After the storm: what the floods have taught us

We can help you create sustainable waterways for generations to come

After the storm: what the floods have taught us

We can help you create sustainable waterways for generations to come

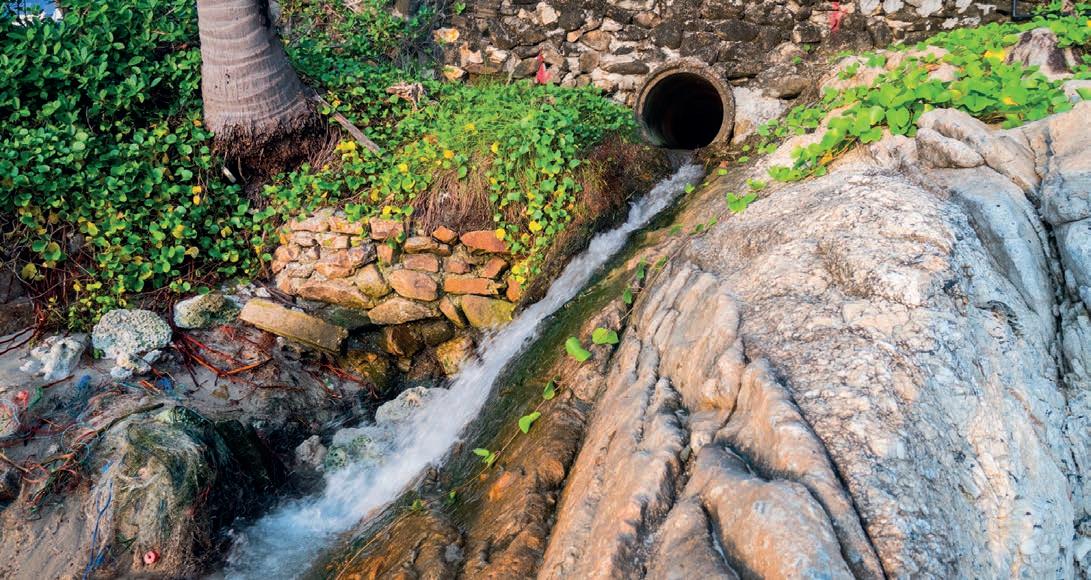

The use of groundwater is one area Australia needs to focus. As the population grows and more pressure is placed on existing water resources, we must consider how to keep our groundwater clean and refresh it. Fascinating research suggests that millions of farmers in Bangladesh have been mitigating flood damage by pumping vast amounts of groundwater. The groundwater is completely replenished during the monsoon seasons because of the permeable rock that contains and transmits groundwater.

While I do not recommend such an approach for Australia, understanding how those farmers have used groundwater to irrigate their rice paddies, boost their agricultural yields, and protect against excess flood damage, could be helpful for authorities worldwide. Understanding groundwater resources, their protection and replenishment will be vital for future generations.

As we approach the end of 2022, it is an excellent opportunity to look at how quickly things have grown for Inside Water. This publication has grown rapidly since the beginning of the year, and now we are publishing our third edition.

In 2022, we have seen thousands of people read our articles and subscribe to our magazine. The industry has welcomed this publication, and I am proud to be a part of it.

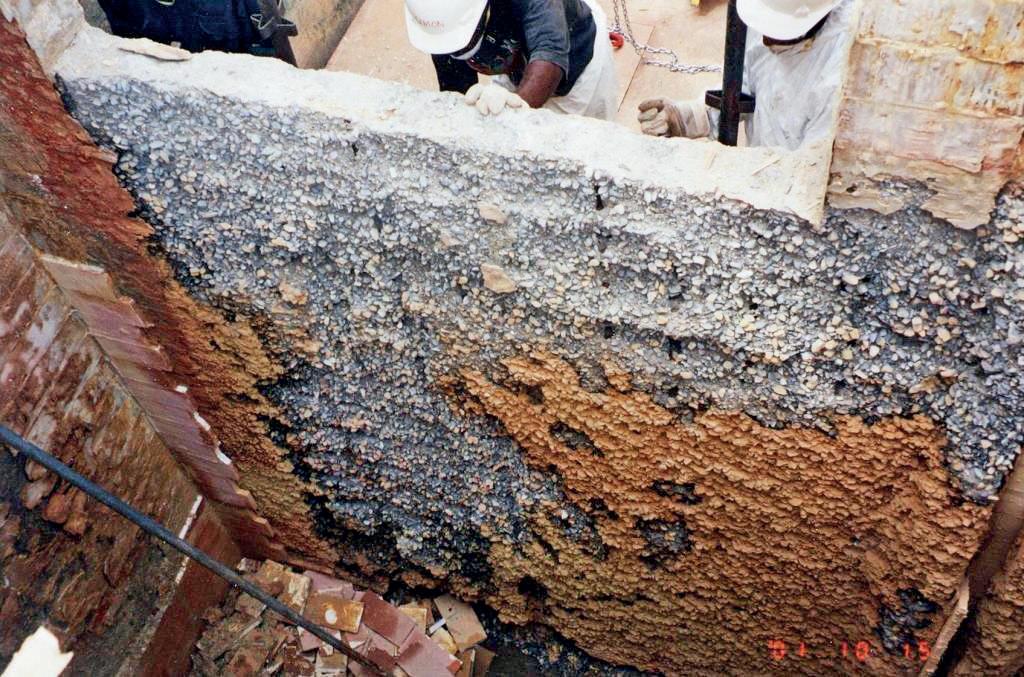

Further, corrosion management continues to be essential for water utilities, local councils, and other groups across the country. With the ageing infrastructure in almost every point around Australia, millions of dollars are being invested in pipes, valves, sensors, and meters that

reduce water leakage and ensure the high quality of drinking water.

A new regular feature starts in this issue, called Young Professionals. It is an opportunity to highlight young researchers, scientists, engineers, and staff across the water industry that are making a difference. Both are at the cutting edge of their fields, and I am excited to introduce more exciting individuals from across the sector to readers of Inside Water.

Along with our regular contribution from media partner VicWater, we also spoke to the Chair of the National Committee for Women in Engineering (NCWIE), Zhenya Pavlinova. NCWIE is an Engineers Australia community group that aims to make engineering more inclusive by valuing, supporting and celebrating the contributions of female engineers.

Getting the insight of an academic is always fascinating, and Professor Stuart Khan from UNSW has a broad interest in how the new federal government addresses a range of water challenges.

As we head out of 2022 and into 2023, all of us here at Inside Water and Prime Creative Media wish everyone the happiest holidays and the best for the New Year!

Chief Executive Officer

John Murphy john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy christine.clancy@primecreative.com.au

Group Managing Editor

Sarah Baker sarah.baker@primecreative.com.au

Managing Editor

Mike Wheeler mike.wheeler@primecreative.com.au

Editor Chris Edwards chris.edwards@primecreative.com.au

Design

Daz Woolley/Tom Anderson

Head of Design Blake Storey blake.storey@primecreative.com.au

Design Production Manager

Michelle Weston michelle.weston@primecreative.com.au

Business Development Manager

Chelsea Daniel-Young chelsea.daniel@primecreative.com.au p: +61 425 699 878

Client Success Manager Glenn Delaney glenn.delaney@primecreative.com.au

Head Office

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.insidewater.com.au

+61 3 9690 8766 subscriptions@primecreative.com.au

Inside Water is available by subscription from the publisher. The rights of refusal are reserved by the publisher

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Inside Water is owned by Prime Creative Media and published by John Murphy.

All material in Inside Water is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Water are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Cover Story – Xylem

Xylem knows that groundwater is a valuable resource. Governments are investigating new ways to manage as climate change stretches this resource. How technology supports groundwater management is part of Xylem Analytics’

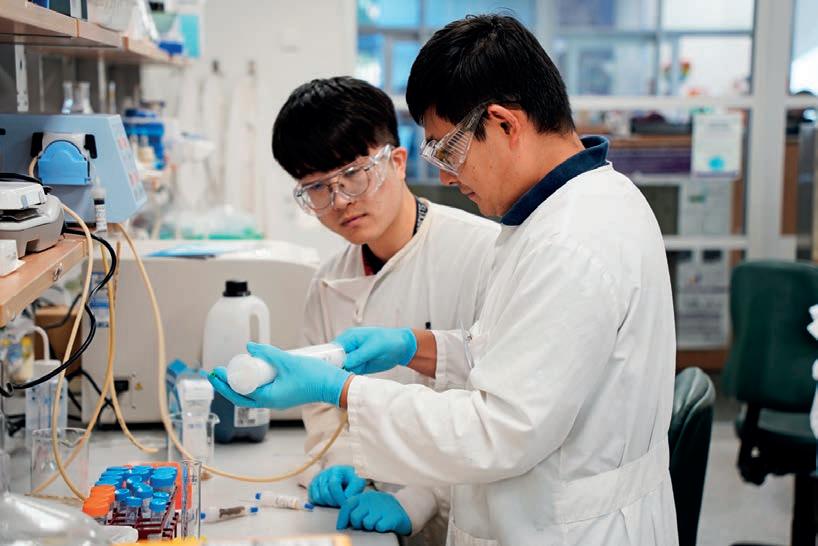

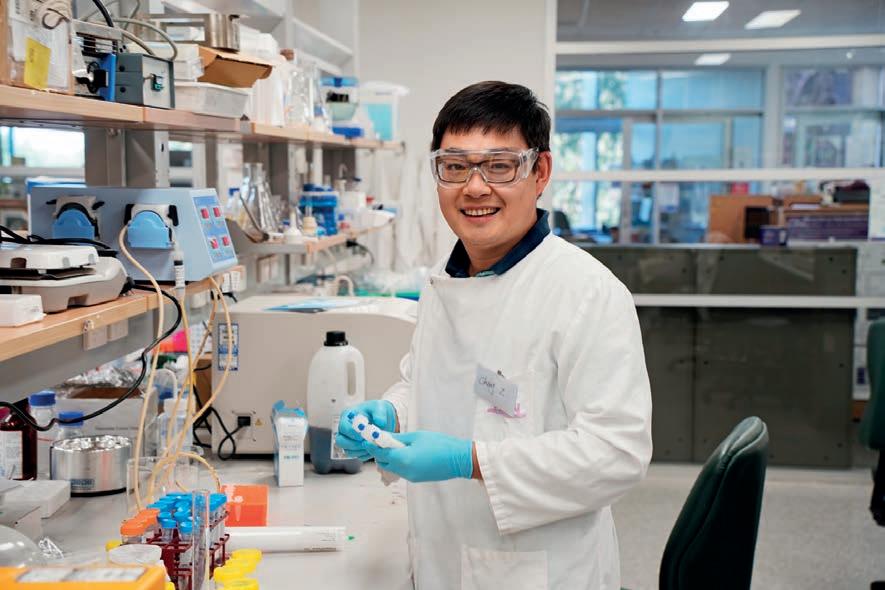

Young Professional Cheng Zhang is a young researcher at the University of Queensland. He has created a reusable substance that could help remove forever chemicals like PFAS from our waterways. Inside Water spoke to him to find out more. Pages 16-18.

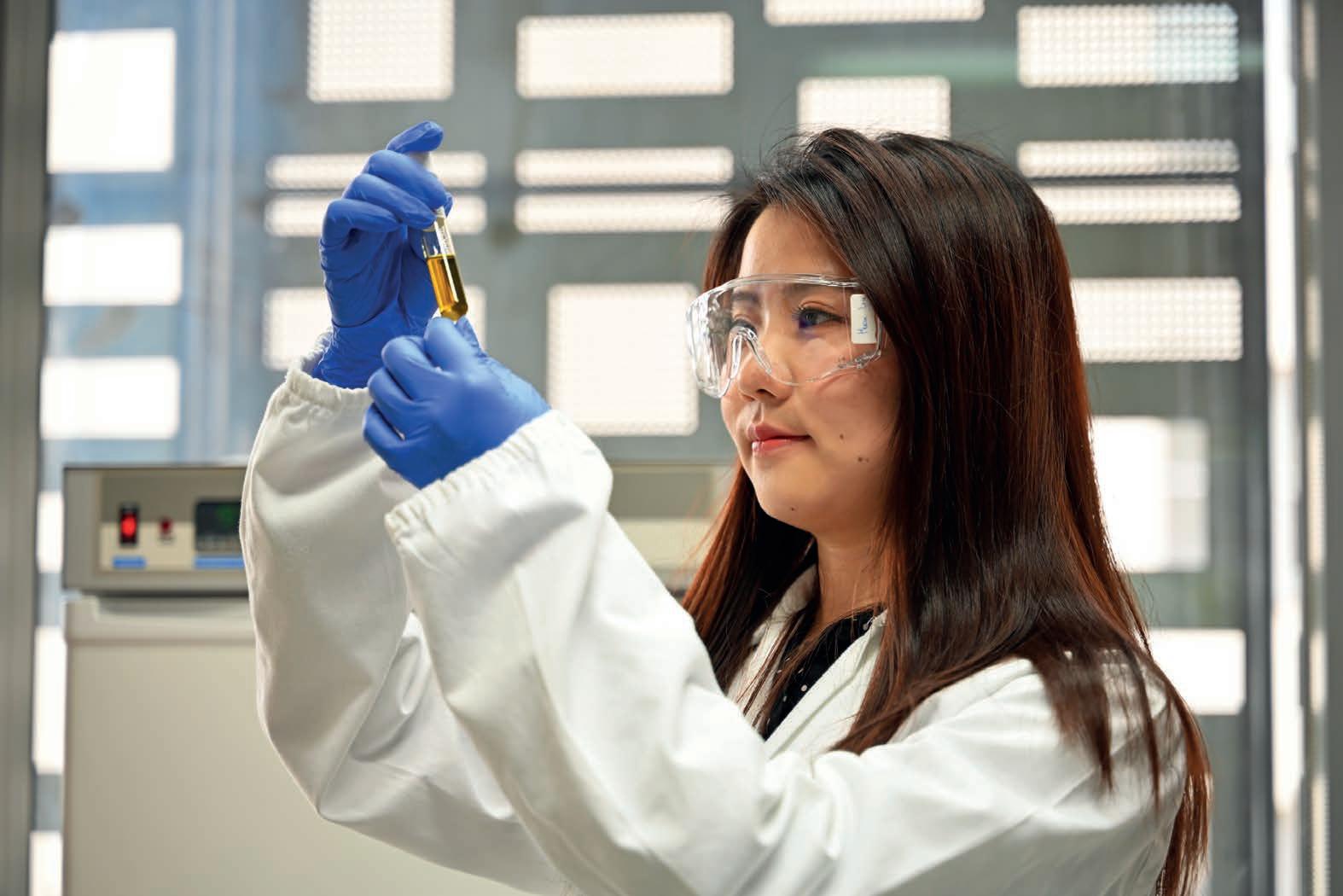

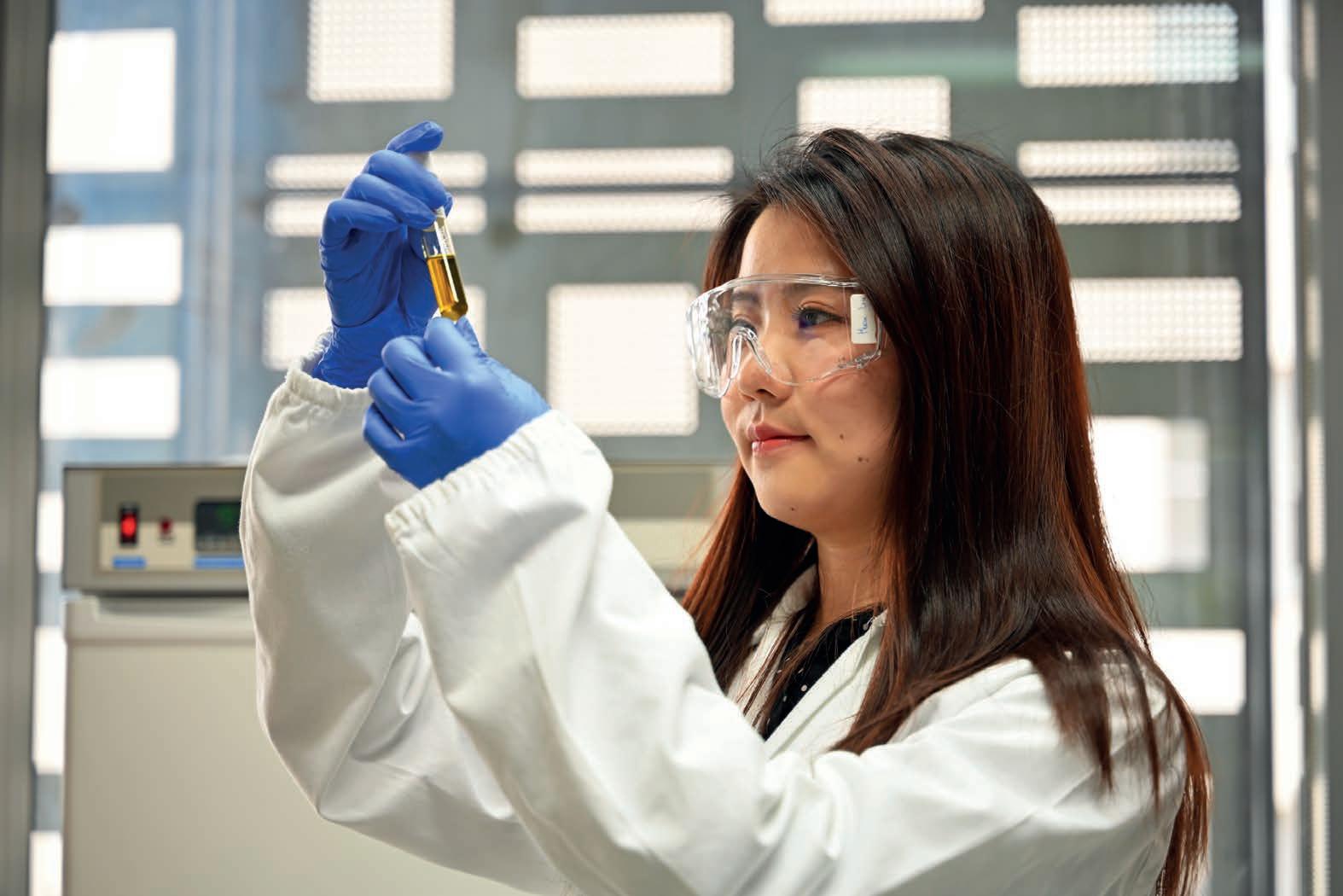

Huan Liu is a PhD student at the University of Technology Sydney (UTS). Her cutting-edge research uses a byproduct from wastewater treatment for sludge disposal. She has developed a new treatment technology that would reduce the amount of waste by 15-40 per cent and recover energy from the

undertook a deliberative engagement process with 32 members of the community that represent a crosssection of customers and their views. Pages 24-26.

SUEZ has been delivering essential water and wastewater services that protect and improve peoples’ quality of life for more than 160 years. With local roots and proud history in Australia, the company has carved out its place as a leader in water infrastructure. It is creating cycles for life for its people, customers, and communities. Pages 28-30.

Maxibor has taken steps to overcome the environmental challenges facing society today. It aims to be a leader in the HDD industry and be part of the global impetus to achieve better environmental outcomes. Pages 32-33.

Taggle Systems has seen the largest flock of its Cockatoo telemetry devices installed in Leeton Shire Council. They can monitor water pressure, lift station levels, river height and rainfall. Leeton Shire Council wanted to monitor water pressure in its reticulation network and issue early warning alerts in response to rising levels in lift stations. It also pairs rain gauges with ultrasonic levels sensors to provide an additional early warning for rising water levels during heavy rainfall. Pages 38-39.

prepare for the future. The feedback from water managers around recent flood events has been characterised by shock and awe. There is no single solution for issues resulting from

spill containment. It is a reusable, magnetically fastened polymer patch. It provides a cost-effective and instant repair method for steel equipment. Pages 50-51.

VicWater has always been committed to providing members with opportunities to come together for thought leadership, professional development, and networking events. With that in mind, it held an Audit and Risk Symposium in early September to cover governance, risk, and assurance practices. Pages 52-53.

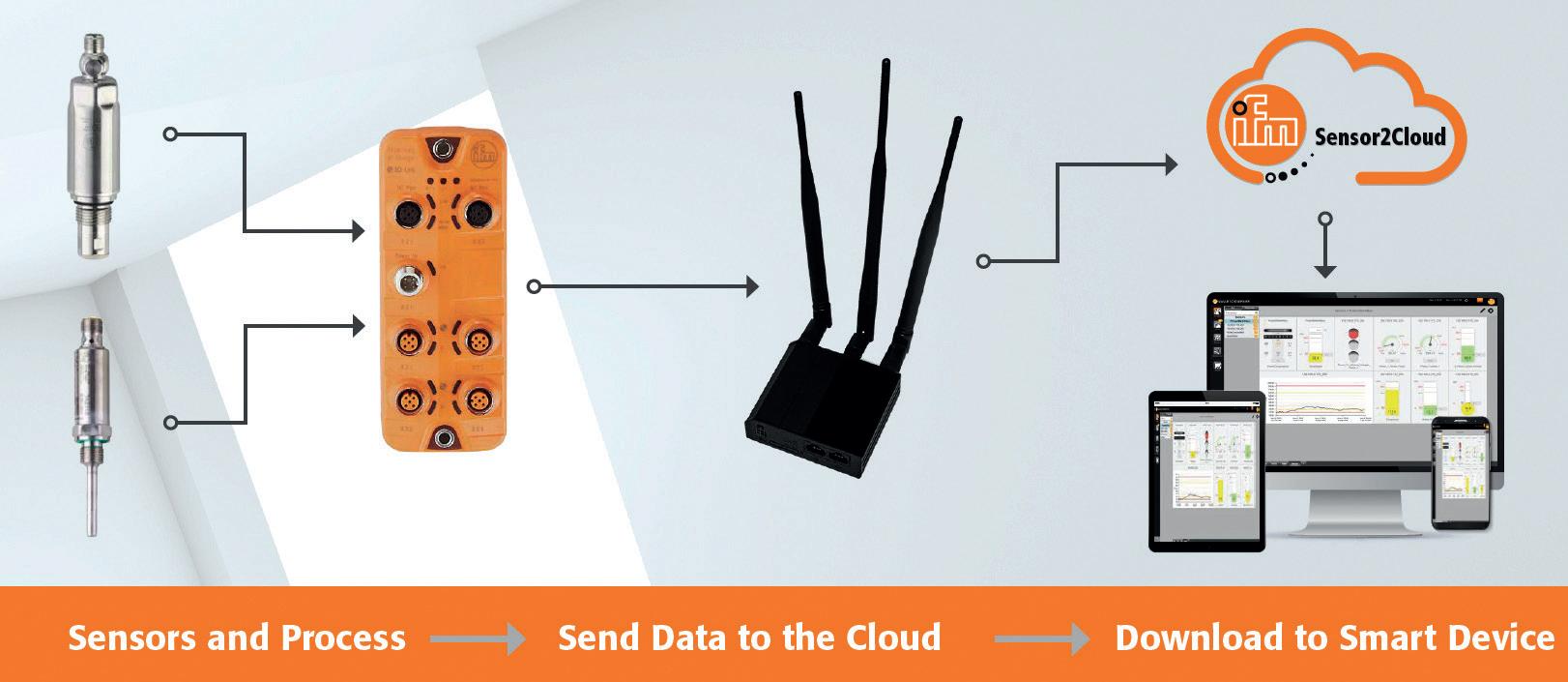

ifm efector understands the challenges of having pumps and sensors spread over a great distance. That is when troubleshooting can require long trips to disparate places. What if data from those remote critical assets could be collected and monitored before setting out? Pages 40-41.

Interflow Australia is conscious of the need to understand how floods impact assets and their management. There is no such thing as a one-size-fits-all solution to the floods experienced yet again in Australia. But a common approach can help mitigate risk and

The Plastic Industry Pipe Association of Australia (PIPA) is the peak industry body representing manufacturers and suppliers of plastics pipe and fittings, plastics resin suppliers, plastic fabricators, pipeline installers, rubber seal ring manufacturers, and training and certification bodies. Pages 44-45.

Chesterton provides a deeper understanding of common corrosion patterns. Operators of wastewater systems can choose the right surface coating to extend component life. When components of wastewater systems corrode prematurely, the consequences can be costly. Pages 46-47.

Iplex has commenced the construction of Stage 2 of the Haughton Pipeline Duplication — one of Queensland’s most significant water projects. It will provide water security to Townsville and its surroundings for the next 50 years. Pages 48-49.

Kinder Australia has the K-Magnaplug, a highly visible product optimal for emergency responses and

Engineers Australia is the peak body for the engineering profession in Australia. They were founded in 1919 and have about 115,000 individual members. We spoke to the chair of the National Committee of Women in Engineering (NCWIE), Zhenya Pavlinova, about the creativity of engineers, education and mentoring.. Pages 54-55.

Stuart Khan has explained that the new Australian government needs to focus on six specific areas to fix Australia’s big water problem. According to Khan, Water Minister Tanya Plibersek has an enormous task in front of her that is vital for securing Australia’s future. Pages 56-57.

If people understand their water use and volumes, they can change their behaviour accordingly.

“Taggle Systems PIPA PIPA

Your infrastructure partner for delivering customised water solutions for open-trench and trenchless pipeline projects.

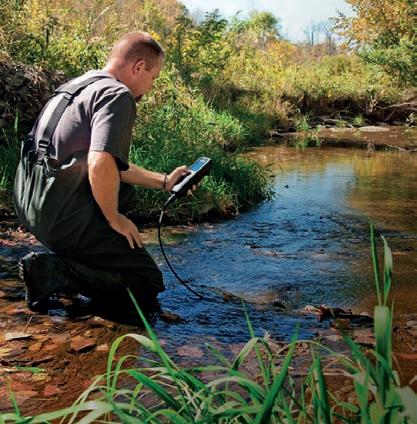

How technology supports groundwater management is part of Xylem’s thinking as a responsible corporate citizen. Inside Water looks at what it has to offer.

When Xylem goes out and works with a partner, it aims to be a leader in high-quality instruments for the water resources market. Xylem is a leading provider of premium field, portable, online and laboratory analytical instrumentation for water and wastewater, ocean/coastal, food and beverage, environmental, chemical and pharmaceutical industries. With its constant stream of innovative products, it connects with its Australasian customers and wants to ensure that high-quality data is collected reliability.

BMT is a maritime-orientated, highend design house and technical consulting firm driven by a passion for solving complex, real-world problems. It delivers design, engineering, and consulting solutions in a world of ever-increasing change: growing compliance, new global

competitors, the pressure to do more with less, ever-faster innovation cycles and less time to exploit market positions or new technologies. It supports customers at every stage of the project life cycle. BMT’s customers worldwide seek cost-effective solutions to business problems requiring technical excellence, independent thinking, and innovation.

With approximately 1,300 professionals in 27 offices in the Americas, Asia, Australia, and Europe, it draws upon a range of experience and expertise to provide high-quality, high-value products and services.

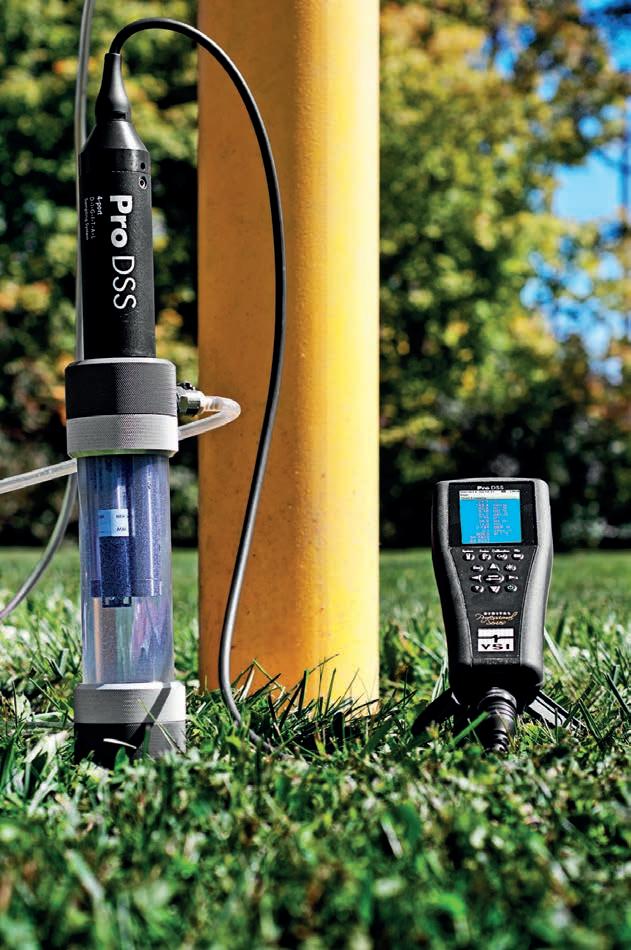

YSI ProDSS preferred technology

When BMT undertakes their sampling programs, it predominantly use the YSI ProDSS, a product manufactured by Xylem.

The YSI ProDSS (digital sampling system) is a portable water-quality

The YSI ProDss can be used for many different types of water.

multiparameter instrument for measuring several critical parameters. Users can measure dissolved oxygen (optical), total algae, turbidity, pH, ORP, conductivity, specific conductance, salinity, TDS, resistivity, TSS, ammonium, ammonia, chloride, nitrate, depth (optional), temperature and GPS coordinates.

It is designed for surface water, groundwater, coastal/estuarine, aquaculture, and wastewater. The rugged ProDSS allows for measuring water quality parameters with digital sensors. The water quality meter uses intelligent sensor technology to enable sensors to be automatically recognised by the handheld device while retaining calibration data.

Brad Grant is a Principal Environmental Scientist at BMT and has been there for nearly 14 years. He explained the importance of proper equipment and how the right gear is critical for groundwater management.

“At BMT, we need reliable equipment, especially when we undertake sampling programs in remote locations such as Papua New Guinea,” said Grant. “A lot of

time cost is involved in mobilising to remote sampling locations, so we need to know the sampling equipment is rugged and reliable, which is why we use the YSI ProDSS.”

The YSI ProDSS features an easyto-read backlit colour display, large memory capacity, simple calibration procedures, a rechargeable battery, and a robust data management program (KorDSS). All these features

combine to make BMT’s sampling experience more convenient.

The optional GPS and depth feature, along with a range of cables and sensors, allows for the complete customisation of the ProDSS. Military spec connectors, IP-67 waterproof rating, rubber overmoulded case and one-metre drop tests ensure durability to provide years of sampling even in harsh field conditions.

BMT measures several physical and

chemical parameters of the water it is testing at different levels. It often seeks data such as pH, electrical conductivity, salinity, turbidity, temperature, and dissolved oxygen.

Given the heavy workload of BMT, the company leans heavily on its instrumentation. The reliability of the YSI ProDSS means that many clients and authorities can rely on the data provided by BMT. Ultimately, instruments need to be accurate, dependable, and consistent.

Instruments must be hard-wearing to handle the demands of sampling in the field. Water-quality devices tend to be expensive, so rugged instruments that last longer are prized over fragile ones.

Grant said BMT sampling equipment can be expensive to purchase, but because the equipment is so rugged, it typically provides many years of trouble-free use. “Over the long term, it is more economical to use YSI equipment over cheaper, less rugged equipment that needs to be replaced more frequently.”

Following BMT’s role in assisting Stockland in environmental assessments and obtaining federal approval for the project, BMT was responsible for preparing and implementing the Water Quality Management Plan for Stockland’s Aura development.

The YSI ProDSS is a rugged and compact tool.

Aura is a master-planned, mixeduse community of more than 20,000 homes on the Sunshine Coast of Queensland, extending more than approximately 2,400 hectares. Located upstream of the internationally protected Pumicestone Passage, a holistic approach to water management is an essential element of the masterplanned community to ensure

that these environments are not negatively impacted.

BMT’s role at the Aura site, along with flood modelling and stormwater assessments, is the implementation of the Water Quality Management Plan, which includes monthly surface water and groundwater monitoring. BMT has been undertaking these monitoring activities on behalf of Stockland since 2008.

“At the Aura development, we regularly use the YSI ProDSS for monthly surface water readings and groundwater sampling,” he said. “The benefits of the ProDSS are that it’s simple to use, easy to calibrate, and the sensor readings are typically very reliable. Furthermore, the GPS comes in handy when a sample is logged to an incorrect site code, with the correct site code able to be identified using the GPS coordinates.”

The BMT team has found that the ProDSS saves time and money while undertaking sampling in the field. It also found that simple calibration, colour display, and long battery life provide benefits. GPS coordinates are logged with every reading. It automatically ties every sample to a specific location, ensuring that data can indicate trends across multiple sites.

BMT has a lot of experience when it comes to water quality field measurement instruments. The YSI ProDSS is the company’s tool of choice for measuring any parameter it wants.

“The YSI ProDSS is our go-to equipment of choice when taking spot measurements in the field,” said Grant.

There are many projects where groundwater needs to be monitored, along with surface water. Such

road tunnels, where the groundwater needs to be measured inside the tunnel, and the water outside the tunnel needs to remain high quality.

An example of this is the Tyne Tunnel in North East England. Ten years ago, a second tunnel was built to account for the increased road traffic in the region. The original tunnel was designed to handle a daily traffic flow of 24,000 vehicles a day but carried 38,000 per day.

With that in mind, the project managers purchased five buoymounted, real-time automatic water quality monitors (AWQMs). Xylem installed the systems to ensure that

screen of the YSI ProDSS ensures that all data can be easily understood.

the water quality in the River Tyne in Newcastle.

Xylem was contracted to provide continuous monitoring data from five locations in the river. It did this by setting up a cloud web viewing access to the key stakeholders to which the data was transmitted in real-time. The AWQMs were installed around 12 months before the commencement of dredging operations so that ‘normal’ water quality conditions could be established. The standards were based on differences between water quality measurements upstream and downstream of the dredging

operations. This allowed the impact of the dredging operation to be distinguished from background variations.

All

Each YSI buoy is fitted with a YSI EXO multiparameter water quality sensor designed to operate in unattended and challenging environments. These systems continuously measure dissolved oxygen, turbidity, and temperature in addition to current speed and direction. The turbidity measurement is critical because it is a surrogate for suspended sediments and contaminants.

The AWQMS raised alarms on a few occasions. These alarms arose primarily because of high turbidity in the overflow from the dock. When the alarms sounded, an email was automatically generated and sent to a mobile phone on the dredger. Dredging would stop until water quality had returned to acceptable levels.

Xylem was delighted that the data contributed to the project’s success. Monitoring water quality in a tidal estuary in various conditions was challenging. The unique anti-fouling technology of the YSI EXO was a huge advantage in extending the deployment time and reducing maintenance costs in these aggressive conditions.

Xylem has completed several projects in which the company has been contracted to supply monitoring data. Darren Hanson

from Xylem said, “This is a growing trend because we have invested in the resources necessary to fulfil contracts of this nature effectively and because recent advances in communications and internet technology have enabled us to transfer live data to customers’ desktops with far greater speed than has ever been possible in the past.”

Xylem has worked to ensure that its solutions come together to integrate smart and connected technologies. It has hundreds of years of accumulated experience in problem-solving through its staff and seeks to empower their clients to deliver transformative outcomes to its end users.

Part of building these data sets

Pairing data sets with a specific location ensures that trends can be detected early.

together is using the right sensors in the right place. With the Tyne Tunnel Project, the YSI EXO2 and EXO3 multiparameter water quality sensors were perfect companions to the smart buoys. The EXO sensors provide an array of data on water quality while remaining properly calibrated throughout their time in the water. They are designed for long-term use and can be integrated into any system.

The staff at Xylem understand the importance of monitoring groundwater and surface water. They have combined their experience to provide a continuous and comprehensive water quantity and quality record. Their instruments generate reliable data in real time so you can work efficiently and reduce costs. Xylem understands the challenges of working in natural environments and builds high-quality devices to handle the most challenging situations.

The YSI ProDSS has a low profile but handles any environment with ease.

To find out more, go to www.xylem.com/en-au/ and www.ysi.com/prodss

While Australia is blessed with an abundance of natural resources, water is not among them. Which is why it is crucial for Australia’s water network to explore more sophisticated and effective methods of treating water so that it is safe to drink.

This is one of the core goals of ifm, who are working with Australian wastewater treatment companies to streamline their operations and make them more efficient through the integration of digital sensor technology.

This white paper discusses the challenges around water treatment and how ifm is working with industry to address these. It also highlights the partnership between ifm and Australian wastewater treatment specialist, Aerofloat, and how ifm’s sensors and easy-to-use IO-Link connectivity solution has saved time and costs for Aerofloat’s customers.

Getting rid of forever chemicals like PFAS out of Australian waterways is an ongoing research question. Cheng Zhang, a researcher at the University of Queensland, has created a reusable substance that could help remove them.

Per- and polyfluoroalkyl substances (PFAS) have become a problem in water across the world. Numerous research teams are taking different approaches to remove it from the water. Some PFAS are effective at resisting heat, stains, grease, and water, making them useful chemicals for various applications. These applications include stain and water protection, photographic materials, cosmetics, and sunscreen. Because they are heat resistant and film-forming in water, some PFAS have also been used as effective ingredients in fire-fighting foams.

In Australia, the historical use of PFAS in fire-fighting foams has resulted in increased levels being detected at airports, defence bases, and other places where firefighting training has been conducted. Increased environmental levels of PFAS have also been found in some industrial areas, effluent outfalls, and landfill sites.

The greatest concern of PFAS is highly mobile in water. It does not fully break down naturally in the environment and is toxic to many animals. While understanding the human health effects of long-term PFAS exposure is still developing, there is global concern about these chemicals in the environment.

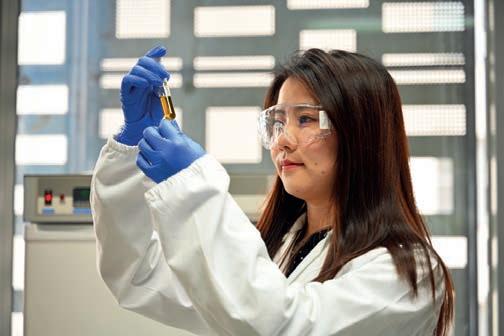

Dr Cheng Zhang from the University of Queensland (UQ) is one of those researchers investigating a new way to remove PFAS from water. His paper on the topic was published in October in the high-profile

Angewandte Chemie International Edition. The paper was titled “Efficient Removal of Perfluorinated Chemicals from Contaminated Water Sources Using Magnetic Fluorinated Polymer Sorbents.”

Originally from Shandong in China, he has lived in Australia for more than ten years. He has enjoyed the research environment at UQ, as well as the living environment in Australia.

As a National Health and Medical Research Council (NHMRC) CJ Martin Research Fellow (2019-2022) and the recipient of a Discovery Early Career Researcher Award (20232025), Zhang is working hard to make a difference.

“I am a polymer chemist, by my research. I only started studying

water management in the last two or three years. However, it is how I started focusing on PFAS,” said Zhang. “Having said that, I have been studying this style of fluoropolymers for over ten years.”

Zhang started his academic life in materials science. His studies in this field got him into studying real-world problems with realworld solutions. The opportunity to remove contaminants from water, such as PFAS, attracted him to move sideways from materials science to polymer chemistry.

What his research has found Zhang and his team focused on capturing PFAS efficiently and selectively. Each PFAS molecule has a hydrophilic “head” and a long, hydrophobic “tail” that contains carbon-fluorine bonds. The carbonfluorine bond is one of the strongest single bonds in nature. That bond gives the molecules persistence in the environment and their “forever” moniker. Legacy PFOA and

PFOS, as well as emerging GenX, which are the focus of most water treatment efforts, can persist in the environment and may pose harm.

On that basis, Zhang started investigating the capture of PFAS using a unique polymer sorbent. His research found that their nowpatented polymer could grab hold of PFAS and be re-used multiple times. It is also efficient and selective.

“The efficient treatment of PFAScontaminated water is becoming an essential consideration for establishing water sustainability in Australia,” Zhang said. “Our product addresses the issue of extensive PFAS pollution in Australia and will deliver

His masters and PhD students are working together to advance the technology. They believe in the importance of collaborating with industry partners.

“Industry partners have been very interested in the technology. Our

a low cost, especially considering it can be reused multiple times.

Compared to any other substance, it is over ten times more efficient than activated carbon,” said Zhang.

“That’s a massive advantage of our technology. It is also an area of research that we are targeting – increasing capacity, improving selectivity, and reducing cost.”

One industry partner that has been

water and environmental industries and local communities.”heavily involved in the research is the industrial corporation Chemours, a spin-off company from Dupont. As the producer of Teflon, Nafion membranes, Krytox lubricants, and Opteon refrigerants, they produce a significant amount of PFAS.

“One possibility is that they can develop a large-scale production facility, given their manufacturing lines in the United States. Chemours has supported us a lot over the last two to three years, and we have a good relationship with them. We have also secured funding from the US Department of Defence and The University of Queensland’s Knowledge Exchange and Translation (Kx&T) ECR Funding. Hopefully, we will be able to use their production lines,” said Zhang. “Once we optimise the materials production procedures, I think they will be happy to move forward on that, as we should be able to generate plenty of revenue.”

There have been several different techniques looking at methods of capturing PFAS. Activated carbon is the most commonly used technology and has been broadly used by our industry partner Chemours for PFAS removal. However, the carbon sorbent has low efficiency, is non-selective, and is non-reusable.

Zhang acknowledged this and other research occurring over the past couple of years. He pointed out that one of the biggest issues for most research teams in this field is that they must operate with concentrated levels of PFAS.

“In the real world, levels of PFAS concentration tend to be very low and even much lower than the nonfluorinated organic and inorganic species. The advantage of the polymer we have developed is that it can selectively and specifically

recognise and grab PFAS. It makes things a lot easier and more realistic. Because our technology focuses on low concentrations of PFAS, the polymer can grab onto more of it,” said Zhang.

He also acknowledged that different techniques could work together to maximise the removal of PFAS. The opportunity to solve a real problem inspires Zhang.

“I think that I am lucky to have identified this real problem and focused on the root cause of the contamination in the environment. Being able to work in related fields where I am creating new materials that solve real societal problems,” said Zhang.

Another area that Zhang is noted for is his experience in communicating his scientific achievements to a broad audience. As a young researcher that collaborates with industry, he has had to learn how to use non-technical language to explain his project.

“Taking part in Fresh Science was an excellent experience,” he said.

“At one point, I needed to explain my research in 100 words or less. That was a challenging experience but revising my language so that industry partners could understand was fantastic. The willingness to understand the different backgrounds of my audience helped enormously. All the training and competitions were great at helping me understand what I was saying and how to express my research to a broad audience.”

Moving from the focus of publishing papers to communicating with a wider audience is an important skill. Zhang acknowledged that he would continue to develop this skill as he grows as an individual and a researcher. He is also a material

Zhang’s focus on the root cause of contamination has been key to his progress.

scientist working in energy storage and medical fields.

“I’m trying to find partners to collaborate with in those two fields.

Cheng Zhang’s reusable sorbent can be reused at least ten times.

Fortunately, I now have experience from my time studying PFAS. That has given me a good base of knowledge to explain my scientific research and how my research career can help industrial partners,” he said.

Huan Liu is a PhD student at the University of Technology Sydney (UTS). Her cutting-edge research uses a by-product from wastewater treatment for sludge disposal.

Treating wastewater in Australia produces 1.4 million tonnes of sludge, which must be treated and then disposed of. The process is responsible for 50 per cent of the total operating costs of wastewater treatment plants. PhD student Huan Liu has developed a new treatment technology that would reduce the amount of waste by 15-40% and recover energy from the sludge itself. Liu’s technology would result in an end-product that is a safer biosolid for fertiliser. Her technology relies on a by-product of wastewater treatment. The closed-loop methodology ensures that fewer resources are used in the process. But who is this woman that has made a ground-breaking difference in wastewater treatment?

Liu is originally from a small city near Xi’an in Shaanxi Province, China. She started her academic career at Northwest University in China. Liu then completed her master’s degree at Shaanxi Normal University. After finishing her master’s degree, Liu started working as an environmental engineer. Her primary focus was oil sludge and sewerage sludge within the solid waste treatment.

“This experience motivated me to go further within sludge. In my working experience, I realised that there are many gaps in research and applications. I wanted to find new technologies in sludge treatment,” said Liu.

When looking to do her PhD, Liu received two offers from different Australian universities. She wanted to study in a robust environmental engineering institution and felt Australia’s environment would be more conducive to her studies. Liu found her way to the Centre for Technology in Water and Wastewater at the University of Technology Sydney (UTS).

Liu is studying under Professor Qilin Wang, an Australian Research Council Future Fellow. She has found him to be an inspirational leader, with him being appointed as a Professor in Environmental Engineering only seven years after receiving his PhD.

“Professor Wang is my principal investigator. He’s very passionate about his work, supportive and responsible for his students,” said Liu. “I have learned a lot of professional knowledge from him about wastewater and sludge. His career has inspired me, particularly in promoting myself to academics

and industry. I’ve seen how he has received funding from different groups, so I want to model myself on him.”

New technology results from luck and collaboration

Liu has developed technology to improve antibiotic-resistant genes and pathogen removal, enhancing anaerobic sludge digestion and boosting the dewaterability of digested sludge.

“I was doing some lab work focusing on the wastewater treatment process. I found that one of the by-products was biocidal for bacteria. I thought this unique by-product could be used in sludge treatment to break down bacteria in sludge. When I tried the idea, it was successful, so the technology came out well,” said Liu.

The process is also much more efficient at removing pathogens. Liu showed a 60 per cent reduction in pathogens and a 20 to 70 per cent reduction in antibiotic-resistant genes compared to traditional procedures.

According to the New South Wales Environmental Protection Agency, the residue waste could achieve Grade A biosolids. That would reduce the health risks of using the treated sludge as fertiliser, creating an additional revenue stream for water authorities and local councils.

“Instead of being a contaminant for wastewater treatment plants, the waste by-product becomes a useful part of the process,” she said.

Industry partners key to progress Partnership and cooperation have been essential to Liu’s research. The water industry has been active in working with researchers across Australia. Liu thanked Water Research Australia Limited, South East Water and the Australia Research Council for supporting her research.

“Not only is the water industry

important for providing us with funding, but they also provide us with research materials,” she said. “We need sludge and wastewater samples to do our testing. It would not be possible without the support of our industrial partner. We cannot get these materials, and they can provide the samples regularly.”

Liu also appreciates the industry’s role in explaining what they are looking for in her research. She explained that they have been clear about their immediate needs, which has helped her broaden her mind. It has given her several practical areas to look at in her research.

She praised UTS for its focus on

the commercialisation of research outcomes. While Liu’s technology is still in its earliest stage, she is working on developing a patent for it. Ideally, her technology will be pushed to a commercial level in the future.

Huan Liu testing her technology that is designed to help dispose of sludge.

“UTS has provided me with an outstanding platform for research,” said Liu. “For example, we did an industry project involving removing antibiotic-resistant genes. A project like this can only be completed with the help of an institution like UTS and industry partners. The platforms that UTS provide have been fantastic for researchers such as myself to develop my skills.”

This experience motivated me to go further within sludge. In my working experience, I realised that there are many gaps in research and applications.

“ ”

In the eyes of Liu, there is enormous potential in developing technology for the water industry, particularly for wastewater treatment plants.

“I noted an Australian-first project that saw wastewater turned to energy, which will support the country’s energy demands,” she said. “I’m also really excited by the possibility that the technology I have developed could bolster the energy recovered from sludge, further supporting the energy grid. That’s a tangible benefit for the public.”

Liu spoke about the potential of biochar in Australia. She believes her focus on biochar provides more opportunities for Australia.

“I have only focused on the biochar produced by sewage sludge. The technology is not widely used in Australia, but in Japan, they rely on pyrolysis to produce biochar,” said Liu. “This is the way they treat the sewage sludge.”

Pyrolysis is a technique where a material is heated above its

decomposition temperature. That temperature will see chemical bonds broken down in the molecules. These fragments can become smaller molecules or combine to produce residues of a larger molecular mass. Some small trials and demonstration plants exist in Australia, particularly in southwest Western Australia, Melbourne, and central Queensland.

“The biochar produced because of pyrolysis needs to be dried first, so the solids content needs to be as high as 90 per cent. This is different from hydrochar, which operates from a slurry,” said Liu. “Having said that, there is undoubtedly potential for hydrochar and biochar -. But the hydrochar and biochar could hardly work together. They use different raw materials and production processes while generating different char properties.”

Beyond the commercialisation of her technique, Liu has two potential avenues for expanding her research.

Huan Liu has found her experience in Australia to be positive and enriching.

“Firstly, I want to focus on the mechanism, performance and application of my technology,” said Liu. “I want to understand how it works from a biological and chemical point of view. Conducting more experiments to investigate the mechanisms will almost certainly provide a broader pathway towards commercialisation.”

Her second area of focus is to expand her research into the water treatment process. A new idea has been developed in her team to reduce sludge production in wastewater treatment instead of treating sludge after the fact. The preliminary results of her research in this area are positive, so Liu wants to conduct further experiments in this field.

“I believe there is the potential for more energy and cost savings by reducing sludge production in wastewater treatment,” said Liu. “We have two ways to reduce sludge production. One way is to produce light sludge, reducing the original volume of sludge. The other way is to improve the technology behind sludge reduction.”

Liu’s original research in Australia focused on reducing sludge after it has been through a wastewater treatment plant. She now wants to focus on reducing the amount of sludge that enters a wastewater treatment plant. In her eyes, it would reduce the energy requirements for the wastewater treatment plants, thereby saving them money.

Liu’s goal is to become an excellent researcher and engineer in the future who can advance the science and practice of urban water management.

Liu is coy about her future in the field.

“I have some new ideas, but it is too early to say what they are.”

Coliban Water has taken a step change in its approach to customer engagement ahead of its 2023-28 Pricing Submission.

Inside Water spoke to Managing Director Damian Wells to find out more.

Damian Wells is the Managing Director of Coliban Water. Having grown up in the small town of Merbein in northern Victoria, he has made his home in Bendigo. He was always around water as a child. His father was an irrigator and grape grower, so Wells spent much of his formative years around the Murray River. He watched his father fix sprinklers, prepare the irrigation, and all water-related issues.

in water. I have worked in lots of different aspects of water. I started in water quality and environmental flows. Then I worked in catchment management and moved on to

operations management for the rural water business and as an environmental regulator at EPA Victoria. Ultimately working at Coliban Water as the Managing Director is probably my dream job,” said Wells.

Water and the community

something for the community and supporting people.

“My parents were certainly a big role model in that regard, and my wife is one of the most generous, selfless people I have ever met. They have all had a big influence on me in this regard. I believe Coliban has had a long customer-oriented and focused culture,” said Wells.

Wells and Coliban Water want to build on the legacy of others when it comes to a customer-focused culture. With that in mind, Coliban Water has proposed doubling its financial investment in its hardship program from a current budget this financial year of $285,000 to $570,000 per year from 2023.

developing good

“Fairness has been a big part of our focus, and it came up a lot in our Pricing Submission works,” said Wells.

As part of its engagement with the community, Coliban Water took a step change in its approach. Like some other water corporations around Victoria, Coliban Water selected 32 people from across the region to participate in a Community Panel. The goal was to get a deeper understanding of what the customer base needed. This deliberative engagement process represented a cross-section of customers and their views. Every member contributed their time, experiences, and energy to the process. The Community Panel came together for five days over five months to consider Coliban Water’s services and pricing. They provided nine recommendations that the Board ultimately accepted.

“This sort of deliberative engagement process is an arm’s length community panel, in that it was independently recruited and facilitated at arms-length from the

Board and management,” said Wells. “We discussed the outcomes and recommendations with the Board. As Board Directors and Executives, we are often trained to try to control things, so it takes a lot of courage to embark on a deliberative engagement process.”

“The Community Panel did a huge amount of preparatory work. They spent the first couple of days listening and learning to grapple with what needs to happen for water services through the region for the next five years,” said Wells.

The Community Panel focused on the need for Coliban Water to invest in its asset base.

“Many of our assets are very old and desperately need renewal,” said Wells. “They are undersized relative to the population that they serve. We need to reform our capital program. We proposed increasing it from about $150 million over five years to $435 million. That’s a significant change, so the panel discussed this at length. They had to weigh up the question of intergenerational equity.”

Coliban Water learned that customers are okay with smooth and modest increases in prices over time, as opposed to dramatic spikes in prices. The panel recommended that Coliban fund most of its growth in capital expenditure through debt while also passing on a modest price increase.

The Community Panel also spoke a lot about fairness. There was, and still is, a strong view that while investments must be made, no one must be left behind.

“Supporting customers experiencing vulnerability is a key part of what Coliban Water stands for. This increased investment will give us more opportunities to assist more customers across our region whilst

having the quality assets to underpin our services.”

One thing to note is that the engagement and learning that Coliban Water has done for the 2023-28 Pricing Submission is not limited to the Community Panel. Wells spoke about engaging with welfare providers, human services agencies, Traditional Owners, and regional local governments.

“We got letters of support from the local branch of Salvation Army and the Dja Dja Wurrung Traditional Owner organisation,” he said. “We also got letters of support from local governments in our region.”

He also noted that the region’s water and climate literacy levels are strong. When web portals, pop-up stalls and surveys were offered, 86 per cent of respondents said Coliban Water had struck the right balance in its proposal. Wells admitted that he was pleasantly surprised at the high number.

“I think people get it, in that climate change is significant. They know the population is growing because they see all the new developments. They see the new houses and ask if there is enough water. Do you have the right assets to serve this? To have such positive feedback from the community is encouraging,” said Wells.

Coliban Water provides water and wastewater services to 49 towns across 16,500sqkm in North-Central Victoria. It services rural and urban areas from Cohuna and Echuca in the north, to Kyneton and Trentham in the south. Coliban Water manages, maintains, and operates 35 reservoirs and water storage basins.

and acknowledge the dispossession, loss and harm experienced by Aboriginal people,” he said. “We support Aboriginal enterprises wherever possible, a commitment our directors and staff hold.”

Coliban Water’s directors and executives have completed cultural competency training. A recent cultural immersion run by Djaara was a highlight in addition to other

Supporting customers experiencing vulnerability is a key part of what Coliban Water stands for.

”

Coliban Water has been rolling out digital water meters throughout its region for a few years. All the small towns have installed digital meters, while Bendigo will have them over the next 18 months.

Wells said that the benefits were being seen already.

“There have been huge water savings in that we can see where there are irregularities in customer water consumption. That almost certainly means a leak on the customer’s side of the meter,” he said.

“Notifying customers of that means they can intervene early, get a plumber in, and fix that leak. It saves money, heartache, and water, so it’s great for network efficiency.”

Digital meters also help Coliban Water understand network demand far better than before. It has helped them plan infrastructure needs and target their water network investment.

“If people can better understand their water use and volumes, they can change their behaviour accordingly,” Wells said. “The benefits are incredible. We could even offer timeof-use pricing, offering discounts on water overnight to fill tanks or incentivise automatic watering systems further.”

Lauriston Reservoir spilling excess

Damian Wells with Rodney Carter, CEO of Dja Dja Wurrung

Lauriston Reservoir spilling excess

Damian Wells with Rodney Carter, CEO of Dja Dja Wurrung

SUBSCRIBE TODAY

Inside Water is a new multi-platform publication for the Australian water industry. It is focused on the people, products and technology that enable sustainable and innovative management of Australia’s water resources. Visit www.insidewater.com.au, select Subscribe and use our easy online form to subscribe today!

www.insidewater.com.au

Faced with growing environmental challenges, for more than 160 years, SUEZ has been delivering essential water and wastewater services that protect and improve peoples’ quality of life.

With local roots and proud history in Australia, the company has carved out its place as a leader in water infrastructure. It is creating cycles for life for its people, customers, and communities.

A name synonymous with innovation, SUEZ is a driven, purpose-filled organisation. It conveys a desire to support its customers through ecological transitions towards net zero while ensuring water resiliency. The company thinks outside the box to ensure that the planet we live on is a place our descendants will be proud to live in.

SUEZ understands that every drop of water is a precious resource and will work to make sure communities have reliable access to clean water and sanitation services.

The proper use of water is a critical issue in SUEZ. To achieve this and to ensure that its customers get

the most value out of their asset management lifecycle, the company offers its clients an array of services across the water and wastewater sectors. As it works to create cycles for life, SUEZ’s commitment to the circular economy and sustainability remains strong.

SUEZ understands its purpose in Australian society. Its local teams are rooted in their communities and intimately understand their customers’ needs. Both locally and globally, SUEZ is committed to providing people and the planet with the resources for a shared future. With teams unified in their knowledge and passion for their work and culture, SUEZ is committed to water conservation and creating value from wastewater. The company collaborates to promote responsible behaviour among its

SUEZ Australia and New Zealand staff installing new systems at the Noosa Wastewater Treatment Plant.

staff, partners, and clients. True to its thirst for innovation, SUEZ has increased its investment in research and development by 50 per cent as part of its circular economy solutions and makes the best possible use of Australia’s finite resources.

One area that SUEZ is known for is being a trusted partner for circular solutions in water and waste. Since its inception, the company has developed a fundamental understanding of the needs of its clients. Its expertise in water and wastewater supports clients in managing complex projects on any scale.

Fundamental to SUEZ is its culture of partnership. At its core is working with its clients to generate environmental and social value. An example of this is the upgrade of the Boneo Water Recycling Treatment Plant. South East Water appointed John Holland, SUEZ and Beca to the project. They were tasked with delivering an innovative, safe, and sustainable water recycling process for the Mornington Peninsula.

The project will incorporate lowenergy nutrient removal and energy

recovery processes to help South East Water achieve its emissions reduction target of 45 per cent by 2025 and will have the potential for the plant to become carbon positive. With the plant’s construction completed, SUEZ worked with its partners to modernise it. The company has utilised several innovative technologies, including optimised anaerobic digestion, breakthrough technologies in wastewater treatment processes, Nitrite Shunt and anammox sidestream. All these technologies are designed to reduce South East Water’s reliance on grid electricity and improve capacity to serve the

current and future needs of the community and environment.

The outcomes achieved through this project will also contribute towards achieving the United Nation’s Sustainable Development Goals by minimising the impact on our environment, reducing emissions and working towards achieving carbon neutrality by 2030.

The SUEZ Strategy SUEZ‘s strategies are built around its core strengths.

SUEZ has the expertise and knowhow in water and wastewater. It builds on its project management skills, particularly when it comes to complex projects on a large scale. Taking a collaborative approach, SUEZ has a partnership culture ingrained in its

DNA. It comes from its commitment to delivering high-quality solutions and services. It also understands the value of maintaining long-term relationships with its clients.

Each multidisciplinary team puts their ingenuity to the test at every opportunity to serve society. They are driven and seek to make a difference by creating solutions that benefit every segment of the community for environmental and societal challenges.

As Australia and the world move faster towards a circular economy, the company’s step-change strategy is built to achieve this and is underpinned by three central pillars.

One pillar focuses on its core business. SUEZ is always looking at the value chain of wastewater,

water, and corollary services. It also examines its core markets that combine resilient and mature markets with an appetite for innovation and high-growth emerging markets.

A second pillar shows how SUEZ differs from others. It differentiates itself through its value propositions for its customers. SUEZ integrates its construction and operational expertise with its role as a digital, end-user experience and innovation leader. This is all collected under the umbrella of ambitious commitments that are proven to support people, the planet and nature.

The third pillar focuses on value creation for its clients. SUEZ looks at all its projects to prioritise cuttingedge technologies, digital solutions, and scalable services to maintain its competitive edge.

So why should companies choose SUEZ for their business? What makes it the right fit?

It’s vital to remember that SUEZ has passionate and committed teams, and they want their clients to succeed. They will enable clients and their businesses to become better.

First, it will ensure that clients can provide water and wastewater solutions to their communities by delivering resilient and innovative solutions. SUEZ will implement actions and bring solutions that will allow clients to grow and improve their quality of life. Through digitisation, SUEZ offers its clients innovative water and wastewater management models. It helps its customers exceed their standards in terms of water quality, recycling, and energy recovery.

Second, SUEZ aims to create value for its customers over the entire lifecycle of its assets and services. They want their clients to extend the operations of their assets with technology and continuous innovation. This approach makes the assets a resource enabler. In the eyes of SUEZ, all these products have value. They also aim to optimise water production and management.

Finally, SUEZ is shepherding its clients forward in the ecological transition, along with its client’s endusers. Being a partner means working with their end users to develop a sustainable lifestyle and protect nature. SUEZ provides a far-reaching set of water solutions. These solutions and services are enhanced with intelligent digital solutions to support responsible behaviours.

SUEZ wants to help users take an active part in preserving their environments.

For more information, head to www. suez.com/en/australia-new-zealand

Maxibor has taken steps to overcome the environmental challenges facing society. It aims to be a leader in the HDD industry and be part of the global impetus to achieve better environmental outcomes.

THE ENVIRONMENT IS the “E” in ESG, the acronym for Environmental, Social, and Governance. Each category of ESG has numerous subcategories, allowing each business or investor to contextualise ESG relative to their goals and values. Maxibor is among the leaders in horizontal directional drilling (HDD). Their HDD sustainability initiatives enable asset owners and principal contractors to respond to community demand for demonstrated action around the ESG environmental principles. The company’s collaborative approach provides asset owners across the water and sewer, rail,

mining, defence, fuel, sea cable, data centre, hydrogen and renewables sectors the means to demonstrate evidence of sustainable infrastructure installation practices.

Climate Change

HDD is an integral part of climate change adaptation action to mitigate the increasing frequency and impact of fire, wind, flood, inundation, drought, and rain bombs. Simultaneous disasters in multiple locations stretch the ability of infrastructure asset owners, emergency services personnel, and resources to respond to these events promptly and effectively.

electricity and telecommunications underground in times of extreme and higher frequency climate changeinduced events provide certainty of supply. They are safely away from the above-ground impact of extreme weather events.

Having infrastructure underground also increases community safety and reduces the recovery effort to reestablish essential services, as is seen along the east coast of Australia and inland in the eastern states.

HDD has a low

Design and constructing long and larger diameter HDD bores are where Maxibor can add value to climate change mitigation projects. Its design expertise in long, challenging pipeline installations and the capacity of its maxi-rigs like the Gallagher 660e, American Auger 660, and Vermeer D330x500 provide a turnkey solution for infrastructure asset owners on these projects. The involvement of the company’s HDD expertise in projects at the concept and early design stages is where its innovative solutions and experience will optimise project value.

HDD is the “go-to” solution for smaller projects. The recent floods have emphasised the importance of not creating future problems by digging up existing road pavement to run utilities across roads. This weakens the trenched section of the road and the surrounding pavement, as water can enter once the “seal” is

Broader and deeper potholes are the consequence. Using HDD to underbore the road to install utilities or repair is a more sustainable asset management solution with a lower whole-of-life cost and safer roads.

HDD also provides solutions to those sectors with too much water. The mining sector has mines filling with excess water, impacting the safe operation of the mines. HDD, with its extended bore capability

and powerful pumps, provides a means to access the water from another direction and divert it to an alternative location.

Similarly, where water and sewer asset owners have water storage areas full, HDD provides a relatively straightforward solution to divert excess water at high rain event times to another path or location to mitigate short-term damage to community assets.

It is incumbent on all industries to reduce carbon emissions. The use of emissions-friendly electric rig spreads can be provided by Maxibor with the Gallagher HDD660e maxirig (The Hulk), powerful pumps and drill mud recycling system assists in a cleaner and lower noise delivery of HDD services. Such an HDD delivery solution is suitable for wellestablished metropolitan areas.

For carbon emissions to be reduced by the civil construction industry, the way we deliver projects needs to select more environmentally friendly methods. Changes in behaviour around design, construction methodologies and equipment used are required. Maxibor’s electric HDD maxi-rig spread and carbon emissions measuring model are examples of how the industry changes its behaviour.

Ageing infrastructure is an increasing issue across Australia. This is particularly so in the water sector, where the negative environmental impact of fluid leaks from ageing infrastructure is unacceptable. HDD is a vital part of the replacement solution to prevent ecological damage and preserve limited resources.

As HDD can undertake its work

at a greater depth than open-cut methods, it is less likely to interfere with existing services. Nevertheless, it is essential to utilise modern services and location equipment to confirm drawings. Using fit-for-purpose steering equipment is also necessary when completing the pilot hole for each bore. All this helps to avoid the pollution of the local water supply and surrounding environment.

Good design in the planning stage with quality geotechnical information and experienced HDD drillers also reduce the underground environmental risks. Preparing and implementing a drill mud management plan will help ensure that the fluid drill materials used are appropriate for the local environment.

Improved drill fluid technology is providing products being better able to address bore hole challenges. Ingredients to address bacterial odour from the drilling mud and unstable boreholes, such as those encountered in water-charged sands, reduce the frequency and extent of unwanted outcomes from HDD projects.

Improved drill fluid disposal practices also reduce the waste that must be transported from the site. Products are now available that solidify the water-based drill fluids on site. This reduces the quantity of

HDD techniques are focused on a smaller footprint.

waste required to be disposed of and the number of vehicle movements for disposal to a licenced facility.

Maxi-rigs like the Gallagher 660e are designed for long pipeline installations.

HDD benefits the environment, especially compared to traditional open-cut trenching and excavation methods. A smaller footprint and the installation of underground pipelines underground with minimal disturbance of the above and surrounding landscape avoids impact on sensitive areas that need to be preserved for environmental or cultural reasons.

For more information, visit www.maxibor.com.au

Hydroflux, an Australian water treatment specialist for groundwater remediation, has developed a ZeroBrine membrane process utilising HyPURE NX nanofiltration

a global phase-out of these products. While PFAS compounds are not manufactured in Australia, they are still in use and are present in a range of imported consumer products.

One of the primary sources of PFAS contamination is firefighting foams. The sale and use of PFAS firefighting foams are banned in South Australia, and New South Wales introduced a range of restrictions in March 2021.

Due to its mobility and persistence, PFAS contamination in the environment from firefighting foams, alongside other sources, are widespread across Australia. The current EPA national environmental management plant for PFAS recommends treating PFOS to 0.00023 µg/L (0.23 ng/L) and PFOA to 19 µg/L before environmental discharge.

Hydroflux has developed a new process to treat PFAS in groundwater. The process can be implemented on new and existing GAC, IX and SAFF systems to reduce operating costs for treating long and short-chain PFAS. The technique also provides environmental benefits through a reduction in energy use. It also avoids the use of pre-treatment chemicals required for traditional filtration processes.

PFAS is a group of synthetic chemicals known as per- and polyfluoroalkyl substances. The hallmark of PFAS compounds is their series of carbon-fluorine bonds, which form part of the “backbone” of these chemicals. The backbone is typically combined with a carboxylic or sulfonic acid functional group.

There are some notable exceptions to this, such as Gen X compounds. The high energy required to break the carbon-fluorine bonds within PFAS substances means they are virtually indestructible, making them ideal for various industrial uses. These products have been used in everything from firefighting foams and Teflon to grease-resistant coatings in carpets and chip packets.

The major challenge with these compounds is that they do not break down in the environment, leading to bioaccumulation within animals and humans.

PFAS molecules are also highly mobile due to their hydrophilic carboxylic acid and sulfonic acid functional groups, enabling them to travel thousands of kilometres in groundwater and surface water.

The combination of their ability to bioaccumulate and mobility has led to

Currently, many treatment technologies are used to remove PFAS from the surface and groundwater. Many of these solutions are only functional on a small scale. Alternatively, these solutions treat highly concentrated waste due to the high energy requirements to operate at extreme temperatures or pH ranges to break down C-F bonds.

Several proven treatment methods exist, including activated carbon (GAC) and/or ion exchange (IX) adsorption and foam fractionation. These technologies have proven effective at PFAS removal when incoming concentrations are high. However, the level of reliability reduces at very low concentrations (1-5 ng/L) while operating costs increase. All technologies also struggle to remove short-chain compounds such as PFBS.

Reverse osmosis and nanofiltration membranes remove PFAS compounds, even at low incoming

concentrations (1-5 ng/L). However, managing waste brine creates a serious and currently unresolved challenge.

HyPURE NX ZeroBrine nanofiltration process for PFAS removal

Hydroflux has developed a process that exploits the benefit of the physical barrier to PFAS compounds offered by nanofiltration membranes without the challenge of handling waste brine.

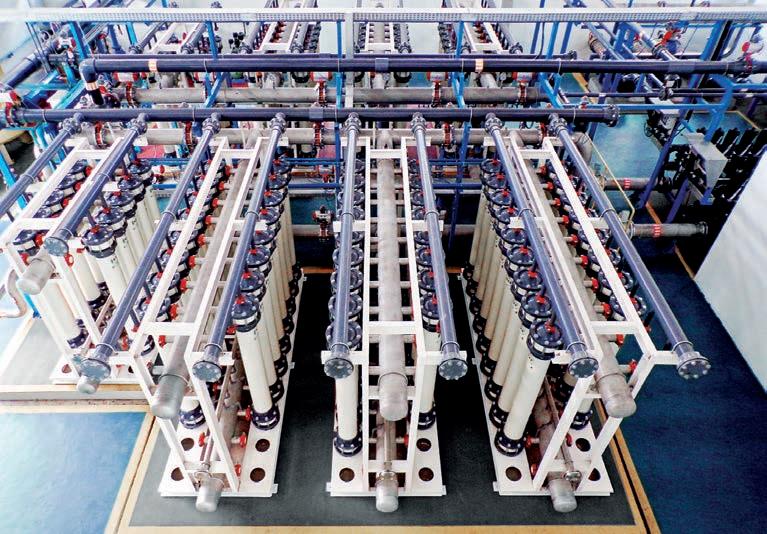

The ZeroBrine process utilises the company’s HyPURE NX system fitted with NX Filtration direct hollow fibre nanofiltration membranes at its core.

The NX Filtration dNF40 and dNF80 membranes are effective at removing PFAS compounds. The pore sizes and unique nanocoating in the membrane are structured to retain PFAS and other organic pollutants while allowing dissolved inorganic salts to pass through.

The HyPURE NX ZeroBrine process can also be retrofitted to existing GAC, IX and foam fractionation systems to provide improved treatment performance, reliability and savings in operating costs. The membrane provides a barrier to remove a range of PFAS compounds.

Removal rates of various PFAS by NX unique 400 DA and 800 DA hollow fibre nanofiltration membranes.

One benefit of the HyPURE NX system is that it removes a broad spectrum of other contaminants in a single process, meaning that other targeted treatment systems do not need to be provided. Some of the many compounds removed by the HyPURE. NX system are:

• Heavy metals, including Zn, Pb, Fe, Mn, Cu, Cd, Cr, As

• Chromium VI (< 1 µg/L ANZG 2018 95 per cent SPL)

• Dissolved hydrocarbons

• Pathogens

• Microplastics.

To find out more, visit hydrofluxindustrial.com.au

Pots and vases are not the first thing to come to mind when measuring groundwater levels. The VEGAWELL 52 and its ceramic measuring cell seek to change your mind.

“THE CERAMIC MEASURING cell is the beating heart of the VEGAWELL 52,” said Tony Scarborough, New South Wales Business Development Manager for VEGA Australia. Scarborough spoke about how the VEGAWELL 52 can impact industries across the country.

The device is a hydrostatic submersible level sensor. The measuring cell detects minute changes in hydrostatic pressure. The pressure increases or decreases depending on the filling level in the vessel. That pressure is converted into an output signal by the integrated electronics. Ceramic-capacitive and metallic measuring cells are used to detect the pressure in hydrostatic pressure measurement.

Scarborough said that the VEGAWELL 52 could also measure temperature, is unaffected by foaming, and is infinitely adaptable to different container sizes.

“The ceramic measuring cell

the water above it. That is called the height or head of water. In fairness, it can measure any liquid in which the VEGAWELL 52 is submersed; there are no limits to what it can do,” said Scarborough.

The ceramic cell is designed for long-term use and minimal maintenance. They are constantly compensating for atmospheric pressure changes using a breather tube that goes from the end of the cable to the back of the cell.

“That way, any changes in atmospheric pressure can be accounted for. Users can also electronically zero the sensor, so there is always a consistent pressure measurement,” said Scarborough.

Advantages of ceramic measuring cell

One of the major benefits of ceramics is that they are inert substances. Generally, they do not react with anything else.

The VEGAWELL 52 works on the principle of hydrostatic pressure.

highly resistant to corrosion and chemicals,” said Scarborough. “Given the potential for large amounts of contaminants and wide range of granules of other materials, the ceramic measuring cell will last longer than other measuring cells.”

The ceramic measuring cell is also designed with a higher overpressure limit. Most products are built to handle three to four times the maximum pressure without compromising the device. The VEGAWELL 52 can manage more than 200 times the overpressure.

The VEGAWELL 52 has been in service for more than 20 years.

the VEGAWELL 52

The VEGAWELL 52 has been used on several underground road tunnels, particularly in New South Wales, Victoria, and Queensland. Of note is the role that the VEGAWELL 52 has played in the NorthConnex project in Sydney.

“The VEGAWELL 52 is intrinsically safe, as it can manage the potential for toxic and combustible fumes. This is always an issue for underground road tunnels,” said Scarborough. “That is because they run parallel to the roadway and operate underground.”

The unit integrates with other devices to manage water levels throughout any system. When looking at groundwater management in a project like NorthConnex, each VEGAWELL 52 is connected to a sump, traditionally above a ventilation shaft of up to 600 metres in length. These shafts are drilled parallel to the road itself. The sumps are all connected to a water treatment plant at one end of the underground road.

“Water levels can be monitored to operate the pumps by measuring the water collected in these shafts. For example, the pumps may wait to turn on when the level in the collection sump reaches 50 per cent. The pumps may remove water until the sump reaches 25 per cent,” said Scarborough.

Traditionally, the VEGAWELL 52 functions through a controller supplied by VEGA Australia. In the earlier stages, the controller was an on/off switch with a couple of relays connected to the unit. More commonly, the VEGAWELL 52 is connected to a programmable logic controller (PLC). The most common controller is the VEGAMET 391, optimised for the water and wastewater industries.

What makes VEGAWELL 52 better?

The cable used in the VEGAWELL 52 is designed for long-term use and low maintenance. The cable is made of PTFE, which is a derivative of Teflon. It is designed for chemical resistance and flexibility, making it suitable for any groundwater situation.

“We also sew Kevlar strands through the cable sheathing,” said Scarborough. “That gives the cable excellent tensile strength, particularly for deep bore level measurement.” Scarborough also highlighted the

The pressure sensor for the VEGAWELL 52.

Placing the VEGAWELL 52 in a wet well.

importance of built-in over-voltage protection in the VEGAWELL 52. This covers lightning strikes or voltage surges.

“This is more common than people may think,” said Scarborough.

“The VEGAWELL 52 is traditionally submerged in a liquid or water. The potential for one to be struck by lightning depends on where it is deployed. This is most common for above-ground water reservoirs. It does not happen as often, given that most reservoirs are closed to the open air. However, it can happen for open-air water dam level measurements.

It’s not just about the groundwater While the VEGAWELL 52 is for groundwater, it has many functions across multiple fields.

“As long as it is submerged in some water, it is doing its job measuring water levels,” said Scarborough. “It could be used in ponds, lagoons, or basins. I know that some clients use it for rainwater harvesting, river levels and managing sewage levels.

The applications continue to grow as users explore its functionality.”

For more information, visit www.vega.com/en-au

Leeton Shire Council has installed its first large flock of Taggle Cockatoo telemetry devices to monitor water pressure, lift station levels, river heights and rainfall.

LEETON SHIRE IS in southwest New South Wales. It is 584km from Sydney, 470km from Melbourne and 371km from Canberra. Leeton is the birthplace of the Murrumbidgee Irrigation Area and was purposely built as part of the Murrumbidgee Irrigation Scheme.

Understanding Leeton means understanding its climate and its relationship to the Murrumbidgee River. Leeton has a semi-arid climate with hot, dry summers and cool winters. The maximum average summer temperature is 32°C, and the maximum average winter temperature is 15°C. The average annual rainfall is 457mm.

The Murrumbidgee River provides vital irrigation water and feeds the Ramsar-listed Fivebough and Tuckerbil Wetlands. These wetlands play an essential part in the local ecology. Up to 174 bird species have been recorded in the Wetlands during the warmer months. Many of these bird species are migratory birds from the Northern Hemisphere.

The council is the water utility and authority for about 4500 people and the sewage provider. In the words of Gerard Simms, the IT Manager of Leeton Shire Council, said, “Leeton is the ideal Goldilocks size for trialling new technology”.

“We are small enough to deploy new technology through our network fairly easily. At the same time, we are not big enough to have too much bureaucracy to slow things down,” he said.

With water central to Leeton Shire, it takes its water monitoring seriously. With that in mind, Leeton went to market three years ago for smart water meters. After

rolling out the smart meters from Taggle, conversations took place around other radio network uses. Taggle’s IoT solutions provided opportunities to look at different use cases to understand the water and wastewater networks through a more comprehensive array of sensors. This is where the Cockatoo telemetry device came into play.

The Cockatoo is Taggle’s recently released versatile telemetry device. It can accommodate a range of sensors, protocols, and radio technologies. The Cockatoo can address unique or specific requirements and challenges. Leeton Shire Council wanted

to monitor water pressure in its reticulation network and issue early warning alerts in response to rising levels in lift stations. It also pairs rain gauges with ultrasonic levels sensors to provide an additional early warning for rising water levels during heavy rainfall.

“One of the biggest benefits of the Cockatoo is that they are batterypowered. The lack of electrical work means that we can install them anywhere and place them somewhere that is unlikely to be vandalised,” said Simms.

The Cockatoo collects the data, which is then processed and delivered via Aqualus Vision, Taggle’s IoT visualisation platform. This platform enables remote visualisation of assets and resources with early warning alerts to inform decisionmaking and to quickly address any issues.

Expertise

Simms has been with Leeton Shire Council for four years, having spent several years in the IT industry. He has a clear understanding of how the system works.

Over time, developers had put pump stations at the end of every street instead of building main trunk lines back to existing pump stations. Some of these pump stations are overgrown septic tanks with a submersible pump – they may only serve one or two houses.

“It’s hard to justify the SCADA investment for that situation, so we needed to find something that would give us full visibility of the system at a lower cost. We wanted to reduce the risk of having unknowns in the system,” said Simms. “One of the biggest problems with automation is that unless you have 100 per cent coverage, you do not know what you do not know. If staff are not looking at every pump station, we will not

enormous challenge. Taggle worked closely with Leeton Shire Council to provide all the water and sewage operators with one platform to find all their data.

“Having one source of truth meant that any alarms come from one place. We wanted to make the system as simple as possible for the end users,” Simms said. “That worked really well.”

What has Leeton Shire Council learned?

The most important thing for any such investment is what a council can learn from the sensors. In the case of Leeton Shire Council, they have learned some trend information from different pump stations around the network. It included trends that they had never known about before.

“We discovered that one pump station hooked up to a sports ground would reach a critical level that may need action, every second Sunday. This occurred at about 5:30 in the afternoon every second Sunday during winter. We figured that it’s the showers and toilets all being used at once after the game,” said Simms. “Ninety-nine per cent of

Monday, all that water is gone.”

Simms added that the pump station is probably an overgrown septic tank that needs to be upgraded at some point. However, the more important issue is how to invest capital appropriately. Finding this trend and having this data will help Leeton make that decision.

A lift station in Leeton Shire

time to act early on issues.

The Cockatoo devices have given Leeton Shire Council the knowledge to manage its water and understand its flows. The more it learns, the better it will understand its future capital investments.

For more information, get in touch

When pumps and sensors are spread over a great distance, troubleshooting can require long trips to disparate places. What if data from those remote critical assets could be collected and monitored before setting out?

REMOTE ACCESS TO machinery and assets in the field has never been more critical. About 5 per cent of machine data is transferred to a local controller, with the remainder lost. Ideally, an organisation could capture that data to optimise its installation. However, it is expensive in terms of costs and time.

Technological advancements and developments have created new pathways to gather accurate data from sensors in real time. Users can make time-critical decisions with the right systems, saving time and money.

What service can provide this?

This is where ifm steps in. It has a new product called Sensor2Cloud. Sensor2Cloud technology allows the collection of process data from the sensor. That data is sent directly to the cloud. No connection to a

controller, computer, or company network is needed.

The Sensor2Cloud can be used to monitor and evaluate remote locations. These locations include machinery and processes that are not connected to company infrastructure. The Sensor2Cloud system can even be connected to assets that don’t even have power connected.

The Smart sensor data is sent directly via a mobile network to the cloud and can be viewed on a webbased dashboard to visualise and analyse cloud data.

What does Sensor2Cloud do differently?

The first thing about the Sensor2Cloud system is that it is simple to set up. Once you mount it and connect it to the system, it is ready to go. This plug-and-play

ifm’s Sensor2Cloud is simple to set-up and user-friendly, as it collects process data from the sensor and sends it to the cloud

setup is designed to operate within any operating system.

Second, the data is transmitted over 4G to the cloud. This allows small businesses to be flexible and manage their sensors while allowing larger businesses to operate them separately from their IT networks. There is also no need to create a stand-alone system for devices. It can all be accessed from any smart device or computer via a multi-factor authentication process.