The REDcycle crisis that never was

By Justin Bonsey

FEW events in waste have captured our attention in recent months like REDcycle’s suspension of soft plastic collections. What the Sydney Morning Herald, The Age and others have dubbed a ‘collapse’ has been variously referred to as a ‘crisis’, ‘debacle’, ‘shock’ and a ‘botched plastic bag recycling program’.

Such myopic interpretations of what is effectively a common value chain disruption to a much-loved cultural institution belie the reality that REDcycle was always the oddsagainst underdog subbing in to do what plastic packaging producers, importers, and retailers – with or without a government mandate – should do as part of a responsible business model: ensuring the cost of doing business is not externalised onto the environment, communities or government.

Putting into perspective the scale of our disproportionate distraction: REDcycle, a small social enterprise, collected only 7,000 tonnes of soft plastics per year, or about three per cent of the roughly 250,000 tonnes

used in Australia annually. Soft plastics constitute about 10 per cent of our plastic waste, of which only 13 per cent is processed for recycling and, presumably but not necessarily, recycled into products. This means that the volume of soft plastics at large represents just under 0.01 per cent of Australia’s 75.8 million tonnes per annum of waste. Of this, there has been market demand for only a small fraction of REDcycle’s collected volumes, leading to warehouses of stockpiled plastics (which may still find a future market). Flipping the maths, we’re many thousands of times more worried than we need to be – and we’re looking in the wrong direction.

This is not to diminish the extraordinary achievement of REDcycle and its partners in setting up a popular drop-off, logistics, and market-making opportunity for highly contaminated, hard-to-recycle, mixed-polymer plastics that no one else wants. Rather, it is to illustrate the absurdity of bemoaning one small piece of a larger puzzle whose true crisis stems from the supply chain, politics, and a tradition of prioritising short-term profit over

long-term distributed benefits. A classic case of polishing the Porsche while the elephant in the room ravages the house behind us, or painting a collapsing hovel in glittering gold.

But a crisis, real or perceived, is a terrible thing to waste, so let’s embrace it as a trigger for refocusing our attention from the comforting bastion of resource recovery to the higher-order principles of a circular economy, the true ESG opportunities that are just beginning to emerge.

Two heartening trends to emerge from the somewhat histrionic media response and subsequent community outcry have been an underlying devotion for soft plastic drop-off akin to that of a cultural institution, and that the rug of soft plastic complaisance has been pulled out from under us, leaving us squinting into the post-BAU glory of possibilities for a top-down strategically co-ordinated whole-of-value-chain approach. This has started to clear the way for the bigger-picture thinking we desperately need to not just stop the bleeding but to heal the wound.

(Continued on page 21)

ONE of the seminars at the recent Waste Expo held in Melbourne was entitled Key Waste Issues and Strategy 2022 and Beyond. Facilitated by TOMRA Cleanaway Communications and Engagement manager, Michelle Mandl-Keating, the panel took a deep dive into some of the key issues in the waste industry that will need addressing over the next 12 months.

One of the panellists was Jared Smith, a waste and sustainability engineer from the Torres Strait Island Regional Council. Smith has a whole list of challenges that he takes into consideration when thinking about the future, mainly because of the geographic outlay of his work area, which comprises 16 inhabited islands and more that 250 uninhabited locales.

The islands cover more than 42,000 square kilometres from the northern tip of Australia’s Cape York to within the reaches of Papua New Guinea. Although the population is relatively small compared to other places, the logistics involved in taking care of the island’s waste needs are eye-opening.

“Being island communities, we replicate several services,” Smith said. “There are 15 different water treatment plants and wastewater treatment plants. We also replicate waste management, which is quite limited at this point. We have faced some significant challenges as you can imagine – logistics are very complex when you’ve got 15 different communities.”

Due to the proximity to Papua New Guinea, the Torres Strait Islands are in a protected biosecurity zone, which produces another set of challenges for Smith and his team.

(Continued on page 24)

ISSUE 112 | FEB/MAR 2023

26 Driving resource recovery 41 Soft plastics solution 52 Equipment news Meet the ZR - Low speed. High torque. Maximum performance. Visit a reference site | Book a trial | Request a free waste audit | info@focusenviro.com.au Planning now for a better tomorrow PP: 100024538 ISSN 1837-5618

3-Stage Grinding Process

Provides Faster Reduction

Astec - Peterson's powerful up-turn 3-stage grinding process provides better fracturing of material and a more consistent product, giving you just the product your buyers are looking for.

The Impact Release System

Protects Your Investment

Astec - Peterson's patented Impact Release System's air bags provides uniform grinding and protection from contaminated feedstock, a feature unique to Astec - Peterson grinders.

The Impact Cushion System

The Second Line of Defence

Urethane cushions and shear pins help protect the mill from catastrophic damage in the event of a severe impact from contaminants in the feedstock.

Astec - Peterson offers horizontal grinders from 433-839 kW, offering grinding solutions with output at the lowest cost per ton. Visit us at www.astecindustries.com and see why we have been leading the industry for over 35 years!

www.komatsuforest.com.au

Land clearing, mulch, compost, asphalt shingle tiles, scrap wood, biomass, green waste-we can handle it am

2710D Horizontal Grinder

Portable 6 Efficient

Engine 433 kW or 570 kW

Length 1612 cm

Weight 30900 kg

Feed Opening 153 x 81 cm

5710D Horizontal Grinder

High Production with Consistent Sizing

Engine 722 kW

Length 1800 cm

Weight 42184 kg

Feed Opening 152 x 102 cm

Astec - Peterson is represented by Komatsu Forest in Australia and New Zealand, providing industry-leading product support and expertise.

6710D Horizontal Grinder

Largest Grinder with Highest Output

Engine 839 kW

Length 1860 cm

Weight 48987 kg

Feed Opening 168 x 127 cm

Komatsu Forest Pty Ltd.

11/4 Avenue of Ame ricas

Newington NSW 2127 Australia

T: +61 2 9647 3600

E: info.au@komatsuforest.com

Ltd

Komatsu Forest Pty

Why words matter

PERCEPTION is an interesting word. How one person sees a situation compared to another can sometimes be subjective. On other occasions, not so much.

The Oxford dictionary defines collapse as “to fall down or fall in suddenly, often after breaking apart”. The word postpone is defined as “to arrange for an event to take place at a later time or date”. Two words miles apart in meaning. This brings me to REDcycle, the soft plastics collection program that was recently postponed.

The number of times mainstream media used the word “collapse” regarding the “postponement” of the REDcycle program has been astounding.

This is no shoddy operation run by ne’er-do-wells hiring out warehouses, filling them with waste, taking the money, and then doing a runner. Those running REDcycle – supported by the two biggest supermarket chains in the country – are a group of passionate resource recovery professionals who are determined to find a solution to one of the smaller but most troublesome waste streams. To undermine all their hard work in the eyes of the public is not only insidious, it’s also unfair.

I guess those who run the recycling program forgot their soothsayers’ hats and should have known that the Close the Loop facility in Melbourne would burn

Chief Operating Officer

Christine Clancy christine.clancy@primecreative.com.au

Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au

Business Development Manager

Chelsea Daniel-Young chelsea.daniel@primecreative.com.au

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Design

Blake Storey, Kerry Pert, Tom Anderson

Client Success Manager Glenn Delaney glenn.delaney@primecreative.com.au

Head Office Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia p: +61 3 9690 8766 enquiries@primecreative.com.au www.insidewaste.com.au

down, causing a backlog of feedstock. However, the bigger problem is that Australia lacks enough infrastructure to deal with the issue. At least two companies are building infrastructure to alleviate that.

One company has imported machinery capable of converting soft plastics back into oil which will be reused in various ways. The machine can convert five tonnes a day. The company will scale up to an even bigger device if all goes well.

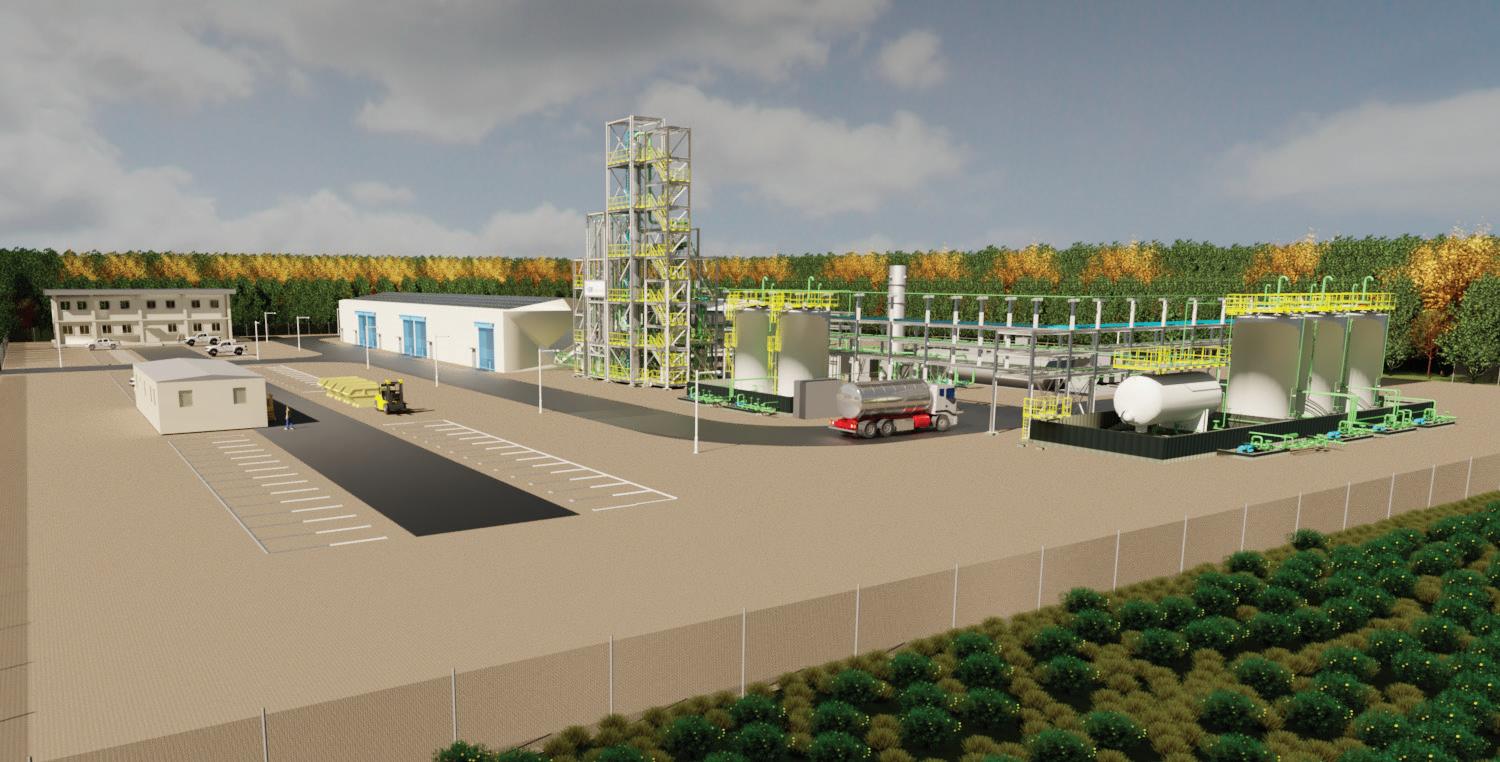

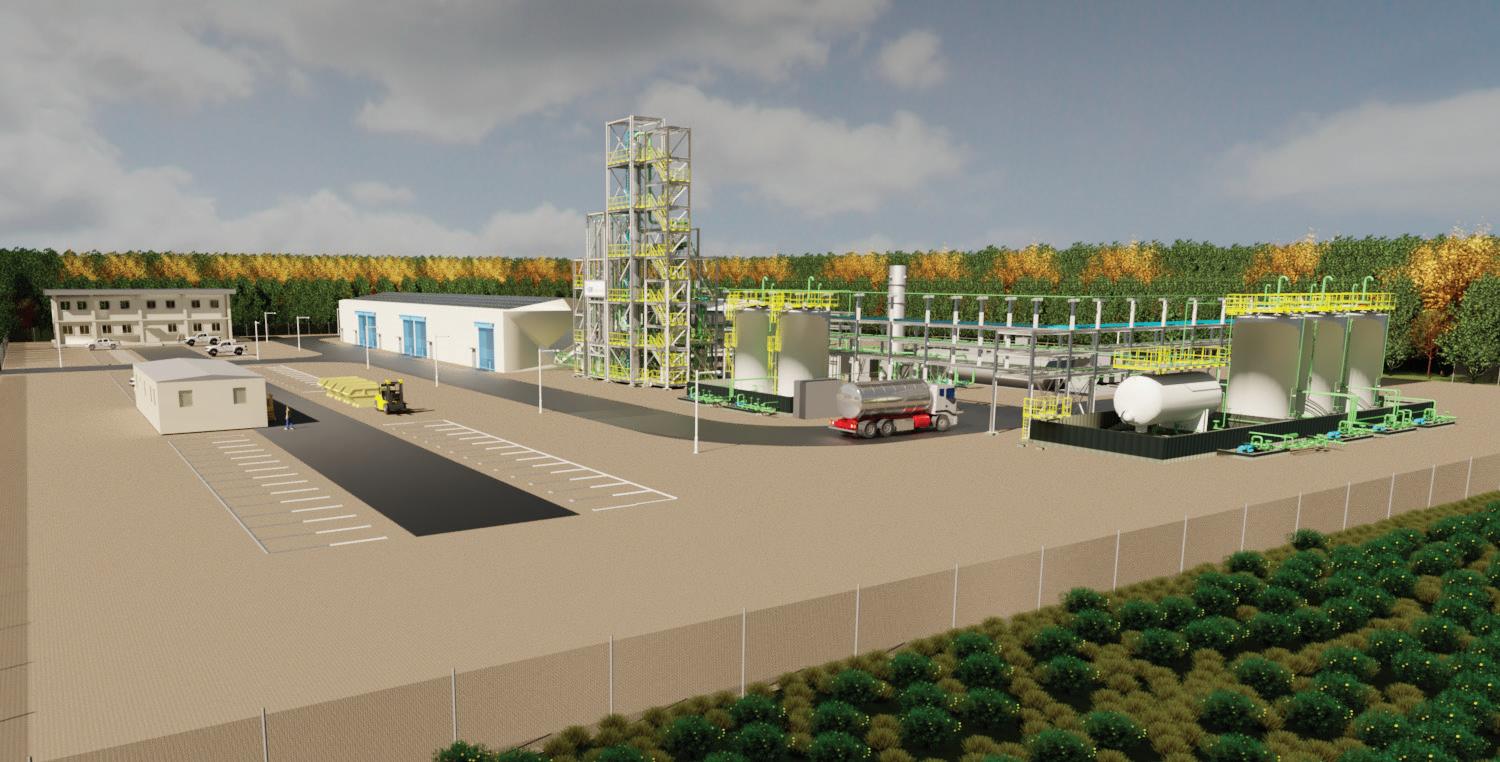

Then there is Licella, which has permission to build a plant in Victoria, which will be able to process 70,000 tonnes of plastics a year soon after commissioning. It will quickly scale up to produce 120,000 tonnes a year of oil. Not only will it do away with soft plastics, but it will create an environment where less virgin plastic is needed.

When you look at the two operations, the 8,000 tonnes of material found in warehouses throughout NSW and Victoria is minuscule. In fact, these two companies may be competing for limited feedstock soon after operations begin.

REDcycle is far from dead and buried. Should there be a debrief and look to find the lessons learned? Absolutely. But to say REDcycle has ‘collapsed’ is not only an exaggeration, it’s simply not true.

Subscriptions +61 3 9690 8766

subscriptions@primecreative.com.au

Inside Waste is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright

Inside Waste is owned by Prime Creative Media and published by John Murphy.

All material in Inside Waste is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Waste are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Call: 03 9706 8066 Email: sales@appliedmachinery.com.au Visit: www.appliedmachinery.com.au or www.genoxmachinery.com.au

THINKING.

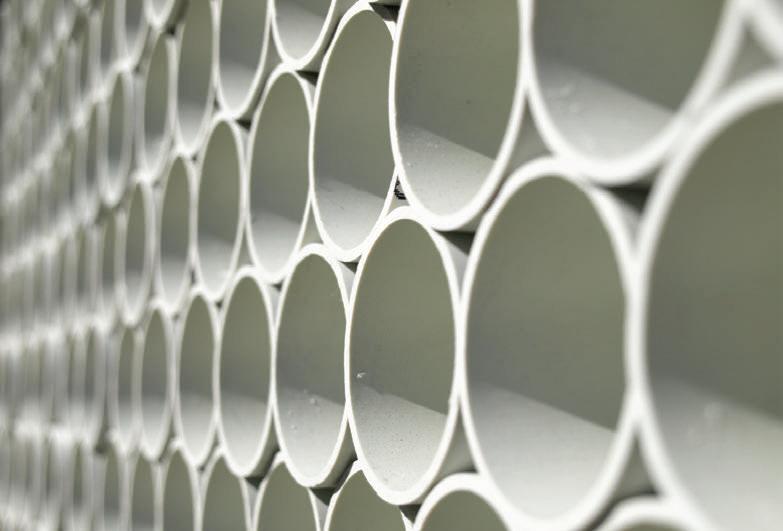

new J-Series pipe shredder is specificially designed for HDPE plastic pipes.

a unique multi-rotor design and long life counter knives, it quickly shreds different diameter and sized pipes. Like all Genox equipment it comes with the support and back up that only a true local machinery partner can provide. Daily news updates at www.insidewaste.com.au Editor’s Note // 4 INSIDEWASTE FEBRUARY/MARCH 2023

GENOX’S NEW SHREDDER IS A PLASTIC PIPE’S WORST NIGHTMARE. THAT’S

APPLIED

Genox’s

With

Millions of dollars secured to get better deal on waste

RATEPAYERS in New South Wales will benefit from a NSW Government program that could save councils an estimated $170 million annually on kerbside bin collection and other waste services via joint waste contracts, according to Local Government NSW.

Environment Protection Authority (EPA) Chief Executive Officer Tony Chappel announced the launch of the $16 million service that will help NSW councils join forces and find waste providers who deliver the best value for communities and focus on driving forward the circular economy.

“Councils are at the frontline of waste management in NSW, spending around $1.7 billion each year on waste and recycling services,” Chappel said. “The EPA’s

new service will support councils around the state to work together to get the most competitive deal, driving down council costs and ensuring ratepayers get the best value for money.

“Finding the best deal on these services can be difficult, especially for councils with small budgets, but our new program will help councils compare waste providers and provide a ‘one-stop-shop’, with a dedicated team providing tailored assistance.”

Chappel said that by lowering costs and simplifying the process, councils can focus their energy on reducing waste in their communities, which in turn, contributes to the circular economy and helps meet a target of net-zero emissions by 2050.”

The new service is part of a $356 million Waste and Sustainable Materials Strategy, which outlines the actions that will be taken to transition towards a circular economy.

From 30 January 2023, councils will have access to the joint procurement service, including:

• a funding pool of up to $500,000 per group to help councils access the best advice to jointly procure services

• an information service via the NSW EPA website to equip councils with quality and timely market data and analysis to help make informed decisions

• an online library of training and guidance materials so councils can navigate complex contract challenges.

Chappel said joint waste contracts can help councils to strategically plan their waste service delivery and infrastructure, ease transaction costs and streamline administrative processes.

ANNEXURE A

Cobra Group convicted and penalised for the contravention of a condition of its environment protection licence

On 2 September 2022, The Cobra Group (Aust) Pty Ltd (Cobra Group) was convicted by the Local Court of an offence against s 64(1) of the Protection of the Environment Operations Act 1997 (the Act) for the contravention of a condition of its environment protection licence. Cobra Group holds an environment protection licence authorising it to carry out certain waste activities at a facility in St Marys. The licence contains a condition limiting the amount of waste that can be received and processed at the facility to 10,000 tonnes per year. The NSW Environment Protection Authority (EPA) reviewed the waste contribution monthly reports submitted by Cobra Group to the Waste and Resource Reporting Portal. The data showed that 21,706.46 tonnes of waste was received, and 21,295.85 tonnes of waste was transported from the facility between 19 September 2020 and 18 September 2021.

The EPA prosecuted Cobra Group in Mt Druitt Local Court. The Court convicted the company of one offence against s 64(1) of the Act and ordered it to:

1. Pay a fine of $55,000.00;

2. Pay the EPA’s legal costs of $13,000; and

3. Publish this notice at its own expense.

Daily news updates at www.insidewaste.com.au 6 INSIDEWASTE FEBRUARY/MARCH 2023 News // If you wish to let our readers know your latest machinery and its capabilities, then you should be in Inside Waste’s Product Profile section. GET YOUR PRODUCT PROFILE IN NOW! For more information on how to make the most of this opportunity contact Chelsea Daniel-Young: Email: Chelsea.daniel@primecreative.com.au Ph: 0425 699 878

The new service is designed to get ratepayers the best value for money.

LGA of SA lobbies for changes in asbestos guide

THE LGA of SA has successfully advocated for changes to the Federal Government’s asbestos guide for local councils following sector-wide consultation.

In September, the LGA went out to the sector to consult on a guide to combat the illegal dumping and improper disposal of asbestos.

Following this consultation, the LGA made a submission to the Federal Government to improve the guide for local councils. The Asbestos Safety and Eradication Agency have made changes based on the recommendations the LGA put forward.

A summary of the changes lobbied for by LGA of SA include:

• The guide has been split into two parts: the guide and supporting

information. The guide now clearly outlines the obligations of councils to have asbestos management and gives advice on how councils can deliver their obligations.

• It also indicates the importance of engaging licensed asbestos professionals in each of the three asbestos waste journey zones: awareness, removal, and disposal.

• The sustainability and resourcing for programs has been recognised as a significant challenge for councils. The Principles for Developing Actions (in the guide) and the Strategy Design Process (in the supporting information) provide suggestions for addressing these challenges.

The guide is now more accessible and has a clear call to action –to take action to address illegal disposal of asbestos. Councils are also encouraged to link to asbestos. sa.gov.au as the single-source for the most up-to-date information. The benefits of collaboration have also been made clearer by the inclusion of more case studies to help encourage more knowledge

sharing and setting out clear demonstrable paths of action.

The documents are intended to help councils consider new ideas and explore opportunities to help combat the illegal disposal of asbestos. The Asbestos Safety and Eradication Agency intend to update these resources as new actions, innovations, and best practice examples arise.

Daily news updates at www.insidewaste.com.au 8 INSIDEWASTE FEBRUARY/MARCH 2023 UP TO 12 FRACTIONS IN A SINGLE SPOT FEEDING BUNKER CONVEYOR 1: DOCKING STATION CONVEYOR 2: DOSING CONVEYOR MAGNETIC SEPARATOR VIBRATORY FEEDER SENSOR BOX ROBOTIC SORTING LINE 1, 2, 3 ROBOT ARMS STANDALONE ROBOT SORTING STATION Fully automated and independent waste sorting station: www.terex.com/zenrobotics This turnkey solution is the fastest and easiest way to get all the benefits of AI-powered sorting at a low operation cost. LOW OPERATION COST RUN UNMANNED EASY TO OPERATE SAFE SORTING UP TO 6900 PICKS PER HOUR

News //

Changes have been made to the asbestos guide for local councils.

AWRE expands footprint and Summit in 2023

THE Australian Waste and Recycling Expo (AWRE) will be back in July 2023 with an expanded schedule including the popular Resource Recovery Summit, getting a whole day of exposure compared to the half day it got at the 2022 event.

Sofie Teh is the product manager of AWRE and Circularity for Diversified Communications, the event organiser. The expansion of the Resource Recovery Summit is due to the popularity of the inaugural event.

“It was sold out and was a great success,” she said. “The AWRE exhibition is fantastic and is a great showcase of products and services within the industry, we also recognise that the industry wants to have a platform for discussion, which is what the Summit provides.”

Teh said it allows a forum to discuss the current state of the waste and resource recovery industry and look at the roadblocks to achieving a sustainable resource recovery system.

The aim of the Summit is to provide a platform to get these key decision makers and industry involved to ‘beat the drum’ on the topic at a national level, as well as trying to get more

government involvement and action in the issue.

Call for speakers for the Seminar Series and Summit is currently open, and more information can be found on the AWRE website.

AWRE will have a couple of new areas of focus including the Recycled Zone showcasing end products that have been produced using recycled materials. In 2022 there was also an Innovation Zone and Pitch Fest, and like the Summit this will return bigger and better due to popular demand. To cap it off, the AORA Zone returns with a focus on organics.

What pleased Teh about the past event was the high number of attendees. There were also a number of interstate and international visitors to AWRE, which was unexpected due to the country only recently coming out of lockdown from COVID-19.

Teh is looking forward to the event, which will again be held at Sydney’s ICC in Darling Harbour from July 26-27. Already some major industry players have signed up for the event including the likes of ISUZU, Liebherr, Komptech and Method Recycling.

Get in touch to find out more or visit awre.com.au

Daily news updates at www.insidewaste.com.au FEBRUARY/MARCH 2023 INSIDEWASTE 9 // News

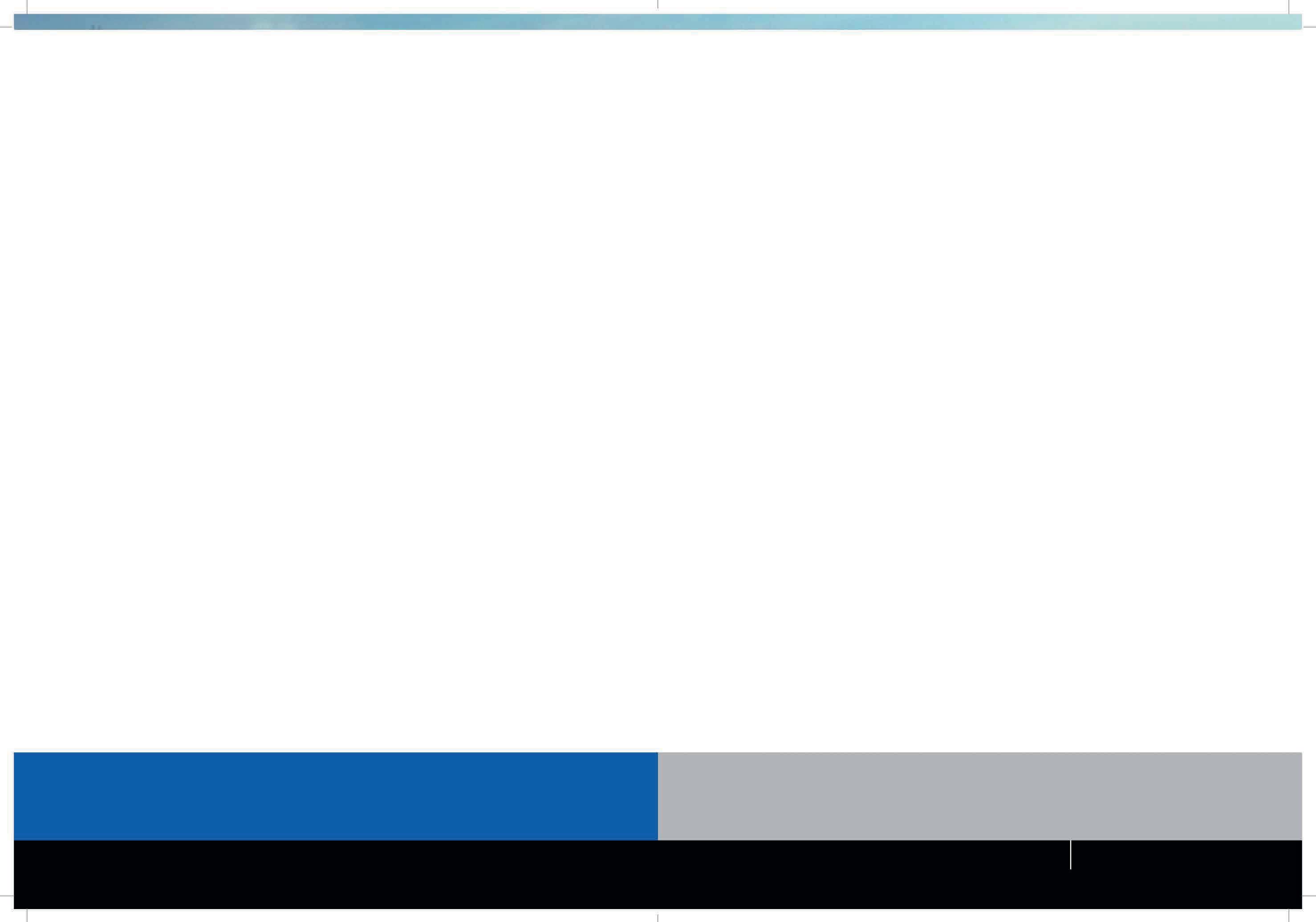

Is your Cooee intuitively captures real-time data, saving time and money with easy reporting via customisable dashboards. Accurate data drives good decisions, so you can check waste quantities and revenues at a glance, seamlessly manage tip passes and even work in off-line environments. Call us on 0447 393 363 or visit us at cooeedata.com We can help for small to medium landfills and transfer stations Get clarity with Cooee

The AWRE Resource Recovery Summit has been extended to a full day in 2023.

Nappy Loop to recycle used nappies

HUGGIES nappies’ manufacturer, Kimberly-Clark, has announced a new Nappy Loop recycling trial that could be Australia’s answer to the 1.5 billion disposable nappies that end up in landfill each year.

With approximately 300,000 babies born in Australia annually, and about 95 per cent of them wearing disposable nappies, the trial called The Nappy Loop has been underway in South Australia since July 2022. It uses anaerobic digestion to turn the organic materials in used Huggies nappies into nutrient-rich compost, as well as bioenergy that is captured and used to power the recycling process.

The Nappy Loop team is being led by Kimberly-Clark Australia, along with Australia’s national science agency, CSIRO South Australian composter, Peats Soils and Garden Supplies, Solo Resource Recovery, and early learning and care provider G8 Education. Together, the team has collected and recycled almost two tonnes of used Huggies nappies, proving that anaerobic digestion is a viable option for the recycling process.

“As Huggies is the most popular nappy brand in Australia, we not only set the standards in baby care, our goal is to set the standards for our industry in sustainability too,” said Kimberly-Clark ANZ Managing Director, Belinda Driscoll.

“Identifying a recycling solution that works hasn’t been easy due to the availability of technology and collection systems.”

The Nappy Loop trial has

adopted a B2B model, with Solo collecting used Huggies nappies from G8 Education’s Welly Road Early Learning Centre in Mount Barker and delivering them to the Peats composting facility for processing. Utilising anaerobic digestion, the organic material in the used nappies is transformed into nutrient-rich compost while the plastic components are separated and evaluated for future recycled products. In addition, the anaerobic digestion process creates bioenergy which is captured and used to power the Peats composting facility.

“CSIRO is working with KimberlyClark Australia to provide scientific validation of The Nappy Loop pilot to help tackle waste,” said CSIRO’s Principal Research Scientist Dr Anu Kumar. “Our research for this Australian trial will help inform the team on the potential scaling of the program to help reduce the number of nappies ending up in landfill.”

“Anaerobic digestion is a growing area of focus and possibility in Australia,” said Peats Soils and Garden Supplies’ Managing Director, Pete Wadewitz. “The process has been used successfully in Toronto, Canada to recycle disposable nappies and we are excited to be introducing this innovative approach in the Southern Hemisphere as we work to solve the nappy waste issue.”

After five months of recycling used nappies, The Nappy Loop team is now exploring the opportunity to scale the program in South Australia and nationally.

Daily news updates at www.insidewaste.com.au FEBRUARY/MARCH 2023 INSIDEWASTE 11 // News

Heavy duty floor topping & repair system for waste handling sites Call us for more information NO DOWNTIME FLOORING 02 8840 8888 enquiries@ascoatings.com.au | www.ascoatings.com.au > Leachate Resistant > Industrial Strength > High Impact Rating > Rapid Cure Times > Joint Repairs AS/NZS 4801

Nappy Loop uses anaerobic digestion to turn the material into nutrient-rich compost.

Process Innovations and Resource Recovery

As part of the APR Kerbside MRF upgrade, works are underway to integrate an automated robotic sorting solution. This technology will allow for picking off Tetra Paks (liquid paperboard cartons) that are currently not being captured from the container line.

The robotic system has the projected capability to remove nearly 1500 Tetra Pak cartons per hour from the recycling stream. These resources will be diverted from landfill with a capture rate and precision that is industry leading.

Once diverted from the remaining streams, the Tetra Pak’s will be processed and recycled for use in SaveBOARD. The shredded materials can be used for up-cycling into building materials for low carbon building products such as lining board applications (plasterboard, cladding and acoustic boards). Being made from 100% recycled waste provides a circular solution.

The APR team are strongly focused on circularity and working in collaboration with industry partners to explore and seize opportunities that will maximise resource recovery and further divert waste from landfill.

After glass, soft plastics was identified as the biggest contaminant of kerbside, yellowlidded bins in Victoria. As an innovative company, the APR Group continuously looks for different ways to achieve and support zero waste strategy goals and give the end user a quality material with minimal contaminants.

Trials for the advanced recycling solution that APR Plastics have brought to market has proven successful to date and resulted in the conversion of the soft plastics into feedstock oil.

Future plans include:

Up-scaling for increased capacity with a 5 tonne machine in the near future Commissioning of a 100 tonne unit to enable processing of even larger volumes Consulting and working in closely with the supply chain, industry partners, government, certification and peak regulatory bodies to collaborate on future collection schemes, processing capabilities and end markets.

APR Kerbside Pty Ltd 9 Felstead Drive Truganina VIC 3029

Delivering Innovation to

Kerbside Recycling

Regardless of what stage your municipality is at in the roll-out of the purple-lidded glass recycling bin, APR Kerbside has proven solutions and alternative options that can assist Councils whilst they prepare to make the switch.

For Municipal Councils that have partnered with APR Kerbside in the Glass-out program, their recyclables are now being received with less than 1% glass. These remarkable results have directly contributed to reducing contamination levels and further diverting waste from landfill. Improving the separation of household recyclables and having no glass in the kerbside commingled stream has led to a significant improvement in the quality of all recyclables.

Key learnings and invaluable experience gained throughout the program well positions APR Kerbside to best support the needs of Municipal Councils who are preparing to implement 'glass out' of the commingled stream, transition smoothly and re-educate residents.

Such benefits include:

Eliminate the issue of glass shards that get into all the other recyclables

and resources such as paper, cardboard, plastic and aluminium market outlets for recyclable products due to glass shards

Significantly recover more recyclable materials Reduce contamination levels and further divert waste from landfill Address and combat the limitations presented to approachable end

Increase the value of recyclables and quality of end product

The value-added sorting facility site has the capability to process:

Recyclables from Metropolitan Melbourne and Regional councils that have removed glass out of their yellow-lidded recycling bins

Paper and Cardboard

Plastics such as HDPE, PET, PP and Soft Plastics

1800 277 800 www.aprkerbside.com enquiry@aprkerbside.com.au

Cleanaway applies to allow PFAS to be landfilled

THE Environment Protection Authority (SA EPA) will undertake formal community consultation on an application to allow PFAScontaminated waste to be disposed of at the Cleanaway Inkerman landfill, north of Adelaide.

Waste Management Pacific SA (Cleanaway) applied to the EPA to add pre-treated PFAS-contaminated solid waste — certified to contain less than 50 mg per kilogram of per- and poly-fluoroalkyl substances (PFAS) — to its existing EPA landfill licence at Inkerman.

Cleanaway’s application is the second received by the EPA since it released the landfill disposal criteria for PFAS-contaminated waste in 2020.

The EPA refused a previous application at McLaren Vale in

2021 due to the location; the fractured rock aquifer beneath the site meant that any failure of the landfill liner would have been difficult to contain and would rely upon immediate intervention.

The SA EPA has since undertaken further work regarding the broader policy and operational management of PFAS-contaminated waste in South Australia, including developing draft site selection factors specific to South Australia to assist the assessment of applications.

These guidelines are being finalised in preparation for community consultation in early 2023.

All landfills are likely to contain PFAS-contaminated waste from everyday household products. However, remediated

waste soils from a known PFAScontaminated site are currently not approved for disposal anywhere in South Australia. South Australia is the only jurisdiction in Australia that doesn’t have landfills where PFAS-contaminated waste can be disposed of.

Until a landfill has been assessed as appropriate to dispose of this waste, it must remain on-site or be transported interstate.

South Australian legislation requires the EPA to engage with nearby property owners in relation to the Cleanaway application for a period of not less than 14 days.

The nearby community was first informed of the application in 2020 and has had regular updates through the established Inkerman Landfill Community Reference Group, which meets three times a year.

Daily news updates at www.insidewaste.com.au 14 INSIDEWASTE FEBRUARY/MARCH 2023 26 Blue Rock Drive, Luscombe, QLD 4207 (07) 5629 0092

News //

Cleanaway has asked the SA EPA to allow PFAS-contaminated waste to be landfilled in north Adelaide.

Metal processing giant WENDT Corp arrives Down Under

CSS Recycling Equipment Solutions, has entered a new partnership with American manufacturer WENDT Corporation.

Based in New York state and specialising in recovered metals, WENDT Corp has worked to develop essential and innovative shredding and separation technologies to achieve minimal landfill waste, reduce manufacturing costs and save labour and energy required to extract raw materials.

“WENDT Corp are the leaders in manufacturing high quality, powerful scrap metal shredders,” said Neil Coyle of CSS Recycling.

“We are excited to represent WENDT Corp in Australia and New Zealand, offering project-based longer term investment for big players, while opening up some

exciting products for mid-sized companies processing ferrous and non-ferrous.”

WENDT’s product line, purposebuilt for the scrap industry, allows CSS Recycling Solutions to offer customers the most powerful metal recovery solutions from concept throughout the life of a custom turnkey plant, Coyle said.

WENDT Corp has also developed a range of modular shredders to fit into existing operations, increasing the recovery of ferrous and non-ferrous material and a powerful option for middle market operators.

WENDT holds exclusive partnerships with industryleading technology suppliers and continuously invests in engineering, research and development.

“Historically in Australia, there were maybe two to three large scrap metal companies processing ferrous and non-ferrous in each state, with many small scrap metal merchants trading ferrous and non-ferrous,” Coyle said. “Over the past decade Australia and New Zealand have seen growth in the number of mid-sized companies processing scrap metal, and there is an opportunity to serve those clients with quality, powerful metal shredders.”

Modular metal shredding units start at 1000-2000hp with diesel or electric options and grow from there.

After 3000hp the equipment is all electric, taking advantage of the power and cost savings available.

For those operators requiring large scale processing, mega shredders range from 7000hp to

10,000hp. Turn-key and custom plant scope and design on application.

WENDT Corp sees Australia and New Zealand metal as strong growth markets.

WENDT Corp and CSS Recycling Solutions have been working together throughout 2022, formalising their association in November.

For more information visit www. cssequipment.com.au

Daily news updates at www.insidewaste.com.au FEBRUARY/MARCH 2023 INSIDEWASTE 15 Putting back to work! with Modular Sorting Feeding / Conveying / Screening / Shredding / Sorting / Separation terex.com/recycling Terex Recycling Systems modular Sorting and Separation equipment can be included in a new or existing recycling plant. Incorporating manual sorting, robotic sorting, air separation and magnetic separation to provide you with a complete recycling solution. // News

CSS Recycling Solutions has partnered with American manufacturer WENDT Corporation.

Inside Construction 2023 set to make debut

THE Inside Construction Expo 2023, presented by Inside Construction magazine, will be making its debut from September 20-21 ,2023 at the Melbourne Convention and Exhibition Centre, with the main focus being Engineering for the Future.

Designed for those working in, or associated with, major infrastructure and civil works, the main event at the Expo will be about Victoria’s Big Build, expanding out to a showcase construction on other infrastructure taking place in the state.

For Australia’s waste and resource recovery sector the Expo is important with C&I and C&D two of the biggest waste streams in the sector. It points to a future

of growing collaboration with the construction and infrastructure industries – one that the inaugural Inside Construction Expo will aim to foster.

According to Show Director, Lauren Winterbottom, the circular economy will be an area of focus for the event.

“We are looking to showcase companies that manufacture solutions for the construction industry out of recycled products,” she says. “We know this is a component of many contract tenders now, and one that will only grow.”

One example is creating synergy with Victoria’s Big Build, which was responsible for recycling 570 tonnes of plastic waste into noise walls; laid 75 tonnes of

100 per cent recycled plastic drainage pipes; used more than 321 tonnes of sustainable road base and asphalt – including more than 202 million bottles worth of recycled glass; and diverted 97 per cent of its construction waste from landfill.

2022 had its share of challenges such as skilled labour shortages and supply chain disruptions, which has meant the sector had to adapt to keep pace with a booming national infrastructure pipeline.

Winterbottom said there is no better time for a new in-person event such as Inside Construction Expo, not only to provide a forum for discussion around these challenges, but to celebrate those who have overcome them.

Daily news updates at www.insidewaste.com.au 16 INSIDEWASTE FEBRUARY/MARCH 2023

News //

Inside Contruction Expo 2023 will be held at the Melbourne Convention and Exhibition Centre.

Monash Council gives ratepayers soft plastic collection point

MONASH Council has established a collection site for Monash residents who want to continue recycling their soft plastics following the suspension of the REDCycle soft plastics recycling program at Coles and Woolworths.

The collection site, which is for Monash residents only, has been operational since December 2022 at the Monash Recycling & Waste Centre in Notting Hill.

The collection point is expected to be in place until mid-2023, when council is expecting additional information about more accessible soft plastics recycling to be available from government and industry.

Mayor, Tina Samardzija, is pleased council can offer an option for residents to recycle soft plastics.

“Monash Council is committed to

reducing what our community sends to landfill, and I am pleased we have been able to work with APR Plastics to establish a soft plastics collection point at our Monash Recycling & Waste Centre,” said Samardzija.

“We acted fast and worked hard to create this option for our residents. While this is a short-term solution which we have been able to quickly implement, I look forward to working with other levels of

government and our supermarkets to establish longer term solutions to capture and recycle soft plastics in Australia.

“The community is working hard to reduce what we send to landfill. In November, we collected a record monthly amount of green organic waste for Monash which will be turned into compost for use on Victoria’s farms, vineyards, and community gardens. Diverting soft plastics from landfill is another way we can support this work.

“Right across Australia we need to embrace and encourage reducing, reusing, and recycling. Monash Council calls for leadership from other levels of government and our supermarkets on how we do this with soft plastics, as the current system is unsustainable.”

Maximise Recovery... Reduce Landfill Costs

Superior Equipment

Innovation Service Support Testing

Eriez equipment enables the recycling industry to maximise the recovery of mixed metals from comingled waste, in turn increasing product purity to achieve the highest value.

Daily news updates at // News

Monash Council’s collection site for soft plastics will be operating until mid 2023.

From the CEO’s desk

2023 is our time to shine

Environment Ministers will meet for the second time this year on 7 December, following the first 2018 Meeting of Environment Ministers (MEM) in April, which was in part a response to the import restrictions driven by China’s National Sword Policy and the effects this policy has had across the Australian waste and resource recovery (WARR) industry. Key decisions derived from the April MEM include:

With 2023 upon us, I am optimistic that this year will be our essential industry’s year. Surely 2023 will be the year that “it will get real” for industry, business, government, and the community if we are serious about meeting Australia’s 2030 targets of 43 per cent reduction of carbon emissions and the 80 per cent average recovery of materials. 2022 was good but 2023 must be better as we have both time and behaviour against us.

•Reducing waste generation, endorsing a target of 100% of Australian packaging being recyclable, compostable or reusable by 2025, and developing targets for recycled content in packaging.

• Increasing Australia’s domestic recycling capacity.

• Increasing the demand for recycled products.

We saw a lot of action in 2022. Not only did the new Federal Government move quickly to set a stronger ambition for net zero, we saw our new Federal Environment Minister, along with state environment ministers, support the move towards a circular economy, with an emphasis on design and market development.

• Exploring opportunities to advance waste-to-energy and waste-to-biofuels.

•Updating the 2009 Waste Strategy by year end, which will include circular economy principles.

With the Circularity Gap report stating that only eight per cent of global materials are circular and over 70 per cent of global emissions stem from material management, the recent Federal directions are necessary, and the set targets non-negotiable. However, we are still miles away from where we need to be.

It is time to take stock and examine what has been achieved since these decisions were announced. Now, seven (7) months may not seem like a long time, however in that time we have seen further markets close (Malaysia, Indonesia, Vietnam) and if you are an operator under continued financial stress, seven (7) months could make or break you.

When we consider Australia’s WARR journey, we could say that 2018 was the year our industry landed hard in the public conscience. We came under the spotlight through the ABC program War on Waste as well as Trashed, and shortly after came China’s National Sword. Oh the ‘shock’ and ‘horror’ when it dawned on people that Australia, as both a net importer of products and with a diminishing manufacturing sector, was exporting valuable secondary raw material commodities offshore to be re-manufactured back into products for the global supply chain.

Following the April MEM, we have had three (3) states step in with varying degrees of financial assistance for industry (councils and operators). This should be expected considering almost all states (except Queensland and Tasmania) have access to significant waste levy income each year. On the eastern seaboard, Victoria has approximately $600 million in waste levy reserves in the Sustainability Fund and NSW raises more than $700 million per annum from the waste levy. There is certainly no lack of funds that can be reinvested into our essential industry.

Funding helps but as we know, the money goes a much longer way with Government support and leadership, as well as appropriate policy levers.

VICTORIA

The penny may have dropped but five years on, we continue to consume too much, with an overwhelmingly proportion of products being made from virgin material. This is despite numerous conversations, the most recent at this year’s COP27, on the need to change consumption and production. Australia continues to focus on retail sales as an indicator of success so, it is unsurprising that we hit Earth Overshoot Day on 23 March (28 July globally), coming in behind the USA, Canada, and UAE. This is NOT a race we want to win.

On a positive note, we do have a National Waste Action Plan but that is where that positivity ends. We can all agree that it is not a particularly good document. The document, which is thankfully up for review, was written at a time by an agency that did not understand the value and role of our industry or the system within which we operate.

Victoria has arguably been the most active and earnest in supporting the industry post-China, with two (2) relief packages announced to support the recycling industry, valued at a total of $37 million. The Victorian Government has also gone above and beyond all others states by announcing it would take a leadership role in creating market demand for recycled products.

SOUTH AUSTRALIA

The result is that despite having significant data at a federal level, there has been no consideration of how to meet our targets or actions informed by evidence and data available. What we do have is a list of actions that have not closed the gap to meet the goals set, a well-intentioned but not well thought through export ban, as well as a lack of market and infrastructure emphasis

Government announced a $12.4 million support package comprising $2 million of additional expenditure, $5 million additional funding for a loan scheme, together with targeted funding from the Green Industries SA budget. The Government has also offered grants for recycling infrastructure.

NEW SOUTH WALES

At first glance, New South Wales’ eye-watering $47 million recycling support package was heralded as the spark of hope industry needed. However, on closer inspection, the bulk of this package that was funded via the Waste Less, Recycle More initiative and therefore the waste levy, was not new, making it very difficult for stakeholders, including local government, to utilise the funds as they were already committed to other activities. Some of the criteria proposed by the NSW EPA also made it challenging for industry to apply to these grants. On the plus side, efforts are being made by the NSW Government to stimulate demand for recycled content through the intergovernmental agency working groups that have been established, though no tangible increase in demand or facilities have developed… Yet.

QUEENSLAND

Unlike its neighbours, Queensland did not provide any financial support to

or co-ordination. There has also been radio silence on the federal and state/ territory regulatory settings we operate by and no mention of carbon, let alone prioritising actions that would make the greatest impact. It is a linear document that in many ways continue to entrench business-as-usual.

We have had a sobering wake-up call with the release of the National Waste Data report, which tells us that even with a plan, we are still not on the path! To get to where we must go, we need to bring on two million additional tonnes of demand for recycled products and material every year from now until 2030, which means another 14 million tonnes of recovery infrastructure alone. That’s not to mention the design, behaviour, and regulatory change needed to support this.

industry however the Queensland Government has embarked on the development of a waste management strategy underpinned by a waste disposal levy to increase recycling and recovery and create new jobs. The State will re-introduce a $70/ tonne landfill levy in March 2019. There are also strong attempts to use policy levers (levy discounts and exemptions) to incentivise the use of recycled material and make it cost competitive with virgin material. However, little has been done to establish new markets and Government has not taken the lead in the procurement of recycled material. There are grants available for resource recovery operations in Queensland although no monies have been allocated to assist in 2018. This is troubling as Queensland rolled out its Container Refund Scheme on 1 November, which will likely impact the cost and revenue models of the State’s MRFs – as we have seen most recently in NSW.

So, in 2023, as we strengthen the National Waste Action Plan, we must capture the missing part of the supply chain that has a role in designing out waste and pollution, keeping materials in use, and fostering markets to achieve a circular economy by 2030. For the WARR sector to continue to grow, we need real and substantive action to make an impact on the five key material streams that emit the most emissions – plastic, food, textiles, construction, and transportation. We need meaty strategies that cover all aspects of the 2.6 million tonnes of plastic and 14.4 million tonnes of organics we generate. These strategies need to also operate nationally, with a focus on the 10Rs that must be supported at end of life by a systemic approach to the waste management hierarchy and associated infrastructure, including energy recovery.

WESTERN AUSTRALIA

The Western Australian Government set up a Waste Taskforce in direct response to the China National Sword. As part of this announcement, the State Government urged all local councils to begin the utilisation of a three (3)-bin system - red for general waste, yellow for recyclables and green for organic waste - over the coming years to reduce contamination. While this taskforce is a step in the right direction, we are yet to see any tangible results from it or any funding for industry. In October, the WA Waste Authority released its draft Waste Strategy to 2030, which comprises a comprehensive and detailed roadmap towards the State’s shared vision of becoming a sustainable, low-waste, circular economy.

COMMONWEALTH

Following the MEM in April, Australia now has a new Federal Environment Minister, Melissa Price, who in October reiterated to media MEM’s commitment to explore waste to energy as part of the solution to the impacts of China’s National Sword, which is troubling (EfW is not a solution to recycling). The Commonwealth has also backed the Australian Recycling Label and endorsed the National Packaging Targets developed by the Australian Packaging Covenant Organisation (APCO), which has to date, failed to incorporate industry feedback in the development of these targets. To the Commonwealth’s credit, there has been significant coordination in reviewing the National Waste Policy, with the Department of Environment bringing together industry players and States during the review process.

For our industry, there must be an understanding that we need to be environmentally and economically sustainable. Continuing to operate in a regulated environment that remains focused on linear low-cost outcomes means we cannot achieve greater outcomes. A shift in perception about the material we process – high value material, not waste – could lead to a much different approach to WARR. We need policies that support this shift, funding to bolster circular models, and regulation that enables an end-to-end approach to material management. In other words, the policy and regulatory levers that would design out waste and pollution to enable access to higher quality raw materials. We also need coordinated and clear infrastructure and licensing planning to ensure that we can access, sort, and remanufacture materials in a consolidated, certain, and cost-competitive manner (e.g., through colocation), and clear and certain regulatory pathways that will keep materials in circulation. A great place to start is an agreed national definition of waste.

And finally, we need real demand. The reality is, if you insist on using material in the market, you need to fund its lifecycle and ensure it goes back into the productive economy, ideally at highest and best use.

The updated Policy will now go before Environment Ministers on 7 December. The Commonwealth can play a key role – one that goes beyond the development of the National Waste Policy. WMAA is supportive of the Federal Government maximising the levers it has, including taxation and importation powers, to maintain a strong, sustainable waste and resource recovery industry.

AHEAD OF MEM 2

The 2023 wish list is long, but I am going to add one more thing. Leadership. Yes, from our governments but also from our industry. We continue to grow and innovate so let’s showcase our work and find ways to do even better. For example, building and then showcasing our facilities made from recycled materials, reusing our materials on share platforms, furnishing our offices with re-purposed or secondhand furniture. We are already making a difference, let’s show the rest of Australia how.

Gayle Sloan, Chief Executive Officer, WMRR

There may be movement across Australia, with some states doing better than others, but the consensus is, progress is still taking way too long. It is evident that there are funds available in almost all States to assist with developing secondary manufacturing infrastructure, however the only way that this will really happen is if there is government leadership around mandating recycled content in Australia now, not later.

Voluntary schemes like the Used Packaging NEPM, under which APCO is auspiced, are not working. We have 1.6million tonnes of packaging waste in Australia, which needs to be used as an input back into packaging. Barriers to using recycled content in civil infrastructure must be identified and removed, and Government must lead in this field and prefer and purchase recycled material. A tax on virgin material should also be imposed as it is overseas. MEM must show strong leadership on this issue. Ministers have, since April, dealt directly with operators and councils that are under stress and we have a chance to create jobs and investment in Australia at a time when manufacturing is declining. Ministers have the opportunity to be leaders of today, not procrastinators – leaders of tomorrow and we are urging

news

WMRR: Suite 4.08 | 10 Century Circuit | Baulkham Hills NSW 2135 | t: 02 8746 5000 | e: info@wmrr.asn.au | w: www.wmrr.asn.au

Chief Executive Officer

WMRR: Suite 4.08 | 57 St Johns Road | Glebe NSW 2037 | t: 02 8746 5000 | e: info@wmrr.asn.au | w: www.wmrr.asn.au Daily news updates at www.insidewaste.com.au 18 INSIDEWASTE FEBRUARY/MARCH 2023

A year in which anything is possible

Let’s continue inventing the world of tomorrow together...

What if...

2023

ENGINEERED FOR RESULTS

Our expert engineers design customised solutions that recover maximum value from challenging waste streams and give you the power to divert tons of waste from landfill.

Our solutions help recover 80 – 100% of valuable materials, creating new revenue streams with an exceptional return on investment.

An integrated water management system recycles up to 90% of process water for immediate re-use in the system, significantly reducing footprint and maintenance of settling ponds.

Visit cdegroup.com

ENGINEERED FOR YOU.

The REDcycle crisis that never was

(Continued from front cover)

WITH the Minister’s Priority List 2022-23 – which identifies a range of problematic and unnecessary plastics – hot off the press; the community up in arms about sending plastics to landfill; and more industry players than ever pursuing circular economy strategies linked to actionable plans and ESG reporting, now is the time to strike.

The best way to feed the elephant without giving up the Porsche – that is, maximising material efficiency while minimising costs, environmental impact, and unnecessary materials – is to phasein mandatory product and packaging design standards to accommodate circular economy principles.

First, design products in a way that minimises the need for packaging. And what packaging is required, use singlematerial formats that can be more easily recovered through municipal and commercial kerbside recycling as this is where most of it will end up. A good example of this is Dyson, which creatively uses simple recycled cardboard in place of polystyrene to protect the product during

shipment, which is one of the easiest materials to recover through kerbside.

If plastic cannot be avoided (and, depending on composition and format, can even be a more sustainable option), allow only higher-value transparent single-polymer formats with a clear processing and end market pathway, such as PET, RPET, PP, HDPE, and (in limited formats) LDPE. Composite materials –such as multiple-polymer plastics; coffee cups, which are cardboard lined on the inside with plastic or polylactic acid (PLA) based ‘bioplastic’; aseptic containers such as Tetrapak, which are liquid paperboard lined on the inside with thin layers of aluminium and plastic; and that pesky Apple packaging, with cardboard enveloped tightly by plastic – should be regulated out as they are so logistically, technologically and energy-intensively difficult to recycle. End markets for these types of recovered materials are so poor, that landfill is the only ‘viable’ destination.

Enforcing higher design standards for Australian and international manufacturers and brand owners will

shift some of the cost of doing business from the Australian community and local governments back to businesses and may even sharpen the teeth of co-regulatory schemes such as the Australian Packaging Covenant Organisation (APCO).

Better design standards in place, phase out all single-use plastics and bioplastics (including all oxo-degradable, biodegradable, compostable light and heavy gauge carry and barrier bags and polystyrene) to be replaced by reusable alternatives. Bring your own, borrow one through Returnr or Green Caffeen, etc, or eat in. No exceptions apart from accessibility related for impaired individuals. Absolutely must provide a carry bag? 5-10¢ per bag is negligible in relatively affluent societies. Charge $1/ bag. This would also further support an already hobbled recycling system.

For packaging that cannot be avoided (i.e. for the purpose of preserving food where there is no other alternative), let’s lend our full support to the development of the National Packaging Recycling Scheme (NPRS). This is a packaging stewardship scheme being developed by

the Australian Food and Grocery Council (AFGC) in collaboration with industry members through an extended product responsibility (EPR) scheme, where trials are underway in metro areas to collect soft plastics from Australian homes through kerbside recycling services. This can be done in conjunction with the REDcycle program. The plastics are then taken to an advanced recycling facility

Daily news updates at www.insidewaste.com.au FEBRUARY/MARCH 2023 INSIDEWASTE 21 // Thought Leadership

The REDcycle controversy offers an opportunity to reset the ESG opportunities that are beginning to emerge, according to Bonsey.

Mandates may be needed so that manufacturers design products that last longer instead of just a few years.

such as that of Licella or Qenos, where they are turned back into oil to produce more plastic packaging. Cracking the nut of kerbside soft plastics collection would enable aggregation of volumes quanta higher than in-store drop-off and enable brands to increase recycled content in packaging. The opportunity is ripe for a small levy to be attached to the sale of unavoidable soft plastics to fund collection and recycling until a future economy of scale achieves a selfsustaining pull market.

Product stewardship schemes often leverage a levy-benefit structure, where a small unit- or volume-based levy is paid at the point of sale by a producer and/ or consumer to cover the cost of product logistics and processing, and is then returned as a refund or other distributed benefits. Despite their success, Australia still has only one mandatory scheme; the others are voluntary or co-regulatory, which generally means they are optional,

vulnerable to loopholes, their success is limited by participation, and our economy is losing a valuable, time-critical opportunity to slow the haemorrhaging of resources embodied carbon emissions.

But why stop at packaging? For other major categories of goods – from consumer goods to building materials, fridges to fit-outs – design products to last and provide access to affordable repair to extend product life as long as possible (including right to repair legislation), design for disassembly and repair, and mandate collection logistics and resource recovery for end-of-life materials. This is where the most significant economic and environmental gains will be made.

Implementing phase-outs and stewardship schemes is almost always an arduous journey through the thicket of vested interests, political capital, stakeholder alignment, community support, election cycles and timing.

But what often eludes consistent quantification – and, sadly, incorporation into business models – are the true social, economic and environmental costs and benefits of losing resources and fugitive carbon emissions both upstream and downstream from a company’s main operations (think scope 3 materials and carbon emissions). If, for example, the business case for a governmentrun fridge buyback scheme were to consider the social and carbon benefits associated with extending fridge life through repairability and redistribution to disaster-affected communities and social programs, political and community support might build themselves. Some products will always post a genuine challenge; but for many, we simply need to take a longer, more comprehensive view of the distributed benefits, including the disastrous costs of not taking any action at all.

Slow they may seem to the

impatient among us, government and corporate sustainability strategies are moving quickly to include circular economy principles that cost-effectively increase material efficiency and social equality while reducing embodied carbon emissions and regenerating ecosystems and biodiversity. They are changing course not only because their stakeholders demand it and it gives us a fighting chance to survive on Planet A, but also to eliminate inefficiencies, demonstrate thought leadership, increase brand loyalty, attract investment, and scale the approach across more products and services.

Whether you’re for making money, protecting the environment, providing equal opportunity, or all of the above, why wait for the next crisis to make a better world?

Daily news updates at www.insidewaste.com.au 22 INSIDEWASTE FEBRUARY/MARCH 2023 Thought Leadership //

Justin Bonsey is principal consultant, circular economy at Edge Environment

If the use of plastics is unavoidable, where possible, make sure the type of plastic being used fits the circular economy mould.

The next-generation of advanced recycling is coming. Advanced

Recycling Victoria (ARV) is bringing Licella’s pioneering Cat-HTRTM advanced recycling solution to Victoria. A truly scalable solution to transform mixed waste plastic into high value oil, enabling the production of food-grade recycled plastic.

part of the revolution to ensure all plastic moves forward in

Find out more advancedrecyclingvictoria.com

Be

circles.

Planning now for a better tomorrow

(Continued from front cover)

THIS includes the inability to move animal and plant matter back to mainland Australia. But that isn’t the main issue – the islands are running out of space to landfill.

“It’s definitely an interesting environment to work in,” Smith said. “In many ways, it’s rewarding because there’s so many solutions to be proposed. We’re working on a few different projects. At the moment we’re moving from island to island cleaning up legacy metal waste.”

This includes wrecked vehicles, plant and machinery, white goods and construction materials littered throughout the communities. Smith is quick to point out that a lot of the rubbish comes from contractors who come to the islands and don’t remove the waste.

Currently, the island is also burning a lot of waste due to the aforementioned lack of land.

Looking to the future, Smith wants the island to adopt more sustainable, long-term plans. What that looks like, he said, is very similar to what happens on the mainland – sorting and recycling, and possibly stewardship-type scenarios.

“That is basically the plan. We’re also talking cap flows, rehabilitating each landfill on the existing footprint,” he said. “However, will the transfer stations have all these processes and staff to manage this waste stream is a question we’re constantly asking ourselves. Then we have to compost on the islands as well because no plant matter is allowed off the islands.”

One area of concern for Smith is the lack of training available to staff. And not just in the Torres Strait Islands.

“We got a grant, so we employed a waste and biosecurity engagement co-ordinator,” he said “But part of the condition of his employment was to provide him with training and career development in waste management. I looked around, and I asked a few different technical consultants about what kind of waste management training could be provided and it turns out not much – even in a national sense. There are nationally accredited courses at certificate level, but they are limited to New South Wales.

“I’d be keen to know if anybody knows of more training opportunities out there. But it’s something that’s a big step forward for us in the Torres Strait, in being

able to provide training to our staff, so that the staff know how to manage waste, and waste management.”

Another panellist was Professor Leanne Wiseman who lectures on intellectual property law at Griffith University. She was on the panel to discuss an issue that has become topical and part of the waste narrative over the past 18 months; the right to repair.

Currently some manufacturers of goods – especially electronics such as computers, smart phones and white goods – do not allow third parties to repair their products if they break down. The reason given is that the manufacturers are worried that their intellectual property will be compromised. However, cynics see it more as a cash grab by the producers to either gouge repair prices (once the product is out of warranty), or as a chance to upgrade a customer to a newer (and more expensive) version of their computer, smart phone or appliance.

Wiseman’s reasoning for being involved in the issue is more of pragmatism – making sure electronics goods last a proper lifetime so they stay out of landfills. As she pointed out, currently Australia has more than 140,000 tonnes of e-waste generated annually. She said there is a range of barriers as to why Australians can’t get their whitegoods and consumer appliances repaired.

“I don’t know if there’s anyone in this room who has any joy in replacing their washing machine, dishwasher, or refrigerator,” she said. “They’re necessary items that we have in our homes. And we know that with our parents and grandparents’ generations, once they got a fridge, it was with them for 30 or 40 years. Now when we buy a fridge, we’re lucky if it lasts for three or five years before we’ll need to replace it.”

Wiseman said that there is a whole range of barriers as to why people can’t

get electronic goods repaired or reused. They range from legal to intellectual property barriers. Any smart product in a home – whether it’s a Fitbit, iPhone, tablet, or dishwasher that connects to the internet – will have software embedded in them. Once there is software involved, copyright sits over those devices.

“Manufacturers can exert incredible control over what you can do with that device,” said Wiseman. “Even though you buy your washing machine, you can’t open it up to look inside, you can’t fix it, you can’t get access to repair or service information. Because often what we hear from manufacturers is that ‘it’s our intellectual property. That’s our R&D. We can’t share it with you’.”

Back in the day, white goods would come with a repair manual and service information as to where consumers could get spare parts for a device. Now, with software embedded into the machine, users will get an error code on a washing machine or fridge or even motor vehicles and farm equipment, whereby they will not be able to repair the product.

“Anything that’s ‘smart’ will have IP sitting over it,” Wiseman said.

Intellectual property is only part of it. Then there are the physical barriers. Wiseman cited Apple, whose devices don’t have any screws in them so you can’t take a battery out and replace it. And there are simple aspects to the device – like the on/ off switch or maybe a filter – that fails but cannot be replaced. It will be headed for a landfill at worst, or to a recycling facility when it still has life left in it.

Which brings us to the nub of Wiseman’s point during her speech. Producer responsibility, which is akin to putting together a product stewardship scheme for whitegoods and smart devices.

“What we don’t hear so much about is enhanced producer responsibility and putting the onus back on manufacturers

Daily news updates at www.insidewaste.com.au 24 INSIDEWASTE FEBRUARY/MARCH 2023 The future of resource recovery //

Right of repair is one issue where government intervention via legislation would be welcomed.

who are making and designing these goods. We need to make sure that they’re made in a way whereby they can be disassembled, that spare parts are available, and repair information is freely available to the people,” Wiseman said.

She said that in the past 12 months the federal government had completed an inquiry through the Productivity Commission looking at why consumers can’t repair and reuse these types of goods in Australia. The Commission came up with a range of recommendations around manufacturer warranties. Wiseman said there’s confusion in the consumer market about when a manufacturer warranty comes into play compared to when a person’s consumer rights come into play.

There were also recommendations that there be a repairability or product durability label on a product. This is what happened recently in France, and it looks like the European Union is considering something similar. When a consumer goes to buy a toaster or washing machine, as well as finding information about whether spare parts are available, there will be information about whether users can get access to repair and service information.

“Why shouldn’t manufacturers who make a fridge tell you how long that fridge should last, so that you can make an informed decision at that point of purchase?” said Wiseman. “There’s so much work that can be done in this space. If we can get manufacturers to design and make products in a way that batteries can be removed simply and easily by anyone with everyday tools that is a huge step in terms of the safety and the environmental effect.”

Which was a nice segue to the next speaker at the event, Libby Chapman who is the CEO of the Battery Stewardship Council. Currently, the council has about 90 per cent of the loose battery market signed up to the scheme. Chapman

believes that although that is a great number, she would like the last 10 per cent to come into the fold – sooner rather than later. That is something the council will be working on over the next 12 months. So far, the scheme has collected about 900 tonnes of batteries from the 2300 drop-off points it has around the country.

“We knew it was important to make battery recycling convenient for people,” Chapman said. “And that really was a key barrier– people were not quite sure what to do with the batteries. Now they do.”

When it comes to moving forward, Chapman believes there is still work to be done in the safety space. She said the organisation wants to convey to people the safety aspects from the beginning to the end of the process. For example?

“Many people aren’t aware that overcharging batteries causes potential for fires,” she said. “We really want to encourage people not to leave their batteries too long on the charging station – just charge up the machine and then take it off the charging station. If you’ve got smaller batteries or powerful batteries, make sure that you’re taping those before you take them to your local drop-off point, because once they’re taped, there’s a smaller chance that they can short circuit and cause fires.”

Also on the panel was Shannon Mead who is the CEO of No More Butts, which,

as the name suggests, is trying to attack the issue of cigarette butts, which are a litter hazard.

Mead started the charitable organisation when he calculated that there were up to one million butts littered in his Local Government Area (LGA) on a weekly basis, and just under nine billion around the country annually.

A key component of the cigarette, its filter, is in Mead’s sight. Not only is it made from cellulose acetate and therefore a problematic waste stream, but the World Health Organisation made a statement in 2022 that filters had zero health benefits, and therefore are unnecessary on cigarettes.

“The question then comes, can we actually look at future changes across all the states,” said Mead. “And in particular, now, could the federal government introduce some kind of harmonisation and initiate a ban on single-use plastic tobacco filter?. If that can’t be started for whatever reason – whether it be political or funding, or costs in terms of duties and excise disappearing – then go to a secondary consideration. That would be things around extended producer responsibility, or the user pays principle.

“In San Francisco, retailers are charged $1.05 US per packet that they sell, and that money goes to the city. It’s not a tax, it’s an abatement fee and it’s determined as

such by the revenue office. It is a model that can and does work.”

While there has been a decline in smoking, there has been a marked increase in vaping. What will be seen over the next 12-18 months, according to Mead, is an increase of vaping machine e-waste such as aluminium, batteries, plastics and a range of other components.

“Now we have a quadruple whammy as a new environmental threat,” he said. “So even if we do solve the worst problem of cigarette butt litter such as tobacco filters, we now have this emerging threat. One of the things I’m asking people in the industry is, ‘are you equipped and ready to start collecting e-waste and start looking at the demographics of those who have started vaping?”

It is with that last point in mind that Mead thinks it is important to start education programs on the waste stream at schools.

“We’ve obviously got great schemes and great experiences in terms of recycling,” he said.

“There are all sorts of programs that we can leverage potentially in the future. There needs to be greater accountability for those that import products, greater visibility of once we have those products where they’re being sold so we can levy them and incorporate them into an existing program.”

Daily news updates at www.insidewaste.com.au FEBRUARY/MARCH 2023 INSIDEWASTE 25 // The future of resource recovery

The panel at the seminar were from an eclectic range of arenas within the waste industry.

Thursday Island is one of 15 inhabited islands in the Torres Strait where room is running out for landfill.

Driving resource recovery to 80 per cent

By Mike Ritchie

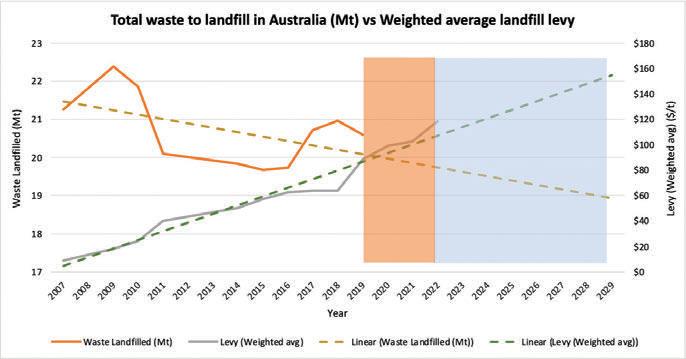

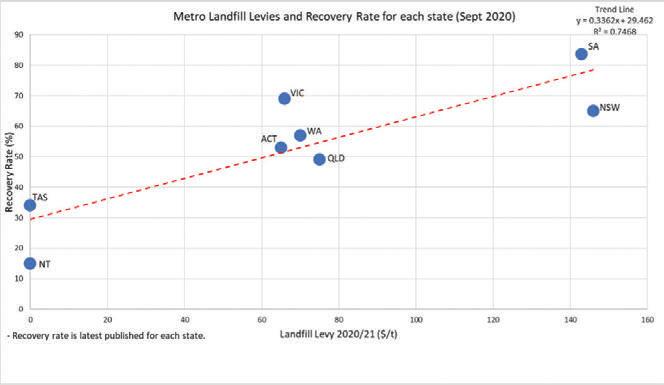

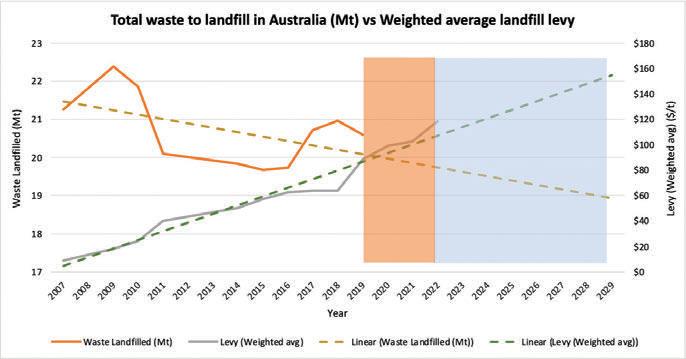

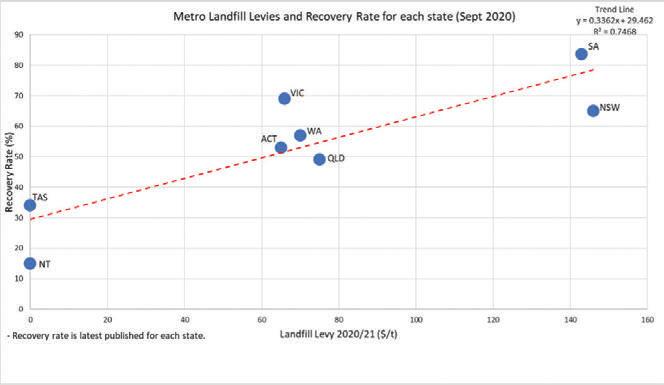

SEVENTY per cent of the growth in recycling in the past 20 years is explained by the rise in landfill levies. They change behaviour by making recycling a cheaper option than landfill.

This article tries to explain the role and contribution that the landfill levies make to resource recovery.

What is a landfill levy?

It is a state government tax paid by you and I on waste we landfill. Each time a tonne of waste goes over a landfill weighbridge, there is a tax levied on the waste. The landfill operator pays the levy to the state government if they landfill that waste. (They do not pay it if they recycle that material and divert it before the hole in the ground).

The levies vary between states as set out below.

and monitoring (40 years) or the cost of asset replacement such as buying a new property or quarry to build the next landfill. Almost none incorporate the costs of methane emissions on climate change. Many don’t even meet their full costs of operation.

That is one reason that we still landfill 40 per cent of the materials generated by the economy as “waste”. This is particularly true in regional Australia and for mixed waste streams.

Recyclers compete with landfill for materials. Higher landfill gate fees, driven by levy increases, allows recyclers to compete for access to recyclable materials as material processing for resource recovery is costly.

Most people in Australia do not realise that recycling is in direct competition with landfill for access to materials. Changing that economic balance is the key role of the levy.

2. Funding and hypothecation

The second and lesser role of the levy is a mechanism to raise funds for government and for grants/subsidies that support business and innovation in recycling.

Interestingly, the rate of hypothecation, which is the dedication or pledge for waste projects, of levy funds is the most controversial aspect of the levy. Payees want more of the levy back than governments generally want to give up. Fair enough.

Supporting recycling

There has been a lot of soul searching around the demise of recyclers including REDcycle in recent times. REDcycle was an innovative soft plastic collection system but it suffered from unstable offtake arrangements and reuse opportunities. These cases prove a number of things:

• it is hard to compete with cheap landfill for low value recycling streams such as soft plastics (84 per cent of plastic packaging goes to landfill);

• it is expensive to collect, sort, wash and process recyclables – recyclers need a decent gate fee;

• recycled products need viable and continuing markets or offtake –recyclers need minimum recycled content rules; and

• collection is not recycling because recyclers need to build reprocessing infrastructure that is profitable. It is easy to recycle some streams such as aluminium. It is ubiquitous, valuable ($1,500/t) and has strong end markets. That is not true for many things we need to recycle – mattresses, soft plastic, polystyrene and timber to name a few. The economics is often marginal at best. That is why companies go broke.

A higher landfill price allows recyclers to charge a higher gate fee for the same recycling activity and reduces their dependence on end markets.

So why don’t we have higher levies?

The main argument against levies is that it is another tax, and we hate taxes. Fair enough.

But if governments must raise revenue via taxes, my argument is that it is better that they be progressive taxes that support the economy and improve sustainability, than regressive taxes such as payroll tax, which taxes employment, or stamp duty which taxes housing.

The tobacco tax is the best-case study I can think of. Higher tobacco tax drove a reduction in the consumption of tobacco, much more than education did. The market signal worked.

People often ask, “But will government reduce other taxes in line with increases in landfill levies?” The short answer is, they should. Governments have a tax revenue requirement – better they raise revenue via a landfill tax than payroll or stamp duty.

Local government have historically been antagonistic to landfill levies because they feel it is a tax on their landfill activities. A couple of points on this:

• Seventy per cent of all landfilled waste across Australia, and therefore payment of the landfill tax, is paid by private companies not local government or householders. They generate 70 per cent of the waste that is landfilled.