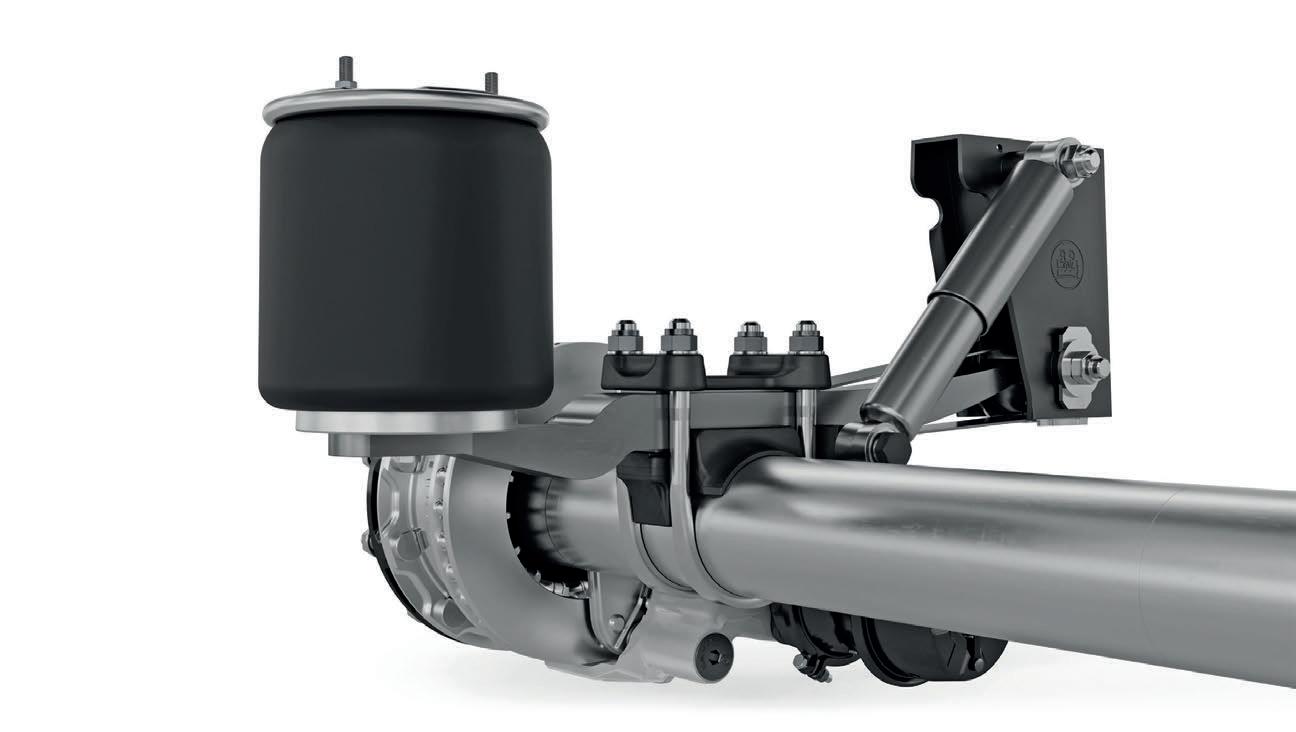

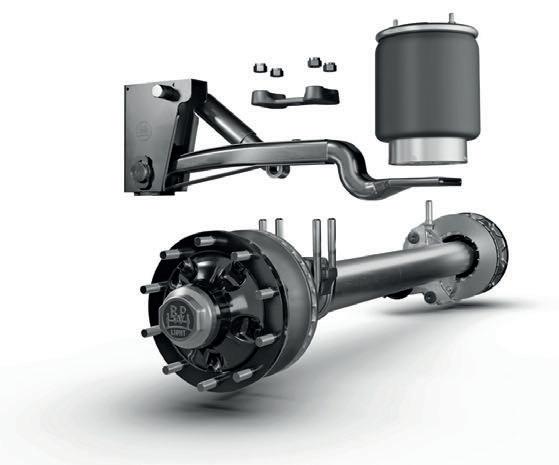

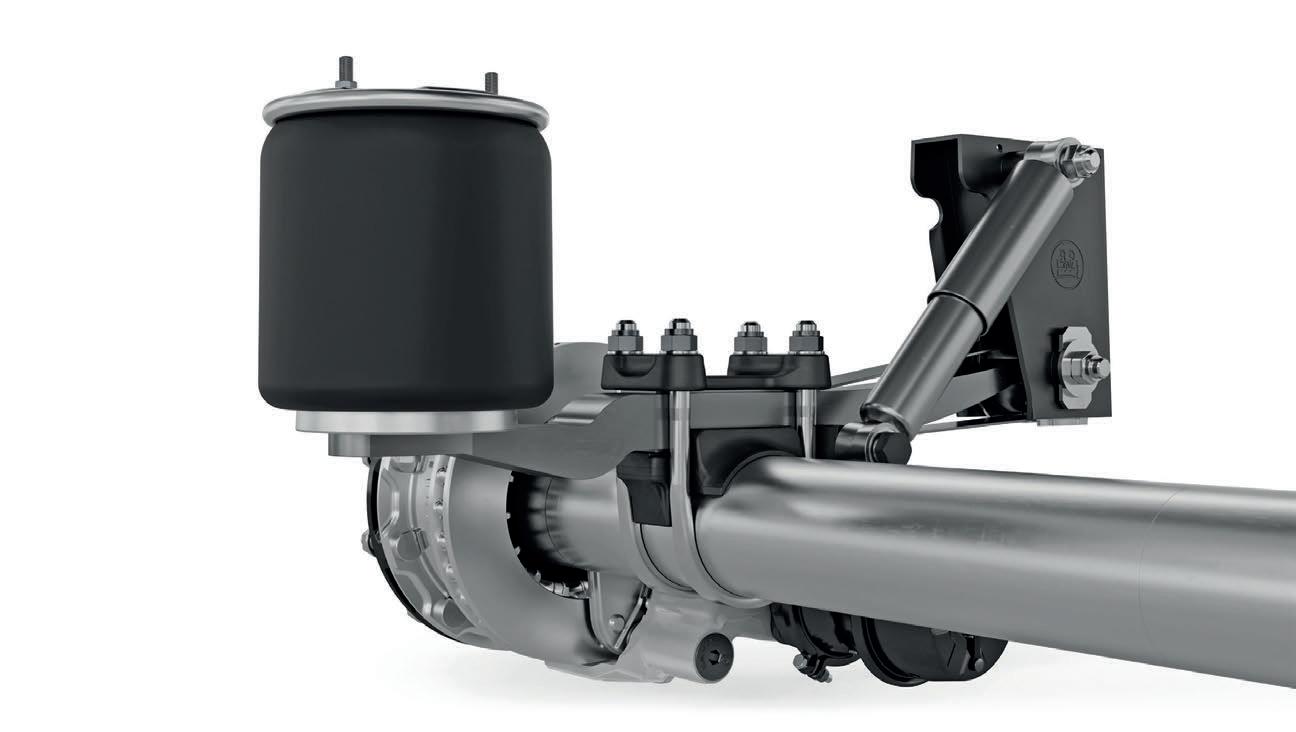

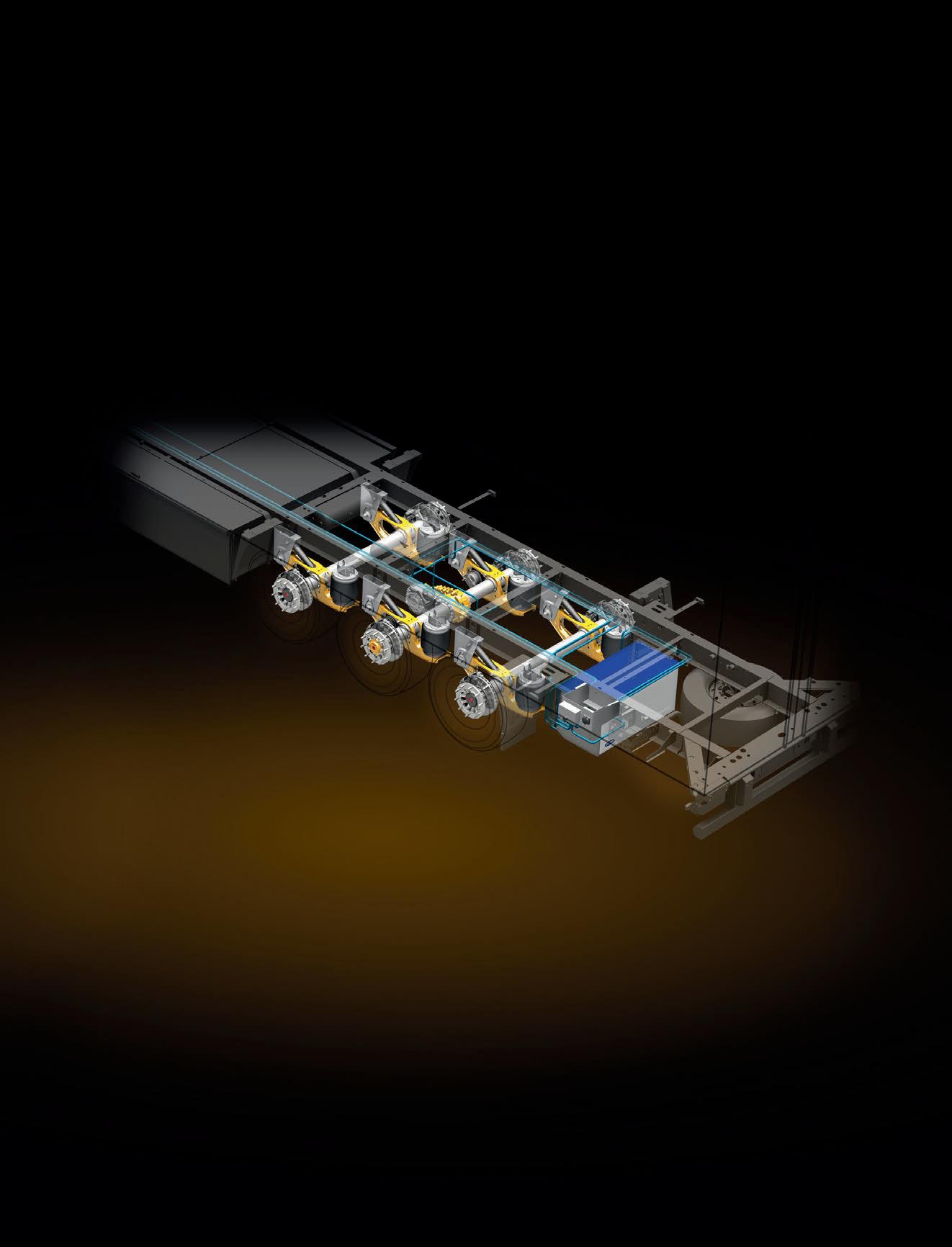

INDIVIDUAL RUNNING GEAR SOLUTIONS FOR SPECIAL TRANSPORT TASKS.

With our running gears and special axle solutions, there is nothing that can’t be transported. Your requirements motivate us to create new things. They inspire us to use our entire engineering expertise and decades of experience to develop innovative and reliable solutions together with you – customised for the type of vehicle and intended use.

The vehicle concepts for low-loaders are as varied as the transportation tasks. The use of air-sprung modules with rigid and steering axles is just one solution from our uniquely wide range of running gear systems for low-loaders. Challenge us!

A

CIMC Vehicles CEO and President, David Li, talks to Global Trailer about China’s trailer market and the company’s domestic and international plans.

By the time the opening ceremonies are celebrated, CEVA Logistics will have moved almost a million pieces of sporting equipment. Find out what else is involved in an event of this magnitude.

Its feline branding is certainly recognisable on UK roads, but then so are the clients the company caters to.

From ASDA and British Gypsum, to Culina and Warburtons, Tiger Trailers and its vast range of semitrailers and rigid truck bodies are in hot demand.

“THE COMPANY’S ETHOS IS TO PROVIDE CUSTOMERS WITH INNOVATIVE DESIGN SOLUTIONS, HIGH BUILD QUALITY AND A COLLABORATIVE, PERSONAL SERVICE.” Tiger Trailer Managing Director, Ed Booth.

From the stormy Irish Sea to the dry deserts of the Middle East, the refrigerated transportation industry is making waves.

It is time for the commercial lighting sector to shine, with a range of innovations vastly improving products and increasing safety.

Lightweight stainless steel, customised breglass sheeting and innovative sliding roof solutions are all covered in this issue.

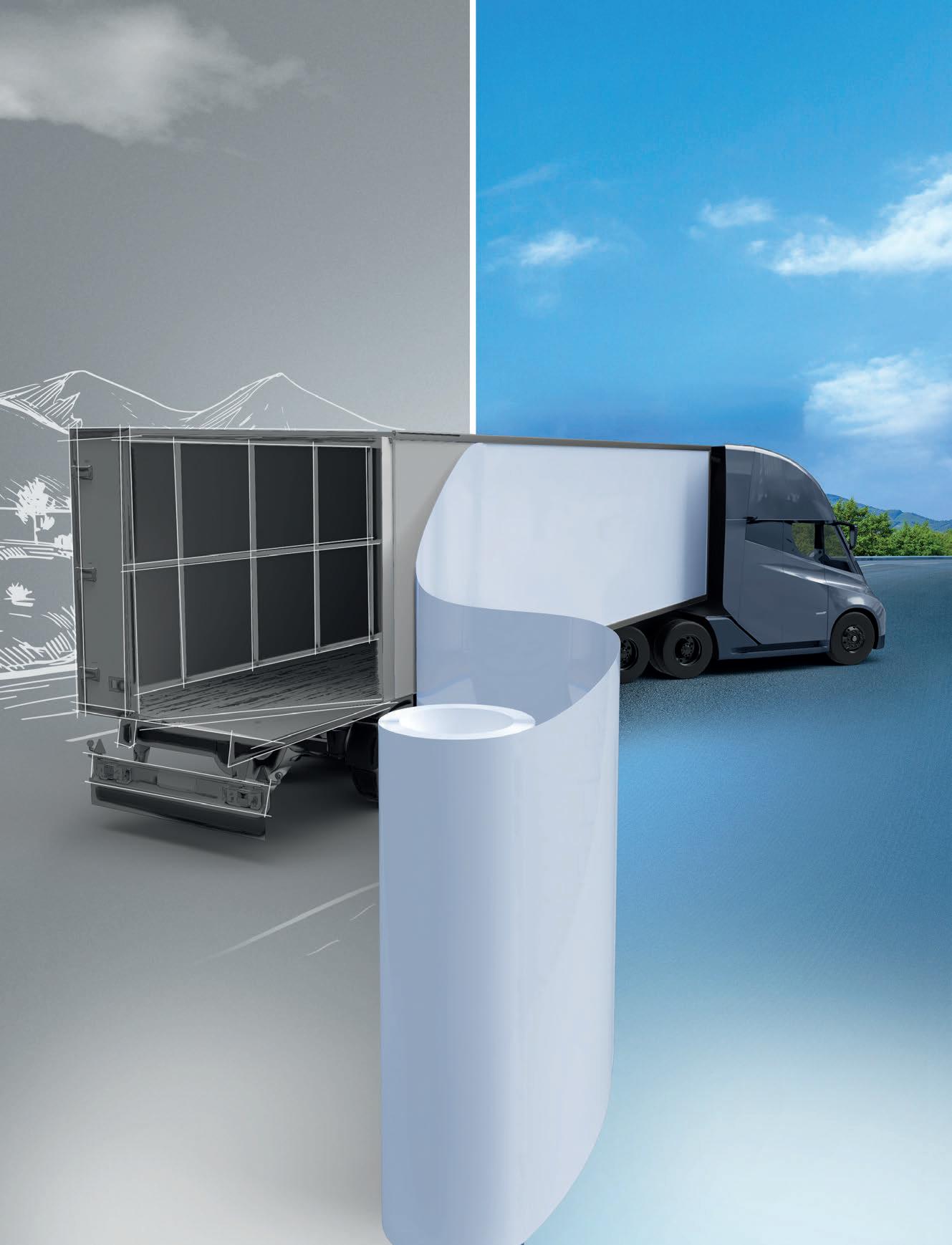

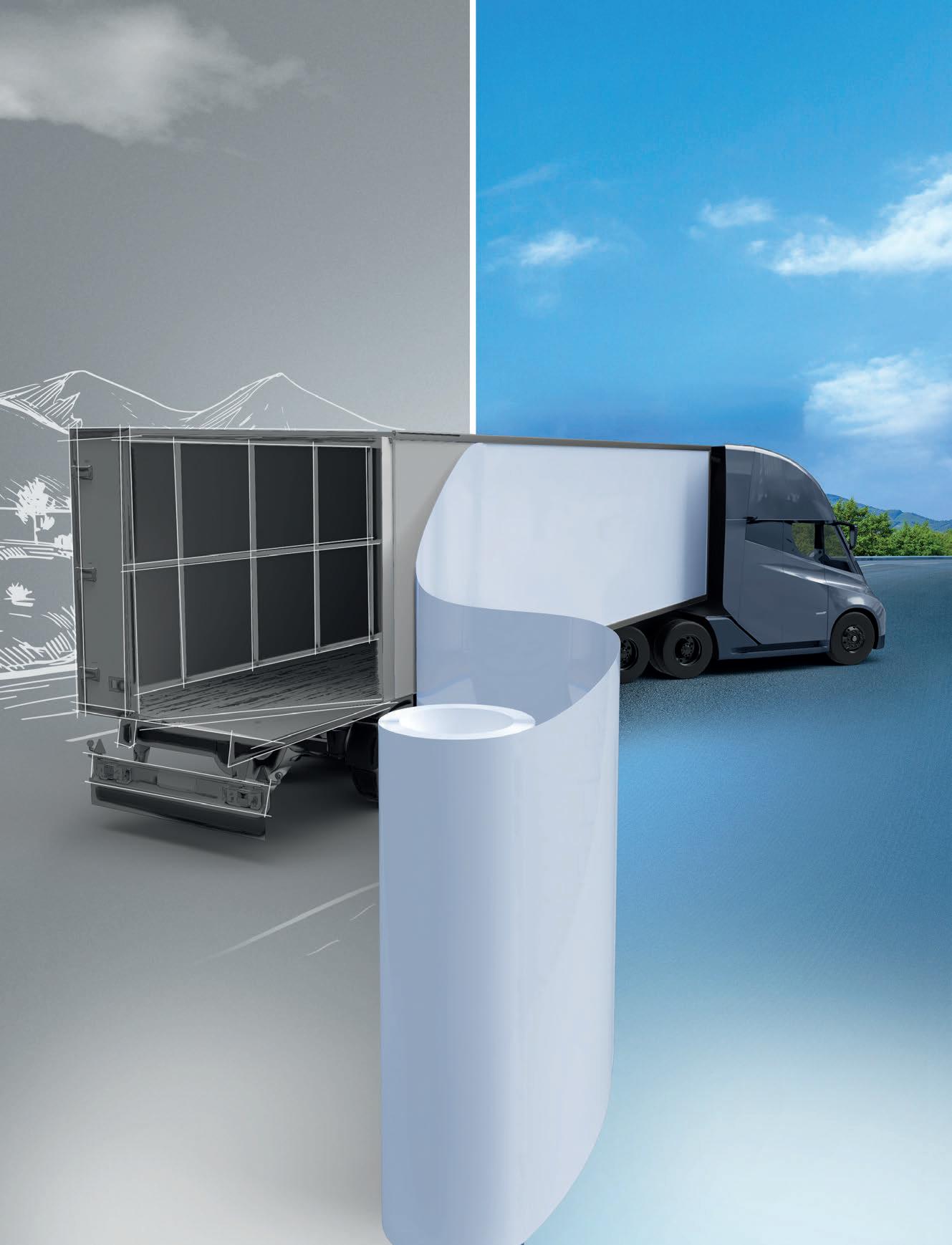

Electric heavy vehicle development has presented opportunities for truck and trailer OEMs, suppliers and specialists to pool their resources and innovate as a collective. It is inspiring to see the best of the best work towards common goals in the pursuit of safer, greener and more e cient road transport equipment.

One recent example is ermo King which announced a partnership with an electric trailer builder, Trailer Dynamics, to provide industry expertise on electri cation and refrigeration solutions. eir commitment to accelerating electri ed trailer technology should result in major wins for the cold chain in terms of enhancing logistics capabilities and providing better, more sustainable freight solutions.

Dr Stefan Binnewies, Chair of the Trailer Dynamics Advisory Board, said the decarbonisation of road freight transport can only succeed fast with strong partnerships. By accelerating the delivery of electri ed trailer technology, we expect to see more electric heavy vehicles in service. Range Energy is working with DB Schenker to test electric-powered trailers to assess route suitability, payload considerations, technical support, data sharing and charging. If the results demonstrate considerable reductions in emissions and boosts in e ciency, then it may just entice more trucking operations to modernise

their eet assets.

In addition to product development and rollout, what is happening with the infrastructure to support the transition?

Two years ago, the German Association of the Automotive Industry (VDA) said the expansion of the charging infrastructure for electric vehicles was one of the most urgent infrastructure tasks for Germany. In recent months, it was found that the necessary costly transformation to electromobility is made more di cult by historically low margins, but it might take a shi in perspective from banks to improve the situation.

Meanwhile, the electri cation of heavy vehicles in Australia, according to Swinburne University, could save the nation $324 billion by 2050. However, the national freight task is rather demanding for heavy loads traveling long distances which could prove to make dynamic wireless charging systems for highways expensive to install and maintain. Such a move would require a collaborative e ort to deliver a sustainable transport ecosystem. A $8.2 million prototype for embedding advanced wireless charging infrastructure on regional roads could be one viable solution.

CEO John Murphy john.murphy@primecreative.com.au

COO

Christine Clancy christine.clancy@primecreative.com.au

INTERNATIONAL SALES

Ashley Blachford ashley.blachford@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALIST

Louise Surette louise.surette@primecreative.com.au

DESIGN PRODUCTION COORDINATOR

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR Blake Storey

DESIGN Laura Drinkwater

CLIENT SUCCESS MANAGER Salma Kennedy salma.kennedy@primecreative.com.au

COVER Image: Tiger Trailers

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia +61 3 9690 8766 enquiries@primecreative.com.au www.globaltrailermag.com

SUBSCRIPTIONS +61 3 9690 8766 subscriptions@primecreative.com.au

Global Trailer is available by subscription from the publisher. e rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Global Trailer is owned by Prime Creative Media and published by John Murphy. All material in Global Trailer is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Global Trailer are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

JOST KKS – push-button trailer coupling

#futurenow – Thanks to our revolutionary coupling system you can now change semitrailer quickly and safely out of the cab. Your start in the future of logistics. Ready to beam up?

Maersk has launched a new 30,000 square metre facility in Tijuana, Mexico.

Recognising the potential of Tijuana as a key player in trade between the US and Mexico, Maersk’s new site will service customers in the technology, automotive, retail and lifestyle sectors, who are looking for cross-border capabilities.

The new facility enjoys a geographical advantage, positioned near major commercial ports, such as Los Angeles/ Long Beach, California and Ensenada, Mexico. It lies just 15 km from the Otay Commercial Port and 20 km away from the San Ysidro Commercial Port, which spans the border between San Ysidro, California, and Tijuana.

Temperature-controlled logistics company, Lineage, has announced new

Canadian cross-border services. Leveraging the strategic positioning of its facilities and transportation network, the program aims to deliver added transportation advantages for customers looking for end-to-end cold chain solutions in the North American market.

The cross-border network offers added transportation value for Lineage customers, including access to multiple delivery points in the Canadian market and strategically positioned transport terminals in Vancouver, Kelowna, Calgary, Edmonton, Saskatoon, Regina, Winnipeg, Toronto, Red Deer and Montreal. A new terminal in Moncton, New Brunswick is planned to be operational later this spring.

American transport company, Saia Inc, has announced a partnership with Fletes Mexico via its less-than-

truckload division, Carga Express. As a result of the collaboration, Saia will service Carga Express shipments entering the US, while Carga Express will handle Saia freight that enters Mexico.

Celebrating its 100-year anniversary this year, Saia began its operations in Louisiana. Today it operates 194 terminals across the United States, with plans to open 15 to 20 new terminals as it adds direct service to new geographies.

DHL Supply Chain has announced major changes to its international leadership team with a partial restructuring of roles and the addition of new members to its Global Board of Management. Patrick Kelleher will assume the role of CEO of DHL Supply Chain North America. Currently serving as Global Chief Development Officer, Kelleher will continue reporting directly to Global CEO, Oscar de Bok. Kelleher will succeed Scott Sureddin, who retires from DHL Group at the end of the year. Under Sureddin’s leadership, the North American business doubled in size, the company said.

Family-owned Stoughton Trailers has broken ground on a new corporate headquarters.

Located in Stoughton, Wisconsin, and at almost a square kilometre in size, area will include community parklands and trails. The facility will feature a workout gym, exercise studio, locker rooms and other amenities for employees. Trailer production will remain at its current location.

Global automated warehouse and cold chain logistics provider, NewCold, has announced plans to invest $222 million (CND) into Canada’s agri-food sector. With support from the province of Alberta’s government, NewCold will expand into the southern Alberta community of Coaldale, creating a food storage facility that will build on the region’s strength as a food corridor. NewCold identified the area as an ideal location to support the growing food processing industry in the region with its automated cold store. NewCold will also invest in improving Canadian Pacific Kansas City rail connectivity, to give businesses ready access to export products.

Trailer telematics provider, FleetPulse, is spinning off as an independent

company, having secured $11 million (USD) in seed funding.

American trailer manufacturer, Great Dane, incubated the company, beginning in 2017.

FleetPulse’s OEM-agnostic telematics platform enables end-to-end visibility into trailer safety and security.

Development on the platform was a result of Great Dane’s own need to improve trailer data insights.

Working with fleet customers who needed to digitise and leverage data across their trailer fleet, Great Dane saw the need to build the technology platform as an independent company. FleetPulse has appointed former Uber Freight executive Carl-Christoph Reckers as Chief Executive Officer.

Temperature-controlled storage and logistics provider, Emergent Cold Latin

America, announced it will open the largest frozen food warehouse in Chile. Located in Talcahuano, a region known for its seafood and fruit export, the facility marks Emergent’s most significant expansion in Latin America. With storage capacity of 294,000 m³ and 37,000 pallets, it is expected to generate 150 direct and approximately 500 indirect jobs, bolstering the local economy and enhancing local cold chain infrastructure.

This is Emergent Cold LatAm’s first completed construction project in Chile, following the acquisition of Friopacífico in 2021 and subsequent acquisitions of Multifrigo and Hook in 2023.

Trailer builder Librelato’s new technical training centre had a successful first month, with 32 students completing its premiere course.

The Brazilian company’s facility is a ‘mini-factory,’ aimed at giving trainees hands on technical experience by offering free and paid professional industry courses.

“Previously, these classes were conducted at Librelato’s headquarters, in a separate location,” said Manufacturing Director, Rodrigo Corso. “Now, with a dedicated and properly equipped space for training, we have made it possible to integrate both initiatives in a single place. With this, we have positioned the Librelato Technical Center as our main professional training hub.”

The first class to complete training, completed a welding and painting course which included 80 hours of specialised content including theoretical and practical study.

A state of the art, upgraded and fully integrated global manufacturing centre of trailer systems and On/Off highway systems. Expertly designed and engineered with worldwide accessibility, offering you private label and OEM manufacturing solutions.

Drawing upon decades of expertise spanning Asia, Australia, US, and in Europe, Fuwa stands as a global manufacturing powerhouse, unrivalled as the foremost network of specialists in truck and trailer components across the globe.

JOST has announced it is providing funding to Swiss start-up company, Aitonomi.

The loan will contribute to Aitonomi’s corporate financing, further strengthening its partnership and driving technical growth within the industry, JOST said in a statement. The two companies are already cooperating on the integration of JOST’s automatic comfort coupling system (KKS) and steering and axle systems with Aitonomi’s AutoPilot. The partnership has already developed fully autonomous transport solutions for depots and port terminals.

Founded in 2014, Aitonomi, develops autopilot technology for navigating commercial vehicles. Its products include autonomously driving electric trucks with smart semi-trailers, as well as autonomously driving delivery robots.

GXO Logistics has secured a partnership with Levi Strauss & Co (LS&Co) to manage its operations from a facility in Dorsten, Germany. The 70,000-square-metre Dorsten Distribution Center (DDC) will open in June.

GXO Logistics will manage all logistics services for LS&Co. at the facility, including value-added services to distribute apparel and accessories across wholesale, retail, digital, ecommerce and marketplace channels. The fully-automated site includes shuttle and miniload systems as well as automatic carton opening, closing and labelling. The facility also features sustainably sourced concrete, walls of vegetation, rooftop solar panels and a green roof, as well as access to electric vehicle chargers.

Wielton is working to fill a large, specialised trailer order from transport company, Agromex.

The Polish trailer builder said the order includes 94 MEGA curtainsiders with an intermodal system, as well as 12 extendable container semi-trailers.

The Curtain Master MEGA semi-trailer with an Intermodal system it ideal for mixed transport of large-sized goods and loads requiring tightness, durability and high loading capacity. It has a reinforced frame and detachable air suspension, as well as appropriate reinforcements in the chassis to enable vertical reloading. The rear edge is protected by roller corner bumpers, and

the location of eight ferry handles on the chassis allow it to be transported by ferry.

Transport and logistics provider, cargopartner, will open its first warehouse in the UK.

Located next to one of its existing offices in Basildon, just outside London, the new 4,460 m² facility complements cargo-partner’s existing UK operational offices across Manchester, Bradford and London.

Equipped with dedicated areas for pallet storage, block storage, storage of small parts and picking/packing, it will integrate with cargo-partner’s global network.

The facility, the Austrian based company said, represents a period of rapid growth in the UK and, alongside a presence in Dublin, Ireland, it is well-positioned to support businesses of all sizes across the British Isles with their local and international trade requirements.

Kuehne+Nagel International’s Board of Directors has approved direct reporting from country organisations, with the aim of creating greater efficiency and profitable growth.

By simplifying responsibilities, the new structure will enable Kuehne+Nagel’s business and functional units to sharpen their strategy in line with rapidly changing market developments and implement business decisions quicker.

The historically evolved regional structure will be discontinued and responsibilities integrated into

Kuehne+Nagel’s Group functions. The Cluster and National Managers will report directly into the Management Board.

Rhenus Ireland has opened a new Dublin facility, strategically located close to both the airport and the city’s port.

The more than 11,000 sqm site will provide integration of the company’s portfolio services across sectors, including energy management, life sciences and healthcare, industrial, retail, chemicals, food and beverage and

automotive, the company said. The site features 12 dock levellers, two grade levels doors and a 17-metre clear internal height, supported by a warehouse roof and an in-rack sprinkler system, as well as a dedicated ambient chamber where temperature is mapped and monitored to pharmaceutical standards.

Krone Trusted spare parts brand, which was launched in 2020, is now expanding its range to include spare parts for trucks.

Just like the more than 300 different

branded spare parts, which cover more than 80 per cent of common wear parts on trailers and are up to 50 per cent cheaper than original spare parts, Krone Truck parts are sold via the Krone online shop.

Krone only markets the truck and trailer parts to workshops and fleet operators, not to other dealers. Under the Krone Trusted brand, the commercial vehicle manufacturer offers more than 300 different branded spare parts. The individual parts are sourced directly from well-known European manufacturers who also supply Krone original equipment.

Transport temperatured goods more cost-effectively with the S.KO COOL reefer. The innovative insulation system FERROPLAST® together with the efficient S.CU cooling unit and the smart TrailerConnect® telematics system ensure optimized and reliable transportation. Also available fully electric as S.KOe COOL. More Information: www.cargobull.com

Freight transporter, El Mosca, has added 80 Lecitrailer semi-trailers to its fleet.

The company, based in Murica, Spain, has taken delivery of 50 ‘Elite’ curtainsiders and 30 container platforms, of which 15 are short and 15 are long. The trailers have been specially designed to withstand the wear and tear of regular boat voyages. With more than 85 years in the industry, El Mosca has a fleet 1,700 semi-trailers which are used to haul general cargo, Dangerous Goods (DG), refrigerated goods, containers and heavy machinery haulage.

Italy’s Gruber Logistics is investing in one of the main European hubs for freight traffic.

Based in Verona’s Quadrante Europa Interport, Gruber said it is investing

more than €2 million in the facility which will be equipped with 70 loading docks and expected to welcome up to 100 new collaborators by the end of this year.

The Verona hub will become a fundamental point of reference for Gruber Logistics, helping to optimise logistics operations by offering integrated solutions, the company said.

Yusen Logistics has announced it has acquired Parts Express which specialises in day and night automotive part distribution in western Europe. “We’re excited to officially welcome Parts Express into the Yusen Logistics family,” said Managing Director of Yusen Logistics Benelux and Germany, Bruno Jacques. “This acquisition represents a strategic milestone for us, propelling us into a new phase of expansion and innovation. By

integrating Parts Express into our network, we’re not just expanding our reach, we’re accelerating our growth trajectory and amplifying our capabilities to better serve our customers.”

The acquisition of Parts Express unlocks numerous opportunities for growth and operational excellence, the company said, with a broader range of resources and expertise.

Dachser continues to strengthen its food storage and transport network with the acquisition of Brummer Logistik in Germany and Brummer Logistic Solutions in Austria.

Established in Bavaria, Brummer focuses on cross-border transport, warehousing and contract logistics services for food between Germany, Austria and neighbouring countries. It covers the full range of temperatures, including frozen foods below −18C. Dachser customers will be able to access the Brummer distribution network in southern Germany, Austria and Slovenia. The company primarily serves this network with 350 plus drivers on the payroll and its own fleet of more than 300 refrigerated trucks.

FM Logistic has announced the acquisition of land in Guadalajara, Spain, as part of its strategy to address its continued growth.

The land found in the Ruiseñor Sur Industrial Estate covers an area of 60,151m² and will serve as buildable space for the new FM Logistic warehouse.

The facility will have similar

characteristics to the warehouse that FM Logistic has in Illescas.

The expansion is expected to generate significant growth in FM Logistic’s workforce, both in the warehouse area and in other key departments. In line with its commitment to sustainability, FM Logistic has committed to following the requirement to guarantee energy efficiency and reduction of environmental impact.

For the first time, SAF-Holland presented alongside its most recent

company acquisitions with a joint trade fair stand at the Transpotec Logitec trade fair in Milan.

SAF-Holland, Haldex and Tecma held a combined showcase as part of the same group of companies, highlighting solutions for energy transition within the commercial vehicle sector.

From electrification to integration of new drive technologies, energy transition is radically transforming the commercial vehicle industry, said Managing Director of SAF-Holland Italia, Cristiano Sturaro.

The SAF INTRA castor steering axle, with VSE auxiliary steering, protects

the tyres and saves fuel.

The Smart Steering gives the vehicle a new level of manoeuvrability, benefiting commercial vehicles that are either moving forward or reversing in urban traffic, with reliable steering angle transfer and active steering assistance. Meanwhile, the SAF TRAKr electric axle for trailers with electric units, such as cooling or pumps, lowers fuel consumption and the emissions of the overall vehicle combination. A high voltage generator unit converts the kinetic energy of the trailer into electrical energy. The generated energy is stored in a Li-ion battery.

Spurred by the increasing prevalence of diseases among an aging population, Kuehne+Nagel will provide new transport service options for medical technology devices.

Addressing the industry’s innovation growth when it comes to diseases such as diabetes, hypertension, asthma and heart failure, the new service will form part of its road freight offering in Europe. It is expected to fill a demand for logistics services that don’t have to fulfil GxP requirements, but still meet the safety and quality requirements of highvalue medical and diagnostics devices. It is available in Germany, France, the UK, the Netherlands, Spain and Italy. As part of the service, products are transported with special handling by trained experts in MedTech competence centres. Customers can also count on end-to-end visibility and white glove deliveries including device installation and removal of packing material.

After 26 years at SSAB and 13 years as

President and CEO, Martin Lindqvist has announced he will leave to further his board career.

A recruitment process to find his replacement is expected to start immediately.

Lindqvist has been employed at SSAB since 1998. Under his leadership, SSAB completed the acquisition of Finnish company Rautaruukki. In 2016, work began to transform the steel industry to fossil-free production through HYBRIT, a joint venture between SSAB, LKAB and Vattenfall.

Thermo King has announced a strategic collaboration with an electric trailer manufacturer.

Trailer Dynamics said the partnership, which follows a recent agreement with trailer manufacturer, Krone, will drive innovation and accelerate the transition to zero-emission transportation. Thermo King will provide its industry expertise on electrification and transport refrigeration solutions. The collaboration is expected to enhance

logistics capabilities for trade, industry, and freight forwarders hauling fresh and frozen goods.

Trailer Dynamic’s eTrailer provides supporting propulsion which reduces diesel and CO2 emission when combined with traditional internal combustion tractors. It also extends the driving range when combined with an electric powered tractor, and has the capability to power electrified or traditional trailer refrigeration units.

UPS Healthcare has announced it will invest €55 million into two of its Italian facilities, implementing the latest in logistic technology.

The move adds 100,000 square meters of warehouse space in Passo Corese, near Rome, and Somaglia, near Milan. The Passo Corese warehouse will come with the latest automation technology, including more than 80 robots, capable of climbing 12-metre shelves and autonomously picking and sorting up to 25,000 crates. The Somaglia hub will offer critical temperaturecontrolled environments from as low as -20C.

Röhlig has established a department devoted to overseas Chinese clients, with the aim of building a strong communication bridge.

The China Desk will be responsible for identifying potential Chinese clients and expanding into new business opportunities, further enhancing the company’s influence in the international market.

For the initial phase, Röhlig China will establish the China Desk in Germany,

Hungary and Mexico which are regions that hold room for development in the international market. The following phase will expand the China Desk to Southeast Asia, Australia and India.

DHL Express has announced the launch of a Hong Kong West Service Center (KWC).

Following an investment of almost $200 million (USD), the new fully automated, eco-friendly facility aims to assist with the company’s longterm growth plan and infrastructural investments in Hong Kong.

Boasting an increase of more than 90 percent in site area, the new facility is now more efficient with capacity to address the increasing demand for international express services within the city and internationally. Featuring a fully automated sorting system, the new facility can handle more than 50,000 shipments a day and will double its sorting capacity.

DP World has partnered with Malaysia’s Sabah Ports to manage the Sapangar Bay Container Port (SBCP) in East Malaysia.

The partnership is expected to more than double the SBCP’s handling capacity and establish Sabah as a trade hub for economies in the east ASEAN growth area.

“With its strategic location and abundance of natural resources, Sabah is well-positioned to reap the immense growth opportunities in the BIMP-EAGA region and beyond,” said DP World group chairman and CEO, Sultan Ahmed bin Sulayem. Sabah Ports is a wholly owned subsidiary of Malaysian public listed investment holding company Suria Capital Holdings.

DP World has announced a $50 million (USD) investment to develop a new logistics centre in Busan New Port, South Korea.

The move is expected to strengthen the port’s position as a logistics hub for Northeast Asia, and reinforce the global standing of the wider Busan-Jinhae Free Economic Zone (BJFEZ) in business and logistics.

Construction of the facility on the 75,000-sqm piece of land is set to commence at the end of 2024, with operations expected to start by the second quarter of 2026. The centre will have capacity to process nearly 80,000 TEUs of cargo per year by 2028 and offer comprehensive value-added logistics services such as assembly, processing and packaging to local and regional customers.

China-based OEM, CIMC Vehicle, has delivered outstanding performance in its domestic and international operations. According to the latest annual results for the 12 months ended 31 December 2023, the semi-trailer and special vehicle manufacturer achieved a revenue of 25,087 million RMB (approx. 3.2 billion euros) which represented a year-on-year increase of 6.21 per cent; a net profit of 2,456 million RMB (approx. 312.9 thousand euros), a significant boost of 119.66 per cent; and an increase in its gross profit margin to 18.96 per cent which was an improvement of 5.68 per cent.

The net profit attributable to the company’s shareholders after deducting non-recurring profit or loss reached a historic high of 1,533 million RMB

(approx. 195.3 thousand euros) which represents substantial growth of 69.68 per cent.

DP World has acquired Savan Logistics which operates the Savannakhet dry port in Laos.

Located on the 1,450km-long EastWest Economic Corridor – linking Laos, Cambodia, Myanmar, Thailand and Vietnam – the dry port is used by key regional logistics companies to connect various supply chains.

The 140,456-square-metre area also boasts 23,000 square metres of warehousing facilities, including a bonded area.

In addition to dry port and warehousing services, DP World will also manage cross-border transport, freight forwarding and integrated logistics solutions.

According to the Asian Development Bank, Laos’ economy is expected to grow by about 4 per cent in 2024. The country’s chairmanship of the

ASEAN summit will also provide Laos with additional international exposure, promoting investment and spurring cross-border cooperation.

Hellmann’s medical logistics arm has opened a new warehouse in Dubai. At the facility, Hellmann Calipar Healthcare Logistics, a joint venture with Indian-based Parekh Integrated Services, will provide a dedicated distribution centre for global medical device company, Boston Scientific. The new facility will serve distributors across the EMEA region, as well as provide localised services. Positioned in Dubai South, the space is 5400 square metres, with capacity for 1900 pallets.

Logistics company, DP World, has joined forces with an electric and autonomous freight mobility company, to electrify inter-terminal container flows at Dubai’s Jebel Ali Port. Einride will partner with DP World to

support approximately 1,600 container movements a day through a fleet of 100 connected electric trucks. At full operational capacity, the initiative is expected to save up to 14,600 tonnes of carbon dioxide and 158 tonnes of nitrogen oxides annually.

Jebel Ali Port is the tenth busiest port in the world, and the collaboration will mark the largest deployment of electric, autonomous freight mobility in the Middle East.

The partnership is integral to Einride’s broader initiative with the UAE Government, fast-tracking the region towards sustainable shipping, the company said in a statement.

Truck and trailer manufacturer, Serco, is currently running at 67 per cent solar power within its factories and offices.

The South African company has installed solar at its three main production facilities. Durban was first, followed by Johannesburg and recently Cape Town. Serco CEO, Clinton Holcroft said environmental sustainability was a priority for his company and hopes to increase its figure to 75 per cent solar.

The initiatives are part of Serco’s drive to reduce its impact on the environment and go hand-in- hand with other “green developments” including recycling of paper and plastic and the use of

rainwater in its wash bays.

Freight and logistics service provider, DB Schenker, has appointed Rob Connoley as head of New Zealand’s operations. Based in Auckland, Connoley has a freight forwarding career that has spanned 19 years and has been responsible for national operations including ocean freight, air freight and domestic cross-dock distribution. Connoley said there is huge potential in the New Zealand freight and logistics market, and he is ready to meaningfully contribute to DB Schenker’s operations in New Zealand.

TRANSPORTATION WASN’T NECESSARILY ON ED BOOTH’S RADAR WHEN HE WAS APPROACHED BY TIGER TRAILERS. WITH A LONG CAREER IN MANUFACTURING, TRAILERS WERE A COMPLETELY NEW FIELD, BUT THE PANDEMIC DEMONSTRATED TO HIM JUST HOW IMPORTANT THE INDUSTRY WAS, AND HOW HE COULD LEAVE A MARK.

Its feline branding is certainly recognisable on UK roads, but then so again are the clients the company caters to.

From ASDA and British Gypsum, to Culina and Warburtons, Tiger Trailers and its vast range of semitrailers and rigid truck bodies are in hot demand. e secrets to its success are varied. Pushing the boundaries on design and innovation have always underpinned the rm’s incremental success, but a growing array of community, charity and inclusivity involvements, now make its name stand out further.

e check list of promises attached to the company’s o ering is extensive, but for Managing Director, Ed Booth, it’s not up for negotiation.

“Our aim is to provide premium trailers, on time, to a tailored speci cation,” he said. “ ey need to be e cient and consider the environment. Everything from cargo capacity and loading speed, to journey reduction and lightweight material, needs to be front of mind.”

“We’re also keenly focussed on being a manufacturer that gives back to its community and makes society a better place,” he added.

Changing its stripes

It was nearing the end of the Covid lockdown when Booth met with the Tiger Trailers founders, John and Steven Cartwright. e brothers were well known in the industry, having worked for 30 years in the family business, vehicle body and trailer manufacturer, Cartwright, until going out on their own with Tiger Trailers.

“It was clear Tiger had put in place a very strong business model with a great product range, and a fantastic production and o ce facility,” Booth said. “A lot of the building blocks were already in place to take Tiger to the next level.”

Originally from Barrow-in-Furness, a port town in the north-west of England, today Booth lives in Gresford, a village in North Wales. He is a quali ed chartered accountant with a degree in business management, and almost his entire career has been in the area of manufacturing, from bathrooms and pharmaceuticals to agricultural equipment.

He joined Tiger in the summer of 2021 as the Finance Director and was appointed Managing Director in January 2022, with the founders keen to shi their focus to board advisory roles.

John and Steven Cartwright established Tiger Trailers together with Darren Holland (Sales Director) and other senior team members from Cartwright in April 2014, when they created a vision of the most advanced trailer and bodywork manufacturing facility in the UK.

Tiger’s den

Today, Tiger Trailers, which is located in Cheshire, has 275 employees and an annual turnover of more than €100 million, supplying blue chip companies in the parcel, retail and logistics sectors. To date it has delivered more than 15,000 trailers and bodies into service, making it one of the UK’s leading trailer and bodywork manufacturers.

Tiger produces all types of semi-trailer, from curtainsiders to box vans in single and double deck heights, and in lengths spanning short ‘urban’ trailers, standard and longer semi-trailer (LST) iterations. Over the last decade it has always manufactured a sizeable volume of rigid bodywork solutions from 3.5-tonne to 32-tonne, including ‘swap-body’ demount and drawbar products. It also makes atbeds and other specialist trailers.

In 2020, Tiger launched its Siberian range of temperature-controlled trailers and rigids, Tiger Trailers - all bases, covered.

which now account for a large proportion of its enquiries and builds, with more than 150 trailers having recently joined the eet of a major UK dairy. Meanwhile, an exciting double deck reefer will be unveiled on the OEM’s stand at the TCS&D Cold Chain Hub exhibition in Birmingham in October.

Its biggest market is in the UK and Ireland where 90 per cent of the trailers end up, working with large parcel carriers, supermarkets and logistics providers.

One of the biggest steps the company took was establishing its factory and o ce facility in 2019, following rapid business growth. e €24.9 million, bespoke facility provided the scope for a doubling of production capacity and 200 new jobs. Laid out over a 20-acre site, it comprised more than 51,000 square metres of state-of-the-art chassis fabrication, body assembly, as well as paint and nal nish facilities. O ces included a 3D engineering suite, a specialist training facility and a full height showroom.

e company has begun putting an emphasis on training, including various initiatives from its HR Director, HR team and its Production, Onborading & Training Manager, which have resulted in retention, skills and morale being at their peak.

“I’m very proud of the working spirit at Tiger Trailers, which is one of collaboration at all levels, free from hierarchy and too much red tape,” Booth said.

Hear them roar

With the directors working on future strategy plans, Booth got to work with the daily running of the company and slid into the culture comfortably.

“Although you can never really know a culture until you start, I just got the feeling it would be a good t for Tiger and myself,” he recalled.

If anything, the culture was a positive one, likely buoyed by a program of growth and improvement that saw a series of successful achievements which began with the move to its new facility. From there, Tiger earned the distinction of being the rst UK manufacturer to design and o er a Double Deck trailer with a moving deck and 52-pallet capacity.

is was followed by a number of other engineering achievements, said Booth, including the development of its Lightweight Clearspan Curtainsider, a pillar-less roof design for

obstruction-free side loading.

Engineers also developed a load securing system called Captive Rave, recently enhanced for 2024 onwards, which replaces the traditional ‘hook’ strap approach with a roof-mounted system featuring ratchets stored individually inside the rear doors, greatly reducing the potential for injury.

Tiger’s milk-speci cation reefer has a tare weight of just 9,500kg, including the tail-li , and has been designed to mitigate bottled milk, transported in small trolleys, from spilling during lateral movement, as this can have a corrosive e ect on steel.

e manufacturer’s latest moving deck double deck box vans, aimed at the pallet network, o er a 44-pallet payload, while the rm’s LST ratchet decks, which incorporate up to four fork-li -operated moving decks, equip operators with a cargo capacity of up to 56 pallets.

“ e company’s ethos is to provide customers with innovative design solutions, high build quality and a collaborative, personal service,” Booth said, adding that the entire design and build process can include visits to the clients’ operations, collaborative consultations which include viewing 3D models, as well as the opportunity for mid-contract visits.

Tiger is also the only UK trailer builder to o er its own in-house nance division, Tiger Finance, providing tailored operating leases for eet additions from a few trailers to several hundred, backed by maintenance packages and other services.

Meanwhile, Tiger Parts o ers thousands of components via a new website, and Tiger Rentals augments operators’ eets with short to long term hire.

e company isn’t all business, however. In fact, Booth points out that one of the biggest changes he’s seen in the company since his arrival has been by way of its corporate social responsibility, demonstrated through community and charity activities.

Among his favourite initiative is the Tiger Safety Team, which was launched in 2021 to teach heavy goods vehicle (HGV) safety to school children through its ‘Stop, Look, Be Seen’ program. More than 1,200 young minds have received this potentially life-saving information thanks to having a truck visit their school. In fact, a growing number of Tiger’s customers are showing an interest in partnering with the manufacturer to deliver this important program nationwide. Tiger is also a corporate member of Women in Transport, with more than a dozen of its people having signed up,

Having garnered a reputation for bespoke problem solving, Tiger Trailers has a collection of unique designs under its belt. Here are a few examples:

• A leading UK hotel laundry hire and services provider, Johnsons Hotel Linen, received y-two 18-tonne Tiger rigids and reported that a er six months, during their busiest period, the vehicles showed no signs of wear and tear, re ecting the overall nish and build quality. Johnsons also received a trio of xed double deck trailers from Tiger, designed for the transport of 74 cages, with the internal neck li described as a ‘revelation’.

• ASDA, a top-four supermarket in the UK, has welcomed 167 Tiger moving deck double decks to its eet for mainland and Northern Ireland ferry-use operations, each with a ferry trestle support built into the neck area for the trailers’ RoRo operations. e vehicles incorporate a three-quarter length moving deck for versatility, powered by the manufacturer’s in-house, four-ram hydraulic system.

• BOC UK & Ireland required ten specialist articulated trailers, plus thirty-two ‘pintle’ rigids on DAF Trucks chassis, designed for the transportation of gas bottles. Tiger took BOC’s typical design, listened to feedback from their people, and from their 3PL, Suttons Group, and modi ed the bespoke rigids to be modular, with a focus on longevity.

including co-founder John Cartwright, as the company seeks to promote manufacturing and logistics careers to women.

It also works with e Prince’s Trust and various charities under the banner of Cheshire Community Foundation, providing work experience to underprivileged young people, and raising funds that allow them to experience things that otherwise wouldn’t be possible. Additionally, Tiger supports ‘Veterans Into Logistics’ as a bronze sponsor, helping ex-military members retrain for ful lling careers in transport.

Its environmental investments have also increased over the past ve years, with initiatives such as doubling the warehouse roof’s solar panel array to 640kW, as well as focussing on sourcing renewable, recyclable or ethically sourced materials. It also has a scheme called ‘More Trees’ through which a tree is planted for each product sold.

For Booth, he enjoys the variety the job o ers him, explaining that as an entrepreneurial company, ideas, whether to enhance capacity or develop a new product, are always at the forefront.

Into the wild

ere have been challenges, but as Booth points out, most companies in the industry have felt the impact of the big issues such as Covid, war in the Ukraine, unpredictable weather, driver shortages as well as the challenge of becoming environmentally sustainable without a ecting pricing.

“We have been fortunate in that our team has been able to mitigate,” he said.

A er ten years of manufacturing, brand awareness and orders for all types of Tiger’s ambient trailers and rigids, are as strong as ever, Booth said, so over the next couple of years the company will seek to increase its share in the temperature-controlled market as well as look to foreign shores.

“We have recently built and delivered our rst semi-trailers for the American market, giving US operators a taste of the bene ts of double deck curtainsiders,” he said. “We already export trailers to the island of Ireland plus a few European countries, so this is also on our radar.”

Booth and his team will continue to centre their approach around having skilled sta on board, ensuring they have the tools, processes and structure to be successful.

“When people are happy in their work and feel supported, they o en overperform,” he said. “We have a lot of hard work ahead of us, but I’m convinced this will strengthen the platform for future business growth.”

As for Booth personally, the transport industry has been a good t, and he sees a bright future.

“Highlighted during the pandemic, the road transport industry plays a vital role, and all items that end up in people’s homes, business premises and society in general will have travelled by truck at some stage,” he said. “I’m proud to work for a key supplier to the industry.”

www.tigertrailers.co.uk

In what could be described as a candid speech at this year’s Advanced Clean Transportation expo in Las Vegas, JB Hunt Transport Services President, Shelley Simpson, told attendees that it is estimated the US would have to increase its electricity production by 40 per cent to charge all registered vehicles in the country.

“Who’s willing to give their electricity up to power their home, for us to charge our entire eet?” she asked the audience. “Imagine what it would take to power all the electric vehicles in the US, in addition to all the passenger vehicles.”

at’s not to say Simpson was all doom and gloom. In fact, quite the opposite. She reiterated that clean energy is a positive movement that the industry needs, but in order for it to reach its overarching goal of reducing transportation-related emissions, something had to change.

“We have pressures that we’re all facing, and those pressures are a ecting our businesses, our decisions, and the future of our industry,” she said. “ e reason that we’re feeling this tension is because there’s a misalignment of sustainable technology, policies to regulate

emissions, and an economic case for incorporating emerging technology.”

According to a recent US study, it is the economic case that Simpson points to that will be the biggest hurdle.

e report, Forecasting a Realistic Electricity In astructure Buildout for Medium- & Heavy-Duty Battery Electric Vehicles, is from Roland Berger and released by the Clean Freight Coalition (CFC). e CFC is an alliance of transportation stakeholders committed to clean energy within America’s commercial vehicle industry. It has consistently held the position that policymakers must address the

cost concerns and infrastructure hurdles to make an electri ed supply chain function smoothly.

According to the report, the charging infrastructure required to electrify all medium and heavy-duty vehicles and charge point operators in the US, is expected to cost $620 billion USD

In addition to this, onsite charging infrastructure for the medium duty segment is forecast to cost $496 billion USD, however heavy-duty vehicles call for more signi cant infrastructure – an average investment of $145,000 USD as opposed to $54,000 USD per medium duty vehicle.

A further $69 billion USD is needed for reliable

A NEW REPORT DETAILING THE BIGGEST CHALLENGES THE US WILL FACE WHEN TRANSITIONING ITS HEAVY VEHICLE FLEETS TO ZERO EMISSIONS HAS BEEN RELEASED AT THE SAME TIME TRANSPORT INDUSTRY LEADERS ARE WEIGHING-IN. IT SEEMS TO ALL COME DOWN TO DOLLARS.

on-route charging for high mileage vehicles. Meanwhile, long haul vehicles would need a dense highway charging network at a cost of $57 billion USD, although this development would be constrained by the capabilities of the transmission grid infrastructure.

To support local charging demand from medium and heavy-duty electric vehicles, the utilities would need the equivalent spend of investments and upgrades previously made over the past 15 years – $370 billion USD.

Much of the pressure eets are feeling comes, in part, from a combination of rigid deadlines at both the state and federal levels in the form of the California Air Resources Board’s Advanced Clean Fleet rule and U.S. Environmental Protection Agency’s latest emission standards for heavy-duty vehicles.

In response, the report highlights the need for greater cross-industry collaboration in regards to electri cation.

It recommends a phased electri cation approach with an initial focus on the medium duty

segment, which would then be followed by technology and infrastructure improvements for heavy duty and long haul.

Another consideration for industry is to be open to alternative decarbonisation routes especially when investment in electri cation in some instances may be prohibitive.

Other ideas include exploration of operational and eet management strategies, potential for freight rate increases due to lack of government and regulatory support and potential for bottlenecks in unmanaged charging demand.

e report found that while medium duty vehicles will face fewer roadblocks, economic and operational constraints make electri cation very challenging for the heavy-duty segment. Furthermore, the study outlined the signi cant improvements in battery range and charging infrastructure capabilities that would be needed to support a path for the electri cation of long-haul vehicles.

Roland Berger Senior Partner, Dr Wilfried Aulbur, said eets will need to look at how they operate and adjust, industry and government need to cooperate and there needs to be an ‘openness’ to alternative technology paths to decarbonising the heavy-duty segment.

“It also is clear that an industry with a yearly turnover of about $800 billion USD and a pro t margin around 5.0 per cent cannot invest $620 billion USD without nancial support or a signi cant increase in freight rates,” he said.

CFC Executive Director, Jim Mullen, said the report thoroughly examines the issues surrounding the infrastructure buildout necessary to electrify commercial vehicles.

“Also, it clearly shows how the heavy-duty vehicle industry’s needs are vastly di erent not just from other sectors of our economy, but from each other.”

American Trucking Associations President and CEO, Chris Spear, said the industry is facing an unfunded $1 trillion USD mandate that carries enormous consequences for the American consumer.

“You don’t overcome obstacles by ignoring them, which this study lays out the high investment costs required to electrify the commercial vehicle industry,” he said.

“Policymakers should take note that pursuing technology-neutral solutions can deliver operational savings and emissions reductions at a fraction of the cost. A real-world understanding of the path to our shared goal of zero emissions is needed, but unrealistic timelines and expectations will break the bank.”

American Truck Dealers President, Laura Perrotta, said dealers are faced with inadequate charging infrastructure and delays, despite investments of nearly one billion in this decade to sell and service electric vehicles.

“ is study puts into perspective the enormous national commercial charging needs and related costs required to meet the Administration’s regulatory goals,” she said.

NATSO President and CEO, Lisa Mullings, said the report demonstrates that policy must not depend on a single technology to reduce carbon emissions from commercial trucks.

“Investing in the necessary charging stations to fuel commercial trucks is expected to require $620 billion USD from truck stops, eets and ultimately consumers,” she said.

“To raise that kind of capital, we need to overcome the many challenges impeding businesses’ ability to recoup these vast investments. is report underscores the critical need for policymakers to incentivise the existing low-carbon fuelling options available today, including renewable diesel and biodiesel, while the industry implements longerterm options.”

National Tank Truck Carriers, President and CEO Ryan Streblow, said the report reinforces the tank

truck industry’s concerns on the current aggressive and unrealistic regulatory approach to zero emissions.

“We will continue to face major electri cation concerns in the tank truck industry – excess weight, limited range, and safety,” he said. “ e tank truck industry is our nation’s insurance policy when natural disasters strike. Before ipping a switch, we need to ensure there is a scalable and a ordable energy source in place to allow the tank truck industry to serve those when they need it the most. e

Roland Berger data is a clear indication our legislators and regulators need to work with the trucking industry to e ectively develop and deploy a sustainable long-term solution.”

is point was one Simpson also focused on in her address, demonstrating that everyone getting on the same page is crucial.

“When state requirements and federal requirements do not align, and they’re not consistent, it does create additional issues with interstate operations and commerce, and the innovation required to meet these regulatory requirements,” she said.

For its part, JB Hunt recently announced an ambitious goal to reduce carbon emission intensity by 32 per cent by the year 2034, focusing on alternative power equipment, biogenic fuel and improved fuel economy.

One of the biggest challenges related to this move forward is the operational ine ciencies associated with battery-electric trucks, according to Simpson, which includes reduced payload capabilities, range, and charging time when compared to operating a diesel truck.

ese ine ciencies would result in the necessity for the JB Hunt team to add more zero-emission vehicles to perform the same amount of work that’s currently being performed with their diesel trucks.

“It’s not economically viable to incorporate zero-emission vehicles into our eet at scale right now, but it is important that we begin to test and the pilot these technologies,” said Simpson, highlighting another concern — an inadequate charging infrastructure for commercial vehicles and the necessary power supply to support it.

Speaking at the same event, Ryder System CEO Robert Sanchez concurred, stating that in order to place a bigger bet on electric vehicles, there needs to be a catalyst that makes the technology more economically and operationally feasible for the commercial trucking industry.

During his keynote address, he said the only way commercial electric vehicles could possibly work is with a large-scale battery technology breakthrough, using the cell phone industry evolution from 1984, as an example.

“We need an in ection point that’s a credible technology breakthrough, that serves as a catalyst for mass adoption of new technology,” said Sanchez. “Like the cell phone, we need electric vehicle costs to come down. We need smaller, lighter, and more powerful battery technology to improve the range and capacity. And like cellular networks, we need a nationwide infrastructure. We need the fastest applicable charges available where professional drivers can conveniently charge their trucks get a bite to eat and rest at the same time.”

www.globaltrailermag.com

more information see: www.koegel.com/

www.koegel.com

MANUFACTURER, GORICA, MUST MAKE SURE ITS PRODUCTS KEEP UP WITH THE PACE. ITS REFRIGERATED TRAILERS ARE SHOWING EXACTLY HOW THAT IS DONE.

The land of oil and gas is shi ing, adding a secondary economy that is service based, and United Arab Emirates’ GORICA Group is well aware of how that translates into a market trend.

e service sector, and its sub sectors, is gaining importance, and generating demand for quality, perishable products that are being transported and stored safely. In turn, cold chain players are putting increased importance in this, especially within a region that can regularly reach temperatures over 50C.

“We’ve seen quite drastic changes in last 20 years,” said GORICA Group’s General Manager of Sales and Marketing, Domen Bockor. “Back in the late nineties, a lot of fresh food was still transported in cargo bodies, with seafood and meat buckets covered by ice. In the past few years there is much greater awareness of the importance in having adequate quality products.”

Frigo Division

Reefers and refrigerated transport products are part of GORICA’s top three solutions in terms of sales volume and market penetration. From both a development and business development standpoint, they get adequate attention and focus, Bockor said.

e GORICA frigo division was founded in 2010, when the company bought its rst

machinery line for frigo body and frigo semitrailer manufacturing. e purchase of the Canon Polyurethane Injection Machine with a Manni Hydraulic Press, as well as the metal (PPGI) decoiling line, marked the beginning of this era.

e purchase of GORICA’s refrigerated division went through rapid expansion in 2013 when it acquired a Krone GRP Reefer factory.

e company’s fourth factory was nalised at the end of 2015, which now specialises in the manufacturing of refrigerated semi-trailers, dry box semi-trailers, refrigerated bodies and dry cargo bodies. ese products complement the existing GORICA Industries products by adding to the full range of products which includes all types of trailers.

e GORICA frigo factory is unique to the Middle East, as it is one of the few trailer and body factories that specialises in manufacturing products that are made of Glass Fibre Reinforced Polymer of Plastic (GRP), alongside the typical Polyester-coated Galvanized Steel (PPGI).

GORICA’s range of GRP skin insulated refrigerated semi-trailers starts at standard 12.4 metre and 13.6 metre semi-trailers, but the most popular is generally 15 metres. GORICA also o ers a range of refrigerated truck mounted bodies from four metres up to eight metres, o ered with a PPGI (metal skin) option if preferred.

ese frigo units are without joints, which helps eliminate any possibility of thermal bridges. is same range is also diversi ed into di erent application trailers. For example, GORICA can cater to medical/vaccine transportation requirements, or

di erent applications such as fresh and frozen meat transportation, where the entire trailer is equipped with roof hanging system for meat carcasses.

“In recent years we’ve produced more and more special refrigerated semi-trailers,” said Bockor. “Many of these are designed for automatic loading and unloading.”

e GRP material used in the refrigerated vehicles is a composite consisting of glass bres embedded in a synthetic polyester resin.

Middle East clients encounter different environmental conditions than their European counterparts, so GORICA encourages them to consider GRP/ berglass as best option for refrigerated semi-trailers panels. Here are a few reasons why:

Fibre-reinforced composites o er excellent strengthto-weight ratios, exceeding those of other materials, making products easy to handle and install. is can save money and time.

By combining resins and reinforcements, the strength of composite materials can be customised to meet any requirement. Composites exhibit high strengthto-weight, sheer strength and impact resistance.

Composites do not rust or corrode. Products made from composites provide long-term resistance to severe chemical and temperature environments. Properly designed, composites have a long service life and minimum maintenance.

Many of the rst GRP enclosures put in place more than 25 years ago have not yet come to the end of their lives. Composites hold up well against fatigue and are resistant to environmental factors such as U.V. damage, temperature uctuations, moisture and sand blasting e ect.

Composites pack a powerful one-two punch with their ability to be melded into complex shapes with precise properties. At a relatively low cost, composites are formed when the resin cures – or solidi es – during production, easily taking on many shapes.

GORICA’s refrigerated temperature-controlled trailers and bodies are part of its perishable logistics program. Together with stainless steel trailers for transportation of fresh milk, aluminium animal feed bulkers, aluminium grain hoppers, aluminium our bulkers and many more, they create a complete o ering of perishable logistics solutions.

GORICA’s target partners come from industries including food producers and processors, mills, chain markets, seafood distribution, specialised logistics companies and institutional clients such as the Red Cross and UNICEF in the Middle East and Africa.

www.goricagroup.com

AS A BUSINESS, IT’S A NICE FEELING TO KNOW THAT NONE OF YOUR DELIVERIES TO CUSTOMERS ARE IMPACTING THE ENVIRONMENT WITH EMISSIONS. A COMBINED EFFORT FROM TWO MAJOR TRANSPORT PLAYERS HAS GIVEN DUTCH COMPANY, DISTRIFRESH, THIS EXACT OPPORTUNITY.

The energy recovery technology is sophisticated, but it o ers a simple outcome – 100 per cent electric customer deliveries.

Cold-chain logistics company, Distrifresh, selected the combined services and solutions of TIP Group and Carrier Transicold. e three businesses worked together to overcome challenges and hit some impressive sustainability goals.

“Distrifresh has embraced the challenge to revolutionise our operations, setting ambitious goals to reduce our direct fuel consumption by 40 per cent and transition to 100 per cent electric reefers for deliveries to our clients by 2024,” said Distrifresh Transport Manager, Koen Relou. “ is strategic shi not only responds to rising fuel costs and our customers’ demands but also aligns with our commitment to sustainability.”

Distrifresh is a subsidiary of Vion Food Group, which has its own targets of a 42 per cent reduction in scopes 1, 2 and 3 non-FLAG (forest, land and agriculture) emissions and a 30.3 per cent reduction in scope 3 FLAG emissions, by 2030.

Since the second half of 2023, Distrifresh has been using 15 Vector eCool e-reefers, supplied by TIP Group and Carrier Transicold. e e-reefers have been achieving a reduction of 16.9 tonnes in CO2 emissions, as reported by the electri cation dashboard in Lynx Fleet, Carrier Transicold’s connected cold chain platform.

Although Distrifresh has employed e-reefers since 2019, partnering with TIP was a strategic move, the company said.

“We have collaborated closely with TIP for four years, building a strong and trusting relationship, so when they o ered a comprehensive package, the decision to go with their solution was naturally straightforward,” Relou said. “We used our own knowledge and data for 75 per cent of the business case calculations. TIP was instrumental in providing the remaining insights needed, leveraging their extensive experience and wealth of data to con rm our future direction and achieve our target of 100 per cent electric deliveries to customers.”

at’s not to say there aren’t still a few challenges, according to Relou, with one of the biggest being securing drivers and making sure they are properly trained in carrying sensitive cargo.

“If the cooling unit’s charge drops to 20 per cent, the driver needs to know it’s time to plug in and recharge,” he said. “ e experts from Carrier Transicold trained our onsite team who then passed on that knowledge to the drivers, showing them how to operate our

equipment and what to watch out for.”

Now that Distrifresh has achieved its 100 per cent electric delivery goal, it is now looking at what can be done with its intra-company logistics.

“With fuel-powered engines on the decline, especially with upcoming regulations against emissions, electric solutions are set to take the lead,” Relou said. “We anticipate improvements in technology and a decrease in costs, which will reshape our business case positively. is evolution, alongside hopefully improved charging infrastructure in the Netherlands, will undoubtedly pave the way for broader adoption of electric transport within our company.”

www.tip-group.com

Strenx® performance steel can meet the challenges facing the transport industry, which is constantly looking for ways to increase payload and improve fuel efficiency. Strenx® is a high-strength structural steel with extremely consistent properties, making it perfect for designing trailer chassis and other transportation products that are stronger, lighter and safer. That’s why we call it performance steel.

The Irish Sea’s notoriously rough, unpredictable waves have tested the skills of even the most advanced seafarers over the years.

Unaccompanied trailers making the crossing can, on occasion, be subject to some damage.

If it does occur, for cold-chain storage and transport specialists McCulla Ireland, this is just one of the bene ts to having Schmitz Cargobull’s refrigerated semi-trailers. is is because the trailer builder’s in-house technicians can simply replace the a ected panels, rather than the whole side of the trailer, thanks to a segmented design.

“We had an issue a few years back and they xed it very quickly,” said the Operations Director at McCulla Ireland, Brian Beattie. “ e customer service they provide is excellent, and the level of attention you receive from their team throughout the process is impressive. It really is a partnership.” is is just one reason why the company has just bolstered its eet with the addition of 33 new S.KO COOL refrigerated semi-trailers, cementing a partnership between the two businesses that is now into its second decade.

“We took our rst two semi-trailers from Schmitz Cargobull in 2008, having been exclusively with another manufacturer before,” Beattie said. “ e trailers we’ve had in the years since have all proved to be robust products with great longevity and build quality.”

Family-owned McCulla Ireland is celebrating 55-years of trading this year and has built its business by cultivating long-term relationships with clients, it said.

Headquartered in Lisburn, near Belfast, the company operates three cold-stores across the Island, with a combined capacity to house 15,000 pallets. It also provides value-added services, including blast freezing and tempering.

Supplied by Kevin Wynd, Regional Sales Manager at Schmitz Cargobull, the latest order comprises single and multi-temperature trailers, and a speci cation honed over many years to meet McCulla Ireland’s exact requirements.

All its latest semi-trailers feature Schmitz Cargobull’s TrailerConnect telematics system

which lets eet managers remotely monitor and control the trailer during multimodal transport involving rail and ferry transport or intermediate stops in transhipment transport.

e S.KO COOL is built on a galvanised Modulos bolted chassis which has a repairfriendly design, based on bolted, hot galvanised technology. It has been designed for both strength and durability, and comes with a 10-year warranty against rust-through on all galvanised parts, but is also easily modi ed at any stage.

e partnership will begin a new chapter later this year with the arrival of a new ‘pharmaceutical speci cation’ S.KO trailer, which features advanced load security.

It will be tted with a double deck loading beam system, which will allow 66 pallets to be transported per load to service the requirements of a speci c McCulla Ireland customer.

www.schmitzcargobull.com

www.flatlaminates.com

We stand right in the middle of every project realization. Close to you since 1962

HIGH QUALITY GRP FOR COMMERCIAL VEHICLES.

LI, CEO

PRESIDENT

In the rst quarter of 2024, the Chinese GDP grew by 5.3 per cent year-on-year, laying a solid foundation for achieving the annual growth target of about 5.0 per cent. e macroeconomic situation showed accelerated industrial production, robust growth in the service sector, a recovery in the consumer market, optimisation of the trade structure and a stable employment situation.

So, as the Chinese economy continues to steadily improve, what does this mean for the trailer market and CIMC Vehicles.

Q: With the Chinese economy making such bright start in 2024, is China’s commercial vehicle market following suit with the same positive results?

A: Yes, it achieved a good performance in the rst quarter of 2024, with market recovery and accelerated growth in the export market. e cumulative production and sales gures have reached 997,000 and 1,033,000 units, respectively, representing increases of 5.1 per cent and 10.1 per cent year-on-year. Among them, domestic sales accounted for 819,000 units, up 6.3 per cent year-on-year. While exports stood at 214,000 units, a signi cant year-on-year growth of 27.5 per cent.

Q: How does this impact CIMC Vehicles?

A: CIMC Vehicles has achieved remarkable performance in recent years, maintaining the top global ranking in the semi-trailer manufacturing industry for 11 consecutive years. e operating pro t margin has reached to 13 per cent, and overseas business revenue has contributed over 50 per cent in 2023.

We have fully launched our third venture, moving to intercontinental operation. It is marked by the ‘Star-chained Manufacturing Network’, focusing on the structural reform of semi-trailer production. Its essence is to enhance the e ciency of intercontinental operation. e venture will be divided into three phases. e rst is ‘Star-chained Manufacturing Network’ from 2023 to 2025, which aims to fully implement a sophisticated manufacturing system, achieving a leap in semi-trailer business in the domestic circulation with signi cant

growth in both revenue and production e ciency. e second stage, from 2025 to 2027, will see the ‘Champion Tanker Business Group’ enter a stage of high-quality development, with the integrated new energy tractor and trailer forming an incremental business.

e third phase, from 2028 to 2030, will integrate new energy tractor and trailer into international circulation.

Looking ahead, CIMC Vehicles will continue to consolidate its global operation strategy of ‘Intercontinental Operation, Local Manufacturing’. e North American business will continue to promote the transformation and upgrading of its corporate governance structure, build a new development paradigm of ‘new quality productivity’, enhance resilience in development, and achieve a robust performance of its operations. The European business will consolidate its high-quality development and actively seek breakthrough opportunities. Meanwhile, we will continue to focus on incremental opportunities in emerging markets.

Q: Can you explain what the Star-chained Manufacturing Network and the Star-chained Plan are?

A: A year ago, we launched the ‘Star-chained Manufacturing Network’, focusing on integrating resources to establish a new type of semi-trailer production organisation which would encompass key value chains, including procurement, production, circulation and distribution.

e priority of the company in 2024 will be the implementation of the Star-chained Manufacturing Network, which will strictly follow up on the achievements and insights so far, ensuring that its strategy rmly shi s from a defensive to an o ensive mindset, so that we can realise our goals with a exible mindset and means, and build a new engine of growth for the third venture.

Q: What does the ‘old for new’ and ‘new quality productivity’ government message mean, and how this impacts the trailer industry.

A: In April 2024, the Ministry of Commerce of China, along with 13 other departments, issued a notice for the ‘Promotion of the Old-for-New Consumer Goods Initiative’.

e general requirements of the policy are to insist on deepening supply-side reform and expand demand. e policy is designed to use the improvement of standards in technology, energy consumption and emissions as a guide, provide incentives through policy measures to gradually establish a method that makes it easier to get rid of the old and more willing to replace with the new.

e policy aims to signi cantly expand domestic demand and promote a shi from post-pandemic recovery, to sustained expansion of consumption.

New quality productivity arises from technological breakthroughs, innovative production and the upgrading of industries.

‘Accelerating the development of new quality productivity’ has been included in this year’s government work report and is listed as one of the top ten tasks for the year 2024.

New productive forces encompass three key elements: new momentum, new models, and new industries. ese are not solely driven by technology but are a combination of technology and business evolution. With Chinese macroeconomy development becoming a new normal, the semitrailer industry is being forced to accept new development concepts and begin to build a new development pattern.

Using the de nition and connotation of new quality productivity for the deduction, we nd that

the semi-trailer industry can build a new development pattern through innovative design and production technology, organisational structure reform of semi-trailer companies and a reallocation of the industry’s surplus capacity resources under dual circulation. is new development pattern can create a higher level of production, better customer experience and sustainable pro tability, which help the entire industry fundamentally escape the situation of involution. My above opinion was also published in the McKinsey China Automotive CEO Digest.

Q: How do you plan on going from ‘old to new’ and ‘forge new quality productivity’ speci cally? How does the competition factor into this?

A: Involution seems to have become the new normal for Chinese manufacturing industry and the cause comes from the massive capacity of ine cient semi-trailers formed during the stage of rapid growth.

Looking back on the previous journey, through the rst venture, CIMC Vehicles has not only launched its own semi-trailer business, but also initiated the regularisation, industrialisation, and scale of the Chinese semi-trailer industry.

Subsequently, the second venture focused on building an intercontinental operation pattern for the semi-trailer business and promoting the construction of a global supply chain for semi-trailers. During the second venture, we basically established a sophisticated manufacturing system and new infrastructure management for the semi-trailer business, but this was not enough to help us escape the increasingly severe involution situation. Our third venture is marked by the ‘Star-chained Manufacturing Network’, focusing on the structural reform of semi-trailer production organisation. Its essence is to improve the intercontinental operation process and greatly enhance the e ciency of intercontinental operation. ere is no precedent for this attempt. Our company, with more than 10,000 sta , is like a ship sailing on a vast sea full of unknowns and crises. However, I rmly believe that only in this way can we fundamentally escape the industry’s involution and once again lead the Chinese semi-trailer industry into a new development pattern.

www.cimcvehiclesgroup.com

THEY MIGHT HAVE A FUNNY NAME BUT THE HAMBURGER LAMP, THE ROUND TAILLIGHTS THAT RESEMBLE THE FAST-FOOD ICON, HAS AN IMPORTANT FUNCTION. LEADING PRODUCER OF LIGHTING SYSTEMS FOR THE COMMERCIAL VEHICLE INDUSTRY, ASPÖCK SYSTEMS, HAS BROUGHT THE HARDWORKING LIGHT BACK, COMPLETE WITH A NEW DESIGN AND NEW NAME.

Full LED and slimmer than ever, Aspöck Systems has launched its new edition of the classic Hamburger Lamp, and it is proving to be a visually unique o ering.

e Ecoround taillight has been designed using Aspöck Systems’ familiar glowing body technology which creates a large and homogenous light image emphasising the company’s commitment to safety both in a work environment and in road tra c.

Its range of applications is diverse, which means it can be mounted on trucks, trailers, caravans, car trailers and agricultural or construction machinery. It is also weather resistant and durable, increasing its scope to include even the toughest working areas.

e Ecoround lamp can be mounted vertically or horizontally in combinations of double, tripe and quadruple, as permitted by law.

Ecoround is rarely tted on its own. In a duo or triple, they are perfectly complemented by the Flatpoint IV series and the FlexLED number plate holder, which are essential components of any trailer lighting concept.

Flatpoint IV

Over the years, trailer lighting has evolved into a safety- rst package, responsible for supporting its driver, other drivers as well as vulnerable road users on two wheels or on foot. e Flatpoint IV position light series therefore supplements the Aspöck combination rear lights with the legally required light sources that are still missing – a side marker light in orange, a taillight in red and the marker light in white.

e latest Light Guide technology is used in all versions. Corresponding light control points ensure three-dimensional illumination and a modern lighting design. As Aspöck’s safety concept is a top priority in every single development, the light emission surface has been signi cantly increased on top of this. e beam angle of all three models has been more than doubled compared to the versions currently available on the market.

FlexLED number plate holder

e FlexLED number plate holder nalises this trailer lighting concept with two functions, one product and a simple installation. Slim and universally applicable, it combines with electrical contacting, and bene ts from waterproof connections AMP and Superseal as well as Aspöck connection system ASS2 or P&R.

ASPÖCK SYSTEMS GMBH

Owner and CEO Karl Aspöck

Key gures for scal year 2022/2023

€165 million sales at Austrian HQ | 390 employees

€230 million sales volume of the Aspöck Group | 1400 employees

Export quota 94 per cent

8 sales subsidiaries | 4 production locations

e bracket o ers the highest protection class IP6K9K. Vibration testing and ADR certi cation, combined with the successful 480-hour saltwater spray test, con rm its sturdy design and durability. It couldn’t be simpler – both the number plate and the number plate holder itself can be clamped with Aspöck’s own smart quick-mounting system, making changing them out a simple.

e illuminated number plate holder is suitable for all EU number plates with a height of 110 and 120 mm and is equipped with the FlexLED medium LED strip light component.

www.aspoeck.com

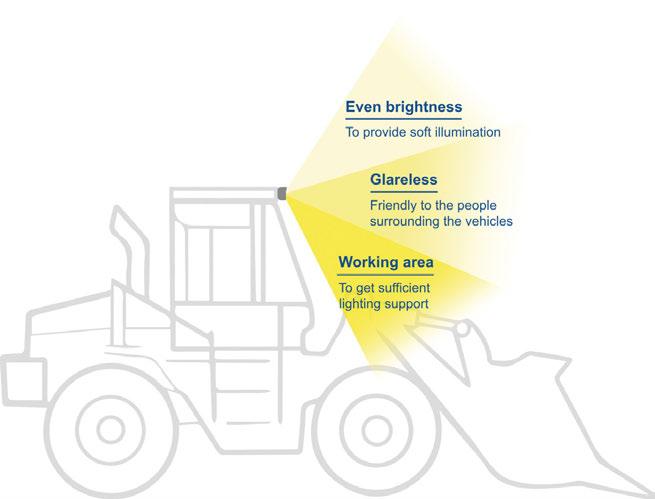

SHAPING A LIGHT BEAM SOUNDS ARTISTIC – ALMOST MAGICAL – BUT THE PROCESS HAS BEEN ALL ABOUT SCIENCE, AND THE REASON IS SAFETY. LED VEHICLE LIGHT MANUFACTURER, LUCIDITY, HAS USED THIS METHOD TO CREATE A DESIGN THAT PREVENTS UNSAFE GLARE AND BLINDING.

Creating light, especially for vehicles and equipment, is an important job, but there is a ne line. Too much light can have consequences that are just as risky as not enough light. is is why Lucidity has expanded its LED work lamp line and anti-glare ood light design, the rst of its kind to use headlight technology in a format designed speci cally for use as auxiliary lighting on working vehicles.