COVER STORY

COLLIERS WA INDUSTRIAL EXPANSION CONTINUES

yet

FLEXIBLE CLEANING WITH REDUCED RISK

The industrial property titan’s West Coast operation is primed for its best year MHD talks shop with Managing Director (ANZ) Jordan ThruppKörber Perspectives

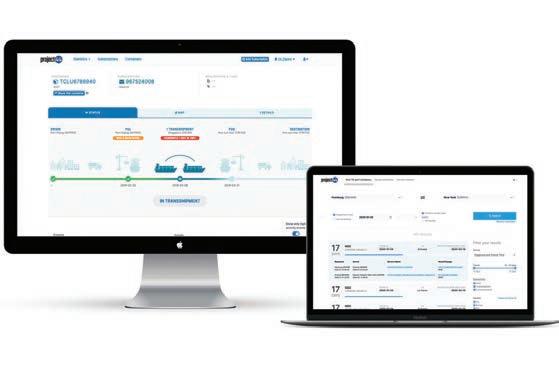

Global supply chains are becoming more complex. Körber Perspectives identifies six of the biggest supply chain challenges our customers are facing today, and how to combat them. They include End User Experience , Facility Optimisation and more.

MHD

Supply Chain Solutions

CONTACT

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

THE TEAM

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Editor: Edward Cranswick

Journalist: Joseph Misuraca

Business Development Manager: Beth Jarvis

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Louis Romero, Kerry Pert

Client Success Manager: Janine Clements

FOR ADVERTISING OPTIONS

Contact: Beth Jarvis beth.jarvis@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST)

1yr (6 issues) for $78.00

2yrs (12 issues) for $120.00 – Saving 20% 3yrs (18 issues) for $157.50 – Saving 30%

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

FAST OUT OF THE GATES

While newspaper headlines continually remind us of the potentially parlous economic times to come – with fears of a return to 1970s style stagflation – you wouldn’t know it by examining the world of supply chain.

Indeed, according to a recent report from CBRE, the competition for industrial property is fiercer than ever, with the national vacancy rate in H2 2022 at 0.6 per cent – the lowest in the world.

Finding the right industrial property for swiftly modernising operations will be a key factor keeping real estate agents and property developers busy in 2023 – as will work retrofitting existing properties until supply can catch up with demand; a possibility currently beyond the horizon.

In our first cover story for 2023, we celebrate the first anniversary of Colliers opening its new office in Perth, and talk to Hayden Dick, Sam Hammond, and Catherine Van der Walt about what the WA I&L team has achieved since the opening – and their goals for 2023.

Maintaining the WA theme, in this issue MHD also interviews Morgan O’Shea of property development firm Lester Group. Perth is second only to Sydney in having the lowest vacancy rate within Australia, so on-the-ground knowledge from local experts like Lester will be essential for decision makers on the east coast exploring western opportunities. Indeed, for Morgan and Lester Group, bridging the gap between east coast decision makers and west coast opportunities is a key priority for 2023.

But a property is only as good as the facility on it, which is why Argon & Co has joined forces with intralogistics experts and ‘warehouse wizards’ Fuzzy LogX. The move, announced in mid-January, is an exciting step for both companies – enhancing the scope and scale of their capabilities and offering to existing and future customers. We sit down with the Argon and Fuzzy teams to learn more.

With so much having occured already in 2023, it’s apparent that the industry has been fast out of the gates – setting a cracking pace for what is sure to be a dynamic and exciting year.

Happy reading. See you next month.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

MHD magazine is owned by Prime Creative Media. All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Edward Cranswick Editor edward.cranswick@primecreative.com.au

AUSTRALIA’S LEADING FORKLIFT COMPANY

FOR ALL YOUR MATERIAL HANDLING NEEDS

MINI EXCAVATORSSKID STEER LOADERS SCISSOR LIFTS

ELECTRIC VEHICLES

ELEVATED WORK PLATFORMS

SWEEPERS AND SCRUBBERS

TOYOTA FORKLIFTS & WAREHOUSE EQUIPMENT

Known for market leading Toyota forklifts and warehouse equipment, Toyota Material Handling is also proud to o er an unparalleled range of products suitable for Australian businesses. With a huge range of forklifts, elevated work platforms, scrubbers and sweepers, Taylor-Dunn electric vehicles, plus Huski skid steers, scissor lifts, and mini excavators available, chances are we’ve got the equipment that will suit. So, if you’re looking to buy hard working, fully backed equipment for your business, Toyota Material Handling has all you need to add value to your operation. That’s the Toyota Advantage.

COVER

REGULAR

SUPPLY

INDUSTRIAL PRECINCT OPENING IN ESSENDON FIELDS

Colliers and CBRE are managing the first stage of a new industrial precinct in Essendon Fields which has gained significant interest from prospective tenants and comprises 30 hectares of land.

New light industrial properties are being developed on the land where there will be manufacturing and logistics facilities close to the CBD, Melbourne Airport, and the rest of Melbourne by the nearby freeway network.

“The plan for stage one of this new light industrial precinct unlocks one of the last major land releases at Essendon Fields and represents the only largescale industrial greenfield site within 15 minutes of the CBD and the Port,” Brendan Pihan, CEO of Essendon Fields, says.

“It’s the best location in Melbourne. Demand for industrial land is insatiable.

The planning regime at Essendon Fields means we can deliver new facilities for customers faster than anyone else. And the location is superior because it’s the closest to the end customer and a talent pool of 1.1 million people within 15 minutes of the site.”

The plan is for a series of 350010,000 sqm industrial facilities to be developed, with construction to start in 2023 in line with market uptake. The end value of the precinct, which will be delivered in stages over the coming years, is expected to exceed $500 million.

“Prospective occupiers will be drawn to Essendon Field’s unique interface and abundance of mixed-use amenity, as well as the ability to capitalise on proximity to Melbourne’s CBD, sea and airports,” Daniel Eramo, Director at CBRE Advisory & Transactions Services,

Industrial & Logistics, says.

Essendon Fields’ strategic location benefits from direct access to the Tullamarine Freeway, Calder Freeway, CityLink and the Western Ring Road. Via these connections, 80 per cent of Melbourne’s population can be reached within 45 minutes.

“We have already received significant interest from occupiers who recognise Essendon Field as one of the most strategic and well-located land estates across Melbourne’s industrial market,” Nick O’Brien, Associated Director Industrial at Colliers, says.

Essendon Fields is already home to several light industrial tenants including Elenium Automation and Suncorp, and recently opened a new 4700 sqm maintenance facility for Bombardier Business Jets and new training centres for Porsche and Volkswagen.

KEY TRANSPORT & LOGISTICS TRENDS IN AUSTRALIA TO WATCH OUT FOR IN 2023

2022 was a challenging year for the transport and logistics sector in Australia. The effects of the COVID-19 pandemic were still making their mark throughout the supply chain, and inflation and international instability continue to impact the sector.

However, we have seen resilience in the supply chain despite the macroeconomic challenges and global inflation. 2023 holds a lot of promise, with businesses set to gradually recover from the setbacks of the past two years. Many are poised to invest in creating a more sustainable and innovative supply chain. We anticipate that key trends for 2023 in the transport & logistics (T&L) space will centre around sustainability, cyber resiliency and tech innovation.

PUSHING TOWARDS NET ZERO AND SUSTAINABLE SUPPLY CHAINS

The impact of climate change continues to ripple around the globe, and climate change is once again set to dominate discourse across a multitude of sectors in 2023.

The T&L industry is no different. Australia now has a target to achieve net zero emissions by 2050, and corporations are being forced to move towards carbon neutral supply chains due to pressure from customers, investors and mainstream environmental, social and governance (ESG) organisations. The time to invest in a sustainable supply chain is now.

Transport emissions have been on the rise since 1990, and according to

the World Economic Forum’s research, eight global supply chains – including those in the food, construction and fashion sectors – are responsible for 50 per cent of carbon emissions.

At the recent COP27 summit, the UN’s Intergovernmental Panel on Climate Change (IPCC) stated that greenhouse gas emissions must peak before 2025 at the latest and decline to 43 per cent by 2030 to limit global warming temperatures to 1.5°C.

There is still a lot of work to be done to reduce emissions in the supply chain to meet these deadlines. If your business is looking to reduce emissions in 2023, data from HERE Technologies can assist businesses through accurate emissions reporting, real-time visibility of the supply chain and optimising fleets.

to go in 20 minutes

It takes just 20 minutes for an order to be picked at Bolloré Logistics’ Blue Hub facility, tailor-built to handle online and store orders for perfumes and cosmetics. A Dematic Goodsto-Person system enables these superior customer service levels for Bolloré clients, optimising order fulfilment speed and accuracy while delivering very high productivity.

With space a premium in Singapore, the Dematic Multishuttle® high-throughput, high-density storage engine provides a 400% increase in capacity. The result: Flexibility, capacity and a superior service for Bolloré Logistics’ clients.

Read more and see it in action at www.dematic.com/bollore

INCREASING IMPORTANCE OF ELECTRIC VEHICLES

Every state and territory in Australia has plans to increase their electric vehicle (EV) fleet and charging networks. On top of that, the government has also committed funding to expand the number of public chargers. The EV Council of Australia has welcomed these commitments, and says this funding will triple the size of the existing fastcharging network.

The EV Council also called on the government to commit to the development and implementation of a mandatory fuel efficiency standard for light vehicles that would support Australia in achieving its target of net zero by 2050.

Looking ahead, there are opportunities for EV manufacturers and map providers to incorporate more data and functionality in their systems to enable contingency planning for a more seamless driving experience. It’s also important to consider the availability of this data.

Location tech enables us to not only visualise where EV chargers are located along a journey, but also knowing their precise locations and charging availability.

Today we see charge points at airports, parking bays, shopping centres, theatres, and while these locations are convenient, having a central and fresh database of EV charge points with real-time availability is key to encouraging mass EV adoption as it allows users to plan and maximise their travels.

As we continue to encourage the uptake of EVs for a greener future, and with the National Electric Vehicle Strategy taking shape, the government, charging-technology providers, operators, and utilities companies should all consider utilising location technology to strategically boost the availability of charging infrastructure in building a truly national EV charging network. Data on EV charge stations and EV maps can optimise routes for businesses investing in hybrid and electric fleets.

SUSTAINABLE FLEET MANAGEMENT

Australia’s freight task is growing, and the urban freight challenge is expected

to see growth of 60 per cent over the next 20 years. Stakeholders in the T&L sector are feverishly working to identify how they can accurately track emissions of their fleets, which will help them understand their carbon footprint before implementing target reduction strategies.

We predict that location technology will play an important role in helping businesses improve their fleet management, including planning, operation and maintenance to reduce downtime at every point in the supply chain. This will ultimately help to reduce fuel costs, driver fatigue and carbon emissions. In 2023, it will also be key for businesses to estimate emissions using data such as vehicle types and detailed maps of routes, including gradients.

Working with Migros, HERE developed a commercial fleet analytics tool that determines the amount of carbon dioxide (CO₂) emissions per route, considering factors such as vehicle and fuel type, weight, traffic conditions and the elevation of the roads on every route. This tool empowers the leading Swiss retailer to reduce their emissions while also optimising their fleet’s navigation routes.

Transportation is one of the biggest carbon emitters, and the sector will continue to focus on reducing pollution. As we enter 2023, we can expect businesses to be more engaged with policymakers as they strive to become sustainability enablers. Technology will play a bigger role in contributing to these data-led solutions.

SUPPLY CHAIN RESILIENCE AND INCREASING CYBER THREAT

We expect to see an improvement of supply chain visibility when it comes to operational resilience. Gartner has predicted that 50 per cent of global product-centric businesses will invest in real-time visibility across their supply chain by 2023.

As supply chains continue to experience freight issues, the push for visibility only gets stronger. Supply chain visibility will become more important in the face of increased cyber threat.

The Optus and Medibank hacks have

dominated headlines recently, but not so publicised were the hacks of major companies in our freight and transport industry. We all need to protect our businesses, suppliers and most importantly our customers.

Digital transformation is giving the supply chain sector the tools to deal better with disruptions, but it is simultaneously providing cybercriminals with ever-increasing opportunities to infiltrate companies. Supply chain operating networks are still very complex and fragmented with multiple data-sharing platforms, devices, software and protocols. This leaves businesses susceptible to:

• Cyber-attacks from interoperability issues between various IoT devices with no standard protocol;

• Other security concerns including inventory theft, physical device tampering, reliance on third-party vendors, cloud data and increasing sensor data; and

• Difficult integration with software vendors due to different EDI (Electronic Data Interchange) formats and systems used by shippers.

Businesses that take cyber threat seriously are best placed to avoid the threat going forward. Those that ignore it may face unwanted consequences down the road.

TECH INNOVATION WILL BE CRUCIAL TO BUSINESS SURVIVAL

As digital transformations happen

Reduce Costs. Improve Efficiency.

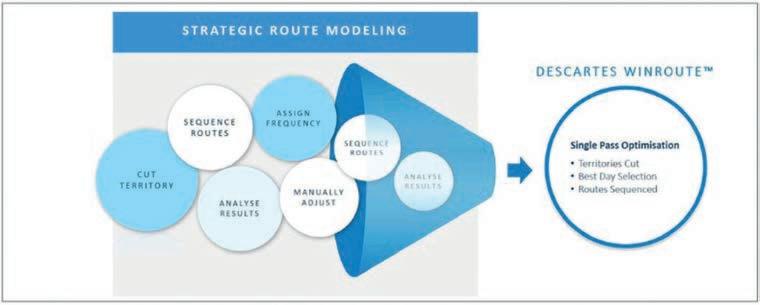

DiscoverhowBestrane’s Route Planning and Optimisation solutions allow you to reduce cost, improve efficiency and customer service outcomes across a wide range of planning modes - from dynamic and same day solutions, to territory or master routing.

• Less vehicles used and distances driven

• Reduced planning and dispatch costs

• Improved fleet and driver utilisation

•Improved customer service outcomes

No two route planning or optimisation problems are the same. We use different optimisers for different problems that enable a broad range of industries to create optimal daily routing solutions. Our solutions feature capabilities including background optimisation, same day routing, and dynamically generated delivery time windows that maximise customer experience.

across all industries, experts are realising they need to focus more on customer centricity. We expect digital innovation to drive changes to meet the evolving customer demands and expectations will be critical to business survival.

Innovative end-to-end digital solutions have become similarly critical to holistic supply chain visibility. These advancements allow multimodal tracking of high-value and time-critical goods with up-to-date information on estimated times of arrival (ETAs) and conditional events.

We also predict that the push for Intelligent Speed Assistance (ISA) will gather momentum. In the Europe Union (EU), for example, new vehicles introduced to the market from July 2022 must have an ISA system fitted.

From July 2024, ISA will be mandatory for every newly registered vehicle. As a result, we anticipate that ISA will become popular in Australia as well. Based on research from around the world – including Australia – ISA can make a significant contribution to road related deaths and injuries, while also contributing to the reduction of

CO2 emissions.

HERE Technologies has significant experience in supporting ISA and is now enabling more than 30 brands from 15 global automakers with HERE ISA Map data to comply with the EU mandate. Based on what is happening overseas, as well as our ISA expertise, we think that Australia should actively pursue ISA as a priority to keep our roads and drivers safer.

By Daniel Antonello, General Manager for Australia & New Zealand, HERE TechnologiesAUSTRALIA POST OPENS NEW PERTH DC

Australia Post opened Perth’s brand-new parcel DC on Thursday December 8 which comes with a dual name in the traditional language of the Noongar Nation, Boorna Wangkiny Mia.

Boorna Wangkiny Mia, which culturally translated means ‘Home of the Message Stick,’ honours Australia’s oldest form of communication and cultural diplomacy.

In naming the new Perth facility Boorna Wangkiny Mia, Australia Post says it honours Indigenous peoples,

recognises their spiritual and cultural knowledge, and celebrates the significant historical and cultural role of the message stick.

“We’re proud of our leading role in promoting awareness of reconciliation, which formally began with our first Aboriginal & Torres Strait Islander Employment Strategy in 1988,” Paul Graham, Australia Post Group Chief Executive Officer and Managing Director, says.

“Working closely with the Traditional Owners to name this brand-new facility is another example of that commitment and reflects our shared purpose of connecting people and communities.

“Online shopping continues to grow in Western Australia. This $82 million facility is a significant investment in our overall network and demonstrates our ongoing commitment to meet growing e-commerce needs.

“The automation inside the new facility means significantly reduced manual handling keeps our people safer, parcels are processed faster with more scanning events, which is fantastic for our customers.”

At 23,000 sqm, Boorna Wangkiny Mia is Perth’s first facility with state-of-the-art automation and the ability to process close to 200,000 parcels a day during peak periods, notes the parcel delivery company.

“Australia Post is a cherished

national institution, from the red post boxes dotted along our streets, to the red vans rolling down every road to deliver online orders,” Michelle Rowland MP, Minister for Communications, says.

“Australia Post is a recognised and trusted organisation which provides essential services to communities right across the country. It is, however, a highly competitive business and ongoing investments, like this facility, are an important part of Australia Post’s transformation strategy to ensure it stays competitive.”

The extra processing capacity delivered by the $82 million investment has already helped Australia Post to process more than 650,000 parcels over the Black Friday and Cyber Monday weekend.

“Message sticks were the first way messages were shared,” Len Collard, Whadjuk Noongar Elder Professor, says. “One man couldn’t travel all the pathways, it had to be passed ceremonially to the representative of the next Country.

“The carried specific symbols to be translated to each carrier as it was passed over from one pathway on Country to another, so the name Boorna Wangkiny Mia works very well for a facility like this that helps to transport items on behalf of other people from Australia and the world.”

Unlocking Industrial Opportunity.

Access our integrated service offering with Colliers industrial experts. National expertise, with a focus on detailed local knowledge. We maximise the potential of property.

LEARN MORE TODAY

SUPPLY CHAIN STRATEGIES IN A CHALLENGING ECONOMY

With an imminent global recession forcing people to tighten their purse strings, the pressure on supply chains has started to ease. Peter Jones, Managing Director and Founder at Prological says this creates the perfect time for supply chains to start planning for the future.

The past few years have exposed supply chains to exceptional pressures. COVID-19 accelerated the move to e-commerce and with that came increasing consumer expectations for next day – often same day – deliveries alongside an explosion in demand. Undeniably, our supply chains bent –often really, really far — but they never seemed to break.

While organisations would be forgiven for taking their foot off the proverbial gas during this brief lull, those who continue to push forward and shift their supply chains into next year will reap the rewards in the future.

POSITIVE AND PROACTIVE PLANNING

With people feeling the pinch of the rising cost of living, consumers had started to reign in some of their spending prior to the Christmas peak and we had started to see volume dropping off and pandemic pressure relieved.

This unfamiliar breathing space within any supply chain is the prime opportunity to invest, and to strengthen the supply chain ahead of when spending and demand return to normal.

Supply chain managers must shift their thinking from being reactive and taking their future supply chain in a positive, proactive direction. What supply chain leaders should continue to do is demonstrate that, as a sector, they have their finger on the pulse when it comes to the future of business planning, the latest technological advancements, and how best to make operations resilient.

PUTTING THE CUSTOMER FIRST

In supply chain, everything you do and every decision you make, is about servicing customers. The business plans

of the future should put customers at the heart of every decision. By realising the consumers’ expectations and understanding their demands organisations will have a much better assessment of what their supply chain must deliver.

While things might be quiet(er) now, when we’re back to normal, not understanding the demands of your customer will undermine your ability to meet their expectations during the next spell of chaos. When the economy starts to recover and demand does turn back on, organisations don’t want to be left with a supply chain lacking the capability to scale and compete as the market returns.

Furthermore, in the face of adversity, businesses that can organise their supply chain to continue to fulfil that customer expectation, will come out of these difficult times, with a much higher degree of customer loyalty and an increase in market share against their competitors.

COST CUTTING

While it may be tempting, this period of calm is not an opportunity for businesses to cut costs in its supply chain – far from it. That decision will only damage an organisation in the long term. The temptation for businesses to start pulling money and resources away from the supply chain is present. However, it has never been more important to invest in supply chain by adopting new technology, using artificial intelligence, and hiring and training more staff.

At Prological, we work with businesses to optimise their current operations while supporting them through the investment and commissioning of new technology. In our white paper: A guide to operational excellence, we laid out how businesses can invest in their supply chain to ensure they are ready for the challenges of the future.

We have seen many businesses change their entire operation in recent years – going from just servicing store networks to high levels of direct-toconsumer fulfilment. With this rapid

evolution in the supply chain there have also been expensive mistakes and fundamental flaws. As we move into a more automated world, any organisation thinking of investing in technology needs a strong, robust business plan to refer back to.

BACK TO BASICS

Planning for the future should be about yourself getting your supply chain strategy lined up with your business’ strategy. There is a sense that 2023 will be all about going back to basics –putting the customer at the very heart of your business plan and understanding how your supply chain can grow to deliver its promise.

The global downturn will shift those businesses back to planning and advocating agility. Businesses should have learnt by now, that the key cog of business success is their supply chain; and so, businesses need to use this opportunity, not to turn attention away from the supply chain, but to take this brief moment of relief to move their supply chain forward.

After the incredible work of supply chains over the last few years, now is the time to push forward, to move to a generation of supply chains that sets businesses up for the next profitable and pressurised season.

Peter Jones, Managing Director & Founder, Prological

FROM GREEN SCREENS TO NEW SCREENS: INTERMAX

If your warehouse is running any warehouse management system (WMS) or enterprise resource planning (ERP), we recommend moving away from old green screens to modern screens that younger staff members are familiar with and which help more experience staff become more efficient. No more heavy-weighted keypad-driven devices. No more ‘Where is the F4 key?’. No more intense staff training.

With a complete Zebra platform of Barcode Scanners, Android devices, printers, and headsets, at Intermax we can offer a proof of concept to let you see your old system with a fresh facelift. A 100 per cent live working system, our solution is device-driven – so no expensive servers or infrastructure is required.

A lot of time can be saved by turning green screens into functional coloured GUI (Graphical user interface) screens, and even adding voice-driven functionality. Imagine what 10 to 15 seconds per pick can make to your total amount of time saved over a day, week, or year. The return on investment (ROI) is potentially within six to 12 months.

With over 25 years in ever-evolving barcode technologies and platforms, Intermax wants to help businesses embrace the latest technology to improve their accuracy, efficiency, and overall work experience. We want to take away the stress of adapting to

new technologies so many companies are fearful of. We know that change is sometimes scary, and we are here to ease that burden. With remote management support, we can upgrade Android versions, software fixes, check if devices are missing and many other features to ensure maximum productivity without loading IT staff with more responsibility.

When Intermax opened its doors in 1996, we quickly learnt that barcode systems could offer nearly any business immediate improvements, significantly increasing accuracy and productivity while reducing staff fatigue.

Barcodes today are on almost everything – with a tailored solution, many businesses can improve their efficiency and bottom line.

Creating this success is not only about providing the right hardware and software, we focus on details often forgotten, such as training, barcode print quality and type, and ensuring the right labels are used for the job. Our expertise and care ensure your success.

Here at Intermax, we are passionate about introducing these new technologies and solutions to everyone! These improvements can benefit all business areas, from small start-up companies to large corporate entities. Our satisfaction is seeing the immediate improvements to the staff experience, the business efficiency, and the company

profit that a well-designed solution can bring.

Our solution has already been deployed to several sites using:

• Zebra TC5X Android Mobile computers;

• Zebra MC3XX Android Mobile computers;

• Zebra RS5100 finger scanners;

• Zebra L10 Android Tablets;

• Zebra ZT410/411 Industrial printers;

• Zebra Desktop printers;

• Zebra ZQ630 Mobile printers; and

• An array of Zebra hand-held scanners.

We understand that cost is a big factor, and so offer flexible purchasing options, such as subscription or leasebased options which can give you up to a 25 per cent productivity gain.

COLES DIGITALISES SUPPLY CHAIN WITH WORLD FIRST IOT SOLUTION

Australian supermarket giant Coles has digitalised its supply chain with Internet of Things (IoT) technology, deploying a world first solution from Loscam and Thinxtra to monitor the location of and measure stock for 4500 smart food bins

moving poultry between farms and its distribution centre.

Coles last year announced a major digital transformation strategy, which includes increasing the resilience of its critical supply chains, such as the Protein Cold Chain, responsible for

sourcing and stocking poultry. The goal was to reduce the number of food bins it loses, understand whether and where these assets are being damaged, improve pooling of equipment for transit, and ultimately increase stock turnaround.

Following a competitive tender, Coles

Leading the way. Transforming business.

Argon & Co is a global management consultancy that specialises in operations strategy and transformation. With expertise spanning the supply chain, procurement, finance and shared

services, we work together with clients to transform their businesses and generate real change. Our people are engaging to work with and trusted by clients to get the job done.

partnered with Loscam, which was the only company to propose an innovative IoT solution. Coles subsequently deployed 4500 smart and foldable food bins manufactured by Loscam and fitted these with Internet-connected devices. The devices communicate location data in real time using Thinxtra’s national, public 0G Network. This information is available to the supermarket via LoscamOnline, a specialised tracking platform.

The combined IoT solution has enabled a connected and transparent supply chain with timely insights into geolocation, geofencing, shock impact events, temperature, and bin status, and allows Coles to optimise transport routes and equipment pooling based on usage patterns.

“The smart food bins ensure that we can track the poultry from the moment they are loaded by our suppliers at farms, right through to the time they reach our distribution centre, reinforcing our food safety standards, while saving time and minimising waste,” says Larry Kavanagh, General Manager National Meat Processing, Coles.

“We partnered with Loscam to deploy a purpose-built device and portal system with Thinxtra connectivity, tailored to the specific needs of our Protein Cold Chain department, giving us full visibility into our supply chain operations in real time. This is a crucial step to retain our

customer-focused, quality-driven service that’s reflected in our supermarkets.”

Loscam and Thinxtra’s IoT solution provides data for each individual smart food bin, rather than just the trucks transporting them. Coles can therefore view the location of each individual asset in transit and receives alerts when food bins aren’t where they should be and any time there is an impact, including when bins are mishandled.

This reduces unnecessary damages and creates accountability for stock quality supported by reliable real-time data.

In addition, the ability to monitor asset performance, including temperature levels, creates assurance for the quality of food. This plays a major role in eliminating waste, and helps Coles maintain safe conditions during transit with the lowest possible energy consumption to support its Environmental, Social and Governance (ESG) objectives.

The innovative combination of foldable food bins and IoT technology reduces the cost of the asset pool required by 25 per cent, tripling the amount of empty bins returned, reducing cost and waste.

“Historical location device solutions generally fell well short of market expectations and needs,” says Daniel Bunnett, Executive Vice President A/NZ at Loscam.

“With a complex large-scale organisation like Coles, IoT has

introduced the capabilities of asset management beyond traditional RFID or GPS tracking, with sensors that can provide insights to optimise logistical operations. Powered by the national Thinxtra 0G Network, our IoT devices give Coles a sustainable, more efficient way of transporting perishable poultry produce, and managing its returnable industrial packaging, all while reducing resource waste.”

Coles selected Loscam as the company’s solution proved more innovative and cost-effective than competing tracking. The IoT technology is fast and simple to install and does not require up-front infrastructure setup investment.

The devices are also batterypowered, with a life of up to five years, giving them the ability to operate independently of any power source.

“Coles, as an iconic Australian brand, has been able to deploy Internet of Things technology to achieve economic viability and operational scalability through streamlining its critical supply chain operations,” says Nicholas Lambrou, CEO of Thinxtra.

“The IoT-powered smart food bins give full traceability of quality assurance and efficiency within the protein cold chain, all the while saving Coles business costs by avoiding unnecessary damages and better pooling equipment for transport.”

TEAM GLOBAL EXPRESS RECEIVES $20.1M FOR BEVS

Team Global Express says ARENA (the Australian Renewable Energy Agency) will give it $20.1 million in funding to deliver Australia’s largest logistics Battery Electric Vehicle (BEV) fleet in Western Sydney.

Team Global Express aims to reduce the emissions profile of its 6500-strong heavy transport fleet, following the large-scale trial which will place 60 BEVs into its Express Parcels fleet.

The 60 electric trucks comprise of 24 Daimler Fuso eCanters and 36 Volvo eFLs. The orders placed with Daimler and Volvo are the single largest orders each company has received for these

electric trucks in the world, to date.

“I want to thank ARENA and Minister Bowen for this opportunity and their support under the Driving the Nation Fund,” Christine Holgate, Group CEO of Team Global Express, says.

“Today is an important step toward progressing Australia’s pathway to reduce Scope 1 emissions and secure a net zero future,” she adds.

“This is the first project of its scale in Australian logistics, as such we are in a unique position to work closely with ARENA to share the knowledge we gain and provide this vital information for the benefit of the entire transport and

logistics sector.”

The Bungarribee site in Western Sydney will host this trial due to its strategic location, the nature of the operations and the suitability of the existing facilities to host the necessary battery and charging infrastructure for the fleet.

The project will see nearly one third of Team Global Express’ Western Sydney fleet transition to electric trucks and operate under a ‘back-tobase’ model with travel from DCs to customers in residential and urban areas, with the trucks returning to the depot for charging.

“This trial will not only reduce emissions, it will also give our valued employees at Bungarribee the opportunity to be trained on charging driving and optimising the electric vehicles of the future,” Christine explains. “For Team Global Express, it’s an important milestone in our

vision to be Australia’s most sustainable logistics company.”

The trucks will be powered and charged on-site at Bungarribee using both on-site solar generation, the installation of a battery energy storage system and the use of renewable energy from the grid.

Construction of the depot and associated charging infrastructure will commence shortly after Christmas peak period and employ more than 50 people. The Bungarribee depot will commence receiving the 60 vehicles over an 18-month period from early 2023.

TMX DEVELOPS NEW SITE FOR THE CONSORTIUM CLEMENGER

TMX has partnered with The Consortium Clemenger (TCC), complex warehousing and fulfilment specialists, which has committed to a new facility in Melbourne’s Truganina and is expanding its Sydney-based Pemulwuy site.

The business transformation consultancy says it has developed fitfor-purpose facilities for TCC to cater to its new business growth and upcoming requirements.

TCC’s client base has recently expanded to service direct-to-consumer cosmetics, health and wellbeing, high-end power tools, valuable finished goods, and additional point of sale material.

“TMX has been fortunate enough to partner with TCC over recent years and numerous deals to support their business with tailored operational, property and project advisory,” Dom Sorbara, Property Director TMX, says.

“These commitments by TCC represent significant growth in their business and it has been our privilege to observe this growth as TCC has moved in step with rapidly changing consumer behaviour and opportunities.”

The industrial property markets in Melbourne and Sydney are tightly held with vacancy rates as low as 0.3 per cent with extremely high rental growth.

TMX and TCC partnered to negotiate and secure the facilities, as well as coordinate the design of the bespoke fitouts, including office and warehouse areas.

“Our partnership with TMX has enabled TCC to commercially grow with confidence and continue to delight our customers,” Chris Kearney, Managing

Director, TCC, says.

“TCC’s unique customer-first focus has led to the demand for our services to grow exponentially over the past three years.

“With our focus on direct-toconsumer fulfilment and bespoke 3PLs and POS distribution, it is vital that we have the right properties in the right locations with optimised layouts. The TMX team have been crucial in supporting our property strategy.”

In Melbourne, the new 11,910 sqm facility has been designed to cater for current client needs and factors in

future automation efficiencies to deliver additional volume and throughput.

This facility will be TCC’s secondlargest DC in Australia. Time & Place and Stockland are developing the Truganina facility in a joint venture with practical completion on track for end of the calendar year.

In Sydney, TMX supported TCC with the expansion of its existing 16,000 sqm Pemulwuy headquarters into the adjoining 3800 sqm space at The Quarry with Dexus. This expansion was spurred by a significant 3PL contract commitment won by TCC.

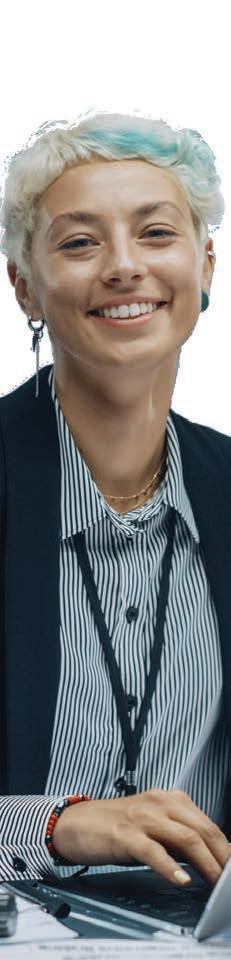

COLLIERS WA INDUSTRIAL EXPANSION CONTINUES

Early 2023 marks the first anniversary of Colliers opening its office in Western Australia’s capital city, Perth. Sam Hammond, Colliers Industrial Director, Hayden Dick, Colliers Industrial Senior Executive, and Catherine Van der Walt, Colliers Industrial Executive, discuss with MHD the market, the future outlook and tips for the year ahead in WA.

Colliers has one of Australia’s largest property teams specialising in Industrial and Logistics facilities. Their national reach and scale mean that their clients benefit from exposure to domestic and international markets. Colliers’ reach is further aided by global collaboration with colleagues providing unrivalled insights and access to all sectors of the industrial market.

From raw land to industrial parks, warehousing to high-tech propositions, and refurbishment to repositioning, they work with their clients to develop the best industrial real estate solutions to suit their clients’ business needs.

“Colliers’ strength lies in providing national expertise with a focus on detailed local knowledge,” Colliers State Chief Executive of Western Australia, Richard Cash, says. “After successfully opening a new company-owned office in Perth, Western Australia, in early 2022, the Industrial team has grown and continues to secure multiple sales and leasing appointments predominantly servicing WA-based high net worth groups, syndicators and Institutional clients.”

MHD sat down with the Industrial team from Colliers in Western Australia to discuss the market, future outlook, and some tips for the year ahead.

GROWING APPETITE FOR SPECULATIVE PRODUCT

The Perth Industrial and Logistics market has recorded significant growth in recent years, with demand outweighing supply and availability by a large margin. Given the influence the resource sector has on Western Australia’s economy, coupled with the dominance of owner-occupiers that often compete with developers to secure core development opportunities, the local Industrial market tends to experience

greater volatility in the delivery of new supply in comparison to the East Coast capital cities.

As a result, supply has proven to contract dramatically during troughs in the local economy, and is often unable to match demand once conditions rebound. Typically, due to lead times for construction and land availability.

“Due to the tightness in the market here in WA, we are seeing an increase in occupiers well in advance of their lease expiries to provide portfolio

advice for the medium to long term,” Colliers Industrial Director, Sam Hammond says. “This tightness in the market is likely to remain with a slow release in future supply. Forward planning is going to be critical for their operational excellence moving forward.”

The revival of the Perth economy following the rebound in the resource sector has led to robust demand since early 2021, and with limited new supply coming online, the vacancy rate has fallen sharply. Just two years ago, the Perth vacancy rate measured 8.2 per cent and was regarded as the highest in the country at the time. Today, the vacancy rate totals just 0.7 per cent in Q4 2022, up slightly from the record low of 0.2 per cent recorded in mid 2022.

“During the 2021 – 2022 financial year, the State’s resources sector generated an all-time record in revenue of $231 billion, with year-onyear growth reflecting 9.5 per cent,” Colliers Director of Research, Luke Crawford says. “Coupled with the ongoing growth in the e-commerce sector, which now represents 13.3 per cent of total retail sales in Australia,

the scene appears set for continued robust leasing demand in 2023 for both workshop and warehouse accommodation.”

As a result, several developers are progressing new speculative product across the Perth market, with a moderate pick-up in new supply forecast in 2023.

Historically, the Perth market has developed less speculative industrial space than the East Coast capital cities, reflective of the skew towards private owners who don’t tend to be as aggressive in growing funds under management as institutional investors, paucity of land availability and a higher proportion of owneroccupiers participating in the market.

However, with institutional groups now estimated to own roughly 25-30 per cent of industrial assets above 5000 sqm across Perth and with rents growing by 20 per cent-plus year-on-year in all submarkets, the appetite for speculative development has shifted and a large (but healthy) pipeline now exists for the next 12 months.

“Owners of industrial land are capitalising on the favourable leasing

market by spec-building product to meet occupier demand,” Colliers Industrial Senior Executive, Hayden Dick says. “The confidence to build without an occupier secured, has

come from the success of most speculative assets brought online nationally over the past 12 months, being leased prior to practical completion. Given current enquiry levels within the Perth market and record low vacancy rates, a similar outcome is anticipated throughout 2023.”

“As it stands, the supply pipeline for 2023 currently totals approximately 215,000 sqm, around 75 per cent of which is expected to eventuate within the East submarket,” Colliers Industrial Executive, Catherine Van der Walt says. “While a large share of the speculative pipeline stems from national institutional groups, there are facilities planned from the likes of Hesperia and Perth Airport who are looking to capitalise on current demand.”

By size, the average speculative facility for 2023 measures approximately 8500 sqm, which does reflect an increase from previous

years. However, by contrast, the average speculative facility size on the East Coast in 2023 measures 15,160 sqm, albeit skewed by a couple of large 30,000 sqm-plus projects (with the ability to be subdivided).

With Perth currently experiencing solid leasing activity, coupled with a period of weak supply, the market is well placed to absorb the forecast speculative development provided that the location, design, flexibility, and size are appropriate for market conditions and demand.

FACTORS DRIVING WA ECONOMY

The Colliers team says different economic drivers are at play in WA compared to the states over on the East Coast with mining as one of the unique financial booms for the country’s largest state.

Sam Hammond says “Our broader state economy benefits so greatly from our large land mass. We have a vast amount of farmland, mineral

During the 2021 - 2022 financial year, the State’s resources sector generated an all-time record in revenue of $231 billion, with year-onyear growth reflecting 9.5 per cent.Colliers WA Industrial team: Sam Hammond, Colliers Industrial Director (left), Catherine Van der Walt, Colliers Industrial Executive (middle), and Hayden Dick, Colliers Industrial Senior Executive (right).

resources and an expansive coastline which is ideal for world-class fishing activities and an abundance of existing and future port locations.

“In addition to this, WA’s gas preservation policies have created stable energy prices. We’re attracting more data centres and heavy workshops to the State because the risk profile of energy costs elsewhere in Australia and globally are creating unacceptable operational risks for many groups. We see this trend continuing over the medium term.”

USING VOLUME AND MEETING ENERGY TARGETS

One of the trends the Colliers WA Industrial team has noticed in the last three years is a big push for facilities around cubic capacity and clearance heights.

As the land prices and rents increase, sheds are also getting bigger, and outgoings are growing. This is prompting occupiers to make their warehouses and DCs more efficient by squeezing as many goods as possible into the space compared to overall outgoings and gross occupation costs.

While this trend has been occurring nationally, it has only started growing in prominence in WA over the last 24 months.

There’s also an increase in the amount of people wanting to invest in real estate, especially industrial, whether it be private or syndicator groups, or institutional grade owners.

“This has really ramped up over the last 12 to 24 months,” Hayden explains. “E-Commerce trends have become more apparent to the broader public over that time hence the inflow of investment capital into this space.

“Due to corporate requirements and ESG targets of certain international and national occupiers, we are now starting to see landlords in Western Australia future-proofing their assets. Many of them have sustainability goals they want to achieve by a certain year. These industrial owners are having to factor this in as they design their buildings not only for current projections but for the future demand in 20 to 30 years’ time.”

THE ROAD AHEAD

While vacancy rates will continue to

be low and demand will remain high in 2023, Colliers will work with its clients in WA to secure appropriate industrial assets that meet their needs and will overcome any challenges impacting the market.

The Perth company-owned office in its first year of operation has driven activity across the market and continually invested in relationships with our valued clients to maximise results and drive enduring value.

The Perth business will continue to expand Colliers’ capabilities, build scale, and grow in 2023, ensuring it maintains servicing the market and acting as trusted advisors for its clients.

Beyond its WA industrial expertise, Colliers services its clients nationally, working with occupiers, developers, and investors to deliver results and exceed expectations.

Its national team of real estate experts deliver enterprising property solutions and market leading advice. Its strength lies in providing national expertise – with a focus on detailed local knowledge – and its ability to collaborate with its global experts. Leveraging, extensive industry experience, market expertise and data driven approaches its team develop key strategies for its clients both locally and globally.

Keep informed on the market, unlock opportunity, and see how Colliers can accelerate your success and maximise the potential of property. ■

For more information on the Colliers Industrial offering, contact one of our experts today.

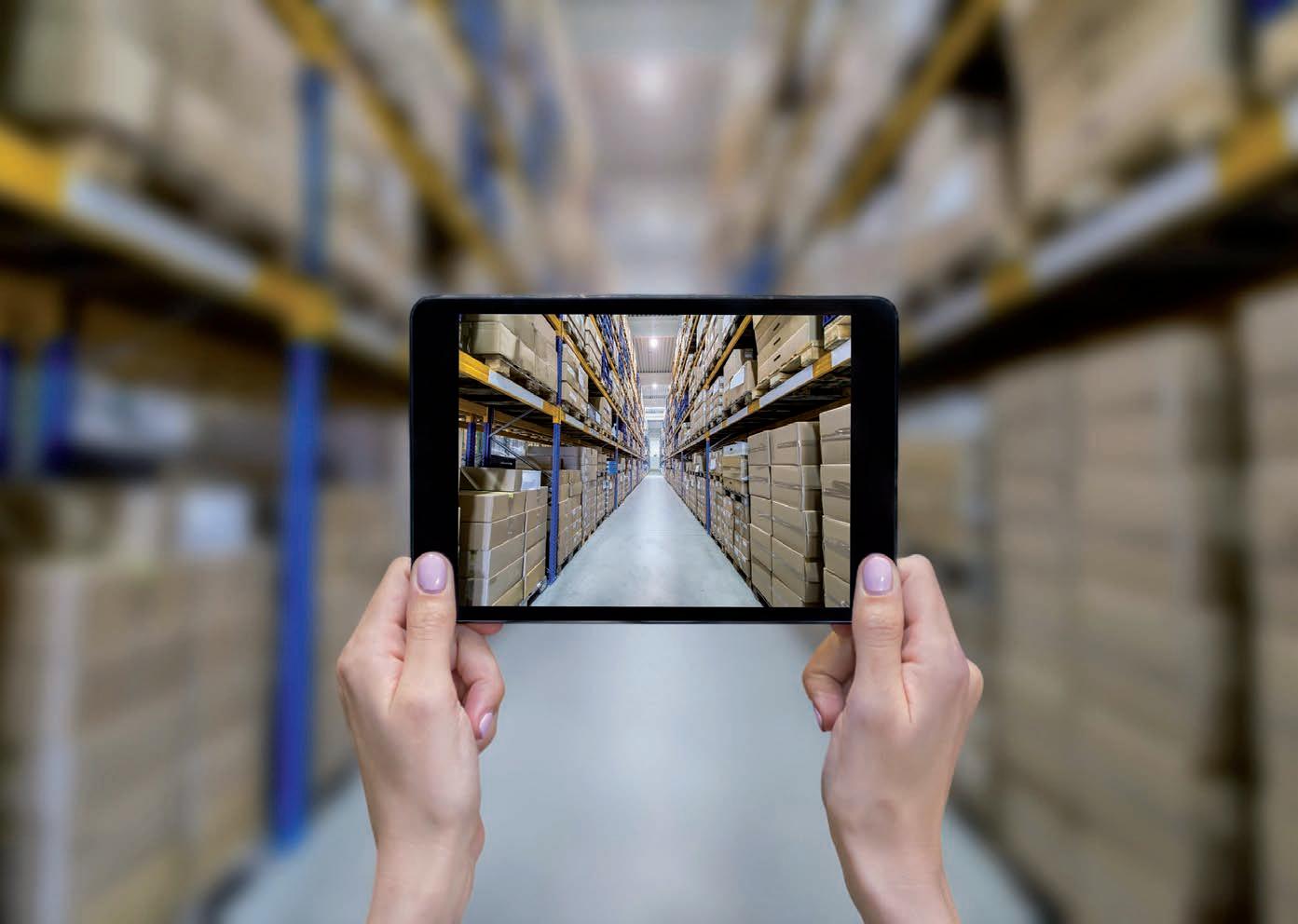

THE CUBIC APPROACH TO WAREHOUSE DESIGN

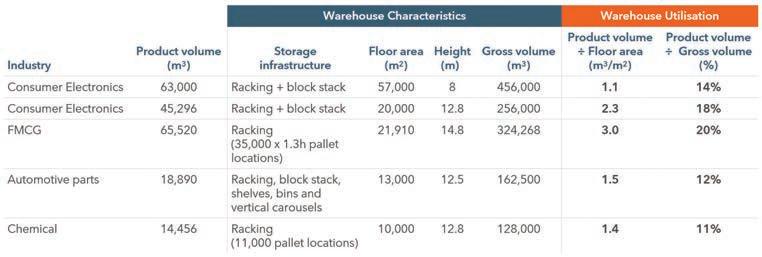

Prological Managing Director Peter Jones discusses how warehouse design has been hamstrung by focusing on square rather than cubic metres, at the cost of proper space utilisation and efficiency – and how to unlock benefits through the cubic approach.

In the world of warehouse design, it is common practice to measure and plan using square metres rather than cubic metres. However, as Peter Jones, Managing Director of supply chain consulting firm Prological points out, this method of measurement may not be the most effective.

“The preference for square metres can be traced back to the traditional purchasing process of industrial property, which is based on land measurements,” Peter says. “Even when companies vote on the construction of a warehouse, the decision is often based on square metres rather than the actual cubic capacity of the facility.”

But Peter argues that thinking about warehouse design in terms of cubic metres rather than square metres can lead to a more efficient use of space.

“In a typical 10,000 square metre warehouse with a 13-metre roof height, the cubic utilisation is only 17 per cent,” he says. “By increasing this utilisation to 25 per cent, there

is the potential for a 50 per cent increase in the cubic utilisation of the facility. This highlights the importance of considering cubic metres in warehouse design to maximize the use of available space.” What accounts, then, for the continuing emphasis on square metres rather than cubic metres?

“The traditional method of measuring warehouse space in square metres may be due to groupthink, a longstanding way of thinking,” Peter says. “However, the increasing use of automation in warehouses has caused some to rethink this method and consider the benefits of considering warehouse space in cubic metres.”

He believes that by considering the cubic usage, companies may increase their utilisation by up to 50 per cent, especially in Greenfield development. He cites one facility designed by Prological that has a cubic utilisation rate of 34 per cent – double the efficiency of many traditional buildings.

“Re-conceptualising warehouse builds in terms of cubic rather than

square metres will change the way we design warehouses,” Peter says. “We are not aware of a traditional build getting close to 25 per cent volumetric utilisation.”

The accompanying table shows five examples of cubic utilisation within existing operations. Even the FMCG example at 21,910M2 and racked spaces for ~35,000 pallets only achieve 20.2 per cent cubic utilisation efficiency. While this facility delivered 1.75 pallets per M2 it still could only manage one in five cubic metres in storage utilisation.

“Despite the prevalence of the traditional process of purchasing industrial real estate land and then building a warehouse on that land, the rise of automation has initiated a shift towards more optimal warehouse design,” Peter says. “An example of this is a new warehouse in Melbourne, which – while espoused as a benchmark facility by the owner, occupier and media –actually has a low cubic utilization rate due to a large proportion (~25 per cent) of the floor space being occupied by automated material handling systems, in this instance AMRs that occupy just 2.4 vertical metres of the 13m high warehouse. This highlights the importance of considering cubic utilisation in warehouse design, rather than simply focusing on square metres.”

Peter notes that some participants in the industrial real estate space may initially be hesitant to shift to a metric of measurement based on cubic metres rather than square

metres in design. The overall incentives in the market strongly point towards the adoption of this new way of thinking, particularly where high levels of automation are incorporated in the operational specification of the facility.

“This shift would allow increased efficiency and therefore enable greater utilisation of industrial land releases, in turn lowering prices and making it more accessible for businesses. Overall, the shift to measuring industrial property in cubic metres would benefit all parties involved, resulting in more efficient use of land and lower costs for businesses. Land owners will derive more overall revenue, industrial real estate brokers will derive more revenue and tenants will benefit from higher efficiency facilities delivering lower operating costs.”

There are still barriers to adoption due to the risk-averse nature of key stakeholders and the long lifespan of industrial assets (more than 50 years), Peter says. “However, companies with the ability to execute Next Generation designs will have a distinct advantage over their competitors. Their operational

cost will be lower, and the building will be more efficient. It may take some time for these concepts to become more widely accepted – as is the case with many innovations and ‘generational’ changes in thinking (slow uptake of solar in the industrial space is just one example) – but the potential increase in utilisation makes it worth considering for companies looking to optimise their warehouse operations. Eventually, this new way of thinking will become the norm.”

But innovative companies are already pushing the boundaries of traditional warehouse design. “At Prological we are working on several innovative designs for these early adopters and industry innovators.

“In the short term, it is likely that only larger, well-established brands with the resources and longterm lease capability will be able to take advantage of this cuttingedge approach.

“However, as more businesses begin to see the cost and operational benefits of these modern warehouses, it is likely that the market will begin to shift towards more sophisticated designs.” ■

“

Overall, the shift to measuring industrial property in cubic metres would benefit all parties involved, resulting in more efficient use of land and lower costs for businesses. ”

NO VACANCY?

CBRE’s Sass J-Baleh and Trevor O’Grady discuss the commercial real estate firm’s recent research into vacancy rates in the industrial and logistics sector.

“CBRE’s last report, for H1 of 2022, showed that the national vacancy rate for industrial and logistics properties was 0.8 per cent, which was then the lowest in the world,” says Sass J-Baleh, Head of Industrial & Logistics Research Australia and Director of NSW Research at CBRE. “Our new report, covering H2 2022, shows that number even lower at 0.6 per cent, maintaining Australia in its position as the world’s tightest I&L market.”

Sydney has the lowest vacancy rate in the nation, lowering to 0.2 per cent, while Melbourne remains roughly constant at 1.1 per cent.

“Below two per cent means that there are – practically speaking – no vacancies on the market, so those numbers are quite striking,” Sass says. “Because of this, there has been growth in rents, with super prime grade face rents rising 25 per cent year on year.”

Again, Sydney takes the cake for rental growth, followed by Perth, which has the second lowest vacancy rate, showing a clear correlation between scarcity of industrial property and rental prices.

With occupier expansion and new space requirements accounting for 90 per cent of lease transactions in 2022, current occupiers – let alone those trying to break into the market – are feeling the heat, Sass says.

But how is it that Australia – a country with such abundant territory –has the lowest I&L vacancy rate in the world?

“There’s simply a chronic undersupply of space, with not enough being brought online in time to meet demand,” says Sass. “Like other countries, Australia saw a strong take-up of space from the e-commerce sector during COVID-19, but what makes Australia unique is that we are a mature economy with an immature e-commerce sector; we are still growing with respect to e-commerce

sales and penetration rate while other countries have already plateaued. Additionally, the I&L sector in Australia faces competition for space from food logistics and food manufacturing sectors – that’s why we’re unique.”

Sass adds that the Australian market is shaped by pent-up demand that will keep vacancy rates at low levels for the next six to twelve months. “Even if economic growth slows there won’t be enough supply to meet demand, our research shows. If we look at the supply pipeline moving forward, it’s notable that only 50 per cent is owing to speculative developments, compared with 70 per cent in the US.”

Trevor O’Grady, National Director for Advisory & Transactions and Occupier – Industrial & Logistics, at CBRE says the scarcity of industrial property has also been affected by slow planning approvals, particularly in NSW. “In NSW planning used to take six to nine months whereas now we’re looking at 12 months-plus,” Trevor says. “With the Badgerys Creek precinct coming

online soon there’ll be some more supply, but we’ll still be waiting on the necessary infrastructure to meet it and the existing problem of incredibly slow planning approval turnarounds. In Melbourne, land has been earmarked for the Western Intermodal Freight Terminal, which is putting increased pressure on Melbourne, too. We need to keep putting pressure on government to keep things moving.”

Part of the reason authorities are moving more slowly on the planning and approvals front, Trevor adds, might be a hangover from COVID, with displaced authority teams taking longer to action approvals and provide reports for or against developments.

Whatever the reason, it’s putting major pressure on tenants.

“There’s three or four bona fide parties missing out on every property,” he says. “That means tenants are forced to renew leases on properties that are no longer sufficient or operationally suitable for their purposes for their purposes. Unless they’ve

planned very well in advance, there’s a strong chance of missing out on more modern speculative or greenfield facilities – so if you’re planning on moving to a new facility, that decision now needs to be made a minimum of two years in advance, you can’t expect to get something that meets all your needs only 12 months before your current lease is due to expire.”

Are such speedy and sharp rises in rent sustainable for occupiers?

“The comment I’ve heard from most of my clients is that consumers will have to pay more for products,” Trevor says. “With current rents, it’s just not sustainable, so tenants will have to pass on those costs to the end-consumer – which will of course put more pressure on inflation if industrial rents continue to rise at such an alarming rate.”

WHAT IS TO BE DONE?

Trevor says that some occupiers are inspecting their national footprints and reconsidering whether to invest in large new facilities, and where they’ll locate them if they do so invest. “With a minimal gap between prime and secondary asset rents tenants would be silly not to consider the efficiency benefits of new facilities with greater cubic capacity and the ability to cater for incorporation of future automation and technology,” he says. “It is a no brainer to invest in new facilities when you look at the fixed storage cost per pallet.

“With the Sydney market so tight and unreliable, companies may opt for Brisbane or Melbourne as alternatives. Another option is to investigate how existing facilities can be retrofitted to meet new needs – for instance investing in floor flatness so the property can support solutions such as an AutoStore solution or AGVs. We’ve been working on the education side of things – getting our clients to start their process earlier and strategize well ahead in what is a tight market. The opportunities will still there if you start the process early enough.”

Sass says that CBRE is working to lobby government through the Property Council of Australia (PCA) to help them expedite their planning and approvals processes.

“I sit on the industrial committee for the Industrial NSW branch of PCA, and we’ve worked with the PCA for a few years on these issues,” Sass says. “We continue to work with the PCA this year to provide data to the government so they can make informed decisions as well as provide guidance on releasing/rezoning/servicing land to alleviate industrial supply pressures. At the end of the day, governments want to attract large occupiers to their states for greater employment opportunities and stimulate economic activity.” ■

To read the full report, use the QR code.

“

There’s three or four bona fide parties missing out on every property ... That means tenants are forced to renew leases on properties that are no longer sufficient for their purposes.

Trevor O’Grady, National Directorfor Advisory & Transactions and Occupier – Industrial & Logistics, at CBRE.

OPTIMISING SUPPLY CHAINS WITH DIGITAL TWIN

Digital twin technology is revolutionising supply chain by allowing businesses to develop simulations of networks and facilities. Argon & Co’s Chris Foord, Associate Partner, and Coupa’s Henry Brunekreef, Regional Vice President, Solution Delivery, ANZ, Japan, and China, explain to MHD how this innovative solution works and what benefits it offers to businesses during these turbulent times.

Digital twin technology has been used to train fighter pilots with flight simulations. Now companies like Argon & Co are using it to help businesses modify or construct their supply chains in what is an unpredictable and constantly changing environment where disruptions are common.

As an enabler of continuous design, the solution has been used by manufacturers for product design, reducing costs and optimising performance. Now supply chains are using this AI-powered decisionmaking, data-and-algorithm-driven tech for modelling.

Gartner, the research consultancy company, refers to the digital supply chain twin as a “dynamic, real-time and time-phased representation of the various associations between the data objects that ultimately make up how the physical supply chain operates” in its 2019 Top Supply Chain Technology Trends You Can’t Ignore. (Gartner, March 11, 2019)

FORECASTING DISRUPTIONS WITH HYPOTHETICAL SCENARIOS

Besides the digital twin being a virtual replica of the physical supply chain, it offers an always-

on reference model to inform operational, tactical, and strategic plans, and to visualise all current state nodes, flows, and policies.

It also allows organisations to recreate their supply chain in the virtual world, to quickly test scenarios in a risk-free manner to learn how decisions will impact the network operations and makes supply chains more agile and resilient. The digital twin’s intelligent response and tailored solutions mean it can provide timely and financially optimal decisions.

“Businesses can develop hypothetical scenarios and test the limits of their modifications and designs by asking rhetorical questions such as ‘What if Shanghai is in lockdown tomorrow and no stock is shipped or flown in from Shanghai to Sydney?’ and ‘What are the implications of that to my service to costs, as well as my working capital implications?’,” Henry Brunekreef, Regional Vice President, Solution Delivery, Coupa, ANZ, Japan, and China, says.

“Supply Chain Management is about two things: it’s the reduction of complexity and the reduction of uncertainty. What we call digital supply chain or digital twin now

is what we used to call ‘what if’ scenarios because that’s ultimately what it is.

“The ‘what if scenario’ is giving you the capability to ask, ‘What if there is a fire in this factory? What impact will that have on the supply of goods? On my working capital, etc? What if that flood is happening in Thailand? Have I got the right inventory in the right place, or do I need to substitute it from elsewhere?’”

From a sustainability perspective, a business can use the digital twin to minimise its carbon footprint and implement ESG initiatives.

The other capability this digital trend provides, is it allows the user to analysis their warehouse or DC so they can improve or alter their tactics. For example, when the COVID-19 pandemic started, there was a dramatic increase in e-commerce, so businesses had to think about how this shift was impacting their facilities, employees, inventory, and freight.

It’s no longer a matter of episodically analysing operations monthly, quarterly, or yearly, it’s now achieved in accordance with continuous optimisation which is what the digital twin enables.

DETERMINING TRADE-OFFS

The digital twin knows the assets a business has in its network, including the network nodes, volume, costs of moving volume, inventory, and servicing levels.

“A company can use all the real data inside the digital twin to turn things on and off, or move them in a different way,” Chris Foord, Associate Partner at Argon & Co explains.

“This can help a business understand the implications across their network, and that’s where it becomes super-powerful because a human being can’t understand the complexity of the supply chain, so this helps simplify it and identify where issues occur, and where the opportunities are.”

In supply chain, there’s always a trade-off that needs to be made, adds Henry – this is between customer service level and logistics costs, including warehousing, distribution, lost sales, and the inability to provide working capital inventory. Now, additionally, there are the ESG and risk factors.

“The digital twin along with the ‘what-if’ scenarios help businesses find answers to trade-off problems by looking at impacts and optimising across the end-to-end supply chain from source to customer,” he says.

“Having access to costs on a realtime basis is important because it helps you make decisions. On top of this, a business’s physical supply chain can respond swiftly and in an agile manner to changing conditions.”

The digital twin operates in exactly the same way both during supply chain disruptions and in normal conditions.

In a state of disruption, the technology can quickly obtain the end-to-end implications while in normal conditions, it’s used in a similar way, but there’s more optimising and tweaking to ascertain value or opportunity rather than reacting to a specific event – although the process is similar – and this is all achieved by feeding the digital twins with real-time information, enabling decisions to be made live in real time.

To make all of this possible, it’s necessary for a supply chain to incorporate some important key elements.

DEVELOPING AN AGILE APPROACH WITH THE SEVEN ELEMENTS

A business’ operating model should connect vision and execution through an end-to-end supply chain covering seven key elements:

1. Organisational design

2. Processes

3. People & capabilities

4. Performance measures

5. Governance & reporting

6. Systems & technology

7. Network infrastructure

Combining these elements provides a future state target operating model. Leveraging a digital foundation, the future operating model will effectively coordinate and control your supply chain activities unlocking efficiency benefits and enabling rapid, sense and respond capability driving operational agility.

“When all of these seven come together in a truly end-to-end operating model,” notes Chris, “you have an integrated way of working where you can coordinate and control the supply chain in a more efficient manner.”

Using digital twin technology can also help a company develop and strengthen its sales and business planning methods.

AUGMENTING S&OP PROCESSES THROUGH DIGITAL TWIN TECHNOLOGY

Augmenting your Sales & Operations Planning (S&OP) or Integrated Business Planning (IBP) process with the insights and optimised outputs of digital twin scenario modelling will highlight potential shortfalls allowing appropriate actions to be taken before they affect business results or customer service.

“Prepared and evaluated endto-end scenarios and options will focus the overall S&OP/IBP process, becoming an effective catalyst for collaboration across the business and providing essential information for decision making,” explains Henry.

“It’s no longer companies that compete, but it’s the supply chains in which they operate. That’s what this optimisation is about. It’s not from ‘me to you’ – it’s the optimisation of the end-to-end supply chain.

“We’re seeing the move from episodic design to continuous optimisation. From this perspective, there are mergers and acquisitions, de-mergers, and there are shocks that are going to take place. We can show the impacts of when a disruption occurs, where it’s felt and what action needs to be taken to remedy it.” ■

KÖRBER ON TRENDS AND PROSPECTS

Anthony Beavis, Managing Director ANZ at Körber Supply Chain Software, discusses what customers are demanding in 2023, and the trends to focus on.

After two to three years in “survival mode” in wake of the pandemic, “many companies are putting forward tenders” and “looking to the future” in planning their supply chain operations, says Anthony Beavis, Managing Director ANZ, at Körber.

COVID-19 was a shock to the system that is still being absorbed, and its lessons learnt, says Anthony. The sudden transition to e-commerce, seemingly overnight, was one such shock – but there is still uncertainty about future projections regarding the size of e-commerce as a proportion of overall sales and what its stable resting place should be post-COVID.

“Using data from pre-COVID to ascertain the right ratio of e-commerce to other sales doesn’t work – but extrapolating data from the COVID years doesn’t work either,” Anthony says.

While reading and forecasting from such numbers is a challenging process, Anthony is confident that in general the industry has now caught its breath sufficiently to get out of “survival mode” and move towards a “flexible” forward planning strategy.

AUTOMATION NOW

A focal point of such flexible forward planning will be the proper use of

automation, of course.

“How can we build something that can scale when we have our next geopolitical issue – be it a war, a major or uncertain election, or a pandemic?” Anthony asks. “These large macroeconomic factors are tremendously important in a country the size of Australia.

The speed of automation implementation – from conception to integration – will be a criterion governing automation business decisions. As will be the ability to scale such automation processes to market fluctuations, and to move equipment if needs be.

“Larger ASRS [automated storage

and retrieval] or goods-to-person [G2P] systems are bolted to the ground,” he notes. “You can’t just move three kilometres of conveyor to a new site, so you’re somewhat stuck with it until you hit your return on investment.”

That’s why autonomous mobile robots – which Körber has deep experience deploying in a variety of contexts – offer some key benefits and advantages.

“Compared to an ASRS system, with AMRs you can change the grid off which they operate, add more robots, or even – if it comes down to it – move the robots to a new site.”

Being flexible with automation

will be vital in Australia in 2023 and beyond, as new pressures limit the flexibility that previously obtained in other areas.

“With a tight industrial property market, companies are having a harder time finding the space to accommodate a larger built-in G2P system, so I think the trends definitely favour AMRs as an automation opportunity.”

Indeed, as Anthony notes, inventory management before, during, and after COVID has presented problems, with a push towards just-in-case stock resulting in many businesses having significant overflow when things calmed down – oftentimes necessitating secondary sites to catch the overflow. “It can get a bit messy – so now I think a lot of companies are seeing how they can rationalize and better organize, take-in, and despatch their inventory. Automation helps here.”

THINK PARTNERSHIP, NOT TRANSACTION

As things continue to speed up, data and visibility of goods become increasingly important to every player in supply chain, Anthony says.

“Our customers want their systems to be interconnected and visible,” he says. “At Körber we can do a WMS system that’s connected to a freight forwarding system and other systems inside and outside the warehouse.

“I’ve heard from customers in the market that COVID made their relationships with suppliers either much stronger or much weaker, because it’s only when there’s a real test that you understand whether it’s a transactional relationship or a true partnership.

“There’s definitely a push for customers to find long term solutions rather than ad-hoc, one-off transactional purchases. Long term partners provide the security that –for better or for worse – we’re all in this together.”

STAYING SUSTAINABLE

A continuing focus in 2023 and beyond, says Anthony, will be the sustainability push.

“Consumers are really driving a greater focus on sustainability and

circular supply chains,” he says. “One of our major retail partners, Officeworks, recently introduced a ‘greener choice’ option into many of their product ranges – with labels indicating ethical and sustainable sourcing. Their feedback has indicated that people are willing to pay a little bit more because they want to do the responsible thing by the environment. Such considerations will be pushed more and more into supply chain, I think.”

A strong program of automation together with good use of data, undergirded by long term partners to implement and provide support, are a boon to sustainability objectives.

“Visibility and reliable partners are indispensable from a sustainability viewpoint,” he says. “We’ve done a few jobs where we’ve included solar panels as part of an AMR implementation project. Take Officeworks, for example. They now have solar panels in their new Melbourne DC and they’re covering close to 80 per cent of their entire running costs for the whole DC – not just the robots – and achieved their goal of making a positive impact on the environment. Installing solar alongside intralogistics solutions like AMRs is a good way of diversifying energy sources and offsetting CO2 with clean power.”

BALANCED AND INTEGRATED SOLUTIONS

Anthony observes that there has

been a greater trend towards holistic, end-to-end solutions over attempts to solve one part of a problem in isolation.

“There’s been an increasing realization that you can break one thing while trying to fix another,” he says. “Take picking, for example. A customer might implement a voice picking solution that increases their pick rate by 30 per cent – but what if that only means the picking outpaces capacity to replenish stocks? You’ll have people picking faster but then go to pick another SKU and it’s not there.

“Part of our message has been to say, ‘Okay, you’re picking faster, so now you don’t need to work as many shifts, and you can reallocate that labour towards replenishment.

“That’s one of the biggest takeaways we saw in 2022 and expect to continue in 2023 – a broader view from our customers on what they’re doing and the consequences of one process for other processes. No longer are customers saying, ‘I need some RF guns, so let’s just put them in.’ Instead Körber and our customers are asking questions like, ‘Okay, but what about either side of that solution? We’ve got all these other systems, so how are we going to interface it?’ We’re seeing a slimming down of some of the smaller siloed solutions and people looking more towards an endto-end perspective.” ■

ONLINE PET STORE USES TMHA RELIABILITY TO BUILD QLD BUSINESS

Budget Pet Products goes from strength to strength with the help of Toyota forklifts.