Do we need private INVESTMENT TO FUND RECOVERY?

Do we need private INVESTMENT TO FUND RECOVERY?

Breaking new ground in the motor grader industry, John Deere SmartGrade Motor Graders offer the first-of-its-kind mastless 3D integrated grade control from the factory, arriving at your jobsite ready to work. Unlike traditional aftermarket grade-control systems, John Deere’s innovative SmartGrade graders have no external masts or cables, allowing virtually unlimited range of grade-control and hydraulic functions. SmartGrade Motor Graders also include a new suite of intuitive automated features designed to lessen operator workload and boost productivity. Plus these machines are backed by your local John Deere dealer support team for added peace of mind. It’s a New Day and a New Deere.

Published by

Monkey Media Enterprises

ABN: 36 426 734 954

204/23–25 Gipps St

Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au infrastructuremagazine.com.au news@infrastructuremagazine.com.au

Editor Jessica Dickers

Journalists

Imogen Hartmann

Eliza Booth

Michelle Goldsmith

National Media and Events Executives

Rima Munafo

Brett Thompson

Design Manager

Alejandro Molano

Designers

Jacqueline Buckmaster

Danielle Harris

Marketing Assistant

Stephanie Di Paola

Publisher Chris Bland

Managing Editor

Laura Harvey

After a disruptive and unpredictable year, we have finally made it to 2021. While all of the challenges of 2020 did not completely disappear when the clock struck midnight, we’re being cautiously hopeful of a successful and fulfilling upcoming year for the infrastructure industry.

Over the last few issues we’ve talked about the sector’s role in the postCOVID economic recovery, and this year we should start to see this more in action with the progress of major projects across the road, rail, port and airport sectors.

A recent Infrastructure Australia (IA) study that looked at the future of infrastructure beyond COVID-19 found that the sector proved itself to be relatively resilient to the pandemic and that the impacts of the last year have helped to accelerate trends such as digitisation, more local and regional infrastructure use, and service innovations and adaptations.

Infrastructure Australia is also set to release its 2021 Priority List in February, and this year it is partnering with Infrastructure magazine for a virtual launch event. The Priority List is a critical document for Australia's infrastructure sector, and we’re very excited to be working with IA to get this key information out to you. For more information and to register, visit www.ipllaunch2021.com.au.

Infrastructure Partnerships Australia also recently released its 2020 Australian Infrastructure Budget Monitor, which showed that across Australia, governments are investing $225 billion in infrastructure over the next four years – an increase of $46 billion from last Budget season. This funding aims to combat the economic downturn from COVID-19, with NSW set

to spend the most – $84 billion over the next four years.

NSW and Victoria ($70 billion) combined account for 68 per cent of total infrastructure funding across the country, so expect to see some more funded projects start to come to fruition this year.

We’ve touched on a few of these topics in this issue of the magazine, with articles on private investment, new service models and opportunities for reform. This edition also looks at the role of software, communications and connectivity in the sector, as well as updates in rail, from asset management to innovation deficits, funding and projects. The rail sector is one area in particular that will be stepping up when it comes to supporting the country’s economic recovery.

As we’ve seen from multiple COVID clusters that broke out over the New Year break, causing rapidly changing restrictions and border closures, there is still a lot of uncertainty and risk around domestic travel, and this seems likely to continue, potentially even once vaccine distribution begins.

This means that for the industry, virtual events are still the best way to network and find out new information and updates on the sector. Infrastructure magazine will be running the Critical Infrastructure Summit virtually over two weeks in April to keep you up to date on projects, industry outlook, funding, asset management, disaster management and the future of infrastructure. Head to www.criticalinfrastructure.com.au to register for free.

In addition, we’ve got other exciting plans for 2021 across our print and digital channels, and will continue to be the voice of the industry as the sector works to meet the post-COVID infrastructure demand.

Jessica Dickers Editor

EARLY ACTION, ADAPTABILITY AND NEW SERVICE MODELS: HOW COVID-19 IS SHAPING INFRASTRUCTURE USE

Infrastructure Australia has released its findings from research into how the COVID-19 pandemic is changing the way Australians use infrastructure, the impact on long-term planning and development, and the key trends that have emerged.

INDUSTRY INSIGHTS

DO WE NEED PRIVATE INVESTMENT TO FUND RECOVERY?

As stimulus spending ramps up, a ten-year trend study shows private investment in new infrastructure has declined since 2010.

FIXED AND PORTABLE INTERNET FOR REMOTE INFRASTRUCTURE PROJECTS

Reliable, business-grade internet is critical to the ongoing operations of infrastructure projects. The necessity of connectivity for continued operation is just as pressing for permanent, fixed sites as it is for temporary, field sites.

REPLACING CRITICAL ASSETS IN A PANDEMIC

THE CRITICAL INFRASTRUCTURE SUMMIT IS BACK IN APRIL 2021

CONSTRUCTION’S COVID-19 OPPORTUNITY FOR REFORM

IT’S TIME TO FOCUS ON THE SOCIAL VALUE OF INVESTMENTS

As the industry voice for design, advisory, and engineering businesses in the built and natural environment sectors, Consult Australia has been working with members to build the case for a greater focus on social value in considering infrastructure investments, which it sees as critical to Australia’s COVID-19.

SIGNALLING, TRACKING AND CONTROL SYSTEMS

DEVELOPING A NEW TRAIN MANAGEMENT SYSTEM

Advanced Train Management System (ATMS) is a modern, communications-based, safe-working system for the ARTC, which has been custom engineered for Australian conditions by ARTC and technology partner Lockheed Martin. It enhances the operation of the national interstate rail network, and provides a quantum leap forward in safety, capacity and productivity for freight rail operations..

CONDITION MONITORING AND MAINTENANCE

PREPARING ASSETS FOR WHATEVER THE SUMMER BRINGS

INFRASTRUCTURE-BASED SENSOR TECHNOLOGY FOR "COOPERATIVE AWARENESS" PROJECTS

CREATING AUSTRALIA'S FIRST SMART AIRPORT

THE DIGITAL TECHNOLOGIES OPTIMISING CONSTRUCTION IN 2021

INTELLIGENT TRANSPORT SYSTEMS: A REVOLUTION ON OUR ROADS

WHAT’S IN STORE FOR THE FUTURE OF DIGITAL TWINS?

The 2020 NSW Spatial Digital Twin is part of the Western Sydney City Deal partnership that brought together federal, state and local government under a set of 38 commitments. The Digital Twin was part of the project’s commitment to coordinating information that supports planning and broader liveability targets.

FINDING THE FAST TRACK FOR RAIL INNOVATION

As COVID-19 restrictions hit Australian supply chains, three quarters of rail businesses surveyed by the Australasian Railway Association (ARA) said they were looking to increase their use of local suppliers to support their operations..

RAIL TRESPASS PREVENTION –DETECTION AND INTERVENTION

RATCHETING PERFORMANCE OF HIGH STRENGTH RAIL STEELS

INTELLIGENT COMPACTION IMPROVING THE QUALITY OF ROAD CONSTRUCTION

VIRTUAL REALITY ENABLING ‘TEST DRIVES’ OF ROAD PLANNING

MATERIALS UNDER THE MICROSCOPE

INFRASTRUCTURE SKILLS IN A POST-COVID WORLD

ECONOMY-WIDE IMPACT OF DRONES

MITCHELL FREEWAY EXTENSION TRAINING AND SKILLS SPATIAL & GIS ROAD SURFACING AND DESIGN

From condition monitoring on remote assets to mapping the spread of bushfires, drones have had a significant impact on many sectors in recent years, including infrastructure. But the technology has even more potential for the future, including a predicted economic boost of $14.5 billion in GDP for Australia and the creation of 5,500 full-time jobs each year, over the next 20 years.

MILLION INVESTMENT INTO NARRABRI TO TURRAWAN RAIL UPGRADE

RUNWAY UPGRADE COMPLETE AT GOLD COAST AIRPORT

HARBOUR BYPASS GETS

Preamble

In this role, Tom is responsible for the design and implementation of all technology and cyber security aspects of Australia’s first smart airport, which is due to open in 2026. Over his career, Tom has been involved in the creation, implementation and operations of complex technology systems across a range of sectors, including financial services, transportation, public sector and media amongst others. With a great deal of experience across both the FMCG and aviation industries, Tom has held a number of transformational technology leadership roles within a range of global brands. He is widely regarded for providing thought leadership in technology outsourcing.

Freptatibus nes ationse aut et aut mo quos aruptatus int, nonsequid magnis nonsedipsunt explitas andi que sandae veles cuptatiis et as ut omnimetur acerum ese eos sit, cus non restrum que nat maximod mi, quia dolupta tustis dent pra prat as sus.

Managing Director, Infrastructure Skills Advisory

With over 20 years’ experience in education, major projects and the private sector, Claire Parry is an internationally recognised expert in social procurement, workforce development and industry participation. Claire is Managing Director of Infrastructure Skills Advisory, a specialist consultancy that enables government, industry and businesses to deliver socio-economic outcomes through major infrastructure projects. She advises organisations that commission, procure or deliver jobs, skills development, diversity and inclusion, and industry outcomes.

Claire works with education and industry to develop and deliver new competency frameworks, qualifications and training programs, and industry training facilities for infrastructure, construction, engineering and rail.

Claire’s experience spans major infrastructure projects in Australia and internationally, including Sydney Metro, Regional Rail, Inland Rail, WestConnex, Sydney and Canberra Light Rails, and Crossrail, UK

Jerome Pun Senior Research Engineer, Monash Institute of Railway TechnologyJerome conducts applied research and consulting work for different railway operators and organisations His expertise includes multi-body dynamic simulation, plastic deformation behaviour of high strength rail steels and contact mechanics. Over the last four years, he has been involved in multiple projects to assist different railway operators and organisations within Australia and overseas resolve various wheel-rail interface related issues, and improve the efficiency of their operations. Jerome also recently won the Australasian Railway Association’s (ARA) Emerging Rail Specialist Award for his work.

Marie was appointed Global Infrastructure Hub CEO in January 2019. Prior to joining the GI Hub, she was the Head of Asia-Pacific for Acuity, the advisory services business of the SNCL group, helping clients in regard to infrastructure project strategy and finance. From 2011 to 2014, Marie headed the Infrastructure Initiatives department of the World Economic Forum, where she led their thought leadership activities, publishing thought leadership reports on best practices in the infrastructure sector. She led the dissemination effort of these best practices to governments and advocated to coalitions such as the B20 and the G20.

Before that, Marie worked for European utilities Essent and RWE where she drove their business development activities in the Africa and Central Asia region for various commodities, including their equity investment in LNG and hydro power plants. She started her career in 2001, and worked for various engineering consulting firms holding several technical and commercial positions for energy and transport projects in Africa, Middle East and Europe.

Nicola Grayson CEO, Consult Australia

Nicola Grayson CEO, Consult Australia

Nicola is responsible for implementing Consult Australia’s strategy, building ongoing external relationships, and for leading its advocacy and government relations agenda on behalf of member firms.

Nicola is a government relations specialist, and has represented industry associations in the United Kingdom, the European Union and Australia. She has worked across a range of sectors including general insurance, consumer finance, alcohol and education, in addition to consulting engineering. She has an Honours Degree in Law from the United Kingdom, and was previously Consult Australia’s Director of Policy and Government Relations.

Steve KanowskiPartner - Transport & Infrastructure, Deloitte Access Economics

Steve has more than 35 years of experience working in transport and infrastructure advisory positions for both Commonwealth and state government organisations, as well as in commercial consultancy.

Steve has extensive experience advising Australian government departments, government-owned corporations and private companies (financial institutions, operating firms and investors) on a range of economic and commercial issues in the transport and infrastructure sectors across aviation and airports, maritime and ports, railways, roads, freight and supply chain logistics, and public transport etc.

Steve joined Deloitte in 2017, after four years in the Queensland Government, with roles including Chief Economist & General Manager (Strategic Policy), Transport & Main Roads, and Chief Economist & Executive Director (Infrastructure Policy) with the Department of State Development, Infrastructure & Planning.

The Federal Government will invest $44.7 million in the Australian Rail Track Corporation’s 35km upgrade of the Narrabri to Turrawan Line between the Hunter Valley Coal Network and Inland Rail.

The project will deliver a corridor from Northern NSW to the Port of Newcastle capable of 25 Tonne Axle Load (TAL) trains at 80km/h. Currently the 35km section of track is only capable of accommodating 20.5TAL and comprises steel and timber sleepers, aging 47kg/m rail for most of the line, and poor track geometry, formation and ballast in some locations, resulting in limitations on its capability.

The upgrade represents a significant benefit to agricultural producers transporting grain, cotton and other primary products from Northern NSW to domestic and export markets, as well as the opportunity to back-haul materials, supplies and agricultural inputs into the region more efficiently and cost-effectively.

Deputy Prime Minister and Minister for Infrastructure, Transport and Regional Development, Michael McCormack, said, “We are investing in this project to greatly improve the quality and capacity of this crucial rail connection, better linking northern New South Wales, Inland Rail and the Port of Newcastle.

“This upgrade will allow longer and heavier freight trains from Northern NSW –transporting food and fibre – to access the Newcastle and Sydney ports.

“Greater volumes of freight moved on each train will reduce transport costs and make Australian exports more competitive.”

The project will see the steel and timber sleepers replaced with heavy-duty concrete ones, as well as upgrading critical level crossings and improving the rail quality on the Narrabri Coal Junction to Turrawan and the Turrawan to Narrabri North sections.

The project will commence in mid2021 and aims to be completed in 2023.

A$5 million upgrade of the Gold Coast Airport runway has been completed, with asphalt resurfaced on the southern 450m of the runway and 280m of adjoining taxiways recently grooved – a process which allows water to run off the surface under aircraft tyres.

The window for night works was increased due to fewer late night and early morning flights during COVID-19 travel restrictions, allowing the project to be completed sooner and delivering a cost saving of about five per cent.

Gold Coast Airport COO, Marion Charlton, said airside infrastructure projects required many months of careful planning and coordination.

“Critical maintenance projects like these are forecasted years in advance,” Ms Charlton said.

“The overlay was a priority project that we needed to deliver and the reduction in flights provided a benefit, allowing the project to happen more quickly and with a cost saving.

“This essential investment is critical to ensuring safe aircraft operations at Gold Coast Airport now and into the future.”

Work was undertaken at night to limit any operational impact as a result of closing the runway.

The project, delivered by Fulton Hogan, covered a total area of 32,000m², requiring 6,500 tonnes of asphalt.

A crew of up to 100 was on-site each night, completing the works in sections of about 90m per night on average.

Overlay projects are generally undertaken every 10-15 years. The other 2km of the runway was resurfaced in 2016.

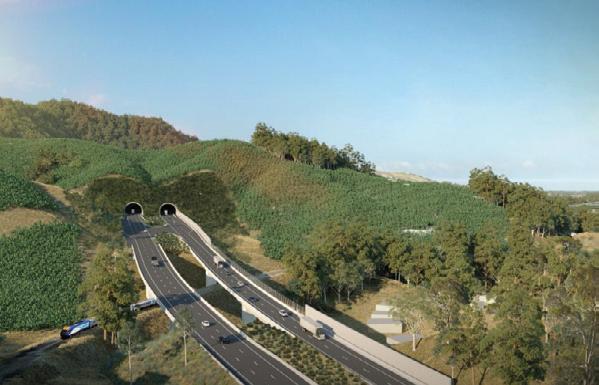

The Federal Government has given the Coffs Harbour bypass, the town’s biggest ever infrastructure project, the green light following its assessment and approval under the Environment Protection and Biodiversity Conservation Act (EPBC Act)

Deputy Prime Minister and Minister for Infrastructure, Transport and Regional Development, Michael McCormack, said the 14km bypass, which received official planning approval, is one of the 15 major projects that the Federal Government committed to fast-tracking in June 2020.

“The bypass is going to take more than 12,000 vehicles a day out of the centre of Coffs Harbour, reduce travel times by as much as 12 minutes by bypassing 12 sets of traffic lights, and improve safety for all road users,” Mr McCormack said.

“Transport for NSW has now received the final stamp of approval after close scrutiny by the NSW Minister for Planning and Public Spaces, and the Australian Minister for the Environment.

“This approval includes the proposed tunnels at Roberts Hill, Shephards Lane and Gatelys Road, as well as assessing the project for its social, environmental, heritage and economic impacts, and gives the project team the green light to go ahead with major work.”

NSW Minister for Regional Transport and Roads, Paul Toole, said the Pacific Highway was a major contributor to Australia’s economy, and the Coffs Harbour bypass would be a key link in this vital piece of the nation’s infrastructure.

“This bypass alone will support about 12,000 jobs over the whole lifecycle of the project, providing about 2,000 local jobs for the community of Coffs Harbour during construction, which shows how serious we are about investment in regional NSW,” Mr Toole said.

“The local community has played a huge role in developing this project – from helping shape the design for the bypass to engaging with the experts in the field to ensure we can get on with the job of delivering on our promise.”

The project is expected to take around five years to build, weather permitting.

The Port of Townsville has announced the winner of the largest contract of the $232 million Channel Upgrade project, with the contract awarded to Hall Contracting.

The works include capital dredging to widen 14.9km of sea channels over two years and reclamation of 62 hectares of land through beneficial reuse of dredged material.

Employing a local workforce of more than 70 full-time employees, the contract follows the extensive work over the past 18 months to build a 2.2km rock perimeter wall to receive the material.

Port of Townsville Chief Executive Officer, Ranee Crosby, said Queensland-based Hall Contracting has partnered with Townsvillebased Pacific Marine Group to offer extensive experience in dredging and reclamation.

The pair has committed to almost 100 per cent of this project being resourced from Queensland-based businesses.

“Hall Contracting has presented the best offer to complete the works,” Ms Crosby said.

“Over the course of the project, they will provide meaningful training across a range of vocations including vessel crew, marine engineers, diesel fitters, hydraulic fitters, boilermakers, earthmoving operators and dredge operators.”

The Channel Upgrade project will widen the current shipping channel from 92m to 180m at the inshore (Port) end, tapering to 120m wide in the Sea Channel, increasing the size of cargo, cruise and defence vessels able to access the Port of Townsville.

“Their strong commitment to local industry and First Nations people’s participation, as well as employment and learning opportunities for tertiary students, apprentices and trainees, presents significant opportunities for our region.

The Port has committed $17 million for environmental monitoring and management programs as part of the project, including those covering dolphins, turtles, seagrass, coral and shorebirds.

An Independent Technical Advisory Committee is also providing expert oversight of the monitoring programs during the capital dredging works. Hall Contracting is expected to begin capital dredging in May 2021.

The Channel Upgrade is a joint project of the Queensland and Australian Governments, and Port of Townsville Limited.

The Channel Upgrade is a key initiative under the Townsville City Deal signed in December 2016.

The South Australian Government appointed a private operator to take over the running of Adelaide’s rail network from 31 January 2021.

Keolis Downer was announced as the new operator of the rail network.

Minister for Infrastructure and Transport, Corey Wingard, met with both the Rail, Tram and Bus Union (RTBU), and a representative from a breakaway group of local train drivers, to discuss the upcoming transition and future employment and training opportunities.

During the meetings, Mr Wingard made it clear the timeline won’t be shifting and that the current offer on the table for drivers to transfer over to Keolis Downer won’t be changed.

“As it stands, a total of 83 drivers have accepted an offer of employment with Keolis Downer and another 88 remaining on the government payroll will be made available to Keolis Downer to ensure essential public transport services continue to be delivered to the community,” Mr Wingard said.

Drivers who’ve accepted a job with Keolis Downer have secured permanent ongoing employment with no loss of terms or conditions, a transfer of all entitlements, free public transport travel, and a $15,000 incentive payment.

They have also secured a commitment of no forced redundancies for the next three years, and the right to transfer to the future operator at the end of Keolis Downer’s contract.

In late-2020, a new enterprise agreement was also reached providing a two per cent per annum pay rise for train drivers and other rail staff.

The RTBU had been pushing for a $65,000 incentive payment and a four per cent per annum pay rise over four years despite both nurses and tram drivers accepting a two per cent rise just months earlier.

“From next month Keolis Downer will also start delivering training programs for drivers to join the workforce,” Mr Wingard said.

“Experienced drivers from other networks will undertake a 22 week program and will be ready to join the workforce in August.

“Further intakes for 33 week-long programs in May and September 2021, and also early in 2022 for new drivers will mean that progressively drivers made available to Keolis for the transition will no longer be required and will be moved into roles elsewhere in government.

“More than 1,000 applications were received by Keolis Downer for train driver positions and it’s clear there’s plenty of people excited and eager to join the sector.

“This transition will not only deliver better services but will also mean very significant savings to SA taxpayers.”

• Pre-award audits of manufacturers, subcontractors and suppliers

• Experienced, certified and qualified inspectors

• Verification of manufacturing and testing in accordance with AS standards

• Surveillance inspections throughout the entire manufacturing process

• Individual inspection and test of completed equipment

• Pre-delivery and ship loading inspections

• ISO 9001-2015 QMS certified company

Defend your industrial networks.

Strengthen network security with cyber secure ready hardware.

As industrial devices become more connected through the Industrial Internet of Things (IIoT) there is not only great potential for businesses to optimise operations, there is also a significant challenge – cybersecurity. Moxa’s range of robust network devices meet the technical security requirements of the globally recognised IEC 62443 standard, which ensures your industrial control systems are well protected against network intrusions or attacks.

Connect with confidence.

Madison Technologies has been distributing Moxa’s reliable networking infrastructure Australia wide for more than 14 years. Our team is dedicated to ensuring our Moxa portfolio is fully supported with an extensive range held locally across our national supply chain, and a team of Moxa certificated sales and technical support engineers.

With increased awareness of cyber security attacks on industry, companies are starting to understand the devastating production and financial losses these attacks are capable of. Industrial networks are often full of legacy hardware that was never envisaged to be connected to the internet. This has led to the rise in targeted attacks on these networks and the need to implement security mechanisms to avoid exploitation and compromise.

The IEC-62443 standard was developed to assist with providing an international framework to work towards securing vulnerabilities in Industrial Automation and Control Systems (IACS) networks. Guidelines for basic, medium and high security levels within the standard denote increasing levels of security policy adoption.

A basic level includes items such as default password changes, account timeouts and enabling trusted access to the device. A high level of adoption may include device configuration file encryption.

Adoption of any level of IEC-62443 is optional and dependent upon a risk assessment of the network. While not a guarantee of threat immunity, it does serve as an excellent and agreed upon starting point.

To assist with adoption of the highest level of IEC-62443 conformity, Moxa has developed an “E” series managed switch range. These easy-to-install and configure switches allow the user to implement the highest level of the IEC62443 standard – with security built into the component. Not limiting itself to just switches, Moxa has also developed a range of compliant devices, including serial to Ethernet servers, protocol gateways, firewalls and wireless access hardware that are also IEC-62443 aware.

Obtaining an understanding of how secure your network is may seem like a difficult and long winded process, however Moxa’s MxView is the component supplier’s answer to a Network Management System (NMS). While it will effortlessly discover all Moxa and non-Moxa hardware on your network, automatically draw a topology map and provide an excellent overview of your network, it can also do a lot more.

The latest version will provide you with a colour coded visual of how secure your network connected devices are.

Four colour codes relate directly to the IEC-62443 standard (open, basic, medium, high). MxView allows you to centrally view security events as well as provide the ability to mass configure settings from a central location.

Being able to deploy changes and updates of settings relating to the IEC standard ensures a uniform deployment across the network. The MxView software suite is licensed based on the number of network connected devices being monitored. This makes it an extremely cost-effective network monitoring tool, with the added benefit of the security awareness monitoring, link bandwidth monitoring, and centralised administration of your network.

The contract for the construction of the fasttracked $215 million Mitchell Freeway Extension has been awarded to a new Joint Venture, with works expected to start in early 2021.

The contract for the highly anticipated Mitchell Freeway Extension from Hester Avenue in Clarkson to Romeo Road in Alkimos was awarded to the Mitchell Extension Joint Venture (MEJV), a consortium of BMD Construction and Georgiou Group.

When complete, this project, combined with the current widening works underway along the Mitchell Freeway northbound, is expected to save drivers travelling from the Narrows Bridge to Alkimos during the PM peak period up to 15 minutes travel time.

Fast-tracked to boost the economy post COVID-19, the $215 million freeway extension is expected to support 1,200 direct and indirect jobs during construction.

Major works are expected to start in early 2021 and completion is scheduled for late 2022.

The Mitchell Freeway will be extended 5.6km and the project scope also includes:

♦ A new interchange at Lukin Drive including duplicating the road between Mitchell Freeway and Connolly Drive

♦ A new connection from Marmion Avenue to Wanneroo Road through the extension and construction of a dual carriageway on Romeo Road in Alkimos

♦ Upgrade of Wanneroo Road to a dual carriageway road from Romeo Road to Trian Road

♦ A priced option to upgrade Butler Boulevard will remain, pending further discussions

The project will improve safety and reduce congestion on the freeway and local road networks within the fast growing outer northern suburbs

of Yanchep, Butler, Alkimos, Eglinton and Nowergup.

The Mitchell Freeway Extension Project, from Hester Avenue to Romeo Road, is jointly-funded by the Australian and Western Australian Governments, with each contributing $107.5 million.

Infrastructure Australia has released its findings from research into how the COVID-19 pandemic is changing the way Australians use infrastructure, the impact on long-term planning and development, and the key trends that have emerged.

As the COVID-19 pandemic spread, Australia's governments took early action, introducing travel bans, lockdowns and border controls, and supporting domestic supply chains. Communities adopted social distancing and moved to working from home. While these early measures successfully contained national case numbers, they prompted profound changes to the way people moved, consumed and worked, which changed patterns of infrastructure use.

The continuation of infrastructure construction across major projects was a key source of economic activity and employment at the height of the COVID-19 pandemic in Australia. However, months of lockdowns, social distancing and working from home has driven sweeping changes in how Australians use critical infrastructure.

Although the pandemic put our infrastructure to the test over the past year, Australia’s governments and infrastructure providers navigated dramatic changes to community behaviour and network requirements, and rapidly adjusted their service provision across the transport, telecommunications, digital, energy, water, waste and social sectors.

Infrastructure Australia’s new report, Infrastructure Beyond COVID 19: A national study on the impacts of the pandemic on Australia, found that compared with other OECD countries, our infrastructure networks have proven to be resilient under pressure and open to innovation.

Developed in collaboration with L.E.K. Consulting, our report presents a moment-in-time snapshot of how the pandemic has

changed the way we use infrastructure, and considers which of these changes could have lasting impacts on how we plan, fund and deliver the services we all rely on.

It finds that while COVID-19 has put a pause on the traditional driver of infrastructure – Net Overseas Migration –the pace of change in the sector has generally increased, with new emerging trends.

Major shifts in how Australians work, travel and consume goods and services in the wake of COVID-19 has driven the redistribution of existing demand, mode or channel switches, and acceleration of longer-term trends that were already underway.

We estimate that around four million Australians have been working from home since March 2020, representing 30 per cent of the total workforce. Our report found that a third of those people would like to continue doing so at least once a week, suggesting a permanent move towards a hybrid structure that will see a split of working time between the office and home –with significant impacts for infrastructure use.

Add to this 17.2 million telehealth consults between March and June 2020, teaching curricula and students moving online, and countless Zoom meetings, the past year has been characterised by a rapid shift from physical to virtual interaction with our health and safety front of mind.

Not surprisingly, this put significant strain on our broadband networks, with spikes in NBN bandwidth congestion growing to an average 60 minutes per week per

service at the height of the lockdowns in March 2020, and increased instances of customer complaints – particularly from small to medium-sized businesses.

The impact of large-scale remote working led to a surge in usage, with telecommunication providers responding by leveraging extra capacity in the network.

Latent broadband capacity was released to cope with the surge in demand – an example of responsive repurposing of infrastructure and assets that speaks to the resilience and adaptability of the network.

However, some suburban areas experienced network outages, and many regional Australians experienced internet access issues during lockdown restrictions, impacting their ability to work from home or undertake schooling remotely.

Working from home also catalysed a rapid uptake of digital collaboration tools – accelerating developing trends and triggering investment in cloud-based systems and cyber security.

Australians also accelerated their move to online retail channels and digital services, resulting in a substantial uplift in online sales and increased broadband network congestion.

The pandemic drove a 100 per cent growth in monthly online retail, five times the annual growth recorded in 2019, resulting in a growth in parcel delivery and micro-freight.

As a result of social distancing and work from home opportunities, some households embraced the opportunity to move away from dense metro areas, resulting in a 200 per cent increase in net migration from capital cities to regional areas. This caused an immediate increase in capital city vacancies, while rental demand increased in regional and coastal towns including Newcastle, Wollongong and the Sunshine Coast.

Some regions are also seeing a local boom of regional

tourism and population growth, and are experiencing less severe COVID-19 impacts. Strengthened regional cities, huband-spoke service models, and improvements to liveability and affordability can refocus regional investment.

The longevity of these changes is uncertain, however the impacts are likely to persist for some time as Australians continue to seek more affordable housing outside of the inner metro areas. If this trend continues, we could see reduced demand for urban transport and increased pressure on broadband networks in regional centres.

In 2020, Australians have evidently cherished greenspaces, both in metro areas and national parks.

There has been a 23 per cent increase in our use of national parks and greenspaces nationally. Research also shows that 87 per cent of Australians have noticed a positive shift in community attitudes towards urban green space, particularly amongst those living in high-density areas.

In a survey conducted by the NSW Department of Planning, Industry & Environment, 46 per cent of respondents claimed to have spent more time in parklands and gardens with many (94 per cent) using these spaces to undertake personal exercise.

Further, 72 per cent of NSW survey respondents cited that local parks have been ‘especially useful’ or ‘appreciated more’ during COVID-19, with Hermitage Foreshore, Western Sydney Parklands and Centennial Park visits up by around 144 per cent and around 100 per cent respectively compared to the previous year.

Generally, increased local activity including intense use of local greenspace could lead to reduced demand on toll roads. Policy reforms and programs supporting access and uptake could drive even greater sustainability.

Across the country, public transport providers moved quickly to support social distancing and hygiene measures, making improvements such as increased cleaning, and applying real-time occupancy data to public transport in line with social distancing initiatives.

However, in a reversal to the earlier trend of increasing public transport use, patronage in most cities fell to 10–30 per cent of normal levels in the initial lockdown and settled at a ‘new norm’ of 60–70 per cent of pre-COVID-19 levels. Traffic levels rebounded quickly, along with an uplift in second-hand car purchases, potentially indicating that higher car mode share may persist for some time.

A key focus for government and industry in 2021 will be to understand the structural impacts of COVID-19 on travel demand within Australia.

Together with the Bureau of Infrastructure and Transport Research Economics, Infrastructure Australia has convened a COVID-19 Cross-jurisdiction Roundtable to facilitate the exchange of ideas, techniques and tools for considering the long-term impacts of COVID-19 in travel demand models.

Taking a collaborative approach, we are working with industry, sector experts and thought leaders across government to understand how COVID-19 has changed the way we use infrastructure.

This will inform the Australian Infrastructure Plan, a major reform document that will provide a roadmap for the infrastructure sector to support recovery from the impacts of the pandemic, due for release in mid-2021.

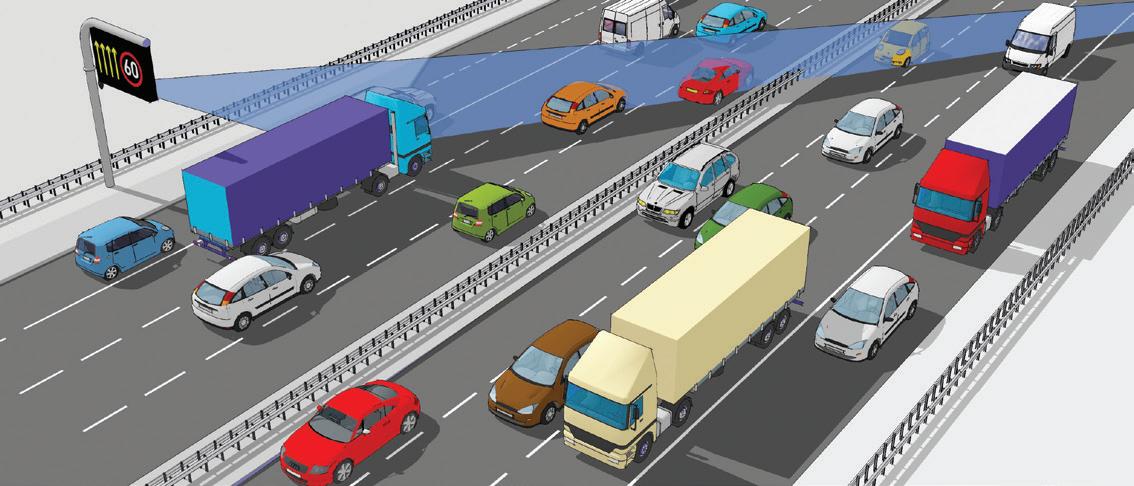

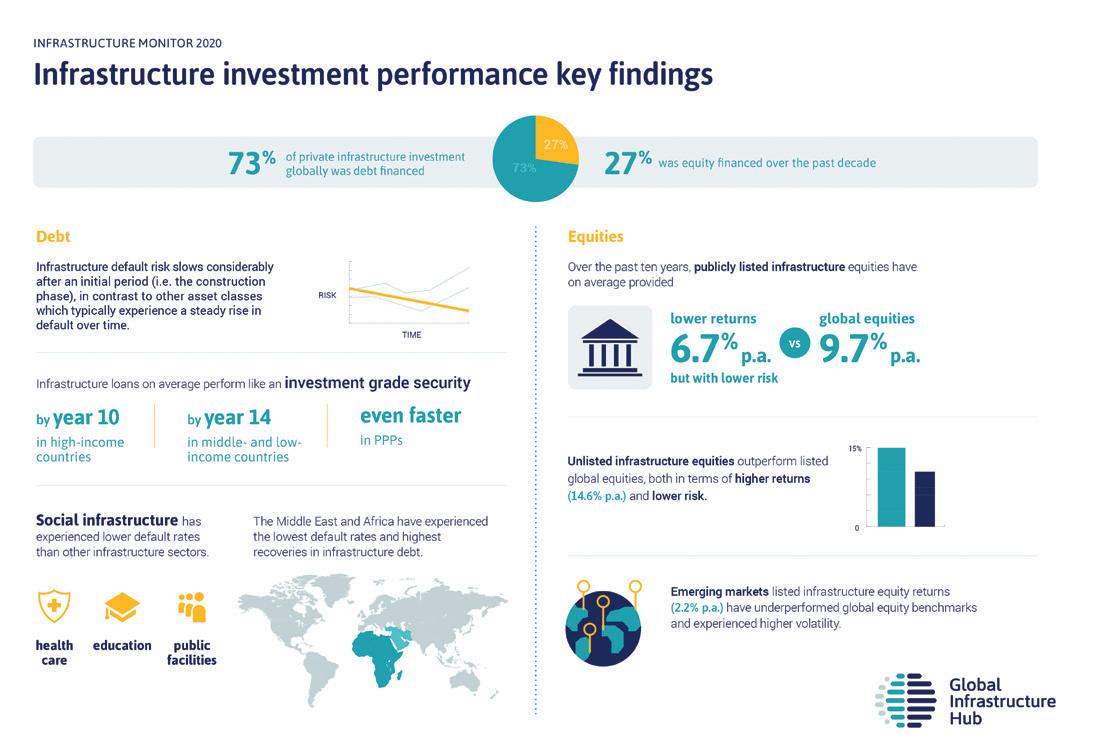

As stimulus spending ramps up, a ten-year trend study shows private investment in new infrastructure has declined since 2010.

Infrastructure is the backbone of developed and emerging economies worldwide. Yet, even as many countries turn to infrastructure stimulus to help drive COVID-19 recovery, the $15 trillion global infrastructure financing gap stands as a stark reminder of what the public sector has not been able to achieve alone.

The latest Global Infrastructure Hub (GI Hub) report, Infrastructure Monitor 2020, shows declining private sector investment in new infrastructure, despite the appealing riskreturn profile of infrastructure investments. Private investment in infrastructure through primary market transactions is only about US$100 billion per year, down from US$156 billion in 2010. This figure is a drop in the ocean compared to the US$15 trillion global infrastructure financing gap that the GI Hub calculated in 2017 based on projections to 2040.

Currently, the industry is taking a hard look at its objectives and practices in light of what the pandemic has taught us about the role infrastructure plays in inclusivity, resilience and other essential aspects of society. This presents a unique opportunity for the public and private sectors to build on their alignment of purpose to increase investment and close, together, the financing gap.

A 2019 Global Infrastructure Investor survey by GI Hub revealed that 97 per cent of investors now believe environmental, social and governance (ESG) factors are important considerations in infrastructure investment decisions, an increase from 86 per cent in 2016.

This widespread recognition by infrastructure fund managers, lenders and investors appears only to have strengthened since the global pandemic. There is a distinct shift in emphasis from viewing ESG factors as useful considerations to seeing them as future-focused must-haves. This can only work in infrastructure’s favour for attracting private investment.

There are a few reasons why investors are looking the other way when it comes to investing in infrastructure. Firstly, there are limited opportunities for investment as the number of public-private partnerships (PPPs) shrinks globally. Infrastructure Monitor showed that private participation in PPP projects has gradually declined as a share of private infrastructure investment – falling from 36 per cent in 2010 to 28 per cent in 2019. There is also a shortage of bankable projects and fewer privatisations coming to market.

Secondly, risk-adjusted returns have become less attractive over the last decade with returns dropping due to serious competition among providers. The risk of infrastructure projects for investors is perceived to be high, particularly if the private sector is being asked to carry the burden of excessive risk. This perception is challenged by Infrastructure Monitor, as it found that infrastructure loans on average perform like an investment grade security by year ten in high-income countries, and by year 14 in middle and low-income countries, and even faster in PPPs.

From a performance perspective, our industry can raise awareness that infrastructure does not perform like other asset classes in having increasing default rates over time. And increasingly, we have the data to show this. In addition to the composite view provided in our Monitor 2020 report, there are the annual Moody’s publication of default and recovery rates of over 7,000 projects, and the EDHECinfra infra300 index of how unlisted infrastructure performs. The data is clear that once through the initial higher-risk phase (i.e. construction), infrastructure that is contracted or regulated by the state generally provides long-term, predictable and stable yields.

This finding is a clear signal to the world that infrastructure is a safe environment to play in, and the time is ripe for private investors to move away from focusing only on high-yield investment. By investing in infrastructure, the private sector

can diversify its portfolio, have a longer retainer and have a social license to play.

Lastly, the industry can break barriers to private investment by understanding how the public sector can be a deterrent to private investment. Capital charges associated with infrastructure investment can push investors towards other asset classes, and low interest rates make investment by the state more attractive and affordable.

As part of our work for the G20, the GI Hub recently conducted a market scan to understand the key challenges to mobilising private capital. We spoke to more than 40 investors, policymakers and market experts globally and identified three primary actions associated with attracting investment into infrastructure.

1. Ensure the availability of programmatic pipelines

Governments need to develop a clear vision for their infrastructure development agenda and goals. Without the required clarity, they will not be able to develop a robust and properly prioritised pipeline of projects. A good example of an infrastructure project pipeline is the online Mexico Project Hub. Launched in 2017, the pipeline aims to accelerate private investment in Mexican infrastructure development. The first of its kind in the world, it has quickly strengthened Mexico’s ability to fund multiple large projects across the nation.

2. Navigate regulatory, political and economic uncertainty

Infrastructure development is often politically complex, requiring the approval of multiple, diverse and sometimes competing stakeholder groups. Misaligned interests can inhibit projects. Therefore, governments need to create the proper

regulatory frameworks and economically robust environments if they are to nurture trust in their infrastructure programs.

One government that succeeded in this is Azerbaijan. Our InfraCompass, which quantifies the strength of countries' enabling environments, found it had the most improved regulatory framework of any InfraCompass 2020 country. In 2018, Azerbaijan made resolving insolvency easier by making insolvency proceedings more accessible for creditors and granting them greater participation in the proceedings, improving provisions on the treatment of contracts during insolvency and introducing the possibility to obtain postcommencement financing. Then, in 2019, Azerbaijan made resolving insolvency even easier by providing for the avoidance of preferential transactions (transfers or payments made to unsecured creditors that result in a creditor receiving a preference over the remaining unsecured creditors at a time when the debtor was insolvent).

3. Develop projects with attractive risk-weighted return profiles

Governments can keep in mind two key principles in the creation of their programs and projects: value creation (ensuring all projects have strong revenue potential) and value capture (ensuring key risks are mitigated and projects are appropriately financed to secure profitability). Projects that do not include plans for the fair and equitable generation and distribution of revenue will struggle to attract willing investors.

Activating private capital is key to closing the global infrastructure financing gap. The industry currently has an opportunity to explore investment options and create stronger partnerships between the public and private sectors, helping drive economic recovery in the short term while also driving longer-term economic and social outcomes.

The Global Infrastructure Hub (GI Hub) supports the G20 to drive an ambitious agenda on sustainable, resilient and inclusive infrastructure through action-oriented programs.

Based in Sydney, Australia and Toronto, Canada, the GI Hub team provides data, insights and best practice to create a common language on infrastructure. Strategic partnership is at the core of what the GI Hub delivers through events, thought leadership and tools. It is the G20’s only dedicated infrastructure entity.

Find out more and engage with the Hub at www.gihub.org.

Reliable, business-grade internet is critical to the ongoing operations of infrastructure projects. The necessity of connectivity for continued operation is just as pressing for permanent, fixed sites as it is for temporary, field sites.

The increasing adoption of remote monitoring systems and near real-time analysis of data flows to-and-from facilities has necessitated a constant, reliable internet service on every site. Activ8me Business Services’ satellite solutions can ensure sites can be connected online no matter how limited the local connectivity options may be.

With consistent data flows being a standard requirement both for operational functionality and safety and compliance, isolated locations can present significant challenges for infrastructure projects, with ongoing work dependent on continuous internet service in regions with very limited or no existing communications infrastructure.

With unlimited satellite internet for fixed and portable infrastructure sites, Activ8me’s custom-built hardware facilitates business-grade communications anywhere, with auto-aligning satellite dishes able to have a service operational in under ten minutes.

With custom contention rates and enhanced business SLAs, Activ8me’s solutions enable continuous, uninterrupted service, which is a common requirement both for operational functionality as well as safety and compliance.

Services can be customised based on requirement, however a typical service includes a 30Mbps download/5Mbps upload speed tier on a 20:1 contention.

Services are augmented to meet the unique requirements of clients, taking into account expected usage of the connection, the volume of users, types of applications and much more to ascertain bandwidth requirements.

IoT connections, for instance, are configured to handle the large amounts of small data packets, routinely transferred to-and-from IoT networks every few seconds. For IoT, a connection of 5Mbps down/5Mbps up with 35:1 contention provides optimal connectivity.

Up to 20 users, or hundreds of small IoT devices, can share a 'pipe,' with customised contention and speed tiers coordinated to best suit the operational aim of the network.

The solution can be used as a redundancy network to backup existing fibre-optic or microwave networks, ensuring that operations can stay up and running in the event of a primary network failure.

These same satellite data services are available in portable solutions, allowing for easy transport and relocation. The satellite dish can be mounted on a vehicle or trailer, be set up using a non-penetrable ground mount, or even built into a case.

This Mobile-On-The-Pause solution is perfect for projects with changing locations or remote project teams. WiFi networks are built into Activ8me’s portable satellite hardware, with optional WiFi antenna for extended range of up to 100m.

With an in-house R&D team, Activ8me often designs customised hardware to meet the unique demands of clients and additional functionality can be built into existing hardware when required.

Point-to-Point and extended WiFi can offer connections over extended distances, while WiFi-Mesh networks and LoraWAN technology can also be incorporated into network architecture.

Utilising these various technologies, Activ8me can formulate an end-to-end networking solution to suit practically any infrastructure project.

For more information, please visit business.activ8me.net.au.

Activ8me Business Services offers communications solutions for utility operators in remote Australia.

Our solutions include:

Unlimited data plans

Low contention rates

Fixed or portable hardware

Solar, self-sufficient options

Optional P2P, Extended Wi-Fi and Public Wi-Fi

Installation & Field Support Australia-wide

Our solutions overcome the communications limitations of operating in remote locations.

With our internet services, operators can access Cloud-based applications, integrate remote monitoring and utilise M2M/IoT technologies.

No matter your challenge, we offer scalable solutions to meet any requirement. Our in-house team can even design a bespoke solution to fit your needs.

For more information contact our Corporate Sales team or visit: business.activ8me.net.au

With COVID-19 restrictions significantly decreasing passenger numbers across all Australian airports in 2020, it became a suitable time to complete large maintenance and construction projects that would have otherwise caused extensive shutdowns. Brisbane Airport used this time to replace the entirety of its skylight that spans the length of the Domestic Terminal to maintain safety compliance.

As the gateway to Queensland for domestic and international visitors, Brisbane Airport's terminals have been designed to create a unique sense of space that makes a welcoming and lasting impression.

This sense of space encapsulates Queensland perfectly, capturing the warmth and light of the Sunshine State by bringing the outdoors in. At Brisbane Airport’s Domestic Terminal, visitors are welcomed by natural light that floods in overhead from the extensive skylight spanning 480m across the terminal’s ceiling. This architectural masterpiece has been a feature of the Domestic Terminal since its construction in the 1980s, providing opportunity for airlines and retailers to reap the resulting ambience and atmosphere.

Like all structures exposed to the elements, the skylight had reached the end of its life and required replacement in order to comply with relevant safety standards and protect the terminal from the elements.

Throughout the COVID-19 pandemic, Brisbane Airport Corporation (BAC), the operator of Brisbane Airport (BNE), reassessed all projects within the pipeline in order to prioritise those that were essential to ongoing operations.

Robert Scodellaro, Head of Project Services at BAC, said the skylight replacement project was identified as essential in order to ensure ongoing compliance of the Domestic Terminal.

“Construction for the replacement commenced in June, with practical completion being reached in October," Mr Scodellaro said.

Despite COVID-19 not having a significant impact on the project, the decreased passenger numbers did allow for some flexibilities around construction.

“The skylight project could only be accessed from the roof of the terminal itself, with all materials being craned to that location.

“In order to have a crane operating in an active airside environment, there are a number of complexities to overcome, including the need for both internal and external exclusion zones.

“With reduced passengers and flights, the removal of aircraft bays from the allocation plan to enable the required exclusion zones resulted in a reduced impact to airlines," Mr Scodellaro said.

Though it wasn’t only the aircraft bays that were affected. Despite operating in a heavily reduced capacity due to border restrictions, Brisbane Airport remained open and operational throughout the pandemic.

“Despite a significant decrease in passengers throughout the terminals, customer experience remained top-of-mind for any construction activities at the airport,” Mr Scodellaro said.

“This meant that all disruptive activities had to occur outside of operational hours, so they largely took place between 10pm and 4am."

The Principal Contractor, Box & Co, took each of these challenges in their stride, delivering the project on time and with an impeccable safety record. Box & Co’s Managing Director, Simon Box, said the project came with its challenges, but the team committed to a collaborative approach with BAC to find solutions.

“As a proud local business, safety is always our priority and this project gave us the opportunity to really practice what we preach and prove our capability.”

With 1,090 glass panels and nearly a kilometre of roofing flashing that needed replacement, Box & Co facilitated 168 crane lifts to the rooftop, all from the airside environment.

“Prior to commencing on site, we worked through risk mitigation and safety procedures. Ultimately, we knew we had to send people to work from a rooftop at night in a really niche environment, so there were a number of challenges we had to design out of the process before we could commence,” Mr Box said.

“On top of the external environment, we were also very aware that the works were occurring above critical airport infrastructure such as check-in counters. We knew that any issues during the night shift could have an impact on airport operations the following morning.

“Scaffold harnessing and catch nets for dust and debris beneath the skylight internally are examples of the types of risk mitigation measures utilised throughout the project."

With the strong team dynamic at Box & Co, Simon Box knew he had the right people on board who would be able to deliver

this project to a high quality, and most importantly, safely.

“We are a small company, and we were in the height of a global pandemic – utilising local suppliers who we have built relationships with over the years was critical to us,” Mr Box said.

“Knowing that we were giving additional work to trusted suppliers made the project a little sweeter in a time that was so unknown for the building industry.

“Box & Co is extremely happy to say that we were able source 93 per cent of construction materials from South East Queensland, with more than 90 per cent of the total employees working on this project living in South East Queensland.

“That not only includes the Box & Co team, but also subcontractors working on various aspects of the works," Mr Box said.

As Brisbane Airport looks to recovery, the newly replaced skylight at the Domestic Terminal will be sure to give passengers a warm welcome to the Sunshine State.

After a huge inaugural event in 2020, the Critical Infrastructure Summit – Australia’s premier event for the whole infrastructure lifecycle – is back to bring infrastructure professionals the latest news, innovations and thought-leading discussion on the industry’s most pressing issues.

In 2021, the Critical Infrastructure Summit will feature four Virtual Conferences over two weeks from 13–22 April.

Brought to you by the team behind Infrastructure magazine, the four free-to-attend conferences will explore the industry’s biggest challenges and predictions across the entire infrastructure lifecycle – construction, asset management and disaster resilience.

The 2021 conferences include:

♦ Critical Infrastructure: State of play – 13 April

♦ Asset Management for Critical Infrastructure – 15 April

♦ Disaster Management – 20 April

♦ The Future of Infrastructure – 22 April WHY ATTEND?

The infrastructure industry is set to play a major role in Australia’s post-COVID recovery, creating enormous growth and opportunities, but also new challenges and pressure to meet demand.

This means it is critical for infrastructure professionals to stay informed on the latest in the industry, from projects to technologies, innovations and the future outlook.

Topics across the four events for 2021 include: meeting COVID recovery demand in 2021; funding; the project pipeline; the last six months in the infrastructure industry; state of the airport sector; operating models and organisational design for success in asset management; digital asset management industry panel; bushfire mitigation; cyber security; futureproofing infrastructure; digital twins; building our future cities – connected, sustainable and accessible; and much more.

As well as the four major Virtual Conference events, the Summit will also feature online networking opportunities, enabling delegates to make genuine connections with other industry professionals.

Building on the high-quality content from the 2020 event, 2021’s Summit will feature a new expert speaker lineup of leaders from across the infrastructure industry.

We want to give delegates more of what they liked best about the inaugural event, so we’ll be dedicating more time for delegate interaction and speaker Q&As. This means greater participation, with attendees becoming a part of the discussion and having greater access to senior industry figures.

COVID-19 made it impossible to network with other infrastructure professionals due to restrictions, but in 2021 we’re introducing a live networking element to the event.

Attendees can still enjoy the entire Summit from the comfort of their homes or offices, but for those who want to get extra value from meeting up with peers in the real world, there will also be two live networking events to make connections and build new relationships.

Pending COVID restrictions, the live networking events will be held on Thursday 15 April in Melbourne and Thursday 22 April in Sydney.

This is the chance for delegates to network with like-minded infrastructure professionals in a fun and informal environment.

Australia’s premier event for the whole infrastructure lifecycle –construction, asset management and disaster resilience.

A thought-leading Summit keynote session on the biggest issues currently facing Australia’s critical infrastructure.

Asset Management for Critical Infrastructure

Bringing together utility and infrastructure leaders to discuss the most pressing issues in asset management.

Helping critical services prepare, survive and thrive in the face of major disaster events.

A look at what’s next for the industry – digital infrastructure, the Circular Economy, skills, funding, future sector trends and more.

Thursday 15 April in Melbourne

Thursday 22 April in Sydney

All 4 virtual events are FREE TO ATTEND

With great optimism, I anticipate 2021 will be the year that marks the turning point in the quest for a more sustainable construction industry. We have a unique opportunity to achieve real and lasting reform, but it will require the support of the entire sector.

Governments are relying heavily on the construction industry to lead the economy out of recession, but our industry is sick. Profitability is at an alltime low and productivity growth over the last 30 years trails that of other significant industries by 25 per cent. Women make up only 12 per cent of the construction workforce, and construction workers are six times more likely to die from suicide than a workplace incident.

There is a broad consensus that this sustainability crisis must be addressed for the construction industry to deliver the planned pipeline of projects efficiently, with the resources available, whilst leveraging opportunities to increase training, local procurement and engagement of indigenous and social enterprise.

In late-2020, the ACA published a series of documents that charted a clear way forward. Starting with an analysis

of the most pressing problems facing the industry, we then developed a framework for a more sustainable sector, followed by an industry charter comprising ten commitments to reform embraced by Australia’s leading construction and infrastructure contracting companies.

Amongst other things, we identified that a sustainable construction industry is one built on the three key pillars of: equitable and aligned commercial frameworks; a strong positive culture; and the capability, capacity and skills to execute the projects it is called upon to deliver.

All three pillars are interlinked, and therefore improvement in one requires improvement in all. As an example, it is widely understood that adversarial commercial frameworks negatively impact culture, and a positive industry culture is a key factor in attracting people into the industry.

Part of the solution to the challenges faced by the industry is greater use of contracts that promote a collaborative industry culture and incentivise innovation. True value can only be achieved when all the parties' interests on a project are aligned, and when open and transparent sharing of information is encouraged.

This is not a call for widespread use of alliance contracts, although the use of alliance contracts to deliver the Level Crossing Removal Program in Melbourne is delivering an exceptional outcome. There will always be instances where the use of lump sum or design and construct contracts are more appropriate. However, there is no reason why these traditional commercial frameworks cannot be drafted to contain more collaborative and equitable provisions, particularly regarding management of project risk.

More collaborative and equitable forms of contracts are in use elsewhere in the world and could easily be adopted here

to save time and effort developing new contracts or amending existing forms. The best example of which is the NEC suite of contracts from the UK.

While there have been some improvements to industry culture in recent times, construction workplaces and behaviours need to take a quantum leap if we are to make our industry a more resilient and attractive sector to work in, particularly for women.

The Construction Industry Culture Taskforce will shortly start consultation on a draft Culture Standard that seeks to align all parts of industry on the requirements necessary to make this leap.

To avoid capacity and capability constraints in the long term, there needs to be increased collaboration between government and industry to better identify potential skills shortages well in advance. This can be achieved through skills mapping and transparent, accurate project pipeline data. The data could then be used to smooth resource peaks by amending project start dates or to inform training initiatives to address potential shortfalls.

In the short term, with closed international borders and long lead times to train new people, we need to focus on increasing the efficiency of our procurement and delivery processes.

For example, we should put our valuable resources to work optimising designs and de-risking projects through advance works, rather than tying them up at tender producing volumes of information that add little or no value.

If we could just halve the gap in productivity growth that has been created between the construction industry and other industries over the past 30 years, we could construct an extra $10 billion of infrastructure every year for the same level of expenditure! This will be vital in a post-COVID-19 world with high levels of government debt, but no less of a requirement to construct productivity-enhancing infrastructure.

As a starting point, we need more collaborative partnerships between state governments and the private sector to enhance the three pillars supporting the sustainability of the industry.

To fully realise this opportunity, the Federal Government needs to take a more active role in defining and incentivising the use of best practice procurement and delivery processes.

The Construction Playbook, recently published by the British Government, accompanied by a direction to use it or explain why not, is a good example of how this could be done.

In comparison to many other countries, Australia has done a remarkable job in managing COVID-19. In part, this is the outcome of strong collaboration between the public and private sectors. This collaboration is transferable, and it is incumbent upon us all to grasp this unexpected opportunity for change with both hands in order to rebuild trust and develop a more sustainable industry for the benefit of all Australians.

For more information, and to view ACA’s document series and industry charter, please visit www.constructors.com.au/initiatives/industry-reform.

As the industry voice for design, advisory, and engineering businesses in the built and natural environment sectors, Consult Australia has been working with members to build the case for a greater focus on social value in considering infrastructure investments, which we see as critical to Australia’s COVID-19 economic response.

Despite sometimes being seen as such, the social value from infrastructure investments is not distinct from its economic value. Instead, an increased focus on social value can help shape and inform our investment decisions, ensuring that what we spend our money on results in economic benefits in areas of greatest community need. We see this as a ‘dual-lens’ approach, as a way to align future growth opportunities from investments with the values, objectives and priorities of our communities – the end users of these assets.

To deliver social value from investments and maximise community benefits, we must consider social impacts as early as possible in infrastructure projects – particularly in the business case phase of a project, where we look at whether an investment stacks up.

Social impacts are the consequences, both positive and negative, experienced by people due to changes in their surroundings from a project. While these social impacts can sometimes be difficult to consistently measure, they are no less real for those experiencing them. The earlier we think about them, the more influence we can have on the social value of a project, which in turn can improve the outcomes from a project and ultimately save time and money.

If we spend more time coming up with better ways to fully understand the impacts on how people live and interact, as well as the community’s composition and sense of place during the business case phase of a project, then we have a more complete picture of the ‘problem’ we are seeking to solve through the investment. This will inform whether or not the proposal is the right solution, and importantly, help refine and shape the proposal to align well with community needs.

It is also important to note that following this process in itself leads to greater social value because it helps create greater community acceptance and lowers the risk of conflict as the project proceeds through its various stages. Arguably, a failure to follow this process is a significant cause for many projects around the country being cancelled or delayed, rather than a failure in the projects’ merits.

So how can we increase our focus on social value through infrastructure business cases?

Many of our members are developing clever ways to better understand social value by utilising new technology and innovative practices – both from a community-wide perspective and for certain cohorts.

The key lesson we are seeing showcased in these new approaches is the need to move away from a one size fits all approach, or cost-benefit analysis thinking, and instead be more flexible and considerate of the context and objectives.

For example, how we consider the social impacts in a business case for a rail project in a rural area should not be applied to a business case for an arts precinct in an inner urban area. The approach taken must be more tangible and specific to the problem or the opportunity that the business case is looking at.

We have also considered the benefits of bringing forward what happens later in the project to the business case development stage – primarily social impact assessments, which usually happen alongside environmental regulatory approvals once the business case is finalised.

Much can also be learned by looking at some of the practices that sit outside typical ‘infrastructure projects’, such as mining projects, as these have a long history of considering the social value and licence to operate from the community. We believe many of these practices are transferable to infrastructure projects.

One example is the NSW Department of Planning, Industry and Environment’s Social Impact Assessment Guidelines, which apply to state significant resource projects. Positively, an updated version of this guide is currently being proposed for all state significant projects, including new infrastructure proposals.

Consult Australia has published a report looking at this topic in more detail which can be viewed at www.consultaustralia.com.au/home/advocacy/pipeline.

We hope that the report adds to the growing public debate about how we can extract more social value from infrastructure investments. We believe Australia’s economic response to COVID-19 is the catalyst to improve how we assess the investments that are important to us as users of infrastructure, and the legacy that we would like to create for future generations. As such, improving how we consider and shape social value from investments is essential.

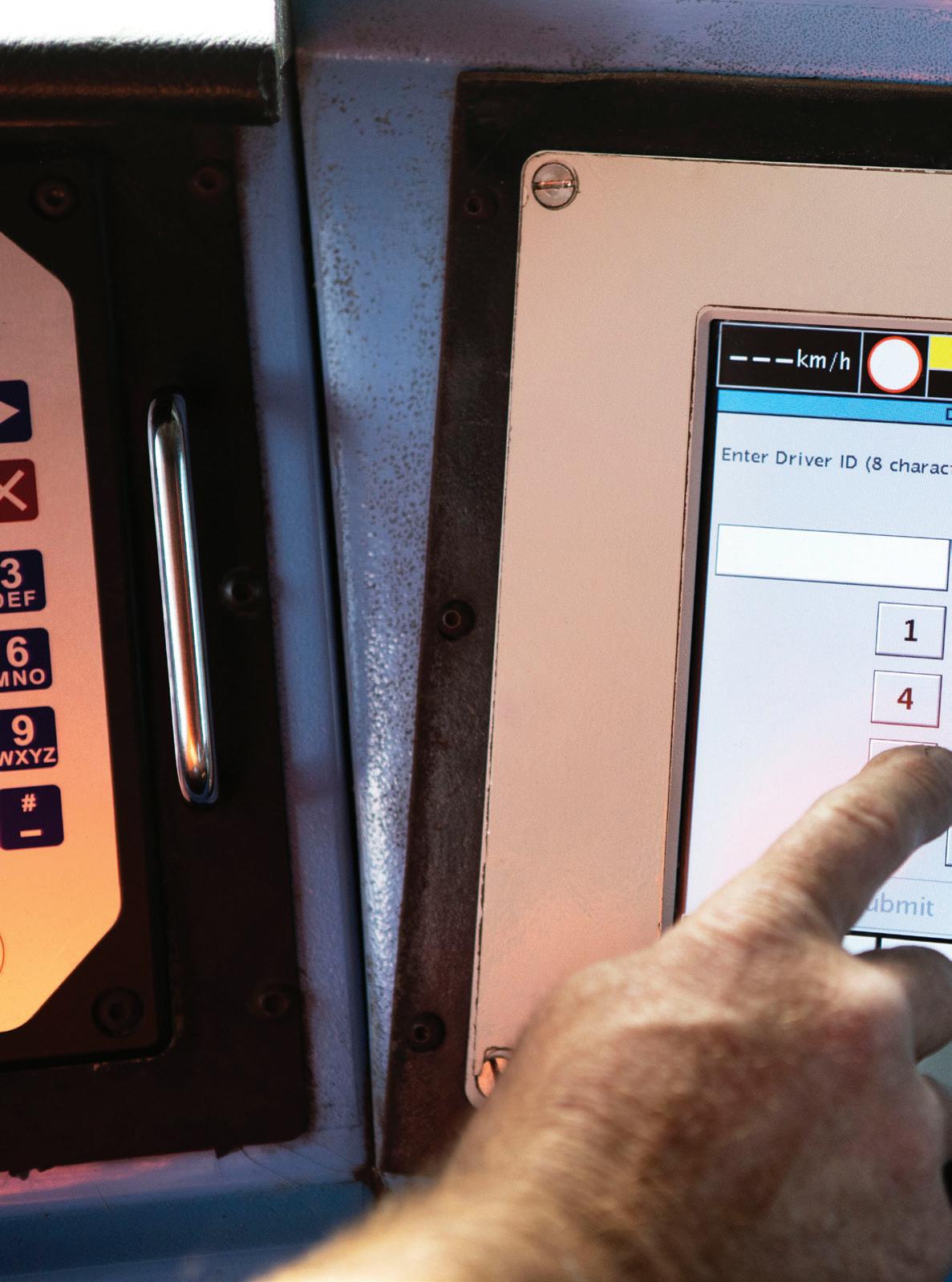

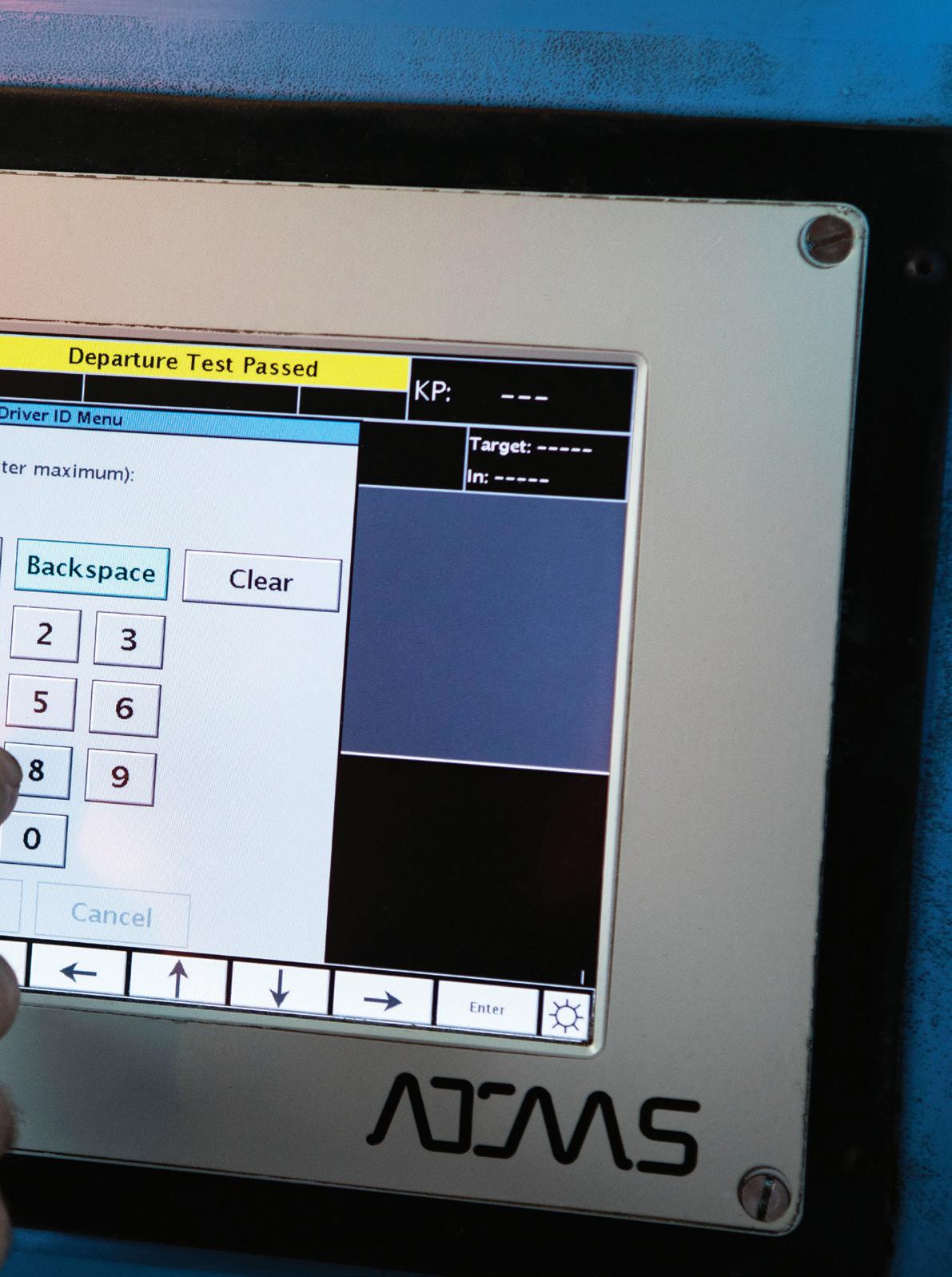

Advanced Train Management System (ATMS) is a modern, communications-based, safe-working system for the ARTC, which has been custom engineered for Australian conditions by ARTC and technology partner Lockheed Martin. It enhances the operation of the national interstate rail network, and provides a quantum leap forward in safety, capacity and productivity for freight rail operations.

ATMS is capable of providing the driver with a 10km look ahead including all rail traffic, track possessions, track speed, end of authority,

ATMS replaces traditional trackside signalling equipment and implements intelligent software technology that allows information to be directly shared digitally between ARTC’s Network Control Centre and a train-borne unit on board a locomotive via mobile telecommunications.

After more than a decade of intense development, testing and design – a cutting-edge train management system has gone ‘live’ in South Australia.

The Advanced Train Management System (ATMS) has completed its final commissioning trials into service and is now the train control system for ‘live’ train services between Port Augusta and Whyalla in South Australia.

The system also has larger ramifications for the national rail network as it will eventually be rolled out nationwide, with work on the next phase along 1,700km of track between Port Augusta and Kalgoorlie already underway.

The Federal Government’s showpiece freight rail infrastructure project – the Inland Rail between Melbourne and Brisbane – will also be ATMS-ready when each section begins operation.

Recently-appointed Australian Rail Track Corporation (ARTC) Chief Executive Officer, Mark Campbell, said this is an important step in the process of upgrading the national network with proven technology that boosts safety, capacity, reliability and enhances the customer experience.

“The Interstate Rail Network is the backbone of our freight system and it’s crucial we have the latest systems and technology available to serve our customers well into the future, especially with the Inland Rail coming online,” Mr Campbell said.

“This will revolutionise the way we manage rail freight services by increasing capacity and improving operational flexibility, safety and reliability.

“ARTC is extremely proud of ATMS which has been ten-years in development. This product has been Australian made to benefit the people of Australia.

“This system has been developed from the ground up for Australian conditions. It has been tested under Australian conditions on the South Australian network. It has undergone rigorous testing before we brought the system into operation in August and it has passed every test.”

Mr Campbell said further benefits and applications will continue to be incorporated as the ATMS is rolled out to new areas.

“Benefits for our customers will continue to flow as we continue to integrate new features such as fuel and energy management systems, as well as better timetabling of trains through the increases of capacity on the network that ATMS will enable,” he said.

“ARTC has ensured that industry has been at the forefront of consultation during the development of ATMS and we

will continue to ensure that this system delivers substantial benefits to our customers.

“Moving more freight from road to rail will benefit the nation as our freight task continues to escalate. To be the mode of choice, rail needs to introduce cutting-edge technologies. ATMS is a key step in that objective.”

The Australian Government has invested $50 million into the development of the system alongside investment from ARTC and Lockheed Martin.

“While rail already has an impressive safety record, ATMS harnesses digital technologies to reduce risk across the rail network even further,” Mr Campbell said.

ATMS is capable of automatically applying the train's brakes where an overspeed has occurred and when predicting the train will exceed its end of authority should a train fail to take appropriate action for the conditions at hand.

For example, ATMS can enforce a train to a stop before it passes an end of authority displaying a stop indication, or before diverging on a switch which is improperly lined, thereby averting a potential collision.

“This system has an automatic safety intervention which provides the ability to apply a train’s brakes which prevents a train from exceeding the section of track it has permission to operate within,” Mr Campbell said.

“ATMS will prevent a range of potential issues such as train-to-train collisions, overspeed derailments and authorised incursions into an established work zone. It also means all ATMS equipped locomotives will ‘talk’ to each other to allow ‘fleeting’ to improve productivity.”

“The rail freight industry and the Federal Government are working closely together to explore the opportunities to accelerate ATMS implementation across the interstate rail network,” Mr Campbell said.

“This is being done through the Freight on Rail Group (FORG) which is reporting on progress to the Deputy Prime Minister, Michael McCormack.

“Rail is an essential part of the freight supply chain and the COVID-19 pandemic has shown just how much we rely on our rail network to support vital domestic trade and manufacturing supply chains.

“With freight demand set to increase, shifting long-haul freight from road to rail is a strategic priority and part of the Australian Government’s broader agenda for a resilient, efficient and sustainable national freight and supply chain network.

“The operation of ATMS marks a leap forward in train control, not only in Australia, but for the rail freight industry worldwide.”

Pacific National Operations Supervisor, Bernie Reid, said after consulting drivers utilising ATMS there were many identified benefits.

Mr Campbell said Australia’s nine leading rail freight businesses identified ATMS as the priority train control project to advance industry as a whole.

Between 2011 and 2031, the total domestic land freight task is expected to grow by 80 per cent. This is being driven by unprecedented population growth, coupled with increased demand from our trading partners in Asia and rapid changes in technology, e-commerce and consumer behaviour.

Without investment and reform to increase capacity and better manage demand, the annual cost of congestion in our capital cities could exceed $53 billion by 2031 underlining the need for better rail infrastructure to combat the growth in the freight task and the impact on road systems.

“The system is easy to use and understand, and there is no need to contact train control and provide times at locations which limits some of the distractions. There is also no need to raise or take a written train working authority, which means less paperwork,” Mr Reid said.

“Once we have entered the information ‘it’s set up and off we go’. Also having the ability to see up to 10km ahead to view oncoming services, any speed restrictions on the line or track worker authorities is a real benefit. The system provides realtime information and feedback with drivers looking forward to interacting with other trains and services.”

Mr Reid added that in the future ATMS will allow for trains to follow each other and have an increased safety aspect.

Victorian electricity distributor United Energy (UE) worked right through Melbourne’s COVID restrictions in 2020 to keep electricity supplies safe and reliable for its customers, but it was also preparing for summer, which usually sees more extreme conditions impact the network and put a strain on power systems.