The benefits that arise from IoT devices

4

11

The

The benefits that arise from IoT devices

4

11

The

AS THE EDITOR of this industry publication, I am constantly intrigued by the dynamic landscape we navigate. From the ever-present challenges like PFAS contamination and cyber threats to the ongoing advancements in pipe technology and purification systems, innovation and vigilance go hand-in-hand.

It’s a pleasure to see IFM go from strength to strength within the water and wastewater management industries. Its commitment to combating water scarcity through Internet of Things (IoT) devices and management platforms provides a range of opportunities for the water industry. Its IO-Link solutions have supported the water and wastewater industries through its passionate team dedicated to solving environmental and water issues.

The spectre of PFAS, or per- and polyfluoroalkyl substances, looms large. These persistent chemicals, linked to various health concerns, have infiltrated water supplies across the globe. Addressing this widespread contaminant demands a multi-pronged approach, encompassing advanced filtration technologies, stricter regulations, and robust public awareness campaigns. Collaborative efforts between researchers, policymakers, and communities are crucial to tackling this complex issue head-on.

Meanwhile, the digital age casts a new shadow on water security. The vulnerability of our increasingly interconnected water infrastructure to cyberattacks poses a significant threat. Implementing robust cybersecurity measures, investing in resilient systems, and fostering a culture of preparedness are essential steps to safeguard our water from malicious actors.

Yet, the most fundamental challenge lies beneath our feet: our aging pipe networks.

Crumbling infrastructure leaks precious water, harbours contaminants, and amplifies the risk of service disruptions. Prioritising pipe replacement and rehabilitation projects while exploring innovative materials and construction techniques is vital to ensure the longevity and efficiency of our water delivery systems.

Fortunately, innovation offers a beacon of hope. Advancements in purification systems, fuelled by cutting-edge technologies like membrane filtration and nanotechnologies, promise to remove emerging contaminants effectively. Decentralised water treatment solutions can also play a role in providing more localised and sustainable water supplies.

As an editor, I believe in the power of informed dialogue and collaborative action. By fostering open communication between experts, policymakers, and the public, we can navigate these turbulent waters and secure a future where clean water is not a privilege but a basic right. Let us join hands to ensure that every drop counts and every community has access to the life-giving resource it deserves.

Together, we can build a more resilient and sustainable water future where innovation meets responsibility, and clean water flows freely for generations to come.

Chief Executive Officer

John Murphy john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy christine.clancy@primecreative.com.au

Publisher

Sarah Baker sarah.baker@primecreative.com.au

Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au

Editor

Chris Edwards chris.edwards@primecreative.com.au

Design

Daz Woolley/Tom Anderson

Head of Design Blake Storey blake.storey@primecreative.com.au

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Brand Manager

Chelsea Daniel chelsea.daniel@primecreative.com.au

p: +61 425 699 878

Client Success Manager

Glenn Delaney glenn.delaney@primecreative.com.au

Head Office

Prime Creative Pty Ltd

379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 enquiries@primecreative.com.au

www.insidewater.com.au

Subscriptions

+61 3 9690 8766 subscriptions@primecreative.com.au

Inside Water is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright

Inside Water is owned by Prime Creative Media and published by John Murphy. All material in Inside Water is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Water are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

The challenge of managing water resources and advancing clean energy production has become paramount in the business world today. At Hydroflux, our commitment to rethinking is ingrained in our DNA because we recognise that each challenge is unique. Whether you’re a local municipality, a global manufacturer, or anything in between, we’re driving sustainable change – now. Specialising in water, wastewater, renewable energy, climate resilience and environmental protection, Hydroflux provides a vast range of certified carbon-neutral products and services to help solve some of your most complex challenges.

With tailored solutions, ongoing support and a commitment to measurable results, Hydroflux is rethinking what’s possible to build a better future.

Call 1300 417 697 or email info@hydroflux.au

Already a dry continent, Australia’s water scarcity issues are likely to be exacerbated by changes to weather patterns – caused by climate change – as well as the increased demands of a growing population.

an abundance of natural resources. However, water is not among them.

As the world’s driest inhabited continent, Australia has always faced challenges in terms of meeting its water consumption needs. Its average rainfall is roughly 470 millimetres a year – well below the global average. Temperatures in Central Australia can reach and exceed 50 degrees Celsius. Further to that, what rainfall Australia does receive is concentrated along the north and east coasts of the country.

The twin challenges of climate change and population growth compound Australia’s inherent water scarcity. Indeed, the Productivity Commission noted in a 2021 report that drought conditions are likely to become more frequent, severe, and prolonged in some regions – owing to climate change – and that reductions in supply should be expected alongside growing demand due to population increase.

In this context, providing safe drinking water is a key challenge, and more sophisticated and effective

methods of treating water are crucial to meeting today’s and tomorrow’s demands.

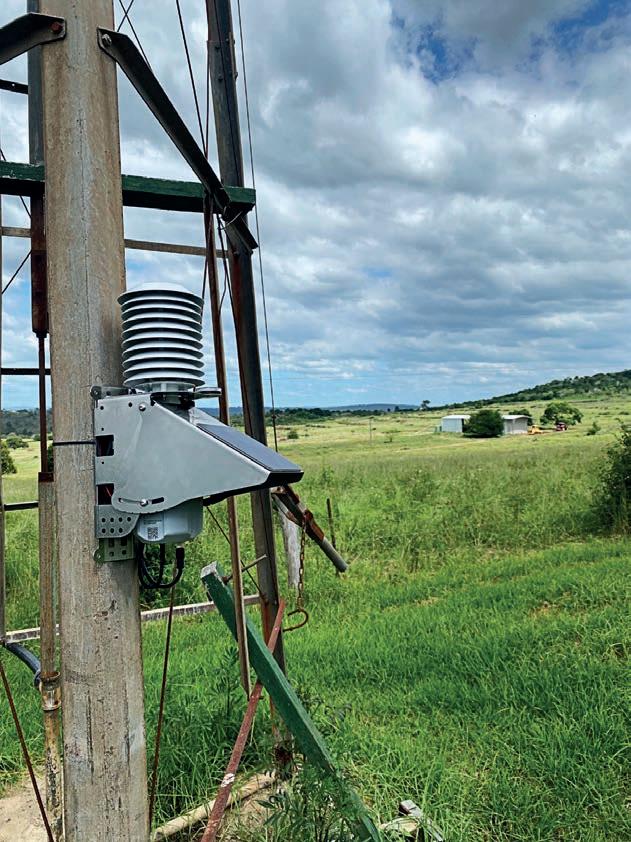

Industry expert Freddie Coertze is the National IoT Business Manager and Digital Strategy Leader for ifm. He said that ifm’s goal is to help maintain Australian water networks and help make them more efficient.

“In Australia, maintaining our water networks is a make-or-break issue,” he said. “This is why ifm is committed to working with local companies tackling water scarcity issues.”

Not all water is created equally or even recycled equally. Each state and territory has its regulatory frameworks, primarily managed by each jurisdiction’s Environmental Protection Agency (or equivalent). These departments or agencies govern how different types of wastewater are treated. Those regulations also set the quality standards to be met when transforming wastewater into usable water for different purposes. On-site wastewater management systems need to perform effectively

The IO-Link system is designed to be plug-and-play.

Images: ifm

and be appropriately managed to reduce risks to the environment and public health.

Among the criteria governing wastewater handling are the source of wastewater, site constraints, treatment methods, and the quality of effluent needed for proposed end-uses of treated water. Australian states and territories have their own regulatory frameworks that govern the conditions under which permits for the construction, installation, and alteration of wastewater management systems will be granted.

Grant Smith, Senior Applications Engineer at ifm, says that the challenge for wastewater treatment operations is to run plants effectively along the entire cycle – producing a result that is economical, effective, safe, and in line with environmental

for richer and more transparent data monitoring and doing away with complex physical wiring processes.

Coertze noted that in more

In Australia, maintaining our water networks is a make-or-break issue. ”

standard cables. Furthermore, expensive analogue input cards are no longer needed with the

“These features save time,” Coertze said. “There’s no need to integrate different data outputs. That also means that companies can save money in the volume of engineering hours needed to integrate different data sets from different operating systems. That also saves on

The IO-Link system is a plug-andplay system. Users screw the cables into place, and the system is ready to go. That’s why it is great for Original Equipment Manufacturers (OEMs).

“With IO-Link, you will get more diagnostics for less wiring,” said Youssef Attallah, New South Wales Branch Manager of ifm.

The Aerofloat experience

Attallah pointed out that ifm has worked with water treatment companies with sensor and control systems for many years. Its sensors

and IO-Link solution is cost-effective for small-to-medium size enterprises (SMEs).

One such enterprise is Aerofloat, an Australian industrial wastewater treatment specialist that ifm has been working with to help provide customers with affordable, Australian-compliant treatment services.

“Aerofloat is an ideal customer for ifm,” said Attallah. “It provides wastewater treatment solutions across various industries. As a homegrown Australian company, it gives new opportunities for ifm products to be utilised in new ways by new companies.”

Aerofloat has a history of dealing with a range of projects. One day, they could be installing a solution in a food factory, the next in a winery, and the third solution could be somewhere else again.

“No two days are the same,” he said. “For ifm, as a company with an international footprint, it’s great to see our products utilised in new ways for new customers. We know that ifm and Aerofloat are not only producing business benefits to the end-user. It will also contribute to the societal good through more provision of a scarce resource in Australia: water.”

Michael Anderson, General Manager of Engineering and Operations at Aerofloat, co-founded the company in 2009. The other co-founders are father and Managing Director Ray Anderson and sister Katie Moor, the General Manager of Business Operations.

Michael says that Ray, a chemical engineer, was doing consulting work when he spotted an opportunity

to solve a problem treating grey water on houseboats on the Murray River in South Australia. The three teamed up to address the issues, complementing their individual skill sets. They combined Ray’s vast experience in the wastewater treatment industry, Katie’s chemical engineering background and business acumen, and Michael’s passion and adeptness in product design.

“We got to work designing the product, got it certified to Australian standards, commercialised it, and installed about 200 systems,” Michael said. “That took roughly three years. At that point, the Environment Protection Authority relaxed its standards for greywater discharge from houseboats on the Murray. The market we had been solely catering to disappeared.”

Michael spoke about how Aerofloat had to pivot by scaling up the technology it had developed to supply a new product. That product was Aerofloat’s Dissolved Air Flotation systems (‘AeroDAF’) and designed for industrial wastewater applications.

From working on relatively small projects, Aerofloat has grown to do projects for industrial wastewater plants, breweries, and food manufacturers. There are also projects for local and state governments.

Aerofloat and ifm

“We’re committed to innovation and sustainable solutions,” Michael said. “We have several patented technologies, and we’re very R&D focused. I’d say our biggest point of differentiation is that we are an end-to-end solution provider in wastewater treatment. Every customer is different. Relationships like the one we’ve built with ifm are critical. We’ve done some reliable wastewater treatment

Originally from Batemans Bay, the Australian Capital Territory’s Minister for Water, Energy and Emissions Reduction has worked tirelessly to build a better water outcomes for the Territory. Inside Water Magazine spoke to Shane Rattenbury.

SHANE RATTENBURY FIRST moved to Canberra in 1984. He attended Canberra Grammar School and gained a BEc and LLB (Honours) from the Australian National University (ANU). The start of his career saw him land a job with the Australian Government Department of Industry, Science and Tourism (now the Department of Industry, Science and Resources). He later worked in the non-government sector on a range of environmental issues.

“I have been campaigning on environmental issues for many years,” Rattenbury said. “I continue to be inspired by the beauty and complexity of nature. From a young age, I was interested in environmental issues, including ozone depletion, Antarctic protection, and forest conservation. I worked for Greenpeace in Australia,

South East Asia and for Greenpeace International. As ACT Minister for Water, I enjoy the opportunity to look after and restore our local waterways that provide valuable habitat for many species.”

The water industry in the ACT

There are many different players, roles, and responsibilities within the water sector in the Australian Capital Territory (ACT). This includes the Territory Government, industry, the water utility (Icon Water) and water users themselves, both industrial and residential.

“The ACT Government is working to improve governance and to clarify roles and responsibilities,” Rattenbury said. “We are all working towards a vision of improved water security and water health and we welcome the water industry to play a part in

Images: Minister Shane Rattenbury

supporting the work of the Office of Water to build robust policy and deliver contemporary programs that result in well-informed users and the efficient use of water.”

As well as being the Minister for Water, Energy and Emissions Reduction, Rattenbury is also the Attorney-General, Minister for Consumer Affairs, and the Minister for Gaming. In the water portfolio, he can point to a series of positive achievements during his tenure.

“We have established the Office of Water which is on a pathway to deliver on its core aims,” he said.

“That includes strengthening the ACT’s water security through holistic and coordinated water management and policy. It’s also been improving engagement with the public on ACT water resource management issues, and continuing to deliver the Healthy Waterways program that is delivering infrastructure, research, education and catchment planning to improve waterway health.

The Office respects the multiple roles and responsibilities across

the water sector. As an advocate for improving regional water management, it is building stronger regional partnerships.

“We are playing an active role in the Murray Darling Basin reforms that aim to promote transparency and accountability in implementing the Basin Plan,” said Rattenbury.

He was heartened by the recent announcements for investment in improving water management in the upper Murrumbidgee River, and the progress made in response to efforts to raise this issue with Federal counterparts, which comes after many years of work by community advocates.

The Healthy Waterways program has been the cornerstone of water quality management across the ACT.

“The findings and lessons learned in the Healthy Waterways program have changed how the ACT Government views water quality management,” he said. “It’s also helping the Office approach solutions to stormwater problems. We are much better able to tackle water quality problems now than a decade ago.”

The latest Catchment Health Indicator Program (CHIP) report released by Upper Murrumbidgee Waterwatch in March 2023 gave a tick of approval.

The CHIP report was drawn from 2000 surveys from more than 200 volunteers at 237 sites in the Cooma, Ginninderra, Molonglo, Southern ACT, and Yass sub-catchments.

“The ACT Government’s investment in and delivery of a large program of constructed wetlands is helping to improve water quality within the ACT,” Rattenbury said. “This is in addition to significant work by catchment groups to re-naturalise and maintain these waterways, as well as changes in community behaviour in managing grass clippings, leaves and fertiliser runoff.”

The higher rainfall rates over the past few years have also provided flushing flows and steady baseflows. That’s been good for the health of waterways across the ACT.

At the same time, the Murrumbidgee River has been closed on occasion due to higher bacterial levels. Rattenbury has continued working with departments and agencies to solve the problem.

“The ACT Government is in the early stages of researching in more detail the sources of bacterial contamination in some ACT waterways,” he said. “The focus up until now has been on studying the more immediate problem of toxic blue-green algal blooms. However, reducing bacteria levels in our

Conserving wetlands in the ACT is vital for improving the quality of stormwater and providing habitat for native plants and animal species.

waterways is also a high priority.”

One potential source of bacterial contamination is livestock accessing the waterways higher up in the catchment. Rattenbury believes that once the sources of the bacteria levels are better understood, the catchment plans will be developed to address the problem.

It’s regularly forgotten that Canberra is located in the Murray Darling Basin, with the Murrumbidgee River running through the ACT and before flowing inland to meet the Murray River near Balranald. As such, the ACT is one of the Basin partners to the MurrayDarling Basin Plan. Rattenbury believes that the Murray-Darling Basin Plan can provide improved water resource management.

“It was established to transcend jurisdictional boundaries,” he said.

“The Murray-Darling Basin Plan allows these significant rivers to be managed in the national interest. The Plan has made some progress. However, there is much more work to do.

Implementation has been slow.

Rattenbury believes that further reforms are required to deliver the Basin Plan, such as lifting the scale of water management to provide a holistic approach to water catchment management, improving

water accounting and water information, incorporating climate projections into water planning and decisions, and incorporating cultural values and interests of First Nations in water planning.

“There are also significant issues that we are seeing in the upper Murrumbidgee River,” Rattenbury pointed out. “Around 95 per cent of the river’s natural flow is diverted to the Snowy Hydro Scheme, where the Basin Plan has yet to take effect. The health of the Murrumbidgee River would benefit from increased environmental flows from Tantangara Dam and the protection of these flows from extraction. We are working towards this aim, and I would like to explore whether it can be achieved through Basin Plan mechanisms.”

The ACT’s location has given rise to it being called the Bush Capital. That has given rise to it being at risk of bushfires on a regular basis.

“Bushfires pose multiple risks to the resilience of our communities in the ACT,” said Rattenbury. “It can have significant impacts on the environment, including water resources. Runoff after fires can taint reservoir water, making it undrinkable or expensive to treat, which happened after the 2003 Canberra Bushfires. The reservoirs eventually recover their good water quality, but this can take some time.”

He notes that the changing climate also poses risks to waterway health. Heavy rainfall after hot fires can strip hillsides of soils, smothering pool-riffle streams with sand, which happened after the 2019-2020 Bushfires. When burnt organic matter is washed into streams, it can lead to oxygen stress, killing sensitive aquatic fauna. Both processes can lead to long-term impacts on waterways.

“Icon Water has contingency plans for when water in a reservoir becomes tainted,” he said. “It works closely with

It’s not your grandma’s hearing aid…

…but it allows you to hear leaks in your water network when they happen!Minister for Water, Energy and Emissions Reduction, Shane Rattenbury, at a redesigned curb outlet in Kambah.

the ACT Government to mitigate problems. For example, in 2003, Icon (then ACTEW Corporation), the ACT Government and the University of Canberra collaborated to release tainted water in Bendora Reservoir to avoid impacts and benefit the downstream waterway health.“

As part of the ACT Healthy Waterways Project, considerable work is being done to manage stormwater entering Lake Tuggeranong. It’s become a bigger issue, with the highest levels of pollution coming from the Kambah and Wanniassa stormwater drains. A network of older stormwater pipes and concrete-lined channels is also designed to move run-off into Lake Tuggeranong as quickly as possible. That’s an older method compared to the nature-lined creeks common in other parts of Australia.

“We are focusing a lot of research and monitoring in the Lake Tuggeranong catchment,” said Rattenbury. “We want to understand the source of plant nutrients driving the algal blooms in the lake. We are also trialling new kinds of water quality infrastructure to reduce pollution. This includes a major channel re-naturalisation in Calwell, bioretention swales around sports fields, roadside drain outlets into green spaces in Kambah, and stormwater treatment and recycling to irrigate sports fields in Kambah.”

Three pilot public education programs have already been undertaken to ensure leaves

and grass clipping do not enter streetside drains.

“These programs have delivered promising results,” he said. “Over the next year, we will use lessons from these and other projects to create a Healthy Waterways plan for Lake Tuggeranong that will canvas options for reducing or eliminating algal blooms from the lake.”

The ACT Government has recently invested $28.5 million in the Expanding Healthy Waterways program. It builds on previous investments by the ACT and Australian governments that represent a commitment to finding the right long-term solutions to ongoing water quality problems.

“At a community level, we have seen that residents enjoy both the amenities of the constructed wetlands and the opportunities created to be a part of the solution to a problem through caring for their local wetlands,” Rattenbury said. “Encouraging community involvement will remain a key priority as Healthy Waterways plans are developed and solutions to water quality problems are implemented.”

He acknowledged that it would take time to improve at a catchment scale. The goal is to achieve the long-term goal of water quality in the lakes and ponds materially improved. Ideally, it would also see problems like blue-green algal blooms having either been eliminated or greatly diminished.

“We are considering several interim in-lake measures while the catchments adjust to deal with problems like blue-green algal blooms and faecal coliforms,” he said. “The National Capital Authority is responsible for Lake Burley Griffin, and the ACT Government will engage with them in preparing the Healthy Waterways plan for the lake.

Rattenbury has a positive outlook for the future of the Territory’s waterways. He has completed a lot of work within his portfolio and is looking to continue that work.

“I would like to continue our work to improve the health of waterways and catchments throughout the ACT through our on-ground programs, new water quality assets like wetlands and creek naturalisations, and community engagement and education programs,” he said. “We are so fortunate to have this beautiful network of waterways through the ACT, and I look forward to continuing to protect and restore their health and provide great outdoor places for Canberrans to enjoy.”

When it comes to specifics, he believes that working on the health of the upper Murrumbidgee River as part of the Murray-Darling Basin Plan and its multi-jurisdictional influence will be of key importance for the coming years.

“I will also be working to improve the health of the upper Murrumbidgee River by delivering increased environmental flows,” said Rattenbury. “I will continue to highlight the need for delivering the MDB Plan in full, ensuring we are measuring the outcomes of the MDB Plan through improved on-ground auditing and working collaboratively with First Nations peoples to deliver cultural flows, protect cultural values and manage waterways across the Basin.”

The proper pressure level in a water network is vital for water loss management. Ashlynn Davies has been studying this and has been rewarded for her project.

regional water utilities, they rarely think about the issues of leaks and high pressure. However, these can be some of the biggest problems facing regional water utilities with smaller connection bases.

Improving the efficiency of water networks is essential for these regulated businesses, and Ashlynn Davies from the University of Sydney studied it at the regional level. Her paper, Improving Water Network Efficiency in Regional New South Wales: Leakage and Energy Use Reduction Through Pressure Management, was nominated as a finalist in the New South Wales branch of the Australian Water Association (AWA) Student Water Prize.

“I had a less conventional path into the water industry,” said Davies. “I was fortunate to receive a Major Industrial Project Placement Scheme Scholarship through the University of Sydney’s School of Chemical and Biomolecular Engineering.”

This program supports outstanding senior students completing a highlevel industrial project during a six-month employment placement. Davies was placed with the Central New South Wales Joint Organisation (CNSWJO), which represents 11 central NSW local government authorities (LGAs). While her project specifically involved collaborating with Parkes, Orange and Bathurst councils, her findings were aimed at having wider applicability across the region.

“The project required me to look at water loss from an energy perspective,” she said. “It was an

expansion of the previous year’s project, which had just looked at water loss. Once I had explored water losses and associated energy losses from each council’s network, I saw an opportunity to expand my project into exploring pressure management to address these inefficiencies.”

The reality is that there are no water utilities of any size that do not have any water leaks anywhere in their systems. The difference between large cities and smaller regional towns can be stark.

“In regional areas, many towns were established over 100 years ago,” Davies said. “Their establishment led to the origins of its water networks. Those networks grew as the population of the towns grew. The challenge is that there is a lot of ageing infrastructure in these areas and limited funding for large-scale infrastructure renewal projects.”

That drove Davies’ motivation for pursuing pressure management options. If there is no money for significant renewal works, what can be done to save water, energy, and money? It’s all about utilising the councils’ resources as effectively as possible.

“Water is a vital resource for regional communities,” she said. “In times of drought, the local population is extremely aware of water scarcity. As we face growing uncertainty around water security in the future, it is increasingly important for these councils to study their systems and understand where they can be improved.”

Davies examining a model of Parkes’ water distribution network in InfoWorks Pro.

Images: Ashlynn Davies

What Davies did

There were four stages to Davies’ research, with the first three working towards the final stage of her research.

“The first thing I did was quantify the water losses,” she said. “Typically, that uses the International Water Association (IWA) water balance method that looks at the entire system. However, I quickly decided it wouldn’t provide the granularity I needed. Instead, I wanted to quantify water and energy losses from each specific network zone rather than just the network as a whole.”

She had to combine various data sets to develop a water balance in each network zone to achieve this. That included billing, geographic information systems (GIS), and Supervisory Control and Data Acquisition (SCADA) systems. The GIS had a layer that showed what areas were fed by what reservoirs. Pairing this information with the billing data allowed her to calculate the total consumption in each zone. Meanwhile, the SCADA system provided the bulk water meter data to estimate the total water delivered to each zone.

“Essentially, I did a water balance across every specific network zone that I could,” said Davies. “That allowed me to pinpoint how much water was lost from each network zone. Surprisingly, there were immediate actions I could identify at this first stage of my research.”

As part of this stage, she found significant water loss in Lucknow, not far from Orange. A repairman was sent out, who found a leak on the line between Lucknow and Orange and fixed it.

“The second stage saw me develop a methodology to calculate the embedded energy lost from water for each specific zone. Each time water is pumped or treated, its embedded energy increases, resulting in greater energy losses when that water is ultimately lost from the network,” Davies said. “This allowed me to determine which zones are the most energy intensive and contribute most to the networks’ overall inefficiency.”

The third stage saw Davies use InfoWorks Pro, a hydraulic modelling software. She used this to perform an energy balance on each network zone to quantify which areas delivered the most excess pressure

The final stage of the research

The fourth and final stage saw Davies combine the first three stages of her research to determine what network segments needed prioritising for pressure management and other efficiency improvements.

“I modelled 12 different actions that could be taken across the three councils I worked with,” she said. “According to my calculations, implementing these would result in a water loss reduction of 184 megalitres annually with an annual retail value of $423,000 and energy savings of 366,000 kilowatt-hours per year.”

Davies specifically recommended actions where little investment is

Davies installed a pressure logger to verify her modelling work.

At Bathurst Water Filtration Plant, Davies with Dave Cashen (plant supervisor). He is one of the many people who were invaluable to the project.

would be the purchase of a pressure relief valve (PRV). However, more than half of the actions required simply changing the configuration of the zones to ensure areas are not supplied by reservoirs at a higher elevation than necessary.

“That meant opening a couple of zone valves and closing a couple of others, as there was often an adjacent reservoir capable of supply the ideal pressure,” Davies said. “Those were the actions that were most surprising to me. It was exciting to find ways for the councils to use the infrastructure already in place to improve water loss and resulting energy loss.”

“Similar actions can likely be found in the networks of other local water utilities across the region, with the methodologies I developed through my project a great place to start.”

Award winner and nominee Davies has been nominated for the NSW AWA Student Water Prize and won the best undergraduate thesis from the University of Sydney’s School of Chemical and Biomolecular Engineering.

“I’m just excited that my work was able to lead to real actionable benefits for the three councils, with the potential to help many other local water utilities. It’s a nomination for a lot of people, for whom a project of this scale otherwise could not happen.”.

Edge devices are not things we often think about when it comes to the water industry. However, one Australian company is looking to shift the paradigm in a new direction.

EDGE DEVICES PROVIDE an entry point into enterprise or service provider core networks. They can be anything from simple sensors up to complex industrial systems. What groups them is that they are all Internet of Things (IoT) devices. You could think of them as every “thing” in the Internet of Things.

are being rolled out by different companies trying to achieve different things. With hundreds of thousands of kilometres of pipes under the ground, there’s not much visibility about what is going on in and around those pipes.

up to the plate. Its range of Series 2 devices is looking to redefine the

capture, measurement, and analysis of data in extreme environments.

The movement from Series 1 to Series 2 was led by feedback from its customers and an understanding of the business models of water utilities.

“We focus on three things at Kallipr,” said Gerhard Loots, the company’s Chief Executive Officer. “We focus on

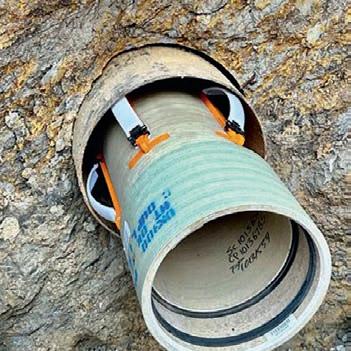

Left: the Captis Series 2, mounted with a radar sensor, on an agricultural site.

Below: a range of battery sizes

detect what type of sensor it has been attached to and load configuration files to it,” Loots said. “We use standard industry protocols that provide us with access to over 600 sensors that are compatible with our system, which we’re constantly expanding”

Installation time is another aspect of that. For example, if a water utility was to have 20,000 units installed, and each one needed 10 minutes to be set up, that’s 200,000 minutes. That’s more than 1.6 years of working days that need to be done by someone who needs to be paid.

“When we were looking at this, we wanted to ensure that shorter installation time worked seamlessly

battery replacement on our device, but I believe our current record is 7.2 seconds.”

Another aspect of the battery is its patent-pending design. One of the challenges of the industry-standard lithium thionyl chloride batteries (Li/SOCl₂) is that the voltage drops immediately once they run out of charge. That makes it hard to know when such a battery might need replacing. Kallipr’s new technology gives users more accuracy as to when the battery needs replacing, resulting in lowering the cost of replacement as it can be planned proactively

“To the best of our knowledge, we are the only company in the world that can do this,” Loots said. “It puts us at the cutting edge of battery technology for data loggers.”

Data loggers are not things the average person is used to seeing as part of their daily lives. That means they get kicked off, moved around, and can wind up in unusual places. Kallipr has prepared for that by assessing the Series 2 against military ruggedness standards.

“We’ve worked hard to be best in class with the Series 2,” said Loots. “We can guarantee operations at five metres underwater. However, we

have successfully tested the device as deep as 20 metres underwater. That’s important when you think about recent flood events in Australia and New Zealand. That data is essential for water utilities, and it’s a big task to get an electronic device to work well under those circumstances.”

The military standards have required Kallipr to rethink how it builds its devices. Its work sees the battery life extended to 20 years. That’s impressive when they are installing small computers in the Series 2, with blockchain and security certificate capabilities.

“That’s critical for environmental compliance data,” he said. “There’s no way to fudge the data. The relevant regulatory authorities can see the data generated from a specific sensor in a determined location at a set time. As far as we know, we are the only company currently doing that.”

Kallipr has thought beyond a single battery pack. It has designed a range of battery packs that can be installed on the Series 2. They’ve also considered connectivity, which can be an issue when specific networks are down.

“We’ve built the Series 2 to have

more than one SIM card inside,” he said. “That gives users flexibility around service providers while also giving backup connectivity.”

Kallipr has also built a sustainable recycling system for the batteries. Given the large number of batteries that need to be replaced regularly, having this recyclability is vital for them.

With the launch of this product, Kallipr and Loots are already looking into the future. It’s not just the water industry that can benefit from their new technology.

“The next step for us is automating as much as possible,” Loots said. “It’s all about having the architecture to collect and interpret the data. That way, we can have people heading out to deal with a problem without needing more people to organise it. You could think of it like Uber, in that a service is provided as required. It’s also providing the opportunity to improve safety for people. The goal is to combine the right data sets so that people in the water, mining, wastewater, and similar sectors can control a robot to go where it is needed. With our systems, we want to build it in a way for the data to be addressable through more than just a dashboard.”

For more information, visit kallipr.com

When it comes to minimal community impact, trenchless technologies are often sought after. That was the case when Interflow came on board for a challenging project.

HUNTER WATER REACHED out to Interflow to help deal with a water main that had failed at several points in Rutherford, near Newcastle, NSW. The pipe ran under a wellestablished and built-up industrial area with substantial traffic flow.

While the water main was isolated, network capacity was reduced. This was an untenable situation, hence the call to Interflow.

The pipe ran under multiple properties, so digging up the whole pipe would disrupt the businesses affected. It’s why a trenchless solution was sought, as it would maximise the residual value of the water main.

Titeflow is Interflow’s die-reduction close-fit lining system which installs a brand-new HDPE water pipe. This offered cost benefits over other rehabilitation alternatives and would result in an acceptable internal diameter.

Allan Moran is the Hunter Region Delivery Manager for Interflow. He was in charge of what turned out to be a mammoth task.

“Titeflow works by pulling a

standard HDPE water pipe through a static die, temporarily reducing its diameter,” said Moran. “Whilst under tension, it’s then pulled through the host pipe. Once the new pipe is in place, the pulling load is released, and the pipe reverts to near its original diameter. This means it fits

Titeflow needed to be laid out in full in the nearby area before being pulled through the existing pipeline.

Images: Interflow

tightly against the host pipe and provides the maximum potential internal diameter. With a wall thickness of 48 millimetres, extreme force was needed to winch all 560 metres of pipe into its place and stretch it through the static die –85 tonnes in total.”

At 560 metres, this was the longest single installation of Titeflow that Interflow has ever installed. It nudged out the previous record of 550 metres in 2014. Interflow has completed many Titeflow installations using similar diameter pipelines and is using this experience to install longer lengths in single pulls.

Hunter Water and regional and local councils were invited to watch the installation and the die-reduction process and see a record-breaking pull and further their understanding of this process.

“We had people from Liverpool Plains, Port Macquarie, and other local government authorities from the region,” Moran said. “It was a great opportunity to teach them what we do and how Titeflow works. One thing we had to show was the extension of the pipe as we pulled it through. There was an extra 42 metres in stretch that returns to size once the tension is removed from the pull.”

Longer installation lengths mean fewer excavations and shorter project durations, which can, in turn, mean fewer traffic disruptions, reduced environmental risk, and minimal community fatigue. The success of this project proves to the water industry that long lengths of new pipe can be installed with minimal community disruption.

There were challenges associated with this project. Moran spoke about a few of them.

“The existing water main and easement transected the industrial parcels,” he said. “Replacing the water main by trenching in the existing alignment would have resulted in the closure of several businesses during the construction period. That was not an option.”

costs if an open-cut approach had been adopted. There had already been several pipe failures, so a key project driver was to rehabilitate the pipe without further impacting business operations.

“It’s why Hunter Water wanted to investigate trenchless technology for rehabilitating the pipe,” said Moran. “They wanted to reduce the community impact of this project.”

What makes this project different from other trenchless rehabilitation projects is the sheer length of the installed HDPE pipe. To avoid interrupting business operations, the entire length needed to be rehabilitated in one pull.

“Once the pipe’s diameter exceeds 180 millimetres, it can no longer be spooled,” he said. “This means the entire length of pipe needs to be delivered in sections, welded together, and laid out flat before installation. The total length of Titeflow that can be installed is usually limited by the space available to string the pipe out. The longer the length, the greater the potential to disrupt the community or to run out of space to store the pipe.”

As part of this project, the new water main could be strung out next to a nearby creek before installing it into the pipeline. That ensured minimal disruption and made Titeflow the most cost-effective trenchless solution.

Following the completion of the project, the water main has been returned to service with confidence that it will not fail. This will allow

of the water pipeline has reduced the short-term water continuity risks while an expansion of the water mains is under design and delivery.

“Utilising trenchless technologies to rehabilitate ageing infrastructure has negated many of the construction risks associated with traditional trench and lay,” Moran said. “The construction footprint, including the requirement for stockpile and sediment and erosion control, is significantly reduced. Since the water main was first installed, heavy commercial development has occurred in the area. Given the nature of the site, the established industrial businesses had considerable hardstand within their yards. Titeflow was able to negate the expensive restoration of brownfield sites.”

The chosen rehabilitation solution was also the most economical. This meant cost benefits for Hunter Water and for their end users. Any solution that required extensive or multiple excavation points would have come with a substantial cost. By choosing a trenchless method, disruption and capital costs were minimised.

“Titeflow had a 20 per cent cost benefit versus other proposed trenchless solutions,” he said. “From our perspective, we had to think outside the box to complete this project, and now we know we can perform these sorts of long pulls.”

“Longer pulls open opportunities to reduce the social, environmental and economic impacts of water main rehabilitation.”

For more information, visit www.interflow.com.au

The Water Services Association of Australia (WSAA) has given Riteline Centralisers the coveted product appraisal certificate. What does this mean for the water industry?

RITELINE CENTRALISERS ARE a product of OptionX Group. Late last year, the technology was approved by WSAA for use in the water and wastewater industry. Under the leadership of Chief Executive Officer Stuart Harrison, OptionX Group has made waves in the trenchless technology field.

“Riteline was developed to overcome several limitations of traditional spacers that can increase the risk on pipeline projects,” Harrison said. “I’m excited to see that the industry has officially recognised the spacers.”

Riteline spacers have been successfully appraised by the Water Services Association of Australia (WSAA). It provides a new option for

pipeline installations and complies with WSA PS-324 for casing spacers. Riteline Centralisers represent an innovative solution designed to revolutionise the accuracy of trenchless installations by supporting the carrier pipe, ensuring its fixed position relative to the bored hole or encasement pipe.

“Contractors and operators can confidently use Riteline Centralisers on their projects, knowing they have been through the necessary tests and third-party analysis,” he said. “The WSAA appraisal serves as a benchmark for quality within the industry. It signifies that Riteline Centralisers have met the highest strength, reliability, and quality assurance standards.”

What are Riteline Centralisers?

Riteline Centralisers have been designed for the horizontal drilling sector, where precision and adaptability are essential. Unlike traditional casing spacers, Riteline Centralisers offer greater flexibility, accommodating pipes ranging from 100 millimetres in diameter.

The ability to make incremental adjustments on-site eliminates the need to purchase specific sizes, reducing time, cost, and stock wastage. It also features adjustable heights spanning from 30 to 125 millimetres. This versatility addresses the diverse needs of trenchless drilling projects, allowing for seamless adaptation to varying conditions.

“One of the limitations of traditional casing spacers was that they needed to be purchased in specific sizes and couldn’t be adapted on-site to meet changing needs,” he said. “This resulted in time, money, and stock wastage. With Riteline Centralisers,

there is no

was fuelled by industry feedback and real-world field data. The collaborative nature of OptionX Group allowed Riteline to address industry frustrations innovatively, resulting in a product that aligns seamlessly with the unique demands of horizontal drilling projects.

A distinctive feature of Riteline Centralisers is their individually attached design, minimising the risk of catastrophic failure. This approach enhances safety and reliability, crucial factors in the success of trenchless drilling projects. Riteline’s design ensures a more secure and resilient installation. This is unlike traditional centralisers that surround the pipe. They can be prone to failure when snagged on obstacles.

The low-profile design of Riteline Centralisers further sets them apart. This engineering facilitates seamless grouting, preventing failures and ensuring secure and accurate installations in trenchless drilling operations. Minimising the risk of grouting issues contributes to

the pipe or must be designed in a size

is called for. Riteline overcomes this limitation as they can be attached to the pipe as needed, with the number of spacers required based on the load, providing a tailored and efficient solution. This feature minimises excess product use, reducing costs and environmental impact.

“As each centraliser is individually attached to the pipe, the risk of catastrophic failure is reduced. Traditional centralisers that surround the pipe can fail when they snag on an obstacle in the bore, which can cause an entire ring of centralisers to move, compromising the installation,” Harrison said.

The system can be used for all pipe materials, including steel, ductile iron, GRP, FRP, concrete, PVC and PE for pressure and non-pressure pipelines. The Flex Series can only be installed in grouted applications,

Left: it is extremely easy to install the Riteline spacers on the pipe, ahead of the pipe’s installation on site.

Right: Riteline spacers can fit smoothly into any pipe.

Image: Riteline Centralisers

whereas the Rigid Series suits both grouted and un-grouted installations.

The Flex series is designed to flex around bore imperfections with its unique spring-like design. This not only allows for tension adjustment but also enables elastic deformation around obstacles, preventing jamming and ensuring a smooth workflow in horizontal drilling applications.

At the same time, the Rigid Series incorporates supports that provide a high load-bearing capacity and is recommended for most installations.

It’s not just the WSAA that has recognised the range of Riteline Centralisers. They were acknowledged as finalists in the New Technology category at the 2023 ASTT awards, attesting to their innovation and game-changing capabilities.

“Riteline Centralisers are Australianowned and manufactured, developed over almost ten years,” Harrison said. “It is fantastic to see them recognised as an innovative and game-changing product.”

For more information, visit riteline.com.au

Today, water utilities and local councils in Australia will lose more than 1.5 times the volume of Sydney Harbour, a staggering 800GL, of perfectly treated drinking water. A new product by WaterGroup aims to change this sad “tradition”.

WHEN IT COMES to water losses, they are at the same rate today as they were 100 years ago. This is despite the significant technological advances, IoT capability, and affordable pricing. In addition, there is increasing pressure on our water supplies and, thus, the need to conserve available resources better.

“Sadly, these underground pipes and their leaks tend to be very much out of sight, out of mind,” said Managing Director of WaterGroup, Guenter Hauber-Davidson.

Leaks can occur from any connection, whether a pipe joint, a bend, a valve or a hydrant. We also need to consider holes in ageing and corroding pipes. For eons, it has been a well-accepted industry rule of thumb to lose at least 10 per

cent (and often much more, over 20-30 per cent, even 50 per cent) of precious potable water.

“We need to shift that paradigm,” he said. “We need to push and reach a point where this is simply unacceptable. This represents a clear call for action.”

WaterGroup and SmartEAR

WaterGroup has entered the pipe monitoring industry with its SmartEAR acoustic Internet of Things (IoT) logger for water networks. The SmartEAR is designed for Australian water utilities but could be utilised in a range of countries.

“By providing better monitoring and visibility, it makes it easier to step up and stop the worst leaks in a system,” said Hauber-Davidson. “If we look

at crime as an analogy, we want to identify and lock up the biggest offenders first. Once security is improved, the organisation can refine their approach and cast a finer net.”

SmartEAR, in the opinion of HauberDavidson, is the quintessential technology that provides visibility relative to underground leaks.

“When people see how the platform operates, they immediately grasp its value,” he said. “Knowing that pipe leaks are detected when they happen allows network operators to sleep easily at night. Most critically, it prevents and avoids disruptive bursts requiring emergency repairs that make the evening news.”

One of the main features of technology is that it gets cheaper as more of it is rolled out. The savings arising from the increased distribution of IoT add to the increased value for water utilities and local councils.

“We’ve seen that increase in value from adopting new technology in an appropriate, practical, cost-effective, and results-driven fashion for our customers,” Hauber-Davidson said. “We’ve been able to demonstrate that over the past 15 years. In a recent audit, we showed that we have saved over $8 million worth of water for our customers just in the last three years. We can do exactly the same with our pipeline monitoring technology, supporting water supply networks for councils and utilities.”

As with any additional internet connection, risks need to be assessed. People are concerned about residential IoT devices being hacked. This extends to commercial IoT data loggers.

The water industry is no exception.

“Cybersecurity is obviously at the front of everyone’s minds,” said Hauber-Davidson. “There have been plenty of well-publicised cases. However, this should not be used as an excuse to not do something.”

Technology moves on, and very few advocate for the return to reams of paper full of hard copies of data. He pointed out that the benefits of electronic data far outweigh the costs (or risks). Hence, we have accepted those risks, and they are typically well-managed. As a result, we are now far better off than in the old days.

One aspect of how WaterGroup reduces cybersecurity risks is by keeping its monitoring solutions separate. For example, the SmartEAR does not interact with or control any asset.

“Even if somebody were to get into the monitoring system,” he said, “all they can see is where a leak might exist. In the grand scheme of things, that’s not too bad. The important thing to remember is that in most of the well-publicised cases, illegal access has been acquired through obtaining poorly secured repeated passwords, often from private social or shopping accounts. It seems almost inconceivable how people could hack a simple IoT logger with minimal bandwidth to create a pathway for back door access such as into the SCADA system.”

One of the most important aspects of cybersecurity and safety is to build in safety and security measures at every level and aspect of the data and communications chain. That extra effort makes it infinitely harder to hack a system.

Hauber-Davidson believes there are benefits in safely and securely sharing different types of data

amongst different organisations.

“That data can be network monitoring data, including water usage, consumption data and perhaps some operating data,” he said. “We still need to put clear segregations in place so that at least the operational control is completely removed from the data.”

almost any water system.

companies like WaterGroup can deliver a valuable resource for water utilities, local councils, and industrial water users.

Hauber-Davidson looked at the work done by Transport for New South Wales (TfNSW). Five or six years earlier, NSW Trains (now TfNSW) allowed open access to certain types of data, including geolocation data, routes, entry and exit data across every station, station maps, occupancy information, and even parking lot capacity.

“This access to data has given rise to a whole raft of companies that have developed mobile apps,” Hauber-Davidson said. “Those apps provide excellent information at a fraction of the cost and much faster than the government could have ever achieved. It shows that data can be shared more openly if organisations and governments are confident in their security.”

The beauty of smart water meters and data loggers is that they help water utilities and local councils see where, how, and when water is used and where it is lost in near real time. However, this data needs to be analysed and acted upon to

“It’s important to remember that once our customers receive more data in a day than they previously received in a whole year, they must have resources to interpret it. We can help by triaging the data, turning it into actionable information, and by assisting to take the corresponding meaningful corrective action.”

In Hauber-Davidson’s eyes, the icing on the cake is to monitor the results of those actions, verify what has been achieved, report on it, and then drive even greater overall system benefits to close that feedback loop. Is it a case of having your cake and eating it?

“Once customers have all that data, they will see a whole range of potential issues,” HauberDavidson said.

“The next challenge is prioritising those issues, as no organisation can deal with them all at once. It’s an opportunity to proactively deal with individual issues and systemic issues. A good dataset will help customers understand what is happening and allow them to pre-emptively deal with them.”

For more information, visit watergroup.com.au

Plastic pipes and fittings have transformed how we live, delivering essential services and utilities to our homes and communities.

IT’S HARD TO comprehend the vast network of plastic pipelines installed and in operation here in Australia and around the world.

The Plastic Industry Pipe Association of Australia (PIPA) is the peak industry body representing manufacturers and suppliers of plastics pipe and fittings, plastics resin suppliers, plastic fabricators, pipeline installers, rubber seal ring manufacturers, and training and certification bodies.

As a non-profit association, PIPA promotes the appropriate and contemporary use of plastic pipes and fittings throughout Australia. This is achieved through its four key pillars of advocate, educate, technical and sustainability.

“By collaborating with our members, industry professionals and global counterparts, we leverage the latest insights and technology to develop robust guidelines for best practice manufacture, installation,

and use of plastic pipeline systems,” said Executive General Manager Cindy Bray.

Underpinning our approach is a commitment to future-focused leadership. Through research, education, technical expertise, and advocacy, we help advance the use of plastic pipes and fittings as an innovative, efficient, and sustainable solution.”

With Australia’s focus on transitioning from a linear to a circular economy, PIPA recognises the importance of educating how plastic pipe systems align with the key principles of the circular economy – better use of resources, closed-looped resource flows and preventing waste and pollution through better design.

“When we talk about a circular economy, we are talking about an

Plastic pipes are designed to remain functional over their lifetime without requiring excess maintenance or repair.

Images: Plastic Industry Pipe Association of Australia (PIPA)

innovative model for rethinking our approach to products by design,” Bray said. “The aim is to ensure products are used efficiently and in use for as long as possible. Plastic pipe systems achieve this with their long life – from design, manufacturing, use, repair, re-use, recovery, and recyclability.

You can see why contractors prefer to replace and upgrade other pipe materials worldwide. This is extremely important for critical infrastructure to last a long time.”

Plastic pipes are engineered products designed to last

The first phase of a circular economy is design and make. This covers efficient use of resources and prevention of waste and pollution through better design and manufacturing processes.

The plastic material used to manufacture pipes is engineered to be robust, reliable, and recyclable. They are intended and designed to last a long time, more than 100 years.

The engineered polymers used are stable materials. These properties suit a product such as pipes requiring long life expectancy.

Part of the circular economy is to design a product that can remain functional over its lifetime without requiring excess maintenance or repair when installed correctly under regular operation.

“For plastic pipes, it is intended that they can be installed and not require any maintenance or repair for decades, unlike other materials,” said Bray.

Plastic pipes withstand the forces to which they are subjected. They do not corrode and resist chemical attack. Plastic pipes resist abrasion and maintain a smooth bore for easy fluid flow and better hydraulics. They are also designed not to leach secondary material into the fluid flow, essential for drinking water applications. Plastic pipes are safe for the people and the planet.

At the end of their long service life, plastic pipe systems in buried infrastructure applications can be reused without removing them from under the ground.

“These services are likely to become a host for a new plastic pipe,” said Bray. “There is a strong focus on recycling, but reusing the pipe significantly reduces the use of energy and resources. It also reduces the environmental impact of digging up a pipeline after 100 years. There are some applications where suitable recycling streams are available, such as pipe off-cuts, but it’s not for all of them.”

Bray says that you can see why plastic is the material choice for pipes when looking at design, manufacture, installation, and performance benefits. They also support a circular economy in a closed-loop system.

Alongside the importance of products being circular, Australia is also focused on reducing greenhouse gas emissions and other environmental impacts. When it comes to plastic pipe systems, the industry has been working on understanding the baseline and determining how carbon-intensive our systems are.

“The most reliable way to do this is through Environmental Product Declarations (EDPs),” Bray said. “These are underpinned by a Life Cycle Assessment (LCA) and consider the whole life cycle of products or services compliant with the ISO standards. It looks at all areas of the lifecycle, including the origin of the raw materials, transportation, processing into production, distribution, installation and product use, maintenance, and end of life. EPDs provide information on environmental impacts, including energy, carbon and emissions.

Some PIPA members have published EPDs for their products. PIPA has worked with these manufacturers to establish an industry perspective on those aspects of the pipes’ lifecycle that are the same irrespective of manufacturer.

Using this information, PIPA has communicated the lifecycle stages of pipes and where the carbon impact occurs. It presents the opportunity to highlight the areas for decarbonisation. It also highlights how small the industry’s carbon impacts are compared to other materials like cement and steel.

“Some people may be surprised that the production plants for manufacturing plastic pipes are relatively simple,” she said. “No combustion or chemical reaction is required. As a result, no smoke or emissions are produced.”

The main inputs are plastic pellets or powder and electricity. Production equipment is electrically powered, and heating is electric as temperatures are relatively low to melt the plastic. This results in a clean and enclosed process. Scrap or re-work material generated in the manufacturing process is reused, designing out waste. Suitable post-consumer and pre-consumer materials can be used to manufacture non-pressure plastic pipes.

EPDs are helpful for manufacturers to benchmark their products. They also meet market demand for science-based, transparent, verified environmental product information and data, supporting sustainable procurement.

“Establishing these benchmarks through an EPD enables our industry to be transparent with our environmental impacts and sets our pathway towards net zero,” Bray said.

“It is easy to see why plastic is the material choice for pipe and supports a circular economy in a closedloop system. By using resources responsibility through better design, we are working smarter. We’re committed and working towards creating a healthier environment and sustainable future.”

For more information, visit www.pipa.com.au

Iplex continues to be one of Australia’s leading manufacturers and distributors of plastic pipe systems, continually working within the Australian water industry by providing innovative products and new perspectives on gravity-fed sewers.

WITH MORE THAN 85 years of experience, Iplex has a good understanding of the challenges the water industry faces. Its experienced team actively work and collaborates with customers to provide safe, secure, and innovative water solutions today and into the future.

Iplex has broad and proven capabilities. It is driven by what is important to the industry, its communities and its customers. The company provides innovative pipeline products and solutions for rural and agriculture applications, residential subdivisions and civil and mining infrastructure projects across Australia.

With that capability, Iplex continues to provide high-quality products such as EZIpit.

In South East Queensland, EZIpits are becoming more popular. The South East Queensland sewer code mandates maintenance holes for sewer network access, which is essential for inspection and ongoing maintenance. These one-metre-wide holes are traditionally constructed on site in concrete. Due to the curing process of concrete, these holes often need to remain open for an extended period. Adding complexity to the project, skilled concreters are necessary to construct concrete benching in the base.

This is where EZIpit steps in. There are three types, each providing unique benefits in sewer construction and flexibility in sewer networks. Water authorities’ environmental, technical, and economic demands for a water-tight, corrosion-proof, stable, and durable

sewer system are now a reality with Iplex EZIpit systems.

Manufactured from polypropylene, the EZIpit is lightweight. The ease of installation allows rapid assembly in the trench and can be backfilled at the same time, reducing the risk of leaving deep excavation holes open, especially overnight.

EZIpit is easy to manage

One of the most experienced people to talk to about EZIpit is Trent Hutchison, Iplex Queensland Regional Sales Manager.

“I’ve had a long history in the water industry,” Hutchison said. “I am extremely passionate about it, as I come from an irrigation family and

farming background. From there, I started working in the manufacturing side of the water industry over 21 years ago across different market sectors.”

From his perspective, EZIpit is a good solution for the water industry. It offers a range of benefits for water authorities across Australia and across the globe.

“Firstly, the EZIpit is very light compared to concrete alternatives,” he said. “That is the biggest benefit for contractors. That comes with a more environmentally friendly outcome, as smaller trucks can transport the EZIpits. Smaller trucks mean less diesel used and less emissions put into the environment.”

Another positive aspect of the EZIpit is its watertight construction. Using polypropylene to manufacture the products ensures a robust, watertight unit. That includes dirt, tree roots, and other contaminants entering the sewer. No contamination means

key issue,” Hutchison said. “Sewer networks tend to build up a lot of bacteria, which can react with sulphates in the water to form hydrogen sulphide. That can create odour problems and the potential to form sulphuric acid. Sulphuric acid attacks concrete pipes and reduces its service life. EZIpit, however, is resistant and is unaffected by hydrogen sulphide attack.”

Plastic does not always strike people as the most sustainable of products. However, Hutchison advocates for EZIpit and what single-use plastic means for the water industry.

“Plastics are usually designed for a single-use, which sounds terrible,” he said. “However, our EZIpit are designed to have a long service life. We can recycle them, but an EZIpit is designed to be in the ground forever. There’s no need to worry about pulling them out because they don’t need to be reworked, relined, or resealed.”

It’s not just environmentally sustainable but also financially sustainable. By having a system that lasts for decades, water utilities do not have to spend as much money on maintenance. It’s a big advantage provided by EZIpit.

“For example, I know of one water utility spending north of $500,000 a year upgrading its manholes,” Hutchison said. “EZIpit provides the opportunity to save that money.

WELCOME TO THE inaugural Inside Water Contractor and Manufacturer Showcase. It’s designed as an easy reference point for any individual or organisation seeking to find a new partner.

Australia’s water and wastewater industry is supporting the development of a circular economy, while also facing down challenges around water quality and scarcity.

Manufacturers remain at the cutting edge of technology. They are testing innovative new techniques and providing solutions for a myriad of questions facing the industry.

At the same time, contractors are working across multiple industries to present water and wastewater management facilities, operations, and maintenance services.

The Water Industry Showcase seeks to be a one-stop shop to connect different aspects of the water and wastewater industry together, across Australia. Working together, there is little to nothing that can stop Australians from protecting and preserving this most precious of resources.

While the team at Inside Water has done its best to include every company in the industry, it takes no responsibility for omissions.

The data was collected through a variety of measures, including mailouts, website survey collection points and emails to comprehensive databases. Companies also actively sought to place themselves in this list. This list will be published online at a later date.

What products does your company manufacture or distribute?

Biochar, biosolids, and biowaste

What products does your company manufacture or distribute?

Filters and screens Internet of Things devices and software Irrigation systems Pipes and coatings Pumps, valves and seals Sludge management Stormwater management Trenchless technology Water meters and sensors, including leak detection Water recycling systems Water storage and tanks Water treatment Other

•

Cooling towers to process water to required temperature to within 3 degrees of location's wet-bulb temperature.

•

What products does your company manufacture or distribute?

Hay

What kinds of services does your company offer?

•

•

What kinds of services does your company offer?

Infrastructure Advisory Group is Australia’s most trusted specialist infrastructure advisory firm, providing transaction, commercial, strategic advisory and delivery services.

Translation of innovative approaches, technologies and new ways of thinking from research to industry application

Cybersecurity systems Design and engineering of facilities

What kinds of services does your company offer?

Education, training, and community consultation Project management ESG management, and reporting Flooding, groundwater and pollution management Maintenance Procurement and tender development Research, strategy, policy, modelling, and planning Supply chain management and logistics

Wastewater auditing and management

Water-sensitive urban design

Other

For your convenience, we present to you a contact list of all participating companies. Whether you would like to connect or learn more about their products and services provided, see below for their details.

Acciona Agua Australia Pty Ltd

South Brisbane, QLD

4101, Australia

Ph: +61 419 923 976

Email: cliff.stone@acciona.com

Web: acciona.com

Office Locations: NSW, SA, VIC, WA, QLD

ADC Plastics

Hallam, VIC 3803, Australia

Ph: 0418 399 244

Email: sales@adcplastics.com.au

Web: adcplastics.com.au

Office Locations: VIC

Ame Pump Specialists

Torrensville, SA

5031, Australia

Ph: 0882 342 090

Email: sales@amepumps.com.au

Web: amepumps.com.au

Office Locations: SA

Amtac Professional Services

Greenbank, QLD 4124, Australia

Ph: +61733804600

Email: sales@amtac.net

Web: qr2id.com

Office Locations: ACT, NSW, QLD

Aquacomb

PRESTONS, NSW

2170, Australia

Ph: 1300 00 8396

Email: sales@aquacomb.com.au

Web: aquacomb.com.au

Office Locations: NSW

Atlas Copco Australia

Blacktown, NSW 2148, Australia

Ph: +61448918604

Email: compressorsau@au.atlascopco. com

Web: atlascopco.com/en-au

Office Locations: NSW, SA, VIC, WA, QLD

Bird Water Services

Kuluin, QLD

4558, Australia

Ph: 0477058453

Email: adrian@adrianbird.com.au

Web: Bird Water Services

Office Locations: QLD

Cable & Pipe Locations Pty Ltd Woolgoolga, NSW 2456, Australia

Ph: 0408730430

Email: shane@cableandpipelocations. com.au

Web: cableandpipelocations.com.au

Office Locations: NSW

Care-Free Conditioners Australia Porepunkah, VIC 3740, Australia

Ph: 1300300235

Email: waterguys@carefree.com.au

Web: carefree.com.au

Office Locations: VIC

Central Highlands Environmental Consultancy

Newtown, VIC 3351, Australia

Ph: 0427803338

Email: raydraper2004@gmail.com

Web: Central highlands Environmental Consultancy.com.au

Office Locations: VIC

Civil Survey Solutions

Notting Hill, VIC 3168, Australia

Ph: 1300254004

Email: sales@civilsurveysolutions.com.

au

Web: civilsurveysolutions.com.au

Office Locations: NSW, SA, VIC

Clean TeQ Water

Melbourne, VIC 3168, Australia

Ph: 0397976700

Email: sales@cleanteqwater.com

Web: cleanteqwater.com/

Office Locations: NT, SA, VIC

Colin Biggers & Paisley

Sydney, NSW 2000, Australia

Ph: 82814522

Email: todd.neal@cbp.com.au

Web: cbp.com.au

Office Locations: NSW, VIC, QLD

CST Wastewater Solutions

Roseville, NSW 2069, Australia

Ph: 0412271279

Email: michaelb@cstwastewater.com

Web: cstwastewater.com

Office Locations: NSW

Data Right Pty Ltd

Mackay, QLD 4740, Australia

Ph: 1300163837

Email: zoea@dataright.com.au

Web: dataright.com.au

Office Locations: QLD

dcs manufacturing dandenong sth, VIC 3175, aus

Ph: 03 9775 1330

Email: sales@dcsmanufacturing.com.au

Web: dcsmanufacturing.com.au

Office Locations: VIC

CSDEE Engineering

Project Management

VARSITY LAKES, QLD 4227, Australia

Ph: 0403568509

Email: christopher@csdee.com.au

Office Locations: QLD

Eco Detection Australia Pty Ltd

Richmond, VIC 3121, Australia

Ph: 0419574097

Email: wani.wall@ecodetection.com.au

Web: ecodetection.com

Office Locations: VIC

Enaxiom

Sydney, NSW 2000, Australia

Ph: 0488133312

Email: info@enaxiom.com

Web: enaxiom.com

Office Locations: NSW

FiberSense

Mosman, NSW 2088, Australia

Ph: n/a

Email: info@fibersense.com

Web: fibersense.com

Office Locations: NSW, VIC, QLD

GROWAUS Pty Ltd

Wilsonton, QLD

4350, Australia

Ph: 0418737642

Email: toowoomba@growaus.com.au

Web: growaus.com.au

Office Locations: QLD

Hay Safety Consultancy

Bingara, NSW 2404, Australia

Ph: 0415502915

Email: greg@hay-safety.com.au

Web: hay-safety.com.au

Office Locations: NSW

Haycarb Holdings

WHEELERS HILL, VIC

3125, Australia

Ph: (03)85550680

Email: manuel@upnaway.com

Web: haycarb.com

Office Locations: VIC, WA

Hays

Melbourne, VIC

3000, Australia

Ph: 1800 805 051

Email: customer.care@hays.com.au

Web: hays.com.au

Office Locations: ACT, NSW, NT, SA, TAS, VIC, WA, QLD

Hydrant Services Pty Ltd

Karana Downs, QLD 4306, Australia

Ph: 32011539

Email: hydrantservices@gmail.com

Web: Hydrant Services Pty Ltd

Office Locations: QLD

Hydroflux Pty Ltd

Sydney, NSW 2000, Australia

Ph: 1300 417 697

Email: info@hydroflux.au

Web: hydroflux.au

Office Locations: NSW, VIC, WA, QLD, New Zealand, Fiji

Infrastructure Advisory Group

Melbourne, VIC 3000, Australia

Ph: +61438247783

Email: info@infragroup.com.au

Web: infragroup.com.au

Office Locations: ACT, NSW, VIC, QLD

Intelligent Water Networks

Melbourne, VIC

3000, Australia

Ph: +61400118459

Email: jason.cotton@iwn.org.au

Web: iwn.org.au

Office Locations: VIC

Kallipr

Murrarie, QLD 4172, Australia

Ph: 0477896886

Email: kim.williams@kallipr.com

Web: kallipr.com

Office Locations: NSW, VIC, QLD

Lakeside Cooling Towers

Oakleigh South, VIC 3167, Australia

Ph: 03 95554844

Email: info@lakesidect.com.au

Web: lakesidect.com.au

Office Locations: VIC

LINQ SOLUTIONS

North Lakes, QLD 4509, Australia

Ph: 0420252221

Email: mal@linqsolutions.com.au Web: linqsolutions.com.au

Office Locations: QLD

Magnachem Contimont

LIMA, LIMA

Lima 18, Perú

Ph: +51994174514

Email: renzo.olcese@hotmail.com

Web: magnachem.net

Office Locations: Argentina

Mejoras Energéticas S.A Las Rozas/ Madrid, Madrid 28232, Spain

Ph: 916403462

Email: mvazquez@mejorasenergeticas.com

Office Locations: ACT, Spain

Motion Asia Pac

BRAESIDE, VIC 3194, Australia

Ph: 0419351078

Email: Leon.stefanec@ motionasiapac.com

Web: motionaus.com

Office Locations: ACT, NSW, NT, SA, TAS, VIC, WA, QLD

Naturalis Spring Water

Perth, WA 6159, Australia

Ph: 1800006462

Email: naturalisspringwater@ yahoo.com

Web: naturalisspringwater.com.au

Office Locations: WA

Nature Positive Solutions

Saskatoon, SK

S7J 4B3, Canada

Ph: +14377785552