Defining

WHAT is the circular economy?

What is its definition? What does it encompass? Does it mean different things to different people? Is there any legislation giving a definition of what it is?

At the recent Australasian Waste and Recycling Expo (AWRE) held in Sydney, one of the more popular seminars was titled Legislative and Regulatory Reform for Achieving a Circular Economy

South Sydney Regional Organisation of Council’s strategic lead for resource recovery, Justin Bonsey, hosted the event. He was joined by panellists Gayle Sloan CEO of Waste Management and Resource Recovery Association of Australia (WMRR), Claire Smith, environmental lawyer from Clayton Utz, and Nancy Chang, the NSW EPA’s executive director regulatory policy, initiatives and advice.

One of the starting points was defining the term circular economy.

circular economy

Was it the same as resource recovery?

Not necessarily. For Sloan, it’s not just about what happens at end of use, she said that if you want a truly circular economy it needs to be thought about differently and start at the beginning, what material we select, how we can re-use, repair and refurbish and how we set up systems to do this.

“It’s not about waste. It is changing that paradigm away from waste, which is almost too late to start in the chain,” she said. “We’re not doing anything around consumption or design. If I hear one more time how well we’re doing on that – consumption/sales etc – I’ll cry.

“We need to look at the start of the supply chain, putting obligations on people to design out waste and pollution – having to think differently. We need to start having a national Circular Economy strategy, as opposed to a national waste

strategy. If we can start thinking about how we drive change and circularity we would go gangbusters over the next 84 months when we need to have 80 per cent diversion in waste and hit our 43 per cent emissions reduction target.”

Is there any legislation in place that currently addresses what a circular economy is, what its parameters are, and how it needs to be implemented to get the best outcome for everybody? The short answer is no.

“We do have a federal piece of legislation called the Recycling and Waste Reduction Act 2020,” said Smith. “And that does have an objective in it, which requires the development of a circular economy that maximises the continued use of products and waste material over their life cycle and accounts for their environmental impacts.

(Continued on page 22)

Should wine and spirit bottles be added to

list?

WHEN the Victorian and Tasmanian governments get their respective container deposit schemes (CDS) in place in 2023, all states and territories will have a system in place whereby consumers can return their empty cans and bottles.

However, now is the time to take it one step further, according to some. Generally, most CDSs accept drink containers including plastic, canned and glass soft drink bottles, in some cases (the ACT being one) cardboard drink containers, and beer bottles.

Missing from the equation are wine/ spirit bottles, plastic milk bottles and cartons, as well as generic plastic and glass jars like those found housing preservatives such as sauces, jams and other spreads.

A who’s who of recycling recently signed an open letter asking the state and territorial environmental ministers, as well as their federal counterpart, to start including wine and spirit bottles in the CDSs around the country.

Signatories of the letter included the Boomerang Alliance’s Jeff Angel, Reloop Pacific’s Rob Kelman, the Australian Beverages Council’s Geoff Parker, the National Retailers Association’s David Stout, Australian Council of Recycling’s Suzanne Toumbourou, and WMRR’s Gayle Sloan. The letter stated:

“Our groups are writing to you to support government action to include wine and spirit bottles in the Container Refund Schemes.

(Continued on page 24)

ISSUE 110 | OCT/NOV 2022

the

INSIDE 28 New NSW EPA CEO 34 IPART and the DWMC 44 Waste Awards Finalists Meet the ZR - Low speed. High torque. Maximum performance. Visit a reference site | Book a trial | Request a free waste audit | info@focusenviro.com.au www.insidewaste.com.au

CDS

PP: 100024538 ISSN 1837-5618

3-Stage Grinding Process

Faster Reduction

Astec Peterson's powerful up-turn 3-stage grinding process provides better fracturing of material and a more consistent product, giving you just the product your buyers are looking for.

clearing,

tiles, scrap wood,

The Impact Release System

Protects Your Investment

Astec Peterson's patented Impact Release System's air bags provides uniform grinding and protection from contaminated feedstock, a feature unique to Astec Peterson grinders.

The Impact Cushion System

The Second Line of Defence

Urethane cushions and shear pins help protect the mill from catastrophic damage in the event of a severe impact from contaminants in the feedstock.

Astec Peterson offers horizontal grinders from 433-839 kW, offering grinding solutions with output at the lowest cost per ton. Visit us at www.astecindustries.com and see why we have been leading the industry for over 35 years!

Provides

Land

mulch, compost,

asphalt

shingle

biomass,

green waste-we can handle it am

www.komatsuforest.com.au

2710D Horizontal Grinder Portable 6 Efficient Engine 433 kW or 570 kW Length 1612 cm Weight 30900 kg Feed Opening 153 x 81 cm 5710D Horizontal Grinder High Production with Consistent Sizing Engine 722 kW Length 1800 cm Weight 42184 kg Feed Opening 152 x 102 cm Astec - Peterson is represented by Komatsu Forest in Australia and New Zealand, providing industry-leading product support and expertise. 6710D Horizontal Grinder Largest Grinder with Highest Output Engine 839 kW Length 1860 cm Weight 48987 kg Feed Opening 168 x 127 cm Komatsu Forest Pty Ltd. 11/4 Avenue of Ame ricas Newington NSW 2127 Australia T: +61 2 9647 3600 E: info.au@komatsuforest.com Komatsu Forest Pty Ltd

New era for the NSW EPA?

THERE ARE fair few people in the waste industry who don’t look towards the NSW EPA as a friend. It is a government department generally loved by those outside the industry as it is seen as a guardian of keeping Australia clean and green, and coming down hard on those who transgress the laws surrounding the handling and disposal of waste.

In this issue there are two articles that relate to the state government entity. One is that Tony Chappel has been appointed the new CEO of the entity after taking over from Tracey Mackey three months ago. In an address to attendees at the Australasian Waste and Recycling Expo (AWRE) Chappel said he believed a new era of co-operation is needed if industry is to meet the recovery and reuse deadlines. He also acknowledged that the government can be a roadblock when it comes to building new infrastructure, especially when it comes to regulations. He also talked about transparency, something that he thinks both the EPA and the industry could do better.

Also, there is a piece on page 26 from regular columnist Gavin Shapiro from Hones Lawyers about some of the

regulatory issues that arise when it comes to who is responsible for what in terms of processing/disposing of waste. He cites a couple of instances where even with the best intentions, some waste operators are caught between a rock and hard place when it comes to being prosecuted by the EPA. In one case, he pointed out that the operator was held liable by the EPA for an incident that seemed to be the fault of a sub-contractor who ignored the Safe Work Method Statements of the operator. While it is intrinsically unfair that an operator is blamed for the actions of a third party, Shapiro points out how important it is that liabilities are spelled out to contractors when engaging them to carry out work on premises.

Finally, the finalists are in for the Waste Innovation and Recycling Awards. We had a record number of nominations, and I can tell you it was a very hard job reducing the number of nominations in each category to the five finalists. It’ll be even harder for the judges to pick a winner, so I don’t envy them that task.

Have a great month.

Creative

John Murphy.

material in Inside Waste

copyright

be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Waste are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

no part

Daily news updates at www.insidewaste.com.au Editor’s Note //

Chief Operating Officer Christine Clancy christine.clancy@primecreative.com.au General Manager (Sydney) Terry Wogan terry.wogan@primecreative.com.au Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au Business Development Manager Chelsea Daniel-Young chelsea.daniel@primecreative.com.au Design Production Manager Michelle Weston michelle.weston@primecreative.com.au Design Blake Storey, Kerry Pert, Tom Anderson Client Success Manager Glenn Delaney glenn.delaney@primecreative.com.au Head Office Prime Creative Pty Ltd 11-15 Buckhurst Street South Melbourne VIC 3205 Australia p: +61 3 9690 8766 enquiries@primecreative.com.au www.insidewaste.com.au Subscriptions +61 3 9690 8766 subscriptions@primecreative.com.au Inside Waste is available by subscription from the publisher. The rights of refusal are reserved by the publisher Articles All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format. Copyright Inside Waste is owned by Prime

Media and published by

All

is

and

may

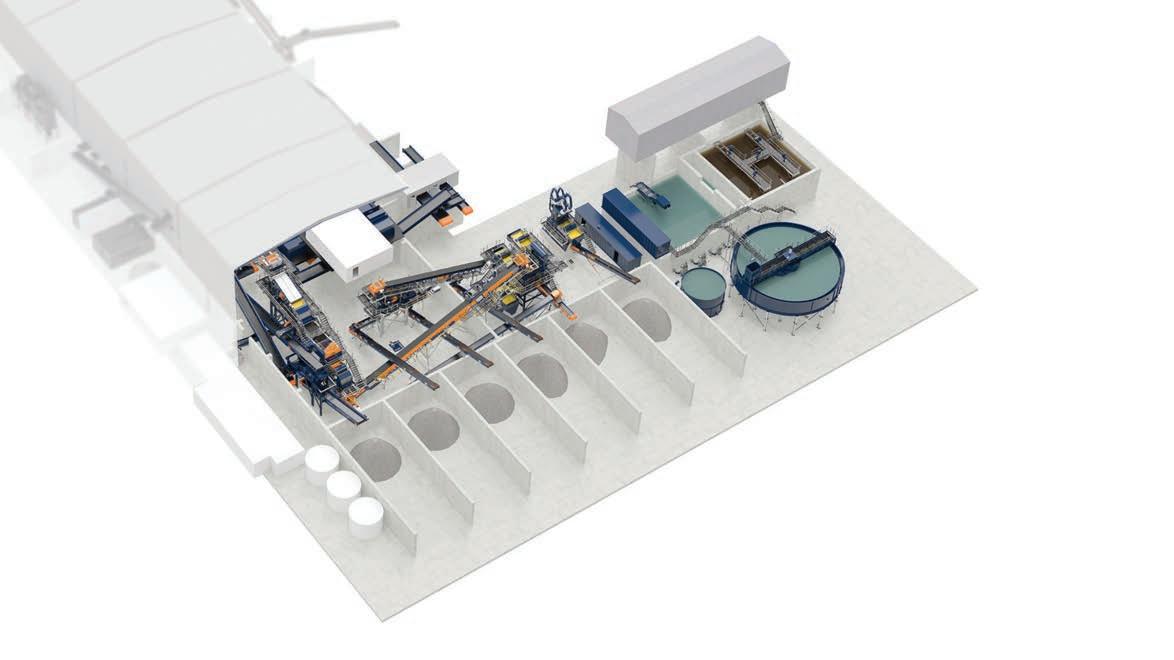

GENOX WASHING PLANTS. INTELLIGENT, COST-EFFECTIVE PLASTIC RECYCLING SOLUTIONS. THAT’S APPLIED THINKING. Genox Washing Plants are high performance recycling systems for rigid or flexible plastics from various sources, including materials with high contamination levels. These modular systems are capable of processing general plastics including HDPE and PET bottles, PP woven bags and PE film (post-consumer or agricultural). Call: Email: Visit: 03 9706 8066 sales@appliedmachinery.com.au appliedmachinery.com.au genoxmachinery.com.au 4 INSIDEWASTE OCTOBER/NOVEMBER 2022

Michael | 0417 281 795 Paul | VIC, SA & TAS | 0488 012 384 Chris | NSW, QLD & NT | 0488 288 374 RUBBLE MASTER 120X triconequipment.com.au This impact crusher boasts the best ratio of weight to throughput capacity, combined with equipment perfectly matched to each application, promising maximum flexibility. The operator can also monitor the status of the machine without leaving the cab. SAFE, POWERFUL & FLEXIBLE Call 1300 859 885 for more information Michael | 0417 281 795 Paul | VIC, SA & TAS | 0488 012 384 Chris | NSW, QLD & NT | 0488 288 374 ARJES IMPAKTOR 250 EVO This double-shaft shredder is best-in-class for processing construction and demolition waste, wood, tyres and plastics. COMPACT, MOBILE & EFFICIENT triconequipment.com.au Call 1300 859 885 for more information

When you’re building a business, reliability is everything.

Since Isuzu Trucks launched in Australia half a century ago, generations of businesses have relied on our trucks to deliver, day-in and day-out. As they’ve grown, we’ve grown along with them to become Australia’s number one truck brand. And we’ll be right here helping build businesses for a long time to come, because we know that reputations are riding on us. To find out how Isuzu can help you grow, visit isuzu.com.au

50 YEARS OF ISUZU TRUCKS

FSA/ISZS1160

Veolia-Opal-Masdar Tribe bottom ash recycling facility approved

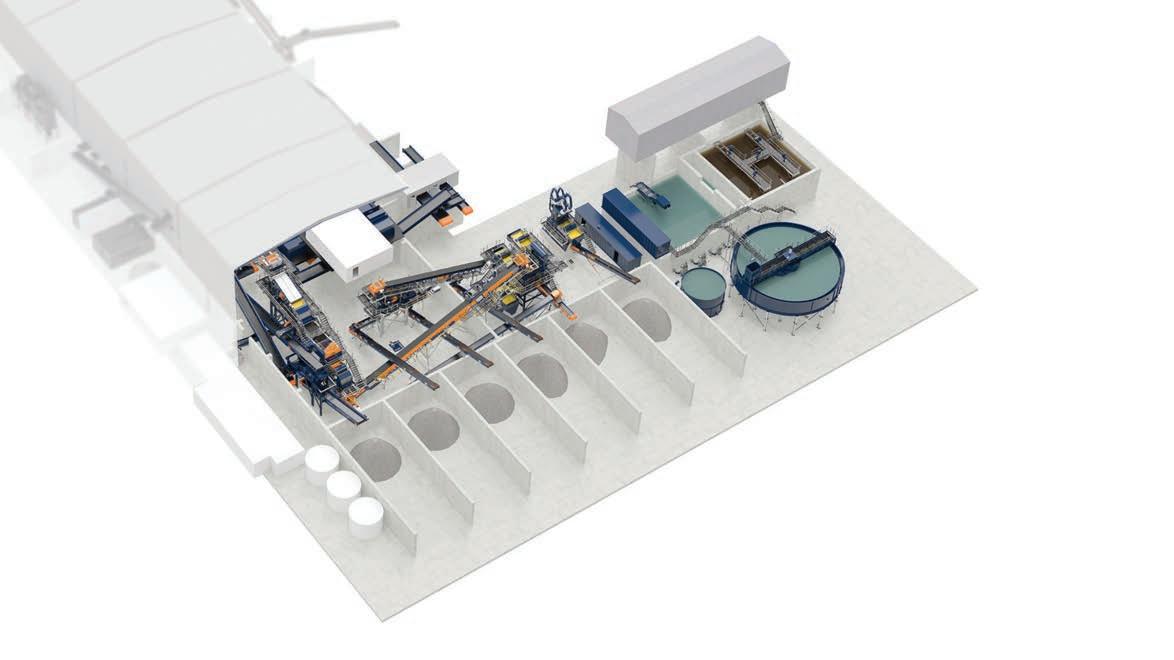

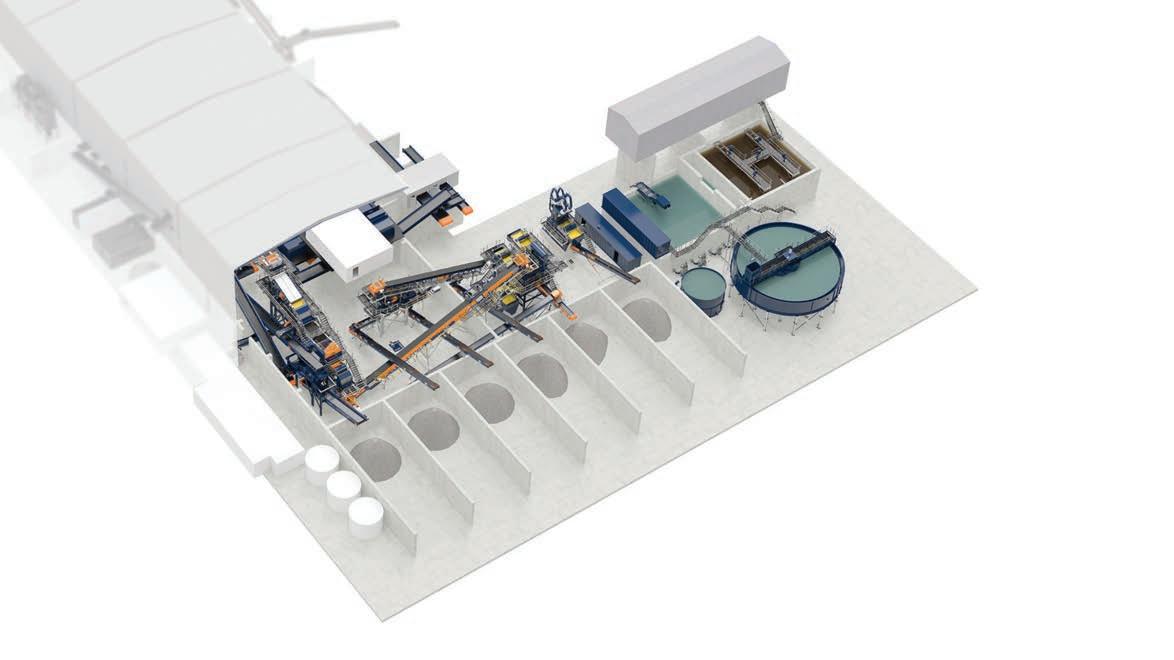

VEOLIA-Opal-Masdar Tribe’s $8 million bottom ash recycling facility has been approved by EPA Victoria. The first facility of its kind to be approved for construction in the state, it will be located with the Maryvale Energy from Waste (EfW) facility.

It will process bottom ash, recovering a range of metals before transferring them for recycling. The remaining inert materials will be suitable for processing in the manufacture of Maryvale Recycled Aggregate (MRA), a product that can be used in road construction. MRA is a lightweight recycled aggregate, unique to the Maryvale EfW facility.

The recycled aggregate will be aligned with VicRoads Class 3 and Class 4 aggregate performance standards, which are used in Victorian road construction.

During construction, the facility is expected to create 25 jobs. Once operational, the facility is expected to support 10 direct ongoing roles.

These would be in addition to the hundreds of direct and flowon Victorian jobs supported by the waste,” said Mayberry.

“Of the 325,000 tonnes of waste

David Jettner, Opal’s General Manager Corporate Development

innovative and emerging industries to the region,” said Jettner. iw

Reusable plastic bags being phased out by Woolworths

SOUTH Australia will be one of the first states to voluntarily phase out 15-cent reusable plastic shopping bags across Woolworths stores and online orders, following the retailer’s commitment to phase out the bags nationwide – a first for a major national supermarket. The change will also simultaneously take place in the Northern Territory.

Over the coming weeks, the supermarket will gradually run down stock of the reusable plastic shopping bags across South Australia and the Northern Territory, in a move that will see more than 916 tonnes of plastic removed from circulation annually.

Eight in every ten Woolworths customers already bring their own bags when they shop, and the retailer is continuing to encourage customers to bring their own bags to boost sustainability, rather than buying them in store. Woolworths’ paper bags made from at least 70 percent recycled paper will remain available to those who need them.

“Bringing your own bags is the very best outcome for the environment, and we encourage our customers to keep up the great work,” said Woolworths’ Assistant State General Manager for SA, Elisha Moore. “Paper bags will continue to be available for

those who forget to bring their own – but ultimately we want to sell less bags altogether.”

Woolworths will provide advanced notice and reminders via email, advertising and signs in store. Woolworths already offers customers reminders to bring their own bags, including signs in supermarket car parks and the option to turn on a reminder message in the Woolworths app.

Following the gradual phase out of the bags, Woolworths will continue its transition away from reusable plastic shopping bags state-by-state, committing to removing the bags from

its network nationwide by end of June 2023.

Stores in Western Australia have already removed these bags from sale in response to state legislation earlier this year.

The paper shopping bag that will remain available to customers is designed to be reused, can carry up to 6kg of groceries and can be easily recycled at home through kerbside recycling.

All paper used is sourced responsibly and is certified by PEFC or FSC, to give shoppers confidence their purchase supports sustainable forest management. iw

Daily news updates at www.insidewaste.com.au8 INSIDEWASTE OCTOBER/NOVEMBER 2022 News //

The new facility will produce aggregate for road projects in Victoria.

Waste Expo Australia set to return late October

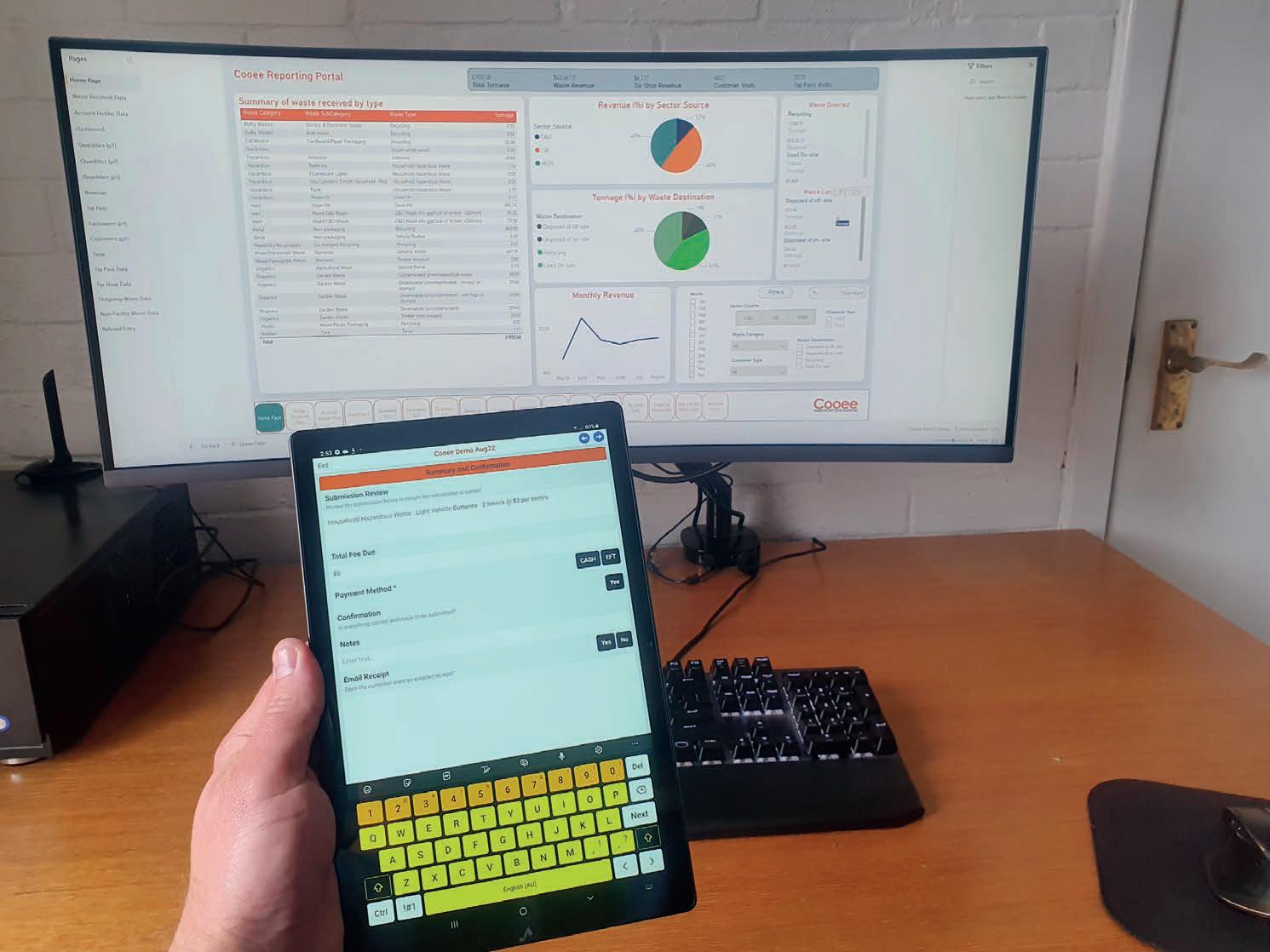

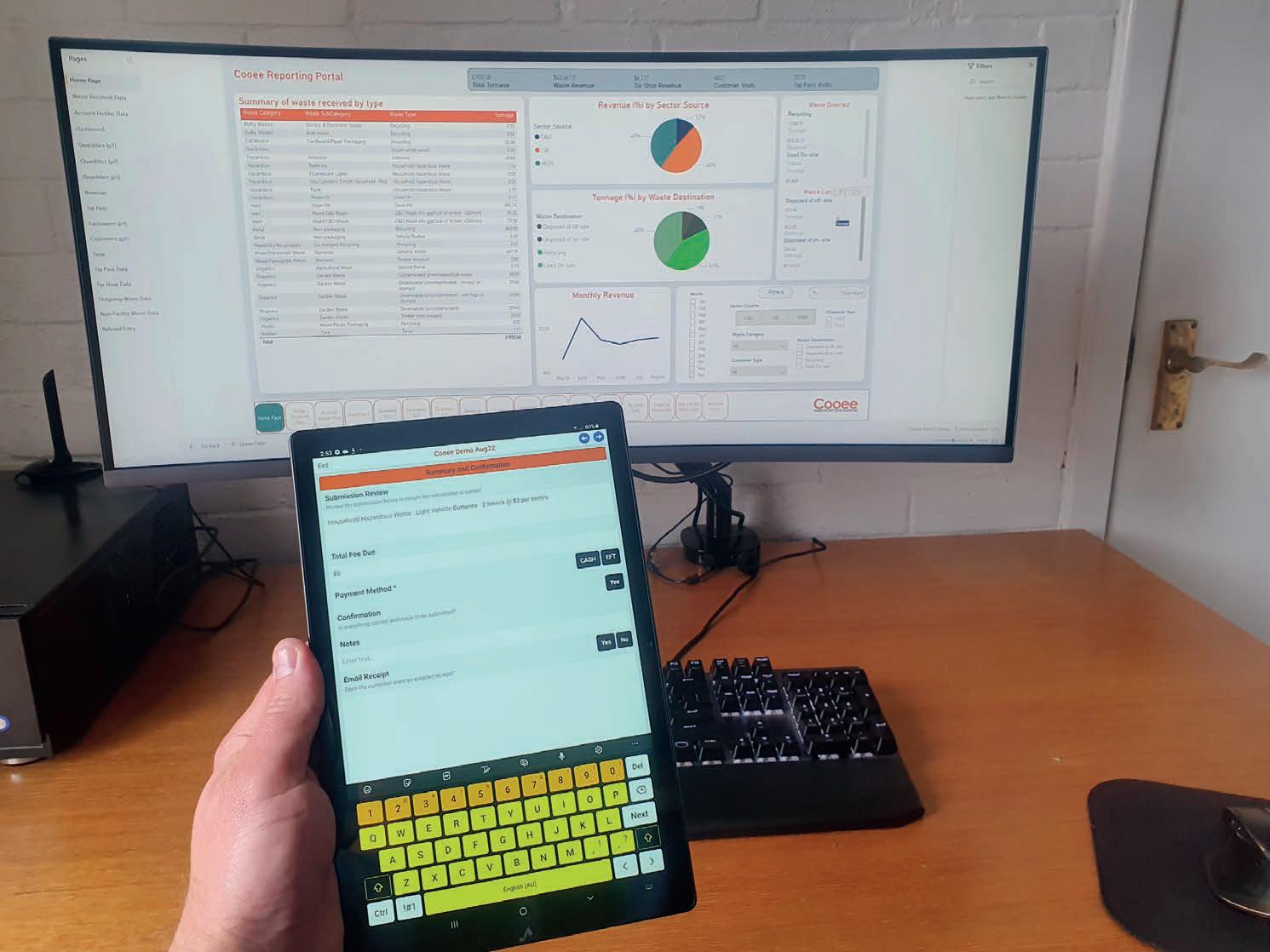

Get clarity with Cooee

WHEN it comes to waste production, Australia is amongst the top developed countries in the world to contribute – responsible for more than 76 million tonnes of waste on a yearly basis – a figure that continues to rise.

As Australia’s waste issues continues to escalate, legislation, better funding and implementation of thorough policies will help to shift the dial and provide a much-needed framework that outlines ways to improve infrastructure, increase recycling rates, tackle food and organic waste, and support better waste management reduction, recycling, and re-use initiatives.

At a crucial turning point for the industry, Waste Expo Australia returns to Melbourne on October 26th and 27th, delivering insight into the latest developments in managing waste and recycling, and covering the pertinent issues impacting the waste and recycling sector.

“Waste Expo is all about collaboration, and this year, the event will provide an opportunity to bring the industry back together in person. The Expo is designed to enable attendees to hear about innovative solutions, and how they can transform

their operations, and gain practical information and insights at the highcalibre conference. There is no other event in Australia that gives you the opportunity to hear from some of the biggest names in the industry and do business with leading suppliers for free,” said Robby Clark, Portfolio Director for the Energy & Waste Portfolio for Reed Exhibitions, who is putting on the Expo.

The free-to-attend conference and exhibition is the country’s largest gathering of waste management and resource recovery professionals. The show floor features over 100 exhibitors showcasing their solutions, with a conference featuring over 70 industry speakers who will deliver key insights on industry innovation, updates on policy and regulation, and case studies with practical and tangible solutions from industry experts who are shaping the future direction of waste and recycling in Australia.

Waste Expo Australia will once again be held in partnership with the Waste Innovation & Recycling Awards. Recognising excellence across waste and resource recovery, the awards will take place on Wednesday 26 October. iw

Daily news updates at www.insidewaste.com.au10 INSIDEWASTE OCTOBER/NOVEMBER 2022 News // Is your Cooee intuitively captures real-time data, saving time and money with easy reporting via customisable dashboards. Accurate data drives good decisions, so you can check waste quantities and revenues at a glance, seamlessly manage tip passes and even work in off-line environments. Call us on 0447 393 363 or visit us at cooeedata.comWe can help for small to medium landfills and transfer stations

The Waste Expo is a great time to see the latest innovations in the waste industry.

Woolies and Pact looking to partner on packaging

WOOLWORTHS Group and Pact are working to establish a new partnership to boost circular packaging, which could see up to 18,000 tonnes of recycled plastic used in Woolworths’ own brand packaging each year.

Woolworths Group is committed to removing plastic from packaging wherever it can, already removing more than 5,800 tonnes of virgin single-use plastic and packaging from its own brand range in FY22.

Where there is currently no viable alternative to plastic for food safety or quality, the company is working to use recycled plastic to reduce the environmental impact. The partnership being developed between Woolworths Group and Pact is expected to represent a multimillion-dollar investment in local recycling and manufacturing capacity. Projections that the partnership could see 18,000 tonnes of newly made plastic replaced with locally produced recycled plastic each year would relate to an estimated decrease in carbon emissions of almost 25,000 tonnes (equivalent to planting more than 37,000 trees) and a saving of almost 500 Olympic swimming pools-worth of water annually.

The intent of the proposed partnership is to establish Pact as Woolworths Group’s key strategic partner by volume in its efforts to deliver more sustainable packaging across its own brand range and deliver a boost to date towards Woolworths

Group’s goal to halve the use of virgin (new) plastic across its own brand packaging by 2024.

Under the proposed partnership, Pact will use recycled plastic to make more sustainable packaging for products across Woolworths’ product range, including in milk bottles, meat trays and beverage bottles, drawing on plastic collected from household recycling and container deposit schemes. Pact currently operates five plastic recycling facilities in Australia, including the recently opened PET recycling plant in Albury-Wodonga, which can recycle up to 1 billion PET beverage bottles a year. Another four facilities are planned for construction by 2025.

Woolworths Group managing director of Format & Network Development, Rob McCartney, oversees Woolworths 360 – the business’ sustainability innovation engine responsible for the development of the partnership.

“As Australia’s largest retailer we have a responsibility to make the products our customers put in their shopping baskets better for the environment,” he said. “We’re working hard to remove plastic from packaging like our bakery trays, however it can be necessary to protect quality and food safety in some products – which is why replacing it with recycled plastic is the next best thing.

“Across the scale of our range, the real challenge is sourcing quality

recycled material in the volumes we need and ensuring it’s coming from within Australia to support the development of our local circular economy and avoid shipping emissions.

“We’re working with Pact on a partnership that would propel us closer towards our sustainable packaging goal than we’ve ever been before, while also helping to grow the Australian recycling industry to meet demand in the years to come.”

“We know that consumers and businesses are increasingly demanding recycled and recyclable plastic packaging and Pact is working with committed partners like Woolworths Group to drive that change,” said Pact

Coffee cups and lids

“must be banned”

PLASTIC, single-use coffee cups and lids are a litter and waste problem in Australia, and have been for the past 30 years so must be banned, according to a spokesperson from the Boomerang Alliance of 55 environment NGOs. With over 1.8 billion coffee cups and lids littered or landfilled every year, it’s urgent to make the switch to reusables.

‘’We are proposing a national policy to Environment Ministers, based upon actions already being taken overseas making reusable coffee

cups and lids commonplace. We want to see plastic coffee cups phased out in Australia by 2024, every cafe offering or selling reusable cups and lids, and a levy imposed on all disposable coffee cups and lids,’’ said Toby Hutcheon, National Campaign Manager.

‘’Already, some states are moving with Western Australia banning plastic coffee cups in 2023 and Queensland also promising action. Our plan is practical with a transitional pathway and takes the move national.”

In the next two years plastic coffee cups and lids will be subjected to new rules around being banned across the European Union and the UK. They are recognised as a waste and litter problem across Europe. Some countries, such as Germany, are introducing laws that require all cafes to offer or sell reusable cups and lids. Other countries are planning a levy on all disposable cups and lids. Fast food chains such as Starbucks are introducing reusable coffee cups in all their European restaurants (and

Group CEO and managing director, Sanjay Dayal. “Plastic packaging that is designed effectively, that is recyclable and recycled properly in Australia can be used again and again, creating a truly local circular economy for plastics.”

In addition to its recycling facilities, Pact is also investing $76 million to install new technology and equipment across its packaging manufacturing facilities as it continues to grow local capacity to support increased use of recycled plastic in Australian packaging.

The investment is supported by a $20 million grant from the Australian Government through the Modern Manufacturing Initiative. iw

in other parts of the world, but not Australia).

‘’There have been false claims made against the use of BYO coffee cups under COVID restrictions. However, making the switch to reusable coffee cups and lids is one of the most obvious, safe options anyone concerned with plastic pollution and litter prevention can make. What we need is for all our governments not just to support reusables as they all do, but to actively intervene to get action,’’ Hutcheon said. iw

Daily news updates at www.insidewaste.com.au12 INSIDEWASTE OCTOBER/NOVEMBER 2022 News //

Left to right: Pact Group’s Sanjay Dayal, NSW Environment Minister James Griffin, and Woolworth’s Rob McCartney.

London, Oslo and Dublin Rely on Our Energy-from-Waste Technology.

So Does Perth.

to be able to

Our solutions are based on efficient and environmentally sound in-house technology, and cover the entire life cycle of an Energy-from-Waste facility. Our proven technologies have been part of more than 700 plants worldwide. As a global leader in energy from waste we are proud

say: We deliver. Check our references. Waste is our Energy www.hz-inova.com

Oslo, Norway Dublin, IrelandLondon, United Kingdom Rockingham, Australia

The trend today is to build lighter waste collection trucks that save fuel and have higher load capacities. This puts special demands on the steel, which must resist corrosion from acidic waste. Hardox® HiAce is developed specifically for these types of aggressive loads. At lower pH levels, Hardox® HiAce can extend service life by up to 3 times in comparison with a conventional AR400 steel. Test has also showed that Hardox® HiAce can outperform ordinary stainless steel, such as SS304 by almost 20%.

Don’t be surprised by unexpected corrosion. Secure your equipment’s service life with Hardox® HiAce for acidic environments. Learn more at hardox.com.

Contact SSAB Brisbane. Melbourne. Perth G1, 28 Balacalva Street Woolloongabba, QLD 4102 australia@ssab.com hardox.com

Wetherill Park waste

A stockpile of unprocessed waste that posed a fire risk has seen the Cleanaway Resource Co Resource Recovery Facility Pty Ltd in Wetherill Park fined $15,000 by the NSW EPA for allegedly failing to store waste in a competent manner.

The facility accepts general solid waste (non-putrescible), which includes such items as timber, plastics, plaster, paper and cardboard which is then processed into a combustible waste material to be used as a fuel.

EPA officers inspected the facility on 4 November 2021 following a complaint about dust emissions coming from the plant.

The EPA offers found a stockpile of unprocessed waste that was in excess of 2400m3 inside a building at Wetherill Park, which was allegedly

blocking fire escapes and firefighting equipment, which was said to increase the risk of a fire within the facility.

On 10 November, the EPA issued a Prevention Notice to the company to stop it from accepting waste until the stockpile of unprocessed waste was made compliant with industry guidelines designed to minimise fire risks in indoor waste facilities.

A $15,000 Penalty Infringement Notice is the largest fine the EPA can issue under its legislation.

Prosecutions is just one of a number of tools the EPA can use to achieve environmental compliance and includes things such as formal warnings, official cautions, licence conditions, notices and directions. iw

The company was fined $15,000 for not storing waste in a competent manner.

Daily news updates at www.insidewaste.com.au OCTOBER/NOVEMBER 2022 INSIDEWASTE 15

facility fined $15,000 // News NSW, ACT & WA Tony Miller 0429 444 451 tony@garwoodinternational.com.au VIC, TAS & SA Ian Pinney 0409 905 451 ian@garwoodinternational.com.au QLD & NT Daniel McHugh 0407 789 370 daniel@garwoodinternational.com.au NEW ZEALAND Andrew Schoer 0413 751 292 andrew@garwoodinternational.com.au A proud Australian-owned family business, Garwood International has been at the forefront of specialised waste collection & compaction equipment design and manufacture for over 45 years, providing high quality, innovation equipment solutions to meet the needs of even the most challenging operating environments. • Rear, Side & Front Loading compaction units • Single and split-body collection vehicles from 4m2 to 33.5m2 • VWS Enviroweigh bin weighing equipment for refuse vehicles AVAILABLE EXCLUSIVELY FROM: www.garwoodinternational.com.au AUSSIE! AUSSIE! AUSSIE! DESIGNED & BUILT OWNED TOUGH

resourceco.com.au TOMORROW’S SOLUTIONS. TODAY • Construction and Demolition Waste • Commercial and Industrial Waste • Tyre Recycling • Energy from Waste • Complete Material Solutions • Circular Economy Carbon Abatement Since 1992, we have repurposed over 60 million tonnes of waste. We are in the business of resource recovery –transforming waste into usable products. Find out what we can do for you.

Huge fine for man after providing false information to EPA

FORMER Royal Demolition and Excavation Pty Ltd director Maher El Masri has been given a fine of $30,000 and ordered to pay $10,000 in legal costs by Parramatta Local Court. El Masri pleaded guilty to providing false and misleading information to the Environment Protection Authority (EPA) as part of its investigation into waste offences.

The fine follows an investigation by the EPA after it was alerted in August 2019 to alleged illegal dumping at a Rossmore property.

When EPA officers inspected the property, which was not permitted to receive waste, they found stockpiles of material.

EPA officers, supported by NSW Police, then observed a truck dump waste at the property, which included bricks, timber, concrete, metal, plastic, terracotta pipes and asbestos.

The truck was registered to Royal Lion Transport Limited, a company owned by El Masri’s former business partner, Eman Masri.

On 4 September 2020, the EPA issued a statutory notice to El Masri for information and records regarding the truck attending the property.

On 20 September, the EPA received a response to the Notice from El Masri who made three false statements, namely: that he personally drove the

truck, the truck was at the premises to remove timber, and that no material was delivered to the property.

On 5 August 2022, El Masri pleaded guilty to the provision of false and misleading information to the EPA.

The EPA was alerted to the alleged waste dumping at a property in Rossmore.

He was fined $30,000, ordered to pay the EPA $10,000 in legal costs, as well as having to publicise the offence in the Liverpool City Champion local newspaper within 28 days. iw

Maximise Recovery... Reduce Landfill Costs

Superior Equipment

ServiceInnovation Support Testing

Eriez equipment enables the recycling industry to maximise the recovery of mixed metals from comingled waste, in turn increasing product purity to achieve the highest value.

Daily news updates at // News

WA govt gives carrot to councils to use recycled C&D

WA councils will receive a financial incentive to use recycled C&D waste in civil projects.

The WA $350,000 Roads to Reuse: Local Government Incentives Program provides a payment of $5 per tonne of product used by local governments and sourced from accredited suppliers.

Payments are capped at $35,000 per local government, equating to 7000 tonnes of product, and issued on a ‘first come first served’ basis.

The initiative was announced by Reece Whitby, Environment Minister, at the recent Waste & Recycle Conference 2022.

“Recycling construction and demolition waste is a priority for the Government and can play an important role in achieving the state’s material recovery targets and a more

circular economy,” Whitby said. “The use of recycled products can be very cost effective, while delivering time, labour and water savings during construction on top of significant environmental benefits.”

The incentive scheme is a State Government initiative developed by the Waste Authority and the Department of Water and Environmental Regulation, in partnership with Main Roads WA, the Department of Health and the Waste and Recycling Industry WA.

Main Roads has used more than 100,000 tonnes of ‘Roads to Reuse’ recycled products in the Kwinana Freeway widening project, as well as the Leach Highway and Tonkin Gap projects, and plans to increase use even more. iw

Daily news updates at www.insidewaste.com.au OCTOBER/NOVEMBER 2022 INSIDEWASTE 19 // News

Heavy duty floor topping & repair system for waste handling sites Call us for more information NO DOWNTIME FLOORING 02 8840 8888 enquiries@ascoatings.com.au | www.ascoatings.com.au > Leachate Resistant > Industrial Strength > High Impact Rating > Rapid Cure Times > Joint Repairs The program provide $5 per tonne of recycled product used by local governments.

news

On Australia’s WARR-path to a circular economy

IT’S been four years since WMRR launched its circular economy conference, and this year, ENVIRO returned, in Canberra, home to a federal government that has made significant climaterelated commitments in just over 100 days office.

Environment Ministers will meet for the second time this year on 7 December, following the first 2018 Meeting of Environment Ministers (MEM) in April, which was in part a response to the import restrictions driven by China’s National Sword Policy and the effects this policy has had across the Australian waste and resource recovery (WARR) industry. Key decisions derived from the April MEM include:

•Reducing waste generation, endorsing a target of 100% of Australian packaging being recyclable, compostable or reusable by 2025, and developing targets for recycled content in packaging.

• Increasing Australia’s domestic recycling capacity.

• Increasing the demand for recycled products.

When we reflect on the conversations that we are having today, we have come a long way. Sustainability no longer simply equates to recycling. Increasingly, we are seeing greater understanding that sustainability starts with material and how we manage it – moving rapidly up the waste management hierarchy and including the entire supply chain, with greater (though arguably, far from enough) consideration of issues such as consumption, product design and the direct impact these have on carbon emissions.

• Exploring opportunities to advance waste-to-energy and waste-to-biofuels.

emerging that five key material streams must be focused on globally if we are serious about tackling climate change, being – food, construction, transport, textiles, and fossil fuel extraction (plastics). Other than food, Australia does not have a national strategies for these materials. It’s time Australia rethought this, and moved from traditional thinking, to develop robust regulatory and national policy frameworks for these specific materials streams.

industry however the Queensland Government has embarked on the development of a waste management strategy underpinned by a waste disposal levy to increase recycling and recovery and create new jobs. The State will re-introduce a $70/ tonne landfill levy in March 2019. There are also strong attempts to use policy levers (levy discounts and exemptions) to incentivise the use of recycled material and make it cost competitive with virgin material. However, little has been done to establish new markets and Government has not taken the lead in the procurement of recycled material. There are grants available for resource recovery operations in Queensland although no monies have been allocated to assist in 2018. This is troubling as Queensland rolled out its Container Refund Scheme on 1 November, which will likely impact the cost and revenue models of the State’s MRFs – as we have seen most recently in NSW.

We saw that better research and data continues to be developed and published on the net benefits of moving to a circular economy, and there are several circularity metrics that should be measured. One that all countries, including Australia, remains fixated on, is carbon emissions. This is an exciting area of development because in quantifying accurately the direct and indirect benefits – jobs, environment, economy – of emissions abatement, we will be able to drive greater policy certainty and circular business model disruption. It really is time that we did our own Circularity Gap report for Australia.

WESTERN AUSTRALIA

•Updating the 2009 Waste Strategy by year end, which will include circular economy principles.

It is time to take stock and examine what has been achieved since these decisions were announced. Now, seven (7) months may not seem like a long time, however in that time we have seen further markets close (Malaysia, Indonesia, Vietnam) and if you are an operator under continued financial stress, seven (7) months could make or break you.

The new federal government has moved quickly on carbon, announcing a review of the ACCUs led by Professor Ian Chubb, consulting on options to reform the Safeguard Mechanism to tackle emissions in line with climate targets. It feels great to be talking openly about carbon and climate change. I believe that this government has its eye on the right thing – finding ways to enable emitters to take ownership of, and reduce their emissions, be it through baselines or incentives. However, these initiatives need to be aligned and integrated. A one-size-fits-all approach to earning ACCUs through the Emissions Reduction Fund (ERF) is unviable given not all emissions nor emitters are the same (e.g., carbon dioxide vs. methane; emissions produced during the manufacturing process vs. emissions produced through the receipt of disposed materials). There must be acknowledgement too that the ERF can capture many more opportunities through our sector with fresh thinking.

The Western Australian Government set up a Waste Taskforce in direct response to the China National Sword. As part of this announcement, the State Government urged all local councils to begin the utilisation of a three (3)-bin system - red for general waste, yellow for recyclables and green for organic waste - over the coming years to reduce contamination. While this taskforce is a step in the right direction, we are yet to see any tangible results from it or any funding for industry. In October, the WA Waste Authority released its draft Waste Strategy to 2030, which comprises a comprehensive and detailed roadmap towards the State’s shared vision of becoming a sustainable, low-waste, circular economy.

COMMONWEALTH

Following the April MEM, we have had three (3) states step in with varying degrees of financial assistance for industry (councils and operators). This should be expected considering almost all states (except Queensland and Tasmania) have access to significant waste levy income each year. On the eastern seaboard, Victoria has approximately $600 million in waste levy reserves in the Sustainability Fund and NSW raises more than $700 million per annum from the waste levy. There is certainly no lack of funds that can be reinvested into our essential industry.

I think that we are on the cusp of real change both in policy and behaviour. ENVIRO provided a forum for presenters and delegates to explore the roles and responsibilities we need based on where we are at, and where we want to be.

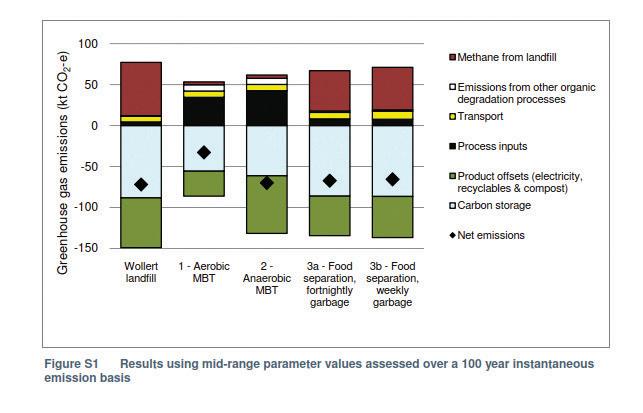

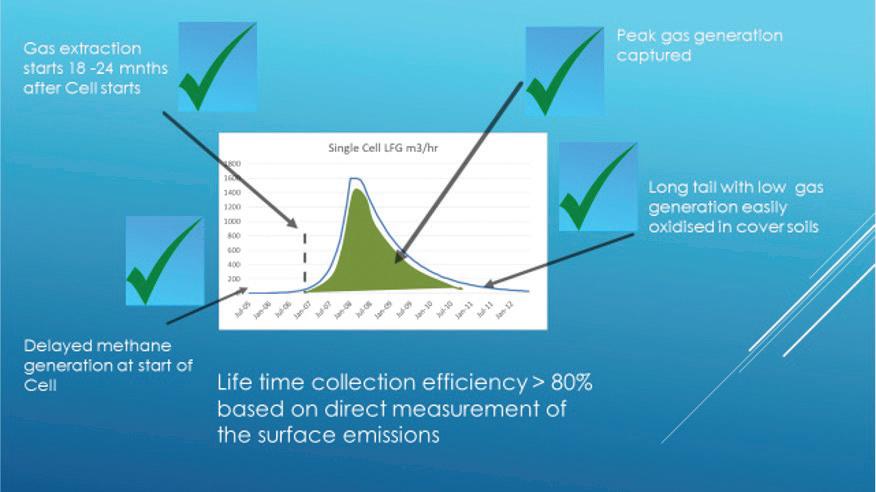

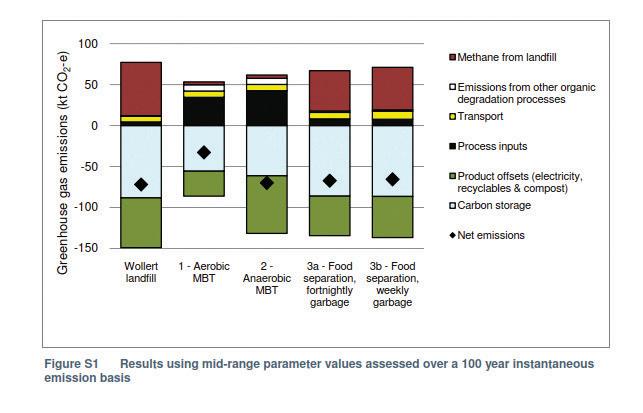

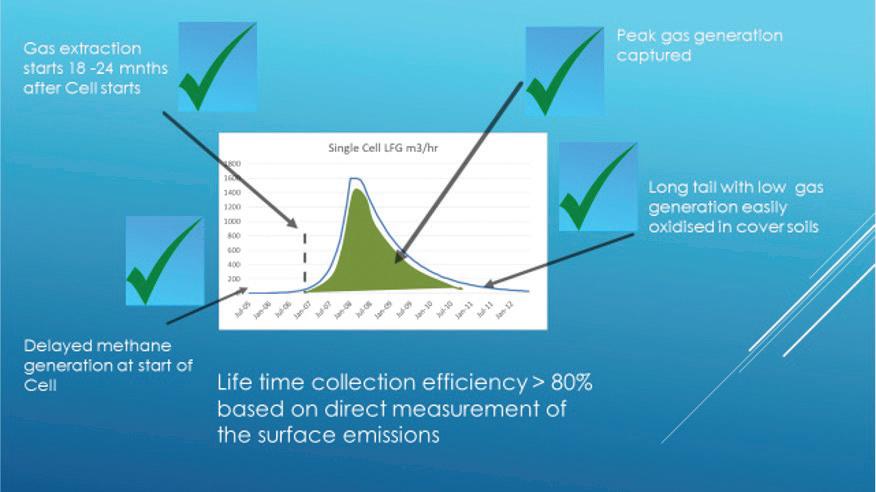

The fascinating presentation by Taku Ide’s of Cleanaway was a highlight, exploring the work being done by Cleanaway to define its emissions reduction targets to align with a 1.5˚C world. There was a real ‘a-ha’ moment as Taku explained the two main greenhouse gases that we should take into account – carbon dioxide and methane – and how they heat or cool the Earth. We need to aim for net zero carbon dioxide equivalent (CO2-e) emissions and de-production of methane. In Australia, methane emissions from landfill contribute about 10 per cent of Australia’s total methane emissions; the remainder come from fugitive emissions from agriculture, oil and gas sectors. Our sector only contributes 2.5-3.5 per cent of Australia’s total emissions of CO2-e. These are tiny volumes compared to other sectors and we already have in place initiatives to maximise mitigation. But we know that our sector is a heavy hitter, often punching above its weight and we can also do that here in three ways – if we displace virgin material with secondary raw material; return carbon-derived products back to soil; and use residual waste to produce low carbon energy.

It is no secret that Australia is behind in the circular economy ‘race’ but there was a definite feeling in Canberra that we are working to close the gap. However, we are missing a clear, agreed vision as to how we get there. The task is not insurmountable as we are not the first to do this. We can get there quicker by drawing on international experience.

Funding helps but as we know, the money goes a much longer way with Government support and leadership, as well as appropriate policy levers.

VICTORIA

Following the MEM in April, Australia now has a new Federal Environment Minister, Melissa Price, who in October reiterated to media MEM’s commitment to explore waste to energy as part of the solution to the impacts of China’s National Sword, which is troubling (EfW is not a solution to recycling). The Commonwealth has also backed the Australian Recycling Label and endorsed the National Packaging Targets developed by the Australian Packaging Covenant Organisation (APCO), which has to date, failed to incorporate industry feedback in the development of these targets. To the Commonwealth’s credit, there has been significant coordination in reviewing the National Waste Policy, with the Department of Environment bringing together industry players and States during the review process.

Victoria has arguably been the most active and earnest in supporting the industry post-China, with two (2) relief packages announced to support the recycling industry, valued at a total of $37 million. The Victorian Government has also gone above and beyond all others states by announcing it would take a leadership role in creating market demand for recycled products.

SOUTH AUSTRALIA

WRAP UK CEO, Dr Marcus Gover and EU advisor, Scott Wyatt presented on the progress made in the region thanks to their various directives, actions on material streams, and the EU’s Green Deal. I have, and will continue, to advocate for our own Green Deal because we need a growth strategy to transform Australia into a modern, competitive economy that is decoupled from resource use and sets out a pathway to net zero. However, that is not all. We also urgently need a national circular economy, or at least a material management strategy that links priority materials and action to carbon mitigation, particularly if we are serious about cutting emissions by 43 per cent by 2030.

There are many reasons why we need to urgently move to a circular economy, which was brilliantly captured in mikebarryeco director, Mike Barry’s presentation. For one, pollution is increasingly visible. Geopolitical factors are having a major impact on our resources – which are quickly depleting as well – and we are seeing greater strategic control of key raw materials. For instance, the global ongoing supply chain challenges that we are facing as a result of the Russia-Ukraine war.

The updated Policy will now go before Environment Ministers on 7 December. The Commonwealth can play a key role – one that goes beyond the development of the National Waste Policy. WMAA is supportive of the Federal Government maximising the levers it has, including taxation and importation powers, to maintain a strong, sustainable waste and resource recovery industry.

I know our sector will continue to do the heavy lifting, we will continue to invest and innovate, continue to make secondary raw materials. And while we are only one part of the circular economy equation, we will play a major part in Australia’s transition to a circular economy.

AHEAD OF MEM 2

We now need the entire supply chain and our governments to work with us to break the linear dynamic of our economy. We are this close to moving from cradle to grave, to cradle to cradle, and I am optimistic that we will get there as efforts ramp up over the next 12 to 18 months.

It was obvious as the ENVIRO program continued, with a clear picture

Government announced a $12.4 million support package comprising $2 million of additional expenditure, $5 million additional funding for a loan scheme, together with targeted funding from the Green Industries SA budget. The Government has also offered grants for recycling infrastructure.

NEW SOUTH WALES

At first glance, New South Wales’ eye-watering $47 million recycling support package was heralded as the spark of hope industry needed. However, on closer inspection, the bulk of this package that was funded via the Waste Less, Recycle More initiative and therefore the waste levy, was not new, making it very difficult for stakeholders, including local government, to utilise the funds as they were already committed to other activities. Some of the criteria proposed by the NSW EPA also made it challenging for industry to apply to these grants. On the plus side, efforts are being made by the NSW Government to stimulate demand for recycled content through the intergovernmental agency working groups that have been established, though no tangible increase in demand or facilities have developed… Yet.

QUEENSLAND

Unlike its neighbours, Queensland did not provide any financial support to

Gayle Sloan, Chief Executive Officer, WMRR

There may be movement across Australia, with some states doing better than others, but the consensus is, progress is still taking way too long. It is evident that there are funds available in almost all States to assist with developing secondary manufacturing infrastructure, however the only way that this will really happen is if there is government leadership around mandating recycled content in Australia now, not later.

Voluntary schemes like the Used Packaging NEPM, under which APCO is auspiced, are not working. We have 1.6million tonnes of packaging waste in Australia, which needs to be used as an input back into packaging. Barriers to using recycled content in civil infrastructure must be identified and removed, and Government must lead in this field and prefer and purchase recycled material. A tax on virgin material should also be imposed as it is overseas. MEM must show strong leadership on this issue. Ministers have, since April, dealt directly with operators and councils that are under stress and we have a chance to create jobs and investment in Australia at a time when manufacturing is declining. Ministers have the opportunity to be leaders of today, not procrastinators – leaders of tomorrow and we are urging

Chief Executive Officer WMRR: Suite 4.08 | 10 Century Circuit | Baulkham Hills NSW 2135 | t: 02 8746 5000 | e: info@wmrr.asn.au | w: www.wmrr.asn.au From the CEO’s desk WMRR: Suite 4.08 | 57 St Johns Road | Glebe NSW 2037 | t: 02 8746 5000 | e: info@wmrr.asn.au | w: www.wmrr.asn.au Daily news updates at www.insidewaste.com.au20 INSIDEWASTE OCTOBER/NOVEMBER 2022

ENGINEERED FOR RESULTS

Our expert engineers design customised solutions that recover maximum value from challenging waste streams and give you the power to divert tons of waste from landfill.

Our solutions help recover 80 – 100% of valuable materials, creating new revenue streams with an exceptional return on investment.

An integrated water management system recycles up to 90% of process water for immediate re-use in the system, significantly reducing footprint and maintenance of settling ponds.

Visit cdegroup.com ENGINEERED FOR YOU.

Defining a circular economy will help reach industry targets

(Continued from Cover)

“BUT it’s just an objective. There’s an awful lot of work to do. We’ve got targets, but we haven’t yet got national standards and a regulatory framework to get us there.”

Sloan thinks we can look to an overseas example to at least get a start on sorting out what a circular economy is and getting a start on it, although she is not confident we are even close to it. Yet.

“If we’re doing this properly, we’re looking at some sort of Green Deal that is similar to what the EU is doing,” she said. “It’s a proper framework that goes from design, finance, carbon, product stewardship, extended producer responsibility, and pulls it together properly. But we are daylight from that.”

Smith agrees and goes one step further.

“What we’re not touching on are those elements around design standards, repairability, reuse and remanufacturing,” said Smith. “You could try and put more stuff in the waste regulation, or you could try and bring it into a broader discussion on sustainability and reducing carbon. I think there will be an enormous amount of progress in the next few years because of those emission reductions targets. If you look at embodied carbon, you look at what’s happening in the development space now, that’s being driven by those net zero commitments, but the indirect effect of that is a circular economy.”

While Chang wouldn’t be drawn on specifics when asked about the types of legislation that might be needed, she does see a role for government(s) to introduce strategies and policies around the circular economy. She said NSW is also being proactive in terms of sustainability, which is part of the circular economy.

“New South Wales introduced the Waste and Sustainable Materials Strategy, which is a 20-year strategy,” she said. “Last year, it was backed by $356 million over four years, which is to be put into both the waste and sustainable materials sector. There is a big shift in the way that the New South Wales Government is thinking about waste and recycling as well as the circular economy.

“If we compare the current strategy,

and the funding that we have in place, to the last strategy, you can see a very different paradigm. The last strategy focused on end of life, and how to deal with normal waste and residual waste. This strategy, as well as the funding that it targets, is much further up the stream. There is a $10 million circular materials fund. There is also $37 million for a carbon abatement project, which is all about industrial and construction materials that can be replaced by lower carbon footprint materials.”

Another issue is product stewardship, which has become intrinsic to any definition of circular economy. There is contention surrounding some of these programs, whether it be the various states’ container deposit schemes (CDS); why certain industries are recalcitrant to move forward with such programs; who should run them; and whether they should be voluntary or not. Some feel that if you hit producers hard – after all they are the ones that are generally paying for any remit that is paid out to the public – it might encourage them to design better packaging that will be easier to reuse.

“When I first became a lawyer in the early 2000s, one of the first things I advised our clients on was producer responsibility under the WEEE Directive, which is the Waste from Electronic and Electrical Equipment Directive. Product stewardship has been around for a while,” said Smith. “I read a piece recently about how the WEEE Directive could have been more successful if it had rewarded companies who designed their equipment in such a way as to make reuse and recycling easier. Australia has a real advantage in that it can cherry pick all the best bits of producer responsibility schemes in the EU and make them better.

“When we’re talking about product stewardship, we’re talking about take back – we’re talking about Apple taking it back, we’re talking about Samsung taking it back, we’re talking about those producers taking their products back and recycling the component parts and then producing the new equipment that stays in the economy. Distributors and retailers can also have a very important roll in that take back.”

“I can assure you that we are having a lot of discussions about product stewardship with other ministries,” said Chang. “We base that in terms of which

industry we touch on. It’s based on the evidence that we see. For example, we have a lot of data on what are the most littered environments – both terrestrial and marine. And that’s where we target those product stewardship conversations.

“We are targeting the [pollutants] that are having the most harmful impact on the environment. And in terms of PFAS issues, we have banned PFAS in terms of firefighting PFAS. We banned that last year. We made it very clear to all our firefighting agencies that unless it’s a catastrophic fire, PFAS cannot be used.”

Chang believes a collaborative approach is possible and cited Coles and Woolworths getting rid of lightweight plastic bags before legislation was introduced. She also mentioned that some major cosmetic manufacturers around the world have voluntarily started banning microbeads that are used for exfoliating.

“I’m not saying that government doesn’t have a role in intervention and stepping in,” she said. “I’m saying that ideally, what will happen in the space is government will signal to industry, or to another sector, in terms of where we would like to go. Usually, it will be through financial things like ‘here’s a grant, this is what we would like you to focus on in the energy space’.”

She also pointed out that the role of the EPA has changed over time. Her appointment as the executive director of policy being an example of where the government department has changed its sails.

“Traditionally, we didn’t have a policy area. We were regulators; we were the boots on the ground. We had technical experts to test the soil and test different products, which made sure that our mission is being delivered,” she said. “But now we go to the heads of EPA meetings, we attend environment ministers’ meetings with our federal colleagues, and we have a seat at the table. We’re not here to police. We’re here to assist. We’re here to work with industry. And we’re here to engage.”

Chang’s comment on having a seat at the table where there is access to the various governments brought up another issue by Bonsey – how complicated would it be to bring in design mandates and others covering reuse and repair, considering there are various forms of government who would have to take in the varying expectations of their various constituents. Sloan, for one, doesn’t think it would take much.

“I don’t think it would be complicated at all,” she said. “We forget that the majority of the goods, and the standards around them, are driven by what is happening in Europe, which are already bound by high standards. While we can say that with microplastics people were ahead of the ban, they were ahead of the ban because of the EU Plastic Pact, which says companies must do this and if you don’t, we’ll legislate. If you look at the 2015 New Plastic Economy document brought out by the Ellen MacArthur Foundation, everything’s basically

Daily news updates at www.insidewaste.com.au22 INSIDEWASTE OCTOBER/NOVEMBER 2022 Circular economy //

SSROC’s Justin Bonsey MC’ed the debate.

designed in Europe, manufactured in Asia, and imported to those standards.”

Sloan also believes that if Australia doesn’t adhere to similar standards, it runs the risk of becoming a dumping ground for all those products that can’t go into other countries that have the aforementioned strict protocols.

“It’s not difficult to do,” she said. “We need to reflect what’s happening in Europe and enforce it here. That’s the bit that I don’t quite get. We don’t do it. And the other thing that’s kind of missing – and is essential – it’s got to be done at a national level for so many reasons. While I understand that we have state-based regulations, we have to have a national vision for the economy that we’re trying to build, because we are one common market. The idea that people in somewhere like Albury think about what they’re buying in New South Wales compared to Victoria is a nonsense. Companies work on a national scale. We actually need to see what sort of economy we want to build nationally.

“It’s non-negotiable. We need to start having genuine sustainable design, material selection and we need to stop allowing our consumers to unknowingly purchase problematic materials that include chemicals such as PFAS and other materials that are not allowed in other nations.”

Sloan does not believe that it might be put in the ‘too hard’ basket in terms of getting all the states and authorities onside and having the time to get all the standards and legislation in place. After all, she pointed out, something similar has been done before.

“When we bought in the national disability standards, we had a 10year timeframe that we had to get all buildings, streets and roads up to code,” she said. “This is the standard we expected for our community, and we did it. And as for the government stating they don’t want to interfere with market forces, what do you think an export ban is? We are very good at sending signals to the market and setting standards.”

Bonsey also asked about carbon abatement due to one of the key targets over the next 20 years being zero net emissions by 2050. He pointed out that a circular economy revolves a lot around materials of efficiency, which he believes opens the opportunity for carbon abatements associated with using less materials, those that are more locally sourced and are durable, which in turn will mean they require less carbon to produce. Chang believes the country will meet those targets.

“The EPA just released its State of the Environment report, which shows that we are well on track to meeting 2050 net zero targets,” she said. “The

EPA will also shortly have something to say around stance on climate change, and there will be an action plan in that regard that will shortly come out for consultation. In terms of carbon credits, there are a number of things that we are looking at. There is the $37 million carbon abatement cost curve program. It hasn’t come out publicly yet, but we’ve been doing targeted consultation, which is all about [carbon abatement]. And if you look at the strategy, that’s one of the biggest funding commitments behind food organics.”

Another subject touched on was ESG, which is a system for how to measure the sustainability of a company or investment in three specific categories: environmental, social and governance.

“ESG as a term has been around since 2004 and was developed to drive sustainable finance,” said Smith. “The sustainable finance industry that’s predicated on ESG metrics, has grown from around $5 billion in 2018, to over $120 billion so far this year. If you’re looking for investment money, if you’re looking for finance, you increasingly need to apply an ESG lens to your business and supply chains e.g. through reducing your carbon emissions, biodiversity conservation, waste minimisation etc. Because companies (particularly, ASX listed companies) are increasingly reporting against their ESG metrics in their sustainability reports; a company’s impact is becoming more transparent. There’s been a big focus over the last few years on reporting against your carbon emissions. But, if you are using one of the UN’s Sustainable Development Goals (SGDs), which is one of the favoured ESG metrics, part of that is actually around the circular economy and resource recovery and waste reduction.

for a long time. When I first started I was largely dealing with the EHS manager at the company. Now, I’m being asked to go and present to the boards – you’ve got the CFO interested, you’ve got the CEO interested. It’s mainstream now and a core focus for businesses in assessing both their risks and opportunities.

Smith said there has been some pushback against the use of ESG metrics because some metrics (particularly social ones) are difficult to measure and there is currently variability and a lack of correlation or standardisation between different ESG metric tools (for example, the same company could get scores varying by up to 50 per cent or more depending on which tool is used). Some critics say that only “E” should be measured and that “E” should stand for “Emissions” as climate change is the most pressing global problem. But in terms of driving a conversation, ESG has been good in driving change and improvements in measuring and standardising metrics will come.

Finally, Bonsey asked the panellists what they thought the priorities would be moving forward. If they could be Prime Minister, Environmental Minister or any similar role that could have a say in effecting change, what would they do? While Chang took a raincheck on the hypothesis, both Smith and Sloan had some solid ideas on what they would like to see happen.

“I would start to have a conversation nationally on material management and how we consume,” said Sloan. “It’s just got to move away from this conversation at the end of the chain, where we build this community, this society, this environment, that values all that we have is in circulation. We need to have a behavioural change

consume and what we do with it. And we need to set up systems and processes that we can start thinking about. Airbnb is a precursor to the sharing economy. We’ve got to move away from owning everything. We can share, we can rent, we have to change our paradigm.”

“Mine is a mix of regulation and the use of ‘radical collaboration’ to build high-trust relationships between all layers of government, business and the technical innovators and entrepreneurs,” said Smith. “And in order to achieve everything that Gayle wants, my view is you need an independent national circular economy authority to drive that radical collaboration. That authority needs to have its own ring fenced funding, and they need to have a board with industry leaders and technical specialists on it so it has credibility. There needs to be a conduit or bridge between government (federal, state and local), major industry players and the up-and-coming entrepreneurs and innovators.

“There also needs to be a few regulatory drivers in there around the producer stewardship schemes or they won’t happen fast enough. There is also a need for more money to be pumped into circular economy initiatives. I would encourage the States and Territories to consider standardising the waste levy amount and ensure that at least 50 per cent of it was ring fenced and rolled back into the circular economy.

“Lastly, that Circular Economy Authority needs public targets in a strategy or business plan that it must publicly report against each year. There needs to be somebody who’s got overall responsibility, because what happens is, if you split the responsibility,

Daily news updates at www.insidewaste.com.au 23 // Circular Economy

Carbon abatement was just one of the subjects that caused interest among the audience.

Should wine and spirit bottles be added to the CDS list?

(Continued from Cover)

“WE believe this can be achieved within 12 months with appropriate arrangements for transition to required labelling and will have an insignificant impact on the price of the products. It will also increase the supply of clean glass for recycling including back into bottles and reduce contamination of the kerbside recyclate bin.”

Reasons for not including them in the current schemes are varied –from the reverse vending machines not set up to take them through to the wine industry itself not keen to be parting with monies, especially as the industry has a lot of smaller, boutique vineyards scattered throughout the country.

Angel is leading the charge and believes that the time is ripe to push forward with the next stage. What is interesting is that the signatories to the letter haven’t always seen eye to eye.

“The significance of the joint letter is there are two groups that were once enemies are now on the same side,” he said. “I think the wine industry is the main issue now with its transition processes, like getting integrated into the collection of various CDSs, pricing, and those sorts of arrangements.

“Some may have an issue with paying for the refunds because they are small producers, but all of that can be accounted for. I think the issue really is the length of the transition period. They were strenuously opposed to it before. They were claiming ‘most of our glass is already recycled, don’t need to regulate, there’s the China issue not wanting to take our wine so we’re already under stress’ etc etc. A $0.10 cent refund has such a tiny impact on pricing that the argument about price impact is irrelevant.”

Lee McLean is the General Manager, Government Relations and External Affairs for Australian Grape and Wine (AGW). The role of the AGW is to ‘provide leadership, strategy, advocacy and support that serves Australian grape and wine businesses now and into the future’. He disagrees with Angel. He points out that the South Australian government is reviewing its CDS and that AGW put in a submission that touched on why the wine industry didn’t need to be included in the scheme.

“Essentially we were frustrated by a couple of points in that process and what was being put forward,” he said. “Firstly, it’s important to note that in the wine industry we want to see the recycling rates increase for

wine bottles. We really do. We have a strong sustainability agenda.

“It’s constantly raised among the industry on how we can improve recycling rates. One of the issues that we’re finding is that a CDS arrangement for wine bottles, is in our opinion, a fairly suboptimal way of achieving better recycling rates and all the costs is to the industry.”

McLean noted that the South Australian EPA has gone down this route of intimating that although the CDS was designed for litter reduction – and it has been successful at doing that – it should now be retrofitted to become a product stewardship scheme.

“Just because they call it a product stewardship scheme doesn’t mean that it is, because true product stewardship shares costs right along the supply chain from the producer to the filler – in our case, we’re filling the bottles – to the glass manufacturers to retailers and everyone else,” said McLean. “But under a CDS model, the cost entirely sits with us, and we have no real meaningful ability to pass that cost on to consumers.”

The reason for not being able to pass on costs, according to McLean, is because Australia has a duopoly in terms of Coles (Liquorland) and

Woolworths (Dan Murphy’s/BWS), which covers about 75 per cent of all retail liquor outlets. He said that there are thousands of different wine brands competing for shelf space at those outlets, which means margins are already stressed.

Angel points out that all small enterprises in the beverage industry had the same issue when CDSs were first introduced.

“We had the same issue with small business impacts when the CDSs came in first,” he said. “Not all the bottlers are big. There are lots of boutique producers and the government’s made various arrangements to cushion the initial transitional issues.”

However, McLean says that it’s just not the $0.10 cent refund that is the issue. And he won’t even get into reports out of Europe – and being mooted in Australia too – that the amount of the refund should go up. There are other costs that need to be considered. AGW sent a report to the South Australian Industry Association of what the true cost to the industry will be if it becomes part of such a scheme.

“The cost to wine businesses will be upwards of $0.50 to $0.55 cents per item in the first year and a bit more than $0.40 cents per unit

Daily news updates at www.insidewaste.com.au24 INSIDEWASTE OCTOBER/NOVEMBER 2022 Container deposit schemes //

AGW would like to see the costs of including wine bottles in a CDS shared by everyone.

every year after that,” he said. “That incorporates things in the first year like labelling changes, registration fees, compliance costs, the actual refund itself, and the record keeping.”

Waste Management and Resource Recovery CEO Gayle Sloan believes it’s about time the wine industry came on board.

“I think there’s a definite acknowledgment that more [categories of containers] should be in the schemes,” she said. “It was a historical throwback that things like wine and fruit juice and milk were out. It makes absolute sense and is less confusing for the consumer to have all those materials in. The more in, the better.”

Another aspect is how much of a problem do wine and spirit bottles cause in terms of litter. Is it disproportionate compared to other beverages, and if so, is that because CDSs don’t cover off on those items?

“There are two answers to that,” said Angel. “Some of the product is going into smaller and smaller containers and that is starting to show up in litter. But the main intent of a CDS is to increase recycling. And we need to get glass out of the yellow kerbside bin. That has the follow through beneficial impacts on improving the quality of the product that’s still left in the yellow bin. What do recyclers hate? Glass-impregnated paper and cardboard out of the yellow bin. It’s not just a litter issue. Anecdotally I’m being told that the smaller containers of wine and spirits are

used in Victoria for glass only?

Unsurprisingly, McLean is a fan, but his objection to the way a CDS would affect the wine industry is not just down to other options being available, but how much of a difference will it actually make.

“What I struggle with is that when you read the South Australian EPA’s discussion paper on the subject, is that, despite this hefty cost and industry – and it is supposed to be about improving the collection/ recovery rates etc – the paper said that this will improve recovery rates of wine, spirits, cordials and those other potentially eligible containers

really significant cost increase with not much in the way of improvement in collection rates.”

And while the wine industry would prefer alternatives, Angel thinks that it might be out of their hands, with legislation likely in the future. How far into the future, he is unsure, but it will happen.

“I think it’s inevitable,” he said. “The question really is how fast we do it.”

Another sticking point when it comes to one of the more popular pieces of infrastructure – the reverse vending machine – is that they currently don’t accept wine or spirit

might think it will take a whole refiguration of the plant, it is a lot simpler than that, said Angel.

“All the machine has to do is read the barcode on the bottle,” he said. “That’s the main change the wine industry – who don’t have barcodes – will have to go through. When you put the glass bottle – assuming it fits – into the RVM it reads the barcode and once it knows that barcode is in the system, it accepts it. There are new products coming on all the time with nationally registered barcode. That barcode goes into the container deposit scheme system and then it becomes an accepted container.”

McLean understands the manufacturers will get social license from supporting such a scheme, but doesn’t get any less irritated that other options go by the wayside.

“I get a little bit frustrated when governments look at the CDSs as being the only way of doing things when there seems to be all sorts of different options; one’s happening in Victoria; one’s happening around the world in terms of other product stewardship schemes, as well as other bottle return mechanisms, which seem to have at least a similar rate of return,” he said.

McLean puts no doubt where he would like to see the debate end up.

“What we want to see is maintaining the status quo, in terms of the scope of containers that go into a CDS,” he said. “We would also like more thought and research go into alternative schemes to help drive improvements in recycling rates in an equitable way that shares cost across the industry.” iw

Daily news updates at www.insidewaste.com.au OCTOBER/NOVEMBER 2022 INSIDEWASTE 25 // Container deposit schemes

According to Angel, reverse vending machines can be easily configured to take new container shapes and size.

McLean said that the true cost to wine makers will be more than $0.10 cents a bottle.

EPA prosecutions put operators between a rock and a hard place

Facilities need to check their contracts thoroughly when outsourcing to third parties.

environment protection licences are fraught with risks. One case shows that even with best-practice systems, procedures, and pro-active maintenance in place, the EPA may still prosecute you when something goes wrong. More concerning still is that the EPA is increasingly prosecuting directors and managers directly, using powers that allow them to hold directors and managers responsible for offences by the company.

Quarrying to the max

In the case of Environment Protection Authority v Crush and Haul Pty Ltd; Environment Protection Authority v Cauchi [2022] NSWLEC 113, the EPA prosecuted a company (Crush and Haul), and the sole director of the company, Luke Cauchi. During 2018, Crush and Haul sold over 90,000 tonnes of quarried material from

extracted material in any year – and Crush and Haul didn’t hold a licence.

Part of the justification for this was that under its lease and management agreement, Crush and Haul agreed to sell a minimum of 30,000 tonnes per annum. But, on the other hand, the lease also required it to hold all required licences and approvals. Crush and Haul, and Cauchi, were aware of the need for a licence – and engaged a consultant during 2018 to apply for a licence. The licence was not forthcoming (including because a previous occupant of the site had a licence suspended a few years prior, and the application was lodged for the wrong party), but Crush and Haul continued selling material, well exceeding the lawful threshold.

Crush and Haul and Luke Cauchi both pleaded guilty. Crush and Haul was fined $225,000, and Cauchi was personally fined $22,500. In addition,

can be thresholds above which you require a licence, annual or yearly throughput, processing, or storage thresholds, or limits related to size and quantities of stockpiles. It is understandable that sometimes, if volume of deliveries or orders exceed expectations, or receival facilities stop accepting deliveries, facilities can unexpectedly approach or exceed thresholds. But this case is a reminder that you cannot assume a licence can be quickly obtained to tweak thresholds – it can take many months, and in some cases, be refused – so it is important to plan ahead. Otherwise, the results for companies, and directors personally, can be crushing.

Best practice still not good enough

After the Crush and Haul case, you may think – great, I have a licence (or have applied for one), now I should be

the EPA.

As part of a pro-active maintenance and upgrade program, a large poultry processing facility engaged specialist refrigeration contractors to conduct a multi-million dollar upgrade of various items of refrigeration plant around its facility. The facility had ISO 14001 audited environmental systems, stretching into hundreds of pages, dealing with all sorts of potential environmental issues –including contractor management, and risk management. It also had regular maintenance programs for plant and equipment, regular internal and external audits of equipment including refrigeration equipment, and ISO 45001 audited WH&S systems.

This included an entire system for managing contractors. As part of that best-practice system, the facility filled out risk assessments for the proposed work and required the contractors

Daily news updates at www.insidewaste.com.au26 INSIDEWASTE OCTOBER/NOVEMBER 2022 Legislation and regulations //

to provide and sign documentation with measures to manage those risks – in this case, Safe Work Method Statements (SWMS), which are commonly used across many industries.

One Friday afternoon, a contractor was working on the roof, having just finished installing some new aircooling equipment. The contractor decided to skip multiple steps in the SWMS (it was a Friday afternoon, after all) which meant he failed to tell the facility he was moving to commissioning (which was required under the SWMS). He did not carry out proper pressure testing using a gauge (required under the SWMS), and instead of carrying out required testing for leaks with an inert gas (required under the SWMS), the contractor skipped ahead, opened the valve to reintroduce ammonia (even though it was tagged ‘out of service’), and lo and behold, there was an ammonia leak for around 5-10 seconds before the contractor closed the valve.

Now, you can be forgiven for thinking that the EPA would not pursue the facility, since, clearly, the contractor was at fault having committed multiple breaches, not the facility. Think again.

The Protection of the Environment Operations Act 1997 makes licence holders guilty for the actions of anyone at a licensed facility unless they were not known to the licence holder – e.g. a burglar that breaks in during the middle of the night. Even though the Court ultimately found on sentencing that the facility had appropriate systems in place, did not in any way fail to appropriately manage contractors, and because of its systems and management essentially had no control over the causes of the incident – i.e. it was entirely the contractor’s fault – the facility was still found guilty of breaching a condition of its licence.

This leads to the other element of the case that should concern all licence holders. The condition the facility was alleged to breach requires it to ensure that it maintains plant and equipment in a ‘proper and efficient manner’. The facility argued that it did, since the plant in question was de-commissioned (and part of it newly installed), isolated and offline – and it was the contractor who erroneously re-introduced ammonia multiple steps before he should have, and before the equipment was ready. The Court agreed that so long as the plant was offline, it was in an appropriate state to be offline. But, it found that by the contractor opening the valve (early), the mere fact that ammonia was released, meant that it was no longer maintained in a ‘proper and

efficient manner’. I.e. by the very act of opening the valve, the contractor put the plant in an unfit state to hold ammonia.