scotland for Aussie farm - provide the flexibility for farmers to do four jobs with one machine

Farmers are constantly in search of equipment that simplifies and streamlines their work. Stewart’s newest innovation has the potential to radically alter this search, with its ability to function as four distinct trailers according to individual needs.

Already adopted by a handful of Australian farms, this Scottish-made trailer is gearing up for its public debut at the AgQuip Field Day this month, with importer Armour Group.

The distinguishing aspect of the VT5500 and VT6100 models lies in their capacity to effortlessly transition between four configurations - functioning as bale, rock and gravel, grain, and silage trailers.

As Armour Group product specialist Owen Dunlop notes, this trailer holds most appeal for mixed farm operations like medium-sized dairy farms, where the need for versatility and multi-functionality in equipment is paramount.

The trailer design features gravel sides

that facilitate road and laneway repairs, as well as farm maintenance and construction.

For silage and hay bales, farmers can remove the sides and insert an extension at the back, converting it into a bale trailer.

This extension can be swapped with a 1.5m side equipped with a grain door, transforming the trailer into a chaser bin or grouper for sowing or harvesting.

An additional 900mm extension can be added for green chop silage processing.

Farmers can also choose between two sizes of this versatile equipment - the 16-tonne VT5500 with a 5.5m body length or the larger 20-tonne VT6100 with a 6.1m body length. Apart from the size, both models share key characteristics, including the use of high tensile Hardox steel to increase wear capacity.

Whether it’s the flat top version or the gravel trailer variant, the equipment features a Hardox steel structure.

One of the unique selling points of the VT trailers is the integration of twin

the tipping cycle.

The interlocking chassis system provides enhanced support in challenging conditions, minimising flex in the overall chassis system.

An additional advantage is the single

The VT6100 shown in silage configuration65mm diameter tip pivot pin, providing more stability during tipping than the standard two-pin system.

Standard across Stewart’s entire range, both VT models come equipped with a plethora of features, including 10-stud axles, high-speed wheel rims, a hydraulic braking system, LED lighting systems, and more.

The trailer is shot-blasted and finished with two pack polyurethane Flexi Paint for a long-lasting finish.

The support provided by Armour Group, a family-owned company with over 45 years in the market, ensures reliable after-sales service.

With three units of the VT5500 already operational on Australian farms, its popularity is expected to grow following the public introduction at AgQuip in New South Wales.

“It’s a novel design and a fresh innovation,” Dunlop says.

“We’ve been developing this with the factory for between 18 months and two years. It’s the next step in the market, providing us with another competitive edge.”

19 tonne (including front blade and rear rippers) with Cummins 160kW engine (Cummins Australia warranty), ZF type powershift transmission - 6 forward / 3 reverse, transmission guarding, no-spin self-locking differential, 17.5x25 tyres, 14 ft blade, front blade, rear rippers, air-conditioned cabin with ROPS, suspension seat, and radio.

$218,000 plus GST = $239,800*

Shantui SG10-B5 Grader

6.45 tonne (including rear rippers) with Cummins 74kW engine (Cummins Australia warranty), torque converter, power-shift transmission - 4 forward / 4 reverse, 16/70-20 tyres, 10 ft blade, rear rippers, air-conditioned cabin with ROPS, suspension seat, and radio.

$105,000 plus GST = $115,500*

New equipment with full warranties

*Pricing may vary due to the exchange rate and the options / attachments selected.

14.2 tonne (approx. with forestry) bulldozer with Cummins 108kw engine (Cummins Australia warranty), powershift transmission - 3 forward / 3 reverse, straight tilt blade, three-shank rear rippers, 460mm wide track shoes, engine side guards, air-conditioned cabin with ROPs, forestry protection, suspension seat, and radio.

$165,000 plus GST = $181,500*

COME AND SEE FOR YOURSELF AT FIELD DAYS

ACROSS AUSTRALIA

Brisbane Mini Excavator Sales has announced plans for the expansion of its Heavy Duty line of machines, with two new dozers and three graders due to arrive by the end of the year

Brisbane Mini Excavator Sales (BMES), the Australian distributor of Hercules wheel loaders, will expand its Hercules range by adding two dozer models and three grader models.

“The Heavy Duty Hercules loaders start at 11 tonnes and go up to 25 tonnes,” BMES sales executive Steven Ragenovich says.

“So, we’re expanding this with the HD816D and the HD822D dozers, which have an operating weight of 17 tonnes and 24 tonnes, and the HG915, HG919 and HG921AWD graders – AWD means it’s all-wheel drive. The graders start at a 12.5 tonne operating weight and go up to 16.5 tonnes.”

Due to arrive at BMES’ site in Yatala, Queensland in the next three or four months, Ragenovich says the machines will come with a full range of attachments, from bush guards and blades to hydraulic rear rippers. The dozers will also come fitted with a winch.

When asked if the new additions come from customer demand, Ragenovich confirms that as the Heavy Duty range of

loaders has been doing so well, it made sense to provide an even greater offering for large-scale earthmoving work.

“Our customers have been so happy with the loaders that they’ve wanted to source other bits of equipment built by us, so it really was through popular demand that we’re bringing in the dozers and graders,” Ragenovich says.

“They’re high-end built and have heavy-duty frames and componentry. The hydraulics are very high quality. The undercarriage is meant for the hard yards.

“This machinery is for people needing to maintain access roads on their properties, along with dam building and clearing land. They’re designed for larger-scale farms and are built for long hours of operation.”

He says that BMES sells a lot of machinery to cattle stations and broadacre farms, as well as logging operations – so having equipment that can withstand difficult conditions in rural Australia has been a key focus for the company.

“It’s high-end equipment that isn’t run by computers, so it’s very mechanical and simple for people to maintain,” Ragenovich says.

With a new 25-tonne addition to the Heavy Duty wheel loader range also recently added to the line-up, BMES will be showcasing its machinery at field days, including AgQuip on August 22–24, Henty in September and the Australian National Field Days in October.

“We’re all over the place showing our wares,” Ragenovich says.

“We’ll also hopefully be showcasing the new graders and dozers at Casino Beef Week next year as well.”

Able to supply Hercules and Sunward earthmoving machinery across Australia, ongoing upgrades to the BMES workshop means aftersales support is always on hand.

“We have a good reputation for not only

our product but also our follow-up with spare parts and technical advice 24/7,” Ragenovich says.

“We’ve been in business for 30 years and we’re getting bigger and better by the year – that’s the way it’s going to continue.”

For more information about the Hercules range of machinery, visit Brisbane Mini Excavator Sales at www.brisbaneminiexcavators.com.au

equipment

The new 4420 DKD is another addition to Bourgault ’s big machines stable and showcases the manufacturer’s ability to cater to all farm challenges

Bourgault’s Australian customers continue to enjoy a series of options, with a deep knife drill added to the manufacturer’s product range.

The 4420 DKD is the machine in question and this latest addition will be prominent at Bourgault’s upcoming field day displays.

It is available in both 12m and 18m working widths, with both sizes folding to 5.5m for transport.

“That’s a selling point for a machine, especially for the 18m model,” Bourgault Australia marketing manager Ryan O’Sullivan says.

“For a seeder of that size it is a pretty good transport width and is what a lot of farmers are looking for.”

Bourgault specialises in big machines, as anyone using the 9000 I series of air carts – with capacities exceeding 45,000L – can attest to.

The new 4420 DKD is also befitting of the ‘big machine’ title.

Beyond the convenient transport width, one of the machine’s biggest advantages lies in the name.

The deep knife drill is part of Bourgault’s new design and offers something which had not previously been available for its customers.

“It’s a new style seeder bar with a new opener, and it’s got a fertiliser knife and a seed knife,” O’Sullivan says.

“The front fertiliser knife is a deep ripping knife that will dig seven or eight inches into the ground.

“This is significantly different to our other style openers, which are typically two or three inches maximum digging depth.

“The fertiliser knife is followed by a seed placing knife that’s in line and is on a parallel with a packing wheel.

“You have your deep ripping knife in front to dig deep and put your fertiliser in front and then the seed knife follows behind on a parallel arm to give your accurate seed placement and depth setting behind it.”

Bourgault says the 4420 DKD’s deep working fertiliser shank is optimised for a 120mm to 165mm with the deep knife shank also able to trip independently over small objects.

Other technical specifications include a rigid shank with on-the-go adjustable hydraulic breakout between 68kg and 450 kg, plus a 16mm wide knife point.

A robust frame construction and heavy-duty rear frame can accommodate drill-mounted liquid tanks.

The heavier built two-row main frame achieves superior penetration, Bourgault

says, while a bolt-on three-row sub-frame offers increased flexibility in opener layout options.

Large tyres, steerable front axle and floating hitch ensure optimal depth control and superior tracking.

There is also ground-following 1:1 contour ratio, easy packing pressure adjustment with a cordless impact driver, and easy depth adjustment with a simple handle and pin.

This is clearly a machine designed for the big jobs and right in the wheelhouse of Australian broadacre farmers, and the extra digging depth over Bourgault’s existing products helps to provide another beneficial point of difference.

O’Sullivan says there are several reasons why the extra depth will help farmers maximise their land’s potential.

Available in 12m and 18m working widths the 4420 DKD can fold to a 5.5m transport width when required

“It depends on the soil conditions - WA is quite a big market for this drill,” he says.

“It also depends on the whole farming setup, which is dependent on soil conditions and even just individual philosophy on getting the best crop.

“Sometimes farmers will use the deep knife to drain moisture away, so digging a bit deeper and leaving some of that moisture on top to soak down can help drive the paddock out in really wet conditions.

“Sometimes it’s for fertiliser toxicity. Farmers can put more starter fertiliser down and start seeding without the concern of burning the seed with too much

“Some guys might be using it for that reason, and in some parts of Western Australia that have sandier country it’s the opposite.

“They are digging deeper because that’s where the moisture is, and it draws the moisture up.

“There are a few different reasons to use a machine like that over a standard one depending on the season, the year and the whole seeding program.”

These reasons show the benefit of having the deep knife drill which Bourgault now offers, but this extra depth is not the only reason why the 4420 DKD has

It can also be paired with any of Bourgault’s air carts, meaning it fits into the manufacturer’s wider philosophy of providing big machines for big jobs.

Both the 12m and 18m working widths mean farmers can get the job done quicker, something which O’Sullivan says becomes even more imperative when some farmers are experiencing shorter seeding windows each year.

“The bigger machinery you’ve got, the more capacity you have to get your crop in quicker,” he says.

“Getting the crops in on time is a massive issue, and obviously if you’ve got a wider

“The

“Another

harder to find good quality staff, so if you’ve got one machine that can do the job of two, then you’re reducing costs and your reliance on staff that are harder to find.

“Some farmers like that aspect of it and they might be able to do the whole seeding program themselves with larger equipment rather than relying on an out-

side workforce, or at least have a reduced outside workforce.”

Bourgault’s 4420 DKD will be on display at upcoming field days across Australia, including AgQuip later this month.

Dixie Holdings has long specialised in customising machinery for both the farming and earthmoving sectors and continues to provide a body of evidence as to the company’s skill

For Queensland-based Dixie Holdings, modifying machinery and adding custom attachments to increase its versatility on farms is simply what the company does.

Countless examples exist of challenges which have been solved using Dixie’s know-how, and some of Australia’s largest and most remote rural properties are benefitting from having multi-use machinery when the alternative of many single-use machines would simply be impractical.

Looking at some of Dixie’s most recent jobs provides more evidence of the company’s ability to adapt, with several fresh machines only completed in the past couple of weeks and set to make their way to farms around the country – plus other environments where machinery of this nature is needed.

A good recent example of a Dixie Holdings job refit is on a John Deere 644K wheel loader, which has been custom-fitted with a 16-foot (5m) walk-in pin-on stick rake.

“This is designed to be carried with the bucket and easily attached to and from the loader with a simple pin-on function,” Dixie Holdings company director Tom McDonald says.

“It is popular for when a machine needs to be used in an application when the bucket and stick rake is needed, as they can be carried to the job from the shed or homestead where the loader is stored.

“An example is when someone needs

to stick rake a fence line then desilt a few dams in the same area of the property.” This same loader has also been fitted with a Bedrock multi shank ripper. This Bedrock ripper was imported and fitted by Dixie Holdings and McDonald

A John Deere 872GP grader also fitted with a double spare-wheel carrier custom-made by Dixie Holdings

says it offers a cheaper alternative to Dixie Holdings’ Australian-built ripper attachment with oscillating tines.

“It is simple yet very effective, used for scarifying earth before digging with the bucket, ripping tree roots out or laying poly pipe in the rural sector,” he says.

The next machines which Dixie has recently worked its magic on are a pair of John Deere graders – one 772GP and one 872GP.

Dixie has fitted one of its own single spare wheel carriers – plus of course a spare wheel – to the 772GP.

This is designed to be easily removed without the use of any tools thanks to its simple up-and-down winch function.

Similar work was done to the 872GP, which now has dual Dixie Holdings spare wheel carriers.

It has received the extra spare wheel as its intended use is in remote locations with excessive rocks and tree stumps, McDonald says.

The 772GP has also been bolstered with a 2.7m Bedrock dozer blade.

This attachment was again both imported and fitted by Dixie Holdings, and McDonald says it is useful for small dozing jobs to utilise the grader’s applications in the rural sector by pushing out creek crossings, pushing over trees and pushing up farm drains and embankments.

Another machine which has recently had a makeover in Dixie’s yard is a John Deere 550K dozer.

Firstly, this dozer has been fitted with certified sweeps.

“These are used in the forestry sector for protecting the cabin and operator, and the machines bonnet and exhaust, to ultimately reduce downtime and increase productivity,” McDonald says.

“This one has also been fitted with a heavy-duty blade-mounted Dixie Holdings tree spear, which is used to increase the purchase point when pushing down larger trees with greater ease.”

These recent examples show how Dixie Holdings is so much more than just a machinery dealer.

The company has an experienced team

of specialist engineers, drafters and fabricators who work to ensure the machine will be exactly what each individual customer requires.

Dixie’s knowledge and network means they can find the ideal parts – even if importing is required as they were for the recent Bedrock attachments – and do the

legwork required to organise logistics.

While the machines themselves are typically also sourced directly through Dixie, the company has also worked with machines which it has picked up directly from OEMs after the customer has purchased them.

Dixie Holdings is based in Woongool-

ba in Brisbane’s southern suburbs, but also offers its own transport solutions to ensure customers anywhere in Australia can have their own, perfectly customised machine.

For more information, visit www.dixieholdings.com.au

Australia’s No1 locally built mulcher for the last 25 years. Available in Low Body or High Body models in various sizes. Great for clearing up paddocks and bush blocks.

The best value for money Front End Loader mounted post hole digger on the market. Standard with Eurohitch connection with other styles available. Various augers sizes and types available

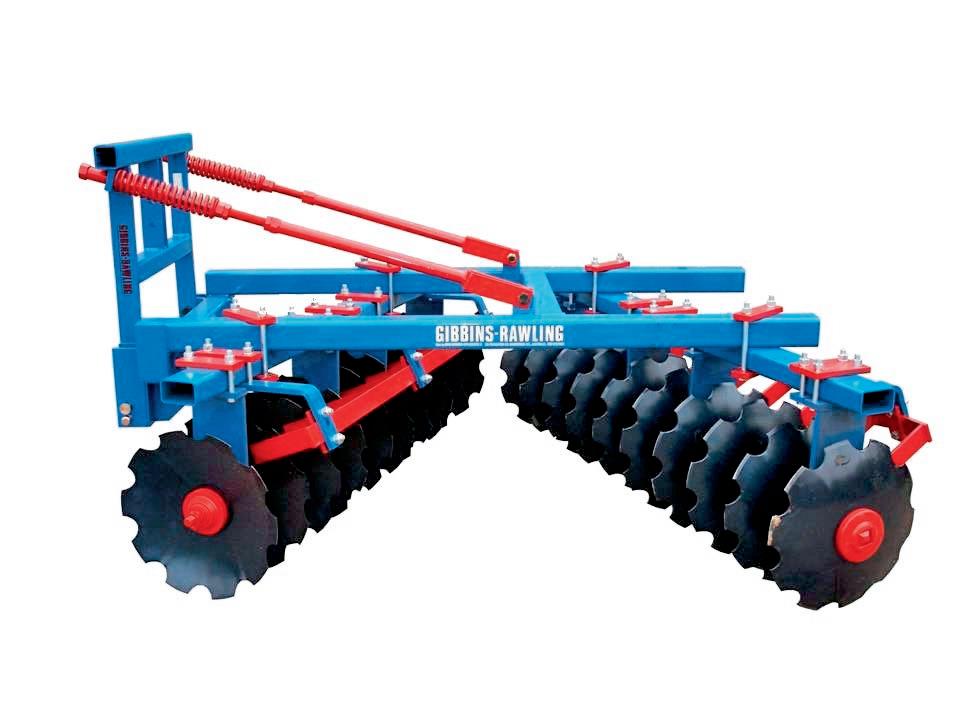

Large range of linkage and trailing disc ploughs to suit all tractors and applications.

Australian Made slashers with 5 year gearbox warranty. Various sizes and models in single and twin rotor set-up. Great value and strength. Also available in galvanised.

Australian made aerators using the Shattertine technology. Great for cracking open hard ground and rejuvenating pastures.

10 ‘ & 12’ Trailing Grader Blades. 2000kg in weight Best value for money blade of its type

Huge range of linkage models available also.

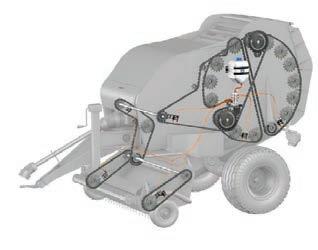

With so many choices available, selecting the right piece of haymaking equipment can be difficult – but a few simple strategies can help make a choice much simpler

The Australian hay and fodder industry is incredibly diverse, spanning legumes, grass and cereal types grown across varied key production zones throughout the country.

So too is the range of haymaking equipment available for purchase, meaning it’s critical that time is taken to identify the right machine to meet the unique production needs of each farmer.

John Deere Australia and New Zealand product specialist, Hay and Forage, Roberto Scheidt, says the most effective way to select equipment is often by working backwards from the paddock.

“When looking at equipment it’s important to think about the setting in which it will be used and the end product that is required, and then working back from there to ensure you purchase machines that are best suited to the job,” he says.

“It may sound simple, but things like bale size, transportation, end markets and the machinery you already have will be important to making the right choices.”

Achieving the right conditioning actions in mower-conditioners (MoCos) can significantly reduce dry down time, meaning less time is needed for curing and the optimisation of feed value.

Scheidt says four conditioner types across the John Deere MoCo range ensure that all crops are covered.

“For example, the impeller conditioner is best for light-stemmed grasses and lucerne, the urethane conditioner is excellent in legumes and grasses and the V10 steel is best for faster dry-down, while the Tri-Lobe is a premium option that suits all cropping conditions,” he says.

“You really need to make sure the conditioning element of your machine suits your use to streamline production in tight harvest windows and maximise quality.”

In total, 17 models across four types of MoCos – centre pivots, side pulls and front and rear mounts – make up the John Deere MoCo range, allowing growers and

Certain types of mower conditioner are better suited to certain crops, Scheidt says

contractors to customise their solution or ‘mix and match’ to cater to their individual requirements.

Quick change knives are available on a variety of models, meaning operators spend less time servicing and more time cutting hay, as well as performing simple in-field knife changes to ensure the best quality cut.

Scheidt says the most foundational baler decision is whether a round or square bale machine is required; however more advanced options, like pre-cutters, can make a significant difference to quality and performance.

“Pre-cutters cut the forage into smaller pieces prior to it being placed into the bale, with studies showing this function carries a range of benefits, including bales that not only weigh more but also better hold their form,” he says.

“It also ensures more simple, efficient mixing of stock feed rations and improved

weight gain as greater palatability encourages animals to eat more.”

The advent of the wrapping baler, also known as the combination or ‘combi’ baler, was transformational for the hay industry, combining the function of baling and wrapping into one machine, reducing the need for multiple tractors and operators.

John Deere’s combination round balers are available in the fixed chamber C441R model or the variable chamber C451R and C461R.

Two of the most relied upon round balers in the John Deere range in local production regions are the 450M for smaller areas and the larger 560R, which carries extensive automation features.

“For land with higher productivity,

where up to 6,000 bales may be made a year, we recommend a baler in the R Series, while for smaller operations, where up to 3,000 may be made, the M Series performs very well,” Scheidt says.

Investing in NetWrap that will last Once the right baler is selected, Scheidt says it is critical the production process is not let down by inferior quality NetWrap Round or Square? Deciding which bale shape is preferred is a foundational hay growing decision

The SKF Lincoln automatic chain lubrication system OCL-M was specifically developed for balers and combines. The robust design of the OCL-M withstands these harsh conditions and dispenses precise amounts of lubricant to the moving chain reducing chain wear and the chance of downtime. Our strength comes from high-quality distribution partners who manage installation, service, technical support & training nationwide.

that may tear during transport or disintegrate due to UV exposure.

“It can seem more affordable to go with a cheap NetWrap option, however these products simply do not withstand transport and climatic conditions well, meaning valuable product and reputation is lost,” he says.

“In the long-term, it is far more cost effective to invest in a better-quality wrap that will protect hay, to ensure bales maintain quality and integrity for extended bale life and enhanced customer satisfaction.”

Scheidt recommends contractors and hay producers ensure they have a “few extra horsepower” when selecting tractors to operate haymaking equipment.

“This is particularly important when towing heaver machines like combi balers and in hilly conditions,” he said.

“The John Deere 5 Series Tractors typically meet the needs of round balers, the 6 Series Tractors are usually ideal for combi balers, while a 7 Series

Tractor will be required to operate a large square baler.

“Oftentimes, the customer will already have a tractor so then it is a matter of making sure the baling equipment you purchase matches the horsepower of your existing machine.”

TRACTORS FROM 250 - 450 HP

•Hydraulic/electric controls of all functions

•Side or front door discharge options

•Single or tandem axle options, both with 435/50R19.5 wheels

•3-year gearbox warranty

Introducing the revolutionary system that combines soil cultivation & raised bed formation in one pass. Bolt on our bed former to a power harrow or rotary tiller and you have the ‘one-pass’ Combovator system. The multipurpose tool that saves time, money and hassle.

John Shearer’s Mk4 Universal seeder bar builds on a lineage of robust and effective Shearer seeding machines - now with a variety of improvements to meet the needs of today’s farms

Since 1877 John Shearer has been providing Australia with high quality farm machinery tailor-made for our tough landscape.

And Shearer’s latest machine – the Mk4 seeder bar – is no exception. The heavy-duty machine has been set to top the market with its unique combination of Shearer’s robust equipment structures and a completely new hydraulic tine opener assembly.

Wider wheels and tyres grant better floatation in soft soil and with a maximum front tine breakout pressure of 620kg, the seeder can handle tough soils.

In the Shearer tradition, the four-row universal seeder bar is designed and built for maximum structural strength and service life.

The main frame includes four rows of 100mm x 100mm mounting ranks, of which the front and rear centre section beams are 9mm thick steel tube.

Both single fold, with narrow and standard centre sections, and double fold (standard centre only) versions are

available, with both versions able to fold for road transport.

Working widths for the double fold model are, 15.2m, 16.8m, 18.3m and for the single fold widths range from 7.9m (26’) through to 13.8m (46’).

“The Mk4 seeder bar is like no other machine on the market,” says John Shearer’s operations manager Franco Perrotta.

“The most notable improvement on the Mk4 seeder bar is the all-new, precision tine opener. Wielding an impressive 590kg of breakout force, the opener has been designed to suit any terrain needed for the everyday agricultural worker.”

The process begins with the opening tine cultivating deeply to help roots seek out moisture and increased water infiltration. Then fertiliser is banded deeply into the open furrow, and then covered by a closer plate, creating a seed bed and preventing seed to fertiliser contact for reduced toxicity.

The seed tube then places the seed above the fertiliser, on the seed bed, with

the seeding tine/tube regulated independently to achieve the desired seed depth – from 6-70mm.

The press wheel then closes the furrow, creating seed to soil contact and a small rainfall-harvesting trench. It does this with the assistance of a parallelogram linkage which allows the whole unit to move up and down, following ground contours, while remaining at the same working angle.

The main hydraulic ram will provide regulated force so that the tine opener can bite into the ground normally and still breakout if an obstacle is encountered.

The press wheel hydraulic ram uses independent pressure from the main ram

to supply constant pressure as it moves, enabling the operator to change packing pressure on the go as the seeding shank and press wheel swivel up to 30 degrees either side.

In conjunction with the advanced hydraulic control system on the Mk4

seeder bar, another advanced piece of Shearer technology – the Active-Packallows the operator to set the required packing pressure on the press wheel. Active-Pack will maintain the desired pressure constantly by varying the hydraulic pressure on the press wheel ram

as conditions change across the paddock, ensuring smooth movement regardless of potential terrain extremities.

For the latest on the Mk4 seeder bar and Active-Pack technology, keep up to date at johnshearer.com.au

Visitors to this year’s AgQuip Field Days will spot a new machine on display –the Rollforce 5517 muck spreader from French manufacturer Rolland.

Imported by Farmgard, the 5517 was first seen by local customers in June at Toowoomba’s FarmFest and will continue its journey at various field days for the rest of the year.

“It is an ideal machine for agricultural contractors and large-scale operations,” Farmgard’s business development man ager Luke Rowney says.

“People that have seen it already love the quality of the build and the general design of the machine.

“Their typical comment is that it looks to be a very robust machine, able to withstand Australian working conditions.”

The 5517 has been Farmgard’s priority within the Rolland range, believing it to be the machine most suited to Australian customers – however there are also plans to bring Rolland’s larger 7322 model Down Under.

These form part of the wider Rollforce range of muck spreaders, with Farmgard able to order and import directly from the factory for any specific requests in Australia and New Zealand.

Rowney says Farmgard’s intention is to continue expanding the range into larger units.

A further recognition of Australian customers’ desire for larger units comes from

customers are working with a capacity of around 20 cubic metres instead – helping to boost efficiency.

“It is a quality, high end product that comes to us from France, and Farmgard

Hungry boards have been added to increase the unit’s capacity

ly-owned company that pride themselves on importing quality products to Australia and providing excellent after-sales market parts and service to support the machines which they choose to bring in.

“They only choose to bring in high quality products that provide longevity and uptime to our customers. Rolland fits the criteria that we set as a standard for Farmgard.”

The 5517 sits roughly in the middle of the Rollforce muck spreader range in terms of size but is bolstered by the extra capacity offered by Farmgard’s hungry boards.

The unit itself comes in at 8.17m long and has an unladen weight of 5,900kg.

The body length is 5.5m and body width is 1.81m at the bottom and 1.46m at the top.

Rowney says there are several other important features which help the machine to stand out.

“It comes with first control which is able to give you control from the operator’s seat

• Super deep ripper! Rips down to 60cm (24 inches)

• One pass operation to super deep rip, mix clay and incorporate lime that also packs the surface for an excellent seed bed.

• The most economical way to transform poor to average sandplain into highly productive country in one pass!

• Medium to heavy country is also responding with great results!

• Special aggressive A-discs, produce the best stubble cutting and mixing action.

• Excellent for incorporating lime and stubble at depth and levelling the paddock.

• Kills weeds and leaves an impressive seedbed with the moisture locked in by the V-ring packer!

• Fixes your seeding trash flow problems in one pass!

over to the slurry door and also the chain

“There is a sprung drawbar on the machine to take off shock loads off the tractor, and the machine comes with hydraulic brakes for safety in undulating terrain, which is important given the machine is quite heavy when fully

There are also two 16mm marine chains and 5mm thick steel box slats every 25cm across the bed.

The durability and robustness are further enhanced by the Rollforce’s exterior being sandblasted, electroplated and powder coated to ensure optimal rust

It is also fitted with ESP21 vertical beaters, and the beater points have an aggressive shred coupled with an angled deck to evenly spread small or large doses.

Some of the other Rollforce 5517’s features include mudguards and a floor

tion tyres, hydraulic jack, electric in-cab controls and integrated hydraulic hoses.

Farmgard has imported and distributed Rolland products since 2021.

Rolland specialises in trailing equipment including muck spreaders, industrial trailers and feed out wagons.

The company has been manufacturing

larger range of muck spreaders known as the Rollmax.

To find out more about the options for Australian customers, check out www.farmgard.com.au or visit Farmgard’s display at field days including AgQuip.

When explaining what ifm’s moneo solution can provide to a farm, factory or plant, Freddie Coertze says it can be likened to a smart watch.

“The moneo DataScience toolbox uses historical data, sensor data and inputted process parameters to diagnose problems, detect anomalies and predict potential issues – just as a smart watch might give you an indication of your health through the monitoring of different physical attributes and the information you feed into it, ” explains the ifm Australia National IoT Business Manager. “This intelligent toolbox is designed to provide a holistic view of asset health and enhances an en-

gineer’s predictive maintenance program and workflow.”

According to Coertze, the moneo DataScience Toolbox lets engineers take a DIY approach to predictive maintenance with its SmartLimitWatcher tool.

“It is a self-service platform and the algorithimic method of the SmartLimitWatcher is trained to measure and compare data against predicted target values,” he says. “It’s comparable to having an in-house doctor that monitors the health and performance of your assets on an ongoing basis, providing suggestions for improvement to prevent deterioration and lengthen the asset life.”

For those getting more sensor data than they know what to do with, ifm’s moneo solution brings it all together – in a way that makes it easy to use

Just as a doctor relies on a patient’s medical history in addition to information they provide as to what’s ‘good’ , the moneo DataScience Toolbox is essentially taught what is ‘good behaviour’ for an asset.

“It then enables automatic and early anomaly detection, giving users the ability to react quickly to deviations within the production process,” says Freddie.

“In other words, you’re not relying solely on historical data to make decisions, and can be proactive about asset management, meaning equipment hasn’t already started to fail by the time you intervene.”

Named the Latin term for ‘to warn or advise’, moneo is a solution that can be scaled according to a business’s needs –whether that’s a standalone asset or an entire plant.

Coertze also points out that implementation of the moneo DataScience Toolbox is cost-effective when compared to an engineer attempting to run a data science project on their own.

“It’s worth doing the comparison to see the value that moneo can provide to a business,” he says.

“Because it is self-service, you’re excluding the need for data scientist expertise which can cost upwards of $20,000.

DataScience

Toolbox include:

• S elf-service, easy to use: No data science expertise required. Provides a simple five-step wizard for users to set up. Data preparation and quality checks are automated.

• Smart: Draws on a best-fit artificial intelligence mathematical model to automate learning and verification of monitoring accuracy.

• Reliable: Uses real-time conditionbased monitoring and historic data to measure performance against target variables.

• Customised: Alarms and warnings are tailored to individual preference, including the sensitivity to anomaly detection.

“It’s fast, it’s scalable, it provides an excellent price-to-performance ratio, and it can be integrated with existing systems,” he says.

manufacturer Orsi to bring its range of mulchers, mowers and more to

The fact Australia has a tough environment has been well established.

So when Clark Equipment found the buyers of its McCormick range of tractors needed higher horsepower equipment to cope with the rigours of Australian agriculture, it set out to find something to suit.

Orsi not only delivered, it is now setting up an established partnership with Clark for future distribution Down Under.

A highly regarded manufacturer with years of experience and a vast array of equipment, and based in Italy’s industrial heartland of Bologna, Italy-based Orsi Group produces Inline Mulchers, Bank Mulchers, Forestry Mulchers, Agri and Professional Boom Mowers and Excavator Mulchers – all designed for extensive farming work.

Orsi has also been rolling out the use of the abrasion-resistant Hardox 450 steel across its range, with the steel structure

combining flexibility and weldability with an option for guaranteed impact toughness in a variety of conditions.

The product will be used in many different components and structures that are subject to wear.

The steel comes with an extra 50 Brinell hardness (over the 400 grade) to provide better dent and abrasion resistance as well as longer wear life.

“This is an exciting partnership as it takes us into new agricultural and maintenance activities and complements not only the demand from our McCormick customers but also our expanding dealer network,” says Clark Equipment’s General Manager Cole Jones.

“We would like to bring in the full range from day one, but we need to start where we have the most demand which is probably models 100 to 200hp.”

Among those is the Orsi River Compact 355 hydraulic reach mower – with the 355 model able to work on a tractor with 25 horsepower and with a maximum reach of 345cm – while the larger 420 works on a

The reach mower can be equipped with end tools including a cutting head, hedge bar, ditch cutter or branch cutter, and comes with a central and high arm to reach over road signs and guard rails.

They come with a PTO shaft and quick uncoupling attachment, along with hy-

high performances.

Also available is the Eagle Plus Rear Shredder, available in models with between 75 and 150hp, and able to attach to the back of a tractor.

Housed within a double internal frame built entirely out of Hardox, and with an

Jadan offers high-performance hay handling systems that are specifically designed for the farming market in Australia. These simple and robust machines create efficient and faster hay handling systems that take the sweat out of handling bales.

electronically balanced rotor, the rear shredder is ideal for shredding grass or straw, or vegetables including corn, beetroot, potatoes and artichokes.

The rows of counter-knives installed inside are said to guarantee excellent cutting quality and ensure a long lifespan for all machinery.

The unit also comes with automatic belts tensioners and a double static knife.

Clark Equipment and Orsi have developed a new website that will directly reflect the Australian product line as the partnership develops - which can be viewed at www.orsigroup.com.au

To

Right now, the technology that defines the future of agriculture in Australia is a start-up. In a speech to young farmers, Trevor Whittington asks if Australia is ready to harness the opportunity

We all know that Governments love to pull policy levers to help their agricultural sectors, but globally governments have a bad track record when it comes to picking and investing in winners, and Australia is no exception.

Think about the White Elephant that was Ord Stage 1, which has become Ord stage II at the cost of another half billion dollars that has gone into a now Chinese controlled farm and is still yet to deliver the promised returns to the state.

So, what has driven good outcomes for agriculture? The one consistent driver of productivity and profitability has been innovation, turning science into solutions.

It is claimed that Australia was developed off the sheep’s back. I would argue that Australia was developed with the help of the scientists and innovators that worked out better ways to get the wool off

the sheep’s back and the wheat out of the ground.

Australia has a long history of innovation in agriculture as reflected in Wolseley’s handpiece, McKay’s Harvester and Farrer – the Wheat Breeder who developed the first selective breeds of wheat for Australia and was featured on the old $2 note.

Australia backed up these innovators with a comprehensive system of agricultural technical colleges like Muresk in Western Australia and Roseworthy in South Australia, plus the university level agricultural science degrees.

Add to that every State had a well-funded Department of Agriculture and a University Faculty of agriculture producing graduates that had a clear career path that often started at the state ag department.

At its peak in the 1970s the Western

Australian Department of Agriculture employed over 2000 staff, running seven research stations employing 20 graduates a year almost all coming from the University of Western Australia (UWA).

But by the year 2000 this had fallen to 1500 and by 2017 they were down to 900 with a collapse of graduate opportunities happening at the same time the number of universities offering some form of ag degree was exploding.

Those students can’t all go into the Department of Agriculture as there is not much of a department left.

They could go into one of the 14 National Research Development Corporations like the Grain Research and Development Corporation (GRDC) and Meat & Livestock Australia that have emerged largely replacing the state departments of agriculture as the drivers of change.

But their funding is limited. The federal government caps its contribution to the growth of farm gate production of 0.5 per cent or around $400 million, so there are no new rivers of gold coming from the feds.

In fact, public funding for agricultural research has fallen by over a third in real terms since the early 1990s, and with it the number of government-funded researchers employed in agriculture declined by 28 per cent between 2004 and 2014 and has not increased much in the last decade.

I believe the future of agriculture for the next generation won’t be through the old ag departments, through the RDCs, neither will it be in the global ag chemical corporates, the big end of town or the public square – but in the small end in struggle street start up.

In the 2022–23 financial year, the federal

government will invest an estimated $9 billion in direct support for research and development.

Around a half billion goes to agriculture via the RDCs and CSIRO and $3.2 billion through the Research and Development Tax Incentive, with another $1 billion coming through in other programs and activities related to science, research and innovation.

This is a pool of money that has largely been overlooked by agriculture – an amount double the entire spend on agricultural research and development.

So, there is gold in them there hills yet to be found.

Currently Australia has just 1 per cent ($100m) of the world’s total ag tech venture capital funding which last year hit US$10 billion.

But that pile of money is growing rapidly and it would not take a lot of tweaking of the government’s R and D funding bucket to put Australian Ag Tech on the map.

The model to follow is that of Silicon Valley – but not being a part of a military industrial complex with deep links to the universities, a patron is needed to underwrite the risk capital for at least a decade to kick start what we have and take it global.

We need to replace the funding that went into training farmers at our regional ag colleges and the funds that went into the various state department of agriculture into ag tech innovation.

Ord but half a billion into a thousand blooming flowers.

The State Government has started to join the dots and has established the $16.7 million New Industries Fund, which supports new and emerging businesses to diversify the WA economy and create new jobs.

The federal government kicks in a 20 per cent tax offset plus a 10-year exemption on capital gains tax, and they could certainly do better.

But taken in aggregate, the federal government has been the most active single financer of Australian AgTech companies.

Between 2005 and the first quarter of 2018, more than 65 per cent of Australian AgTech investments have been financed by government grants and research initiatives, incubators and accelerators, with that amount rising to 88 per cent in 2017.

Venture Capital would be a game changer, and the VC sector in Australia has achieved significant growth over the past six years.

AgTech-specific accelerators only emerged in Australia in 2017, with SproutX being the first in this space.

In 2017 more than A$1 billion was raised, double the amount raised in 2016, and funds raised by those firms in the 2015 and 2016 financial years are larger than the combined amount raised over the six preceding years.

What we need for the next generation

National Farm Safety Week took place last month, and Monash University mechanical and aerospace engineering senior lecturer Chao Chen discusses the opportunities for agricultural robots to create safer and more efficient farms

Monash University’s Laboratory of Motion Generation and Analysis (LMGA) has the mission of solving real world challenges for better industry and society by means of advanced robotic technologies.

Under the leadership of Associate Professor Chao Chen, who also established LMGA, the Victorian university has set forward a technology that could change the face of agritech as it is known – cobots.

“Advanced technologies, including robotics, are on the cusp of revolutionising the farming industry, enhancing efficiency, safety and sustainability,” says Chen.

“Robotics technology plays a pivotal role by providing automated solutions for labour-intensive tasks.”

Cobots can take on physically demanding, repetitive, and labour-intensive jobs, such as lifting heavy ladders or performing strenuous activities, thus reducing the risk of musculoskeletal injuries and fatigue among human workers.

As technology equipped with advanced

sensors and sophisticated vision systems, cobots can detect and avoid obstacles and hazards in real-time to prevent accidents and injuries on the farm.

The cobots can perform tasks in hazardous environments, such as handling toxic chemicals including pesticide or fertilisers, or working in extreme weather conditions which are harmful to human workers.

“Agricultural robots, thanks to their advanced computer vision and machine learning algorithms, can accurately detect crops, sense their surroundings, execute harvest tasks, apply fertilisers, and manage irrigation, effectively reducing resource waste and boosting crop yields,” Chen says.

“Robots don’t get tired, they can work day and night, and operate in adverse weather optimising farm resource allocation and maximising productivity.

“This not only ensures uninterrupted operations but also minimises human

exposure to harsh environments and hazardous machinery.”

Chen says there are several benefits of cobot technology for the future of agricultural work.

The first of these is harvesting and sorting, as cobots can perform these tasks autonomously, ensuring efficient and accurate crop collection.

Cobots can also perform precise seed planting, apply fertilisers, and spray pesticides, which optimises resource usage, minimises environmental impact, and promotes sustainable farming practices.

Another benefit is that cobots can handle physically demanding tasks, such as lifting heavy objects and moving agricultural equipment, reducing the strain on farm workers and preventing musculoskeletal injuries.

The future integration of cobot technology in the agricultural sector will revolve around several aspects, Chen says.

Technological advancements in robotic design, motion control, sensors, perception, and AI will ensure safer and more efficient operations in unstructured agriculture environment.

Collaborations and partnerships among universities, government agencies, industry associations, plus robot and equipment manufacturers, will promote the widespread adaptation of cobots in agriculture.

Educational outreach among growers, farmers, and relevant workers, such as workshops, training programs, and engaging activities, will accelerate cobots’ applications in agriculture and leverage the technology effectively in the farming practices.

Cobots can assist workers and replace some human labour in repetitive and labour-intensive jobs.

Chen also says cobots will create more professional jobs in farms.

“Embracing the power of robotics enables the farming industry to streamline operations, improve resource utilisation and cultivate a safer working environment,” he says.

“The integration of advanced technology into agricultural practices empowers farmers to elevate productivity, curtail waste, and foster sustainable agricultural systems, ultimately contributing to a safer, more productive, and environmentally conscious farming industry.”

Industry trends and ways of tackling upcoming challenges formed the basis of discussions at last month’s Tractor and Machinery Association conference

Making the agriculture industry – and businesses within it – an attractive place to build a career formed a major part of last month’s Tractor and Machinery Association annual conference.

A sold-out crowd converged on Stamford Plaza Sydney Airport on July 19 for the conference, with numerous leading industry figures speaking.

A particular conference highlight was the launching of a new awareness campaign, which – as the name suggestsaims to raise awareness about the variety of career opportunities available in the

agriculture industry. Luciano Mesiti from Primary Industries Education Foundation Australia (PIEFA) spoke about the need for education resources for schools to help make students aware of what is available and shared both physical resources and education tools which PIEFA has provided to students.

Another challenge beyond simply attracting staff is the ability to subsequently retain them.

Mark Lewis, director of consulting practice Leading People and Culture, spoke about the importance of positive work-

place cultures and making businesses an ‘employer of choice’ for people entering the industry.

The day also featured a broader look at the economic side of agriculture – both past and future.

Westpac senior economist Justin Smirk analysed the current economy and discussed the immediate outlook, which highlighted factors such as inflation as being crucial in agriculture’s next 12 months.

Kynetec’s Melinda Haley also shared a summary of the last year’s tractor sales –which is collected through monthly data and shared via the TMA in each edition of Farms & Farm Machinery.

One piece of data revealed 7,670 tractors had been sold in the first half of 2023, which is down 16 per cent on the same period last year.

Another of the day’s highlights was a presentation from Kim E. Buoy of shipping company Willenius Wilhelmsen.

He discussed the impact of COVID-19 on global shipping and said demand remained high, and that while many of the issues have eased from their peak there were still significant capacity challenges.

The Tractor and Machinery Association says tractor sales were steady in June as the government’s temporary full expensing program came to an end

June ended the federal government’s highly successful temporary full expensing program, which had been introduced during the COVID-19 pandemic.

This program has helped the industry not just continue to operate during this difficult period, but to prosper.

The TMA has been concerned that the termination of this program will cause problems for the industry and has lobbied the government for relief for customers that ordered equipment but were unable to take delivery before June 30 due to the prevalent supply chain issues, however we were unsuccessful.

It remains to be seen now what the full repercussions of the end of this program are for the industry, particularly given the ever-increasing predictions of an El Niño weather pattern which is likely to dominate Australia for the next nine to 12 months.

Looking at tractor sales for the month, there were around 2,500 tractors delivered in June which represents around 60 fewer deliveries than during the same month last year.

This now means that the year-to-date figure is 16 per cent behind the same period last year.

Sales around the nation were generally down across the board.

Victoria was off five per cent on the same month last year and is now 24 per cent behind for the year to date.

Queensland recorded a slight increase of 1.9 per cent on the same month last year and is now 11 per cent behind for the year to date, while New South Wales sales were in line and now sit 17 per cent off the 2022 year-to-date figure.

Sales in Western Australia reported a drop of 17 per cent and remains 13 per cent behind last year.

South Australia was an improverrecording a 9 per cent rise for the month - and now sits 6 per cent behind on the year to date.

Tasmania was off 4 per cent for the month and is 24 per cent behind for the year to date, while sales in the Northern Territory finished 36 per cent down and remain 10 per cent down for the year to date.

Looking at the machine categories, the small, under-40hp (30kw) category - which is the category most likely to be affected by interest rates - was down by 8 per cent for the month and is now 16 per cent behind year to date.

The 40 to 100hp (30-75kw) range en-

joyed a small rise of 2 per cent and is now 17 per cent behind year to date, while the 100 to 200hp (75-150 kw) category was down by 3 per cent and remains 20 per cent behind on the year to date.

Finally, the 200hp plus (150kw plus) range slipped slightly, down 2 per cent to remain 5 per cent behind last year.

Sales of combine harvesters continue to gather pace with more than 200 units delivered in the month.

This puts us well ahead of the same time last year, up by a significant 78 per cent, and expectations are for an outstanding year ahead.