Supporting water management across NSW

positive culture

Digitising internal processes bolsters e ciency

Supporting water management across NSW

positive culture

Digitising internal processes bolsters e ciency

DIGITISATION

24 South East Water

BIOGAS

40 Hydroflux

COVER STORY

6 Kallipr and SigSense Getting a SigSense for non-urban water metering

INDUSTRY INSIGHT

10 Jo Palmer

Minister Jo Palmer’s insights on Tasmanian irrigation show how the state’s premium agriculture industry is driving change

15 Jane Coram

CSIRO leader encouraging a positive culture for young and middle career researchers

YOUNG PROFESSIONAL

18 Mariah Sampson

Riparian restoration of river changes the way we look at natural waterways

22 Interflow

Progress is in the pipeline

ASSOCIATIONS

50 VicWater

Transforming organisations enabled by technology

54 ASTT

Digging up for trenchless technology

LAST WORD

58 The Lighter Side of Water

People are key to digitisation, by enhancing the customer experience and optimising water network operations

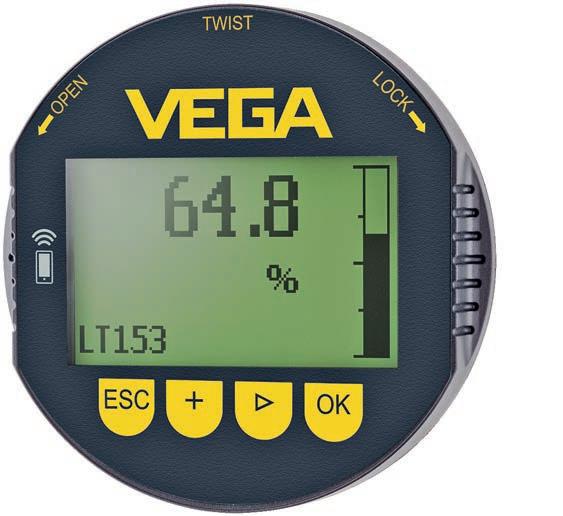

26 Vega

Bluetooth makes sensor adjustment simple and easy as it has a growing impact in industrial sectors

28 SUEZ ANZ

Digitising internal processes improve operational efficiency by shifting paper forms online

30 Voeu

Digitisation powers and unlocks project value through management of costs and risks

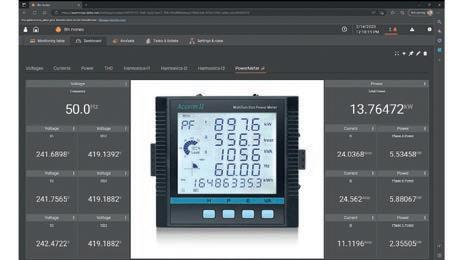

32 ifm

The power of moneo in reducing energy use through its industrial IoT platform

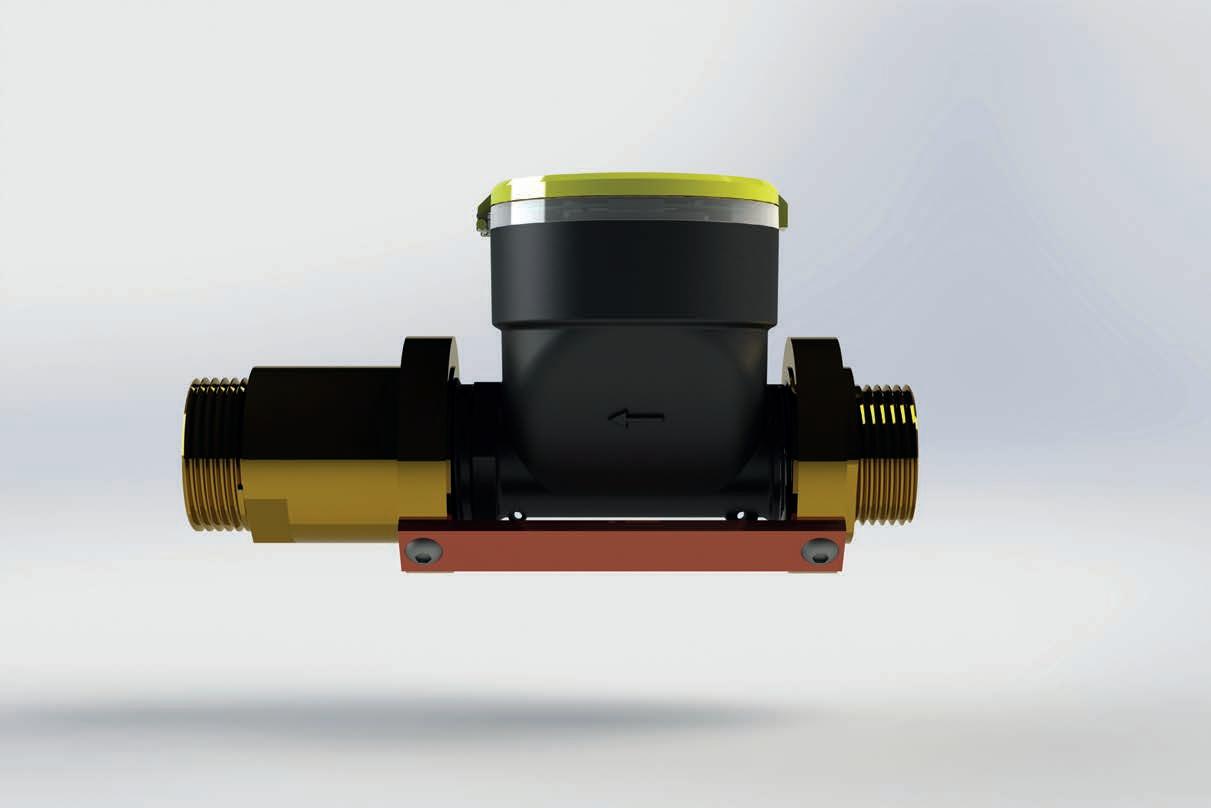

SMART WATER METERS

34 AMS Water Metering

Ultrasonic technology reshapes smart water meters, as the newly certified Qalcosonic W1 is ready for the Australian water market

37 Taggle Systems

Smart water metering makes resource management easier, with Southern Rural Water improving health and safety

Biogas from anaerobic digestion is to benefit Australia by capturing and using biomethane for a range of areas

EVENTS

44 kwik-ZIP

kwik-ZIP maintains its exhibition presence at WIOA Victoria, OzWater 23 and No Dig Down Under

PRODUCTS

46 Pulsar Measurement

Velocity flow meters monitor open irrigation channels with a range of devices

48 Powell Industrial

Powering on with Powell Industrial as a leading enterprise for integrated industrial and hydraulic hose and fittings packages

50 Pilot Air

Air compressors make waves in waterworks, as water treatment plants adjust to extreme weather events

As we approach the one-year anniversary of the first edition of Inside Water magazine, it strikes me how collaborative and supportive the water industry has been since we began this journey.

When I first started, I had to learn an awful lot extremely quickly. The people I have spoken to across the country have always been incredibly welcoming. I have learned so much from different people, companies, councils, and authoritative figures, and I hope that continues to be the case.

The digitisation of the water sector has been continuing at a rapid pace, with water authorities and local councils across the country experimenting and innovating. Companies like SigSense have partnered with larger device manufacturers like Kallipr to help with this transition. Even though most of Australia’s population lives in urban centres, it is critical that non-urban water users are properly metered and assessed for their water use.

Often when we look at the digitisation of the water industry, time is spent looking at customer-facing processes. Not enough time is spent looking at those internal processes that can improve operational efficiencies. It is people like Andrew Forster-Knight at South East Water and Megan Boardman at SUEZ, who work in different areas of their respective businesses. They’ve found ways to transform their areas of responsibility for the betterment of their companies.

We are thrilled to have the Tasmanian Minister for Primary Industries and Water, the Hon Jo Palmer, give us her time in this issue. She gave us her insights into Tasmania’s irrigation industry, how the Greater South East Irrigation Scheme is working to support better agricultural outcomes for Tasmania, and the intersection of innovation and environmental management. The presence of

Minister Palmer in our pages shows the interest of leading decision makers across the country in our publication. Similarly, speaking to Jane Coram from CSIRO was an enlightening experience. Her insight and knowledge were incredible to hear. She is an outstanding leader and role model for female scientists and early and midcareer scientists.

When we look at the continuing growth in smart water meters, there is considerable work in the field. Companies like AMS Water Metering and Taggle Systems continue to push the boundaries with what they are doing for their clients. It is also interesting to look at the issues facing urban and non-urban water users as they transition from traditional water meters to smart water meters for different purposes.

Our ongoing media partner VicWater connected me with Goulburn Valley Water and Tony Wulff. Tony provided a unique perspective on the challenges of the digitisation of a rural water authority, along with the opportunities for partnerships and collaboration. With the middle of the year approaching, I look forward towards the second half of the year and the upcoming issues. We have some incredible industry stories coming up, and I cannot wait for you to be a part of that journey.

Chief Executive Officer John Murphy john.murphy@primecreative.com.au

Chief Operating Officer Christine Clancy christine.clancy@primecreative.com.au

Group Managing Editor Sarah Baker sarah.baker@primecreative.com.au

Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au

Editor Chris Edwards chris.edwards@primecreative.com.au

Design Daz Woolley/Tom Anderson

Head of Design Blake Storey blake.storey@primecreative.com.au

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Brand Manager Chelsea Daniel chelsea.daniel@primecreative.com.au p: +61 425 699 878

Client Success Manager Glenn Delaney glenn.delaney@primecreative.com.au

Head Office Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.insidewater.com.au

Subscriptions +61 3 9690 8766 subscriptions@primecreative.com.au

Inside Water is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright Inside Water is owned by Prime Creative Media and published by John Murphy.

All material in Inside Water is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Water are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

At Hydroflux, we strive to provide our customers the most practical, efficient, and commercially sound solutions that consistently perform.

Our extensive experience along with the product range and services we offer to our customers covers all the requirements for design or provision of sustainable water, wastewater, and bioenergy solutions, equipment, and services within the industrial and municipal treatment sectors.

The NSW government created a new system to better manage non-urban water resources in NSW. Sigsense and Kallipr have joined forces to support this initiative to provide a cost-effective alternative for water licence holders to achieve regulatory compliance.

IN 2018, THE NSW government introduced new regulations and legislation requiring telemetry devices to be installed at water extraction points in rural areas. Telemetry allows the government and the landowners to better monitor and manage water usage. These legislative changes aimed to enhance transparency, improve compliance, support sustainable water management, and build public trust in managing water resources. But to achieve these outcomes, the framework required the market to innovate and provide telemetry that met the government’s requirements around data quality, security, and compliance with regulatory requirements – at a price that made sense.

This is where SigSense stepped in. SigSense provides pre-configured telemetry devices to authorised installers (DQPs, or Duly Qualified

People) and offers a range of services to help address the resourcing gap the project created and to ensure consistent quality in telemetry installations.

“The NSW non-urban framework is Australia’s first open market meter telemetry framework. For many installers, this was their first exposure to telemetry systems. SigSense sought to help installers, end users and even government officers address the complexity and associated quality risk of this nation’s first project,” said Ben Starr, Director of SigSense.

Starr believes that the partnership between Kallipr and SigSense showcases the solution for secure, reliable and cost-effective automatic meter readings.

“SigSense and Kallipr have been instrumental in changing how NSW monitors and manages its water consumption,” said Starr.

SigSense is the Kallipr authorised reseller of the Captis device for the NSW water metering market and emerging markets in other Australian states. SigSense focuses on making compliance simple, with close relationships with all meter manufacturers and installers nationwide.

What are the regulations introduced by Water NSW?

Water NSW and the NSW Government are committed to implementing a robust metering framework to improve the standard and coverage of non-urban water meters across NSW.

The changes in requirements for metering and telemetry were implemented by the gazetting of the Data Logging and Telemetry Specifications under the NSW Water Management Regulation 2018 and modifications of several sections of the Water Management Act 2000

As part of this project, the regulator requires all license holders to acquire compliant water meters that accurately measure water consumption, and to connect these meters to Local Intelligence Device (or LID), that records water usage on-site and transmits that data to

the government’s Data Acquisition System (DAS) for compliance and water accounting.

“These devices will make it easier and more accurate for water users to record their water take. It ensures greater fairness in how we share

water in NSW,” said Scott Mathieson, Senior Investigator for the NSW Natural Resources Access Regulator.

LIDs are subject to robust testing against the NSW government’s strict technical and functional requirements over months before

being accepted and listed as an approved solution. The patternapproved meters comply with AES 4747 and have been assessed by the National Measurement Institute of Australia as compliant.

“SigSense is solving part of the nonurban metering challenges in getting the data from the meters back to the government. We have 56 registered installers nationwide installing a planned 6400 telemetry devices over the next five years. I believe this is one of Australia’s largest rollouts of automatic meter readers for nonurban water,” said Starr.

To develop a solution that would meet the requirements of the NSW Government, SigSense worked to understand the needs of the government.

“Once we knew what the government required, we needed to find the right device,” said Starr.

“We knew that as landholders were purchasing the devices almost exclusively to satisfy a regulatory requirement, low pricing would be important. We also realised that the installer network of DQPs had limited experience in telemetry and system

integration. That meant a system that allowed us to configure and support our installer network remotely would be critical.”

“Pricing had to consider total cost, which means simplicity for installations and long operational life in the field.”

“We found the Captis device, developed by Kallipr for urban metering applications, to be ideally suited for non-urban use. Unlike traditional scientific data loggers, the Captis is designed for large-scale deployment, with tens of thousands of units per project. That drives down costs and enables easy installation. This mass production creates economies of scale, making it a more affordable solution for regulatory markets.”

The Captis devices leverage IoT technology, making it a suitable, cost-effective solution operating in areas with minimal connectivity. Telstra’s NB-IoT coverage across NSW means that the devices can service almost every meter in the state.

The Captis devices are low-cost, easy to use and can be configured remotely for DQP installers. They use wireless communication capabilities to ensure connection in remote areas and are flexible. It provides seamless integration with all patternapproved meters, making it easier to scale as the program expands.

Starr talked about a few minor modifications that needed to take

place to the existing Captis devices, such as increasing the onboard storage capacity to accommodate five years of data and adding eyelets to receive tamper-evident seals to meet the requirements of the regulator. Kallipr accommodated these changes to support the NSW non-urban metering framework.

Sigsense has supplied over 4,600 Captis devices which have been installed across 800,000 square kilometres of land, and the solution has gained certification as an

approved LID is the supplier of choice for WaterNSW for the 2600 government-owned meters.

What has been learned? What can be applied in the future?

With any non-urban metering project utilising an open market approach, the biggest challenge is the vast number of options available to users and the complexity this introduces to the government in administering the framework.

Consider an urban water metering initiative. The utility will purchase and install meters and telemetry devices at each endpoint and recover installation and maintenance costs with an annual service charge. In this scenario, hardware will be installed by the utility’s contractor, allowing work to be programmed, going door to door to install devices. This installation method is significantly more efficient than the ad-hoc basis required in an open-market approach.

“It’s conceivable in the current open market model that two separate DQPs make a 10-hour return trip to install two LIDs on neighbouring blocks, said Starr. “If installed on a roll-out basis, this would be a 50 per cent reduction in install time (and cost).”

This is why the open market model is so significantly different from the traditional models faced by urban water utilities.

“In an open market model, landholders may choose from one of seven telemetry devices and connect these to one of fifteen meters. They can then use one of the eighty approved installers, transmitting over one of four different data transport methods over three cellular telemetry bands. We’re dealing with over 100,000 combinations and permutations,” he said.

Part of the value that SigSense provides is managing the quality risk for our DQPs and end-customers dealing with this system’s complexity. Starr said SigSense does this in various ways.

“We document the installation method for each Pattern-approved meter to achieve standardisation of installation method. During this process, we identified some errors with the meter vendor’s documentation which have since been remedied. We’ve removed the need for DQPs to be intimately familiar with the configuration of devices, instead offering this as a service so the Captis can be plugand-play when they arrive at the site. Despite this, each authorised Captis installer undergoes mandatory device training,” he said.

SigSense also assists with telemetry design, NB-IoT signal strength modelling, and installation site recommendations. It provides advice on the optimal antennae type for each location and the best elevation and azimuth angle for directional antennae.

“We also assist our DQP clients with navigating the administrative processes of the government,” said Starr. “We have DQPs on staff who have undergone the Irrigation Australia Certified Meter Installer training, so we’re up to speed with requirements.”

Bringing people on the journey

It’s not just the NSW government that benefits from installing Captis water meters. The farmers and other non-urban water users are reaping the rewards of their actions.

“I think that when we look at the entire program holistically, it fosters a more equitable and efficient management system. The framework ensures that all water users are held accountable for their water usage. That builds trust among stakeholders and demonstrates that compliant farmers are operating within their allocated limits. It also allows the government to recognise those farmers who have been using water efficiently and sustainably. This could lead to additional incentives or benefits, explicit or otherwise,” said Starr.

Part of achieving that outcome has been working with non-urban water users. A study out of Monash University indicated that nearly two in three non-urban water users supported metering and telemetry. Respondents said that they understood it was needed to manage compliance action.

“This data is detecting nonconformance, so it is working, and it should build public trust,” he said. “I would expect that public trust will continue to build over time as we see illegal water use detected and, ideally, stopped.”

There has been much interest in the NSW scheme from other states. Starr is collaborating with other state government departments across Australia to implement their own non-urban metering frameworks, leveraging the lessons learnt from the NSW rollout.

“There are regions in Australia where landholders with water licenses only self-report usage once or twice a year,” he said. “This is very different from urban areas, where being metered for our meagre water use at our house and being billed for consumption by the litre has been normalised.”

Starr pointed out that measuring water extracted for irrigation and accounting for water usage against licenses is a critical element of water management that is an issue of national importance.

“I can envisage that every pump extracting water from groundwater or surface water will be metered over the next decade. That consumption will be transmitted. In this way, the non-urban water market will catch up to the state of play with every family in Australia.”

For more information, visit www.sigsense.com.au/ and kallipr.com/

management of water entitlement and licenses is a key focus of government.

Irrigation has been vital to developing Tasmania’s premium agriculture industry. Tasmanian Minister for Primary Industries and Water, Jo Palmer, provided her thoughts on its importance to Tasmania.

JO PALMER HAS been the Member of the Tasmanian Legislative Council for Rosevears since August 2020. Her rise into cabinet has been rapid, having been the Minister for Primary Industries and Water, the Minister for Disability Services, the Minister for the Prevention of Family Violence, and the Minister for Women since April 2022.

Originally from Christchurch in New Zealand, Palmer grew up in Trevallyn, Launceston, near the banks of the River Tamar since she was six years old. Her profession saw her as a trusted voice in the media, with a 20-year career as a journalist and newsreader for 7 Tasmania.

With such an established profile in Tasmania, a movement into politics made sense, and Palmer was elected in a tight battle in 2020, and is due for re-election in 2026. The electorate of Rosevears is diverse, and she understands the importance of it to Tasmania’s premium agriculture industry.

Since Tasmanian Irrigation was established in 2011, the company has managed inherited assets. These assets include dams, irrigation schemes and river work. Tasmanian Irrigation has also constructed 15 new irrigation projects, with one in construction and advanced planning on five more projects.

Results from surveys undertaken by the company on five of the ten Tranche One schemes have demonstrated that essential community benefits accrue after

commissioning the irrigation schemes. Those benefits include the increased ability for farming enterprises to diversify their business activities, increase their profits and margins, keep people working in the regions, maintain community and rural services, and improve community well-being.

From Palmer’s point of view, having irrigation water has been vital for giving landowners the confidence to invest, expand, diversify, and employ more people.

“Across Tasmania, there are so many examples of farmers who have diversified from traditional grazing to high-value horticultural crops,” she

said. “This was after being allowed to access water from one of Tasmanian Irrigation’s 18 operational schemes around Tasmania.”

The Tasmanian Government recognises the importance of having access to high-surety irrigation water. That is why Palmer and Tasmanian Irrigation (TI) is committed to continuing to work with the Australian Government and landowners to build additional schemes as part of the unique public-private funding model.

“We’ve also set an ambitious target, as a government, to increase the farmgate value of Tasmania’s agricultural industries to $10 billion a year by 2050. Irrigation has, and will continue to play, a pivotal role in enabling this target to be met.

Tasmanian Irrigation now delivers reliable and fit-for-purpose water to almost 1000 farmers around the state,” said Palmer.

Tranche Three is a set of 10 irrigation projects being developed by TI. It includes the underconstruction Don Irrigation Scheme. The water from this scheme will enable farmers to invest confidently to produce a range of high-value crops. This includes wine grapes, berries, leafy greens, and vegetables. Farmers can also undertake grain and other cropping, expand dairy herds and finish livestock.

“The expansion of irrigation across Tasmania is seeing the development of new industries across the state. There has been an expansion of berry, wine grape and horticulture production and commencement of hemp, carrot, grass, and other seed crops,” said Palmer.

She pointed to the importance of providing access to high-surety water, as it has given Tasmanian farmers the confidence to grow their businesses and contribute towards the Government’s ambitious target to increase the farmgate value of the State’s agricultural industries.

“We’ve also seen increased

investment in on-farm irrigation infrastructure,” she said. “This irrigation water also means traditional sectors such as horticulture, grains, poppies, vegetables and dairy can be sustained and grown.”

What makes Tasmania unique in terms of its water use and irrigation?

In the eyes of Palmer, Tasmania is the envy of the nation when it comes to access to water resources. It is also committed to innovation and developing irrigation infrastructure.

“In Tasmania, we are building irrigation schemes with a 95 per cent surety of supply,” she said.

“That has been modelled around climate change and is built to last 100 years without impacting our terrestrial or aquatic environments. Our innovative approach is centred around the State Governmentowned entity Tasmanian Irrigation. It is our vehicle to manage the sustainable development of irrigation schemes across the state.”

TI is not the only body responsible for water in Tasmania. Under TI CEO Andrew Kneebone, landowners through the dry southeast have worked with Tasmanian Irrigation to find a new water source.

“The existing South East Irrigation Schemes Stages One, Two and Three were opened in 1986, 1992 and 2015, respectively,” he said. “As landowners increasingly realised the value of high-surety irrigation water, demand grew for additional water and a new water source. Water for South East Stages Two and Three had been sourced from TasWater, which is not viable for future years.”

As a result, TI has been working with farmers in this region to determine the best possible solution to secure an alternate, reliable, and costeffective water source to provide additional irrigation water to existing and new irrigators. The scheme has also sought to interconnect all three schemes and standardise entitlement contracts for landowners.

“We are now assessing the applications for water entitlements. As a state-owned company, Tasmanian Irrigation looks forward to working with irrigator communities across this vast region to continue to develop this important project and prepare a business case and funding justification,” said Kneebone.

Innovation at the heart of Tasmanian Irrigation

With more than $1 billion of irrigation investment planned for the coming years, there is no doubt that Tasmanian farmers are committed to innovation, technology, and investment to optimise this irrigation water.

“After constructing 15 new schemes, Tasmanian Irrigation has ensured that learnings from each project are incorporated into future builds,” said Palmer. “A great example of this is Tasmanian Irrigation’s new

design partnership with GHD, Pinion Advisory and Blue Tier Consulting to strengthen the design and delivery component of Tranche Three projects. This approach aims to reduce duplication, enhance crossscheme learning, simplify procedures and provide more certainty to contractors. Design specifications have been standardised for engineering, hydraulics, electrical plans, pumps, pipelines, and dams, leading to a more consistent system control and data acquisition, and assisting with water delivery and asset management operations.”

It’s not just about physical infrastructure. There is a focus on having the right climate modelling and digital infrastructure to understand what might be happening and what could affect Tasmania. Having lived in Tasmania for most of her life, Palmer understands how vital it is to be a leader in this field.

“Tasmania’s nation-leading climate modelling has already been built into the design of every scheme built or developed by Tasmanian Irrigation. Climate change is a key risk and opportunity for Tasmanian Irrigation. In designing new schemes and determining the reliability of the water supply, a conservative approach is taken when considering the potential impacts of climate change,” she said.

The impacts of severe weather events are also considered when designing the schemes and associated infrastructure. Updating and improving the climate science that informs water allocation is ongoing.

“The Department of Natural Resources and Environment Tasmania is undertaking a Federal and State Government-funded project to provide the best pathway forward and improve understanding of the future climate impacts on irrigation schemes,” said Palmer.

Managing environmental issues

Palmer is cognisant of the challenges associated with balancing a premium agricultural industry with the environment’s needs. Under her watch, Tasmanian Irrigation has implemented various procedures to ensure all activities meet statutory environmental requirements. Those activities are also conducted in an environmentally responsible manner.

Kneebone also pointed to the extensive monitoring and reporting programs Tasmanian Irrigation runs.

“Tasmanian Irrigation once again reported in 2021/22 that there were no discernible impacts from its operations across all monitoring programs, and no incidents of environmental harm were recorded,” he said. “Tasmanian Irrigation also works with all irrigators to develop Farm Water Access Plans

We’ve also set an ambitious target to increase the farmgate value of Tasmania’s agricultural industries to $10 billion a year by 2050.

(Farm WAPs). They are propertyspecific documents that guide the sustainable application of Tasmanian Irrigation water and assist with the long-term viability of land for agricultural production.”

A Farm Water Access Plan (Farm WAP) is a property-specific document that guides the sustainable application of TI water. Farm WAPs assist with the longterm viability of land for agricultural production. It identifies where TI water will be applied and details actions to manage potential risks, ensuring that water is only used for irrigable land.

“Each plan identifies relevant management practices to ensure the long-term sustainability of irrigation application and manage the environmental values and risks (soil, water and biodiversity) associated with irrigation on and near the property, as well as highlighting other key guidelines, regulations and codes of practice that exist across Tasmania,” said Kneebone.

Tasmania must have a lot of sunlight to operate a high-value farmgate agriculture industry. As such, installing solar arrays at 12 TI pump stations around the state seems like a no-brainer.

“The Tasmanian Government has put $2.5 million into the Energy on Farms Solar Project. These installations are expected to deliver direct savings to farmers by offsetting electricity usage at pump stations and generating surplus power to be fed back into the grid. Farmers will save up to $5 per megalitre. This is great news and another example of Tasmanian Irrigation’s commitment to delivering high-surety irrigation water as efficiently and costeffectively as possible,” said Palmer.

Landholders across Tasmania are working with TI to install solar arrays at various locations. Construction will commence in May 2023, intending to complete construction by the end of the year.

The Tasmanian government is also working with TI to enable it to supply bulk raw water to the Tasmanian Green Hydrogen Hub at Bell Bay using the proposed Tamar Irrigation Scheme. Common-use water infrastructure will ensure a sustainable and cost-effective water supply. Importantly, any water supply to a green hydrogen producer will be sourced from the existing Hydro Tasmania water allocation to ensure

no additional pressures are placed on Tasmania’s water supplies.

“It will support the Tasmanian Renewable Hydrogen Action Plan, which sets the ambitious goal of transforming Tasmania into a globally significant exporter of green hydrogen from 2030,” said Palmer.

“This proposal has the in-principle support of the Tasmanian Farmers and Graziers Association. It will help secure the prospects for the proposed Tamar Irrigation Scheme to benefit both irrigators and green hydrogen producers.”

For more information, visit www.tasmanianirrigation.com.au

The Commonwealth Scientific and Industrial Research Organisation (CSIRO) has long been a jewel in the crown of Australia’s scientific progress.

THE FORMER DIRECTOR of the Land and Water Business Unit, Jane Coram, is an experienced organisational leader with a 30-year career in environmental sciences. She is passionate about helping people and organisations solve complex and intractable problems, including building positive work cultures.

“When people think of CSIRO, they might think about products like Aerogard, the permanent pleat in fabrics, polymer banknotes, or Wi-Fi technology. Others may consider its research in vast scientific fields, including space, agriculture, energy, and the environment. But CSIRO is also uniquely positioned as the national science agency to tackle big, multifaceted issues like climate change, where no single discipline or sector can solve them. CSIRO is vital in partnering, collaborating, and helping Australia understand

the challenges and respond constructively,” said Coram.

What got her interested in the earth sciences?

As a child, Coram was always fascinated by the massive question of “Where did we come from?” She was intrigued by earth and planetary processes, and how they shaped the environment and human civilisation. But that fascination did not lead to an immediate decision to pursue an earth sciences career.

“As a student, I was tantalised by many potential science fields and career paths. Among other things, I explored earth and geological sciences,” she said. “I didn’t see it as a career at the time. Later, I realised I could build on my formal education to help understand and contribute to environmental management.”

One thing that Coram believes as she has moved through her career

is that the rigours of the scientific process are vital to understanding complex environmental issues, as are having integrated biophysical, social and economic analyses. Excellent communication and engagement skills are also critical to ensuring that science has an impact and can contribute to tractable solutions. Coram’s belief underpins her commitment to applying an interdisciplinary approach to environmental challenges, borne from her involvement in many nationally controversial water-related issues.

Coalition of pathways between CSIRO and the water industry CSIRO has been working on water security for many years, and Coram hopes that their work is well regarded by the water industry.

“Looking forward, I would say that we can contribute a great deal to the water industry through our work in combining biophysical modelling with social and economic insights”, she said. “We want to do that in partnership and collaboration with the water industry, building on our

historical strengths with innovative digital approaches to remotely observing and predicting future challenges”.

“I think it’s pretty clear that the future is going to look different, and I don’t think there is much doubt that it’s going to be more challenging for water management in many ways,” said Coram. “However, different and more challenging does not necessarily have to mean bad. It could be the catalyst for finding better ways of managing water for people and the environment than we are doing right now, despite the enormity of climate change impacts.”

As a woman in the physical sciences, Coram understands the challenges of attracting and retaining women in STEM careers. Her interests include strategy and organisational leadership while facilitating the development of emerging talent and leaders, especially from underrepresented diversity groups.

“As a senior STEM leader, one of my ambitions is to help create workplace cultures that inspire and support everyone to contribute and flourish,”

she said. “And I think workplace cultures have improved dramatically since the early stages of my career, as have expectations around a robust organisation and good organisational behaviour.”

She pointed out that many organisations have adopted codes of conduct and devised behavioural expectations that encourage contributions from everyone, regardless of gender, race, sexual orientation, or creed.

“I’m optimistic that things will continue to improve in the coming decades as we have more conspicuous and influential female leaders,” she said. “However, I also encourage women to believe they have an important contribution to make to the water sector. It can be an amazing career. But they need to back themselves, take chances and seize opportunities – believe in the influence they already have and the contribution they can make.”

researchers studying waterbirds in the Murray Darling Basin.

sector, it still remains maledominated, particularly at senior leadership levels. Coram mused that the careers of capable women can still be adversely affected by unconscious bias and the absence of deliberate organisational processes to support diversity.

“There is scope for improvement. There are plenty of amazing women working in the water sector, and making opportunities for them to be visible role models for other women is important,” she said. “Showcasing what they are doing and celebrating the diversity of styles, thinking, and achievements of women and other diversity groups in the water sector will make a real difference.”

women thrive in the water sector

While Coram has seen progress in identifying factors that hinder women from thriving in the water

One area that Coram thinks is critical is mentoring. In her eyes, one of the impediments to women thriving in any career is their own self-limitation and unwillingness to take chances or back themselves.

“Mentoring can help overcome these personal barriers,” she said. “I do my best to be available as a mentor, and I’ve had some fantastic

mentoring experiences where I have learned as much as the person I’ve mentored. But like other male-dominated fields, one of the challenges for female leaders in the water sector is that the demand on us for mentoring is incredibly high, and there are only so many of us available.”

With that in mind, Coram has had to consider more creative ways to share her experiences. She is in no doubt that sharing challenges and lessons learnt is vital to supporting women in the industry.

“I’m very aware that in my position, I’m a role model for female scientists

and early and mid-career scientists. As a woman, I have to be authentic in demonstrating that it is possible to have a thriving and rewarding career in STEM,” she said.

Reflecting on her professional experiences in several science organisations, Coram believes it is essential to try and give people from every diversity group the opportunity to have visibility and speak in formal engagements for CSIRO.

“It’s that visibility and seeing the diversity that is very important for role modelling. So I encourage everyone to back themselves and be visible role models and

Coram is committed to supporting young and mid-career researchers as they grow into their roles.

active contributors to shaping organisational cultures where everyone can thrive. If we can get that right, we’re going to be far better placed to respond to the water-related challenges of climate change.”

For more information, visit csiro.au.

The Upper East Barwon River is a vital waterway for Geelong and its surroundings. PhD candidate Mariah Sampson has been studying its riparian environment, and the impact of removing willows and restoration works on streams in the area.

MANY YEARS AGO, willows were historically planted along waterways across Victoria for erosion control and aesthetic purposes. However, the spread of willows has been found to degrade rivers and riparian lands.

Barwon Water worked with Deakin University and Water Research Australia to assess the effectiveness of riparian restoration, with a focus on willow removal from a 3.5-kilometre stretch of the Upper East Barwon River. Mariah Sampson is a PhD candidate working with landholders and stakeholders to undertake this assessment.

Sampson is from regional southeast Queensland. She grew up during the millennium drought, where her family relied on tank water.

“I think that gave me an appreciation for how important water was. However, it wasn’t until later that I fully appreciated it,” she said.

An important moment for continuing advanced studies in water research was in 2019 while doing an industrial traineeship with CSIRO Land and Water.

“I was in Brisbane, and southeast Queensland had a bad drought just before the bushfires began. It really motivated me to want to keep studying and exploring the balance between human and environmental water needs,” said Sampson.

Sampson’s PhD research topic is titled Evaluating riparian buffer zones in temperate streams, and she received the Nancy Millis Memorial

Award in 2022. On receiving this scholarship, she found it a humbling and motivating experience.

“Nancy Millis was a very impressive woman,” said Sampson. “I’d like to live up to what the award embodies. It also represents how important water research is in Australia.”

What is her research about?

Sampson’s research focuses on the Upper East Barwon River, located outside Forrest, Victoria. Barwon Water transfers water from its West Barwon Reservoir via a 3.5-kilometre section of the East Barwon River. At this point, it diverts into the Wurdee Boluc inlet channel. It travels about 57 kilometres to the Wurdee Boluc Reservoir, where it is treated and

supplied to customers in the greater Geelong region.

Willow infestation had caused a loss of transfer capacity through this section of the East Barwon River. The infestation of willows had reduced Barwon Water’s ability to transfer water, and led to more frequent water logging of adjacent properties. Since 2019, Barwon Water has been working with local landowners and other key stakeholders to develop an agreed approach to removing the willows and remediating the river. These works were completed in May 2022.

“This combination of environmental, ecological and engineering goals is the sort of thing that I enjoy,” said Sampson.

In terms of her research, Sampson understands that the willows were planted in Victoria to deal with erosion following deforestation for grazing, agriculture, or logging.

“Willows tend to proliferate and are easy to plant. People can stick willow branches in the mud, and they will

grow fast. Where they are endemic in Europe and North America, that makes perfect sense, and willows are not a problem. It’s only when they are planted where they are not supposed to be that it can become a problem,” she said.

It would have been hard for people to know this at the time, and they would have argued about the usefulness of the trees.

“These willows are now a problem,” said Sampson. “They are highly successful riparian invaders and have been linked with erosion and channel widening. They can grow and migrate into river channels. By blocking channels, they slow the river down and can reduce dissolved oxygen concentrations, resulting in potential problems for aquatic species.”

Riparian restoration is considered one of the best ways to protect streams and tributaries from runoff.

Sampson’s research is looking into better understanding the processes of restoring the land around waterways and whether this significantly influences water quality variables.

“Healthy riparian ecosystems can act as a mechanical and chemical buffer, slowing down sediments and preventing nutrients from running into waterways through processes such as denitrification in the soil or the uptake of nutrients by riparian plants,” she said. “Riparian buffers can also create habitat and habitat connectivity across landscapes while providing thermal buffering and shading for the stream environment. This canopy cover can also shade out pest aquatic plants that often

reduce stream flow capacity. Some aquatic species have a limited thermal tolerance, so a healthy riparian zone can help to keep stream temperatures cool.”

The other significant impact is that a functioning riparian ecosystem can ameliorate flooding. This has been a big issue within the Corangamite catchment area. Geelong and the Barwon River fall within that catchment, which dealt with significant amounts of rain in the latter half of 2022.

“When willows are growing in the stream channel, a lot of rain can see the willows impede the flow of floodwater through the channel,” said Sampson. “That will see the water flow out over the floodplain and erosion of the channel embankment. Improving the flow of water through the system is a key reason why willows have already been removed within the catchment.”

The ultimate goal of the research is to increase the scientific understanding of how replacing willows with riparian buffers that consist of native plants affects stream ecology, morphology, and water quality.

As part of her research, Sampson has been liaising with local landholders and stakeholders under the supervision of Brigid Creasey, a Water and Catchment Officer at Barwon Water. In her experience, the local landholders and stakeholders have

“They allow me access to their properties, and they care about the river running through them,” Sampson said.

Sampson pointed out that talking to the local landholders can be important for additional information and context. This is particularly true when some have been using the same land for over 60 years.

“For part of the study, we looked for sites that do not have willows or revegetation. These additional sites have native riparian trees, such as

the Australian blackwood (Acacia melanoxylon),” she said. “We have talked to some landholders who would tell us that the blackwoods have been there for 65 years, or they might tell us that the blackwoods were planted after the streams were straightened at some point in the past. We have also seen landholders doing their own restoration and bringing back the original meander. On at least one occasion, an owner said that a particular point in the river was three to four metres deep.

measured it, we found out that it was. That background knowledge of landholders is vast.”

Another stakeholder of note is the Corangamite Management Authority. Sampson said that she collaborates with them regularly.

“They have also connected me with landholders and different sites across the region. I also try to keep them up to date on what I am up to.

“ Hopefully, my research results will be useful for their forward planning,” she said.

Many early career researchers in the water industry have pointed to the support of Water Research Australia (WaterRA). Sampson agrees that WaterRA has done a fantastic job of supporting her.

“They have connected me with a mentor within the water industry and other great women in water science and management,”

Sampson said. “They also have a great research capability manager who takes care of all the students, ensures that everyone’s funding arrives, organises social events and encourages students to attend conferences. WaterRA is a great support.”

In terms of her future, Sampson sees herself in the water industry.

“I want to get some solid findings from my research first and then to be able to communicate it in a meaningful way to landholders, industry, and catchment management authorities. I’d love to work in the water industry, especially catchment management. It’s only going to become more important in the future.”

For more information, visit www.barwonwater.vic.gov.au/ and www.waterra.com.au/

In 2023, construction remains the most male-dominated sector in Australia, with female participation at just 13 per cent. How does the sector build workplaces that are attractive to everyone and that women can thrive in?

WOMEN REMAIN AN untapped talent pool for many blue-collar industries in Australia. Only two per cent of women in the construction sector are in trades, but industry bodies are working to improve the numbers. For example, the National Association of Women in Construction (NAWIC) has set a goal of 25 per cent female participation by 2025.

This trend also appears in the water sector. Shifting values within urban water businesses have seen an increased focus on diversity and inclusion. Gender equity is a meaningful way to foster better outcomes for workers, customers, and the community.

Across the sector, authorities and councils put ‘gender on the tender’, asking contractors and suppliers to meet a minimum standard of policies, plans and targets. The Victorian Government is leading the way with gender mandates for publicly funded projects of $20 million or more.

Targets and quotas are essential in keeping diversity on the agenda and encouraging women through the door. The other piece of the puzzle is creating an inclusive environment that enables women to stay in a business or sector once they arrive.

Tracy Keevers, the Executive Manager of People & Capability at pipeline infrastructure company, Interflow, shares her insight.

“True inclusion means removing the barriers preventing women from entering, staying, and thriving in a sector or an organisation,” she said. “The barriers might arise from a poor

internal culture or a negative public perception of a particular industry. We need to consider everything from the behaviours and capability of leaders right down to having inclusive uniform policies and the right facilities for everyone.”

Construction has been the most male-dominated industry in the country for many generations. As a result, it can have outdated masculine work methods that can make women feel unwelcome. The sector has come a long way in recent years. However, work still needs to be done to rid workplaces of exclusive behaviours. Communicating the broader benefits

of structural and cultural change is part of the solution for men and women. Another is equipping people with the tools to recognise biases and check attitudes undermining an inclusive culture.

“Respect at work policies are a great first step,” said Keevers. “Just as important is giving people the tools and training to be the best versions of themselves at work and home.”

Keevers also spoke about their success with positive behaviourfocused programs and language. It has given its people the confidence to respectfully call out what Interflow calls ‘below the waterline’ behaviour, knowing that the business will support them for doing so.

If greater diversity in the industry is the key to building a more robust industry, how then do we attract women to roles in the first place?

One part of the solution is encouraging young women to join the industry or learn a trade from an early age. Perceptions of a sector or career, whether valid or mistaken, can be formed at an early age and influence decisions later in life.

A study has shown that school-aged girls aren’t aware of the opportunities the industry presents and can’t picture themselves in the job. Coupled with a lack of visible role models, working in construction isn’t on the radar for many school-aged girls. Programs exist to encourage young women into STEM fields, but their opportunities aren’t always visible within the construction sector.

Interflow’s Talent Acquisition

Business Partner, Daniella Saumatua, says the opportunities for women in the construction and utility sectors are abundant.

“We have women in the field and on the tools, leading crews, and working as engineers,” she said. “We also have women in highly transferable roles between sectors, like in our people team, finance, safety and quality, marketing, IT, community relations, business development – you name it.”

Saumatua pointed out that the scale and variety within the sector mean people can choose their path. They

Long hours, rigid work practices, and ever-changing job locations have long been associated with the construction sector. While these factors disadvantage everyone, they can exclude people with caring responsibilities, most often women.

The industry is becoming more attractive to everyone. This came with a growing trend towards flexible work options, paid parental leave for all parents, a push towards a guaranteed five-day work week, and a growing focus on wellbeing. Flexible working arrangements, like those provided by Interflow, enable more women to return to work after taking parental leave.

Interflow’s Georgina Hilder, Community Relations Manager, had her second child while working at Interflow and is currently on parental leave.

“Knowing there are flexible options available means I don’t need to choose between my career and my family,” said Hilder. “When women are reassured, they can balance a fulfilling career with their personal lives, and they will be more likely to return after taking time off to start a family.”

Inclusion begins with the hiring process

While platforms like WORK180 help women make informed choices about whom they work for, the hiring experience starts and ends with the organisation. Uplifting the capabilities of hiring managers is one way to support inclusive hiring practices. Honing interview skills and teaching leaders to recognise their biases can open the door to a more diverse range of candidates. Other ways include having clear and transparent selection processes, writing compelling job ads that outline policies like flexible work options, and focussing on transferable skills.

“We’re shifting the conversation from ‘who is most qualified for the job?’ to ‘who is best for the team, who will add to the culture and bring new ideas?’”

Saumatua said. “There are so many fulfilling opportunities within the construction and water sectors. When we work together to break down the barriers to entry, we’re giving women a chance to build a brighter future for themselves and their communities.”

For more information, visit www.interflow.com.au

South East Water has invested in intelligent technology to enhance its customer experience and optimise its water network operations. Andrew Forster-Knight is the General Manager of Digital Utility and understands the importance of this transformation.

SOUTH EAST WATER has been rolling out digital water meters across its network since 2020. Over 80,000 have been installed, saving at least 600 megalitres of water that otherwise would have been wasted. This has left about $350 per quarter in each customer’s pocket.

These savings are at the heart of what Andrew Forster-Knight has worked to deliver as the General Manager of Digital Utility at South East Water. Having started his career at South East Water straight out of university as a chemical engineer, he transitioned into a process engineer, focusing on process control and optimisation.

“Once I was working with South East Water, I gravitated towards

the areas where automation was happening in the business and got heavily involved in process automation and optimisation,” he said. “That took me down a technology path into operational technology. I rode a wave of sorts and got heavily involved in technology and digitisation, which has led me to where I am today.”

Forster-Knight works with emerging and cutting-edge Internet of Things (IoT) technologies and systems to drive innovative and technical solutions that change and improve business processes.

Every day, he needs to consider how new technology might impact the millions of people across the network.

One of the most significant issues for water authorities is maintaining customer trust and a social license to operate. When investing in any new technology or undergoing any new transformation, Forster-Knight has understood the importance of the direct impact on customers.

“We must maintain the trust of our customers. To do that, we have to take them on the journey. We started with small-scale trials and pilots, which allowed us to test how we engaged with customers, what worked, what didn’t work, where they were getting messages, and explaining why. Once the customers see what we are doing and why, it’s much easier for them to understand. They can really see the short, medium, and long-term benefits,” said Forster-Knight

Developing a communication strategy with customers has been a fundamental part of the change management strategy. He acknowledged that bringing the South East Water team along was also critical.

“It cuts across so many parts of

the business,” he said. “We had to create a change team specifically for this digital initiative. While we already have a change management team within the business, it was vital to have that in-depth, constant engagement across multiple areas, particularly when there are so many moving parts, and things could change quickly.”

Part of adapting to change was ensuring that the customer-facing side of the business understood what was happening, what was being

provided to the customers, and how they could help.

“Initially, we created a dedicated team within our large customer contact centre while doing the small-scale trials and pilots,” said Forster-Knight. “We could triage all our digital metering-related questions to this team. That team was educated on what the customer was looking at and could see what the customer saw. As we rolled out more meters, we developed some subject matter experts within the team, who have become champions within the overall customer contact centre.” Having done the hard yards early, these champions have assisted the rest of the customer contact centre with understanding what is happening with their customers. If a customer calls in, the entire team is prepared to look at the portal and see what the customer sees.

“These are conversations that we were unable to have with customers before. While it’s a work in progress, it’s been fantastic so far,” he said.

What South East Water has learned from digitising processes

Forster-Knight believes South East Water has learned a lot from its digital transformation. One thing that needs to be considered is the impact on legacy systems.

“We estimate that about 70 per cent of our systems were

changed or touched by our digital transformation,” he said. “That’s a significant piece of work. It’s not as simple as installing a new piece of software because it impacts most of our systems.”

Preparing for the change management side of things is the other key learning from the digitisation project.

“It’s probably the number one learning in hindsight, in terms of how we’ve gone about our program. It’s not a project where you can infrequently engage your staff because things are moving and changing quickly. Even on a weekly basis, operations were changing. You need to have that constant change management in place,” said ForsterKnight.

It’s also about finding new ways to use data to enhance the customer experience and optimise the water network. As an organisation, South East Water had to adjust to accumulating vast volumes of data they had never dealt with before.

“There is exponentially more data than we were previously dealing with. The big question was, what are we going to do with it? How do we find the insights to change and improve the business? That’s the challenge.”

For more information, visit southeastwater.com.au

Bluetooth devices have become ubiquitous in the lives of consumers. VEGA is at the forefront of integrating Bluetooth with industrial devices.

BLUETOOTH SOLUTIONS ARE being used more in industrial applications. Wireless data transmission now enables convenient operation with smartphones and tablets, making configuring inaccessible devices, or those in harsh environments, easier. Since access to the sensors is wireless, Bluetooth makes the complex hazardous area authorisation procedures/permits that are usually required a thing of the past.

Modularity, compatibility, and simple setup and operation have been the top priority at VEGA ever since the introduction of the plics platform. The best proof of this is PLICSCOM, the display and adjustment module that can be used on any plics sensor. Of the more than 1.5 million plics transmitters sold since 2002, approximately 700,000 were delivered with this universal display and adjustment module. Adding an optional Bluetooth option into PLICSCOM allows a sensor to be remotely adjusted from about 25 metres away. In some instances, adjustments can be made from further away.

This modern communication standard allows convenient setup, adjustment, measured value display and diagnosis via smartphone or tablet. The functions are integrated into the free, universal VEGA Tools app. The user does not have to load additional apps for different sensors on his smartphone. No update of the sensor software is necessary. The adjustment structure

is straightforward like the one most users use on their PC.

Sensors can also be parameterised wirelessly via PC or laptop via a Bluetooth USB adapter. This communication channel makes it possible to access connected sensors via PACTware and adjust them in the usual way.

Designed to be user friendly PLICSCOM is backwards compatible and can be integrated into any plics sensor supplied since 2002 easily. Additionally, no firmware changes are required. Sensors can then be wirelessly adjusted right away. It applies to about 70 different level and pressure transmitter variants. This is further multiplied by the different VEGA housings, flanges, and electronic versions.

Bluetooth support for IIoT sensors are in a range of VEGA models.

In many production facilities, measuring points are sometimes challenging and often located in dangerous places. Cereal, flour, and animal feed are usually stored in tall silos. The level sensors are installed at the top of such containers. Climbing to the top in bad weather with equipment can be a challenging, if not dangerous, task.

This is often the case if technicians need to adjust on-site. They may have to brave dust, heavy rain, strong winds, extreme temperatures and even snow to ensure optimal utilisation of the facilities. With Bluetooth, such challenges can be handled from a safe distance, conveniently and more costeffectively. The main argument for this modern transmission standard is its great convenience: no cabling, ladders, or scaffolding. Hot work permits for hazardous areas are generally not required. With the new display and adjustment module, a magnetic pen can also be used for contactless

sensor adjustment through the window of the closed lid. This keeps the sensor well protected. In demanding, dirty measuring environments, technicians can adjust on-site without removing their gloves. Since the housing remains closed during operation, permits for Ex areas (fire prevention certificates) are not required. This new tool is unique in the process industry.

In the digital age, data security is of paramount importance. Companies must protect their free flow of data in wireless networks against hackers and Internet criminals. PLICSCOM, with Bluetooth, is equipped with a two-fold data protection system. First, a four-digit PIN must be entered to connect the sensor to the VEGA Tools app. Authorised users can change this PIN at any time if needed.

In addition, Bluetooth communication is encrypted and thus protected against unauthorised access to data. This double protection ensures that the user’s data is always secure. Bluetooth communication can also be switched off via a physical switch.

The third generation PLICSCOM is the latest step VEGA has taken in expanding and perfecting the setup, adjustment, and diagnostic functions of its standardised, modular instrument platform plics. There are four methods of operation available to the user. Two occur directly on site –conventional finger-touch operation and noncontact operation with a magnetic pen. The other two can take place at a safe distance with wireless – PACTware/DTM on a PC or laptop with Bluetooth USB adapter and VEGA Tools app on a smartphone or tablet.

For more information, visit www.vega.com

and monthly checklists. Generally, these checks ensure the safety and operations of the Kooragang plant.

THE KOORAGANG INDUSTRIAL Water Scheme (KIWS) treats effluent through microfiltration and reverse osmosis. That water is provided to a couple of industrial customers who use up to 10.5 ML of water every day. This means that those companies are not taking water from the drinking water supply for Newcastle and the Hunter Valley.

Megan Boardman is a recent but valuable addition to the water industry, having joined SUEZ Australia and New Zealand in May 2018. While initially starting in an administrative role, Boardman found herself wanting to learn more about the Kooragang plant.

“When it came to raising purchase orders and doing other duties, I was intrigued about what the products are, what they mean, and what effect they have on the plant,” she said.

“I put my hand up and showed my interest in learning more. SUEZ helped me get my Certificate III in

Water Industry Treatment, Water Quality and Wastewater Treatment Management, and Recycling Technology. This allowed me to expand my knowledge and take part in on-site training with the plant manager.”

While Boardman still has some of her administrative duties, she has been balancing them with her role as a water operator. SUEZ has also supported her in completing a Certificate in Work Health and Safety.

“SUEZ has been extremely accommodating in helping me change from an administrative role to a water operator. They are more than happy to support people who want to learn and grow,” said Boardman.

Digitising internal processes for more efficient work Boardman was tasked with finding ways to reduce the volume of paper used in the plant’s daily, weekly,

“I wanted to find something already available to us rather than introducing something new to our existing systems,” said Boardman. “I discovered that I could create forms within Teams using Microsoft Forms. These forms allow us to conduct daily, weekly, and monthly checks by logging all the data as we walk around the plant and filling in the forms on our mobile phones.”

As part of creating these forms, a lot of paperwork was eliminated while keeping a clear audit trail for future reference. In addition, the completed sheets were automatically emailed to everyone in the team, and photos or videos could be added to the form.

“When we walk around the plant and spot something that isn’t quite right, we can share that information instantly with the whole team. It worked well during COVID when there were not many people on site. If you’re working from home, you know if an issue needs to be dealt with,” she said.

The benefits of this system mean that all the checks are done faster, with the relevant comments built into

When thinking about digitisation, one thing that is often forgotten is the internal processes. Many of these processes can often benefit from digitisation, and Megan Boardman from SUEZ took the initiative to do just that.

the system. Issues can be tracked over time based on observations and ratings, and the effort of scanning in large volumes of paper has been eliminated.

“We still have the option of downloading the report as a PDF and saving it,” Boardman said. “We can also track the data by exporting an Excel spreadsheet, which means we can track the information and see any trends emerging.”

QR codes modernise stock management

Another project that Boardman developed was a series of QR codes associated with spare parts. The QR codes are placed on shelves under the corresponding part, so people would scan the QR code before taking the needed part. This has significantly improved SUEZ’s stock management at the plant.

“I was finding that people were going in and taking part because they want to fix the problem straight away,” she said.

“We would not know until one or two months later, and the stock had not been properly booked through our existing systems. With this new system, scanning the QR code automatically identifies the part and the part number. All the forms go into one folder, so I know who is taking what part for what job.”

While the scans do not integrate into the stock management system, they will let Boardman know what is being used. She can follow through to ensure that parts are where they should be.

“Technicians focus on fixing problems, so the last thing they were thinking about was stock levels. This is a backup system that ensures nothing gets missed. The best part is I already had a label maker in the office, so it didn’t take much effort to make labels for all the parts,” she said.

Benefits and the future Boardman pointed out that her forms had been a timesaver while reducing the amount of paper used and keeping the entire team informed.

“By moving to a digital process, people get automatic email notifications whenever the checklist is done. It has meant that everyone is kept in the loop, regardless of where they are at the time,” said Boardman. In terms of the future, Boardman wants to finish her certificate in work health and safety. However, it’s not the only area in which Boardman wants to improve herself, and SUEZ

said the digitisation of internal processes has eliminated the need for paper. Megan Boardman has improved efficiency through digitisation.

is big on women getting involved in the business through self-education and self-improvement.

“I’m a person who wants to improve upon myself continually. I want to keep growing and learning; SUEZ will help me progress,” she said.

“There will probably be an opportunity to skill up my certificate in water operations to a higher level, and I feel that in the five years I have been here, I have achieved quite a lot.”

For more information, visit www.suez.com/en/Australia-newzealand

Organisations face impacts from rising costs and resource scarcity in infrastructure. Digitisation can help navigate cost, risk, and productivity challenges through project delivery. Voeu has thoughts on how digitisation can unlock project value.

PROJECT DELIVERY FOLLOWS a natural value cycle. It includes cost management, price estimation, project control, and reporting. This cycle works best when visible real-time data is combined with integration between the process steps, enabling a seamless flow of information to enhance effective project delivery.

To achieve organisational best practices, it is essential to establish an integrated system that incorporates all steps into a

homogeneous enterprise-wide system. This system should require minimal or no intervention for its operation. Best practice can be realised when systems are based on the same data framework that is automatically shared across functions. This eliminates repetition and reduces reworking costs. Systems coordination can be achieved through separate programs that efficiently communicate with each other. Alternatively, a full-blown cloud-based Enterprise Resource

Planning (ERP) implementation can be adopted. Success in attaining system coordination depends on facilitating interaction between the system elements rather than focusing solely on the underlying technology.

Efficient data capture combined with a robust technology platform is crucial for success. Instead of reworking the data, it’s more effective to capture it accurately from the start and build upon it. This helps avoid duplication and ensures data accuracy.

Standard cost codes are one effective system integration and cost management method for use across the project value continuum. Cost

codes organised in a cost library can serve as a basis for many aspects of project delivery. They include estimating prices, preparing budgets, tracking purchases, and identifying incurred costs. They can also be used for calculating costs to complete and reporting purposes.

Cost codes are a simple yet powerful integration approach that can unlock value. It gives project managers visibility into historical, estimated, budgeted, and actual costs, providing valuable insights to manage performance.

The value of digitisation can be enormous

Digitisation is a powerful enabler that unlocks value by enhancing project outcomes. Many benefits arise from digitisation.

Improved operational efficiency is one benefit of digitisation. It reduces the time and cost of data collection, analysis, and reporting, enabling better decisions to be made faster. These efficiencies can improve project outcomes by saving time and resources, allowing focus on other aspects of the project.

Digitisation also improves the accuracy of the data collected. Reducing errors avoid the downstream risk of the impact of incorrect information. It results in more precise project planning, budgeting, scheduling, and resource allocation.

Teams and stakeholders can better collaborate by removing paperwork and other physical bureaucracy from projects. Common platforms allow sharing information, tracking progress, communicating project

updates, and increasing transparency. Similarly, progress tracking can be completed in real-time or near realtime. This increases the opportunity to identify potential issues before they become problems. Teams can then take mitigating actions that can prevent delays and cost overruns. Digitisation reduces the overall administrative resources required. As a result, the cost of providing information along the steps of the project value continuum also falls. This frees up resources that can be utilised elsewhere.

All these elements unlock value by improving project outcomes through improved efficiency, accurate data collection, enhanced collaboration, real-time monitoring, and reduced administrative burden. By leveraging digital tools, project managers can achieve better project outcomes and ensure their projects align with project goals.

A basic example of digitisation involves replacing paper timesheets with electronic forms. This can help to reduce the time and errors associated with manual data entry, leading to more accurate project tracking.

Less than 20 per cent of organisations have an effective system in place to unlock the maximum value of a project. This usually results in inefficiencies and cost overruns.

In more advanced cases, digitisation can take the form of cloud-based telemetry. This level of digitisation can automatically capture data on equipment productivity. It allows project managers to monitor and optimise equipment performance in real time. This tends to lead to better project outcomes and cost savings. Integrating cost libraries into the design can provide dynamic, valuebased consideration of construction alternatives using computer-aided design (CAD) or building information management (BIM). Digital tools can assist in the determination of the best choice based on relevant variables that support the optimal design and project outcomes.

The benefits of adopting digital tools in project delivery are clear. Digitisation can improve efficiency, accuracy, collaboration, and real-time monitoring, leading to better project outcomes that align with project goals. Digitisation presents an opportunity to streamline the project delivery process along the value continuum. Although the water sector is advanced in product and engineering technologies, there is still room for improvement in utilising digitisation to enhance the management of project costs, risks, and productivity management.

Voeu is a specialist water sector advisory and consulting practice that delivers advice and improvement projects for infrastructure owners, operators, and delivery providers.

To find out more about Voeu, visit www.voeu.com.au.

Collaboration and data management are key to improving operational efficiency.

Coertze, the National IoT Business Manager for ifm Australia, moneo draws on all the data collected from an industrial power meter. This includes historical data and livestream analytics. The company then uses artificial intelligence (AI) to provide insights that can be actioned immediately.

“Unlike other systems that only monitor power usage, moneo will measure voltage, current, power factor and harmonics,” said Coertze. “This data is commonly used to identify a lot of mechanical faults. Having these insights available can be hugely beneficial to an industrial business. For starters, you can determine your power factor and if this needs to be corrected.”

Power factor expresses the ratio of actual power used in a circuit compared to the power delivered. The higher the power factor, the more energy efficient you are. In comparison, a lower power factor indicates inefficiency.

“If I explain this using the beer analogy, the true power factor is the useful beer liquid in the glass, whereas the total power delivered includes the useful beer liquid and the foam on top. The head on a beer, or the foam, represents lost or wasted power. It is energy being produced but not doing any work. If

your circuit is 100 per cent efficient, then the power delivered to you is all useful. It’s the good stuff, the liquid part of the beer,” said Coertze.

If a business has a lot of ‘foam’, they are also potentially wasting a lot of money.

“Once you have corrected your power factor, moneo can be used to set a benchmark on that,” said Coertze. “That means you can set limits with moneo to provide ongoing monitoring. If something changes, moneo will flag you and let you know your power factor is out again. It will let you know about things like the condition of a machine, a degrading motor, or a short circuit.”

While the power factor is important, Coertze says that the moneo toolbox can provide a host of insights to help industrial businesses be more energy efficient.

“By having this extended visibility of the energy used at your site, you can actively optimise your system to save power,” he said. “The other

aspect of this is the harmonics. This tells you what’s happening with your machines in real-time.”

However, Coertze stresses that moneo isn’t just a condition monitoring tool. It is a predictive maintenance platform that gives you information before any event. The point of difference is that moneo has been designed as an out-of-the-box, all-in-one solution that is easy to integrate with existing systems at an industrial operation.

“It comes with the hardware, software and predictive formulas included so that you just hook it up to your power meter, and it will give you insights straight away,” Coertze concludes. “It is self-service, and you can expand easily. I like to call it, ‘grow as you know.’ For example, you can start with your power meter but then expand into water tracking for water monitoring or temperature tracking. There are no limits as to what it can do. Whereas other suppliers can give you an energy monitoring platform, moneo can enable a successful predictive maintenance program across your entire facility.”

For more information, visit www.ifm.com/au

As industrial businesses strive to reduce their energy use to be more sustainable and save on operational costs, ifm’s self-service IIoT platform, moneo offers an easy solution.The team at ifm are committed to making businesses more sustainable.