Clear Ridge Fabrication has made its Supa Bin even more super, adding a precision control system to a product which was already proving a winner >> Page 12

Counting blessings

Clear Ridge Fabrication has made its Supa Bin even more super, adding a precision control system to a product which was already proving a winner >> Page 12

Counting blessings

WITH A FULL 8 YEAR WARRANTY AS STANDARD*

PLUS, THE MAXAM AGRIXTRA RANGE DELIVERS MINIMAL SOIL COMPACTION, A COMFORTABLE RIDE AND IMPROVED TRACTION WHICH SURPASSES ALL AGRICULTURAL TYRE EXPECTATIONS. WHEN PACKAGED WITH ONE OF THE BEST WARRANTIES IN THE INDUSTRY, THE AGRIXTRA DELIVERS THE PERFORMANCE YOUR FARM DESERVES!

45

38

41

48

50

34

54

Normally when I start this column in each edition, I try to find an overarching theme or think about any articles that particularly deserve highlighting.

What struck me this month is just how much content we have managed to fit into our 88 pages.

One of my favourite things to do in this job is talk to farmers who are using the machinery we are writing about and getting to tell their stories.

There are multiple great examples of that in this edition, based on products big and small.

We speak to a New South Wales dairy farmer who enjoyed his McCormick X7 tractor so much he chose to purchase another one.

Also in New South Wales, one farmer’s use of a Jadan bale plunge counter – a small and simple product at its essence – has “completely changed the way I operate the machine”.

This is a glowing endorsement and it was a pleasure to share this farmer’s experience, as it was to write about a Victorian equine therapy charity’s use of a Rata Equipment Power Claw, which the operator called the “best piece of farm equipment I’ve seen.”

We were also fortunate enough to speak with new National Farmers Federation president David Jochinke.

This was a comprehensive interview discussing his journey to the role, what he sees as the biggest issues for agriculture, and most importantly – how he plans to advocate for Australian farmers.

On the cover of this edition is Clear Ridge Fabrication’s Supa Bin, which has been upgraded over time to improve on an already successful product.

We delve deep into what makes this

unique and how it is making life easier for its users.

It is time for celebration at Victorian dealership Massaro Motors.

February 28 will mark 50 years in operation for the dealership, and we spoke to owner and founder Ray Massaro about his highlights from half a century in business along with how the Gippsland farming region has changed.

Dixie Holdings has continued its growth journey with the acquisition of new trailers that will bolster its capacity to transport heavy equipment to customers around Australia.

We also take a look at Merlo’s Multifarmer machines that combine the benefits of tractors and telehandlers, review a Kuhn wrapper, and take a look ahead at the Australian Bulk Handling Expo, where grain handling will be a prominent topic.

There is a comprehensive look at the Natural Capital Accounting project which we discussed in the previous edition, along with a stack of industry news and new products and technologies both within Australia and overseas.

There is something for everyone in this edition and we hope the stories we have told will inspire your next farm purchase.

The applications are limited by your imagination

Global supply disruptions and excellent weather led Australian agricultural exports to a new record last financial year

Australia exported a record high $80.4 billion worth of agriculture, fisheries and forestry (AFF) products in the 2022-2023 financial year, according to a Commonwealth government report.

The Department of Agriculture, Fisheries and Forestry report revealed a 17 per cent increase on the previous year which saw AFF exports land just under $70 billion.

A record crop production in 2022-2023 coincided with an increase in demand for Australian grain due to global supply disruptions and increased prices – allowing significant gains for Australian farmers.

Some of the biggest factors contributing to the record export number were emerging and expanding markets, higher commodity prices and a favourable climate for crops.

The report finding are summerised below:

Higher levels of rainfall caused by the 2022-2023 La Niña event provided favoura-

There will soon be a new owner for Australia’s largest producer of cotton

ble conditions for crop production.

This in turn allowed Australia to gain an advantage over its key competitors who faced unfavourable crop-growing conditions – reducing global supply and increasing export prices, the report states.

Overtaking Canada and the US in 2022, Australia has become the second largest wheat exporter in the world after the European Union.

China remains Australia’s largest single export market, worth approximately $17 billion in 2022-2023.

The market share of other Asian markets continued to grow, particularly for fast-growing economies in the Association of Southeast Asian Nations (ASEAN) ($19 billion), with exports to Indonesia alone rising 25 per cent to $4.9 billion..

In 2022-2023, ASEAN’s share of Australia’s AFF exports reached a record high 23 per cent –Japan ($6 billion) and the Re -

Australia’s largest cotton processor –Namoi Cotton – has been bought out by the Louis Dreyfus Company Asia (LDC).

LDC already owned 17 per cent of Namoi Cotton and announced last month it had signed a binding agreement to acquire the remaining 83 per cent of shares.

“As a longstanding partner of LDC for the past decade, we look forward to working closer with a leading global agribusiness and cotton merchant,” Namoi Cotton executive chairman Tim Watson says.

“With our combined capability, we will further develop our excellence in cotton processing and marketing, delivering additional value to Australian cotton growers.”

Namoi Cotton’s history dates back to 1962 and operates both a cotton processing and supply chain business.

It has a ginning capacity of 1.6 million bales each year and an extensive logistics network, including 10 cotton gins in New South Wales and southern Queensland, along with three warehouse facilities that provide a combined static capacity for

Australia recorded a record high for AFF exports in the 2022-2023 financial year.

Image: VietDung / stock.adobe.com

public of Korea ($5 billion) also grew their market share.

The value of exports to India more than doubled – rising 106 per cent – after the Australia-India Economic Cooperation and Trade Agreement entered into force, with lentils and cotton the chief beneficiaries.

And the value of exports to Mexico rose 71 per cent to $482.2 million in 2022-23, following the start of canola exports, the value of which reached $169.9 million.

Inedible tallow, a key ingredient in some types of biofuel, recorded a 9 per cent commodity price increase in 2022-2023 –in response to higher global oil prices.

For the first time, Australian inedible tallow exports exceeded $1 billion.

Non-favourable grain production conditions in other major exporting countries contributed to higher global grain prices –benefiting Australian exporters.

Destructive flooding in Pakistan and drought in the US contributed to reduced global production of cotton – increasing Australia’s average export price for cotton 31 per cent compared to the previous financial year.

In 2021-2022, cotton was Australia’s seventh most valuable exported AFF commodity, in 2022-2023 it was the fourth most valuable, with Vietnam, Indonesia, India and Bangladesh major buyers for their new and established textile industries.

half a million bales.

Namoi also operates two joint ventures with LDC, namely the Namoi Cotton Alliance and Namoi Cotton Market Alliance.

The movie is expected to be implemented by mid-year subject to a number of conditions including regulatory and shareholder approvals.

LDC’s head of cotton Joe Nicosia says the move represents a long-term commitment by the company to Australia’s cotton industry.

“The proposed transaction reflects LDC’s long-term commitment to growing with Australia, promoting sustainable agricultural practices, supporting farming communities and contributing to local economic growth,” he says.

“The addition of Namoi Cotton into our Australian cotton operations also aligns with LDC’s global strategy to reinforce its leadership in core merchandising activities – in this case by strengthening our service to local cotton farmers, through an expanded ginning and logistics footprint.”

2024 is officially underway, and with better weather and lower input costs, Rabobank predicts Australian agriculture has plenty to look forward to

pressure, as markets globally and locally battle with a supply outlook for 2024 that is more plentiful than in past years,” he says.

Australia’s agricultural sector is “moving confidently into 2024”, with an overall positive outlook for the nation’s farmers and agribusiness industries in the year ahead, Rabobank says in its annual outlook.

Better-than-expected seasonal conditions and lower input costs have helped set up the sector for a strong year despite a predicted slump in some agricultural commodity prices and ongoing concerns about global economic circumstances.

Report lead author, RaboResearch general manager Australia and New Zealand Stefan Vogel, said the “major agri sectors” were moving into 2024 with a confident outlook, after “El Niño didn’t turn out as bad as feared, with recent significant rainfall received across most farming areas except Western Australia”.

“Grain farmers are set to plan more optimistically for the purchase of farm inputs and the upcoming planting period for winter crops like wheat, barley and canola,” he says, “especially in the growing areas outside Western Australia, which was the only region that hasn’t received much rain.

“For beef and sheep producers, the outlook for farm-grown feed in the first half of 2024 overall looks more promising, allowing them to hold on to more of their livestock and go to market with heavier weight lambs for example.”

Vogel says price developments will vary per sector, with the Rabobank Rural Commodity Price Index pointing to prices tracking at improved levels in the year ahead and near the five-year average.

“Grain prices are likely to remain under

“For a significant 2024 price upside for grain, the world would need to see weather-related supply shortages arise.”

Dairy process are likely to improve with domestic markets supporting farmgate prices, he says, while the beef and sheep price outlook is more optimistic and above the 2023 lows.

“The animal protein sector will continue to work through large Australian production volumes that need to move into quite congested global markets, and the economic headwinds that are expected to continue in 2024 won’t help to much improve global demand,” Vogel says.

“Still, we expect 2024, especially the first half of the year, to see higher beef and sheep prices compared with the second half of 2023.”

Farm input prices for fertilisers and plant protection products are forecast to be below last season, Vogel says, with markets likely to finally recover from the shocks of COVID-19 and the war in Ukraine.

The bank expects to see local nitrogen fertiliser costs decline by 10 to 20 per cent and phosphate by 10 to 15 per cent this year compared with 2023 prices.

“Potash has an even higher potential to ease farming budgets, with prices expected to trend down even more than the other fertilisers,” the report says.

Agricultural chemical prices are also forecast to decline in 2024 – primarily driven by a “massive increase” in Chinese

production capacity in the past three years which is seeing the beginnings of a supply glut in 2024, Vogel says.

However, these price reductions may take some time to be felt at Australian farm gates, as older stock makes its way through the system.

Crude oil prices have remained “surprisingly subdued,” Rabobank says, despite conflicts in the Middle East, while shipping prices are below their 2021 COVID-19 high.

Vogel says the global economic outlook is subdued, with global markets now effectively navigating reduced exports from Ukraine, while they continue from Russia.

“This makes the possibility of massive grain price swings like the ones seen two years ago rather unlikely,” he says.

“China’s economy is likely to remain slow, which isn’t the best set up for our exports to the region, as Chinese consumer demand will need more time to gear up into full swing.”

Locally there is more positive news, with interest rates forecast to plateau for most of the next six months before rate cuts come in towards the last quarter of the year.

The Australian dollar is also expected to gain modestly towards the end of the year, bottoming out at US 65 cents before rallying up towards US 70c, the report says.

“This upward move in the currency would slightly contribute to relieving some of the cost pressure for imported inputs and goods used on farm, although it would not be enough to notably hurt Australia’s competitiveness when it comes to agricultural exports,” Vogel says.

The NSW government will allow farmers to drive unregistered vehicles they use for firefighting purposes within a 100km radius of their home

Transport for NSW and the NSW Rural Fire Service (RFS) have partnered to launch a trial registration exemption for farmers to help rural firefighting efforts.

The trial, ending on March 31, will allow farmers to protect their own and neighbouring properties in the event of a bush or grass fire, especially before emergency services arrive to the scene.

“Landholders in rural areas can play a key firefighting role and this trial allows us to test an arrangement that rural advocates have been calling for,” NSW emergency services minister Jihad Dib says.

“It is expected this exemption will make it easier for landholders to fight fires on or near their properties.”

vehicles (FFFVs) will now be able to drive on public roads, within a 100km radius of their home, even if the vehicle is not registered.

Many rural advocates and farmers have been calling for the legal use of these vehicles on public roads to attend nearby fires, the NSW government says.

“This will lead to an even more integrated relationship between farmers and the RFS, leveraging all available resources and the expertise and dedication of farmers in safeguarding our communities,” RFS commissioner Rob Rogers says.

NSW Farmers Rural Affairs committee member Garry Grant also says he sees this as an opportunity to further develop

This trial will allow farmers to better combat fires. Image: Ingus Evertovskis/stock.adobe.com

RFS, whilst being able easier fight fires.

“Stopping fires as soon as we can to minimise damage and loss is the ultimate goal,” he says.

In order to be eligible for this exemption, the vehicle must be maintained in a safe operating condition and have firefighting equipment permanently attached.

Informing future options for FFFVs, this trial will run until March 31.

To nominate a farm fire fighting vehicle for the trial, submit the completed Farm Fire Fighting Vehicle nomination form and include two photographs.

The form can be downloaded at tfnswforms.transport.nsw.gov. au/45065859-farm-fire-fightingvehicle-nomination.pdf

One photograph should be taken from the front, which includes the driver’s side of the vehicle and one from the rear, which includes the passenger side of the

Researchers are looking at ways to incorporate hydrogen fuel cells into the powertrains of tractors and other farming equipment

Federation University Australia is collaborating with the Commonwealth Scientific and Industrial Research Organisation (CSIRO) to develop simulations and perform small-scale system-integration studies, with the aim of retrofitting powertrains in tractors with a hydrogen fuel cell-electric system.

Australian-owned distributor of new energy heavy vehicles, Foton Mobility, is also collaborating to incorporate hydrogen fuel cells into the powertrains of tractors and other farming equipment – most of which have been fuelled by diesel for generations.

As the transition to renewable energy gathers pace across the nation, Federation University associate professor of hydrogen technologies Surbhi Sharma says there are clear advantages to hydrogen cells being considered for the agricultural sector.

“The significant advantage with the systems we are looking at is that they use hydrogen and oxygen from the air to produce electricity and water, there are no emissions except water vapour,” Sharma says.

“It’s important to note that these hydrogen systems generate electricity but use a

completely electrochemical process.

“With no internal combustion, the hydrogen combines with oxygen to make water and electricity, with a small amount of electricity used to generate an initial electrochemical reaction.

“This technology does not burn hydrogen, unlike what many people might think when they hear of hydrogen technology replacing diesel or petrol.

“The farm equipment will also have a small battery similar to the current equipment, making it a fuel cell-electric hybrid.

“The interesting part is having no internal combustion engine, it’s a very different system whose application into tractors will be studied as part of this project.”

As part of the project, the systems will be tested to see how they perform in a real-life agricultural environment, while researchers study the degradation of these components in seasonal and ambient conditions and at varying degrees of load and operation cycles.

Sharma says having battery-only systems would be a disadvantage for farmers with heavy vehicles because bigger capacity batteries add significant weight, meaning much more power would be required to operate the vehicle.

Unlike battery-only systems, hydrogen fuel cell systems aren’t weighed down by heavy batteries and will be able to generate a current as long as hydrogen is in supply.

“With tractors, the more load you have, the more soil compaction will happen, which is not what farmers want. They can’t afford the tractors to be heavy beyond a certain point,” Sharma says.

A second key consideration for not adopting battery electric systems for agriculture is the charging requirements.

“Farmers can’t afford to be charging their tractors for 12 hours or more at a time during their peak season,” she says.

“We are looking at large-scale decarbonisation with the entire agriculture sector going for electric or hybrid tractors. If they’re only dependent on batteries, that will put excessive strain on the electricity grid.”

Having all tractors charged at night with a growing number of electric cars would be too much for an electricity grid to handle, Sharma states.

“This is why we need a mix of hydrogen and battery technologies to come into the transportation and agriculture sectors together.”

The

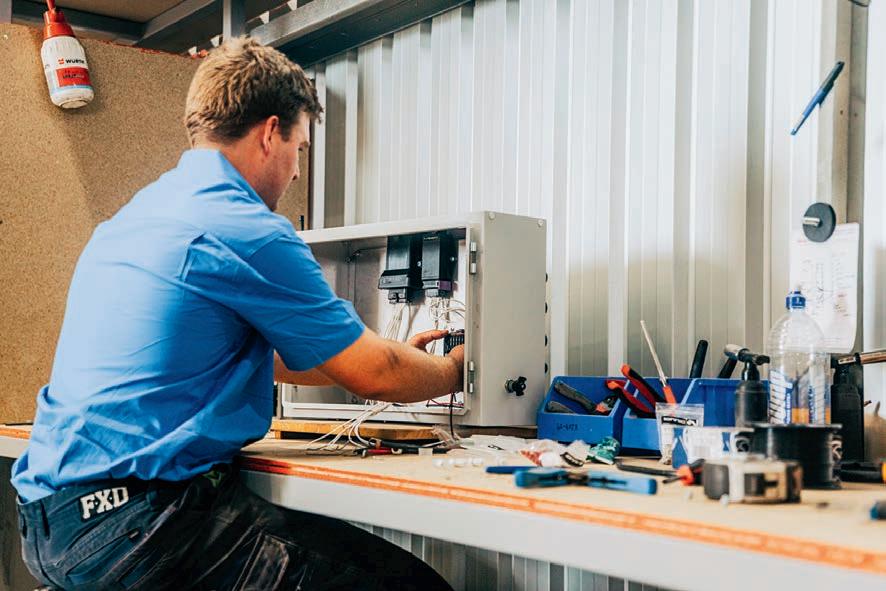

Clear Ridge Fabrication has made its SUPA Bin even more super, adding a precision control system to a product which was already proving a winner

In many ways, Clear Ridge Fabrication has come across the ideal formula for success.

Identify an issue, devise a solution, then continue to evolve and perfect said solution.

For the New South Wales-based company, the winning formula comes via its multi award winning SUPA Bin.

At its simplest definition, the product is a self-contained grain and fertiliser handling grouper bin – but to use such a concise summary would be doing a disservice to both the extent of its capability and the continuing development which has seen additional features added.

Developed and manufactured by Kaidan and Dallas Boyd on their family farm near West Wyalong in NSW’s Riverina region, the SUPA Bin combines the brothers’ expertise as qualified welders along with their experience as grain farmers.

The product has been on the market

for nearly five years now and meets the fundamental criteria for any successful product - solving a common problem experienced by its customer base.

“We designed a product to overcome a very common issue at sowing time,” Kaidan says.

“The issue was inefficient, unsafe and often labour-intensive air-seeder filling with contamination, between products usually thrown in – just to add to the frustration of the operator.

“Efficiency and safety were our main objectives, but we have achieved more than that.

“We have successfully produced a very user-friendly unit, that doesn’t require tipping in the paddock, has a higher load capacity and higher unloading capacity than the majority of competitor units and can easily be operated by one person.

“Some operators use multiple trucks and/or bins to fill their air-seeders with the various products required, but the Supa

Bin is a single, fully remote-controlled standalone unit that handles four separate products, with the option of more, plus a combined product capacity of up to 50,000 litres and that means less labour.”

One major development in the product’s evolution has been the addition of the SUPA Tube tubulator.

The SUPA Tube was developed to stop contamination when transferring products from the grouper into air seeders.

“It is one thing to get the products out of the bin contamination free, but it’s another thing to get them from the bin into an air-seeder contamination free,” Kaidan says.

“This is where the SUPA Tube comes into its own.

“A lot of the traditional groupers feed into an air-seeder’s own filling auger, which usually is quite a labour intensive, inefficient operation, often causing contamination due to the auger not being able to clean itself.” Images: Clear Ridge

maximum working heights of around 3.5m, 4.5m and 5.5m respectively.

The tubulator has a delivery capacity of around two tonnes per minute, depending on what height it is running at and what products are being dispensed.

All tubulator lengths remain within legal road widths when folded to their transport position, which involves the SUPA Tube being lowered and folded another 90 degrees to lay alongside the base of the bin and rest in a cradle on the left-hand side of the unit.

All the SUPA Tube’s functions, including rotation and height, are hydraulically and remotely controlled, providing ultimate con

Design and manufacturing occurs in New South Wales

The SUPA Tube is another of Clear Ridge Fabrications’ products

Design and manufacturing occurs in New South Wales

The SUPA Tube is another of Clear Ridge Fabrications’ products

with Kaidan saying large-scale cropping farmers and corporate farms are Clear Ridge Fabrication’s biggest customer base.

The impressive unloading rate of up to four tonnes per minute also makes the SUPA Bin an efficient option for transferring grain at harvest time, either into on-farm storage or directly into the various bulk handling systems.

The SUPA Bin is available in lengths and capacities ranging from 6m/22,000 litres up to 12m/50,000 litres with other options also available.

According to the company, the most popular sizes are the two-compartment, 6m-long single unit with a 60-40 product split and the four-compartment, 12m-long double unit with each bin again split 60-40.

Far from resting on its laurels with a successful product that has filled a gap in the market, the team at Clear Ridge Fabrication is constantly looking to improve it.

While Kaidan says blending products

percentages controlled by a touch screen mounted in a control box conveniently located on the bin.

A new remote control hand piece allows for multiple preset opening percentages to be simply programmed in, creating the operator’s commonly desired blends which then can easily be adjusted via the touch screen if a further different blend is required.

The actuators are programmable to enable door openings on any compartment anywhere from one to 100 per cent.

“With our old system, there was room for human error,” Kaidan says.

“The new system having computerised door control enables the operator to ‘set and forget’ knowing that the often expensive products feeding out of the bin are the exact blend they are looking for with each and every transfer, and products aren’t being wasted.

“With the old system you could tap the remote button to open the compartments

that it is not just limited to blending into air seeders, but it can also be used for blending into fertiliser spreaders, blending stockfeed grains into feeders and it can even be used to blend harvested grain that has high screenings with grain of a higher quality so as to raise it to a higher grade.

Recognising that not all customer needs are the same, Clear Ridge Fabrication also offers various customisable options including different bin compartment configurations, custom paint and sticker colours, various trailer options and more.

The Australian-designed and manufactured grouper bins have proven to be reliable for their owners around the country but are also backed up by 24-hour aftersales phone support.

The CRF SUPA Bin is available by contacting Kaidan Boyd on 0447 534 055 or visiting www.crfab.com.au

A seaweed-based cattle feed supplement said to reduce enteric methane emissions by up to 90 per cent has made its first commercial sale

CH4 Global, a company that delivers products that enables the food industry value chain to reduce greenhouse gas emissions, has begun deliveries of a cattle feed supplement which it says can reduce enteric methane emissions by up to 90 per cent.

Enteric methane emissions refer to the release into the atmosphere of methane gas from the digestive processes of ruminant animals such as cows, sheep and goats.

Since 2018, CH4 Global has been working to commercialise a cattle feed supplement containing the native Australian seaweed Asparagopsis, which has been found to inhibit the bacteria that produces methane.

The company has now made its first delivery of its seaweed-based food supplement dubbed ‘Methane Tamer’ to

meat processor CirPro, for use at its partner feedlot HB Rural, located south of Port Pirie.

CirPro plans to scale the use of the supplements up to 10,000 cattle daily by early 2025.

“2024 marks a pivotal year, one when the world wakes up to seaweed’s massive potential for curbing enteric methane emissions and we as a company aggressively scale up our efforts to combat climate change,” CH4 Global CEO Steve Meller says.

The company has also has started construction of the world’s first commercial-scale facility for growing Asparagopsis in Louth Bay, South Australia.

Scheduled to begin operations later this year, the ‘EcoPark’ facility will cultivate the red seaweed in large-scale saltwater ponds

Deep rooted legumes may help farms be more resilient during times of drought, a series of New South Wales producers have been told

Examining the soil structure and legume roots in the pasture formed part of the demonstration days. Image: UNE

Almost 200 producers in New South Wales are now better equipped to manage future droughts, the University of New England says, following field demonstrations it led last year.

Agronomists joined with UNE for the demonstrations as part of the ‘Overcoming the knowledge gaps’ project.

The project is funded by the federal government’s Future Drought Fund and aims to showcase the benefits of implementing deep-rooted legumes as a way of increasing farm resilience.

Held across a range of properties in drought-prone areas of NSW, the field days allowed producers to get a first-hand look at benefits such as land regeneration, improved soil health and structure, and increased productive pastures.

“The feedback was overall really positive, and the attendees enjoyed being able to get out and experience the success others have had with legumes as a drought management strategy,” associate professor and project lead David McNeill says.

“The workshops incorporated activities that asked producers to apply the learn-

and then turn it into the Methane Tamer feed.

The Louth Bay facility is estimated to produce enough Asparagopsis to supply 30,000 cattle per day, CH4 Global says.

“The first commercial delivery of Methane Tamer and the commencement of our EcoPark construction are concrete milestones in our quest to achieve a billion metric tons reduction in CO2-equivalent emissions by 2030,” Meller says.

Methane is over 80 times more potent than carbon dioxide (CO2) in trapping heat in the atmosphere over a 20-year period, according to CH4 Global.

The company hopes its EcoPark facility will be the first of many that will eventually be built around the world.

ings to their own properties, giving them a really good starting point to actually take action and facilitate change.

“We were also able to give people useful contacts to reach out to, so that we can ensure this is a continuous learning process into the future.”

The property managers and various speakers who addressed participants emphasised the importance of grazing management to support plant diversity and groundcover, which they said would help maximise the value of rainfall during dry seasons.

The ‘Overcoming the knowledge gaps’ project has also seen more than 5,000 hectares of contrasting legumes sown across 12 participating properties since early last year.

The aim is to identify and address common constraints faced when implementing legumes, while also demonstrating their value to soil and livestock health.

“The main message we are trying to get across through the Overcoming the Knowledge Gaps project is that grazing management is essential for productive pastures, and incorporating legumes into your grazing system can be a great way to do this in areas prone to drought.” McNeill says.

prescriptions that target weed pressures across the field.

Crop imaging system could help eliminate the need for human involvement in crop monitoring, developers say

Canada’s Croptimistic Technology has developed a crop monitoring tool which it says could revolutionise the process.

It’s a recent development for the company, which has distribution partners for its current product range in Victoria, Queensland, South Australia and Western Australia.

Mounted on sprayer booms, Croptimistic’s SWAT CAM imaging system captures images every 60 feet (18.3m) as it is driven through a paddock.

The technology comes with no cab interface, so there is no action required by the farmer – images are automatically uploaded to Croptimistic’s SWAT records software where machine learning models assess and segment crop versus weed data.

After the data separates the weed from crop, an auto-generated map summarises these populations by zone.

This allows farmers and agronomists to evaluate and adjust variable-rate seed/ planting, fertiliser, or herbicide strategies to

Stock Containment Areas could help prevent stock losses when adverse weather means keeping them in broader paddocks isn’t an option

An SCA can hold, feed and water livestock during adverse weather.

Source: CJO Photography / stock.adobe.com

Agriculture Victoria is encouraging the use of stock containment areas (SCA) to protect livestock during periods of extreme weather.

Agriculture Victoria land management extension officer Clem Sturmfels says an SCA can help minimise loss and illness to livestock during floods, droughts and bushfires.

An SCA is a selected area of a farm that is set up to hold, feed and water livestock during adverse weather conditions.

Typical SCA pens measure 50m by 50m and can hold approximately 500 sheep or 170 cattle, according to Sturmfels, with plenty of room for livestock to move around.

In addition to keeping livestock safe and well-cared for, an SCA can make management on a farm easier and more efficient.

By containing animals in an SCA, farmers can maintain ground cover across the rest of their property, protecting soils,

A newly developed plant stand count feature analyses each image and calculates individual plants per acre, as well as the average measurements of plant spacing, with the tool currently available for canola, soybeans, corn and potatoes.

“With SWAT CAM now having the ability to perform plant stand counts, it completely eliminates the need for human involvement in this labour-intensive process,” Croptimistic vice president of research and development Derek Rude says.

“It provides a 1000 times higher resolution of counts and is completely objective and consistent.”

“SWAT CAM uses constantly improving machine learning models to conduct these assessments. This is the pinnacle of observing what’s happening in the field,” he says.

water and pastures.

“It’s vital stock have enough feed and supply of fresh water, plus shade during the hotter times of the day,” Sturmfels says.

SCAs should be located close to existing feed and stock handling facilities, and away from houses, waterways and dams, he says.Sturmfels adds it is important that livestock enter an SCA in good health.

“They (livestock) should be drenched, vaccinated, and conditioned to a grainbased diet,” he says.

“Diseases and health issues can spread quickly in containment, so regular inspection and monitoring is essential.

“Common issues such as acidosis and shy feeders need to be identified early, with affected stock being moved to a pen of their own.”

For more information on stock containment areas visit www.agriculture.vic.gov.au

Backed by more than a century of history, Merlo combines the strength of Italian manufacturing with a local presence to ensure Australian needs are met.

The name Merlo bears resemblance to a popular red wine variety of similar spelling, and the machines the company produces can also be described as robust.

Solid and strong machines are a necessity for any Australian farmer, but even more so for heavier-duty products designed for the broadacre setting.

Adaptability and versatility are also sought-after characteristics, and Mer-

Merlo’s Multifarmer is the ideal solution for farmers who need the dual benefits of both tractors and telehandlers The Multifarmer is a versatile piece of farm machinery Merlo’s Multifarmer MF44.9lo’s appropriately named Multifarmer has this in spades.

The company describes the Multifarmer as a “unique and unrivalled telescopic tractor”.

In a farming environment where telehandlers are growing in popularity, the ability to combine the benefits of a telehandler with those of a tractor in the one machine holds considerable appeal.

Two models of the Multifarmer are imported to Australia – the MF44.7 and MF44.9.

The MF44.7 offers a 4,400kg maximum

load capacity, 6.8m lift height and a reach of 1.7m while at maximum load capacity or 3.6m otherwise. The unit itself weighs in at 9,150kg – smaller than the 9,350kg weight of the MF44.9.

This larger telehandler also has an increased lift height of 5.8m and greater maximum reach of 5.8m, although the maximum load capacity of 4,400kg and reach of 1.7m while carrying the maximum load are both the same as the MF44.7.

Merlo highlights four areas which have been key to the Multifarmer’s develop-

ment – comfort, efficiency, performance and safety.

Within the realm of comfort, Merlo says an “unprecedented design” groups the information provided to the driver and various controls for optimal ergonomics, while the steering wheel’s reverse shuttle is also on the joystick.

The cabin door can be opened by up to 180 degrees to ensure simple and easy access, while a large handrail on the door’s inside further enhances this.

The air-conditioning has been developed in a way that cuts the warm-up and

•

•

•

•

•

•

•

•

•

•

•

•

•

•

cool-down times in half when compared to a conventional system, the manufacturer says.

Efficiency is bolstered by full electronic management of the transmission and engine.

This helps to minimise RPM and fuel demand, therefore reducing fuel consumption and overall operating costs.

The axles ensure the maximum steering angle and make manoeuvring in tight spaces earlier, an aspect which is crucial to telehandler use.

Three different steering options are available.

Performance is at the forefront of every operator’s mind, and Merlo has given this careful consideration.

The Multifarmer has excellent braking capacity when the accelerator pedal is released, the manufacturer says, guaranteeing high torque to the wheels during materials handling and transfers.

The Multifarmer also features a four-cylinder combustion engine in an original Merlo mounting layout, designed to not only increase visibility but also provide maximum accessibility

to all components when maintenance is required.

All axles are manufactured and developed in-house by Merlo and can be equipped with differential lock.

In terms of safety, the Multifarmer can be configured with an aerial work platform that complies with EN280 standards.

They also have a metal structure above the glass roof to comply fully with FOPS Level II standard and protect operators from falling objects. Tipping prevention is also an important feature.

“In order to remain fully compliant with

The

regulations in frontal tipping prevention, Merlo handlers are equipped with features developed specifically to keep the operator safe from frontal tipping, without sacrificing performance, particularly of boom speed and lifting capacity,” the company says.

The Multifarmer is distributed by Merlo Australia, whose head office is at 120-124 Toongabbie Road in the Sydney suburb of Girraween.

The full range can be viewed online at www.merlo.com/aus/en

AGRICULTURE FARMING EDUCATION WASTE MANAGEMENT RESOURCE MANAGEMENT

CONSERVATION MANUFACTURING RESOURCES

ENERGY HEALTH & SAFETY INFRASTRUCTURE ENGINEERING MINING CONSTRUCTION

QUARRYING AGRICULTURE FARMING EDUCATION

WASTE MANAGEMENT RESOURCE MANAGEMENT

CONSERVATION MANUFACTURING RESOURCES

ENERGY HEALTH & SAFETY INFRASTRUCTURE ENGINEERING MINING CONSTRUCTION

QUARRYING AGRICULTURE FARMING EDUCATION

WASTE MANAGEMENT RESOURCE MANAGEMENT CONSERVATION MANUFACTURING RESOURCES

ENERGY HEALTH & SAFETY INFRASTRUCTURE ENGINEERING MINING CONSTRUCTION

QUARRYING AGRICULTURE FARMING EDUCATION

WASTE MANAGEMENT RESOURCE MANAGEMENT

SEARCH FOR TOP INDUSTRY TALENT THROUGH OUR JOBS BOARD.

CONNECT WITH ALIGNED CANDIDATES.

BOOST YOUR CHANCES OF FINDING SKILLED APPLICANTS.

SCAN TO CREATE AN ACCOUNT TODAY AND DISCOVER YOUR PERFECT MATCH!

Some might say nature is priceless, but the results of the Natural Capital Accounting project will put a value on a farm’s natural assets for both customers and other farm stakeholders

Farmers will be able to put a numerical value on the natural capital of their properties, as well as a value on its maintenance and support, following a four-year research project.

Natural capital refers to all living and non-living elements of the natural environment that combine to provide benefits or services to people.

This incorporates everything from the soil and water that support crops and pastures, to plants that provide food and shelter, and native animals (e.g., insects, reptiles, birds) that provide services such as pollination, pest control and waste decomposition.

Many of the services delivered by natural capital provide direct benefits for agricultural production – either through providing resources or avoiding expenses – and for the broader community, such as carbon sequestration and habitats for wildlife.

All these assets have value – but it’s not a value that can be recorded in one’s accounting ledgers or relayed to the bank manager. Until now.

For the past four years, 50 farms across Victoria, New South Wales and Tasmania have been involved in a La Trobe

University project aiming to help farmers place a value on the water, birds and trees on their land.

The ‘Farm-scale Natural Capital Accounting’ project has created a set of concepts and methods allowing farmers to measure the contributions their natural capital makes and the extent to which their investments and activities are having an impact.

This helps them improve both their farm performance and their management of natural capital, while maintaining natural resources and biodiversity.

Lead researcher Jim Radford says putting a value on natural capital means

farmers can use their sustainability credentials for commercial benefit.

“This is the first time whole-of-farm natural capital accounts have been produced in bulk from different geographic locations across a range of farming sectors, such as grazing, cropping, mixed farming and farm forestry,” he says.

“This project demonstrates that it is possible to generate detailed, comprehensive, farm-scale environmental accounts.”

Natural capital accounts make it easy to see how natural capital assets benefit production and therefore can help farmers see where they can improve farm productivity and profitability.

By providing information relating to environmental health and sustainability, farm management decisions can be more informed.

For example, farmers can identify where to plant native shrubs and trees to increase pollination or pest control services.

Farmers are now being asked for details about how well their farms are doing in terms of environmental issues like climate and nature risk.

By using natural capital accounts, farmers can provide solid data on their sustainability efforts.

Having a foundation of accurate and reliable data will enable farmers to market their farms as environmentally friendly and avoid accusations of falsity.

Farmers can easily share these accounts with various parties who need to reveal their own environmental impacts.

Special contracts, better prices and more secure sales can come to those who show off responsible environmental practices.

Across the 50 farms that were involved in the research project, about one-quarter of all Australia’s bird species were recorded – including 34 species listed as threatened.

One of the farms involved was Orana Park, a 5,250ha cropping and grazing operation in central Victoria, and its account showed more than 70 species of birds and 145 species of plants, including four threatened species.

“Our team has always understood the value of nature to farming and the future, but it was the lack of data for farmers about their natural capital which was the limitation,” farm manager Matt Davis says.

Another beneficiary of the project are sheep farmers Jo and Greg Bear from northern Victoria.

“As long-term farmers, we have witnessed first-hand the tremendous impact that looking after natural capital has had on all facets of our business and our personal life, but we had no data or evidence to back up this experience,” Jo says.

“Natural Capital Accounting fills in the missing link by providing valuable evidence to key stakeholders in our business now and into the future.”

Researchers believe natural capital accounting will benefit the entire agricultural supply chain, right through to consumers.

The Farm-scale Natural Capital Account Report is comprised of three key sections: Natural Capital Asset Accounts, Ecosystem Service Accounts and Environmental Performance.

Natural Capital Asset Accounts: - Register of natural capital assets (type, condition and extent)

- Biodiversity assets (birds, native plants)

Project participants John and Isabelle Atkinson

Ecosystem Service Accounts:

-

for pollination decomposition and pest control services

- Measures of soil condition – ground cover and soil organic carbon (provided by Downforce Technologies)

- Forage production (for livestock grazing properties)

- Shade and shelter services

- A dashboard that summarises key metrics and results

Environmental Performance:

- Greenhouse gas emissions position – for whole of farm and per product

- Rainfall use efficiency

- Use of non-renewable (finite) resources

- Resource-use intensity – pollution generated per unit of product for whole of farm and per product

- Maps showing the distribution of different types of natural capital assets and provision of services across the farm

- L ist of all bird species, plant species and invertebrate species detected on the farm

- E xplanatory documents providing detailed information about modelling, datasets and terminology

- Access to the customised ‘Sensand Technologies’ digital platform that houses a digital copy of the account, including a user interface to examine the accounts and results of individual rapid ecological assessments, plant surveys and bird surveys at point location

- Access to ‘Downforce Technologies’ portal to view the results of the soil organic carbon assessments

Investing in Jadan Group’s bale plunge counter has transformed one New South Wales farmer’s operations

In agriculture, as with all industries, every little advantage and improvement counts.

The hope for any new product is that it will provide a modest but worthwhile boost to efficiency, thanks to a formula which will be continually refined over time.

Very rarely, however, something comes along that makes a farmer wonder how they ever coped without it.

For Bathurst-based Peter Kirkman, that moment arrived recently when he started using a bale plunge counter from Jadan Group.

“This one item has completely changed the way I operate the machine,” he says.

“It really makes you a better operator and gives you a better quality item.”

Endorsements do not come much more emphatic or glowing than Kirkman’s, particularly for a product which is so simple and straightforward to use.

Jadan’s bale plunge counter, as the name suggests, counts baler plunges as they happen and helps to ensure consistency – which is the key to achieving bale length

consistency. The counter resets after every bale, and also keeps track of how many bales have been produced.

It is simple for an operator to install, with Kirkman easily setting his up despite relying solely on the instructions and having not seen one physically installed elsewhere prior to purchase.

Sensor cables and power cables are provided, along with all the hardware for mounting the unit.

Neither the bale plunge counter’s pur-

pose nor operation is particularly complex, but Kirkman’s story emphasises its value.

Like so many farming stories, it begins with an endorsement from a nearby mate.

“My mate and I had a few conversationshe’s a much bigger operator than I am - and he got one put on when he bought his new baler,” Kirkman says.

“Over a number of conversations last year, he was saying how it had helped him out so much and how he was getting more consistent bales.

“I’ve also been told previously by another gentleman out of Cowra a few years ago, who had one of the first-generation ones, that it was one of the best things he had. That started the ball rolling.”

With the idea now in Kirkman’s head, the decision to install a Jadan bale plunge counter paid off both instantly and comprehensively.

“I’ve done small squares for five to six years now on my own and am still relatively young on the hay side of things, but I’ve always struggled with inconsistent bales,” he says.

“It’s a little bit to do with the inconsistencies in your crops, which obviously turn into an inconsistent windrow.

“I put this on and it straight away slowed me down. I was always travelling too fast.

“Literally within two packs of bales I’d settled into a steady speed and the bales were coming out nearly basically exactly the same length.

“What this plunge counter is doing is helping you keep the flow of material going through that baler the same.

“It’s the same as a water flow meter really - if you can keep that the same going in, you’ve got the same coming out.

“It’s made my bales so much more even in weight and length, and the consistency of

size is the most important thing.”

Its ease of use is another benefit which Kirkman cites as an advantage.

“You can put somebody in the tractor or on the baler that potentially doesn’t have a lot of experience and say ‘right, this is the speed you need to go’,” he says.

“You can tell them to watch the bale counter and it will tell you how much faster or slower you have to travel to get the right number of plunges.”

In addition to a positive experience with the product, Kirkman also has nothing but praise for his customer experience.

The relationship is, in some senses, an unlikely one – and there was also an element of fortune in how Kirkman came into contact with Jadan Group.

Kirkman had bought his baler second-hand and was experiencing issues with the scales, which he mistakenly thought had

been installed by Jadan – a company which is located in Cowra, not far from his farm in Bathurst.

A call to Jadan’s Lorin Wallace not only cleared up the confusion, but started a customer-manufacturer relationship which has since thrived.

“Lorin said ‘they aren’t actually ours’, but from not knowing me, he helped me out, talked me through what the problem was and how to fix it,” Kirkman says.

“From that day forward, I haven’t gone anywhere else.

“They’re down to earth people who are just trying to help keep the local guys going and who go out of their way to help you.

“I can’t thank them enough for their information and help, and obviously for making these products which then helps me make a better bale.”

Kirkman’s also believes his bale plunge counter has already paid for itself despite only being operational for a short time.

“Everything has been positive for me out of it, and I should have had it years ago,” he says.

“People might say it costs you money, but it’s going to make me money.

“The bale is more consistent, so it’s easier to stack them on the truck and you’re saving time there.

“Anyone who doesn’t have one should be buying one. That’s one of the first things they should buy.”

Jadan Group is located at 45 Fishburn Street, Cowra.

The bale plunge counter, along with the company’s full product range, can be viewed at www.jadan.net.au or by calling 1300 523 263.

Quality service and a product that exceeded all expectations has one customer singing the praises of Rata Equipment’s Power Claw

They say every cloud has a silver lining.

For Dean Mighell, director of Victorian equine therapy charity Path of the Horse, the silver lining from the damaging storm clouds of June 2021 was that it introduced him to the “best piece of farm equipment

That product was Rata Equipment’s mid-range Power Claw, which caught Mighell’s eye as a solution for managing fallen trees, but which has far exceeded his expectations.

Path of the Horse’s story provides an

agricultural products such as the Power Claw.

Based in Trentham, north-west of Melbourne, Path of the Horse works with veterans, emergency service workers, community groups and National Disability Insurance Scheme (NDIS) participants.

Its work is led by Mighell, who is not only a registered psychotherapist but also a National Australian Equine Therapist of the Year recipient.

“Path of the Horse is a charity that was founded to assist veterans who were being medically discharged, most with post-traumatic stress disorder,” Mighell

“I’m a psychotherapist and I have 10 beautiful equine assistants assisting me in the process, who are just masters of helping people calm and self-regulate.”

While not a traditional farm in terms of its output, the charity’s needs are still similar to those of any large landowner.

Path of the Horse’s property is bordered on all four sides by state forest – making fallen trees a regular occurrence.

Mighell counted 47 big trees which fell during the June 2021 storms that hit much of Victoria, and the regularity of this occurrence is highlighted by another two eucalyptus trees falling just last month and crashing through fences on the property.

Path of the Horse director Dean Mighell with his Power Claw

Images:

Path of the Horse director Dean Mighell with his Power Claw

Images:

Rarely does a catch-all solution reveal itself, but the Power Claw has provided just that for Path of the Horse.

“Since we got the Power Claw, we’re able to not just pick up the logs we cut into lengths and manoeuvre them to split and stack them, but also using the facility on the front to bunch up all the rest of it for burning off has been a blessing,” Mighell says.

“It’s not just picking up logs and stumps and moving them, it can grab just about anything.

“I use it for all the rest of the rubbish that comes down with the fallen trees and I use it to spread out old hay bales for my horses.

“We depend on feed on our paddock and clear space for the horses. They love their tree cover, but the reality is that we’ve also got to deal with falling trees.”

The simplest way of describing the Pow-

er Claw’s general purpose would be to call it a substitute for the four-in-one buckets which are ubiquitous on Australian farms.

Rata says its regular feedback from customers is that the Power Claw’s versatility makes it the ideal replacement for buckets – and Mighell’s experience is no exception.

“I haven’t put my four-in-one bucket back on the tractor since I put the Power Claw on,” Mighell says.

“Once it was a nightmare to deal with fallen trees, but now that job has become a lot easier and a lot faster.

“It’s just a tough, robust, effective bit of kit - it’s exceeded my expectations to be honest.”

Rata Equipment was founded in New Zealand over 40 years ago and develops a wide variety of tractor and telehandler attachments, including multiple sizes within the Power Claw range.

Path of the Horse uses a mid-range

Power Claw, which is designed for tractors between 45hp and 75hp, along with small loaders.

This mid-range Power Claw is available in two widths – 1.5m and 1.8m – with the units weighing about 270kg and 300kg respectively.

Rata’s standard Power Claw – the largest model - is designed for tractors larger than 75hp, plus telehandlers.

The company also offers a compact Power Claw for tractors between 25hp and 45hp, and this model recently benefitted from a redesign which added a new folded-plate back frame.

Standard features across the Power Claw range include the tines being made from AR450 grade high tensile steel to ensure maximum strength and durability, plus interlocking tines to help with grabbing everything from large logs to a single stick.

The Power Claw has helped Mighell to move large logs

The Power Claw has helped Mighell to move large logs

Rata has also grown its presence in Australia during recent years, adding Bronson Crick as sales and operations manager of its Ballarat facility.

Having a full-time presence within Australia has allowed Rata to devote more time to specific customer needs on this side of the Tasman, while Crick’s engineering background also proved valuable for Path of the Horse during its purchasing process.

Mighell is full of praise for Crick and the wider Rata team during what was an unconventional purchasing process, saying “they deserve every bit of praise they get”.

“We put a feeler out because the Power Claw looked like it would be really useful and they looked well made,” Mighell says.

“The difficulty we had is our tractor was all we could afford years back, and it proved to have a completely different way of attaching.

“There were countless calls and emails as Bronson and I, and the engineering team in New Zealand, did the specs to get it to fit.

“It wasn’t a straightforward attachment but they just put in so much time and effort - measured, re-measured, did the drawings, swapped them back and forward.

“I reckon it would be the most difficult Power Claw project he’s probably ever had, but he was great to deal with and nothing was too much trouble.

“If you wanted good customer service and support, you just couldn’t ask for more than what I got – I can’t speak more highly of Bronson and the team.”

Fast forward six months of “pretty solid work” by the Power Claw on Path of the Horse’s property, and the only thing exceeding Mighell’s satisfaction with his customer experience is his satisfaction with the unit itself.

“It hasn’t had an easy life in the last six months and there’s not one thing that’s even bent, crooked or non-functional on it - the quality of engineering is just outstanding,” Mighell says.

“In terms of safety, we’re doing less cutting around a fallen tree, we’re moving that timber away and cutting it where it’s clear under foot. I don’t know how you put a price on those things.

“With the time it’s saved and the value

it’s given us, I reckon it’s paid for itself over and over.

“I’m 61 and I reckon it’s the best piece of farm equipment I’ve seen. I’ll never be without one. It’s that good.”

Depending on when you read this, Massaro Motors will have either officially celebrated – or be about to celebrate – 50 years in business.

The dealership in Victoria’s Gippsland region opened its doors on February 28, 1974 under the leadership of Ray Massaro.

It remains this way to this day, with Ray owning and operating the dealership, but it also a true family business with a succession plan in place for son Luke to take over.

With a half-century in business, and being embedded in his local region for a lifetime, the stories Ray has to tell could fill several editions of this magazine alone.

In many ways, these tell the story of the Gippsland region, the evolution of Australian agriculture and the changing methods of doing business.

As Massaro Motors begins a year of celebrations to mark the half-century, Ray reflects on the journey to this point while keeping one eye on what lies ahead.

“We started way back then with Chrysler cars and Dodge trucks, and then not long after that went into tractors and farm machinery,” Ray says.

“A lot of our products are out there in the paddocks and the fields.

“In 50 years, we often have five generations of families out there.”

“We’re an older dealer than Kubota as Kubota Australia, but even in our council we’re a rate payer and local business for 50 years.

“It’s pretty big for the region too, I think there’s only two other families that have had businesses for that long in the whole of 76,000-odd people in Latrobe City Council.”

Kubota is the brand most associated with Massaro Motors, and customers can select from everything in the manufacturer’s range, from the likes of mowers and through to larger 175hp tractors.

Beyond this, Massaro Motors customers also have access to Kubota sub-brands such as Krone hay equipment, Baroness golf course equipment, Kubota farm implements and several manufacturers of other equipment to suit all farming needs.

Stocking everything for a wide variety of customer types speaks volumes about a dealership that understands the needs of its region’s farmers.

It should be little surprise, with Ray having spent a lifetime watching the Gippsland region’s agricultural profile evolve.

“I’ve been in business for 50 years but I was a farmer’s son prior to that and watched it from a farmer’s point of view,” Ray says.

“I used to catch the school bus and go to the high school and there were 25 dairy farms along one particular road - now there’s none.

“That land is owned by five farmers who cleared up and plant potatoes, onions and have cattle and sheep. The family farm has completely changed.”

Much of the Gippsland region’s farming history can be traced back to the Soldier Settlement Scheme, which occurred after both world wars and gave soldiers access to farming land to rebuild their lives.

“The hobby farm now is virtually what the old farm used to be with 100 acres,” Ray says.

“The soldiers got 100 acres each to go farming. Those farms all became little dairy farms and those little dairy farms eventually became bigger dairy farms.

“Instead of milking 20 cows and sending cream off in cream cans, they bulk batch thousands of litres and they’re all buying next door and getting bigger.

“The farmer doesn’t do a lot of that work personally any more. He engages contractors that carry out some of that work, so it’s completely changed as far as the family farm goes.

“A farmer milks his cows and runs the herds, and somebody else is doing the fencing, driveways and laneways.

“Sometimes they don’t even milk the cows themselves because they have employees to do that, and now even have robots. Farmers can control the production of the herd more by just monitoring that aspect.”

These are far from the only changes Ray has observed, with technology, larger machinery and legislative requirements all influencing how farming occurs.

“Going back to after the war in the 1950s and 1960s, even the demographic of farms has changed a lot since then,” he says.

“Other than the hobby farmers, the machinery the farmers use is much bigger and a lot more automation has gone into it.

“I think the number of purchases per property is considerably less in numbers, but the value is much higher, like a $200,000 tractor instead of a two-wheel drive tractor that did everything, for example.

“You used to be able to sit on the back of a potato planter and drop potatoes in, now you don’t do that any more.

“Agriculture has changed too. They used to grow 10 or 15 tonnes per acre in potatoes, now it’s 20 to 25 tonnes per acre.

“You used to water with hand sprayers but now it’s all big machines with centre pivots to irrigate anything.

“You also used to pump water out of the creek, but you can’t anymore - you’ve got to have licences and permits and put in big dams and reservoirs or out of the aquifers. That’s all completely changed and become regulated.”

Even the nature of doing business has changed, to a more formal setup than the implied trust a handshake would provide.

“Back then you would discuss their needs, shake hands, look each other in the eye and we’ve done the deal - your word was your bond,” Ray says.

“As long as we met their needs, wants and costing and established trust we did a deal, we didn’t even need to have any paperwork back then. Not anymore.”

This year’s milestone is undoubtedly a time to reflect, but also provides the ideal opportunity to celebrate.

A 50-year staff reunion is being organised, while other events and celebrations

will occur over the next 12 months to mark Massaro Motors half-century.

Located at 497 Princes Drive in Morwell, the dealership’s physical site has huge significance for both the company and Ray himself.

“It’s been on this site from the very beginning when it also had a three-bedroom house, where I got married and lived in for a few years and where our first two children were born,” he says.

“There have been a lot of changes here as far as facilities and buildings go. Everything got pulled down and virtually rebuilt over the years.”

For all the changes in farm machinery, farming demographics and customer

needs – the core principle of Massaro Motors existing to serve the Gippsland region’s farmers will never change.

“Our philosophy has always been that we’re in the people business,” Ray says.

“I think if you’re in the people business, you’re doing business with the farmer and not necessarily electronically where you don’t even see the farmer.

“We have loyalty and respect for them from the onset because we run this business to satisfy their needs.”

The company’s full range can be viewed at www.massaromotors.com.au, by visiting them at 497 Princes Drive, Morwell or calling (03) 5134 1422.

Expanding and diversifying are two key words that sum up the recent history of Dixie Holdings, but these two words only tell a fraction of the story

Dixie Holdings is a good example of a company not resting on its laurels just because it does its primary job well.

“We’re an earthmoving equipment dealership, but we like to differentiate ourselves from other dealerships in that we like to do everything in-house,” director Tom McDonald says.

“This includes our engineering and manufacturing of attachments, our workshop rebuild facility, our machine sales, machine rental and heavy haulage.”

It is this last aspect in which Brisbane-based Dixie Holdings has most recently invested. Last month, it took delivery of its new 5x8 swingwing and 2x8 dolly trailers from Drake, bolstering its capabilities in the heavy haulage division.

This division is managed by his brother Charlie McDonald, maintaining Dixie’s status as a family business after being founded in the 1970s.

Tom says the new acquisition has allowed the company to offer transport between one tonne and 90 tonnes, while also continuing the “longstanding relationship” it has with Drake.

“They’re known as the best trailer man-

many recent steps towards upscaling its

investing heavily in our transport division

Dixie Holdings moves machinery around Australia

Dixie Holdings moves machinery around Australia

prime movers, drop deck road train combinations, 50 tonne float and dolly combinations, and then the latest acquisition of the swingwing with dolly combination,” McDonald says.

“We have the transport equipment for the machines we’re buying and selling and renting out, but we’re also trying to capitalise on the shortage of these kind of combinations in Australia.

“Not only are we just doing transport for our customers that are buying equipment from us, but we’re also now concentrating heavily on external work and basically treating it as a separate avenue from the rest of the business.”

This is certainly adding another string to Dixie Holdings’ bow and helps to show the extent to which the company is identifying and addressing its customers’ needs.

It complements the other aspects of the business which Dixie has become known for, primarily the customisation of

machinery for the farming and earthmoving sectors.

The likes of wheel loaders, dozers, excavators and graders are staples of the operation – having custom attachments manufactured and added by Dixie’s expert team to ensure the machine can always meet the end user’s needs.

With so many of the machines headed to remote locations such as cattle stations, where single-use machines are impractical and versatility is paramount, having the skill and knowledge to turn these products into such all-rounders is why customers seek out Dixie Holdings.

Adding the ability to transport these finished machines anywhere around Australia without relying on third parties is just the cherry on top.

Dixie Holdings has become a one-stop shop and its growth pattern is showing no sign of easing up. Being able to offer so much to customer is something McDon-

ald is proud of – with the increased transport capabilities only adding to this.

“We’re trying to look after our existing customers and any new customers that need equipment moved professionally and quickly,” he says.

“A provider like us has the right insurances, the right permits and new equipment so that they don’t have the risk of worrying about things not turning up to site on time, because everyone always needs things done quickly.

“For us as a company, the only time we seem to have issues is when we’ve got to rely on other people to do things for us, so the more that we can do in-house, the more effective we can be in doing things properly and quickly.”

Dixie Holdings is based at 1343 Stapylton Jacobs Well Road in the Brisbane suburb of Woongoolba, and its full range can be viewed at www.dixieholdings.com.au

Dixie’s latest acquisition will allow the company to increase its heavy haulage

Dixie’s latest acquisition will allow the company to increase its heavy haulage

a power harrow and the rest of the time it’s either topping, running a mixer, pulling a trailer or moving bales.

trol, plus we run a seeder, slurry tank, and front mower.”

In many ways, the Pearce family’s story

op a good relationship with the distributor and its local branch to the point of adding other machines from the same source.

“We’ve had McCormicks in the past and we’ve still got an old CX85 in the shed, an old open cab tractor,” Tom says.

“Dad had a thing for McCormicks from years back, and we came across the newer X7s at a field day.

“We liked the updates they had made and the price point they were at compared to some of the other big players.

“Coming out of the Clark stable, they’ve got a bit of industry presence with Bobcat and all the other brands they do, so it

pretty easy to get in contact with,” Tom says.

The Pearces’ nearest Clark Equipment branch is in Fyshwick, and Tom is thankful for both the skill of the mechanics and speed of work when they have been called upon.

“The mechanics have been useful and they have got some pretty tech savvy people within the network,” he says.

“It’s handy that Clark is a larger company and they can probably draw from differ-

The X7 works alongside multiple attachments.

Image: Tom Pearce

McCormick’s X7 range comes with five different models, including the X7.660 and X7.690 which the Pearces own.

All X7 models are manufactured in Italy and are equipped with 6.7L, six-cylinder engines. The top-end X7.690 P6-Drive delivers a maximum of 225hp (166kW) when equipped with McCormick’s Power Plus, while the X7.660 P6-Drive offers a maximum of 181hp (133kW).

They offer a maximum torque of 897Nm and 738Nm respectively when boosted by

Both tractors are heavily used on the Pearces’ farm.

Image: Tom Pearce

It is far from the only step which McCormick has taken to ensure operator comfort while inside an X7.

The Premiere Cab is designed to ensure a clean and dust-free environment with a sound insulation system that McCormick says maintains an in-cab noise level of only 70dB.

Premiere Cab is also “a new-concept four-post design with rear hinged doors that provides unobstructed visibility in all directions, giving the driver full view of blind spots without the need to change position”.

The McCormick X7.660 and X7.690 are two models sold by Clark Equipment. Images this page: Clark Equipment

The McCormick X7.660 and X7.690 are two models sold by Clark Equipment. Images this page: Clark Equipment

After a successful event in 2022, the Australian Bulk Handling Expo will return in September

The bulk handling industry is a diverse sector – made up of businesses that transport and handle bulk solids.

At first glance it might seem that grain handling – the element most relevant to the agricultural sector – may not have much in common with a major iron ore mine or cement plant.

However, they each use similar equipment like conveyors, silos, hoppers, and more to move their materials from one point to another.

A range of strategies are being implemented across the country to help address the issue of labour shortages, but there is no silver bullet.

It has led many organisations to begin looking at innovations like autonomous machinery to help increase their efficiencies as much as possible, whether it’s a port, mine, or manufacturer.

The Australian Bulk Handling Expo (BULK2024) plans to bring this diverse industry together under the one roof in September.

Located at the Melbourne Exhibition and Convention Centre, the event aims

to help spread industrial knowledge, showcase the latest technologies and innovations and provide an opportunity to network with likeminded peers.

BULK2024 show director Lauren Chartres says the event is the only dedicated Australian expo for producers of bulk commodities such as grain and animal feed.

“The bulk handling industry is a vital part of Australia’s economy, with a wealth of knowledge and expertise to share,” she says.

“To have all these exhibitors under one roof is not only a great place for business opportunities, but a fantastic occasion to network within this essential industry.”

BULK2024 is aimed at bulk commodity producers who are looking to run their businesses more efficiently and keep one step ahead of the competition.

To ensure they can do that, the latest in equipment will be on display, including conveyors, silos, motors and drives, belt scrapers, container tipplers, dust control systems and weighing or level measuring products.

Attendees will have the chance to connect with industry leaders and innovators on the show floor and at various networking opportunities at the show.

The expo will be held in conjunction with one of Australia’s biggest transport, logistics and supply chain events, MEGATRANS2024, with one ticket entry for access to both exhibitions.

It will also host the 2024 Australian Bulk Handling Awards, and nominations are currently open.

“We’re inviting everyone to be a part of this game-changing expo – from hands-on decision makers in the bulk handling industry to CEOs, COOs, regulatory bodies, and government at all levels,” Chartres says.

“We’ve seen how impactful bringing the industry together was at BULK2022 and are excited to see the industry continue to grow.”

BULK2024 will be held on September 18 and 19 and the event’s website is www.bulkhandlingexpo.com.au

David Jochinke outlines his goals as new National Farmers Federation president, while discussing some of the issues he has advocated for

New National Farmers Federation president David Jochinke has a simple goal – ensuring every farm in Australia is a profitable business.

Jochinke was elected president of the industry’s peak national body in October, replacing Fiona Simson who had served in the role for seven years.

In many ways, Jochinke was a logical successor – having served as NFF’s vice-president since 2017 and has also spent time in a top job, being the Victorian Farmers Federation president between 2016 and 2020.

He is also still a grain and livestock farmer in western Victoria and remains actively involved, having been “front and centre with the other lads” earlier in the morning when he spoke to Farms & Farm Machinery.

While he says NFF business will always take precedence while he is president, it is this day-to-day involvement on the land that he believes makes him an ideal advocate for Australian farmers.

“First of all, I’m one of them,” he says.

“Whatever the concerns they have, whatever issues they have and whatever government policy they hear or read about affects me as well.

“I have huge empathy for agriculture and the people who work within it, and

we’re constantly learning about different production systems and different farming communities. “Any time I’m on the road, I try to give as much time as I can to the locals to understand them and their issues.”

Agriculture is a complex industry with a raft of different issues at local, state and national levels, including some which may only affect a percentage of farmers.

It can be a delicate balancing act for Jochinke and the NFF and make it difficult to condense their overall ambitions down to one single answer, but Jochinke’s guiding principle is clear.

“When people ask ‘if you had a magic wand, what’s the one thing you can do’, it has always been to make sure that every farm is a profitable business,” he says.

“I want to talk in business language, and I want farmers to be respected as business people.

“I don’t care if we’re liked or not, but I do care that people know our opinion and they know we stand for something.”

The NFF has also has a stated goal of $100 billion in national farm gate output by 2030, and the push towards this target will form a major part of Jochinke’s tenure.

Farms & Farm Machinery spoke to Jochinke about this ambition, along with his

other priorities as president and his journey to the top job.

What drew you to these leadership positions within agriculture?

I’ve always wanted to be a part of an industry that had a voice and where we could get things done.

When I first came home at 18 and started working on the farm, I wanted to make sure that we had a voice and that if there was an issue that we get on and solve it.

I always believe every problem has got a solution and people need to work on fixing any problems and not just admiring it.

As a part of that, and my grandfather was very active in the community too, it was only natural that I wanted to have the opportunity to speak up and have my voice heard.

From there, I just rose through the ranks and had the great honour of being where I am now.

How do you balance your role as president with your work on farm?

The NFF always takes precedence, but when I’m home I try to make sure I keep my hand in all the farming.

I’m still very active on the farm, but it’s very simple - if there’s an issue, or the need for me

to travel or give time to any of the causes of the NFF then that always takes precedence.

I did a Nuffield Scholarship back in 2007 and the words of advice I had from some ag leaders I met around the world was ‘you’ve got to make sure you can create time’.

When the elections were on for the NFF president, we put an extra person on the farm and that has given me capacity to have time and dedicate and focus on national farming issues.

How important is the $100 billion in farmgate output target to the NFF?